Page 1

Worldwide

Contacts

Series DS-3 Dry-Type Sprinklers

11.2K Horizontal Sidewall

Standard Response, Extended Coverage

www.tyco-fire.com

General

Description

TYCO Series DS-3 Dry-Type Sprinklers,

11�2K Horizontal Sidewall, Standard

Response, Extended Coverage, Ordinary Hazard (ECOH) are decorative

glass bulb automatic sprinklers� They

are intended for use in applications

where the sprinklers and/or a portion of

the connecting piping may be exposed

to freezing temperatures; for example,

horizontal piping extensions through a

wall to protect an unheated area of a

building�

Series DS-3 Extended Coverage

Ordinary Hazard Horizontal Sidewall,

Dry-Type Sprinklers are designed for

extended coverage use in ordinary

hazard occupancies ( ECOH) per NFPA

13�

Series DS-3 Dry-Type Sprinklers

provide protection of coverage areas

up to 16 ft x 20 ft (320 ft2) as compared

to standard coverage horizontal sidewall sprinklers having a maximum coverage area of 10 ft x 10 ft (100 ft2) for

ordinary hazard occupancies�

NOTICE

Series DS-3 Dry-Type Sprinklers

described herein must be installed

and maintained in compliance with this

document, as well as with the applicable standards of the NATIONAL FIRE

PROTECTION ASSOCIATION (NFPA),

in addition to the standards of any other

authorities having jurisdiction. Failure

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and

installation can permanently damage

a sprinkler system or its components and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

to do so may impair the performance

of these devices.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Series DS-3 Dry-Type Sprinklers must

only be installed in fittings that meet

the requirements of the Design Criteria

section. Installation of Series DS-3 DryType Sprinklers in a recessed installation will void all sprinkler warranties, as

well as void the sprinkler’s laboratory

Approvals.

Sprinkler

Identification

Number (SIN)

TY5339

Technical

Data

Approvals

UL and C-UL Listed

Refer to Table A and the Design Criteria

section

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connections

1 Inch NPT

ISO 7-R 1

Discharge Coefficient

Refer to Table B

Temperature Ratings

155°F (68°C) and 200°F ( 93°C)

Finishes

Sprinkler: Refer to Table E

Escutcheon: Refer to Table E

Physical Characteristics

Inlet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � Copper

Plug � � � � � � � � � � � � � � � � � � � � � � � � � � � � � Copper

Yok e ����������������������� Stainless Steel

Casing �������������Galvanized Carbon Steel

Insert � � � � � � � � � � � � � � � � � � � � � � � � � � � � �Bronze

Bulb Seat � � � � � � � � � � � � � � � � � � � � � � � � � �Bronze

Bulb �������������������������Glass (3 mm )

Compression Screw � � � � � � � � � � � � � � � � �Bronze

Deflector � � � � � � � � � � � � � � � � � � � � � � � � � �Bronze

Frame � � � � � � � � � � � � � � � � � � � � � � � � � � � �Bronze

Gu id e Tu be � � � � � � � � � � � � � � � � � Stainless Steel

Water Tube � � � � � � � � � � � � � � � � � Stainless Steel

Spring ��������������������� Stainless Steel

Sealing Assembly ��Beryllium Nickel w/TEFLON

Pin ������������������������ Stainless Steel

Button Spring � � � � � � � � � � � � � � � Stainless Steel

Helper Spring � � � � � � � � � � � � � � � Stainless Steel

Escutcheon � � � � � � � � � � � � � � � � � � � Carbon Steel

Operation

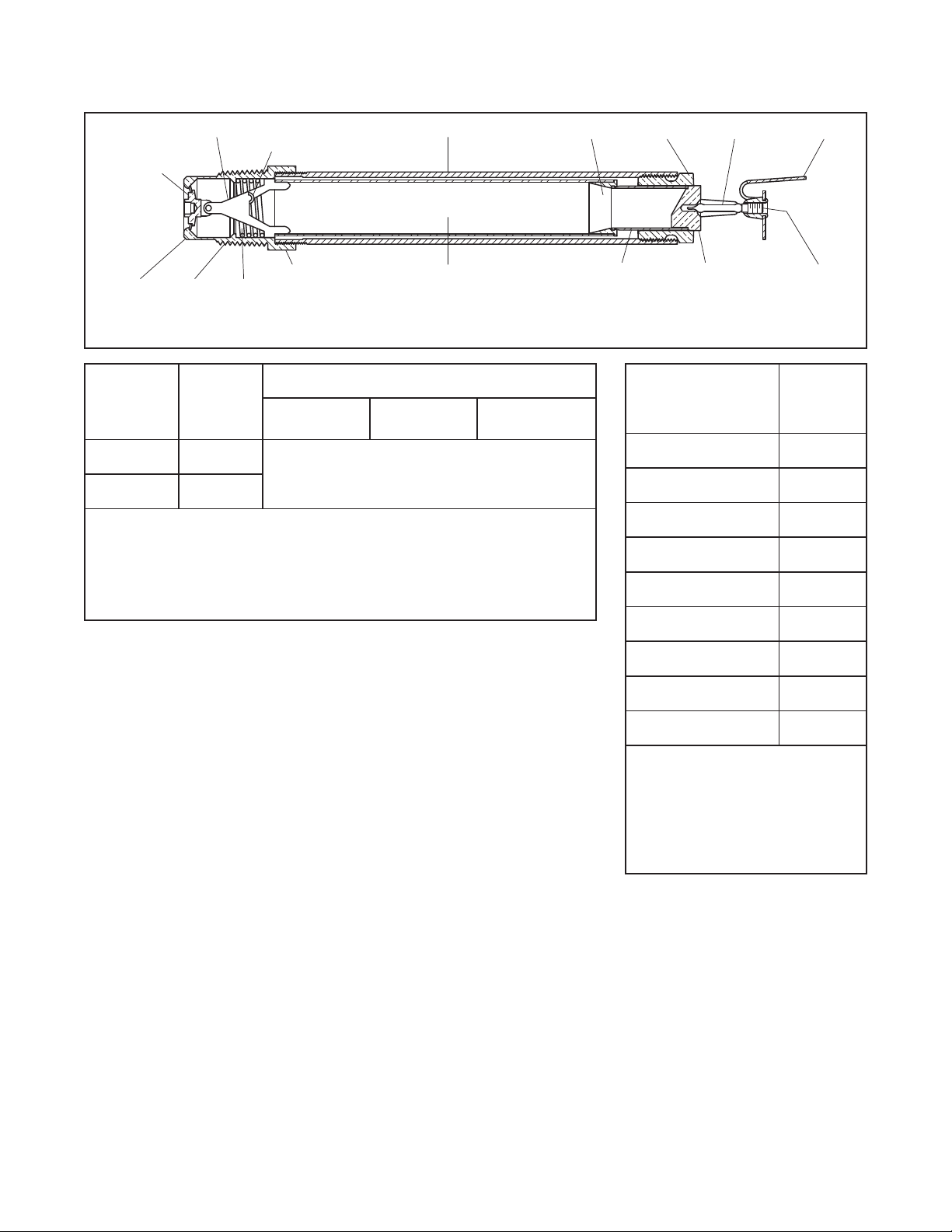

When TYCO Series DS-3 Dry-Type

Sprinklers, 11�2K Horizontal Sidewall,

Standard Response, Extended Coverage, Ordinary Hazard (ECOH) are in

service, water is prevented from entering the assembly by the Plug with

Sealing Assembly (Ref� Figure 1) in the

Inlet of the sprinkler�

The glass bulb contains a fluid that

expands when exposed to heat� When

the rated temperature is reached, the

fluid expands sufficiently to shatter

the glass bulb, and the Bulb Seat is

released�

The compressed Spring is then able

to expand and push the Water Tube as

well as the Guide Tube outward� This

action simultaneously pulls inward on

the Yoke, withdrawing the Plug with

Sealing Assembly from the Inlet allowing the sprinkler to activate and flow

wa te r�

Page 1 of 8 AUGUST 2018 TFP550

Page 2

TFP550

1" NPT

SPRINGINLET

TUBE

PLUG

SPRING SEAL

PLUG WITH

YOKE CASING

SCREW

COMPRESSION

SEAT

TUBE

DEFLECTORINSERT FRAME

BULB

BAND

Page 2 of 8

GASKETED

PLATE

SPRING

INLET

WATER

FIGURE 1

SERIES DS-3 HORIZONTAL SIDEWALL DRY-TYPE SPRINKLER TY5339 (ECOH )

AS S E MBLY

Temperature

Rating

155° F (68°C) Red

200°F (93°C) Green

Notes:

1. Listed by Underwriters La boratori es, Inc. (ma ximum orde r length of 4 8 inches)

2. Listed by Under writers L aborato ries for us e in Canada (ma ximum ord er length of 48 inches).

Bulb

Color Code

Natural

Brass

SPRINKLER FINISH

Chrome

Plated

1, 2

TABLE A

SERIES DS-3 HORIZONTAL SIDEWALL DRY-TYPE SPRINKLERS

EXTENDED COVERAGE, ORDINARY HAZARD (TY5339)

LABORATORY LISTINGS AND APPROVALS

Sprinkler Fittings

Design

Install 1 inch NPT Series DS-3 Dry-Type

Sprinklers in the 1 inch NPT outlet or

Criteria

The TYCO Series DS-3 Dry-Type Sprinklers, 11�2K Horizontal Sidewall, Standard Response, Extended Coverage,

Ordinary Hazard (ECOH) are for use in

ordinary hazard occupancies with noncombustible unobstructed construction

and with a ceiling slope not exceeding 2 inches per foot (9�2° ), using the

design criteria provided in Table C, as

well as any additional requirements

specified in NFPA 13 for Extended Coverage Sidewall Spray Sprinklers�

A 36 in� (914 mm) clearance must be

maintained between the top of the

sprinkler deflector and any miscellaneous storage�

Series DS-3 Dry-Type Sprinklers may

be installed on sloped ceilings in

loading docks with a maximum roof

slope of 4 inches per foot (18�4°) as

run of the following fittings:

•

malleable or ductile iron threaded

tee ttings that meet the dimensional requirements of ANSI B16.3

(Class 150)

•

cast iron threaded tee ttings that

meet the dimensional requirements

of ANSI B16.4 (Class 125)

Do not install Series DS-3 Dry-Type

Sprinklers into elbow fittings� The Inlet

of the sprinkler can contact the interior

of the elbow�

The unused outlet of the threaded tee is

plugged as shown in Figure 6�

Series DS-3 Dry-Type Sprinklers can

also be installed in the 1 inch NPT outlet

of a GRINNELL Figure 730 Mechanical

Tee� However, the use of the Figure 730

Tee for this arrangement is limited to

wet pipe systems�

shown in Figure 8 and using the design

criteria provided in Table C�

White

Polyester

GUIDE

(381 mm to 476 mm)

(483 mm to 584 mm)

(591 mm to 679 mm)

(692 mm to 794 mm)

(800 mm to 895 mm)

(902 mm to 1003 mm)

(1010 mm to 1105 mm)

(111 mm to 1219 mm)

Notes:

• K-factor Le ngth is dete rmined as f ollows:

• Flush: Order Lengt h from Figur e 2 plus 1/2 in.

• Deep: Or der Lengt h from Figure 4 plus 3-1/4 in.

• Withou t Escutche on: Order Length from Figure 5

BULB

Length,

Inches

(mm)

2-1/2 to 14-3/4

(63 mm to 375 mm)

15 to 18-3/4

19 to 23

23-1/4 to 2 6- 3/4

27-1/4 to 31-1/4

31-1/2 to 35-1/4

35 -1/ 2 t o 3 9-1/2

39-3/4 to 43-1/2

43-3/4 to 48

(12,7 m m)

(82,6 mm)

minus 2-1/4 in. (57,2 mm)

TABLE B

DISCHARGE COEFFICIENTS

K-factor,

gpm/psi

(lpm/bar½)

11. 2

(161, 3)

10.9

(1 57,0 )

10.8

(155 ,5)

10.7

(154 ,1)

10.6

(152,6)

10.5

(151,2)

10.4

(149,8)

10.3

(148,3)

10.2

(146,9)

½

Page 3

TFP550

Page 3 of 8

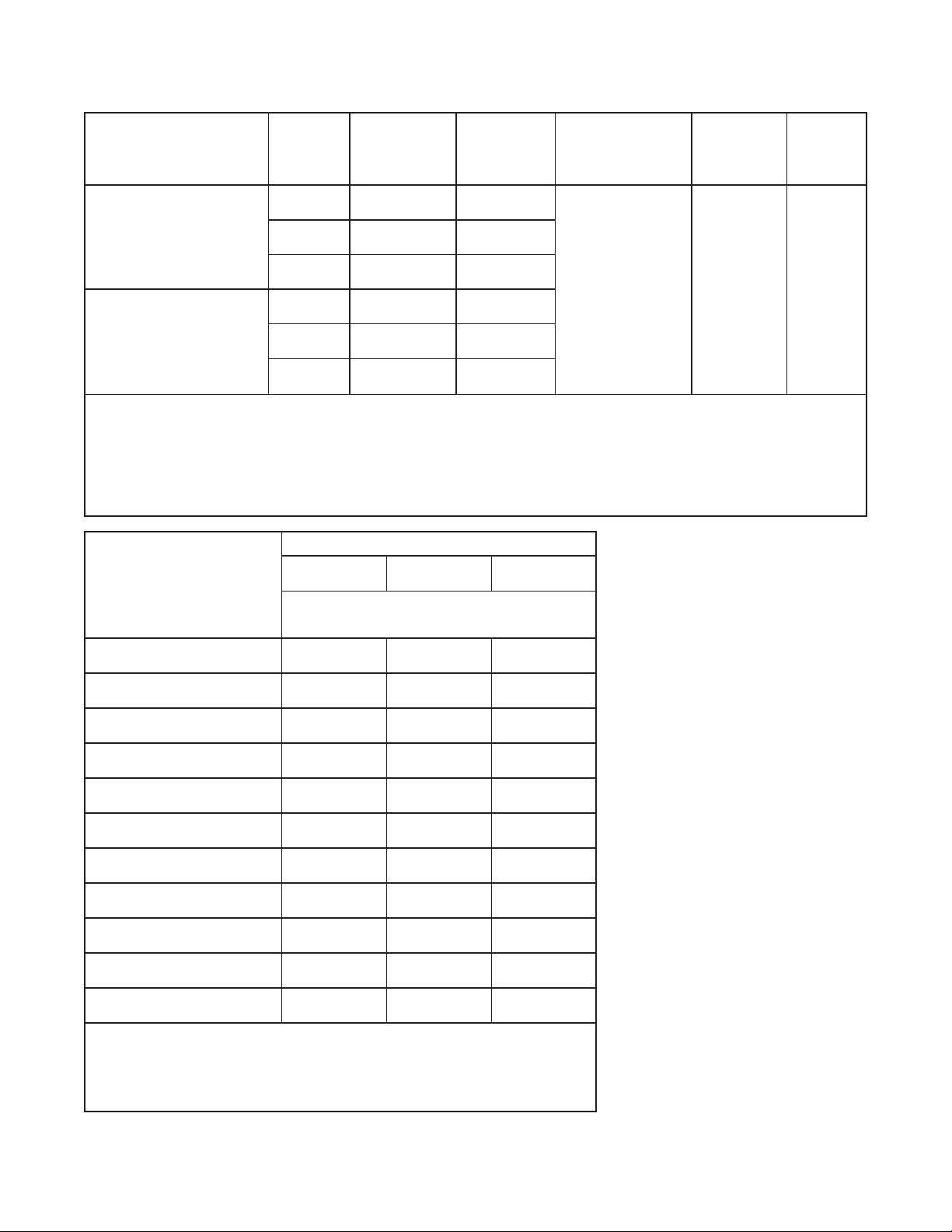

Coverage

1

Application

Series DS-3 (TY5339)

Horizontal Sidewall

Dry-Type Sprinkler (ECOH)

OH Group 1 (0.15 gpm/sq.ft)

Standard Response

Series DS-3 (TY5339)

Horizontal Sidewall

Dry-Type Sprinkler (ECOH)

OH Group 2 (0.20 gpm/sq.ft)

Standard Response

Notes:

1. Backwall (where sprinkler is located) by sidewall (length of throw).

2. Req uirement i s based on mi nimum ow in GPM f rom each sp rinkler. The i ndicated r esidual p ressure s are based o n the nomina l K-factor of 11.2.

3. T he center line of the sprinkler waterway is located below t he deecto r as shown in Figures 2, 3, and 4.

4. M inimum spa cing is for la teral dist ance betw een sprin klers loc ated along a s ingle wall. O therwi se adjacent sprinkl ers (that is, sidewall sprinklers on an adjac ent wall,

on an opp osite wall, or p endent sp rinkler s) must be loc ated outside of the maximum liste d protecti on area of the ex tended coverage sidewall sprin kler bein g utilized.

Area

W x L,

ft x ft

(m x m)

16 x 16

(4,9 x 4,4)

16 x 18

(4,9 x 5,5)

16 x 20

(4,9 x 6,1)

16 x 16

(4,9 x 4,4)

16 x 18

(4,9 x 5,5)

16 x 20

(4,9 x 6,1)

Minimum

Flow2,

gpm

(lpm)

38

(144)

43

(163)

48

(182)

51

(193)

58

(220)

64

(242)

Minimum

Pressure2,

psi

(bar)

11. 5

(0,79)

14.7

(1,01)

18.4

(1,27)

20.7

(1,4 3)

26.8

(1,85)

32.7

(2,25)

Top of

Deflector-to-Ceiling

Distance3,

Inches

(mm)

6 to 12

(150 to 300)

Temperature

Rating

155°F, 200°F

(68°C, 93°C)

Minimum

Spacing4,

TABLE C

SERIES DS-3 EXTENDED COVERAGE HORIZONTAL SIDEWALL DRY-TYPE SPRINKLERS

UL AND C-UL LISTING COVERAGE AND FLOW RATE CRITERIA

Temperatures for Heated Area

Ambient Temperature

Discharge End of Sprinkler

Notes:

1. For prote cted area te mperatu res that occ ur betwee n values lis ted above, us e the next coo ler tempe rature.

2. The se lengths are inclus ive of wind velo cities up to 3 0 mph (18,6 kph).

Exposed to

40°F

(4°C)

30°F

(-1° C)

20°F

(-7° C)

10°F

(-12 °C)

0°F

(-18 °C )

-10°F

(-23°C)

-20°F

(-29°C)

-30°F

(-34°C)

-40°F

(-40°C)

-50°F

(-46°C)

-60°F

(-51°C)

40°F

(4°C)

Minimum Exposed Barrel Length2,

0 0 0

0 0 0

4

(100)

8

(200)

12

(305)

14

(355)

14

(355)

16

(405)

18

(455)

20

(510)

20

(510)

50°F

(10°C)

Inches

(mm)

0 0

1

(25)

3

(75)

4

(100)

6

(150 )

8

(200)

8

(200)

10

(255)

10

(255)

1

60°F

(16°C)

0

0

1

(25)

3

(75)

4

(100)

4

(100)

6

(150 )

6

(150 )

The configuration shown in Figure 7 is

only applicable for wet pipe systems

where the sprinkler fitting and waterfilled pipe above the sprinkler fitting are

not subject to freezing and where the

length of the Dry-Type Sprinkler has the

minimum exposure length depicted in

Figure 10� Refer to the Exposure Length

section�

For wet pipe system installations of 1

inch NPT Series DS-3 Dry-Type Sprinklers connected to CPVC piping, use

only the following TYCO CPVC fittings:

•

1 in. x 1 in. NPT Female Adapter

(P/N 80145)

•

1 in. x 1 in. x 1 in. NPT Sprinkler

Head Adapter Tee (P/N 80249)

For dry pipe system installations, use

only the side outlet of maximum 2-1/2

inch reducing tee when locating Series

DS-3 Dry-Type Sprinklers directly

below the branch line� Otherwise, use

the configuration shown in Figure 6 to

assure complete water drainage from

above Series DS-3 Dry-Type Sprinklers

and the branch line� Failure to do so

may result in pipe freezing and water

damage�

TABLE D

EXPOSED SPRINKLER BARRELS IN WET PIPE SYSTEMS

MINIMUM RECOMMENDED LENGTHS

ft

(m)

8

(2,4)

Page 4

TFP550

OF WATERWAY

ORDER LENGTHS:

2-1/4" (57,2 mm)

CRITERIA SECTION)

OF WATERWAY

3-11/16" DIA.

ORDER LENGTHS:

FACE OF

OF WATERWAY

3-1/2" DIA.

ORDER LENGTHS:

FACE OF

Page 4 of 8

3" to 45-1/4" (76,2 to 1149,4 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF

SPRINKLER FITTING

1" NPT,

NOMINAL MAKE-IN

9/16" (14,3 mm)

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

2-3/4" DIA.

(69,9 mm)

FIGURE 2

SERIES DS-3 ECOH HORIZONTAL SIDEWALL DRY-TYPE SPRINKLER

WITH FLUSH ESCUTCHEON ( TY5339 )

1" to 44" (25,4 to 1117,6 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF

SPRINKLER FITTING

1" NPT,

NOMINAL MAKE-IN

9/16" (14,3 mm)

SPRINKLER FITTING

(REFER TO DESIGN

CRITERIA SECTION)

2-3/4" DIA.

(69,9 mm)

FIGURE 3

SERIES DS-3 ECOH HORIZONTAL SIDEWALL DRY-TYPE SPRINKLER

WITH DEEP ESCUTCHEON (TY5339 )

5-1/4" to 48" (133,4 to 1219,2 mm)

IN 1/4" (6,4 mm) INCREMENTS

FACE OF SPRINKLER FITTING

1" NPT,

NOMINAL MAKE-IN

9/16" (14,3 mm)

SPRINKLER FITTING

(REFER TO DESIGN

FIGURE 4

SERIES DS-3 ECOH HORIZONTAL SIDEWALL DRY-TYPE SPRINKLER

WITHOUT ESCUTCHEON (TY5339)

MOUNTING

SURFACE

MOUNTING

SURFACE

2" ± 1/8"

(50,8 ± 3,2 mm)

9/16" (14,3 mm)

(93,7 mm)

CENTERLINE

4-1/8" ± 3/8"

(104,8 ± 9,5 mm)

9/16" (14,3 mm)

(88,9 mm)

CENTERLINE

MINIMUM

DEFLECTOR TO

MOUNTING

SURFACE

9/16"

(14,3 mm)

CENTERLINE

NOTICE

Do not install Series DS-3 Dry-Type

Sprinklers into any other type fitting

without first consulting the Technical

Services Department. Failure to use the

appropriate fitting may result in one of

the following:

•

failure of the sprinkler to operate

properly due to formation of ice

over the Inlet Plug or binding of the

Inlet Plug

•

insufficient engagement of the

Inlet pipe-threads with consequent

leakage

Drainage

In accordance with the minimum

requirements of the NATIONAL FIRE

PROTECTION ASSOCIATION for dry

pipe sprinkler systems, branch, cross,

and feed-main piping connected to Dry

Sprinklers and subject to freezing temperatures must be pitched for proper

drainage�

Exposure Length

When using Dry Sprinklers in wet pipe

sprinkler systems to protect areas

subject to freezing temperatures, use

Table D to determine a sprinkler’s

appropriate exposed barrel length to

prevent water from freezing in the connecting pipes due to conduction� The

exposed barrel length measurement

must be taken from the face of the

sprinkler fitting to the surface of the

structure or insulation that is exposed

to the heated area� Refer to Figure 7 for

an example�

For protected area temperatures

between those given above, the

minimum recommended length from

the face of the fitting to the outside of

the protected area may be determined

by interpolating between the indicated

values�

Clearance Space

In accordance with NFPA 13, when

connecting an area subject to freezing and an area containing a wet pipe

sprinkler system, the clearance space

around the sprinkler barrel of Dry-Type

Sprinklers must be sealed. Due to

temperature differences between two

areas, the potential for the formation of

condensation in the sprinkler and subsequent ice build-up is increased. If

this condensation is not controlled, ice

build-up can occur that might damage

the Dry-Type Sprinkler and/or prevent

proper operation in a re situation.

Use of the Model DSB-2 Dry Sprinkler Boot, described in Technical Data

Sheet TFP591 and shown in Figure 9,

can provide the recommended seal.

Page 5

TFP550

DSB-2

PLUGGED

BOOT)

2-3/4" DIA.

DISTANCE

EXPOSURE

Page 5 of 8

TO DRY

SYSTEM

DSB-2

INTENDED

FOR FREEZER

STRUCTURES

AREA

SUBJECT

TO

FREEZING

FIGURE 5

SPRINKLER FITTING

UNHEATED AREA

MAXIMUM

THROW

RUN

OUTLET

INTENDED

FOR FREEZER

STRUCTURES

SPRINKLER

FITTING

(SEE DESIGN

CRITERIA

SECTION)

TO DRY

SYSTEM

AREA

SUBJECT

TO

FREEZING

FIGURE 6

SPRINKLER FITTING

UNHEATED AREA

(69,9 mm)

CLEARANCE

HOLE

ADHESIVE

DSB-2

BOOT

LENGTH

(SEE DESIGN

CRITERIA SECTION)

FACE OF

SPRINKLER

FITTING

DSB-2

INTENDED

FOR FREEZER

STRUCTURES

HEATED

AREA

FIGURE 7

SPRINKLER FITTING

HEATED AREA

INSULATED

FREEZER

STRUCTURE

6" (152,4 mm)

TO 12" (304,8 mm)

CEILING TO TOP

OF SPRINKLER

DEFLECTOR

4/12

SLOPE

MAXIMUM

FIGURE 8

SPRINKLER PLACEMENT

UNDER SLOPED CEILINGS

IN LOADING DOCKS

STRAP TIES

(ENDS ON

OPPOSING

SIDES OF

DS-3

SHOWN

WITH FLUSH

ESCUTCHEON

FIGURE 9

MODEL DSB-2 DRY SPRINKLER

BOOT WITH SERIES DS-3

DRY-TYPE PENDENT SPRINKLER

Page 6

TFP550

SHOWN

WRENCH FLAT

Page 6 of 8

Installation

TYCO Series DS-3 Dry-Type Sprinklers,

11�2K Horizontal Sidewall, Standard

Response, Extended Coverage, Ordinary Hazard (ECOH) must be installed

in accordance with this section�

General Instructions

Series DS-3 Dry-Type Sprinklers must

only be installed in fittings that meet

the requirements of the Design Criteria section� Refer to the Design Criteria

section for other important requirements regarding piping design and

sealing of the clearance space around

the Sprinkler Casing� With reference to

Figure 10, do not grasp the sprinkler

by the deflector� Failure to follow this

instruction may impair performance of

the device�

Do not install any bulb-type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb� With the sprinkler held horizontally, a small air bubble

should be present� The diameter of the

air bubble is approximately 1/16 in�

(1,6 mm) for the 135°F (57°C) rating to

1/8 in� (3,2 mm) for the 360°F (182°C)

rating�

A leak-tight 1 inch NPT sprinkler joint

should be obtained by applying a minimum-to-maximum torque of 20 to

30 lb-ft (26,8 to 40,2 N·m)� Higher

levels of torque may distort the sprinkler Inlet with consequent leakage or

impairment of the sprinkler�

Do not attempt to compensate for

insufficient adjustment in an escutcheon plate by under or over-tightening

the Sprinkler� Re-adjust the position of

the sprinkler fitting to suit�

Step 1. Install horizontal sidewall sprinklers with the center line of waterway

parallel to the ceiling and perpendicular to the back wall surface� The word

“TOP” on the deflector must face

upwards toward the ceiling�

Step 2. With a non-hardening pipethread sealant such as TEFLON applied

to the Inlet threads, hand-tighten the

sprinkler into the sprinkler fitting� Do

not grasp the sprinkler by the deflector

(Ref� Figure 10)�

Step 3. Wrench-tighten the sprinkler

using either:

•

a pipe wrench on the Inlet Band or

the Casing (Ref. Figure 1)

•

the W-Type 8 Sprinkler Wrench on

the Wrench Flat (Ref. Figure 11)

Apply the Wrench Recess of the

W-Type 8 Sprinkler Wrench to the

Wrench Flat�

FIGURE 10

DO NOT GRASP

DEFLECTOR

Note: If sprinkler removal becomes

necessary, remove the sprinkler using

the same wrenching method noted

above� Sprinkler removal is easier when

a non-hardening sealant was used

and torque guidelines were followed�

After removal, inspect the sprinkler for

damage�

Step 4. After applying a wall finish,

slide on the outer piece of the escutcheon until it comes in contact with the

mounting surface�

For Deep Escutcheons, slide the outer

skirt over the inner cup to make firm

contact with the mounting surface�

Care and

Maintenance

TYCO Series DS-3 Dry-Type Sprinklers,

11�2K Horizontal Sidewall, Standard

Response, Extended Coverage, Ordinary Hazard (ECOH) must be maintained and serviced in accordance with

this section�

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

systems from the proper authorities

and notify all personnel who may be

affected by this action�

Absence of the outer piece of an

escutcheon, which is used to cover a

clearance hole, may delay the time to

sprinkler operation in a fire situation�

A Vent Hole is provided in the Bulb Seat

(Figure 1) to indicate if the Dry Sprinkler

is remaining dry� Evidence of leakage

from the Vent Hole indicates potential leakage past the Inlet seal and the

need to remove the sprinkler to deter-

ENGAGEMENT

AREA

WRENCH

FLATS

APPLY

WRENCH AS

FIGURE 11

W-TYPE 8

SPRINKLER WRENCH

mine the cause of leakage; for example,

an improper installation or an ice plug�

Close the fire protection system control

valve and drain the system before

removing the sprinkler�

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced�

Automatic sprinklers must never be

painted, plated, coated, or otherwise altered after leaving the factory�

Modified sprinklers must be replaced�

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush�

Care must be exercised to avoid

damage to the sprinklers – before,

during, and after installation� Sprinklers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced� Also, replace any sprinkler

that has a cracked bulb or that has lost

liquid from its bulb� (Refer to Installation Section�)

The owner is responsible for the inspection, testing, and maintenance of their

fire protection system and devices in

compliance with this document, as well

as with the applicable standards of the

NATIONAL FIRE PROTECTION ASSOCIATION (e�g�, NFPA 25), in addition to

the standards of any other authorities

having jurisdiction� Contact the installing contractor or product manufacturer

with any questions�

Automatic sprinkler systems are recommended to be inspected, tested,

and maintained by a qualified Inspection Service in accordance with local

requirements and/or national codes�

Page 7

P/N* 61 — XXX — X — XXX

TFP550

Page 7 of 8

ESCUTCHEON TYPE

161

163

171

173

151

153

Notes:

1. Does no t apply to ass emblies without esc utcheon.

2. Dr y-Ty pe Sprink lers are fu rnished b ased upon “ Order Len gth” as meas ured per Figures 2, 3 & 4.

3. A fter the me asureme nt is taken, ro und it to the ne arest 1/4 inch inc rement.

* Use Pre x “I” for ISO 7-R1 Con nection (e.g ., I-61-161-1-0 55).

Flush Escutcheon

(1 in. NPT), 155°F (68°C)

Flush Escutcheon

(1 in. NPT), 200°F (93°C)

Deep Escutcheon

(1 in. NPT), 155°F (68°C)

Deep Escutcheon

(1 in. NPT), 200°F (93°C)

Without Escutcheon

(1 in. NPT), 155°F (68°C)

Without Escutcheon

(1 in. NPT), 200°F (93°C)

SPRINKLER

1

SIGNAL WHITE

4

9

0

FINISH

NAT URA L

BRASS

(RAL9003)

POLYESTER

CHROME

PL ATED

CHROME

PL ATED

TABLE E

SERIES DS-3 HORIZONTAL SIDEWALL, DRY-TYPE SPRINKLERS (ECOH)

PART NUMBER SELECTION

Limited

Warranty

For warranty terms and conditions, visit

www�tyco-fire�com�

Ordering

Procedure

Contact your local distributor for availability� When placing an order, indicate the full product name, including

description and Part Number (P/N)�

Dry-Type Sprinklers

When ordering Series DS-3 Dry-Type

Sprinklers, 11�2K Horizontal Sidewall,

Standard Response, Extended Coverage, Ordinary Hazard (ECOH), specify

the following information:

• SIN TY5339

• Order Length:

Dry-Type Sprinklers are furnished

based upon Order Length as

measured from the face of the wall

to the face of the sprinkler tting

(Ref. Figures 2, 3 & 4). After the

measurement is taken, round it to

the nearest 1/4 inch increment.

• Inlet Thread Connections:

1 Inch NPT

(Standard)

ISO 7-R 1

(For information on ISO Inlet Thread

Connections, contact your Johnson

Controls Sales Representative�)

• Temperature Rating

• Sprinkler Finish

•

Escutcheon Type and Finish, as

applicable

• Part Number from Table E

ESCUTCHEON

SIGNAL WHITE

(RAL9003)

POLYESTER

SIGNAL WHITE

(RAL9003)

POLYESTER

1

FINISH

BRASS

PL ATED

CHROME

PL ATED

ORDER

LENGTH

055 5.50 in.

082 8.25 in.

180 18.00 in.

187 18.75 in.

372 37. 25 i n .

480 48.00 in.

2

Sprinkler Wrench

Specify W-Type 8 Sprinkler Wrench,

P/ N 56-8 92-1- 0 01

Sprinkler Boot

Specify Model DSB-2 Dry Sprinkler

Boot, P/N 63-000-0-002

This Part Number includes one (1)

Boot, two (2) Strap Ties, and 1/3 oz

of Adhesive (a sufficient quantity for

installing one boot)�

Page 8

TFP550

Page 8 of 8

1400 Pennbroo k Parkwa y, Lansdale, PA 1944 6 | Telephon e +1-215-362- 0700

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

TEFLON is a regi stered tradema rk of DuPont

Loading...

Loading...