Page 1

OPERATION

&

MAINTENANCE

MANUAL

Tabletop Autoclaves

Models

1730, 2340, 2540, 3140, 3850, 3870 M & MK

1730MK Valueklave

Cat. No. MAN205-0007000EN Rev. Q

Tuttnauer U.S.A. Co, Ltd. 25 Power Drive Hauppauge, NY, 11788, USA. Tel (631) 737 4850, (800) 624 5836, Fax: (631) 737 0720

Page 2

Page 3

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1 GENERAL................................................................................................................3

1.1 Incoming Inspection .....................................................................................3

1.2 Warranty........................................................................................................3

1.3 Warranty Statement ......................................................................................3

2 TECHNICAL DATA ................................................................................................5

2.1 Introduction ..................................................................................................5

2.2 Storage Conditions ........................................................................................6

2.3 Operating Conditions ....................................................................................6

2.4 Standards.......................................................................................................6

2.5 Construction ..................................................................................................6

2.6 Utilities ..........................................................................................................7

2.7 Waste Water Disposal ...................................................................................7

2.8 Environment Emission Information .............................................................7

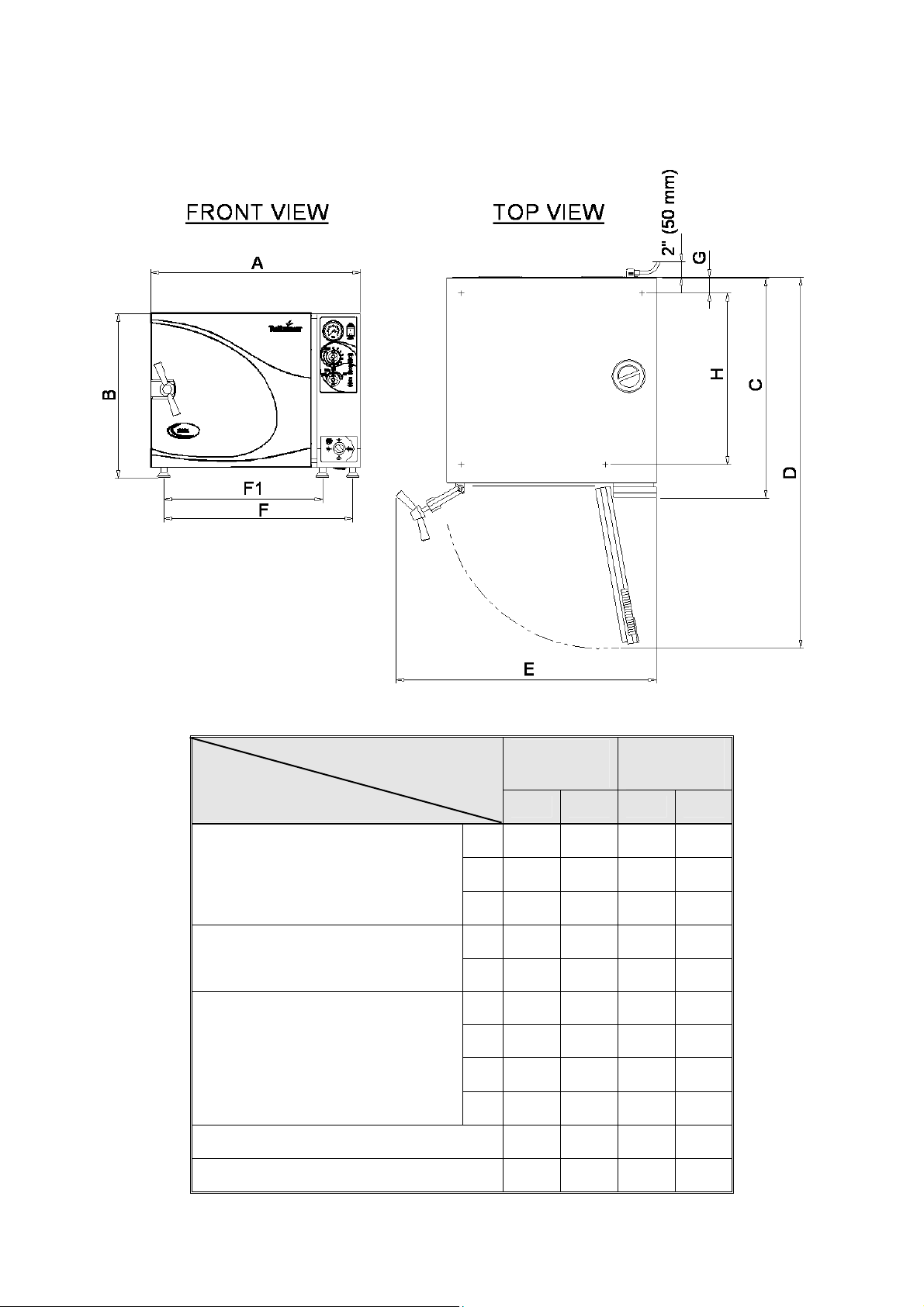

2.9 Dimensions, Models 1730 .............................................................................8

2.10 Dimensions, Models 2340, 2540 ...................................................................9

2.11 Dimensions, Models 3140 ...........................................................................10

2.12 Dimensions, Models 3850, 3870 .................................................................11

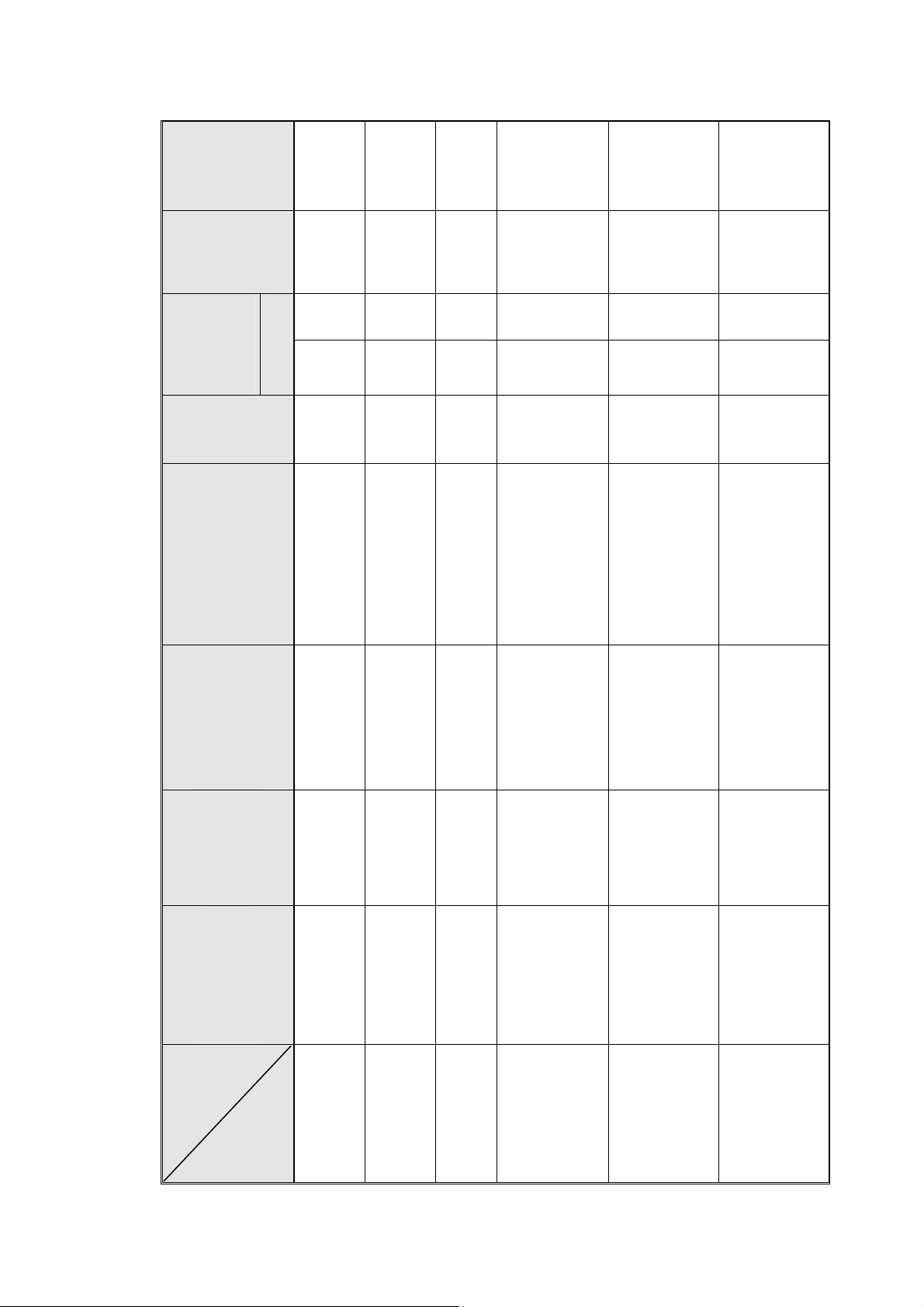

2.13 Technical Specifications .............................................................................12

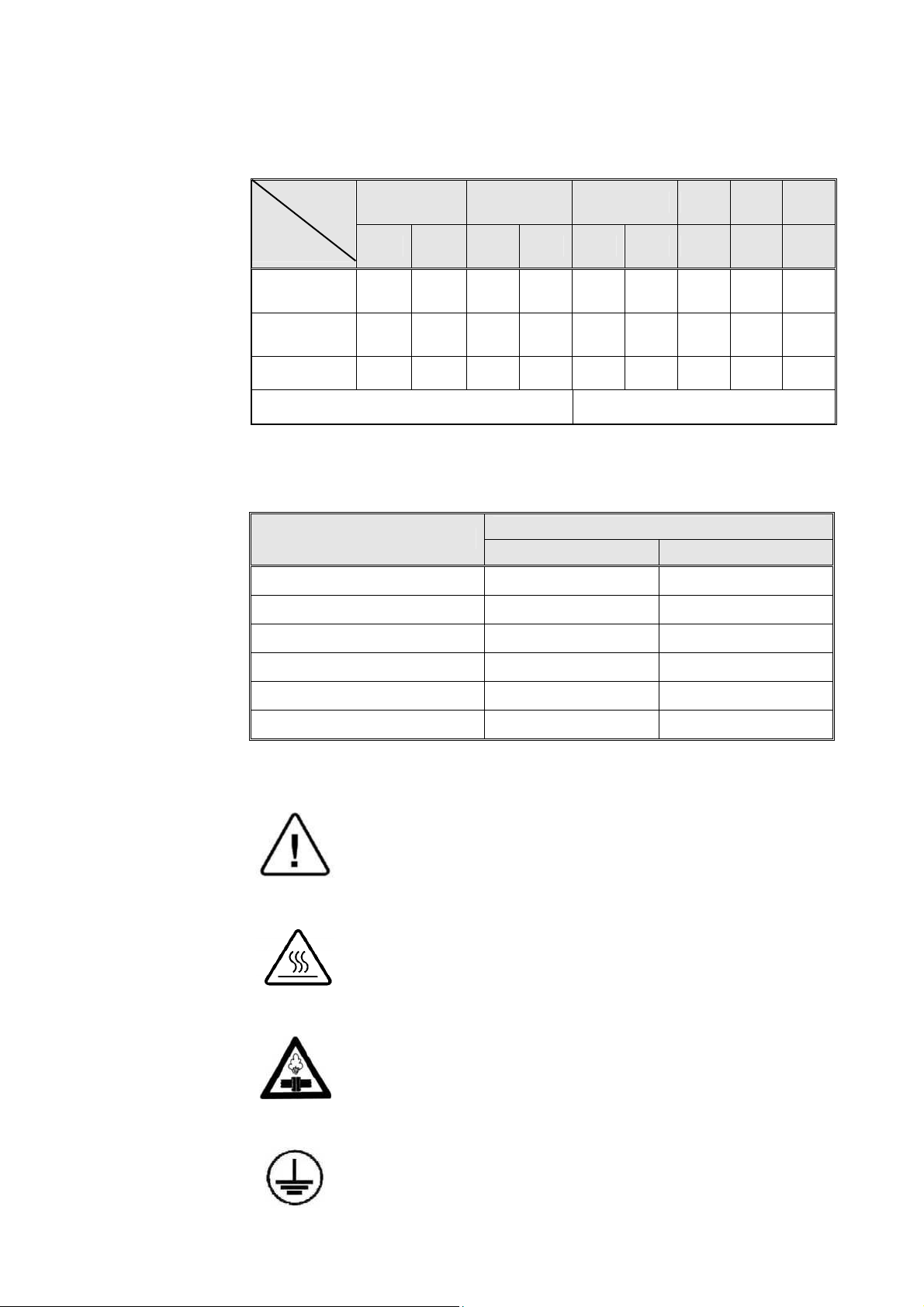

2.14 Electrical Data ............................................................................................13

2.15 Maximum Solid Load Sizes.........................................................................13

2.16 Symbol Description .....................................................................................13

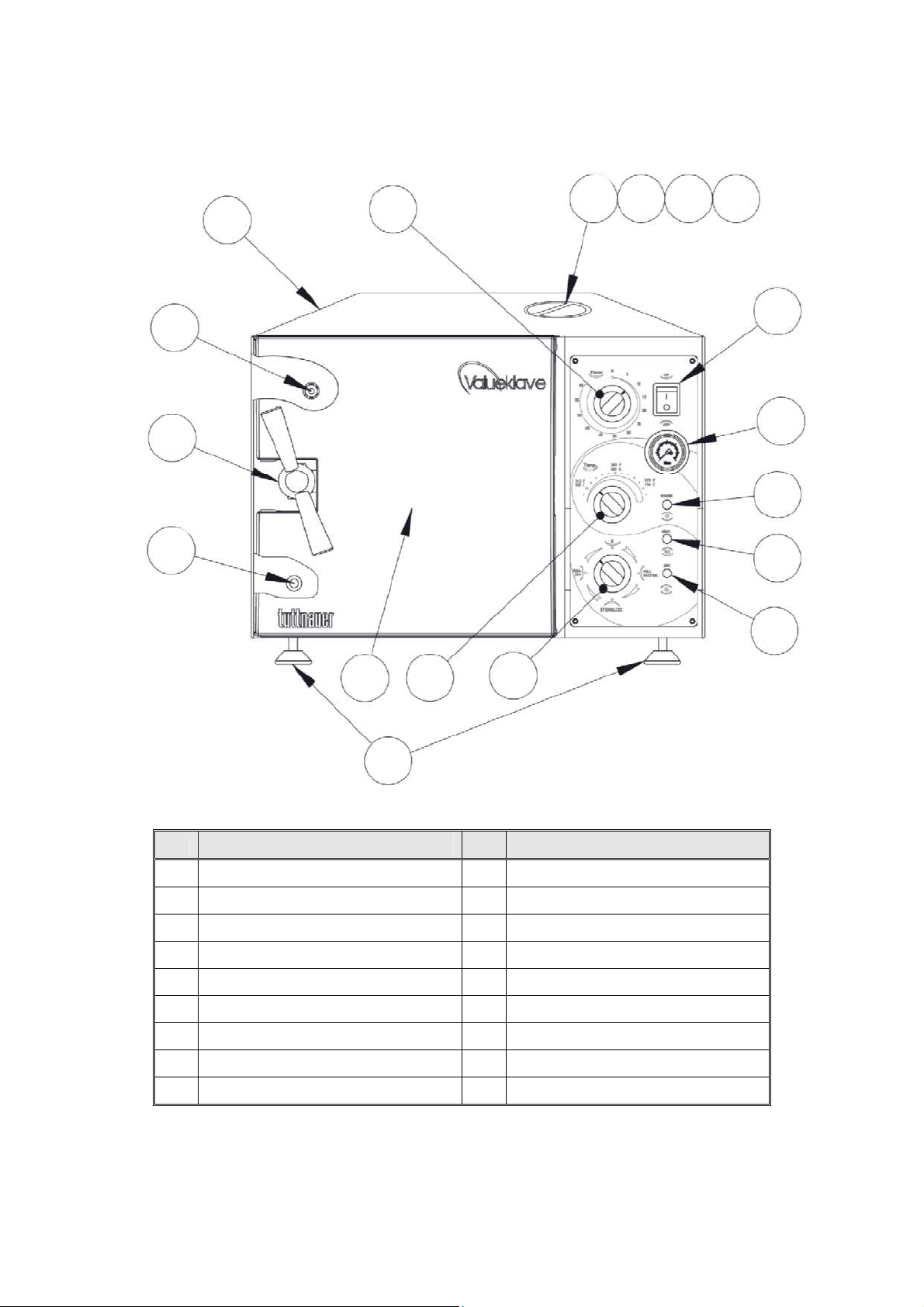

3 DESCRIPTION OF COMPONENTS....................................................................19

3.1 Control Panel ..............................................................................................19

3.2 Other Components ......................................................................................19

4 INSTALLATION INSTRUCTIONS ......................................................................20

4.1 Electrical .....................................................................................................20

4.2 Setup ............................................................................................................20

4.3 Lifting and Carrying ...................................................................................21

5 WATER QUALITY ................................................................................................22

6 PREPARATION BEFORE STERILIZATION .....................................................23

7 OPERATION .........................................................................................................27

7.1 Loading and Unloading the Device ............................................................27

7.2 Fill the Water Reservoir..............................................................................27

8 SERVICE AND MAINTENANCE INSTRUCTIONS...........................................32

8.1 Preventive and Scheduled Maintenance.....................................................32

8.2 Draining the Reservoir................................................................................33

8.3 Cleaning the Air Jet ....................................................................................34

8.4 Replacing the Door Gasket .........................................................................35

8.5 Checking the Safety Valve ..........................................................................36

8.6 Unclogging the Multi-Purpose Valve or Fill Piping. .................................37

9 CLEANING THE TABLETOP AUTOCLAVES WITH CHAMBER BRITE™ ...38

10 TROUBLESHOOTING .........................................................................................40

11 LIST OF ACCESSORIES......................................................................................50

1

Page 4

TABLE OF CONTENTS (Cont.)

DRAWINGS PAGE NO.

Front View Model 1730 M, MK-Valueklave.................................................................. 14

Front View Model 2340/2540 M, MK ............................................................................ 15

Front View Model 3140 M.............................................................................................. 16

Front View Model 3850/3870 M..................................................................................... 17

Rear View ........................................................................................................................18

Tray Handle CT530020 .................................................................................................. 48

Pouch Rack ..................................................................................................................... 48

Tray .................................................................................................................................. 48

Tray Holder ..................................................................................................................... 49

2

Page 5

1 GENERAL

Read the Operating Instructions carefully, before beginning any operation

on the autoclave!

1.1 Incoming Inspection

Upon receiving your Tuttnauer Autoclave carefully inspect the outside

of the shipping carton for signs of damage. If any damage to the carton

is found, note the location with respect to the autoclave and check that

area of the autoclave carefully once it is fully unpacked. Observe

packing method and retain packing materials until the unit has been

inspected. Mechanical inspection involves checking for signs of physical

damage such as: scratched panel surfaces, broken knobs, etc.

If any damage is found, contact your dealer as soon as possible so

that they can file a claim with the shipping carrier and also notify

Tuttnauer.

All Tuttnauer products are carefully inspected prior to shipment and all

reasonable precautions are taken in preparing them for shipment to

assure safe arrival at their destination.

Note: Lifting and carrying should always be done by two people.

1.2 Warranty

We certify that this instrument is guaranteed to be free from defects in

material and workmanship for one year against faulty components and

assembly.

This warranty does not include routine cleaning and preventive

maintenance to be performed according to instructions in

section 8.1 (Preventive and Scheduled Maintenance).

Tuttnauer warrantees all new Manual autoclaves for a period of one full

year, covering both parts and labor. This one year warranty covers

defects in materials and workmanship on every part in the autoclave

except door gaskets and HEPA filters (they are wear items).

Tuttnauer warrantees all chambers for a period of ten (10) years against

defects in materials and workmanship. This chamber warranty went

into effect January 1997.

This warranty does not apply to any instrument that has been subjected

to misuse, neglect, accident or improper installation or application, nor

shall it extend to autoclaves that have been repaired or altered outside

the factory without prior authorization from Tuttnauer.

Tuttnauer’s obligation is limited to the repair or replacement of parts

for the autoclave. This warranty will be void if the unit is not purchased

from an authorized Tuttnauer dealer. No other warranties or obligations

are expressed or implied.

The Autoclave should only be used in a manner described in this

manual!

1.3 Warranty Statement

To activate the warranty, the registration card must be completed and

returned to Tuttnauer within fourteen (14) days of purchase or you may

call our customer service department at the number listed below.

No product will be received or accepted for repair without prior return

authorization from Tuttnauer. All transportation charges to and from

Tuttnauer must be paid by the owner of the autoclave. During the first

3

Page 6

90 days after purchase of an autoclave, Tuttnauer will pay shipping

costs on an individually evaluated basis and ONLY with pre-approval.

Note:

If you have any questions or there are any difficulties with this

instrument and the solution is not covered in this manual, please

contact your dealer or our Technical Service Dept. at the address

below. Do not attempt to service this instrument yourself.

Tuttnauer USA Co., Ltd. 25 Power Drive Hauppauge, NY, 11788,

USA

: (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720

e-mail:info@tuttnauerUSA.com

4

Page 7

2 TECHNICAL DATA

2.1 Introduction

This tabletop autoclave is designed for the sterilization of wrapped and

unwrapped instruments and related items found in dental, medical and

This autoclave is an electrically heated sterilizer using steam as the

The operator can select a sterilization temperature from within a range

All models feature an easy to use control panel. The machines are

This manual is intended for the user and gives the user a general

After reading this manual, operating the autoclave will be easy.

Only technical personnel having proper qualifications and holding

veterinary clinics, first aid rooms, laboratories, etc.

sterilizing agent. It is a manually operated device, with a control

system based upon steam pressure.

of 212ºF - 273ºF (100ºC - 134ºC). This allows for the sterilization of

heat sensitive material at a low sterilization temperature, as well as

providing for faster sterilization at higher temperatures for materials

able to withstand the higher sterilization temperatures.

ruggedly built using 316L stainless steel, copper, brass and aluminum.

To guard against rusting, no iron components are used. All models

include a drying system for wrapped items.

2.1.1 Safety features

The safety features include a double locking door

mechanism (door tightening bolt and locking bellows), a

mechanical pressure relief valve, over temperature

thermostats and a double pole circuit breaker.

Pressure Door Lock System (Door Bellow)

The Door Bellows is a safety device that prevents the door

from opening when the chamber is pressurized.

The system utilizes the buildup of pressure in the chamber

to expand a flexible Silicon-rubber bellows. The bellows

pushes a metal pin into a grove on the tightening bolt of the

Door Closing Device.

This prevents the operator from opening the door when

there is pressure in the chamber. When the steam is

released, this bellow returns to its original position, drawing

the pin with it and releasing the tightening bolt.

understanding of the instrument and the best ways to operate and take

care of it, in order to obtain optimum effective results.

However, since this instrument is built with high technology sensitive

components, no attempt should be made by the user or any other

unauthorized person to repair or recalibrate it.

technical documentation (including a technician manual) and

adequate information are authorized to service the apparatus.

5

Page 8

2.2 Storage Conditions

The packed or unpacked autoclave shall be stored in “indoor

conditions” (protected from rain and water).

2.3 Operating Conditions

This device is intended for indoor use.

This autoclave is intended for NORMAL environment conditions as

follows:

♦ Altitude up to 2000m.

♦ Minimum room temperature 41ºF (5ºC).

♦ Installation Category II.

♦ Pollution Degree 2.

♦ Maximum relative humidity 80% for temperature up to 31ºC

decreasing linearly to 50% relative humidity at 40ºC.

♦ Mains supply voltage fluctuations up to ±10% of nominal voltage.

♦ The sterilizer should be loaded only with autoclavable material.

2.4 Standards

2.4.1 Technical standards

1. A.S.M.E. Code, Section VIII div.1 for unfired pressure

vessels.

2. FDA Cleared.

3. UL61010-1 General Safety.

4. UL61010-2-041 Particular Safety for Autoclaves.

2.4.2 Quality standards

1. EN ISO 9001:2008– Quality System

2. ISO 13485:2003 – Quality systems – Medical devices.

2.5 Construction

The main parts of the autoclave are made of materials as indicated

below:

♦ Chamber is built of electro-polished stainless steel 316 L.

♦ Door is made of stainless steel CF8.

♦ Trays are made of stainless steel 304.

♦ Door handle is made of hard plastic material that is safe to touch

and thermo-insulated.

♦ Water reservoir is made of hard plastic material.

6

Page 9

2.6 Utilities

Utilities Unit

Value

V-A 1ph, 120V – 16A,50/60 Hz

Power supply (as appropriate)

V-A 1ph, 230V – 16A,50/60 Hz

Attention:

1. The electrical net must be protected with a current leakage safety

relay (GFI Receptical or Circuit Breaker).

2. The electrical network must comply with local rules or regulations.

3. The autoclave must be connected to a properly grounded outlet.

2.7 Waste Water Disposal

Caution !

Waste water must be brought into the public water piping in

accordance with the local rules or requirements, i.e. only nonhazardous liquids may be disposed in public sewage!

2.8 Environment Emission Information

A. The peak sound level generated by the sterilizer is < 70 / dBA with

background noise of 60 dB.

B. The total heat transmitted by the sterilizer is < 100 W/h for

1730/2340/2540 models and < 150 W/h for 3140/3850/3870

models.

7

Page 10

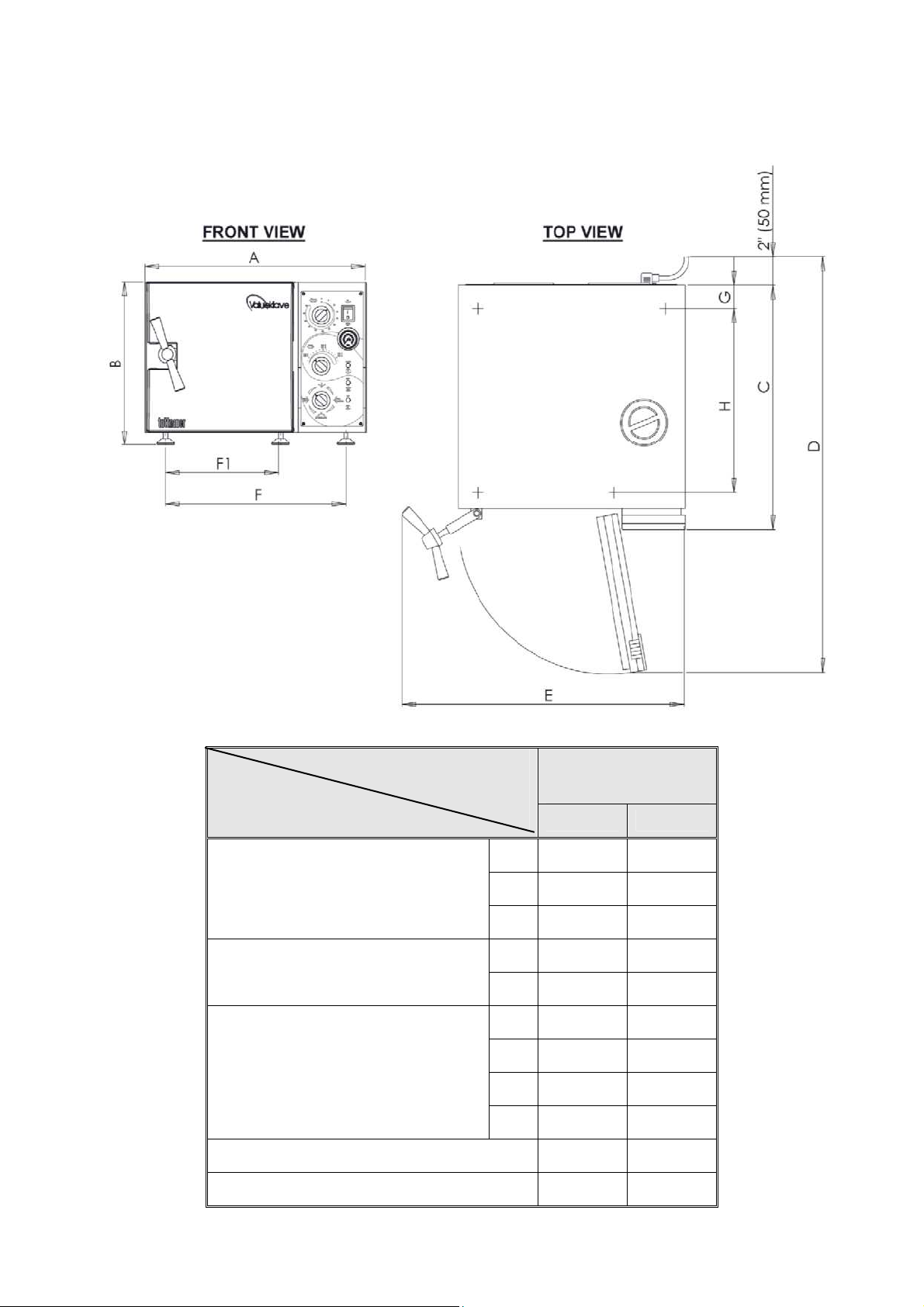

2.9 Dimensions, Models 1730

Dimensions

Model

M, MK-Valueklave

1730

in mm

A 17.4 440

Overall Dimensions

B 12.0 305

C 17.9 455

D 29.5 750

Maximum Dimensions (door open)

E 22.0 560

F1 13.7 347

Distance

F1-front legs

F -rear legs

Between Supporting

Legs

F 13.4 339

G 2.0 50

H 12.4 315

Chamber Diameter 6.7 170

Chamber Depth 13.4 340

8

Page 11

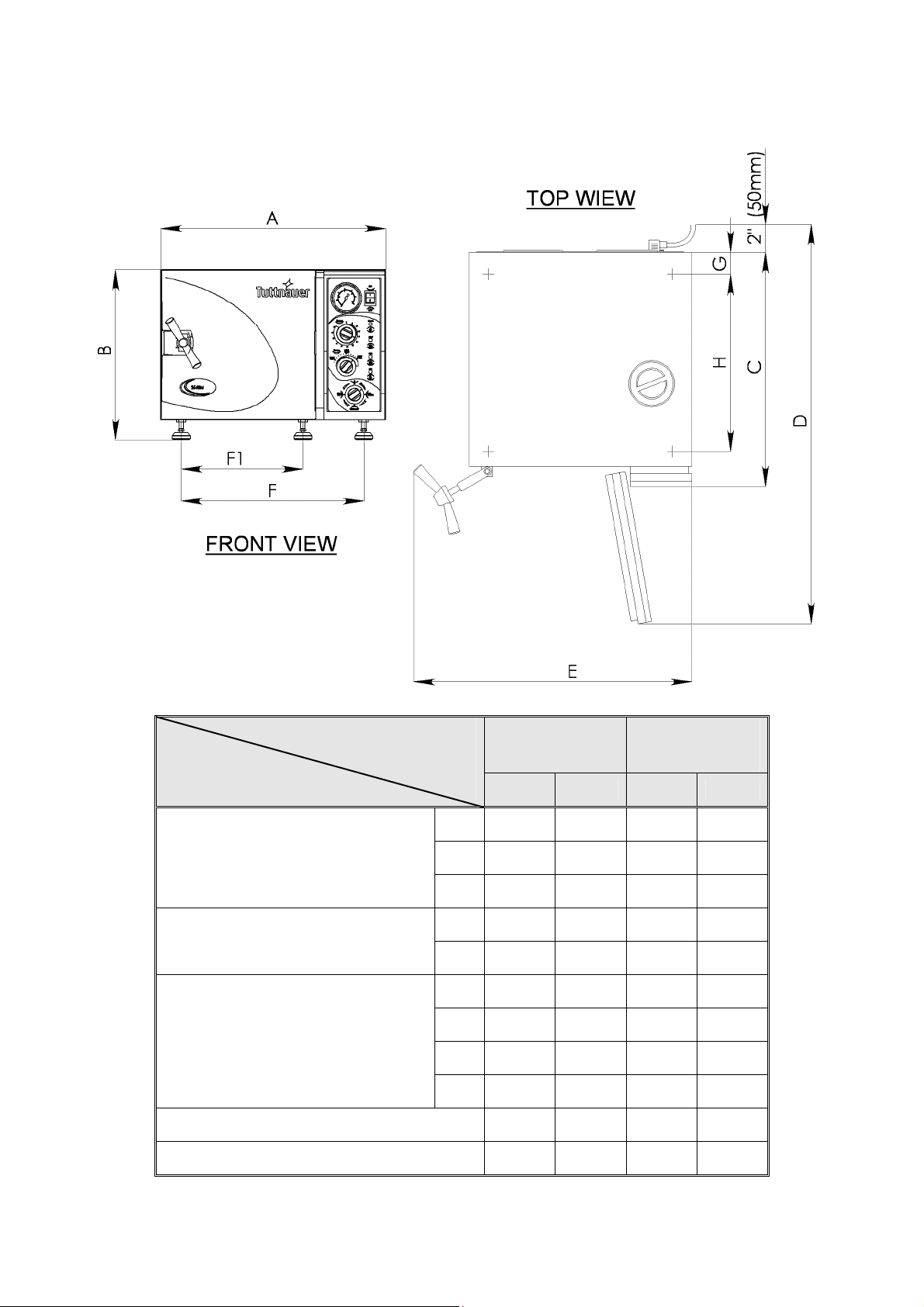

2.10 Dimensions, Models 2340, 2540

Dimensions

Model

2340

M, MK

2540

M, MK

in mm in mm

A 20.0 510 20.0 510

Overall Dimensions

B 14.4 365 14.4 365

C 21.5 545 21.5 545

D 35.8 910 35.8 910

Maximum Dimensions (door open)

E 25.8 655 25.8 655

F1 11.8 299 11.8 299

Distance

F1-front legs

F -rear legs

Between Supporting

Legs

F 16.6 422 16.6 422

G 2.0 50 2.0 50

H 15.8 400 15.8 400

Chamber Diameter 9.1 230 10 254

Chamber Depth 18.5 470 18.7 475

9

Page 12

2.11 Dimensions, Models 3140

Dimensions

Model

3140

M

in mm

A 23.2 590

Overall Dimensions

B 17.7 450

C 21.9 556

D 39.0 990

Maximum Dimensions (door open)

E 29.7 755

F1 19.2 488

Distance

F1-front legs

F -rear legs

Between Supporting

Legs

F 14.6 371

G 2.0 50

H 15.2 386

Chamber Diameter 12.3 312

Chamber Depth 15.4 391

10

Page 13

2.12 Dimensions, Models 3850, 3870

Dimensions

Model

3850

M

3870

M

in mm in mm

A 26.0 665 26.0 665

Overall Dimensions

B 20.7 525 20.7 525

C 27.5 695 34.5 875

D 45.5 1155 53.0 1335

Maximum Dimensions (door open)

E 32.0 815 32.0 815

F1 17.7 450 17.7 450

Distance

F1-front legs

F -rear legs

Between Supporting

Legs

F 22.2 564 22.2 564

G 2.0 50 2.0 50

H 21.8 555 30.5 725

Chamber Diameter 15.1 384 15.1 384

Chamber Depth 22.8 580 29.9 760

11

Page 14

Full + Half

)

3

)

3

)

3

)

3

)

3

)

3

Volume

Shipping

Weight

Shipping

6.35 cu.f.

(0.18 m

54.7 lbs.

(24.8 kgs.)

2

No. of

Standard

(Optional)

Cassettes

of

No.

Trays

3

9.4 cu.f.

(0.27m

9.4 cu. f.

(0.27m

78.7 lbs.

2

2

3

83.3 lbs.

(35.7 kgs.)

(47.8 kgs.)

3

3

4

12.4 cu.f

(0.35 m

132 lbs.

(60 kgs)

4

4

2

22.2cu.f.

(0.63 m

196 lbs.

(89 kgs.)

10

2

26.8cu.f

(0.76m

225 lbs.

(102 kgs.)

15

2

D x W x H

Tray Dimensions

11.6" x 4.7" x 0.8"

(295 x 120 x 20 mm)

16.3 " x 6.7" x 0.8"

16.3 " x 6.7" x0.8"

(415 x 170 x 20 mm)

16.1" x10.1" x 1"

(415 x 170 x 20 mm)

16.1" x7.8" x 1"

(408 x 250.6x 25 mm)

20" x 11" x 1"

(408 x 198x 25 mm)

20" x 14" x 1"

(500 x 280 x 25 mm)

26" x 11" x 1"

(500 x 350 x mm)

26" x 14" x 1"

(670 x 280 x mm)

(670 x 350 x mm)

Volume of

Mineral Free

(3.0 liters)

0.66 US gal.

(3.0 liters)

0.66 US gal.

(3.0 liters)

0.66 US gal.

(3.0 liters)

0.66 US gal.

(7.5 liters)

2.0 US gal.

(7.5 liters)

2.0 US gal.

Water Reservoir

2 US gal.

Chamber

Volume of

(7.5 liters)

5 US gal.

6 US gal.

(19 liters)

(23 liters)

7.8 US gal.

(34.4 liters)

(65 liters)

17US gal.

(84 liters)

22 US gal.

ф x L

Chamber

Dimensions

2.13 Technical Specifications

6.7" x 13.4"

MK-

1730 M, MK

9" x 18.5"

(170 x 340 mm)

(230 x 470 mm)

10" x 18.7"

(254 x 475 mm)

12.3" x 15.4"

(312 x 391 mm)

3140 M

Valueklave

2340 M, MK

2540 M, MK

15" × 23"

(380 × 580 mm)

3850 M

15" x 30"

(380 x 760 mm)

3870 M

12

Page 15

2.14 Electrical Data

Model

Specifications

Total power

model 120V

Total power

model 230V

1730 2340 2540 3140 3850 3870

M

MK

MK-V

M MK M MK M M M

8.8A 11.2A 11.7A - 11.7A - 20.0A - -

4.6A 5.9A 6.0A 9.6A 6.0A 9.6A 10.4A 10.4A 13A

Heaters W 1050 1350 1400 2200 1400 2200 2400 2400 3000

Degree of protection by enclosure IP31

2.15 Maximum Solid Load Sizes

(Textile load = 1/3 of solid load)

Models

Loads

lbs kg

1730 6.0 2.7

2340 7.0 3.2

2540 8.8 4.0

3140 11.0 5.0

3850 13.6 6.0

3870 14.0 6.4

2.16 Symbol Description

Caution! Consult accompanying documents

Caution! Hot Surface.

Caution! Hot steam.

Ground

13

Page 16

18

12

6

11

5

4

10

9

8 7

2

3

13

14

15

16

17

1

FRONT VIEW MODEL 1730 M, MK-Valueklave

No.

1. Front legs 10. Air trap jet

2. Reservoir water drain valve 11. Main power switch

3. Door closing device 12. Pressure gauge

4. Door microswitch 13. Power indicator light

5. Autoclave cover 14. Heat indicator light

6. Timer 15. Dry indicator light

7. Water reservoir cover 16. Multipurpose valve

8. Water reservoir 17. Thermostat (B10) knob

9. Safety valve 18. Door cover

Description No.

14

Description

Page 17

FRONT VIEW MODEL 2340/2540 M, MK

19

18

17

16

15

14

13

No.

1 2 3 4

Description No.

5

6

7

8

9

10

11

12

Description

1. Water reservoir cover 11. Thermostat (B10) knob

2. Water reservoir 12. Multipurpose valve

3. Safety valve 13. Front legs

4. Air trap jet 14. Rear legs

5. Pressure gauge 15. Reservoir water drain valve

6. Main power switch 16. Door closing device

7. Timer 17. Door microswitch

8. Power indicator light 18.

9. Heat indicator light 19. Autoclave cover

10. Dry indicator light

Door cover

15

Page 18

FRONT VIEW MODEL 3140 M

18

1 2 3 4

5

6

17

7

16

15

3140

8

9

10

14

11

13

12

No.

Description No.

Description

1. Water reservoir cover 10. Dry indicator light

2. Water reservoir 11. Thermostat (B10) knob

3. Safety valve 12. Multipurpose valve

4. Air trap jet 13. Front legs

5. Pressure gauge 14. Reservoir water drain valve

6. Main power switch 15. Door closing device

7. Timer 16. Door microswitch

8. Power indicator light 17. Door cover

9. Heat indicator light 18. Autoclave cover

16

Page 19

FRONT VIEW MODEL 3850/3870 M

18

17

16

15

14

13

No.

Description No.

1 2 3 4

Description

5

6

7

8

9

10

11

12

1. Water reservoir cover 10. Dry indicator light

2. Water reservoir 11. Thermostat (B10) knob

3. Safety valve 12. Multipurpose valve

4. Air trap jet 13. Front legs

5. Pressure gauge 14. Reservoir water drain valve

6. Main power switch 15. Door closing device

7. Timer 16. Door microswitch

8. Power indicator light 17. Door cover

9. Heat indicator light 18. Autoclave cover

17

Page 20

REAR VIEW

18

Page 21

water

This

air during

3 DESCRIPTION OF COMPONENTS

3.1 Control Panel

Description Operation

PRESSURE GAUGE

TIMER 0-60 min.

THERMOSTAT

Position

FILL WATER

MULTIPURPOSE

VALVE

STERILIZE

EXH.& DRY

“ 0 ”

HEAT INDICATOR

LIGHT

DRY INDICATOR LIGHT

POWER INDICATOR

LIGHT

MAIN SWITCH

0-60 psi, (0-4bar) indicates the chamber pressure

and includes maximum point indicator.

Sets the time for sterilization and drying cycles

(see section 7 for correct cycle time settings).

Note: The power to the heating elements is

switched off when the Timer reaches 0 minutes.

Sets the desired sterilization temperature for each

cycle within the range of 212ºF - 273ºF (100ºC 134ºC).

Water flows from the water reservoir into the

chamber.

Valve closed to all directions.

Exhausts the steam from the chamber into the

reservoir after the sterilization cycle is finished.

Heating elements are disconnected, no cycle is in

progress.

Lights to indicate that the heaters are activated.

It will cycle off and on when the temperature

reaches the preset valve.

Lights to indicate that drying cycle is in process.

Light to indicate that the main switch is on.

Main power switch, which supplies electric power

to the autoclave.

3.2 Other Components

Description Operation

WATER DRAIN VALVE

WATER RESERVOIR

SAFETY VALVE

AIR TRAP JET

SAFETY THERMOSTAT

CUT-OUT THERMOSTAT

Enables the drainage of water from the reservoir.

Holds water for sterilization and also serves as a

condenser for the hot steam during the exhaust

phase.

Located in the water reservoir. Protects the chamber

by releasing any pressure above 40psi (2.7bar).

Safety Valve is required and approved by ASME.

Located in the water reservoir. Eliminates

heat up phase to insure correct sterilization

temperature is reached. Also prevents air pockets

and pockets of cold steam from forming in the

chamber.

Prevents overheating during the sterilization and

drying stages, will automatically reset itself.

Cuts off the power in case of overheating if the

safety thermostat does not operate. This thermostat

does not reconnect automatically but must be reset.

19

Page 22

4 INSTALLATION INSTRUCTIONS

Caution:

The sterilizer must be placed on a rigid and leveled surface. The stand must

be able to hold the load of the device and loaded material.

Note:

Make sure, when placing the autoclave, to leave space around the machine,

to give the technician access to service the machine.

4.1 Electrical

The electrical connection should comply with the devices power

requirement. It must also comply with local installation and safety rules

and regulations. The voltage supplied to the device must comply with

the label ± 5%.

In order to avoid any injury by electrical hazard, it is mandatory for the

customer to have installed an earth leakage relay (GFI outlet or circuit

breaker) in the electrical circuit to which the autoclave is connected.

This relay disconnects all the poles of the electrical power line in case

of accidental contact by the power line, with the autoclave’s metal

Note: Keep the back and the right side of the autoclave approximately 1”

Connect the power cord to the socket on the rear side of the autoclave;

enclosure.

(25mm) away from the wall to allow for ventilation.

plug it into the supply outlet.

4.2 Setup

Proper adjustment of the chamber pitch is one of the most important

things you can do for the sterilizer. Proper chamber pitch insures that

among other things, the sterilizer will have the proper amount of water

in the chamber at the beginning of each cycle. Insufficient water in the

chamber, at the beginning of the cycle, will cause the unit to overheat

and activate one of the safety thermostats. This will occur at some

point during the cycle when the water level becomes too low. If, on the

other hand, there is too much water in the chamber, this will extend the

heating portion of the cycle. Extending the heat up time will shorten

the sterilization time, causing items to not be sterilized, indicator strips

to not change color and spore tests to fail.

For proper setup please follow these setup steps (see drawing below):

♦ The autoclave should be turned off and unplugged.

♦ Make sure the counter is level and sturdy (3).

♦ Make sure all the feet are on the autoclave and none have been lost.

♦ Make sure the feet are free to move in and out (2).

♦ Position the autoclave on the counter.

♦ Fill the reservoir with distilled water (see sec 7.2).

♦ The chamber should be empty of any instruments, trays or leftover

water.

20

Page 23

♦ The chamber pitch now needs to be adjusted.

350

15

450

480

23

690

27

810

♦ Measure to the proper amount of distilled water for the appropriate

model unit as listed below.

1730 2340/2540 3140 3850 3870

10-12

oz

300-

ml

12-

oz

350-

ml

14-16

oz

420-

ml

20-

oz

600-

ml

24-

oz

720-

ml

♦ Pour the proper amount of water into the chamber through the front

door of the unit (4).

♦ This water should cover the bottom of the chamber to within +/- ½

inch of the groove in the front (1).

♦ If necessary, adjust the front leveling feet, up or down, so that the

water lays in the chamber correctly (2).

♦ Once the chamber pitch adjustment is completed, the unit is ready to

operate.

Note: It is imperative to have the correct amount of water in the

chamber each cycle for proper operation of the autoclave.

4.3 Lifting and Carrying

Caution:

Before moving the autoclave, make sure that the electric cord is

disconnected from the power and there is no pressure in the

chamber.

1. Disconnect the power supply cord.

2. Drain the water from the reservoir and vessel.

To avoid injuries, lifting and carrying should be done by two people.

Do not drop this device!

21

Page 24

5 WATER QUALITY

The distilled or mineral free water supplied to the autoclave should have the

physical characteristics and maximum acceptable level of contaminants

indicated in the table below:

Physical Characteristics and Maximum acceptable contaminants levels

in steam for sterlizers

(According to EN 13060:2004).

Element Condensate – allowable content

Silicium oxide. SiO2 ≤0.1 mg/kg

Iron ≤0.1 mg/kg

Cadmium ≤0.005 mg/kg

Lead ≤ 0.05 mg/kg

Rest of metals except iron, cadmium,

lead

Chloride (Cl) ≤0.1 mg/kg

Phosphate (P2O5) ≤0.1 mg/kg

Conductivity (at 20°C) ≤3 µs/cm

≤0.1 mg/kg

pH value (degree of acidity) 5 to 7

Appearance Colourless clean without sediment

Hardness (Σ Ions of alkaline earth) ≤0.02 mmol/l

Compliance with the above data should be tested in accordance with

acknowledged analytical methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The use of water for

autoclaves that does not comply with the table above may have severe impact

on the working life of the sterilizer and can invalidate the manufacturer’s

warranty.

22

Page 25

6 PREPARATION BEFORE STERILIZATION

The purpose of packaging and wrapping items for sterilization is to provide an

effective barrier against contamination during storage, once the items have

been sterilized.

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in paper or

cotton bags in order to prevent the multi-purpose valve and the autoclave

openings from becoming clogged with remnants of the material.

Packaging and wrapping materials should be approved for use in a steam

sterilizer and permit the removal of air and penetration of the steam during the

sterilization process.

The basic principle of determining the size, mass and contents of instrument

and hollowware packs is that the contents are sterile and dry immediately upon

completion of the drying cycle.

Instruments to be sterilized must be clean and free from any residual matter,

such as debris, blood, pads or any other material. Such substances may cause

damage to the instruments themselves or the sterilizer.

1. Clean instruments immediately after use. It is recommended that

instruments be ultrasonically cleaned in a Tuttnauer Clean and Simple

Ultrasonic Cleaner, using Tuttnauer Clean and Simple enzymatic

cleaning solution.

2. After ultrasonic cleaning, rinse under tap water for 30 seconds and pat dry

to remove residual minerals. If your tap water has a high mineral content,

rinse a second time in a bath of distilled water and pat dry.

3. Launder textile wraps prior to reuse, but do not use bleach.

4. Follow the instrument manufacturer’s instructions for cleaning and

lubricating instruments.

5. Be sure that instruments of dissimilar metal (stainless steel, carbon steel,

etc.) are separated. Carbon steel instruments should be bagged or placed

on autoclavable towels and not directly on stainless steel trays. (Mixing

will result in the oxidation of these metals).

6. Load items within the boundaries of the tray so that they do not touch the

chamber walls, or fall off when the tray is inserted into the autoclave. The

chamber walls are very hot; items that come into contact with the wall can

be damaged

7. Check the manufacture’s instructions as to the proper procedure for

sterilizing each item. The instrument manufacturer can give specific

information on proper sterilization temperature and sterilization time for

any item.

8. Place a sterilization indicator in each tray or inside each wrapped pack.

9. When using a paper / plastic bag, the plastic side should always be down.

Use single-use wraps once only and discard after use.

10. Verify that the packaging method is in accordance with good practice

approach and the packaging materials are in accordance with the

applicable standards (e.g. EN868 series).

23

Page 26

Pouch Rack

11. At least once per week use a biological spore test (Bacillus

Stearothermophilus) in any load to insure proper sterilization. (Be aware

testing standards may vary).

12. All instruments must be sterilized in an open position. Place instruments

with ratchets opened and unlocked or clipped on the first ratchet position.

Surfaces that are hidden because the item is in a closed position will not

be exposed to the steam and will not be sterilized.

13. Disassemble or sufficiently loosen multiple-part instruments prior to

packaging to permit the sterilizing agent to come into contact with all

parts of the instrument.

14. Make sure that all instruments remain apart during the sterilization

process. Surfaces that are hidden because items are covering other items

will not be exposed to the steam and will not be sterilized.

15. Items prone to trapping air or moisture, e.g. hollowware, should be tilted

on edge. This will allow a minimal resistance to the removal of air or

condensate during sterilization and drying.

16. The operator may use racks to allow for adequate separation of packaged

instruments.

17. Do not overload the sterilizer trays. Overloading will cause inadequate

sterilization and poor drying. Load trays loosely to capacity. Instruments

should be loaded one level deep only. See table in section 2 for

recommended loading capacities.

18. Tubing should be rinsed after cleaning. When placed in the tray, make

sure that both ends of the tubing are open and there are no sharp bends or

twists.

19. Empty canisters should be placed upside-down, in order to prevent

accumulation of water.

20. Allow a distance of approximately 1” (2.5 cm) between trays or cassettes

to permit steam circulation.

21. Wrapped instruments should be packed in material which will allow steam

penetration and promote drying, such as autoclave bag, autoclave paper,

or muslin towels.

22. Do not stack pouches.

It is recommended that a Tuttnauer

Pouch Rack be used. This will allow

the operator to place pouches on their

side, which will increase capacity and

will allow for better exposure to

steam for sterilization and better

circulation of air for drying.

24

Page 27

23. If spotting is detected on the instruments, the first step would be to use an

ordinary eraser to remove the spot. If there is no pitting under the spot, the

spot was only dirt. Dirt spots on an instrument may be an indication that the

autoclave needs to be cleaned or that the instruments were not adequately

cleaned or dried. If removal of the spot reveals pitting, the spot was most

likely rust. Rust spots on an instrument are not uncommon on inexpensive

instruments. It may also be an indication that the instruments were rinsed in

tap water with a high content of minerals. These minerals when exposed to

high temperature and steam will accelerate the oxidation of the metal. One

suggestion would be to final rinse the instruments in distilled water.

24. If the instruments exhibit a discoloration, this can be due to the mixing of

carbon steel and stainless steel. When these two metals come into contact

with each other electrolysis occurs that breaks down the metal. The best

solution is to separately wrap the carbon steel to insulate it from other

instruments or the trays.

25. Packs

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in paper

or cotton bags in order to prevent the multi-purpose valve and the

autoclave openings from becoming clogged with remnants of the

material.

1. Place packs upright on trays, side by side.

2. Packs should not touch the chamber walls.

3. Pack instrument sets in a manner that prevents damage to delicate items.

4. Pack hollowware sets so that all openings face the same direction and

so that the contents cannot move inside the pack.

5. Load packs of folded operating room drapes with layers vertical,

allowing air to be removed from the packs rapidly.

6. Do not place packs of hollowware and trays of instruments above

textile packs or soft goods in order to avoid wetting caused by

condensation from items above.

7. Load items packed in flexible packaging materials on edge with paper

to laminate, or flat with the plastic surface downwards.

Note: The instrument manufacturer’s recommendations shall be observed,

concerning the sterilization data for each type of material.

25

Page 28

26. Tubing

1. When placing in a tray, make sure that both ends are open, without

sharp bends or twists.

Wrong

Right

27. Cassettes

1. Instruments may be sterilized in cassettes. The advantage of the

cassettes is that the sterilized instruments may remain organized in

the cassettes ready for use, while stored in a sterile area.

2. If using models 2340 / 2540, remove the trays and slide the cassettes

into the chamber on the rack system.

3. If using models 3850 / 3870, place the cassettes directly on the tray,

either lying flat (but no stacking) or on edge.

26

Page 29

7 OPERATION

To avoid possible damage, do not leave the autoclave unattended while in

operation.

Make sure the power cord is plugged into the back of the unit and also

plugged into a power source.

7.1 Loading and Unloading the Device

7.1.1. Safety

Protective equipment, clothes and other safety instructions

should be implemented in accordance with local and national

regulations and/or rules!

For proper sterilization - Do not overload the chamber. Only

autoclavable products shall be used; please refer to the

material or instrument manufacturer's instructions for

sterilization of unknown materials or instruments.

7.1.2. Loading

Correct loading of the autoclave is essential to successful

sterilizing for several reasons. Efficient air removal from the

chamber and the load will permit steam penetration and

saturation, and allow proper drainage of condensate.

Additionally, correct loading will reduce damage to packs

and their contents and maximize efficient use of the

sterilizer.

For detailed loading instructions, see sec. 6 (Preparation

before sterilization).

7.1.3. Unloading

On completion of the cycle, the load shall be immediately

removed from the sterilizer and a visual inspection made to

ascertain that the load is dry, and that sterilizing indicators

have made the required color change.

7.2 Fill the Water Reservoir

7.2.1. Ensure that the drain valve is in a CLOSED position.

7.2.2. Remove the water reservoir cover.

7.2.3. Pour distilled water into the reservoir through the opening

on top of the autoclave, until it reaches the base of the safety

valve holder. Under no circumstances fill any higher than

the base of the safety valve holder.

7.2.4. For proper operation make sure the water level is above the

coils of the cooling coil.

Caution:

Under no circumstance should water be filled above the safety

valve holder.

27

Page 30

7.2.5. USE DISTILLED WATER ONLY. Use water-having

characteristics as per table in sec 5. The impurities in tap

water will create the need for more frequent cleaning and

maintenance, in addition, they will accumulate and block the

hole of the Air Jet. This will prevent the temperature in the

chamber from rising properly. This will cause spore tests to

fail and indicator strips will not change color. It is

essential from time to time, during heating and sterilization

phases, that a spray of steam should escape, from the Air Jet,

causing a hissing sound. If no escaping steam is evident or

no hissing sound heard, follow the instructions in sec 8.3 for

cleaning the Air Jet.

EXIT FOR STEAM SPRAY

Caution:

Daily before operation, check the water level in the reservoir and add

water when required. Once a week or after 20 cycles (the shorter

period) replace the water in the reservoir.

7.3. Move the ON / OFF rocker switch, located on the front panel, to the

ON position. The green Power Light will turn on, indicating that power

is ready to be supplied to the Heating Elements.

7.4. Turn the red tracking needle on the pressure gauge counterclockwise to

0 psi. The tracking needle will indicate the highest pressure reached

during the cycle.

7.5. Open the front door of the autoclave and set the Multi-purpose valve

knob to the FILL WATER position.

7.5.1. The water will now flow into the chamber.

7.5.2. The water should cover the bottom of the chamber up to the

groove in the front. This amount of water should be in

accordance with the table in sec 4.2.

7.5.3. When the water reaches the mark at the front of the autoclave,

set the multi-purpose valve knob to the STERILIZE

position.

Note:

When used for the first time, the multi-purpose valve requires slight

effort, but with use it will turn smoothly and easily.

Warning

The Multi-purpose valve knob should be turned in a clockwise direction only!

28

Page 31

7.6. Load the autoclave. See section “Preparation for Sterilization” for

C)

information on proper loading.

7.7. Shut the door, move the Door Closing Devise into position and tighten,

making sure that the Door Switch is activated.

NOTE:

Due to the inherent elasticity of the door gasket, it is important to

tighten the door bolt until “hand tight”. Do not overtighten the bolt as

this may result in damage to the gasket.

Should the autoclave fail to reach the sterilizing temperature/pressure,

always check first that the door is fully sealed. If not, tighten the door

bolt further, as described above, until completely sealed.

7.8. Turn the Thermostat knob to the desired sterilization temperature.

Note: This autoclave is designed according to all international

standards, which allows the temperature to raise 4ºF (2ºC)

over the working temperature.

Sterilization Time Table

TOTAL STERILIZATION TIME

(does not include drying)

Material

a. Unwrapped instruments,

open glass or metal

containers and any other

items where such

temperature is suitable.

Single Instruments 12min. 9min.

STE.

TEMP

273ºF

(134ºC)

MK M

Cold

Start

Hot

Start

Cold

Start

Hot

Start

16min. 11min. — — 1730

27min. 13min. 2340

30min. 14min. 2540

21min. 11min.

32min. 23min.

20min. 15min. — — 1730

b. Wrapped instruments,

standard cassettes,

rubber tubing and any

other items where such

temperature is suitable.

c. Packs and any other

items where such temp.

is suitable.

d. Any items where a

lower sterilization temp.

is required.

273ºF

(134ºC)

273ºF

(134ºC)

250ºF

(121

º

25min. 15min.

25min. 20min. 45min. 35min.

30min. 25min. 60min. 50min.

31min. 17min. 2340

34min. 18min. 2540

36min. 27min.

Note: The table shows different times for M (Standard Manual) & MK

(Kwiklave Manual) units as well as for hot and cold starts.

Make sure you are using the correct times for your model machine.

A hot start is any cycle that is begun within 1 hour of a previous cycle ending

(including drying time).

Note: These sterilization times are based on the unit being supplied the

correct voltage, as indicated on the Technical Label attached to the outer

Models

3140,

3850,

3870

3140,

3850,

3870

All

models

All

models

29

Page 32

cabinet. If the voltage supplied is substantially less than the indicated voltage,

additional time must be added to each cycle.

7.9. Set the Timer to the desired sterilization cycle time according to the

Sterilization Time Table.

7.9.1. The Heat Light will come on, indicating that power is being

supplied to the Heating Elements and remain on until the

correct sterilization pressure is achieved.

7.9.2. Once the correct pressure is reached the Heat Light will cycle

on and off, indicating that the Heating Elements are turning

on and off to maintain the correct sterilization pressure.

7.9.3. When the Timer reaches 0 min, the Heating Elements are

turned off and a buzzer will sound indicating that the

sterilization cycle is complete.

7.10. If unwrapped instruments were sterilized and no drying is required,

follow these steps.

7.10.1. Once the Timer has reached 0 min, turn the Multi-purpose

valve knob promptly to the Exhaust / Dry position. This will

allow the steam and leftover water to return to the reservoir.

7.10.2. When the white needle on the pressure gauge has reached

0 psi, the door can be opened.

7.10.3. Unscrew the Door Closing Device, move it to the side and

open the door to remove the instruments.

7.10.4. Now turn the Multi-purpose valve knob to the “0” or off

position.

Note: The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to a non-sterile environment.

7.11. If wrapped instruments were sterilized and drying is required, follow

these steps.

7.11.1. Once the Timer has reached 0 min, turn the Multi-purpose

valve knob promptly to the Exhaust / Dry position. This will

allow the steam and leftover water to return to the reservoir.

Do not allow the pressure to drop below 10 psi before

beginning this procedure. This will cause water to remain in

the bottom of the chamber even after the Multi-purpose

valve has been turned to Exh / Dry. Resetting the Timer for

drying will only be heating up this water and not drying the

instruments.

If the pressure has dropped below 10 psi, leave the unit in

the STERILIZE position, leave the door closed and locked.

Now reset the Timer for 10 minutes.

When the Timer reaches 0 min, the pressure should be above

10 psi (if not, add 5 more minutes to the Timer). Now turn

the Muli-purpose valve to the Exh / Dry position. This will

insure that all the water has been returned to the reservoir.

Note: The sooner the Multi-purpose valve is turned to

Exh / Dry at the end of the sterilization cycle, the

more effective and efficient will be the drying.

7.11.2. When the white needle on the pressure gauge has reached

0 psi the door can be opened.

30

Page 33

7.11.3. Unscrew the Door Closing Devise as far as it will go, but do

not move it to the side, this will allow the door to open

about ¾ of an inch.

7.11.4. Leave the Multi-purpose valve knob in the Exhaust / Dry

position.

7.11.5. Reset the Timer for drying, 20 – 30 minutes, the Dry Light

will come on indicating that Drying is active and the

Heating Elements are back on.

7.11.6. When the Timer reaches 0 min., the drying is complete and

the Dry Light and Heating Elements will turn off.

7.11.7. Unscrew the Door Closing Device, move it to the side and

open the door to remove the instruments.

7.11.8. Now turn the Multi-purpose valve knob to the “0” or off

position.

Warning

Multi-purpose valve knob should be turned in a clockwise direction

only.

7.12. At the end of the day, turn the ON / OFF rocker switch to the OFF

position.

31

Page 34

8 SERVICE AND MAINTENANCE INSTRUCTIONS

8.1 Preventive and Scheduled Maintenance

The maintenance operations described in this chapter need to be

followed as indicated to keep the device in good working condition.

The instructions that follow can easily be carried out by the office

personnel and do not require a service technician.

Should the need arise, technical assistance or a service technician can be

requested by either calling your dealer or Tuttnauer USA.

8.1.1 Daily

Clean the door gasket with a mild detergent, water and a soft

cloth or sponge. The gasket should be clean and smooth.

8.1.2 Weekly

1. ONCE PER WEEK, clean the air jet. To ensure that the

temperature inside the chamber rises properly, it is

necessary to keep the air jet clean. A dirty air jet will

prevent indicator strips from changing color and cause

spore tests to fail. See sec. 8.3.

2. Once per week, clean and descale the chamber, copper

tubes and the reservoir using Chamber Brite (see sec. 9).

Caution

Do not use steel wool, steel brush or bleach as this can

damage the chamber and trays!

3. Take out the tray holder and trays. Clean the tray holder

and trays with detergent or a non-abrasive stainless steel

cleaner and water, using a cloth or sponge. Rinse the tray

holder and trays immediately with water to avoid staining

the metal.

4. Put a few drops of oil on the 2 door pins and door

tightening bolt screw shaft and bearing.

5. Clean the outer parts of the autoclave with a soft cloth.

8.1.3 Periodically

1. Once every month, clean and check the safety valve (see

sec. 8.5).

2. Replace the door gasket every 12 months, or as needed

(see sec. 8.4).

3. Once a year, inspect the locking device for excessive

wear.

32

Page 35

8.2 Draining the Reservoir

Caution

Before starting, ensure that the electric cord is disconnected and

there is no pressure in the autoclave.

The drain valve is located on the front left side of the autoclave after the

door is opened. The function of the drain valve is to drain the water

reservoir.

1. Connect the silicone hose, supplied with the autoclave, to drain

into a bucket.

2. Turn drain valve counterclockwise to the open position.

3. Fully drain the reservoir.

4. With a quart of tap water, flush out the reservoir.

5. Turn drain valve clockwise to the close position.

6. Connect the electric cord to power source.

7. Fill the reservoir with distilled water to just below the safety

valve (see sec 7.2).

8. Turn on the main power switch.

9. The autoclave is now ready for use.

33

Page 36

8.3 Cleaning the Air Jet

(Located in the water reservoir.)

A dirty air jet is the number one cause of failed spore tests

The elimination of air from the sterilization chamber during heat up is

critical to the proper operation of the autoclave. Failure of the air

removal system will be responsible for incomplete sterilization, indicator

strips that do not change color and failed spore tests.

The air jet consists of a small orifice with a clean out wire inserted in it

(wire is permanently installed and will not come out). It is required that

the air jet be cleaned once per week or more often if necessary, to

remove any accumulated dirt and debris.

It is preferred to clean the air jet when the unit is running a cycle and

under pressure. This is so that any loosened debris will be blown away,

however, it can be done while the unit is idle.

1. Remove the water reservoir cover.

2. Clean the hole of the jet by manipulating the air trap wire (A) back

and forth 10 times.

Note:

It is important to clean the hole of the air trap, as described in point 2

before starting operation of the autoclave, for the first time.

34

Page 37

8.4 Replacing the Door Gasket

Pull off the gasket from the door groove. Install the new gasket as

described in drawings 1, 2 and 3 below.

Caution!

This gasket is designed with a trapezoidal cross section. The gasket

should be placed with the widest side towards the door.

35

Page 38

8.5 Checking the Safety Valve

(Located in the water reservoir)

In order to prevent the safety valve (6) from becoming blocked, it is

necessary to allow the steam pressure to escape through the valve. This

procedure should be done every month as follows:

1. Run a sterilization cycle with a sterilization temperature of 273ºF

according to the manual.

2. Allow a pressure of approximately 30 psi (260 kpa ) to build up in

the chamber.

3. Turn the timer back to 0 minutes.

4. Remove the water reservoir cover.

Caution!

This next step will expose you to HOT STEAM

Caution!

To avoid being burned, by hot steam, do not place your face over the

safety valve.

5. Pull the ring of the safety valve using a tool, i.e. screwdriver, hook

etc. and open the safety valve for 2 seconds then release. Be careful

not to burn your hands.

6. Verify that the valve releases steam and closes immediately.

7. If the safety valve is stuck in the “open” position, let the pressure

decrease to zero (atmospheric pressure).

8. After the pressure in the chamber decreases to zero, pull the valve

ring to release the valve.

9. Repeat operations 1 to 6.

10. If the valve is stuck again in the open position, call for service.

11. After a successful check, turn the multi-purpose valve to the

Exh/Dry position.

12. Wait until the pressure decreases to zero, only then can the door be

opened.

36

Page 39

8.6 Unclogging the Multi-Purpose Valve or Fill Piping.

1. Pour distilled water into the chamber, according to quantities

mentioned in para. 4 (Installation Instructions).

2. Close the door.

3. Turn the multi-purpose valve to STERILIZE position.

4. Move the main switch to the ON position.

5. Turn the Thermostat knob to 273ºF (134ºC).

6. Turn the Timer knob to 20 minutes.

7. After the timer has reached “0” turn the multi-purpose valve

(clockwise) to the FILL WATER position, do not stop at any

other position.

In most cases, the pressure pushes the obstructing substance out

and the steam exhausts into the water reservoir.

8. When the pressure gauge reaches 0, turn the multi-purpose valve

to the "0" position, and the main switch to OFF.

9. Open the door.

10. Replace the water in the water reservoir.

The autoclave is ready for the next cycle.

11. If this procedure does not clear up the clogging, a technician will

be required to replace the multi-purpose valve or clear the piping.

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in

paper or cotton bags in order to prevent the multi-purpose valve and

the autoclave openings from becoming clogged with remnants of the

material.

37

Page 40

9 CLEANING THE TABLETOP AUTOCLAVES WITH

CHAMBER BRITE™

CHAMBER BRITE ™ is a cleaning and descaling agent designed specifically

for the cleaning and removal of water deposits, oxides and other sediments

that are found in steam sterilizers. The material is a combination of acidic salts

and additional cleaning materials.

Chamber Brite™ autoclave cleaner has been formulated specifically to be a

fast, powerful and easy to use cleaner for steam sterilizers.”

If the autoclave is not cleaned regularly, dirt and debris will build up and clog

the tubing and valves. This dirt can also be transmitted to the instruments

during sterilization. In addition, a layer of dirt on the stainless steel chamber

traps moisture against the metal and will lead to the chamber becoming porous

and failing.”

“It is recommended that your autoclave be cleaned with

CHAMBER BRITE™ once per week”

Caution!

NEVER use bleach, steel wool, a steel brush

or anything abrasive to scrub or clean the

chamber.

Cleaning Procedure

1. Important – all steps in this procedure

must be completed without interruption.

2. When the autoclave chamber is cold,

remove instruments and trays from the

autoclave.

3. Open the door and spread the contents of a

packet in a straight even line along the

bottom of the chamber, from back to front.

4 Start a sterilization cycle* with water and

No Drying Cycle according to the

manufacturer's instructions. When the

cycle is finished, exhaust the unit.

5. At the end of the exhaust cycle, drain the

water from the reservoir.

6. Fill the water reservoir with distilled

water.

7. Repeat a sterilization cycle without

Chamber Brite™ powder, to remove any

excessive dirt in the pipes. Start a

sterilization cycle* with water and No

Drying Cycle according to the

manufacturer's instructions. When the

cycle is finished, exhaust the unit

8. At the end of the exhaust cycle, drain the

water from the reservoir.

9. Turn the autoclave off and allow chamber

to cool.

38

Page 41

10. Remove the tray holder; wipe the interior of the chamber with a damp

cloth.

11. Fill the reservoir with distilled water only.

12. Wipe the tray holder with a damp cloth and return it to the chamber.

13. Turn fill knob to fill position and allow a small amount of water (2-4

ounces) to fill chamber. Remove water from chamber.

14. The autoclave is ready to use.

IMPORTANT!

DO NOT sterilize instruments during the cleaning process!!!

CAUTION!

Keep out of reach of children. Contains mildly acidic ingredients. Avoid

contact with the skin, eyes or clothing. Wash hands well after touching the

powder, in the case of eye contact flush with continuous running water for

at least 15 minutes. If irritation persists get medical attention. If

accidentally swallowed, do not induce vomiting, drink large amounts of

water and obtain medical attention. MSDS available upon request.

For models 1730, 2340, 2540 use one packet of CHAMBER BRITE ™.

For models 3140, 3850, 3870 use two packets of CHAMBER BRITE ™.

Clean every 20 cycles or as needed.

* Total cycle time for cleaning Tuttnauer “M” series is 30 minutes at 273°F

(134°C). Total cycle time for cleaning Tuttnauer “MK” series is 15

minutes at 273°F (134°C). All cycles referenced are from a cold start.

39

Page 42

Corrections

the wall outlet and the back of the unit or

restore power to the wall outlet.

1.1 Make sure the power cord is plugged into

Possible Cause Checkup and Tests

has no power.

1.1 The unit is not plugged in or the wall outlet

1.2 Reset the circuit breaker.

1.3 Reset the cut out thermostat.

1.2 Circuit breaker is tripped.

light.

1.4 Have a technician replace the “Power”

1.3 Cut out thermostat is tripped.

15

to

the

timer

to

the

set

valve

and

purpose

-

position

”

multi

Dry

the

/

Exh

“

minutes.

1.4 Turn

burned out. When finished, turn the timer

If the “Dry” light is on, the “Power” light is

1.5 Have a technician checkout the unit.

back to 0 minutes.

1.5 If the “Dry” light does not come on, there is

2.1 Have a technician replace the “Heat” light.

an internal electrical problem.

2.1 The “Heat” light is burned out.

STERILIZE position.

3.1 Turn the multi-purpose valve to the

3.2 Close the door tightly.

STERILIZE position.

3.1 The multi-purpose valve is not in the

3.2 The door is not closed tightly.

activator. When adjusting – turn the

activator screw, in or out, by ¼ turn until

the door microswitch is pushed in when the

door is closed.

3.3 Replace or readjust the door switch

3.4 Turn the timer on.

3.5 Have a technician checkout the unit.

adjusted correctly.

3.3 The door switch activator is missing or not

3.4 The timer is off.

3.5 There is an internal problem.

Symptom

qualified technician needs to be called. Please call your dealer or Tuttnauer USA Co.

This troubleshooting section is for use by the Operator of the autoclave. If a problem develops that is not covered in this section, a

10 TROUBLESHOOTING

light up when the ON / OFF

switch is in the ON position.

1. Power indicator light does not

light up at the beginning of the

sterile cycle. The Power light is

on and the unit does heat up.

2. Heat indicator light does not

light up at the beginning of the

3. Heat indicator light does not

up.

sterile cycle. The Power light is

on and the unit does NOT heat

40

Page 43

to unclog

to unclog

. 6. A Tuttnauer Pouch Rack

Corrections

position.

4.1 Have a technician replace the “Dry” light.

Possible Cause Checkup and Tests

4.1 The “Dry” light is burned out.

5.1 Turn the multi-purpose valve to the DRY

5.2 Turn the timer on.

5.3 Have a technician check out the unit.

6.1 Fill the reservoir with distilled water.

position.

5.1 The multi-purpose valve is not in the DRY

5.2 The timer is off.

5.3 There is an internal problem.

6.1 There is no water in the reservoir.

the valve.

6.2 Follow the instructions in para. 8.6

6.2 The multi-purpose valve is clogged.

the piping.

6.3 Follow the instructions in para. 8.6

7.1 Clean the air jet, see para. 8.3

Load Sizes" table in sec. 2.

7.2 Adjust loading according to "Maximum

and not stacked. See preparations for

sterilization para

is recommended

7.3 Items to be sterilized should be separated

7.4 Check table para 7.

proper operating pressure”.

7.5 See para. 10.9 “unit does not reach the

pressure reading on the gauge.

7.1 Air jet is clogged.

7.2 Unit may be overloaded.

7.3 The load may be too densely packed.

7.4 Sterilization time may not be correct.

6.3 The fill piping is clogged.

7.5 Unit not reaching the correct sterilization

Symptom

Chamber when the multi-

light up at the beginning of the

dry cycle. The Power light is on

and the unit does heat up.

4. Dry indicator light does not

light up at the beginning of the

dry cycle. The Power light is on

and the unit does NOT heat up.

5. Dry indicator light does not

6. Water does not enter the

WATER position.

purpose valve is in the FILL

indicator strips are not changing

color according to instructions

of indicator's manufacturer.

7. Spore tests are failing or

41

Page 44

sterilization para. 6. A Tuttnauer Pouch Rack

operating

correct

for

Corrections

2.6

table

cycle, immediately turn the multi-purpose

valve to the “Exh / Dry” position. Once

venting is complete, start the drying cycle.

8.1 Once the timer rings at the end of the sterile

Possible Cause Checkup and Tests

after the sterile cycle.

8.1 The unit is not being vented immediately

Load Sizes" table in sec. 2.

8.2 Adjust loading according to "Maximum

8.3 Items to be sterilized should be separated

8.2 Units may be overloaded.

8.3 The load may be too densely packed.

is recommended.

and not stacked. See preparations for

8.4 Have a technician check the unit.

8.4 Units may not be heating properly.

voltages.

9.1 Check

9.1 Unit is not getting the correct voltage.

instructions.

procedures. See sec. 4 for installation

9.2 Check section 7 for correct operating

replace the door gasket.

9.3 Tighten the door more, if leaking persists,

amount of water.

9.2 Chamber was not filled with the correct

9.3 Door gasket is leaking steam.

replace the bellows.

9.4 Door bellows is leaking, have a technician

9.4 Steam is leaking at the closing device.

valve.

persists have technician replace the Safety

9.5 Follow procedure in section 8.5. If leaking

9.5 Safety Valve is leaking.

front of the unit higher to allow more water

into the chamber. See installation

instructions section 4.2/maximum load table

section 2.

9.6 Sterilize fewer towels or gowns or adjust the

available steam (cloth towels or gowns).

9.6 Items being sterilized are absorbing all

internal steam leak. Have a technician

check the unit.

9.7 Unit may be out of calibration or there is an

9.8 Have a technician check the unit.

is reached.

9.7 Heat light goes out before correct pressure

9.8 One or more of the heating elements is bad.

Symptom

not dry. See also section 10.32

and section 8.8.

8. Wrapped or bagged items do

operating pressure.

9. Unit does not reach the proper

42

Page 45

Corrections

instructions.

procedures. See sec. 4 for installation

10.1 Check section 7 for correct operating

Possible Cause Checkup and Tests

amount of water.

10.1 Chamber was not filled with the correct

of the chamber.

10.2 Make sure no items are touching the walls

10.2 Items are lying up against the chamber.

table in section 7.

10.3 Set the sterilization time according to the

10.3 The sterilization time is set too high.

the front of the unit higher to allow more

water into the chamber. See installation

instructions section 4.2/maximum load

table section 2.

10.4 Sterilize fewer towels or gowns or adjust

available steam (cloth towels or gowns).

.

10.4 Items being sterilized are absorbing all

replace the door gasket.

10.5 Tighten the door more. If leaking persists,

10.5 Door gasket is leaking steam.

replace the bellows.

10.6 Door bellows is leaking, have a technician

10.6 Steam is leaking at the closing device.

valve.

persists have technician replace the Safety

10.7 Follow procedure in section 8.5. If leaking

10.7 Safety Valve is leaking.

10.8 Have a technician check the machine.

10.8 There is an internal steam leak or electrical

11.1 Follow instruction in section 10.31.

problem.

11.1 Door bellow locking pin is trapped.

white lithium grease to the screw and

8.1.2.4.

bearing of the closing device, see sec

12.1 Apply 1 or 2 drops of 3 in 1 oil or some

12.1 Closing device needs oil.

burning or melting.

Symptom

10. Items in the chamber are

43

when pressure gauge reads 0

psi.

11. Closing device does not open

close.

12. Closing device is hard to

Page 46

Corrections

leaking persists, have technician

instructions.

procedures. See sec. 4 for installation

7.2.

sterilized, this is not a problem.

open the door right away.

reservoir. The open end of the cooling

coil should not be below the water line.

thermostat; if the problem persists have a

technician check the machine.

a) Check section 7 for correct operating

persists, replace the door gasket.

b) Tighten the door more; if leaking

replace the Safety valve.

c) Follow procedure in section 8.5. If

the front of the unit higher to allow more

water into the chamber.

See installation instructions section

4.2/maximum load table section 2.

d) Sterilize fewer towels or gowns or adjust

e) Have a technician check the machine.

13.1 Do not fill above the safety valve. See sec

Possible Cause Checkup and Tests

13.1 Water level too high in the reservoir.

13.2 If unwrapped instruments are being

13.2 Waiting too long to exhaust after

For wrapped instruments see sec 7.11.

14.1 Once the chamber is finished venting,

sterilization is complete.

14.1 Leaving the multi-purpose valve in the

Also, straighten the cooling coil in the

“Exh/Dry” position while leaving the door

closed and having a cooling coil that is

mispositioned in the reservoir.

15.1 Correct the cause and reset the Cut out

beginning of the cycle.

condition due to too little water in the

chamber caused by either:

a) Incorrectly filling the chamber at the

15.1 The unit has detected an overheating

b) A leaking door seal.

d) Absorbent material being sterilized.

c) A leaking safety valve.

e) An internal steam leak.

Symptom

the chamber at the end of

sterilization.

13. Water is left in the bottom of

the door is open.

14. Water spills on the floor when

15. Cut out thermostat trips.

44

Page 47

Corrections

to the up position. If the problem persists,

have a technician check the unit.

compressed air into the valve. This should

where it can be removed. Cover the

reservoir opening to avoid splatter.

blow the clog back into the reservoir

compressed air into the valve. This should

where it can be removed. Cover the

reservoir opening to avoid splatter.

blow the clog back into the reservoir

Chamber Brite, section 9.

Chamber Brite, section 9.

16.1 Reset the red lever of the circuit breaker

Possible Cause Checkup and Tests

16.1 A power surge or spike.

17.1 Open drain valve completely and blow

17.1 Drain valve is clogged.

18.1 Open drain valve completely and blow

properly.

18.1 Debris is stopping the valve from seating

18.2 Have a technician replace the o-rings.

18.2 Drain valve o-rings are worn.

19.1 Follow cleaning instructions using

19.1 Unit has not been cleaned recently.

20.1 Use 100% steam distilled water.

20.2 Follow cleaning instructions using

20.1 Not using distilled water.

20.2 Unit has not been cleaned recently.

21.1 Have a technician replace the door bellows.

21.1 The door bellows is leaking.

22.1 Tighten the door more.

22.2 Replace the door gasket (see sec. 8.4).

22.1 Door may not be tightened down enough.

22.2 Door gasket may be worn or cracked.

Symptom

looking.

16. Circuit breaker trips.

17. Reservoir does not drain.

18. Drain valve is leaking.

45

19. Chamber is black or dirty

along bottom.

20. Chamber has a water mark

device area.

21. Steam escaping from the closing

seal.

22. Steam leaking from the door

Page 48

Corrections

knob and the glass of the gauge. Turn the

knob back and forth to work the oil onto

purpose valve.

purpose valve.

the internal shaft.

small screw in the center of the silver

knob.

set hammer.

then pull on the ring of the safety valve.

This will relieve the vacuum in the

chamber.

23.1 Have a technician replace the multi-

Possible Cause Checkup and Tests

23.1 The internal spring in the multi-purpose

24.1 Have a technician replace the multi-

valve has broken.

24.1 Poor maintenance will result in the multi-

25.1 Place one drop of oil between the silver

purpose valve binding.

25.1 No lubrication on the needle shaft.

25.2 Use a small screwdriver to adjust the

26.1 Have a technician replace the timer.

27.1 Have a technician replace the timer.

27.2 Timer must be turned past 10 minutes to

off.

28.1 Follow the instructions in sec 8.5.

hammer

valve.

29.1 Follow instructions in sec 6.23.

dirt.

30.1 Make sure pressure gauge reads 0 psi, and

and a vacuum developed.

25.2 Internal spring is too tight.

26.1 Internal gearing has worn down.

27.1 The hammer on the timer bell has broken

27.2 Timer was not turned far enough to set

28.1 Debris has lodged in the seat of the safety

29.1 The first step is to determine if it is rust or

30.1 Unit was left to cool with the door closed

Symptom

backwards.

23. Multi-purpose valve turns

turn.

24. Multi-purpose valve does not

gauge is hard to set.

25. Red tracking needle on pressure

26. Timer does not time down.

27. Timer bell does not ring.

28. Safety valve is leaking.

29. Instruments are rusting.

device is open.

30. Door will not open, closing

46

Page 49

Corrections

recommended to provide proper spacing

of bagged instruments. This will allow

for better exposure to steam for

sterilization and better circulation

(closing direction). The pin will be

released, enabling the operator to

EXH. & DRY.

1. a. Turn the Multi-purpose valve to

Device ¼ of a turn in the clockwise

b. Turn the handle of the Door Closing

open the door.

Technician will need to be called

2. If this does not correct the problem, a

a. A Tuttnauer Pouch Rack is

of air for drying.

the instruments on the tray are only one

level deep and that the paper / plastic

bags are plastic side down.

b. If a Pouch Rack is not used, make sure

31.1

Possible Cause Checkup and Tests

31.1 Locking pin is trapped.

32.1

each other.

32.1 Bagged instruments are placed too close to

32.2 End cycle according to para. 7.

correctly.

32.2 Cycle ending has not been performed

Symptom

the

door to be opened

and there is no pressure in the

be turned counter-clockwise for

chamber.

31. Door handle cannot

are not drying properly (see also

sec 7.11).

32. Wrapped or bagged instruments

47

Page 50

TRAY HANDLE CT530020

For 1730, 2340, 2450 models only

POUCH RACK

TRAY

TYPE

CAT No.

2340

2540

AR910

AR920 3870

MODEL SIZE CAT. No.

1730 CU520010

2340 CT520010

2540 CT520010

Big TRY314-0001

3140

Small TRY314-0002

Big CF520010

3850

Small CF520020

Big CC520010

3870

Small CC520020

48

Page 51

TRAY HOLDER

MODEL TRAY HOLDER CAT. NO.

1730 CU510010

2340 CT510010

2540 CV510010

3140 TRH314-0000

3850 CF510010

3870 CC510010

49

Page 52

11 LIST OF ACCESSORIES

Description

1730 2340 2540 3140 3850 3870

Cat. No.

Tray Handle, TTA

1730, 2340, 2540

Pouch Rack

Big

Tray

Small

Tray Holder

Silicon drain tube

Chamber Brite 1 case

(12 boxes)

CT530020 CT530020 CT530020 — — —

— AR910 AR910 — — AR920

TRY314-0001 CF520010 CC520010

CU520010 CU520010 CU520010

TRY314-0002 CF520020 CC520020

CU510010 CT510010 CV510010 TRH314-0000 CF510010 CC510010

02620016 02620016 02620016 02620016 02620016 02620016