Tuson TPMS User Manual

Tuson TPMS Retrofit Kit User Manual

Contents

For TPMS4W & TPMS6W Models

1. Warning .............................................................................................................................................. 3

2. Product Parts List & Description ......................................................................................................... 5

3. Product Specifications ...................................................................................................................... 10

4. TPMS Sensor Installation ................................................................................................................. 12

5. TPMS Repeater Installation ............................................................................................................. 19

6. TPMS Receiver Installation .............................................................................................................. 23

7. Driving Mode Menu .......................................................................................................................... 27

8. Settings Mode Menu: ....................................................................................................................... 39

9. Alarm Warning and Display Symbols ............................................................................................... 59

10. Troubleshooting ................................................................................................................................ 62

11. Customer Service ............................................................................................................................. 64

12. Notes ................................................................................................................................................ 65

13. Limited Warranty .............................................................................................................................. 68

1. Warning

1.1 Federal Communication Commission Interference Statement:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

3

1.2 Product Warning:

1.2.1 Do not adjust the TPMS receiver while driving. The company is exempt from all consequences

because of driver’s careless and improper operation.

1.2.2 The system uses wireless RF transmission signals. In some special circumstances, interference or

erroneous methods of operation or installation may cause weaker signal or its inability to receive

signals. If the insulation adhesive sticker of the windshield contains metal material, it may affect

signal reception. If the tire pressure and temperature readings on the TPMS receiver are displayed

as “---”, this indicates that the receiver is not receiving the signals emitted by the sensors. Drive the

vehicle away from the current location (where there may be some signal interference) or drive the

vehicle to a tire shop to check.

1.2.3 If the battery status of the TPMS sensors inside the tire is low, “---” will be shown on the receiver

display (if abnormal conditions continue to occur, the TPMS sensors will continuously emit signals

to warn the driver, resulting in shorter sensor battery life). Please go as soon as possible to a

service station to confirm whether the TPMS Sensors need to be replaced.

1.2.4 Temporary resealing or re-inflation products containing internal sealants or propellants in any tire

assembly may adversely affect the operation of the sensor/transmitter. The product manufacturer

does not assume any liability as to the customer’s use of internal sealants or propellants with the

tire sensors used with this TPMS.

1.2.5 Do not leave the sensors in contact with chemicals, it may cause the sensors to fail.

4

Part No.

TPMS4W

TPMS6W

Sensor 4 6

Interchangeable Valve

Stem (0.625” / 0.453”)

4

6

TPMS Receiver (Monitor)

1

1

Repeater 1 1

1.2.6 The TPMS needs to be installed by qualified technicians in accordance with the installation manual

for the TPMS warranty to be valid. If the TPMS sensor is improperly installed or disassembled

causing damage to the sensors, the warranty will not cover this type of damage.

2. Product Parts List & Description

Accessories in the box:

• Cigarette Lighter Cable (Vin=12~24V) x 1

• Suction Cup Holder x 1

• Wheel Orientation Mark Sticker Sheet x 1

• Cable Tie x 5

• User Manual x 1

• Registration Card x 1

5

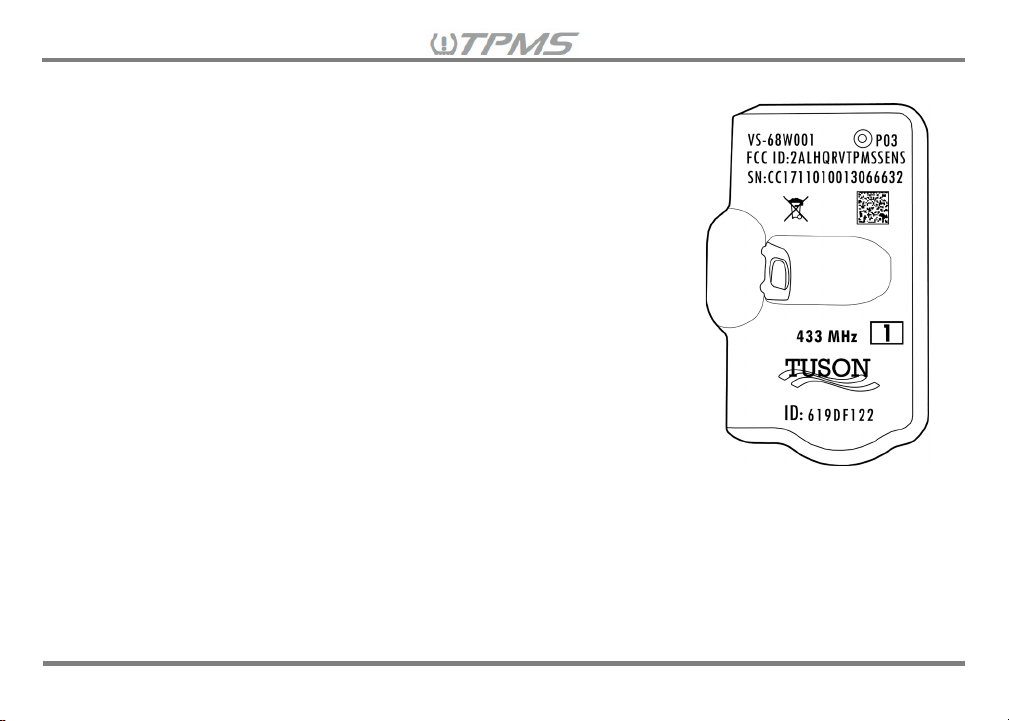

2.2 Sensor Description

The Tuson TPMS Retrofit Kit sensors are automotive-grade sensors

designed to monitor tire pressure and temperature consistently and

wirelessly transmit data to the receiver. Each sensor has a unique ID# to

identify the sensor to the receiver. These are internal sensors that are

securely mounted to the valve stem or using a band and bracket kit (not

included) inside the tire to prevent damage and/or theft. Internal sensors

provide more accurate pressure and temperature readings than external

sensors. The sensors are motion-activated and will go into sleep mode

when the wheels stop moving to preserve sensor battery life. Sensors

may take a few minutes to wake-up. Once the wheel speed is over 12

mph/20 kph, then the sensor will wake-up and will continue transmitting

messages to the receiver every minute while moving. As a general

reference, the sensor battery life is about 5 years when driven 4 hours

per day. See section “4. TPMS Sensors Installation” on how to install

the sensors.

6

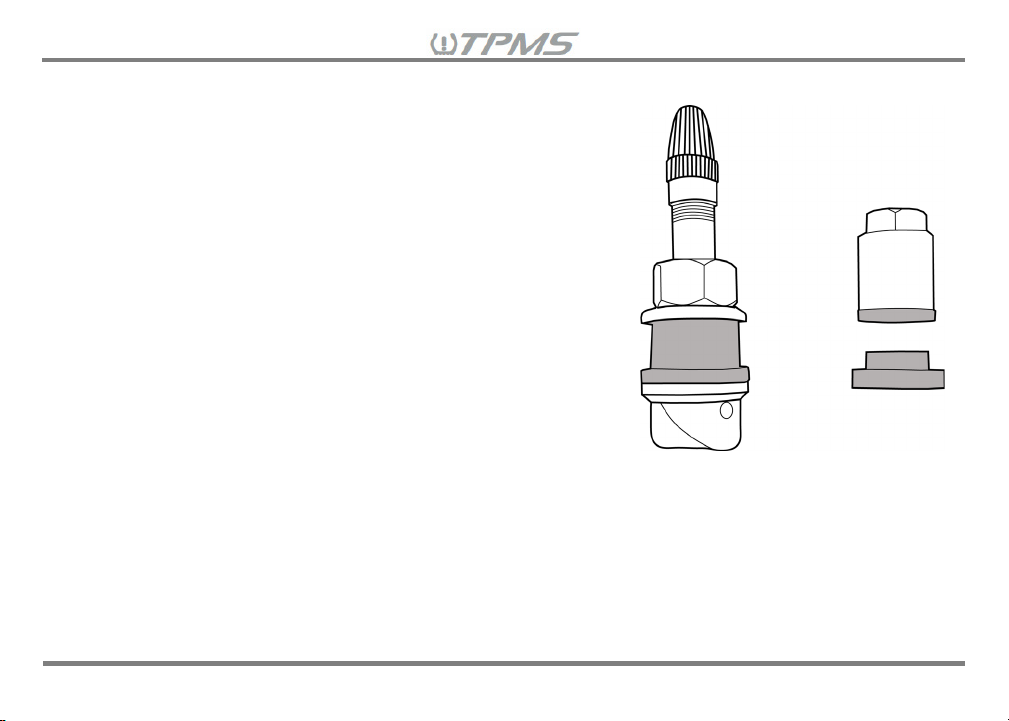

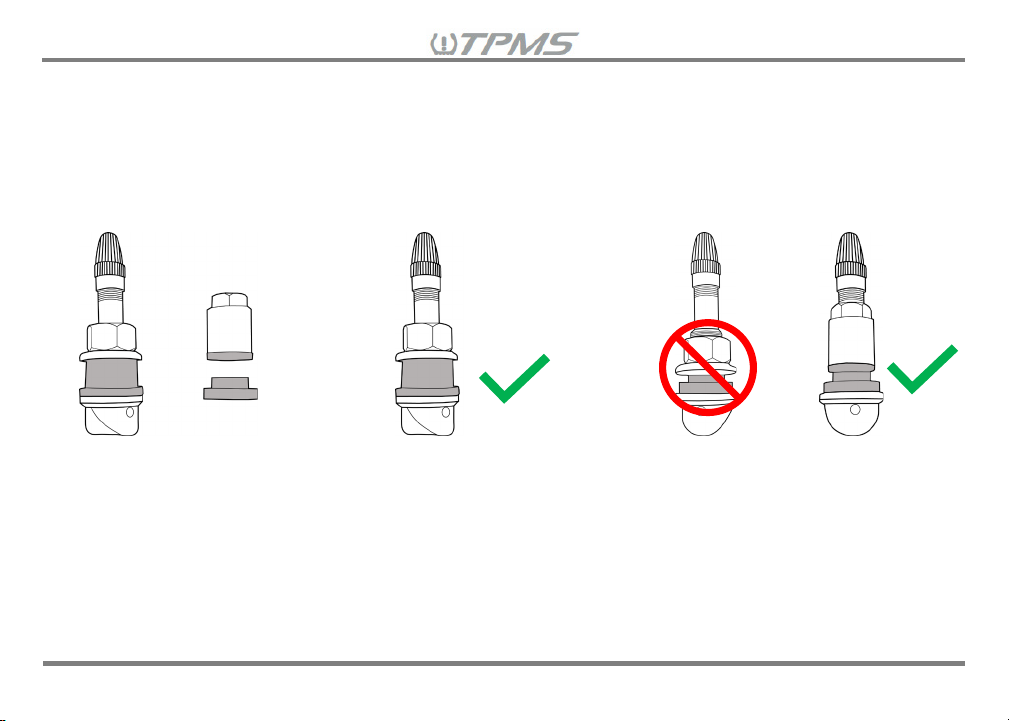

2.3 Interchangeable Valve Stem (IVS) Description

The Tuson TPMS’ tire sensors use a metal interchangeable valve

stem (IVS) that is designed to fit through either 0.453" or 0.625"

diameter wheel valve holes for your convenience. The IVS is

compatible with both steel and aluminum wheels. The valve stem

and nut portion of the IVS are made of brass and the washer is

made of nickel-plated steel. A polybag containing the IVS comes

pre-assembled with the 0.625” diameter rubber grommet; metal

washer; 0.625” diameter nut and valve cap on the valve stem. A

0.453” diameter rubber grommet and nut are also included in the

polybag for each IVS. The IVS should be installed in the wheel

using a single rubber grommet only. WARNING! – Do not use

both sizes of the included grommets to install the valve stem. See

Section “4. TPMS Sensors Installation” on how to install the

sensors.

7

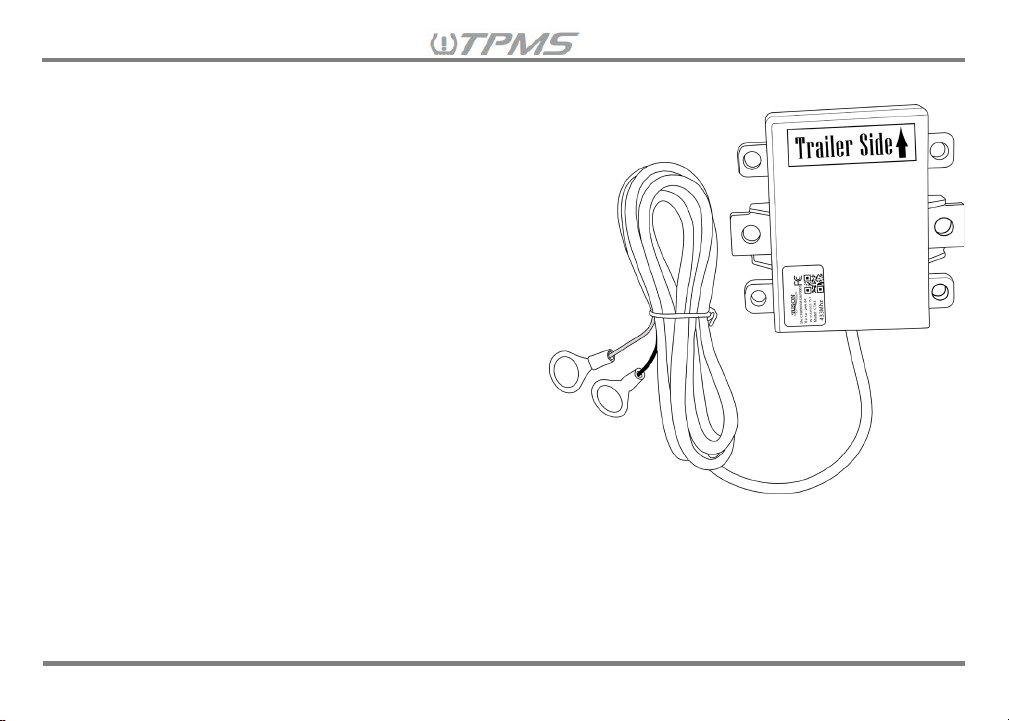

2.4 Repeater Description

The Tuson TPMS Retrofit Kit includes a repeater. The

repeater features power (red) and ground (black) wires

to connect to the trailer battery or any power source

that provides a constant 12/24V power. The repeater

is designed to boost the signal strength from the tire

sensors to the receiver (monitor) in the tow vehicle.

The repeater is waterproof and can be exposed to the

outside elements without being damaged. On trailers

greater than 20 feet long, the repeater must be

installed to provide the receiver enough signal strength

from the sensors. For small trailers, the receiver may

pick up the sensors without the repeater installed

however, we highly recommend you install the

repeater. In addition to boosting signal strength, the

repeater is also designed to transmit the trailer battery

voltage to the receiver. The repeater does not need to

be disconnected from the power source, because it is

motion activated and will go into sleep mode when the trailer is not moving. Therefore, the repeater may

take a few minutes while driving to wake-up and start transmitting messages to the receiver. See section

“5. TPMS Repeater Installation” on how to install the repeater.

8

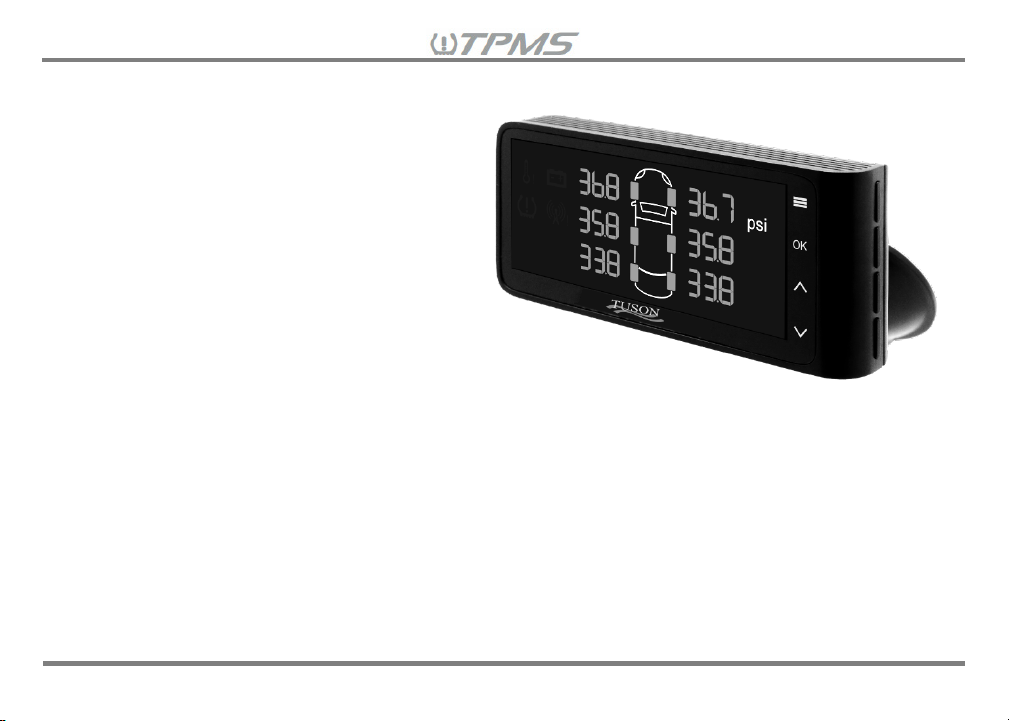

2.5 Receiver Description

The receiver (monitor) allows the driver to

monitor the tire pressure and temperature of up

to 10-wheels for up to 3-vehicle memory

selections. The receiver will also monitor trailer

battery voltage when the repeater is connected

to a trailer battery. A 12~24V cigarette lighter

cable is included to power the receiver in the

tow vehicle. The Tuson Display Power Cable

(sold separately) can also be used to power the

receiver with a 9V battery to make the “Tire

Sensor ID Pairing” in section 9.5 easier. The

receiver has two menus: Driving Mode and

Setting Mode. When in Driving Mode, the

receiver will automatically cycle between pressure, temperature, and trailer battery for that selected vehicle

memory. When in Settings Mode, you can select the vehicle memory to customize and monitor when in

Driving Mode. When monitoring more than 6-wheels on a vehicle memory, the Driving Mode will display

the pressure and then temperature for the first 6-wheels and then the pressure and temperature for the

additional wheels in the next screen before moving to the trailer battery voltage screen. Alerts on the

receiver will continue to appear until the issue with the sensor or repeater has been addressed/cleared.

See section “6. TPMS Receiver Installation” on how to install the receiver and button functions.

9

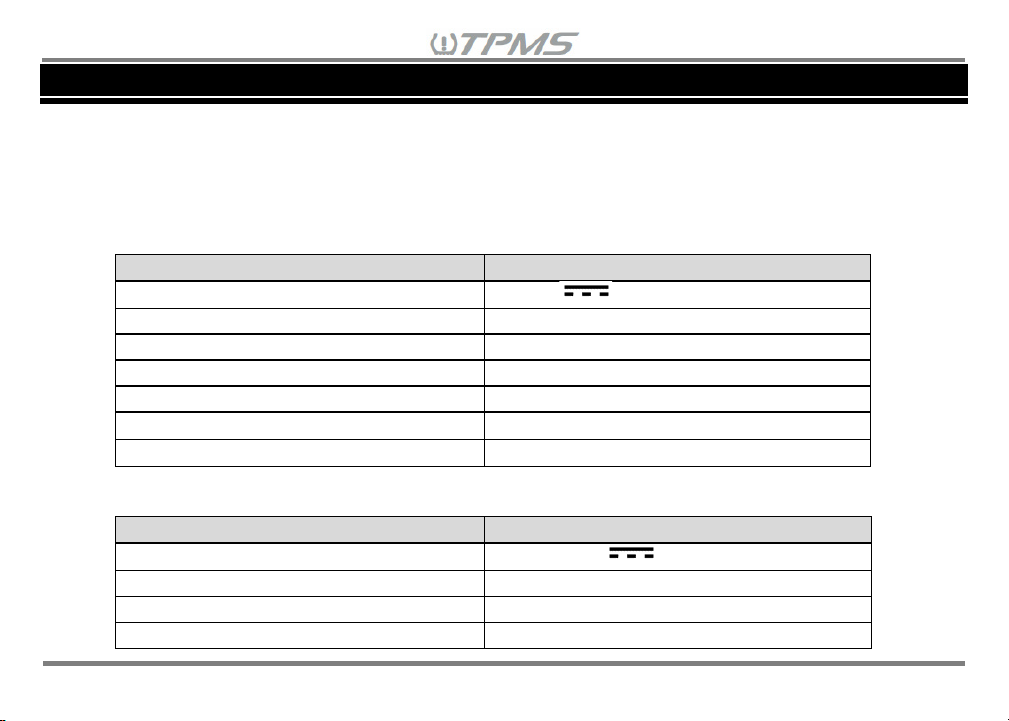

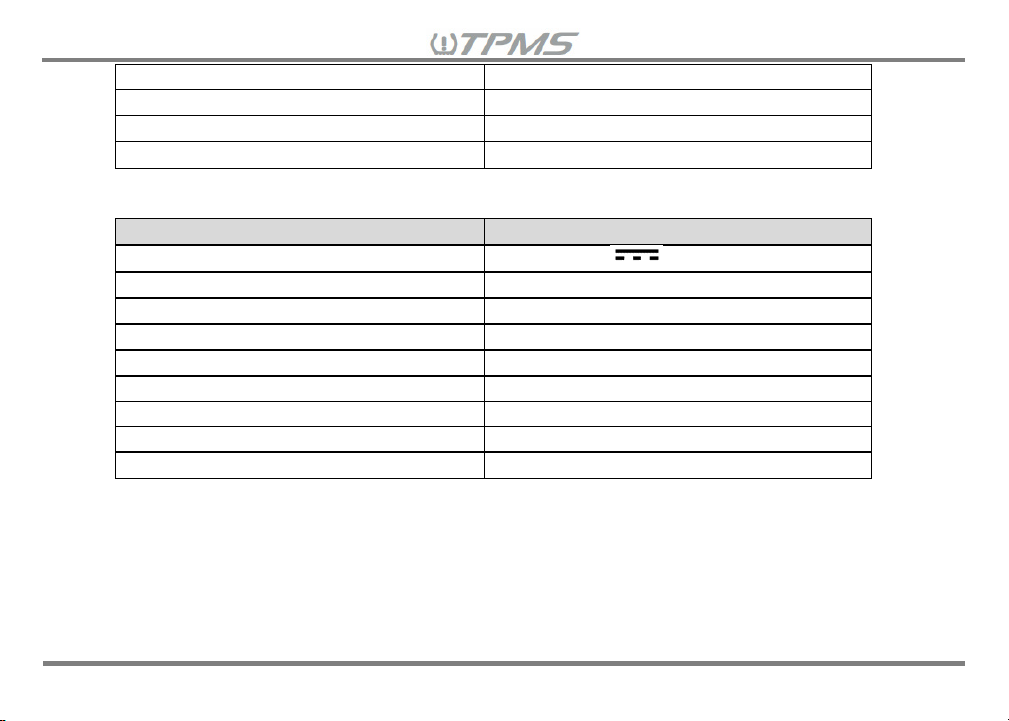

ITEM

SPECIFICATION

Operating Voltage

3V DC

Operating Frequency

433 MHz

Operating Temperature

-22°F~257°F (-30°C~125°C)

Storage Temperature

-40°F~257°F (-40°C~125°C)

Tire Pressure Monitoring Range

0~203 ±1.5 psi (0~1400 ±10 kPa)

Tire Temperature Monitoring Range

-40°F~257°F±5.4°F (-40°C~125°C±3℃)

Weight

30 g (1 Oz)

ITEM

SPECIFICATION

Operating Voltage

12~24V DC

Operating Current

11.2 mA

Operating Frequency

433 MHz

Operating Temperature

-4°F~185°F (-20°C~85°C)

3. Product Specifications

Vehicle Types for TPMS use (Maximum 10-wheels):

Tuson TPMS is designed for all types of RV, commercial and livestock trailers. Great for commercial and

passenger vehicles as well!

3.1 Sensor Specifications

3.2 Repeater Specifications

10

Storage Temperature

-40°F~185°F (-40°C~85°C)

Cable Length

90 inches (2300 mm)

Size

3.5”x3.8”x0.9” (88 x 96 x 23 mm)

Weight

6 Oz (170 g)

ITEM

SPECIFICATION

Operating Voltage

12~24V DC

Operating Current

120 mA

Operating Frequency

433 MHz

Operating Temperature

-4°F~185°F (-20°C~85°C)

Storage Temperature

-40°F~185°F (-40°C~85°C)

Monitored Pressure Range

0~203 ±1.5 psi (0~1400 ±10 kPa)

Monitored Temperature Range

-40oF~257oF ±5.4oF (-40oC~125oC ±3oC)

Size

4.5”x2.1”x1” (116.5 x 53 x 25 mm)

Weight

3.4 Oz (95 g)

3.3 Receiver Specifications

Note: When using kPa as the unit of air pressure, the monitor will display “Hi” if the air pressure is over

999kPa. The actual air pressure values will be displayed numerically when the unit of measure selected is

in psi or Bar.

11

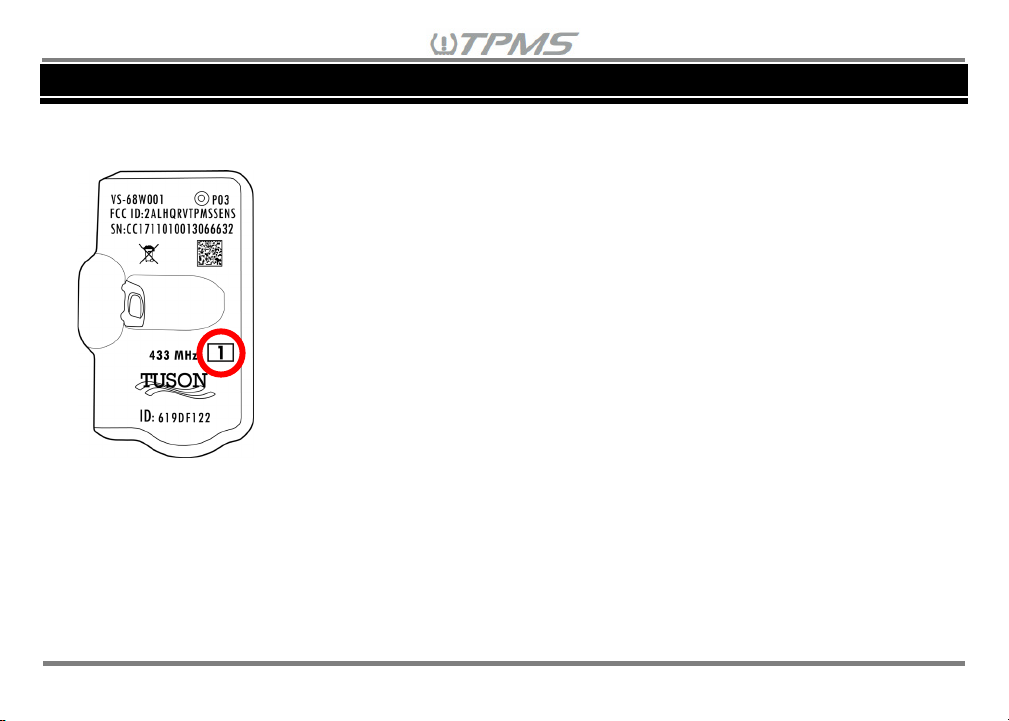

Figure 4.1 Wheel

4. TPMS Sensor Installation

<IMPORTANT 1>

Each sensor has a unique Sensor ID# to identify the sensor to the receiver. The

sensors included in the kit are already paired to the receiver from the factory for

ease of installation and have a designated wheel orientation mark (□

the sensor (see Figure 4.1). The wheel orientation mark on each kit sensor

corresponds to a tire location on the vehicle and/or trailer. It is important to install

the kit sensors to the corresponding wheels on the vehicle and/or trailer (see

Table 4.1 for reference). If the sensors are installed in the correct corresponding

wheel locations in Table 4.1 for up to six (6) sensors, then you can skip Setting

“8.5 Tire Sensor ID Pairing to the Receiver” from Section “8. Settings Mode

Menu” (Note: If installing additional sensors not included in the kit, the “8.5 Tire

Sensor ID Pairing to Receiver” must be performed for the additional sensors only.)

Orientation Mark

1,□2

,…□6) on

12

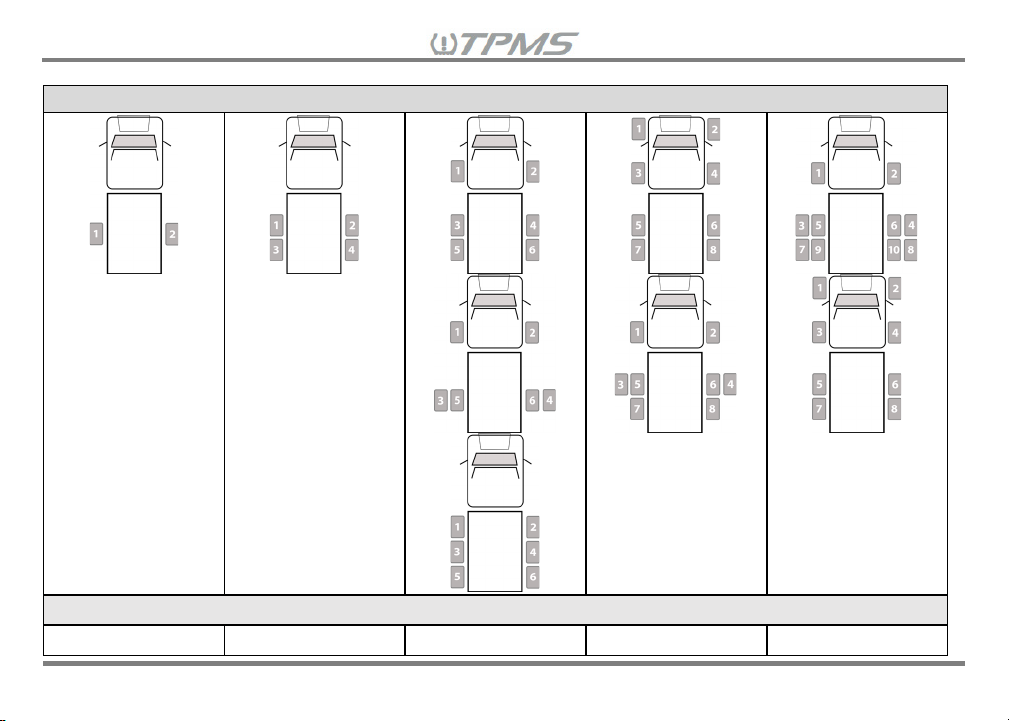

Vehicle Tire Location

Sensor Wheel Orientation Mark Numbers for CAR 1*

1-2

1-4

1-6

1-8

1-10

Table 4.1 Sensor Wheel Orientation Mark Numbers and Vehicle Tire Location for CAR 1*

13

For Other Custom Vehicle Configurations, please see note below:

Note: For initial installation, the sensor orientation mark should be installed in the following order:

*Wheel orientation marks used per vehicle selection: CAR 1 ~ 1-10, CAR 2 ~ 11-20, CAR 3 ~ 21-30

1. Sensors on the LEFT side are ODD numbered

2. Sensors on the RIGHT side are EVEN numbered

3. Each vehicle side will have sensors increase in odd or even consecutive order from front to back

4. For vehicles with dually axles, the outside tires should have the lower numbered marking and

the inside tires should have the higher numbered marking.

<IMPORTANT 2>

The sensors’ ID# and wheel orientation mark included in the kit are listed in Section “12.3 Sensor ID#s

List for Each Vehicle Memory Selection” of each user manual. BEFORE installing additional sensors

not included in the kit, it is highly recommended that the sensor ID#s be recorded in Section 12.3 next to

the corresponding wheel orientation mark for easy identification when pairing.

The Interchangeable Valve Stem (IVS) Service Kit

The Tuson TPMS tire sensors use a metal interchangeable valve stem (IVS) that fits through 0.453" and

0.625" diameter wheel valve holes. (Note: If neither grommet size fits the wheel valve hole, a TPMS band

and cradle kit can be purchased separately without replacing the existing valve stem.)

Please circle the grommet size that was used for your tire application for easy identification and

replacement: 0.453” or 0.625”.

14

<IMPORTANT 3>

Each IVS service kit comes with two (2) rubber grommet sizes: one (1) fits 0.453” diameter wheel valve

holes and one (1) fits 0.625” diameter wheel valve holes. The IVS should be installed using a single

grommet only. WARNING! – Do NOT use both sizes of the included rubber grommets to install a single

valve stem. Please check and make sure that the correct grommet size is used for the valve stem and fits

the wheel’s valve hole diameter prior to TPMS sensor installation.

The IVS service kit comes

pre-assembled with the

0.625” diameter rubber

grommet; metal washer;

0.625” diameter nut and valve

cap on the valve stem and

includes a separate 0.453”

diameter grommet and nut in

the polybag.

Please use the preassembled 0.625” diameter

grommet on the valve stem if

the wheel valve hole is 0.625”

diameter.

When the valve hole of the wheel is

0.453” diameter, disassemble the

pre-assembled IVS valve stem.

Remove the 0.625” diameter rubber

grommet, metal washer, nut from

the valve stem. Assemble the

0.453” diameter grommet, nut and

cap in order.

15

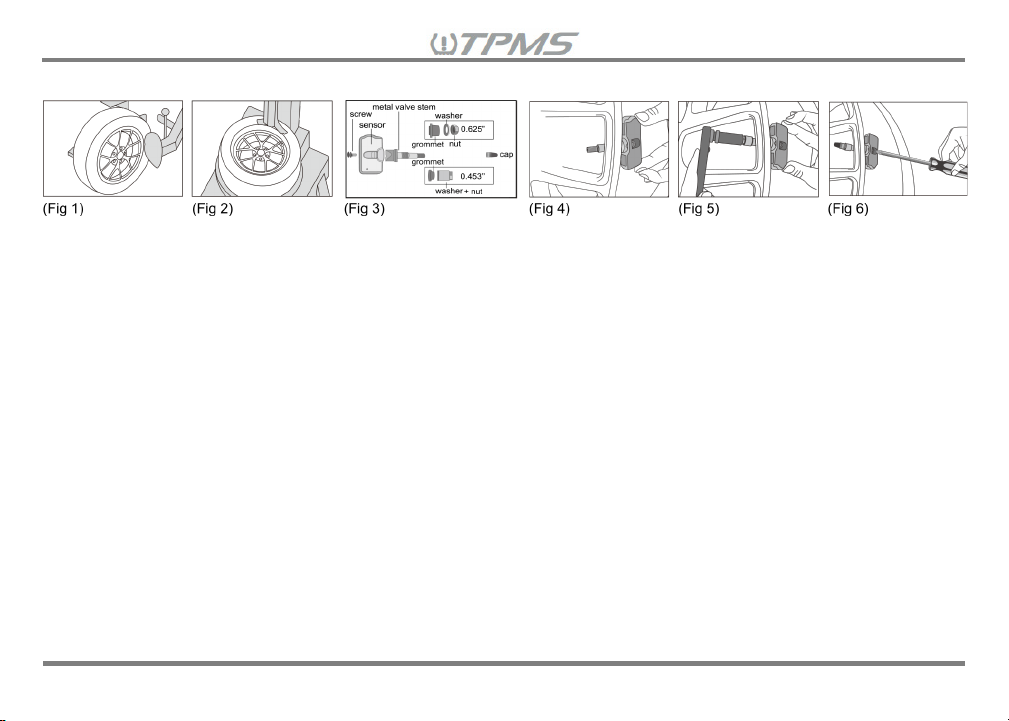

4.1 TPMS Sensor Installation:

(Fig 1) & (Fig 2) Deflate and remove the tire from the wheel using a tire mounting machine.

(Fig 3) Assemble the sensor to the metal valve stem using the mounting screw (make sure to use the

correct grommet size is on the metal valve stem), then remove the cap, 0.625" washer and nut (OR 0.453"

nut) from the metal valve stem.

(Fig 4) Insert the metal valve stem through the wheel’s valve hole, making sure to properly seat the rubber

grommet in the valve hole. Then place the back of the sensor body to face the inner surface of the rim, so

that the sensor is parallel to the rim.

(Fig 5) Holding the sensor in place, guide the washer (for 0.625" ONLY) onto the metal valve stem on the

outside of the valve hole. Then secure the 0.625" OR 0.453" nut on the metal valve stem and torque to

2.95 Ft-lbs (4 N-m). Once secured, affix the cap to the metal valve stem.

(Fig 6) Secure the sensor to the metal valve stem and torque the screw to 1.48 Ft-lbs (2N-m).

16

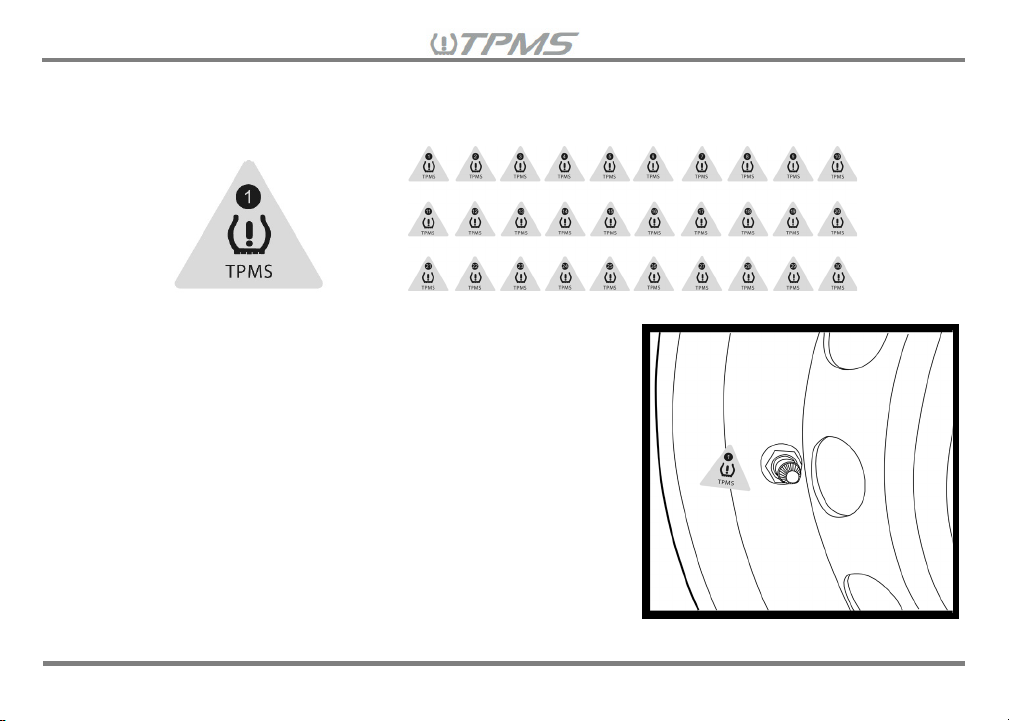

Now remount the tire back onto the wheel, being careful not to damage the tire pressure sensor during

mounting of the tire. Each TPMS retrofit kit comes with a wheel orientation mark sticker sheet to easily

identify wheel location on the receiver display and for which vehicle selection.

To apply the sticker to the wheel, clean the surface of the wheel

near the valve stem with isopropyl alcohol and allow to dry

completely. Do not use brake cleaner or other harsh chemical

solvents to prepare the wheel surface for sticker application.

Make sure the wheel surface is clean and dry then adhere the

corresponding wheel ID sticker to the clean surface near the valve

stem. This will help remind technicians to install the wheel back

to the correct location according to your defined wheel position.

Lastly, balance the wheel as you would normally, adding weights

if necessary, to achieve rotational balance.

17

<IMPORTANT 4>

When removing the tire from the wheel rim to install our Tuson TPMS Retrofit Kit, be aware that if the valve

stem is secured by a nut, there might be a sensor already installed, be careful not to damage the sensor

during the tire removal process.

18

5. TPMS Repeater Installation

5.1 Repeater Image

5.2 Installation Steps

The repeater is designed to boost the sensors’ RF signals to the receiver in the tow vehicle. The mounting

location of the repeater will depend on the type of trailer (bumper pull trailer, 5

the TPMS will be installed on. Select a horizontal surface location to mount the repeater on the front section

of the trailer, keeping in mind that the cable ends of the power cord will need to connect to the trailer battery.

For optimal signal performance, the key is to have the least obstructed transmission path between the

sensors, repeater and receiver. Ideally, to get the best RF transmission between repeater and tire pressure

sensors, the repeater should be in an open space with no barriers between the tire pressure sensors and

the receiver. Do NOT locate the repeater in an enclosed metal space that will block the RF signals.

19

th

wheel or gooseneck trailer)

The repeater is waterproof and can be exposed to the outside elements without being damaged. To review

the repeater specification, please refer to the Section 3.2.

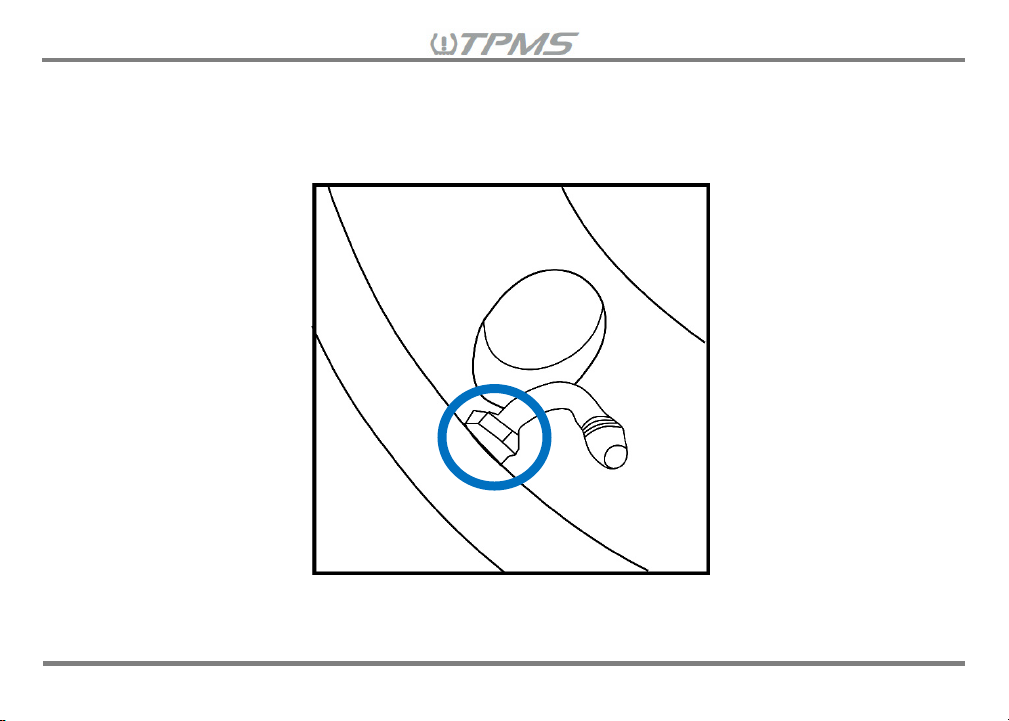

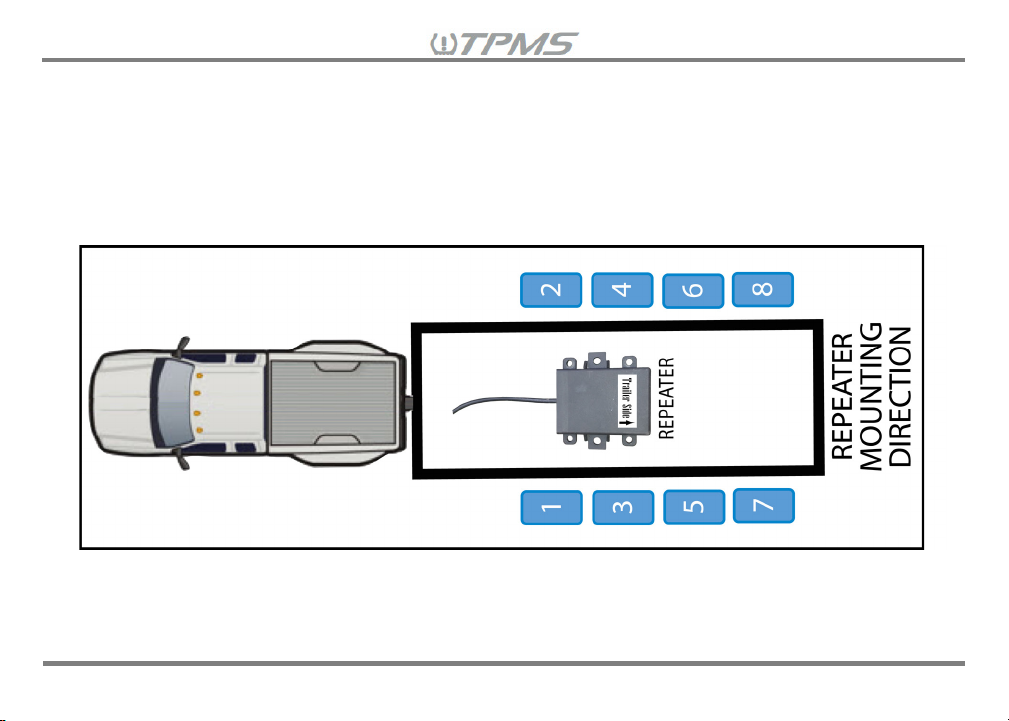

<IMPORTANT 5>

When mounting the repeater, the power cord side of the repeater must be facing the tow vehicle and the

arrow on the “Trailer Side↑” sticker must be pointing toward the trailer wheels in order to work properly as

shown in FIGURE 5.2

Figure 5.2 Repeater Mounting Direction

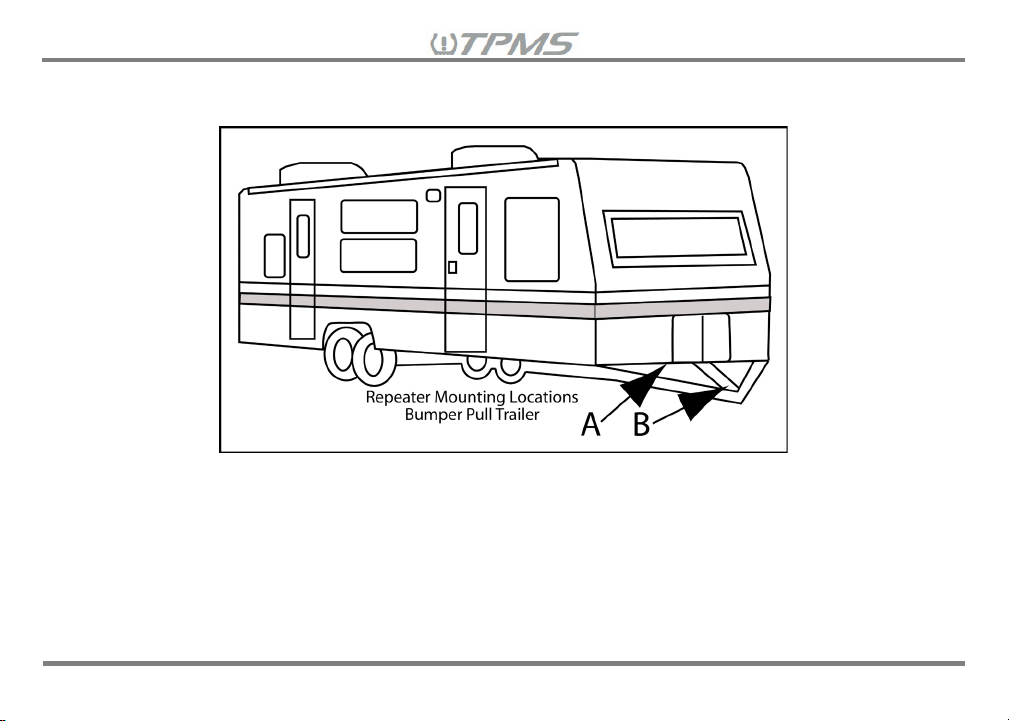

5.2.1 For travel, cargo or equipment trailers with a bumper pull A-frame hitch, see Figure 5.2.1

locations “A” and “B” for recommend repeater mounting locations. Location “A” is on an exposed

20

frame member on the underside of the trailer and location “B” is on the A-frame of the bumper pull

trailer.

Figure 5.2.1 Repeater Mounting Locations Bumper Pull Trailer

For 5th Wheels and gooseneck trailers select a location for the repeater near the house battery

5.2.2

but NOT inside a metal enclosure. See Figure 5.2.2 locations “A” and “B” for recommend repeater

mounting locations. Location “A” is on an exposed frame member on the underside of the trailer

and location “B” is inside the storage compartment of your fifth wheel or gooseneck trailer.

21

Loading...

Loading...