Page 1

Installation Instructions

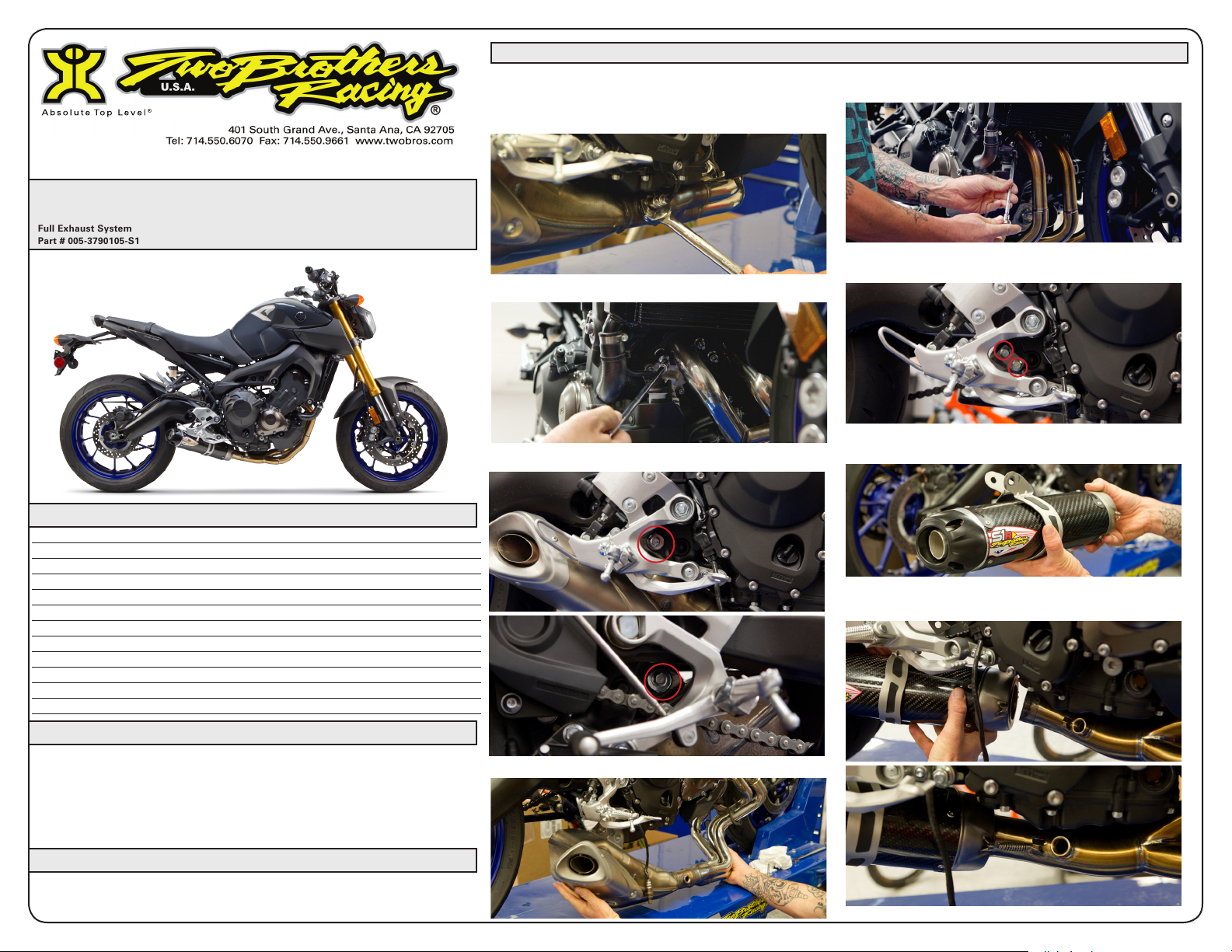

Yamaha

FZ-09

Full Exhaust System

Part # 005-3790105-S1

Parts List

Qty. Description Part Number

1 Mufer 10” Carbon S1

1 Mufer Clamp 005-2C-S1H

1 Header Assembly 005-37901H

1 Bracket 005-379-B

2 8x30mm Flange Bolt 005-FB830

2 45mm Swivel Hook Spring 005-S45

1 8x16mm Socket Head Cap Screw 005-SH816

3 8mm Flange Nut 005-FN8

1 Permatex Anti-seize Lubricant 031-P09175

2 Zip Ties 005-ZT458B

1 Air Block Off Plug 005-PLUG-1

IMPORTANT - PLEASE READ CAREFULLY

We recommend that this performance part be installed by a qualied

motorcycle technician. If you have any doubts as to your ability to install this

performance part, please consult with your local motorcycle dealer. Read

all instructions rst before starting installation. Make sure the vehicle and

exhaust system are completely cool before starting the installation. Also, make

sure the vehicle is secure on a center stand or ideally a service lift during

installation. Be sure to save all stock components for possible use later.

Warranty

Two Brothers Racing products are intended for closed course competition purposes only, and therefore are sold “as is”

without warranty. Two Brothers Racing specifically disclaims any warranties of merchantability or fitness for a particular

purpose and disclaims all responsibility for consequential and incidental damages or any other losses arising from the use

of these products or parts.

1. Make s ure the bike is completely cool before starting

the ins talla tion. Make sure the bike is secure on the side

stand or ideally a rear service s tand.

2. Remove O2 sensor from OEM header pipe.

3. Loosen head pipe hardware .

4. Remove mufer mounting bolts.

5. Remove OEM exhaust assembly.

6. Attach the TBR header assembly using OEM hard ware

and gaskets . Leave loose for now.

7. Attach supplied mufer mounting bracket using t wo

8x3 0mm bolts and two 8mm ange nuts.

8. Slide S1R muf er c lamp over S1R mufer assembly.

Note: Direc tion of mufer clamp for install.

9. Slide mufer onto header assembly and attach with

provided springs. Note: Apply a small amount of anti-

seize b etween mufer and head pipe.

Page 2

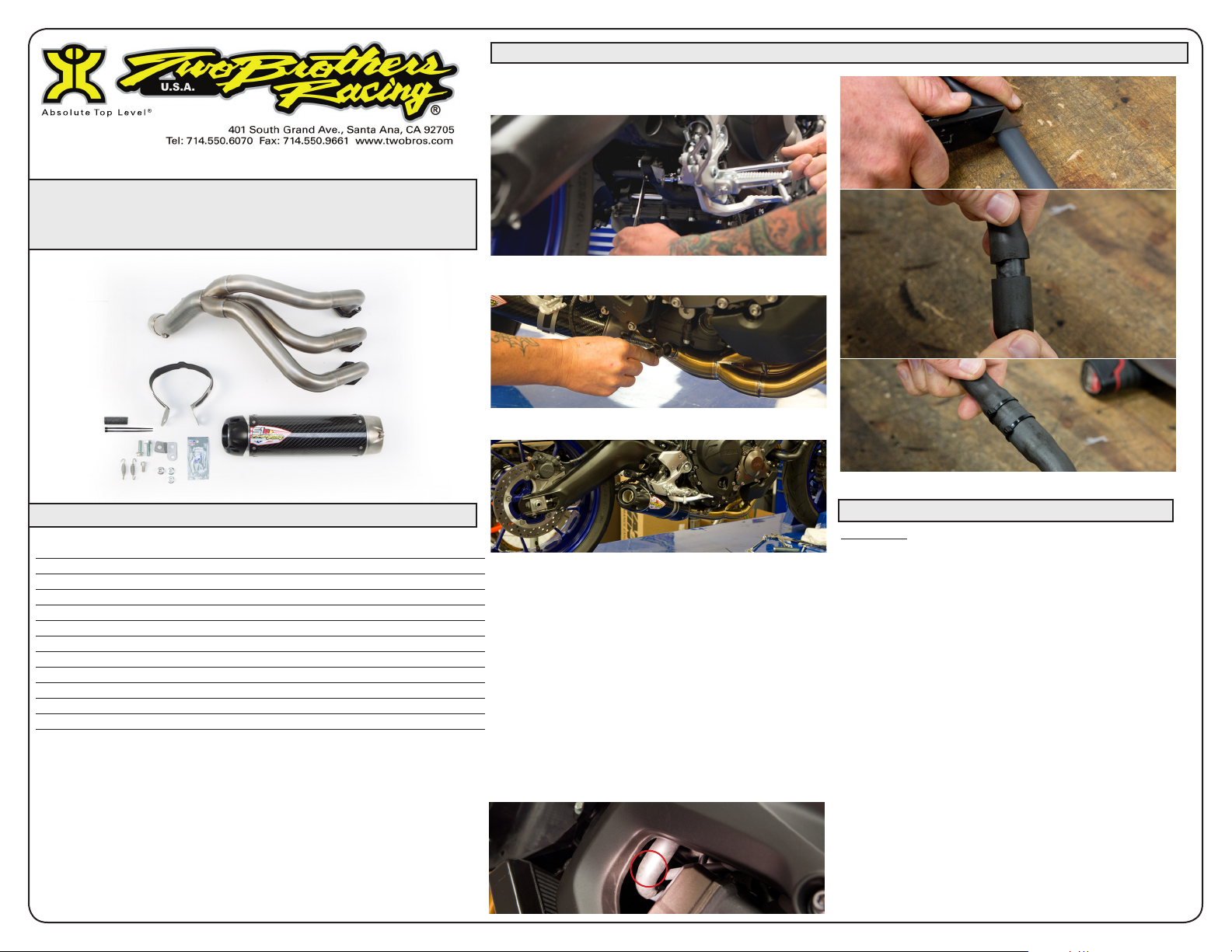

Yamaha

FZ-09

Full Exhaust System

Part # 005-3790105-S1

Installation Instructions

10. Attach mufer clamp to bracket using supplied 8x16mm

socket head bolt and 8mm ange nut. Leave lo ose for

now.

11. Apply small amount of anti-seize to O2 sensor threads

and install O2 s ensor into head pipe.

12. Tighten all hardware st arting with header, mufer clamp,

and bracket .

Parts List

Qty. Description Part Number

1 Mufer 10” Carbon S1

1 Mufer Clamp 005-2C-S1H

1 Header Assembly 005-37901H

1 Bracket 005-379-B

2 8x30mm Flange Bolt 005-FB830

2 45mm Swivel Hook Spring 005-S45

1 8x16mm Socket Head Cap Screw 005-SH816

3 8mm Flange Nut 005-FN8

1 Permatex Anti-seize Lubricant 031-P09175

2 Zip Ties 005-ZT458B

1 Air Block Off Plug 005-PLUG-1

13. Before you run the bike, clean off all ngerprint s and

dirt , as any oily residue will etch the metal and be come

somew hat permanent when the sys tem ge ts hot. Run

the bike and enjoy. It is normal for some white s moke to

appear the rst time you start the bike. This is packing/

manufacturing oil from inside the pipe burning of f.

Check for gaps or leaks. If you nd a leak , a lit tle high

temperature silic on sealant should x it. After 50 to 100

miles, recheck all fasteners for tightness.

14. Note: Due to the fact that the catalytic converter is no

longer present, the PAIR (Pulsed Air Induc tion Re ed)

valve is not needed and will not e ffect performance

when eliminated. It is recommended that the PAIR

valve be modied to eliminate popping or backring

on deceleration. Plugging the air line is a simple and

eff ective procedure. This is accessible from the left side

of the motorcycle. Start by cut ting the pictured air hose

and install the provided plug in line. Zip tie both sides of

hose over the plug.

Care & Cleaning

Care & Cleaning

Keep system free of dirt and moisture. Store in a cool, dry place. Make sure vehicle is

completely cool before maintenance.

Stainless Header System: Polished stainless steel pipes will turn a light golden hue

after a few heat cycles, this is a normal characteristic of high quality stainless steel.

Clean using a mild water based spray cleaner. Always apply cleaner or polish with a

soft, clean cloth.

Titanium Header System: Polished titanium pipes will experience color shift ranging

from deep blue/purple through amber after a few heat cycles. This is a normal

characteristic of high quality titanium. Clean using a mild water based spray cleaner.

Always apply cleaner or polish with a soft, clean cloth.

Polished Aluminum Canisters: Use an aluminum or mag wheel polish to restore the

bright nish to factory spec.

Brushed Aluminum Canisters: Clean using a mild water based spray cleaner. Always

apply cleaner or polish with a soft, clean cloth.

Carbon Fiber Canisters: Clean using a mild water based spray cleaner. Always apply

cleaner or polish with a soft, clean cloth. Always make sure the berglass packing inside

is in good condition and not burned out, as exhaust heat inside an empty canister will

deteriorate the carbon ber sleeve.

TBR sells repack kits (Road - #005-10038, Off road - #005-10038MX) that include

everything you need to easily do it yourself.

Titanium Mufers: For cleaning use a mild water based spray cleaner. Always apply

cleaner or polish with a soft, clean cloth. Always make sure the berglass packing inside

is in good condition and not burned out, as exhaust heat inside an empty canister will

deteriorate the carbon ber sleeve.

TBR sells repack kits (Road - #005-10038, Off road - #005-10038MX) that include

everything you need to easily do it yourself.

Repack all road canisters every 3,000 miles. Part #005-10038

Repack all Off road canisters after every 10 hours of use. Part #005-10038MX

NEVER dyno test your bike with carbon ber or titanium canisters installed - the

intense heat and lack of cooling air can quickly burn through the canister material. Two

Brothers Racing does not provide a warranty for burned canisters.

Loading...

Loading...