Page 1

Yamaha R6

Complete Exhaust System

Part # 005-4060105-S1

Installation Instructions

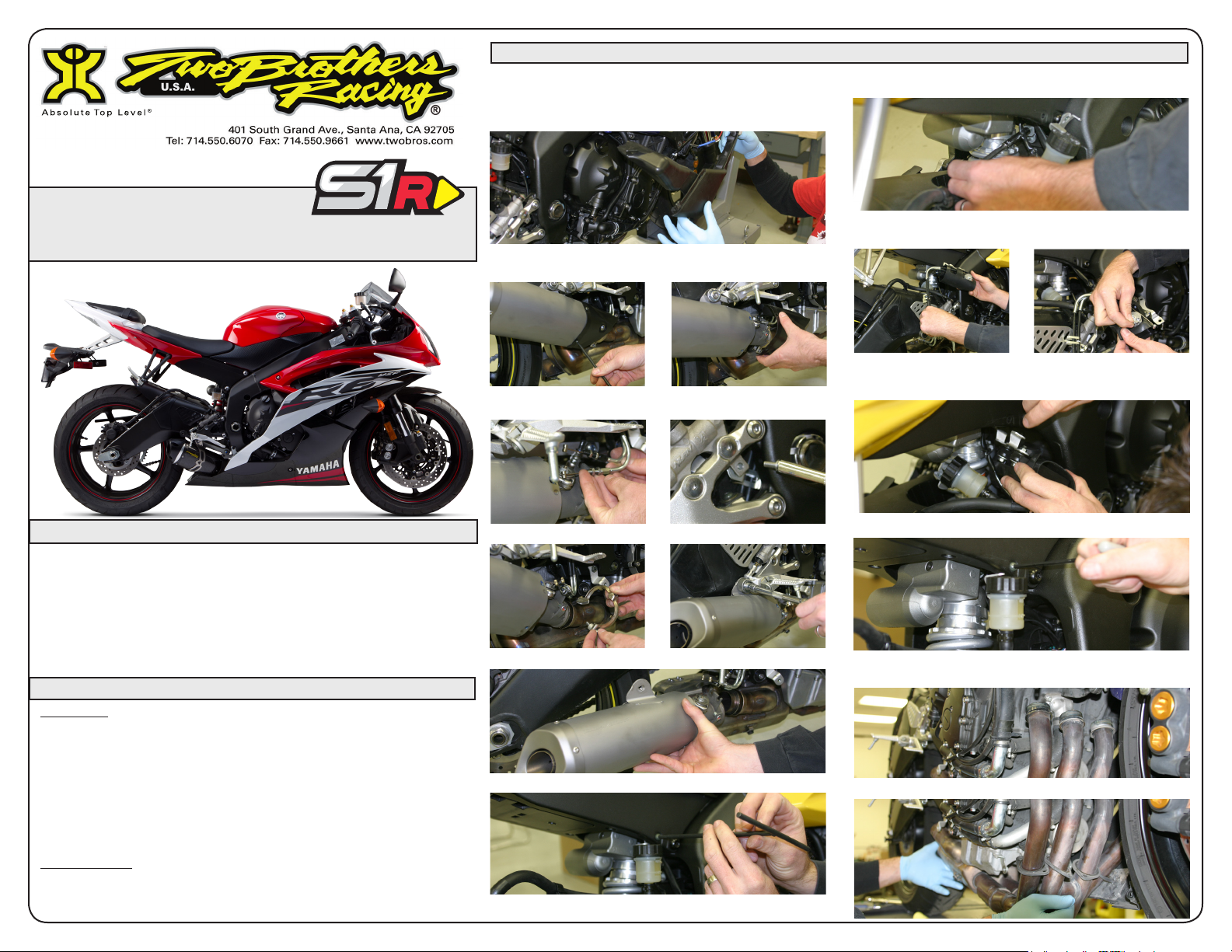

1. Make sur e the bike is completely cool before starting the

installation. Make sure the bike is secure on a rear stand or

ideally a service lift.

2. Remove lower right fairing from the motorcycle.

3. Remove mufer inlet cover from front of mufer to expose

exhaus t valve cables (noise reduction valve).

4. Remove cables from mufer and cable clamp from right

side rear set assembly.

8. Remove the noise reduction valve servo bracket from the

frame.

9. Remove servo by pulling out from the r ight side of the

motorcycle and disconnect the cables. Disregard cables.

10. Remount the servo without the cables. Make sure servo is

plugg ed into wiring harness . This step is n ecessa ry in order to

keep an error code from being displayed on the LCD screen.

IMPORTANT - PLEASE READ CAREFULLY

Two Brothers Racing products are intended for closed course competition purposes

only.

We recommend that this performance part be installed by a qualied motorcycle

technician. If you have any doubts as to your ability to install this performance

part, please consult with your local motorcycle dealer. Read all instructions rst

before starting installation. Make sure the motorcycle and exhaust system are

completely cool before starting the installation. Also, make sure the bike is secure

on a centerstand or ideally a service lift during installation. Be sure to save all stock

components for possible use later.

Care & Cleaning / Warranty

Care & Cleaning

Keep system free of dirt and moisture. Store in a cool, dry place. For cleaning use a mild spray cleaner.

Always apply cleaner or polish with a soft, clean cloth.

Stainless Header System: Polished stainless steel pipes will turn a light golden hue after a few heat

cycles, this is a normal characteristic of high quality stainless steel.

Carbon Fiber Mufers: Always make sure the berglass packing inside is in good condition and not

burned out, as exhaust heat inside an empty canister will deteriorate the Carbon Fiber sleeve. TBR sells

repack kits (TBR part # 005-10038) that include new rivets and repack material as well as a drill bit (#30),

making it easy to do yourself. Also, NEVER dyno test your bike with carbon ber mufers installed - the

intense heat and lack of cooling air can quickly cause the CF material to burn. Two Brothers Racing does

not provide a warranty for burned carbon ber.

Aluminum Mufers: Use an aluminum or mag wheel polish such as Mother’s to restore the bright nish to

factory spec.

Warranty Information

Two Brothers Racing products are intended for closed course competition purposes only, and therefore are sold “as

is” without warranty. Two Brothers Racing specifically disclaims any warranties of merchantability or fitness for

a particular purpose and disclaims all responsibility for consequential and incidental damages or any other losses

arising from the use of these products or parts.

5. Remove muf er joint c lamp and muf er mounting bolt.

6. Remove muf er assembly.

7. Remove bracket holding the brake res ervoir to the frame.

11. Reinstall the brake reservoir.

12. Remove the stock header exhaust port nuts (8 nuts total) in

order to remove the stock headers.

13. Allow the head pipe assembly to swivel downward.

Page 2

Installation Instructions

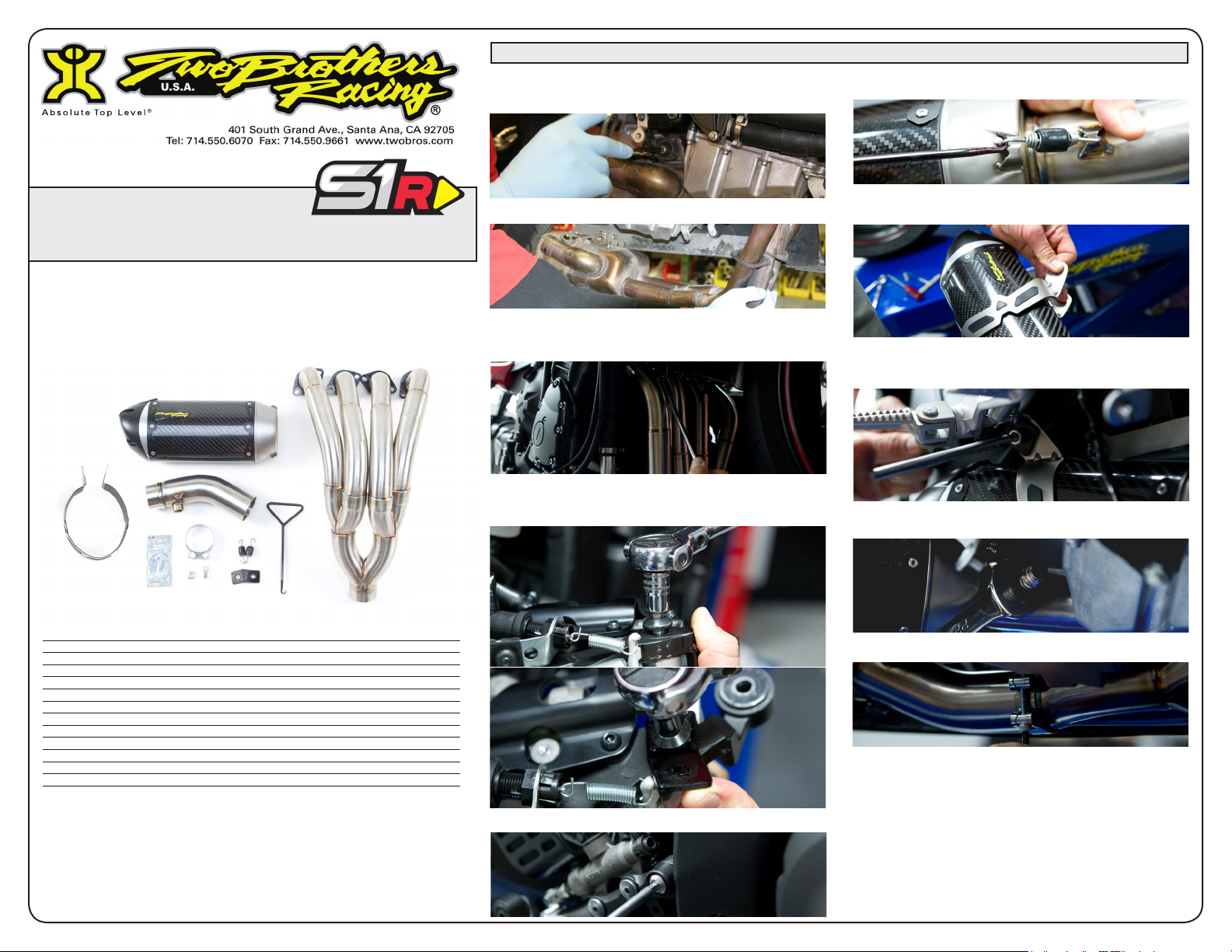

14. Remove both 8mm allen bolts an d the O2 sensor plug from

rear of head pipe assembly, making sure to support it wi th

your hand from underneath.

19. Ap pl y a thin la yer of an ti -s ei ze to sli p tube an d at ta ch t o S1R

using supplied hook springs.

Yamaha R6

Complete Exhaust System

Part # 005-4060105-S1

Qty. Description Part Number

1 Mufer Canister 8” S1R

1 Header 005-40601H

1 Slip-Tube 005-40601S

1 Mufer Clamp 005-2C-S1

1 Mufer Clamp Liner 005-2C-S1-C

1 Bracket 005-406-B

1 8mm Flange Nut 005-FN8

1 66mm Barrel Clamp 005-27-66MSH

1 8x20mm Socket Head Cap Screw 005-SH820

2 Spring 005-S45

1 Spring Puller 005-SP

1 Permatex Anti-Seize 031-P09175

15. Remove the head pipe assembly from the bike.

16. Attach TBR headers to exhaust port s with the stock ange

nuts . Make sure to keep OEM copper gasket s between the

head pipe and cylinder head.

17. Detach right side rear set f rom frame to gain access to peg

bo lt . Re move bo lt a nd i ns tall TB R mu f er b ra ck et as sho wn .

Some adjustment may be required for prop er alignment.

18. Re-attach rear set to frame.

20. Slide S1R clamp over mufer and barrel clamp onto slip

tube inlet. Att ach to TBR head tube collector.

21. Adju st f or p roper t an d ali gn ment th en a tt ac h S1R c la mp to

bracket with supplied 8x16mm socket head bolt and ange

nut. Clamp goes to inner inside of bracket.

22. Apply anti-seize to O2 sensor threads and install onto TBR

slip tube.

23. Tighten barrel clamp.

24. Double check your work and make sure all hardware is

securely tightened.

25. Be fore yo u ru n the bik e, clea n of f al l ng er pr ints and di rt , as

any oily residue will etch the metal and become somewhat

pe rm an ent whe n the sys te m ge ts hot. Run the bi ke and en joy.

It is normal for some white smoke to appear the rst time

you start the bike. This is pac king/manufacturing oil from

inside the pipe burning off. Check for gaps or leaks. If you

n d a leak, a l it tl e high te mperatu re s ilicon se alant s ho uld x

it. Af ter 50 to 100 mile s, reche ck all fasteners for tightness.

Loading...

Loading...