Page 1

Raider 10,000 Pro

DC CC/CV Welding Generator

STICK

MIG

AUXILIARY POWER

Owners Manual

Date 06/01/04 KLA

MI335-06-00-05

1

Manual 430429-501

Page 2

Date 06/01/04 KLA

2

Manual 430429-501

Page 3

Table of Contents

Statement of Warranty .................................................................................................................................................................5

SECTION 1: GENERAL INFORMATION ................................................................................................................................6

1.01 Notes, Cautions and Warnings........................................................................................................................................6

1.02 Important Safety Precautions..........................................................................................................................................6

1.03 Publications.....................................................................................................................................................................7

1.04 Note, Attention et Avertissement....................................................................................................................................8

1.05 Precautions De Securite Importantes ..............................................................................................................................8

1.06 Documents De Reference..............................................................................................................................................10

SECTION 2: TECHNICAL SPECIFICATIONS....................................................................................................................13

2.01 Specifications.................................................................................................................................................................13

2.02 Volt-Amp Curve ............................................................................................................................................................14

2.03 Duty Cycle .....................................................................................................................................................................14

2.04 Front Panel Descriptions................................................................................................................................................14

2.05 Dimensions and Weight.................................................................................................................................................15

2.06 Maximum Welding Generator Operating Angles ..........................................................................................................15

2.07 Installing Welding Generator.........................................................................................................................................16

2.08 Location .........................................................................................................................................................................16

2.09 Air Flow Clearance........................................................................................................................................................16

2.10 Generator Auxiliary Power System................................................................................................................................17

2.11 Wiring Optional 230 Volt Plug ......................................................................................................................................18

2.12 Grounding The Generator ..............................................................................................................................................18

2.13 When Connecting To Home, Shop, or Farm Wiring......................................................................................................19

2.14 Auxiliary Power Requirements......................................................................................................................................19

2.15 Simultaneous Welding and Power .................................................................................................................................21

2.16 Selecting and Preparing Weld Output Cables................................................................................................................21

SECTION 3: TROUBLE SHOOTING GUIDE.........................................................................................................................23

3.01 There is No Auxiliary Voltage and/or Welding Current................................................................................................24

3.02 The Generator Is De-Energized when Load is connected ..............................................................................................24

3.03 Excessive Fall of Voltage When The Load is Connected ..............................................................................................25

3.04 Single Phase Receptacle Out Of Balance While at Idling..............................................................................................25

3.05 Insufficient Welding Current .........................................................................................................................................25

3.06 The Battery Runs down Frequently................................................................................................................................25

Section 5 Parts List ....................................................................................................................................................................26

5.01 Stator Parts.....................................................................................................................................................................26

5.02 Front Panel Parts............................................................................................................................................................28

5.03 Sheet Metal Parts ...........................................................................................................................................................30

5.04 Engine Related Parts......................................................................................................................................................32

5.05 Common Engine Part Numbers......................................................................................................................................34

5.06 Schematic.......................................................................................................................................................................35

5.07 14 pin Receptacle Signals ..............................................................................................................................................36

Date 06/01/04 KLA

3

Manual 430429-501

Page 4

Proposition 65

WARNING: This product, when used for welding or cutting,

produces fumes or gases which contain chemicals known to the

State of California to cause birth defects and, in some cases,

cancer. (California Health & Safety Code Sec.25249.5 et seq.)

Date 06/01/04 KLA

4

Manual 430429-501

Page 5

Statement of Warranty

LIMITED WARRANTY: Thermal Arc®, Inc., A Thermadyne Company, hereafter, “Thermal Arc” warrants to customers of its

authorized distributors hereafter “Thermal; Arc” that its products will be free of defects in workmanship or material. Should any failure to

conform to this warranty appear within the time period applicable to the Thermal Arc products as stated below, Thermal Arc shall, upon

notification thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance with Thermal

Arc’s specifications, instructions, recommendations and recognized standard industry practice, and not subject to misuse, repair, neglect,

alteration, or accident, correct such defects by suitable repair or replacement, at Thermal Arc’s sole option, of any components or parts of

the product determined by Thermal Arc to be defective.

THERMAL ARC MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHERS, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: Thermal Arc shall not under any circumstances be liable for special, indirect or consequential damages,

such as, but not limited to, lost profits and business interruption. The remedies of the Purchaser set forth herein are exclusive and the

liability of Thermal Arc with respect to any contract, or anything done in connection therewith such as the performance or breach thereof,

or from the manufacture, sale, delivery, resale, or use of any goods covered by or furnished by Thermal Arc whether arising out of contract,

negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly provided herein, exceed the price of the goods

upon which such liability is based. No employee, agent, or representative of Thermal Arc is authorized to change this warranty in any way

or grant any other warranty.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF REPLACEMENT PARTS OR ACCESSORIES ARE

USED WHICH IN THERMAL ARC’S SOLE JUDGEMENT MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY

THERMAL ARC PRODUCT.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE PRODUCT IS SOLD TO PURCHASER BY NONAUTHORIZED PERSONS.

The warranty is effective for the time stated below beginning on the date that the authorized distributor delivers the products to the

Purchaser. Notwithstanding the foregoing, in no event shall the warranty period extend more than the time stated plus one year from the

date Thermal Arc delivered the product to the authorized distributor.

POWER SUPPLIES POWER SUPPLIES & WIRE FEEDERS LABOR

MAIN POWER MAGNETICS (STATIC & ROTATING) 3 YEAR 3 YEAR

ORIGINAL MAIN POWER RECTIFIER 3 YEAR 3 YEAR

POWER SWITCHING SEMI-CONDUCTORS & CONTROL PC BOARD 3 YEAR 3 YEAR

ALL OTHER CIRCUITS AND COMPONENTS INCLUDING 1 YEAR 1 YEAR

BUT NOT LIMITED TO, CONTACTORS, RELAYS,

SOLENOIDS, PUMPS, SWITCHES, MOTORS

ENGINES: ENIGINES ARE NOT WARRANTED BY THERMAL ARC, ALTHOUGH MOST ARE WARRANTED BY THE

ENGINE MANUFACTURER, SEE THE ENGINE MANUFACTURES WARRANTY FOR DETAILS.

CONSOLES, CONTROL EQUIPMENT, HEAT 1 YEAR 1 YEAR

EXCHANGES, AND ACCESSORY EQUIPMENT

PLASMA TORCH AND LEADS, AND REMOTE CONTROLS 180 DAYS 180 DAYS

REPAIR/REPLACEMENT PARTS 90 DAYS 90 DAYS

NOTE: Dragster

Warranty repairs or replacement claims under this limited warranty must be submitted to Thermal Arc by an authorized Thermal Arc repair

facility within thirty (30) days of purchaser’s notice of any Warranty Claim. No transportation costs of any kind will be paid under this

warranty. Transportation charges to send products to an authorized warranty repair facility shall be the responsibility of the Purchaser. All

returned goods shall be at the Purchaser’s risk and expense. This warranty supersedes all previous Thermal Arc warranties.

Thermal Arc® is a Registered Trademark of Thermadyne Industries Inc.

TM

80 excluded from this policy. Refer to Dragster

TM

80 warranty in Dragster

TM

80 Owner’s Manual.

Effective April 1, 2002

Date 06/01/04 KLA

5

Manual 430429-501

Page 6

SECTION 1: GENERAL

INFORMATION

1.01 Notes, Cautions and

Warnings

Throughout this manual, notes, cautions, and warnings are

used to highlight important information. These highlights

are categorized as follows:

NOTE

An operation, procedure, or background

information which requires additional emphasis

or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may

cause damage to the equipment.

WARNING

A procedure which, if not properly followed, may

cause injury to the operator or others in the

operating area.

1.02 Important Safety

• Use an air-supplied respirator if ventilation is not

adequate to remove all fumes and gases.

• The kinds of fumes and gases from the arc

welding/cutting depend on the kind of metal being

used, coatings on the metal, and the different

processes. You must be very careful when cutting or

welding any metals which may contain one or more

of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets (MSDS)

that should be supplied with the material you are

using. These MSDSs will give you the information

regarding the kind and amount of fumes and gases

that may be dangerous to your health.

• For information on how to test for fumes and gases in

your workplace, refer to item 1 in Subsection 1.03,

Publications in this manual.

• Use special equipment, such as water or down draft

welding/cutting tables, to capture fumes and gases.

• Do not use the welding torch in an area where

combustible or explosive gases or materials are

located.

• Phosgene, a toxic gas, is generated from the vapors of

chlorinated solvents and cleansers. Remove all

sources of these vapors.

Precautions

WARNING

OPERATION AND MAINTENANCE OF ARC

WELDING EQUIPMENT CAN BE

DANGEROUS AND HAZARDOUS TO YOUR

HEALTH.

To prevent possible injury, read, understand and

follow all warnings, safety precautions and

instructions before using the equipment. Call 1603-298-5711 or your local distributor if you

have any questions.

GASES AND FUMES

Gases and fumes produced during the Arc welding/cutting

process can be dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area.

Keep your head out of the welding fume plume.

ELECTRIC SHOCK

Electric Shock can injure or kill. The arc welding process

uses and produces high voltage electrical energy. This

electric energy can cause severe or fatal shock to the

operator or others in the workplace.

• Never touch any parts that are electrically “live” or

“hot.”

• Wear dry gloves and clothing. Insulate yourself from

the work piece or other parts of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist

or damp.

GENERAL INFORMATION

6

Page 7

• Install and maintain equipment according to NEC

code, refer to item 4 in Subsection 1.03,

Publications.

• Disconnect power source before performing any

service or repairs.

• Read and follow all the instructions in the Operating

Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or

the arc weld.

• Be sure there is no combustible or flammable

material in the workplace. Any material that cannot

be removed must be protected.

• Ventilate all flammable or explosive vapors from the

workplace.

• Do not cut or weld on containers that may have held

combustibles.

• Provide a fire watch when working in an area where

fire hazards may exist.

• Hydrogen gas may be formed and trapped under

aluminum workpieces when they are cut underwater

or while using a water table. DO NOT cut

aluminum alloys underwater or on a water table

unless the hydrogen gas can be eliminated or

dissipated. Trapped hydrogen gas that is ignited

will cause an explosion.

NOISE

Noise can cause permanent hearing loss. Arc

welding/cutting processes can cause noise levels to

exceed safe limits. You must protect your ears from loud

noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear

protective ear plugs and/or ear muffs. Protect others

in the workplace.

• Noise levels should be measured to be sure the

decibels (sound) do not exceed safe levels.

• For information on how to test for noise, see item 1 in

Subsection 1.03, Publications, in this manual.

ARC WELDING RAYS

Arc Welding/Cutting Rays can injure your eyes and burn

your skin. The arc welding/cutting process produces very

bright ultra violet and infra red light. These arc rays will

damage your eyes and burn your skin if you are not

properly protected.

• To protect your eyes, always wear a welding helmet

or shield. Also always wear safety glasses with side

shields, goggles or other protective eye wear.

• Wear welding gloves and suitable clothing to protect

your skin from the arc rays and sparks.

• Keep helmet and safety glasses in good condition.

Replace lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use

protective booths, screens or shields.

• Use the shade of lens as recommended in Subsection

1.03, item 4.

1.03 Publications

Refer to the following standards or their latest revisions

for more information:

1. OSHA, SAFETY AND HEALTH STANDARDS,

29CFR 1910, obtainable from the Superintendent of

Documents, U.S. Government Printing Office,

Washington, D.C. 20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND

CUTTING, obtainable from the American Welding

Society, 550 N.W. LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC

WELDING AND GAS WELDING AND CUTTING,

obtainable from the Superintendent of Documents,

U.S. Government Printing Office, Washington, D.C.

20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR

OCCUPATION AND EDUCATIONAL EYE AND

FACE PROTECTION, obtainable from American

National Standards Institute, 1430 Broadway, New

York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY-TOE FOOTWEAR, obtainable from the

American National Standards Institute, 1430

Broadway, New York, NY 10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE

USE OF CUTTING AND WELDING PROCESSES,

obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

7. AWS Standard A6.0, WELDING AND CUTTING

CONTAINERS WHICH HAVE HELD

COMBUSTIBLES, obtainable from American

Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS

FOR WELDING, CUTTING AND ALLIED

PROCESSES, obtainable from the National Fire

Protection Association, Batterymarch Park, Quincy,

GENERAL INFORMATION

MA 02269

7

Page 8

9. NFPA Standard 70, NATIONAL ELECTRICAL

CODE, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING

PROCESSES, obtainable from the National Fire

Protection Association, Batterymarch Park, Quincy,

MA 02269

11.CGA Pamphlet P-1, SAFE HANDLING OF

COMPRESSED GASES IN CYLINDERS, obtainable

from the Compressed Gas Association, 1235 Jefferson

Davis Highway, Suite 501, Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN

WELDING AND CUTTING, obtainable from the

Canadian Standards Association, Standards Sales, 178

Rexdale Boulevard, Rexdale, Ontario, Canada M9W

1R3

13. NWSA booklet, WELDING SAFETY

BIBLIOGRAPHY obtainable from the National

Welding Supply Association, 1900 Arch Street,

Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1,

RECOMMENDED SAFE PRACTICES FOR THE

PREPARATION FOR WELDING AND CUTTING

OF CONTAINERS AND PIPING THAT HAVE

HELD HAZARDOUS SUBSTANCES, obtainable

from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

15 ANSI Standard Z88.2, PRACTICE FOR

RESPIRATORY PROTECTION, obtainable from

American National Standards Institute, 1430

Broadway, New York, NY 10018

AVERTISSEMENT

Toute procédure pouvant provoquer des

blessures de l’opérateur ou des autres personnes

se trouvant dans la zone de travail en cas de

non-respect de la procédure en question.

1.05 Precautions De

Securite Importantes

AVERTISSEMENT

L’OPÉRATION ET LA MAINTENANCE DU

MATÉRIEL DE SOUDAGE À L’ARC AU JET

DE PLASMA PEUVENT PRÉSENTER DES

RISQUES ET DES DANGERS DE SANTÉ.

Il faut communiquer aux opérateurs et au

personnel TOUS les dangers possibles. Afin

d’éviter les blessures possibles, lisez, comprenez

et suivez tous les avertissements, toutes les

précautions de sécurité et toutes les consignes

avant d’utiliser le matériel. Composez le + 603298-5711 ou votre distributeur local si vous avez

des questions.

1.04 Note, Attention et

Avertissement

Dans ce manuel, les mots “note,” “attention,” et

“avertissement” sont utilisés pour mettre en relief des

informations à caractère important. Ces mises en relief

sont classifiées comme suit :

NOTE

Toute opération, procédure ou renseignement

général sur lequel il importe d’insister

davantage ou qui contribue à l’efficacité de

fonctionnement du système.

ATTENTION

Toute procédure pouvant résulter

l’endommagement du matériel en cas de nonrespect de la procédure en question.

FUMÉE et GAZ

La fumée et les gaz produits par le procédé de jet de

plasma peuvent présenter des risques et des dangers de

santé.

• Eloignez toute fumée et gaz de votre zone de

GENERAL INFORMATION

respiration. Gardez votre tête hors de la plume de

fumée provenant du chalumeau.

• Utilisez un appareil respiratoire à alimentation en air

si l’aération fournie ne permet pas d’éliminer la

fumée et les gaz.

• Les sortes de gaz et de fumée provenant de l’arc de

plasma dépendent du genre de métal utilisé, des

revêtements se trouvant sur le métal et des

différents procédés. Vous devez prendre soin

lorsque vous coupez ou soudez tout métal pouvant

contenir un ou plusieurs des éléments suivants:

antimoine cadmium mercure

argent chrome nickel

arsenic cobalt plomb

8

Page 9

baryum cuivre sélénium

béryllium manganèse vanadium

• Lisez toujours les fiches de données sur la sécurité

des matières (sigle américain “MSDS”); celles-ci

devraient être fournies avec le matériel que vous

utilisez. Les MSDS contiennent des renseignements

quant à la quantité et la nature de la fumée et des

gaz pouvant poser des dangers de santé.

• Pour des informations sur la manière de tester la

fumée et les gaz de votre lieu de travail, consultez

l’article 1 et les documents cités à la page 5.

• Utilisez un équipement spécial tel que des tables de

coupe à débit d’eau ou à courant descendant pour

capter la fumée et les gaz.

• N’utilisez pas le chalumeau au jet de plasma dans une

zone où se trouvent des matières ou des gaz

combustibles ou explosifs.

• Le phosgène, un gaz toxique, est généré par la fumée

provenant des solvants et des produits de nettoyage

chlorés. Eliminez toute source de telle fumée.

CHOC ELECTRIQUE

Les chocs électriques peuvent blesser ou même tuer. Le

procédé au jet de plasma requiert et produit de l’énergie

électrique haute tension. Cette énergie électrique peut

produire des chocs graves, voire mortels, pour l’opérateur

et les autres personnes sur le lieu de travail.

• Ne touchez jamais une pièce “sous tension” ou

“vive”; portez des gants et des vêtements secs.

Isolez-vous de la pièce de travail ou des autres

parties du circuit de soudage.

• Réparez ou remplacez toute pièce usée ou

endommagée.

• Prenez des soins particuliers lorsque la zone de

travail est humide ou moite.

• Montez et maintenez le matériel conformément au

Code électrique national des Etats-Unis. (Voir la

page 5, article 9.)

• Débranchez l’alimentation électrique avant tout

travail d’entretien ou de réparation.

• Lisez et respectez toutes les consignes du Manuel de

consignes.

INCENDIE ET EXPLOSION

Les incendies et les explosions peuvent résulter des

scories chaudes, des étincelles ou de l’arc de plasma. Le

procédé à l’arc de plasma produit du métal, des étincelles,

des scories chaudes pouvant mettre le feu aux matières

combustibles ou provoquer l’explosion de fumées

inflammables.

• Soyez certain qu’aucune matière combustible ou

inflammable ne se trouve sur le lieu de travail.

Protégez toute telle matière qu’il est impossible de

retirer de la zone de travail.

• Procurez une bonne aération de toutes les fumées

inflammables ou explosives.

• Ne coupez pas et ne soudez pas les conteneurs ayant

pu renfermer des matières combustibles.

• Prévoyez une veille d’incendie lors de tout travail

dans une zone présentant des dangers d’incendie.

• Le gas hydrogène peut se former ou s’accumuler

sous les pièces de travail en aluminium lorsqu’elles

sont coupées sous l’eau ou sur une table d’eau. NE

PAS couper les alliages en aluminium sous l’eau ou

sur une table d’eau à moins que le gas hydrogène

peut s’échapper ou se dissiper. Le gas hydrogène

accumulé explosera si enflammé.

RAYONS D’ARC DE PLASMA

Les rayons provenant de l’arc de plasma peuvent blesser

vos yeux et brûler votre peau. Le procédé à l’arc de

plasma produit une lumière infra-rouge et des rayons

ultra-violets très forts. Ces rayons d’arc nuiront à vos

yeux et brûleront votre peau si vous ne vous protégez pas

correctement.

• Pour protéger vos yeux, portez toujours un casque ou

un écran de soudeur. Portez toujours des lunettes de

sécurité munies de parois latérales ou des lunettes

de protection ou une autre sorte de protection

oculaire.

• Portez des gants de soudeur et un vêtement protecteur

approprié pour protéger votre peau contre les

étincelles et les rayons de l’arc.

GENERAL INFORMATION

• Maintenez votre casque et vos lunettes de protection

en bon état. Remplacez toute lentille sale ou

comportant fissure ou rognure.

• Protégez les autres personnes se trouvant sur la zone

de travail contre les rayons de l’arc en fournissant

des cabines ou des écrans de protection.

• Respectez le teint de lentille recommandé dans le

article 4, page 5.

• Hydrogen gas may be present under aluminum

workpieces during the cutting process when being

cut underwater or using a water table. DO NOT cut

aluminum underwater or on a water table unless the

hydrogen gas can be eliminated as the hydrogen gas

may detonate.

BRUIT

9

Page 10

Le bruit peut provoquer une perte permanente de l’ouïe.

Les procédés de soudage à l’arc de plasma peuvent

provoquer des niveaux sonores supérieurs aux limites

normalement acceptables. Vous dú4ez vous protéger les

oreilles contre les bruits forts afin d’éviter une perte

permanente de l’ouïe.

• Pour protéger votre ouïe contre les bruits forts, portez

des tampons protecteurs et/ou des protections

auriculaires. Protégez également les autres

personnes se trouvant sur le lieu de travail.

• Il faut mesurer les niveaux sonores afin d’assurer que

les décibels (le bruit) ne dépassent pas les niveaux

sûrs.

• Pour des renseignements sur la manière de tester le

bruit, consultez l’article 1, page 5.

1.06 Documents De

Reference

Consultez les normes suivantes ou les révisions les plus

récentes ayant été faites à celles-ci pour de plus amples

renseignements :

1. OSHA, NORMES DE SÉCURITÉ DU TRAVAIL

ET DE PROTECTION DE LA SANTÉ, 29CFR

1910, disponible auprès du Superintendent of

Documents, U.S. Government Printing Office,

Washington, D.C. 20402

2. Norme ANSI Z49.1, LA SÉCURITÉ DES

OPÉRATIONS DE COUPE ET DE SOUDAGE,

disponible auprès de la Société Américaine de

Soudage (American Welding Society), 550 N.W.

LeJeune Rd., Miami, FL 33126

3. NIOSH, LA SÉCURITÉ ET LA SANTÉ LORS

DES OPÉRATIONS DE COUPE ET DE

SOUDAGE À L’ARC ET AU GAZ, disponible

auprès du Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C.

20402

4. Norme ANSI Z87.1, PRATIQUES SURES POUR

LA PROTECTION DES YEUX ET DU VISAGE

AU TRAVAIL ET DANS LES ECOLES, disponible

de l’Institut Américain des Normes Nationales

(American National Standards Institute), 1430

Broadway, New York, NY 10018

5. Norme ANSI Z41.1, NORMES POUR LES

CHAUSSURES PROTECTRICES, disponible

auprès de l’American National Standards Institute,

1430 Broadway, New York, NY 10018

6. Norme ANSI Z49.2, PRÉVENTION DES

INCENDIES LORS DE L’EMPLOI DE

PROCÉDÉS DE COUPE ET DE SOUDAGE,

disponible auprès de l’American National Standards

Institute, 1430 Broadway, New York, NY 10018

7. Norme A6.0 de l’Association Américaine du

Soudage (AWS), LE SOUDAGE ET LA COUPE

DE CONTENEURS AYANT RENFERMÉ DES

PRODUITS COMBUSTIBLES, disponible auprès

de la American Welding Society, 550 N.W. LeJeune

Rd., Miami, FL 33126

8. Norme 51 de l’Association Américaine pour la

Protection contre les Incendies (NFPA), LES

SYSTEMES À GAZ AVEC ALIMENTATION EN

OXYGENE POUR LE SOUDAGE, LA COUPE

ET LES PROCÉDÉS ASSOCIÉS, disponible

auprès de la National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

9. Norme 70 de la NFPA, CODE ELECTRIQUE

NATIONAL, disponible auprès de la National Fire

Protection Association, Batterymarch Park, Quincy,

MA 02269

10. Norme 51B de la NFPA, LES PROCÉDÉS DE

COUPE ET DE SOUDAGE, disponible auprès de

la National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. Brochure GCA P-1, LA MANIPULATION SANS

RISQUE DES GAZ COMPRIMÉS EN

CYLINDRES, disponible auprès de l’Association

des Gaz Comprimés (Compressed Gas

Association), 1235 Jefferson Davis Highway, Suite

501, Arlington, VA 22202

12. Norme CSA W117.2, CODE DE SÉCURITÉ

GENERAL INFORMATION

POUR LE SOUDAGE ET LA COUPE, disponible

auprès de l’Association des Normes Canadiennes,

Standards Sales, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada, M9W 1R3

13. ivret NWSA, BIBLIOGRAPHIE SUR LA

SÉCURITÉ DU SOUDAGE, disponible auprès de

l’Association Nationale de Fournitures de Soudage

(National Welding Supply Association), 1900 Arch

Street, Philadelphia, PA 19103

14. Norme AWSF4.1 de l’Association Américaine de

Soudage, RECOMMANDATIONS DE

PRATIQUES SURES POUR LA PRÉPARATION

À LA COUPE ET AU SOUDAGE DE

CONTENEURS ET TUYAUX AYANT

RENFERMÉ DES PRODUITS DANGEREUX ,

disponible auprès de la American Welding Society,

550 N.W. LeJeune Rd., Miami, FL 33126

15. Norme ANSI Z88.2, PRATIQUES DE

PROTECTION RESPIRATOIRE, disponible auprès

de l’American National Standards Institute, 1430

Broadway, New York, NY 10018

10

GENERAL INFORMATION

Page 11

SECTION 2: TECHNICAL SPECIFICATIONS

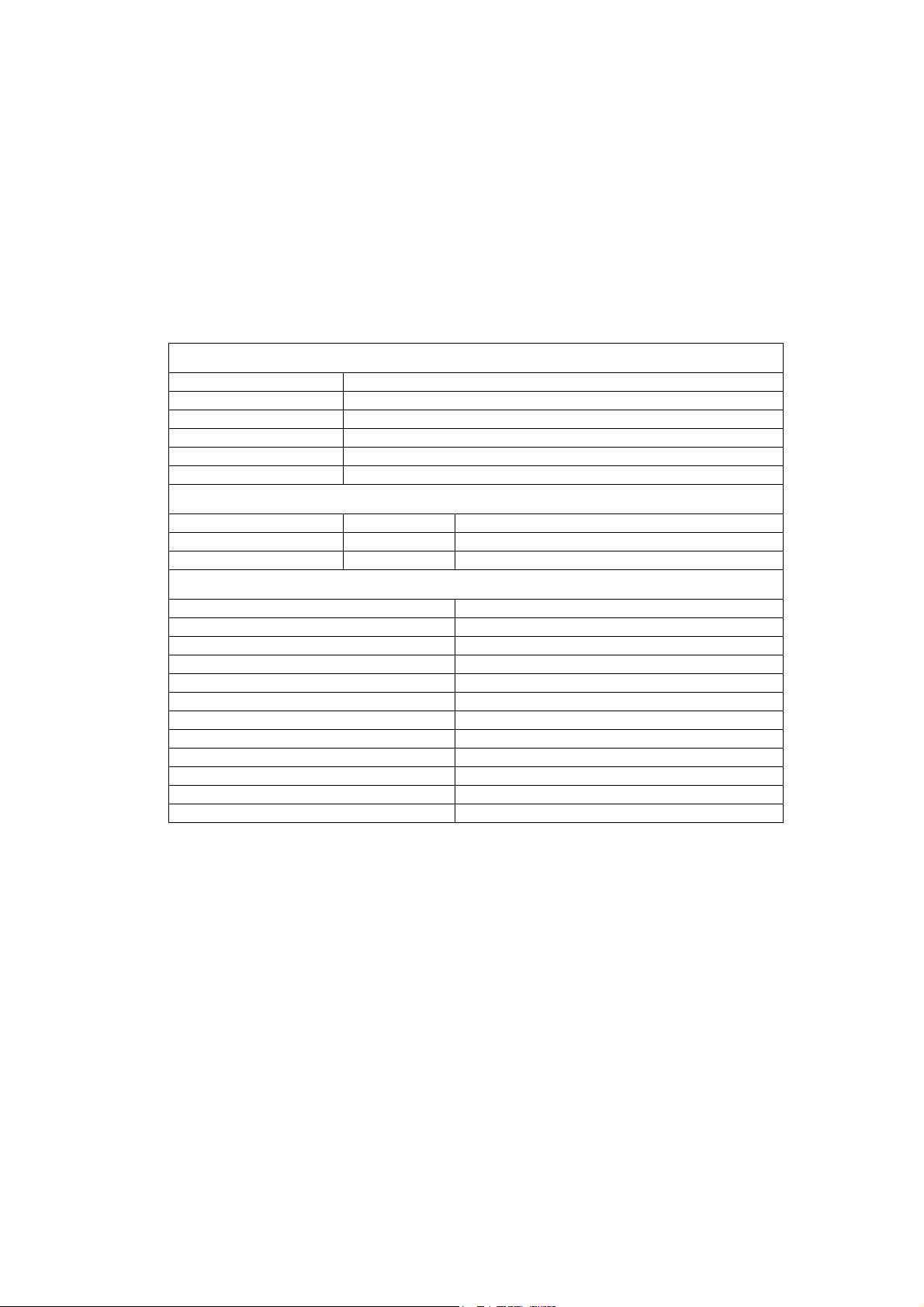

2.01 Specifications

The Thermal Arc Raider 10,000 Pro is a gasoline engine driven DC welding generator with selectable Constant Current (CC)

and Constant Voltage (CV) output characteristics. This unit is designed for use with Shielded Metal Arc Welding (SMAW),

Gas Metal Arc Welding (GMAW), and GAS Tungsten Arc Welding - (GTAW) processes.

Specifications

DC

Amperage Range 15 – 270

Duty Cycle 270 @ 60%

AC/DC welding current 250 @ 100%

Volt Range CV Mode 16 – 30

OCV CC Mode 70 VDC

Auxiliary Power

Single Phase 115 2ea GFCI Duplex Receptacles 3.5Kva

Single Phase 115/240 8.5Kva

Three Phase 460 10Kva

Engine

Make/Type HONDA

Model series GX 620K1

Number of cylinders 2

Displacement 614 cc.

Power 20 HP

Engine Speed 3750 rpm no load

Engine speed 2600 rpm Idle

Cooling system Air

Oil capacity 1.5 l. - 0,42 gl.

Fuel capacity 37.5 l. - 10 gl.

Fuel consumption 5.2 l/h – 1.4 gl./Hr

Battery 12V 340A

13

TECHNICAL SPECIFICATIONS

Page 12

2.02 Volt-Amp Curve

NOTE

Volt-ampere curves show the voltage and amperage

output capabilities of the welding power source. Curves of

other settings will fall between the curves shown.

2.03 Duty Cycle

The duty cycle of a welding generator is the percentage of

a ten-minute period that a welding generator can be

operated at a given output without causing overheating

and damage of the unit. This unit is rated at 60 percent

duty cycle when operated at 270 amperes. The unit can be

operated at 270 amperes for six consecutive minutes, but

it must operate at no load for the remaining four minutes

to allow proper cooling. If the welding amperes decrease,

the duty cycle increases. If the welding amperes are

increased beyond rated output, the duty cycle will

decrease.

CAUTION: CONTINUAL OPERATION

EXCEEDING THE DUTY CYCLE RATINGS CAN

CAUSE DAMAGE TO THE WELDING POWER

SOURCE.

2.04 Front Panel

Descriptions

5

4

6

CC

3

7

2

8

9

1

CV

0

10

SMAW

CONTACTOR

A/V

CONTACTEUR

+-

14

14

14

24V 10A

ENGINE

/ MOTEUR

START

METTRE

ON

EN

MARCHE

MARCHE

OFF

COUPE

55

TM

/ PUISSANCE D' AUXILIAIRE

115V A C/CA

140

95

23 185

21

25

28

225

18

30

16

8

15

270

)

115V 3A

115/230V 50A

230V AC/CA

3 Year

Warranty

3 Ans

Garantie

See Warranty Policy dated 4/1/02

Voir Garantie Police date 4/1/02

RAIDER 10000 PRO

++ +8

AUXILIARY POWER

115V 20A

115V 20A

Front Panel

1. 230/115V Single Phase Receptacle - Supplies 60 Hz

single-phase power at weld/power speed.

2. Earth connection – used to earth ground the generator

for auxiliary power.

3. 230/115V 50A Circuit breakers - Push to reset.

Controls 230/115V power source for the 230/115V

receptacle.

4. 115V 20A Circuit Breakers - Push to reset. Controls

115V power source for the 115V duplex GFCI

receptacles.

5. 115 V Single Phase GFCI Receptacle – Supplies 60

Hz single-phase power at weld/power speed

6. Welding Receptacle Work: Negative output welding

connection for CC (Constant current) STICK.

7. Welding receptacle Work : Negative output welding

connection for CV (Constant voltage) MIG.

8. 115V 3A Circuit breaker – Push to reset. Controls

115V power source for wire feeders Controlled

through the 14 pin receptacle.

9. Oil Level Lamp - When the ON/OFF Switch is

turned on the Oil Level Lamp will Not Glow. Should

the oil sensor in the engine detect a low oil condition

the Oil Level Lamp will turn-on and the engine will

shut off.

10. Amperage /Voltage control – detects the desired

Amperage or voltage (depending on mode) within the

entire range of the welding generator. The scale

surrounding the control represents approximate actual

values.

14

GENERAL INFORMATION

Page 13

11. Battery Charge Lamp – When the ON/OFF Switch is

turned on the Battery Charge Lamp will Glow. For

normal operation when the engine is running the

Battery Carge Lamp will be off. Should the Charging

circuit or Battery fail the Battery Warning Lamp will

Turn-on and the engine will shut off.

12. Remote AMPERAGE / VOLTAGE Switch – Allows

remote amperage/voltage device operation through

the 14 pin receptacle.

13. Process Selector switch : CC/CV – Allows the

operator to select the CC (Constant Current) process

or CV (Constant voltage) process.

14. Remote Contactor switch – Allows for the output

contactor to be controlled through the 14 pin

receptacle. When in the Panel position welding

output is present at the output terminal when the

engine is running. When in Remote position output is

controlled through a 14 pin remote device.

15. Arc Control – The Arc Control is use in the SMAW

mode only. Rotate the control clockwise to increase

the short circuit current available to control the

welding arc.

16. 14 Pin receptacle - Used for remote Contactor,

amperage control, and wire feeder control.

17. Serial number.

18. Welding Receptacle: Electrode-Positive output

welding connection for CC (Constant Current) and

CV (Constant Voltage).

19. Choke – Pull knob out engges Choke. Push knob in

for normal operation.

20. 24V AC 10A Circuit breaker – Push to reset.

Controls 24V power source for wire feeders.

Controlled through the 14 pin receptacle.

21. Hour meter - Monitors Time in hours when the

engine is on.

22. Fuel Gauge – Monitors fuel level

23. START button – Used to start the engine. Set the

ON/OFF switch to ON, push START button to the

start the engine. When engine starts release button

24. Engine ON/OFF switch - Place in the ON position to

operate generator. Use the START button to start the

engine. To shut off engine place switch in stop

position.

25. Engine Min/Max R.P.M. switch

26. 13A Circuit breaker - 3 poles circuit breaker controls

460V three phase power source.

27. 460V Output - Access for three phase 460V 60 Hz

connections. Connect Line1, 2 and 3 to the output

side of the circuit breaker and the ground to the bolt

mounted beside the circuit breaker.

2.05 Dimensions and Weight

Height 710mm 27.9”

Width 530mm 20.86”

Length 1080mm 42.52”

A 15mm .59”

B 1050mm 41.34”

C 34.5mm 1.36”

D 424mm 16.69”

E 10.5mm Dia. .41” Dia.

Weight 248 Kg 546.5 lb

2.06 Maximum Welding

Generator Operating Angles

Do not exceed operating angles while running or engine

damage will occur.

The operating angle is a maximum of 25 degrees.

15

GENERAL INFORMATION

Page 14

2.07 Installing Welding

Generator

1. Lifting forks.

2. Lifting Eye. Use lifting eye or lifting forks to move

unit. If using lifting forks, extend forks beyond

opposite side of unit.

3. Trailer - Install unit on trailer according to trailer

manufacturing.

Movement - Do not lift unit from end.

1 2

2.09 Air Flow Clearance

Maintain at least 19.7 inch (500mm) of unrestricted space

on all sides of the unit, and keep underside free of

obstructions. Do not place any filtering device over the

intake air passages of this welding generator. Warranty is

void if any type of filtering device is used.

The service life and operating efficiency of this unit is

reduced when the unit is subjected to high levels of dust,

dirt, moisture, and corrosive vapors.

2.08 Location

A proper installation site should be selected for the welding

generator if the unit is to provide dependable service and

remain relatively maintenance free.

CAUTION: OPERATE IN OPEN, WELLVENTILATED AREAS, OR IF OPERATED

INDOORS, VENT ENGINE EXHAUST OUTSIDE THE

BUILDING. KEEP ENGINE EXHAUST OUTLET

AWAY FROM BUILDING EXTERIER, INTERIER

WALLS & AIR INTAKES.

WARNING: SPARKS CAN CAUSE BATTERY

GASES TO EXPLODE BATTERY ACID CAN

BURN EYES AND SKIN.

• Stop engine before disconnecting or connecting

battery cables.

• Always wear a faceshield and proper protective

clothing when working on battery.

• Do not allow tools to cause sparks when working on

a battery.

• Place the engine control switch in the STOP position.

• Remove bolts and pull out tray.

• Connect the cables

• Reinstall battery tray.

16

TECHNICAL SPECIFICATIONS

Page 15

WARNING: ENGINE FUEL CAN CAUSE FIRE OR

EXPLOSION.

• Stop engine before fueling.

• Do not fuel while smoking or near sparks or flames.

• Do not overfill tank-clean up any spilled fuel.

REMOVE FUEL CAP SLOWLY-FUEL SPRAY

MAY CAUSE INJURY. FUEL MY BE UNDER

PRESSURE. Rotate fuel cap slowly and wait until

hissing stops before removing cap. Engine must be

cold and on a level surface.

2.10 Generator Auxiliary

Power System

Standard Receptacles

(1) Circuit breakers to protect (2) GFCI receptacles from

overload.

(2) 120 V 15 A AC Duplex GFCI receptacle. Supplies 60

Hz single-phase power at maximum speed (3600 rpm).

Maximum output each receptacle is 1.8 kVA/kW.

(3) Circuit breakers to protect (4) 240 V receptacle from

overload.

460 Three Phase connection

(1) 460 V 13 A AC three phase Circuit Breaker

connection. Supplies 60 Hz three-phase power at

maximum speed (3600 rpm). Maximum output is 10

kVA/kW.

To connect load remove the two retaining knobs holding

the access panel. After opening the panel connect a cable

to be used to supply the 460V three phase load to the

three phase circuit breaker mounted to the access panel.

Connected the ground cable to the bolt mounted next to

the circuit breaker. Route the cable through the cable

clamp (2) and secure cable. Re-secure the access panel

with the two retaining knobs to the front panel.

(4) 240 V 50 A AC receptacle. Supplies 60 Hz singlephase power at maximum speed (3600 rpm). Maximum

output is 8.5 kVA/kW.

(5) Earth ground connection.

5

17

TECHNICAL SPECIFICATIONS

Page 16

2.11 Wiring Optional 230

2.12 Grounding The

Volt Plug

The plug can be wired for a 230V, 2-wire load or a

115/230V, 3-wire load. See diagram below

White - Neutral terminal.

YYY - Load 1 terminal.

XXX - Load 2 terminal.

Green - Ground terminal.

Generator

TO A TRUCK OR TRAILER FRAME

1. Generator base.

2. Metal vehicle frame.

3. Equipment grounding terminal.

4. Grounding cable. Use # 10 AGW or larger insulated

copper wire.

NOTE: FOR THE GFCI RECEPTACLES TO

PERFORM PROPER PROTECTION THE WELDING

GENERATOR MUST BE EARTH GROUNDED.

Select proper insolated and grounded equipment.

1) Auxiliary power receptacles are Neutral bonded to

frame.

2) 3-Prong plug for case Grounded equipment

3) 2-Prong plug for double insulated equipment.

18

TECHNICAL SPECIFICATIONS

Page 17

2.13 When Connecting To

Home, Shop, or Farm

Wiring

NOTE: THIS UNIT SHOULD NEVER BE USED AS

THE MAIN SOURCE OF POWER.

1. Equipment grounding terminal.

2. Grounding cable. Use # 10 AGW or larger insulated

copper wire.

3. Water meter.

4. Metal water pipe

5. Driven ground rod.

NOTE: It is the installer's responsibility to follow the

applicable rules from the National Electrical Code

(NEC), state, local, and OSHA codes for the

installation and use of auxiliary power generators.

Typical connection to supply emergency or standby power.

1. Power Company Service Meter.

2. Main and Branch Over-current Protection.

3. Double-Pole, Double-Throw Transfer Switch.

Obtain and install correct switch. Switch rating

be same as or greater than the branch over-current

protection.

4. Circuit Breaker or Fused Disconnect Switch. Obtain

and install correct switch.

5. Extension Cord. Generator Connections. Connect

terminals or plug of adequate amperage capacity to

cord. Follow all applicable codes and safety

practices. Turn off or unplug all equipment

connected to generator before starting or stopping

engine. When starting or stopping, the engine has

low speed which causes low voltage and frequency.

6. Load connections.

must

Customer-supplied equipment is required if generator is to

supply standby power during emergencies or power

outages.

2.14 Auxiliary Power

Requirements

The following section provides some general guidelines for

the installation and operation of an auxiliary power generator.

Not all the guidelines may be applicable to this specific unit.

The auxiliary power supplied from the generator is most

commonly used in industrial, small business and

residential applications. For industrial applications, a

portable unit can be moved to the job site to power

portable tools, lights, compressors, etc. For small

business and residential applications, the generator

supplies standby power during a power outage.

It is the installer’s responsibility to follow all applicable

codes when installing an auxiliary power generator. It is

also the installer’s responsibility to determine if the

generator is capable of supplying adequate power for a

specific application. When installing consult qualified

19

TECHNICAL SPECIFICATIONS

Page 18

local personnel and follow all applicable codes for safe

and proper installation.

Before the generator may be used to supply power, the

installer must first become familiar with and meet all

codes applicable to the installation of an auxiliary

generator. It is the installer's responsibility to follow the

applicable rules from the National Electrical Code (NEC),

state, local, and OSHA codes for the installation and use

of auxiliary power generators.

LOAD EVALUATION

Before connecting or operating the auxiliary power

generator, the installer must determine if the generator is

capable of supplying adequate power for a specific

application. Load and generator evaluation is essential for

satisfactory generator and equipment operation.

Motor-starting Requirements

Starting amperage requirements are many times the

running amperage of the motor. Starting requirements

must be determined to assure that the generator is capable

of starting the motor without damaging it. This can be

done by examining the motor nameplate and identifying

the code letter specifying the starting kVA/HP required.

Motor Start

Code Leter

G6.3

H7.1

J8.0

K9.0

L 10.0

M 11.2

N 12.5

P 14.0

KVA/HP

TYPES OF LOAD

Load requirements depend on the type of load connected

to the generator. There are two types of loads, resistive

and non-resistive. A resistive load, such as a light bulb,

requires a constant amount of power from the generator.

A non-resistive load, such as a portable grinder, requires

variable amounts of power from the generator. Because a

grinder requires more power for motor starting and is

rarely used with a constant, even pressure, the load

requirements can change greater than the operator

anticipates.

RUNNING LOAD REQUIREMENTS

The total running load applied to the generator is

calculated by adding up all the individual loads. Some

requirements are rated in amperes, others in watts. The

requirements for most equipment is provided on its

nameplate.

Example 1: If a drill requires 5 amperes at 115 volts,

calculate its running power requirements in watts.

VOLTS x AMPERES = WATTS

115V x 5A = 575W

Therefor, the individual load applied by the drill is 575

watts.

Example 2: If a light bulb is rated at 200 watts, the

individual load applied the light bulb is 200 watts. If

three 200 watt light bulbs are used with the drill from

example 1 add the individual loads to calculate total load.

(200W + 200W + 200W) + 575W = 1175W

If the kVA/HP requirement, motor horsepower, and

voltage rating are known, the starting amperage can be

calculated.

Example: Calculate the starting amperage required for a

230V, ¼ HP motor with a motor start code of G.

Equation

KVA/HP x HP x 1000

= STARTING AMPERAGE

VOLTS

Volts = 230

HP = ¼

Code G results in kVA/HP = 6.3

6.3 x ¼ x 1000

= 6.85A

230

Therefore, starting the motor requires 6.85 amperes.

If a code letter is not present on the motor nameplate,

approximate starting amperage is equal to six times

running amperage. This is a reasonable approximation for

all applications where the generator rated amperage is at

least twice the motor requirement. If the generator-tomotor-size ratio is less than 2:1 acquire the needed

information to properly determine the motor-starting

requirement.

Therefore the total load applied by the three light bulbs

and drill is 1175 watts.

20

TECHNICAL SPECIFICATIONS

Page 19

2.15 Simultaneous Welding

and Power

((ssiinnggllee oorr tthhrreeee pphhaassee)

Weld

Current

270A 1,200 10A 5A 1.5A

220A 3,660 15A x 2 15.25A 4.6A

170A 4,500 15A x 2 18.75A 5.65A

120A 7,000 15A x 2 29A 8.8A

70A 8,500 15A x 2 35.4A 10.68A

0A 10,000 15A x 2 35.4A 12.5A

CCoommbbiinneedd oouuttppuutt ooff aallll rreecceeppttaacclleess lliimmiitteedd ttoo rraattiinngg ooff tthhe

ggeenneerraattoorr.

Total

Power

in Watts

.

120 volt

GFCI

Recept.

)

240 volt

Recept.

8500 max.

460 volt

Three

phase

WELD CABLE CONNECTIONS

1. Do not touch live electrical parts.

2. Shut down unit before making any weld output

connections.

3. Do not change position of the welding cable

connectors while welding

4. Be sure that the connectors are secure in receptacle

before welding.

TYPICAL PROCESS CONNECTIONS

SEQUENCE OF OPERATION

e

WARNING: Read and follow all safety precaution

before proceeding with operation.

EExxaammppllee:: IIff wweellddiinngg aatt 112200AA aanndd 1155AA iiss ddrraawwnn ffrroomm tthhe

112200VV GGFFCCII dduupplleexx rreecceeppttaaccllee,, 1100AA iiss ddrraawwnn ffrroomm tthhe

224400VV rreecceeppttaaccllee,, oonnllyy 33..55AA iiss aavvaaiillaabbllee ooff 446600VV tthhrreeee-

.

pphhaassee.

e

-

2.16 Selecting and Preparing

Weld Output Cables

CONNECTOR INSTALLATION

Install the supplied male connectors onto proper cables.

1. Obtain cable of desired length and proper size for

installation.

2. If the installation requires cable large than 3/0 AWG,

prepare one end of 3/0 AWG pigtail no longer than 2

ft (0,61 m) for connector installation. The remaining

end of the pigtail is connected to the main run of 3/0

AWG or larger weld cable.

3. Push weld cable through insulator.

4. Remove 0.79 in (20 mm) of insulation from end of

cable.

5. Install supplied sleeve on stripped end of cable.

6. Insert cable with sleeve into connector body so that

cable is snug and against bottom of connector body.

7. Install and tighten set screw with supplied hex wrench

to secure connector body onto cable.

7. Push insulator onto connector body to cover set

screw.

e

SHIELDED METAL ARC WELDING (SMAW)

1. Install and connect unit according to the installation

section.

2. Wear gloves, Welding Helmet and protective clothing.

3. Connect work clamp at workplace.

4. Select proper electrode.

5. Place the selector switch in STICK position.

6. Place the OUTPUT CONTACTOR switch in ON

position.

7. If remote amperage control is not used, place the

Amperage/Voltage switch in panel position.

8. Rotate the Amperage/Voltage control to desired

position.

9. Insert electrode into electrode holder.

GAS TUNGSTEN ARC WELDING (GTAW) Lift Start only

1. Install and connect unit according to the Installation

section.

2. Select proper tungsten electrode.

3. Prepare tungsten electrode and connect the torch to

the negative output terminal.

4. Wear gloves, welding helmet and protective clothing.

5. Connect work clamp to positive output terminal and

work place.

6. Place the process selector switch in Lift Tig position.

7. For remote contactor and/or amperage control connect

a remote device to the 14 pin receptacle.

8. For remote amperage control place the

Amperage/Voltage switch in the panel position.

9. For remote contactor control place the contactor

switch in the panel position.

10. Rotate Amperage/Voltage control to desired position.

11. Turn on shielding gas and water supplies as

applicable.

12. Touch electrode to work and lift to start arc.

13. Begin welding.

21

TECHNICAL SPECIFICATIONS

Page 20

GAS METAL ARC WELDING (GMAW)

1. Install and connect unit according to the Installation

section.

2. Install and connect wire feed system according to

wire feeder installation guide.

3. Wear gloves, welding helmet and protective

clothing.

4. Connect work lead to the negative CV terminal.

5. Place the process selector switch in CV position.

6. If remote voltage control is not used, place the

Amperage/Voltage switch in panel position.

7. Rotate Amperage/Voltage control to desired position.

8. Turn on shielding gas supply and set desired flow

rate.

9. Begin welding.

SELECTING WELD CABLE SIZES

Weld cable size (AWG) is based on either a 4 volts or less

drop or a current density of more than 300 circular mils

per ampere.

100ft

(30 m)

Welding

Amperage

100 4 4 3 2

150 3 2 1 1/0

200 2 1 1/0 2/0

250 1 1/0 2/0 3/0

300 1/0 2/0 3/0 4/0

60-100%

Duty Cycle

150ft.

(45 m)

10-100% Duty Cycle

200ft.

(60 m)

250ft.

(70 m)

22

TECHNICAL SPECIFICATIONS

Page 21

SECTION 3: TROUBLE SHOOTING GUIDE

The Raider 10,000 Pro is an asynchronous (brush-less) style generator. The basic theory of this style generator is as follows:

A permanent magnet (rotor) is rotating at a high speed inside a winding wrapped around a laminated steel core (stator). This

produces a small voltage at a very low intensity, 1 to 2 volts at 1 amp in the exciter windings. This low voltage charges the

excitation capacitors connected in series and directly connected to both ends of the exciter windings. This produces a chargedischarge situation that augments to the point at which it stabilizes itself in proportion to the magnetic force of the rotor

winding wire’s size and length, capacity of the capacitors, and engine speed (3600 rpm) at about 60 times per second. The

Charge-discharge effect produces a collapsing of magnetic field in the laminated steel, thus creating a current all of its own.

This current produced is proportional to the main winding characteristics, size, length, et

Auxiliary

Output

Control

Bridge

Control PC

Board

23

TROUBLE SHOOTING

Page 22

3.01 There is No Auxiliary Voltage and/or Welding Current

In examining this particular fault it must be remembered that an asynchronous generator with excitation by capacitors

has the characteristic of becoming automatically de-energized while it is functioning (no longer supplies current). Also an

asynchronous generator will not self-excite when it is started up if there is a short-circuit whether outside of the generator

(in the user circuit) or inside it (in the windings and in the control equipment).

TROUBLE

POSSIBLE CAUSE

The GFCI is open or when

actuated in the closed position

suddenly trips open.

The generator is connected to the

maximum load, in particular

induction motors.

The + and - welding cables are in

short-circuit through electric

contact between them.

Excitation Capacitors are

shorted.

Output welding receptacles loose

or shorted.

Output Welding Rectifier is

shorted.

Faulty winding in stator. Have stator checked by

The reset of the G.F.C.I. must be

in the closed position. Check that

the user circuit does not have a

phase to earth.

When starting, the current plugs

should not be connected directly

with the load, but with a switch

interposed that will allow the set

to be started with the load

disconnected.

The electrode & Work lead are

connected in short circuit

condition.

Disconnect the capacitors from

the generator and from the

equipment. Refer to test section

for excitation capacitors.

Check the cable connections to

the receptacles. Check for burnt

or loose receptacle insulation.

Have Rectifier checked by

authorized service agent.

authorized service agent.

REMEDY

Close the GFCI and disconnect

the plugs from the current

sockets. If the GFCI does not

remain closed even if the reset is

slowly closed, this means that

the GFCI is faulty and that it

must be replaced.

Remove the load in the starting

phase. If necessary, disconnect

the plugs from the current

sockets. If generator still does

not generate welding current

refer to test section for exciter

capacitors & Stator.

Disconnect electrode & Work

leads. If generator still does not

generate welding current refer to

test section for exciter capacitors

& Stator.

If necessary, replace the

capacitors.

Replace the receptacle parts

necessary.

3.02 The Generator Is De-Energized when Load is connected

PROBABLE CAUSE CONTROLS REMEDIES

There is a short-circuit on the

user circuit.

Excessive overload; induction

motors (especially 2-pole)

connected of higher power than

the Generators specifications.

Check the load for shorts Repair load circuit.

See that the induction motors are

not of higher power than the

specification of the generator.

24

Reduce load to within the

specifications of the generator.

Page 23

3.03 Excessive Fall of Voltage When The Load is Connected

PROBABLE CAUSE CONTROLS REMEDIES

The engine does not maintain the

nominal speed.

Check whether the fine current

control is functioning.

Check engine fuel system. Refer to Engine manual for

Check with an ammeter whether

the load is greater than the rated

load of the generator.

Replace or repair Fine Current

control assembly.

testing fuel system.

Reduce load to within generator

specifications.

3.04 Single Phase Receptacle Out Of Balance While at Idling

PROBABLE CAUSE CONTROLS REMEDIES

A capacitor of one phase is

disconnected or is no longer

working properly.

Check the connections at the

terminals of the capacitors. See

capacitor testing in the the

Troubleshooting Guide.

Repair the faulty capacitor

connections. Replace any

capacitor that may be found to

be defective.

3.05 Insufficient Welding Current

PROBABLE CAUSE CONTROLS REMEDIES

The engine does not obtain

maximum speed.

One phase on the capacitors or

on the rectifiers is disconnected.

Check the Fine Current Control

function.

Check engine throttle linkage,

Fuel and electrical systems.

Check that all the internal

connections have a sound

electrical connection.

Repair or replace the Fine

Current Control.

Refer to engine manual.

Fix any connections that may

have worked loose.

3.06 The Battery Runs down Frequently

PROBABLE CAUSE CONTROLS REMEDIES

Battery defective: does not

maintain the load.

Engine charge circuit defective Test charge circuit according to

Check for shorted battery cell. Replace battery.

engine manual.

25

Page 24

Section 5 Parts List

5.01 Stator Parts

26

Page 25

Item Part Number Description

1 11-3284 Washer

2 11-3283 Fan

3 11-3077 Seeger ring

4 11-3078 Bearing

5 11-3633 Rotor tie-rod

6 11-3308 Flange with bearing seat

7 11-3954 Stator

8 11-3597 Hook

9 11-3281 Rotor

10 11-3307 Tie rod

11 11-3873 Engine bulkhead

12 11-3869 Silencer

13 11-3499 Flap

14 11-3721 Oil drain cap

15 11-3722 Hose clamp

16 11-3868 Clamp

17 11-3720 Oil drain pipe

18 11-3533 Washer

19 11-3851 Nut M8 mm

20 11-3017 Engine shock absorber 30x30 mm

21 11-3896 Screw M8x25 mm

22 11-3795 Engine holder

23 11-3871 Flange nut M5x16 mm

24 11-3659 Engine connection flange

25 11-3872 Washer M10 mm

26 11-3870 Screw M3/8’x1,¼ mm

27 11-3664 Stator plate

28 11-3660 Stator shock absorber 40x25 mm

27

Page 26

5.02 Front Panel Parts

28

Page 27

Item Part Number Description

1 11-3779 13A 3 poles circuit breaker

2 11-3143 3 poles circuit breaker cover

3 11-3138 Cable holder

4 11-3245 Circuit breaker support

5 11-3510 Protection cover

6 11-3087 Rubber wire holder

7 11-3936 Earth clamp

8 11-3810 O-ring

9 11-3150 Fuel gauge – Monitor fuel level

10 11-4133 230V 50A 14-50 single phase outlet

11 11-3789 230V 50A 14-50 single phase cover

12 11-3050 115V 2x15A GFCI 5-15R single phase outlet

13 11-3375 115V 2x15A GFCI 5-15R single phase outlet cover

14 11-3049 Circuit breaker cover

15 11-3048 Ring

16 11-3148 20A circuit breaker

17 11-3149 50A circuit breaker

18 11-3232 Male Texas plug

19 11-3231 Welding outlet

20 11-3146 3A circuit breaker

21 11-4160 Potentiometer knob assembly

22 11-4156 1K potentiometer

23 11-3876 Oil pressure signal lamp

24 11-3875 15 ohm ½ W resistor

25 11-3227 Battery charge signal lamp

26 11-3723 Switch cover

27 11-3809 CC/CV switch assembly

28 11-4167 Aluminium front plate

29 11-4166 Front plate sheet

30 11-4157 10K potentiometer

31 11-3316 12V relay

32 11-3792 Switch (1 pole)

33 11-3145 14 poles wire feeder connector

34 11-3147 10A circuit breaker

35 11-3318 Amperometric transformer

36 11-3243 Choke knob assembly

37 11-3865 Switch (4 poles)

38 11-3152 Start Button

39 11-3137 Circuit breaker support

40 11-3151 Hour meter

41 11-3153 Start button cover

29

Page 28

5.03 Sheet Metal Parts

30

Page 29

Item Part Number Description

1 11-4082 Frame

2 11-4083 Canopy

3 11-3610 Hook gasket

4 11-3611 Fuel tank cap gasket

5 11-3612 Fuel tank cap

6 11-4129 15VA Transformer

7 11-3614 3 poles terminal board

8 11-3332 GS9705 electronic panel

9 11-3331 P02041 electronic panel

10 11-4126 Electronic panel support

11 11-4084 Panel

12 11-4164 Shock absorber for electronic panel

13 11-3262 Tie rod

14 11-3615 Fuel level gauge

15 11-3949 Positive battery charging clip

16 11-4138 Engine ring

17 11-3948 Negative battery charging clip

18 11-4137 Battery cover

19 11-4093 Rear panel

20 11-3895 Battery clamp

21 11-3544 Battery tie rod

22 11-3543 12V 44Ah battery

23 11-3616 Frame

24 11-3878 Rubber wire holder

25 11-3790 Support

26 11-3677 Fuel tank

27 11-3087 Rubber wire holder

28 11-3619 Lower conveyor

29 11-3618 Bridge for capacitor

30 11-3942 3x50µF capacitor

31 11-3662 Spacer

32 11-3329 Tie rod

33 11-3674 Reactor

34 11-4026 200 VA Transformer

35 11-4027 Transformer support

36 11-3578 Rectifier bridge right support

37 11-3104 100 ohm – 75 W resistor

38 11-3478 Insulator

39 11-3299 Rectifier bridge tie rod

40 11-3679 Rectifier bridge

41 11-3107 Shunt

42 11-3577 Rectifier bridge left support

43 11-3682 Rectifier bridge assembly

44 11-3676 Transformer support

31

Page 30

5.04 Engine Related Parts

32

Page 31

Item Part number Description

1 11-3901 Screw M5x12 mm

2 11-3886 Washer M5 mm

3 11-4193 Solenoid protection

4 11-3235 Solenoid

5 11-4200 12x18x0,5 ring

6 11-4201 12x18x1 ring

7 11-3902 Nut M5 mm

8 11-3904 Washer M12 mm

9 11-4192 Solenoid support

10 11-3903 Low nut M12 mm

11 11-4123 Throttle plate

12 11-3894 Fuse 5A

13 11-4179 Fuse holder

14 11-3891 Washer M8x18 mm

15 11-3892 Washer M6 mm

16 11-3893 Screw M6x40 mm

17 11-4170 Fuse 25A

18 11-3900 Throttle spring

19 11-4143 Oil load extension

33

Page 32

5.05 Common Engine Part Numbers

Engine Type

Item Honda Part Number differences.

Oil Filter 15400-PR3-014 Key type Starting box

Air Filter Element 17210-ZJ1-841 Generator style choke

Fuel Filter 16910-ZE8-015 Generator Style Throttle assembly

Fuel Pump 16700-ZJ8-003 Red blower housing

Fuel Solenoid 16200-ZJ1-003

Spark Plug 98079-5585V

Starter Solenoid 31204-ZJ1-HO1

Starter Motor 31210-ZJ1-811

Voltage Regulator 31710-ZJ1-811

Model number Identification Miscellaneous Parts

G General Purpose Engine

X Over Head Valve NA Battery 12V/340A Style DT50

620 20hp 11-4033 Engine Fuel Warning label

V Tapered PTO Shaft 11-4041 Predator Label

X Oil Alert (shut-down) 11-4037 Oil Drain Label

E 3A Charge Circuit 11-4035 General Warning Label

GX620K1VXE8

Catalog Number Description

Honda suggested replacement Engine type

GX620K1VXE2 with the following

11-4039 Battery Warning label

11-4034 Lift Warning Label

34

Page 33

5.06 Schematic

35

Page 34

5.07 14 pin Receptacle Signals

Socket Pin Function

A

B Input to energize solid state contator (Contact closure between pin A and pin B)

C 5k ohm (maximum) connection to 5k ohm remote control potentiometer

D

E Wiper arm connection to 5k ohm remote control potentiometer

F Not Used

G 24/115 VAC circuit common, also connected to chassis

H Not Used

I 115 VAC auxiliary high side

J 115 VAC input to energize solid state contactor (Contact closure between pin I and pin J)

K Chassis ground

24VAC auxiliary high side.

Zero ohm (minimum) connection to 5k ohm remote control potentiometer

36

Loading...

Loading...