Page 1

50

60

Hz

1

PHASE

SMAW

GTAW

INVERTER

DC

CC

115V230

V

English

Français

Español

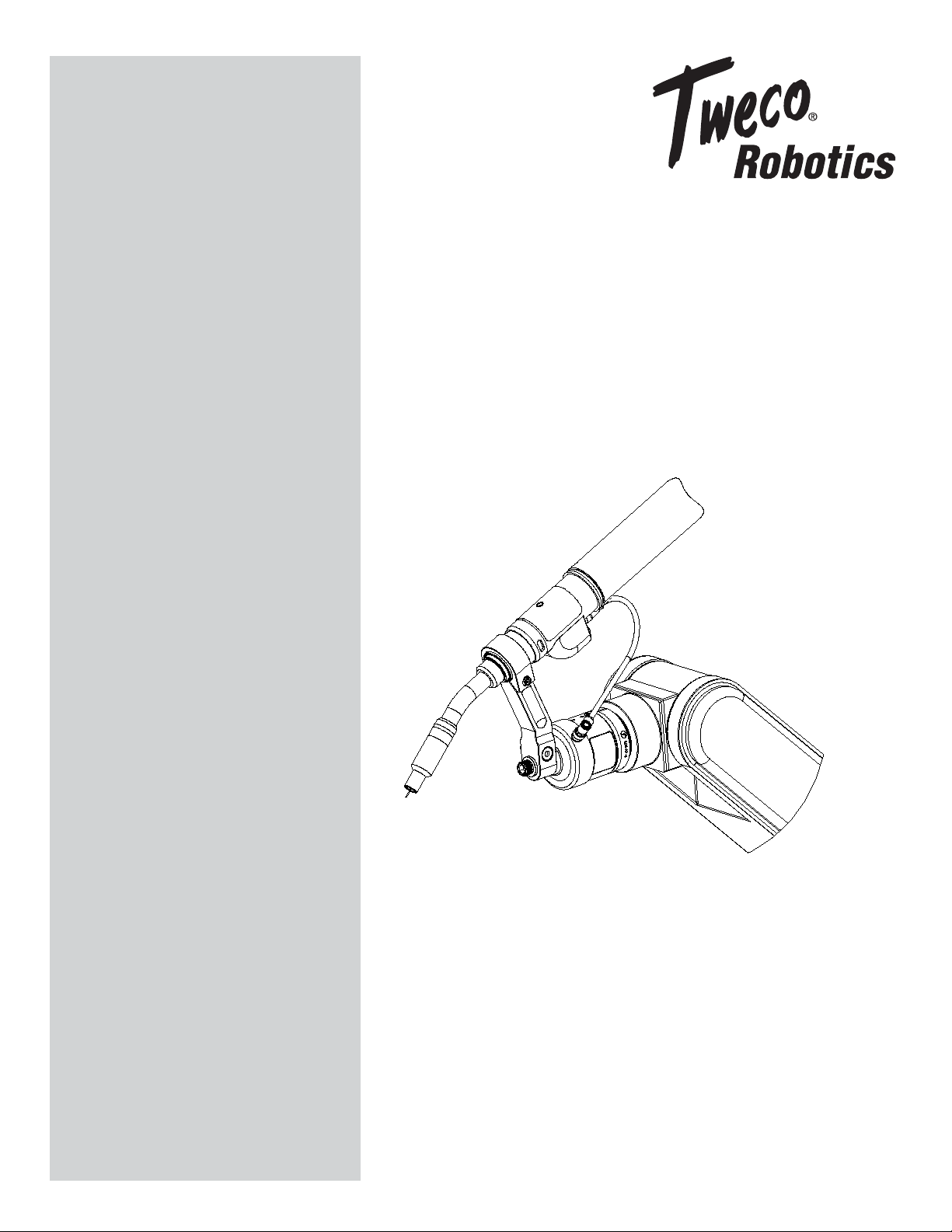

QUICK ROBOTIC

TORCH

Installation Guide and

Replacement Parts Manual

Version No: AA:01 Issue Date: June 30, 2006 Manual No: SM-QRTORCH (06/06)

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Tweco® Robotics product. We are proud to

have you as our customer and will strive to provide you with the best

service and reliability in the industry. This product is backed by our

extensive warranty and world-wide service network. To locate your nearest

distributor or service agency call 800-426-1888, or visit us on the web

at www.tweco.com.

This Manual has been designed to instruct you on the correct installation

and use of your Tweco® Robotics product. Your satisfaction with this

product and its safe operation is our ultimate concern. Therefore, please

take the time to read the entire manual, especially the Safety Precautions.

They will help you to avoid potential hazards that may exist when working

with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Tweco® Robotics is a Global Brand of Arc Welding Products for Thermadyne

Industries Inc. We manufacture and supply to major welding industry

sectors worldwide including; Manufacturing, Construction, Mining,

Automotive, Aerospace, Engineering, Rural and DIY/Hobbyist.

We distinguish ourselves from our competition through market-leading,

dependable products that have stood the test of time. We pride ourselves

on technical innovation, competitive prices, excellent delivery, superior

customer service and technical support, together with excellence in sales

and marketing expertise.

Above all, we are committed to develop technologically advanced products

to achieve a safer working environment within the welding industry.

Page 3

!

WARNING

Read and undeRstand this entiRe Manual and youR eMployeR’s safety pRactices befoRe installing,

opeRating, oR seRvicing the equipMent.

While the infoRMation contained in this Manual RepResents the ManufactuReR’s best judgMent,

the ManufactuReR assuMes no liability foR its use.

Quick Robotics Torch

Installation Guide and Replacement Parts Manual

Instruction Manual Number SM-QRTORCH

Published by:

Tweco® Products Inc.

2800 Airport Road

Denton, TX 76208

(940) 566-2000

www.tweco.com

Copyright © 2006 by

Thermadyne Industries Inc.

® All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss or damage caused by any error or

omission in this Manual, whether such error results from negligence, accident, or any other cause.

Publication Date: June 30, 2006

Record the following information for Warranty purposes:

Where Purchased: ________________________

Purchase Date: ________________________

Equipment Serial #: ________________________

Registered Trademarks ABB® FANUC® Miller® Lincoln® Panasonic® Motoman® and Kevlar® are the respective property of their owners, not Thermadyne Industries, Inc.

i

Page 4

Quick Robotic toRch

SECTION 1:

SAFETY INSTRUCTIONS AND WARNINGS .................................................. 1-1

1.01 Welding Hazards .......................................................................................1-1

1.02 Principal Safety Standards ........................................................................1-3

1.03 Safety and Health ......................................................................................1-3

SECTION 2:

INTRODUCTION AND DESCRIPTION ......................................................... 2-4

2.01 How to Use this Manual ............................................................................2-4

2.02 Receipt of Equipment ................................................................................2-4

2.03 Introduction ..............................................................................................

2.04 Standard Features .....................................................................................2-4

SECTION 3:

INSTALLATION AND DISASSEMBLY ......................................................... 3-6

Table of Contents

2-4

3.01 Installation ................................................................................................

3.02 Disassembly .............................................................................................

3.03 Changing The Cartridge Kit .......................................................................

SECTION 4:

WIRING ..........................................................................................4-10

SECTION 5:

WATER-COOLED TORCH BODY AND CABLE ASSEMBLY .................................5-11

SECTION 6:

MAINTENANCE .................................................................................6-12

SECTION 7:

TROUBLESHOOTING ..........................................................................7-13

SECTION 8:

REPLACEMENT PARTS ....................................................................... 8-14

QRA & QRAS Series Replacement Parts .........................................................8-15

QRW & QRWS Series Replacement Parts ......................................................8-19

QRWA & QRWAS Series Replacement Parts ..................................................8-25

3-6

3-8

3-8

SECTION 9:

ROBOTIC CONDUIT LINERS ..................................................................9-31

SECTION 10:

FACTORY REPAIR CENTER ................................................................. 10-32

LIMITED WARRANTY .............................................................................. 10-33

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION ..................................... 10-35

ii

SM-QRTORCH

Page 5

Quick Robotic toRch

!

SECTION 1:

SAFETY INSTRUCTIONS AND WARNINGS

WARNING

SERIOUS INJURY OR DEATH May Result if Welding and cutting equipMent is not pRopeRly installed,

used and Maintained. Misuse of this equipMent and otheR unsafe pRactices can be hazaRdous.

the opeRatoR, supeRvisoR and helpeR Must Read and undeRstand the folloWing safety WaRnings

and instRuctions befoRe installing oR using any Welding oR cutting equipMent.

the Welding and cutting pRocess is used in Many potentially dangeRous enviRonMents such

as elevated heights, aReas of liMited ventilation, close quaRteRs, aRound WateR, in hostile

enviRonMents, etc., and it is iMpoRtant that the opeRatoR(s) aRe aWaRe of the dangeRs associated

With WoRking in these types of conditions. be ceRtain that the opeRatoR(s) aRe tRained in

safe pRactices foR enviRonMents in Which they aRe expected to WoRk and undeR coMpetent

supeRvision.

it is essential that the opeRatoR, supeRvisoR and all otheR peRsonnel in the WoRk aRea aRe aWaRe

of the dangeRs of the Welding oR cutting pRocess. tRaining and pRopeR supeRvision aRe iMpoRtant

foR a safe WoRk place. keep these instRuctions foR futuRe use. additional RecoMMended safety

and opeRating infoRMation is RefeRenced in each section.

1.01 Welding Hazards

WARNING

electRic shock can cause injuRy oR

death.

ins ta l l and M aintain eq uipMen t in

accoRdance With the national electRical

code (nfpa 70) and local codes. do not

seRvice oR RepaiR equipMent With poWeR on.

do not opeRate equipMent With pRotective

insulatoRs oR coveRs ReMoved. seRvice

oR RepaiR to equipMent Must be done by

a qualified RepaiR technician, oR tRained

peRsonnel only.

1.

Do not touch live electrical parts.

2.

Do not touch an electrode with bare skin and electrical

ground at the same time.

3. Always keep welding gloves dry and in good condition.

NOTE

Aluminized protective clothing can become part

of the electrical path.

4. Keep oxygen cylinders, chains, wire ropes, cranes, hoists,

and elevators away from any part of the electrical path.

5. All ground connections must be checked periodically

to determine that they are mechanically strong and

electrically adequate for the required current.

6. When engaged in alternating current, welding, or cutting

under wet conditions or warm surroundings where

perspiration is a factor, the use of reliable automatic

controls for reducing the no-load voltage is recommended

to reduce shock hazard.

7. When the welding or cutting process requires values of

open circuit voltages in alternating current machines

higher than 80 volts, and direct current machines higher

than 100 volts, means must be provided to prevent the

operator from making accidental contact with the high

voltage by adequate insulation or other means.

8. When welding is to be suspended for any substantial length

of time, such as during lunch or overnight, all electrodes

should be removed from the electrode holder and the

electrode holder carefully located so that accidental

contact cannot occur.

9. The holder must be disconnected from the power source

when not in use.

10. Never immerse Mig-Guns, electrode holders, tig torches,

plasma torches, or electrodes in water.

SM-QRTORCH

1-1

SAFETY INSTRUCTIONS AND WARNINGS

Page 6

Quick Robotic toRch

WARNING

should be closed and cuffs sewn shut. Leather aprons,

sleeves, leggings, etc., should be worn for out-of-position

welding and cutting or for heavy operations using large

electrodes. High top work shoes provide adequate protection

from foot burns. For added protection use leather spats.

sMoke, fuMes and gases can be dangeRous

to youR health.

11. Keep smoke, fumes, and gases from the breathing area.

12. Fumes from the welding or cutting process are of various

types and strengths, depending on the kind of base metal

being worked on. To ensure your safety, do not breathe these

fumes.

13. Ventilation must be adequate to remove smoke, fumes, and

gases during the operation to protect operators and other

personnel in the area.

14. Vapors of chlorinated solvents can form the toxic gas

“Phosgene” when exposed to ultraviolet radiation from an

electric arc. All solvents, degreasers, and potential sources

of these vapors must be removed from the work area.

15. Fumes produced by welding or cutting, particularly in confined

places, can cause discomfort and physical harm if inhaled

over an extended period of time.

16. Provide adequate ventilation in the welding or cutting area.

Use air-supplied respirators if ventilation is not adequate to

remove all fumes and gases. Never ventilate with oxygen.

Oxygen supports and vigorously accelerates fire.

21. Flammable hair preparations should not be used when

welding or cutting. Wear ear plugs to protect ears from

sparks.

22. Where the work area permits, the operator should be enclosed

in an individual booth painted with a finish of low reflectivity

such as zinc oxide. This is an important factor for absorbing

ultraviolet radiations, and lamp black. The operator should be

enclosed with non-combustible screens similarly painted.

WARNING

Welding spaRks can cause fiRes and

explosions.

23. Causes of fire and explosion are: combustibles reached by

the arc, flame, flying sparks, hot slag, or heated material.

Remove combustibles from the work area and/or provide a

fire watch.

24. Avoid oily or greasy clothing as sparks may ignite them. Have

a fire extinguisher nearby, and know how to use it.

25. Be alert to the danger of conduction or radiation. For example,

if welding or cutting is to be done on a metal wall, partition,

ceiling or roof, precautions must be taken to prevent ignition

of combustibles on the other side.

WARNING

aRc Rays, hot slag and spaRks can injuRe

eyes and buRn skin .

17. The welding and cutting processes produce extreme localized

heat and strong ultraviolet rays.

18. Never attempt to weld or cut without a welding helmet with

the proper lens. Ensure that the lens complies with federal

guidelines. A number 12 to 14 shade filter lens provides the

best protection against arc radiation. When in a confined

area, prevent the reflected arc rays from entering around the

helmet.

19. Ensure all personnel in the work area are protected from arc

rays and sparks. Approved shielding curtains and appropriate

goggles should be used to provide protection to staff in the

surrounding area and operators of nearby equipment.

20. Unprotected skin should also be covered from arc rays, heat

and molten metal. Always wear protective gloves and clothing

that does not allow skin to become exposed. All pockets

SAFETY INSTRUCTIONS AND WARNINGS

26. Do not weld or cut containers that have held combustibles.

All hollow spaces, cavities and containers should be vented

prior to welding or cutting to permit the escape of air or gases.

Purging with inert gas is recommended.

27. Never use oxygen in a welding torch. Use only inert gases or

inert gas mixes as required by the process. Use of combustible

compressed gases can cause explosions resulting in personal

injury or death. Arcing against any compressed gas cylinder

can cause cylinder damage or explosion.

WARNING

noise can daMage heaRing.

28. Noise from the air carbon-arc process can damage

your hearing. Wear protective hearing devices to ensure

protection when noise levels exceed OSHA standards.

Adequate hearing protection devices must be worn by

operators and surrounding personnel to ensure personal

protection against noise.

1-2

SM-QRTORCH

Page 7

!

1.02 Principal Safety Standards

1.03 Safety and Health

Quick Robotic toRch

NOTE

Be sure to read and fully comprehend the safety

instuctions and warnings contained within section

1 of this manual before performing any welding

or cutting operations.

seRious injuRy oR death May Result if

Welding and cutting equipMent is not

pRopeRly installed, used and Maintained.

Misuse of this equipMent, oR otheR unsafe

pRactices, can be hazaRdous.

Electric shock can cause injury or death.

•

Smoke, fumes, and gases can be dangerous to your

•

health.

Arc rays, hot slag, and sparks can injure or burn

•

protected eyes and skin.

Welding sparks can cause fires and explosions.

•

Excessive noise can damage your hearing.

•

WARNING

SM-QRTORCH

1-3

SAFETY INSTRUCTIONS AND WARNINGS

Page 8

Quick Robotic toRch

!

SECTION 2:

INTRODUCTION AND DESCRIPTION

2.01 How to Use this Manual

To ensure safe operation, read the entire manual, including

the chapters on safety instructions and warnings.

Throughout this manual, the words WARNING, CAUTION, and

NOTE may appear. Pay particular attention to the information

provided under these headings. These special annotations

are easily recognized as follows:

a WaRning gives infoRMation RegaRding

possible peRsonal injuRy.

A CAU TION refers to possi ble equipment

damage.

A NOTE offers helpful information concerning

certain operating procedures.

WARNING

CAUTION

NOTE

2.02 Receipt of Equipment

When you receive the equipment, check it against the invoice

to make sure it is complete and inspect the equipment for

possible damage due to shipping. If there is any damage,

notify the carrier immediately to file a claim. Furnish complete

information concerning damage claims or shipping errors to

the location in your area listed in the inside back cover of this

manual. Include a full description of the parts in error.

If you want additional or replacement copies of this CD,

please contact Tweco® Robotics at the address and phone

number in your area listed on the inside back cover of this

manual. Include the Manual number (from page i) and CD

part number: 64-2601.

2.03 Introduction

Tweco® Robotics Quick Robotic Torch series provide many

features that will enhance your robotic welding application.

The Quick Robotic Torch series are offered in either air-cooled,

water-cooled or water/air-cooled cable assemblies. The

series also include a push button “inch-switch” positioned

at the front end of the torch block that allows the welding

wire to be manually fed through the torch prior to the welding

sequence.

Another separate line of the Quick Robotic Torch series offer a

nozzle-sensing feature which will help locate the relationship

between the conductor tube nozzle to the weld joint position.

All Quick Robotic Torches are offered in lengths ranging from

3ft. (91cm) – 15ft. (5m).

2.04 Standard features

Quick conductor tube lock for easy conductor tube

•

replacement.

E-stop cable with connections.

•

Inner cable protective jacket.

•

Heavy cable support springs on both front and rear.

•

Kevlar®/Nylon outer protective cable cover.

•

Water-cooled cables have built in water shut-off valves

•

in the front housing.

Quick hose connections on all water-cooled cables.

•

Internal purge hose for spraying anti-spatter through

•

the conductor tube and nozzle.

All cable assemblies are furnished with a Tweco®,

•

Miller®, and Lincoln® rear connector plug.

INTRODUCTION AND DESCRIPTION

2-4

SM-QRTORCH

Page 9

Quick Robotic toRch

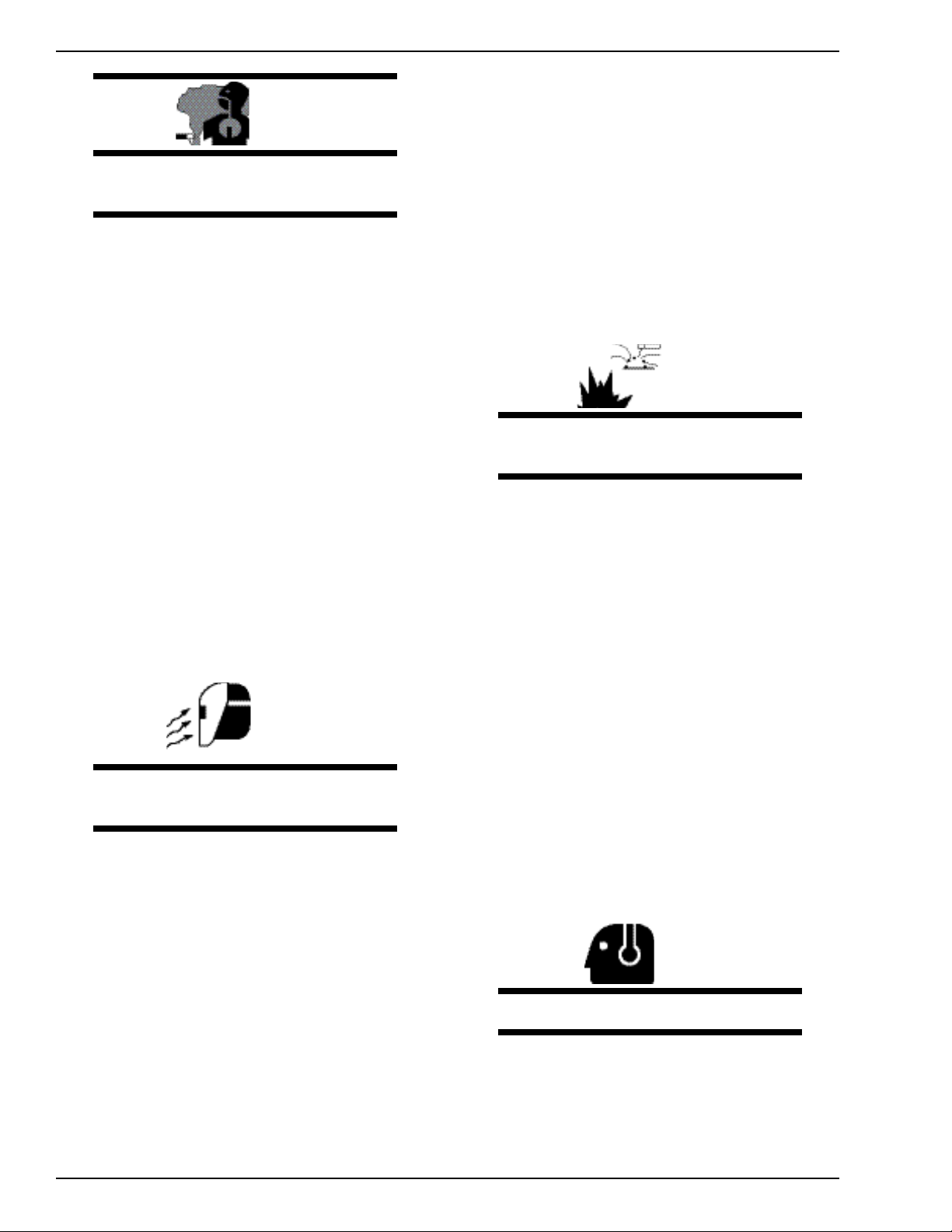

QRA Series Air-cooled Robotic Torch and Cable Assembly

The air-cooled QRA cable assembly uses QTR66 air-cooled conductor tubes. It has an air-cooled power cable rated at 600

amperes @ 60% duty cycle.

QRW Series Water-cooled Robotic Torch and Cable Assembly

The water-cooled QRW cable assembly uses QTRW63, QTRW64, or QTRW66 water-cooled conductor tubes. It is furnished

with a water-cooled power cable rated up to 600 amperes @ 100% duty cycle.

QRWA Series Water/ Air Robotic Torch and Cable Assembly

The QRWA cable assembly is a hybrid using QTRW63, QTRW64, or QTRW66 water-cooled conductor tubes but it utilizes an

air-cooled power cable assembly rated up to 600 amperes @ 80% duty cycle. If water flow is interrupted, amperage rating

is decreased. This provides a torch that has water-cooling of the front consumables while providing a trouble free rugged

air-cooled cable assembly.

QRAS, QRWS, and QRWAS Robotic Nozzle-sensing Torch Cable Assembly

This series of torch and cable assemblies incorporates the same power cables and are rated at the same amperage rating

as the series mentioned above. The only difference is the torch block and the use of the QTRW64-ST series conductor tube

assembly.

A wide variety of conductor tube and front-end consumables are also offered. Contact your local welding distributor and/or

Tweco® Customer Service Department (1-800-426-1888) for assistance in choosing the correct conductor tube and consumables

for your welding application.

SM-QRTORCH

2-5

INTRODUCTION AND DESCRIPTION

Page 10

Quick Robotic toRch

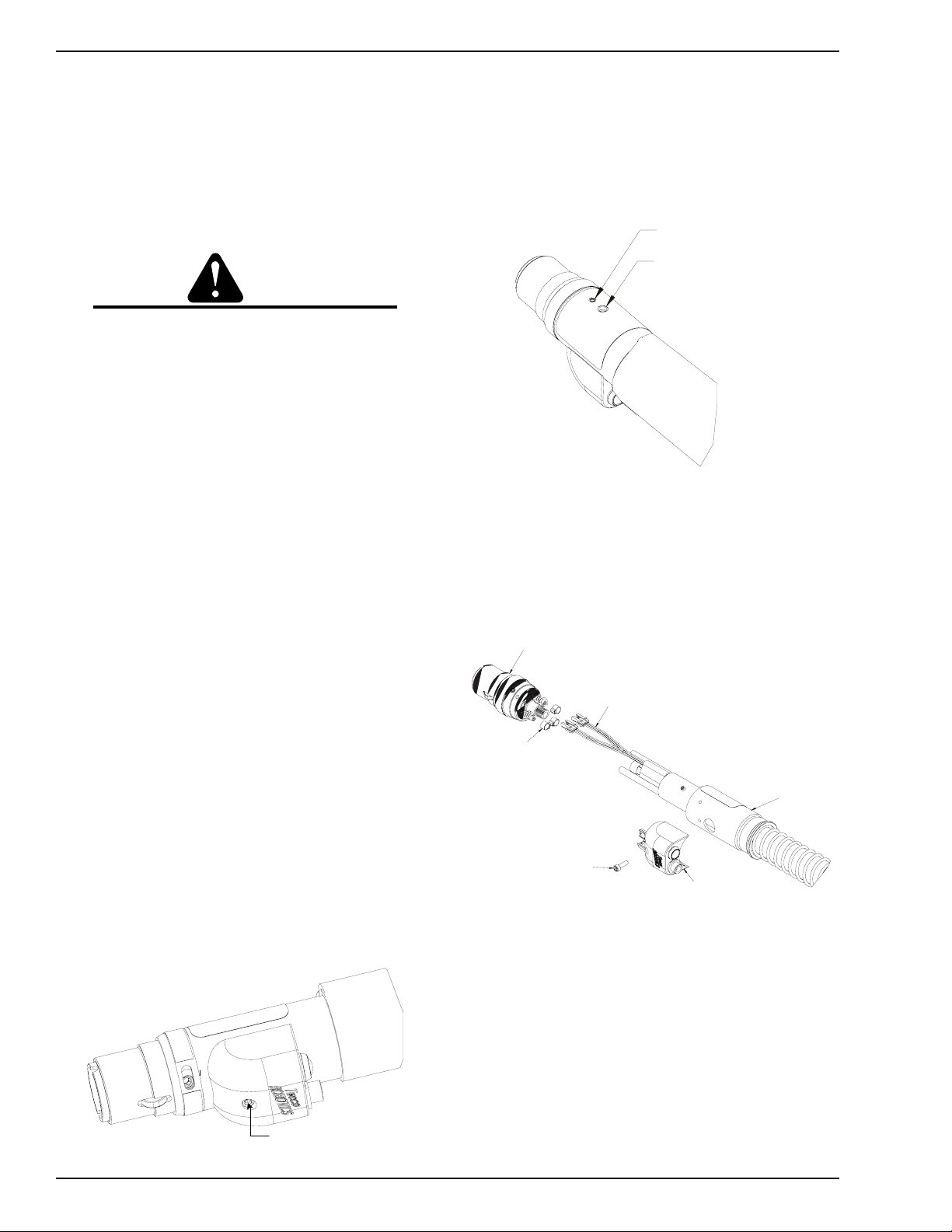

ROTATE FRONT SLEEVE COVER

TO EXPOSE SET SCREW. ROTATE

COVER TO CONCEAL SET SCREW

PRIOR TO TORCH OPERATION.

SET SCREW

(5/32" ALLEN KEY)

WHEN CONDUCTOR TUBE IS FULLY SEATED,

GROOVE ON TUBE SHOULD LINE UP WITH

EDGE OF INSULATING SLEEVE.

SET SCREW

TWECO PLUG

CONDUIT ASSEMBLY

MILLER PLUG

CONDUIT ASSEMBLY

PLUG NIPPLE

SECTION 3:

INSTALLATION AND DISASSEMBLY

3.01 Installation

1. Remove the torch and cable assembly from the carton,

and lay the assembly in a straight and untwisted position

on a workbench or floor.

2. Verify that the overall cable length is correct to fit between

the feeder - robot torch mount combination.

NOTE

For cable assemblies longer than 5ft. (1,52m), it

is recommended incorporating a spring-loaded

stabilizer bar/balancer to the robot work cell to

provide support to the center of the cable assembly.

This will eliminate both excessive drooping of the

cable assembly and any interference with the

fixtures and tooling in the work area.

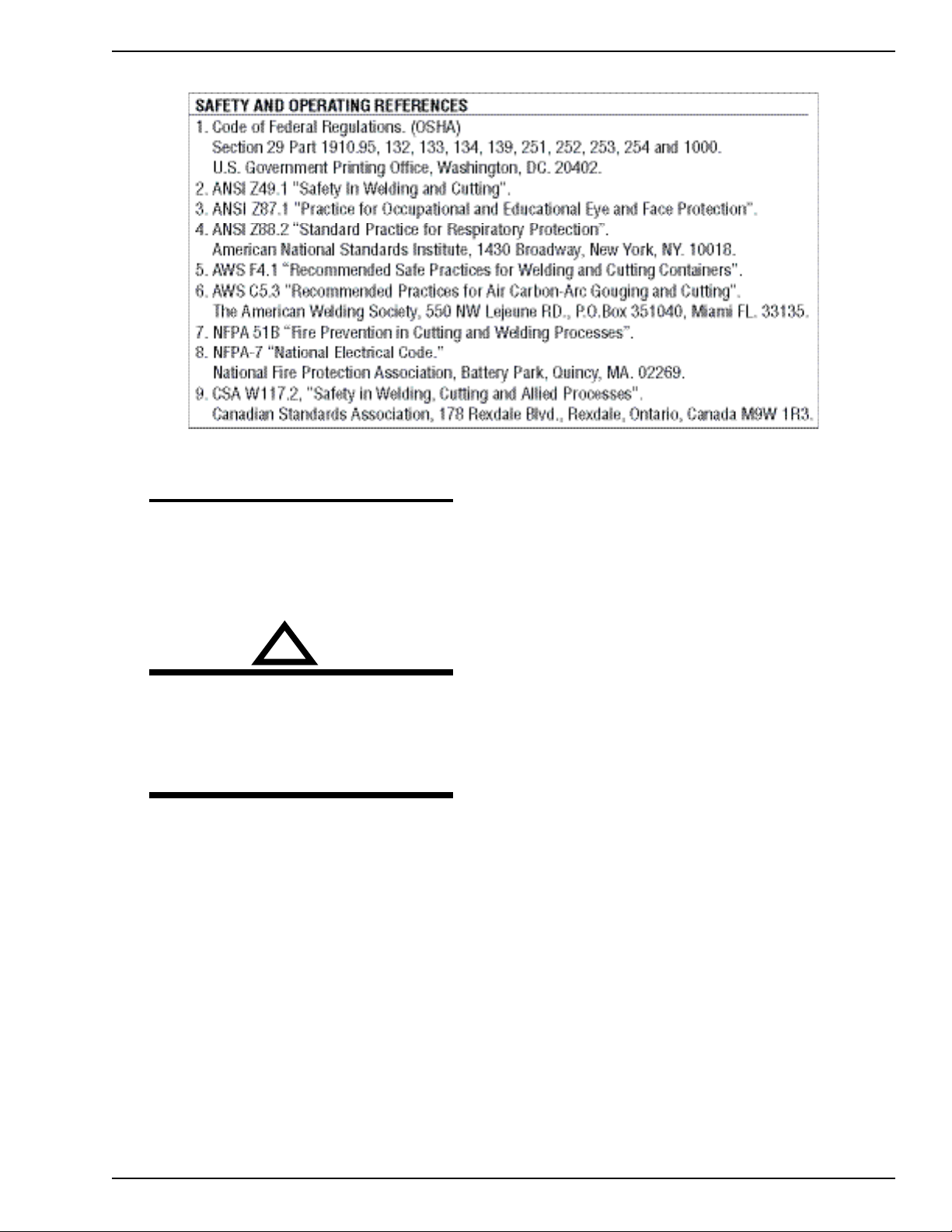

3. Rotate the front sleeve cover to expose the stainless steel

set screw located in the torch block assembly. Insert the

factory supplied 5/32” T-handle Allen wrench into the set

screw and rotate counterclockwise until it stops as shown

in Figure 3-1.

6. Remove the gas diffuser, tip and nozzle from the conductor

tube assembly.

7. The torch and cable assembly comes with the Miller

®

rear

connector plug installed. If the feeder requires a different

rear connector plug, select the correct rear connector plug

for the feeder being used and thread the plug into the rear

of cable assembly. This connection should be wrench

tight.

8. The QR Series torch and cable assemblies are furnished

with R45-116 conduit and the rear connector plugs to

fit this series of conduit. If a different conduit and rear

connector plug is required, refer to Page 9-31 listing the

various conduits that are available.

9. Remove the conduit from the package and uncoil

carefully.

CAUTION

Bending or distorting the conduit can cause wire

feed problems.

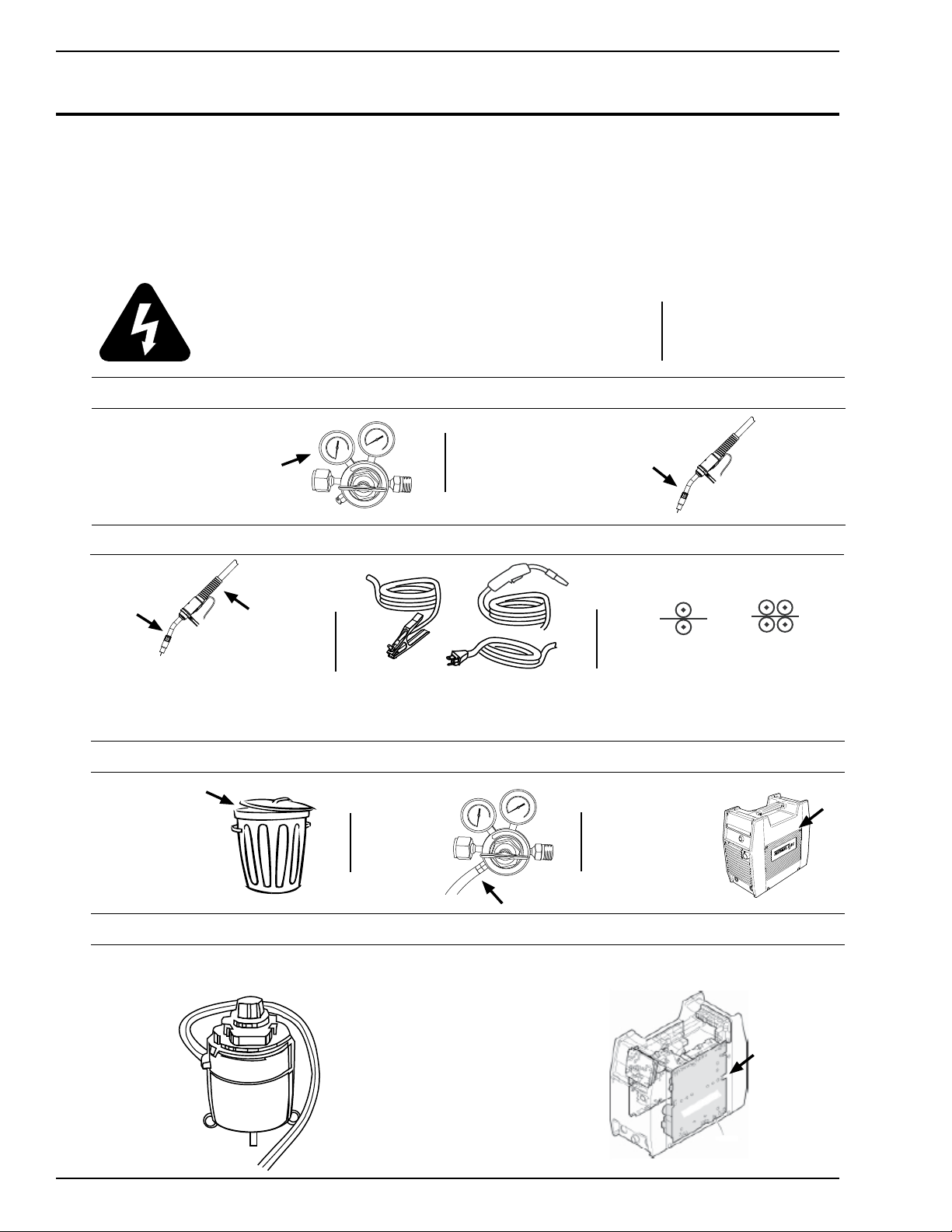

10. Loosen the set screw located on the Tweco

®

, Panasonic®

and Lincoln® rear connector plug to ensure the conduit will

feed through properly. For Miller® style plug, remove the

threaded connector plug nipple from the rear connector

plug on the torch assembly. Refer to Figure 3-3 & 3-4.

Figure 3-1: Conductor Tube Locking Set Screw

4. Insert the conductor tube assembly into the torch block

assembly. The conductor tube is positively located into

the torch body by the use of two stainless steel alignment

pins.

5. Push the conductor tube assembly into place until the

stainless steel set screw can drive the back plug on the

conductor tube into its locked operating position. The

conductor tube has a machined locating groove around

its rear diameter. This groove will be flush with the front

housing when properly installed as shown in Figure 3-2.

Figure 3-2: Conductor Tube Installation

INSTALLATION AND DISASSEMBLY

Figure 3-3: Conduit Installation with Set Screw

Figure 3-4: Conduit Installation with Plug Nipple (Miller® Style)

11. Insert the factory-supplied 5/32” T-handle Allen wrench

through the hole on the aluminum front handle cap,

identified as “Conduit Set Screw” on the label, and rotate

the set screw counterclockwise until it stops rotating.

3-6

SM-QRTORCH

Page 11

12. Insert the exposed raw coil end of the conduit, factory

CONDUIT SET SCREW HOLE

A

rt # JB-00012

KEYSTOCK

CUT LINE

A

”B“ DOHTEM”A“ DOHTEM

Art # JB-00013

supplied, into the rear connector plug. Feed the conduit

through the gun and conductor tube assembly. If the

conduit attempts to hang up, rotate the conduit liner

counterclockwise while gently pushing.

13. When the conduit is completely through the torch and

conductor tube assembly, seat the brass conduit stop

firmly against the connector plug.

14. Tighten the set screw on the Tweco

®

, Panasonic®, and

or Lincoln® rear connector plug. For Miller® style rear

connector plug, re-install the threaded connector plug

nipple. This connection should be wrench tight.

15. Re-insert the factory-supplied 5/32” T-handle Allen

wrench into the hole for the “Conduit Set Screw” on the

front handle cap and rotate the set screw clockwise. The

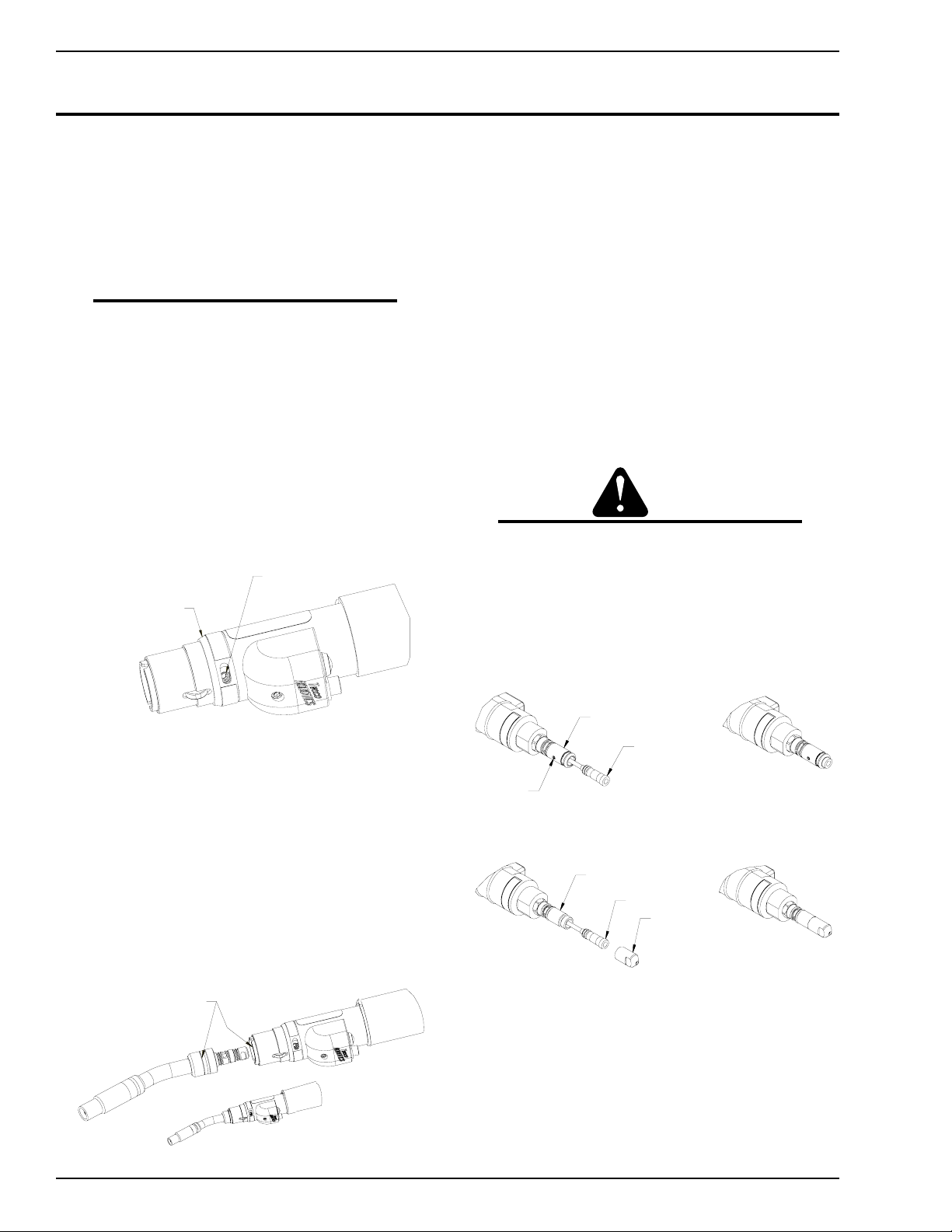

set screw should be hand tight. Refer to Figure 3-5.

Quick Robotic toRch

17. After trimming to length, remove any obstructions from

the end of the conduit radius.

18. Re-install the diffuser, tip and nozzle into the conductor

tube assembly.

19. Loosen the robot mount arm connection on the robot arm,

and insert the cartridge kit of the torch and conductor tube

assembly into position on the robot arm. The keystock

located on the cartridge kit should be placed into the

mating slot on the mount arm until the sleeve bottoms

against the robot arm. Re-tighten the connection to secure

the assembly in place. Refer to Figure 3-7.

Figure 3-7: Locating Keystock

NOTE

For cable assemblies longer than 5ft. (1,52m), it

is recommended incorporating a spring-loaded

Figure 3-5: Access Hole for Conduit Set Screw

stabilizer bar/balancer to the robot work cell to

provide support to the center of the cable assembly.

16. Trim the conduit extending from the front of the conductor

tube assembly by following the steps below:

This will eliminate both excessive drooping of the

cable assembly and any interference with the

fixtures and tooling in the work area.

Method “A” – Using a tape measure or scale, mark and cut the

conduit to the cut length noted in the table below. Refer

to Figure 3-6 — Method “A”.

Method “B” – The diffusers have a machined groove around

the outer diameter. Position the diffuser as shown in Figure

3-6 — Method “B” and mark and cut the conduit.

20. Install the rear connector plug into the feeder.

21. Install the E-stop Cable between the robot deflection mount

and the cable front housing on the torch.

22. Attach an adapter cable, sold separately, to the rear

connection on the yellow E-stop cable located at the rear

of the cable assembly. Refer to Section 4 for detail on

optional adapter cables and wiring instructions.

Conductor Tube Assy. Cut Length “A”

QTR66 Series – (For use with QRA series torch/cable assemblies) 1-5/16” (33,32mm)

QTRW63 Series – (For use with QRW & QRWA series torch/cable assemblies) 15/16” (23,80mm)

QTRW64 Series – (For use with QRW & QRWA series torch/cable assemblies) 1/4” (6,35mm)

QTRW66 Series – (For use with QRW & QRWA series torch/cable assemblies) 5/16” (7,92mm)

SM-QRTORCH

Figure 3-6: Conduit Cut Length

3-7

INSTALLATION AND DISASSEMBLY

Page 12

Quick Robotic toRch

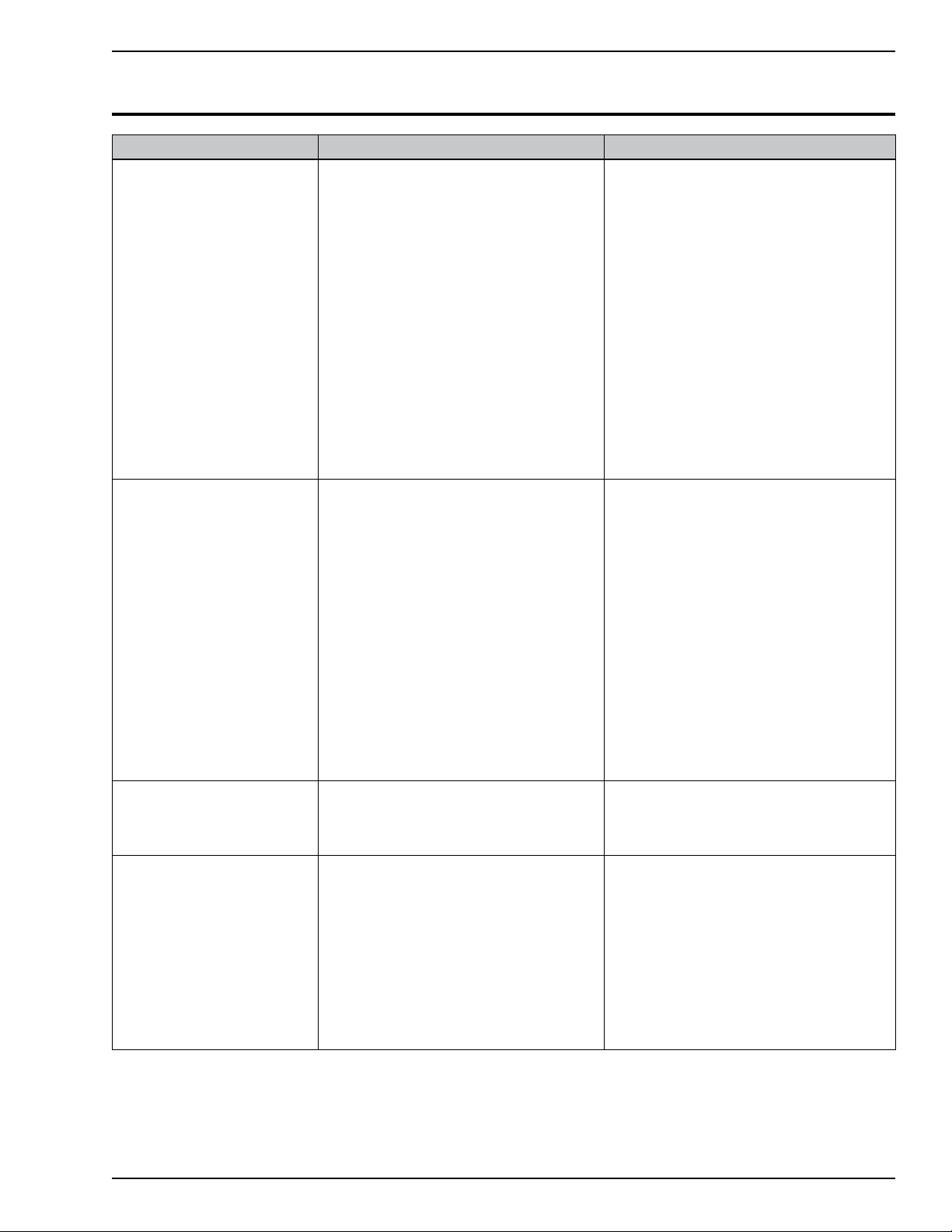

SOCKET SET SCREW

ACCESS HOLE FOR SET SCREW

CONDUIT SET SCREW HOLE

FRONT SLEEVE COVER

& SPRING

INCH SWITCH HOUSING

SOCKET HEAD

CAP SCREW

ELECTRICAL CONNECTIONS

HOSE CLAMPS

CARTRIDGE

KIT

23. Plug or wire the other end into the proper pin locations on

the robot. Refer to the manufacturer recommendations

and installation instructions.

24. If the torch being installed is a water-cooled QRW or QRWA

series, a water supply providing not less than ¾ gallons/

minute (2.84 liters/minute) water flow must be used

during operation. The water supply should be installed

to run when the power source is turned “on” if possible

to avoid any damage to the torch and cable assembly.

CAUTION

Operating a water-cooled torch and cable

assembly without water or restricted flow will

result in damage to the cable assembly.

25. The torch and cable assembly is furnished with a purge

hose that can be used to supply inert gas and or antispatter through the torch block and conductor tube

assembly. To use this purge hose, remove the plastic plug

and connect accordingly.

26. The torch is now ready to place into operation. Be sure to

check the TCP and single step the robot through the robot

program to ensure that the conductor tube positioning is

correct.

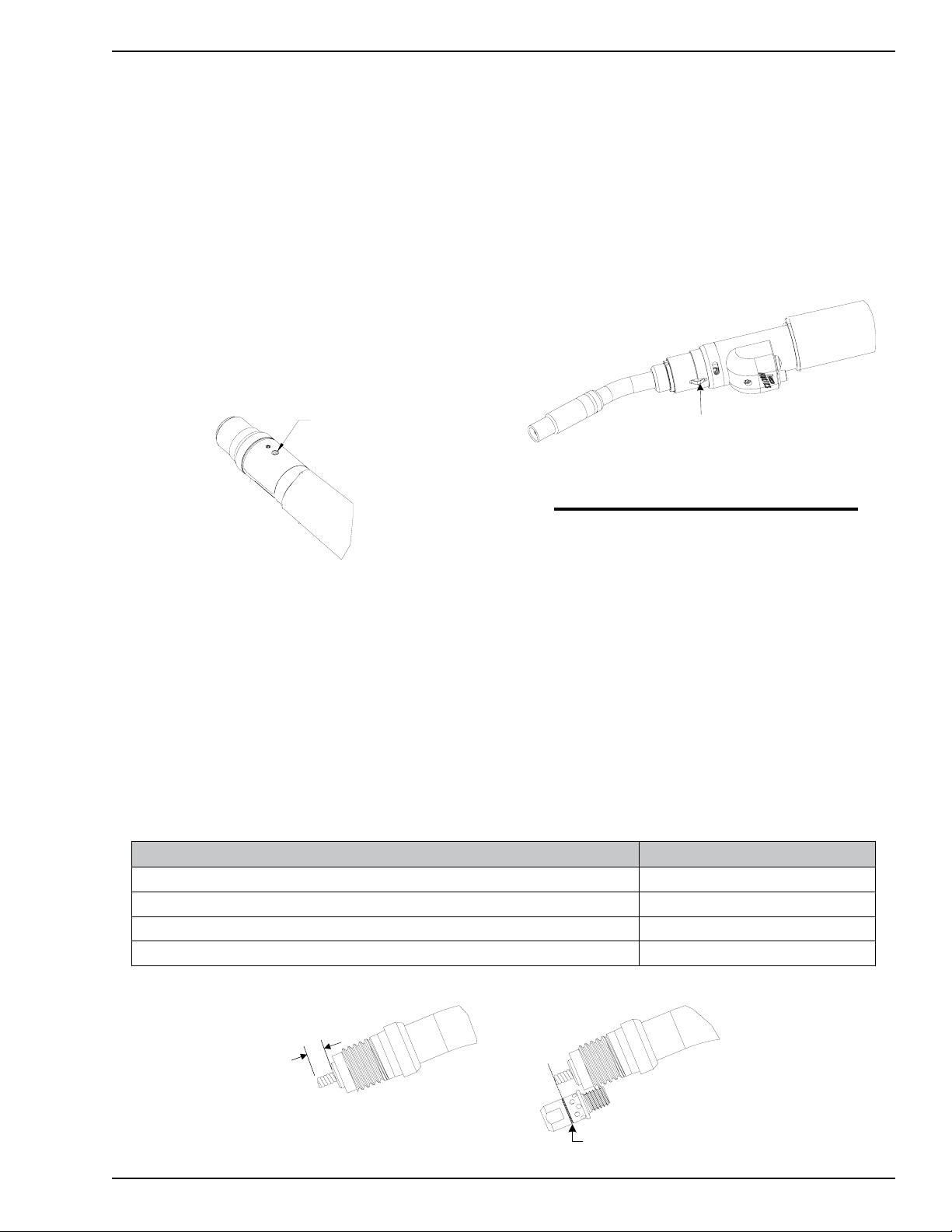

3.02 Disassembly

1. To disassemble the torch and cable assembly from the

robot arm, reverse the steps noted in Section 3.01

(d) With the housing away from the front sleeve cover,

insert the factory-supplied 3/32” Allen wrench into the

two (2) access holes for the set screws and loosen. A

third set screw will need to be loosened along with the

two mentioned. This set screw is located 180° from

the molded housing screw hole and approximately

½” (12,7mm) below the “Conduit Set Screw” hole

noted on the label. Refer to Figure 3-9.

Figure 3-9: Access Hole for Set Screw

(e) Push the 3/32” Allen wrench through the label and

insert the set screw and loosen.

(f) Slide the front sleeve cover and support spring away

from the cartridge kit. Refer to Figure 3-10.

3.03 Changing The Cartridge Kit

1. To remove and replace the correct cartridge kit, follow the

steps below:

(a) Cut the metal straps holding the outer cover in place on

both ends.

(b) Pull the protective outer cover away from the cable

assembly.

(c) Remove the socket head cap screw located on the molded

inch switch housing. Once the housing is loose and can

be pulled away from the front sleeve cover, pull apart the

two exposed electrical connections. Refer to Figure 3-8

Figure 3-10: Exploded View of Torch

(g) Remove the heat shrink and clamp holding the inch

switch cable to the cablehoz.

Figure 3-8: Removal of Inch Switch Housing

INSTALLATION AND DISASSEMBLY

3-8

SM-QRTORCH

Page 13

(h) Remove the steel hose clamps from the various hose

CLAMP

VALVE

SPRING

POWER CABLE

assemblies. Using pliers, position the tabs on the steel

clamps to allow the clamp to be held. Twist the tab

clockwise until the clamp breaks apart.

CAUTION

Do not bend the nipple(s) while twisting the tab(s)

to break the clamp apart.

(i) Remove the cable hose connector away from the

existing cartridge kit.

Quick Robotic toRch

(d) Remove the threaded power cable connection from

the block assembly. Refer to Figure 3-12.

Figure 3-12: QRW Series Check Valve

(j) Follow the above steps in reverse order to re-assemble

the new cartridge kit.

CAUTION

When connecting the cablehoz connector, be

sure to apply a high strength thread locking

adhesive compound to the threads of the brass

block assembly before threading the cablehoz

connector onto the block. This connection must

be tightened to a torque of 120 inch/pounds.

Failure to tighten this connection properly could

cause the power cable to overheat.

(k) Use the clamps, supplied with the cartridge kit, to

hold the inch switch cable in place. Refer to Figure

3-11.

(e) Re-insert the lead wire coming from replacement

cartridge kit into the connector assembly.

NOTE

Make sure the components making up the check

valve remains inside of the block assembly. If the

components are removed, make sure they are

installed as shown in Figure 3-12.

(f) Follow Steps (a) through (g) in reverse order to

re-assemble the new cartridge kit.

CAUTION

When connecting the cablehoz connector, be

sure to apply a high strength thread locking

adhesive compound to the threads of the brass

block assembly before threading the cablehoz

connector onto the block. This connection must

be tightened to a torque of 30-35 inch/pounds.

Failure to tighten this connection properly could

cause the power cable to overheat.

Figure 3-11: Location of Clamps

2. Follow the steps below to replace the cartridge kit on a

QRW and QRW-S torch and cable assemblies:

(a) Follow Steps (a) through (g) for removing the cartridge

kit on QRA, QRAS, QRWA, and QRWAS series torch

and cable assemblies.

(b) When replacing or re-installing the cartridge kit having

the nozzle sensing feature, the wire lead for the nozzle

sensing must be disconnected or connected inside

the molded housing.

(c) Using needle-nose pliers, pull the existing wire

lead away from the cartridge kit to the connector

assembly.

SM-QRTORCH

3-9

INSTALLATION AND DISASSEMBLY

Page 14

Quick Robotic toRch

PIN 1 RED

NORMALLY OPEN

PIN 2 GREEN COMMON

PIN 3 ORANGE NORMALLY CLOSED

PIN 4 --- -- -

PIN 5 BLUE NOZZLE SENSING

PIN 6 --- -- -

PIN 7 WHITE SW1

PIN 8 --- -- -

PIN 9 BLACK SW2

CONTROL CABLE ASSEMBLYINCH SWITCH/E-STOP ASSEMBLY

PIN

PIN

SOCKET

SOCKET

GREEN

RED / BLACK

RED / WHITE

BLACK SW1

BLACK SW2

BLACK ST3

GREEN

RED

ORANGE

WHITE

BLACK

BLUE

RECEPTACLE AMP 206 705-2

HOUSING AMP 207008-1

E-STOP

CONNECTOR

INCH SWITCH

NOZZLE SENSING SWITCH

RED/BLACK

RED/WHITE

GREEN

SECTION 4:

WIRING

The QRA, QRW, & QRWA torches are furnished with a switch

housing mounted on the front case. This housing contains a

push button inch switch for feeding the welding wire through

the gun. Mounted next to the inch switch is a 3-pin socket

that will accept the E-stop cable from the robot deflection

mount.

Connection Part No. Stock No.

Without Connector QRJC-010 3045-1241

Burndy (ABB®) QRJC-020 3045-1242

4-pin Amp (Motoman®) QRJC-030 3045-1243

5-pin DDK connector (Fanuc®) QRJC-040 3045-1244

5-pin DDK connector (Panasonic®) QRJC-050 3045-1245

Table 4-1: E-Stop Adapter Jumper Cables

Both the switch and socket are connected to a 6-wire cable

that runs along the inside of the inner protective jacket. The

end of this cable extends approximately 12” (304.8mm) out

of the rear case and comes standard with a 9-pin amp plug.

Adapter jumper cables are available to connect this cable to

most robots. See Table 4-1.

WIRING

Wiring Schematic for E-Stop Cable

4-10

SM-QRTORCH

Page 15

Quick Robotic toRch

HOSE NIPPLE

SPRING

VALVE

VALVE

SPRING

HOSE NIPPLE

SECTION 5:

WATER-COOLED TORCH BODY AND CABLE ASSEMBLY

The water-cooled torch and cable assemblies incorporate water shut-off valves allowing the conductor tube to be removed

without shutting off the water supply. This reduces the chance of introducing moisture into the conductor tube and conduit.

Refer to Figure 5-1 & 5-2 showing the water shut-off valves on the QRW and QRWA Series Torch Body and Cable Assembly.

Figure 5-1: QRW Series Check Valves

Figure 5-2: QRWA Series Check Valves

A water supply providing not less than 3/4 gallons/minute (2.84 liters/minute) water flow must be used during operation. The

water supply should be installed to run when the power source is turned “on” if possible to avoid any damage to the torch

and cable assembly.

CAUTION

Operating a water-cooled torch and cable

assembly without water or restricted flow will

result in damage to the cable assembly.

If the threaded power connection is removed from the QRW series block assembly make sure the component parts making up the

check valve remains inside of the block assembly. If the components are removed, make sure they are installed properly.

SM-QRTORCH

5-11

WATER-COOLED TORCH BODY AND CABLE ASSEMBLY

Page 16

Quick Robotic toRch

Each Use

Visual check of torch

Consumable parts

Weekly

Visually inspect the torch

body and consumables

Visually inspect the

cables and leads.

Replace as needed

3 Months

Clean

exterior

of power supply

6 Months

Replace all

broken parts

Visually check and

use a vacuum to carefully

clean the interior

Gas and

air lines

Visually inspect the Wire

feed mechanisms

Warning!

Disconnect input power before maintaining.

Maintain more often

if used under severe

conditions.

Visual check of

regulator and pressure

SECTION 6:

MAINTENANCE

Contact tips and nozzles should be cleaned frequently. Spatter

buildup may cause bridging between nozzle and tip. This

could cause electrical shorting between the nozzle and work

piece as well as restricting gas flow.

Regularly inspect the conductor tube, torch and cable

assembly for abrasions, cuts and undue wear. Replace or

repair any parts as needed.

The torch and conductor tube assemblies have o-rings for

seals. Lubrication of these o-rings should be done periodically

and periodical inspections should be made to ensure that the

o-rings do not degrade, allowing water and or shielding gas

leaks to occur. When removing the conductor tube from the

torch assembly, be sure the single o-ring located in the bottom

of the hole remains in place.

MAINTENANCE

6-12

SM-QRTORCH

Page 17

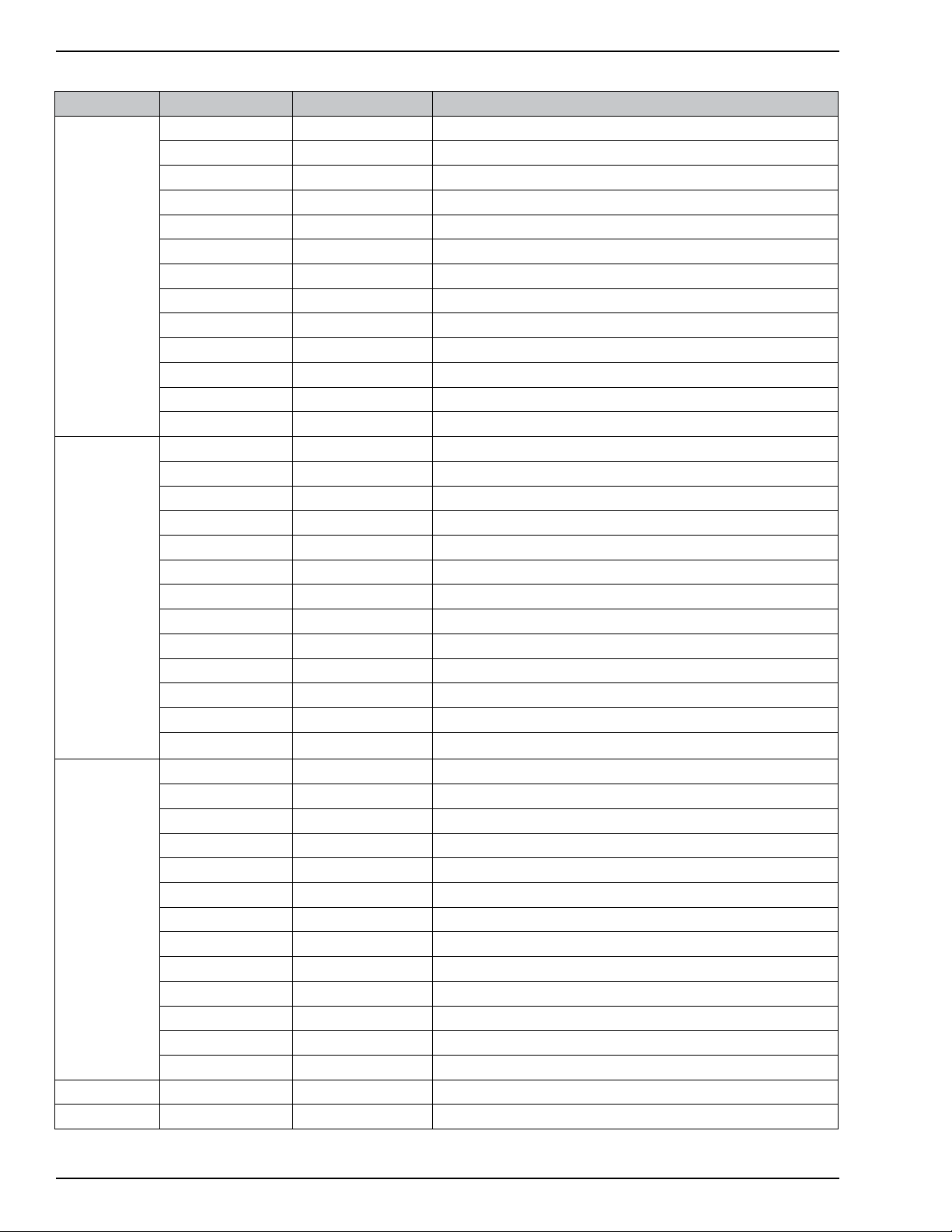

Problem Possible Cause Corrective Action

Wire feed inconsistent or not

smooth.

SECTION 7:

TROUBLESHOOTING

1. Loose drive Rollers on feeder.

2. Dirty or plugged conduit.

Quick Robotic toRch

1. Tighten drive rollers.

2. Replace conduit.

Torch and cable assembly is

running hot.

3. Conduit pulled back from diffuser.

4. Sharp bends or kinks in conduit.

5. Machine improperly adjusted.

6. Spatter buildup on end of contact tip.

7. Loose contact tip or diffuser.

8. Excessively worn contact tip.

9. Loose ground cable or ground clamp.

1. Loose power connection.

2. Loose or undersize ground cable or

ground clamp.

3. Conductor tube not tight in torch block.

4. Loose contact tip or diffuser.

5. Operating torch and cable assembly

above recommended amperage rating.

3. Reposition conduit and tighten front

screw.

4. Remove and replace conduit.

5. Reset machine per machine and wire

manufacturers’ recommendations.

6. Clean or replace contact tip.

7. Tighten contact tip and diffuser plier

tight.

8. Replace contact tip.

9. Tighten or replace as required.

1. Inspect complete torch and cable for

loose connections and tighten.

2. Tighten or replace as required.

3. Tighten stainless setscrew in torch

block.

4. Tighten contact tip and diffuser.

5. Readjust machine to correct setting for

size of torch being used.

6. Power cable assembly damaged.

7. Restricted water flow (only QRW and

QRWA series torch).

Robot will not start. 1. Deflection mount not at “home”

position.

2. Check E-stop cable connection

Porous weld. 1. Poor or improper gas flow.

2. Moisture from torch/conductor tube.

3. Dirty or contaminated wire.

4. Base metal contamination.

6. Inspect and replace accordingly.

7. Inspect water lines for any excessive

bends.

1. Check to ensure the mount arm and

mount location.

2. Check E-stop cable connection.

1. Check gas flow out of conductor tube

nozzle. Check for leaks or restrictions

in gas hoses and connections.

2. Check O-rings on conductor tube and

torch block. Check the torch block for

any scarring, gouges to the surface.

3. Change wire.

4. Replace base metal.

SM-QRTORCH

7-13

TROUBLESHOOTING

Page 18

Quick Robotic toRch

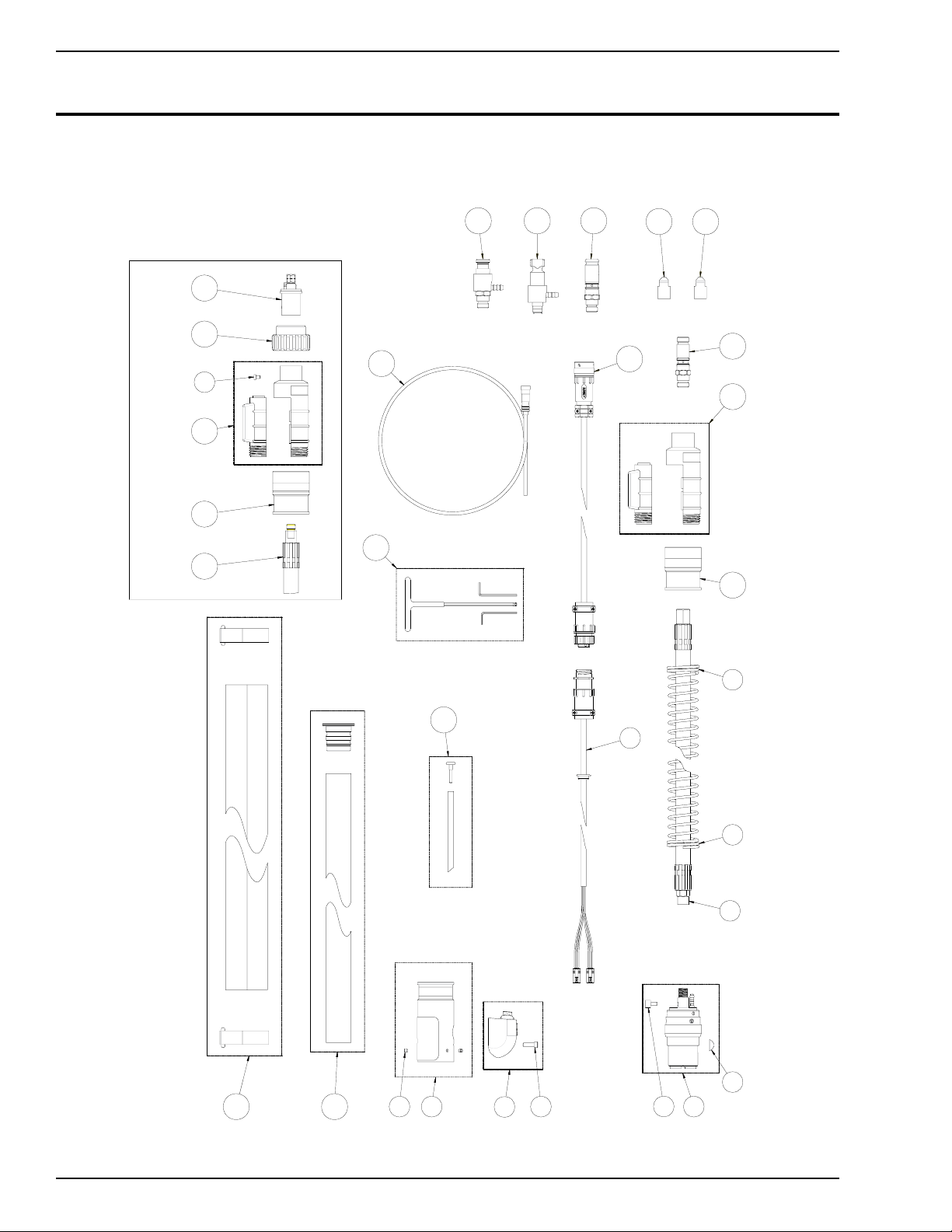

14

22

1

4

5

10

11

14

12

EURO-KWIK REPLACEMENT PARTS

9

18

20

19

25

16

17

21 13

23 24C

26

3

2

6

7

8 13 15

A

B

27

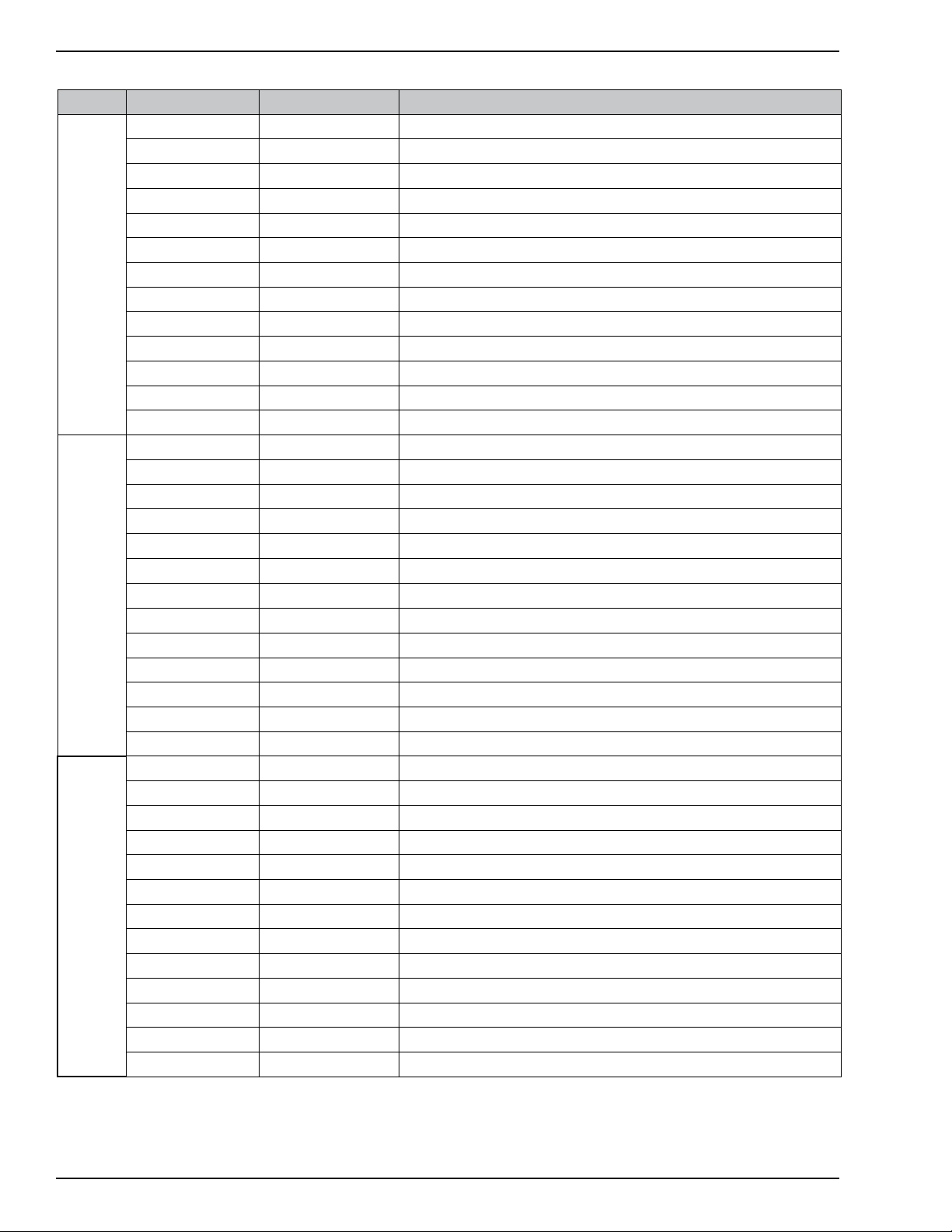

SECTION 8:

REPLACEMENT PARTS

QRA & QRAS Series Replacement Parts

REPLACEMENT PARTS

8-14

SM-QRTORCH

Page 19

Quick Robotic toRch

QRA & QRAS Series Replacement Parts

Item No. Part No. Stock No. Description

1 --- --- Cartridge Kit - (Includes Item #2, #3, and Hose Clamps)

QRA-1BC 3045-1150 For use with 1-5/8” (41,28mm) Ø Mount – QRA Series - ***

QRA-2BC 3045-1151 For use with 1-1/2” (38,10mm) Ø Mount – QRA Series

QRA-3BC 3045-1152 For use with 1-3/8” (34,93mm) Ø Mount – QRA Series

QRA-4BC 3045-1153 For use with 36mm Ø Mount – QRA Series

QRAS-1BC 3045-1195 For use with 1-5/8” (41,28mm) Ø Mount – QRAS Series - ***

QRAS-2BC 3045-1196 For use with 1-1/2” (38,10mm) Ø Mount – QRAS Series

QRAS-3BC 3045-1197 For use with 1-3/8” (34,93mm) Ø Mount – QRAS Series

QRAS-4BC 3045-1198 For use with 36mm Ø Mount – QRAS Series

NS QR106RLS 3045-1341 Replacement Locking Set Screw F/Torch Block (Pkg. of 5 ea.)

2 --- --- Key

QTRMS-BS 3045-1156 For use with QRA-1BC Cartridge Kit (Pkg. of 5 ea.)

QR3MS-BS 3045-1157 For use with QRA-2BC & QRA-3BC Cartridge Kits (Pkg. of 5ea.)

3 QR106-S 3045-1158 Conduit Screw (Pkg. of 5 ea.)

4 --- --- Inch Switch & E-Stop Housing Assembly (Includes Item “A”)

QR-SH 3045-1159 For use with 1-5/8” Diameter Cartridge Kit

QR-SH3 3045-1476 For use with 1-3/8” Diameter Cartridge Kit

QR-SH4 3045-1477 For use with 36mm Diameter Cartridge Kit

5 QR-FCS 3045-1160 Front Case (Includes Item “B”)

6

--- --- QRA Power Cable Assy (Includes Hose Clamps)

QR603-CH 3045-1164 For use with 3ft. (91cm) torch

QR6035-CH 3045-1165 For use with 3.5ft. (1,07m) torch

QR604-CH 3045-1166 For use with 4ft. ( 1,22m) torch

QR6045-CH 3045-1167 For use with 4.5ft. (1,37m) torch

QR605-CH 3045-1168 For use with 5ft. (1,52m) torch

QR6055-CH 3045-1169 For use with 5.5ft. (1,68m) torch

QR606-CH 3045-1170 For use with 6ft. (1,83m) torch

QR607-CH 3045-1171 For use with 7ft. (2,13m) torch

QR608-CH 3045-1172 For use with 8ft. (2,44m) torch

QR610-CH 3045-1173 For use with 10ft. (3m) torch

QR612-CH 3045-1174 For use with 12ft. (4m) torch

QR615-CH 3045-1175 For use with 15ft. (5m) torch

7 --- --- Front Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5ft. (1,07m) torches

QR-SPR 3045-1177 For use with 4ft. (1,22m) through 7ft. (2,13m) torches

QR-SPHD 3045-1178 For use with 8ft. (2,44m) through 15ft. (5m) torches

8 --- --- Rear Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5ft. (1,07m) torches

QR-SPHD 3045-1178 For use with 4ft. (1,22m) through 15ft. (5m) torches

SM-QRTORCH

8-15

REPLACEMENT PARTS

Page 20

Quick Robotic toRch

QRA & QRAS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

9 --- --- Control Cable Assembly (includes Hose Clamp)

QR03-CC 3045-1181 For use with 3ft. (91cm) torch

QR035-CC 3045-1182 For use with 3.5ft. (1,07m) torch

QR04-CC 3045-1183 For use with 4ft. ( 1,22m) torch

QR045-CC 3045-1184 For use with 4.5ft. (1,37m) torch

QR05-CC 3045-1185 For use with 5ft. (1,52m) torch

QR055-CC 3045-1186 For use with 5.5ft. (1,68m) torch

QR06-CC 3045-1187 For use with 6ft. (1,83m) torch

QR07-CC 3045-1188 For use with 7ft. (2,13m) torch

QR08-CC 3045-1189 For use with 8ft. (2,44m) torch

QR10-CC 3045-1190 For use with 10ft. (3m) torch

QR12-CC 3045-1191 For use with 12ft. (4m) torch

QR15-CC 3045-1192 For use with 15ft. (5m) torch

10 --- --- Purge Hose Assembly (Includes Hose Plug Nipple & Clamp)

QR03-PH 3045-1200 For use with 3ft. (91cm) torch

QR035-PH 3045-1201 For use with 3.5ft. (1,07m) torch

QR04-PH 3045-1202 For use with 4ft. ( 1,22m) torch

QR045-PH 3045-1203 For use with 4.5ft. (1,37m) torch

QR05-PH 3045-1204 For use with 5ft. (1,52m) torch

QR055-PH 3045-1205 For use with 5.5ft. (1,68m) torch

QR06-PH 3045-1206 For use with 6ft. (1,83m) torch

QR07-PH 3045-1207 For use with 7ft. (2,13m) torch

QR08-PH 3045-1208 For use with 8ft. (2,44m) torch

QR10-PH 3045-1209 For use with 10ft. (3m) torch

QR12-PH 3045-1210 For use with 12ft. (4m) torch

QR15-PH 3045-1211 For use with 15ft. (5m) torch

11

--- --- Cable Cover Kit

QR03-CV 3045-1213 For use with 3ft. (91cm) torch

QR035-CV 3045-1214 For use with 3.5ft. (1,07m) torch

QR04-CV 3045-1215 For use with 4ft. ( 1,22m) torch

QR045-CV 3045-1216 For use with 4.5ft. (1,37m) torch

QR05-CV 3045-1217 For use with 5ft. (1,52m) torch

QR055-CV 3045-1218 For use with 5.5ft. (1,68m) torch

QR06-CV 3045-1219 For use with 6ft. (1,83m) torch

QR07-CV 3045-1220 For use with 7ft. (2,13m) torch

QR08-CV 3045-1221 For use with 8ft. (2,44m) torch

QR10-CV 3045-1222 For use with 10ft. (3m) torch

QR12-CV 3045-1223 For use with 12ft. (4m) torch

QR15-CV 3045-1224 For use with 15ft. (5m) torch

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-16

SM-QRTORCH

Page 21

Quick Robotic toRch

QRA & QRAS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

12

13

14

15

16

17

18

19

20

21

22

23

*** Standard On All QR Series Torch Body and Cable Assemblies

SM-QRTORCH

--- --- Outer Cover Assembly (Includes Nylon Cable Tie – 2 ea.)

QR03-LC 3045-1226 For use with 3ft. (91cm) torch

QR035-LC 3045-1227 For use with 3.5ft. (1,07m) torch

QR04-LC 3045-1228 For use with 4ft. ( 1,22m) torch

QR045-LC 3045-1229 For use with 4.5ft. (1,37m) torch

QR05-LC 3045-1230 For use with 5ft. (1,52m) torch

QR055-LC 3045-1231 For use with 5.5ft. (1,68m) torch

QR06-LC 3045-1232 For use with 6ft. (1,83m) torch

QR07-LC 3045-1233 For use with 7ft. (2,13m) torch

QR08-LC 3045-1234 For use with 8ft. (2,44m) torch

QR10-LC 3045-1235 For use with 10ft. (3m) torch

QR12-LC 3045-1236 For use with 12ft. (4m) torch

QR15-LC 3045-1237 For use with 15ft. (5m) torch

QR-RC 3045-1238 Rear Spring Cap

QRA-CS 3045-1239 Rear Case Assembly

R176MH 2060-2184 Miller® Connector Plug (Includes Items #16 & 17) - ***

R174MH 2035-2109 Miller® Connector Plug (Includes Items #16 & #17)

R175M-N045 2050-2181 Miller® Plug Nipple, .045” (1,0mm) Wire (Use w/R176MH) - ***

R174M-N045 2040-2192 Miller® Plug Nipple, .045” (1,0mm) Wire (Use w/R174MH)

R175M-N116 2050-2182 Miller® Plug Nipple, .062” (1,6mm) Wire (Use w/R176MH) - ***

R174M-N116 2040-2191 Miller® Plug Nipple, .062” (1,6mm) Wire (Use w/R174MH)

176S-H 2060-2177 Tweco® Connector Plug - ***

350-174H 2035-2110 Tweco® Connector Plug (Uses R44 series Conduit)

350-174PH 2035-2172 Panasonic® Connector Plug (Uses R44 series Conduit )

QTR176LH 2086-2624 Lincoln® Connector Plug (2.71” – 68,83mm OAL.) - ***

EL176LH 2060-2680 Lincoln® Connector Plug (3.84” – 97,54mm OAL)

QTR174LH 2086-2623 Lincoln® Connector Plug (Uses R44 series Conduit)

--- --- XQRA Power Cable Assy (Includes Hose Clamps)

XQR603-CH 3045-1375 For use with 3ft. (91cm) torch

XQR6035-CH 3045-1376 For use with 3.5ft. (1,07m) torch

XQR604-CH 3045-1377 For use with 4ft. ( 1,22m) torch

XQR6045-CH 3045-1378 For use with 4.5ft. (1,37m) torch

XQR605-CH 3045-1379 For use with 5ft. (1,52m) torch

XQR6055-CH 3045-1380 For use with 5.5ft. (1,68m) torch

XQR606-CH 3045-1381 For use with 6ft. (1,83m) torch

XQR607-CH 3045-1382 For use with 7ft. (2,13m) torch

XQR608-CH 3045-1383 For use with 8ft. (2,44m) torch

XQR610-CH 3045-1384 For use with 10ft. (3m) torch

XQR612-CH 3045-1385 For use with 12ft. (4m) torch

XQR615-CH 3045-1386 For use with 15ft. (5m) torch

XQRA-CS 3045-1240 Rear Case Assembly (Includes Item “C”)

174X-2S 2040-2177 Euro-Kwik Nut

8-17

REPLACEMENT PARTS

Page 22

Quick Robotic toRch

QRA & QRAS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

24 E171-1TS 2011-2172 Euro-Kwik Adapter

25 --- --- Conduit (Refer to Page 25)

26 QTR-TOOLS 2062-2034 Tool Kit

27 --- --- E-stop Jumper Cable Assembly

QRJC-010 3045-1241 Without Connector – 3ft. (91cm) Long

QRJC-020 3045-1242 With Burndy (ABB®) Connector – 3ft. (91cm) Long

QRJC-030 3045-1243 With 4-pin Amp Connector (Motoman®) – 3ft. (91cm) Long

QRJC-040 3045-1244 5-pin DDK connector (Fanuc®)

QRJC-050 3045-1245 With 5-pin DDK Connector (Panasonic®)

Standard Fasteners

These standard fasteners are not sellable items and must be purchased at a local hardware or fastener supply house.

Item No. Description

A #10-32 x 5/8” Socket Head Cap Screw

B #10-32 x 3/16” Stainless Cup Point Set Screw

C M4 x .07 Head Screw

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-18

SM-QRTORCH

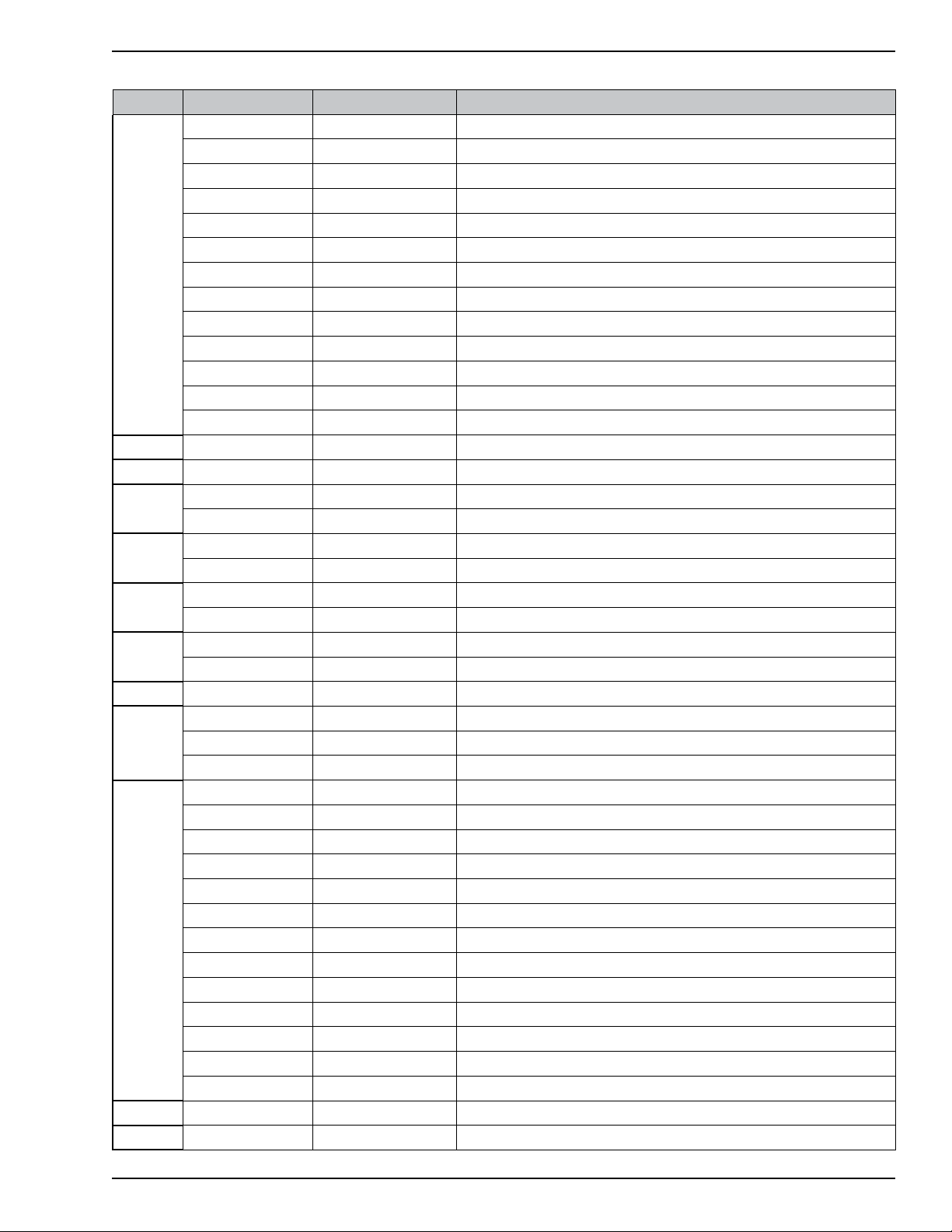

Page 23

Quick Robotic toRch

1

4

5

13

16

17

26

28 30

19

EURO-KWIK REPLACEMENT PARTS

12

34

23

25

24

31

21

22

32

2

3

8

9

7 10 11 2018

B

A

15

14

18 C 2

9

B

27

33

6

QRW & QRWS Series Replacement Parts

SM-QRTORCH

8-19

REPLACEMENT PARTS

Page 24

Quick Robotic toRch

QRW & QRWS Series Replacement Parts

Item No. Part No. Stock No. Description

1 --- --- Cartridge Kit - (Includes Item #2 , #3, and Hose Clamps)

QRW-1BC 3045-1300 For use with 1-5/8” (41,28mm) Ø Mount – QRW Series - ***

QRW-2BC 3045-1301 For use with 1-1/2” (38,10mm) Ø Mount – QRW Series

QRW-3BC 3045-1302 For use with 1-3/8” (34,93mm) Ø Mount – QRW Series

QRW-4BC 3045-1303 For use with 36mm Ø Mount – QRW Series

QRWS-1BC 3045-1342 For use with 1-5/8” (41,28mm) Ø Mount – QRWS Series - ***

QRWS-2BC 3045-1343 For use with 1-1/2” (38,10mm) Ø Mount – QRWS Series

QRWS-3BC 3045-1344 For use with 1-3/8” (34,93mm) Ø Mount – QRWS Series

QRWS-4BC 3045-1345 For use with 36mm Ø Mount – QRWS Series

NS QR106RLS 3045-1341 Replacement Locking Set Screw F/Torch Block (Pkg. of 5 ea.)

2 --- --- Key

QTRMS-BS 3045-1156 For use with QRA-1BC Cartridge Kit (Pkg. Of 5 ea.)

QR3MS-BS 3045-1157 For use with QRA-2BC & QRA-3BC Cartridge Kits (Pkg. of 5ea.)

3 QRW106-S 3045-1340 Conduit Screw (Pkg. Of 5 ea.)

4 --- --- Inch Switch & E-Stop Housing Assembly (Includes Item “A”)

QR-SH 3045-1159 For use with 1-5/8” Diameter Cartridge Kit

QR-SH3 3045-1476 For use with 1-3/8” Diameter Cartridge Kit

QR-SH4 3045-1477 For use with 36mm Diameter Cartridge Kit

5 QR-FCS 3045-1160 Front Case (Includes Item “B”)

6 QRW-CV 3045-1304 Check Valve Assembly (Includes O-rings)

7

--- --- Conduit/Gas Hose Assy (Includes Hose Clamps)

QRW603-CGH 3045-1310 For use with 3ft. (91cm) torch

QRW6035-CGH 3045-1311 For use with 3.5ft. (1,07m) torch

QRW604-CGH 3045-1312 For use with 4ft. ( 1,22m) torch

QRW6045-CGH 3045-1313 For use with 4.5ft. (1,37m) torch

QRW605-CGH 3045-1314 For use with 5ft. (1,52m) torch

QRW6055-CGH 3045-1315 For use with 5.5ft. (1,68m) torch

QRW606-CGH 3045-1316 For use with 6ft. (1,83m) torch

QRW607-CGH 3045-1317 For use with 7ft. (2,13m) torch

QRW608-CGH 3045-1318 For use with 8ft. (2,44m) torch

QRW610-CGH 3045-1319 For use with 10ft. (3m) torch

QRW612-CGH 3045-1320 For use with 12ft. (4m) torch

QRW615-CGH 3045-1321 For use with 15ft. (5m) torch

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-20

SM-QRTORCH

Page 25

QRW & QRWS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

--- --- QRW Power Cable Assy (Includes Hose Clamp)

8

QRW603-PC 3045-1325 For use with 3ft. (91cm) torch

QRW6035-PC 3045-1326 For use with 3.5ft. (1,07m) torch

QRW604-PC 3045-1327 For use with 4ft. ( 1,22m) torch

QRW6045-PC 3045-1328 For use with 4.5ft. (1,37m) torch

QRW605-PC 3045-1329 For use with 5ft. (1,52m) torch

QRW6055-PC 3045-1330 For use with 5.5ft. (1,68m) torch

QRW606-PC 3045-1331 For use with 6ft. (1,83m) torch

QRW607-PC 3045-1332 For use with 7ft. (2,13m) torch

QRW608-PC 3045-1333 For use with 8ft. (2,44m) torch

QRW610-PC 3045-1334 For use with 10ft. (3m) torch

QRW612-PC 3045-1335 For use with 12ft. (4m) torch

QRW615-PC 3045-1336 For use with 15ft. (5m) torch

9

--- --- Front Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5 (1,07m) torches

QR-SPR 3045-1177 For use with 4ft. (1,22m) through 7ft. (2,13m) torches

QR-SPHD 3045-1178 For use with 8ft. (2,44m) through 15ft. (5m) torches

10

--- --- Rear Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5ft. (1,07m) torches

QR-SPHD 3045-1178 For use with 4ft. (1,22m) through 15ft. (5m) torches

11

12

QRW174 3045-1306 Rear Block Assembly (Includes Hose Clamps)

--- --- Control Cable Assembly (Includes Hose Clamp)

QR03-CC 3045-1181 For use with 3ft. (91cm) torch

QR035-CC 3045-1182 For use with 3.5ft. (1,07m) torch

QR04-CC 3045-1183 For use with 4ft. ( 1,22m) torch

QR045-CC 3045-1184 For use with 4.5ft. (1,37m) torch

QR05-CC 3045-1185 For use with 5ft. (1,52m) torch

QR055-CC 3045-1186 For use with 5.5ft. (1,68m) torch

QR06-CC 3045-1187 For use with 6ft. (1,83m) torch

QR07-CC 3045-1188 For use with 7ft. (2,13m) torch

QR08-CC 3045-1189 For use with 8ft. (2,44m) torch

QR10-CC 3045-1190 For use with 10ft. (3m) torch

QR12-CC 3045-1191 For use with 12ft. (4m) torch

QR15-CC 3045-1192 For use with 15ft. (5m) torch

Quick Robotic toRch

*** Standard On All QR Series Torch Body and Cable Assemblies

SM-QRTORCH

8-21

REPLACEMENT PARTS

Page 26

Quick Robotic toRch

QRW & QRWS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

13 --- --- Purge Hose Assembly (Includes Hose Plug Nipple & Hose Clamp)

QR03-PH 3045-1200 For use with 3ft. (91cm) torch

QR035-PH 3045-1201 For use with 3.5ft. (1,07m) torch

QR04-PH 3045-1202 For use with 4ft. ( 1,22m) torch

QR045-PH 3045-1203 For use with 4.5ft. (1,37m) torch

QR05-PH 3045-1204 For use with 5ft. (1,52m) torch

QR055-PH 3045-1205 For use with 5.5ft. (1,68m) torch

QR06-PH 3045-1206 For use with 6ft. (1,83m) torch

QR07-PH 3045-1207 For use with 7ft. (2,13m) torch

QR08-PH 3045-1208 For use with 8ft. (2,44m) torch

QR10-PH 3045-1209 For use with 10ft. (3m) torch

QR12-PH 3045-1210 For use with 12ft. (4m) torch

QR15-PH 3045-1211 For use with 15ft. (5m) torch

14 QRW00-WO 3045-1262 Water-Out Hose Assy - (Includes Hose Clamp) – For All Torches

15 --- --- Water-In Hose Assembly (Includes Hose Clamp)

QRW03-WI 3045-1275 For use with 3ft. (91cm) torch

QRW035-WI 3045-1276 For use with 3.5ft. (1,07m) torch

QRW04-WI 3045-1277 For use with 4ft. ( 1,22m) torch

QRW045-WI 3045-1278 For use with 4.5ft. (1,37m) torch

QRW05-WI 3045-1279 For use with 5ft. (1,52m) torch

QRW055-WI 3045-1280 For use with 5.5ft. (1,68m) torch

QRW06-WI 3045-1281 For use with 6ft. (1,83m) torch

QRW07-WI 3045-1282 For use with 7ft. (2,13m) torch

QRW08-WI 3045-1283 For use with 8ft. (2,44m) torch

QRW10-WI 3045-1284 For use with 10ft. (3m) torch

QRW12-WI 3045-1285 For use with 12ft. (4m) torch

QRW15-WI 3045-1286 For use with 15ft. (5m) torch

16 --- --- Cable Cover Kit

QR03-CV 3045-1213 For use with 3ft. (91cm) torch

QR035-CV 3045-1214 For use with 3.5ft. (1,07m) torch

QR04-CV 3045-1215 For use with 4ft. ( 1,22m) torch

QR045-CV 3045-1216 For use with 4.5ft. (1,37m) torch

QR05-CV 3045-1217 For use with 5ft. (1,52m) torch

QR055-CV 3045-1218 For use with 5.5ft. (1,68m) torch

QR06-CV 3045-1219 For use with 6ft. (1,83m) torch

QR07-CV 3045-1220 For use with 7ft. (2,13m) torch

QR08-CV 3045-1221 For use with 8ft. (2,44m) torch

QR10-CV 3045-1222 For use with 10ft. (3m) torch

QR12-CV 3045-1223 For use with 12ft. (4m) torch

QR15-CV 3045-1224 For use with 15ft. (5m) torch

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-22

SM-QRTORCH

Page 27

QRW & QRWS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

17

--- --- Outer Cover Assembly (Includes Nylon Cable Tie – 2 ea.)

QR03-LC 3045-1226 For use with 3ft. (91cm) torch

QR035-LC 3045-1227 For use with 3.5ft. (1,07m) torch

QR04-LC 3045-1228 For use with 4ft. ( 1,22m) torch

QR045-LC 3045-1229 For use with 4.5ft. (1,37m) torch

QR05-LC 3045-1230 For use with 5ft. (1,52m) torch

QR055-LC 3045-1231 For use with 5.5ft. (1,68m) torch

QR06-LC 3045-1232 For use with 6ft. (1,83m) torch

QR07-LC 3045-1233 For use with 7ft. (2,13m) torch

QR08-LC 3045-1234 For use with 8ft. (2,44m) torch

QR10-LC 3045-1235 For use with 10ft. (3m) torch

QR12-LC 3045-1236 For use with 12ft. (4m) torch

QR15-LC 3045-1237 For use with 15ft. (5m) torch

18

19

20

QR-RC 3045-1238 Rear Spring Cap

QRW-CS 3045-1307 Water-cooled Rear Case Assembly

R176MH 2060-2184 Miller® Connector Plug (Includes Items #22 & #23) - ***

R174MH 2035-2109 Miller® Connector Plug (Includes Items #22 & #23)

21

R175M-N045 2050-2181 Miller® Plug Nipple, .045” (1,0mm) Wire (Use w/R176MH) - ***

R174M-N045 2040-2192 Miller® Plug Nipple, .045” (1,0mm) Wire (Use w/R174MH)

22

R175M-N116 2050-2182 Miller® Plug Nipple, .062” (1,6mm) Wire (Use w/R176MH) - ***

R174M-N116 2040-2191 Miller® Plug Nipple, .062” (1,6mm) Wire (Use w/R174MH)

23

176S-H 2060-2177 Tweco® Connector Plug - ***

350-174H 2035-2110 Tweco® Connector Plug (Uses R44 series Conduit)

24

25

350-174PH 2035-2172 Panasonic® Connector Plug (Uses R44 series Conduit )

QTR176LH 2086-2624 Lincoln® Connector Plug (2.71” – 68,83mm OAL.) - ***

EL176LH 2060-2680 Lincoln® Connector Plug (3.84” – 97,54mm OAL)

QTR174LH 2086-2623 Lincoln® Connector Plug (Uses R44 series Conduit)

26

27

28

29

30

31

32

33

XQRW174 3045-1308 Water-cooled Euro-Kwik Rear Block Assy (Includes Hose Clamp)

WC174X-B2S 2044-2185 O-ring (Pkg. of 5 ea.)

XQRW-CS 3045-1309 Euro-Kwik Water-cooled Rear Case Assembly

174X-2S 2040-2193 Euro-Kwik Nut

WC174X-1S 3045-1339 Euro-Kwik Adapter

--- --- Conduit (Refer to Page 25)

QTR-TOOLS 2062-2034 Tool Kit

--- --- E-Stop Jumper Cable Assembly

QRJC-010 3045-1241 Without Connector – 3ft. (91cm) Long

QRJC-020 3045-1242 With Burndy Connector (ABB) – 3ft. (91cm) Long

QRJC-030 3045-1243 With 4-pin Amp Connector (Motoman)– 3ft. (91cm) Long

QRJC-040 3045-1244 With 5-pin DDK Connector

QRJC-050 3045-1245 With 5-pin DDK Connector (Panasonic)

34

400LK-QC 2044-2000 Quick Connector Male & Female

Quick Robotic toRch

*** Standard On All QR Series Torch Body and Cable Assemblies

SM-QRTORCH

8-23

REPLACEMENT PARTS

Page 28

Quick Robotic toRch

QRW & QRWS Series Replacement Parts (cont.)

Standard Fasteners

These standard fasteners are not sellable items and should be purchased at a local hardware or fastener supply house.

Item No. Description

A #10-32 x 5/8” socket head cap screw

B #10-32 x 3/16” stainless cup point set screw

C M4 x .07 head screw

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-24

SM-QRTORCH

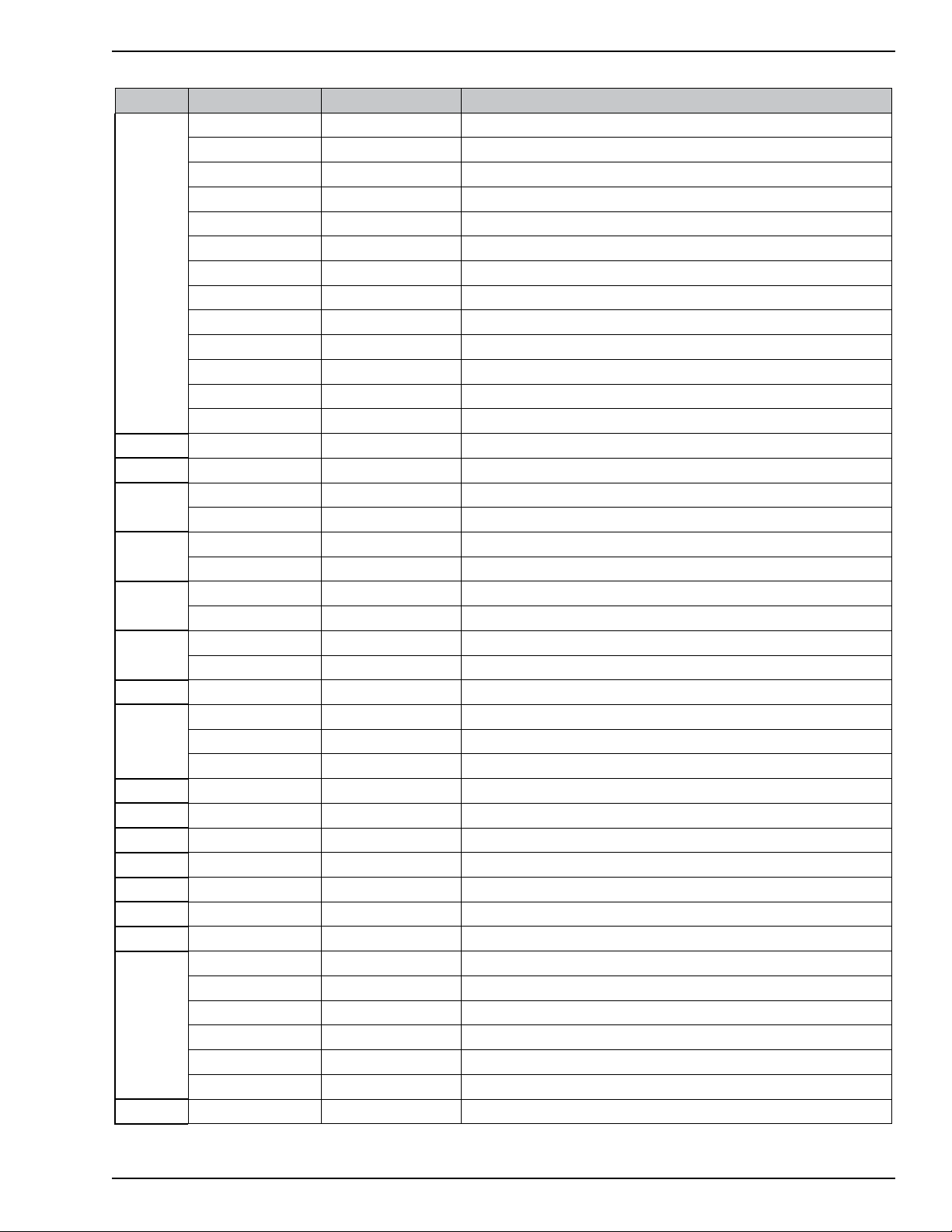

Page 29

Quick Robotic toRch

12

1

4

5

11

14

15

17

25

EURO-KWIK REPLACEMENT PARTS

6

10

2

3

7 8 9 16 18

A

B

13

31

21

23

22

28

19

20

24

16 26 27

C

29

30

QRWA & QRWAS Series Replacement Parts

SM-QRTORCH

8-25

REPLACEMENT PARTS

Page 30

Quick Robotic toRch

QRWA & QRWAS Series Replacement Parts

Item No. Part No. Stock No. Description

1 --- --- Cartridge Kit - (Includes Item #2, #3 and Hose Clamps)

QRWA-1BC 3045-1288 For use with 1-5/8” (41,28mm) Ø Mount – QRWA Series - ***

QRWA-2BC 3045-1289 For use with 1-1/2” (38,10mm) Ø Mount – QRWA Series

QRWA-3BC 3045-1290 For use with 1-3/8” (34,93mm) Ø Mount – QRWA Series

QRWA-4BC 3045-1291 For use with 36mm Ø Mount – QRWA Series

QRWAS-1BC 3045-1295 For use with 1-5/8” (41,28mm) Ø Mount – QRWAS Series

- ***

QRWAS-2BC 3045-1296 For use with 1-1/2” (38,10mm) Ø Mount – QRWAS Series

QRWAS-3BC 3045-1297 For use with 1-3/8” (34,93mm) Ø Mount – QRWAS Series

QRWAS-4BC 3045-1298 For use with 36mm Ø Mount – QRWAS Series

NS QR106RLS 3045-1341 Replacement Locking Set Screw F/Torch Block (Pkg. of 5 ea.)

2 --- --- Key

QTRMS-BS 3045-1156 For use with QRA-1BC (Pkg. Of 5 ea.)

QR3MS-BS 3045-1157 For use with QRA-2BC & QRA-3BC cartridge kits (Pkg. Of 5ea.)

3 QR106-S 3045-1158 Conduit Screw (Pkg. Of 5 ea.)

4 --- --- Inch Switch & E-Stop Housing Assembly (Includes Item “A”)

QR-SH 3045-1159 For use with 1-5/8” Diameter Cartridge Kit

QR-SH3 3045-1476 For use with 1-3/8” Diameter Cartridge Kit

QR-SH4 3045-1477 For use with 36mm Diameter Cartridge Kit

5 QR-FCS 3045-1160 Front case (Includes Item “B”)

6 QRW-CV 3045-1304 Check Valve Assembly (Includes O-rings)

7 --- --- QRWA Power Cable Assy (Includes Hose Clamp)

QR403-CH 3045-1250 For use with 3ft. (91cm) torch

QR4035-CH 3045-1251 For use with 3.5ft. (1,07m) torch

QR404-CH 3045-1252 For use with 4ft. ( 1,22m) torch

QR4045-CH 3045-1253 For use with 4.5ft. (1,37m) torch

QR405-CH 3045-1254 For use with 5ft. (1,52m) torch

QR4055-CH 3045-1255 For use with 5.5ft. (1,68m) torch

QR406-CH 3045-1256 For use with 6ft. (1,83m) torch

QR407-CH 3045-1257 For use with 7ft. (2,13m) torch

QR408-CH 3045-1258 For use with 8ft. (2,44m) torch

QR410-CH 3045-1259 For use with 10ft. (3m) torch

QR412-CH 3045-1260 For use with 12ft. (4m) torch

QR415-CH 3045-1261 For use with 15ft. (5m) torch

8 --- --- Front Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5ft. (1,07m) torches

QR-SPR 3045-1177 For use with 4ft. (1,22m) through 7ft. (2.13m) torches

QR-SPHD 3045-1178 For use with 8ft. (2,44m) through 15ft. (5m) torches

9 --- --- Rear Spring

QR-SP 3045-1176 For use with 3ft. (91cm) & 3.5ft. (1,07m) torches

QR-SPHD 3045-1178 For use with 4ft. (1,22m) through 15ft. (5m) torches

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-26

SM-QRTORCH

Page 31

QRWA & QRWAS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

10

--- --- Control Cable Assembly (Includes Hose Clamp)

QR03-CC 3045-1181 For use with 3ft. (91cm) torch

QR035-CC 3045-1182 For use with 3.5ft. (1,07m) torch

QR04-CC 3045-1183 For use with 4ft. ( 1,22m) torch

QR045-CC 3045-1184 For use with 4.5ft. (1,37m) torch

QR05-CC 3045-1185 For use with 5ft. (1,52m) torch

QR055-CC 3045-1186 For use with 5.5ft. (1,68m) torch

QR06-CC 3045-1187 For use with 6ft. (1,83m) torch

QR07-CC 3045-1188 For use with 7ft. (2,13m) torch

QR08-CC 3045-1189 For use with 8ft. (2,44m) torch

QR10-CC 3045-1190 For use with 10ft. (3m) torch

QR12-CC 3045-1191 For use with 12ft. (4m) torch

QR15-CC 3045-1192 For use with 15ft. (5m) torch

11

--- --- Purge Hose Assembly (Includes Hose Nipple Plug & Hose

Clamp)

QR03-PH 3045-1200 For use with 3ft. (91cm) torch

QR035-PH 3045-1201 For use with 3.5ft. (1,07m) torch

QR04-PH 3045-1202 For use with 4ft. ( 1,22m) torch

QR045-PH 3045-1203 For use with 4.5ft. (1,37m) torch

QR05-PH 3045-1204 For use with 5ft. (1,52m) torch

QR055-PH 3045-1205 For use with 5.5ft. (1,68m) torch

QR06-PH 3045-1206 For use with 6ft. (1,83m) torch

QR07-PH 3045-1207 For use with 7ft. (2,13m) torch

QR08-PH 3045-1208 For use with 8ft. (2,44m) torch

QR10-PH 3045-1209 For use with 10ft. (3m) torch

QR12-PH 3045-1210 For use with 12ft. (4m) torch

QR15-PH 3045-1211 For use with 15ft. (5m) torch

12

--- --- Water-Out Hose Assembly (Includes Hose Clamp)

QRW03-WO 3045-1263 For use with 3ft. (91cm) torch

QRW035-WO 3045-1264 For use with 3.5ft. (1,07m) torch

QRW04-WO 3045-1265 For use with 4ft. ( 1,22m) torch

QRW045-WO 3045-1266 For use with 4.5ft. (1,37m) torch

QRW05-WO 3045-1267 For use with 5ft. (1,52m) torch

QRW055-WO 3045-1268 For use with 5.5ft. (1,68m) torch

QRW06-WO 3045-1269 For use with 6ft. (1,83m) torch

QRW07-WO 3045-1270 For use with 7ft. (2,13m) torch

QRW08-WO 3045-1271 For use with 8ft. (2,44m) torch

QRW10-WO 3045-1272 For use with 10ft. (3m) torch

QRW12-WO 3045-1273 For use with 12ft. (4m) torch

QRW15-WO 3045-1274 For use with 15ft. (5m) torch

Quick Robotic toRch

*** Standard On All QR Series Torch Body and Cable Assemblies

SM-QRTORCH

8-27

REPLACEMENT PARTS

Page 32

Quick Robotic toRch

QRWA & QRWAS Series Replacement Parts (cont.)

Item No. Part No. Stock No. Description

13 --- --- Water-In Hose Assembly (Includes Hose Clamps)

QRW03-WI 3045-1275 For use with 3ft. (91cm) torch

QRW035-WI 3045-1276 For use with 3.5ft. (1,07m) torch

QRW04-WI 3045-1277 For use with 4ft. ( 1,22m) torch

QRW045-WI 3045-1278 For use with 4.5ft. (1,37m) torch

QRW05-WI 3045-1279 For use with 5ft. (1,52m) torch

QRW055-WI 3045-1280 For use with 5.5ft. (1,68m) torch

QRW06-WI 3045-1281 For use with 6ft. (1,83m) torch

QRW07-WI 3045-1282 For use with 7ft. (2,13m) torch

QRW08-WI 3045-1283 For use with 8ft. (2,44m) torch

QRW10-WI 3045-1284 For use with 10ft. (3m) torch

QRW12-WI 3045-1285 For use with 12ft. (4m) torch

QRW15-WI 3045-1286 For use with 15ft. (5m) torch

14 --- --- Cable Cover Kit

QR03-CV 3045-1213 For use with 3ft. (91cm) torch

QR035-CV 3045-1214 For use with 3.5ft. (1,07m) torch

QR04-CV 3045-1215 For use with 4ft. ( 1,22m) torch

QR045-CV 3045-1216 For use with 4.5ft. (1,37m) torch

QR05-CV 3045-1217 For use with 5ft. (1,52m) torch

QR055-CV 3045-1218 For use with 5.5ft. (1,68m) torch

QR06-CV 3045-1219 For use with 6ft. (1,83m) torch

QR07-CV 3045-1220 For use with 7ft. (2,13m) torch

QR08-CV 3045-1221 For use with 8ft. (2,44m) torch

QR10-CV 3045-1222 For use with 10ft. (3m) torch

QR12-CV 3045-1223 For use with 12ft. (4m) torch

QR15-CV 3045-1224 For use with 15ft. (5m) torch

15 --- --- Outer Cover Assembly (Includes Nylon Cable Tie – 2 ea.)

QR03-LC 3045-1226 For use with 3ft. (91cm) torch

QR035-LC 3045-1227 For use with 3.5ft. (1,07m) torch

QR04-LC 3045-1228 For use with 4ft. ( 1,22m) torch

QR045-LC 3045-1229 For use with 4.5ft. (1,37m) torch

QR05-LC 3045-1230 For use with 5ft. (1,52m) torch

QR055-LC 3045-1231 For use with 5.5ft. (1,68m) torch

QR06-LC 3045-1232 For use with 6ft. (1,83m) torch

QR07-LC 3045-1233 For use with 7ft. (2,13m) torch

QR08-LC 3045-1234 For use with 8ft. (2,44m) torch

QR010-LC 3045-1235 For use with 10ft. (3m) torch

QR012-LC 3045-1236 For use with 12ft. (4m) torch

QR015-LC 3045-1237 For use with 15ft. (5m) torch

16 QR-RC 3045-1238 Rear Spring Cap

17 QRWA-CS 3045-1293 QRWA Rear Case Assembly

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-28

SM-QRTORCH

Page 33

Quick Robotic toRch

QRWA & QRWAS Series Replacement Parts

Item No. Part No. Stock No. Description

18 R176MH Miller®Connector Plug (Includes Items #19 & #20)

R174MH Miller®Connector Plug (Includes Items #19 & 20)

19 R175M-N045 Miller®Plug Nipple, .045” (1,0mm) Wire (Use w/R176MH)

- ***

R174M-N045 Miller®Plug Nipple, .045” (1,0mm) Wire (Use w/R174MH)

20 R175M-N116 Miller®Plug Nipple, .062” (1,6mm) Wire (Use w/R176MH)

- ***

R174M-N116 Miller®Plug Nipple, .062” (1,6mm) Wire (Use w/R174MH)

21 176S-H Tweco Connector Plug - ***

350-174H Tweco Connector Plug (Uses R44 series Conduit)

22 350-174PH Panasonic®Connector Plug (Uses R44 series Conduit )

23 QTR176LH Lincoln Connector Plug (2.71” – 68,83mm OAL.) - ***

EL176LH Lincoln Connector Plug (3.84” – 97,54mm OAL)

QTR174LH Lincoln Connector Plug (Uses R44 series Conduit)

24 --- XQRWA Power Cable Assy (Includes Hose Clamp)

XQR403-CH For use with 3ft. (91cm) torch

XQR4035-CH For use with 3.5ft. (1,07mm) torch

XQR404-CH For use with 4ft. ( 1,22m) torch

XQR4045-CH For use with 4.5ft. (1,37m) torch

XQR405-CH For use with 5ft. (1,52m) torch

XQR4055-CH For use with 5.5ft. (1,68m) torch

XQR406-CH For use with 6ft. (1,83m) torch

XQR407-CH For use with 7ft. (2,13m) torch

XQR408-CH For use with 8ft. (2,44m) torch

XQR410-CH For use with 10ft. (3m) torch

XQR412-CH For use with 12ft. (4m) torch

XQR415-CH For use with 15ft. (5m) torch

25 XQRWA-CS QXRWA Rear Case Assembly

26 174X-2S Euro-Kwik nut

27 E171-1TS Euro-Kwik adapter

28 --- --- Conduit (Refer to Page 25)

29 QTR-TOOLS Tool kit

30

31 400LK-QC Quick Connector Male & Female

--- E-stop Jumper Assembly

QRJC-010 Without Connector – 3ft. (91cm) Long

QRJC-020 With Burndy Connector (ABB) – 3ft. (91cm) Long

QRJC-030 With 4-pin Amp Connector (Motoman) – 3ft. (91cm) Long

QRJC-040 With 5-pin DDK Connector (Fanuc)

QRJC-050 With 5-pin DDK Connector (Panasonic)

*** Standard On All QR Series Torch Body and Cable Assemblies

SM-QRTORCH

8-29

REPLACEMENT PARTS

Page 34

Quick Robotic toRch

QRWA & QRWAS Series Replacement Parts (cont.)

Standard Fasteners

These standard fasteners are not sellable items and should be purchased at a local hardware or fastener supply house.

Item No. Description

A #10-32 x 5/8” socket head cap screw

B #10-32 x 3/16” stainless cup point set screw

C M4 x .07 head screw

*** Standard On All QR Series Torch Body and Cable Assemblies

REPLACEMENT PARTS

8-30

SM-QRTORCH

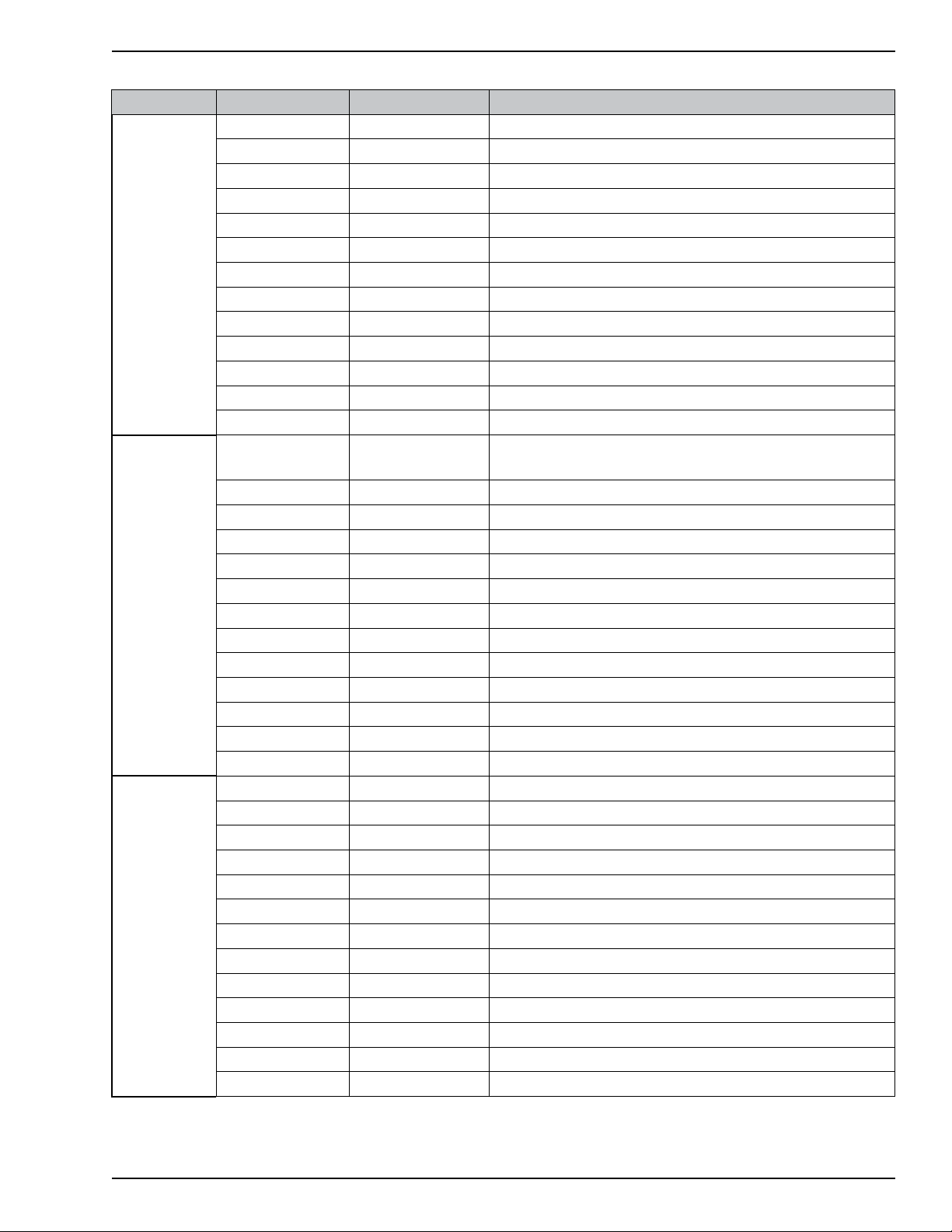

Page 35

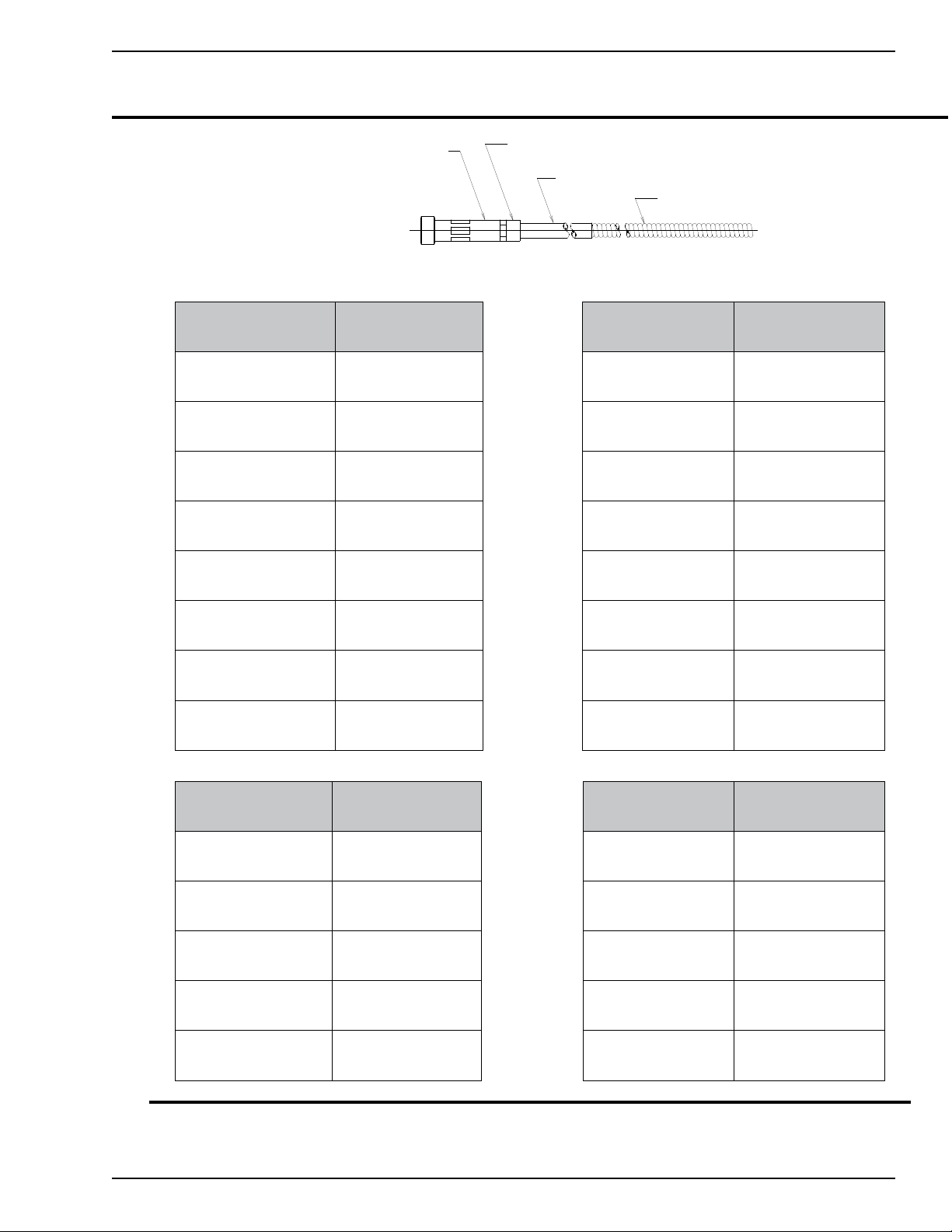

MACHINED CONDUIT STOP

WIRE CONDUIT

NEOPRENE SEAL

HEAT SHRINK

R44 Series Conduits R45 Series Conduits

(Steel Welding Wire) (Steel Welding Wire)

Wire Size

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

SECTION 9:

ROBOTIC CONDUIT LINERS

Part No.

Stock No. Wire Size

R44-3545-1

1440-1223

R44-3545-4

1440-1224

R44-3545-8

1440-1225

R44-3545-15

1440-1226

R44-116-1

1440-1228

R44-116-4

1440-1229

R44-116-8

1440-1230

R44-116-15

1440-1231

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

.052” / 1/16”

1,53mm / 1,6mm

Quick Robotic toRch

Part No.

Stock No.

R45-3545-1

1450-1027

R45-3545-4

1450-1024

R45-3545-8

1450-1025

R45-3545-15

1450-1026

R45-116-1

1450-1028

R45-116-4

1450-1029

R45-116-8

1450-1030

R45-116-15

1450-1031

SM-QRTORCH

(Aluminum Welding Wire) (Aluminum Welding Wire)

Wire Size

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

1/16”

1,6mm

1/16”

1,6mm

Part No.

Stock No. Wire Size

R44WN-3545-4

1440-1040

R44WN-3545-8

1440-1041

R44WN-3545-15

1440-1042

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

.035” / .045”

0,9mm / 1,2mm

R44WN-116-8

1440-1046

R44WN-116-15

1440-1047

1/16”

1,6mm

1/16”

1,6mm

Part No.

Stock No.

R45WN-3545-4

1450-1041

R45WN-3545-8

1450-1042

R45WN-3545-15

1450-1043

R45WN-116-8

1450-1044

R45WN-116-15

1450-1045

NOTE

R44 series conduits are shipped with all Euro-Kwik Torch Bodies and Cable Assemblies

“WN” = Wire Nylon Wrapped

9-31

ROBOTIC CONDUIT LINERS

Page 36

Quick Robotic toRch

SECTION 10:

FACTORY REPAIR CENTER

Tweco® Robotics Factory Repair Center (FRC) offers a repair service for our customers on the various cable assemblies and peripheral

products. The majority of our consumers do not want to spend the time involved with repairs and generally do not have the necessary

equipment and tools to perform repairs.

Other key benefits in considering the “FRC” service repairs on your product:

All products will be rebuilt and tested following the established test procedures and specifications for the specific

•

product.

All repairs are done using original Tweco® Robotics parts to ensure maximum product performance.

•

Our FRC has highly-trained employees utilizing the appropriate tools and test equipment.

•

30-day warranty on the newly installed parts and labor on all cable assemblies.

•

30-day warranty on QRM-100 and RDM-2000 peripherals.

•

60-day warranty on QRC™-2000 and QWT-120 peripherals.

•

Factory Repair Center

Domestic Toll Free Phone Number: 1-800-426-1888

Fax Number: 1-620-229-9926

FACTORY REPAIR CENTER

10-32

SM-QRTORCH

Page 37

STATEMENT OF WARRANTY

LIMITED WARRANTY: THERMADYNE® warrants that its products will be free of defects in workmanship or material. Should

any failure to conform to this warranty appear within the time period applicable to the THERMADYNE products as stated below,

THERMADYNE shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and

maintained in accordance with THERMADYNE’s specifications, instructions, recommendations and recognized standard industry

practice, and not subject to misuse, repair, neglect, alteration, or accident, correct such defects by suitable repair or replacement,

at THERMADYNE’s sole option, of any components or parts of the product determined by THERMADYNE to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: THERMADYNE shall not under any circumstances be liable for special or consequential damages,

such as, but not limited to, damage or loss of purchased or replacement goods, or claims of customers of distributor (hereinafter

the “Purchaser”) for service interruption. The remedies of the Purchaser set forth herein are exclusive and the liability of

THERMADYNE with respect to any contract, or anything done in connection therewith such as the performance or breach

thereof, or from the manufacture, sale, delivery, resale, or use of any goods covered by or furnished by THERMADYNE whether

arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly provided

herein, exceed the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH MAY IMPAIR

THE SAFETY OR PERFORMANCE OF ANY THERMADYNE PRODUCT.