Table of Contents

1. Introduction....................................................................... 4

Overview..................................................................... 4

Icons........................................................................... 5

Hardware Specifications/Features................................. 6

Software Specifications.................................................8

Technical Support......................................................... 8

Returning Merchandise for Service................................ 9

2. Board Installation.............................................................. 10

Unpacking.................................................................... 10

Installation.................................................................... 11

Setting Jumpers............................................................ 11

3. Onboard Resource Settings.............................................. 12

Quick Reference for Jumpers........................................12

Map of Motherboard Jumpers....................................... 13

Soft Power Connector...................................................16

Sleep Button Connector.................................................16

Speaker Connector Installation...................................... 17

Hardware Reset Switch Connector Installation............... 17

CMOS RTC................................................................. 17

Flash EEPROM........................................................... 18

Hardware CMOS & Password Reset............................ 18

DRAM Installation....................................................... 18

Installing the CPU........................................................ 20

Peripheral Device Installation........................................ 25

Connecting the Power Supply........................................ 25

Frequently Asked Questions.......................................... 27

4. BIOS Configuration........................................................... 30

Standard Setup............................................................. 30

BIOS Features Setup.................................................... 32

Advanced Setup........................................................... 33

Chipset Setup............................................................... 38

Power Management Setup............................................ 47

PCI/PnP Setup............................................................. 50

Peripheral Setup........................................................... 53

Flash Writer Utility........................................................ 56

5. System Resources............................................................. 58

POST Checkpoint Codes.............................................. 58

Beep Codes................................................................. 66

Troubleshooting System Problems.................................. 67

Displayed Error Messages............................................ 68

Chapter 1

chapter 1

Introduction

Overview

The S1692S Tiger and S1692D Tiger 2 ATX are quality, high performance motherboards designed for Intel’s Pentium II microprocessors.

These motherboards utilize Intel’s 440LX AGP series chipset (also

called AGPset) and support Pentium II CPU speeds of 233MHz to

300MHz.

The S1692S/D mainboards with built-in AGP slot provide high performance capabilities that are ideal for a wide range of demanding applications such as CAD, CAM, CAE, desktop publishing, 3D animation,

and video production. The S1692S/D boards are suitable as powerful

workstations, and as internet, intranet, file, network, and database

servers. The Tiger 2 S1692D ATX’s superior dual processor technology

increases performance and productivity drastically for multi-processor

enabled operating systems such as Microsoft Windows NT, Novell

Netware SMP, and SCO Unix.

These integrated system boards achieve high reliability with numerous

features and yet are small enough to be supported in ATX form-factors.

Some of the features included are onboard dual channel PCI

4

UltraDMA 33, onboard floppy controller, and onboard high speed I/O.

The S1692S/D boards are built to be both flexible and expandable. With

I/O and drive controller support built onboard, the five 32-bit PCI BUS

Master and two ISA slots (one shared, seven usable) are available for

add-on expansion cards.

Icons

In order to help you navigate this manual and set up your system, we

have added several icons to our format.

This icon alerts you to particularly important details regarding

!

the setup or maintenance of your system. This icon often

appears next to information that may keep you from damaging

your board or system. While we will often point out the most vital

paragraphs in a chapter, you should always read every word in the text.

Failing to do so can lead to exasperation and expense.

Wherever possible, we have included step-by-step instructions for setting up your system, which are indicated by this

icon. However, it is in your best interest to read an entire

section (and perhaps the entire manual) before you begin to alter the

settings on your motherboard.

INTRO

While we have alerted you to potential dangers in several

places in this manual with this icon, these warnings should not

be regarded as the whole of your safety regimen. Never

forget that computers are electrical devices, and are capable of delivering a burn or shock. Prevent damage to yourself and to your board:

always ensure that your system is turned off and unplugged whenever

you are working with it, and that you are equipped with a static safety

device.

5

Chapter 1

Hardware Specifications/Features

Processor Information sPentium II 233-300 MHz.

sS1692D: Two SEC slots (Slot One).

sS1692S: One SEC slot (Slot One).

s2 VRM components installed

onboard.

s3 onboard CPU fan connectors.

sIntel MPS v1.4 compliant.

Chipset Information sIntel 440LX AGPset.

sIntel 82371AB (PIIX4).

sS1692D: Intel 82093 I/O APIC chip.

Voltage and Power sATX power supply connector.

Information s+12 V power source for DC fan

onboard.

s3.3V or 5.0V DRAM support.

sUtilizes GTL+ BUS, reducing power

consumption and EMI.

sPower recovery after interrupt.

sBulit-in overload protection that

automatically shuts down the system

in case of power surge.

Main Memory sUp to 1024MB (1GB) EDO onboard.

sUp to 512MB SDRAM support.

sFour 168-pin DIMM slots.

sEDO or SDRAM support.

sECC support.

System Management sWake-on LAN 3-pin connector for

remote booting by Network

Administrator.

sOnboard National LM75 chip for

CPU temperature sensing.

6

sOnboard National LM78 thermal

control chip for heat, fan, and voltage.

Reports to the operating system for

system monitoring. LANdesk

compatible.

sIntel LANDesk Client Manager

software, and/or Intel LANDesk

Server Manager software (with LM78

installed).

Expansion Slots sOne AGP slot for 3D graphics card.

sFive 32-bit PCI BUS Master slots

(PCI 2.1 compliant).

sTwo 16-bit ISA slots.

sOne shared, seven usable.

Physical Dimensions sIntel ATX design.

s9.5 x 12 inches.

sDouble-row ATX connectors.

BIOS Information sAMI Plug and Play flash BIOS.

sDeep Green and Energy Star

compliant.

sACPI, Year 2000, and PC97/98

ready; PCI 2.1 compliant.

sSoft power-down, multiple boot

options.

sWin98 Ready, DMI 2.0 compliant.

sSupport for easy BIOS upgrades with

flash EEPROM chip.

INTRO

IDE Disk Drive & sTwo PCI BUS Mastering EIDE

System I/O channels.

sSupports EIDE CD-ROMs.

sPIO Mode 3 & 4 (up to 17MB/sec

DTR).

7

Chapter 1

sUltraDMA 33 BUS Mastering Mode

(up to 33MB/sec DTR).

sTwo floppy drives (up to 2.88MB).

sTwo ATX serial ports (16550

UARTs).

sOne ATX ECP/EPP parallel port.

sOne IR (InfraRed) I/O interface

port.

sTwo USB rev 1.2 (universal serial

BUS) ports.

sOne ATX PS/2 mouse port.

sOne ATX PS/2 keyboard connector.

Software Specifications

Operating System sOperates with MS-DOS, Windows

3.x, Windows for WorkGroups 3.x,

Windows 95, Windows NT, OS/2,

Novell Netware, Solaris, and SCO

Unix.

Technical Support

If a problem arises with your system, you should first turn to your

dealer for help. Your system has most likely been configured by them,

and they should have the best idea of what hardware and software

your system contains. Hence, they should be able to be of the most

assistance. Further, if you purchased your system from a dealer near to

you, you can actually bring your system in to them to have it serviced,

instead of attempting to yourself (which can have expensive consequences).

If your dealer is unable to assist you:

try our web page – http:// www.tyan.com,

or user newsgroup – alt.comp.periphs.mainboard.tyan.

8

Returning Merchandise for Service

During the warranty period, contact your distributor or system vendor

FIRST for any product problems. This warranty only covers normal

customer use and does not cover damages incurred during shipping or

failure due to the alteration, misuse, abuse, or improper maintenance of

products.

For Resellers Only:

A receipt or copy of your invoice marked with the date of purchase is

required before any warranty service can be rendered. You can obtain

service by calling the manufacturer for a Return Merchandise Authorization (RMA) number. The RMA number should be prominently

displayed on the outside of the shipping carton and the package should

be mailed prepaid, or hand-carried to the manufacturer. Shipping and

handling charges will be applied for all orders that must be mailed when

service is complete.

Trademarks

AMI BIOS/Flash are trademarks of American Megatrend Inc.

Windows is a trademark of Microsoft Corporation.

IBM, PC, AT, PS/2 are trademarks of IBM Corporation.

INTEL, Pentium II are trademarks of Intel Corporation.

S1692S/D Tiger Series ATX is a trademark of TYAN Computer

Corporation.

All other trademarks are the property of their respective companies.

INTRO

Disclaimer

Information presented in this publication has been carefully checked for

reliability. However, no responsibility is assumed for inaccuracies. The

information contained in this document is subject to change without

notice.

9

Chapter 2

chapter 2

Board Installation

Unpacking

The mainboard package should contain the following:

S1692S/D mainboard

One IDE 40-pin cable

One 34-pin floppy cable

User’s manual

One retention module (S1692S)

or Two retention modules (S1692D)

The mainboard contains sensitive electric components which can be

easily damaged by static electricity, so the mainboard should be left in

its original packaging until it is ready to be installed.

With the power supply plugged in and turned off, touch an unpainted

area of the system chassis immediately before handling the mainboard

or any component. Doing so discharges any static charge your body

may have acquired.

10

After opening the mainboard carton, extract the system board–holding

it by its edges–and place it on a grounded anti-static surface, component side up. Inspect the board for damage. Press down on any of the

socket ICs if it appears that they are not properly seated (the board

should still be on an anti-static mat). Do not touch the bottom of the

board.

DO NOT APPLY POWER TO THE BOARD IF IT HAS BEEN

!

DAMAGED!

Installation

You are now ready to install your mainboard. The mounting hole pattern

of the S1692S/D matches the ATX system board specifications. Your

chassis should be that of a standard ATX mainboard form

factor.

Setting Jumpers

In this manual, the terms “closed” and “on” are used when referring to

jumpers (or jumper pins) that are active; “open” and “off” are used

when referring to jumpers (or jumper pins) that are not connected.

Jumpers and pins are connected by slipping the black plastic jumper

connector overtop of two adjacent jumper pins. The metal rod inside

the plastic shell bridges the gap between the two pins, completing the

circuit. See the pictures below for examples of “on” and “off” pins and

jumpers.

INSTALL

2 pin jumpers

off on

3 (or more) pin jumpers

1-2 2-3 open

1

2

3

11

1

2

3

1

2

3

Chapter 3

chapter 3

Onboard Resource Settings

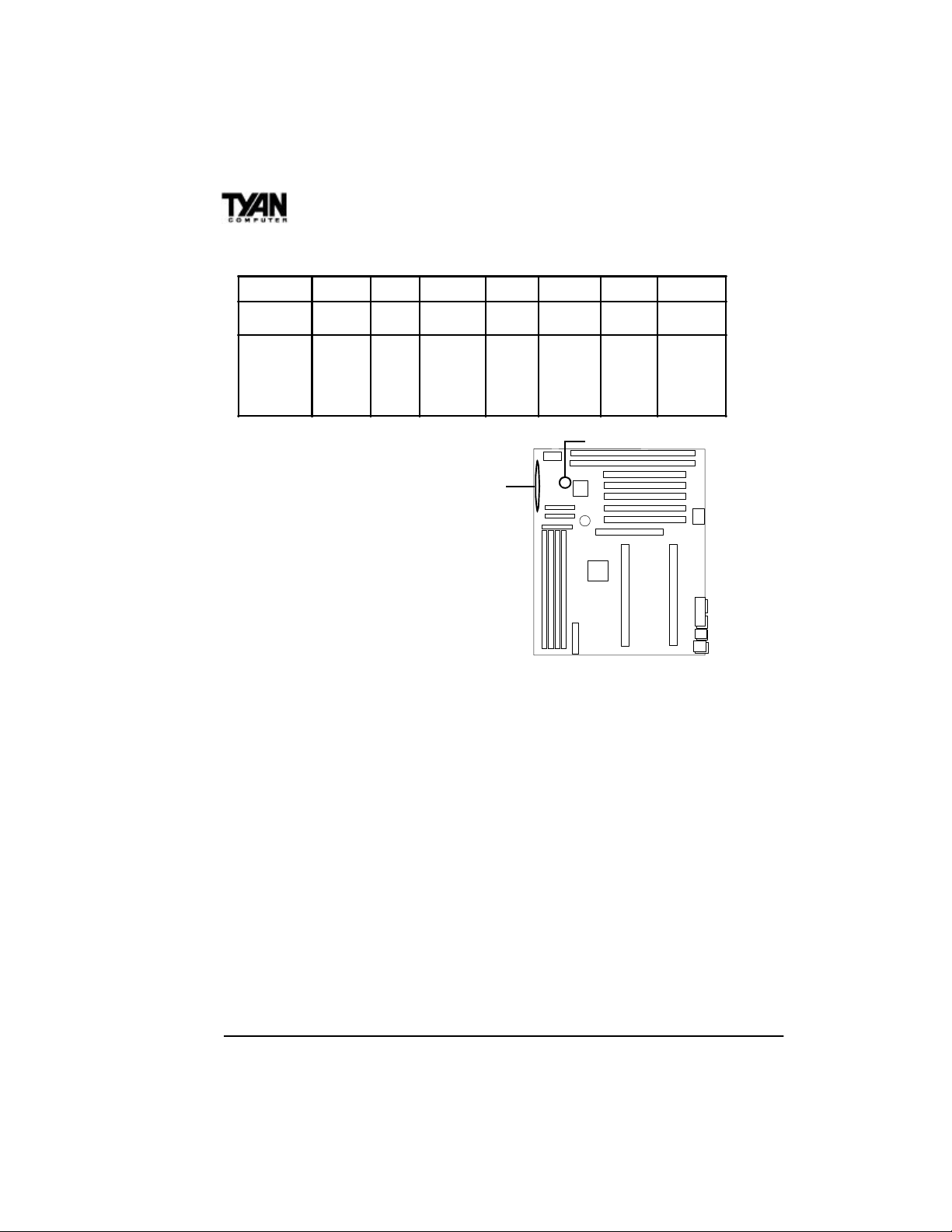

Quick References for Jumpers

The following tables will help you set the jumpers for CPU speed, memory

voltage settings, and CMOS, among others. The miniature motherboard

maps will help you locate the jumpers on your board. A full-page map of

the motherboard can be found on the facing page.

12

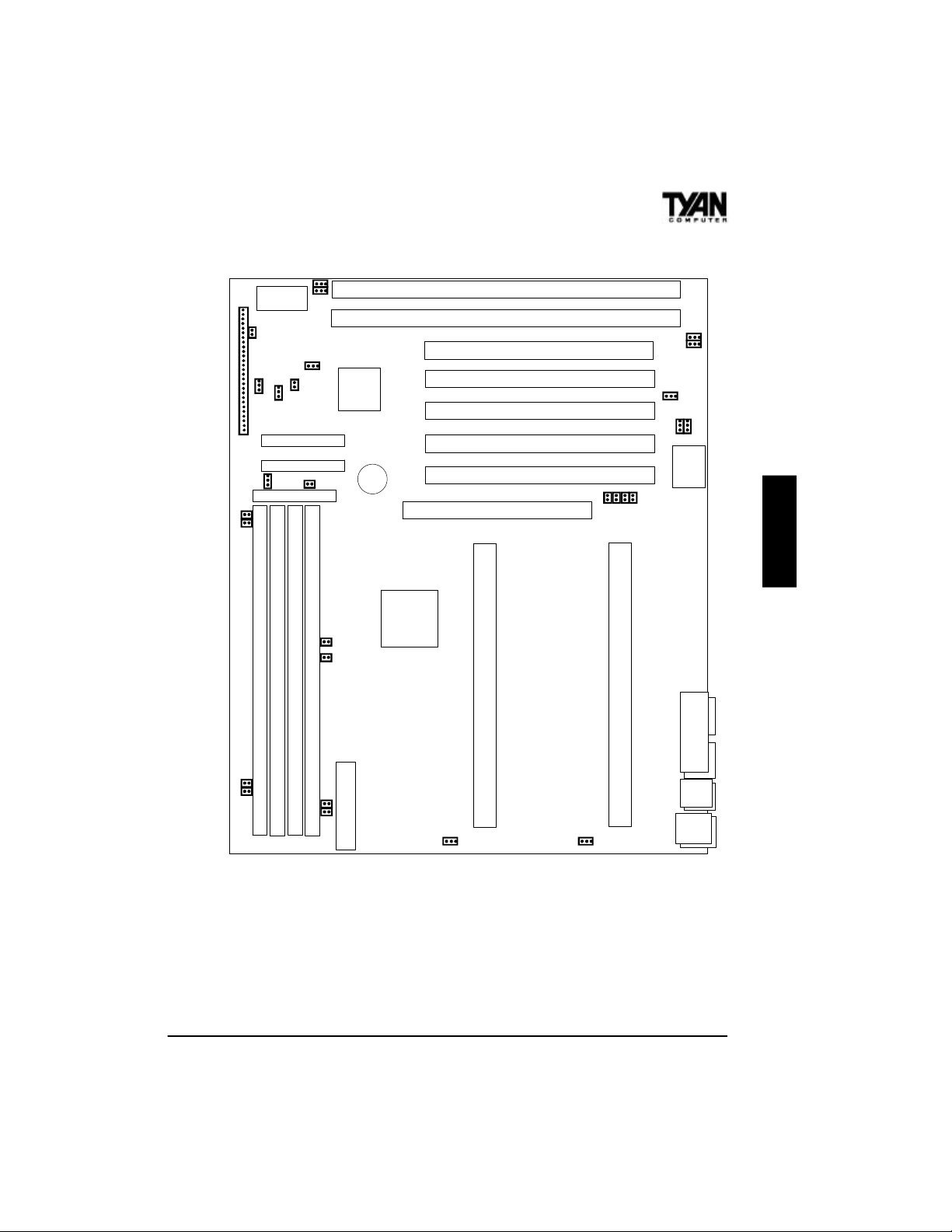

Map of Motherboard Jumpers

1

JP4

1

BIOS

J25

24

J20

22

18

13

CH FAN

10

1

8

3

1

JP3

JP22

JP21

JP5

JP2

JP44

1

JP6

Primary IDE

Secondary IDE

JP43

1

Floppy

1

82371AB

1

1

1

JP15

JP16

3 volt

battery

Intel

82443LX

chip

AGP (Accelerated Graphics Port)

ISA slot 2

ISA slot 1

PCI slot 5

PCI slot 4

PCI slot 3

PCI slot 2

PCI slot 1

1

J18

J19

1

1

JP23

JP41

JP42

1

1

Super I/O

National 309

JP8

JP10

JP7

JP9

ONBOARD

DIMM Bank 3

JP20

JP19

DIMM Bank 2

DIMM Bank 1

DIMM Bank 0

JP18

JP17

power connector

Pentium II CPU Slot 2 (S1692D only)

1 1

FAN

FAN

Pentium II CPU Slot 1

Printer Port

USB2

Mouse

The tiny “1”s next to jumpers of 3 pins or more indicate the position of

pin 1 for that jumper. Refer to pages 14-16 for the jumper and pin

assignments.

13

COM2 COM1

USB1

Keyboard

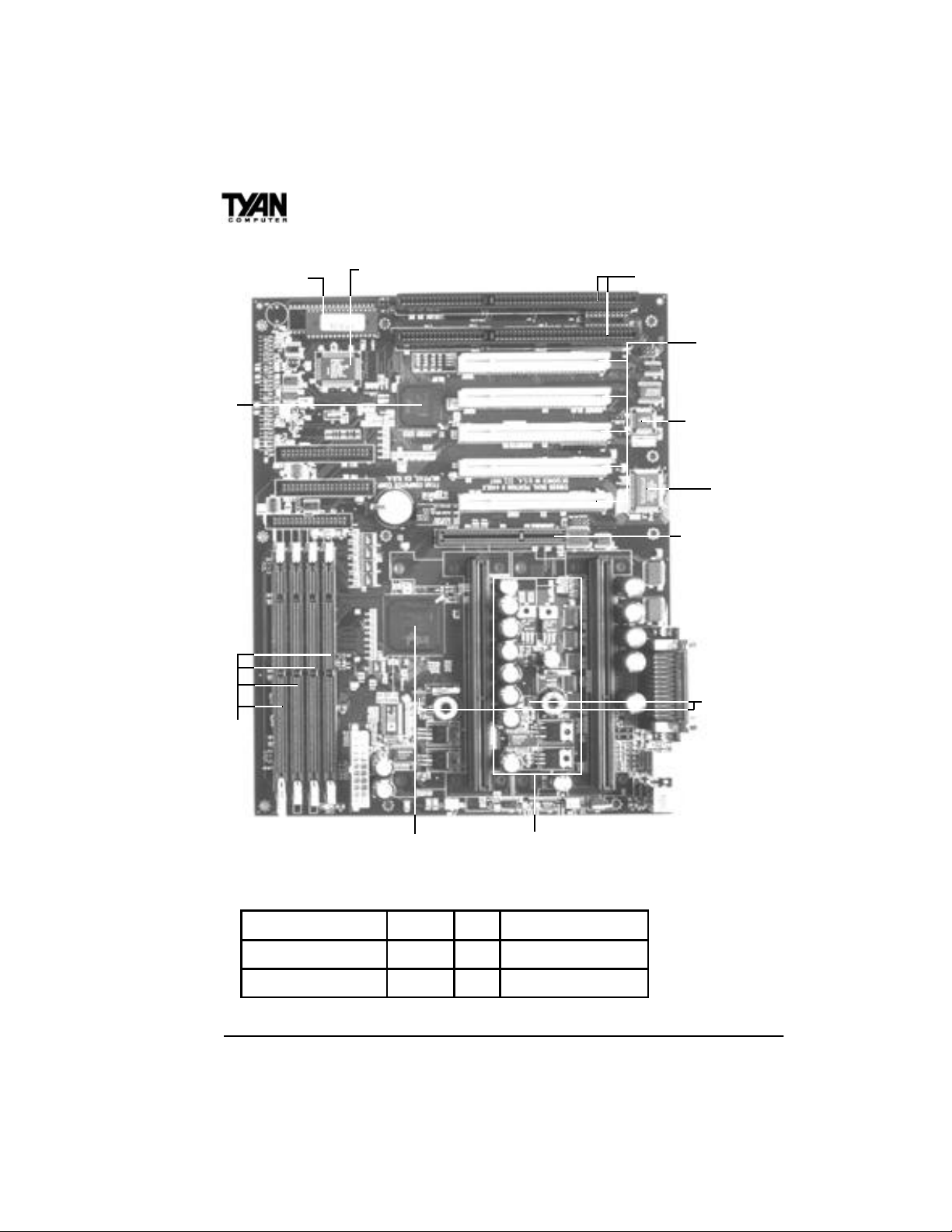

Chapter 3

Flash BIOS

SB82371AB (PIIX4)

Advanced Programmable Interrupt Controller

for Multiprocessor (S1692D only)

2 PnP ISA slots

PCI slots

National LM78

Accelerated

Graphics Port

National LM75

5 BUS Master

National 309 Super I/O

4 DIMM sockets

Pin Assignments

JP6 (Wake-on LAN)

FAN1-FAN3

(-- indicates pin is absent)

82443LX

Built-in dual VRM with

overload protection

1 2 3

Standby 5V GND Wake (Power-on Active High)

GND VCC Fan Monitor

14

CPU Clock Settings

JP7 JP8 JP9 JP10

233MHz

266MHz

300MHz

*333MHz

ON OFF OFF ON

ON ON ON OFF

ON OFF ON OFF

ON ON OFF OFF

*This speed has not been tested

due to the unavailability of the

CPU at the time of printing.

CMOS Discharge Settings

JP3 Pins

Normal (default)

Clear CMOS

1-2

2-3

Flash Memory Settings

JP4 Pins

5V (default)

12V

1-2

2-3

The speed of your CPU is printed on the edge of the

processor. It is a three digit number after “PX”. The

processor shown below is 233MHz.

JP4

JP3

JP21-JP22

JP15-JP16

JP19-JP20

JP17-JP18

JP7-JP10

ONBOARD

DRAM Voltage Settings

JP15 JP16 JP17 JP18 JP19 JP20 JP21 JP22

3.3V

(default)

CLOSED CLOSED CLOSED CLOSED OPEN OPEN OPEN OPEN

OPEN OPEN OPEN OPEN CLOSED CLOSED CLOSED CLOSED

5V

InfraRed Settings

JP41

JP42

JP43

JP44

2 FDD

(default)

1-2 2-3

1-2 2-3

Closed Open

Open Closed

InfraRed

JP44

15

JP43

JP41JP42

Chapter 3

J25 Settings

Pins 1-2 3-4 6-11 13-16 18-20 22-23 24-27

Function

Assignment

Soft Power

On/Off

1=Power

2=GND

Sleep IR Connector HDD LED Power LED Reset Speaker

6=VCC

3=GND

4=Sleep

7=NC

8=IR RX

9=GND

10=IR TX

11=MODE

13=VCC

14=NC

15=-

16=+

18=GND

19=NC

20=+

JP2

22=GND

23=Reset

Soft Power Connector

J25

The Soft Power Connector is

located on pins 1 and 2 of jumper

block J25. Pressing the Soft

Power Button will turn the system

on (and off).

Sleep Button Connector

24=GND

25=NC

26=INT-SPK

27=-

The sleep button connector is located on

pin 3 and pin 4 of jumper block J25. Pressing this button will put the

system in Sleep or Suspend mode. Pressing it once more will wake up the

system. The power LED will blink when the system is in Sleep mode.

A four second override feature is built into the motherboard according to

PC98 specifications. If you hold the sleep button for more than four seconds, the system will shut itself down. Use the four second override feature when the system hangs or crashes. This feature is not intended for

normal shutdown operation. Please use the regular soft power button for

a normal shutdown.

16

Speaker Connector Installation

The S1692S/D provides a 4-pin header to connect the speaker. The

speaker is connected to pins 24-27 of jumper block J25.

Hardware Reset Switch Connector

Installation

The Reset switch on your case’s display panel provides you with the

Hardware Reset function, which is the same as power on/off. The

system will do a cold start after the Reset button is pushed. The Reset

switch is a 2-pin connector and should be installed on pins 22 and 23 of

jumper block J25.

Windows 95 Users:

!

You may encounter problems with some of the devices in the Intel 82371AB

chipset. Neither the PCI Bridge nor the PCI Universal Serial BUS device

IDs for this chipset (also called PIIX4) are recognized by Windows 95.

This is a software problem, not a hardware problem, and can be easily

remedied by either upgrading to Windows 98 or downloading the 82371AB

patch found at http://www.tyan.com or at ftp://download.intel.com/design/pcisets/busmastr/setupex.exe. (Note: USB requires Windows 95 OSR

2.1 or above; please contact Microsoft for the USB update.)

ONBOARD

CMOS RTC

The 440LX AGPset includes an internal

battery and Real Time Clock circuit. The

RTC provides the date and time for the

system. If the battery is low, it will

prevent your system from POSTing, and

you will not get a display. Normally the

life span of an RTC internal battery is 10

years, but if yours is running low, you will

need to replace it with a new 3V lithium

battery (Duracell DL2032).

17

Battery

Chapter 3

Flash EEPROM

The S1692S/D uses flash memory to store BIOS programs. It can be

updated as new versions of the BIOS become available. You can

upgrade your BIOS easily using the flash utility (see page 56).

JP4 determines which type of EPROM is used. This jumper has been

set to match the onboard BIOS chip. The factory default for the

S1692S/D is on pins 1-2. Depending on the type of EPROM used,

some boards will have JP4 on pins 2-3.

Hardware CMOS & Password Reset

If you have been locked out of your system because you forgot your

password or set the CMOS incorrectly, follow the instructions below.

1. Power off the system

2. Set jumper JP3 to pins 2 and 3 (see previous page for

location of JP3).

3. Wait for 2 seconds, then return jumper JP3 to pins 1 and 2.

4. Power on the system again.

By following this procedure, you will erase your password and reset

the CMOS to the BIOS defaults.

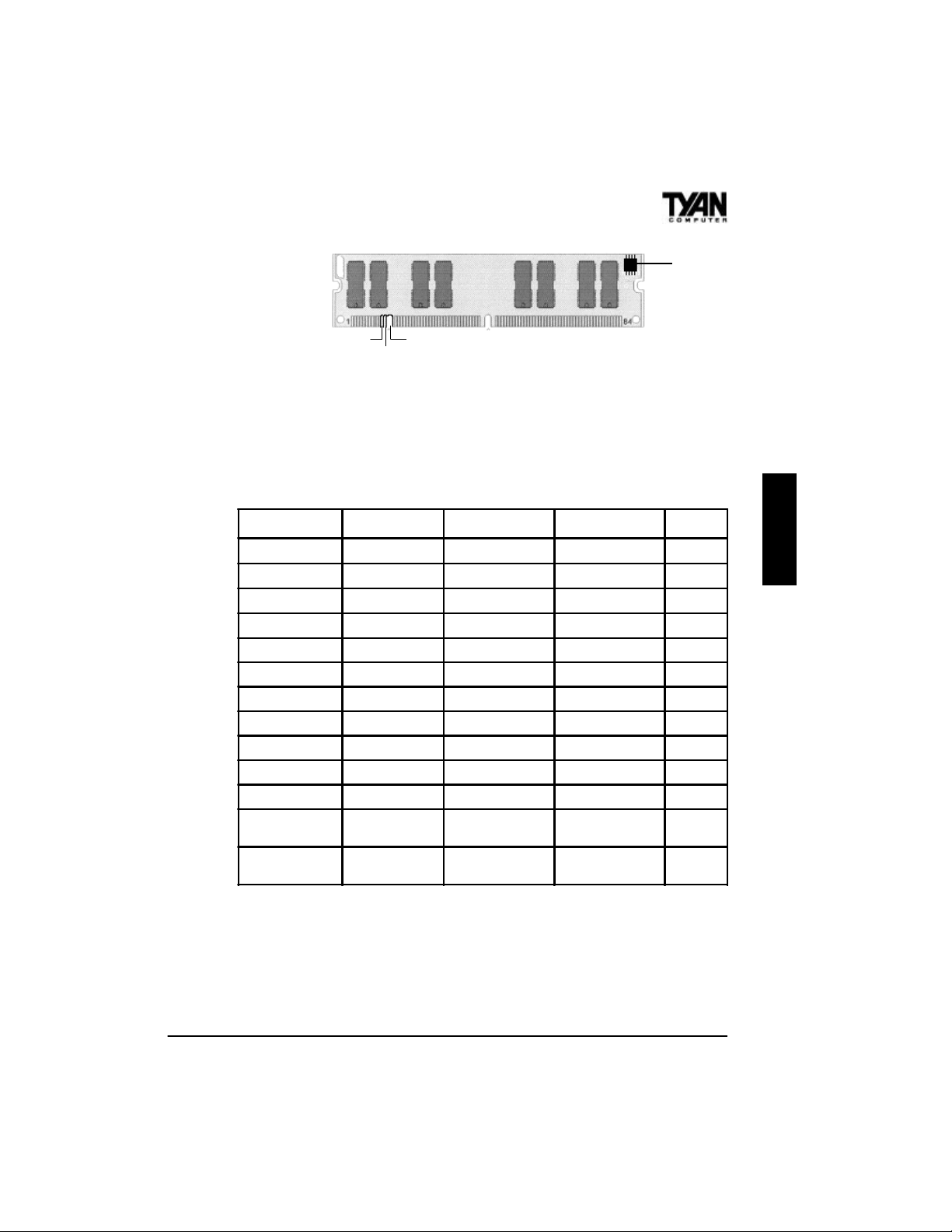

DRAM Installation

The S1692S/D uses a 64-bit data path from memory to CPU and can

accommodate up to 1024MB of EDO RAM and 512MB of SDRAM.

SDRAMs (Synchronous DRAMs) are supported in the DIMM slots.

DIMMs must be of the unbuffered variety. The position of the notch

in the DRAM Key Position will tell you whether or not a DIMM is

unbuffered (see figure on the next page). All installed memory will be

automatically detected, so there is no need to set jumpers. The 440LX

AGPset can cache up to 512MB of RAM.

18

EEPROM

Buffered

Unbuffered

168-pin DIMM

RFU

Some details of memory installation:

s One unbuffered DIMM must be installed for the system to POST.

s The mainboard supports 8MB, 16MB, 32MB, 64MB, 128MB, and

256MB DIMM modules. 256MB DIMM modules must be EDO.

The table below shows some of the possible memory configurations.

DIMM Bank 0 DIMM Bank 1

16MBx1 0 0 0 16MB

16MBx1 16MBx1 0 0 32MB

32MBx1 0 0 0 32MB

16MBx1 16MBx1 16MBx1 0 48MB

32MBx1 32MBx1 0 0 64MB

64MBx1 0 0 0 64MB

32MBx1 32MBx1 32MBx1 0 96MB

16MBx1 16MBx1 32MBx1 32MBx1 96MB

32MBx1 32MBx1 32MBx1 32MBx1 128MB

64MBx1 64MBx1 0 0 128MB

64MBx1 64MBx1 64MB 64MBx1 256MB

128MBx1 128MBx1 128MBx1 128MBx1

256MBx1 256MBx1MBx1 256MBx1 256MBx1

DIMM Bank 2 DIMM Bank 3

Total

512MB

(SDRAM)

1024MB

(EDO only)

ONBOARD

19

Chapter 3

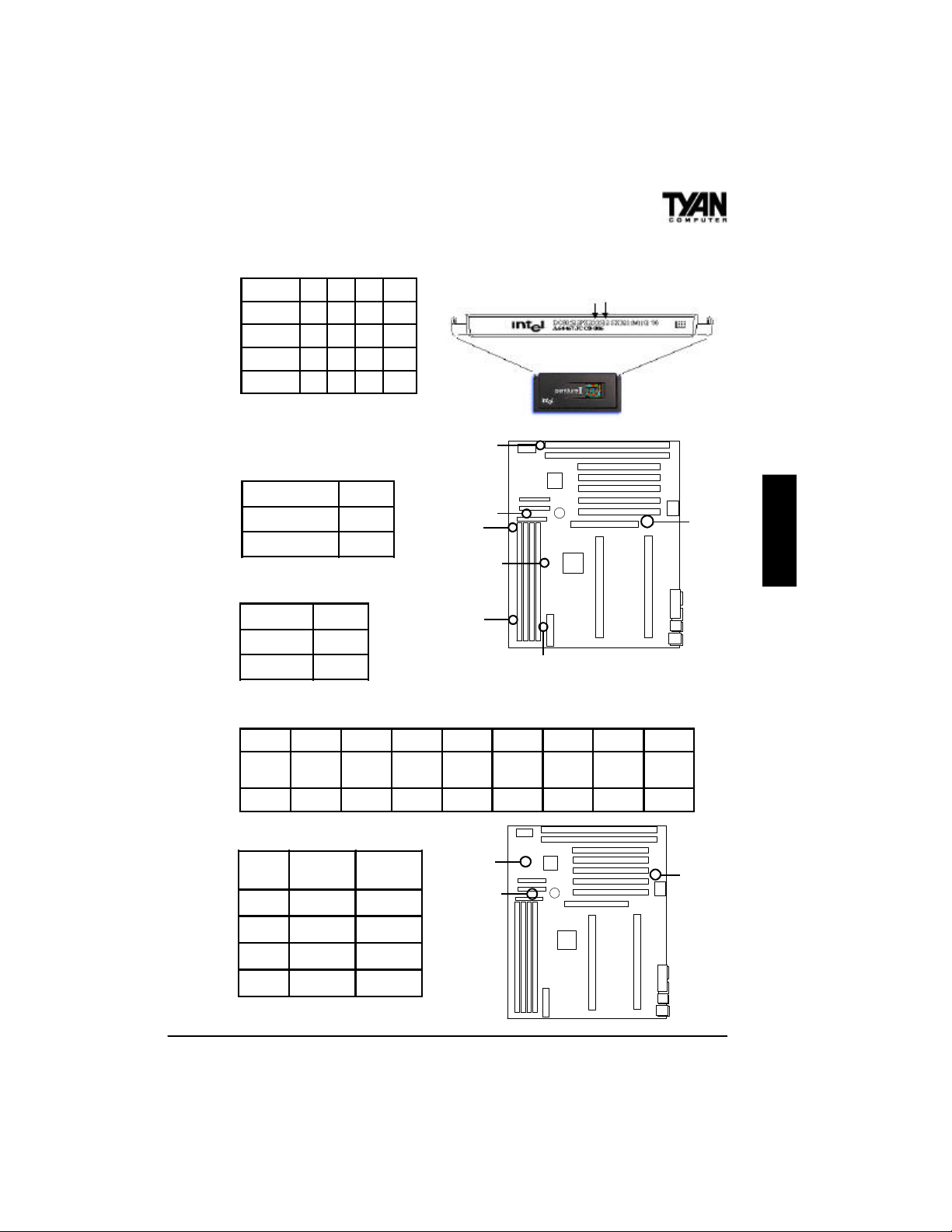

Installing the CPU

Pentium II processors (233 through 333MHz) can be used on the S1692S/

D. Please refer to page 15 for the correct CPU jumper settings for your

board. Although the S1692DL motherboard is designed as a dual CPU

system, it will also function with a single CPU.

The S1692S/D board provides two slots for Pentium II processors, called

the Pentium II primary and secondary slots. If only one CPU is used, that

CPU should be plugged into the primary slot. When two CPUs are used,

they should be of the same speed and type.

Remember:

s The CPU is a sensitive electronic component and it can easily be

damaged by static electricity. Do not touch the CPU pins with your

!

fingers.

s When installing the CPU into the socket, match the CPU pins to

the socket pins. Note that one corner of the socket’s top is different

from the other three corners. Likewise, one corner of the CPU’s

bottom is different from the other three corners. Line the unique

socket corner up with the unique CPU corner.

s Before the CPU is installed, the mainboard must be placed on a

flat surface. You should be able to insert the CPU with minimal,

but firm, pressure. Do not press down hard on the CPU.

Active and Passive Processors

Currently, Intel produces two types of Pentium II processors: the active

(or boxed) processor and the passive processor (refer to the pictures on

the following page). These two types of processors are essentially the

same in design; the only difference lies in their cooling methods. The

active processor is equipped with a cooling fan and heat sink, while

the passive processor is equipped with a heat sink alone. Both types of

CPUs provide the user with the same performance, and both types can

be installed in the Pentium II slots on the S1692S/D board. Refer to

page 21 for instructions regarding the installation and removal of

Pentium II processors.

20

Pentium II Active (Boxed) CPU

Shown with Power Connector for Fan

Pentium II Passive CPU

Shown with Heat-sink

Installation of Pentium II Active (Boxed) Processors

Active processors are equipped with cooling fans. When installing an

active CPU, you also need to connect the cooling fan cable to its

connector.

Installing CPU Retention Modules

1. Installation of a Pentium II active processor requires a CPU

retention module, which is first secured onto the motherboard. (Refer

to the motherboard layout on page 13.)

2. To attach the retention module, place

the motherboard on a flat surface.

3. Locate the key pin on one end of the

Pentium II slot on the board. Then

carefully line up the key notch on the

retention module with the key pin on

the Pentium II slot (the key pin on the

Pentium II slot indicates the correct

Pentium II Slot Connector

and Key Pin

orientation of the CPU).

ONBOARD

21

Chapter 3

4. Drop the retention module down over the

Pentium II slot so that the retention module

sits flat against the motherboard. Tighten the

screws in a clockwise manner to secure the

module to the board. Warning: Do not

overtighten the screws as you may damage

Retention Module

the module and/or the motherboard.

Installing the Active Processor

1. When the retention module is securely installed, you are ready to plug

the CPU into the retention module.

2. Press firmly on the CPU until you hear a

“click.” This clicking sound indicates that the

CPU is fully locked into the retention module.

3. After the CPU is securely seated on the retention module in the Pentium II slot, connect

the CPU’s cooling fan cable to the cooling fan

power connector on the board.

Installing CPU Cooling Fans

1. Locate the cooling fan connectors (3 connectors: FAN1-FAN3) on the

motherboard.

2. Plug the CPU’s cooling fan cable into the cooling fan connector on

the board. Make sure that the black wire of the cable is plugged into

pin 1 of the connector. Refer to pin 1 marked on the layout on page 13.

Pin assignments: pin 1–ground (black), pin 2–12 V (red), pin 3– signal

(yellow).

Installation of Pentium II Passive Processors

Unlike active processors, passive processors are not equipped with

cooling fans. Instead, they are equipped with heat sinks.

22

Each CPU package should contain

the following:

One CPU retention module

One heat sink retention bracket with

Pentium II Passive

CPU Module

mounting locks

Two mounting attach-mounts

One heat sink lock

Installing CPU Retention Modules

1. When installing the CPU retention module, make sure that you have

the appropriate end of the module lined up with the key notch on the

Pentium II slot connector. This will ensure that the module is installed

properly.

2. Before tightening the screws, make certain that the module is flush

against the motherboard. If one end of the module is raised above the

board, check the orientation of the module.

3. Install the module on the board by turning the screws in a clockwise

direction. Do not over-tighten the screws.

ONBOARD

Installing Heat Sink Mounting Brackets

1. The heat sink mount has

two pins on the bottom and

four pins on the top. Notice

that the bottom two pins are

of different sizes. The size of

Heat Sink Mounting

Bracket

the pins and the holes in the

motherboard will determine the correct orientation. A correctly installed

bracket can be verified by making sure that the four pins on the top are

closest to the Pentium II CPU slot.

23

Chapter 3

2. Insert the heat sink mount into the holes on the motherboard. When

the bracket is properly inserted into the holes on the motherboard, you

will hear a clicking noise.

3. Lock the heat sink mount to the board by

inserting the two mounting locks into the pins

of the heat sink mounting bracket which are

now below the mainboard. There will be a

click when the locks are securely fastened.

Installing the Passive Processor

Mounting Locks

1. Align the CPU with the CPU retention module. Make sure the heat

sink is lined up with the heat sink mount bracket. If you put the CPU in

the wrong way, you may damage the CPU, the motherboard, and/or the

CPU socket.

2. Slowly press down on the CPU module until the CPU locks into

place. A clicking noise will be heard when the CPU is locked securely

into the module.

Installing Heat Sink Locks

The heat sink lock has four notches which will correspond to the four

pins on the heat sink mounting bracket. Gently slide the lock between

the heat sink onto the heat sink

mounting bracket until both sides of

the lock are firmly secured. A

Heat Sink Lock

clicking sound will be heard when

the lock is securely fastened to the

heat sink mounting bracket. To

remove the lock from the heat sink mounting bracket, gently press the

ends of the locks inward and pull.

24

Removing Pentium II Passive Processors and CPU Retention

Modules

To remove the CPU, move the locks to the center of the CPU. A click

will be heard when the CPU has been unlocked. Gently pull up on the

CPU, taking care not to bend the motherboard or the CPU retention

module.

Removing Heat Sink Locks

To remove the lock from the retention bracket, gently press the ends of

the locks inward and pull.

Peripheral Device Installation

After all the jumpers on the mainboard have been set, the mainboard

can be mounted into the case. You may then install the display card

and any other peripheral devices that you may have.

If a PCI-BUS interface card is to be installed in the system, any one of

the four PCI-BUS slots can support either a Master or a Slave device.

After installing the peripheral controllers, you should check the CPU

and all of your devices again before preparing to power on the system.

Connecting the Power Supply

The female power supply connector on the mainboard fits with the

male power supply connector from a 3.3V, 5V, or 12V power supply.

Beware: incorrect installation of the power supply can result in serious

damage to the system board and connected peripherals. Before connecting the leads from the power supply, you should first make sure that

the power supply is unplugged.

ONBOARD

25

Chapter 3

Most male power supply connectors will have twenty wires, seven of

which are black. The black wires will be in the middle of the connector.

The easiest way to orient the connectors properly is to line up the

plastic clip on the male connector with the tab on the female connector.

The plastic clip should be facing the edge of the motherboard.

Align the plastic guide pins on the male connector with their receptacles on the mainboard. You may need to hold the lead at an angle in

order to properly line it up with the onboard connector. Once you have

the guide pins aligned, press the lead into the connector so that the

plastic clip on the lead snaps into place and secures the lead to the

connector. Please see the figure below.

Power supply connector

Onboard connector

clip

tab

26

Frequently Asked Questions

Q: Why don’t I get a display after I put in my old DIMM module?

A: The 440LX chipset requires the memory manufacturer to program

an EEPROM chip with SPD (Serial Presence Detection) on the

module in order for the BIOS to program the 440LX’s timing registers

properly. Your DIMM may not have the EEPROM chip on the module,

or the EEPROM may not contain the correct program. Check with

your memory vendor for details. The figure below shows a DIMM

module with an EEPROM chip.

EEPROM

ONBOARD

RFU

Buffered

Unbuffered

168-pin DIMM

Q: My system sometimes becomes unstable. How should I check the

system?

A: The first thing to do is to check and see if you have any device

conflict in address, IRQ, or DMA. If you are using Windows 95, the

Device Manager is a good place to start. Please consult your operating

system manual for detail. Second of all, slowing down the memory

timing in the BIOS’s chipset setup section will help the situation, as

well. Many memory modules are not suitable for high performance

systems and are probably the main source of your problem.

Q: I’ve installed Windows NT with one CPU and with the multiproces-

sor kernel. However, when I add a second CPU later, only one CPU is

detected during the Windows NT boot up.

A: AMI BIOS only builds multiprocessor tables according to the

number of CPUs present during Windows NT installation. Therefore,

you must either reinstall NT with two CPUs or use the Windows NT

resources kit to change from a uniprocessor to a multiprocessor

system.

27

Q: How do I know if the system detects the number of CPUs

properly?

A: The AMI BIOS will show a “Pentium–II x2” message during the

memory check to indicate the presence of two CPUs.

Q: How many devices can I hook up to each SCSI channel?

A: You can cascade up to fifteen 16-bit devices per channel and seven

of them can be 8-bit devices.

Q: How do I use the RAID port on my motherboard?

A: The RAID port allows you to put in an Adaptec Array 1000 family

card which will enable the SCSI chip on the motherboard to perform

the RAID function under Netware and Windows NT. RAID 0 is used

for performance purposes (increases SCSI speed), RAID 1 is used for

mirroring (creates two drives with identical information), and RAID 5 is

used for redundancy (if one drive goes down, another will take its

place).

Q: Can I mix EDO DIMM with SDRAM DIMM on this

motherboard?

A: Yes. However, the AGP graphics card performs better with

SDRAM installed on the motherboard because the AGP card can store

the texture map in the system memory.

Q: What is AGP (Accelerated Graphics Port)?

A: AGP (Accelerated Graphics Port) is a new BUS architecture for

3D graphics. The AGP slot eliminates the PCI bandwidth bottleneck by

bypassing the PCI interface and accessing the system memory directly.

Currently, the AGP supports 1X and 2X which yields bandwidths of

256MB/s at 66MHz and 512MB/s at 133MHz BUS speeds, respectively. Compare with 132MB/s at 33MHz bus speed with PCI bus.

28

Q: Does my operating system support AGP?

A: Currently, only Windows 98 and Windows NT 5.0 will have built-in

support for AGP. Some AGP cards require Windows 95 OSR2.1 or a

special driver from Intel. Please check with your graphics vendor for

more detail.

29

Chapter 4

chapter 4

BIOS Configuration

Standard Setup

Select the AMIBIOS Setup options below by choosing Standard Setup

from the AMIBIOS Setup main menu. Standard Setup options are

described below.

Floppy Drive A: and B:

Move the cursor to these fields via the arrow keys and select the floppy

type. The settings are 360KB 5¼ inch, 1.2 MB 5¼ inch, 720KB 3½

inch, 1.44MB 3½ inch, or 2.88MB 3½ inch.

Primary Master, Primary Slave, Secondary Master, Secondary

Slave

Select these options to configure the drive named in the option. Select

Auto Detect IDE to let AMIBIOS automatically configure the drive. A

screen with a list of drive parameters appears. Click on OK to configure the drive.

30

Type How to Configure

SCSI

IDE

CD-ROM

Standard MFM

Non-Standard MFM

Select Type. Select Not Installed on the drive parameter screen. The

SCSI drivers provided by the SCSI manufacturer should allow you to

configure the SCSI drive.

Select Type. Select Auto to let AMIBIOS determine the parameters.

Click on OK when AMIBIOS displays the drive parameters. Select

LBA Mode. Select On if the drive has a capacity greater than

540MB.

Select Block Mode. Select On to allow block mode data transfers.

Select 32-Bit Mode. Select On to allow 32-bit data transfers. Select

the PIO Mode. It is best to select Auto to allow AMIBIOS to

determine the PIO mode. If you select a PIO mode that is not

supported by the IDE drive, the drive will not work properly. If you

are absolutely certain that you know the drive's PIO mode, select PIO

mode 0-4, as appropriate.

Select Type. Select CDROM. Click on OK when AMIBIOS displays

the drive parameters.

Select Type. You must know the drive parameters. Select the drive

type that exactly matches your drive's parameters.

Select Type. If the drive parameters do not match the drive

parameters listed for drive types 1-46, select User and enter the

correct hard disk drive parameters.

Entering Drive Parameters

You can also enter the hard disk drive parameters yourself. The drive

parameters are as follows:

Parameter Description

Type The number for a drive with certain identification parameters.

Cylinders The number of cylinders in the disk drive.

Heads The number of heads.

The actual physical size of a sector gets progressively smaller as the

track diameter diminishes. Yet each sector must still hold 512 bytes.

Write Precompensation

Landing Zone

Sectors

Capacity

Write precompensation circuitry on the hard disk compensates for the

physical difference in sector size by boosting the write current for

sectors on inner tracks. This parameter is the track number on the

disk surface where write precompensation begins.

This number is the cylinder location where the heads normally park

when the system is shut down.

The number of sectors per track. MFM drives have 17 sectors per

track. RLL drives have 26 sectors per track. ESDI drives have 34

sectors per track. SCSI and IDE drives have even more sectors per

track.

The formatted capacity of the drive is the number of heads times the

number of cylinders times the number of sectors per track times 512

(bytes per sector).

BIOS

31

Chapter 4

Type Cylinders Heads

1 306 4 128 305 17 10 MB

2 615 4 300 615 17 20 MB

3 615 6 300 615 17 31 MB

4 940 8 512 940 17 62 MB

5 940 6 512 940 17 47 MB

6 615 4 65535 615 17 20 MB

7 462 8 256 511 17 31 MB

8 733 5 65535 733 17 30 MB

9 900 15 65535 901 17 112 MB

10 820 3 65535 820 17 20 MB

11 855 5 65535 855 17 35 MB

12 855 7 65535 855 17 50 MB

13 306 8 128 319 17 20 MB

14 733 7 65535 733 17 43 MB

16 612 4 0 663 17 20 MB

17 977 5 300 977 17 41 MB

18 977 7 65535 977 17 57 MB

19 1024 7 512 1023 17 60 MB

20 733 5 300 732 17 30 MB

21 733 7 300 732 17 43 MB

22 733 5 300 733 17 30 MB

23 306 4 0 336 17 10 MB

24 925 7 0 925 17 54 MB

25 925 9 65535 925 17 69 MB

26 754 7 754 754 17 44 MB

27 754 11 65535 754 17 69 MB

28 699 7 256 699 17 41 MB

29 823 10 65535 823 17 68 MB

30 918 7 918 918 17 53 MB

31 1024 11 65535 1024 17 94 MB

32 1024 15 65535 1024 17 128 MB

33 1024 5 1024 1024 17 43 MB

34 612 2 128 612 17 10 MB

35 1024 9 65535 1024 17 77 MB

36 1024 8 512 1024 17 68 MB

37 615 8 128 615 17 41 MB

38 987 3 987 987 17 25 MB

39 987 7 987 987 17 57 MB

40 820 6 820 820 17 41 MB

41 977 5 977 977 17 41 MB

511 981 5 981 981 17 41 MB

43 830 7 512 830 17 48 MB

44 830 10 65535 830 17 69 MB

45 917 15 65535 918 17 114 MB

46 1224 15 65535 1223 17 152 MB

Write

Precompensation

Landing

Zone

Sectors Capacity

32

Advanced Setup

The Advanced Setup options included in the AMIBIOS Setup generated through AMIBCP and the AMIBIOS for the Intel 440LX chipset

are described in this chapter. Select Advanced Setup from the

AMIBIOS Setup main menu to display the Advanced Setup options.

Default Settings

Every option in AMIBIOS Setup contains two default values: an FailSafe default and the Optimal default value.

Optimal Defaults

The Optimal default values provide optimum performance settings for

all devices and system features.

Fail-Safe Defaults

The Fail-Safe default settings consist of the safest set of parameters.

Use them if the system is behaving erratically. They should always

work but do not provide optimal system performance characteristics.

Advanced Setup

Quick Boot

Set this option to Enabled to instruct AMIBIOS to boot quickly when

the computer is powered on. This option replaces the old Above 1 MB

Memory Test Advanced Setup option. The settings are:

Setting Description

AMIBIOS tests all system memory.

AMIBIOS waits up to 40 seconds for a READY signal from the IDE hard disk drive. AMIBIOS waits for .5

Disabled

seconds after sending a RESET signal to the IDE drive to allow the IDE drive time to get ready again.

AMIBIOS checks for a <Del> key press and runs AMIBIOS Setup if the key has been pressed.

AMIBIOS does not test system memory above 1MB.

AMIBIOS does not wait up to 40 seconds for a READY signal from the IDE hard disk drive. If a READY signal

is not received immediately from the IDE drive, AMIBIOS does not configure that drive. AMIBIOS does not

Enabled

wait for .5 seconds after sending a RESET signal to the IDE drive to allow the IDE drive time to get ready again.

You cannot run AMIBIOS Setup at system boot, because there is no delay for the Hit <Del> to run Setup

message.

The Optimal and Fail-Safe default settings are Disabled.

BIOS

33

Chapter 4

1st Boot Device

This option sets the type of device for the first boot drives that the

AMIBIOS attempts to boot from after AMIBIOS POST completes.

The settings are Disabled, Network, Floptical, SCSI, CDROM, IDE-0,

IDE-1, IDE-2, or IDE-3. The Optimal and Fail-Safe default settings are

IDE-0.

2nd Boot Device

This option sets the type of device for the second boot drives that the

AMIBIOS attempts to boot from after AMIBIOS POST completes.

The settings are Disabled, Floppy, Floptical, CDROM, or IDE-0. The

Optimal and Fail-Safe default settings are Floppy.

3rd Boot Device

This option sets the type of device for the third boot drives that the

AMIBIOS attempts to boot from after AMIBIOS POST completes.

The settings are Disabled, Floptical, Floppy, CDROM, or IDE-0. The

Optimal and Fail-Safe default settings are CD-ROM.

Try Other Boot Devices

Set this option to Yes to instruct AMIBIOS to attempt to boot from any

other drive in the system if it cannot find a boot drive among the drives

specified in the 1st Boot Device, 2nd Boot Device, and 3rd Boot

Device options. The settings are Yes or No. The Optimal and Fail-Safe

default settings are Yes.

Initial Display Mode

This option specifies the initial display mode when the system boots.

The settings are as follows:

Setting Description

BIOS The messages that AMIBIOS displays before booting the system will appear on the system monitor.

Silent The messages that AMIBIOS displays will not appear on the system monitor.

34

Display Mode At Add-On ROM Init

This option specifies the system display mode that is set at the time

that AMIBIOS POST initializes an optional option ROM. The settings

are as follows:

Setting Description

Force BIOS The display mode currently being used by AMIBIOS is used.

Keep Current The current display mode is used.

Floppy Access Control

This option specifies the read/write access that is set when booting

from a floppy drive. The settings are Read/Write or Read-Only. The

Optimal and Fail-Safe default settings are Read/Write.

Hard Disk Access Control

This option specifies the read/write access that is set when booting

from a hard disk drive. The settings are Read/Write or Read-Only. The

Optimal and Fail-Safe default settings are Read/Write.

S.M.A.R.T. For Hard Disks

Set this option to Enabled to permit AMIBIOS to use the SMART

(System Management and Reporting Technologies) protocol for

reporting server system information over a network. Enabling this

feature allows you to back up your data when your hard disk is about

to fail. The settings are Enabled or Disabled. The Optimal and FailSafe default settings are Disabled.

BIOS

Boot Up Num Lock

Set this option to Off to turn the Num Lock key off when the computer

is booted so you can use the arrow keys on both the numeric keypad

and the keyboard. The settings are On or Off. The default settings are

On.

35

Chapter 4

PS/2 Mouse Support

Set this option to Enabled to enable AMIBIOS support for a PS/2-type

mouse. The BIOS will allocate IRQ12 for the PS/2 mouse. The settings

are Enabled or Disabled. The Optimal and Fail-Safe default settings

are Enabled.

Primary Display

This option configures the type of monitor attached to the computer.

The settings are Mono, CGA40x25, CGA80x25, VGA/EGA, or

Absent. The Optimal and Fail-Safe default settings are VGA/EGA.

Password Check

This option enables password checking every time the system boots or

when you run AMIBIOS Setup. If Always is chosen, a user password

prompt appears every time the computer is turned on. If Setup is

chosen, the password prompt appears if AMIBIOS is executed. See the

Advanced Setup chapter for instructions on changing a password. The

Optimal and Fail-Safe defaults are Setup.

Boot To OS/2

Set this option to Enabled if running OS/2 operating system and using

more than 64 MB of system memory on the motherboard. The settings

are Enabled or Disabled. The Optimal and Fail-Safe default settings

are Disabled.

CPU Microcode Update

Set this option to Enabled to permit the BIOS to update the CPU at any

time. The settings are Enabled or Disabled. The Optimal and Fail-Safe

default settings are Enabled.

Internal Cache

This option sets the type of caching algorithm used by the L1 internal

cache memory on the CPU. The settings are WriteBack, WriteThru, or

Disabled. The Optimal and Fail-Safe default settings are Disabled.

36

System BIOS Cacheable

When set to Enabled, the contents of the F0000h system memory

segment can be read from or written to cache memory. The contents of

this memory segment are always copied from the BIOS ROM to

system RAM for faster execution. The settings are Enabled or Disabled. The Optimal default setting is Enabled. The Fail-Safe default

setting is Disabled.

C000,16K Shadow and C400,16K Shadow

These options specify how the 32 KB of video ROM at C0000h is

treated. The settings are:

Setting Description

Disabled The contents of the video ROM are not copied to RAM.

Enabled

Cached

The contents of the video ROM area from C000h-C7FFFh are copied (shadowed) from ROM to

RAM for faster execution.

The contents of the video ROM area from C000h-C7FFFh are copied from ROM to RAM and can

be written to or read from cache memory.

The Optimal and Fail-Safe default settings are Cached.

C800,16K Shadow; CC00,16K Shadow; D000,16K Shadow;

D400,16K Shadow; D800, 16K Shadow; and DC00,16K Shadow

These options enable shadowing of the contents of the ROM area

named in the option. The ROM area not used by ISA adapter cards is

allocated to PCI adapter cards. The settings are:

BIOS

Setting Description

Disabled The contents of the video ROM are not copied to RAM.

Enabled

Cached

The contents of the video ROM area from C000h-C7FFFh are copied (shadowed) from ROM to

RAM for faster execution.

The contents of the video ROM area from C000h-C7FFFh are copied from ROM to RAM and can

be written to or read from cache memory.

The Optimal and Fail-Safe default settings are Cached.

37

Chapter 4

Chipset Setup

Choose Chipset Setup on the AMIBIOS Setup main menu. All Chipset

Setup options are then displayed. AMIBIOS Setup can be customized.

AMIBIOS Setup can be customized via AMIBCP. See the AMIBIOS

Utilities Guide for additional information.

USB Function

Set this option to Enabled to enable USB (Universal Serial Bus)

support. The settings are Enabled or Disabled. The Optimal and FailSafe default settings are Enabled.

USB Keyboard/Mouse Legacy Support

Set this option to Enabled to enable support for older keyboards and

mouse devices if the USB Function option is set to Enabled. The

settings are Enabled or Disabled. The Optimal and Fail-Safe default

settings are Disabled.

EDO DRAM Speed (ns)

This option specifies the RAS Access Time in nanoseconds for the

EDO DRAM system memory installed in this computer. The settings

are Auto (AMIBIOS automatically determines the RAS access Time

parameter), Manual, 50, 60, or 70. The Optimal and Fail-Safe default

settings are Auto.

EDO Read Burst Timing

This option specifies the timings for EDO DRAM system memory for

Read operations in burst mode. The settings are x222 or x333. The

Optimal and Fail-Safe default settings are x333. Setting this switch

incorrectly may result in system failure.

EDO Write Burst Timing

This option specifies the timings for EDO DRAM system memory for

Write operations in burst mode. The settings are x222 or x333. The

Optimal and Fail-Safe default settings are x333. Setting this switch

incorrectly may result in system failure.

38

EDO RAS Precharge

This option specifies the length of the RAS precharge part of the

DRAM system memory access cycle when EDO DRAM system

memory is installed in this computer. The settings are 3 CLKs or 4

CLKs. The Optimal and Fail-Safe default settings are 4 CLKs.

EDO RAS To CAS

This option specifies the length of the delay inserted between the RAS

and CAS signals of the DRAM system memory access cycle when

EDO DRAM system memory is installed in this computer. The settings

are 2 CLKs or 3 CLKs. The Optimal and Fail-Safe default settings are

3 CLKs.

MA Wait State

This option specifies the length of the delay inserted between MA

signals. The settings are Slow or Fast. The Optimal and Fail-Safe

default settings are Slow.

SDRAM Timing Latency

This option specifies the latency for the Synchronous DRAM system

memory signals. The settings are Auto (AMIBIOS automatically

determines the optimal delay) or Manual. The Optimal and Fail-Safe

default settings are Auto.

BIOS

RAS To CAS

This option specifies the length of the delay inserted between the RAS

and CAS signals of the DRAM system memory access cycle. The

settings are 2 CLKs or 3 CLKs. The Optimal and Fail-Safe default

settings are 3 CLKs.

CAS Lat.

This option sets the latency period for the CAS signal. The settings are

2 CLKs or 3 CLKs. The Optimal and Fail-Safe default settings are 3

CLKs.

39

Chapter 4

RAS Precharge

This option specifies the length of the RAS precharge part of the

DRAM system memory access cycle when EDO DRAM system

memory is installed in this computer. The settings are 3 CLKs or 4

CLKs. The Optimal and Fail-Safe default settings are 4 CLKs.

VGA Frame Buffer USWC

Set this option to Enabled to enable the VGA video frame buffer using

USWC (Uncacheable, Speculatable, Write-Combined) memory. The

settings are Enabled or Disabled. Older ISA VGA card drivers may not

behave correctly if this option is not set to Disabled. The Optimal and

Fail-Safe default settings are Disabled.

PCI Frame Buffer USWC

Set this option to Enabled to enable the USWC memory attribute and

improve video performance when a PCI video adapter is installed.

However, some VGA card drivers may not behave correctly when this

option is set to Enabled. The settings are Disabled or Enabled. The

Optimal and Fail-Safe defaults are Disabled.

DRAM Integrity Mode

This option sets the type of system memory checking. The settings are:

Setting Description

Non ECC No error checking or error reporting is done.

Multibit errors are detected and reported as parity errors. Single-bit errors are

ECC Only

ECC

corrected by the chipset. Corrected bits of data from memory are not written back to

DRAM system memory. If Level I is selected, the J25 External SMI software jumper

on the Series 745 board is disabled.

Multibit errors are detected and reported as parity errors. Single bit errors are corrected

by the chipset and are written back to DRAM system memory. If a soft (correctable)

memory error occurs, writing the fixed data back to DRAM system memory will resolve

the problem. If a hard (uncorrectable) error occurs, writing the fixed data back to

DRAM system memory does not solve the problem. In this case, the second time the

error occurs in the same location, a parity error is reported, indicating an uncorrectable

error. If ECCI is selected, AMIBIOS automatically enables the System Management

Interface (SMI). If you do not want to enable power management, set the Power

Management/APM option to Disabled and set all Power Management Setup timeout

options to Disabled. To enable power management, set Power Management/APM to

Enabled and set the Power Management Setup timeout options as desired.

40

Fixed Memory Hole

This option specifies the location of an area of memory that cannot be

addressed on the ISA bus. The settings are Disabled, 15 MB-16 MB, or

512KB-640KB. The Optimal and Fail-Safe default settings are Disabled.

TypeF DMA BufferControl1 and TypeF DMA Buffer Control2

These options specify the DMA channel where TypeF buffer control is

implemented. The settings are Disabled, Channel-0, Channel-1,

Channel-2, Channel-3, Channel-5, Channel-6, or Channel-7. The

Optimal and Fail-Safe default settings are Disabled.

DMA-0 Type, DMA-1 Type, DMA-2 Type, DMA-3 Type, DMA-5

Type, DMA-6 Type, DMA-7 Type

These options specify the bus that the specified DMA channel can be

used on. The settings are PC/PCI, Distributed, or Normal ISA. The

Optimal and Fail-Safe default settings are Normal ISA.

AGP Aperture Size

This option specifies the amount of system memory that can be used

by the Accelerated Graphics Port (AGP). The settings are 4 MB, 8 MB,

16 MB, 32 MB, 64 MB, 128 MB, or 256 MB. The Optimal and FailSafe default settings are 256 MB.

BIOS

System Type

This option sets the system type. The settings are Auto (AMIBIOS

automatically determines the system type), DP, or UP. The Optimal

and Fail-Safe default settings are Auto.

41

Chapter 4

USWC Write I/O Post

This option sets the status of USWC posted writes to I/O. The settings

are:

Setting Description

Enabled USWC posted writes to I/O are enabled.

Disabled USWC posted writes to I/O are disabled.

AMIBIOS automatically determines if USWC posted writes to I/O should be enabled and sets this

Auto

option accordingly.

The Optimal and Fail-Safe default settings are Auto.

MECC Buf. Strength

This option sets the strength of the signal for the MECC buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

MD Buf. Strength

This option sets the strength of the signal for the MD buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

WE Buf. Strength

This option sets the strength of the signal for the WE buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

MAX Buf. Strength

This option sets the strength of the signal for the MAX buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

MA Buf. Strength

This option sets the strength of the signal for the MA buffer. The

42

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

SCAS3 Buf. Strength

This option sets the strength of the signal for the SCAS3 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

SCAS2:0 Buf. Strength

This option sets the strength of the signal for the SCAS2:0 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

SRAS3 Buf. Strength

This option sets the strength of the signal for the SRAS3 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

BIOS

SRAS2:0 Buf. Strength

This option sets the strength of the signal for the SRAS2:0 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

DQMX5 Buf. Strength

This option sets the strength of the signal for the DQMX5 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

DQMX1 Buf. Strength

This option sets the strength of the signal for the DQMX1 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

43

Chapter 4

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

DQM Buf. Strength

This option sets the strength of the signal for the DQM buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 42mA, 38mA, or 33mA. The Optimal and Fail-Safe default

settings are Auto.

CSX Buf. Strength

This option sets the strength of the signal for the CSX buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

CS7:6 Buf. Strength

This option sets the strength of the signal for the CS7:6 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

CS5:0 Buf. Strength

This option sets the strength of the signal for the CS5:0 buffer. The

settings are Auto (AMIBIOS automatically determines the correct

setting), 48mA, 42mA, or 22mA. The Optimal and Fail-Safe default

settings are Auto.

PAC Bus SERR#

Set this option to Enabled to enable the SERR# signal on the PAC bus.

The settings are Enabled or Disabled. The Optimal and Fail-Safe

default settings are Enabled.

AGP Common SERR#

Set this option to Enabled to permit a common SERR# signal for AGP

and the standard PC bus. The settings are Enabled or Disabled. The

Optimal and Fail-Safe default settings are Enabled.

44

AGP System Error Forwarding

Set this option to Enabled to enable AGP system errors to be forwarded. The settings are Enabled or Disabled. The Optimal and FailSafe default settings are Enabled.

AGP Parity Error Response

Set this option to Enabled to enable AGP parity error response. The

settings are Enabled or Disabled. The Optimal and Fail-Safe default

settings are Enabled.

IRQ12

This option specifies how IRQ12 is used. The settings are:

Setting Description

Auto AMIBIOS automatically determines how IRQ12 should be allocated.

Standard IRQ12 is made available for use on the ISA BUS.

Mouse IRQ12 is used by the PS/2 mouse.

The Optimal and Fail-Safe default settings are Auto.

PIIX4 SERR#

Set this option to Enabled to enable the SERR# signal for the Intel

PIIX4 chip. The settings are Enabled or Disabled. The Optimal and

Fail-Safe default settings are Disabled.

BIOS

USB Passive Release Enable

Set this option to Enabled to enable passive release for USB. The

settings are Enabled or Disabled. The Optimal and Fail-Safe default

settings are Disabled.

PIIX4 Passive

Set this option to Enabled to enable passive release for the Intel PIIX4

chip. The settings are Enabled or Disabled. The Optimal and Fail-Safe

default settings are Enabled.

PIIX4 Delayed Transaction

Set this option to Enabled to enable delayed transactions for the Intel

45

Chapter 4

PIIX4 chip. The settings are Enabled or Disabled. The Optimal and

Fail-Safe default settings are Enabled.

Master Lat. Timer

This option specifies the latency for the Timer. The settings are 00h

through F8h in increments of 08h. The settings are 00h.

46

Power Management Setup

The AMIBIOS Setup options described in this section are selected by

choosing Power Management Setup from the AMIBIOS Setup main

menu.

ACPI Aware OS

Set this option to Enabled to enable Advanced Configuration and

Power Interface (ACPI) BIOS for an ACPI-aware operating system,

such as Windows 98.

Power Management/APM

Set this option to Enabled to enable the chipset power management

and APM (Advanced Power Management) features. The settings are

Enabled or Disabled. The Optimal and Fail-Safe default settings are

Disabled.

Power Button Function

This option specifies how the power button mounted externally on the

computer chassis is used. The settings are:

Setting Description

On/Off Pushing the power button turns the computer on or off.

Suspend Pushing the power button places the computer in Suspend mode or Full On power mode.

The Optimal and Fail-Safe default settings are On/Off.

Instant On Support

Set this option to Enabled to enable AMIBIOS support for the Intel

InstantON specification. The settings are Enabled or Disabled. The

Optimal and Fail-Safe default settings are Disabled.

Green PC Monitor Power State

This option specifies the power state that the green PC-compliant

video monitor enters when AMIBIOS places it in a power saving state

after the specified period of display inactivity has expired. The settings

47

BIOS

Chapter 4

are Off, Standby, Suspend, or Disabled. The Optimal and Fail-Safe

default settings are Disabled.

Video Power Down Mode

This option specifies the power state that the video subsystem enters

when AMIBIOS places it in a power saving state after the specified

period of display inactivity has expired. The settings are Standby,

Suspend or Disabled. The Optimal and Fail-Safe default settings are

Disabled.

Hard Disk Power Down Mode

This option specifies the power conserving state that the hard disk

drive enters after the specified period of hard drive inactivity has

expired. The settings are Disabled, Standby, or Suspend. The Optimal

and Fail-Safe default settings are Disabled.

Hard Disk Timeout (Minute)

This option specifies the length of a period of hard disk drive inactivity. When this length of time expires, the computer enters powerconserving state specified in the Hard Disk Power Down Mode option

(see the previous page). The settings are Disabled, 1 min. (minute), 2

min, 3 min., 4 min., 5 min., 6 min, 7 min., 8 min., 9 min., 10 min., 11

min., 12 min., 13 min., 14 min, and 15 min. The Optimal and Fail-Safe

default settings are Disabled.

Standby/Suspend Timer Unit

This option specifies the unit of time used for the Standby and Suspend timeout periods. The settings are 4 msec, 4 sec, 32 sec, or 4 min.

The Optimal and Fail-Safe default settings are 4 min.

Standby Timeout

This option specifies the length of a period of system inactivity while

in Full power on state. When this length of time expires, the computer

enters Standby power state. The settings are Disabled, 4 msec, 8 msec,

12 msec, 16 msec, up to 508 msec, in increments of 4 msec. The

Optimal and Fail-Safe default settings are Disabled.

48

Suspend Timeout

This option specifies the length of a period of system inactivity while

in Standby state. When this length of time expires, the computer enters

Suspend power state. The settings are Disabled, 4 msec, 8 msec, 12

msec, 16 msec, up to 508 msec, in increments of 4 msec. The Optimal

and Fail-Safe default settings are Disabled.

Slow Clock Ratio

This option specifies the speed at which the system clock runs in the

Standby Mode power saving state. The settings are expressed as a

percentage between the normal CPU clock speed and the CPU clock

speed when the computer is in the power-conserving state. The settings

are 0-12.5%, 12.5-25%, 25-37.5%, 37.5-50%, 50-62.5%, 62.5-75%, or

75-87.5%. The Optimal and Fail-Safe default settings are 50-62.5%.

Display Activity

When set to Monitor, this option enables event monitoring on the video

display. If set to Monitor and the computer is in a power saving state,

AMIBIOS watches for display activity. The computer enters the Full

On state if any activity occurs. AMIBIOS reloads the Standby and

Suspend timeout timers if display activity occurs. The settings are

Monitor or Ignore. The Optimal and Fail-Safe default settings are

Ignore.

BIOS

Device 6 (Serial Port 1), Device 7 (Serial Port 2), Device 8 (Parallel

Port), Device 5 (Floppy Disk), Device 0 (Primary Master IDE),

Device 1 (Primary Salve IDE), Device 2 (Secondary Master IDE),

and Device 3 (Secondary Slave IDE)

When set to Monitor, these options enable event monitoring on the

specified hardware interrupt request line. If set to Monitor and the

computer is in a power saving state, AMIBIOS watches for activity on

the specified IRQ line. The computer enters the Full On state if any

activity occurs. AMIBIOS reloads the Standby and Suspend timeout

timers if activity occurs on the specified IRQ line. The settings for

each of these options are Monitor or Ignore. The Optimal and Fail-Safe

default settings are Ignore.

49

Chapter 4

PCI/PnP Setup

Choose PCI/Plug and Play Setup from the AMIBIOS Setup screen to

display the PCI and Plug and Play Setup options, described below.

Plug and Play Aware O/S

Set this option to Yes to inform AMIBIOS that the operating system

can handle plug and Play (PnP) devices. The settings are No or Yes.

The Optimal and Fail-Safe default settings are No.

PCI Latency Timer (PCI Clocks)

This option specifies the latency timings (in PCI clocks) for PCI

devices installed in the PCI expansion slots. The settings are 32, 64,

96, 128, 160, 192, 224, or 248. The Optimal and Fail-Safe default

settings are 64.

PCI VGA Palette Snoop

When this option is set to Enabled, multiple VGA devices operating on

different buses can handle data from the CPU on each set of palette

registers on every video device. Bit 5 of the command register in the

PCI device configuration space is the VGA Palette Snoop bit (0 is

disabled). For example, if there are two VGA devices in the computer

(one PCI and one ISA) and this field is set for:

Setting Description

Disabled Data read and written by the CPU is only directed to the PCI VGA device's palette registers.

Enabled

Data read and written by the CPU is directed to the both the PCI VGA device's palette registers and

the ISA VGA device palette registers, permitting the palette registers of both devices to be identical.

This option must be set to Enabled if any ISA adapter card installed in

the system requires VGA palette snooping. The Optimal and Fail-Safe

default settings are Disabled.

Allocate IRQ To PCI VGA

Set this option to Yes to allocate an IRQ to the VGA device on the PCI

bus. The settings are Yes or No. The Optimal and Fail-Safe default

settings are Yes.

50

PCI IDE Bus Master

Set this option to Enabled to specify that the IDE controller on the PCI

bus has bus mastering capability. The settings are Disabled or Enabled.

The Optimal and Fail-Safe default settings are Disabled.

Offboard PCI IDE Card

This option specifies if an offboard PCI IDE controller adapter card is

used in the computer. You must also specify the PCI expansion slot on

the motherboard where the offboard PCI IDE controller card is installed. If an offboard PCI IDE controller is used, the motherboard

onboard IDE controller is automatically disabled. The settings are

Disabled, Auto, Slot1, Slot2, Slot3, Slot4, Slot5, or Slot6. If Auto is

selected, AMIBIOS automatically determines the correct setting. The

Optimal and Fail-Safe default settings are Auto. This option forces IRQ

14 and 15 to a PCI slot on the PCI local bus. This is necessary to

support non-compliant PCI IDE adapter cards.

Offboard PCI IDE Primary IRQ

This option specifies the PCI interrupt used by the primary IDE

channel on the offboard PCI IDE controller. The settings are Disabled,

Hardwired, INTA, INTB, INTC, or INTD. The Optimal and Fail-Safe

default settings are Disabled.

Offboard PCI IDE Secondary IRQ

This option specifies the PCI interrupt used by the secondary IDE

channel on the offboard PCI IDE controller. The settings are Disabled,

Hardwired, INTA, INTB, INTC, or INTD. The Optimal and Fail-Safe

settings are Disabled.

PCI Slot1 IRQ Priority, PCI Slot2 IRQ Priority, PCI Slot3 IRQ

Priority, and PCI Slot4 IRQ Priority

These options specify the IRQ priority for PCI devices installed in the

PCI expansion slots. The settings are Auto, (IRQ) 3, 4, 5, 7, 9, 10, and

11, in order of priority. The Optimal and Fail-Safe default settings are

Auto.

BIOS

51

Chapter 4

DMA Channel 0, DMA Channel 1, DMA Channel 3, DMA

Channel 5, DMA Channel 6, and DMA Channel 7

These options allow you to specify the bus type used by each DMA

channel. The settings are PnP or ISA/EISA . The Optimal and FailSafe default settings are PnP.

IRQ3, IRQ4, IRQ5, IRQ7, IRQ9, IRQ10, IRQ11, IRQ12, IRQ14,

and IRQ15

These options specify the bus that the specified IRQ line is used on.

These options allow you to reserve IRQs for legacy ISA adapter cards.

These options determine if AMIBIOS should remove an IRQ from the

pool of available IRQs passed to devices that are configurable by the

system BIOS. The available IRQ pool is determined by reading the

ESCD NVRAM. If more IRQs must be removed from the pool, the

end user can use these options to reserve the IRQ by assigning an ISA/

EISA setting to it. Onboard I/O is configured by AMIBIOS. All IRQs

used by onboard I/O are configured as PCI/PnP. IRQ12 only appears if

the Mouse Support option in Advanced Setup is set to Disabled. IRQ14

and 15 will not be available if the onboard PCI IDE is enabled. If all

IRQs are set to ISA/EISA and IRQ14 and 15 are allocated to the

onboard PCI IDE, IRQ9 will still be available for PCI and PnP devices,

because at least one IRQ must be available for PCI and PnP devices.

The settings are ISA/EISA or PCI/PnP. The Optimal and Fail-Safe

default settings are PCI/PnP.

Reserved Memory Size

This option specifies the size of the memory area reserved for legacy

ISA adapter cards. The settings are Disabled, 16K, 32K, or 64K. The

Optimal and Fail-Safe default settings are Disabled.

Reserved Memory Address

This option specifies the beginning address (in hex) of the reserved

memory area. The specified ROM memory area is reserved for use by

legacy ISA adapter cards. This option does not appear if the Reserved

Memory Size option is set to Disabled. The settings are C0000, C4000,

C8000, CC000, D0000, D4000, D8000, or DC000. The Optimal and

Fail-Safe default settings are N/A.

52

Peripheral Setup

Peripheral Setup options are displayed by choosing Peripheral Setup

from the AMIBIOS Setup main menu. All Peripheral Setup options are

described here.

Onboard FDC

Set this option to Enabled to enable the floppy drive controller on the

motherboard. The settings are Auto (AMIBIOS automatically determines if the floppy controller should be enabled), Enabled, or Disabled. The Optimal and Fail-Safe default settings are Enabled.

Onboard Serial Port1

This option specifies the base I/O port address of serial port 1. The

settings are Auto (AMIBIOS automatically determines the correct base

I/O port address), Disabled, 3F8h, 2F8h, 2E8h, or 3E8h. The Optimal

and Fail-Safe default settings are Auto.

Onboard Serial Port2

This option specifies the base I/O port address of serial port 2. The

settings are Auto (AMIBIOS automatically determines the correct base

I/O port address), Disabled, 3F8h, 2F8h, 2E8h, or 3E8h. The Optimal

and Fail-Safe default settings are Auto.

BIOS

Serial Port2 Mode

This option specifies the operating mode for serial port 2.This option

only appears if the Onboard Serial Port2 option is not set to Auto or

Disabled. The settings are IrDA, ASK IR, or Normal. The Optimal and

Fail-Safe default settings are Normal.

IR Transmission Mode

This option specifies the infrared transmission method. This option

only appears if the Onboard Serial Port2 option is not set to Auto or

Disabled. The settings are Full Duplex or Half Duplex. There are no

default settings.

53

Chapter 4

Receiver Polarity

This option specifies if the IRQ signal for IR transmission is Active

High or Active Low. The settings are Active High or Active Low. There

are no default settings.

Transmitter Polarity

This option specifies if the IRQ signal for IR transmission is Active

High or Active Low. The settings are Active High or Active Low. There

are no default settings.

Onboard Parallel Port

This option specifies the base I/O port address of the parallel port on

the motherboard. The settings are Disabled, 378h, 278h, or 3BCh. The

Optimal default setting is 378h. The Fail-Safe default setting is Disabled.

Parallel Port Mode

This option specifies the parallel port mode. The Optimal default

setting is Normal. The Fail-Safe default setting is Disabled. The

settings are:

Setting Description

Normal The normal parallel port mode is used.

Bi-Dir Use this setting to support bidirectional transfers on the parallel port.

The parallel port can be used with devices that adhere to the Enhanced Parallel Port

EPP

(EPP) specifications. EPP uses the existing parallel port signals to provide asymmetric

bidirectional data transfer driven by the host device.

The parallel port can be used with devices that adhere to the Extended Capabilities Port

ECP

(ECP) specifications. ECP uses the DMA protocol to achieve data transfer rates of up

to 2.5 Megabits per second. ECP provides symmetric bidirectional communication.

EPP Version

This option specifies the Enhanced Parallel Port specification version

number that is used in the system. This option only appears if the

Parallel Port Mode option is set to EPP. The settings are 1.7 or 1.9.

There are no Optimal and Fail-Safe default settings because the default