Page 1

1

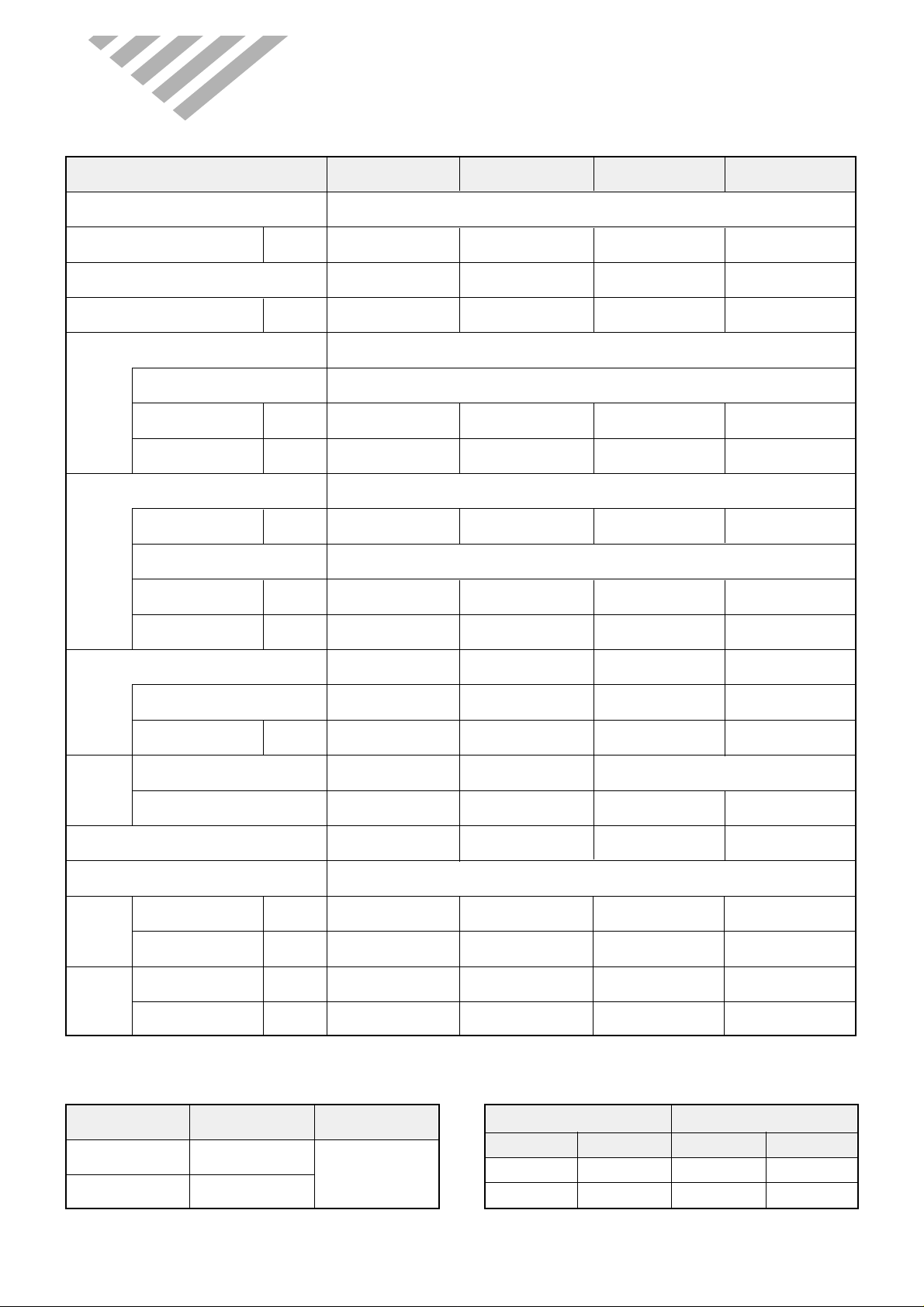

1. SPECIFIC A TIONS

ITEM TAS-12 TAS-15 TAS-18 TAS-24

Function Cooling

Capacity BTU/H 11500 15000 18000 22000

SEER 10.6 10.3 10.3 10.0

Dehuminication L/H 1.5 1.8 2.5 3.0

Electrical Data

Main Power

Running Current A 4.5 6.4 7.5 9.5

Watts W 1010 1420 1060 2110

Refrigerant R-22

Quantity OZ 35.3 (1000g) 40.5 (1150g) 42.3 (1200g) 63.5 (1800g)

Connection Flare

Gas Side inch 3/8" (9.52mm) 1/2" (12.7mm) 1/2" (12.7mm) 5/8" (15.9mm)

Liquid Side inch 1/4" (6.35mm) 1/4" (6.35mm) 1/4" (6.35mm) 3/8" (9.52mm)

Compressor QK164KBD RCA155U001 RCA180U001 QP325KBB

O.L.P MRA 98996-12026 MRA 12013-696 MRA 12138-696 Internal

LRA A 24 39 42 68

Motor Indoor FDA353DWA FDA353DWB FDA353DWC

Outdoor YDK-50-6B1 YDK-50-6B1 YDK-50-6B1 A2929GS010

Capacitor Dual 3/30µF 400VAC 3/30µF 400VAC 3/35µF 400VAC 5/40µF 400VAC

Dimension

Indoor W x H x D mm 815x285x195 1035x322x205 1080x298x200 1080°ø298°ø200

Weight (net) lb 20.3 (9.2kg) 26.7 (12.1kg) 32.4 (14.7kg) 32.4 (14.7kg)

Outdoor

W x H x D mm 800x615x320 800x615x320 800x615x320 872x675x325

Weight (net) lb 110.3 (50kg) 110.3 (50kg) 110.3 (50kg) 141.1 (64kg)

Unit conversion : 1 inch = 25.4 mm

AC 208/230V~ , 60Hz , 1 Ph

Indoor Temp Outdoor Temp Indoor Humidity

65~90°F 70~109°F Less than 80%

(18~32°C) (21~43°C)

❃ The Ranges of Temperature And Humidity.

Indoor Outdoor

DB WB DB WB

80°F 67°F 94°F 75°F

(26.7°C) (19.4°C) (35.0°C) (23.9°C)

❃ Standard Rating Condition

Page 2

No Part Name Q'ty Remark No Part Name Q'ty Remark

1 Installation Plate 1 6 Battery 2

2 Remote Controller 1 7 Nail 4

3 Remote Holder 1 8 Screw 4

4 Deodorizing Filter 1 9 Outdoor Cover 1

5 Electrostatic Filter 1 10 Foot Cushion 4

2

BASIC ACCESSORIES

2. INST ALLA TION

This Installation section explains how and where to connect this new air conditioner. Please read make sure all accessories are included as shown below and read manual thoroughly. This Installation section is provided to assist the person knowledgeable in air conditioner installation and should not be installed by anybody who is not thoroughly familiar

with this type of installation. Please contact a professional installer if necessary.

ACCESSORIES SUPPLIED WITH THE UNIT:

9

0

AUTO

(24 Series Only)

Page 3

3

OPTIONAL ACCESSORIES

ACCESSORIES NOT SUPPLIED WITH THE UNIT :

No Part Name Q'ty Description Remark

1 Drain Hose Extension 1 PVC, 20mm x 2M

2 Tape Finish 1 PVC, W80mm x 25M

3 Insulator Plate 1 PE, T8.0

4 Putty 1 Gray, 80g

5 Wall Cap 1 HIPS,

6 Bracket Saddle 2 SCT, T0.8 24 Series Only

7 Cable Tie 2 DACT-190A 24 Series Only

1234

567

Page 4

4

INSTRUCTION OF INSTALLATION

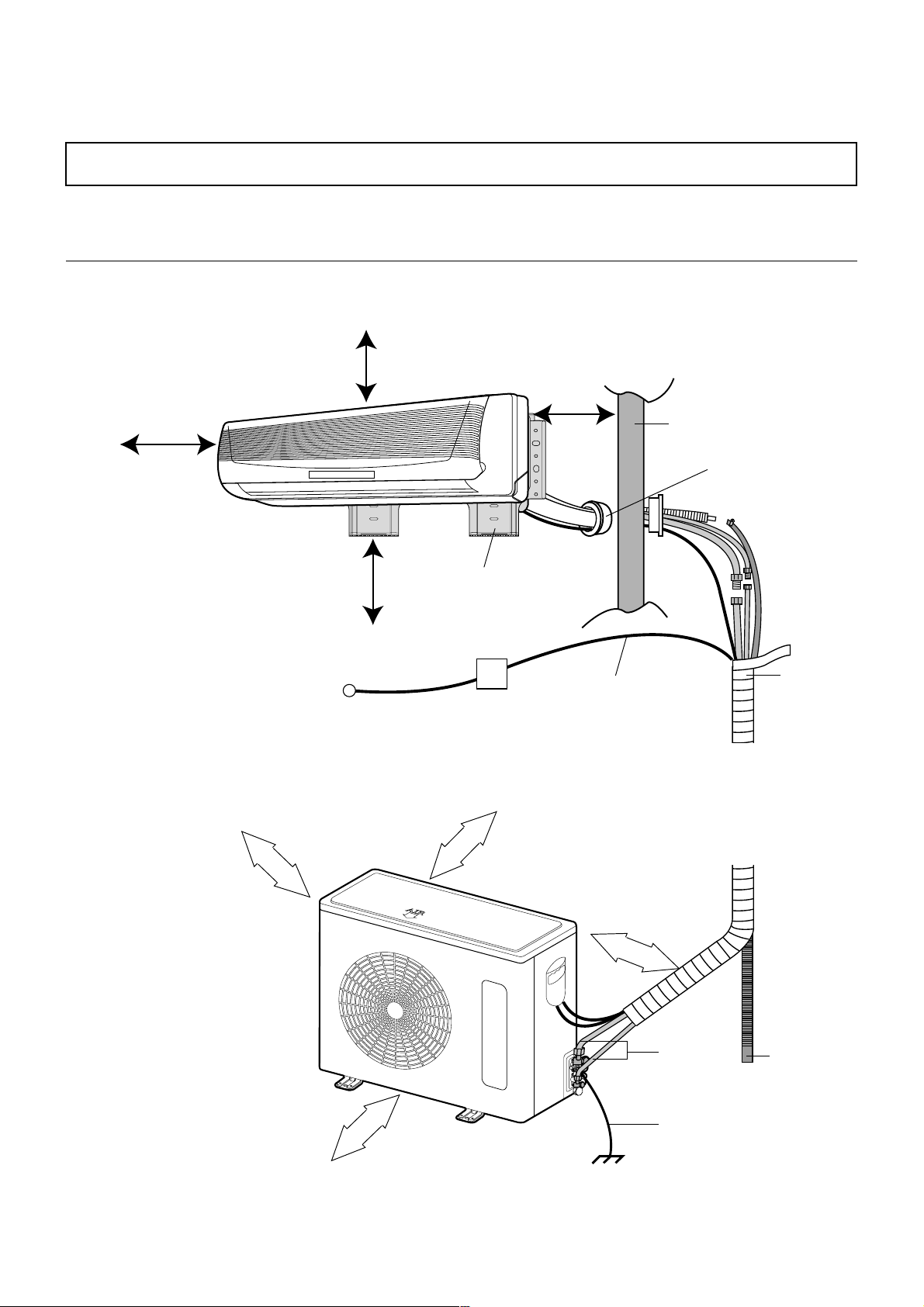

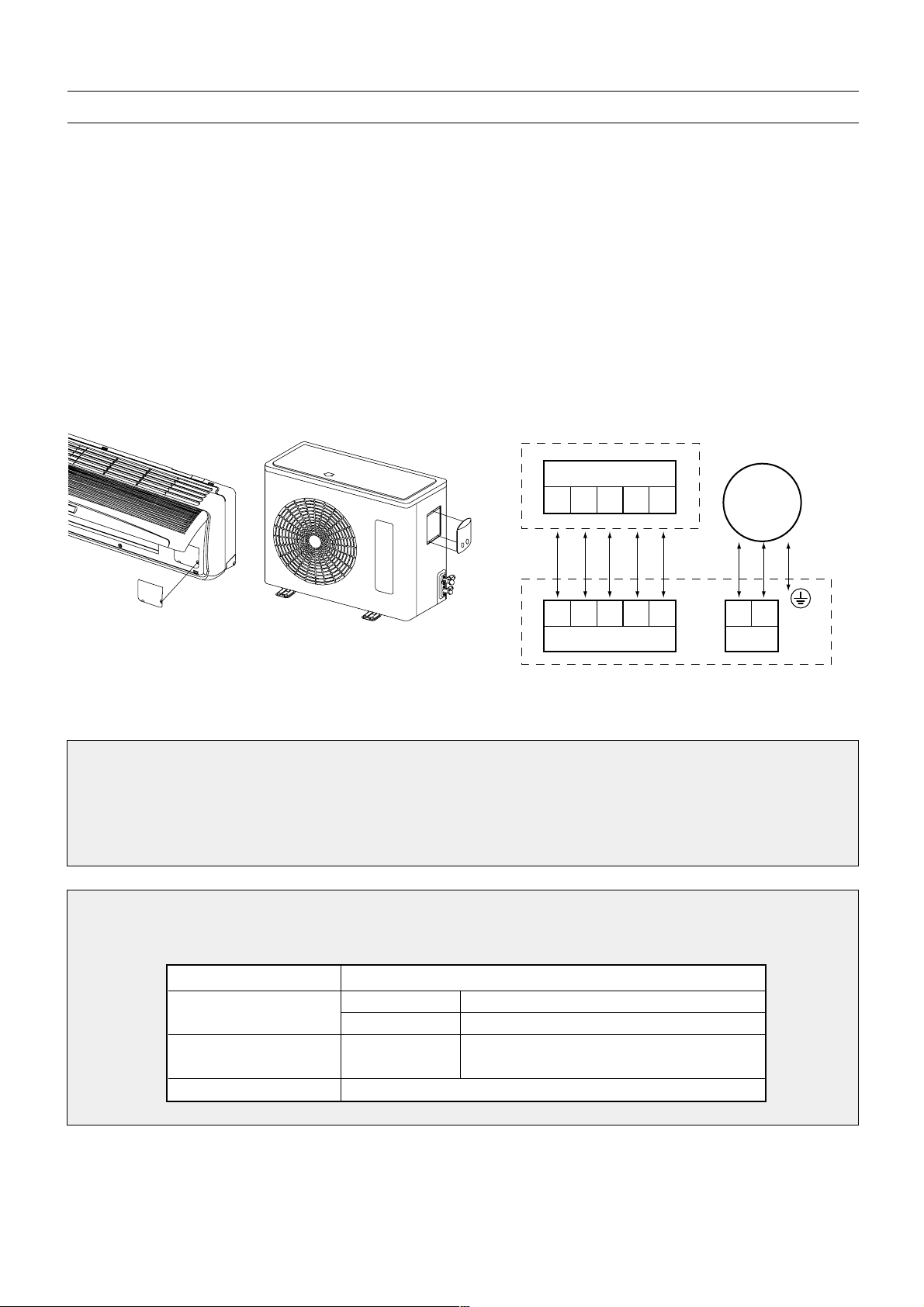

Below is an overview for the connection of the Indoor unit to the Outdoor unit.

O VERVIEW

This appliance must be installed according to national power supply acquirement.

10cm (3.95in)

from ceiling

10cm (3.95in) from

side wall

30cm (11.8in) from

side wall

Wall

Wall Cap

At least 30cm

(11.8in) from unit

10

cm

more than

4 inch

Power

Source

more than

4 inch

Installation Plate

Circuit Breaker

10

cm

Adding additonal tubing will decrease efficiency.

Power cable

Maximum Height 7M (21Ft)

Maximum Length 15M (49Ft)

Standard Length: 25ft (7.6m)

Adding Refrigerant: 0.32 oz/ft (30g/m)

more than

27 inch

70

cm

Wrap with

Tape

cm

60

more than

24 inch

Copper

Tubing

(Not Supplied)

Ground Wire

(Not Supplied)

Drain

Hose

Page 5

5

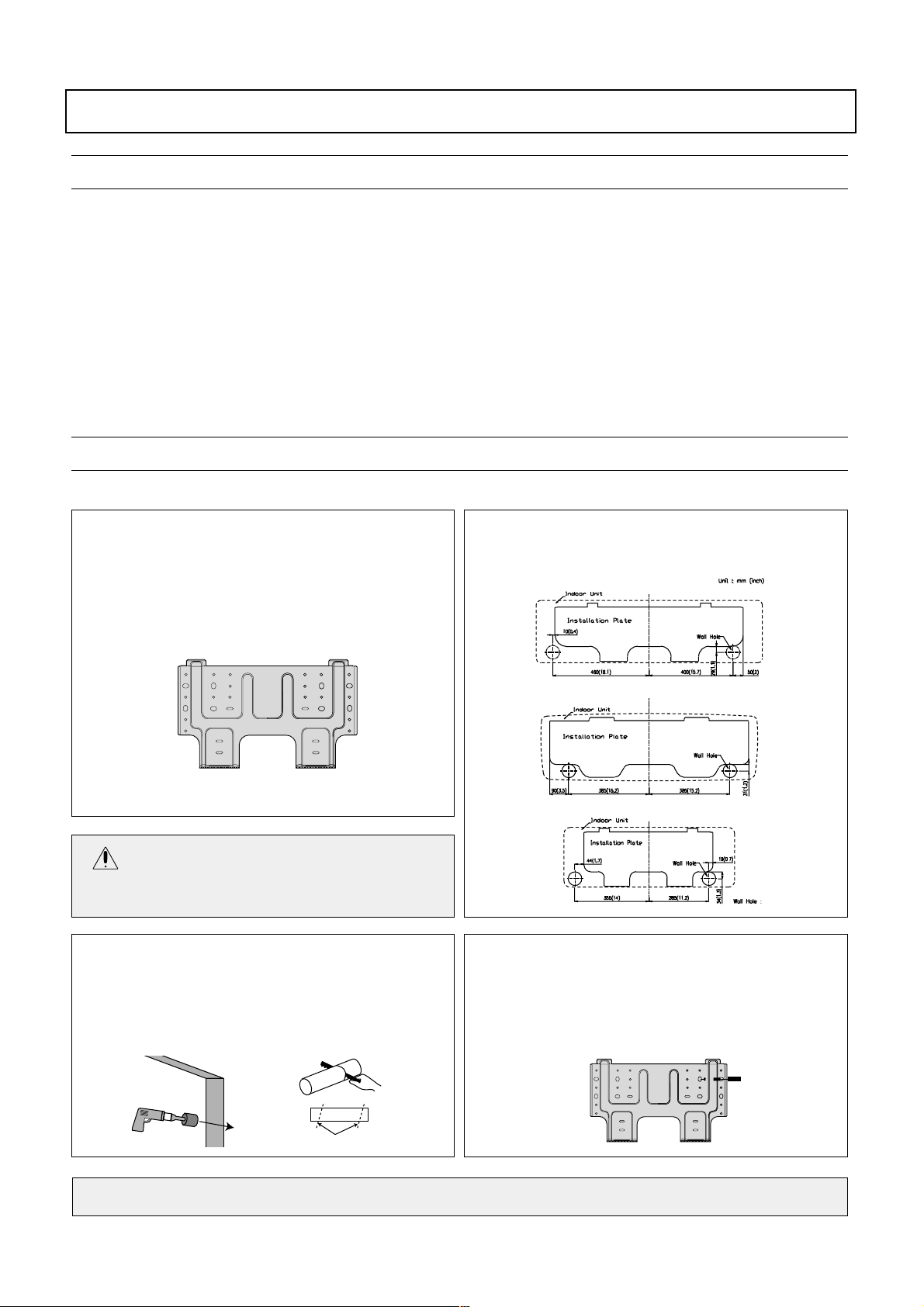

INSTALLATION

1. Determine the type of wall (sheetrock, concrete, etc.)

and make sure it is strong enough to hold indoor unit.

Select an approximate position for the unit, taking the

required distances away from walls/AC outlet into

consideration.

INDOOR UNIT

• Do not install the unit in an area with direct sunlight, near

heat sources (radiator, etc.), or an area where leakage of

flammable gas may be expected.

• Select a position in the room, high on the wall, where the

whole room can be uniformly cooled.

• Select a location that can hold the weight of the unit and

where the copper tubing, drain hose and Indoor to Outdoor

Wire have the shortest distance to the Outdoor unit.

• Make sure the Indoor unit is installed at least 10cm (3.95in)

away from the top and left side wall and at least 30cm

(11.8in) from AC outlet and right side wall.

OUTDOOR UNIT

• Do not install the unit in an area near heat sources,

exhaust fans, or an area where leakage of flammable gas

may be expected.

• Do not install the unit in a humid, damp or uneven location.

• Select a location that is well ventilated .

• Leave enough room around the unit for air intake, exhaust

and possible maintenance.

2. Determine if the hole is to be made at the left or right

hole location.

3. Using drill with hole-cutting attachment or equivalent, cut

a hole 70mm (2.75") in diameter. The hole should be

made at a slight downward slant to the outdoor side.

Measure the thickness from the inside to outside edges

and cut a PVC pipe at a slight angle 1/4" shorter than the

thickness of the wall and insert pipe in wall.

4. For sheetrock, wooden or similar wall, measure down

from the ceiling using a level or tape measure and attach

the wall bracket to the wall using 4 screws. If you are not

able to line up the holes with the beams, use toggle

bolts. Make sure the wall bracket is even and flush

against the wall.

Indoor Outdoor

Cut at slight angle

CAUTION

• Before making hole, make sure there are no studs, pipes,

electrical wiring or conduit directly behind the area to be cut.

For Concrete, or similar type wall, make holes into the wall and insert concrete nails instead of screws.

INST ALLING THE INSTALLATION PLATE

To install the wall bracket, follow the procedures below. One hole is required for the tubing and may be either on the left or right side.

SELECTING A SITE:

• TAS-18/24

• TAS-15

• TAS-12

70(2.75)

Page 6

6

2. Make sure the drain hose and copper tubing are

wrapped with the rubber insulation. Using the tape,

wrap the indoor/outdoor wire, copper tubing and drain

hose together.

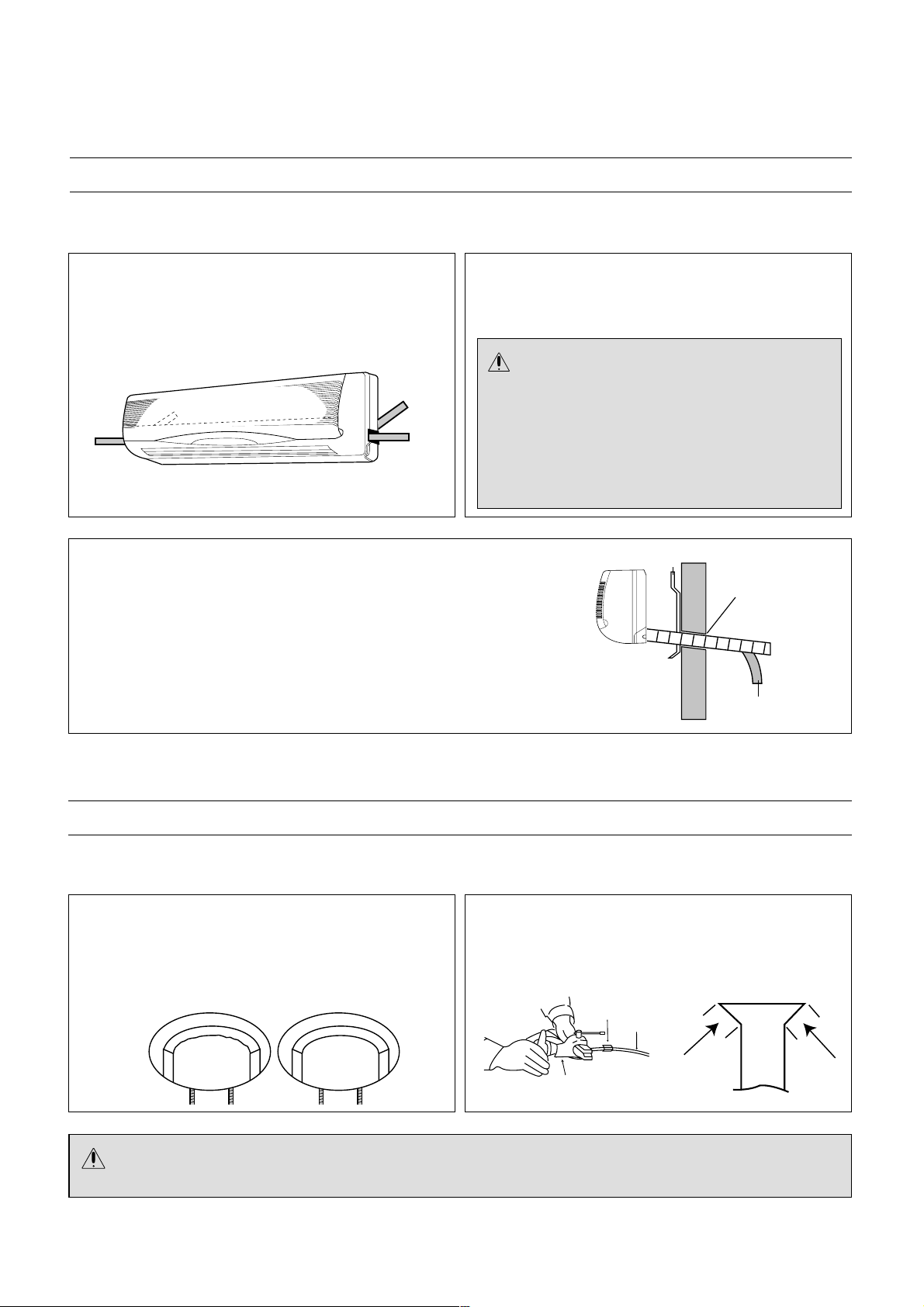

MOUNTING THE INDOOR UNIT

The Indoor unit must be mounted before connecting the indoor/outdoor wire, drain hose and copper tubing. To mount,

follow the procedures below:

1. The tubing can be extended in 4 directions as shown

below. No cutting is necessary for left/rear and

right/rear tubing connections. If using left or right tubing connections, remove the plastic area with a hacksaw so pipes can go through.

Left

Tubing

Right

Tubing

Left/Rear

Tubing

Right/Rear

Tubing

CAUTION:

• Make sure the Indoor unit’s AC cord is not connect-

ed to AC power when performing these procedures.

• Be sure to comply with local codes on running a wire

from the indoor to the outdoor unit.

• DO NOT LET THE INDOOR/OUTDOOR WIRE

COME IN DIRECT CONTACT WITH THE TUBING

OR HOSE!

3. Shape the tubing so it can easily go through the hole

in the wall. Push the indoor/outdoor wire, copper tubing and drain hose through the hole in the wall angling

downward. Situate the indoor unit on the wall bracket

by lifting the indoor unit slightly above the wall bracket

and then down so it is securely locked in place.

Installation Plate

Insert Putty

Drain Hose

CAUTION:

• When using the tube reamer, hold the tube downward and make sure no copper scraps fall into the tubing.

2. Make a flare at the end of the copper tube with a flare

tool.

Make sure the inside surface and edges are smooth

and the sides are uniform length.

1. Cut the copper tube extension to the desired length

with a tube cutter. It is highly recommended that 1 foot

is added to the requested length. After cutting, deburring may be necessary (see below diagram). Perform

this with a tube reamer.

BEFORE AFTER

PREPARING THE COPPER TUBING (NOT INCLUDED)

A copper tubing extension (not included) may need to be cut. If this is the case, it will also have to be deburred and

flared as shown below:

Flare tool

Flare nut

Connection

pipe

Page 7

7

1. Remove the flare nut stoppers from the inside unit.

Determine the location of the copper tubing and

where the bends will be. Gently bend the copper tubing, making sure to use big angles so no crimping will

occur. Try to do this on the first try as repeated bending may break or crimp the tubing.

2. Remove the plastic stoppers from the tubing. Connect

the large and small copper tubing to the respective

extension and rotate the flare nut with your finger until

a smooth match is made. Make sure the copper

extension has foam rubber (insulation) on it.

Flare Nutcoupler

CONNECTING THE COPPER TUBES

To connect the copper tubes, follow the procedures below:

NOTE:

When removing the flare nut stopper from the inside unit, confirm “Ping”, sounds because the mixed gas is charged in

the inside unit,

3. Once a smooth match is made, tighten the flare nut

using a wrench. Be very careful not to strip the

threads or flare nut. Repeat this process for the small

and large tubing. When tightening the flare nut, use

another wrench to securely hold the coupler from

twisting and possibly damaging the tubing.

4. Remove the flare nut stoppers from the outdoor unit’s

valves. Connect the larger copper tubing to the larger

valve on the outdoor unit. Connect the smaller copper

tubing to the smaller valve on the outdoor unit.

5. Perform a leak test on all copper tube connections. To

prevent heat loss and damage to walls from condensation, the copper tube connections coming from the

wall must be insulated. Do this by wrapping foam rubber or equivalent around the connection approximately 8mm thick so no copper tubing is exposed.

NOTES:

• As with all wiring and hookups on this unit, make sure

the AC plug on the indoor unit is unplugged.

• Be very careful not to strip the threads or flare nut.

• When insulating the connections, use foam rubber or

equivalent.

1. Connect the drain hose extension to the drain hose

coming from the indoor unit by loosing the clamp on

the extension using a phillips screwdriver, attaching

the hoses together and then tightening the clamp.

2. Run the drain hose, slanted downward, outside. If the

drain pipe is exposed

indoors, make sure it is

thoroughly insulated so

condensation does not

ruin walls or furniture or

come in contact with the

AC connection or extension. Also, do not crease

or form a trap in the tubing.

Insert Putty

Drain Hose

CONNECTING THE DRAIN HOSE

To connect the drain hose, follow the procedures below:

Page 8

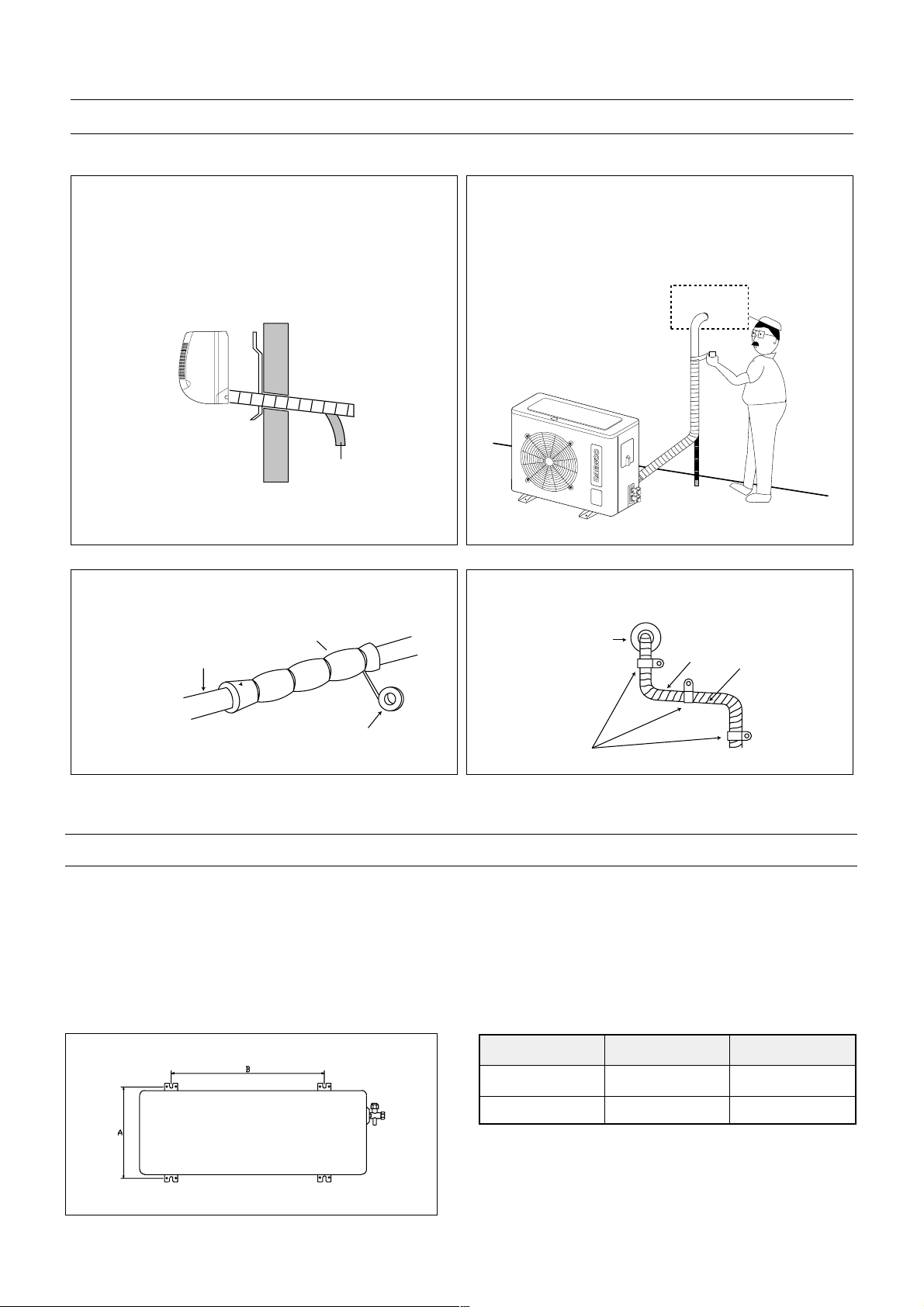

CONNECTING THE CABLES

One electric power cable must be connected to the outdoor unit. The indoor unit is connected to outdoor unit through the

connection cable. To install the cables follow as below.

1. Open the connection cover on the indoor unit.

2. Open the SVC cover on the side of outdoor unit.

3. Connect the connection cable to terminal blocks of the indoor and outdoor unit as shown below.

- Must be connected with the same terminal number of indoor and outdoor unit.

- Be sure not to slip the cables out of terminal.

4. Connect the power cable and earth cable.

5. Reinstall the connection cover and the SVC cover.

6. Install the conduit kit. (The conduit kit is optional)

[Connetion Cable]

Indoor Unit

Terminal Block

1

2 3 4 5

Circuit breaker

(Main Power)

1

Terminal Block

Outdoor Unit

CAUTION

• The supply voltage must be the same as the rated voltage of air conditioner.

• Prepare the power source for exclusive use with the air conditioner.

• A circuit breaker must be installed between the power source and the unit.

• This air conditioner must be installed according to the national electric rules.

INFORMATION

• The information for the cables of this air conditioner is as below.

ITEM SPECIFICATIONS

POWER CABLE

CONNECTION CABLE 12K~24K BTU/h

CONDUIT SIZE 0.875 inch (22.2mm)

12K~15K BTU/h 3G AWG 14 SJT or SPT-3

18K~24K BTU/h 3G AWG 12 SJT or SPT-3

5G AWG 16~18 SJT

3G AWG 18~20 SJT+2G AWG 16~18 SJT

2 3 4 5 1

2

T/B 2

8

Page 9

9

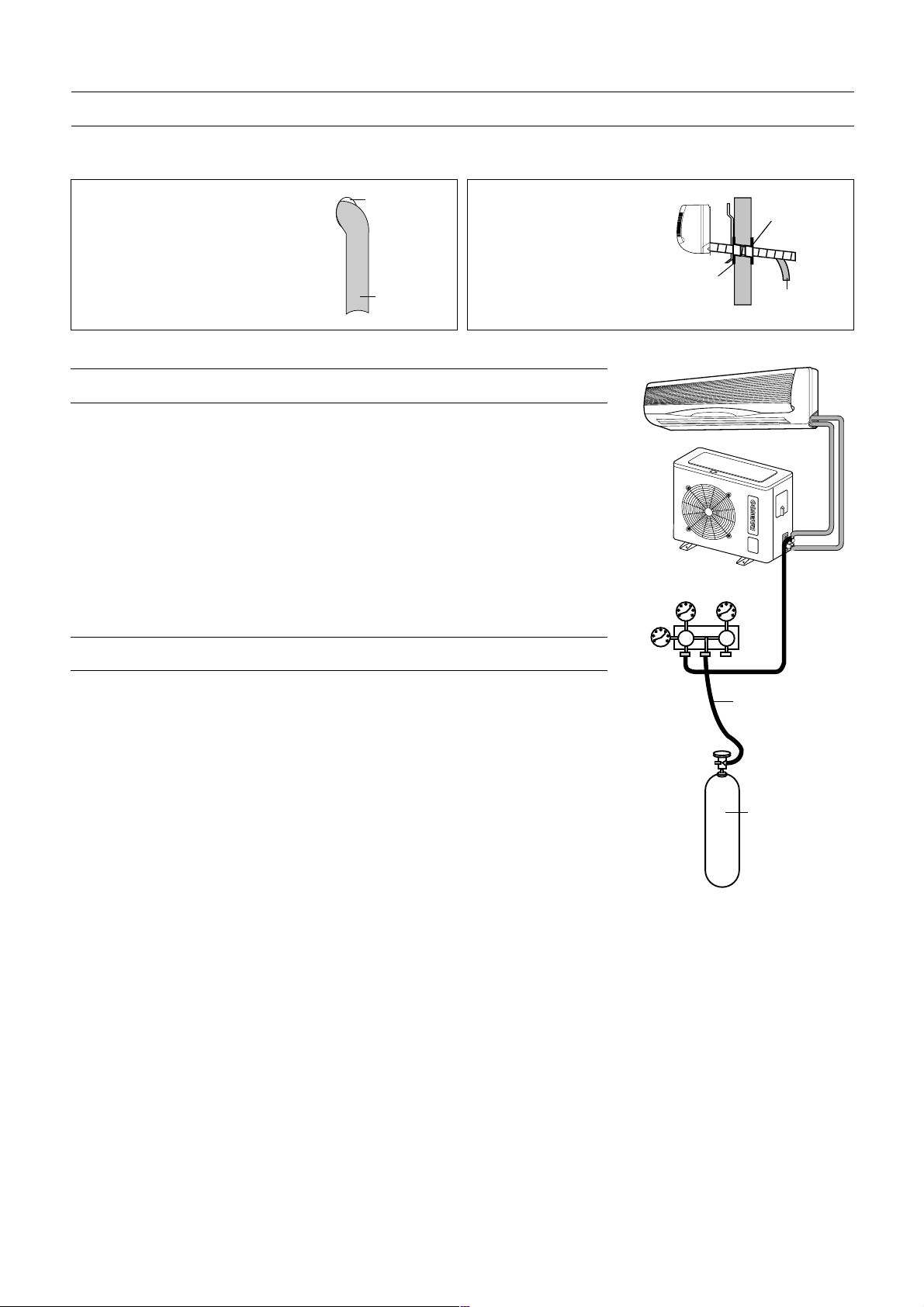

TAPING UP THE WIRE/TUBES/HOSE

MOUNTING OUTDOOR UNIT

1. After selection the appropriate site, position the outdoor unit and make sure the space around the outdoor unit.

(See overview instruction of installation)

2. Mount the outdoor unit on appropriate base using anchor bolts.

3. Install the CUSHION RUBBER provided to prevent vibration and noise.

4. If the outdoor unit is expose to direct sunlight or strong wind, install shield around the outdoor units.

❈ The outdoor unit must be installed on stable and rigid base.

Model A B

TAS-12/15/18 360 580

TAS-24 350 550

After running the wire, hose and tubing outside, tape them up as shown below to insulate.

1. Tape the two copper tubes, drain hose (and the

electrical wiring if local codes permit) together with

the supplied tape. Make sure the electrical wiring

does not come in direct contact with the copper tubing or drain hose. Approximately 1 foot outside the

hole, let the drain hose out and separate from the

copper tubing and wiring.

Drain hose

3. Wrap the piping joints with the

insulator plate and fas

ten it with vinyl tape.

pipe

Plate

2. Begin wrapping from the point the tubing comes out of

the outdoor unit and continue to the hole in the wall.

Leave no gaps or breaks and cover the entire length

of the tubing. As you wrap, overlap the previous turn

by half the width of the tape.

4.

After wrapping the connection pipe with tape,

fasten it to the outside wall with saddles, etc.

Wall cap

Pipe

Tape

vinyl tape

Saddle

(Not supplied)

Page 10

10

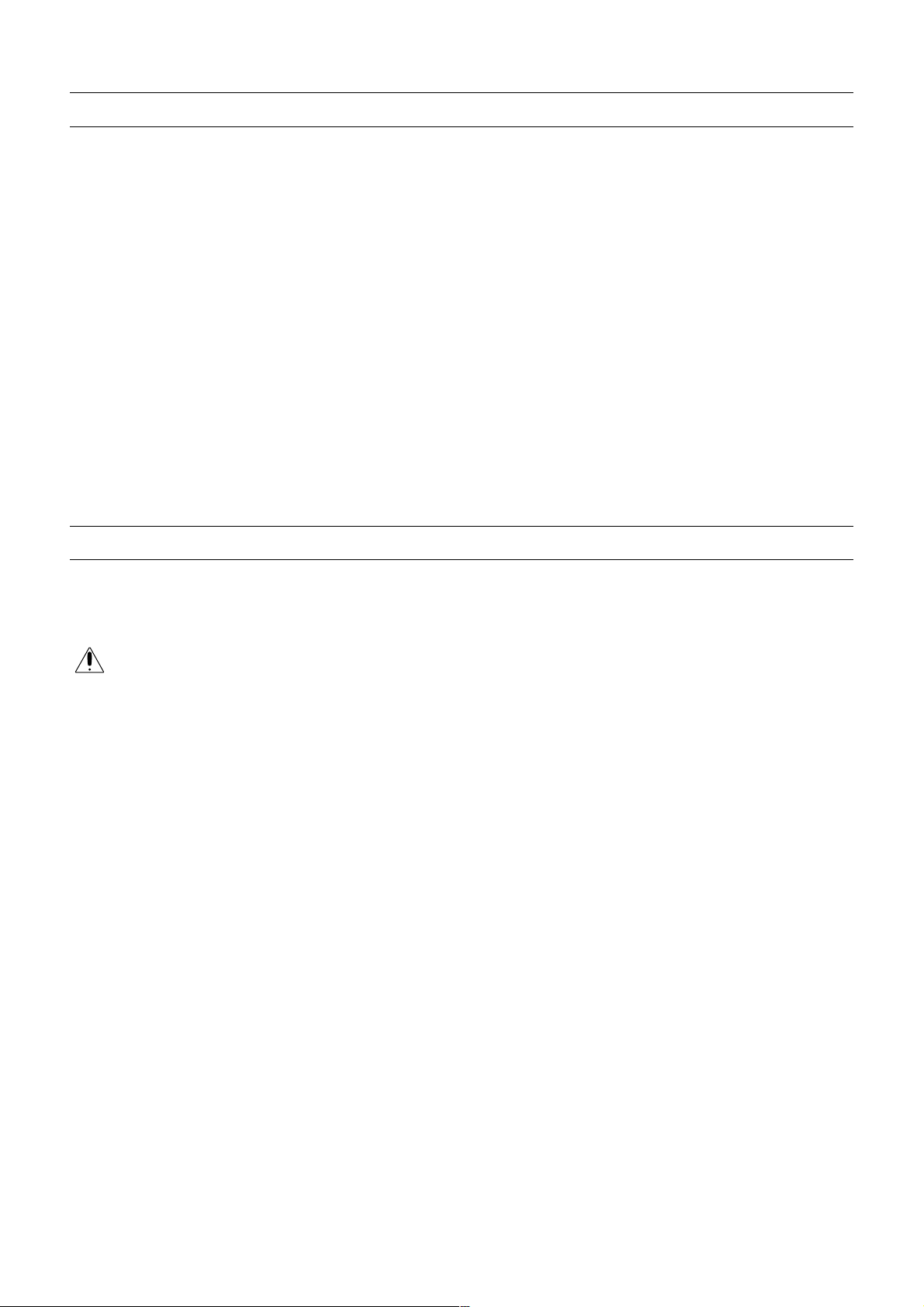

AIR PURGING

Air and moisture remaining in the refrigerant system may create adverse conditions

as indicated below:

• pressure in the system rises

• operating current rises

• cooling efficiency drops

• moisture in the refrigerant circuit may freeze and block capillary tubing

• water may lead to corrosion of parts in the refrigerant system

Therefore, the indoor unit and tubing between the indoor and outdoor unit must

AIR PURGING WITH VACUUM PUMP (TEST RUN)

Remove the valve caps from the wide and narrow service valves on the

outdoor unit. Note that both narrow and wide tube service valves on the outdoor

unit are kept closed at this stage (shipping position).

Leak Test

(Save for reuse.)

CA UTION:

Be sure to use a manifold valve for air purging. If it is not avail able, use a stop valve for this purpose.

The “Hi” knob of the manifold valve must always be kept closed.

3. Pressurize the system to no more than 150 P.S.I.G. with dry nitrogen gas and close the cylinder valve when the

gauge reading reaches 150 P.S.I.G. Next, test for leaks with liquid soap.

CA UTION:

To avoid nitrogen entering the refrigerant system in a liquid

state, the top of the nitrogen gas cylinder must be higher than its bottom when you pressurize the system. Usually, the

cylinder is used in a vertical standing position.

4. Do a leak test of all joints of the tubing (both indoor and outdoor) and both wide and narrow service valves. Bubbles

indicate a leak. Be sure to wipe off the soap with a clean cloth.

5. After the system is found to be free of leaks, relieve the nitrogen pressure by loosening the charge hose connector at

the nitrogen cylinder. When the system pressure is reduced to normal, disconnect the hose from the cylinder.

Lo Hi

Pressure

Gauge

Manifold Valve

Outdoor Unit

Indoor Unit

Charge Hose

Nitrogen Gas

Cylinder

(Vertical

Position)

1. Apply the putty to any area

on the outside hole that air

or rain can get into.

Apply Putty

Here

Tubing

2. After applying putty,

insert the wall Cap at

Indoor side

and Outdoor side.

Insert Putty

Wall Cap

(For DS-110R)

Drain Hose

APPLYING PUTTY AND INSERTING THE WALL CAP

After running the wires and tubing outside, putty should be inserted around the opening on the outside to protect against

rain, wind, etc. To apply putty, see below:

Indoor side Wall

Outdoor side

be leak tested and evacuated to remove any noncondesables and moisture from

the system.

Confirm each tube (narrow and wide tubes) between the indoor and outdoor units

has been properly connected and all wiring for the test run has been completed.

1. With the service valves on the outdoor unit remaining closed, remove the

threaded cover on the wide tube service port.

2. Attach a manifold valve (with pressure gauge) and dry nitro gen gas cylinder

to this service port with charge hoses.

Page 11

11

Evacuation

1. Attach the charge hose end described in the leak test

area to a vacuum pump to evacuate the tubing and

indoor unit. Confirm the Lo knob of the manifold valve is

open. Then, run the vacuum pump. The operation time

for evacuation varies with the tubing length and capacity

of the pump. The following table shows the amount of

time for evacuation:

2. When the desired vacuum is reached, close the Lo knob

of the manifold valve and stop the vacuum pump.

Finishing the job

1. With a hex wrench, turn the narrow tube service valve

stem counter-clockwise to fully open the valve.

2. Turn the wide tube service valve stem counter-clockwise

to fully open the valve.

CA UTION:

To avoid gas from leaking when removing the charge hose,

make sure the wide tube service valve is fully open and

turned all the way out.

3. Loosen the charge hose connected to the wide tube ser-

vice port slightly to release the pressure, then remove the

hose.

4. Replace the threaded cover on the wide tube service port

and fasten it securely. This process is very important to

prevent gas from leaking from the system.

5. Replace the valve caps at both wide and narrow service

valves and fasten them securely.

This completes air purging with a vacuum pump. The air

conditioner is now ready to test run..

Lo Hi

Pressure

Gauge

Manifold Valve

Outdoor Unit

Indoor Unit

Charge Hose

Vacuum

Pump

If tubing length is less than

33 ft. (10 m)

10 min. or more

If tubing length is longer than

33 ft. (10 m)

15 min. or more

Required time for evacuation when 30 gal/h vacuum

pump is used

Page 12

12

TEST RUN

Check that all tubing and wiring have been completed correctly. Check again that the wide and narrow tube service

valves are fully opened. Turn on the power and run the system.

Service Valve Construction

• Valve Position Closed

The valve systems of both the wide and narrow tubes are turned all the way in. The unit is shipped from the factory in

this position and it is also used for Pump Down and Air Purging.

• Valve Position Fully Open

The valve stems of both the wide and narrow tubes are turned all the way out. This is normal operating and Test Run

position.

• Valve Position Half Open

With the narrow tube valve stem is turned to the halfway-down position. This position is used for pressure measurement and gas charging.

CAUTION:

When opening or closing the service valve stem, be sure to use a hex wrench.

PUMP DOWN

Pump Down means collecting all refrigerant in the outdoor unit without loss in refrigerant gas.

This is performed when the unit is to be relocated or the refrigerant circuit is serviced.

CAUTION:

Be sure to perform Pump Down procedure with the unit cooling mode.

Pump Down Procedure

1. Connect a low-pressure gauge manifold hose to the charge port on the wide tube service valve.

2. Open the wide tube service valve halfway and purge the air from the manifold hose using the refrigerant gas.

3. Close the narrow tube service valve (all the way in).

4. Turn on the unit s operating switch and start the cooling operation.

5. When the low-pressure gauge reading becomes 1 to 0.5 kg/cm2 (14.2 to 7.1 psi), fully close the wide tube valve stem

and then quickly turn off the unit. At that time, Pump Down has been completed and all refrigerant gas will have been

collected in the outdoor unit.

Page 13

13

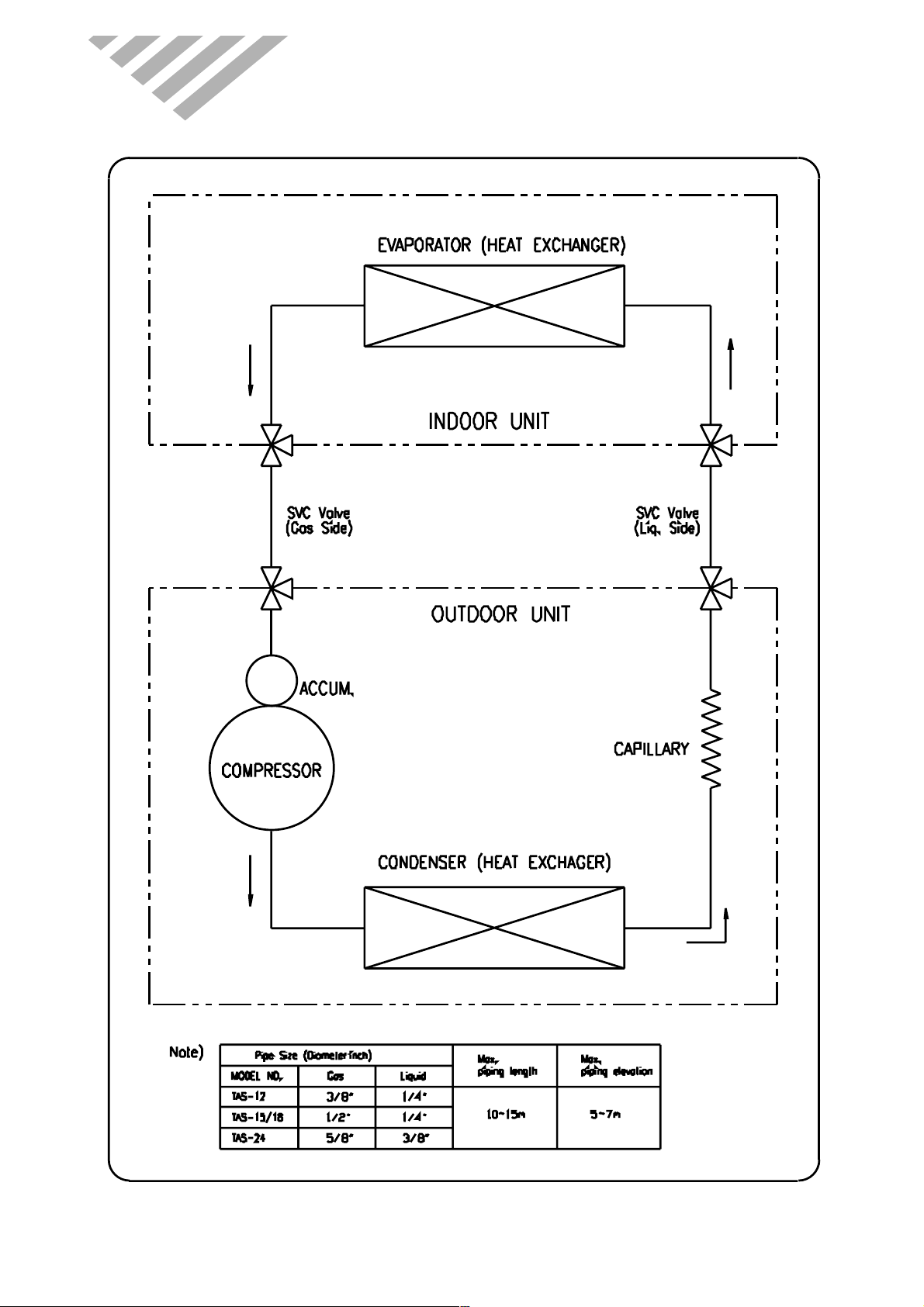

3. REFRIGERANT CYCLE DIA GRAM

Page 14

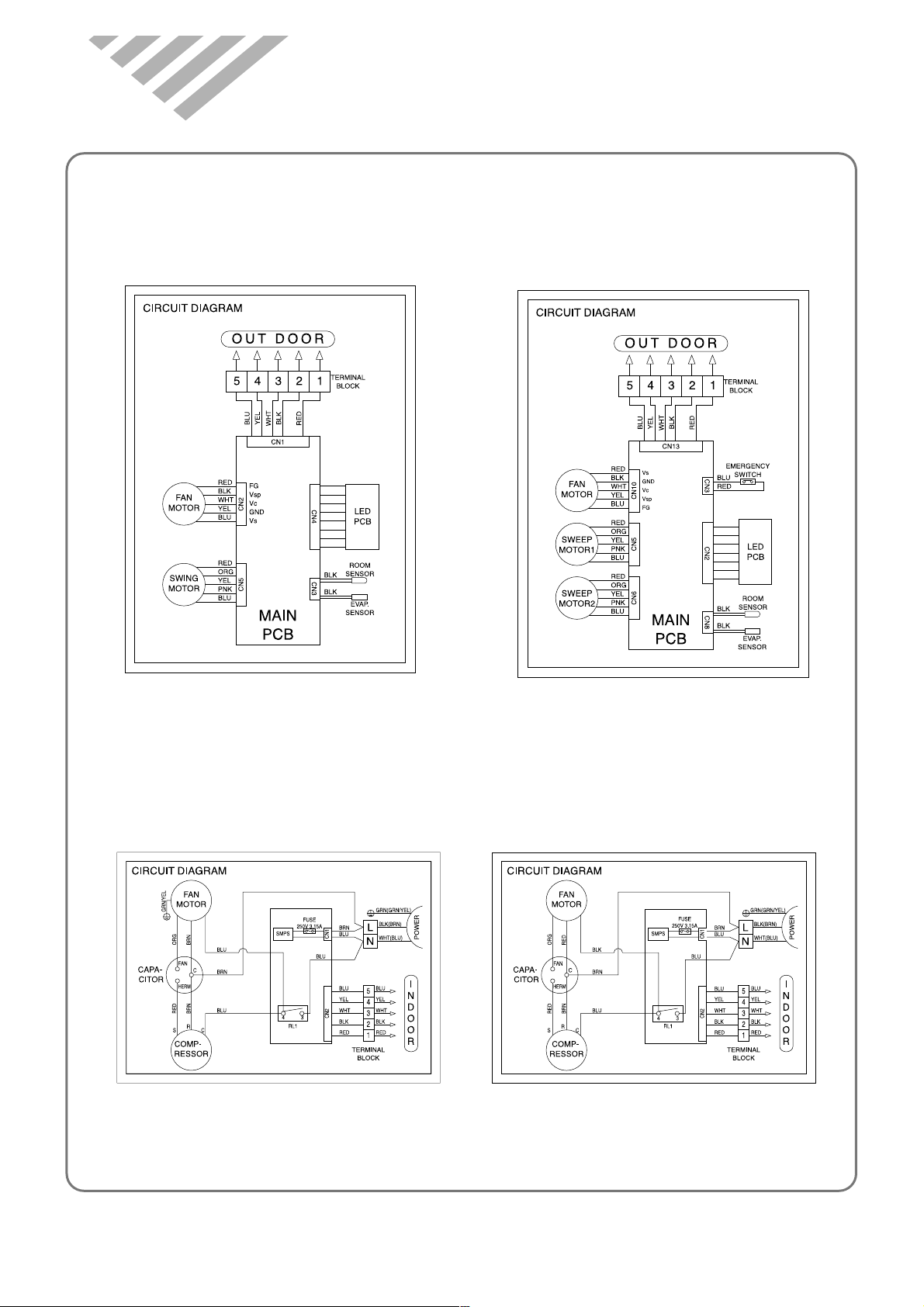

14

4. WIRING DIA GRAM

• Indoor Unit

◆ TAS-12/18/24 ◆ TAS-15

• Outdoor Unit

◆ TAS-12/15/18 ◆ TAS-24

Page 15

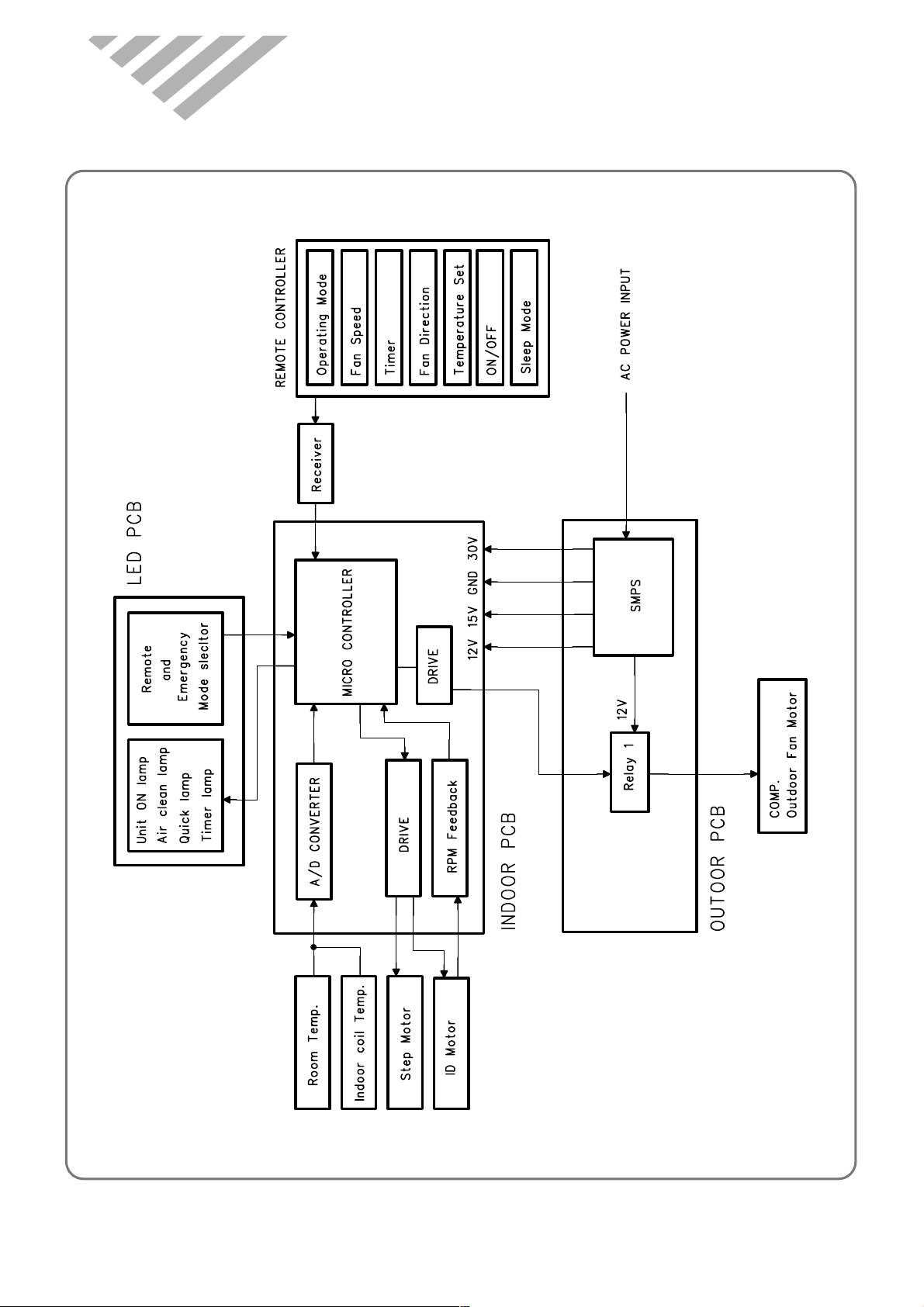

15

5. CONTROL BLOCK DIA GRAM

Page 16

16

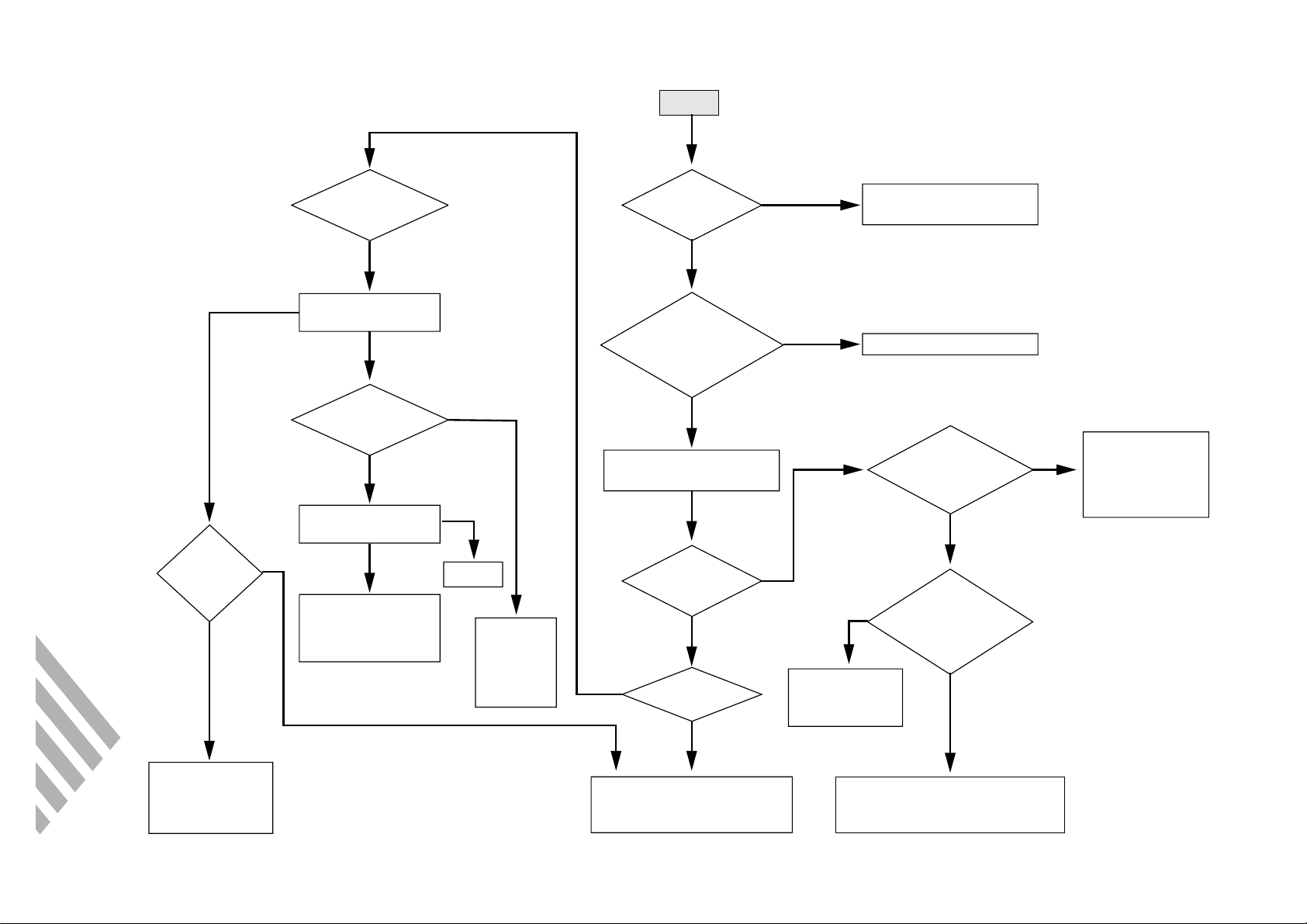

6. TROUBLE SHOOTING

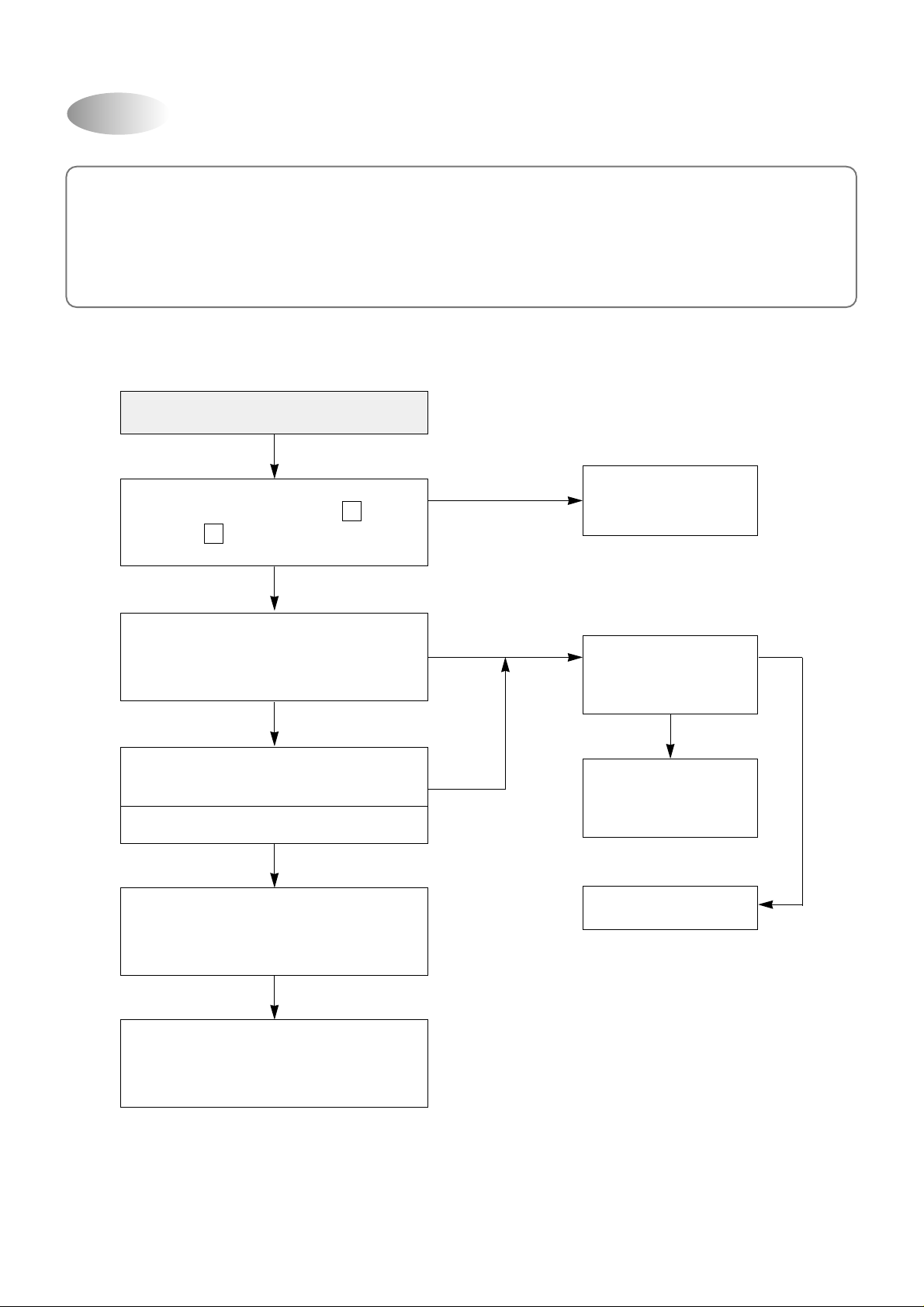

Outdoor unit does

not run?

Does

the compressor run

normally?

Indoor unit does

not run

Check the failure

code according to

the self diagnostic

Is the unit

display

mormal?

check the failure

code according to

the self-diagonostic

Normal

check the

connecting

point of

magnetic

contactor

YES

YES

YES

YES

NO

NO

YES

Is the power

applied to the

unit

Is the

power normal?

check the voltage between

L & N of terminal

block

press the power ON/OFF

button on remote controller

Does the

beeper beep two

times?

Is the display

all off?

• Check the connector on display

PCB connected to control PCB

• Check the display PCB itself

Check power supply mains

or interconnection wires

Check the wiring of indoor

Is the

switch position

on switch pannel at

"Remote"

Does

control PCB

status LED repeat one

second "on and

off"?

• control PCB fault

• Micom or reset

IC fault

• Check the remote signal receiver

• Check the connection between signal

receiver and control PCB

Place the switch

position to the

"Remote" and then

Check it once

more

YES

NO

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

NO

NO

NO

Is the

unit display

normal?

Trouble

Page 17

17

Note 1)

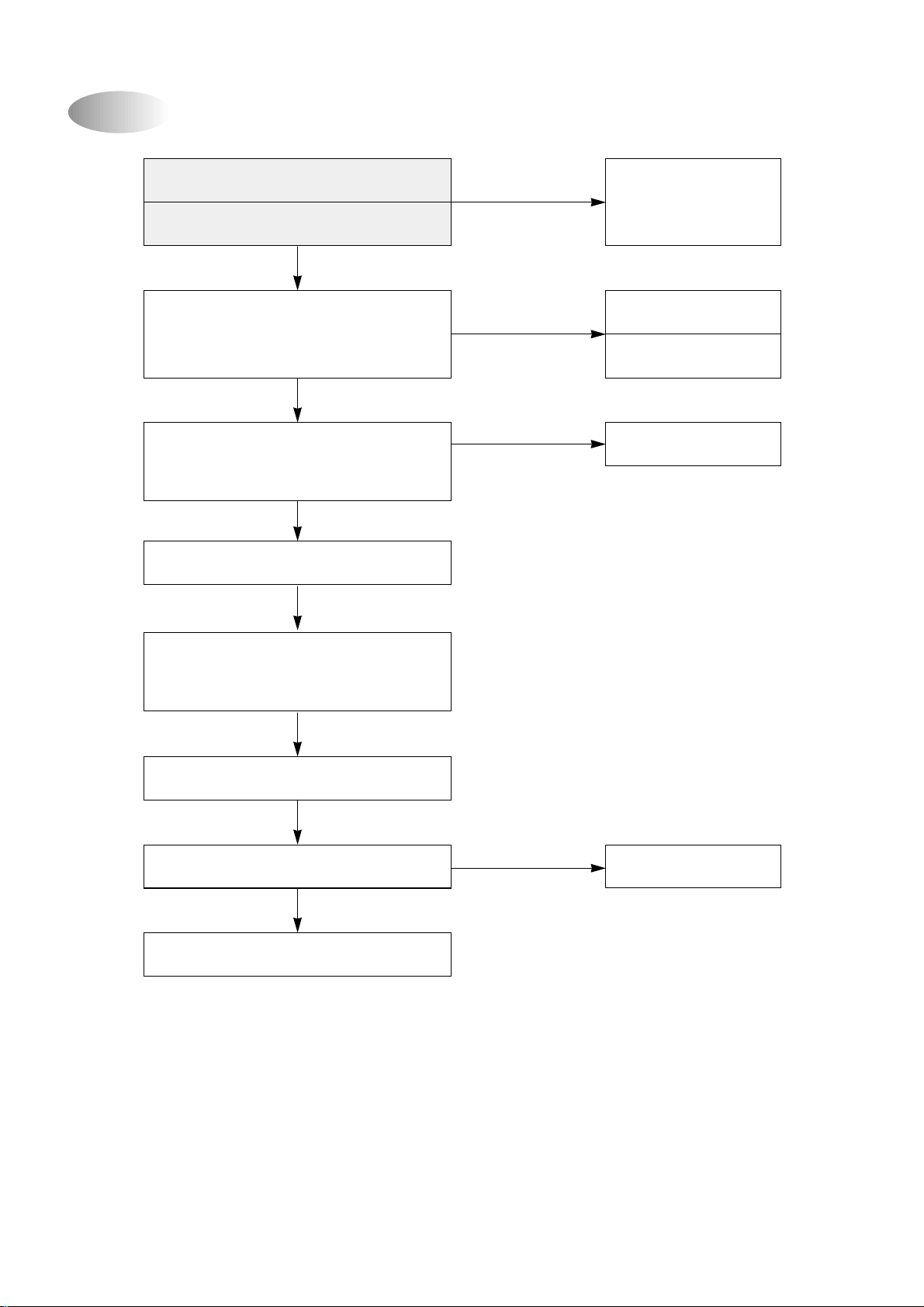

1 Neither indoor unit nor outdoor unit runs.

Check the following points first. (There are f ollo wing case in normal operation)

a. Is the timer mode set the "timer ON".

b. Is the timer mode set the "timer-OFF" and the time had passed?

2 Neither outdoor fan nor compressor runs while indoor fan runs.

Check following points first. (There are f ollo wing cases in normal operation)

a. Is the temperature set point suitable?

b. Has the 3 minutes time guard f or compressor operated?

1. Error Code I - ON LED blinking 3 times at Emergency Mode

1 When the compressor do not run.

i) Check the voltage between and of terminal block.

(Indoor Unit, Outdoor Unit)

ii) Check connecting wire of indoor unit and outdoor unit.

iii)Check relay RL1 on pow er P.C.B (outdoor PCB)

2 Check fixing of indoor coil thermistor.

3 Check the GAS LEAKAGE of the pipe.

2. Error Code 2 - ON LED blinking

1 Check the sensor and its circuit.

2 It occurs when sensor is open or short.

3. Error Code 3 – TIMER LED blinking

1 Check the Indoor Fan Motor.

2 Check the RPM feedback circuit.

③ Indoor Fan Motor does not work for 5 seconds.

Y

L

Self-Diagnostic Function

Page 18

18

Confirm following statement.

When the unit operate normally , Sometimes the outdoor unit and indoor unit cannot operate.

1 Check the function select switch. Is it timer mode?

2 The function select switch locate the sleep mode and is the setting time over?

3 Is the setting mode DEHUMIDIFIER mode?

The power is applied to the unit

Check the voltge between and

of terminal block

Y

L

Check the

Breaker or Fuse

Self Diagnostic

function is ON

Check according to

self Diagnostic function

Control P.C.B defect

Check the indoor unit display

is the display all off?

Press the ON/OFF switch of

Remote Control

Is the indoor unit display all off?

Pull out the power plug

and then insert the power plug

after 5 second

Control P.C.B is normal

Recheck from the beginning

Rating voltage more than 90%

Rating voltage

under 90%

No No

No

Yes

Yes

Neither Indoor Unit nor Outdoor Unit Runs

Page 19

Outdoor Unit Runs but Indoor Fan Do Not Run

Check rotation of indoor fan

Rotate indoor fan by hand

YES

Check input Voltage (Vs) of Fan

Motor connector at power P.C.B

DC POWER OK

Check the winding resistance of

Indoor unit fan motor

Normal

Check the Vsp of indoor PCB

NO

DC 30V(Vs),

DC 15V(Vc)

Fail

Open or short

❈ Vsp=0~5V DC

Check the F an Motor

bearing and fan

Check the power P.C.B.

(outdoor PCB)

The circuit for DC POWER

Change of fan motor

Check the connecting wire of

indoor fan motor

Run again

Check the starting of indoor fan motor

Run again

No

Normal

19

Page 20

20

Confirm following statement.

When the unit operate normally , Sometimes the outdoor unit and indoor unit cannot operate.

1 Is the setting temperature proper?

2 Is the unit during 3min. Time delay of compressor.

3 During frost prevention of lndoor unit.

Outdoor Fan and Compressor Do Not

Check the voltge between and

of indoor unit terminal

Y

L

Check the voltge between and

of outdoor unit terminal

Y

L

Check the voltge between and

of outdoor unit terminal

Y

L

Check compressor ,

outdoor fan motor individually

Check the

connecting wire

Check the

connecting wire

Check the wiring

and voltage

within doors

Rating voltage

under 90%

Rating voltage

under 90%

Rating voltage

under 90%

Page 21

21

- Check the following at cooling mode

Check the voltge between and

of indoor unit terminal

Y

L

Check the voltge between and

of outdoor unit terminal

Y

L

Check the wiring of outdoor unit

Check the compressor

(Check the winding resistance)

Check the compressor capacitor

Check the connecting

wire between indoor

and outdoor.

Change the control

P.C. B

Change the

compressor.

Check the control P.C.B

the circuit for relay

driving.

Rating voltage

less than 90%

NG

Open or Short

Rating voltage

less than 90%

Rating voltage more than 90%

Rating voltage more than 90%

OK

Only Compressor Do not Run

Page 22

7. PCB DESCRIPTION

1

PCB CIRCUIT DIAGRAM

◆ TAS-12/18/24 (Indoor Unit)

Page 23

Page 24

◆ TAS-15 (Indoor Unit)

Page 25

Page 26

◆ TAS-12/15/18/24 (Outdoor Unit)

Page 27

Page 28

26

◆P ART LIST OF INDOOR PCB (TAS-12)

Location Part Code Q'ty Part Name Description Unit

BZ1 3105698200 1 BUZZER DP-2520BA EA

CA1 CN5XD104M- 1 C-ARRAY 6P(F5)X 104Z EA

CA2 CN4XD104M- 1 C-ARRAY 5P(F4)X 104Z EA

CA3 CN3XD104M- 1 C-ARRAY 4P(F3)X 104Z EA

CC1 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC10 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC11 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC12 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC2 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC3 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC4 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC6 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC7 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC8 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC9 CCXE1H104M 1 C-CERA 104M 50VDC EA

CE1 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE2 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE3 CEXE1C106A 1 C-ELEC 10MF 16V SS EA

CE4 CEXE1C475A 1 C-ELEC 4.7MF 50V SS EA

CE5 CEXE1E476C 1 C ELEC 47UF 25V SG EA

CN1 3108803200 1 WAFER YW396-06V EA

CN2 3108803100 1 WAFER YW396-05V EA

CN3 3118702310 1 WAFER YMAW025-04R EA

CN4 3108804800 1 WAFER SMAW250-08 EA

CN5 3118700800 1 WAFER SMAW250-06 EA

D1 DZN4148FTB 1 DIODE 1N4148 AUTO 26MM EA

IC1 13GS87PH46 1 IC MICOM TMP87PH46N(OTP) EA

IC2 1L7805CV-- 1 IC REGULATOR L7805CV EA

IC3 1KD65004AP 1 IC DRIVER KID65004AP EA

IC4 1KD65004AP 1 IC DRIVER KID65004AP EA

IC5 1KA7042P-- 1 IC RESET KIA7042P 5L EA

JS2 3109400100 1 JUMPER 10MM EA

JS3 3109400100 1 JUMPER 10MM EA

OSC 5PRT800MG- 1 RESONATOR RT8.00MG EA

PC1 1LTV817C-- 1 IC PHOTO COUPLER LTV-817C EA

PCB 3114308210 1 PCB CONTROL TAS12(176.5*121*1.6T,FR1) EA

R1 RD-2K102J- 1 RESISTOR 1/2W - 1K EA

R10 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R11 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R12 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R13 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

Page 29

27

Location Part Code Q'ty Part Name Description Unit

R14 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R15 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R16 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R17 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R18 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R19 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R2 RN-4K1001F 1 R METAL FILM 1/4 1K OHM F EA

R21 RN-4K5761F 1 R METAL FILM 1/4 5.76K OHM F EA

R23 RN-4K2432F 1 R METAL FILM 1/4 24.3K OHM F EA

R25 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R26 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R27 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R28 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R3 RN-4K1501F 1 R METAL FILM 1/4 1.5K OHM F EA

R31 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R32 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R33 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R34 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R35 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R36 RD-4K562J- 1 R CARBON FILM 1/4 5.6K OHM J EA

R37 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R4 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R5 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R6 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R7 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R8 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R9 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

RA1 RA8K5103J- 1 RESISTOR ARRAY 6P(5)X 103J EA

RA2 RA8K4103J- 1 RESISTOR ARRAY 5P(4)X 103J EA

RA3 RA8K3103J- 1 RESISTOR ARRAY 4P(3)X 103J EA

Page 30

28

◆P ART LIST OF INDOOR PCB (TAS-15)

Location Part Code Q'ty Part Name Description Unit

BZ1 3105698200 1 BUZZER DP-2520BA EA

CA1 CN5XD104M- 1 C-ARRAY 6P(F5)X 104Z EA

CA2 CN3XD104M- 1 C-ARRAY 4P(F3)X 104Z EA

CC1 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC10 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC11 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC12 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC13 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC14 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC15 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC16 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC2 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC3 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC4 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC6 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC7 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC8 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC9 CCXE1H104M 1 C-CERA 104M 50VDC EA

CE1 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE2 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE3 CEXE1C106A 1 C-ELEC 10MF 16V SS EA

CE4 CEXE1C475A 1 C-ELEC 4.7MF 50V SS EA

CE5 CEXE1E476C 1 C ELEC 47UF 25V SG EA

CN1 3108803200 1 WAFER YW396-06V EA

CN2 3108803100 1 WAFER YW396-05V EA

CN3 3118702310 1 WAFER YMAW025-04R EA

CN4 3108804100 1 WAFER SMW250-07 EA

CN5 3108802000 1 WAFER SMW250-06 EA

CN7 3108804200 1 WAFER SMW250-02 EA

CN8 3108802000 1 WAFER SMW250-06 EA

D1 DZN4148FTB 1 DIODE 1N4148 AUTO 26MM EA

IC1 13GS87PH46 1 IC MICOM TMP87PH46N(OTP) EA

IC2 1L7805CV-- 1 IC REGULATOR L7805CV EA

IC3 1KD65004AP 1 IC DRIVER KID65004AP EA

IC4 1KD65004AP 1 IC DRIVER KID65004AP EA

IC5 1KA7042P-- 1 IC RESET KIA7042P 5L EA

JS2 3109400100 1 JUMPER 10MM EA

JS3 3109400100 1 JUMPER 10MM EA

OSC 5PRT800MG- 1 RESONATOR RT8.00MG EA

PC1 1LTV817C-- 1 IC PHOTO COUPLER LTV-817C EA

PCB 3114308310 1 PCB CONTROL TAS15(110*130*1.6T,FR1) EA

Page 31

29

Location Part Code Q'ty Part Name Description Unit

R1 RD-2K102J- 1 RESISTOR 1/2W - 1K EA

R10 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R11 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R12 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R13 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R14 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R15 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R16 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R17 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R18 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R19 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R2 RN-4K1001F 1 R METAL FILM 1/4 1K OHM F EA

R21 RN-4K1022F 1 R METAL FILM 1/4 10.2K OHM F EA

R23 RN-4K4122F 1 R METAL FILM 1/4 41.2K0HM F EA

R25 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R26 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R27 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R28 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R3 RN-4K1501F 1 R METAL FILM 1/4 1.5K OHM F EA

R31 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R32 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R33 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R34 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R35 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R36 RD-4K562J- 1 R CARBON FILM 1/4 5.6K OHM J EA

R37 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R38 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R39 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R4 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R40 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R41 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R5 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R6 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R7 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R8 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R9 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

RA1 RA8K5103J- 1 RESISTOR ARRAY 6P(5)X 103J EA

RA2 RA8K3103J- 1 RESISTOR ARRAY 4P(3)X 103J EA

Page 32

30

◆P ART LIST OF INDOOR PCB (TAS-18/24)

Location Part Code Q'ty Part Name Description Unit

BZ1 3105698200 1 BUZZER DP-2520BA EA

CA1 CN5XD104M- 1 C-ARRAY 6P(F5)X 104Z EA

CA2 CN4XD104M- 1 C-ARRAY 5P(F4)X 104Z EA

CA3 CN3XD104M- 1 C-ARRAY 4P(F3)X 104Z EA

CC1 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC10 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC11 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC12 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC2 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC3 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC4 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC6 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC7 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC8 CCXE1H103M 1 C-CERA 103M 50VDC EA

CC9 CCXE1H104M 1 C-CERA 104M 50VDC EA

CE1 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE2 CEXE1E107C 1 C-ELEC 100UF 25V EA

CE3 CEXE1C106A 1 C-ELEC 10MF 16V SS EA

CE4 CEXE1C475A 1 C-ELEC 4.7MF 50V SS EA

CE5 CEXE1E476C 1 C ELEC 47UF 25V SG EA

CN1 3108803200 1 WAFER YW396-06V EA

CN2 3108803100 1 WAFER YW396-05V EA

CN3 3118702310 1 WAFER YMAW025-04R EA

CN4 3108804800 1 WAFER SMAW250-08 EA

CN5 3118700800 1 WAFER SMAW250-06 EA

D1 DZN4148FTB 1 DIODE 1N4148 AUTO 26MM EA

IC1 13GS87PH46 1 IC MICOM TMP87PH46N(OTP) EA

IC2 1L7805CV-- 1 IC REGULATOR L7805CV EA

IC3 1KD65004AP 1 IC DRIVER KID65004AP EA

IC4 1KD65004AP 1 IC DRIVER KID65004AP EA

IC5 1KA7042P-- 1 IC RESET KIA7042P 5L EA

JS2 3109400100 1 JUMPER 10MM EA

JS3 3109400100 1 JUMPER 10MM EA

OSC 5PRT800MG- 1 RESONATOR RT8.00MG EA

PC1 1LTV817C-- 1 IC PHOTO COUPLER LTV-817C EA

PCB 3114308410 1 PCB CONTROL TAS18/24(163.25*123*1.6T,FR1) EA

R1 RD-2K102J- 1 RESISTOR 1/2W - 1K EA

R10 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R11 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R12 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R13 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

Page 33

31

Location Part Code Q'ty Part Name Description Unit

R14 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R15 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R16 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R17 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R18 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R19 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R2 RN-4K1001F 1 R METAL FILM 1/4 1K OHM F EA

R21 RN-4K5761F 1 R METAL FILM 1/4 5.76K OHM F EA

R23 RN-4K2432F 1 R METAL FILM 1/4 24.3K OHM F EA

R25 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R26 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R27 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R28 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R3 RN-4K1501F 1 R METAL FILM 1/4 1.5K OHM F EA

R31 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R32 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R33 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R34 RN-4K1272F 1 R METAL FILM 1/4 12.7K OHM F EA

R35 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R36 RD-4K562J- 1 R CARBON FILM 1/4 5.6K OHM J EA

R37 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R4 RD-4K331J- 1 R CARBON FILM 1/4 330 OHM J EA

R5 RD-4K103J- 1 R CARBON FILM 1/4 10K OHM J EA

R6 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R7 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R8 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R9 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

RA1 RA8K5103J- 1 RESISTOR ARRAY 6P(5)X 103J EA

RA2 RA8K4103J- 1 RESISTOR ARRAY 5P(4)X 103J EA

RA3 RA8K3103J- 1 RESISTOR ARRAY 4P(3)X 103J EA

Page 34

32

◆P ART LIST OF OUTDOOR PCB

Location Part Code Q'ty Part Name Description Unit

BD1 DKBJ408G-- 1 DIODE BRIDGE KBJ408G 4A 800V EA

CC1 CH1BBN103K 1 C CERA BN 103K 1KV DC EA

CC2 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC3 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC4 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC5 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC6 CCXE1H104M 1 C-CERA 104M 50VDC EA

CC7 CH1BBN221K 1 C CERA BN 221K 1KV DC EA

CC8 CH1BBN221K 1 C CERA BN 221K 1KV DC EA

CE1 CEXE2G686C 1 C-ELEC 68UF 400V SG EA

CE10 CEXE1H226A 1 C-ELEC 22MF 50V EA

CE2 CEXE1E476C 1 C ELEC 47UF 25V SG EA

CE3 CEXE1H105A 1 C-ELEC 1UF 50V EA

CE4 CEXE1H477C 1 C-ELEC 470UF 50V RX EA

CE5 CEXE1H227C 1 C-ELEC 220UF, 50V EA

CE6 CEXE1V337C 1 C-ELEC 330UF, 35V RX EA

CE7 CEXE1V227C 1 C-ELEC 220UF 35V EA

CE8 CEXE1E227C 1 C-ELEC 220UF 25V EA

CE9 CEXE1E107C 1 C-ELEC 100UF 25V EA

CL1 CLV-B3104M 1 C-LINE ACROSS 275V 104K(PILKOR) EA

CLIP 3107000600 2 FUSE CLIP AFC-520 EA

CN1 3108802500 1 WAFER YW396-03AV EA

CN2 3108803200 1 WAFER YW396-06V EA

D1 DP6KE200A- 1 DIODE TVS P6KE200A EA

D2 DUF1007--- 1 DIODE UFR UF1007, 1000V/1A EA

D3 DZN4148FTB 1 DIODE 1N4148 AUTO 26MM EA

D4 DHER503--- 1 DIODE UFR HER503, 200V/5A EA

D5 DUF2003--- 1 DIODE UFR UF2003, 200V/2A EA

F1 52F153K002 1 LINE FILTER SQE2424,15MH,2A EA

F2 52F2550R2- 1 FILTER BEAD BFS2550 R2 EA

F3 52C3R3K000 1 CHOKE COIL 3.3UH,2A EA

F4 52C3R3K000 1 CHOKE COIL 3.3UH,2A EA

FUSE 5FVLB3152L 1 FUSE GLASS TUBE 250V/50T 3.15A EA

HS1 3015700110 1 HEAT SINK T35XW20XH40 EA

HS2 3015700110 1 HEAT SINK T35XW20XH40 EA

HS3 3105797200 1 HEAT SHINK 22(H)*23*17 EA

IC1 1TP247YGX- 1 IC SMPS TOP247Y-GX EA

IC2 1L7815CV-- 1 IC REGULATOR L7815CV EA

IC3 1L7812CV-- 1 IC REGULATOR L7812CV EA

IC4 1K1A431--- 1 IC REGULATOR KIA431 EA

PC1 1LTV817C-- 1 IC PHOTO COUPLER LTV-817C EA

Page 35

33

Location Part Code Q'ty Part Name Description Unit

PCB 3114308510 1 PCB POWER TAS(170*89*1.6T,FR1) EA

R1 RS02Y683J- 1 R M-OXIDE FILM 2W 68K OHM J EA

R10 RD-4K271J- 1 R CARBON FILM 1/4 270 OHM J EA

R11 RD-2K512J- 1 R CARBON FILM 1/2 5.1K OHM J EA

R12 RD-4K153J- 1 R CARBON FILM 1/4 15K OHM J EA

R13 RS02Y683J- 1 R M-OXIDE FILM 2W 68K OHM J EA

R2 RD-4K105J- 1 R CARBON FILM 1/4 1M OHM J EA

R3 RD-4K105J- 1 R CARBON FILM 1/4 1M OHM J EA

R4 RD-4K689J- 1 R CARBON FILM 1/4 6.8 OHM J EA

R5 RD-4K479J- 1 R CARBON FILM 1/4 4.7 OHM J EA

R6 RD-4K102J- 1 R CARBON FILM 1/4 1K OHM J EA

R7 RD-4K100J- 1 R CARBON FILM 1/4 10 OHM J AT26 EA

R8 RN-4K1002F 1 R METAL FILM 1/4 10.0K OHM F EA

R9 RN-4K1103- 1 R METAL FILM 1/4W 110K OHM F EA

RL1 5SC010141B 1 SW RELAY PCF-112-D-1M EA

TRS1 5EMU2834-- 1 TRANS SMPS 265U,2834 EA

VAR D15G561K-- 1 VARISTOR 15G561K/350V EA

YC1 CH1BFB222K 1 C CERA 2200PF,250V,Y1 EA

Page 36

34

Power Supply(1)

DESCRIPTION

The DC power is SMPS power source. DC Power Supply in circuit needs 30V , 15V and 12V.

+12V is used for Compressor Driving Relay, Buzzer Driving Swing and Swing Motor.

DC 30V is used for Indoor F an Motor P o wer and DC 15V(Vc) is used f or Motor Drive .

(Refer to PCB Circuit Diagram : Outdoor Unit)

Oscillator(2)

19

OSC

CC13

104

5V

8M

20

VDD-10%

V

SS+10%

Fig 2-1

DESCRIPTION

Oscillatory Frequency drive Micom, it is made up 8MHz resonator oscillatory Freqency.

Ocillatory wave is as follo wing Fig 2-1.

Page 37

Sensor(3)

ROOM SENSOR

I/D SENSOR

CN3

R7R6330

330

CC5

103

103

CC6

24

25

MICOM

R10

12.7KF

R11

12.7KF

Room temperature and Evaporator temperature Sensor Input

DESCRIPTION

Temperature

Number 24, 25 of Micom is Terminal of A/D

convertor Input.

Room temperature and Evaporator temperature is

sensing by change of Thermister Resistance,

Micom is put in 5V by ratio between R10 (12.7KΩ)

and R11 (12.7KΩ).

Relation between temperature and voltage is

following Table 3-1.

CC5, 6 is Noise filter.

Voltage (V)

(°C)

No. 1 No. 3

-5 1.127 1.127

0 1.378 1.378

5 1.650 1.650

10 1.936 1.936

15 2.228 2.228

Table 3-1

Indoor Fan Motor Control(4)

DESCRIPTION

Indoor Fan motor pow er is DC30V(Vs)

Indoor Fan motor RPM is controled by Vsp(0~5V)

Vsp control pulse OUTPUT is Pin6, IC1

PIN31 is Indoor Fan motor RPM f eed back input.

35

Page 38

36

DESCRIPTION

Signal from Remote Controller put in only Control Data Signal at Micom Terminal of Number 33, which is gotten

fid of Carrier (38KHz) from Receive Module. Signal Wa ve repeat third as f ollo wing Fig 5-1.

But in Secondary Wave Custom Code is Re v ersed F ace .

LEADER CODE

CUSTOM

CODE

DATA

CODE

CHECK

SUM

TAILER

9ms 4.5ms 16bit 16bit24bit 8bit

Fig 5-1

Fig 5-2

BIT STRUCTURE

Remote Controller(5)

0.56ms 0.56ms1.69ms

1.12ms 2.25ms

bit 0 bit 1

Selecting Mode(6)

(SELECT S/W INPUT, OUTPUT)

MICOM

13

R25

1K

RA2

5V

CA2

F4104Z

P2

MODE

SELECT

PUSH S/W

DESCRIPTION

There are Mode according to SW position as

following Table 6-1.

According as port of fixed Micom is Low, the unit is

operating as following Table 6-1.

Table 6-1

POSITION MODE

OPEN REMOCON

GND EMERGENCY

Page 39

37

DESCRIPTION

MICOM Po wer is supplied 5V at Number 42 using VDD, Number 19, 20 Vsing Oscillator, CC10 is noise filter.

Micom Power Supply(7)

VDD 42

CE3

10µF

16V

CC3

104

CC10

104

+

5V

41

40

39

22

21

19

OSC

8MHz

20

VSS

MICOM

Page 40

38

DESCRIPTION

V oltage less than about 0.8V put in Micom Terminal of Number 18 and then Micom reset. Reset IC detect

Po wer ON and Voltage less than 4.25V , and then send Reset Signal.

Reset(8)

R38 5.6K

1K R35

18

CC4

CE4

4.7uF/50V

IC5

7042P

10.3

MICOM

4.25V

H

L

t

t

POWER

ON

Vcc (+5V)

DELAY TIME

FOR POWER ON

RESET

Page 41

39

DESCRIPTION

Micom 34 Terminal put out Buzzer Dr iving Pulse,

its output is driving Buzzer through Buffer .

Ocillatory Frequency of buzzer is selected by

internal Micom.

This unit is setting at 4KHz.

VCC

12V

KID 65004

MICOM

34

611

R37

1K

BZ1

Buzzer Driving(10)

DESCRIPTION

* When power source is put at fist, Funtion selection input is recognized.

And when the unit is running the microcomputer ignore variation of funtion selection input.

• JS3: open (°C), short (°F)

• R21, R23: Indoot Fan Motor RPM select option with A/D signal.

Function Selecting(9)

Page 42

40

DESCRIPTION

There are one Stepping Motor for Flap (up and down) and it is used 4 face Drive Method.

It is driving as following Fig 12-1. (Ring Count Method of 8 Status)

Ø 4

Ø 3

Ø 2

Ø 1

B

+

6

5

4

3

2

1

12V

IC3

KID65004

CN5

1

MICOM

2

3

4

M1

FOR SWING

Fig 12-1

(Normal Rotating) (Reversed Rotating)

Stepping Motor Driving(12)

Ø 4

Ø 3

Ø 2

Ø 1

Page 43

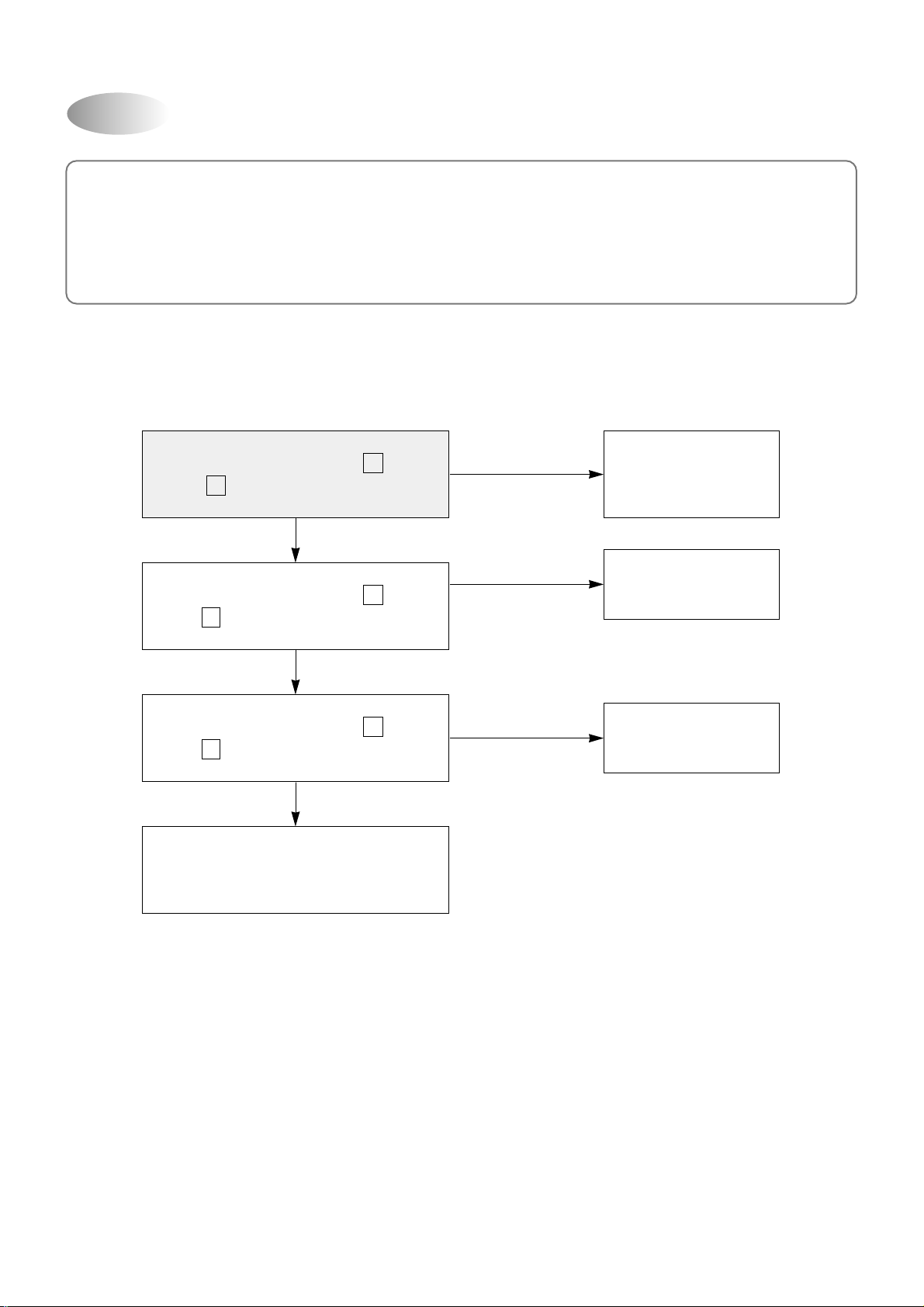

ERROR

No

ERROR

No

ERROR

No

No

No

No

Yes

Select ON/OFF button

Select Mode button

Select F AN SPEEDbutton

Select F AN DIR. b utton

Po wer Supply

TEST START

Po wer supply again

Check the Follo wing

BATTERY SPRING

MICOM

PCB

LCD

Is Display at the

beginning ON?

Is Display at the

beginning ON?

Is it normal?

Is it normal?

Is it normal?

• REMOTE CONTROLLER ASSMBLY FUNCTIONAL TEST METHOD

41

ERROR

No

ERROR

No

(Whenever y ou selectted Temp.

Button, it is changed by 1°C (18~32°C)

▲

( ▼)

Select TEMP. Button (▲,▼)

Select ON/OFF button

Is display at the

begining ON?

Is it normal?

Page 44

42

(0.5~24 HOUR)

ERROR

No

Select TIMER ON Button

Select Timer Enter Button

Select CANCEL Button

Select ON/OFF Button

Select OFF (Timer) Button

Select SLEEP Button

Select SLEEP Button

TEST OK!

Is LCD display OFF?

Is it normal

display?

TIMER

Is all display OFF?

Is it normal?

SLEEP MODE

Display ON?

Is display at the

beginning ON?

ERROR

No

ERROR

No

ERROR

No

ERROR

No

ERROR

No

ERROR

No

Page 45

43

(1) U1 (MICOM)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

VDD

(XTOUT)P22

(XTIN)P21

(INT5/STOP)P20

P17

P16

(TC2)P15

(PPG)P14

(DVO)P13

(INT2/TC1)P12

(INT1)P11

(INTO)P10

(AIN7)P67

(AIN6)P66

(AIN5)P65

(AIN4)P64

(AIN3)P63

(AIN2)P62

(AIN1)P61

(AIN0)P60

VAREF

P77(HSO)

P76(HSCK)

P75(SO)

P74(SI)

P73(SCK)

P72(PDO/PWM)

P71(INT4)

P70(INT3/TC3)

P07

P06

P05

P04

P03

P02

P01

P00

TEST

RESET

XIN

XOUT

(VASS)VSS

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

Steppping Motor

Driving

Indoor Unit Motor Driving

Buzzer Driving

Remocon Input

Comp Relay Driving

Zero Crosing Detect

Function S/W

Temperature

Sensor Input

LED Driving

Emergency

Mode

Function

S/W

Reset Curcuit

Oscillation

8. KEY COMPONENTS OF ELECTRONIC CIRCUIT

Page 46

(2) U2, 4 (KID65004) DARLINGTON ARRAYS

IN1 1 16 OUT 1

IN2 2 15 OUT 2

IN 3 3 14 OUT 3

IN 4 4 13 OUT 4

IN5 5 12 OUT 5

IN6 6 11 OUT 6

IN7 7 10 OUT 7

GND 8 9 COMMON FREE

WHEELING DIODES

COMMON

10.5KΩ

7.2KΩ

3KΩ

OUTPUT

GND

INPUT

100K 500

100

100

0.3

10K

6K

500

1K

5K

28K

6K

30pF

2K

5K

200

240

1.4

K

2.7

K

3.3

K

0.19K

INPUT

OUTPUT

GND

SCHEMATIC DIAGRAM

1

2

3

Fin 2 is ground

for Cose 221A.

Case is ground

for Case 1.

10K

INPUT

GND

10K

300

36K

64K

520

26K

60K

29K

20K

20K

40

pF

50K

50 200

300

200

100

16K

210

012

OUTPUT

KID65004AP

(Equivalent Circuit)

(Top View)

(3) U8 (KIA7805P) : VOLTAGE REGULATOR (5VDC)

Pin 1. INPUT

2. GROUND

3. OUTPUT

(4) U7 (KIA7812P) : VOLTAGE REGULATOR (12VDC)

Pin 1. INPUT

2. GROUND

3. OUTPUT

44

(Equivalent Ciircuit)

Page 47

45

(5) U9 (KIA7042P) : RESET IC

KIA70

42P

OUTLINE

INPUT

GROUND

OUTPUT

VCC

1

3

2

OUT

GND

Page 48

46

1

INDOOR UNIT

PROCEDURES PHOTOS

1. Stop the Air conditioner and disconnect the power cord from the wall

outlet.

2. Removing the Insert Grille and Frame Grille. (Fig 1~2)

1 Draw up the Insert Grille and remove it.

2 Loosen one screw for fixing the Cov er Ter-Block.

3 Loosen two screw at the Fr ame Grille.

4 Remove the F rame Grille.

3. Removing the Control Box. (Fig 3)

1 Remove room and coil thermistors.

2 Disconnect the fan motor lead wire from connection at the

Control PCB.

3 Disconnect the stepping motor lead wire from connection at the

Control PCB.

4 Remove the select switch from connection at the Control PCB.

5 Loosen a screw for fixing ground wire.

6 Remove the Control Box

4. Removing the Drain Pan. (Fig 4)

1 Disconnect the Body drain hole. (left and right Body)

2 Disconnect three hook and remove the Drain Pan.

5. Removing the Indoor Evaporator . (Fig 5~6)

1 Remove one screw f or fixing indoor Ev aporator at the Body.

2 Remove the hook for fixing Brac k et Pipe at the back of Body.

3 Remove Indoor Evaporator.

6. Removing the Cross Flow F an. (Fig 7)

1 Remove set screw f or fixing Motor shaft.

2 Remove Cross Flow Fan.

7. Remove Motor IDU and Bearing Plastic.

9. DISASSEMBLY INSTRUCTIONS

Fig 1

Fig 3

Fig 4

Fig 5

Fig 6

◆TAS-12

Fig 2

Fig 7

Page 49

47

◆TAS-15

PROCEDURES PHOTOS

1. Stop the Air conditioner and disconnect the power cord from the wall

outlet.

2. Removing the Insert Grille and Frame.

! Loosen three screws for fixing the the Insert Grille and Frame.

(Pull out the frame cap before loosening three screws) (Fig 1)

@ Loosen three screws at the Drain Pan.

# Remove the Insert Grille and Frame.

3. Removing the Control Box.

After doing above procedures:

! Disconnect indoor room and coil thermistors. (Fig 3)

@ Disconnect the fan motor lead wire from connection at the main

PCB. (Fig 3)

# Disconnect the swing motor connection wire.

$ Loosen a screw for fixing ground wire.

% Loosen two screws for fixing the body.

4. Removing the Drain Pan.

After doing above procedures:

! Loosen a screw for fixing body. (Fig 4)

@ Unhook the right part of Drain Pan.

5. Removing the Indoor Coil.

After doing above procedures:

! Loosen four screws for fixing indoor coil at left and right side. (Fig 5)

@ Loosen a screw for fixing the brack et tube at the back side. (Fig 6)

# Remove the indoor coil. (Fig. 6-1)

6. Removing the fan motor .

After doing above procedures:

! Loosen two screws for fixing holder moter at left and right side.

(Fig 7, 8)

@ Loosen a screw for fixing fan motor and b low er .

# Renove the fan motor.

Fig 2

Fig 1

Fig 3

Fig 4

Fig 5

Fig 6

Fig 6-1

Page 50

48

PROCEDURES PHOTOS

7. Removing the blower.

After doing above procedures:

! Loosen a screw for fixing holder bearing.

@ Remove the blow er .

Fig 8

Fig 7

Page 51

49

PROCEDURES PHOTOS

1. Stop the operation of the Air conditioner and disconnect the power cord

from the wall outlet.

2. Removing the Insert Grille and Frame Grille. (Fig 1~2)

1 Draw up the Insert Grille and remove it.

2 Loosen the screws fixed at the Cov er Ter-Block.

3 Loosen two screw at the Fr ame Grille.

4 Remove the F rame Grille.

3. Removing the Control Box. (Fig 3)

1 Remove room and coil thermistors.

2 Disconnect the fan motor lead wire from connection at the

Control PCB.

3 Disconnect the stepping motor lead wire from connection at the

Control PCB.

4 Remove the select switch from connection at the Control PCB.

5 Loosen the screw fixed at the ground wire.

6 Remove the Control Box

4. Removing the Drain Pan. (Fig 4)

1 Disconnect the Body drain hole. (left and right Body)

2 Disconnect three hooks and remove the Drain Pan.

5. Removing the Indoor Evaporator . (Fig 5~6)

1 Remove the hook fixed at the Plate mounting of the back of Body.

2 Remove Indoor Evaporator.

6. Removing the Cross Flow F an. (Fig 7)

1 Remove the set screw fix ed at the Motor shaft.

2 Remove the Cross Flow F an.

7. Remove the Motor IDU and the Bearing Plastic.

Fig 1

Fig 3

Fig 4

Fig 5

Fig 6

◆T AS-18/24

Fig 2

Fig 7

Page 52

50

2

OUTDOOR UNIT

◆TAS-12/15/18

PROCEDURES PHOTOS

1.Stop the operation of the air conditioner and dis connect the wire from in

door unit to out door unit.

2. Disassemble the case. (Fig 1~2)

1 Remove the Top Panel.

2Remove the Side Cabinet.

3Remove the Front Cabinet.

3. Removing the Propeller Fan. (Fig 3)

1Loosen the screw fixed at the motor bracket.

2Remove the Plain Washer .

3Remove the Propeller Fan.

4. Remove the panel control. (Fig 4)

1Disconnect the wire at the control panel.

2Loosen the screw fixed at the panel control.

3Remove the parts on panel control.

5. Remove the partition panel. (Fig 5)

1Loosen four screws at the bracket motor.

2Disconnect the wire at the control panel.

6. Removing the Over load Protector . (Fig 6)

1Remove the cocondenser

2Loosen three volts at compressor.

3Remove the compressor.

Fig 1

Fig 2

Fig 3

Fig 5

Fig 4

Fig 6

Page 53

51

◆TAS-24

PROCEDURES PHOTOS

1.Stop the operation of the air conditioner and disconnect the wire from in

door unit to out door unit.

2. Disassemble the case. (Fig 1~2)

1 Remove the Top Panel.

2Remove the Front Cabinet.

3Remove the Side Cabinet and Bac k Cabinet.

3. Removing the Propeller Fan. (Fig 3)

1Loosen the screw fixed at the motor bracket.

2Remove the Plain Washer .

3Remove the Propeller Fan.

4. Removing the panel control. (Fig 4)

1Disconnect the wire at the control panel.

2Loosen the screw at the panel control.

3Remove the parts on the panel control.

5. Removing the vaccum pump .

6. Remove the partition panel. (Fig 5)

1Loosen four screws at the bracket motor.

2Disconnect the wire at the control panel.

7. Removing the Over load Protector . (Fig 6)

1Remove the cocondenser

2Loosen three volts at the compressor.

3Remove the compressor.

Fig 1

Fig 2

Fig 3

Fig 5

Fig 4

Fig 6

Page 54

10. EXPLODED VIEW AND PART LIST

INDOOR UNIT

1

◆TAS-12

52

Page 55

◆Indoor Unit Part List (T AS-12)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3110058500 BODY Ass`y 1 HIPS T2.0 (GY258A)

2 3118008200 MOTOR IDU 1 FDA3530DWA

3 3111503800 CUSHION MOTOR 2 CR

4 3106400400 BEARING PLASTIC Ass`y 1

5 3110046000 CFF Ass`y 1 SAN+G.F.30% •’100.0xL615

6 3113000400 HOLDER MOTOR L 1 HIPS T2.0

7 3113000500 HOLDER MOTOR R 1 HIPS T2.0

8 3110054100 EVAPORATOR Ass`y 1 3R-3C (FP=1.5)

9 3112500900 GUIDE EVAP. 1 PVC

10 3114503300 PLATE EVAP. L 1 PP T2.0(GY176A)

11 3110059500 PAN DRAIN Ass`y 1 HIPS T2.0 (GY258A)

12 3108003910 MOTOR STEPPING 1 MP24GA

13 3116501001 BLADE VERTICAL 3 P.P. T1.5 (GY176A)

14 3117600101 FLAP 1 HIPS T2.5 (GY171A)

15 3103210010 DRAIN HOSE Ass'y 1

16 3104301700 LED PCB Ass'y 1

17 3110063610 CONTROL BOX Ass`y 1 HIPS(T2.0 BLACK)

18 3114208600 CONTROL PCB Ass'y 1

19 3110400200 BODY TOP 1 HIPS T2.0

20 3110063700 FRAME GRILLE Ass`y 1 HIPS T2.5

21 3103401400 KNOB SWITCH 1

22 3111403400 COVER T/BLOCK 1 HIPS T2.0

23 3111901400 FILTER FRAME 2 P.P. T2.0 (BLACK)

24 3101902510 FILTER CARBON Ass`y 1 BLACK

25 3101902610 FILTER ELECTRO Ass`y 1 WHITE

26 3110063800 INSERT GRILLE Ass`y 1 HIPS T2.5 (GY171A)

27 3114503800 PLATE MOUNTING 1 SGCC

28 3112501410 GUIDE SAFETY - A 1 SUS 304 ø1.5

29 3112501420 GUIDE SAFETY - B 1 SUS 304 ø1.5

53

Page 56

26

25

20

10

27

1

6

9

5

4

54

◆TAS-15

23

22

24

21

12

14

13

17

11

18

19

16

2

3

7

8

Page 57

◆Indoor Unit Part List (T AS-15)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100410000 BODY Ass`y 1 HIPS (GY177A)

2 3118008210 MOTOR IDU 1 FDA3530DWB

3 3111503800 CUSHION MOTOR 2 CR

4 3106400100 BEARING PLASTIC 1 RUBBER I.D.ø6.0

5 3101800200 CFF Ass`y 1 O.D.ø102xL861

6 3103000700 HOLDER BEARING 1 ABS (BLK)

7 3103000600 HOLDER MOTOR L 1 ABS (BLK)

8 3110606600 BRACKET MOTOR 1 HIPS

9 3107400010 EVAPORATOR Ass`y 1 Fp=1.4

10 3108120020 PAN DRAIN Ass`y 1 HIPS (GY171A)

11 3108004300 STEPPING MOTOR 2 DC12V 400mm

12 3106500401 BLADE VERTICAL 16 PP (GY171A)

13 3107600100 FLAP TOP 1 ABS (GY171A)

14 3107600200 FLAP UNDER 1 ABS (GY171A)

15 3103210010 DRAIN HOSE Ass`y 1 P.P. + INSULATOR

16 3100005270 CONTROL BOX Ass`y 1

17 3114308700 CONTROL PCB Ass'y 1

18 3104300301 SWITCH PCB Ass'y 1

19 3104300401 LED PCB Ass'y 1

20 3102210020 FRAME GRILLE Ass`y 1 ABS (GY171A)

21 3101403700 COVER T/BLOCK 1 ABS (GY171A)

22 310191000C FILTER PRE R Ass'y 1 P.P. BLACK

23 310192000C FILTER PRE L Ass'y 1 P.P. BLACK

24 3101930000 FILTER ELECTRO Ass`y 1 WHITE

25 3101940000 FILTER CARBON Ass`y 1 BLACK

26 3110017600 INSERT GRILLE Ass`y 1 HIPS (GY171A)

27 3104500300 PLATE MOUNTING 1 SGCC T0.8

28 3106300500 BAR DRAIN 2 SUS 304 ø1.5

29 3100601400 BRACKET DRAIN 1 SUS 304 T1.0

55

Page 58

◆TAS-18/24

56

Page 59

◆Indoor Unit Part List (T AS-18/24)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100076200 BODY Ass`y 1 HIPS T2.5

2 311009F000 MOTOR IDU 1 FDA3530DWC

3 3111503800 CUSHION MOTOR 2 CR

4 3106400200 BEARING PLASTIC Ass`y 1 O.D.ø37.0xI.D.ø6.0

5 3100076400 CFF Ass`y 1 O.D.ø100xL864

6 3103003800 HOLDER MOTOR L/B 1 DSB-240L/LH

7 3110606700 BRACKET MOTOR 1 HIPS T2.0

8 3103004000 HOLDER BEARING 1 ABS T2.5

311009AC11 EVAP. Ass`y 1 Fp=1.4 , 2R-5C TAS-18

9

311009AC01 Fp=1.4 , 2R-5C TAS-24

10 3102501400 GUIDE EVAP. 1

11 3100076810 PAN DRAIN Ass`y 1 HIPS T2.0 (GY258A)

12 3108007600 MOTOR STEPPING 1 GSP-24RW-062

13 3106502700 BLADE VERTICAL M 2.5 P.P. T1.5

14 3107600500 FLAP UP 1

15 3107600600 FLAP DOWN 1

16 3103200800 DRAIN HOSE Ass`y 1

17 3104301700 LED PCB Ass`y 1

18 3100077060 CONTROL BOX Ass`y 1 P.P. + Talk 20%

19 3104308800 CONTROL PCB Ass'y 1

20 3100400700 BODY TOP 1

21 3100077150 FRAME GRILLE Ass`y 1

22 3103401400 KNOB SWITCH 1

23 3101406820 COVER T/BLOCK 1 ABS

24 3100094400 FILTER ELECTRO Ass`y 1 WHITE

25 3100094300 FILTER CARBON Ass`y 1 BLACK

26 3102201500 FILTER FRAME 2 DSB-240L/LH

27 3100077200 INSERT GRILLE Ass`y 1

28 3104511800 PLATE MOUNTING 1 SGCC T0.7

29 3112501510 GUIDE SAFETY - C 1 SUS304 ø1.5 (Black)

30 3112501520 GUIDE SAFETY - D 2 SUS304 ø1.5 (Black)

57

Page 60

OUTDOOR UNIT

2

◆TAS-12/15/18

58

Page 61

◆Outdoor Unit Part List (T AS-12/15/18)

No PART CODE PART NAME Q'TY SPEC REMARK

1 311000750P PAN BASE Ass`y 1 SECC T1.2 (GY-171D)

COMPRESSOR 1 QK164KBD

2 3117104320 RCA155U001

3117109500 RCA180U001

MRA 98996 - 12026

3 3RC7928RE0 COMP. OLP 1 MRA 12013 - 696

3RC7928ME0 MRA 12138 - 696

4 3110018920 CONDENSER Ass`y 1 ø7.0 (2R-3C) Fp=1.4

5 3112400700 GRILLE COND. 1 PE

6 310061000P BRKT SERVICE Ass`y 1 SECC T1.6

3115401900

7

3105400100 C3771,1/2" TAS-15/18

8 3105400200 SERVICE VALVE 1 C3771 1/4"

3114464500 ø12.7xT0.7 TAS-12

9 3114464510 PIPE SUCTION 1 ø12.7xT0.7 TAS-15

3114464520 ø12.7xT0.7 TAS-18

3114464600 ø9.52xT0.7 TAS-12

10 3114464610 PIPE DISCHARGE 1 ø9.52xT0.7 TAS-15

3114464620 ø9.52xT0.7 TAS-18

311009F400 O.D.ø3.2xI.D.ø1.8xL1,000 TAS-12

11 311009F410 PIPE CAPILLARY Ass`y 1 O.D.ø3.2xI.D.ø1.8xL600 TAS-15

311009F420 O.D.ø3.2xI.D.ø2.0xL1,000 TAS-18

12 3114500800 PLATE PARTITION 1 SGCC T1.0

13 3110600200 BRACKET MOTOR 1 SGCC T1.2

14 3118007160 MOTOR ODU 1 208-230V/60Hz,YDK-50-6A1

15 3101800100 FAN PROPELLER 1 ABS+G/F, OD420

16 3110025810 PANEL CONTROL Ass`y 1 SECC T0.8

17 3114308900 ODU PCB Ass'y 1

18 3111101400 CASE PCB ODU 1 P.P.=Talk 20%

3109506320

19

3116903120 3.0+35µF/400VAC TAS-18

20 3101301100 CLAMP CAPACITOR 1 SECC T1.0

21 311080021P CABINET FRONT 1 SECC T0.8

22 3112400300 GRILLE DISCHARGE 1 STEEL WIRE

23 3112500300 GUIDE SUPPORT 1 SECC T1.2

24 311080030P CABINET SIDE 1 SECC T0.8

25 311420050P PANEL TOP 1 SECC T0.8

26 3111408300 COVER SERVICE 1 SECC T0.8

27 3102101000 CUSHION RUBBER 4 NR

SERVICE VALVE 1

CAPACITOR DUAL 1

C3771 3/8" TAS-12

TAS-12/15/18

3.0+30µF/400VAC TAS-12/15

59

Page 62

◆TAS-24

60

Page 63

◆Outdoor Unit Part List (T AS-24)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100041702 BASE PAN Ass`y 1 SECC T1.2 (GY-171D)

2 3117141200 COMPRESSOR 1 QP325KBB

3 - COMP. OLP 0 INTERNAL

4 3106800500 CONDENSER Ass`y 1 FP=1.5

5 3102402100 GRILLE COND. 1 PE

6 3100041201 BRACKET SERVICE Ass`y 1 SECC T1.6 (GY-171D)

7 3105401300 SERVICE VALVE 1 5/8"

8 3105401200 SERVICE VALVE 1 3/8"

9 3114456700 PIPE SUCTION 1 O.D.ø15.88xT0.8

10 3114456800 PIPE DISCHARGE 1 O.D.ø12.7xT0.7

11 3100089310 PIPE CAPILLARY Ass`y 1 O.D.ø3.2xI.D.ø2.0xL500

12 3105300400 SUPPORT MOTOR 1 SGCC-M-Z22 T1.6

13 3118008000 MOTOR ODU 1 A2929GS010

14 3101802001 FAN PROPELLER 1 ABS + G.F.20%

15 3100031702 PLATE PARTITION Ass`y 1 SGCC-M-Z22 T0.8

16 3100088680 PANEL CONTROL Ass`y 1 SGCC T0.8

17 3114308900 ODU PCB Ass'y 1

18 3111101400 CASE PCB ODU 1 P.P. + Talk 20%

19 3116904800 CAPACITOR DUAL 1 5.0+40UF 400VAC

20 3101201100 CLAMP CAPACITOR 1 SBHG1 T1.0

21 3100031400 CABINET FRONT Ass`y 1 SECC T0.8 (GY-171D)

22 3102102000 GRILLE DISCHARGE 1 STEEL WIRE

23 3100041100 GUIDE SUPPORT 1 SECC T1.6 (GY-171D)

24 3100031520 CABINET SIDE 1 SECC T0.8 (GY-171D)

25 3100041500 PANEL TOP 1 SECC T0.8 (GY-171D)

26 3100089220 COVER SERVICE 1 SECC T0.8 (GY-171D)

27 3111500400 CUSHION RUBBER 4 NR

61

Page 64

SERVICE MANUAL

R

C

US

LISTED

UL and

CUL listed

ROOM AIR CONDITIONER

MODEL #:

TAS-12

TAS-15

TAS-18

TAS-24

CONTENTS

1. SPECIFICATIONS

2. INSTALLATION

3. REFRIGERANT CYCLE

4. WIRING DIAGRAM

5. CONTROL BLOCK DIAGRAM

6. TROUBLE SHOOTING

7. PCB DESCRIPTION

8. KEY COMPONENTS OF ELECTRONIC CIRCUIT

9. DISASSEMBLY INSTRUCTIONS

10. EXPLODED VIEW AND PART LIST

✔ Caution

: In this Manual, some parts can be changed for

improving, their performance without notice in the

parts list.

Loading...

Loading...