Page 1

Single- and Two-Stage Regulators

For Standard and Edge™ Series Regulators

English

Canadien Français

Americas Español

Safety and Operating Instructions

Issue Date: December 3, 2012

Revision: JForm No.: 0056-1625

VictorTechnologies.com

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Victor® product. We are proud to have you as our customer

and will strive to provide you with the best service and reliability in the industry. This

product is backed by our extensive warranty and worldwide service network. To

locate your nearest distributor or service agency, please contact a representative at

the address and phone number in your area listed on the inside back cover of this

manual, or visit us on the web at www.victorequip.com.

This Operating Manual has been designed to instruct you on the correct use and

operation of your Victor® product. Your satisfaction with this product and its safe

operation is our ultimate concern. Therefore, please take the time to read the entire

manual, especially the Safety Precautions. They will help you to avoid potential hazards

that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Victor® is a Global Brand of gas equipment products for Victor Technologies

International, Inc. We manufacture and supply to major welding and cutting industry

sectors worldwide, including: Manufacturing, Construction, Mining, Automotive,

Aerospace, Engineering, Rural and DIY/Hobbyist, Scrap, Demolitions and Shipyards.

We distinguish ourselves from our competition through market-leading, dependable

products that have stood the test of time. We pride ourselves on technical innovation,

competitive prices, excellent delivery, superior customer service and technical support,

together with excellence in sales and marketing expertise.

Above all, we are committed to develop technologically advanced products to achieve

a safer working environment within the welding industry.

Page 3

WARNING

Read and understand this entire manual and your employer’s safety practices

before installing, operating, or servicing the equipment. While the information

contained in this manual represents the Manufacturer’s judgment, the

Manufacturer assumes no liability for its use.

Single- and Two-Stage Regulators

Safety and Operating Instructions

Part Number 0056-1625

Published by:

Victor Technologies International, Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.victorequip.com

U.S. Customer Care: (800) 426-1888

International Customer Care: (940) 381-1212

Copyright © 2011, 2012 Victor Technologies International, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this manual, whether such error

results from negligence, accident, or any other cause.

Publication Date: January 20, 2011

Revision Date: December 3, 2012

Record the following information for Warranty purposes:

Where Purchased: _______________________________________________

Purchase Date: _________________________________________________

Equipment Serial #: ______________________________________________

i

Page 4

Table of Contents

SECTION 1: INTRODUCTION ...........................................1-1

SECTION 2: GENERAL SAFETY INFORMATION ...............2-3

2.01 Fire Prevention ..........................................2-3

2.02 Housekeeping ............................................2-4

2.03 Ventilation ................................................2-4

2.04 Personal Protection ..................................2-4

2.05 Compressed Gas Cylinders ......................2-5

SECTION 3: REGULATORS: SAFETY AND OPERATION .... 3-7

3.01 Standard Regulators .................................3-7

3.02 Edge Series Regulators ...........................3-11

3.03 Leak Testing the System .........................3-15

SECTION 4: WHEN YOU FINISH USING THE REGULATOR 4-16

4.01 Storage ...................................................4-16

SECTION 5: STATEMENT OF WARRANTY ......................5-17

ii

Page 5

SECTION 1:

INTRODUCTION

This booklet is a guide to the safe and efficient operation of

regulators used in oxy-fuel applications. If the apparatus is not

used in an oxy-fuel application, the operator must still follow

safety and operating procedures that apply. Regulator usage

presents several potential hazards. Read this booklet thoroughly

and carefully before operating this equipment.

All operations should conform to applicable Federal, State,

County, or City regulations for installation, operation, ventilation,

fire prevention, and protection of personnel. ANSI Standard

Z49.1, “Safety in Welding and Cutting” contains detailed safety

instructions. It is available from the American Welding Society,

P.O. Box 351040, Miami, FL 33135.

A system of notes, cautions, and warnings emphasize impor tant

safety and operating information in this booklet:

NOTE

Conveys installation, operation, or maintenance information

which is important but not hazard-related.

CAUTION

Caution indicates a potentially hazardous situation which,

if not avoided, may result in injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING

1-1

Page 6

WARNING

This product contains chemicals, including lead, or

otherwise produces chemicals known to the State of

California to cause birth defects and other reproductive

harm. Wash hands after handling.

WARNING

DO NOT attempt to use this apparatus until you thoroughly

read and understand all safety and operating instructions

provided. For your safety, practice the safety and operating

procedures described in this booklet every time you use the

apparatus. Deviating from these procedures may result in

fire, explosion, property damage and/or operator injury. If

at any time the apparatus you are using does not perform

in its usual manner, or you have any difficulty in the use of

the apparatus, STOP using it immediately. DO NOT use the

apparatus until the problem has been corrected!

WARNING

Service or repair of apparatus should be performed only

by a qualified repair technician capable of servicing gas

apparatus in strict accordance to applicable Part and Service

bulletins for Victor® manufactured prod ucts. Improper

service repair, or modification of the product could result in

damage to the product or injury to the operator. Improper

service repair, USE OF NON-GENUINE VICTOR® PARTS,

or modification could result in damage to the product or

injury to the operator.

2-2

Page 7

SECTION 2:

GENERAL SAFETY INFORMATION

Read and understand all safety and operating instructions provided

before using this apparatus. RETAIN THESE INSTRUC TIONS IN A

READILY AVAILABLE LOCATION FOR FUTURE REFERENCE.

2.01 FIRE PREVENTION

Welding and cutting operations use fire or combustion as a basic

tool. The process is very useful when properly controlled. However,

it can be extremely destructive if not performed cor rectly in the

proper environment.

1. The work area must have a fireproof floor.

2. Work benches or tables used during welding or cutting

operations must have fireproof tops.

3. Use heat resistant shields or other approved material to protect

nearby walls or unprotected flooring from sparks and hot metal.

4. Keep an approved fire extinguisher of the proper size and type

in the work area. Inspect it regularly to ensure that it is in proper

working order. Know how to use the fire extin guisher.

5. Move combustible materials away from the work site. If you

can not move them, protect them with fireproof covers.

WARNING

NEVER perform welding, heating, or cutting operations

on a container that has held toxic, combustible or flammable

liq uids, or vapors. NEVER perform welding, heating, or

cutting operations in an area containing combustible vapors,

flam mable liquids, or explosive dust.

2-3

Page 8

2.02 HOUSEKEEPING

WARNING

NEVER allow oxygen to contact grease, oil, or other flam-

mable substances. Although oxygen by itself will not burn,

these substances become highly explosive. They can ignite

and burn violently in the presence of oxygen.

Keep ALL apparatus clean and free of grease, oil and other

flammable substances.

2.03 VENTILATION

WARNING

Ade quately ventilate welding, heating, and cutting work

areas to prevent accumulation of explosive or toxic concentrations of gases. Certain combinations of metals, coatings,

and gases generate toxic fumes. Use respiratory protection

equipment in these circumstances. When welding/brazing,

read and understand the Material Safety Data Sheet for the

welding/brazing alloy.

2.04 PERSONAL PROTECTION

Gas flames produce infrared radiation which may have a harm ful

effect on the skin and especially on the eyes. Select goggles or a

mask with tempered lenses, shaded 4 or darker, to protect your

eyes from injury and provide good visibility of the work.

Always wear protective gloves and flame-resistant clothing to protect

skin and clothing from sparks and slag. Keep collars, sleeves, and

pockets buttoned. DO NOT roll up sleeves or cuff pants.

When working in a non-welding or cutting environment, always

wear suitable eye protection or face shield.

2-4

Page 9

WARNING

Practice the following safety and operation precautions

EVERY TIME you use pressure regulation equipment.

Deviation from the following safety and operation

instructions can result in fire, explosion, damage to

equipment, or injury to the operator.

2.05 COMPRESSED GAS CYLINDERS

The Department of Transportation (DOT) approves the design and

manufacture of cylinders that contain gases used for welding or

cutting operations.

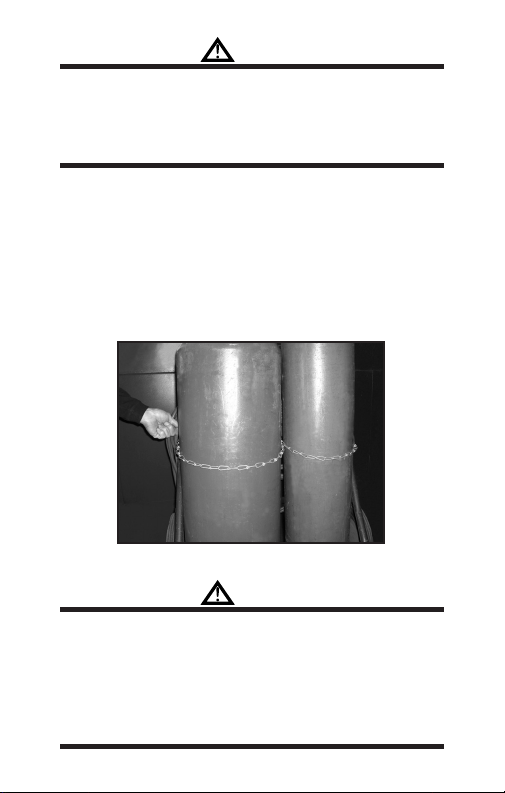

1. Place the cylinder (Figure 1) where you will use it. Keep the

cylinder in a vertical position. Secure it to a cart, wall, work bench,

post, etc.

Figure 1: Gas Cylinders

WARNING

Cylinders are highly pressurized. Handle with care. Serious

accidents can result from improper handling or mis use of

compressed gas cylinders DO NOT drop the cylinder, knock

it over, or expose it to excessive heat, flames or sparks.

DO NOT strike it against other cylinders. Contact your gas

supplier or refer to CGA P-1 “Safe Handling of Compressed

Gases in Containers” publication.

2-5

Page 10

NOTE

CGA P-1 publication is available by writing the Compressed

Gas Association, 4221 Walney Road, 5th Floor, Chantilly,VA

20151-2923

2. Place the valve protection cap on the cylinder whenever mov ing

it, placing it in storage, or not using it. Never drag or roll cylinders

in any way. Use a suitable hand truck to move cylin ders.

3. Store empty cylinders away from full cylinders. Mark them

“EMPTY” and close the cylinder valve.

4. NEVER use compressed gas cylinders without a pressure

reducing regulator attached to the cylinder valve.

5. Inspect the cylinder valve for oil, grease, and damaged parts.

WARNING

DO NOT use the cylinder if you find oil, grease or

damaged parts. Inform your gas supplier of this condition

immediately.

6. Momentarily open and close (called “cracking”) the cylinder valve

to dislodge any dust or dirt that may be present in the valve.

CAUTION

Open the cylinder valve slightly. If you open the valve too

much, the cylinder could tip over. When cracking the cylinder

valve, DO NOT stand directly in front of the cylinder valve.

Always perform cracking in a well ventilated area. If an

acetylene cylinder sprays a mist when cracked, let it stand

for 15 minutes. Then, try to crack the cylinder valve again.

If this problem persists, contact your gas supplier.

3-6

Page 11

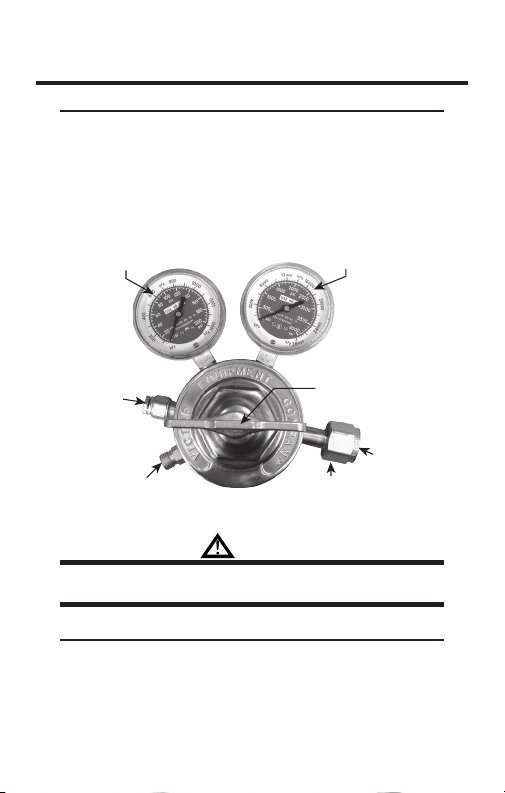

SECTION 3:

LOW PRESSURE

GAUGE (DELIVERY)

HIGH PRESSURE

GAUGE (SUPPLY)

PRESSURE

ADJUSTING

SCREW

OUTLET

CONNECTION

RELIEF

VALVE

INLET

CONNECTION

INLET

FILTER

REGULATORS: SAFETY AND OPERATION

NOTE

For Edge Series regulators go to section 3.02

3.01 STANDARD REGULATORS

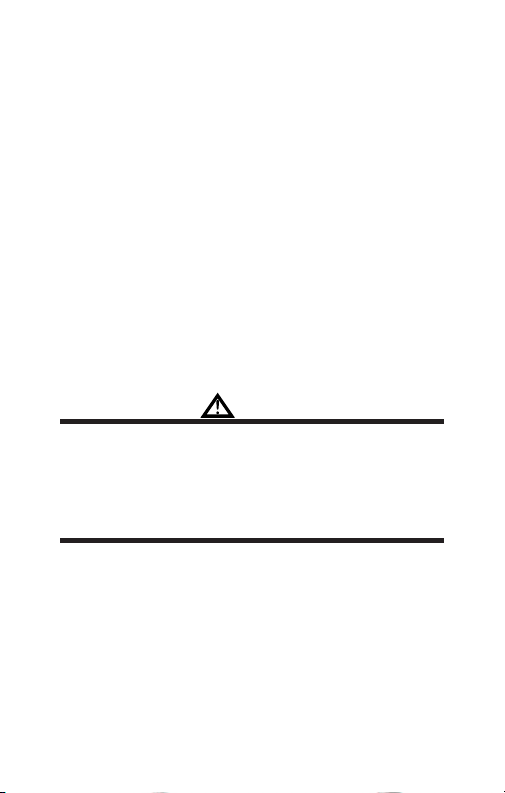

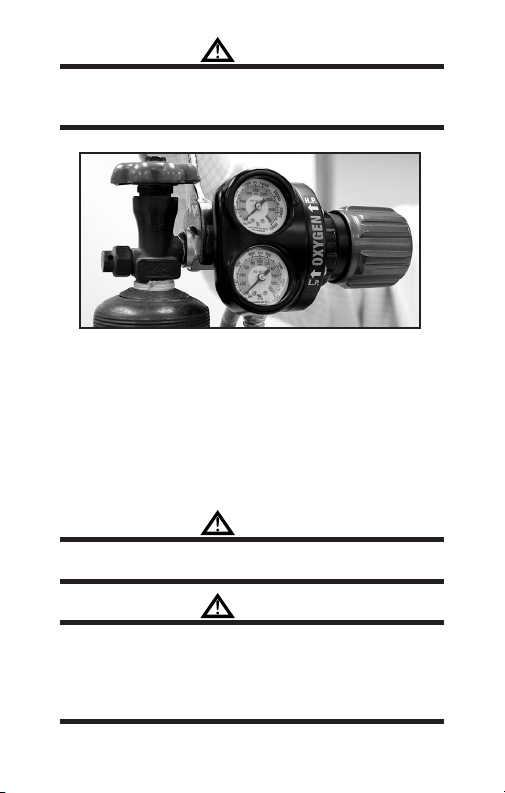

Pressure regulators (Figure 2) attached to the cylinder valve reduce

high cylinder pressures to suitable low working pressures for

welding, cutting, and other applications.

Figure 2: Pressure Regulator

WARNING

Use the regulator for the gas and pressure for which it is

designed. NEVER alter a regulator for use with any other gas.

NOTE

Regulators purchased with open 1/8”, 1/4”, 3/8”, or 1/2”

NPT ports must be assembled to their intended system.

3-7

Page 12

1. Note the maximum inlet pressure stamped on the regulator. DO

NOT attach the regulator to a system that has a higher pressure

than the maximum rated pressure stamped on the regulator.

2. The regulator body will be stamped “IN” or “HP” at the inlet

port. Attach the inlet port to the system supply pressure

connection.

3. Wrap pipe threads with Teflon tape 1 1/2 to 2 turns to effect a

seal. If other sealants are used, they must be compatible with

the gas that will be used in the system.

4. If gauges are to be attached to the regulator and the regu lator

is stamped and listed by a third party (i.e. “UL” or “ETL”). The

following requirements must be met:

a) Inlet gauges over 1000 PSIG (6.87 mPa) shall conform with

the requirements of UL 404, “Indicating Pressure Gauges

for Compressed Gas Service.”

b) Low pressure gauges must be UL recognized for the class

of regulator they are being used on according to UL252A.

WARNING

DO NOT use a regulator that delivers pressure exceeding

the pressure rating of the downstream equipment unless

pro visions are made to prevent over-pressurization (i.e.

system relief valve). Make sure the pressure rating of the

down stream equipment is compatible with the maximum

delivery pressure of the regulator.

5. Be sure that the regulator has the correct pressure rating and

gas service for the cylinder used.

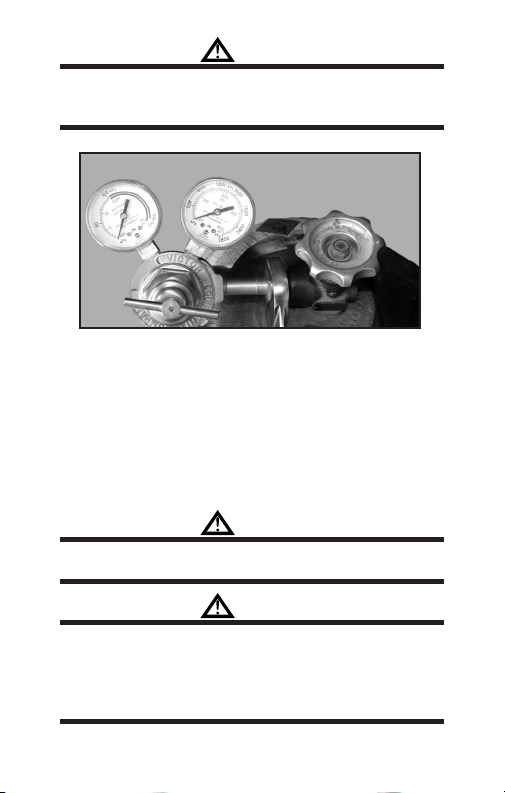

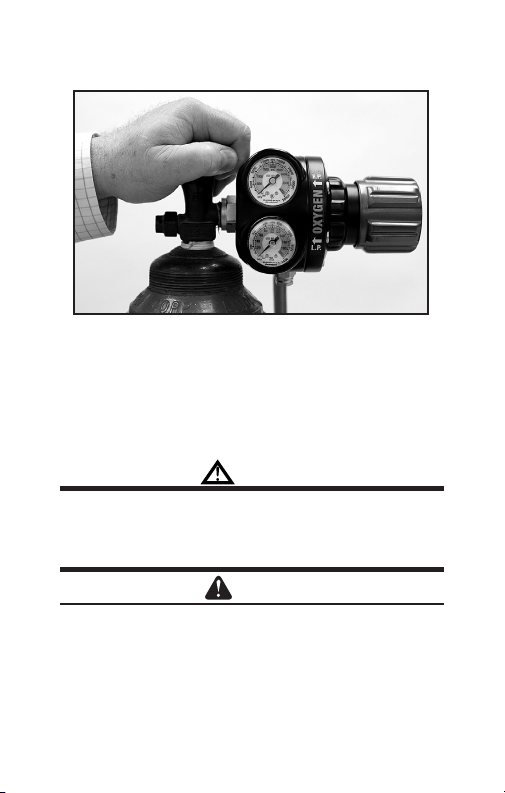

6. Carefully inspect the regulator for damaged threads, dirt, dust,

grease, oil, or other flammable substances. Remove dust and

dirt with a clean cloth. Be sure the inlet swivel filter is clean and

in place. Attach the regulator (Figure 3) to the cylinder valve.

Tighten securely with a wrench.

3-8

Page 13

WARNING

DO NOT attach or use the regulator if oil, grease, flamma ble

substances or damage is present! Have a qualified repair

technician clean the regulator or repair any damage.

Figure 3: Regulator to Cylinder Valve

7. Before opening the cylinder valve, turn the regulator adjusting

screw counterclockwise until there is no pressure on the

adjusting spring and the screw turns freely.

8. Relief Valve (where provided): The relief valve is designed to

protect the low pressure side of the regulator from high pressures. Relief valves are not intended to protect down stream

equipment from high pressures.

WARNING

DO NOT tamper with the relief valve or remove it from the

regulator.

WARNING

Stand to the side of the cylinder opposite the regulator when

opening the cylinder valve. Keep the cylinder valve between

you and the regulator. For your safety, NEVER STAND IN

FRONT OF OR BEHIND A REGULATOR WHEN OPENING

THE CYLINDER VALVE!

3-9

Page 14

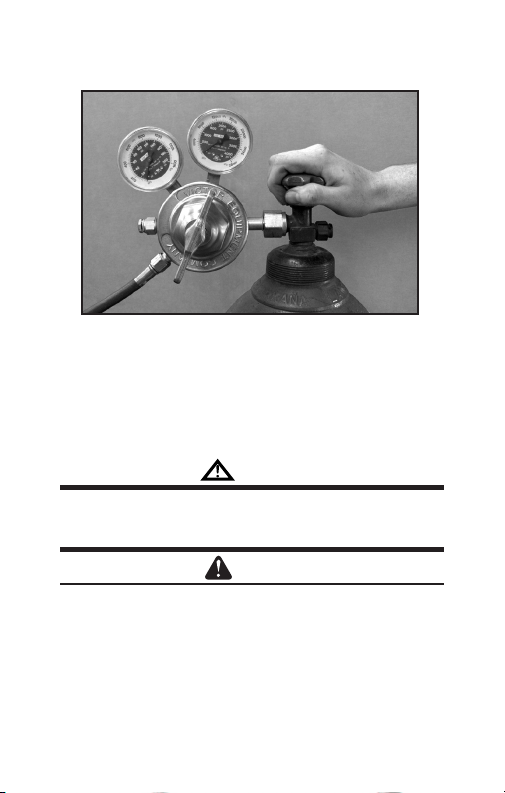

9. Slowly and carefully open the cylinder valve (Figure 4) until the

maximum pressure shows on the high pressure gauge.

Figure 4: Open Cylinder Valve

10. On all cylinders, except acetylene, open the valve completely to

seal the valve packing. On gaugeless regulators, the indicator

will register the cylinder contents only.

11. On acetylene cylinders, open the valve 3/4 of a turn and no

more than 1-1/2.

WARNING

Acetylene delivery pressure must not exceed 15 PSIG (103 kPa)

or 30 PSIG (207 kPa). Acetylene can dissociate (decompose

with explosive violence) above these pressure limits.

CAUTION

Keep the cylinder valve wrench, if one is required, on the

cylinder valve to turn off the cylinder quickly, if necessary.

12. Attach the desired downstream equipment.

3-10

Page 15

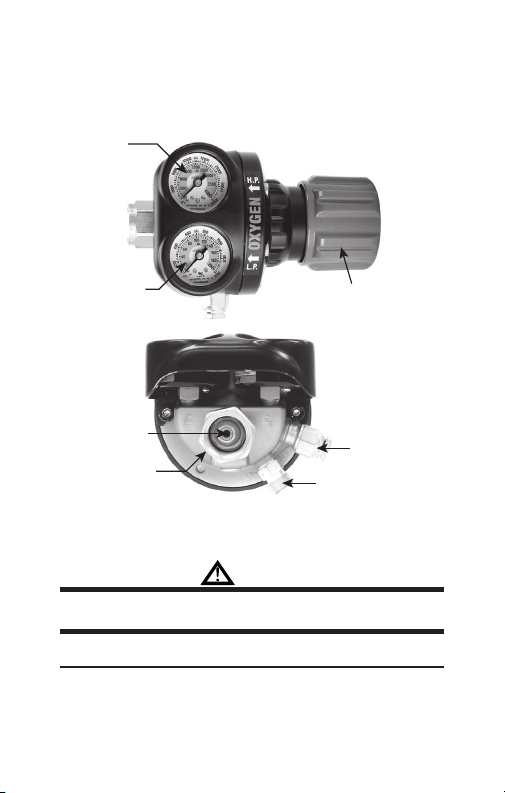

3.02 EDGE SERIES REGULATORS

Edge Series Pressure regulators (Figure 5) attached to the cylinder

valve reduce high cylinder pressures to suitable low working

pressures for welding, cutting, and other applications.

HIGH

PRESSURE

GAUGE

(SUPPLY)

LOW

PRESSURE

GAUGE

(DELIVERY)

INLET

FILTER

INLET

CONNECTION

PRESSURE

ADJUSTING KNOB

RELIEF VALVE

OUTLET

CONNECTION

Figure 5: Edge Series Pressure Regulator

WARNING

Use the regulator for the gas and pressure for which it is

designed. NEVER alter a regulator for use with any other gas.

NOTE

Regulators purchased with open 1/8”, 1/4”, 3/8”, or 1/2”

NPT ports must be assembled to their intended system.

3-11

Page 16

1. Note the maximum inlet pressure stamped on the regulator. DO

NOT attach the regulator to a system that has a higher pressure

than the maximum rated pressure stamped on the regulator.

2. The regulator body will be stamped “IN” or “HP” at the inlet

port. Attach the inlet port to the system supply pressure

connection.

3. Wrap pipe threads with Teflon tape 1 1/2 to 2 turns to effect a

seal. If other sealants are used, they must be compatible with

the gas that will be used in the system.

4. If gauges are to be attached to the regulator and the regu lator

is stamped and listed by a third party (i.e. “UL” or “ETL”). The

following requirements must be met:

a) Inlet gauges over 1000 PSIG (6.87 mPa) shall conform with

the requirements of UL 404, “Indicating Pressure Gauges

for Compressed Gas Service.”

b) Low pressure gauges must be UL recognized for the class of

regulator they are being used on according to UL 252A.

WARNING

DO NOT use a regulator that delivers pressure exceeding

the pressure rating of the downstream equipment unless

pro visions are made to prevent over-pressurization (i.e.

system relief valve). Make sure the pressure rating of the

down stream equipment is compatible with the maximum

delivery pressure of the regulator.

5. Be sure that the regulator has the correct pressure rating and

gas service for the cylinder used.

6. Carefully inspect the regulator for damaged threads, dirt, dust,

grease, oil, or other flammable substances. Remove dust and

dirt with a clean cloth. Be sure the inlet swivel filter is clean and

in place. Attach the regulator (Figure 6) to the cylinder valve.

Tighten securely with a wrench.

3-12

Page 17

WARNING

DO NOT attach or use the regulator if oil, grease, flamma ble

substances or damage is present! Have a qualified repair

technician clean the regulator or repair any damage.

Figure 6: Regulator to Cylinder Valve

7. Before opening the cylinder valve, turn the regulator adjusting

knob counterclockwise until there is no pressure on the

adjusting spring and the knob turns freely.

8. Relief Valve (where provided): The relief valve is designed to

protect the low pressure side of the regulator from high pressures. Relief valves are not intended to protect down stream

equipment from high pressures.

WARNING

DO NOT tamper with the relief valve or remove it from the

regulator.

WARNING

Stand to the side of the cylinder opposite the regulator when

opening the cylinder valve. Keep the cylinder valve between

you and the regulator. For your safety, NEVER STAND IN

FRONT OF OR BEHIND A REGULATOR WHEN OPENING

THE CYLINDER VALVE!

3-13

Page 18

9. Slowly and carefully open the cylinder valve (Figure 7) until the

maximum pressure shows on the high pressure gauge.

Figure 7: Open Cylinder Valve

10. On all cylinders, except acetylene, open the valve completely

to seal the valve packing. On gaugeless regulators, the indicator

will register the cylinder contents open.

11. On acetylene cylinders, open the valve 3/4 of a turn and no

more than 1-1/2.

WARNING

Acetylene delivery pressure must not exceed 15 PSIG

(103 kPa) or 30 PSIG (207 kPa). Acetylene can dissociate

(decompose with explosive violence) above these pressure

limits.

CAUTION

Keep the cylinder valve wrench, if one is required, on the

cylinder valve to turn off the cylinder quickly, if necessary.

12. Attach the desired downstream equipment.

3-14

Page 19

3.03 LEAK TESTING THE SYSTEM

Leak test the system before putting into operation.

1. Be sure that there is a valve in the downstream equipment to

turn off the gas flow.

2. With the cylinder valve open, adjust the regulator to deliver the

maximum required delivery pressure.

3. Close the cylinder valve.

4. Turn the adjusting screw/knob counterclockwise one turn.

a) If the high-pressure gauge reading drops, there is a leak

in the cylinder valve, inlet fitting, or high-pressure gauge.

b) If the low-pressure gauge drops, there is a leak in the

down stream equipment, hose, hose fitting, outlet fitting or

low-pressure gauge. Check for leaks using an approved

leak detector solution.

c) If the high-pressure gauge drops and the low-pressure

gauge increases at the same time, there is a leak in the

regulator seat.

d) If the regulator requires service or repair, take it to a

qualified repair technician.

5. Once leak testing has been performed and there are no leaks

in the system, slowly open the cylinder valve and proceed.

WARNING

If a leak has been detected anywhere in the system, discontinue use and have the system repaired. DO NOT use

leaking equipment. Do not attempt to repair a leaking

system while the system is under pressure.

3-15

Page 20

SECTION 4:

WHEN YOU FINISH USING THE REGULATOR

1. Close the cylinder valve.

2. Open the valve on the downstream equipment. This drains all

pressure from the system.

3. Close the valve on the downstream equipment.

4. Turn the adjusting screw counterclockwise to release the tension on the adjusting spring.

5. Check the gauges after a few minutes for verification that the

cylinder valve is closed completely.

4.01 STORAGE

When the regulator is not in use and has been removed from the

cylinder, it should be stored in an area where it will be pro tected

from dust, oil, and grease. The inlet and outlet should be capped

to protect against internal contamination and prevent insects

from nesting.

4-16

Page 21

SECTION 5:

STATEMENT OF WARRANTY

LIMITED WARRANTY: Victor Technologies International, Inc. warrants that

its products will be free of defects in workmanship or material. Should any

failure to conform to this warranty appear within the time period applicable to

the Victor Technologies products as stated below, Victor Technologies shall,

upon notification thereof and substantiation that the product has been stored,

installed, operated, and maintained in accordance with Victor Technologies’s

specifications, instructions, recommendations and recognized standard industry

practice, and not subject to misuse, repair, neglect, alteration, or accident,

correct such defects by suitable repair or replacement, at Victor Technologies’s

sole option, of any components or parts of the product determined by Victor

Technologies to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: Victor Technologies shall not under any

circumstances be liable for special or consequential damages, such as, but not

limited to, damage or loss of purchased or replacement goods, or claims of

customers of distributor (hereinafter the “Purchaser”) for service interruption.

The remedies of the Purchaser set forth herein are exclusive and the liability of

Victor Technologies with respect to any contract, or anything done in connection

therewith such as the performance or breach thereof, or from the manufacture,

sale, delivery, resale, or use of any goods covered by or furnished by Victor

Technologies whether arising out of contract, negligence, strict tort, or under any

warranty, or otherwise, shall not, except as expressly provided herein, exceed

the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR

ACCESSORIES ARE USED WHICH MAY IMPAIR THE SAFETY OR PERFORMANCE

OF ANY VICTOR TECHNOLOGIES PRODUCT.

THIS WARRANTY IS INVALID IF THE PRODUCT IS SOLD BY NON-AUTHORIZED

PERSONS.

This warranty is effective for the time stated in the Warranty Schedule

beginning on the date that the authorized distributor delivers the products to

the Purchaser.

Warranty repairs or replacement claims under this limited warranty must be

submitted by an authorized Victor Technologies repair facility within thirty (30)

days of the repair. No transportation costs of any kind will be paid under this

warranty. Transportation charges to send products to an authorized warranty

repair facility shall be the responsibility of the Purchaser. All returned goods shall

be at the Purchaser’s risk and expense. This warranty supersedes all previous

Victor Technologies warranties.

5-17

Page 22

5 Years Parts / No Labor

Victor® Slimlite Medical

Victor® Professional

3 Years Parts / No Labor

TurboTorch

®

2 Years Parts / No Labor

CutSkill®, Oxygen Conservers, Victor® VSP,

HP&I Brass regulators/manifolds

All other Victor® Medical product

1 Years Parts / No Labor

FirePower

®

Steel Cylinders, Cutting Machine Motors (i.e. VCM 200)

HP&I Stainless regulators/manifolds

Parts in Rental Applications

(from the date sold by seller to authorized distributor)

90 days parts / No Labor

HP&I Corrosive Gas Regulators/Manifolds

Victor Technologies limited warranty shall not apply to: Consumable Parts for MIG,

TIG, Plasma welding, Plasma cutting and Oxy fuel torches, O-rings, fuses, filters or

other parts that fail due normal wear.

* Warranty repairs or replacement claims under this limited warranty must be submitted

by an authorized Victor Technologies repair facility within thirty (30) days of the repair.

* No employee, agent, or representative of Victor Technologies is authorized to change

this warranty in any way or grant any other warranty, and Victor Technologies shall

not be bound by any such attempt. Correction of non-conformities, in the manner

and time provided herein, constitutes fulfillment of Victor Technologies’s obligations

to purchaser with respect to the product.

* This warranty is void, and seller bears no liability hereunder, if purchaser used

replacement parts or accessories which, in Victor Technologies’s sole judgment,

impaired the safety or performance of any Victor Technologies product. Purchaser’s

rights under this warranty are void if the product is sold to purchaser by unauthorized

persons.

5-18

Page 23

Régulateurs à un ou deux étages

Pour Détendeurs Standards et de Série Edge™

English

Canadien Français

Americas Español

Guide d’installation et d’utilisation

Date d’émission : 3 decembre, 2012

Révision : JNº de document : 0056-1625

VictorTechnologies.com

Page 24

VOTRE ACTIVITÉ NOUS INTÉRESSE!

Félicitations pour votre nouveau produit VictorMD. Nous sommes fiers de vous avoir

comme client et nous tâcherons de vous fournir les meilleurs services et fiabilité

dans l’industrie. Ce produit est soutenu par une vaste garantie et un réseau mondial

de service. Pour localiser votre distributeur ou agence de service le plus proche,

veuillez communiquer avec un représentant à l’adresse ou au numéro de téléphone

correspondant à votre région, indiqué au verso de la couverture du manuel, ou visitez

notre site web www.victorequip.com.

Ce Manuel d’utilisation a été conçu pour vous permettre d’utiliser et de faire fonctionner

correctement votre produit VictorMD. Votre satisfaction et le fonctionnement en toute

sécurité de votre produit sont nos principaux soucis. Par conséquent, veuillez prendre

le temps de lire tout le manuel, spécialement en ce qui concerne les Précautions de

Sécurité. Ceci vous aidera à éviter déventuels accidents qui pourraient survenir en

travaillant avec ce produit.

VOUS ÊTES EN BONNE COMPAGNIE!

La Marque de Choix pour les Entrepreneurs et les Fabricants

dans le Monde.

VictorMD est une marque mondialement reconnue pour ses produits d’équipement de

gaz pour Victor Technologies International, Inc. Nous fabriquons et fournissons dans

le monde entier aux secteurs industriels majeurs de soudage et coupage, incluant

fabrication, construction, exploitation minière, automobile, aérospatiale, ingénierie,

rural et bricolage/hobby, recyclage, démolition et construction navale.

Nous nous distinguons de notre concurrence grâce à nos produits en tête du marché,

fiables, ayant résisté à l’épreuve du temps. Nous sommes fiers de notre innovation

technique, nos prix compétitifs, notre excellente livraison, notre service clientèle et

notre support technique de qualité supérieure, ainsi que de l’excellence dans les

ventes et l’expertise en marketing.

Surtout, nous nous engageons à développer des produits utilisant des technologies

de pointe pour obtenir un environnement de travail plus sécurisé dans l’industrie

de la soudure.

Page 25

AVERTISSEMENT

Lisez et comprenez tout le Manuel et les pratiques de sécurité de l’utilisateur

avant l’installation, le fonctionnement ou l’entretien de l’équipement. Même si

les informations contenues dans ce Manuel représentent le meilleur jugement

du Fabricant, celui-ci n’assume aucune responsabilité pour son usage.

Régulateurs à un ou Deux Étages

Guide d’installation et d’utilisation

Numéro du Manuel d’Instructions pour 0056-1625

Publié par :

Victor Technologies International, Inc.

2800 Airport Road

Denton, TX 76208

(940) 566-2000

www.victorequip.com

Copyright © 2011, 2012 par Victor Technologies International, Inc. MD Tous droits

réservés.

La reproduction, de tout ou partie de ce manuel, sans l’autorisation écrite de l’éditeur,

est interdite.

L’éditeur n’assume pas et dément toute responsabilité pour perte ou dommage causés

à une partie par erreur ou omission dans ce manuel, si une telle erreur résulte d’une

négligence, d’un accident, ou de toute autre cause.

Date de Parution : 20 janvier 2011

Révisé le : 3 decembre, 2012

Complétez les informations suivantes à des fins de garantie :

Lieu D’achat : __________________________________________________

Date D’achat : __________________________________________________

Numéro de : ___________________________________________________

i

Page 26

Table des matières

CHAPITRE 1 : INTRODUCTION .......................................F1-1

CHAPITRE 2 : INFORMATIONS GÉNÉRALES DE

SÉCURITÉ ...................................................F2-3

2.01 Prévention D’incendie .............................F2-3

2.02 Entretien des Locaux ...............................F2-4

2.03 Aération ...................................................F2-4

2.04 Protection Personnelle ............................F2-4

2.05 Bouteilles de Gaz Comprimé ...................F2-5

CHAPITRE 3 : RÉGULATEURS : SÉCURITÉ ET

FONCTIONNEMENT ....................................F3-7

3.01 Détendeurs Standards .............................F3-7

3.02 Détendeurs de Série Edge .....................F3-11

3.03 Test de Fuites du Système .....................F3-16

CHAPITRE 4 : QUAND VOUS AVEZ FINI D’UTILISER LE

RÉGULATEUR ...........................................F4-17

4.01 Stockage ...............................................F4-17

CHAPITRE 5 : GARANTIE .............................................F5-18

ii

Page 27

CHAPITRE 1 :

INTRODUCTION

Ce fascicule est un guide pour une utilisation sécurisée et efficace des régulateurs utilisés dans les applications à gaz oxygène

carburant. Si l’appareil n’est pas utilisé dans cet environnement,

l’opérateur doit malgré tout appliquer les procédures d’emploi qui

s’appliquent à son application particulière. Il y a plusieurs dangers

potentiels à j’utilisation des régulateurs. Lisez complètement

et soigneusement ce fascicule avant de faire fonctionner cet

équipement.

Toutes les opérations doivent être en conformité avec les règlements fédéraux, d’état, de province ou ville applicables, pour l’installation, le fonctionnement, la ventilation, la prévention d’incendie

et la protection des personnes. La norme ANSI Z49.1, “Sécurité

en soudage et découpe”, contient des instructions de sécurité

détaillées. Elle peut s’obtenir auprès de l’American Welding Society,

P.O. Box 351040, Miami, FL 33135, U.S.A.

Un ensemble de conseils attirant l’attention et avertissant met

en avant des informations importantes sur la sécurité et le fonctionnement dans ce document. Il s’agit de :

AVIS

L’avis donne de conseils d’installation ou des informations

d’entretien qui sontimportants mais n’impliquent pas

derisques.

MISE EN GARDE

La mention d’mise en garde indique une situation

potentiellement dangereuse qui, sans précautions, peut

entraîner des dom .

AVERTISSEMENT

L’avertissement indique une situation potentiellement dan

gereuse qui, sans précautions, peut entraîner des dommages graves voire mortels.

F1-1

Page 28

AVERTISSEMENT

Ce produit contient des produits chimiques, comme le

plomb, ou engendre des produits chimiques, reconnus

par l’état de Californie comme pouvant être à l’origine,

de malformations fœtales ou d’autres problèmes de

reproduction. Il faut se laver les mains après toute

manipulation.

AVERTISSEMENT

N’essayez pas d’utiliser cet appareil sauf si vous êtes formé à

sa bonne utilisation ou bénéficiez d’une supervision qualifiée.

Pour votre sécurité, mettez en pratique les procédures de

sécurité et de mode opératoire décrites dans ce fascicule

à chaque fois que vous utilisez cet appareil. Si vous déviez

de ces procédures, cela peut entraîner incendie, explosion,

dégâts matériels et/ou blessures corporelles. Si à un moment

quelconque l’appareil que vous utilisez ne se comporte pas

de la façon habituelle, ou si vous éprouvez des difficultés à

le faire fonctionner, arrêtez immédiatement de l’utiliser. Ne

vous en servez plus jusqu’à ce que le problème ait été corrigé!

AVERTISSEMENT

L’entretien ou la réparation de l’appareil ne doit être effectué

que par un technicien de support qualifié à même de

s’occuper d’un appareillage à gaz en stricte conformité avec

les notes techniques de pièces et réparation applicables

pour les produits construits par VICTORMD. Une mauvaise

exécution de réparation, ou une modification du produit,

peut entraîner des dommages au produit ou/blesser son

opérateur. La réparation inexacte de service, L’UTILISATION

DES PIÈCES NON-VÉRITABLES DE VICTORMD, ou la

modification ont pu avoir comme conséquence les

dommages au produit ou les dommages à l’opérateur.

F2-2

Page 29

CHAPITRE 2 :

INFORMATIONS GÉNÉRALES DE SÉCURITÉ

Lisez et assimilez toutes les instructions de sécurité et de

fonctionnement fournies avant d’utiliser cet appareil. GARDEZ

TOUTES CES INSTRUCTIONS À UN EMPLACEMENT FACILEMENT

ACCESSIBLE COMME RÉFÉRENCE ULTÉRIEURE.

2.01 PRÉVENTION D’INCENDIE

Les opérations de soudage utilisent le feu ou la combustion comme outil

de base. Ce processus est très utile quand il est cor rectement contrôlé.

1. La zone doit comporter un sol ignifugé.

2. Les établis ou tables utilisés pendant les opérations de

soudage doivent avoir un revêtement ignifuge.

3. Utilisez des écrans résistants à la chaleur ou en matériau

approuvé pour protéger les cloisons proches ou le sol vul nérable

des étincelles et du métal chaud.

4. Gardez un extincteur approuvé du bon type et de la bonne taille dans

la zone de travail. Inspectez-le régulièrement pour vous assurer qu’il

est en état de fonctionner. Apprenez à vous en servir.

5. Enlevez tous les matériaux combustibles de la zone de travail. Si vous

ne pouvez pas les enlever, protégez-les avec une cou vre ignifuge.

AVERTISSEMENT

N’effectuez JAMAIS d’opérations de soudage sur un récipient

qui a contenu des liquides ou vapeurs toxiques, combustibles

ou inflammables. N’effectuez JAMAIS d’opérations de

soudage dans une zone contenant des vapeurs combustibles,

des liquides inflammables ou des poussières explosives.

F2-3

Page 30

2.02 ENTRETIEN DES LOCAUX

AVERTISSEMENT

Ne laissez jamais l’oxygène en contact avec la graisse,

l’huile ou d’autres substances inflammables. Bien que

l’oxygène elle même ne brûle pas, ces substances peuvent

devenir extrême ment explosives. Elles peuvent prendre feu

et brûler violem ment en présence d’oxygène.

Gardez TOUS les appareils propres et exempts de graisse, huile

ou autres substances inflammables.

2.03 AÉRATION

AVERTISSEMENT

Ventilez les zones de soudage, chauffage et découpage

de façon adéquate pour éviter l’accumulation de gaz

explosifs ou toxiques. Certaines combinaisons de métaux,

revêtements et gaz génèrent des fumées toxiques :

Utilisez un équipement de protection respiratoire dans ces

circonstances. Si vous soudez ou brasez, lisez et assimilez

la fiche technique de sécurité de matériau relative à l’alliage

de soudage/brasage.

2.04 PROTECTION PERSONNELLE

Les flammes de gaz produisent une radiation infrarouge qui peut

avoir un effet néfaste sur la peau, et particulièrement sur les yeux.

Choisissez des lunettes ou un masque avec des verres trempés

assombris au niveau 4 ou plus sombre, pour protéger vos yeux des

dommages et garder une bonne visibilité sur le travail.

Portez en permanence des gants de protection et des vête ments

ignifuges pour la protection de la peau et des vêtements contre les

étincelles et le laitier. Gardez col, manches et poches boutonnés.

Il ne faut pas remonter vos manches ou les pantalons à revers.

Quand vous travaillez dans un environnement non dédié au soudage

ou découpage, portez toujours une protection des yeux appropriées

ou un masque facial.

F2-4

Page 31

AVERTISSEMENT

Mettez en pratique les procédures de sécurité et de mode

opératoire suivantes à chaque fois que vous utilisez cet

appareil de régulation de pression. Si vous déviez de ces

procédures, cela peut entraîner incendie, explosion, dégâts

matériels et/ou blessures corporelles pour l’opérateur.

2.05 BOUTEILLES DE GAZ COMPRIMÉ

Le Département des Transports américain (DOT) approuve la

conception et la fabrication des bouteilles qui contiennent les gaz

utilisés pour les opérations de soudage ou de découpage.

1. Placez la bouteille (Le schéma 1) là où elle sera utilisée. Gardez-la en

position verticale. Fixez-la sur un chariot une cloison, un établi, etc.

Le schéma 1 : Cylindres de gaz

AVERTISSEMENT

Les bouteilles sont sous haute pression. Manipulez-les avec

précautions. Des accidents sérieux peuvent résulter d’une

mauvaise manutention ou d’un mauvais emploi des bouteilles

de gaz comprimé. NE faites PAS tomber la bouteille, ne la cognez

pas, ne l’exposez pas à une chaleur excessive, aux flammes ou

étincelles. NE la cognez PAS contre d’autres bouteilles. Contactez

votre fournisseur de gaz ou reportez vous à la publication CGA P-1

“Manipulation sécurisée des gaz comprimés en conteneur” pour

plus d’informations sur l’utilisation et la manutention des bouteilles.

F2-5

Page 32

AVIS

Ce document CGA p. t peut être obtenu en écrivant à

“Compressed Gas Association”, 4221 Walney Roed, 5th

Floor. Chantilly, VA 20151.2923, USA.

2. Placez le bouchon de protection de vanne sur la bouteille à

chaque fois que vous la déplacez ou ne l’utilisez pas. Ne faites

jamais glisser ou rouler d’aucune manière les bouteilles. Utilisez

un diable approprié pour les déplacer.

3. Entreposez les bouteilles vides à l’écart des bouteilles pleines.

Marquez-les “VIDE” et refermez leur vanne.

4. N’utilisez JAMAIS des bouteilles de gaz comprimé sans un

régulateur de pression en série sur la vanne de bouteille.

5. Inspectez la vanne de bouteille pour y détecter de l’huile ou de

la graisse, ou dès pièces endommagées.

AVERTISSEMENT

N’UTILISEZ PAS la bouteille si vous trouvez de l’huile, de la

graisse ou des pièces endommagées. Informez immédiatement votre fournisseur de’ gaz de cet état.

6. Ouvrez et fermez momentanément la vanne de la bouteille,

délogeant ainsi d’éventu lIes poussières ou saletés. qui pourraient être présentes dans la vanne.

MISE EN GARDE

Ouvrez la vanne de bouteille légèrement. Si vous l’ouvrez

trop en grand, la bouteille pourrait se renverser. Quand

vous ouvrez/fermez rapidement la vanne de bouteille, ne

vous tenez pas directement devant. Opérez toujours cette

opération dans une zone bien ventilée. Si une bouteille

d’acétylène crache un brouillard, laissez reposer pendant

15 minutes. Essayez de nouveau la vanne. Si le problème

persiste, con tactez votre fournisseur de gaz.

F2-6

Page 33

CHAPITRE 3 :

MANOMÈTRE BASSE

PRESSION (ÉCHAPPEMENT)

MANOMÈTRE

HAUTE PRESSION

(ADMISSION)

VIS OU BOUTON

DE RÉGLAGE DE

PRESSION

RACCORDEMENT

D’ÉCHAPPEMENT

RACCORDEMENT

D’ADMISSION

FILTRE

D’ADMISSION

SOUPAPE

DE SÉCURITÉ

RÉGULATEURS : SÉCURITÉ ET

FONCTIONNEMENT

AVIS

Pour les détendeurs de Série Edge, allez à la CHAPITRE 3.02

3.01 DÉTENDEURS STANDARDS

Les régulateurs de pression (Le schéma 2) reliés aux vannes de

bouteilles réduisent les hautes pressions de cylindres jusqu’à des

pressions de service convenant au soudage, au découpage et aux

autres applications.

Le schéma 2 : Régulateur de pression

AVERTISSEMENT

Utilisez le régulateur pour le gaz et pour la pression pour

lesquels il a été conçu. Ne modifiez JAMAIS un régulateur

pour l’utiliser avec n’importe quel autre gaz.

F3-7

Page 34

AVIS

Les régulateurs achetés avec ses ports ouverts 1/8, 1/4,3/8

ou 1/2 doivent être montés sur le système pour lequel ils

sont prévus.

1. Notez la pression d’admission maximale imprimée sur le

régulateur. NE BRANCHEZ PAS le régulateur sur un sys tème qui

a une pression plus élevée que la pression nomi nale maximale

imprimés sur le régulateur.

2. Le corps de régulateur aura gravé “lN” (entrée) ou “HP” (haute

pression) sur le port d’admission. Raccordez ce port d’admission

sur la connexion fournissant la pression de gaz d’alimentation.

3. Enveloppez les filets de tube a vec de la bande téflon sur 1 à 2 tours,

pour assurer une étanchéité. Si d’autres produits d’étanchéité sont

utilisés, ils doivent être compatibles avec le gaz qui sera utilisé

dans le système.

4. Si les jauges sont à connecter au détendeur et si le détendeur

est estampillé et listé par un tiers (c’est-à-dire, “UL” ou “ETL”).

Les exigences suivantes doivent être satisfaites :

a) Les manomètres d’admission au-delà de 6,87 mPa (1000

PSIG) doivent être conformes aux exigences UL 404, “Jauges

indicatrices de pression pour le service des gaz compressés”.

b) Les manomètres pour basse pression doivent être nor-

malisés UL pour la classe de régulateurs sur lesquels ils

seront montés, suivant UL 252A.

AVERTISSEMENT

N’utilisez pas un régulateur qui délivre en sortie une

pression excédant la pression nominale de l’équipement

en aval, sauf si des précautions sont prises pour empêcher

une surpression (par exemple une vanne de délestage du

système). Assurez-vous que la spécification de pres sion de

l’équipement aval est compatible avec la pression maximale

d’échappement du régulateur.

5. Assurez-vous que le régulateur a la pression nominale correcte et

peut desservir le gaz correspondant à la bouteille de rac cordement.

F3-8

Page 35

6. Inspectez soigneusement le régulateur pour trouver éventuelle ment

des filets endommagés, de la saleté ou poussière, de la graisse ou de

l’huile ou d’autres substances inflammables. Enlevez poussière ou

saletés avec un chiffon propre. Assurez vous que le filtre d’admission

pivotant est propre et en place. Fixez le régulateur sur la vanne de

bouteille. Serrez soigneuse ment avec une clé (Le schéma 3).

AVERTISSEMENT

NE FIXEZ PAS ou n’utilisez pas le régulateur si de l’huile, de

la graisse ou des substances inflammables ou des dommages

sont présents! Un technicien de réparation qualifié doit nettoyer alors le régulateur ou réparer ses dommages.

Le schéma 3 : Régulateur à la valve de cylindre

7. Avant d’ouvrir la vanne de bouteille de gaz, tournez la vis de

réglage du régulateur dans le sens du dévissage, jusqu’à ce

qu’il n’y ait plus de pression sur le ressort de réglage et que

la vis tourne librement.

8. Vanne de délestage (non fournie) - La vanne de délestage est

conçue pour protéger le côté basse pression du régulateur des

pressions élevées. Les vannes de délestage n’ont pas pour but

de protéger des hautes pressions l’équipement en aval.

AVERTISSEMENT

N’altérez pas la vanne de délestage ou ne l’enlevez pas

du régulateur.

F3-9

Page 36

AVERTISSEMENT

Tenez-vous sur le côté de la bouteille opposé au régulateur quand

vous ouvrez la vanne de la bouteille de gaz. Gardez la vanne de

bouteille entre vous et le régulateur. POUR VOTRE SÉCURITÉ,

NE VOUS TENEZ JAMAIS DEVANT OU DERRIÈRE UN RÉGULATEUR QUAND VOUS OUVREZ LA VANNE DE BOUTEILLE!

9. Ouvrez lentement et soigneusement la vanne de bouteille (Le

schéma 4) jusqu’à ce que la haute pression maximale soit

établie sur le manomètre d’admission.

Le schéma 4 : Régulateur à la valve de cylindre

10. Sur toutes les bouteilles, sauf pour l’acétylène, ouvrez la vanne

complètement pour assurer l’étanchéité de la garniture de vanne.

Si le régulateur est du type sans manomètres, son indi cateur va

enregistrer que la bouteille de gaz est ouverte.

11. Sur les bouteilles d’acétylène, ouvrez la vanne de trois-quarts

(3/4) de tour, et de pas plus de un tour et demi (1-1/2).

AVERTISSEMENT

La pression d’alimentation en acétylène ne doit pas

dépasser 15 PSIG (103 kPa) ou 30 PSIG (207 kPa).

L’acétylène peut se dissocier (se décom poser avec une

violence explosive) au-delà de ces limites de pression.

F3-10

Page 37

MISE EN GARDE

Gardez la clé de vanne de bouteille, s’il y en a besoin

d’une, sur la vanne de bouteille pour refermer rapidement

la bouteille en cas de nécessité.

12. Rattachez en sortie de régulateur l’équipement aval voulu.

3.02 DÉTENDEURS DE SÉRIE EDGE

Les détendeurs de pression de série Edge (Le schéma 5) reliés aux

vannes de bouteilles réduisent les hautes pressions de cylindres

jusqu’à des pressions de service convenant au soudage, au

découpage et aux autres applications.

MANOMÈTRE

HAUTE

PRESSION

(ADMISSION)

MANOMÈTRE

BASSE

PRESSION

(ÉCHAPPEMENT)

VIS OU BOUTON

DE RÉGLAGE DE

PRESSION

FILTRE

D’ADMISSION

RACCORDEMENT

D’ADMISSION

SOUPAPE

DE SÉCURITÉ

RACCORDEMENT

D’ÉCHAPPEMENT

Le schéma 5 : Détendeur de Pression de Série Edge

F3-11

Page 38

AVERTISSEMENT

Utilisez le régulateur pour le gaz et pour la pression pour

lesquels il a été conçu. Ne modifiez JAMAIS un régulateur

pour l’utiliser avec n’importe quel autre gaz.

AVIS

Les régulateurs achetés avec ses ports ouverts 1/8, 1/4,3/8

ou 1/2 doivent être montés sur le système pour lequel ils

sont prévus.

1. Notez la pression d’admission maximale imprimée sur le

régulateur. NE BRANCHEZ PAS le régulateur sur un sys tème qui

a une pression plus élevée que la pression nomi nale maximale

imprimés sur le régulateur.

2. Le corps de régulateur aura gravé “lN” (entrée) ou “HP” (haute

pression) sur le port d’admission. Raccordez ce port d’admission

sur la connexion fournissant la pression de gaz d’alimentation.

3. Enveloppez les filets de tube a vec de la bande téflon sur 1 à 2 tours,

pour assurer une étanchéité. Si d’autres produits d’étanchéité sont

utilisés, ils doivent être compatibles avec le gaz qui sera utilisé

dans le système.

4. Si les jauges sont à connecter au détendeur et si le détendeur

est estampillé et listé par un tiers (c’est-à-dire, “UL” ou “ETL”).

Les exigences suivantes doivent être satisfaites :

a) Les manomètres d’admission au-delà de 6,87 mPa (1000

PSIG) doivent être conformes aux exigences UL 404, “Jauges

indicatrices de pression pour le service des gaz compressés”.

b) Les manomètres pour basse pression doivent être nor-

malisés UL pour la classe de régulateurs sur lesquels ils

seront montés, suivant UL 252A.

F3-12

Page 39

AVERTISSEMENT

N’utilisez pas un régulateur qui délivre en sortie une

pression excédant la pression nominale de l’équipement

en aval, sauf si des précautions sont prises pour empêcher

une surpression (par exemple une vanne de délestage du

système). Assurez-vous que la spécification de pres sion de

l’équipement aval est compatible avec la pression maximale

d’échappement du régulateur.

5. Assurez-vous que le régulateur a la pression nominale correcte et

peut desservir le gaz correspondant à la bouteille de rac cordement.

6. Inspectez soigneusement le régulateur pour trouver éventuellement des filets endommagés, de la saleté ou poussière, de la

graisse ou de l’huile ou d’autres substances inflammables.

Enlevez poussière ou saletés avec un chiffon propre. Assurez

vous que le filtre d’admission pivotant est propre et en place.

Fixez le régulateur sur la vanne de bouteille. Serrez soigneusement avec une clé (Le schéma 6).

AVERTISSEMENT

NE FIXEZ PAS ou n’utilisez pas le régulateur si de l’huile, de

la graisse ou des substances inflammables ou des dommages

sont présents! Un technicien de réparation qualifié doit nettoyer alors le régulateur ou réparer ses dommages.

Le schéma 6 : Régulateur à la valve de cylindre

F3-13

Page 40

7. Avant d’ouvrir la vanne de bouteille de gaz, tournez la vis de

réglage du régulateur dans le sens du dévissage, jusqu’à ce

qu’il n’y ait plus de pression sur le ressort de réglage et que

la vis tourne librement.

8. Vanne de délestage (non fournie) - La vanne de délestage est

conçue pour protéger le côté basse pression du régulateur des

pressions élevées. Les vannes de délestage n’ont pas pour but

de protéger des hautes pressions l’équipement en aval.

AVERTISSEMENT

N’altérez pas la vanne de délestage ou ne l’enlevez pas

du régulateur.

AVERTISSEMENT

Tenez-vous sur le côté de la bouteille opposé au régulateur quand

vous ouvrez la vanne de la bouteille de gaz. Gardez la vanne de

bouteille entre vous et le régulateur. POUR VOTRE SÉCURITÉ,

NE VOUS TENEZ JAMAIS DEVANT OU DERRIÈRE UN RÉGULATEUR QUAND VOUS OUVREZ LA VANNE DE BOUTEILLE!

9. Ouvrez lentement et soigneusement la vanne de bouteille (Le

schéma 7) jusqu’à ce que la haute pression maximale soit

établie sur le manomètre d’admission.

Le schéma 7 : Régulateur à la valve de cylindre

F3-14

Page 41

10. Sur toutes les bouteilles, sauf pour l’acétylène, ouvrez la vanne

complètement pour assurer l’étanchéité de la garniture de vanne.

Si le régulateur est du type sans manomètres, son indi cateur va

enregistrer que la bouteille de gaz est ouverte.

11. Sur les bouteilles d’acétylène, ouvrez la vanne de trois-quarts

(3/4) de tour, et de pas plus de un tour et demi (1-1/2).

AVERTISSEMENT

La pression d’alimentation en acétylène ne doit pas

dépasser 15 PSIG (103 kPa) ou 30 PSIG (207 kPa).

L’acétylène peut se dissocier (se décom poser avec une

violence explosive) au-delà de ces limites de pression.

MISE EN GARDE

Gardez la clé de vanne de bouteille, s’il y en a besoin

d’une, sur la vanne de bouteille pour refermer rapidement

la bouteille en cas de nécessité.

12. Rattachez en sortie de régulateur l’équipement aval voulu.

F3-15

Page 42

3.03 TEST DE FUITES DU SYSTÈME

Vérifiez que le système ne présente pas de fuites avant de le mettre

en fonctionnement.

1. Vérifiez qu’il y a bien une vanne sur l’équipement aval pour

couper le débit de gaz.

2. Avec la vanne de bouteille ouverte, réglez le régulateur pour qu’il

délivre la pression d’échappement au maximum souhaité.

3. Fermez la vanne de bouteille.

4. Tournez d’un tour dans le sens du dévissage la vis de réglage.

a) Si l'indication du manomètre de la haute pression tombe, il

y a une fuite dans la vanne de bouteille, le raccord d'admission ou le manomètre de haute pression.

b) Si l'indication du 'manomètre de la basse pression tombe, il

y a une fuite dans l'équipement aval, le flexible, le raccord

de flexible, le raccord d'échappement ou le manomètre de

basse pression. Cherchez les fuites en utilisant une solution

de détection approuvée.

c) Si l'indication du manomètre de la haute pression tombe,

et qu'en même temps l'indication du manomètre de basse

pression monte, il y a une fuite au niveau du siège du régulateur.

d) Si le régulateur a besoin d'une intervention ou d'une répara-

tion, amenez-le à un technicien de réparation qualifié.

5. Une fois que le test de fuites a été effectué, et qu'aucune fuite

n'est décelée sur le système, ouvrez lentement la vanne de

bouteille et poursuivez.

AVERTISSEMENT

Si une fuite a été détectée n’importe où sur le système,

arrêtez l’utilisation et faites réparer le système. N’UTILISEZ

PAS d’équipement qui fuit. N’essayez pas de réparer un

sys tème qui fuit en le maintenant sous pression.

F3-16

Page 43

CHAPITRE 4 :

QUAND VOUS AVEZ FINI

D’UTILISER LE RÉGULATEUR

1. Fermez la vanne de bouteille.

2. Ouvrez la vanne de l’équipement en aval. Cela fait tomber toute

la pression du système.

3. Refermez la vanne de l’équipement en aval.

4. Tournez la vis de réglage du régulateur dans le sens du dévissage pour détendre le ressort de réglage.

5. Vérifiez les manomètres au bout de quelques minutes pour

vérifier que la vanne de bouteille a bien été fermée totalement.

4.01 STOCKAGE

Quand le régulateur n’est pas en utilisation et a été débranché de la

bouteille, il doit être entreposé dans une zone où il restera à l’abri

de la poussière, de l’huile et de la graisse. Les orifices d’ad mission

et d’échappement doivent être bouchés pour protéger contre une

contamination de l’intérieur et éviter que les insectes ne viennent

y nicher.

F4-17

Page 44

CHAPITRE 5 :

GARANTIE

GARANTIE LIMITÉE : Victor Technologies International, Inc. garantit que ses produits

seront exempts de tout vice de fabrication et de matériaux. Si un défaut devait

apparaître durant la période de garantie applicable aux produits de Victor Technologies

telle que décrite ci-dessous et qu’un avis de défaut était dûment émis démontrant que

le produit a été entreposé, installé, exploité et entretenu selon les spécifications, les

instructions, et les recommandations de Victor Technologies ainsi que les pratiques

normalisées acceptées dans l’industrie, sans avoir été soumis à des abus, réparations,

négligences, modifications ou accidents, alors Victor Technologies corrigera le défaut

par une réparation appropriée ou un remplacement, à sa seule discrétion , des

composants ou des pièces du produit que Victor Technologies jugera défectueux.

CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTES AUTRES GARANTIES

EXPRESSES OU IMPLICITES INCLUANT TOUTE GARANTIE D’APTITUDE OU DE

QUALITÉ MARCHANDE À UNE FIN PARTICULIÈRE.

LIMITATIONS DE RESPONSABILITÉ : Victor Technologies ne sera responsable

sous aucune circonstance de dommages particuliers ou conséquents tels que,

sans en exclure d’autres, des dommages ou perte de marchandises achetées ou

de remplacement, ou de réclamations des clients du distributeur (désignés ci-après

comme l’”Acheteur”) pour interruption de service. Les recours de l’Acheteur exposés

dans le présent sont exclusifs et la responsabilité de Victor Technologies envers tout

contrat ou toute action prise à ce sujet telle que le rendement ou un manquement

au rendement, ou de la fabrication, la vente, la livraison, la revente ou l’usage de

marchandises couvertes ou fournies par Victor Technologies découlant soit d’un

contrat, d’une négligence, d’un délit spécifique, ou en vertu de toute garantie, ou

autrement, ne devront pas, excepté si expressément prévus dans le présent, excéder

lecoû des marchandises sur lequel de telles responsabilités sont basées.

CETTE GARANTIE SERA INVALIDE SI DES PIÈCES DE RECHANGE OU DES

ACCESSOIRES UTILISÉS POURRAIENT DIMINUER LA SÉCURITÉ OU LE

RENDEMENT DE TOUT PRODUIT VICTOR TECHNOLOGIES.

CETTE GARANTIE N’EST PAS VALIDE SI LE PRODUIT EST VENDU PAR DES

PERSONNES NON AUTORISÉES.

Cette garantie est effective pour la durée spécifiée dans le Tableau des garanties

et débute la journée à laquelle le distributeur autorisé livre le produit à l’Acheteur.

Les réclamations pour la réparation ou le remplacement en vertu de cette garantie

limitée doivent être soumises par un Centre de réparation autorisé de Victor

Technologies dans les trente (30) jours suivant la réparation. Aucun frais de transport

quel qu’il soit ne sera payé en vertu de cette garantie. Les frais de transport pour

envoyer les produits à un Centre autorisé de réparation en vertu de cette garantie

seront aux dépens de l’Acheteur. Toutes les marchandises retournées le seront aux

risques et dépens de l’Acheteur. Cette garantie remplace et annule toutes les garanties

précédentes de Victor Technologies.

F5-18

Page 45

5 Years Parts / No Labor

Victor® Slimlite Médical

Victor® Professionnel

3 Years Parts / No Labor

TurboTorch

®

2 Years Parts / No Labor

CutSkill®, Conservateurs d’oxygène, Victor® VSP,

HP&I cuivre régulateurs/divers

Tout l’autre Victor® le produit Médical

1 Years Parts / No Labor

FirePower

®

Les Cylindres en acier, Coupant Moteurs de Machine

(i.e. VCM 200)

HP&I Sans tache régulateurs/divers

Les parties dans les Applications de Location

(de la date vendue par le vendeur au distributeur autorisé)

90 days parts / No Labor

HP&I Gaz corrosif Régulateurs/Divers

La garantie limitée de Victor Technologies ne s’applique pas à :

Pièces consommables pour les soudeurs MIG, TIG et au plasma, pour les torches de

découpe au plasma et les torches de carburant Oxy, les joints d’étanchéité, les fusibles,

les filtres ou les autres pièces qui brisent en raison de l’usure normale.

* En vertu de cette garantie limitée, les demandes de réparation ou de remplacement

sous garantie doivent être présentées à un centre de réparation Victor Technologies

agréé dans les trente (30) jours de la réparation.

* Aucun employé, agent ou représentant de Thermal Arc n’est autorisé à modifier

la présente garantie d’une manière quelconque ni à octroyer toute autre garantie.

Thermal Arc ne peut être tenue responsable d’une telle tentative. La correction des

éléments non conformes du produit, selon les méthodes et les délais précisés dans

la présente, constitue l’ensemble des obligations de Thermal Arc envers l’Acheteur.

* La présente garantie est nulle et non avenue, et par conséquent le vendeur n’assume

aucune responsabilité, si l’Acheteur utilise des pièces de rechange ou des accessoires

qui, du seul avis de Thermal Arc, nuisent à la sécurité ou au rendement des produits

Thermal Arc. En vertu de la présente garantie, les droits de l’Acheteur sont annulés

si le produit lui est vendu par du personnel non autorisé.

F5-19

Page 46

Reguladores mono y bietápicos

Para reguladores estándares y serie Edge™

English

Canadien Français

Americas Español

Instrucciones de seguridad y uso

Fecha de edición: 3 deciembre 2012

Revisión: JNo de Forma: 0056-1625

VictorTechnologies.com

Page 47

¡NOSOTROS APRECIAMOS SUS NEGOCIOS!

Felicitaciones por su nuevo producto Victor®. Estamos orgullosos de tenerlo como

nuestro cliente y nos esforzaremos para ofrecerle el mejor servicio y confiabilidad

del ramo. Este producto está respaldado por nuestra garantía extendida y una red

mundial de servicios. Para ubicar su distribuidor más cercano, comuníquese con un

representante a la dirección y número telefónico de su zona, indicado en la contratapa

de este manual, o visítenos en la Web en: www.victorequip.com.

Este manual ha sido elaborado para instruirle en lo referente al correcto uso y

funcionamiento de su producto Victor®. Su satisfacción con este producto y su

operación segura es nuestra preocupación más importante. De esta forma, por favor,

tómese el tiempo necesario para leer todo el manual, especialmente las Precauciones

de Seguridad. Esto le ayudará a evitar peligros potenciales que pueden existir al

trabajar con este producto.

¡USTED ESTÁ EN BUENA COMPAÑÍA!

La Marca Elegida por Contratistas y Fabricantes del Mundo entero.

Victor® es una marca mundial de productos de equipo de gas de Victor Technologies

International, Inc. Nosotros manufacturamos y distribuimos a los mayoria de los

sectores de la industria del corte y soldadura a nivel mundial, incluyendo: Manufactura,

Construccion, Mineria, Automotriz, Espacial, Ingenieria, Rural y pasatiempos,

Desperdicios, Demoliciones y Astilleros.

Nos distinguimos de nuestros competidores por el liderazgo en el mercado, con

productos confiables que han resistido a la prueba del tiempo. Nos enorgullecemos

de la innovación técnica, precios competitivos, excelente entrega, superior servicio

al cliente y soporte técnico, juntamente con la excelencia en las ventas y en la

experiencia de comercialización.

Pero más que nada, estamos comprometidos con el desarrollo de productos

tecnológicamente avanzados para alcanzar un ambiente de trabajo más seguro en

la industria de la soldadura.

Page 48

ADVERTENCIA

Lea y comprenda este manual completo y las prácticas de seguridad de su

empresa, antes de instalar, manejar o realizar el mantenimiento del equipo.

Aunque la información contenida en este manual represente la opinión más

razonada del Fabricante, éste no asume responsabilidad alguna por su uso.

Reguladores Mono y Bietápicos

Instructions de seguridad y uso

Manual de instrucciones número 0056-1625

Publicado por:

Victor Technologies International, Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.victorequip.com

Copyright © 2011, 2012 Victor Technologies International, Inc. Reservados todos

los derechos.

Queda prohibida la reproducción de esta obra, total o parcialmente, sin permiso por

escrito del editor.

El editor no asume, y por la presente se descarga de cualquier responsabilidad a

cualquier parte por cualquier pérdida o daños causados por error o cualesquier

omisión en este manual, sin importar si el error deriva de negligencia, accidente o

cualquier otra causa.

Fecha de publicación: 20 de enero de 2011

Fecha de revisión: 3 deciembre 2012

Anote la siguiente información para su garantía:

Lugar de Compra: _______________________________________________

Fecha de Compra: _______________________________________________

No de Serie del Equipo: ___________________________________________

i

Page 49

Contenido

SECCIÓN 1: INTRODUCCIÓN ...............................................S1-1

SECCIÓN 2: INFORMACIÓN GENERAL DE SEGURIDAD ...S2-3

2.01 Prevención de Incendios ........................ S2-3

2.02 Orden y Aseo .......................................... S2-4

2.03 Ventilación.............................................. S2-4

2.04 Protección Personal ............................... S2-4

2.05 Cilindros de Gas Comprimida ................. S2-5

SECCIÓN 3: REGULADORES: SEGURIDAD Y MANEJO ...S3-7

3.01 Reguladores estándares ......................... S3-7

3.02 Reguladores serie Edge ........................ S3-11

3.03 Prueba de Fugas en el Sistema ............ S3-15

SECCIÓN 4: UNA VEZ QUE TERMINE DE

UTILIZAR EL REGULADOR ..........................S4-16

4.01 Almacenamiento ................................... S4-16

SECCIÓN 5: DECLARACIÓN DE GARANTÍA ..................S5-17

ii

Page 50

SECCIÓN 1:

INTRODUCCIÓN

Este manual tiene el objetivo de servir de guía para el

manejo seguro y eficiente de los reguladores utilizados en

las aplicaciones de oxígeno-combustible. Aunque el aparato

no vaya a utilizarse en aplicaciones de oxígeno combustible,

el operario deberá ejecutar los mismos procedimientos de

seguridad y operación que aplican a su trabajo en particular.

Existen varios riesgos potenciales cuando se utilizan los

reguladores. Lea atentamente este manual completo antes

de manejar ese equipo.

Todas las operaciones deben cumplir con las normativas federales, estatales, nacionales o municipales correspondientes

relati vas a la instalación, manejo, ventilación, prevención

de incendios y protección del personal. La norma Z49.1 de

ANSI, “Seguridad en los procesos de soldadura y corte”

contiene las instrucciones de seguridad detalladas. Puede

solicitarse a la American Welding Society, P.O. Box-351040,

Miami, FL 33135.

Un sistema de notas, precauciones y advertencias pone de

relieve la importante información de seguridad y manejo en

este manual. Estos son:

NOTA

Comunica información sobre la instalación, manejo o

manten imiento que es importante, pero no es indicativo

de peligro.

PRECAUCION

Indica una situación potencialmente peligrosa que, de no

evi tarse, puede resultar en una lesión.

ADVERTENCIA

Indica una situación potencialmente peligrosa que, de no

evi tarse, puede resultar en una lesión grave o la muerte.

S1-1

Page 51

ADVERTENCIA

Este producto contiene sustancias químicas, dentro de las

que se incluye el plomo, o de otro modo produce sustancias

químicas que el Estado de California sabe que provocan

defectos congénitos y/u otros daños reproductores. Lávese

las manos después de haber estado en contacto con estas

sustancias.

ADVERTENCIA

NO intente utilizar este aparato sin antes haber leído

detenidamente y comprendido todas las instrucciones de

seguridad y manejo provistas. Para su seguridad, ejecute

los procedimientos de seguridad y manejo descritos en este

manual cada vez que utilice este aparato. El incumplimiento

de estos procedimientos puede dar por resultado un

incendio, explosión, daño físico y/o lesiones al operador.

Si en cualquier momento durante su utilización el aparato

no funciona como de costumbre, o si usted tiene dificultad

para manejarlo, INTERRUMPA inmediatamente su uso

¡NO lo vuelva a utilizar hasta haber corregido el problema!

ADVERTENCIA

EI servicio o reparación del aparato deberá ser ejecutado

solamente por un técnico calificado en la reparación de

aparatos de gas según las estrictas instrucciones contenidas

en los boletines de piezas y servicio correspondientes de

los productos fabricados por VictorMD. El servicio, reparación

o modificación incorrectos del producto podría producir

como resultado daños al producto o lesiones al operario. La

reparación incorrecta del servicio, EL USO DE LAS PIEZAS

NO-GENUINAS DE VICTORMD, o la modificación podían dar

lugar a daño al producto o a lesión al operador.

S2-2

Page 52

SECCIÓN 2:

INFORMACIÓN GENERAL DE SEGURIDAD

Antes de utilizar este aparato, lea y comprenda todas las

instrucciones de seguridad y manejo provistas. GUARDE

ESTAS INSTRUCCIONES EN UN LUGAR DE FACIL ACCESO

PARA CONSULTAS EN EL FUTURO.

2.01 PREVENCIÓN DE INCENDIOS

Las operaciones de soldadura y corte utilizan fuego o combustión como una herramienta fundamental. El proceso es

muy útil cuando está bien controlado. Sin embargo, puede ser

extremadamente destructivo si no se realiza correctamente en

el ambiente adecuado.

1. El lugar de trabajo debe tener un piso ignífugo.

2. Los bancos o mesas de trabajo utilizados durante las operaciones de soldadura deben tener cubiertas ignífugas.

3. Utilice pantallas termo resistentes u otro material aprobado

para proteger las paredes cercanas o el piso desprotegido de

las chispas y metal caliente.

4. Mantenga un extintor de incendios aprobado de la medida y tipo

apropiados en el lugar de trabajo. Inspecciónelo periódica mente

para asegurarse que está en buenas condiciones. Aprenda

utilizar el extintor.

5. Retire los materiales combustibles a un lugar alejado del sitio de

trabajo. Si no puede retirarlos, protéjalos con cubiertas ignífugas.

ADVERTENCIA

NUNCA efectúe trabajos de soldadura, calentamiento o corte

en un envase que ha contenido líquidos o vapores tóxicos,

combustibles o inflamables. NUNCA ejecute operaciones de

soldadura en un lugar que contenga vapores combustibles,

líquidos inflamables o polvo explosivo.

S2-3

Page 53

2.02 ORDEN Y ASEO

ADVERTENCIA

No permita NUNCA que el oxigeno quede en contacto con

grasa, aceite u otras sustancias inflamables. Aunque el

oxígeno por sí solo no arde, estas sustancias puede volverse

muy explosivas. Pueden inflamarse y arder violentamente

en presencia de oxígeno.

Mantenga TODOS los aparatos limpios y libres de grasa, aceite

y otras sustancias inflamables.

2.03 VENTILACIÓN

ADVERTENCIA

Ventile los lugares donde se estén haciendo trabajos de

sol dadura, calentamiento y corte para evitar la acumulación

de concentraciones explosivas o tóxicas de gases. Ciertas

com binaciones de metales, revestimientos y gases generan

vapores tóxicos. En tales casos, use un equipo protector de

respiración. ANTES de soldar, lea y comprenda la hoja de

información de seguridad de los materiales correspondiente

a las aleaciones para soldar.

2.04 PROTECCIÓN PERSONAL

Las llamas gaseosas producen radiación infrarroja que puede

tener efectos nocivos en la piel y especialmente en los ojos.

Escoja gafas o una máscara con lentes templados de matiz 4

ó más oscuro para protegerse los ojos contra lesiones y tener

una buena visibilidad del trabajo.

Use siempre guantes protectores y ropa incombustible para

proteger la piel y las prendas de vestir contra chispas y escoria.

Mantenga los cuellos, mangas y bolsillos abotonados. NO se

enrolle las mangas ni los pantalones con bastilla.

Cuando trabaje en un ambiente que no sea para soldar o cor tar,

use siempre protección adecuada para los ojos o una careta.

S2-4

Page 54

ADVERTENCIA

Practique las siguientes precauciones de seguridad y

manejo CADA VEZ que use un equipo regulador de presión.

El incumplimiento de las instrucciones de seguridad

y manejo pueden producir por resultado un incendio,

explosión, daños al equipo o lesiones al operario.

2.05 CILINDROS DE GAS COMPRIMIDA

El Departamento de Transporte de EE.UU. (DOT) aprueba el

diseño y la fabricación de cilindros (La figura 1) que contienen

gases utilizados para las operaciones de soldadura y corte.

1. Coloque el cilindro donde lo va a utilizar. Manténgalo en posición vertical. Sujételo a un carro, la pared, banco de traba jo,

poste, etc.

Figura 1: Cilindros de Gas

ADVERTENCIA

Los cilindros tienen contenido a alta presión. Manipúlelos con

cuidado. Pueden ocurrir accidentes graves como resultado de

la manipulación incorrecta o el maltrato de los cilindros de gas

comprimido. NO deje que el cilindro se caiga, vuelque o quede

expuesto a calor excesivo, llamas o chispas. NO lo golpee

contra otros cilindros. Póngase en contacto con su proveedor

de gas o consulte la publicación “Manejo seguro de los gases

comprimidos envasados” de CGA P-1*.

S2-5

Page 55

NOTA

La publicación CGA P-1 puede solicitarse escribiendo a

Compressed Ges Assoclation,. 4221 Welney Road, 5th Floor.

Chantifly. VA 20151-2923

2. Coloque la tapa protector de la válvula en el cilindro cada

vez que los traslade de lugar, guarde en almacén o no lo esté

uti lizando. Nunca arrastre ni haga rodar los cilindros. Use una

car retilla de mano adecuada.

3. Guarde los cilindros vacíos lejos de los llenos. Márquelos

“VACIO” y cierre la válvula del cilindro.

4. NUNCA utilice cilindros de gas comprimido sin antes haber

conectado un regulador reductor de presión a la válvula del

cilindro.

5. Inspeccione la válvula del cilindro para ver si tiene aceite, grasa

y piezas dañadas.

ADVERTENCIA

NO use el cilindro si encuentra que tiene aceite, grasa o

piezas dañadas. Avísele inmediatamente al proveedor de

gas de lo sucedido.

6. Abra y cierre momentáneamente la válvula del cilindro para

desalojar el polvo o tierra que pudiera haber en la válvula.

PRECAUCION

Abra ligeramente la válvula del cilindro. Si la abre

demasiado, el cilindro podría tumbarse. Cuando abra y

cierre momen táneamente la válvula del cilindro, NO se sitúe

directamente delante de ella. Haga siempre esta operación

en un lugar bien ventilado. Si un cilindro de acetileno

lanza un chorro atomiza do al abrirlo, déjelo reposar por 15

minutos. Después, pruebe abrirlo ligeramente nuevamente.

Si el problema persiste, con sulte a su proveedor de gas.

S2-6

Page 56

SECCIÓN 3:

MANOMETRO DE BAJA