Page 1

KANGAROO ePump

tyco

/ Healthcare

Αντλία εντερικής σίτισης — Εγχειρίδιο λειτουργίας και σέρβις

See Instructions

0123

™ Trademark of Tyco Healthcare Group LP or its affi liate.

™*SPRAY-NINE

is atrademark of

Spray-Nine Corporation.

is atrademark of

Smith Kline Beecham Corp.

is atrademark of

Tubifoam Ltd.

VESTA-SYDE

is atrademark of

Steris, In

c.

TYCO HEALTHCARE GROUP LP

•

MANSFIE

L

MADE I

U.S.A.

•

© 2005 TYCO HEALTHCARE GROUP LP

ALL RIGHTS RESERVED

•

0503

28

www.TycoHealthcare.com

GOSPORT,

PO13 0AS, U.K.

SWISS DISTRIBUTOR: TYCO HEALTHCARE SWITZERLAND LTD.

AU SWITZERLAND

�

Enteral Feeding Pump

™

Page 2

Thank you for purch

asing the

KANGAROO

e

ump

Enteral Feeding P

ump.

With proper care, this device will provide you with years of precision service.

TABLE OF CONTENTS

Page

Section I —

General Information

..........................................................................................

5

Section II

Safety and Warnings

..................................................................................................

Section III —

...........................................................................................

8

Section IV —

Attaching the A/C Adapter Power Cord

........................................................................................................

9

..............................................................................................................................................

9

Attaching Pole Clamp

................................................................................................................................

0

Secti

on V —

Quick Start

.................................................................................................................................................

General Startup

.........................................................................................................................................

Placement/Mounting

..........................................................................................................................

A/C Power Operation

...........................................................................................................................

2

Battery Power Operation

......................................................................................................................

Power On/Off

Language Selection, First Power Up

.......................................................................................................

2

Keep

or Clea

r Prior Pump Settings

.........................................................................................................

....................................................................................................................................

3

Prime Pump

..............................................................................................................................................

4

Auto Priming

......................................................................................................................................

5

Hold-To-Prime

...................................................................................................................................

5

Re-priming after Bag Empty

.................................................................................................................

5

Selecting Continuous or Intermittent Feed Mode

......................................................................................

6

2

KANGA

R

OO

e

English English

© 2005 Tyco Healthcare Group LP

Page 3

3

TABLE OF CONTENTS

Page

Continuous Mode (Adjust Feed)

.................................................................................................................

Continuous Mode Feeding

...................................................................................................................

6

Continuous Mode Flushing

...................................................................................................................

7

..............................................................................................................

Intermittent Mode Feeding

...................................................................................................................

Intermittent Mode Feeding -

Bolus Max

.................................................................................................

Intermittent Mode Flushing

..................................................................................................................

Run

...................................................................................................................................................

0

Hold

..................................................................................................................................................

2

Flush Now

.........................................................................................................................................

More Options

.............................................................................................................................................

3

Buzzer Alarm Volume

.........................................................................................................................

2

3

History

..............................................................................................................................................

3

Language Selection

.............................................................................................................................

2

3

Continuous/Intermittent Mode

.............................................................................................................

3

............................................................................................................................................

2

4

Accessing the BioTech Screen

................................................................................................................

BioTech Screen Data

............................................................................................................................

2

4

Lock Settings Feature (Program Locked)

.................................................................................................

...................................................................................................................................

5

Section VI — Re

-Certification of

System Performance Re-Certification

........................................................................................................

2

5

Certifyi

...............................................................................................

6

Section VII — Cleaning

.......................................................................................................................

6

Section VIII — Battery Replacement

..........................................................................................

28

© 2005 Tyco Healthcare Group LP

Page 4

4

OO

e

TABLE OF CONTENTS

Page

Se

ction

IX — Error/War

System Error

..............................................................................................................................................

29

Hold Error

..................................................................................................................................................

3

0

Rotor Error

.................................................................................................................................................

3

Feed Error

..................................................................................................................................................

3

Flush Error

.................................................................................................................................................

3

Flow Error

..................................................................................................................................................

3

Pump Set Dislodged Error

..........................................................................................................................

3

2

Battery

...............................................................................................................................................

3

3

Feeding Complete

.....................................................................................................................................

3

3

Pump Set Use >24 Hours Warning

............................................................................................................

3

3

...................................................................................................................................................

3

4

Section X

Specifications

and Symbols

Specifications

............................................................................................................................................

3

4

Symbols on Pump and Accessories

............................................................................................................

3

6

Section

Customer Service

......................................................................................................

3

Section X

Side Door Enclosing Pump Set Loading Area

.............................................................................................

3

7

Battery Pack

..............................................................................................................................................

38

..............................................................................................................................................

38

................................................................................................................................................

38

................................................................................................................................................

38

Section X

S

ervice Part Numbers

..........................................................................................

38

Section XIV —

Warranty

....................................................................................................................

38

Section XV —

....................................................

39

Section XVI —

AccuSystem

√

............................................................................................................

4

0

English English

© 2005 Tyco Healthcare Group LP

Page 5

5

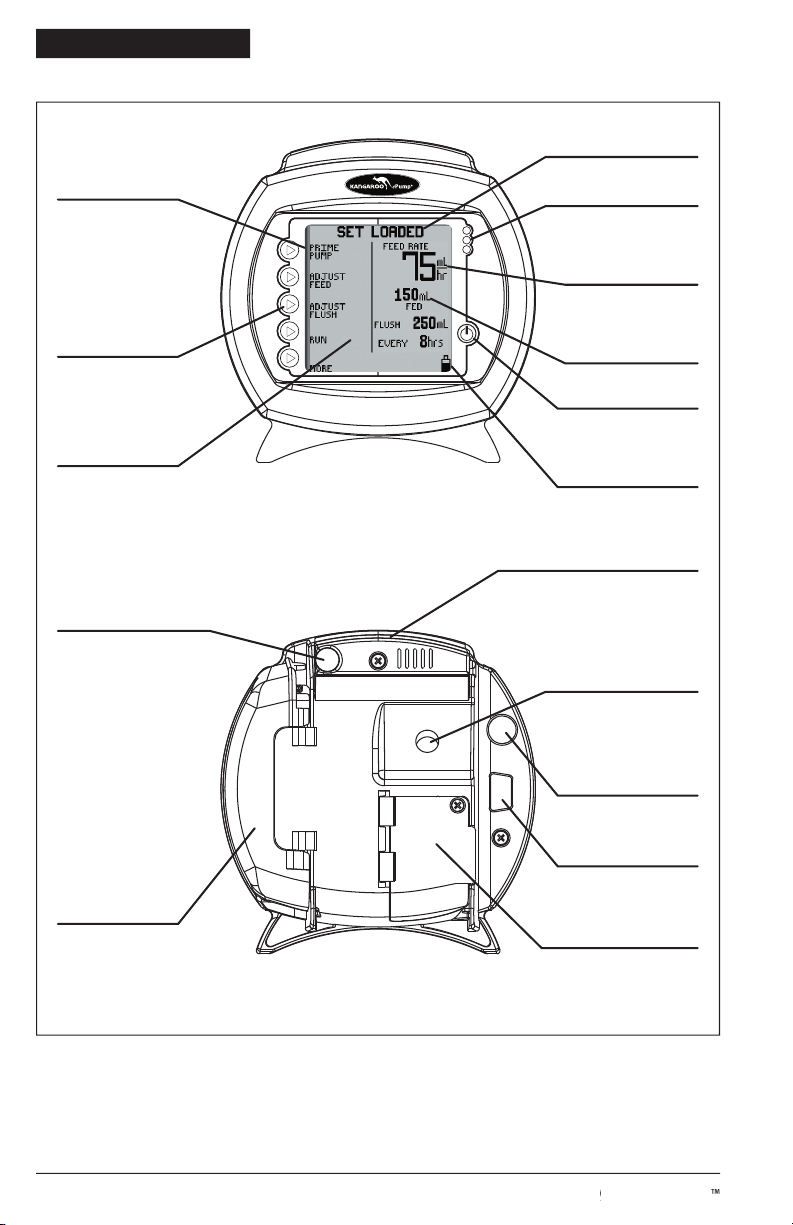

Section I –

General Information

The KANGAROO ePump enteral feeding pump is a simple-to-use, precision enteral feeding pump. It is easily programmed

to provide patients with either continuous or intermittent feeding, and can provide automatic flushing capability when

• Intuitive user interface

• Large, backlit LCD display

• Step-by-step prompts to guide programming and operation

• “Stoplight” LED array

visually

s

• Quiet operation

• Compact, aesthetic design

• Tabletop usage or IV pole mounting

• Simple loading of Pump Sets

• Transparent side door to protect Pump Set

• Integrated handle for easy transport

• MISTIC (Magnetic Intelligent Set Type Identification Connector) Feed-Only vs. Feed & Flush Set identification system to

ensure match between the pump’s user interface and Pump Set type

• Automatic Anti-Free-Flow (AFF) System

• Audible alarm to indicate errors or Pump Set loading conditions

• Attitude-independent design eliminates need for drip chamber on pump set

• Sensor technology detects both upstream and downstream flow conditions

• Continuous feed, intermittent feed, and flush capability

• Auto-prime feature reduces the need for time-consuming manual priming

• Hold feature with programmable restart

• Stores previous 72 hours of feeding and flushing history

Service:

• Serial I/O port for data retrieval and software updates

• Uses replaceable, rechargeable NiMH Battery Pack for 15 hours of backup power

• Removable Power Cord

• Removable Pole Clamp

© 2005 Tyco Healthcare Group LP

Page 6

6

OO

e

© 2005 Tyco Healthcare Group LP

English English

Page 7

Section II — Safety and Warnings

CAUTION:

U.S. federal law restricts the sale of this device to physicians or to their direct representatives.

2. Do not use this device near flammable anesthetics.

3. Disconnect power supply before cleaning or servicing.

4. Use only KANGAROO ePump

enteral feeding pump

Section

XIII - Service Part

5. Use only KANGAROO ePump

enteral feeding pump

compatible with other

6. For re-certification, see Section VI - Re-certification of

other integrity checks,

consult with a

qualified Biomedical technician or contact the manufacturer

(Section XI -

Customer Service).

7. F

or service or for te

chnical information, please contact Custom

er Service (Section XI).

8. Do not open the

s inside. Opening

may affect function of device

and voids the warranty.

To replace battery, see Se

ction VIII.

9.

ose of old battery-powered electronic equipment in a manner consistent with institutional policy for expired

equipment disposal.

actices must be consistent with institutional policy for cleaning of non-sterile devices. See

Section VII - Cleaning, for instructions on cleaning the KANGAROO ePump

enteral feeding pump

© 2005 Tyco Healthcare Group LP

Page 8

8

KANGA

R

OO

e

English English

e

the performance of this device.

WARNING:

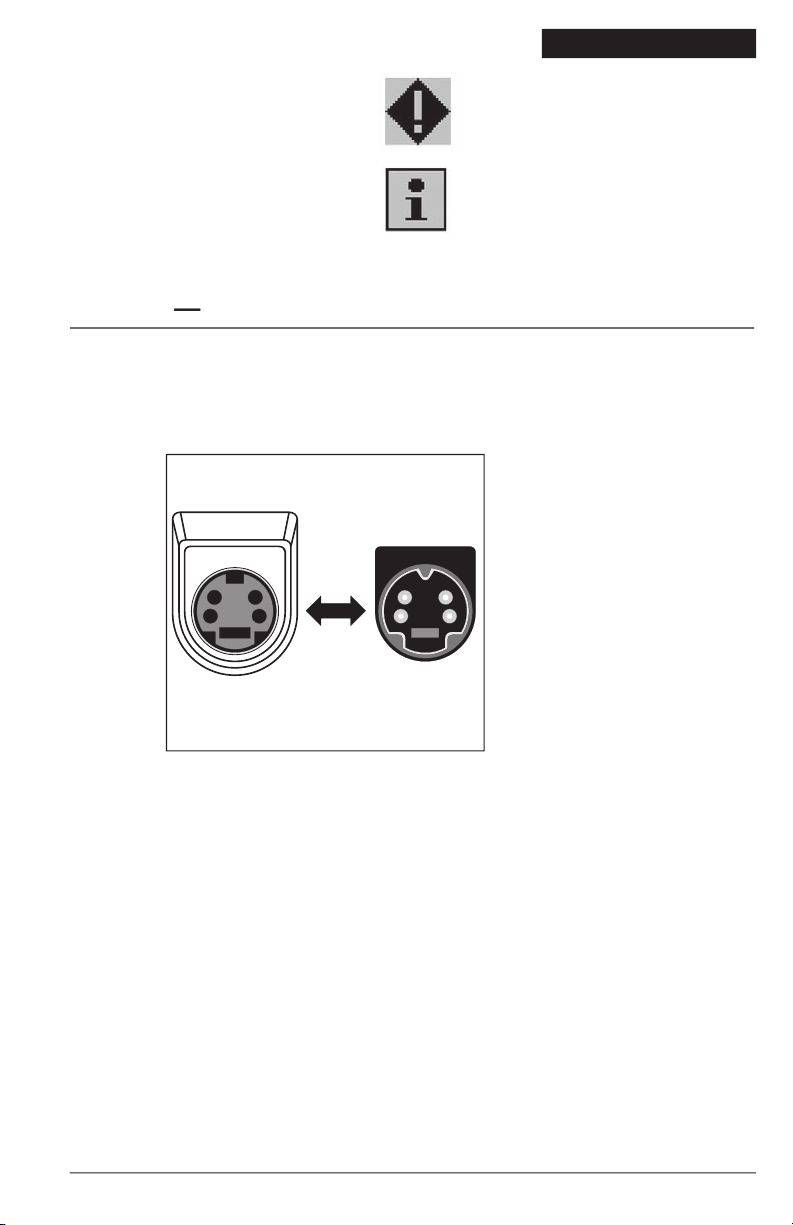

The DB9 serial I/O port (see Figure 1A) is intended only for use by the manufacturer.

Any accessory equipment that can be connected to the DB9 Serial I/O port, and which does not comply with the

equivalent safety requirements of this equipment, may lead to a reduced level of safety of the pump. While use of

the pump’s DB9 port is not recommended for customers, the following should be considered in the event that the

customer decides to connect to this port:

• The accessory is specifically certified as complying with the safety requirements for accessories used with the

60601-1 and/or IEC 60601-1-1 harmonized national standard.

• Under no circumstances should the certified accessory be used while the pump is in use for enteral feeding of a

CAUTION

This enteral feeding pump should only be used for patients who can tolerate the flow rates and accuracy

feeding pump.

Section III –

Vertically-moving droplet in

RUNNING

screen indicates Run

• Full charge

• 2/3 or less charge

• 1/3 or less ch

arge

• Very low battery (15 minutes max.

)

Auto Priming Indicator

When auto priming, the bar will progress

to show auto prime feature is active.

Volume Setting

© 2005 Tyco Healthcare Group LP

Page 9

9

r Indicator

This indicates information only,

and does not require any

Section IV

Initial Setup

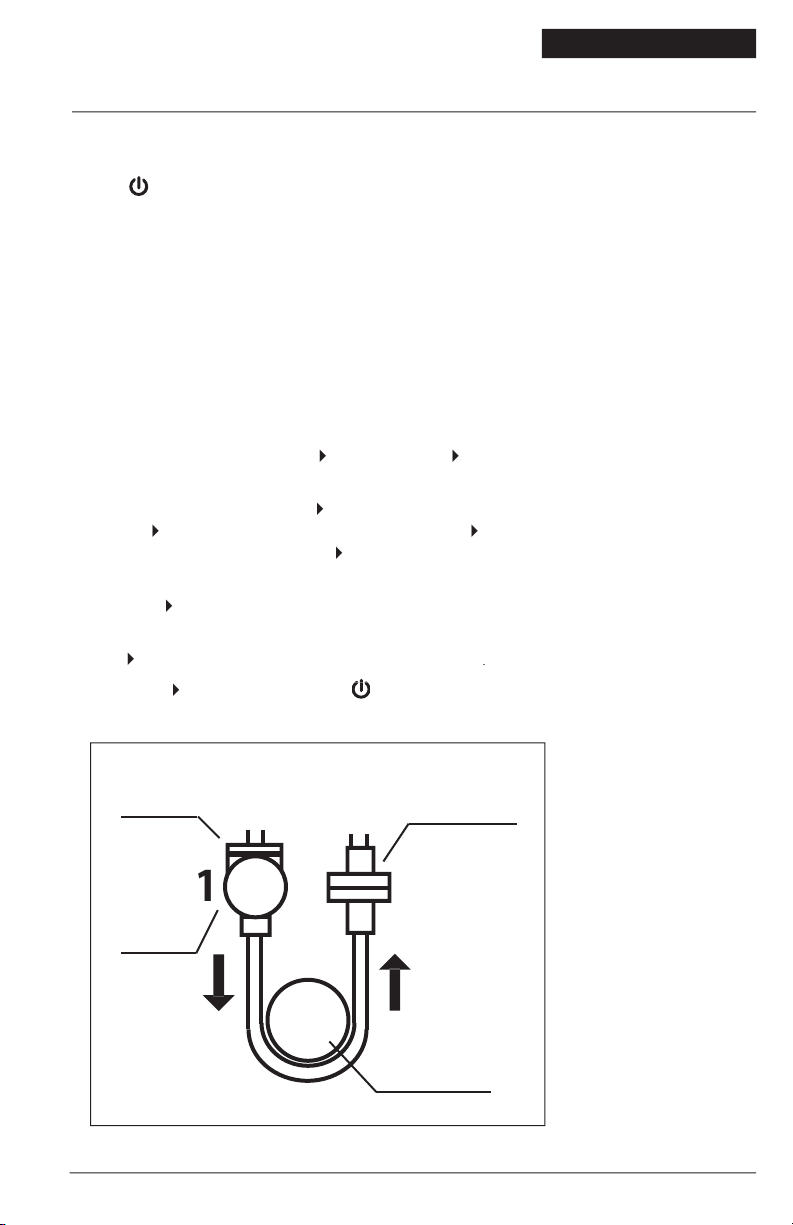

Attaching the A/C Adapter Power Cord

of the location of the pins and tab on the plug to properly orient the plug.

The connector, which attaches to the back of the pump, has a spring-loaded locking sleeve that locks into the pump, thus

sleeve member and pull. Do not detach the connector by pulling on the cord only.

Setup

The battery pack is fully charged before shipping, and is left unconnected to optimally preserve battery life.

WARNING:

The battery should be connected before using the pump.

will charge continuously whenever the pump is plugged into a wall outlet, including during normal use of the pump with

A/C power.

A new battery pack will provide approximately 15 hours of service before needing to be recharged.

A/C Adapter plug with

pump’s adapter port.

© 2005 Tyco Healthcare Group LP

Page 10

OO

e

English English

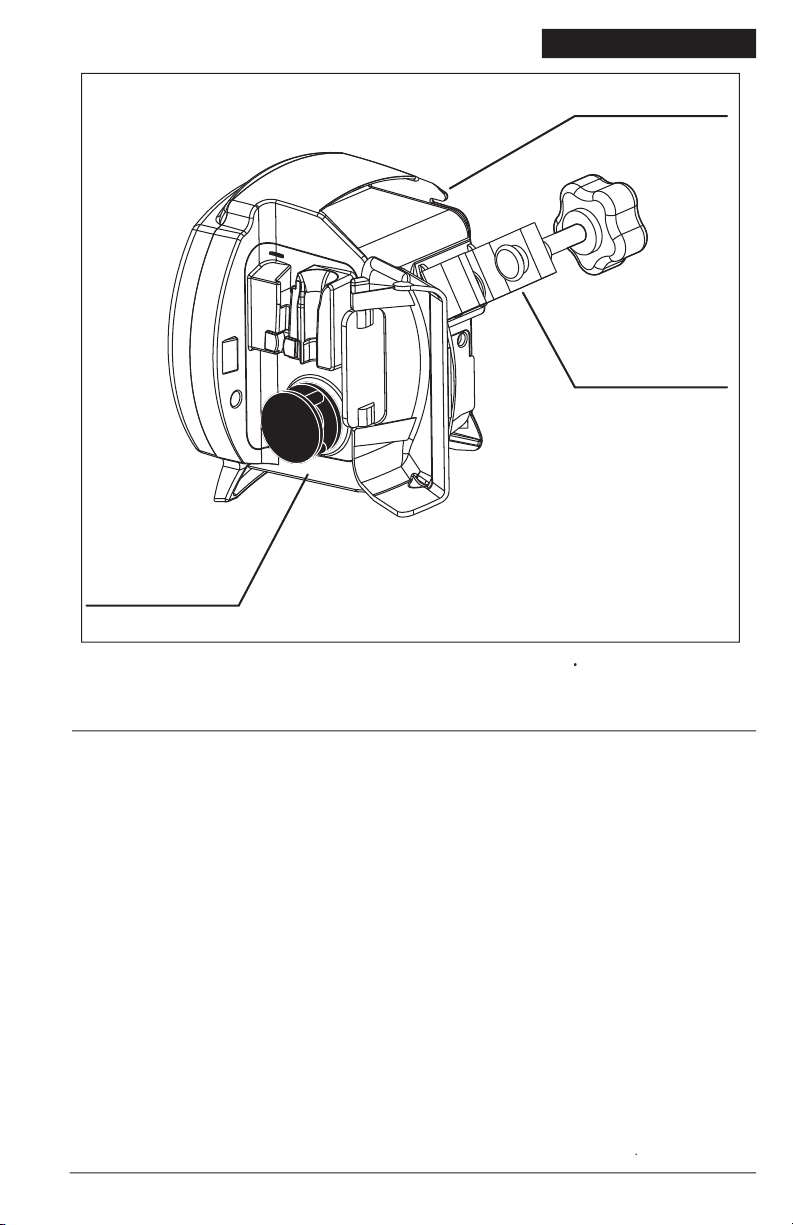

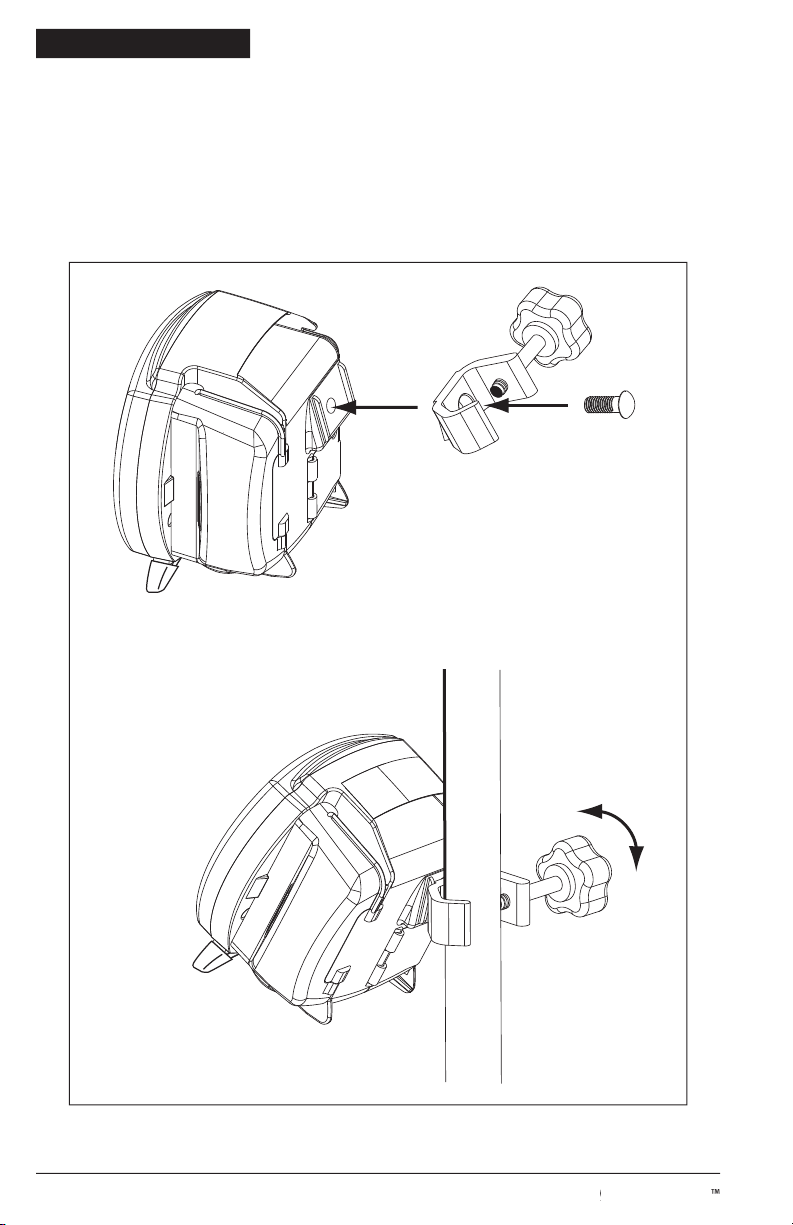

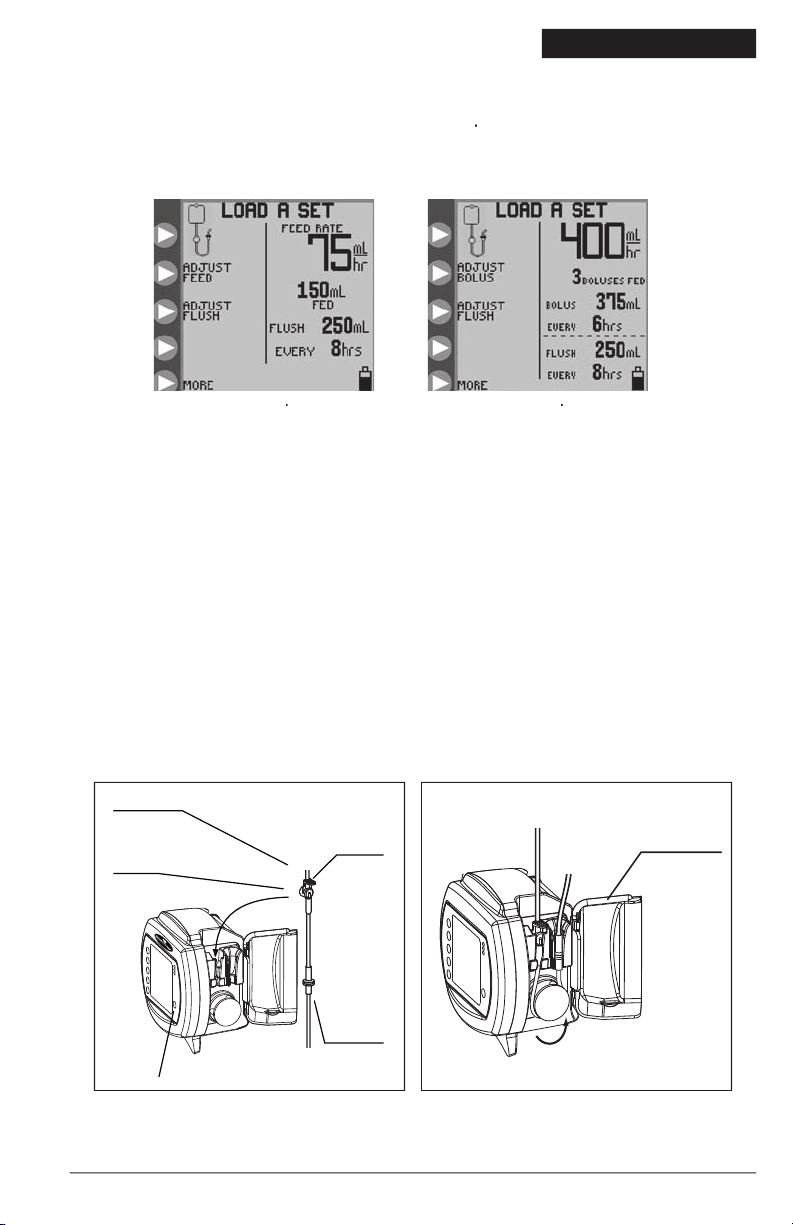

Attaching Pole Clamp

The KANGAROO ePump

enteral feeding pump

can be attached to a vertical pole using the Pole Clamp, included with the

To attach the Pole

Clamp to the KAN

GAR

OO ePump

enteral feeding pump

, align the hole on the Pole Clamp with the

ounting hole on the back

of the pump. U

se a 3/8” - 16 bolt to fasten together, as shown in Figure 3.

© 2005 Tyco Healthcare Group LP

Page 11

Section V —

Quick Start

on lower, right-hand corner of control panel.

2. Open blue door enclosing Pump Set loading area.

3. To load Pump Set (refer to Figure 4):

• Grasp finger tab on valve and insert into left pocket (1).

• Grasp black ring retainer and gently stretch tubing around rotor (2). Pull up on retainer and insert into right pocket

• Press down on finger tab to ensure that valve is fully seated.

• Close blue door.

(

display status line should read

SET LOADED

).

4. To automatically prime the pump, press

and

AUTO PRIME

will prime both lines.

5. To directly control pump priming, press

and then press and hold the

until the flushing

fluid has reached the valve, and then press

until the feeding fluid has reached past the

valve and down to the distal end connector.

6. Use buttons

on left side of LCD to set the feeding parameters. Set flushing parameters if a Feed & Flush Set is

MORE

options menu.

7. Press

when ready to start. The screen will display

RUNNING

8. To stop, press

or press and hold the

OWER

button.

(MISTIC)

Tab

Valve

© 2005 Tyco Healthcare Group LP

Page 12

OO

e

English English

General Startup

There are two recommended placement methods for the KANGAROO ePump

enteral feeding pump

• Attached to a vertical IV pole via the Pole Cla

• Placed feet down on any horizontal surface.

A/C Power Operation

enteral feeding pump

wer is interrupted, a built-in rechargeable battery will run the pump.

A fully-charged, new battery will supply 15 hours of backup power at 125 ml/hr before requiring recharging. Contact

Customer Service, Section XI, to replace the Battery Pack if battery life degrades.

To power up the pump, press the

OWER

OWER

button until the pump display turns off.

age Selection, First Power Up

) or (

) buttons. When the language is selected, push the fifth button (

) to enter the language

selection. After the language is selected the first time the pump is powered up, the language selection screen will not

appear during future power up operations. Should the language need to be changed after the initial power up, it can be

changed through the “

MORE OPTIONS

” menu (see Figure 16).

or Clear Prior Pump Settings

- Select this option to start with the same settings that were most recently programmed into the

mL FED

”

” (Intermittent Feed Mode) and

mL F”

are also maintained.

CLEAR SETTINGS

- Select this option to reset all input feeding settings and the output feed totals to zero. It will then

The

output feed totals (“

,

,” “

mL FLUSH

”) can be cleared at any time, and without

clearing the

•

Start the pump

RUNNING

•

Press

•

CLEAR VOLUME

The status line of the pump will then show

LOAD

A SET

(Figure 5), or, if the Pump Set is already loaded, it will show

SET LOADED

(Figure 7).

© 2005 Tyco Healthcare Group LP

Page 13

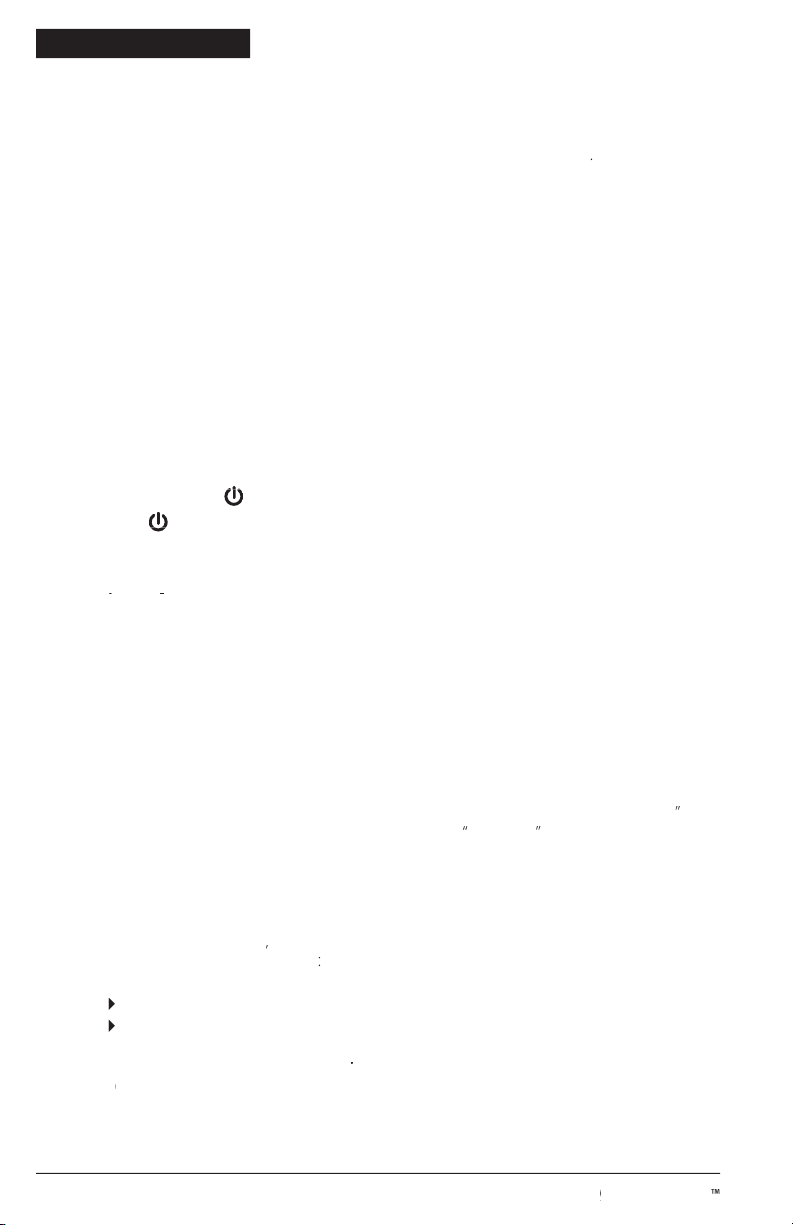

The KANGAROO ePump

enteral feeding pump

will indicate

LOAD A SET

in the screen’s status line if a Pump Set is not

screen for continuous feeding mode and Figure 5B shows the screen for intermittent feeding mode.

To load a Pump Set, follow the steps below:

2. Load the Pump Set by holding the finger tab on the valve, and inserting the valve down into the slot on the left.

3. Grasp the MISTIC retainer end (black ring retainer) and wrap the tubing counterclockwise around the rotor.

4. Carefully pull the MISTIC retainer end upwards to position it over the slot on the right, and then lower the retainer

5. Press down on the valve’s finger tab to ensure proper seating.

6. Close blue transparent door.

LOAD A SET

opening menu

screen for Continuous

LOAD A SET

opening menu

screen for Intermittent

© 2005 Tyco Healthcare Group LP

Page 14

OO

e

English English

The display should read

SET LOADED

and will show one of the following opening menus, depending on the type of

The KANGAROO ePump

enteral feeding pump

flushing line if a Feed & Flush Set is loaded. The pump can also be primed in a more interactive method using the hold-

to-prime feature.

After a Pump Set has been loaded and the status line shows

SET LOADED

, press

in the opening menu

PRIME PUMP

menus shown in Figure 8.

for Continuous Feed mode

with a Feed-Only set.

for Continuous Feed mode

with a Feed & Flush set.

for Intermittent Feed mode with a

for Intermittent Feed mode

with a Feed & Flush set.

menu for Feed-Only set.

menu for Feed & Flush set.

© 2005 Tyco Healthcare Group LP

Page 15

Auto Priming

The

AUTO PRIME

option will be available if the pump senses that the currently installed Pump Set was not previously

AUTO PRIME

to automatically prime the line(s). For Feed & Flush Pump Sets, the auto prime feature will automatically prime both

STOP

to cancel

AUTO PRIME

When auto-priming is completed, the status line will show

AUTO PRIME COMPLETE

and will no longer show the

AUTO PRIM

option. Be sure that the line(s) are fully primed. If not, use the hold-to-prime option(s) to complete the

The hold-to-prime options allow for precise interactive control of the priming process.

until the

feed line has been primed down to the stepped end connector at the end of the Pump Set.

to

to prime the feed line down to the stepped

end connector at the end of the Pump Set.

until the flushing fluid has

until the feeding fluid has reached past the valve and

down to the stepped end connector. If the feeding line is primed first, subsequent priming of the flushing line will force

the air between the flush solution bag and valve into the main line, which already has been primed with enteral formula.

A Pump Set bag that has been emptied will trigger the

screen. In this condition the Pump Set

To re-prime the Pump Set, do the following:

• Disconnect the feeding line from the patient

• Refill the bag

• Press

CONTINUE

to begin the pump

• Press

• Press

ADJUST SETTINGS

• Press

• Press

to prime the line(s)

© 2005 Tyco Healthcare Group LP

Page 16

OO

e

English English

Continuous Mode (Adjust Feed)

Continuous Mode Feeding

CONTINUOUS

feeding mode, the

ADJUST FEED

option is available in the opening menus (Figure 7A for Feed-

Only sets or Figure 7B for Feed & Flush sets). Select this option to program the feeding parameters from the

ADJUST

FEED

screen, Figure 10A.

in Figure 10A to define the rate of delivery. Press the

from 1 to 400 in increments of 1 ml/hr. Press

(top button) to exit the menu.

in Figure 10A to define the Volume To Be Delivered. Press the

(top button) to exit the menu. If the

is set to zero, the pump will run until the supply is exhausted.

When a

is set, the remaining volume to be delivered (remaining VTBD) will be displayed next to

the v icon on the lower right-hand portion of the screen (Figure 10A). If the

is reprogrammed during

a feeding, from

HOLDING

mode, the pump will restart the feeding and deliver the entire volume of the new VTBD

setting.

MORE OPTIONS

menu.

SELECT MODE

menu for

continuous or intermittent mode

selection.

Selecting Continuous or Intermittent

The KANGAROO ePump

enteral feeding pump

can be programmed to feed continuously or intermittently.

The continuous feeding mode will deliver the enteral nutrition at a steady rate, either until the programmed volume has

The Intermittent feeding mode delivers boluses of enteral nutrition

at programmed time intervals. The bolus volume and feed rate are also programmed.

To select continuous feed mode or intermittent feed mode, press

MORE

on the opening menu, shown in Figures 5 or 7,

to access the

MORE OPTIONS

menu, Figure 9A.

The

MORE

option is available either before a Pump Set has been loaded (Figure 5) or after the Pump Set is loaded (Figure

7). See subsection “More Options” for information on the other options in the

MORE OPTIONS

menu.

Select

CONTINUOUS/

under the

MORE OP

CONTINUOUS

MODE

or

from the

SELECT MODE

menu, Figure 9B. Press

to

exit.

© 2005 Tyco Healthcare Group LP

Page 17

ADJUST FEED

menu.

Volume to be Delivered.

Continuous Mode Flushing

CONTINUOUS

feeding mode with a Feed & Flush Set loaded, the opening menu will appear as shown in

7B. Press

ADJUST FLUSH

in Figure 7B to program the flushing parameters from the

ADJUST FLUSH

screen,

shown in Figure 11A.

in Figure 11A to define the volume per flush occurrence. Press the

to program the flush volume from 10 to 500 in increments of 1 ml. Press

(top button) to exit the menu.

i

the

(top button) to

exit the menu.

The pump will automatically limit flushing settings which

exceed pump capabilities

to deliver.

CAUTION:

The KANGAROO ePump enteral feeding pump flushes at a rate of 1960 mL/hr (32.7 mL/minute). Use care

when programming the flush volume so that it matches the patient’s need.

The pump will automatically flush an additional 25 ml of water after completing the programmed delivery of

formula, as long as at least one flush had occ

ADJUST FLUSH

menu, continuous mode.

Volume.

© 2005 Tyco Healthcare Group LP

Page 18

OO

e

English English

feeding mode, the

ADJUST BOLUS

option is available in the opening menus (Figure 7C for

a Feed-Only set or Figure 7D for a Feed & Flush set). Select this option to program the feeding parameters from the

ADJUST BOLUS

screen, Figure 12A.

in Figure 12A to define the rate of delivery.

(top button) to exit the menu.

in Figure 12A to define the total number of boluses to be delivered.

buttons in Figure 12C to program the number of boluses, up to a maximum of 99.

(top button) to exit the menu. The number of boluses can be set as zero, in which case the pump will

VOLUME PER BOLUS

in Figure 12A to define the Volume to be delivered in each bolus.

(top button) to exit the menu.

in Figure 12A to define the time interval between starts of bolus deliveries.

(top button) to exit the menu.

The pump will automatically limit bolus settings which

exceed pump capabilities

to deliver. For example, a bolus

delivery volume of 200 mL cannot be made once per hour if a rate of 150 mL/hr is already programmed. In this case,

the maximum volume allowed would be 150 mL.

If the

is reprogrammed during a feeding (from HOLD mode), the pump will restart

the bolus feeding and will deliver all the boluses as defined by the new setting.

© 2005 Tyco Healthcare Group LP

Page 19

ADJUST BOLUS

menu.

between starts of bolus.

Max

The

option can be used to deliver a bolus at a high rate, similar to gravity feeding

MAX

menu, Figure 12B, to program the

The feeding rate

for

is 999 mL/hr

feeding mode with a Feed & Flush Set, the opening menu, shown in Figure 7D, will show

the

ADJUST FLUSH

option. Press

ADJUST FLUSH

in Figure 7D to program the flushing parameters from the

ADJUST FLUSH

screen, Figure 13A.

© 2005 Tyco Healthcare Group LP

Page 20

20

OO

e

English English

The nature of two interm

periodic bolus feeding and periodic flushing, is such that occasional

conflicts can arise where each process need

s

to

be running at the same time.

T

over the feeding process for Feed & Flush pump sets. “Flushing precedence” means that a flush cycle will run to its end

even if a bolus delivery is scheduled to begin. It also means that a flush cycle will interrupt a bolus feeding cycle that

therefore possible that the net feeding volume is reduced from what may be intended, over a given time period.

in Figure 13A to define the volume per flush cycle. Press the

(top button) to exit the menu.

in Figure 13A to define the time interval between starts of flushing. Press the

to exit the menu.

The pump will automatically limit flushing settings which exceed pump capabilities to deliver.

CAUTION:

The KANGAROO ePump enteral feeding pump flushes at a rate of 1960 mL/hr (32.7 mL/minute). Use care

when programming the flush volume so that it matches the patient’s need.

The pump will automatically flush an additional 25 ml of water after completing the programmed delivery of

formula, as long as at least one flush had occ

The KANGAROO ePump

enteral feeding pump

will only run when a Pump Set is properly loaded and the necessary

feeding parameters have been programmed. For a Feed & Flush Set, the flushing parameters do not have to be set for the

After the pump has been programmed, press

to start operation. Figure 14 shows the

RUNNING

screen for

continuous feeding with flushing. The status line will indicate

RUNNING

, and the droplet icon will move vertically on

the screen. The green LED indicator will be illuminated to give a quick visual indication of positive status in a darkened

The

screen shows the feed rate, amount fed, flushing data if a Feed & Flush Pump Set is used, and the

ADJUST FLUSH

menu, intermittent mode.

Volume.

© 2005 Tyco Healthcare Group LP

Page 21

21

RUNNING

mode screen for

continuous feed mode.

while it is

RUNNING

, such as in Figure 14. The status line will

HOLDING

and the yellow LED indicator will be lit up to give a quick visual indication of an informational

status in a

darkened room.

the pump’

s alarm will sound if it has been left

for 10 minutes withou

t further input. It can be

tart after a specified time per

__ MIN.

tt

on.

Ther

e are five options available during

HOLDING

The

option can be selected from the following screens, if the proper parameters are programmed and the Pump Set

•

SET LOADED

screens (Figure 7)

ADJUST FEED

screen, continuous mode (Figure 10A)

ADJUST FLUSH

screens (Figure 11A, 13A)

•

HOLDING

screens (Figure 15)

HOLDING

mode

options, continuous feeding mode.

HOLDING

mode

options, intermittent feeding mode.

© 2005 Tyco Healthcare Group LP

Page 22

22

OO

e

English English

Clear Volume Fed

CLEAR VOLUME

to re-zero the

output feed totals

“

m

,” “

,” and “

mL FLUSH

Adjust Settings

ADJUST SETTINGS

to return to one of the opening menus shown in Figure 7, thus allowing any setting to be

, the opening menu will show

LOAD A SET

, as seen

to immediately input a time in minutes in which to resume operation. Each press of

will increment the resume time by 5-minute increments, up to 30 minutes. After “30” is

the time immediately counts down after the incremental value is reached.

to immediately restart pump operation. This option will not be available if the Pump Set is removed during

View History

to access the

HIST

ORY

screen. Use this screen to review feeding and flushing history. See subsection

“More Options” below for further information.

RUNNING

mode, the pump can be diverted to immediately perform a flush (flush on demand) by

in the

RUNNING

menu. See Figure 14.

When

is pressed, the screen

will prompt for the volume to be immediately flushed, and will show the previously programmed flush volume as

default. The screen will appear as the standard Flush input screen as shown in Figure 11B (or 13B). Setting the

flushing volume is temporary and will not change the main/periodic flushing volume previously programmed

is pressed by accident, the screen will return to the

RUNNING

screen after 10 seconds, if there is no

© 2005 Tyco Healthcare Group LP

Page 23

23

MORE

OPTIONS

menu.

up to 72 hours of previous history,

excluding data from the current

hour.

More Options

MORE

in one of the opening menus, Figures 5 or 7, to access the

MORE OPTIONS

screen, Figure 16.

in the

MORE OPTIONS

menu to change the preferred language for the screen interface.

Continuous/Intermittent Mode

CONTINUOUS/INTERMITTENT

in the

MORE OPTIONS

menu to access the

SELECT MODE

menu, Figure 9B.

Continuous or Intermittent Feed Mode” for more information.

in the

MORE OPTIONS

menu to exit the menu.

in the

MORE OPTIONS

menu to access the

BUZZER

screen and increase or decrease the alarm buzzer

volume. The alarm will be audible as the volume setting is changed. This sets the volume level for any warning or error

that may occur with the pump. Critical erro

SYSTEM ERROR

and

PUMP SET DISLODGED

will always use the

in the

MORE OPTIONS

menu to access the

HISTORY

screen. Press the

the time history of interest. The totals of

and

will be shown for the requested history time.

WARNING:

A maximum of 72 hours of past history can be retrieved, excluding data from the current hour.

© 2005 Tyco Healthcare Group LP

Page 24

24

OO

e

English English

SN

is the serial number of the pump.

SW

shows the software version number in this pump.

shows the version number of the flash data installed in this pump.

CERT INTV

indicates the number of times the pump has been powered on since the last re-certification. See Section

VI for details of re-certifying the pump.

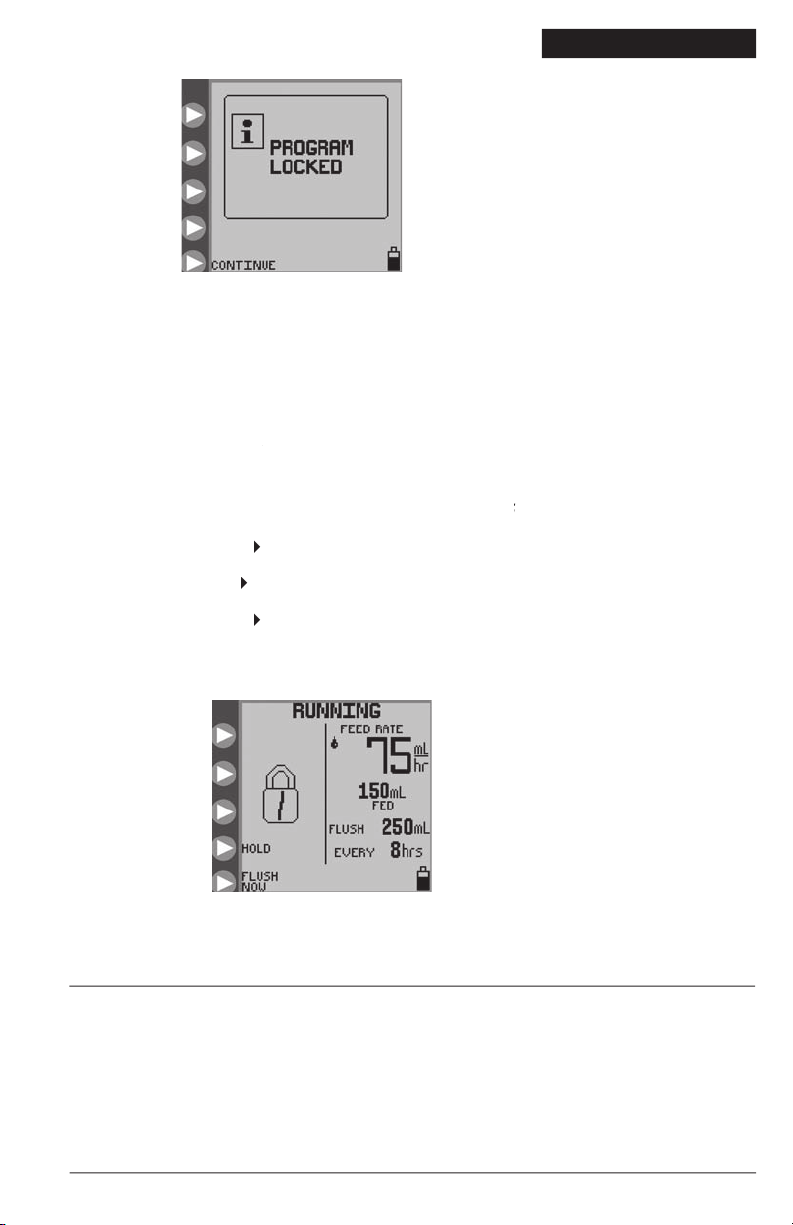

To “lock” the settings against unauthorized changes, press

to get the check mark, as shown inFigure

to remove the check mark.

are locked and a change is attempted, the screen will indicate

, and will not allow access to the

The pump can be

or set to

,

, et

c. when settings are locked.

to exit the BioTech menu. To re-enter this menu screen, power down the pump and then power it up

again and hold the top

The BioTech screen will show technical information about the pump, and has a lock feature to lock the Pump Settings

against unauthorized changes.

Accessing the BioTech Screen

To get the BioTech screen, press the power button to start the pump, and press and hold the top

startup sequence (Kangaroo icon “hops” across the screen) executes. You must be pressing the top

the sequence in order to access the BioTech menu. Figure 18 shows the BioTech screen.

unauthorized changes.

© 2005 Tyco Healthcare Group LP

Page 25

25

The KANGAROO ePump

enteral feeding pump

can be set to

and then locked out from unauthorized use. While the

feature prevents only changes to the input parameters, the

feature will lock out any

or

, except power off.

when the pump is running and there is a need to prevent tampering such as putting the pump into an

RUNNING

screen will show a padlock to indicate that no changes can be made without unlocking

the screen.

To lock the screen, use the following procedure while the pump is in

RUNNING

mode:

Press and hold the second

• Press and hold the third

at least

2 seconds, and then release it.

• Press and hold the second

at least

2 seconds.

To unlock the screen, use the same procedure above.

Section VI – Re-Certification of

System Performance Re-Certification

A series of self-diagnostic checks can be run to re-certify pump performance. It is recommended that this re-certification

XIII-Service Part Numbers for ordering new Re-Certification Pump Sets.

which indicates the pump is in LOCK

SETTINGS mode.

indicates pump is in

© 2005 Tyco Healthcare Group LP

Page 26

26

OO

e

English English

C

ertification Pump Set. The pump will automatically recognize the

Set and g

ve

brief

end of the test.

Certifying the Accuracy of Pump Flow Rate

accuracy:

• Perform test at room temperature

22° C±

2C±

3

with a new Pump Set.

• Fully fill a new Feed-Only Pump set bag with water.

• Load the Pump Set.

• Suspend the Pump Set bag so that the bottom of the bag is 18 inche

s abo

ve the pump.

• Make sure pump is plugged into A/C power (do not run test with battery power).

• Program a Continuous Mode fee

d r

ate (see below for suggested example rates).

• Run the pump for 15 minutes to achieve steady state operation.

• Then begin collecting the water in a calibrated measuring container, such as a large-capacity graduated cylinder, for

exactly 30 minutes.

The amount of water collected in 30 minutes will be half of the value programmed for the hourly flow rate,

within

± 10%, or 0.5 ml, whichever is larger.

Rate Set Amount Expected in 30 Minutes

75 mL/hr 33.7

150

Section VII — Cleaning

Cleaning should be performed as needed. It may also be desireable to define cleaning intervals based on knowledge of

the environment in which the pump is used. Only personnel trained in the cleaning of medical devices should perform

cleaning.

CAUTION: Do not immerse pump or power cord in water or other cleaning solution; clean using a

damp (not wet) cloth or sponge. Failure to follow the cleaning procedures described herein could

result in hazards to users. As with any AC powered electrical device, care must be taken to prevent

components.

trained in servicing KANGAROO ePump

enteral feeding

• wetting of the pump’s power cord or leakage into the pump interior during cleaning.

• spillage of large amounts of formula onto the pump exterior, or any spillage onto the power cord.

© 2005 Tyco Healthcare Group LP

Page 27

27

General Cleaning Directions

Cleaning of KANGAROO ePump

enteral feeding

CAUTION: Disconnect pump from AC power source before cleaning. After cleaning, do not connect to

AC power source until pump and power cord are thoroughly dry.

• A mild detergent should be used for general cleaning. If necessary, the pump may be cleaned with a 10:1 water and

alcohol, applied with a damp (not wet) cotton swab, may be used for cleaning difficult-to-reach areas, however, it

should be used sparingly because repeated cleaning may damage the case.

• DO NOT USE strong cleaners such as Spray-Nine™*, Phisohex™*, Hibiclens™*, or Vesta-Syde™* because damage to

the pump case housing can result.

• Refer to General Cleaning Directions before starting.

• Clean outside surface with a damp (not wet) cloth or sponge and keep pump in upright position as much as

• Avoid excess moisture near pole clamp area.

• Do not allow cleaning solution to enter the vertical vents in the housing, underneath the handle.

• Refer to General Cleaning Directions before starting.

• Unless soiling is observed, the power cord should not be cleaned.

• If cleaning of the power cord is necessary, unplug from outlet and wipe the exterior surfaces of the wall plug with a

cloth dampened with isopropyl alcohol.

CAUTION:

Avoid exposing power cord to excess moisture, as this can lead to an electrical shock or

fire hazard.

• Open the blue door enclosing the Pump Set loading area.

getting any moisture in the rot

or shaft opening.

•

Clean rollers tho

To replace rotor, align set screw on hub of rotor with the flattened section of the

output shaft.

•

© 2005 Tyco Healthcare Group LP

Page 28

28

OO

e

English English

This pump must be per

vice. To arrange for Tyco Healthcare Group LP Factory Service, call 1-800-448-0190

926)

Section VIII — Battery Replacement

See Figure 21 and do the following to replace the Battery Pack:

• Loosen the Battery Door screw, on back of pump.

• Open Battery Door and disconnect wire harness. A small straight-bladed screw driver may be needed to disconnect

the connector tab.

• Slide Battery Pack out of compartment.

• Slide a new Battery Pack into compartment with wire harness extending out.

• Align connector with red wire at upper right.

• Push connector in until properly latched.

• Tuck wires into slot between connector and battery to insure wires are not pinched. Re-tighten Battery Door screw.

Replacement Battery Packs are

available

from Tyco

WARNING:

CAN BE DANGEROUS AND

VOIDS

ALL WARRANTIES

AND PERFORMANCE SPECIFICATIONS.

The battery will charge continuously whenever the pump is plugged into a wall outlet. Eight hours of charging is required

to fully recharge the Battery Pack.

© 2005 Tyco Healthcare Group LP

Page 29

29

Section IX — Error/Warning/Informational Screens and Troubleshooting

enteral feeding pump

display will show the error indicator icon, with

specific information regarding the error condition, and will sound the alarm.

The following conditions will trigger error conditions and will activate audible and visible alarms:

• Feed or Flush containers are empty

•

•

Tube becomes occluded between pump and patient

•

•

System errors, see below

The MISTIC connector is removed during

AUTOPRIMING

or

RUNNING

The Error, Warning, and Information Screens are described below:

System Error

The system error screen is the most general form of error, Figure 22. The only way to exit from a System Error is to power

down. No

CONTINUE

option is allowed because of the severity of the error. An error number is also displayed on the

screen, for reference purposes. This number should be reported when calling the Customer Service Support Line.

Error # Related Sub-system

0 Internal timer stopped.

1 Flash Chip missing OR version incompatible.

2 Too many graphic screens in memory.

4 Never got a ADC ISR for motor current.

5 Never got a ADC ISR for battery level.

6 Never got a ADC ISR for battery temperature.

7 Never got a ADC ISR for Ultrasonic Upstream Occlusion or Bag-Empty checks.

8 Never got a ADC ISR for Ultrasonic during Downstream Occlusion.

9 RS232 Communications Transmit.

10 Flash Write Error.

11 Flash Read Error.

12 Stopcock Time Out.

13 Time Out for Buzzer Test

© 2005 Tyco Healthcare Group LP

Page 30

30

OO

e

English English

rror # Related Sub-system

20 Could not find Stop Cock Flush Position during prime routine.

21 Could not find Stop Cock Feed Position during prime routine.

22 Motor Error during Tubing AutoLoad.

23 Motor Failsafe Time Out Error. Possible damaged gearbox encoder or flex cable.

33 Motor Control Failure.

50 Graphic Display Error - Timeout during GDStatusCheck function.

51 Graphic Display Error - Timeout during GDAutoModeDataWriteCheck function.

52 Graphic Display Error - Timeout during GDWriteBytes function.

Turn the power off and back on to try to clear the error. If the error cannot be resolved in a timely manner, press

OWER

to stop operation of the pump and put a different pump into service.

The

screen will appear if the pump has been inactive, without input, for more than 10 minutes. See

subsection “Hold” for description of

HOLDING

mode.

CONTINUE

to return to the previous screen. Where settings can be adjusted, the pump

can be set to run

HOLDING

menu screen.

P

OWER

to stop operation of the pump and put a different pump into service.

P

section.

© 2005 Tyco Healthcare Group LP

Page 31

31

The

screen appears during

RUNNING

or

PRIMING

, when the pump has detected an unusual operating

condition for the rotor. See Figure 24. The

generally results from a problem with the Pump Set tubing

around the rotor.

Check that the Pump Set is not damaged, and re-load the tubing around the rotor as described in subsection “Loading

CONTINUE

to restart.

OWER

to stop operation of the pump and put a different pump into service.

The

screen appears when the enteral formula is no longer being delivered because the bag is empty or

occlusion cannot be cleared, load a new Pump Set, prime it, and

OWER

to stop operation of the pump and put a different pump into

service.

The

screen appears when the flushing solution is no longer being delivered because the flush bag is

empty or because of a clog between the pump and flush bag. Check the flush line to find the occlusion causing the

© 2005 Tyco Healthcare Group LP

Page 32

32

OO

e

English English

OWER

to stop operation of the pump and put a different pump into

service.

The

screen appears when either the feeding or the flushing solution is no longer being delivered because

of a clog between the pump and the patient. Check the line to find the occlusion causing the blockage.

If the error cannot

error. Clean and dry the valve pocket. If the error still cannot be resolved, load a new Pump Set, prime it, and

feeding

OWER

to stop operation of the pump and put a different pump into

service.

Error

The

screen will appear if the black ring retainer (MISTIC) is not properly loaded in the MISTIC

cannot be resolved, load a new Pump Set, prime it, and

OWER

to stop operation of the pump and put a different pump into service

© 2005 Tyco Healthcare Group LP

Page 33

33

The

screen appears and the alarm beeps continuously when the battery needs to be recharged. There is

approximately 15 minutes of battery life remaining when this screen appears

to the screen that was active prior to the

error.

The battery will charge continuously whenever the pump is plugged into a wall outlet. Eight hours of charging is

The

information screen appears after completion of the programmed feeding. Press

to turn off the pump. Press

CONTINUE

to return to the

SET LOADED

opening menu, Figure 7.

The Pump Set usage warni

RUNNING

screen if a Pump Set has been used for 24 or more

does not require action.

RUNNING

screen, where a Feed & Flush Set has been in use for more than 24 hours.

The informational warning indicat

or shows up in the upper left on the screen.

recharged immediately.

notifi cation screen.

left of the screen.

© 2005 Tyco Healthcare Group LP

Page 34

34

OO

e

English English

Section X — Specifications and Symbols

Specifications

Type Infusion Device

Volumetric

olus Volume

increments

Medical Electrical Equipment

accordance with UL60601-1.

The pump status LED array on the upper right of the pump gives a quick visual indication of the pump status, especially in

darkened rooms.

A green light status indicates normal pump operation.

A yellow light status indicates an informational or warning situation for a low battery condition, the pump in

HOLDING

, , , and

A red light status indicates a critical pump error. The screen will show one of the following error messages:

SYSTEM

,

, or

ROTOR ERROR

© 2005 Tyco Healthcare Group LP

Page 35

35

Accuracy

±22° C±

2° C (

72°

±

3° F),

using a new pump set with less than the recommended 24 hours of maximum usage.

Occlusion Pressure

Weight

Material

to complete battery discharge, a low battery alarm will occur (see subsection “Battery Low” in Section IX). When

complete discharge occurs, the pump will automatically turn itself off.

The battery will charge continuously whenever the pump is plugged into a wall outlet. Eight hours of charging is

Alarms

• System Error

Error

•

•

Alarm Volume

© 2005 Tyco Healthcare Group LP

Page 36

36

OO

e

English English

Symbols on Pump and Accessories

The following symbols are found on the pump or on the accesories, such as the A/C adapter.

Type BF Protection (Degree of

protection against electrical

shock - there is no conductive

connection to the patient)

Manufacturing Date Code

Serial Number

Alternating Current

Class II Equipment (degree of

protection against electrical

shock), Double Insulated

against ingress of fl uids)

CE Mark – European

Community Certifi cation

Screen Prompts

9V DC 1.5 Amp

Communication Port

Caution: For indoor use only

24 hours

open or damaged

See Kangaroo ePump

Manual for Feeding Set

VDE in Europe

and Canada

Japanese

Certifi cation

Maximum

operating pressure

Assure that the

white cap and red

stepped connector

are securely

tightened

Operating Temp

erature

0 - 40

C (

50

- 1

04

Storage Temperature

0 - 50

C (

32

- 1

22

Type of Protection Against Electrical Shock

Class II, Internally-powered Equipment

Degree of Protection Against Electrical Shock

Type BF

Mode of Operation

Continuous or programmed intermittent operation

Degree of Protection Against Ingress of Fluids

Drip-proof-IPX1

insert into left pocket

2. Grasp black ring retainer and

gently stretch tubing around rotor

3. Pull up on retainer and insert into

right pocket

© 2005 Tyco Healthcare Group LP

Page 37

37

S

ection XI —

Customer Service

The circuitry of the KANGAROO ePump enteral feeding pump is not customer serviceable. In particular, electronic

assembly rework by non-authorized KANGAROO ePump

enteral feeding pump

technicians will likely affect accuracy.

Certain replacement items, as listed in Section XIII - Service Part Numbers, are available from the service centers listed

All service personnel must be properly trained and qualified with operation of the KANGAROO ePump

enteral feeding

2. Pack the instrument carefully and ship the insured parcel to:

Tyco Healthcare Group LP

98.6 Faichney Drive

Watertown, NY 13601

1-800-448-0190 or (315) 788-5246

Outside of U.S. and Canada

)

Tyco Healthcare Group LP

20 Garryduff Road

Ballymoney, BT53 7AP

+44-28276-61719

Section XII —

e

WARNING:

Do not open the main housing, as there

are no user-serviceable parts inside. Opening of device may affect

function of device and voids the warranty.

The following maintenance items/parts can be replaced by the customer on the

ANGAROO ePump

enteral feeding

Numbers and Section XI for contacting Customer Servic

e.

S

To replace the Side Door, see Figure 32 and do the following:

2. Carefully press down on the bottom of the door to spread the

door hinges apart.

3. Place the bottom Door Hinge onto the Bottom Hinge Pin.

Canada

Tyco Healthcare Canada

7300 Trans-Canada

Pointe-Claire, Québec, Canada, H9R 1C7

Top

Hinge

Top Door

Lower Door

Hinge

Lower Hinge

Pin

© 2005 Tyco Healthcare Group LP

Page 38

38

OO

e

English English

See Section VIII for full instructions on replacing Battery Pack.

the pump, battery discharge and deactivation may tend to occur. It

The battery may need to be charged and discharged several times

to restore optimal capacity.

To replace Battery Door, see Figure 33 and do the following:

2. Snap the hinge

s onto the hinge pins.

3. Screw down the door to hold in p

wer Cord

Se

e Section IV for initial setup, including Power Cord attachment.

See Section

IV for initial setup, including attachment of the

Section XIII –

Service Part Numbers

To place an order for parts, or if technical assistance is required, call customer service.

The KANGAROO ePump

enteral feeding pump

contains a limited number of serviceable parts. User maintenance is to be

Visit our web site at:

www.TycoHealthcare.com

. . . . . . . . . . . . . . .

oor)

. . . .

. . . . . . . . . . . . . . . . . . . . . .

(with Screw)

. . . . . . . . . . .

. . . . . . . . . .

3

82491

. . . . . . . . . . . . . . . . . . . . . . . . . .

382492

3

82493

Re-Certification Pump Set

776150

Section

Warranty

Kendall, a Tyco Healthcare Group LP company, warrants to the original purchaser (“Customer”)

that this product will be free of defects in materials and workmanship, under normal use, for one (1) year from the

date of original purchase from Kendall or its authorized distributor. If this product does not operate as warranted above

during the applicable warranty period, Kendall may, at its option and expense, replace the defective part or product with

a comparable part or product, repair the defective part or product, or, if neither replacement nor repair is reasonably

available, refund to Customer the purchase price for the defective part or product. Dated proof of original purchase will

essed

or implied, including any implied warranty of merchantability or fitness for a particular purpose or application other than

as expressly set forth in the product labeling.

3

2

4

5

© 2005 Tyco Healthcare Group LP

Page 39

Section XV – Electromagnetic Conformity Declaration

The KANGAROO ePump enteral feeding pump has been built and tested according to UL60601-1, E181931 CSA-C22.2

The KANGAROO ePump enteral feeding pump is intended for use in the electromagnetic environment specifi ed below.

The user of the pump should assure that it is used in such an environment.

Em

issions Test Compliance Electromagnetic Environment - Guidance

RF emissions

(CISPR 11) Group 1

RF emissions

(CISPR 11) Class B

Harmonic emissions

(IEC 61000-3-2) Class A

Voltage fl uctuations/ fl icker emissions

(IEC 61000-3-3) Complies

Radiated Disturbance Immunity

(EN60601-1-2 / IEC 61000-4-3:2002) Complies

Conducted Disturbance Immunity

(EN60601-1-2 / IEC 61000-4-6:2001) Complies

Power Frequency Magnetic Field Immunity

(EN60601-1-2 / IEC 61000-4-8:2001) Complies

Voltage dips and sags Immunity

(EN60601-1-2 / IEC 61000-4-11:2001) Complies

Electrical Fast Transient / Bursts Immunity

(EN60601-1-2 / IEC 61000-4-4:2001) Complies

Electrostatic Discharge Immunity

(EN60601-1-2 / IEC 61000-4-2:2001) Complies

Surge Immunity

(EN60601-1-2 / IEC 61000-4-5:2001) Complies

39

The KANGAROO ePump uses RF energy only for its

internal function. Therefore, its RF emissions are very

The KANGAROO ePump is suitable for use in all

establishments, including domestic establishments

and those directly connected to the public low-

voltage power supply network that supplies buildings

© 2005 Tyco Healthcare Group LP

Page 40

40

OO

e

English

Section

XVI –

AccuSystem

The KANGAROO ePump is a reliable and accurate enteral feeding device. The reason for the accuracy of the KANGAROO

ePump enteral feeding pump is the design, controlled calibration methods, and stringent manufacturing controls. One

of the most critical functional parts of the KANGAROO ePump enteral feeding platform is the AccuSystem

feeding

set produced by Tyco Healthcare. The functionality of the KANGAROO ePump Accu

S

ystem

feeding set is extremely

delivery of nutrition and hydration.

The reason

the KANGAROO ePump enteral feeding pump and the KANGAROO ePump AccuSystem

feeding sets have

satisfied our customers’ expectations is due to the integration of these two parts during the manufacturing process.

The

feeding set manufacturing process parameters are tightly controlled at Tyco Healthcare

to minimize variation and produce consistent and reliable products. The special grades of thermoplastic materials are also

tightly controlled, and are specifically chosen to deliver consistent quality and accurate flow delivery with the KANGAROO

ePump enteral feeding pump. The factory calibration and final determination of an acceptable KANGAROO ePump

enteral

feeding pump is dependent on the use of acceptable Tyco Healthcare KANGAROO ePump Acc

feeding sets. The

eneric feeding sets or other feeding sets not pr

oduced by Tyco Healthcare is not supported or sanctioned by Tyco

ePump enteral feeding pump. Check your feeding set for the AccuSystem

logo to be certain that your KANGAROO

ePump enteral feeding pump will deliver accurately every time it is utlized.

© 2005 Tyco Healthcare Group LP

Page 41

™ Trademark of Tyco Healthcare Group LP or its affi liate.

TYCO HEALTHCARE GROUP LP

•

MANSFIE

L

D, MA 02048 •

MADE I

U.S.A.

•

© 2005 TYCO HEALTHCARE GROUP LP • ALL RIGHTS RESERVED

•

050310 •

PRODUCT INFO

I

•

www.TycoHealthcare.com

GOSPORT,

PO13 0AS, U.K.

SWISS DISTRIBUTOR: TYCO HEALTHCARE SWITZERLAND LTD. • ROOSTRASSE 53, POSTFACH CH-8832, WOLLER

AU SWITZERLAND

0123

�

KANGAROO

e

tyco

/ Healthcare

Enteral Feeding Pump

Serial Number

The undersigned hereby certifi es that the above referenced pump has been tested per the pump’s internal re-certifi cation

Manual Tests

Buzzer Tes

t

LED Test

MISTIC Test

Auto Te

st

(

Name) (Signature)

Facility

Address

City

, State, Zip

Page 42

kENDALL

KANGAROO ePump

™

Enteral Feeding Pump

tyco

/ Healthcare

Enteral Feeding Pump — Operation and Service Manual

Nutripompe — Manuel d’utilisation et d’entretien

Pumpe für die enterale Ernährung — Betriebs- und Serviceanleitung

Pompa di alimentazione enterale — Manuale operativo e di manutenzione

Bomba para alimentación enteral — Manual de operación y servicio

Enteral matningspump — Användar- och servicemanual

Enterale voedingspomp — Handleiding voor bediening en onderhoud

Bomba de alimentação entérica — Manual de funcionamento e assistência

Enteraalinen ravitsemuspumppu — Käyttö- ja huolto-opas

Pumpe til enteral ernæring — Betjenings- og servicehåndbog

Αντλία εντερικής σίτισης — Εγχειρίδιο λειτουργίας και σέρβις

Pumpa pro enterální výživu — Provozní a servisní příručka

Enterális táplálópumpa — Kezelési és karbantartási kézikönyv

Насос для энтерального питания — Руководство по эксплуатации и техническому обслуживанию

Pompa żywienia dojelitowego — Instrukcja obsługi i serwisowania

Enteral Besleme Pompası — Operasyon ve Servis Kılavuzu

Enteral ernæringspumpe — Bruker- og vedlikeholdshåndbok

Operation and Service Manual

See Instructions

0123

ONLY

™ Trademark of Tyco Healthcare Group LP or its affi liate.

SPRAY-NINE

is atrademark of

Spray-Nine Corporation.

PHISOPHEX

is atrademark of

Smith Kline Beecham Corp.

HIBICLENS

is atrademark of

Tubifoam Ltd.

VESTA-SYDE

is atrademark of

Steris, In

c.

TYCO HEALTHCARE GROUP LP

•

MANSFIE

L

D, MA 02048

MADE I

N

U.S.A.

•

© 2005 TYCO HEALTHCARE GROUP LP

ALL RIGHTS RESERVED

•

050310

PRODUCT INFORMATION

N U.S. 1-800-962-9888

www.TycoHealthcare.com

EC REP: TYCO HEALTHCARE U.K. LTD

GOSPORT,

PO13 0AS, U.K.

SWISS DISTRIBUTOR: TYCO HEALTHCARE SWITZERLAND LTD.

ROOSTRASSE 53, POSTFACH CH-8832, WOLLER

AU SWITZERLAND

182388

TM

™ Trademark of Tyco Healthcare Group LP or its affi liate.

TYCO HEALTHCARE GROUP LP

•

MANSFIE

L

D, MA 02048 •

MADE I

N

U.S.A.

•

© 2005 TYCO HEALTHCARE GROUP LP • ALL RIGHTS RESERVED

•

050310 •

PRODUCT INFO IN U.S. 1-800-962-9888

•

www.TycoHealthcare.com

EC REP: TYCO HEALTHCARE U.K. LTD

•

GOSPORT,

PO13 0AS, U.K.

•

SWISS DISTRIBUTOR: TYCO HEALTHCARE SWITZERLAND LTD. • ROOSTRASSE 53, POSTFACH CH-8832, WOLLER

AU SWITZERLAND

0123

TM

KANGAROO

e

kENDALL

tyco

/ Healthcare

KANGAROO ePump

Enteral Feeding Pump

Serial Number

Date of Re-Certifi cation

The undersigned hereby certifi es that the above referenced pump has been tested per the pump’s internal re-certifi cation

protocol with the following results

:

Manual Tests

Passed Failed

Buzzer Tes

t

LED Test

Battery Test

MISTIC Test

Auto Te

st

Inspector

(

Name) (Signature)

Facility

Address

City

, State, Zip

English

TM

Norwegian

Loading...

Loading...