Page 1

SC-3000

PRECISION TORCH

HEIGHT CONTROL

Operating Manual

Rev. AC Date: February 4, 2010 Manual # 0-5100

Operating Features:

PRECISION

PLASMA

12kg

26.4 lb.

CAPACITY

220mm

8.66in

STROKE

Art # A-08652

TACTILE

IHS

115230

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Thermal Dynamics product. We are

proud to have you as our customer and will strive to provide you

with the best service and reliability in the industry. This product is

backed by our extensive warranty and world-wide service network.

To locate your nearest distributor or service agency call 1-800-4261888, or visit us on the web at www.thermal-dynamics.com.

This Operating Manual has been designed to instruct you on the

correct use and operation of your Thermal Dynamics product. Your

satisfaction with this product and its safe operation is our ultimate

concern. Therefore please take the time to read the entire manual,

especially the Safety Precautions. They will help you to avoid potential hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators

Worldwide.

Thermal Dynamics is a Global Brand of manual and automation

Plasma Cutting Products for Thermadyne Industries Inc.

We distinguish ourselves from our competition through marketleading, dependable products that have stood the test of time.

We pride ourselves on technical innovation, competitive prices,

excellent delivery, superior customer service and technical support,

together with excellence in sales and marketing expertise.

Above all, we are committed to developing technologically advanced products to achieve a safer working environment within

the welding industry.

Page 3

!

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement, the

Manufacturer assumes no liability for its use.

Precision Torch Height Control

SC-3000™

Operating Manual Number 0-5100

Published by:

Thermal Dynamics Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

Copyright 2009, 2010 by

Thermadyne Corporation

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the

publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this Manual, whether such error

results from negligence, accident, or any other cause.

Printed in the United States of America

Original Publication Date: January 9, 2009

Revision Date: February 4, 2010

Record the following information for Warranty purposes:

Where Purchased:_______________________________ ________________

Purchase Date:__________________________________ ________________

Power Supply Serial #:___________________________ ________________

Torch Serial #:___________________________________ ________________

i

Page 4

This Page Intentionally Blank

Page 5

TABLE OF CONTENTS

SECTION 1:GENERAL INFORMATION ...................................................................................1-1

1.01 Notes, Cautions and Warnings ...................................................................1-1

1.02 Important Safety Precautions .....................................................................1-1

1.03 Publications.................................................................................................1-2

1.04 Note, Attention et Avertissement ................................................................1-3

1.05 Precautions De Securite Importantes .........................................................1-3

1.06 Documents De Reference ...........................................................................1-5

1.07 Declaration of Conformity ...........................................................................1-6

1.08 Statement of Warranty ................................................................................1-7

SECTION 2 SYSTEM:INTRODUCTION .................................................................................2-1

2.01 How To Use This Manual ............................................................................2-1

2.02 Equipment Identification .............................................................................2-1

2.03 Receipt Of Equipment .................................................................................2-1

2.04 System Specifications .................................................................................2-2

2.05 System Componants ..................................................................................2-3

2.06 Application and System Description ...........................................................2-7

SECTION 3 SYSTEM: INSTALLATION ...................................................................................3-1

3.01 Unpacking ................................................................................................... 3-1

3.02 Handling Options ........................................................................................3-1

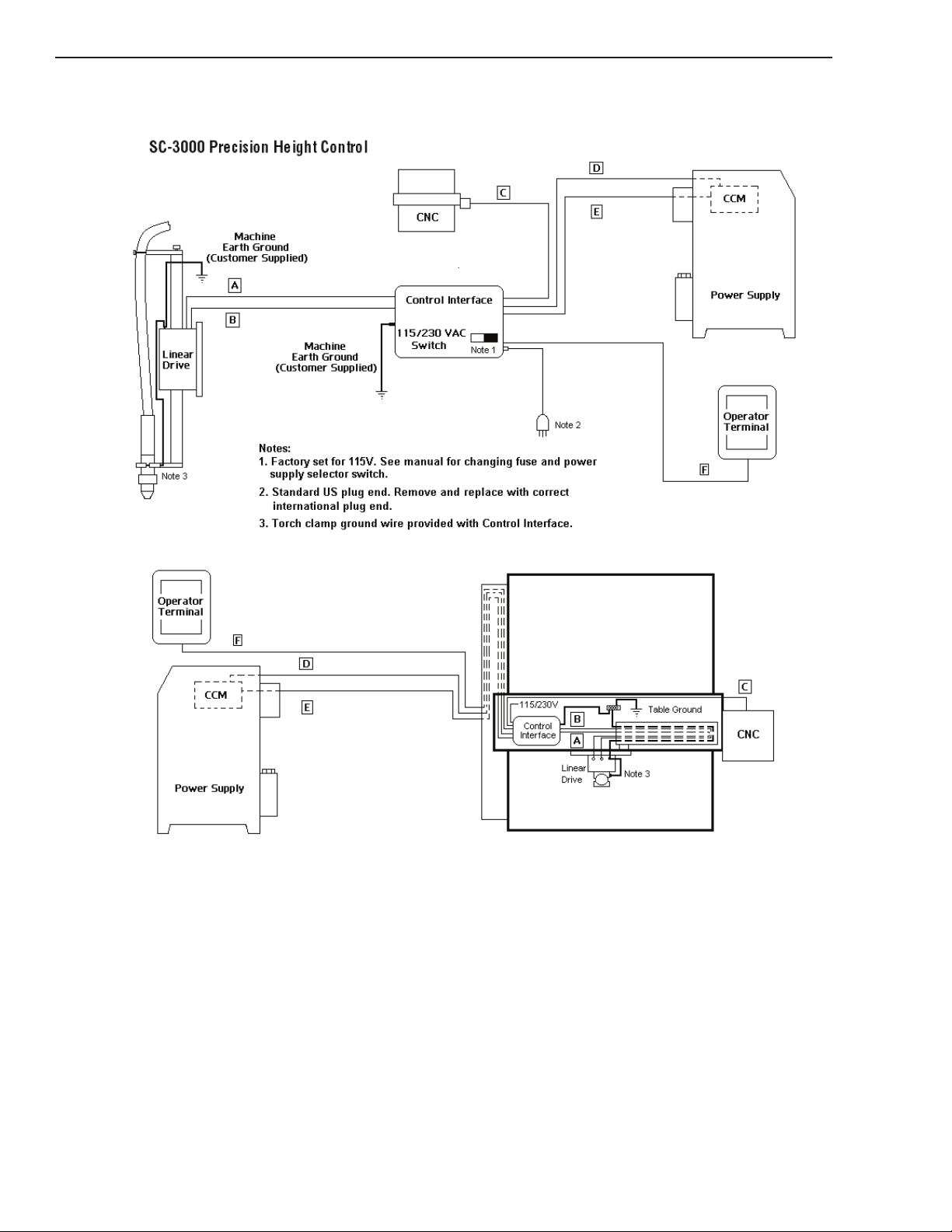

3.03 System Layout ............................................................................................3-2

3.04 Installation ...................................................................................................3-4

3.05 Checking of Grounding .............................................................................3-18

SECTION 4 SYSTEM: OPERATION ........................................................................................ 4-1

4.01 Requirements and Check List for first Start-up ........................................... 4-1

4.02 Power Up ....................................................................................................4-1

4.03 OPERATOR TERMINAL Menu-Overview ...................................................4-3

4.04 OPERATOR TERMINAL SETTINGS ..........................................................4-4

4.05 SIGNAL FLOW DURING PLASMA CUTTING ............................................4-9

4.06 SC 3000 Operation Sequence .................................................................... 4-9

4.07 LOSS OF PLASMA ARC ..........................................................................4-12

4.08 DETECTION OF KERFS AND EDGES DURING CUTTING ....................4-12

4.09 SCRAP CUTTING ....................................................................................4-14

4.10 PROCEDURE WITH GAS PRE-FLOW ....................................................4-16

4.11 SC 3000 Torch Height Control (THC) Modes of Operation .......................4-18

4.12 Parameter Setting ..................................................................................... 4-19

SECTION 5 SYSTEM:SERVICE ..............................................................................................5-1

5.01 General Maintenance .................................................................................5-1

5.02 Troubleshooting ...........................................................................................5-2

SECTION 6:PARTS LISTS ....................................................................................................... 6-1

6.01 Introduction .................................................................................................6-1

6.02 Ordering Information ................................................................................... 6-1

6.03 Replacement Parts ....................................................................................6-2

Page 6

TABLE OF CONTENTS

APPENDIX 1: DEFINITIONS .................................................................................................. A-1

APPENDIX 2: GROUNDING A CUTTING MACHINE ............................................................ A-2

APPENDIX 3: POWER SUPPLY ............................................................................................ A-4

APPENDIX 4: INTERFACE .................................................................................................... A-5

APPENDIX 5: OPERATOR TERMINAL-REMOTE ................................................................. A-7

APPENDIX 6: CNC CONNECTIONS TO OTHER CONTROLLERS ..................................... A-8

APPENDIX 7: CONTROLLER SCHEMATIC ........................................................................ A-12

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION ......................... Inside Rear Cover

Page 7

SC 3000

!

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings are used to

highlight important information. These highlights are categorized as

follows:

NOTE

An operation, procedure, or background information

which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may cause

damage to the equipment.

WARNING

A procedure which, if not properly followed, may cause

injury to the operator or others in the operating area.

1.02 Important Safety Precautions

• The kinds of fumes and gases from the plasma arc depend on

the kind of metal being used, coatings on the metal, and the

different processes. You must be very careful when cutting

or welding any metals which may contain one or more of the

following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets (MSDS) that should

be supplied with the material you are using. These MSDSs

will give you the information regarding the kind and amount of

fumes and gases that may be dangerous to your health.

• For information on how to test for fumes and gases in your

workplace, refer to item 1 in Subsection 1.03, Publications in

this manual.

• Use special equipment, such as water or down draft cutting

tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or

explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors of chlorinated solvents and cleansers. Remove all sources of these

vapors.

• This product, when used for welding or cutting, produces

fumes or gases which contain chemicals known to the State

of California to cause birth defects and, in some cases, cancer.

(California Health & Safety Code Sec. 25249.5 et seq.)

WARNINGS

OPERATION AND MAINTENANCE OF PLASMA ARC

EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS

TO YOUR HEALTH.

Plasma arc cutting produces intense electric and

magnetic emissions that may interfere with the proper

function of cardiac pacemakers, hearing aids, or other

electronic health equipment. Persons who work near

plasma arc cutting applications should consult their

medical health professional and the manufacturer of

the health equipment to determine whether a hazard

exists.

To prevent possible injury, read, understand and follow

all warnings, safety precautions and instructions before

using the equipment. Call 1-603-298-5711 or your local

distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting process can be

dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area. Keep your

head out of the welding fume plume.

• Use an air-supplied respirator if ventilation is not adequate to

remove all fumes and gases.

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process uses and

produces high voltage electrical energy. This electric energy can cause

severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live” or “hot.”

• Wear dry gloves and clothing. Insulate yourself from the work

piece or other parts of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist or

damp.

• Install and maintain equipment according to NEC code, refer

to item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any service or

repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or the plasma

arc.

• Be sure there is no combustible or flammable material in the

workplace. Any material that cannot be removed must be

protected.

• Ventilate all flammable or explosive vapors from the workplace.

Manual 0-5100 1-1 GENERAL INFORMATION

Page 8

SC 3000

• Do not cut or weld on containers that may have held combustibles.

• Provide a fire watch when working in an area where fire hazards

may exist.

• Hydrogen gas may be formed and trapped under aluminum

workpieces when they are cut underwater or while using a water

table. DO NOT cut aluminum alloys underwater or on a water

table unless the hydrogen gas can be eliminated or dissipated.

Trapped hydrogen gas that is ignited will cause an explosion.

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can

cause noise levels to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of hearing.

1.03 Publications

Refer to the following standards or their latest revisions for more

information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910,

obtainable from the Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C. 20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND CUTTING,

obtainable from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS

WELDING AND CUTTING, obtainable from the Superintendent

of Documents, U.S. Government Printing Office, Washington,

D.C. 20402

• To protect your hearing from loud noise, wear protective ear

plugs and/or ear muffs. Protect others in the workplace.

• Noise levels should be measured to be sure the decibels (sound)

do not exceed safe levels.

• For information on how to test for noise, see item 1 in Subsection 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The plasma

arc process produces very bright ultra violet and infra red light. These

arc rays will damage your eyes and burn your skin if you are not

properly protected.

• To protect your eyes, always wear a welding helmet or shield.

Also always wear safety glasses with side shields, goggles or

other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin

from the arc rays and sparks.

• Keep helmet and safety glasses in good condition. Replace

lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use protective

booths, screens or shields.

• Use the shade of lens as suggested in the following per ANSI/

ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly seen.

Experience has shown that lighter filters may be used

when the arc is hidden by the workpiece.

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION

AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable

from American National Standards Institute, 1430 Broadway,

New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S SAFETY-TOE

FOOTWEAR, obtainable from the American National Standards

Institute, 1430 Broadway, New York, NY 10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE OF CUT-

TING AND WELDING PROCESSES, obtainable from American

National Standards Institute, 1430 Broadway, New York, NY

10018

7. AWS Standard A6.0, WELDING AND CUTTING CONTAIN-

ERS WHICH HAVE HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR

WELDING, CUTTING AND ALLIED PROCESSES, obtainable

from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, obtainable

from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES,

obtainable from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED

GASES IN CYLINDERS, obtainable from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Suite 501,

Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING

AND CUTTING, obtainable from the Canadian Standards Association, Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

LEAD WARNING

This product contains chemicals, including lead, or otherwise produces

chemicals known to the State of California to cause cancer, birth defects

and other reproductive harm. Wash hands after handling. (California

Health & Safety Code § 25249.5 et seq.)

GENERAL INFORMATION 1-2 Manual 0-5100

from the National Welding Supply Association, 1900 Arch

Street, Philadelphia, PA 19103

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable

Page 9

14. American Welding Society Standard AWSF4.1, RECOM-

!

MENDED SAFE PRACTICES FOR THE PREPARATION FOR

WELDING AND CUTTING OF CONTAINERS AND PIPING THAT

HAVE HELD HAZARDOUS SUBSTANCES, obtainable from the

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PROTECTION, obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

1.04 Note, Attention et Avertissement

Dans ce manuel, les mots “note,” “attention,” et “avertissement” sont

utilisés pour mettre en relief des informations à caractère important.

Ces mises en relief sont classifiées comme suit :

NOTE

Toute opération, procédure ou renseignement général

sur lequel il importe d’insister davantage ou qui contribue

à l’efficacité de fonctionnement du système.

ATTENTION

Toute procédure pouvant résulter l’endommagement

du matériel en cas de non-respect de la procédure en

question.

AVERTISSEMENT

Toute procédure pouvant provoquer des blessures de

l’opérateur ou des autres personnes se trouvant dans

la zone de travail en cas de non-respect de la procédure

en question.

1.05 Precautions De Securite Importantes

SC 3000

FUMÉE et GAZ

La fumée et les gaz produits par le procédé de jet de plasma peuvent

présenter des risques et des dangers de santé.

• Eloignez toute fumée et gaz de votre zone de respiration. Gardez

votre tête hors de la plume de fumée provenant du chalumeau.

• Utilisez un appareil respiratoire à alimentation en air si l’aération

fournie ne permet pas d’éliminer la fumée et les gaz.

• Les sortes de gaz et de fumée provenant de l’arc de plasma dépendent du genre de métal utilisé, des revêtements se trouvant sur le

métal et des différents procédés. Vous devez prendre soin lorsque

vous coupez ou soudez tout métal pouvant contenir un ou plusieurs

des éléments suivants:

antimoine cadmium mercure

argent chrome nickel

arsenic cobalt plomb

baryum cuivre sélénium

béryllium manganèse vanadium

• Lisez toujours les fiches de données sur la sécurité des matières

(sigle américain “MSDS”); celles-ci devraient être fournies avec le

matériel que vous utilisez. Les MSDS contiennent des renseignements quant à la quantité et la nature de la fumée et des gaz pouvant

poser des dangers de santé.

• Pour des informations sur la manière de tester la fumée et les gaz

de votre lieu de travail, consultez l’article 1 et les documents cités

à la page 5.

• Utilisez un équipement spécial tel que des tables de coupe à débit

d’eau ou à courant descendant pour capter la fumée et les gaz.

• N’utilisez pas le chalumeau au jet de plasma dans une zone où se

trouvent des matières ou des gaz combustibles ou explosifs.

• Le phosgène, un gaz toxique, est généré par la fumée provenant

des solvants et des produits de nettoyage chlorés. Eliminez toute

source de telle fumée.

• Ce produit, dans le procéder de soudage et de coupe, produit de

AVERTISSEMENTS

L’OPÉRATION ET LA MAINTENANCE DU MATÉRIEL

DE SOUDAGE À L’ARC AU JET DE PLASMA PEUVENT

PRÉSENTER DES RISQUES ET DES DANGERS DE

SANTÉ.

Coupant à l’arc au jet de plasma produit de l’énergie

électrique haute tension et des émissions magnétique qui

peuvent interférer la fonction propre d’un “pacemaker”

cardiaque, les appareils auditif, ou autre matériel de santé

electronique. Ceux qui travail près d’une application à

l’arc au jet de plasma devrait consulter leur membre professionel de médication et le manufacturier de matériel de

santé pour déterminer s’il existe des risques de santé.

Il faut communiquer aux opérateurs et au personnel

TOUS les dangers possibles. Afin d’éviter les blessures

possibles, lisez, comprenez et suivez tous les avertissements, toutes les précautions de sécurité et toutes les

consignes avant d’utiliser le matériel. Composez le +

603-298-5711 ou votre distributeur local si vous avez

des questions.

Manual 0-5100 1-3 GENERAL INFORMATION

la fumée ou des gaz pouvant contenir des éléments reconnu dans

L’état de la Californie, qui peuvent causer des défauts de naissance

et le cancer. (La sécurité de santé en Californie et la code sécurité

Sec. 25249.5 et seq.)

CHOC ELECTRIQUE

Les chocs électriques peuvent blesser ou même tuer. Le procédé au jet

de plasma requiert et produit de l’énergie électrique haute tension. Cette

énergie électrique peut produire des chocs graves, voire mortels, pour

l’opérateur et les autres personnes sur le lieu de travail.

• Ne touchez jamais une pièce “sous tension” ou “vive”; portez des

gants et des vêtements secs. Isolez-vous de la pièce de travail ou

des autres parties du circuit de soudage.

• Réparez ou remplacez toute pièce usée ou endommagée.

• Prenez des soins particuliers lorsque la zone de travail est humide

ou moite.

Page 10

SC 3000

• Montez et maintenez le matériel conformément au Code électrique

national des Etats-Unis. (Voir la page 5, article 9.)

• Débranchez l’alimentation électrique avant tout travail d’entretien

ou de réparation.

• Lisez et respectez toutes les consignes du Manuel de consignes.

INCENDIE ET EXPLOSION

Les incendies et les explosions peuvent résulter des scories chaudes,

des étincelles ou de l’arc de plasma. Le procédé à l’arc de plasma

produit du métal, des étincelles, des scories chaudes pouvant mettre

le feu aux matières combustibles ou provoquer l’explosion de fumées

inflammables.

• Utilisez la nuance de lentille qui est suggèrée dans le recommendation qui suivent ANSI/ASC Z49.1:

Nuance Minimum Nuance Suggerée

Courant Arc Protective Numéro Numéro

Moins de 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* Ces valeurs s’appliquent ou l’arc actuel est observé

clairement. L’experience a démontrer que les filtres

moins foncés peuvent être utilisés quand l’arc est caché

par moiceau de travail.

• Soyez certain qu’aucune matière combustible ou inflammable ne

se trouve sur le lieu de travail. Protégez toute telle matière qu’il

est impossible de retirer de la zone de travail.

• Procurez une bonne aération de toutes les fumées inflammables

ou explosives.

• Ne coupez pas et ne soudez pas les conteneurs ayant pu renfermer

des matières combustibles.

• Prévoyez une veille d’incendie lors de tout travail dans une zone

présentant des dangers d’incendie.

• Le gas hydrogène peut se former ou s’accumuler sous les pièces

de travail en aluminium lorsqu’elles sont coupées sous l’eau ou

sur une table d’eau. NE PAS couper les alliages en aluminium sous

l’eau ou sur une table d’eau à moins que le gas hydrogène peut

s’échapper ou se dissiper. Le gas hydrogène accumulé explosera

si enflammé.

RAYONS D’ARC DE PLASMA

Les rayons provenant de l’arc de plasma peuvent blesser vos yeux et

brûler votre peau. Le procédé à l’arc de plasma produit une lumière

infra-rouge et des rayons ultra-violets très forts. Ces rayons d’arc

nuiront à vos yeux et brûleront votre peau si vous ne vous protégez

pas correctement.

• Pour protéger vos yeux, portez toujours un casque ou un écran

de soudeur. Portez toujours des lunettes de sécurité munies de

parois latérales ou des lunettes de protection ou une autre sorte

de protection oculaire.

BRUIT

Le bruit peut provoquer une perte permanente de l’ouïe. Les procédés

de soudage à l’arc de plasma peuvent provoquer des niveaux sonores

supérieurs aux limites normalement acceptables. Vous dú4ez vous

protéger les oreilles contre les bruits forts afin d’éviter une perte

permanente de l’ouïe.

• Pour protéger votre ouïe contre les bruits forts, portez des tampons

protecteurs et/ou des protections auriculaires. Protégez également

les autres personnes se trouvant sur le lieu de travail.

• Il faut mesurer les niveaux sonores afin d’assurer que les décibels

(le bruit) ne dépassent pas les niveaux sûrs.

• Pour des renseignements sur la manière de tester le bruit, consultez

l’article 1, page 5.

PLOMB AVERTISSEMENT

Ce produit contient des produits chimiques, comme le plomb,

ou engendre des produits chimiques, reconnus par l’état de

Californie comme pouvant être à l’origine de cancer, de malformations fœtales ou d’autres problèmes de reproduction.

Il f a u t s e laver l e s mains a p r è s toute ma n i p u l a t i o n .

(Code de Californie de la sécurité et santé, paragraphe 25249.5 et

suivants)

• Portez des gants de soudeur et un vêtement protecteur approprié

pour protéger votre peau contre les étincelles et les rayons de

l’arc.

• Maintenez votre casque et vos lunettes de protection en bon état.

Remplacez toute lentille sale ou comportant fissure ou rognure.

• Protégez les autres personnes se trouvant sur la zone de travail

contre les rayons de l’arc en fournissant des cabines ou des écrans

de protection.

GENERAL INFORMATION 1-4 Manual 0-5100

Page 11

1.06 Documents De Reference

Consultez les normes suivantes ou les révisions les plus récentes ayant

été faites à celles-ci pour de plus amples renseignements :

1. OSHA, NORMES DE SÉCURITÉ DU TRAVAIL ET DE PROTECTION

DE LA SANTÉ, 29CFR 1910, disponible auprès du Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402

2. Norme ANSI Z49.1, LA SÉCURITÉ DES OPÉRATIONS DE COUPE

ET DE SOUDAGE, disponible auprès de la Société Américaine de

Soudage (American Welding Society), 550 N.W. LeJeune Rd.,

Miami, FL 33126

3. NIOSH, LA SÉCURITÉ ET LA SANTÉ LORS DES OPÉRATIONS DE

COUPE ET DE SOUDAGE À L’ARC ET AU GAZ, disponible auprès

du Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402

4. Norme ANSI Z87.1, PRATIQUES SURES POUR LA PROTECTION

DES YEUX ET DU VISAGE AU TRAVAIL ET DANS LES ECOLES,

disponible de l’Institut Américain des Normes Nationales (American National Standards Institute), 1430 Broadway, New York, NY

10018

5. Norme ANSI Z41.1, NORMES POUR LES CHAUSSURES PROTECTRICES, disponible auprès de l’American National Standards

Institute, 1430 Broadway, New York, NY 10018

SC 3000

14. Norme AWSF4.1 de l’Association Américaine de Soudage, RECOMMANDATIONS DE PRATIQUES SURES POUR LA PRÉPARATION À

LA COUPE ET AU SOUDAGE DE CONTENEURS ET TUYAUX AYANT

RENFERMÉ DES PRODUITS DANGEREUX , disponible auprès de

la American Welding Society, 550 N.W. LeJeune Rd., Miami, FL

33126

15. Norme ANSI Z88.2, PRATIQUES DE PROTECTION RESPIRATOIRE,

disponible auprès de l’American National Standards Institute, 1430

Broadway, New York, NY 10018

6. Norme ANSI Z49.2, PRÉVENTION DES INCENDIES LORS DE

L’EMPLOI DE PROCÉDÉS DE COUPE ET DE SOUDAGE, disponible

auprès de l’American National Standards Institute, 1430 Broadway,

New York, NY 10018

7. Norme A6.0 de l’Association Américaine du Soudage (AWS), LE

SOUDAGE ET LA COUPE DE CONTENEURS AYANT RENFERMÉ

DES PRODUITS COMBUSTIBLES, disponible auprès de la American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126

8. Norme 51 de l’Association Américaine pour la Protection contre les

Incendies (NFPA), LES SYSTEMES À GAZ AVEC ALIMENTATION

EN OXYGENE POUR LE SOUDAGE, LA COUPE ET LES PROCÉDÉS

ASSOCIÉS, disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

9. Norme 70 de la NFPA, CODE ELECTRIQUE NATIONAL, disponible

auprès de la National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

10. Norme 51B de la NFPA, LES PROCÉDÉS DE COUPE ET DE SOUDAGE, disponible auprès de la National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. Brochure GCA P-1, LA MANIPULATION SANS RISQUE DES GAZ

COMPRIMÉS EN CYLINDRES, disponible auprès de l’Association

des Gaz Comprimés (Compressed Gas Association), 1235 Jefferson

Davis Highway, Suite 501, Arlington, VA 22202

12. Norme CSA W117.2, CODE DE SÉCURITÉ POUR LE SOUDAGE

ET LA COUPE, disponible auprès de l’Association des Normes

Canadiennes, Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada, M9W 1R3

13. Livret NWSA, BIBLIOGRAPHIE SUR LA SÉCURITÉ DU SOUDAGE,

disponible auprès de l’Association Nationale de Fournitures de

Soudage (National Welding Supply Association), 1900 Arch Street,

Philadelphia, PA 19103

Manual 0-5100 1-5 GENERAL INFORMATION

Page 12

SC 3000

1.07 Declaration of Conformity

Manufacturer: Thermal Dynamics Corporation

Address: 82 Benning Street

West Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (European Council Directive

73/23/EEC as amended by Council Directive 93/68/EEC) and to the National legislation for the enforcement of this Directive.

The equipment described in this manual conforms to all applicable aspects and regulations of the "EMC Directive" (European Council Directive 89/336/

EEC) and to the National legislation for the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit and date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements. Among them are:

* CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

* UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boards used.

* CENELEC EN50199 EMC Product Standard for Arc Welding Equipment.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associated accessories.

* For environments with increased hazard of electrical shock, Power Supplies bearing the 'S' mark conform to EN50192 when used in conjunction with

hand torches with exposed cutting tips, if equipped with properly installed standoff guides.

* Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing process. This is to

ensure the product is safe, when used according to instructions in this manual and related industry standards, and performs as specified. Rigorous

testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design specifications.

Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture.

Manufacturers responsible representative: Steve Ward

Thermadyne Europe

Europa Building

Chorley N Industrial Park

Chorley, Lancashire,

England PR6 7BX

Operations Director

GENERAL INFORMATION 1-6 Manual 0-5100

Page 13

SC 3000

1.08 Statement of Warranty

LIMITED WARRANTY: Subject to the terms and conditions established below, Thermal Dynamics® Corporation warrants to the original retail purchaser

that new Thermal Dynamics SC-3000™ Precision Height Control systems sold after the effective date of this warranty are free of defects in material

and workmanship. Should any failure to conform to this warranty appear within the applicable period stated below, Thermal Dynamics Corporation

shall, upon notification thereof and substantiation that the product has been stored operated and maintained in accordance with Thermal Dynamics’

specifications, instructions, recommendations and recognized industry practice, correct such defects by suitable repair or replacement.

This warranty is exclusive and in lieu of any warranty of merchantability or fitness for a particular purpose.

Thermal Dynamics will repair or replace, at its discretion, any warranted parts or components that fail due to defects in material or workmanship within the

time periods set out below. Thermal Dynamics Corporation must be notified within 30 days of any failure, at which time Thermal Dynamics Corporation

will provide instructions on the warranty procedures to be implemented.

Thermal Dynamics Corporation will honor warranty claims submitted within the warranty periods listed below. All warranty periods begin on the date

of sale of the product to the original retail customer or 1 year after sale to an authorized Thermal Dynamics Distributor.

LIMITED WARRANTY PERIOD

Product

SC-3000™

This warranty does not apply to:

1. Consumable Parts, such as tips, electrodes, shield cups, o - rings, starter cartridges, gas distributors, fuses, filters.

2. Equipment that has been modified by an unauthorized party, improperly installed, improperly operated or misused based upon industry

standards.

In the event of a claim under this warranty, the remedies shall be, at the discretion of Thermal Dynamics Corporation:

1. Repair of the defective product.

2. Replacement of the defective product.

3. Reimbursement of reasonable costs of repair when authorized in advance by Thermal Dynamics.

4. Payment of credit up to the purchase price less reasonable depreciation based on actual use.

These remedies may be authorized by Thermal Dynamics and are FOB West Lebanon, NH or an authorized Thermadyne service station. Product returned

for service is at the owner’s expense and no reimbursement of travel or transportation is authorized.

LIMITATION OF LIABILITY: Thermal Dynamics Corporation shall not under any circumstances be liable for special or consequential damages such

as, but not limited to, damage or loss of purchased or replacement goods or claims of customer of distributors (hereinafter “Purchaser”) for service

interruption. The remedies of the Purchaser set forth herein are exclusive and the liability of Thermal Dynamics with respect to any contract, or anything

done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of the goods covered

by or furnished by Thermal Dynamics whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as

expressly provided herein, exceed the price of the goods upon which liability is based.

Control Interface and Terminal

(Parts and Labor)

1 Years 1 Year

Linear Drive

(Parts and Labor)

This warranty becomes invalid if replacement parts or accessories are used which may impair the safety or performance of any Thermal Dynamics

product.

This warranty is invalid if the Thermal Dynamics product is sold by non - authorized persons.

Effective January 5, 2009

Manual 0-5100 1-7 GENERAL INFORMATION

Page 14

SC 3000

This Page Intentionally Blank

GENERAL INFORMATION 1-8 Manual 0-5100

Page 15

SC-3000

!

SECTION 2 SYSTEM:

INTRODUCTION

2.01 How To Use This Manual

This Owner’s Manual applies to just specication

or part numbers listed on page i.

To ensure safe operation, read the entire manual,

including the chapter on safety instructions and

warnings.

Throughout this manual, the words WARNING,

CAUTION, and NOTE may appear. Pay

particular attention to the information provided

under these headings. These special annotations

are easily recognized as

follows:

WARNING

A WARNING gives information regarding

possible personal injury.

CAUTION

A CAUTION refers to possible equipment damage.

NOTE

2.02 Equipment Identification

The unit’s identication number (specication or

part number), model, and serial number usually

appear on a data tag attached to the rear panel.

Equipment which does not have a data tag such

as torch and cable assemblies are identied

only by the specication or part number

printed on loosely attached card or the shipping

container. Record these numbers on the bottom of

page 1 for future reference.

2.03 Receipt Of Equipment

When you receive the equipment, check it against

the invoice to make sure it is complete and inspect the equipment for possible damage due to

shipping. If there is any damage, notify the car-

rier immediately to le a claim. Furnish complete

information concerning damage claims or shipping errors to the location in your area listed in

the inside back cover of this manual.

Include all equipment identication numbers as

described above along with a full description of

the parts in error.

Move the equipment to the installation site before

un-crating the unit. Use care to avoid damaging

the equipment when using bars, hammers, etc., to

un-crate the unit.

A NOTE offers helpful information concerning

certain operating procedures.

Additional copies of this manual may be

purchased by contacting Thermadyne at the

address and phone number in your area listed

in the inside back cover of this manual. Include

the Owner’s Manual number and equipment

identication numbers.

Electronic copies of this manual can also be

downloaded at no charge in Acrobat PDF format

by going to the

Thermal Dynamics web site listed below and

clicking on Thermal Dynamics and then on the

Literature link:

http://www.thermal-dynamics.com

Manual 0-5100 2-1 INTRODUCTION

Page 16

SC-3000

2.04 System Specifications

Power supply 115/230 VAC ±10%

Current 2A/1A max.

Initial Position Finding -tactile

Clearance control in plasma mode by plasma arc voltage

Accuracy appr. ± 0.012" (± 0.3 mm)

Linear Drive Stroke = 8.3" (210 mm)

Speed = 3.1" / sec (80 mm / sec)

Load = 26.45 lbs (12 kg)

Collision protection built in.

INTRODUCTION 2-2 Manual 0-5100

Page 17

2.05 System Componants

Linear Drive

Operator

Terminal

SC-300 Interface

Enclosure

Linear Drive

Cable

Linear Drive

Power Cable

Operator Terminal

Cable

Power

Supply

CNC Cable

Art # A-08798_AB

OVERVIEW

SC-3000

Linear Drive contains the motor and control electronics for positioning the torch and controlling its

height.

Interface Enclosure provides the system power and the common connection point for all the systems

cables.

Remote Operator Terminal allow the operator to set and monitor all the parameters used to position and

control torch height.

Manual 0-5100 2-3 INTRODUCTION

Page 18

SC-3000

Art # A-08800

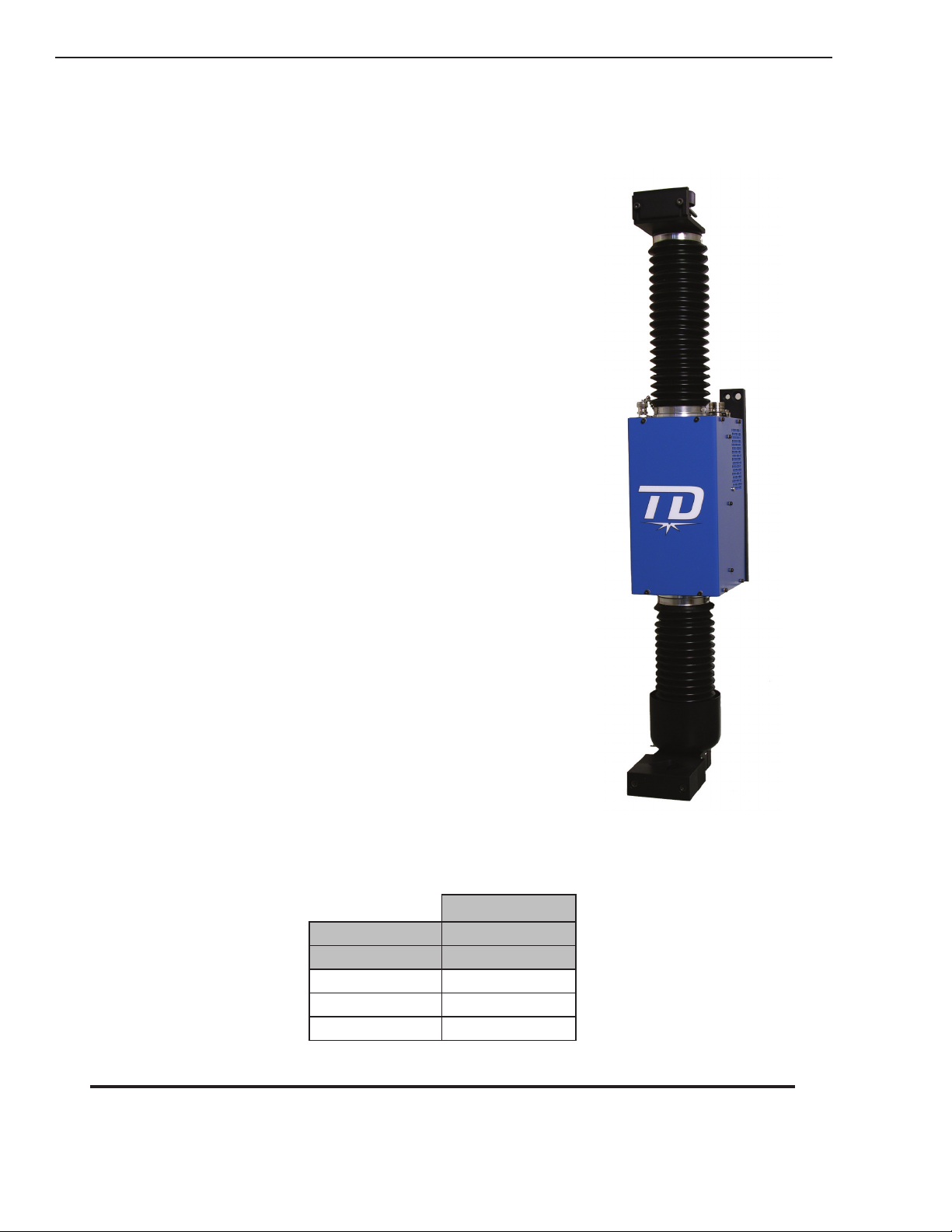

LINEAR DRIVE

Features

• Fast vertical drive for precise clearance control of plasma torches to metal sheets

• Integrated control

• Dust proof chamber protects rail and gear

• Built-in vertical collision protection

• 3-dimensional collision protection at the torch clamp

• Clamp for torch and leads

• High temperature proof bellows made of silicone rubber

• US Patent No. US 6,239,573 B1 / Euro Patent No. 0997801

General technical data

Motor 24 VDC / max. 6.5A

Power 100 W

Stroke 8.3" (210 mm)

Torch Clamp

for Torch Diameter 1.4"-2.1" (35-53 mm ) standard or

1.2"-1.4" (30-35 mm ) optional

Protective Earth Connector Screw M4

Weight 26.45 lbs. (12 kg )

Dimension of Housing approx. 4.5"x8.9"x6.3" (WxHxD)

(115x226x160 mm)

Dimensions overall 4.7"x2.8"x9.8" (WxHxD)

(approx.120x730x250 mm)

Features of versions

LINEAR DRIVE

Model SC-3000

TDC part no. 9-0404

Stroke 8.3" (210 mm)

Speed 3.1"/s (80 mm/s)

Load 26.45 lbs (12 kg)

Note:

The LINEAR DRIVE can only be used for vertical operation!

INTRODUCTION 2-4 Manual 0-5100

Page 19

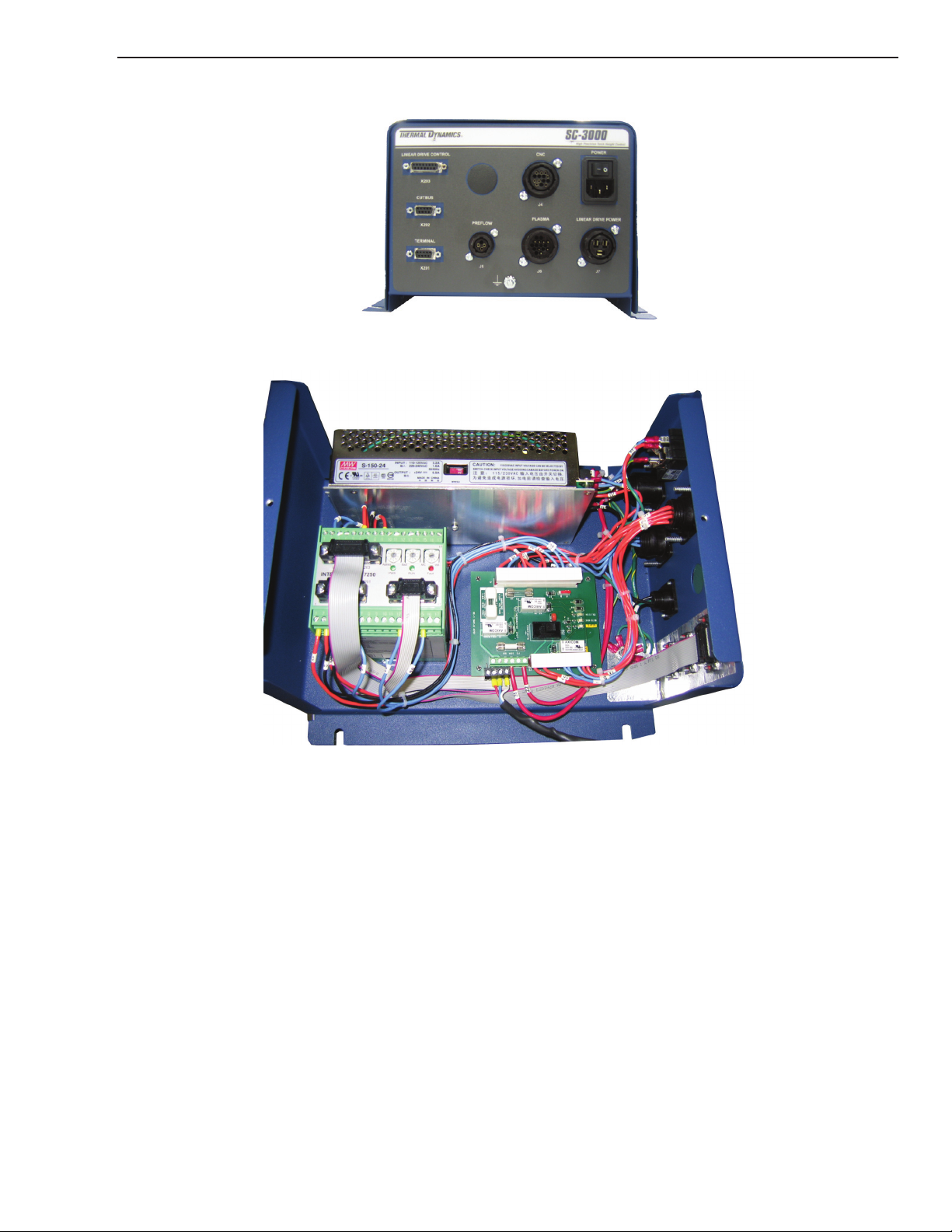

SC 3000 Interface Enclosure

Art # A-09098

Art # A-8938_AB

SC-3000

The Interface Enclosure is the central connection point for all the cables of the SC 3000 system. It contains:

• System power supply, 120 / 240 VAC to 24 VDC @ 6.5A (Appendix 4).

• Interface IHT 7250 Module providing communication between the Operator Terminal, the Plasma

Supply and the Linear Drive (Appendix 5).

• 9-0433 Control PCB providing system fuses, relays, selection switches for OK to Move and some

LEDs to assist troubleshooting.

Manual 0-5100 2-5 INTRODUCTION

Page 20

SC-3000

Art # A-08948_AB

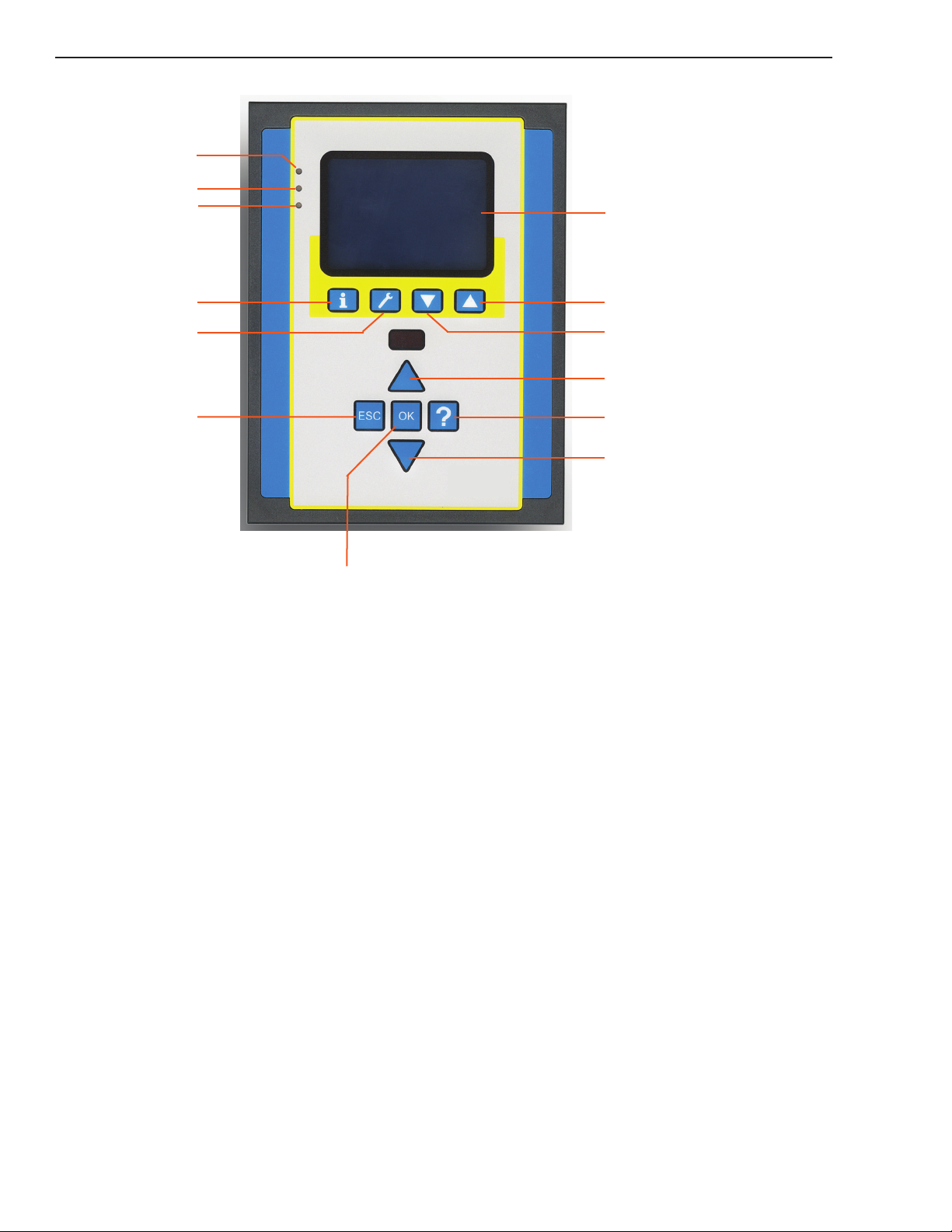

Information menu

Fast settings

ESCAPE

Back to menu

Manual UP/Clear Error

Manual DOWN

Menu upwards

Help Menu

Me

nu downwards

Ready

Communication

Error

Display

OK

ENTER

Control Panel

Technical Information

Power 24 VDC ±10%, with integrated reverse voltage protection

Consumption 60 mA

Over Voltage protection 30 V

Graphic Display 128x64 pixel blue/white with LED backlight

Serial Interface RS485

Environment temperature 32°-122°F (0 to +50°C)

Relative Humidity 98% (non condensing)

Protection class IP10 EN60529/IEC529 for assembly into operator console

Dimensions 6.3"x4.8"x1.4" (160x120x35 mm)

Weight approx. 0.4 kg

SC-3000 part no. 9-0427

Connecting cables can be found in table / chapter Devices and spare parts.

INTRODUCTION 2-6 Manual 0-5100

Page 21

SC-3000

Art # A-8938_AB

2.06 Application and System Description

The SC-3000 height control system enables a precise clearance control of plasma and oxyfuel torches

on cutting machines.

Using this height control system leads to high quality results when cutting with or without the inuence

of water.

The SC-3000 system automatically controls the distance between the plasma torch and the metal sheet.

Initial position finding of the work piece

Before the system starts cutting SC-3000 precisely detects the position of the work piece and nds the

pre-selected PIERCE HEIGHT (ignition height). This process is called initial position nding.

When cutting with plasma

• tactile, by softly touching the work piece

Explanation of the system and using the Interface Enclosure

SC3000 Torch Height Control system consists of a Linear Drive (Torch Lifter Station), a Remote

Operator Terminal and an Interface Enclosure plus various cables. The Interface Enclosure contains a

115V/230V to 24VDC power supply, an interface module and a PCB with fuses, relays, LEDs and set

up switches.

Inside the SC 3000 Enclosure 9-8145

Power Supply provides 24 VDC to operate the SC 3000. It is switch selectable for either 115 VAC or

230 VAC 50-60 Hz but failure to put the switch in the correct position can cause failure of the power

supply.

Interface Module

Interface Module is the green box next to the PCB. It has 3 rotary switches which allow selecting the

Address of the unit, The Baud Rate and the arc voltage input ratio. The Address and Baud Rate are used

for communication over the serial Cutbus. For now they should remain at their factory settings.

The Arc voltage may be set to accommodate different divided arc voltage ratios.

Manual 0-5100 2-7 INTRODUCTION

Page 22

SC-3000

ARC voltage

from

plasma-source

OPERATOR

TERMINAL

Art # A-08799_AB

CNC

Movement of Torch

The vertical torch movement for initial position nding and clearance control is handled using the SC-

3000- LINEAR DRIVE.

The built in electronics in this LINEAR DRIVE processes all control signals from the CNC and the

plasma arc voltage for height control.

The Electronic Enclosure connects to the CNC-machine control, to the plasma sources for receiving the

plasma arc voltage and connects to the OPERATOR TERMINAL.

System overview

INTRODUCTION 2-8 Manual 0-5100

Page 23

SECTION 3 SYSTEM:

!

INSTALLATION

3.01 Unpacking

1. Use the packing lists to identify and account for each item.

2. Inspect each item for possible shipping damage. If damage is evident, contact your distributor

and / or shipping company before proceeding with the installation.

3. Record each componant's model and serial numbers, purchase date and vendor name, in the information block at the front of this manual.

3.02 Handling Options

Be sure unit is lifted and transported safely and securely.

WARNING

Do not touch live electrical parts.

Disconnect input power cord before moving unit.

SC-3000

FALLING EQUIPMENT can cause serious personal injury and can damage equipment.

• Only persons of adequate physical strength should lift the unit.

• Lift unit using two hands. Do not use straps for lifting.

• Use optional cart or similar device of adequate capacity to move unit.

• Place unit on a proper skid and secure in place before transporting with a fork lift or other vehicle.

• Do not grip or lift the Linear Drive by the belows.

Manual 0-5100 3-1 INSTALLATION

Page 24

SC-3000

Art # A-08904

3.03 System Layout

CONNECTING CABLES

INSTALLATION 3-2 Manual 0-5100

Page 25

SC-3000

KEY DESCRIPTION 15’ (5m) 25’

(7.62m)

Linear Drive Control 9-0406 9-0407

A

B

C

D

E

Linear Drive Power 9-0408 9-0409

* CNC Control 9-8312 9-8313 9-8315 9-8316

Preflow Control 9-0430 9-0431 9-0432 9-0433

Plasma Control 9-0426 9-0427 9-0428 9-0429

F

Operator Terminal 9-0416 9-0417

* CNC Control also available in 125’ (38m) -- 9-8317

Table 3-1 SC3000 Cables

30’ (10m) 50’

(15.24M)

65’ (20m) 75’

(22.86m)

100’

(30.48m)

User supplied ground cables required for Linear Drive and Interface Enclosure must be minimum of 8

AWG (8qmm). Larger is better.

Manual 0-5100 3-3 INSTALLATION

Page 26

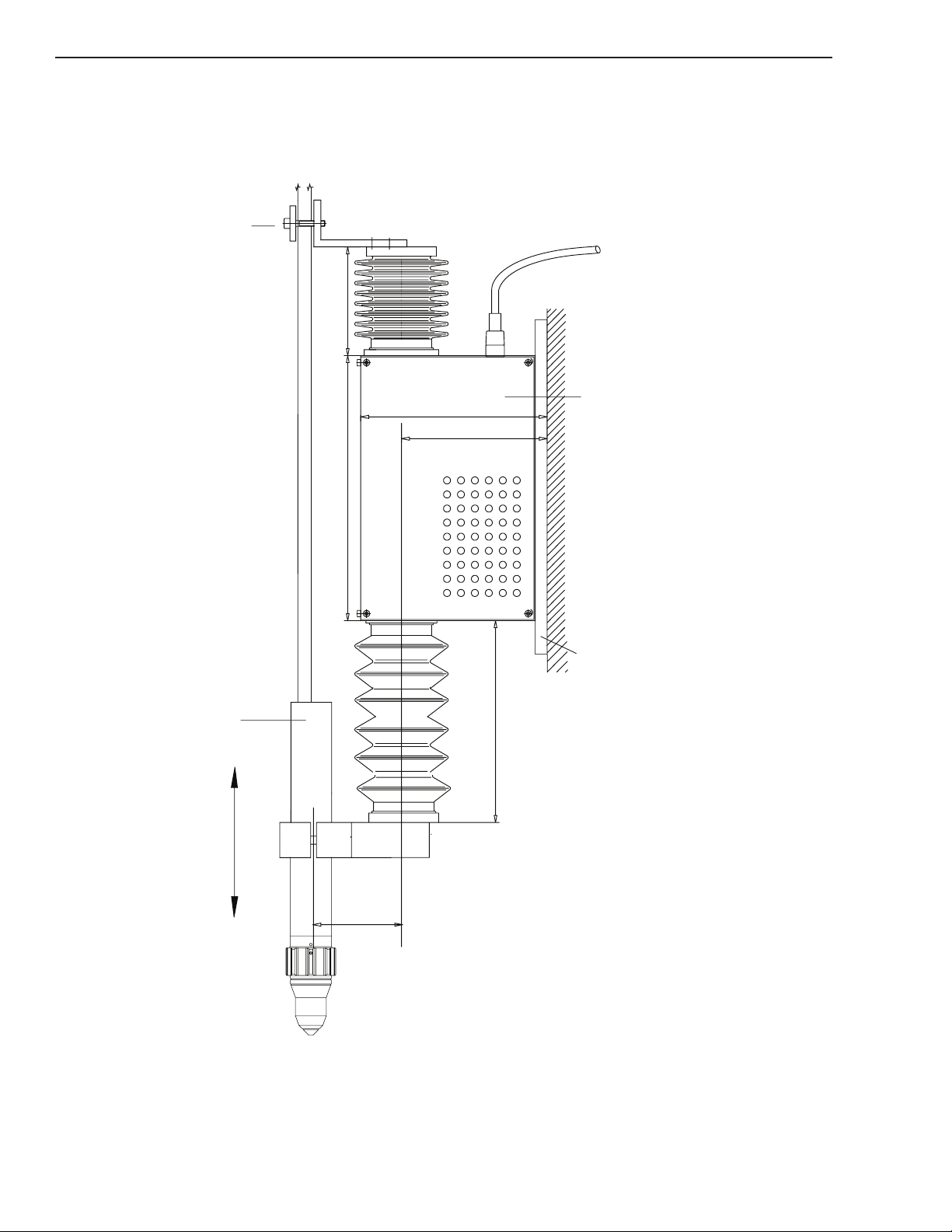

3.04 Installation

22 6mm - 8.9”

max. 360 / min.14 0mm

14.2” / 5.5”

min. 90 /max. 31 0mm

3.5” / 12.2”

160mm - 6.3”

120,4mm - 4.7”

76 mm

3”

Torch

Rear Mounting Plate

Cutting Machine

Linear Drive SC-3000

Hose Clamp

Art # A-08842

SIDE VIEW OF LINEAR DRIVE

View with plasma torch.

Dimensions in inches and milimeters

SC-3000

INSTALLATION 3-4 Manual 0-5100

Page 27

TOP VIEW LINEAR DRIVE SC-2343

Coax Cable

connector

for capacitiv

(Not Used)

Connector for Linear Drive

Control Cable

Connector for Linear

Drive Power Cable

PE

Grounding connector, to be

connected to machine ground

160mm

6.3”

120mm

4.7”

Art # A-08843

Electircal connectors

Dimensions inches and milimeters

SC-3000

CAUTION

Caution must be exercised to protect the bellows. Inspect for inward folds as these will cause premature wear.

Damaged bellows must be replaced as infiltrating dust can cause damage to the drive.

Manual 0-5100 3-5 INSTALLATION

Page 28

SC-3000

Front

Alternative

4 x M6 for rear

mounting

Art # A-08844

For vertical mounting at the cutting machine.

Optionally 4 screws M6 DIN 912 (drill hole dimensions 70x270 mm) or

4 screws M8 DIN 912 (drill hole dimensions 100x270 mm) can be used to x the Linear Drive from the

front.

INSTALLATION 3-6 Manual 0-5100

Page 29

SC-3000

Plasma Torch

Hoses, Cables

Check the sliding part of

LINEAR DRIVE:

Lift up here and

release it again.

The lifter slide must rest

lightly on the lower stop.

Adjust pressure with the

weight compensation knob.

A

djusting Knob for

Weight Compensation

LINEAR DRIVE - ADJUSTMENT OF WEIGHT COMPENSATION

This feature enables the adjustment of minimum vertical downward force when the nozzle

touches the work piece while getting the initial position.

The plasma torch must be mounted, the cable and the hose package must be clamped. The cable and

hoses outside must be exible so the sliding part of the LINEAR DRIVE is not hindered.

If the drive is hindered from moving, do not secure the cables and hoses in the clamp. If necessary use

an extended bracket.

1. Rotate the knob Weight Compensation clockwise until a slight lift up of the torch occurs. You

may hear a high pitched tone.

2. Rotate the knob counter clockwise until the tone stops and the lifter slide rests lightly on its

lower stop.

3. Check the weight compensation:

CAUTION!

To avoid excessive pressure between the torch and work piece, rotate knob “Weight Compensation”

counter clockwise only as far as necessary to lightly rest on the lower chock.

Manual 0-5100 3-7 INSTALLATION

Page 30

SC-3000

Push here

Ensure that deflection is not

blocked when adjusting screw has

been driven to hard.

Put in hex. wrench

#5mm

Hex. wrench #5mm

Collision

Protection Unit

Hose Clamp

Art # A-08907

LINEAR DRIVE - CHECK OF COLLISION PROTECTION

1. Push the torch clamp out of it’s normal position until the recess is left and release it again.

Check: The torch must return into correct vertical direction.

2. If the torch doesn’t safely return into the vertical direction then check that the hose does not hin-

dered the deection. If necessary correct the position of the hose.

However if the torch does not move exactly to the vertical direction then increase the deection

loading force:

3. Turn adjusting screw clockwise with a hex-wrench #5mm.

CAUTION!

Turn clockwise only as far as necessary to maintain sufficient deflection. The adjustment range of the vertical deflection force is from 30 to 120 N. If this is not maintained, the built-in collision switch doesn’t function and the

unit may be damaged in case of collision.

INSTALLATION 3-8 Manual 0-5100

Page 31

SC-3000

Pull out buckled folds

Art # A-08908_AB

CAUTION

Caution must be exercised to protect the bellows. Inspect for inward folds as these will cause premature wear.

Damaged bellows must be replaced as infiltrating dust can cause damage to the drive.

Manual 0-5100 3-9 INSTALLATION

Page 32

SC-3000

LINEAR DRIVE

PE

Grounding Terminal

Connector 6.3 mm/0.25 in. Faston

or terminal for M4 screw

Wire minimum 6 qmm/AWG8

Connect as short as possible

to machine ground

(less than 0.5 m).

LINEAR DRIVE

CONTROL CABLE

LINEAR DRIVE

POWER CABLE

Art # A-08909_AB

LINEAR DRIVE - ELECTRICAL CONNECTIONS

KEY DESCRIPTION 15’ (5m) 25’

A

B

INSTALLATION 3-10 Manual 0-5100

C

D

E

F

(7.62m)

30’ (10m) 50’

(15.24M)

65’ (20m) 75’

(22.86m)

(30.48m)

Linear Drive Control 9-0406 9-0407

Linear Drive Power 9-0408 9-0409

* CNC Control 9-8312 9-8313 9-8315 9-8316

Preflow Control 9-0430 9-0431 9-0432 9-0433

Plasma Control 9-0426 9-0427 9-0428 9-0429

Operator Terminal 9-0416 9-0417

* CNC Control also available in 125’ (38m) -- 9-8317

100’

Page 33

LINEAR DRIVE – GROUNDING OF TORCH CLAMP

Torch Clamp

Torch Clamp Grounding

Cable (Provided)

Grounding Cable

connect as short as possible

to machine ground

wire gauge min. 6 qmm/AWG8

(Customer Provided)

Art # A-08802_AB

This cable is required for safe operation !

The notes of grounding described in the Appendix must be observed for

proper usage.

Cable length: 0.6 m

Cable: 6 qmm/AWG 8, yellow/green lengthwise striped

2 connectors: Faston 6.3mm / 0.25 in.

SC-3000

CAUTION!

The length of the grounding cable up to the lower limit switch must not be so short as to hinder the movement of

the lifter.

Manual 0-5100 3-11 INSTALLATION

Page 34

SC-3000

24 VDC

DISABLE

(9)

OK to MOVE (0 VDC or Contact)

24VDC COMM

(15)

OK to MOVE +

24 VDC

24 VDC

OK TO MOVE (20VDC or C ontact)

OK to MOVE -

Plasma S tart

Co n t a ct cl o su r e

o r 2 0 V DC

(a p p l y 2 4V D C)

(13)

PLASMA START (24 VDC)

24 VDC

(12)

(a p p l y 2 4V D C)

24 VDC

(14)

J4 CNC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

(10)

(11)

Height Control D is able 24VDC

24 VDC

24 VDC

(16)

OK

SW 1

SW1

2

1

3

5

4

6

+20 VDC

Ar t # A -0 909 1

Ar t # A -0 909 2

CNC OUTPUT

'

+

USER RELAY

'

VDC

Use DCV from CNC for relay coil or if us ing 24 VDC from SC 3000

must als o connect CNC common to SC 3000 24 VDC COMM

''

''

'

'

'

'

24 VDC @ J4-1

24 VDC @ J4-3 or J4- 10

START (J4- 4 ) or D ISABLE ( J4-11)

DIOD E

24 VDC COMM @ J4-2

Revers e E MF protection

Diode required for DC relay

Single ended.

CNC I/O Requirements for SC 3000 Electronic Enclosure

Plasma Start and Height Control Disable require +24 VDC to activate. If the CNC outputs can supply

+24V it can be used directly if it is referenced to the 24 VDC Common at J4-2.

If the CNC has relays with NO contacts the 24 VDC available from the SC 3000 at J4-1, 3 & 10 may

be routed through those relays to supply the required input signal.

For other CNC outputs such as single ended open collector user supplied relays will need to be added.

INSTALLATION 3-12 Manual 0-5100

Page 35

SC-3000

Discrete signal

inputs X301

Discrete signal

ouputs X305

Art # A-09093

OK to MOVE

OK to Move output from SC-3000 is factory set for relay contacts. SW1 on the PCB in the SC-3000

Electronic Enclosure can be set to supply 20-24 VDC through the OK to Move contacts. Total current

from all the 24 VDC should not exceed 500 ma. Too much current will blow F1, 1A fuse on the SC3000 Enclosure PCB.

Other Optional Functions

The SC-3000 Electronic Enclosure provides an access hole for user installed connections. Most of

these functions may be selected with the remote operators terminal but may be more convenient to have

separate controls for some of them.

IHT 7250 Interface Module (inside Electronic Enclosure)

Manual 0-5100 3-13 INSTALLATION

Page 36

SC-3000

COL

J3

1

2

3

4

5

6

Art # A-09099

Inputs X301

All of these require 24 VDC applied to activate. 24 VDC is available at output terminal X305-1 or one

of the +V terminals of the 24 VDC power supply.

X301-10 ------ Retract to ¾” (20 mm)

X301-11 ------ Retract to 2” (50 mm)

X301-12 ------ Scrap Cutting (bypasses nding height, set cutting height manually,

apply START.)

X301-14 ------ Manual Up

X301-15 ------ Manual Down

Outputs X305

Output signals are 20-24 VDC when active. Their mane purpose is to indicate to the CNC what the

status of the SC3000 is. These outputs could also be used to drive indicators lights for a visual status

indication.

They are:

X305-7 ----- Upper Limit. Arc voltage error has exceeded upper limit setting disabling

the height control until arc voltage drops below the limit. See explanation

of setting Upper Limit for more details.

X305-8 ----- Delay Time. SC3000 is not actively controlling height until Pierce Delay

and Control Delay has ended.

X305-10---- Control Active. SC3000 is actively controlling height.

X305-11 ---- Error. An error has occurred.

X305-14 ---- Reference/Retract Position. Torch has moved to it’s selected retract

position.

X305-16 ---- Reference Position. Torch has moved to it’s initial maximum retract

Position, possibly due to an error or a collision?

J3-4,5,6 ---- Collision is a special case where we have provided NO (normally open)

and NC (normally closed) relay contacts driven by the SC 3000’s built in collision sensor. Make con-

nections to J3 on the Interface PCB inside the Interface Enclosure.

For contact closure connect to J3-5 (comm.) and J3-6 (NO). For NC contact that opens with collision connect between J3-5 (comm.) and J3-4 (NC). Can also connect the J3-5 to +24 VDC (or other

voltage) if a voltage signal is require instead of contact closure.

INSTALLATION 3-14 Manual 0-5100

Page 37

R3

10k

R4 22k

R3

3,3k

C1

220n

R5 10k

74HCT14

GND

Input

Art # A-08946

Digital Input of Control Signals

R1

10k

PTC

+24V

T1

125 Ohm

R2 22 Ohm

Output

D1

D2

GND

Art # A-08947

SC-3000

Digital Output of Control Signals

Manual 0-5100 3-15 INSTALLATION

Page 38

SC-3000

Art # A-08919

Connection for

OPERATOR TERMINAL CA BLE

not used

not used

Attention when mounting the operator panel:

Connect PE-Terminal to PE-potential

of machine grounding.

Faston connector 6.3 mm / 0.25 in.

Wire gauge 0.75 qmm / 18 AWG

Art # A-08920_AB

OPTIONAL MOUNTING OF THE OPERATOR TERMINAL 9-0410

INSTALLATION 3-16 Manual 0-5100

Page 39

SC-3000

1 2 3 4 5 6

ON

█ █ █ █

OFF

█ █

Art # A-08921

OPERATOR TERMINAL CABLE

Art # A-09090

DEFAULT SETTING OF DIP-SWITCH

Do not change this setting!

OPERATOR TERMINAL - ELECTRICAL CONNECTION

The Operator Terminal Cable connects the Operator Terminal with the connector X201 at the Interface.

The power supply is provided by this cable as well.

Manual 0-5100 3-17 INSTALLATION

Page 40

SC-3000

3.05 Checking of Grounding

The following componants must be connected to

machine ground (PE) as described in the installation instructions to obtain a safe and reliable

operating system

• Control Interface 9-0405

• Linear Drive 9-0404

• Torch Clamp

INSTALLATION 3-18 Manual 0-5100

Page 41

SECTION 4 SYSTEM:

!

Both green LED’s should be on

Art # A-08923

OPERATION

WARNING!

Never put your hand under the torch.

4.01 Requirements and Check List for first Start-up

Step Instruction OK √

1 Are all cables and wires connected and locked properly?

2 Can the torch move in all directions without hitting anything?

Is the linear drive in vertical direction and mounted correctly?

3 Are the torch and the cable hose mounted correctly, weight

compensation and collision protection set properly?

4 Are all settings and signals from and to SC-3000 correct?

5 Are all grounding connections from the SC-3000 system

to the cutting machine and all cable shields connected to

machine ground as described in the instructions?

SC-3000

6 Is the power supply (+ 24V/6A) of the SC-3000 System

installed properly?

7 Is the resistance between ground and earth of the plasma

source less than 3 Ohm?

8 All shields of cables going to the plasma source should

not be connected at the plasma source. They must be

connected in the control cabinet with the shortest possible

connection to the machine ground.

4.02 Power Up

1. The Linear Drive moves the torch up to the upper reference position .

2. Operation check at the interface (Inside Electrical Enclosure).

3. Check operation at the Operator Terminal. After the power is switched on, an initialisation process runs for approx. 5 seconds. The green LED at the Operator Terminal is on.

Manual 0-5100 4-1 OPERATION

Page 42

SC-3000

Firmware Version

and Date

Active Keys

Status of

Initialisation

Art # A-08924

Art # A-08925

Art # A-08926

4. After initialisation, the main menu appears.

5. If the terminal displays ‘Communication Error’ the serial communication has failed. At the same

time the yellow LED will ash.

Check the power to Linear Drive.

Check the connection to Operator Terminal Cable.

OPERATION 4-2 Manual 0-5100

Page 43

4.03 OPERATOR TERMINAL Menu-Overview

Art # A-08948_AB

Information menu

Fast settings

ESCAPE

Back to menu

Manual UP/Clear Error

Manual DOWN

Menu upwards

Help Menu

Me

nu downwards

Ready

Communication

Error

Display

OK

ENTER

Operator Terminal

7260

Mode Select

Cutting Height

ARC Voltage

Capacitive Height

Device Info

Device Info

Serial No.

Hardware Version

Software Version

Status Info

Commands

Status

Corner ? Ref. Position ?

Upper Treshold ? Cap . Active ?

Control Active ? Cycle active ?

Real Voltage 122.5 V

Reset

Regulator Off

Threshold Off

Scrap Cut

Cut Height

Pierce Delay

Pierce Height

Control Delay

Ideal Voltage

Linear Drive

UP/DOWN

Help Text

?

ESC

Error Register

Automatic in the Display

Fault Weight Compensation ?

Fault ARC Voltage ?

Collision ?

Overload ?

Motor Polarity ?

Encoder ?

Error ?

OK

Error Reset

Press Button MAN UP

Parameter Cutheight

Dependent on choice of

control mode

Pierce Delay

Dynamic

Elevation Height

Retract Position

Pierce Height

Control Delay

Upper Threshold

Gas Pre-Flow

System Properties

Languages

English

German

System Parameters

Startup Time

OK

OK

OK

OK

Display

Cutting Height

Ideal Voltage

Real Voltage

i

OK

Main Menu

Commands and Status

Parameter Favorite

Cutting Height

for kerf and edge detection

Select mm / inch

End of Cut

Art # A-08927

SC-3000

Manual 0-5100 4-3 OPERATION

Page 44

SC-3000

Operator Terminal

Device Info

ESC

Parameter Cutheight

System Properties

Languages

English

German

System Parameter

OK

Display

Cutting Height

Ideal Voltage

Real Voltage

Main Menu

Control Mode

Art # A-08928_AB

ESC

OK

Device Info

Select MM/Inch

Unit Select

Unit: MM

Unit: Inch

System Properties

4.04 OPERATOR TERMINAL SETTINGS

Setting of Language and measurement units.

OPERATION 4-4 Manual 0-5100

Page 45

SC-3000

Operator Terminal

Mode Select

ARC Voltage

Device Info

ESC

Parameter Cutheight

System Properties

OK

Display

Cutting Height

Ideal Voltage

Real Voltage

Main Menu

Cutting Height Standard Setting

Art # A-08929

SETTING OF OPERATION MODES

There are two Operation Modes. For more detailed explanation of modes and their effects go to section

4.11.

1. ARC Voltage

Cutting height will be set via arc voltage setting.

This mode can be used for test cuts.

Example: 130.0 V

2. Cutting Height

Cutting height will be directly set in mm.

This is the standard operation mode.

Example: 2.5 mm

Manual 0-5100 4-5 OPERATION

Page 46

SC-3000

Mode Select

Device Info

ESC

Parameter Cutheight

Dependent on choice of

control mode

Pierce Delay

Dynamic

Elevation Height

Retract Position

Pierce Height

Control Delay

Upper Threshold

Gas Pre-Flow

System Properties

OK

Main Menu

Cutting Height

Select mm / inch

End of Cut

Operator Terminal

Display

Cutting Height

Ideal Voltage

Real Voltage

Time during piercing

Starts with signal START XY

Additional lifting during ignition

Distance during igntion

Reaction rate of clearance control

Blocking of clearance control when crossing kerfs

Height after end of cutting

Gas Pre-Flow starts with START INITIAL POSITION FINDING

Setting in percent of ideal arc voltage to detect end of cut

standard setting 85%

Height during cutting

Art # A-08930

CUTTING SETTINGS

For detailed explanation go to section 4.12.

OPERATION 4-6 Manual 0-5100

Page 47

COMMANDS AND STATUS

Operator Terminal

Status Info

Commands

Status

Corner ? Ref. Position ?

Kerf ?

Control active ?

Cycle active ?

Real Voltage 122.5 V

Reset

Regulator Off

Threshold Off

Scrap Cut

OK

Display

Cutting Height

Ideal Voltage

Real Voltage

i

OK

Commands and

Status

Linear Drive moves to upper reference

position

Clearance control is stopped

Initial position finding is stopped

Kerf and edge detection off

The Status shows the functions which are active during cutting.

Art # A-08931

SC-3000

Manual 0-5100 4-7 OPERATION

Page 48

SC-3000

Operator Terminal

Cut Height

Pierce Delay

Pierce Height

Control Delay

Display

Cutting Height

Ideal Voltage

Real Voltage

Parameter Favorite

Art # A-08932

Operator Terminal

Ideal Voltage

Linear Drive

UP/DOWN

Help Text

?

Display

Cutting Height

Ideal Voltage

Real Voltage

Art # A-08933

FAVORITE MENU

Using this menu, the main cutting parameters can be set quickly.

ADDITIONAL FUNCTIONS

OPERATION 4-8 Manual 0-5100

Page 49

4.05 SIGNAL FLOW DURING PLASMA CUTTING

From To Signal

CNC Initial Pos. Start

Plasma

Separate Ignition

Plasma

CNC Ok To Move

Delay Time

Control Active

Surface of work piece

Reference Position

Cutting Height

Plasma

Time / Track

Cutting On

Cutting Off

Pierce Height

Elevation Height

Start XY

Retract Position

Corner

1 2

3 4

5 6 State

Clearance

Art # A-08934_AB

SC-3000

SC-3000

SC-3000

SC-3000

SC-3000

SC-3000

SC-3000

SC-3000

OK PS

Plasma

CNC

SC-3000

4.06 SC 3000 Operation Sequence

Denitions:

THC

• Torch Height Control, in this case refers to the SC3000.

Initial Position Start

• Input where Start from CNC is applied to start THC’s height nding sequence.

Ready (Start XY)

• Input to THC for arc transferred signal from plasma (OK to Move).

Manual 0-5100 4-9 OPERATION

Page 50

SC-3000

Enable Ignition Plasma

• Originally intended to start the plasma, now used to start preow while nding height when that

feature is enabled (Operator Terminal Preow set to non-zero)

Separate Ignition Plasma

• Signal activates Start relay on PCB to supply isolated Start to plasma.

OK to Move-PS (plasma)

• Signal from plasma indicating arc transfer has occurred. Is routed directly to the THC and indirectly to CNC controller via OK to Move relay on PCB .

THC Pierce Delay

• Time (parameter set on the operator terminal) following arc transfer that torch remains at pierce or

elevated height.

OK to Move (THC)

• Signal from THC, active at end of THC pierce delay.

CNC Pierce Delay

• Dwell time after CNC receives OK to Move from THC or Plasma before CNC starts torch horizontal motion.

THC Preow time

• Setting on Operator Terminal (OT) used for preow during height nding. When the Operator Terminal Preow is set to zero plasma preow will not start until THC has positioned torch at pierce

height. Then gas ows for the full plasma preow time, default setting is 2 sec.

• Setting Preow to anything other than zero will activate Enable Ignition Plasma sending signal

to the plasma supply’s Preow On input (when cable is wired to TB2-3&4 of CCM) to start gas

ow at the same time that Initial Position Start is received from CNC. Gas ow starts immediately

and continues until Separate Ignition Plasma sends Start to plasma. If the time has already exceed

the plasma preow time (default is 2 sec) then pilot ignites immediately. If time has been less than

plasma preow time, plasma waits for the time remaining before igniting pilot.

THC Control delay

• Often called AVC delay, this is time starting when torch is moved to cut height until THC starts

controlling height to the sampled arc voltage.

OPERATION 4-10 Manual 0-5100

Page 51

Operation Sequence:

Assumes SW2, OK Source switch, on enclosure PCB set to “B” its factory default position.

1. CNC Start to THC Initial Position Start input.

a. If Preow on THC terminal is set to zero the Torch moves to nd plate then moves to pierce

height.

b. If Preow is not zero Enable Ignition Plasma becomes active starting preow via the plasma’s

Preow On input (Refer to section 4.10 for more details).Torch moves to nd the plate then

moves to pierce height.

2. Height found, torch at pierce height.

a. If Preow on THC terminal is set to zero the Start (Enable Ignition Plasma) to plasma imitates

the plasma Preow (default time 2 secs).. As Preow time ends pilot arc is ignited.

b. If Preow is not zero the Separate Ignition Plasma becomes active, sends Start to the Plasma.

The plasma whose preow was already started by Enable Ignition Plasma, ignites its Pilot arc

immediately if plasma’s preow timer has ended or as soon as it does end.

3. Arc Transfers, Plasma supply OK to Move on.

SC-3000

a. OK from plasma sent to THC Ready (Start XY) input. This moves torch to Elevate Height if

any set. This starts THC Pierce Delay.

NOTE

Torch remains at pierce or elevate height until THC Pierce Delay ends. This should be set equal to or longer than

CNC pierce delay. Longer allows torch to move away from the pierce slag before coming down to cut height.

b. At the same time, OK from plasma closes OK relay on SC3000 Enclosure PCB sending OK

to Move to the CNC.

• Motion delay for piercing is determined by CNC delay. In case CNC does not have ability

to set Pierce Delay then set SW2 to “A” and set desired pierce dwell time on THC Pierce

Delay. Torch will come down to cut height same time motion starts.

4. CNC Pierce dwell (delay) time ends.

a. CNC start moving torch horizontally.

5. THC Pierce Delay ends, torch moves down to Cut Height.

a. Control Delay time starts. THC is sampling the arc voltage, at end of control delay THC uses

the last stable sampled voltage as a reference to control height for rest of cut.

6. Corner

a. As the cutting table moves the torch through a corner or small radius the speed will be re-

duced. This causes the arc voltage to increase but we don’t want the THC to respond to this

change as it would move the torch into the plate. The CNC (cutting table controller) provides

a signal when it reduces speed which can be used to inhibit, disable or lock out the height control during these speed reductions.

Manual 0-5100 4-11 OPERATION

Page 52

SC-3000

7. End of Cut

a. The SC3000 requires 3 things happen to recognize the cut has ended.

• Start signal (Initial Position Start) from the CNC is removed.

• Cutting arc has ended (Ok to Move at Ready input is removed).

• Plasma Power supply output voltage reduces to a % of the normal cutting voltage set by

the End of Cut parameter (default 85%).

8. Retract

a. Following the end of cut the torch retracts to clear tipped up parts while moving to the next

cut position. The retract distance is set by the Retract Position parameter.

4.07 LOSS OF PLASMA ARC

It is possible that the plasma arc is lost during cutting process

The Linear Drive moves back up to the reference position as arc voltage is missing and the clearance

control cannot operate anymore.

4.08 DETECTION OF KERFS AND EDGES DURING CUTTING

This feature avoids that the plasma torch moves down into the kerf which has already been cut whilst

moving across.

If the adjustable Upper Threshold exceeds the limit during cutting, the clearance control will be disabled

when crossing kerfs.

Upper Threshold

When crossing a kerf or hole or going off the edge of the plate, arc voltage rises very rapidly. System

will respond to the rise in voltage by lowering the torch trying to keep voltage constant. To prevent this

an Upper Limit is set so when arc voltage exceeds the cutting voltage by the % specied by the Upper

Limit setting system stops trying to control height.

NOTE

For thicker metal which tend to be fairly flat and using lower cutting speeds the arc voltage doesn’t change very

rapidly except when crossing kerfs & holes so using a lower % will respond quicker, typically 5-10%. For higher

speeds on thinner or warped metal where normal cutting voltage changes more rapidly, use a higher number around

10-15% or even 20%.

OPERATION 4-12 Manual 0-5100

Page 53

Start

Crossing Kerf

Work piece

Threshold

e.g. 125V

ARC Voltage

e.g. 120V

Time / Track

Display at Operator Terminal in

the Status-Menu

Clearance Control on

Clearance Control off

Art # A-08935

SC-3000

Manual 0-5100 4-13 OPERATION

Page 54

SC-3000

From To Signal