Turbosound flexarray, flexarray TFA-600H/DP mid/high, flexarray TFA-600HW/DP wide dispersion mid/high, flexarray TFA-600L/DP low frequency Quick Start Manual

Page 1

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 1

TFA-600H/DP mid/high

TFA-600HW/DP wide dispersion mid/high

TFA-600L/DP low frequency

Rigging User Guide

(Please refer to www.turbosound.com for the latest updates)

Version 1.2 December 2010

Page 2

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 2

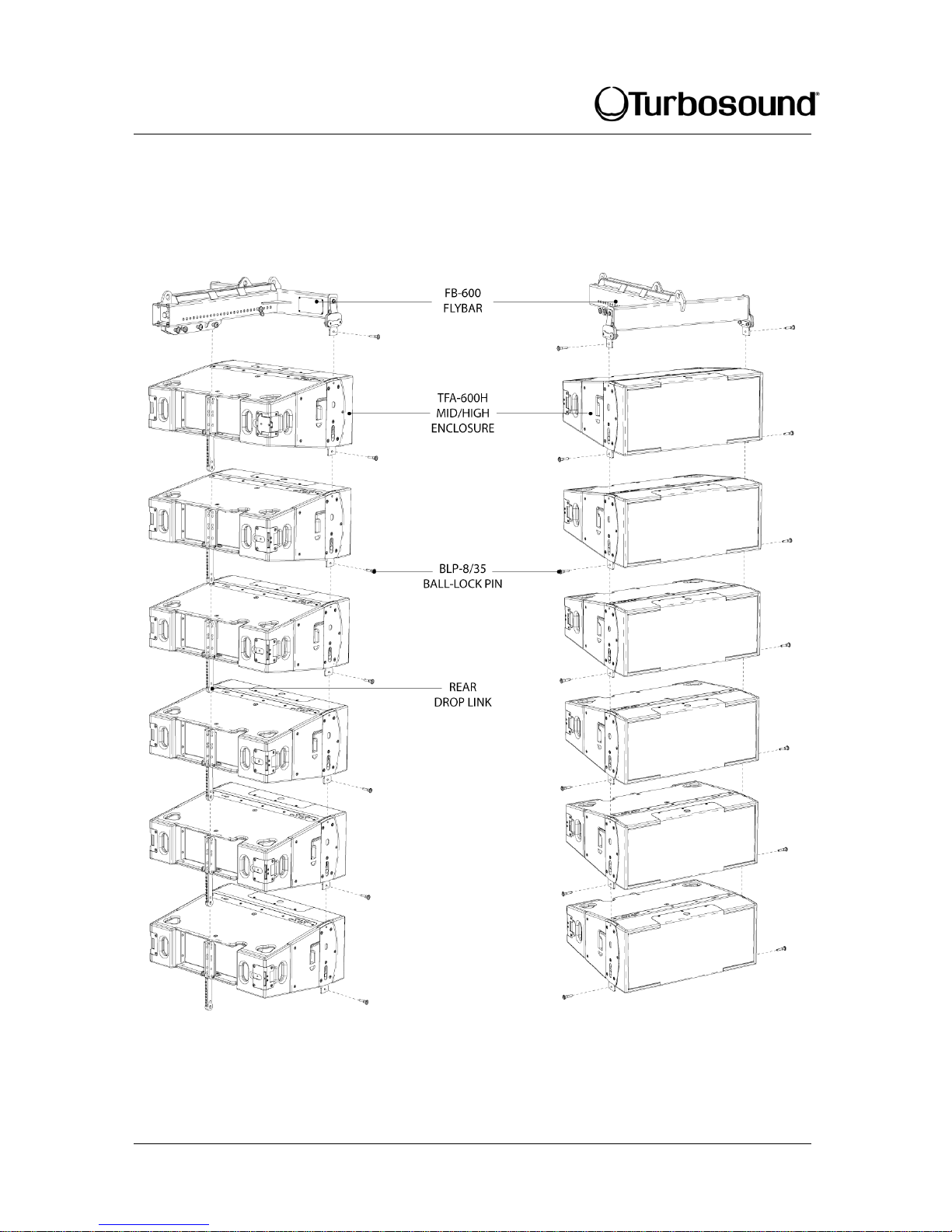

The Flex Array Flying System

Page 3

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 3

SAFETY INFORMATION

Safety Notes on Rigging

The Turbosound rigging system has been designed and constructed to a high standard of safety,

and tested to the most demanding of specifications. In order to ensure the highest safety standards,

the information following on the assembly and safe use of rigging accessories must be carefully

understood and followed.

Only use Turbosound recommended rigging accessories, which are specifically designed for their intended

purpose. Do not use Turbosound rigging with other types or brands of loudspeakers. This practice may

compromise safety standards and Turbosound will not be responsible for damage or injury so caused. Do not

modify the rigging accessories, or use them in a way other than that described in this user manual. Rigging

components supplied as part of a complete assembly are non-interchangeable and must not be exchanged with

the component parts of any other assembly. The component parts of a Turbosound rigging accessory must only

be assembled using the fasteners and methods of assembly recommended in this guide. The use of fasteners and

methods of assembly not specified or approved by Turbosound may result in an unsafe rigging assembly.

Welding, or any other means of permanently fixing rigging components to each other or to cabinet fixing points is

not allowed. Rigging assemblies must only be assembled using the appropriate parts and fixings as specified in

this manual using the specific mounting instructions. Rigging components or assemblies must only be fixed to

Turbosound loudspeaker cabinets using the cabinet fixing points, assembly methods and fasteners specified in

this guide and the specific mounting instructions.

Secondary Safeties

All loudspeakers flown in theatres, studios or other places of work and entertainment must, in addition to the

principle load bearing means of suspension, be provided with an independent, properly rated and securely

attached secondary safety. Only steel wire ropes or steel chains of an approved construction and load rating may

be used as secondary safeties. Plastic covered steel wire ropes are not permitted for use as secondary safeties.

Safety Inspections

Carefully inspect rigging systems components and cabinets for defects or signs of damage before

proceeding to assemble a flown array. If any parts are damaged or suspect, DO NOT USE THEM.

Regular, more rigorous test and inspection of rigging components must also be carried out. Safety

legislation and test and inspection requirements will vary from country to country. In most cases, annual

independent test and inspection by a suitably approved and qualified inspector will be required. Users must

ensure compliance with all applicable safety requirements. Turbosound recommends regular safety inspections

and further recommends that a logbook be kept detailing the test and inspection history of each Turbosound

rigging accessory. Always wear protective headwear, footwear and eye protection in accordance with local

regulations. Anyone involved in flying ANY sound system should take note of the following advice:

The rigging of a flown sound system may be dangerous unless undertaken by qualified personnel with the

required experience and certification to perform the necessary tasks. Fixing of hanging points in a roof should

always be carried out by a professional rigger and in accordance with the local rules of the venue. The house

rigger and/or building manager must always be consulted.

Flying System components have been individually tested in accordance with the following regulations:

Page 4

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 4

The Health and Safety at Work Act 1974

The Supply of Machinery (Safety) Regulations 1992

The Lifting Operations and Lifting Equipment Regulations 1998

GENERAL DESCRIPTION

To take full advantage of the extremely flexible properties of the Flex Array system, the rigging is fully integrated

into the enclosure. The flying systems are inherently safe, flexible, self-contained and simple to use. The load is

taken entirely through the flygear and not through the cabinet’s woodwork.

The rigging design allows the creation of clusters and arrays that can be assembled quickly and with a minimum

number of crew, and with full control of the vertical angles between enclosures and their vertical inclination.

RIGGING PARTS

The rigging system consists of steel flygear rebated into the short sides of the loudspeaker enclosure, working

together with integrated drop links which locate into the flygear of the cabinet directly underneath, and form the

pivot point about which cabinets can be angled. The drop links are secured in position with captive ball-lock pins

and retract into the flygear for transportation.

The Flex Array rigging system includes all the necessary hardware to enable vertical suspension of TFA-600 series

cabinets from a single rigging point and using a single motor rated at up to and including 1 tonne.

The rigging system permits a range of inter-cabinet angle adjustment in 2° increments from 0° to 16°. A rear link

locates into a clevis connection plate with multiple holes at the rear of the cabinet.

FB-600 Flybar

A rigid ‘T’ shaped flybar with screw thread front-to-rear adjustment of the pickup point that enables the

suspension of loads up to the SWL of 700kg. The frame is constructed from a rectangular box section with a

unique formed rear spine that forms a channel in which the movable lift point is located.

A single hang of up to 12 mid/high cabinets, or a combination of mid/high and low frequency cabinets of equal

weight, can be flown using this bar and a single one-tonne motor. The drop links at the front of the bar locate into

the Flex Array cabinet’s integrated flygear and are secured with ball-lock pins.

Page 5

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 5

The movable lift point can be traversed along the spine by means of a screw which is turned by a 22mm (7/8”)

socket (available from Turbosound) fitted to a speed brace or electric drill.

Turning the drive nut on the end of the shaft the lift point moves along the rear spine, tilting the load by varying

the motor connection point relative to the centre of mass of the cluster. The screw is located in polymer sealed

bearings requiring no maintenance under normal operating conditions, and is designed to last the lifetime of the

product.

A 100mm / 4” ball locking pin is supplied attached to the flybar and must be fitted through the appropriate holes

in both the moving lift point and the rear spine to ensure that when the TFA-600 cabinets are in use the vibration

cannot cause unwanted tilt adjustment. The holes are based on a vernier scale adjustment ensuring precise

alignment for tilt angles as specified in the Array Calculator. The adjustment holes do not represent the angle of

the flybar to the horizontal and are used to lock the flybar where required.

Connection to TFA-600 cabinets

Floating drop links are located at the ends of the box section enabling the easy connection of the FB-600 to the

mid/high or low frequency cabinets, ensuring that the link will easily slide into any cabinet assembly. To link the

rear of the FB-600 to the appropriate loudspeaker a pair of cabinet connection drop links is provided, each at the

correct spacing to ensure easy assembly.

Page 6

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 6

Important Safety Notes

To ensure the continued safe operation of the FB-600 flybar the following points should be noted:

A. The 100mm / 4” locking pin should always be fitted to lock the moving tilt point

B. Four ball lock pins must be fitted to ensure the safe lifting of the cluster

Page 7

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 7

C. Under no circumstances should hands be placed in the open top of the spine when the flybar is in use.

D. Two safety lifting lugs are provided for attaching wire safety rope. No other part of the flybar can be used for

this purpose.

Page 8

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 8

E. Any components that are damaged should be repaired / replaced by an approved service centre.

F. In the extremely unlikely event if the failure of the screw, the safety of the bar is not compromised.

Page 9

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 9

CF-600 Conversion Frame

The conversion frame is used to interface between bass cabinets and mid/high cabinets in a flown column of Flex

Array loudspeakers. The conversion frame has a SWL of 520kg which enables a column of up to a maximum of 12

TFA-600H cabinets to be suspended below it.

The CF-600 conversion frame also functions as a ground stacking frame, interfacing between ground stacked TFA600L bass cabinets and the mid-high cabinets positioned on top.

The net weight of the conversion frame is 11kg (24.2lbs)

Page 10

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 10

CF-600 Conversion Frame in a Flown Column

The conversion frame is fitted underneath the lowest TFA-600L low frequency cabinet in a flown column as shown

in the diagram below. TFA-600H cabinets are suspended from the conversion frame using the captive ball-lock

pins

Connection to the first TFA-600H cabinet is made via two 10mm ball-lock pins which are engaged into the rear

spine of the mid/high cabinet (one pin is located on the loudspeaker and one pin is located on the conversion

frame).

The drop link from the TFA-600L low frequency cabinet is released by removing one of the pins and pivoting the

link into the conversion frame.

The drop link from the conversion frame locates into the clevis connection plate of the top mid/high cabinet in one

of several predetermined locations, which allows for a range of inter-cabinet angles.

Page 11

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 11

Ground Stacking with the CF-600 Conversion Frame

In this application the conversion frame locates on the top of a ground stacked bass cabinet(s) and engages into

the flygear of the first mid/high cabinet. The system allows for the lowest mid/high cabinet to be tilted down by

approximately 8°.

Page 12

Quick Start Guide

FLEX ARRAY

FLEX ARRAY Quick Start Guide - Page - 12

Rigging a Single Column of Flex Array TFA-600 Cabinets

1. Choose flying points as necessary and attach a chain motor to the flybar’s pickup point. Note that the

pickup point is adjustable from front to rear and can be moved even when under load.

2. Wheel in a block of three pre-rigged cabinets in their transport case, position them under the flybar and

secure the enclosure tabs into the top cabinet with ball-lock pins.

3. Raise the array to allow a further block of three cabinets to be positioned underneath, extend the drop

links on the third cabinet and secure them to the fourth cabinet‘s flygear with ball-lock pins.

4. Repeat with additional cabinets as necessary.

Setting The Angle Between Cabinets

Precise adjustment of inter-cabinet angle is achieved by selecting one of nine possible engagement positions of

the rear link and the clevis, giving a maximum angle of 16° in 2° increments.

The following table shows the position of the rear link relative to the cabinet clevis to achieve the required intercabinet angle.

Hole No. on Link Hole Letter on Clevis Angle Setting

1 A 0°

1 B 2°

2 A 4°

2 B 6°

1 C 8°

1 D 10°

2 C 12°

2 D 14°

1 E 16°

Turbosound Ltd, Star Road, Partridge Green, West Sussex RH13 8RY

t: +44 (0)1403 711447 f: +44 (0)1403 710155 w: www.turbosound.com

Loading...

Loading...