Tweco SL100 RPT User Manual

82 Benning Street, West Lebanon, NH 03784 USA

(603) 298-5711 • www.thermal-dynamics.com

Manual 0-2937

Model SL100 RPT

Replacement Plasma Cutting

Machine T orc hes

Installation and Operation Instructions

General Information

The SL100 SureLok® T or ch works with most plasma cutting power supplies. The Torch is equipped with either

O2B connectors or the Thermal Dynamics ATC connector . Installation requires an Adapter Kit sold separately.

The Torch provides cutting capabilities of up to 100 amperes. The torch uses compr essed air as both the plasma

and secondary gas. Single - gas operation provides a

smaller torch and inexpensive operation.

Refer to the Complete Assembly Replacement page for

configurations and catalog numbers.

These instructions are important for the proper installation of the Torch. Read the instructions thoroughly before attempting the installation. Keep these instructions

for reference.

Supplied Parts

The Replacement Torch kits include:

• Torch With Leads - 1 each

• Installation Instructions - 1 each

• Consumables (SureLok MaximumLife

Starter Cartridge, Tip, and Shield Cup)

TM

Electrode,

Options

The following options are available. Refer to the parts

lists for catalog numbers.

• A TC Adapter Kit (for T or ches with A TC connections)

• Leads extensions (for T orches with A TC connections)

• Leather Leads Covers

• Ohmic Clip Kit

• Pinion

• 5" / 127 mm Positioning Tube

Torch Specifications

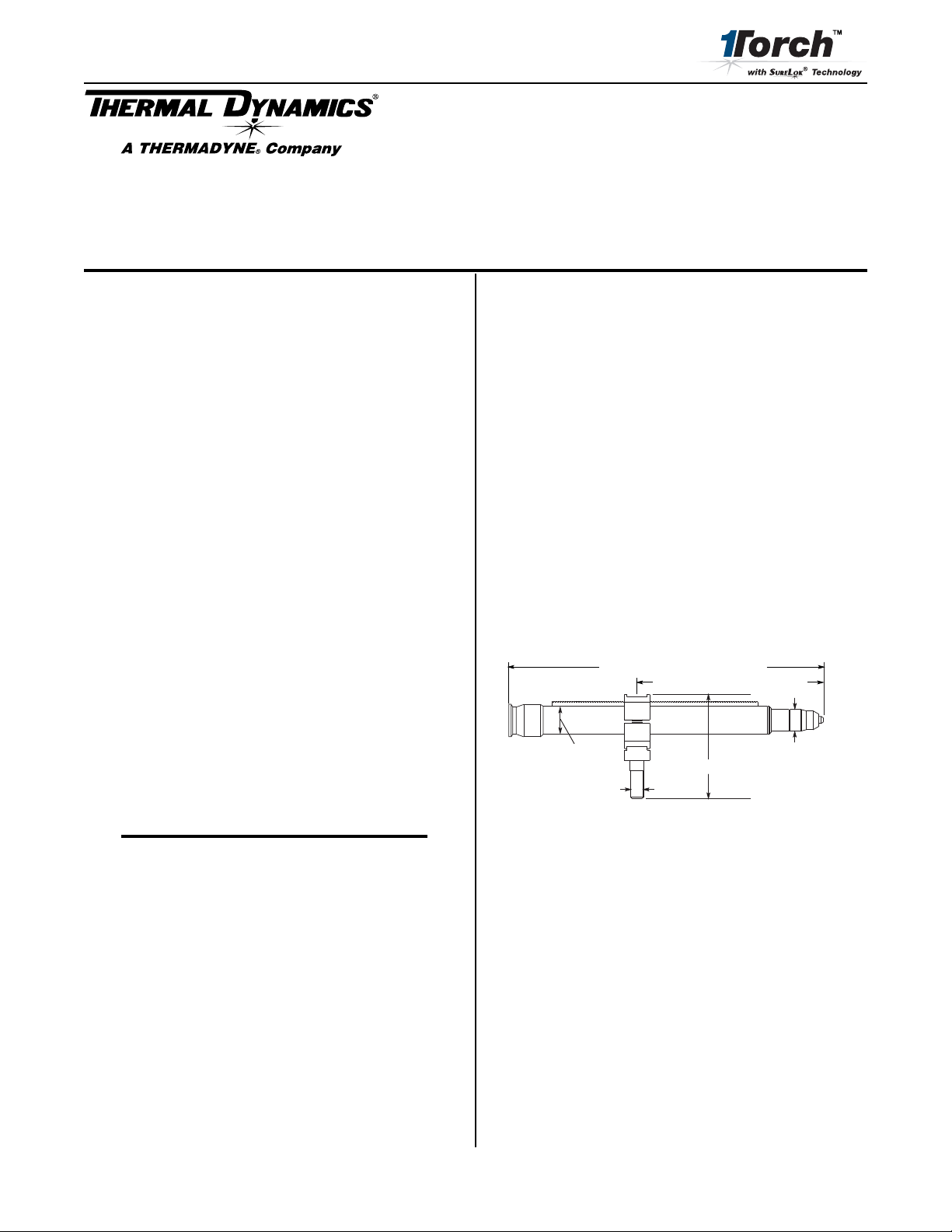

A. Torch Configuration and Dimensions

The T orch is available with mounting tube with rack and

pinch block assembly.

15.875" / 403 mm

9.285" / 236 mm

1.375" / 35 mm

4.95" / 126 mm

0.625" / 16 mm

1.175" / 30 mm

A-02998

NOTE

The consumable parts installed in the Torch may

not necessarily be optimized for your Power Supply or cutting application. For best results, refer

to the selection chart in this manual to choose the

proper consumables.

© 2002 by Thermal Dynamics Corporation, Printed in USA

June 6, 2003 1 Manual 0-2937

B. Torch Leads Lengths

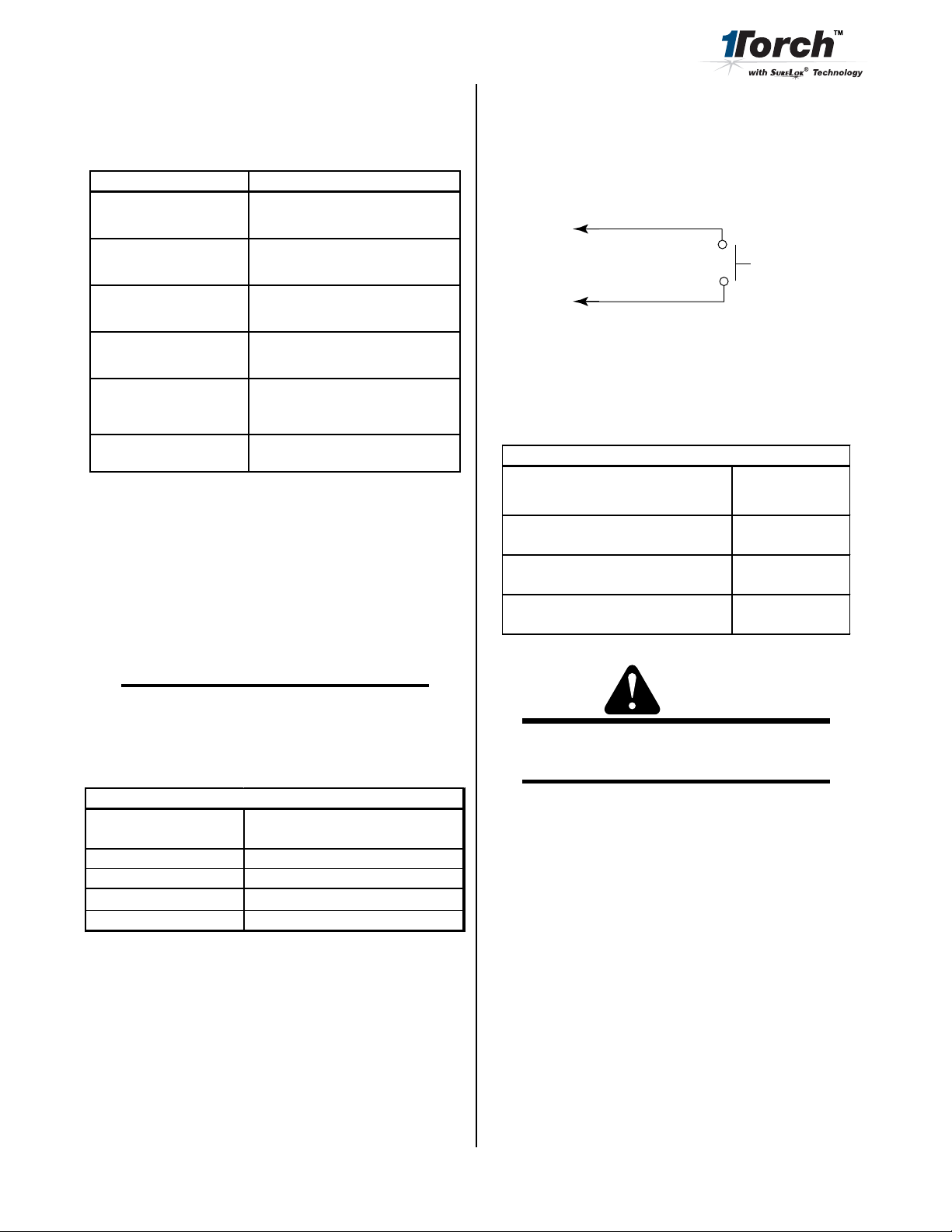

F. Parts - In - Place (PIP) Circuit - 12 vdc

The torch is available with leads as follows:

Leads Type Lengths Avail able

Unshielded Leads,

O2B C onnec tors

Shielded Leads,

O2B C onnec tors

Unshielded Leads,

ATC Connectors

Shielded Leads,

ATC Connectors

Unshielded Ex tensions,

ATC Connectors

Shielded E xtensions,

ATC Connectors

25 foot / 7.6 m, 50 f oot / 15.2 m

25 foot / 7. 6m, 50 fo o t / 15.2 m

5 foot / 1. 5 m, 10 foot / 3.05 m,

25 foot / 7.6 m, 50 f oot / 15.2 m

5 foot / 1. 5 m, 10 foot / 3.05 m,

25 foot / 7.6 m, 50 f oot / 15.2 m

15 foot / 4.6 m, 25 f oot / 7.6 m,

50 foot / 15. 2 m

25 foot / 7. 6 m,

50 foot / 15. 2 m

For torch leads with ATC Connectors, leads extensions are available to extend the leads to a maximum

of 50 feet / 15.2 m. Total leads lengths must not exceed the power supply manufacturer's recommendations.

C. Current Rating (Refer to Note)

The torch and leads include circuitry called Parts In - Place (PIP). This circuit includes a switch located at the torch head. The shield cup closes this

switch when properly installed. The torch will not

operate if this switch is open.

To Control

Cable Wiring

PIP Switch

Shield Cup

A-03504

G. Direct Contact Hazard

For exposed tip the recommended standoff is 3/16" / 4.7

mm.

H. Gas Requirements

SL100 T or ch Gas Spe ci fi cation s

Gas (P l asma and Sec ondary ) Compressed Air

Operating P res sure

Refer to NOTE

Maximum Input Pres sure

Gas Flow

55 - 70 psi

3.8 - 5.2 bar

125 psi / 8. 6

bar

300 - 500 sc fh

142 - 235 lpm

• Up to 100 Amps, DC, straight polarity

NOTE

Power Supply characteristics will determine material thickness range.

D. Torch Ratings

SL100 Torch Ratin

Ambient

Tem

perature

Duty Cy cle

Maxi mu m C u r r e n t

Voltage (V

peak

)

Arc Stri king Vo l ta g e

100% @ 100 Amps @ 400 scfh

gs

104° F

40° C

100 Amps

500V

7kV

E. Type of Cooling

Combination of ambient air and gas stream through

torch.

W ARNING

This torch is not to be used with oxygen (O

).

2

NOTE

Operating pressure varies with torch model, operating amperage, and torch leads length. Refer to

gas pressure settings charts.

Connecting T orc h

There are two types of connection for the Torch Leads.

One type uses the Thermal Dynamics A TC connector . The

other uses standard (O2B) connections for gas and circuitry. Both types may require an adapter kit sold separately.

June 6, 2003 2 Manual 0-2937

Connections with Adapter Kits

Spare Parts Label

Leads with ATC Connectors

Connect the torch leads to the power supply per the instructions provided with the appropriate adapter kit.

W ARNING

The shield connectors on the Adapter Leads should

be connected to the power supply in accordance

with instructions provided by the power supply

manufacturer. Use of a shielded torch on power

supplies not specifically designed for shielded leads

may result in damage to the power supply or improper function.

Inspect the halves of the A TC Connector. Align the male

connector with the female receptacle and push them together by hand until they seat fully. Turn the Locking

Ring until it pulls the halves of the connector together

fully. Do not use tools to tighten the connector . If ther e

is any resistance to the ring turning, pull the halves of the

connector apart, realign the inner components, ensure that

the threaded components are aligned, and push the halves

of the connector together again.

Control Cable

Connector (Machine

Torches Only)

ATC Male

Connector

To

Power Supply

1

Torch Leads

2

The parts kit provided with this torch includes an adhesive label. Select the small perforated section showing

the appropriate pressure setting for the amperage output and leads length to be used with this torch. Refer to

the charts. Apply this section in the ‘Gas Supply’ area of

the label under the ‘Recommended operating pressure’

text. Discard any pressure setting sections of the label

that will not be used. Apply the large label to the power

supply, where the operator can see it for easy refer ence.

Torch Parts Selection

Refer to the Consumables Selection Chart for the various torch parts for the application and operation.

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

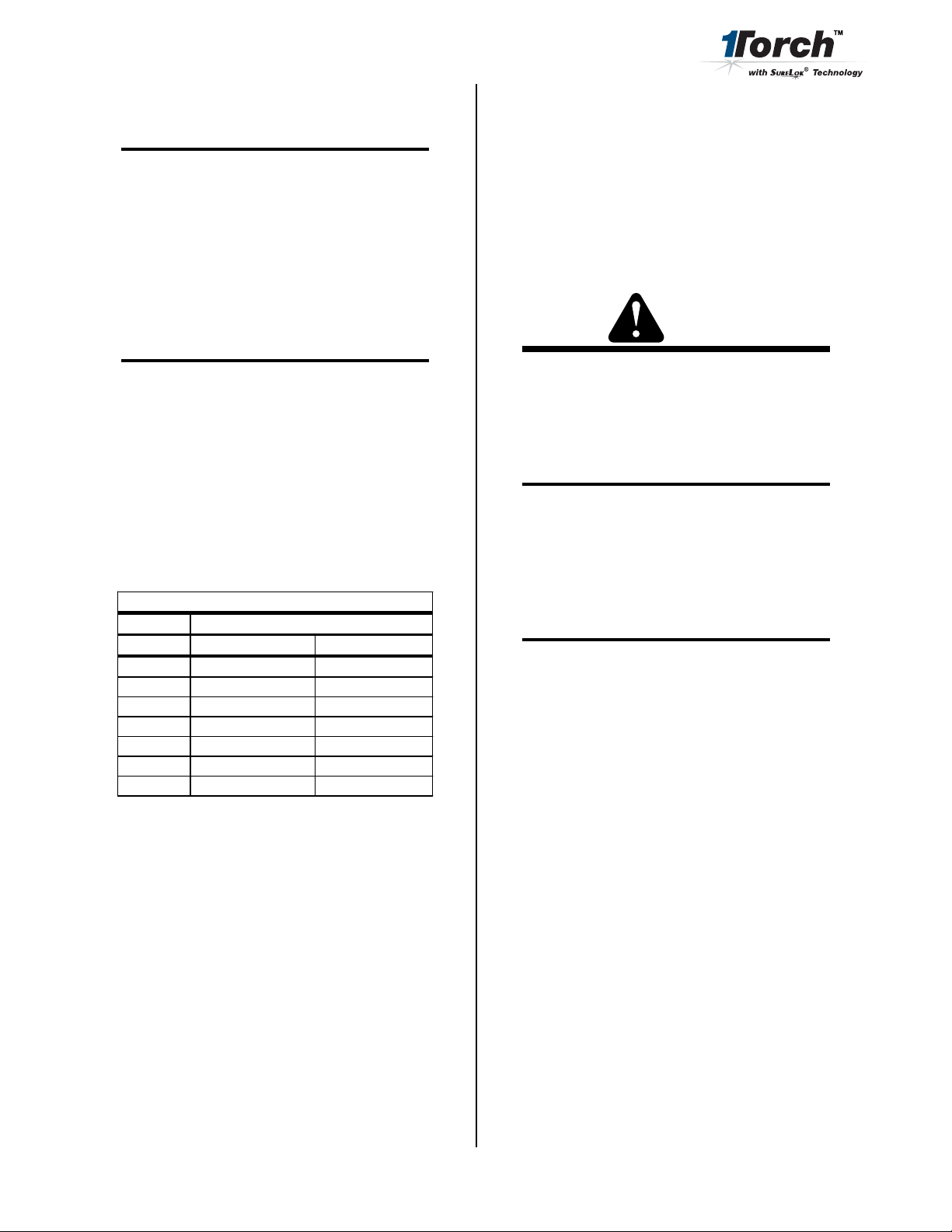

The shield cup (or shield cup body and end cap or deflector) holds the tip and starter cartridge in place. Put

one hand under the shield cup to catch the tip and starter

cartridge when the cup is removed.

Change the torch parts as follows:

1. Unscrew and remove the shield cup from the torch

head.

Torch Head

ATC Adapter

Female Receptacle

Leads with Standard (O2B) Connectors

A-03582

Electrode

Starter Cartridge

Connect the torch leads to the power supply per the instructions provided with the appropriate adapter kit.

Tip

Shield Cup

Assembly

A-03598

June 6, 2003 3 Manual 0-2937

2. Fit the starter cartridge and desired tip onto the electrode.

NOTE

Refer to the consumables selection chart for the

proper combination of torch parts, including shield

retainers and cups.

3. Fit the shield cup onto the torch head.

4. Hand tighten the shield cup until it is seated on the

torch head. Do not use tools to tighten the cup. If

resistance is felt when installing the cup, check the

threads before proceeding.

NOTE

When operating the torch in a normal condition, a

small amount of gas vents through the gap between

the shield cup and torch handle. Do not attempt to

over tighten the shield cup as irreparable damage

to internal components may result.

Operating Gas Pressure

Set gas pressure at the power supply regulator accor ding

to the following chart. This chart is a guide only; adjust

as necessary for best performance.

Sequence of Operation

1. Turn on power and adjust gas pr essure on the Power

Supply pressure gauge. Refer to the chart for optimum pressure settings for the combination of torch

consumables and total leads lengths (including extensions) in use.

2. Adjust current output on the Power Supply to match

the selected tip and attach the work clamp firmly to

the work or to the cutting table.

WARNING

Maximum current for this torch is 100 Amps. Operation of this torch at higher outputs may damage the torch, the leads, the components, or the

Power Supply. DO NOT operate the torch at mor e

than 100 Amps.

NOTE

The gas preflow and postflow are characteristics of

the power supply and not a function of the torch.

3. Recommended standoff distance is 3/16" / 4.7 mm.

SL100 Ga s Pressure Settings

Total Leads Length

Tip

30A 55 psi / 3.8 bar 60 psi / 4.1 bar

40A 55 psi / 3.8 bar 60 psi / 4.1 bar

50/55A 60 psi / 4.1 bar 65 psi / 4.5 bar

60A 60 psi / 4.1 bar 65 psi / 4.5 bar

70A 60 psi / 4.1 bar 65 psi / 4.5 bar

80A 60 psi / 4.1 bar 65 psi / 4.5 bar

90 / 100 A 65 psi / 4.5 bar 70 psi / 5.2 bar

Up to 25' / 7.6 m 50' / 15.2 m

4. Follow normal recommended cutting practices as provided in the power supply operator's manual.

NOTE

When the shield cup is properly installed, there is

a slight gap between the shield cup and the torch

handle. Gas vents through this gap as part of normal operation. Do not attempt to force the shield

cup to close this gap. Forcing the shield cup against

the torch head or torch handle can damage components.

Cutting With Machine Torch

The machine torch can be activated by remote control pendant or by a remote interface device such as CNC.

Common Operating Faults

The following are the more common cutting faults and

the possible causes:

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non - Genuine Thermal Dynamics Parts

June 6, 2003 4 Manual 0-2937

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Torch standoff too high from workpiece

Inspection and Replacement of

Consumable T orch Parts

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non - Genuine Thermal Dynamics Parts

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non - Genuine Thermal Dynamics Parts

4. Short T orch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Gas pressure too low

e. Improperly assembled torch

f. Non - Genuine Thermal Dynamics Parts

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

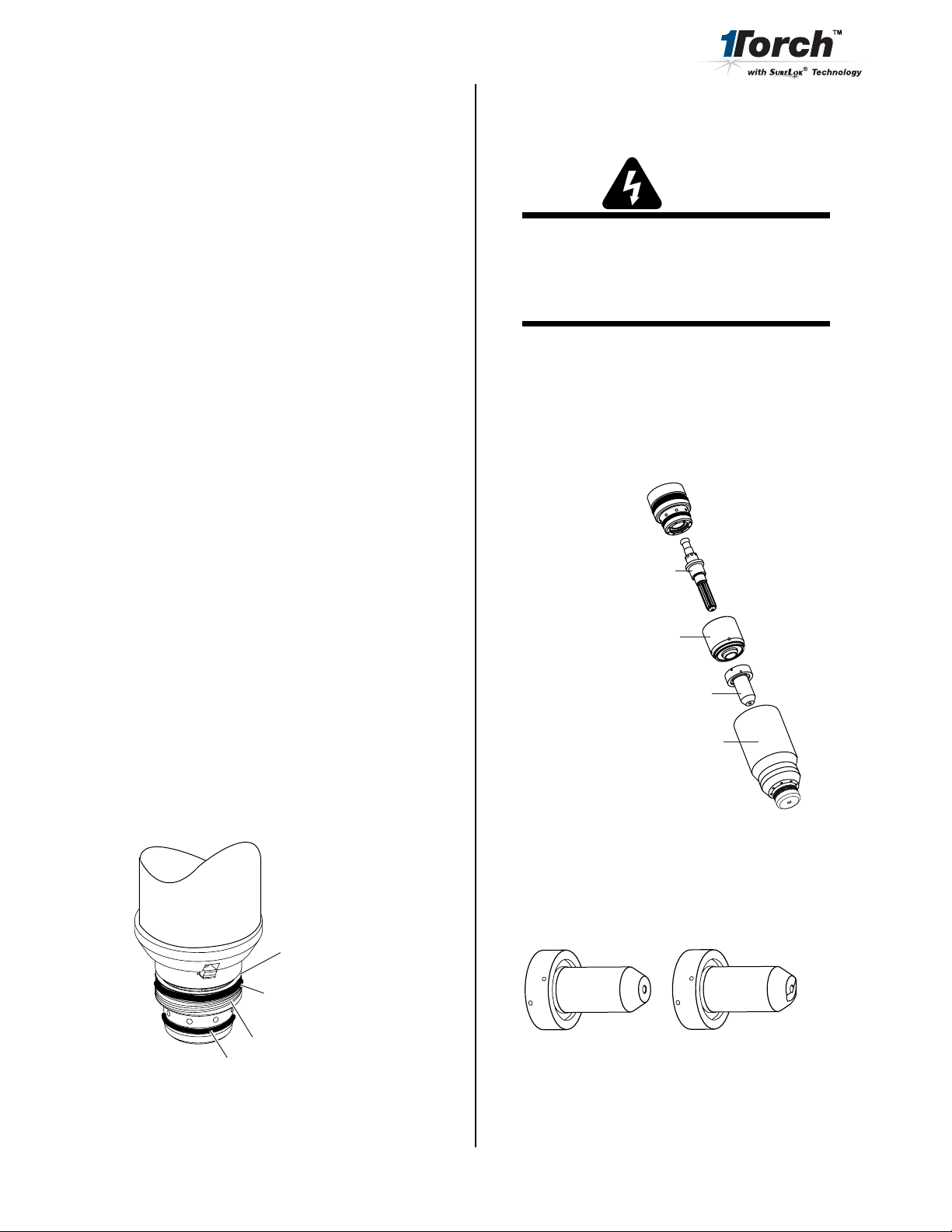

Remove the consumable torch parts.

1. Inspect the cup for damage. Wipe it clean or replace

if damaged. Slag built up on the shield cup that cannot be removed may affect the performance of the

system.

Torch Head

Electrode

Starter Cartridge

5. Difficult Starting

a. Worn torch consumables

b. Non - Genuine Thermal Dynamics Parts

6. Torch will not pilot

a. Upper O-ring on torch head in wrong position

Upper Groove

with V ent Holes

Must Remain Open

Upper O-Ring

in Correct Groove

Threads

Lower O-Ring

A-03725

Tip

Shield Cup

Assembly

A-03598

2. Check the tip for excessive wear (indicated by an elongated or oversized orifice). Clean or replace the tip if

necessary.

Good Tip

Worn Tip

A-03406

June 6, 2003 5 Manual 0-2937

Loading...

Loading...