Page 1

SERVICE MANUAL

DC Inverter Multi-Split Air-Condition Unit

TAS-09EH/O TAS-12EH/O TAS-18EH/O TAS-24EH/O TAS-24MVH/O

TAS-18MVH/O

Indoor Unit Outdoor Unit

TAS-09MVH

TAS-12MVH

TAS-09EH TAS-09EH/O

TAS-12EH TAS-12EH/O

TAS-18EH TAS-18EH/O

TAS-24EH TAS-24EH/O

TAS-18MVH/O

TAS-24MVH/O

REFRIGERENT

R410A

HEAT PUMP

1 SERVICE MANUAL FOR AMERICA

Page 2

Table of Contents

1. INTRODUCTION .................................................................................................. 1-1

2. PRODUCT DATA SHEET ................................................... ................................. 2-1

3. RATING CONDITIONS ........................................................................................ 3-1

4. OUTLINE DIMENSIONS ...................................................................................... 4-1

5. PERFORMANCE DATA ...................................................................................... 5-1

6. PRESSURE CURVES .......................................................................................... 6-1

7. ELECTRICAL DATA .............................................................................................. 7-1

8. WIRING DIAGRAMS ............................................................................................ 8-1

9. REFRIGERATION DIAGRAMS ........................................................................... 9-1

10. TUBING CONNECTIONS ...................................................................................... 10-1

11. CONTROL SYSTEM ............................................................................................ 11-1

12. TROUBLESHOOTING ......................................................................................... 12-1

13. EXPLODED VIEWS AND SPARE PARTS LISTS ................................................ 13-1

14. APPENDIX A

2 SERVICE MANUAL FOR AMERICA

Page 3

1. INTRODUCTION

1.1 General

The new CMV and CS is a high efficiency DC inverter technology outdoor unit,

since it’s a lego concept unit, it can be matched to several inverter indoor units such as wall

mounted type with a capacity range of 9000 – 12000 BTU for each single indoor unit.

1.2 Main Features

DC Inverter

R410a

sine wave form and 120 degree rectangular wave form in compressor driver

sensor less inverter compressor driver

high speed calculation for accurate sine wave form vector control

smart PFC control

fuzzy logic con

High SEER

Lego Concept

Pre-Charged.

Cooling operation at outdoor temperature down to 50

Heating operation at outdoor temperature down to 5

Variable Speed outdoor fan.

Low noise level

EEV for each indoor unit

trol

0

0

F.

F

1.3 Tubing Connections

Flare type interconnecting tubing to be produced on site.

For further details please refer to APPENDIX A on this manual, and to the relevant indoor service

Manual,

1.4 Inbox Documentation

Each indoor unit is supplied with its own installation and operation manuals.

3 SERVICE MANUAL FOR AMERICA

Page 4

2. PRODUCT DATA SHEET

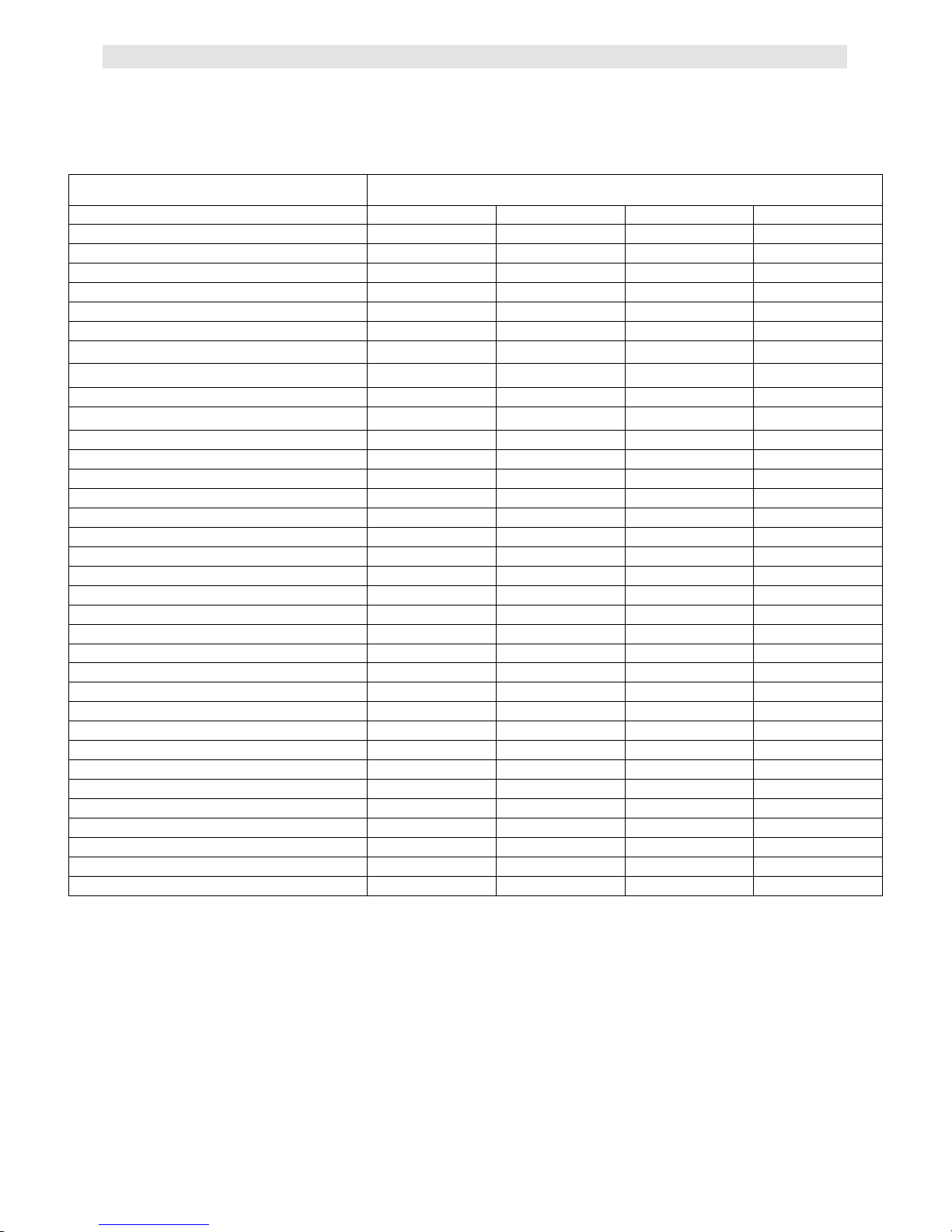

2.1 Outdoor unit data

2.1.1 DC Invertor 1:1.

Item

Capacity (BTU)

Cooling

Heating

SEER

HSPF

EER Cooling/COP Heating

Op Range Cool °F

Op Range Heat °F

Remote control setting temp.range °F

Dehumidification (Pts/hr)

Voltage

Current (A) Rated/Max Cooling

Heating

Power Consumption (KW)Rated/Max Cooling

Heating

Max Overload Protection

Indoor Air Circulation: L / M / H(CFM)

Indoor Noise level dB(A): L / M / H

Outdoor Fan Speed (RPM)

Outdoor Noise Level dB(A)

Indoor Fan Speeds

Connection Method

Max Pipe Length (Ft.)

Max Elevation (Ft.)

Pipe Size (In.)

Service Port Connection (In.)

Indoor Dimensions W x D x H(In.)

Indoor Package Dimensions W x D x H(In.)

Indoor Net Weight (lbs.)

Indoor Gross Weight(lbs. )

Outdoor Dimensions W x D x H(In.)

Outdoor Package Dimensions W x D x H(In.)

Outdoor Net Weight (lbs.)

Outdoor Gross Weight(lbs. )

Refrigerant

DC INVERTER 1:1

Inverter 9K Inverter 12K Inverter 18K Inverter 24K

9000

11000

18.00 18.00 17.17 15.69

8.6 8.7 8.7 8.5

4.0/3.7 4.0/3.6 3.60/3.60 2.87/3.18

5~131 5~131 5~131 5~131

minus 4 ~ 109 minus 4 ~ 109 minus 4 ~ 109 minus 4 ~ 109

61~90 61~90 61~90 61~90

1.58 2.11 2.989 4.4

115/60 115/60 230/60 230/60

5.5/9.32 7.53/10.8 5.929/10.1 11.09/12.22

7.1/9.8 10.4/13.0 6.732/9.31 10.24/12.23

0.61/1.06 0.862/1.236 1.345/2.3 2.504/2.765

0.8/1.11 1.19/1.496 1.532/2.124 2.314/2.768

20 20 20 25

212/270/315 341/382/430 441/530/618 518/588/677

42/38/35 42/38/35

100~900 100~900 100~900 100~900

~ 57 ~ 57 ~ 57 ~ 57

950/1150/1300 750/900/1000 950/1100/1230 1080/1180/1280

Flare Flare Flare Flare

82ft/25m 82ft/25m 82ft/25m 82ft/25m

32.8 Ft/10m 32.8 Ft/10m 32.8 Ft/10m 32.8 Ft/10m

1/4" / 3/8" 1/4" / 1/2" 3/8" / 5/8" 3/8" / 5/8"

1/2" 1/2" 1/2" 1/2"

33.4×13.4×9.8 38.4×14.3×11.0 45.8×15.2×12.0 52.0×15.6×12.0

33.9×13.8×10.4 39.0×14.8×11.8 46.3×15.6×12.6 52.6×16.1×12.6

22

26 37 51 55

35.6×12.7×22.6 38.6×15.7×26.0 38.2×15.6×29.9 40.2×17.1×34.1

36.2×13.2×23.0 39.2×16.3×26.8 39.0×16.1×30.3 40.6×17.3×37.8

73 106 123 143

77 117 132 154

R410A R410A R410A R410A

12000 18000 24000

15000 19000 24500

50/47/44 50/47/44

31 40 44

4 SERVICE MANUAL FOR AMERICA

Page 5

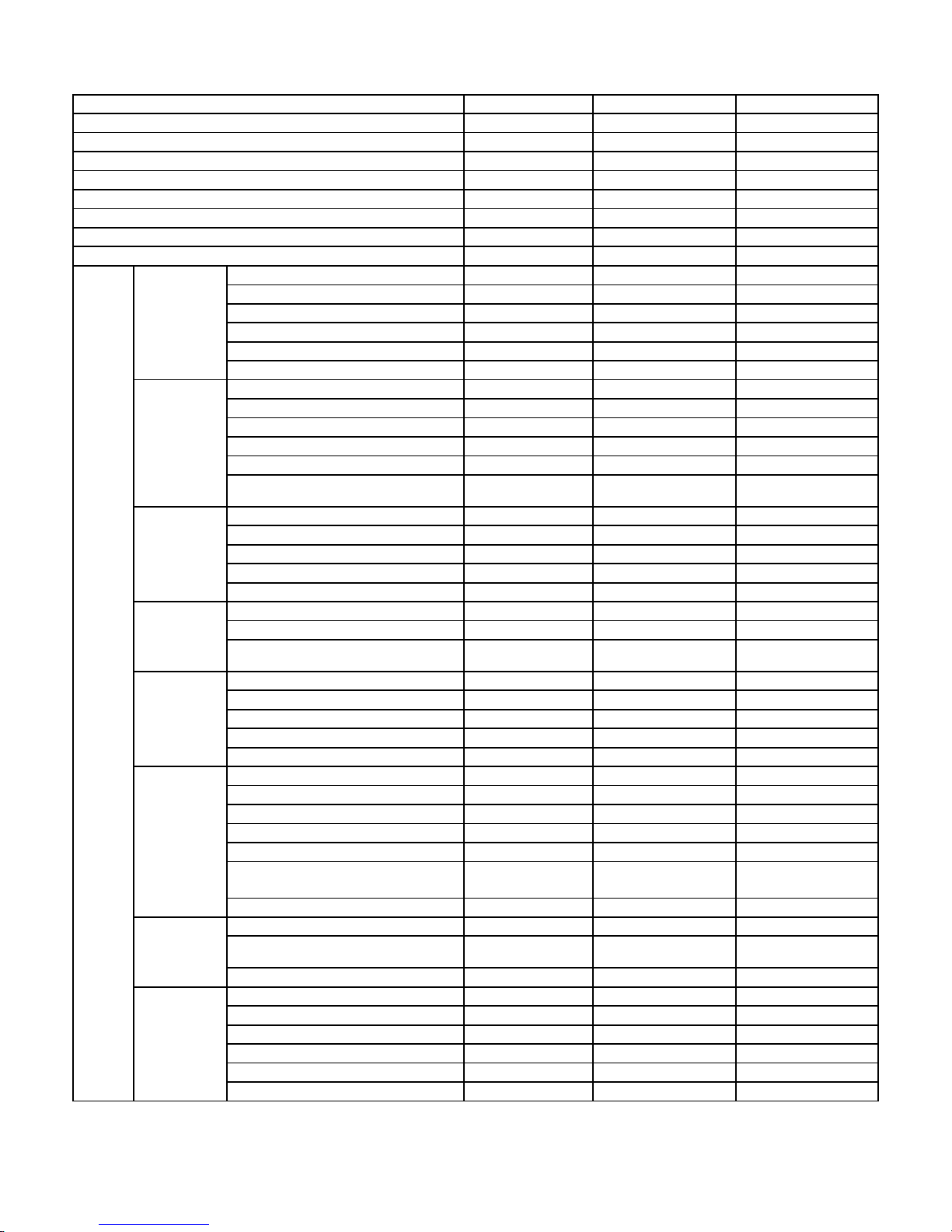

2.1.2 DC Inverter 1:2

TAS-18MVH/O TAS-24MVH/O

Function Heat Pump

Rated Voltage 208-230 VAC

Rated Frequency 60 Hz

Circuit Breaker Size 20A

Op Range Cool °F

Op Range Heat °F

Rated Current (RLA) (Heating/Cooling) 6 / 6.7 A

Refrigerant (lbs) R410A / 3.88

Rated Capacity (Btu) 18,000 24,000

Capacity Invert Range (W) 5000(1650-7100) 6400(1750-8300)

Cooling

Heating

Fan Motor

Outdoor

Fan

outdoor

Compressor

Condenser

Dimensions

Connection

Input / Actual Input (W) 1380/1450 1830/1882

Max. Power (W) 2420 2990

Max Current (A) 10.5 13

SEER 14.8 15.6*

Rated Capacity (Btu) 22,000

Capacity Invert Range (W) 5800(1790-7800) 7200(2000-8400)

Input / Actual Input (W) 1,550 / 1,580 2,000 / 2,060

Max. Power (W) 2579

Max Current (A) 11.3

Declared COP / Actual COP

(w/w.h.)

Model YDK-60A-6C

Input (W) 196

Capacitor (UFD) 4 / 450 VAC

Fan Motor FLA (A) 0.98 0.98

Fan Speed (RPM) 900/750/500

Fan Type Axial

Fan Blade Diameter (in) 18.1

Air Flow Volume of Outdoor Unit

(CFM)(M^3/h)

Model C-6RZ146H1A

TYPE DC

Brand Sanyo

Capacity (W) 6420

Input (W) 1635

Number of Row s 2-26 2-26

Tube Pitch x Row Pitch 1 x .866 in

Fin spacing 0.0708 in

Fin Type Louvered Fin

Tube Outside Dia. and Type 0.375" Rifled Tube 0.375" Rifled tube

Coil Length x Height x Width

Number of circuits

Unit Dimensions (W x H x D) (in) 36.5 x 14.25 x 27.6

Packing dimensions (W x H x D)

(in)

Net / Gross Weight (lb)

Design Length 16.4'

Max Line Set Height 16.4'

Max Line Set Length 49.21'

Charge over Design Length 0.20 oz / Ft. 0.20 oz / Ft.

Connection Pipes 1/4" / 3/8"

Design Pressure (PSI) 623.66

5~131 5~131

minus 4 ~ 109 minus 4 ~ 109

3.75 / 3.65 3.5 / 3.4

2800 3200

28.66 x 25.6 x .866

28.66 x 25.6 x .988

4 4

39 x 16.14 x 30.32 41.73 x 18.5 x 36.41

114.64 / 123.47 163.14 / 185.18

Heat Pump

208-230 VAC

60 Hz

30A

8 / 8.7 A

R410A / 6.61

25,000

3,200

13.9

YDK-60A-6C

196

4/ 450 VAC

900/750/500

Axial

18.5

C-7VRN153HOW

DC

Sanyo

7110

1770

1 x .866 in

0.0708 in

Louvered Fin

30.23 x 31.96 x .866

31.57 x 31.96 x .866

37.8x13.54x33.31

16.4'

16.4'

49.21'

1/4" x 1/2"

623.66

5 SERVICE MANUAL FOR AMERICA

Page 6

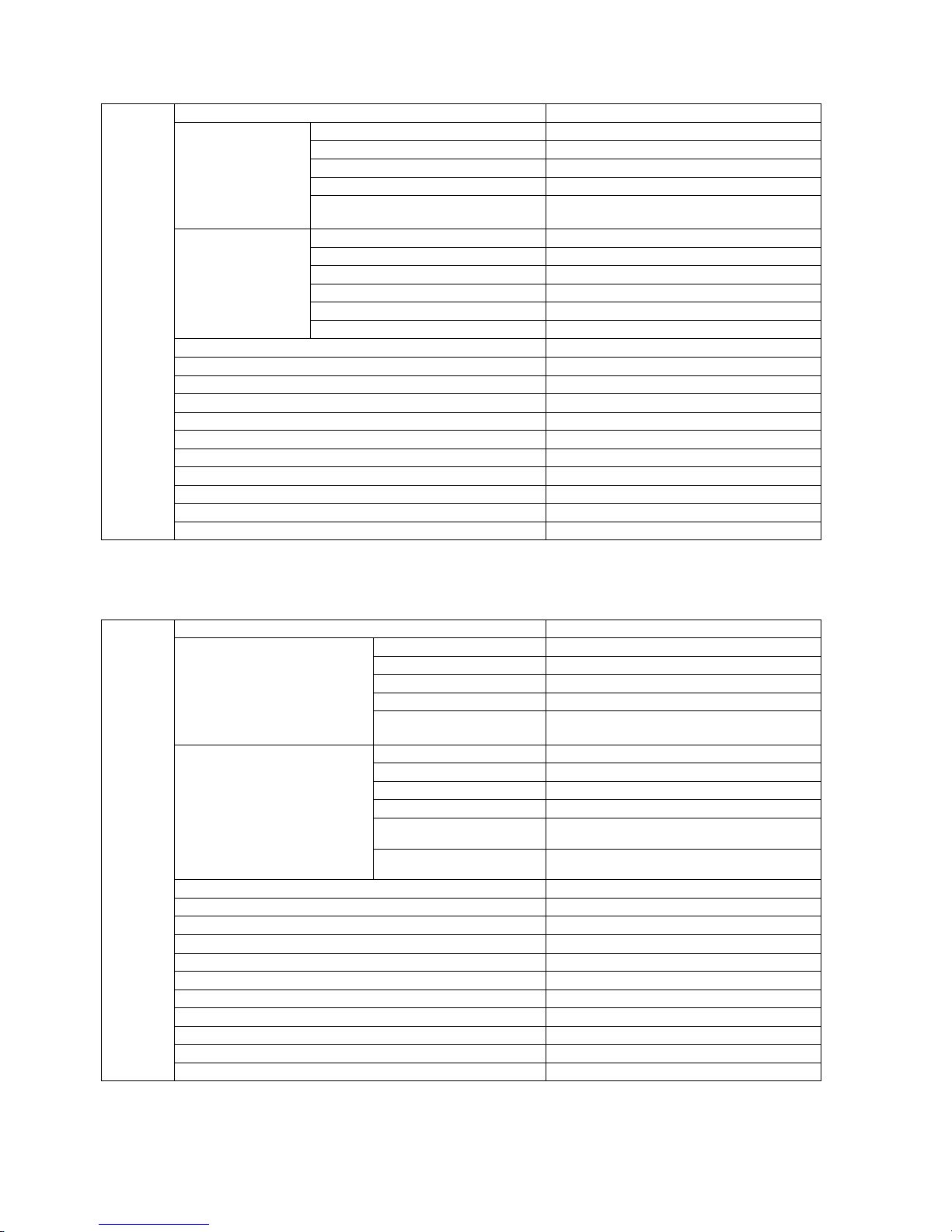

2.2 Indoor Units Data

2.2.1 TAS-09MVH Specifica tions

Indoor

Model

Input (W)

FAN MOTOR

Evaporator

Air Flow (Hi/Med/Low) (CFM) 353 / 306 / 194

Noise Level (dB(A) ≤42

Fan Type Cross Flow

Fan Diameter (in) 3.661

Fan Length (in) 24.921

Design Pressure (PSI) 551.14

Unit Dimensions (W x H x D) (in) 31.1 x 10.63 x 8.27

Packing Dimensions W x H x D) (in) 33.86 x 13.78 x 10.43

Net / Gross Wt (lbs) 26.45 / 30.86

Dehumidifying Volume (pt/hr) 1.8

Auto-restart YES

Capacitor (UFD)

Fan Motor FLA (A)

Speed (Hi/Med/Low) (RPM) 1150 / 950 / 750

Number of rows

Tube pitch row / pitch (in) .69 / .50

Fin spacing (in)

Fin Type

Tube outside dia.(in) / Type 0.2756 Rifled Tube

Coil Length x height x width (in) 25.39 x 11.06 x 1

TAS-09MVH

YDK-16-4C

54

1.2/450VAC

0.25

22

0.0614

Louvered Fin

2.2.2

Indoor

TAS-12MVH Specifica tions

TAS-12MVH

Model

Input (W) 54

FAN MOTOR

Evaporator

Air Flow (Hi/Med/Low) (CFM) 459 / 406 / 218

Noise Level (dB(A) ≤45

Fan Type Cross Flow

Fan Diameter (in) 3.818

Fan Length (in) 30.393

Design Pressure (PSI) 551.14

Unit Dimensions (W x H x D) (in) 36.61 x 10.83 x 8.27

Packing Dimensions W x H x D) (in)

Net / Gross Wt (lbs) 30.86 / 37.48

Dehumidifying Volume (pt/hr)

Auto-restart YES

Capacitor (UFD) 1.2/450VAC

Fan Motor FLA (A) 0.25

Speed (Hi/Med/Low)

(RPM)

Number of rows

Tube pitch row / pitch (in) .69 / .50

Fin spacing (in)

Fin Type

Tube outside dia.(in) /

Type

Coil Length x height x

width (in)

1200 / 950 / 850 (Cooling) 1200 / 950 / 750

YDK-16-4C

(Heating)

22

0.059

Louvered Fin

0.2756 Rifled Tube

30.98 x 11.06 x 1

39.96 x 13.97 x 12.79

3.03

6 SERVICE MANUAL FOR AMERICA

Page 7

3. RATING CONDITIONS

Standard conditions in accordance with ANSI/AHAM RAC-1-2003, and UL 484.

Cooling:

Indoor: 80

Outdoor: 95

o

FDB 67oF WB

o

F DB 75oF WB

Heating:

Indoor: 70

Outdoor: 47

o

F DB 60 oF WB

o

F DB 43 oF WB

3.1 Operating Limits

Cooling

Upper limit (DB)

Lower limit (DB) 5oF

Heating

Upper limit (DB) 75

Lower limit (DB) 5oF

Voltage

2PH 198–264V/115V

3PH N/A

Outdoor

o

F

110

o

F

4. OUTLINE DIMENSIONS

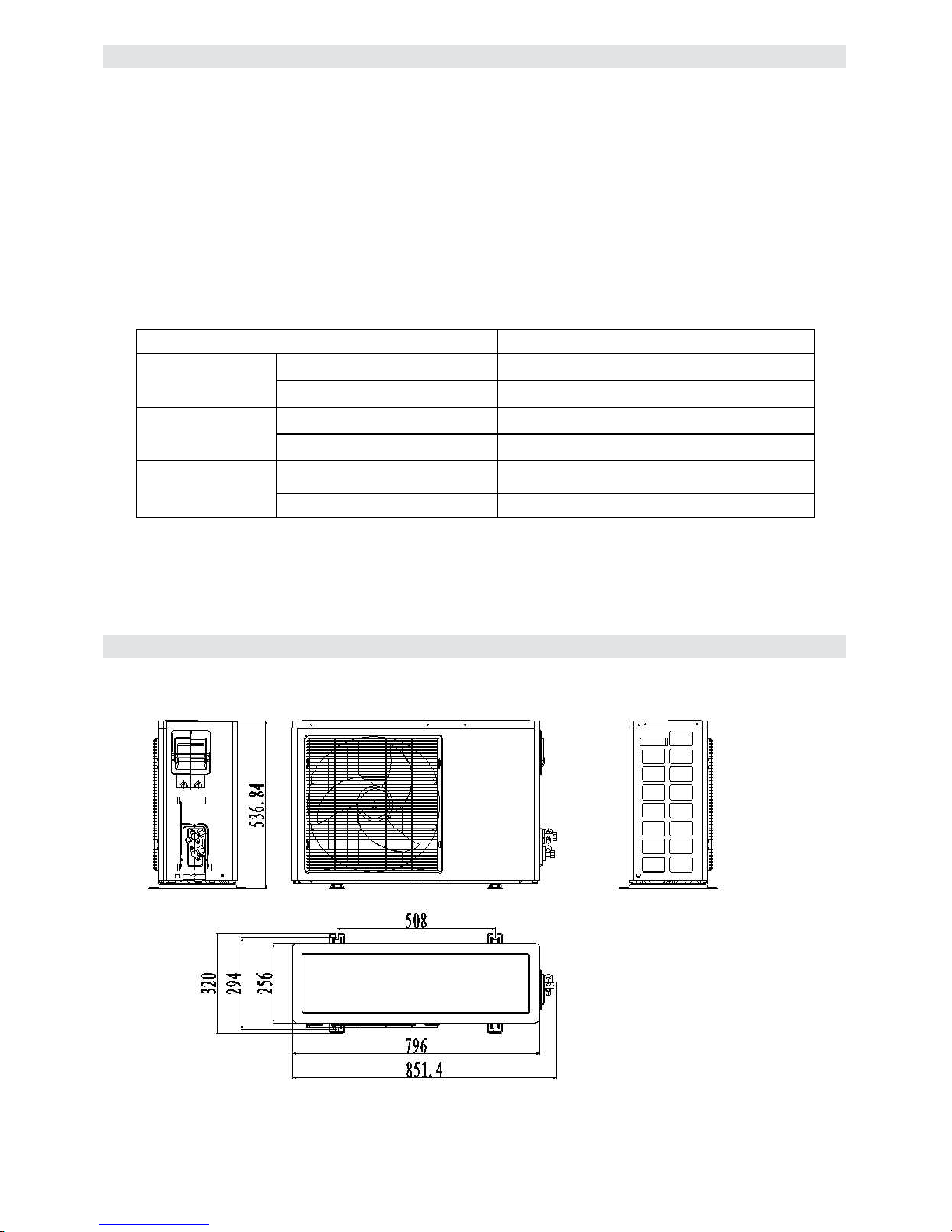

4.1 outdoor Unit: TAS-09EH/O

7 SERVICE MANUAL FOR AMERICA

Page 8

4.2 outdoor Unit: TAS-12EH/O

4.3 outdoor Unit: TAS-18EH/O

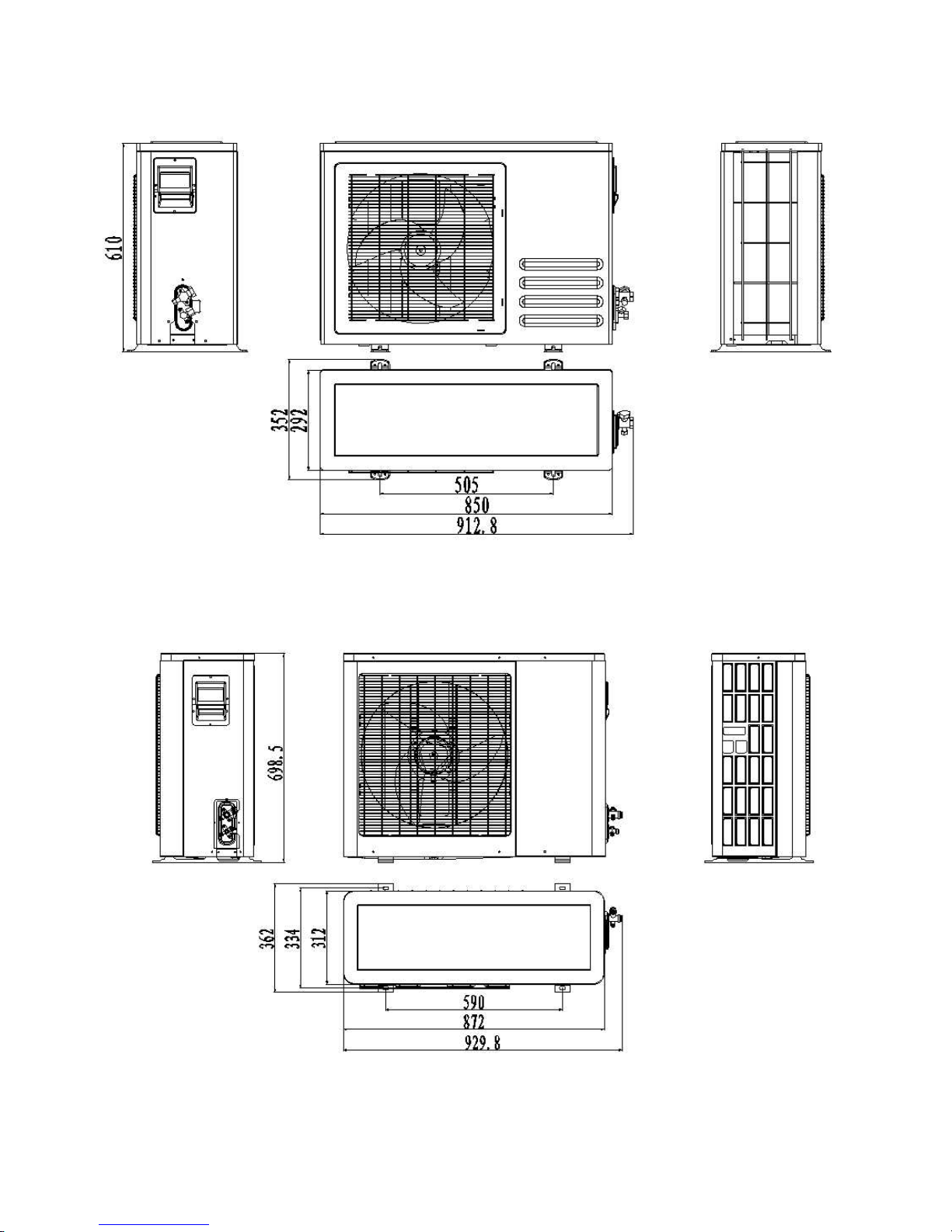

4.4 outdoor Unit: TAS-24EH/O

8 SERVICE MANUAL FOR AMERICA

Page 9

4.5 outdoor Unit: TAS-18MVH/O

9 SERVICE MANUAL FOR AMERICA

Page 10

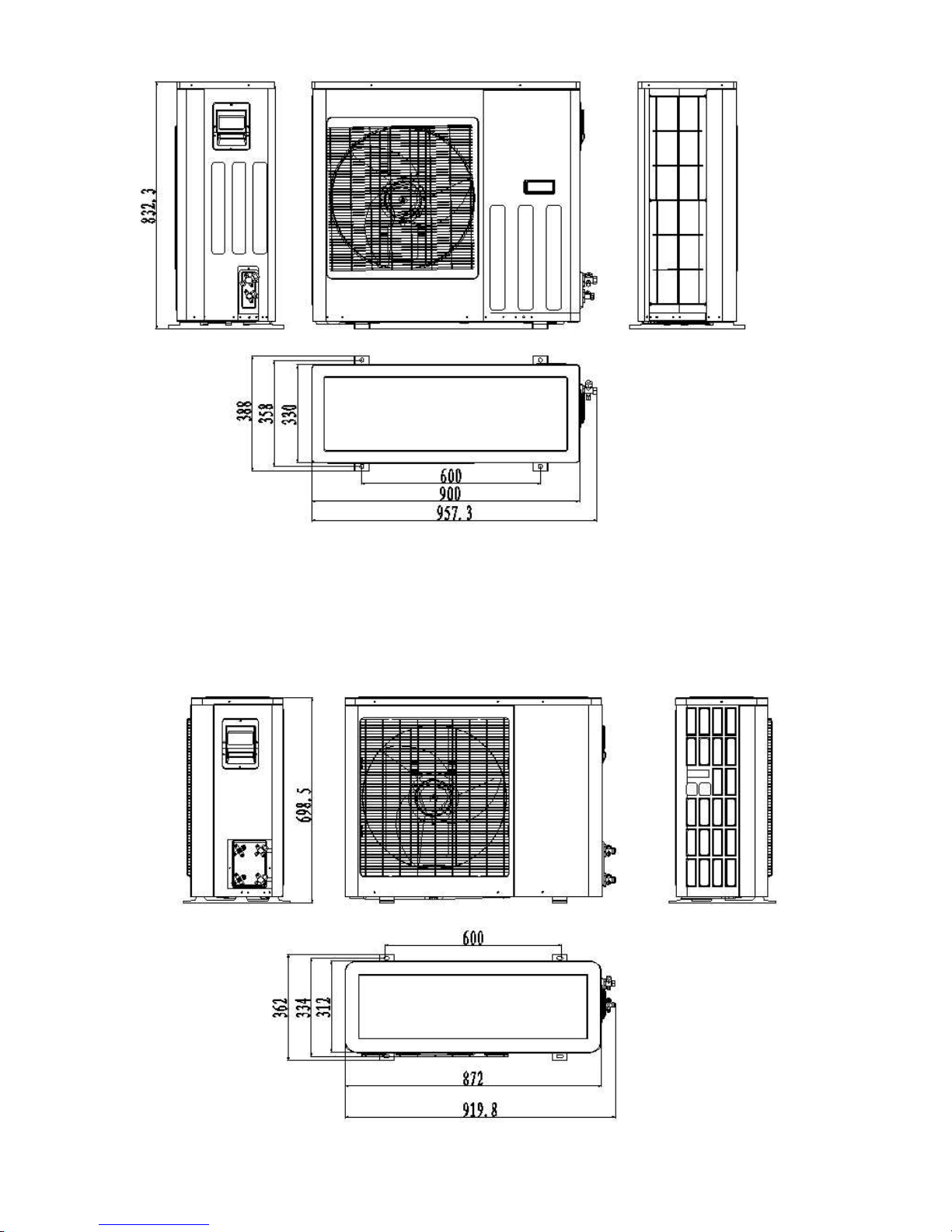

4.7 outdoor Unit:

50×3(=150)

50

72

TAS-24MVH/O

956

50

825

845

351

342

560

378

5. PERFORMANCE DATA

5.1 Indoor Units Data

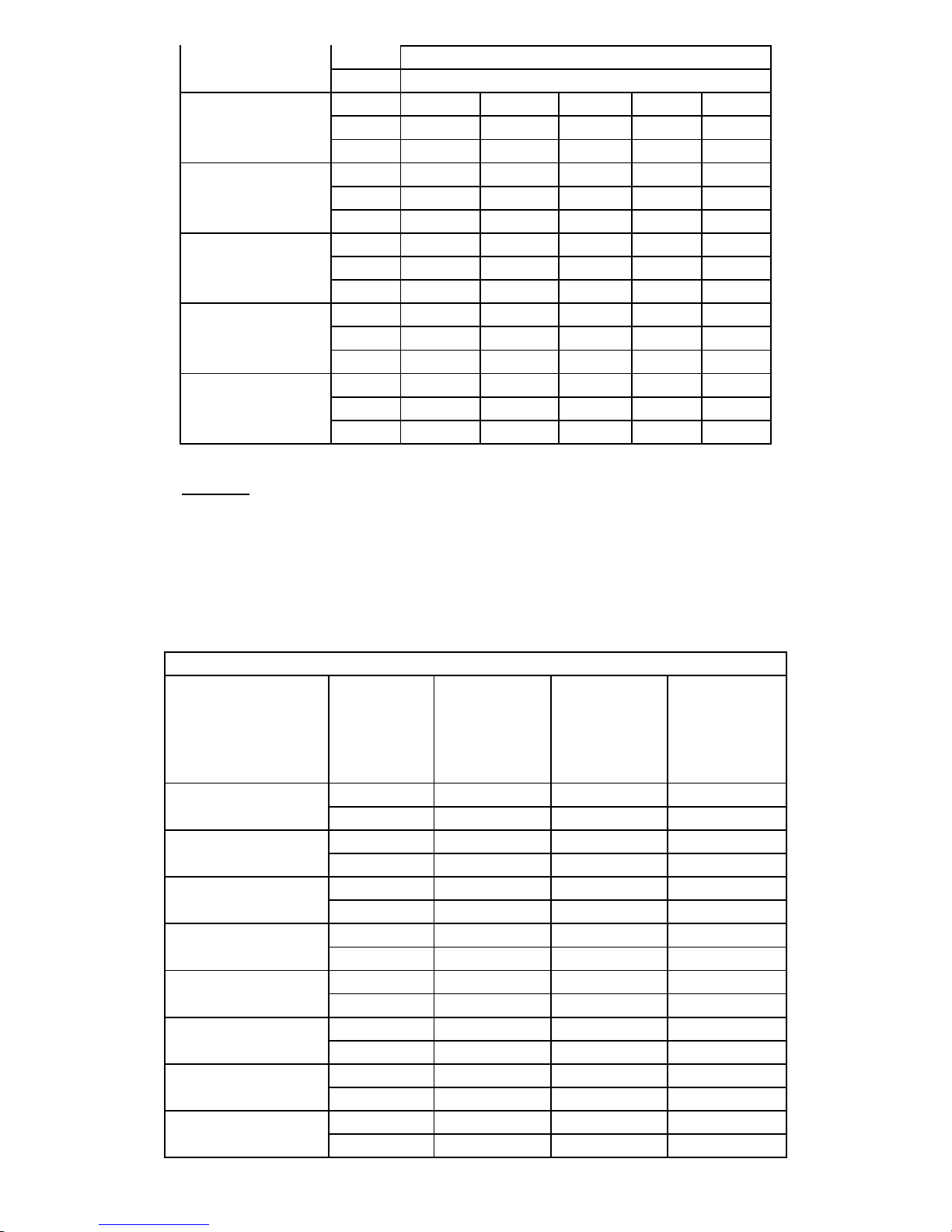

5.1.1 Indoor Units Capacity For 9000BTU

Capacity Model

9000BTU

5.1.1.1 Cooling Capacity (BTU)---Run Model (Unit A,B,C or D),230/115V,Indoor fan at

TAS-09MVH

TAS-09EH

high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [0F]

OUTDOOR

ENTERING AIR DB

TEMPERATURE[

14~68

0

F]

DATA 72/59 75/63 81/66 84/70 90/73

TC 80 - 110 % of nominal

10 SERVICE MANUAL FOR AMERICA

Page 11

(protection range)

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 8712 9252 9828 10404 10980

77

SC 6273 6382 6528 6638 6784

PI 0.58 0.59 0.6 0.61 0.62

TC 8280 8856 9432 9972 10548

86

SC 6091 6236 6346 6492 6601

PI 0.65 0.66 0.67 0.68 0.69

TC 7848 8424 9000 9576 10152

95

SC 5945 6054 6200 6346 6455

PI 0.71 0.72 0.74 0.75 0.76

TC 7452 8028 8568 9144 9720

104

SC 5799 5908 6054 6164 6309

PI 0.78 0.79 0.8 0.81 0.82

TC 6948 7524 8064 8640 9216

115

SC 5580 5726 5835 5981 6091

PI 0.86 0.87 0.88 0.89 0.91

LEGEND

TC – Total Cooling Capacity, BTU SC – Sensible Capacity, BTU PI – Power Input, kW

WB – Wet Bulb Temp., (

0

F

) DB – Dry Bulb Temp., (

0

F

) ID – Indoor OD – Outdoor

5.1.1.2 Heating Capacity (BTU)---Run Model (Unit A,B,C or D),230/115V,Indoor fan at

high speed

ID COIL ENTERING AIR DB TEMPERATURE [0F]

OD COILENTERING

AIR DB/WB TEM

PERATU RE[

0

F]

5/3

14/10

20/18

30/28

36/34

45/43

50/48

59/54

DATA 59 68 77

TC 6912 6372 5940

PI 0.49 0.54 0.59

TC 7668 7128 6696

PI 0.59 0.64 0.70

TC 8208 7776 7236

PI 0.67 0.72 0.77

TC 8532 8100 7560

PI 0.71 0.75 0.80

TC 8748 8208 7776

PI 0.89 0.95 1.01

TC 11232 10800 10368

PI 0.77 0.82 0.87

TC 11880 11448 10908

PI 0.82 0.87 0.92

TC 12528 12096 11556

PI 0.86 0.90 0.96

11 SERVICE MANUAL FOR AMERICA

Page 12

59~75

(Protection Range)

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

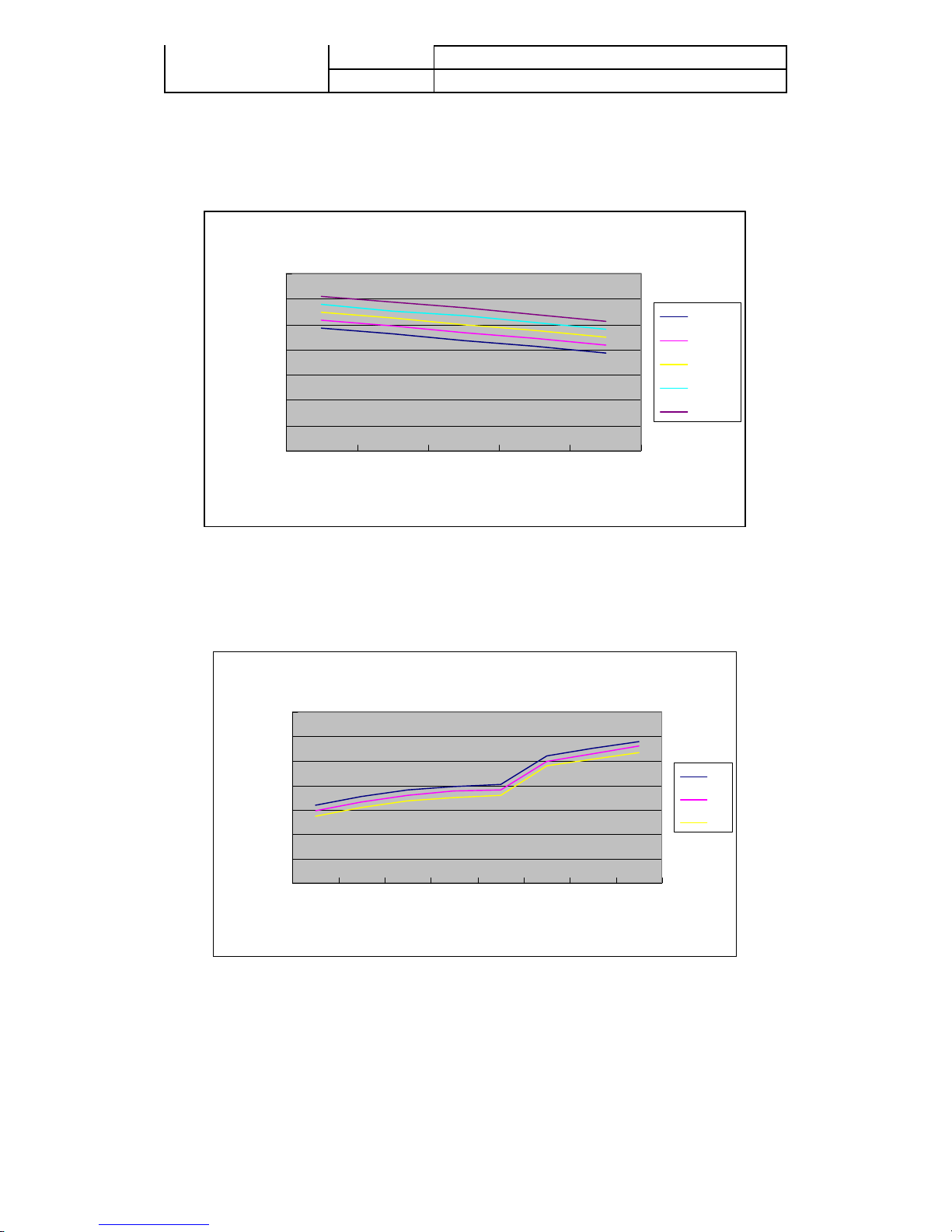

5.1.1.3 Capacity Correction Factors

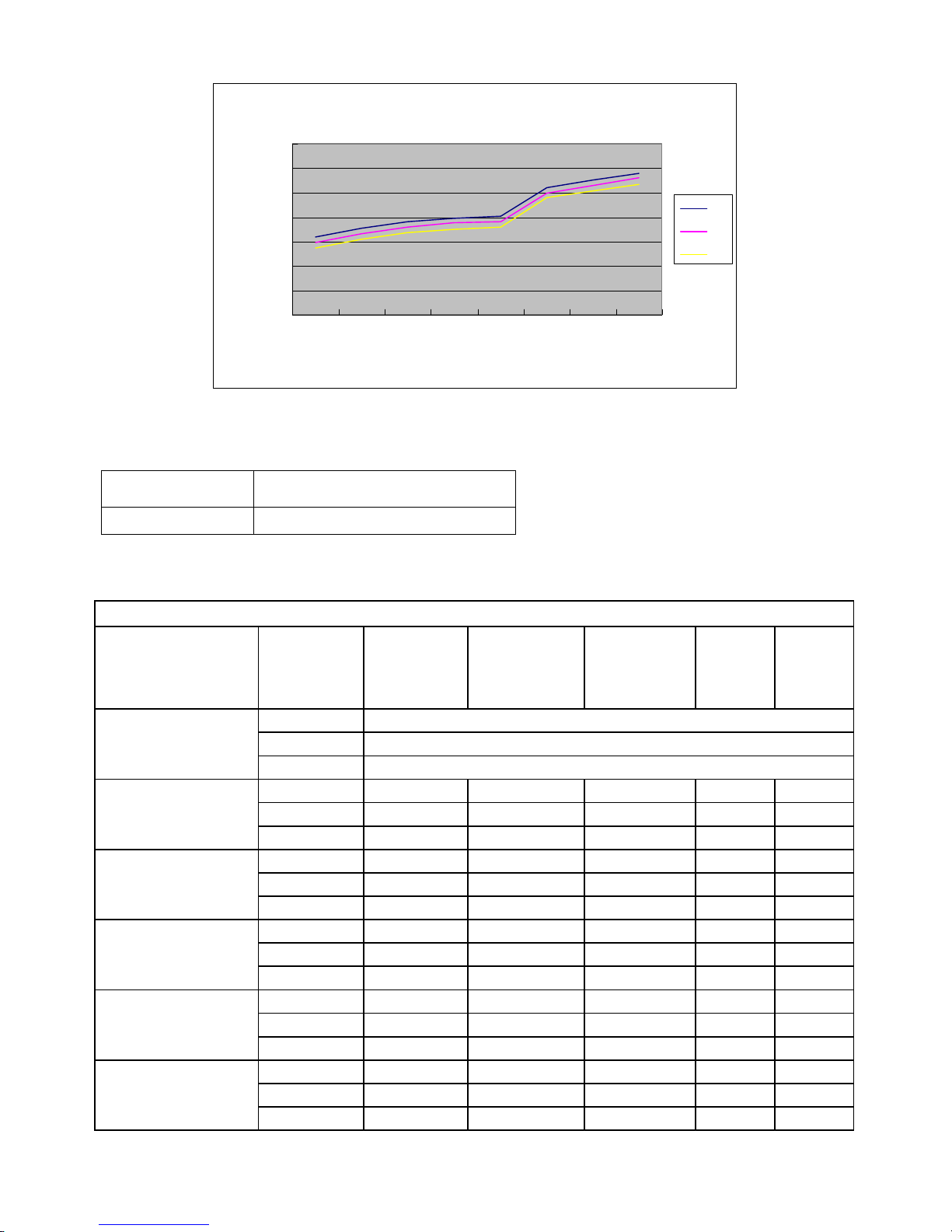

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

77 86 95 104 115

Outdoor Temp.(deg F)

90/73

84/70

81/66

75/63

72/59

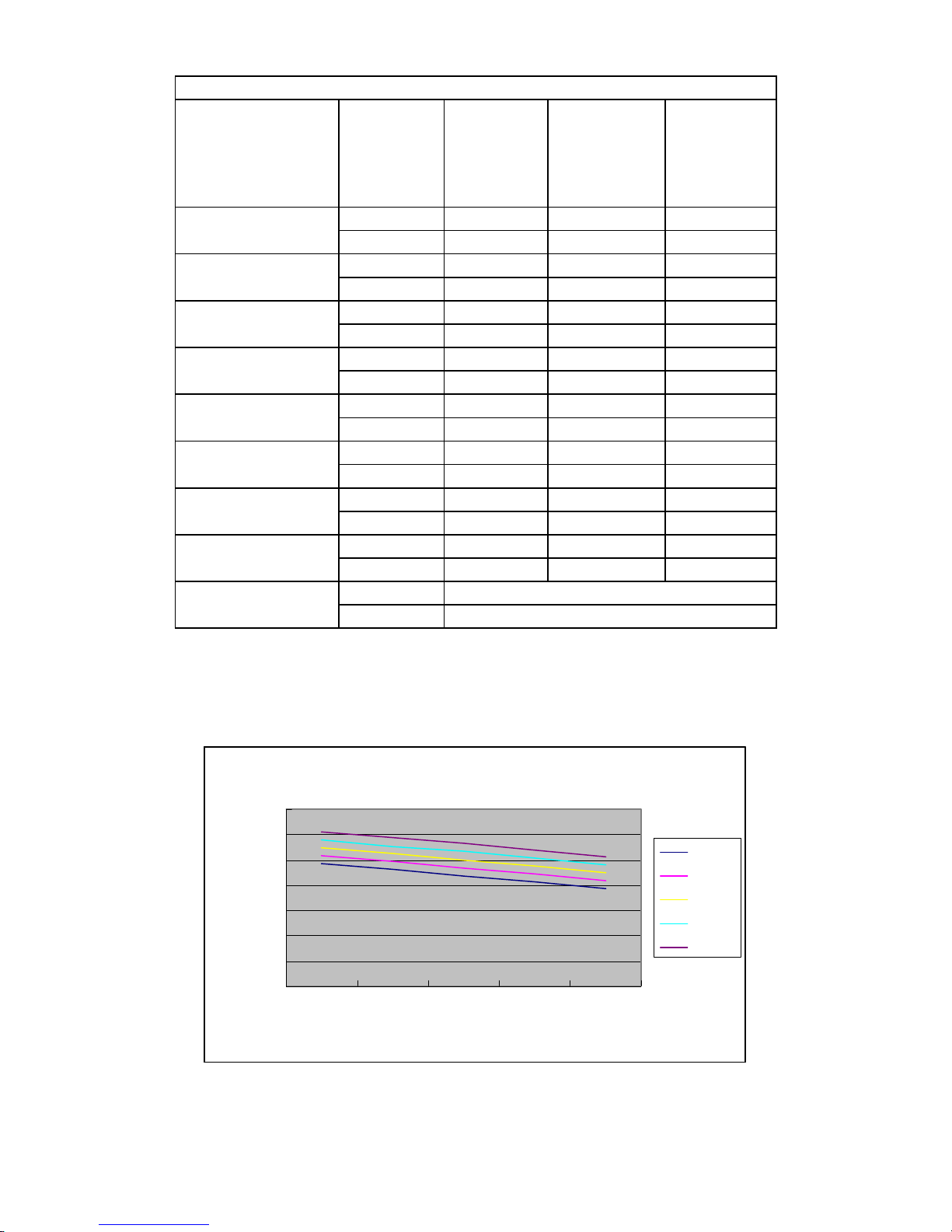

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

5 14203036455059

Outdoor Temp.(deg F)

59

68

77

12 SERVICE MANUAL FOR AMERICA

Page 13

5.2.1 Indoor Units Capacity For 12000BTU

Capacity Model

12000BTU

TAS-12MVH

TAS-12EH

5.2.1.1 Cooling Capacity (BTU)---Run Model (Unit A,B,C or D),230/115V,Indoor fan at

high speed

OUTDOOR

ENTERING AIR DB

TEMPERATURE[

14~68

(protection range)

77

86

95

104

115

INDOOR ENTERING AIR DB/WB TEMPERATURE [0F]

0

F]

DATA 72/59 75/63 81/66 84/70 90/73

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 11616 12336 13104 13872 14640

SC 10421 10603 10845 11027 11269

PI 0.72 0.73 0.75 0.76 0.77

TC 11040 11808 12576 13296 14064

SC 10118 10361 10542 10785 10966

PI 0.81 0.82 0.83 0.85 0.86

TC 10464 11232 12000 12768 13536

SC 9876 10058 10300 10542 10724

PI 0.88 0.90 0.92 0.93 0.94

TC 9936 10704 11424 12192 12960

SC 9634 9815 10058 10239 10482

PI 0.97 0.98 0.99 1.01 1.02

TC 9264 10032 10752 11520 12288

SC 9270 9512 9694 9936 10118

PI 1.07 1.08 1.09 1.11 1.13

13 SERVICE MANUAL FOR AMERICA

Page 14

5.2.1.2 Heating Capacity (KW)---Run Model (Unit A,B,C or D),230V,Indoor fan at high

speed

ID COIL ENTERING AIR DB TEMPERATURE [0F]

OD COILENTERING

AIR DB/WB TEM

PERATU RE[

0

F]

DATA 59 68 77

5/3

14/10

20/18

30/28

36/34

45/43

50/48

59/54

59~75

(Protection Range)

TC 8960 8260 7700

PI 0.66 0.73 0.80

TC 9940 9240 8680

PI 0.80 0.87 0.95

TC 10640 10080 9380

PI 0.91 0.97 1.04

TC 11060 10500 9800

PI 0.96 1.02 1.08

TC 11340 10640 10080

PI 0.99 1.06 1.12

TC 14560 14000 13440

PI 1.04 1.11 1.18

TC 15400 14840 14140

PI 1.11 1.18 1.25

TC 16240 15680 14980

PI 1.16 1.22 1.30

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

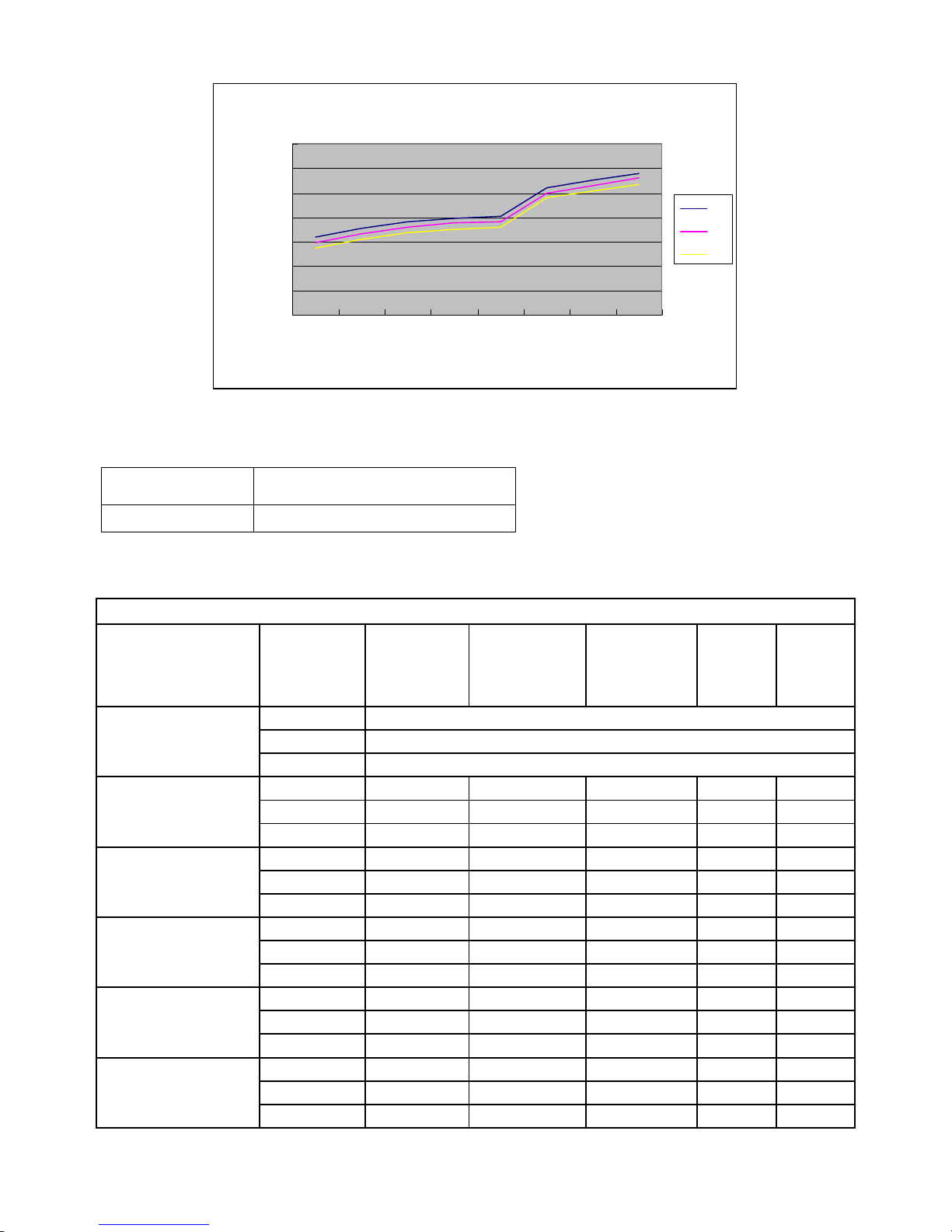

5.2.1.3 Capacity Co rrection Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

77 86 95 104 115

Outdoor Temp.(deg F)

14 SERVICE MANUAL FOR AMERICA

90/73

84/70

81/66

75/63

72/59

Page 15

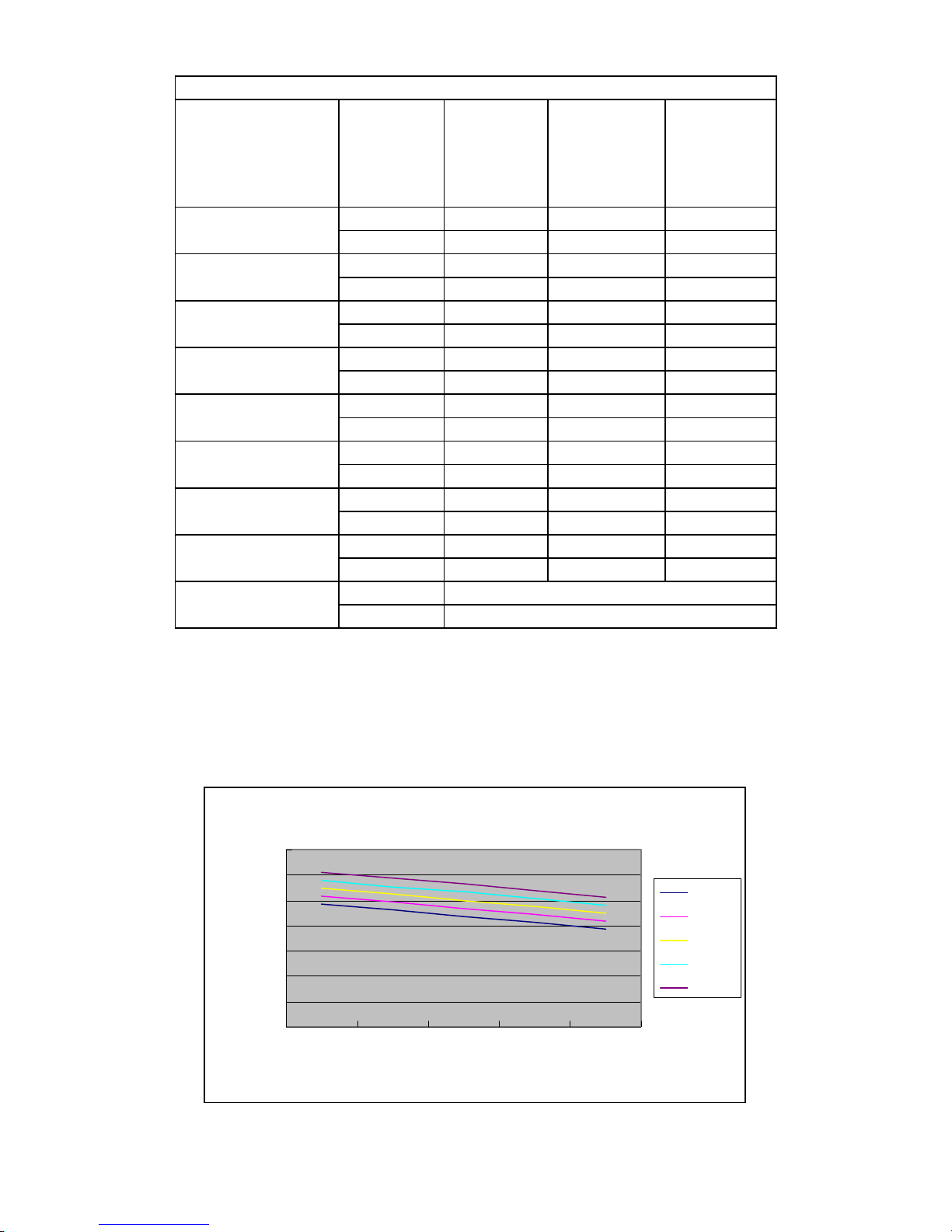

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

5 14203036455059

Outdoor Temp.(deg F)

5.2.3 Indoor Units Capacity For 18000BTU

59

68

77

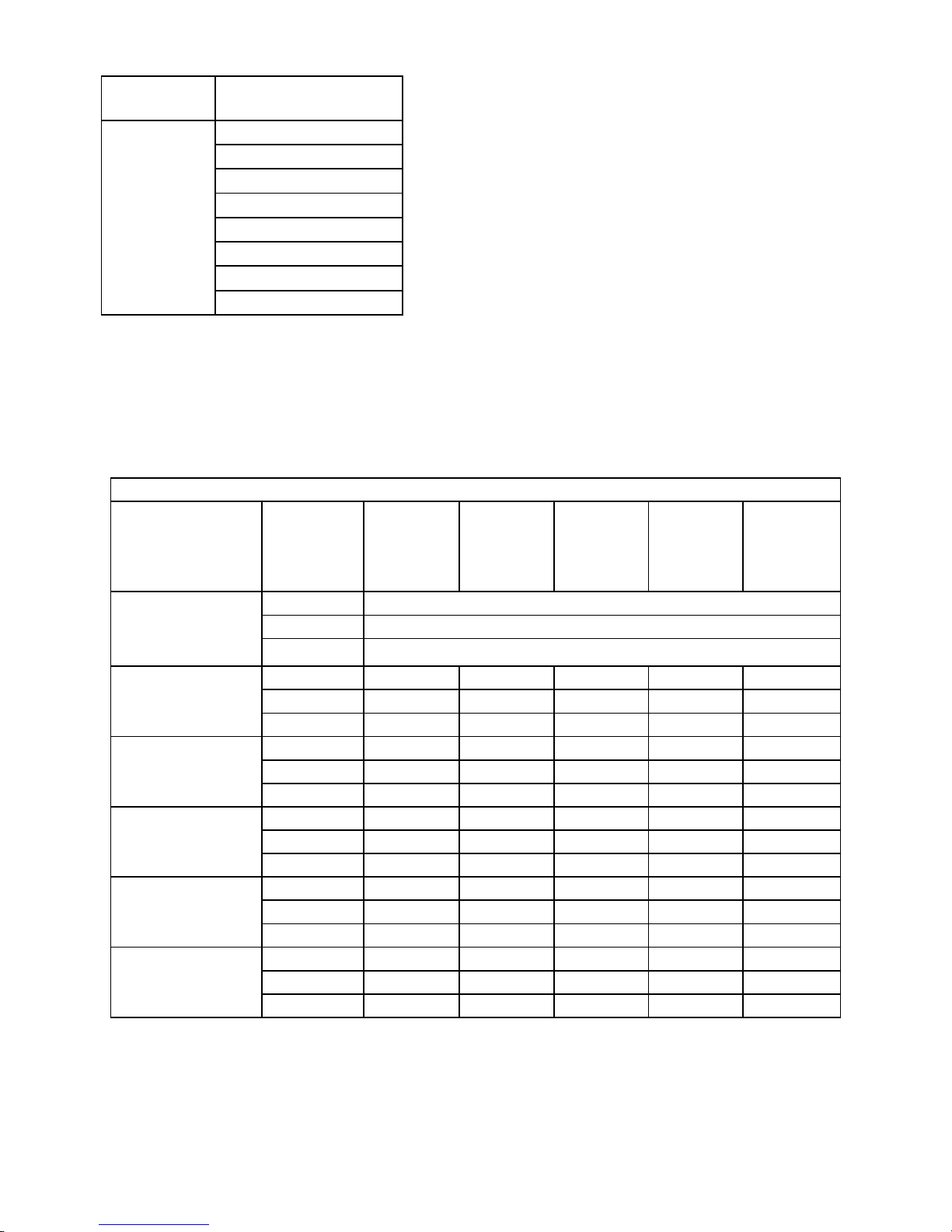

Capacity Model

18000BTU TAS-18EH

5.2.3.1 Cooling Capacity (BTU)---Run Model ,230V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [0F]

OUTDOOR

ENTERING AIR DB

TEMPERATURE[0F]

14~68

(protection range)

77

86

95

104

115

DATA 72/59 75/63 81/66 84/70 90/73

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 17424 18504 19656 20808 21960

SC 15480 15750 16110 16380 16740

PI 1.19 1.21 1.23 1.25 1.27

TC 16560 17712 18864 19944 21096

SC 15030 15390 15660 16020 16290

PI 1.34 1.36 1.38 1.40 1.42

TC 15696 16848 18000 19152 20304

SC 14670 14940 15300 15660 15930

PI 1.46 1.48 1.52 1.54 1.56

TC 14904 16056 17136 18288 19440

SC 14310 14580 14940 15210 15570

PI 1.60 1.62 1.64 1.66 1.68

TC 13896 15048 16128 17280 18432

SC 13770 14130 14400 14760 15030

PI 1.77 1.79 1.81 1.83 1.87

15 SERVICE MANUAL FOR AMERICA

Page 16

5.2.3.2 Heating Capacity (BTU)---Run Model,230V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [0F]

OD COILENTERING

AIR DB/WB TEM

PERATU RE[

0

F]

DATA 59 68 77

5/3

14/10

20/18

30/28

36/34

45/43

50/48

59/54

59~75

(Protection Range)

TC 12160 11210 10450

PI 0.96 1.05 1.15

TC 13490 12540 11780

PI 1.15 1.25 1.37

TC 14440 13680 12730

PI 1.31 1.40 1.50

TC 15010 14250 13300

PI 1.39 1.46 1.56

TC 15390 14440 13680

PI 1.42 1.52 1.62

TC 19760 19000 18240

PI 1.50 1.60 1.70

TC 20900 20140 19190

PI 1.60 1.70 1.80

TC 22040 21280 20330

PI 1.68 1.76 1.87

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

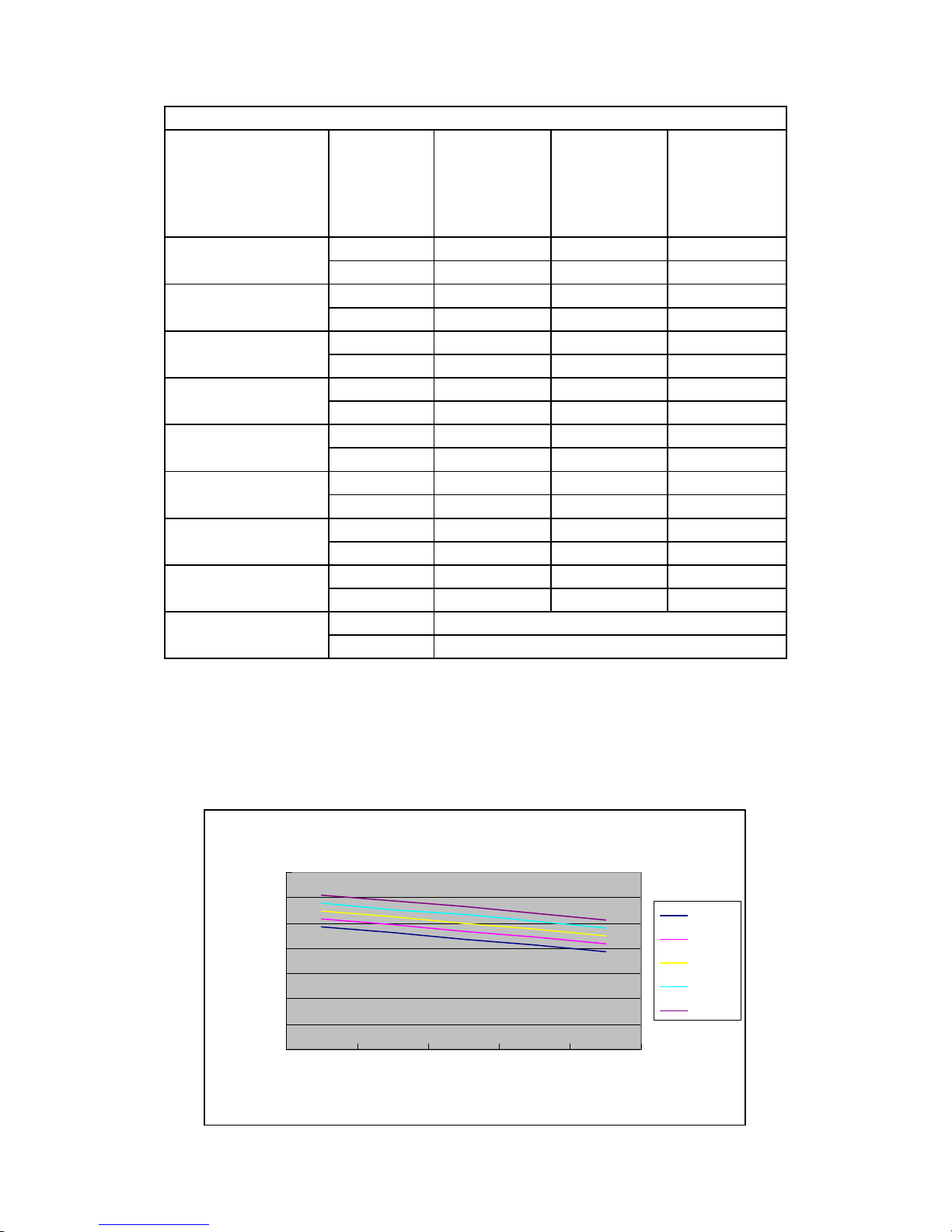

5.2.3.3 Capacity Co rrection Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

77 86 95 104 115

Outdoor Temp.(deg F)

90/73

84/70

81/66

75/63

72/59

16 SERVICE MANUAL FOR AMERICA

Page 17

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

5 14203036455059

Outdoor Temp.(deg F)

5.2.4 Indoor Units Capacity For 24000BTU

59

68

77

Capacity Model

24000BTU TAS-24EH

5.2.4.1 Cooling Capacity (BTU)---Run Model,230V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [0F]

OUTDOOR

ENTERING AIR DB

TEMPERATURE[0F]

14~68

(protection range)

77

86

95

104

115

DATA 72/59 75/63 81/66 84/70 90/73

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

PI 25 - 50 % of nominal

TC 23232 24672 26208 27744 29280

SC 20640 21000 21480 21840 22320

PI 1.72 1.75 1.78 1.81 1.84

TC 22080 23616 25152 26592 28128

SC 20040 20520 20880 21360 21720

PI 1.93 1.96 1.99 2.02 2.05

TC 20928 22464 24000 25536 27072

SC 19560 19920 20400 20880 21240

PI 2.11 2.14 2.20 2.23 2.26

TC 19872 21408 22848 24384 25920

SC 19080 19440 19920 20280 20760

PI 2.32 2.35 2.38 2.41 2.44

TC 18528 20064 21504 23040 24576

SC 18360 18840 19200 19680 20040

PI 2.56 2.59 2.62 2.65 2.71

17 SERVICE MANUAL FOR AMERICA

Page 18

5.2.4.2 Heating Capacity (BTU)---Run Model,230V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [0F]

OD COILENTERING

AIR DB/WB TEM

PERATU RE[

0

F]

DATA 59 68 77

5/3

14/10

20/18

30/28

36/34

45/43

50/48

59/54

59~75

(Protection Range)

TC 15680 14455 13475

PI 1.35 1.49 1.63

TC 17395 16170 15190

PI 1.63 1.76 1.93

TC 18620 17640 16415

PI 1.85 1.98 2.12

TC 19355 18375 17150

PI 1.96 2.07 2.20

TC 19845 18620 17640

PI 2.01 2.15 2.29

TC 25480 24500 23520

PI 2.12 2.26 2.40

TC 26950 25970 24745

PI 2.26 2.40 2.54

TC 28420 27440 26215

PI 2.37 2.48 2.65

TC 85 - 105 % of nominal

PI 80 - 120 % of nominal

5.2.4.3 Capacity Co rrection Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

77 86 95 104 115

Outdoor Temp.(deg F)

90/73

84/70

81/66

75/63

72/59

18 SERVICE MANUAL FOR AMERICA

Page 19

Heating Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Correction Factor

1.4

1.2

1

0.8

0.6

0.4

Capacity Ratio

0.2

0

5 14203036455059

Outdoor Temp.(deg F)

59

68

77

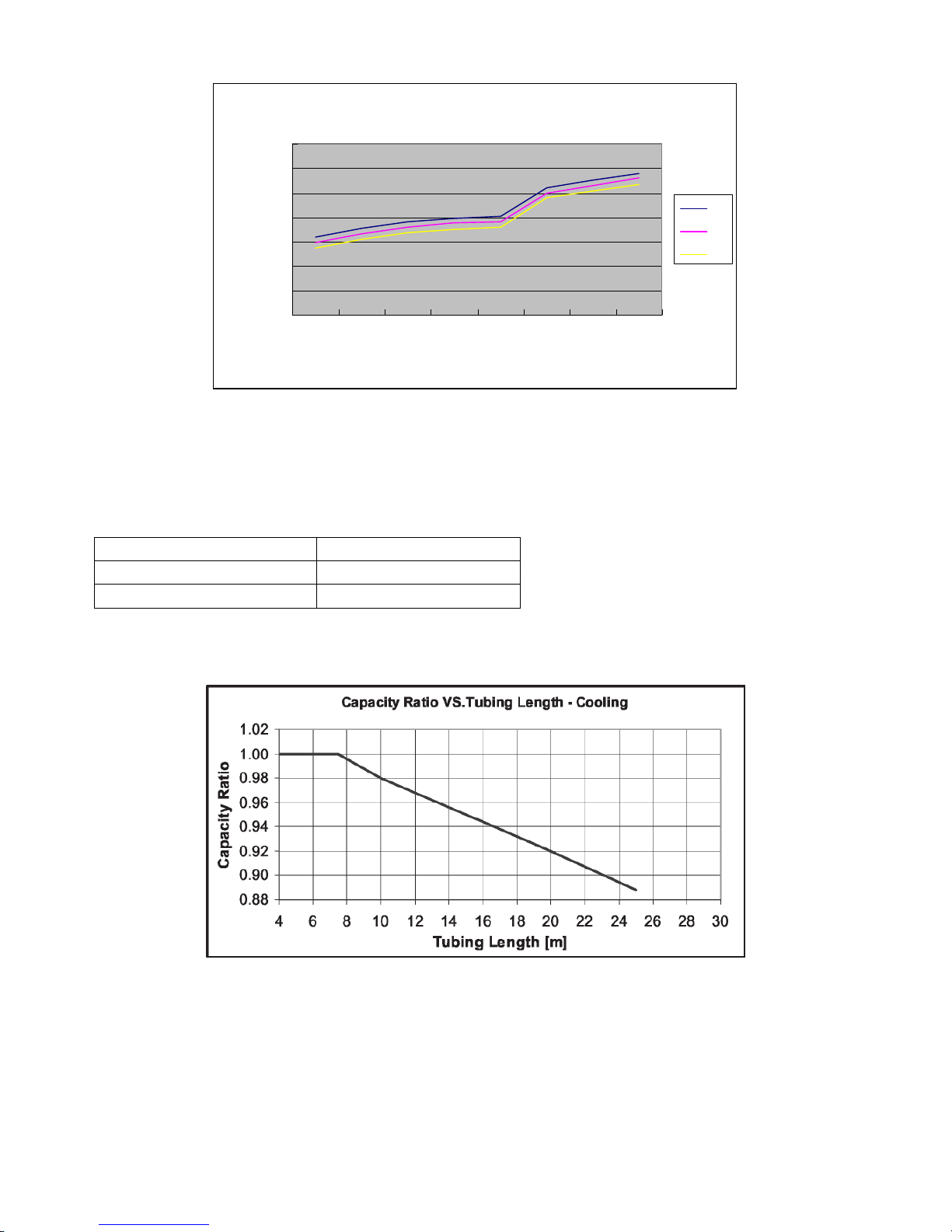

5.3 Capacity Correction Factor Due to Tubing Length (One Way)

5.3.1 Indoor units Model

TAS-09MVH TAS-12MVH

TAS-09EH TAS-12EH

TAS-18EH TAS-24EH

5.3.1.1 Cooling

5.3.1.2 Heating

19 SERVICE MANUAL FOR AMERICA

Page 20

6. Pressure Curve

6.1 Model

TAS-09EH/O TAS-18MVH/O

TAS-12EH/O TAS-24MVH/O

TAS-18EH/O

TAS-24EH/O

6.1.1 Suction Pressure Curve

6.1.2 Discharge Pressure Curve

20 SERVICE MANUAL FOR AMERICA

Page 21

7. ELECTRICAL DATA

Model

TAS-09EH/O

Power Supply 1 PH, 115 VAC,60Hz

Connected to Outdoor

Maximum Current 9.3A

Inrush Current 40A

Starting Current 1A

Circuit breaker 30A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

Model

2 X 4 X 1 mm

TAS-12EH/O

2

Power Supply 1 PH, 115 VAC,60Hz

Connected to Outdoor

Maximum Current 10.8A

Inrush Current 40A

Starting Current 1A

Circuit breaker 30A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

Model

2 X 4 X 1 mm

TAS-18EH/O

2

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 10.1A

Inrush Current 40A

Starting Current 1A

Circuit breaker 30A

21 SERVICE MANUAL FOR AMERICA

Page 22

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

Model

2 X 4 X 1 mm

TAS-24EH/O

2

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 12.2A

Inrush Current 35A

Starting Current 1A

Circuit breaker 30A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

Model

2 X 4 X 1 mm

TAS-18MVH/O

2

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 10.5A

Inrush Current 40A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

Model

2 X 4 X 1 mm

TAS-24MVH/O

2

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 13A

Inrush Current 35A

Starting Current 1A

Circuit breaker 30A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

2 X 4 X 1 mm

2

Note:

Inrush current is the current when power is up. (charging the DC capacitors at outdoor unit

controller).

Starting current is the current when starting the compressor

Power wiring cord should comply with local lows and electrical

regulations requirements.

NOTE

22 SERVICE MANUAL FOR AMERICA

Page 23

8. WIRING DIAGRAMS

8.1 TAS-09EH/O Wiring Diagram

8.2 TAS-12EH/O Wiring Diagram

23 SERVICE MANUAL FOR AMERICA

Page 24

8.3 TAS-18EH/O Wiring Diagram

8.4 TAS-24EH/O Wiring Diagram

8.5 TAS-18MVH/O Wiring Diagram

24 SERVICE MANUAL FOR AMERICA

Page 25

8.6 TAS-24MVH/O Wiring Diagram

8.4 TAS-18MVH/O TAS-24MVH/O

Indoor-Outdoor Wiring Diagram

25 SERVICE MANUAL FOR AMERICA

Page 26

8.5 TAS-09EH/O TAS-12EH/O TAS-18EH/O TAS-24EH/O

Indoor-Outdoor Wiring Diagram

9. REFRIGERATION DIAGRAMS

26 SERVICE MANUAL FOR AMERICA

Page 27

9.1 TAS-09EH/O Refrigeration Diagram

9.2 TAS-12EH/O Refrigeration Diagram

9.3 TAS-18EH/O TAS-24EH/O Refrigeration Diagram

27 SERVICE MANUAL FOR AMERICA

Page 28

9.4 TAS-18MVH/O Refrigeration Diagram

9.5 TAS-24MVH/O Refrigeration Diagram

28 SERVICE MANUAL FOR AMERICA

Page 29

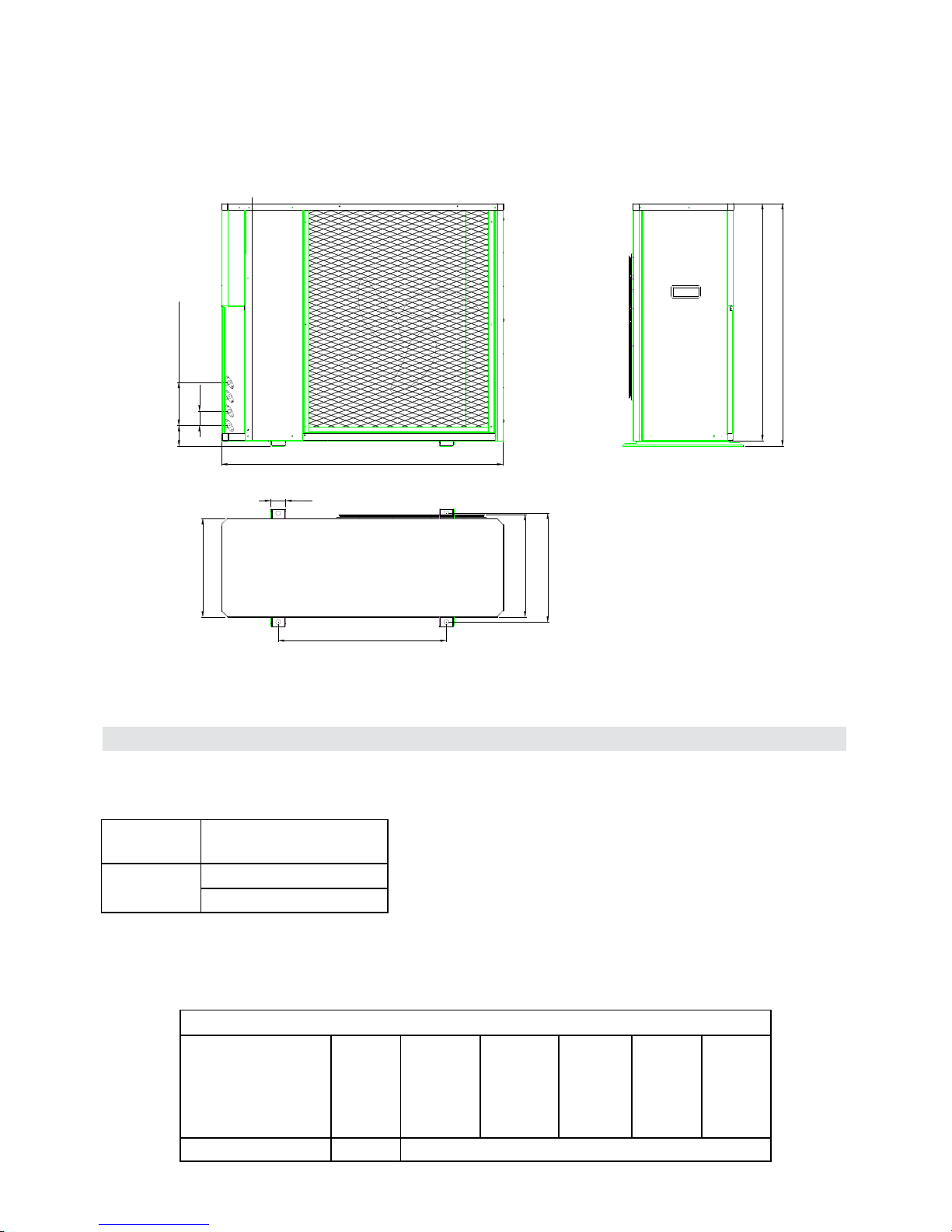

10. TUBING CONNECTIONS

29 SERVICE MANUAL FOR AMERICA

Page 30

TUBE (Inch)

TORQUE (Nm)

Flare Nuts

Valve Cap

Service Port Cap

¼” ~” ½” ~” ¾”

11-13 40-45 60-65 70-75 80-85

13-20 13-20 18-25 18-25 40-50

11-13 11-13 11-13 11-13 11-13

1. Valve Protection Cap-end

2. Refrigerant Valve Port (use Allen wrench to open/close)

3. Valve Protection Cap

4. Refrigerant Valve

5. Service Port Cap

6. Flare Nut

7. Unit Back Side

8. Copper Tube

When the outdoor unit is installed above the indoor unit an oil trap is required every 5m along the suction line at the

lowest point of the riser. Incase the indoor unit is installed above the outdoor, no trap is required

11. CONTROL SYSTEM

30 SERVICE MANUAL FOR AMERICA

Page 31

Function of Inverter indoor unit

一、summary

1. This control is use for DC Multi-Spilt air conditioners.

2. Power of indoor unit supply is 220-240V/50Hz, voltage range is 170V~270V.

3. Control precision of indoor temperature is ±1.8

4. Indoor fan motor is PG motor.

5. Control accord with :

GB5956-91《safe requirement of air conditioner》

GB7725-2004《air conditioner》;GB3797-87《control equipment of electrical equipment》

Vibrancy test:frequency 50Hz,acceleration 2.5g

PCB ought to accord with GB4588.1 and GB4588.2

Electromagnetism compatibility ought to accord with relate standard of nation.

二.Base parameter

1. Use condition:ambient temperature 5 OF~185 OF, relative humidity =30-95%.

2. Receive distance of remote:<10m

3. Angle of remote:<120 degree

O

4. Control precision of temperature: ±1.8

F

5. Speed precision of indoor fan motor: ±10RPM

6. Time precision: <0.1%

三.Major function of control

1. Remote

Turn on/off

Mode select

auto

cooling

dehumidify

heating

ventilation

Indoor fan speed select

manual mode: high, middle, low speed

auto mode: accord difference of indoor room temp. and set temp. automatic select.

Temperature setting

Cooling: 60

Heating : 60

Dehumidify: default is 77

Auto: default is 77

Ventilation: 60

Sleeping

It can set or cancel 24HR sleep .

Timer on or timer off

Timer can set 24HR on or off.

Air flower control.

Turbo running

Hold key

2. Main PCB board

O

F――90 OF, default is 77 OF

O

F――90 OF, default is 77 OF

O

O

F――90 OF, default is 77 OF

O

F and it can’t adjust.

F and it can’t adjust.

O

F.

31 SERVICE MANUAL FOR AMERICA

Page 32

five running modes

Auto, cooling, heating, dehumidify, ventilation.

Timer function

Indoor temperature detect.

Indoor coil temperature detect.

Indoor fan speed control

cooling: turbo/high speed/middle speed/low speed/ lower speed

heating: turbo/high speed/middle speed/low speed/ lower speed

Indicate lamp

green—running indicate

yellow—timer indicate

red—turbo running

green—economic running

Indoor temperature control

Coil pipe of indoor unit overheat protection

Coil pipe of indoor unit anti frost protection

Sleep

Swing

Anti cold air in heating mode

Indoor fan motor protection

Fault display

DC Inverter 1:1

24000BTU:

mode high middle low

Cooling

speed

Heating

speed

1280 1180 1080

1280 1180 1080

18000BTU:

mode high middle low

Cooling

speed

Heating

speed

1230 1000 950

1230 1000 950

12000BTU:

mode high middle low

Cooling

speed

Heating

speed

1000 900 750

1000 900 750

9000BTU:

mode high middle low

Cooling 1300 1150 950

32 SERVICE MANUAL FOR AMERICA

Page 33

DC Inverter 1:2

PG motor speed:

12000BTU:

9000BTU:

speed

Heating

speed

1300 1150 950

mode higher high middle low lower

Cooling

speed

Heating

speed

1250 1200 950 850 850

1250 1200 950 850 750

mode higher high middle low lower

Cooling

speed

Heating

speed

1250 1150 950 750 750

1250 1150 950 750 750

四、operating mode

Air conditioner have four operating mode: auto, cooling, dehumidify, heating.

1.Cooling(ΔT=Troom temp.-Tset temp.)

range of set temp. 60

compressor running as below figure:

CONT 5 MIN

off

compressor

on

It require outdoor unit to reduce power if indoor room temp. continuous less than set

temp. for 5 minutes.

Air blow function:indoor blower fan continuous running 20 seconds at low speed after

air conditioner turn off in cooling mode. if the flap is swing, shutdown the flap after

turn off indoor blower fan.

Indoor blower fan can select one of four speed.

Fan speed is determined by the difference of room temp. and set temp. in auto wind.

high

middle

speed

low

It have anti freeze protection of indoor coil ,fan motor fault protection, sensor

fault protection, unit abnormal protection in cooling mode.

2.Dehumidify:(ΔT=Troom temp.-Tset temp.)

range of set temp.: default is 77

The indoor blower fan is running at low speed for thirty seconds after air conditioner

shutdown in dehumidify mode.

O

F~90OF;

O

-2

F +2

O

2

F 5 OF 9 OF ΔT

O

F ΔT

O

F and it can’t change.

33 SERVICE MANUAL FOR AMERICA

Page 34

The indoor blower fan is running at low speed and it can’t change.

Air conditioner haven’t turbo and economic function in dehumidify mode.

Flap position: flap at 85 degree position and it can’t change.

It require indoor unit to reduce power if indoor room temp. continuous less than or

equal to 15 degree for 5 minutes, when room temp. is more than or equal to 17 degree,

it add the power of indoor unit.

3.Heating(ΔT=Troom temp.-Tset temp.)

Range of set temp. 60

O

F~90 OF;

Compressor running as below figure.

CONT 5 MIN

off

-7

compressor

on

O

F -4 OF ΔT

It require outdoor unit to reduce power if indoor room temp. continuous more than set

temp. for 5 minutes.

Indoor blower fan continuous running for 30 seconds at current speed after indoor unit

reduce power.

Indoor blower fan can select one of four speed.

Fan speed is determined by the difference of room temp. and set temp. in auto wind.(but

anti cold wind is prior)

high

middle

speed

low

O

0

F 4 OF 6 OF 9 OF ΔT

Anti cold wind:

When air conditioner first power on or change mode, indoor blower fan didn’t running. When the

coil pipe temp. of indoor unit is more than 86

O

F,start turnning on indoor blower

fan(lower speed).if the coil pipe temp. of indoor unit drop to less than or equal

O

to 77

F,it shutdown indoor blower fan.

Heat wind control:

O

If coil pipe temp. of indoor unit is more than or equal to 90

F, indoor blower fan is running

at set speed.

If coil pipe temp. of indoor unit is less than 90

figure.

set speed

lower

77

Note:①When Tp≤86

speed

turn off

O

F, it is running at set speed and flap revert to prior state.

≥90

②If Tp≤77

O

F 86 OF 90 OF coil pipe temp.

O

F,flap is open at 85°and is running at lower speed, when Tp

O

F,turn off indoor blower fan.

Defrost control

Indoor blower fan turn off when it enter defrost.

Clear quantity of heat

O

F, indoor blower fan is running as below

34 SERVICE MANUAL FOR AMERICA

Page 35

Turn off air conditioner in heating mode, if the coil pipe temp. of indoor unit is

more than 104

of indoor unit is less than or equal to 104

O

F, indoor blower fan is running at low speed. If the coil pipe temp.

O

F or turn off air conditioner over 2 minutes,

It shutdown indoor blower fan.

4. Auto mode

O

set temp. is 77

F and it can’t change;

Press emergency key in waiting state or select auto mode by remote, air conditioner

enter auto mode and set temp. is 77

O

F.

Indoor blower fan is running for 20 seconds at lower speed after select auto mode,

the running lamp is light, it select correspond running mode accord to room temp.:

O

room temp. >79

room temp. <70

O

F≤room temp.≤79 OF,select ventilation mode.

70

F, select cooling mode.

O

F, select heating mode.

When the running mode has confirmed, it can’t change, if it reenter auto mode, it

select running mode again accord to room temp..

When the mode of auto select is clash with other indoor unit running mode:

If it auto select is cooling mode and other indoor unit is running heating mode, then it select

ventilation mode.

If it auto select is heating mode, but other indoor unit is running cooling mode, display error of mode

clash.

if it select is ventilation mode, then it running is ventilation.

5.Ventilation

1) Range of set temp.:60

O

F -90 OF.

2) Indoor blower fan is operate same as cooling mode.

3) Flap is operate same as cooling mode.

4) Indoor unit no power require in ventilation mode.

6. Timer and sleep

timer

Remote can set 1-24 hours timer on or timer off.

Air conditioner is running .

If set timer off, air conditioner is continuous running and display timer time, when timer time is

end, it shutdown air conditioner.

air conditioner is shutdown .

If set timer on, air conditioner at waiting state, it display timer time. when timer time is end, it turn

on air conditioner.

when it set timer , the timer lamp is light and display set temp.

sleep

If set sleep, the sleep lamp is light, set temp. and fan speed can be adjust.

Timer and sleep can set together, which time is end then perform this function.

7. Air flow control

Define:flap full open angle is 0°, and full close angle is 125°。

35 SERVICE MANUAL FOR AMERICA

Page 36

Full open

Fixed

Full close

Power on, flap run to full close position.

Turn off air conditioner, flap run to full close position.

Turn on air conditioner, flap first run to full open position, then run to correspond position.

Fixed wind:

If turn on air conditioner and set fixed wind at first power on, flap first run to full open

position then stop at 40°position.

If change to fixed wind from swing wind or natural wind, the flap stop at current position

and store the position.

Swing wind:

Flap start position is 20°.

Flap is running between 20°and 85°.

Natural wind is swing two cycle and stop 15 seconds, flap is stop at current

position at that moment.

Flap stop at 85°at anti cold wind or defrost procedure in heating mode.

Flap stop at 85°in first 20 seconds of auto mode.

Flap is drive by step motor.

8. Turbo function

Turbo is use in cooling /heating/ventilation mode, the indoor blower fan is running

at super speed.

(1) enter condition: press turbo key of remote.

(2)end condition:

① running time more than or equal to 15 minutes.

② press turbo key of remote again.

(3) all restrict and protect condition are active in turbo running.

(4) return to prior state after end turbo running.

五、Protection

1. Prevent frost of indoor coil pipe (cooling and dehumidify mode)

When the temp. of middle coil pipe is less than or equal to 32

is running at high speed, if the temp. less than or equal to 30

it turn off compressor, when the temp. more than or equal to 45

2. Overheat of indoor coil pipe(heating mode)

When the temp. of middle coil pipe more than or equal to 135

is running at high speed, if the temp. more than or equal to 149

O

unit, when the temp. less than or equal to 129

F, it exit protection.

3. Indoor fan motor fault(only PG motor)

O

F, indoor blower fan

O

O

O

F for 5 minutes,

F, it exit protection.

O

F, indoor blower fan

F , it turn off outdoor

36 SERVICE MANUAL FOR AMERICA

Page 37

If no feedback signal continuous 30 seconds during PG motor running, it turn off

air conditioner and display fan motor error.

4. Communicate fault

If it can’t receive correct signals after air conditioner has run for 60 seconds,

it turn off air conditioner and display communicate error.

5.Indoor sensor fault

When indoor sensor cut off or short, it shutdown air conditioner and display sensor

error.

6. When outdoor unit is fault, indoor unit only display fault.

六、Other function

Emergency key

Press emergency key after power on, air conditioner select auto mode, auto fan speed, natural wind, it

set temp. is 77

O

F. If press emergency key again, air conditioner is shutdown.

七、Sound indication

1. The buzzer will sound when air conditioner turn on , turn off, power on or receive remote signal.

八、Display

1.After turn on air conditioner, mode clash display d1 and timer lamp flash (light one

second, extinguish one second), defrost display dF , the running lamp flash (light one second,

extinguish one second)indicate anti cold wind ,when air conditioner is normal running ,

the running lamp is light.

2.Set timer or sleep , the yellow lamp is light.

3.Outdoor unit and indoor unit fault display:

Fault display of indoor unit:

fault display

Communicate fault F1

Fan motor fault F4

Room temp. sensor fault F2

Temp. sensor of coil pipe outlet fault

Temp. sensor of coil pipe entrance

fault

Temp. sensor of coil pipe middle

fault

Fault display of outdoor unit:

fault display

Transducer module protection

Over current

Discharge temperature of

compressor overheat, ambient

temperature overheat

DC voltage of outdoor unit abnormal

Leakage or reverse valve fault

Outdoor sensor fault F6

Compressor drive fault

F3

F3

F3

P2

P3

P4

P7

P8

FC

九、Test Model

37 SERVICE MANUAL FOR AMERICA

Page 38

1、Cooling

Condition Entering Method

label Capacity Pressing Tubro for 5 times+Setting temp.77 OF

A2 Pressing Tubro for 5 times+Setting temp.75 OF

B2 Pressing Tubro for 5 times+Setting temp.73 OF

B1 Pressing Tubro for 5 times+Setting temp.71 OF

F1 Pressing Tubro for 5 times+Setting temp.69 OF

EV Pressing Tubro for 5 times+Setting temp.67 OF

A2:Indoor temp. 95 OF,Compressor max

B2:Indoor temp. 82 OF,Compressor max

B1:Indoor temp. 82 OF,Compressor min

F1:Indoor temp. 67 OF,Compressor min

EV:Indoor temp.87 OF,Compressor mid

2、Heating

Condition Entering Method

label Capacity Pressing Tubro for 5 times+Setting temp.77 OF

H01 Pressing Tubro for 5 times+Setting temp.79 OF

H11 Pressing Tubro for 5 times+Setting temp.81 OF

H12 Pressing Tubro for 5 times+Setting temp.83 OF

H22 Pressing Tubro for 5 times+Setting temp.85 OF

H32 Pressing Tubro for 5 times+Setting temp.87 OF

H2V Pressing Tubro for 5 times+Setting temp.89 OF

H01:Indoor temp. 62

H11:Indoor temp. 47

H12:Indoor temp. 47

H22:Indoor temp. 35

H32:Indoor temp. 17

H2V:Indoor temp. 35

O

F,Compressor min

O

F,Compressor min

O

F,Compressor max

O

F,Compressor max

O

F,Compressor max

O

F,Compressor mid

Function of Dual DC Inverter Type

38 SERVICE MANUAL FOR AMERICA

Page 39

一. System Frame Drawing

R

everse Valve(Current in cooling condition)

Condenser of Ou td oo r Un it

Temperature of Exhaust

Expansion Valve 1 Expansion Valve 2

Temperature of the Middle of Outdoor Coils

Temperature of suction M M

Compressor

Liquid Tank T11 T12 T13

Evaporator 1 of Indoor Unit

Ambient Temperature of Indoor 1

Ambient Temperature of Outdoor T21 T22 T23

Evaporator 2 of Indoor Unit

Ambient Temperature of Indoor 2

Diagram 1

二.Major Performance Index

a) Voltage of Power Supply: AC220V ±15%;

b) Power of Controller: ≤15W;

c) Output of Three-phase Frequency Conversion:

Wire Voltage: 70V∽180V; Power: ≤5KW; Frequency: 10Hz∽120Hz;

d) Precision of Temperature Control:±1℃;

e) Applicable Environment:

Temperature:-20∽55℃,Relative Humidity: ≤90%RH (No dew);

f) Conservation Environment:

Temperature:-25∽70℃,Relative Humidity: ≤95%RH (No dew);

g) Executive Standard: GB/T7725-2004 & GB4706.32-2000.

三.Input & Output of Outdoor Controller

1. Outputs of one three-phase Frequency Conversion, two relays, one indicator led and one

communication signal:

1) Controlling the three-phase output of compressor

2) Controlling the output of outdoor motor

3) Controlling the output of 4-way valve

4) Controlling the output of communication signals of indoor unit

5) Controlling the output of expansion valve

2. Inputs of five analogue inputs (the temperature measuring points distributing as Diagram 1, all the

analogues go through digital filter for disposal), and two switch signals and two communication

signals:

a) Signal input of outdoor ambient temperature

b) Signal input of median temperature of outdoor coil

c) Signal input of discharge temperature of compressor

d)

Signal input of suction temperature of compressor

e) Signal input of power supply voltage

f) over-heat protection signal of compressor

g) communication signal of indoor unit 1

h) communication signal of indoor unit 2

i) protection signal of outdoor IPM module

四. Operation in Cooling Mode

39 SERVICE MANUAL FOR AMERICA

Page 40

Control of Expansion Valve in Cooling Mode

1. Reset of Expansion Valve

In the first time ,the expansion valves in all channels shall be shut down 600 steps, then the

expansion valve corresponding to the indoor unit in normal communications with the outdoor unit shall

be opened to standby mode steps. If accomplished, the outdoor unit shall be on standby mode, until the

turn-on the indoor unit.

2. Adjustment of Expansion Valve

1) Setting of Basic Step

After the confirmation of the turn-on order of cooling mode, the expansion valve of the relevant

indoor unit shall be set to the basic step and the other to zero step.

2) Adjustment of Expansion Valve according to the difference in temperature between the inlet and

outlet of evaporator

During the first ten minutes of cooling mode, the expansion valve of the indoor unit at the request

of cooling shall be set to the basic step. Ten minutes later, the expansion valve step and its adjust

cycle shall be adjusted according to the difference in temperature between the inlet and outlet of

evaporator.

Control of compressor’s frequency:

1.Range of compressor’s frequency:Fmin~Fmax (Fmin:the lowest frequency, Fmax:the highest

frequency)

2.Frequency decrease protection of compressor: frequency decrease protection is prior

during frequency adjustment of compressor (Frequency decrease protection have: high

temperature of compressor discharge, high temperature of outdoor coil pipe, high

temperature of indoor coil pipe, low temperature of compressor suction, over

current)

Control of fan motor in cooling mode:

1.The fan motor of outdoor unit is ahead run 20 seconds before compressor turn on.;

2.After compressor turn off, the fan motor of outdoor unit delay 30 seconds.

3. The fan motor speed of outdoor unit as below table in normal running, it has 20 seconds delay after

speed change.

Speed table of outdoor fan motor

indoor unit

capacity

outdoor ambient

<2hp

cooling Speed grade

T<66 OF

O

66

F≤T<81 OF low middle high

T≥81 OF

low low middle

middle high high

compressor

≥2hp ≥3hp

40 SERVICE MANUAL FOR AMERICA

Page 41

outdoor FM

20s 30s 30s

figure 3

五.Operation in Dehumidify Mode

Dehumidify mode is same as cooling mode.

六.Operation in heating Mode

Adjustment of Expansion Valve:

1.Reset of Expansion Valve

In the first time,the expansion valves in two channels shall be shut down 600 steps, then the

expansion valve corresponding to the indoor unit in normal communications with the outdoor unit shall

be opened to standby mode steps. If accomplished, the outdoor unit shall be on standby mode, until the

turn-on the indoor unit.

2.Adjustment of Expansion Valve

1) Setting of Basic Step

After the confirmation of the turn-on order in heating mode, the expansion valve of the relevant

indoor unit shall be set to the basic step.

2) Adjustment of Expansion Valve according to the difference in temperature between the inlet and

outlet of evaporator

During the first ten minutes of heating mode, the expansion valve of the indoor unit shall be set to

the basic step and can’t adjust. Ten minutes later, the expansion valve step and its adjust cycle

shall be adjusted according to the difference in temperature between the inlet and outlet of

evaporator.

Control of compressor’s frequency

Range of compressor’s frequency:Fmin~Fmax (Fmin:the lowest frequency, Fmax:the highest

frequency)

Control of fan motor in heating mode:(figure 5)

1. The fan motor of outdoor unit is ahead run 20 seconds before compressor turn on.

2. After compressor turn off, the fan motor of outdoor unit delay 30 seconds.

3. The fan motor speed of outdoor unit as below table in normal running, it has 20 seconds delay after

speed change.

4. The control of outdoor fan motor as figure 6 during defrost process.

Speed table of outdoor fan motor

indoor unit

capacity

outdoor ambient

<2hp ≥2hp ≥3hp

heating Speed grade

T≥68 OF low low middle

O

54

F≤T<68 OF

T<54 OF

low middle high

middle high high

Control of reverse valve(figure 5)

1. The reverse valve is ahead run 20 seconds before compressor turn on.

2. After compressor turn off, the reverse valve delay 60 seconds shutdown.

3. The control of reverse valve as figure 6 during defrost process.

compressor

41 SERVICE MANUAL FOR AMERICA

Page 42

outdoor FM

reverse valve

20s 30s 30s

figure 5

七.Defrost of heating mode(figure 6)

1. Defrost start condition

If outdoor ambient is more than or equal to 61

O

F,it can’t defrost. When the time of defrost

interval is end , outdoor coil pipe temp. and outdoor ambient temp. continuous meet

all conditions for 5 minutes, it enter defrost process:

1) If outdoor ambient temp. less than or equal to 32

O

F,when T盘≤0.8T环+a OF(a is a adjust

constant), it enter defrost process.

O

2) If outdoor ambient temp. more than 32

≤ 0.2 T环+a

O

F, it enter defrost process.

3) If outdoor temp. sensor is failure, when outdoor coil temp. T

F and less than or equal to 59 OF,when T

≤+a OF, it enter defrost

盘

process.

4) If coil temp. sensor of outdoor unit is failure, when defrost interval time is end, it enter defrost, the

time of defrost is four minutes.

5) During the first ten minutes of outdoor running in heating mode, the time is clear and it judge

whether outdoor coil pipe temp. and outdoor ambient temp. satisfy defrost condition, if the

frequency of compressor is 25HZ and satisfy defrost condition, then if enter defrost process. After

end defrost process or over 10 minutes it return normal running.

2. Defrost end condition

1) T

≥b OF(b is a adjust constant)or defrost time more than or equal to c minutes

盘

(c is a adjust constant),it exit defrost process.

2) When outdoor coil pipe sensor is failure, defrost time is four minutes, it exit defrost process after

four minutes.

3. Interval time of defrost

1) Defrost interval time restriction: Max 120 minutes, Min 25 minutes.

2) The first frost interval time is 0 minute after heating.

3) The second defrost interval time is base on 60 minutes, it adjust according to below table.

4) Form second time, defrost interval time adjustment as below table.

Interval time(Td) change

Td <2 minutes Last interval time add 5

minutes

3 minutes≥Td≥2

minutes

≥4 minutes Last interval time reduce 5

Same as last interval time

minutes

4. Time sequence of defrost process(figure 6).

盘

42 SERVICE MANUAL FOR AMERICA

Page 43

八.Control of oil return circle

1. Oil return circle period

When air conditioner has run for 10 minutes or accumulate time T

msro is end, it execute oil return

circle once.

2. When compressor is running to oil return circle, the indoor unit which have communication is

return oil, expand valve is open fully and compressor’s frequency increase more than 3/5 of

max frequency for 90 seconds, the expand valve of indoor unit which no communication is close.

九. Operation mode control of outdoor unit(dehumidify、cooling or heating)

The indoor unit can require cooling mode and dehumidify mode tog ether, but it can’t require cooling mode or

dehumidify with heating mode together, the outdoor unit operate state is decided by the indoor unit which is applied

first.

十.Protect function:

1. Delay protection of compressor

The compressor can’t run after it stop within 3 minutes.

2. Fault protection of module

The air conditioner stop running immediately and display error code if the module is

fault.

3. Protection of communicate fault

The control of outdoor unit can connect with all indoor units, when it power on, it

sent data to each indoor unit continuously, if it receive a correct data from correspond

indoor unit, then the indoor unit is exist. when the control of outdoor unit didn’t

receive communication data from indoor unit which is exist within 30 seconds, it will

display communication fault. If all communication channels are failure, air

conditioner will shutdown and display fault code.

43 SERVICE MANUAL FOR AMERICA

Page 44

4. Leakage or reverse valve fault

The air conditioner shutdown immediately when meet one of below conditions.

1) Heating: coil pipe temp. of outdoor unit can’t decrease 3 degree within setting

time and coil pipe temp. of indoor unit can’t increase 3 degree all along.

2) Cooling: coil pipe temp. of outdoor unit can’t increase 3 degree within setting

time and coil pipe temp. of indoor unit can’t decrease 3 degree all along.

5. High temp. protection of compressor discharge

1) The protection don’t effect if the temp. sensor of compressor discharge fault.

2) The air conditioner stop running immediately and display error code when the temp.

of compressor discharge more than Tsd.

3) The compressor decrease frequency until the temp. of compressor discharge less

than 210

normal frequency when the temp. of compressor discharge less than 194

6. Temperature switch protection of compressor

O

F if the temp. of compressor discharge more than 203 OF. The compressor resume

O

F.

The air conditioner will shutdown immediately and display fault code if the temp.

switch of compressor switch off.

7. High temp. protection of middle coil pipe of condenser

1) The protection don’t effect if the temp. sensor of middle coil pipe fault.

2) The compressor decrease frequency until the temp. of middle coil pipe less than

O

136

F.if the temp. of middle coil pipe more than 134 OF..

3) It resume normal frequency when the temp. of middle coil pipe less than133

O

F..

8. High temp. protection of indoor coil pipe

1) The compressor decrease frequency until the temp. of indoor coil pipe more than

(Tsce-2) if the temp. of indoor coil pipe less than (Tsce-2)in cooling mode.

The compressor decrease frequency until the temp. of indoor coil pipe less than

(Tsce+2) if the temp. of indoor coil pipe more than (Tsce+2) in heating mode.

2) It resume normal frequency when the temp. of indoor coil pipe less than Tsce(cooling mode) or

less than Tshe(heating mode).

9. Low temp. protection of compressor suction

1) The protection don’t effect if the temp. sensor of compressor suction fault or compressor don’t

run or in heating mode..

2) The compressor decrease frequency until the temp. of compress suction more than

Tss if the temp. of compressor suction less than Tss. It resume normal frequency when the

temp. of compressor suction more than (Tss+2).

10. Fault protection of outdoor sensor

The air conditioner is running at the frequency of less than (3/5)*Fmax and display fault code if

the temp. sensor of compressor discharge fault, or the temp. sensor of outdoor middle coil

pipe fault, or the temp. sensor of compressor suction fault, or the temp. sensor of outdoor

ambient fault.

11. High temp. of ambient

1) The protection don’t effect if the temp. sensor of outdoor ambient fault.

2) The air conditioner stop running immediately and display error code if outdoor

O

ambient temp. more than 131

F or less than -4 OF.

12. Over current protection of compressor

44 SERVICE MANUAL FOR AMERICA

Page 45

1) The air conditioner stop running immediately and display error code when input

current more than or equal to Imax.

2) The compressor decrease 2Hz per 3 seconds until input current less than or equal

to (Imax-13) when the input current more than (Imax-13).

2)

The compressor decrease 1Hz per 3 seconds until input current less than or equal

to (Imax-16) when the input current more than (Imax-16).

3) It resume normal frequency when the input current less than or equal to (Imax-20).

13.DC voltage of wire protection

1) The air conditioner stop running and display DC voltage abnormal when it less than

260V.

2)The compressor decrease frequency and display FA6 when DC voltage less than 285V.

3) The air conditioner resume normal running when DC voltage more than 290V.

十一、Outdoor unit fault of indoor unit display

fault display

Transducer module protection

Over current

Discharge temperature of

P2

P3

P4

compressor overheat, ambient

temperature overheat

DC voltage of outdoor unit abnormal

Leakage or reverse valve fault

P7

P8

Outdoor sensor fault F6

Compressor drive fault

45 SERVICE MANUAL FOR AMERICA

FC

Page 46

12. TROUBLESHOOTING

When Power Up – the whole outdoor unit controller, including the wiring, is under HIGH

Never open the Outdoor unit before turning off the Power!!!

When turned off, the system is still charged (400V)!!!

It takes about 3 Min. to discharge the system.

Touching the controller before discharging may cause an electrical shock!!!

For safe handling of the controller please refer to section 1.6 below.

WARNING!!!

VOLTAGE!!!

1.1 Air Conditioner Failures and Corrective Actions

F1:

1,Communicate wire cut off ,loose or wrong wiring---check wires

2,Communication interfere---check wires connection with circuit diagram.(earth line must be wired)。

F2:

1,Temp. sensor of indoor room short or cut off.---change sensor

F3:

1,Temp. sensor of indoor coil pipe outlet short or cut off.---change sensor.

2,Temp. sensor of indoor coil pipe entrance short or cut off.---change sensor.

3,Temp. sensor of indoor coil pipe middle short or cut off.---change sensor.

F4:

1,PG motor fault.---change motor. PG.

2,Fixed screw loose.---fix cross flow fan.

3,Communication interfere. (earth wire can’t with communicate wire in same cable)---check cable.

F6:

1,Temp. sensor of discharge short or cut off.---change sensor.

2,Temp. sensor of suction short or cut off.---change sensor.

3,Temp. sensor of condenser middle short or cut off.---change sensor.

P2:(auto-restart)

1,over current protection of inverter module.

2,over voltage protection of inverter module.

3,high temp. protection of inverter module.

P3:

1,over load (outdoor ambient temp. more high).

2,Voltage over low.

46 SERVICE MANUAL FOR AMERICA

Page 47

P4:

1: discharge temp. too high.---maybe leak refrigerant, add refrigerant.

2:outdoor ambient temp. too high, if (T<-4

O

F,T>131 OF), it will alarm.

3:temp. switch of compressor cut off.。

4:Communication interfere. (earth wire can’t with communicate wire in same cable)---check cable.

P7:

1,PFC board fault.---change PFC board.

2,Communication of main board and PFC board fault.---check wires of main board and PFC board.

P8:

1,Less refrigerant.---add refrigerant.

2,Coil pipe sensor can’t contact with coil pipe.

3,4-way valve fault.---change 4-way vavle fault.

47 SERVICE MANUAL FOR AMERICA

Page 48

13. EXPLODED VIEWS AND SPARE PARTS LISTS

13.1 outdoor unit : TAS-09EH/O

NO. description name number NO. description name number

1 前网罩 Front Grill 1 11 电器盒盖 Top of the Electric box 1

2 面 板 Front Plate 1 12 阀座板 Valve installation plate 1

3 轴流风轮 Axial flow fan 1 13 低压阀 Low-pressure valve 1

4 电 机 Motor 1 14 高压阀 Ligh-pressure valve 1

5 电机支架 Motor support 1 15 毛细管组件 Capillary Assy 1

6 冷凝器 Condenser 1 16 电子膨胀阀 Electronic expansion valve 1

7 顶盖板 Top panel 1 17 四通阀组件 Four-way valve assembly 1

8 电控盒 Electric box 1 18 压缩机 Compressor 1

9 背网 Rear Grill 1 19 中隔板 Partition board 1

10 右侧板 Right panel 1 20 底盘 Base 1

48 SERVICE MANUAL FOR AMERICA

Page 49

13.2 outdoor unit : TAS-12EH/O

NO. description name number NO. description name number

1 顶盖板 Top panel 1 12 高压阀 High-pressure valve 1

2 电控盒 Electric box 1 13 压缩机 Compressor 1

3 背网 Rear Grill 1 14 底盘 Base 1

4 中隔板 Partition board 1 15 冷凝器 Condenser 1

5 四通阀 Four-way valve 1 16 电机支架 Motor support 1

6 电子膨胀阀 Electronic expansion valve 1 17 电机 Motor 1

7 干燥过滤器 Desiccation filter 1 18 轴流风机 Axial flow fan 1

8 右侧板 Right panel 1 19 前网罩 Front Grill 1

9 大抽手 Large handle 1 20 前面板 Front Plate 1

10 阀座板 Valve installation plate 1 21 左护网 Left protect net 1

11 低压阀 Low-pressure valve 1 22 左侧板 Left panel 1

49 SERVICE MANUAL FOR AMERICA

Page 50

13.3 outdoor unit : TAS-18EH/O

NO. description name number NO. description name number

1 前网罩 Front Grill 1 11

2 面 板 Front Plate 1 12

四通阀组

件

电子膨胀

阀

Four-way valve assembly 1

Electronic expansion valve 1

3 轴流风轮 Axial flow fan 1 13 右侧板 Right panel 1

4 电 机 Motor 1 14 电器盒盖 Top of the Electric Box 1

5 左侧板 Left panel 1 15 阀座板 Valve installation plate 1

6 电机支架 Motor support 1 16 低压阀 Low-pressure valve 1

7 冷凝器 Condenser 1 17 高压阀 High-pressure valve 1

8 顶盖板 Top panel 1 18 维修板 Maintenance plate 1

9 电器盒 Electric box 1 19 压缩机 Compressor 1

10 背网 Rear Grill 1 20 中隔板 Partition board 1

21 底盘 Base 1

50 SERVICE MANUAL FOR AMERICA

Page 51

13.4 outdoor unit : TAS-24EH/O

NO. description name number NO. description name number

1 顶盖板 Top panel 1 13 维修板 Maintenance plate 1

2 减振块 Anti-vibration pad 1 14 小抽手 Small handle 2

3 中隔板 Partition board 1 15 压缩机 Compressor 1

4 电控盒 Electric box 1 16 底盘 Base 1

5 四通阀 Four-way valve 1 17 冷凝器 Condenser 1

6 干燥过滤器 Desiccation filter 1 18 电机支架 Motor support 1

7 电子膨胀阀 Electronic expansion valve 1 19 电机 Motor 1

8 右侧板 Right panel 1 20 轴流风机 Axial flow fan 1

9 电器盒盖 Top of the Electric box 1 21 前网罩 Front Grill 1

10 阀座板 Valve installation plate 1 22 前面板 Front Plate 1

11 低压阀 Low-pressure valve 1 23 左护网 Left protect net 1

12 高压阀 High-pressure valve 1 24 左侧板 Left panel 1

51 SERVICE MANUAL FOR AMERICA

Page 52

13.5 outdoor unit : TAS-18MVH/O

NO. description name number NO. description name number

1 前网罩 Front Grill 1 14 电器盒盖 Top of the Electric Box 1

2 面 板 Front Plate 1 15 阀座板 Valve installation plate 1

3 轴流风轮 Axial flow fan 1 16 A 机 DN4 截止阀 DN4 valve 1

4 左侧板 Left panel 1 17 A 机 DN10 截止阀 DN10 valve 1

5 电机支架 Motor support 1 18 B 机 DN4 截止阀 DN4 valve 1

6 冷凝器 Condenser 1 19 B 机 DN10 截止阀 DN10 valve 1

7 顶盖板 Top panel 1 20 维修板 Maintenance plate 1

8 电器盒 Electric box 1 21 干燥过滤器 Desiccation filter 1

9 背网 Rear Grill 1 22 压缩机 Compressor 1

10 汽液分离器

11 四通阀组件

12 电子膨胀阀

13 右侧板 Right panel 1

Steam liquid

segregator

Four-way valve

assembly

Electronic

expansion valve

1 23 中隔板 Partition board 1

1 24 底盘 Base 1

2 25 电 机 Motor 1

52 SERVICE MANUAL FOR AMERICA

Page 53

13.6 outdoor unit : TAS-24MVH/O

NO. description name number NO. description name number

1 前网罩 Front Grill 1 14 电器盒盖 Top of the Electric Box 1

2 面 板 Front Plate 1 15 阀座板 Valve installation plate 1

3 轴流风轮 Axial flow fan 1 16 A 机 DN4 截止阀 DN4 valve 1

4 左护网 Left protect net 1 17 A 机 DN10 截止阀 DN10 valve 1

5 电机支架 Motor support 1 18 B 机 DN4 截止阀 DN4 valve 1

6 立 柱 Pillar 1 19 B 机 DN10 截止阀 DN10 valve 1

7 顶盖板 Top panel 1 20 维修板 Maintenance plate 1

8 冷凝器 Condenser 1 21 小抽手 Small handle 2

9 中隔板 Partition board 1 22 干燥过滤器 Desiccation filter 1

10 电器盒 Electric box 1 23 压缩机 Compressor 1

11 四通阀组件 Four-way valve assembly 1 24 油汽分离器 Oil and steam separator 1

12 电子膨胀阀 Electronic expansion valve 2 25 底盘 Base 1

13 右侧板 Right panel 1 26 电 机 Motor 1

53 SERVICE MANUAL FOR AMERICA

Page 54

APPENDIX A

APPENDIX A

INSTALLATION AND OPERATION MANUAL

INSTALLATION MANUAL CMV

54 SERVICE MANUAL FOR AMERICA

Page 55

Foreword

This instruction Manual is the universal-purpose version for the models of separate wall-mounted air

conditioners manufactured by our Co. The appearance of the units that you purchase might be

slightly different from the ones described in the Manual, but it does not affect your proper

operations and usage.

Please read carefully the sections corresponding to the specific model you choose, and keep the

Manual properly so as to facilitate your reference at later time.

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards.

As the installer or service person, it is an important part of your job to install or service the system so it

operates safely and efficiently.

For safe installation and trouble-free operation, you must:

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all danger, warning, and caution notices given in this manual. WARNING:

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or

death.

CAUTION: This symbol refers to a hazard or unsafe practice which can result in personal injury and

the potential for product or property damage.

CONTENTS

LOCATION OF OUTDOOR UNIT 1

ELECTRICAL CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT 3

INSTALLATION/SERVICE TOOLS (ONLY FOR R410A PRODUCT) 7

REFRIGERANT TUBING 9

FINAL TASKS

NOTE: This manual is for Multi split applications only.

For indoor units installation please refer to the

installation manual supplied

55 SERVICE MANUAL FOR AMERICA

11

Page 56

within the indoor unit packa

1 LOCATION OF OUTDOOR UNIT

Select the location considering the following:

OUTDOOR UNIT

1 .The location must allow easy servicing and provide good air circulation as shown in fig2. 2.The

unit may be suspended from a wall by a bracked(Optional)or located in a free standing position on

the floor(preferably slightly elevated).

3.If the unit is suspended , ensure that the bracket is firmly connected and the wall is strong

enough to withstand vibrations.

4.Unit location should not disturb neighbours with noise or exhaust air stream.

5.Place the mounting pads under the unit legs.

6.Refer to figure 2 for allowed installation distances.

Fig 1 Fig 2

Fig 2

56 SERVICE MANUAL FOR AMERICA

Page 57

2 ELECTRICAL CONNECTION BETWEEN

OUTDOOR AND INDOOR UNIT

ELECTRICAL REQUIREMENTS

Electrical wiring and connections should be made by qualified electricians and in accordance with

local electrical codes and r egulation.The air conditioner units m us t be grounded. The air

conditioner units must be connected to an adequate power outlet from a separate branch circuit

protected by a time delay circuit breaker,as specified on unit's nameplate. Voltage should not vary

beyond ± 10% of the rated voltage.

1 .Remove the power supply cable that is connected to the indoor unit!

2.To connect the indoor units to the outdoor units,use the following electrical cabl es .

Electrical connections:

Power input cable: 1 group 3 wiresX2.5mm

cable between indoor and

outdoor units: 1 group 4 wiresX 1.0mm

see Fig 6.7.8.9.10 for detail .

2

2

3.Prepare the cable ends for the power input and for the cables between outdoor and indoor units

as shown in figure 3a and 3b respectively.

4.Connect the cable ends to th e term in al s of the i ndoo r and ou tdoor uni ts , as sh ow i n fig4 , fi gs.

Please select corresponding connection according to the different indoor units. 5.Secure the

multiple wire power cable with the cable clamps.

•Power input cable

57 SERVICE MANUAL FOR AMERICA

Page 58

A

A

3 INSTALLATION/SERVICE TOOLS

(ONLY

CAUTION

New Refrigerant Air Conditioner Installation

This air conditioner adopts the new HFC refrigerant (R410A) which does not destroy ozone layer.

R410A refrigerant is approx . 1.6 times of refigerant R22. Accompanied with the adoption of the

new refrigerant , the refrigeration machine oil has also been changed.

Therefore,during installation work, be sure that water , dust , former refrigerant , or refrigeration

machine oil does not enter into the new type refrigerant R410A air conditioner circuit.The system

must not be left open to the atmosphere for any reason for any period of time as the systems oil

quickly absorbs moisture and will contaminate and damage the system.

A refrigerant liquid line drier is recommended.

To prevent mixing of refrigerant or refrigerating machine oil ,the sizes of conneting sections of

charging port on main unit and installation tools are different from those used for the conventional

refrigerant units. Accordingly,special tools are required for the new refrigerant (R410A) units, For

connecting pipes use new and clean piping materials with high pressure fitting made for R410A

only, so that water and/or dust does not enter.Moreover, do not use the existing piping because

there are some problems with presure fittings and possible impurities in existing piping .

FOR R410A PRODUCT)

Changes in the product and components

In air conditioners using R410A ,in order to prevent any other refrigerant from being accedentally

charged .the service port diameter size of the outdoor unit control valve (3 way valve) has been

changed. (1/2 UFN 20 threads per inch)

• In order to increase the pressure resisting strength of the refrigerant piping ,flare processing

diameter and opposing flare nuts sizes have been changed.( fot copper pipes with nomensions 1/2

and 5/8)

New tools for R410A

Nes tools for R410A Applicable to R22 model

Gauge manifold x

Charge hose x

Electronic balance for

refrigerant charging

Torque wrench

(nominal dia.1/2,5/8)

x

s the working pressure is high ,it is impossible

to measure the working pressure using

conventional gauges . In order to prevent

any other refrigerant from being charged ,

the port diameters have been changed.

In order to increase pessure resisting strength.

hose materials and port sizes have been changed(

to 1 /2 UNF 20 threads per inch).

When puchasing a charge hose,be sure to confirm

the port size.

s working pressure is. high and gasification

speed is fat ,it is difficult to read the indicated

value by means of charging cylinder ,as air

bubbles occur.

The size of opposing flare nuts have been

increased ,incidentally,a common wrench is

used for nominal diameters 1/4 and 3/8.

58 SERVICE MANUAL FOR AMERICA

Chages

Page 59

p

Flare tool

(clutch type)

Gauge for projection

adjustment

Vacuum pump adapter 0

Gas leakage detector x Exclusive for HFC refrigerant

•Incident ally,the "refrigerant cylinder"comes with the refrigerant designation(R410A)and

protector coating in the U.S's ARI specified rose color (Ari color code; PMS 507).

•Also the "charge port and packing for refrigerant cylinder"requires 1/2 UNF 20 theads per inch

corresponding to the charge pOse's port size.

0

_

By incressing the clamp bar'receiving hole

size , strength of spring in the tool has been

improved.

Used when flare is made by using conventional

flare tool.

Connected to conventional vacuum pum p,it is

necessary to use an adapter to prevent vacuum

pump oil from flowing back into the charge

hose ,

The charge hose connecting part has two

ports-one for conventional refrigerant (7/16

UNF 20 theads

er inch )and one for R41 OA ,if

59 SERVICE MANUAL FOR AMERICA

Page 60

4 REFRIGERANT TUBING

CONNECT THE INDOOR TO THE OUTDOOR UNIT

The indoor unit contains a small quantity of nitrogen.Do not unscrew the nu ts from the uni t until you

are ready to

connect the tubing.Th e o utdoor uni t is sup pli ed wit h suffci e nt r efrig eran t ch arge( R41 0A) . Refer to

outdoor unit nameplate.

To prevent crushing,bend tubes using a bending tool.

NOTE:Use refrigeration R410Atype copper tubing only.

1.Open the valve cover.

2.Use tubing diameter that corresponds to the tubing diameter of the indoor and outdoor units. Note

that the liquid an d su c tio n tu b es have different diameters.(See tube size,torqu e tigh tening table.)

3.Place flares nuts on tube en ds b efo re pr eparin g th em with a fl arin g tool .U se th e flar e nu ts that are

mounted on the supplied outdoor and indoor units.

4.Connect the all ends of the tubing to the indoor and outdoor units.Notice the sign . All ends

should correspond one by one.

5.Insulate each tube separa tel y,an d th eir uni on s,wit h at least 6 mm thi ck of ins ula tion . Wrap t he

refrigerant tubing,drain hose and electric cables

together with a vinyl tape (UV protected)

Fig 11

1.INDOOR UNIT

2.Liquid tube(small dia.)

3.Suction tube(large dia.)

4. Plugs

5.Flare nuts

6.Tubing between units

7.Suction tube

8.Liquid tube

9.OUTDOOR UNIT

10.FIare nuts

11 .Suc t ion valve(larg e r ) 12.Li qui d valve(smal )

NOTE:1.For unit use connectionsA,B and D

2.For large indoor unit of 5.0KW Use the lower

connection(unit D) and use the

3/8"-1/2"transition( supplied)

3.The electric control channel must match the

tube channel.

Caution!

When unscrewing the

valve caps, do not stand

in front of them or the

spindles at any time,as

the system is under

pressure.

60 SERVICE MANUAL FOR AMERICA

Page 61

Tightening torques

of unions and

valve caops:

TUBE SIZE TORQUE

Liquid line 1/4" 1 5 -20 N.M.

Suction line 3/8" 30-35 N.M.

Suction line 1/2" 50-54 N.M.

Suction line 5/8" 75-78 N.M.

Fig 13 To prevent refrigerant

leakage,coat the flared

surface with

refrigeration oil

Fig 14 1.Suction

valve 2.Service port

3.Liquid valve

EVACUATION OF THE REFRIGERATION TUBES AND THE INDOOR UNIT

After connecting the unions of the indoor and outdoor units,evacuate the air from the tubes and

indoor unit as follows:

1.Connect the charging hoses with a push pin to the low and high sides of the charging set and the

service ports of the suction and liquid valves.

Be sure to connect the end of the charging hose with the push pin to the service ports.

2.Connect the center hose of the charging set to a vacuum pump.

3.Open Fully the low and high pressure sides of the manifold gauge valves.

4.Turn on the vacuum pump.Perform evacuating for at least 30 minutes and than confirm that the

needle in the gauge moves from 0 MPa(Ocm Hg) t0-0.1 MPa(-76cm Hg).

5.Close the valves of the low and high sides of the charging set and turn off the vacuum pump. After

few minutes,if the gauge needle has moved,there is a leak which must be found and repaired

before moving to the next stage.

6.Disconnect the charging hose from the vacuum pump and from the service ports of the suction and

liquid valves.

7.Tighten the service port caps of suction and liquid valves.

8.Remove the valve caps from all valves,and open them using a hexagonal Allen wrench,

9.Securely tighten the caps onto all of the valves.

10.Check for gas leaks from all the connecting position.Test with electronic leak detector or with a

sponge immersed in soapy water for bubbles.

61 SERVICE MANUAL FOR AMERICA

Page 62

1 .Charging set 5.Cap 9.Liquid valve

2.Vacuum pump 6.Suction valve 10.INDOOR UNIT

3.OUTDOOR UNI T 7.Service valve 1 1.Suction flare connection