Page 1

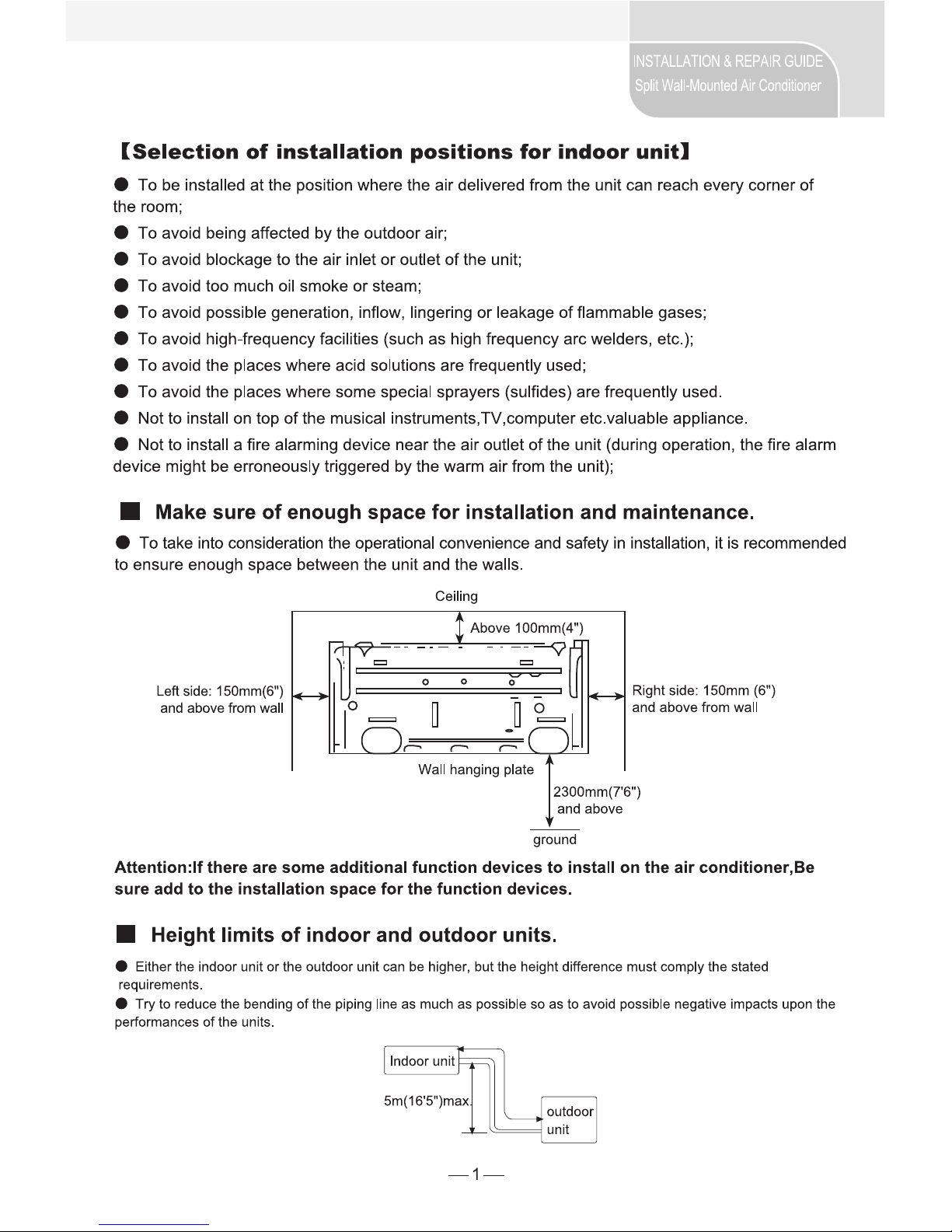

1

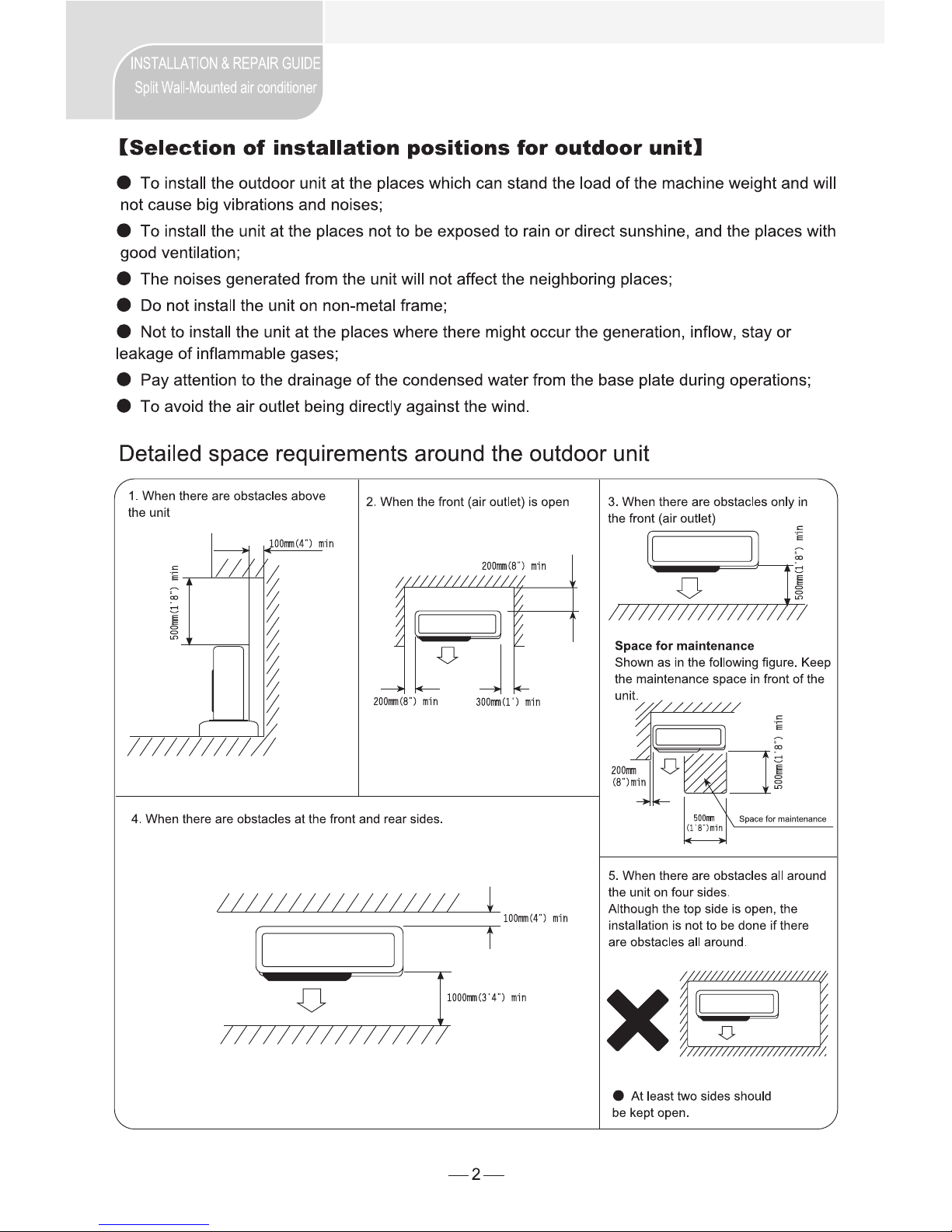

Service mannal

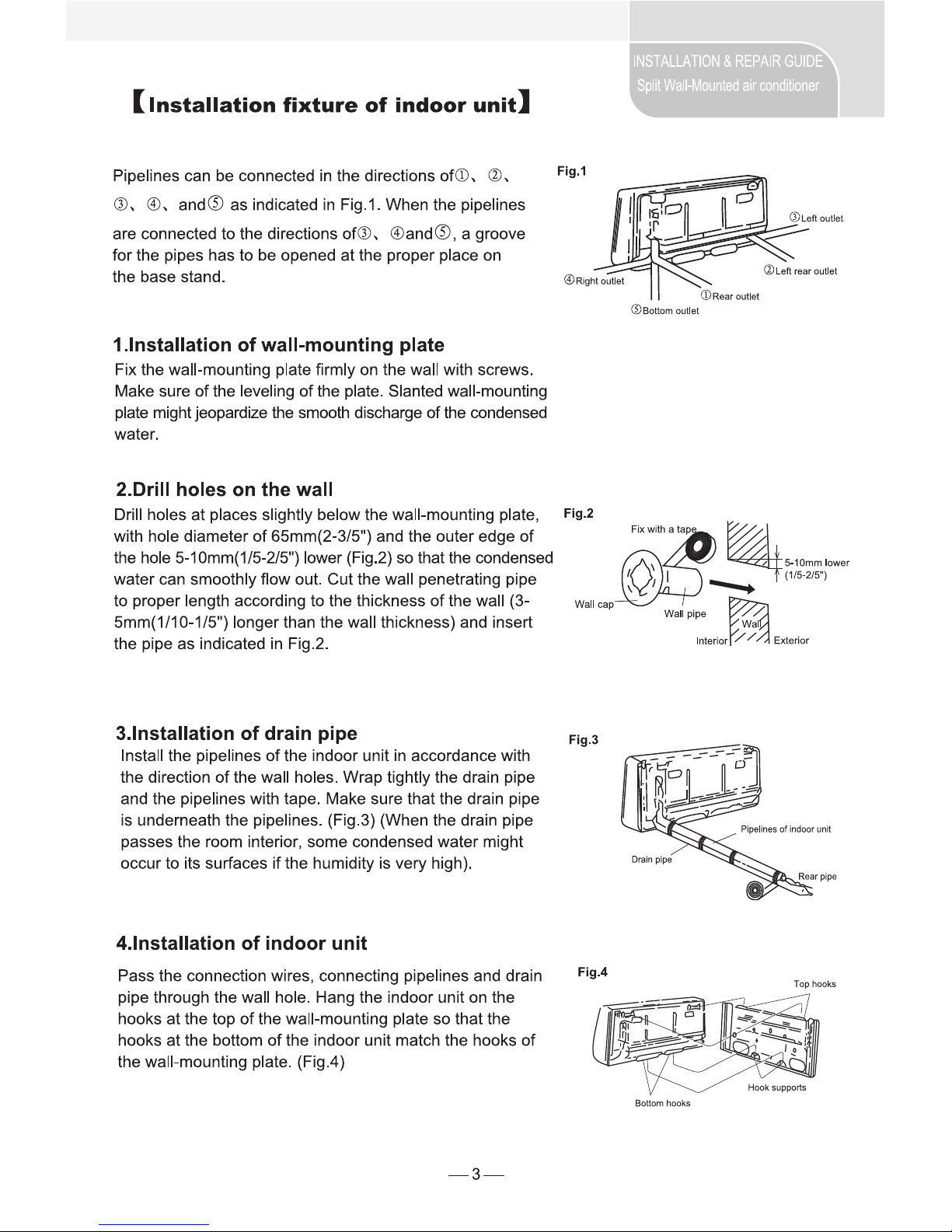

Room airconditioner

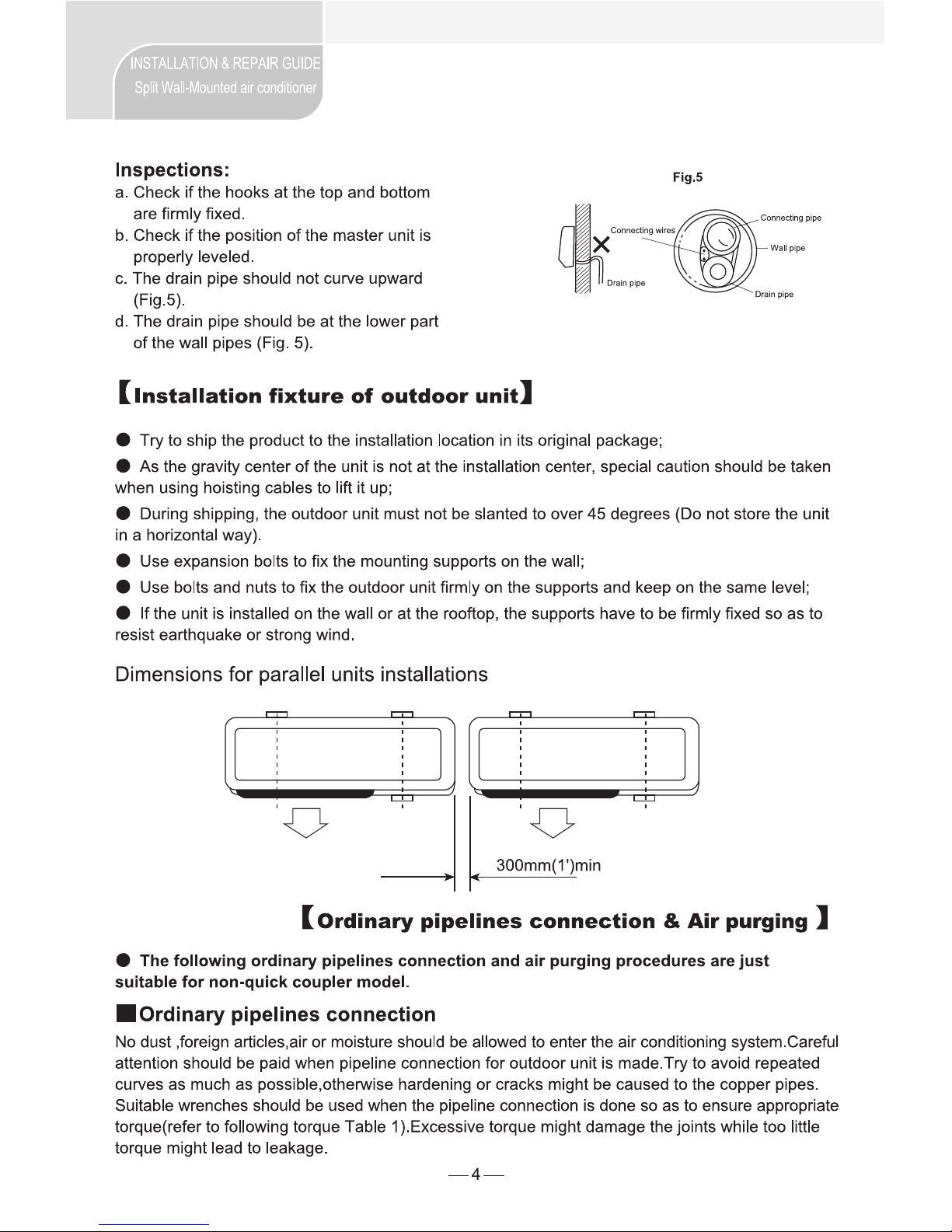

Split Wall-Mounted Type

NOTE:

Before servicing the unit, please first read the service

manual and then contact with your service center if

meet problem

Page 2

2

Table of Contents

1、Summary

………………………………………………………………………………………………………………3

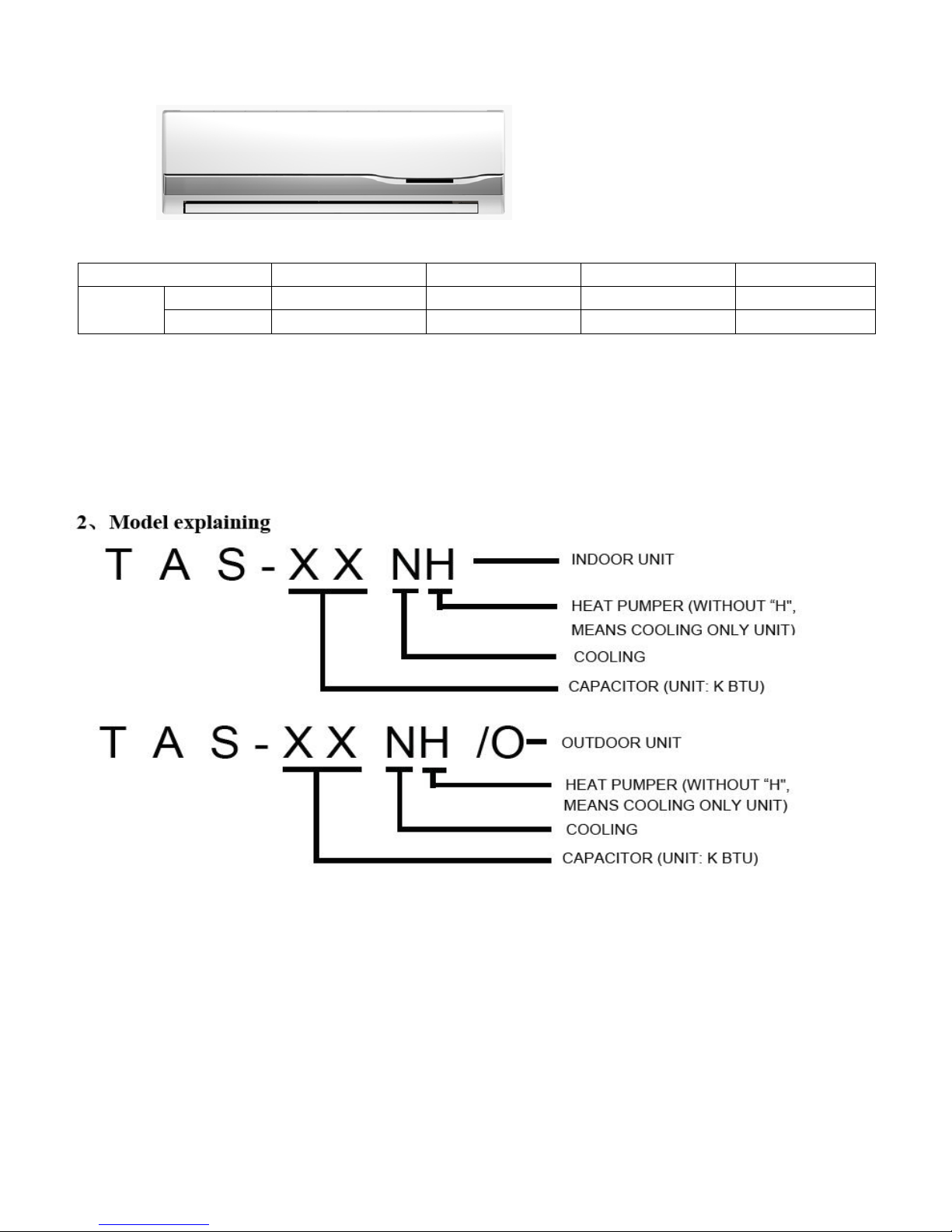

2、Model explaining

…………………………………………………………………………………………………….5

3、Installation

……………………………………………………………………………………………………………..4

4、Exploded view and part list

………………………………………………………………………………………..8

5、Operation principle

………………………………………………………………………………………………….8

6、Parameter

………………………………………………………………………………………………………………9

7、Wiring diagrams

……………………………………………………………………………………………………...13

8、PCB principle chart

……………………………………………………………………………………………….....17

9、PCB function …………………………………………………………………………………......

17

10、Troubleshooting………………………………………………………………………………....

30

Page 3

3

1. Summary

model

indoor unit 790×270×180 790×270×180 940×270×180 1080×335×245 Net

Dimension

outdoor unit 700×225×500 795×255×510 795×255×510 870×310×700

3. Attention of installation

3.1 Safety Precaution

■

To prevent injury to the user or other people and property damage, the following instructions must be

followed.

■

Incorrect operation due to ignoring instruction will cause harm or damage.

■Before service unit, be sure to read this service manual at first.

3.2 Warning

﹥Installation

■

Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

TAS-09NH

TAS-12NH

TAS-18NH

TAS-24NH

Page 4

4

There is risk of fire or electric shock.

■

For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized service center.

Do not disassemble or repair the product, there is risk of fire or electric shock.

■

Always ground the product.

There is risk of fire or electric shock.

■

Install the panel and the cover of control box securely.

There is risk of fire of electric shock.

■

Always install a dedicated circuit and breaker.

Improper wiring or installation may cause fore or electric shock.

■

Use the correctly rated breaker of fuse.

There is risk of fire or electric shock.

■Do not modify or extend the power cable.

There is risk of fire or electric shock.

■

Do not install, remove, or reinstall the unit by yourself (customer).

There is risk of fire, electric shock, explosion, or injury.

■

Be caution when unpacking and installing the product.

Sharp edges could cause injury, be especially careful of the case edges and the fins on the condenser and evaporator.

■ For installation, always contact the dealer or an Authorized service center.

There is risk of fire, electric shock, explosion, or injury.

■Do not install the product on a defective installation stand.

It may cause injury, accident, or damage to the product.

■Be sure the installation area does not deteriorate with age.

If the base collapses, the air conditioner could fall with it, causing property damage, product failure, and personal injury.

■

Do not let the air conditioner run for a long time when the humidity is very high and a door or a windows is left open.

Moisture may condense and wet or damage furniture.

■

Take care to ensure that power cable could not be pulled out or damaged during operation.

There is risk of fire or electric shock.

■

Do not place anything on the power cable.

There is risk of fire or electric shock.

■

Do not plug or unplug the power supply plug during operation.

There is risk of fire or electric shock.

■

Do not touch (operation) the product with wet hands.

There is risk of fire or electric shock.

■

Do not place a heater or other appliance near the power cable.

There is risk of fire and electric shock.

■

Do not allow water to run into electric parts.

It may cause fire, failure of the product, or electric shock.

■

Do not store or use flammable gas or combustible near the product.

There is risk of fire or failure of product.

■

Do not use the product in a tightly closed space for a long time.

Oxygen deficiency could occur.

■

When flammable gas leaks, turn off the gas and open a window for ventilation before turn the product on.

Do not use the telephone or turn switches on or off. There is risk of explosion or fire.

■If strange sounds, or small or smoke comes from product. Turn the breaker off or disconnect the power supply cable.

There is risk of electric shock or fire.

■

Stop operation and close the window in storm or hurricane. If possible, remove the product from the window before the hurricane

arrives.

There is risk of property damage, failure of product, or electric shock.

Page 5

5

■Do not open the inlet grill of the product during operation. (Do not touch the electrostatic filter, if the unit is so equipped.)

There is risk of physical injury, electric shock, or product failure.

■

When the product is soaked (flooded or submerged), contact an Authorized service center.

There is risk of fire or electric shock.

■Be caution that water could not enter the product.

There is risk of fire, electric shock, or product damage.

■Ventilate the product from time to time when operating it together with a stove, etc.

There is risk of fire or electric shock.

■

Turn the main power off when cleaning or maintaining the product.

There is risk of electric shock.

■

When the product is not be used for a long time, disconnect the power supply plug or turn off the breaker.

There is risk of product damage or failure, or unintended operation.

■

Take care to ensure that nobody could step on or fall onto the outdoor unit.

This could result in personal injury and product damage.

﹥

CAUTION

■

Always check for gas (refrigerant) leakage after installation or repair of product.

Low refrigerant levels may cause failure of product.

■Install the drain hose to ensure that water is drained away properly.

A bad connection may cause water leakage.

■

Keep level even when installing the product.

To avoid vibration of water leakage.

■

Do not install the product where the noise or hot air from the outdoor unit could damage the neighborhoods.

It may cause a problem for your neighbors.

■

Use two or more people to lift and transport the product.

Avoid personal injury.

■Do not install the product where it will be exposed to sea wind (salt spray) directly.

It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins, could cause product malfunction or

inefficient operation.

﹥

Operational

■

Do not expose the skin directly to cool air for long periods of time. (Do not sit in the draft).

This could harm to your health.

■

Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a consumer air conditioner, not a

precision refrigerant system.

There is risk of damage or loss of property.

■ Do not block the inlet or outlet of air flow.

It may cause product failure.

■

Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

There is risk of fire, electric shock, or damage to the plastic parts of the product.

■

Do not touch the metal parts of the product when removing the air filter. They are very sharp.

There is risk of personal injury.

■

Do not step on pr put anything on the product. (outdoor units)

There is risk of personal injury and failure of product.

■

Always insert the filter securely. Clean the filter every two weeks or more often if necessary.

A dirty filter reduces the efficiency of the air conditioner and could cause product malfunction or damage.

■

Do not insert hands or other object through air inlet or outlet while the product is operated.

There are sharp and moving parts that could cause personal injury.

Page 6

6

■

Do not drink the water drained from the product.

It is not sanitary could cause serious health issues.

■Use a firm stool or ladder when cleaning or maintaining the product.

Be careful and avoid personal injury.

■Replace the all batteries in the remote control with new ones of the same type. Do not mix old and mew batteries or different types of

batteries.

There is risk of fire or explosion.

■ Do not recharge or disassemble the batteries. Do not dispose of batteries in a fire.

They may burn of explode.

■

If the liquid from the batteries gets onto your skin or clothes, wash it well with clean water. Do not use the remote of the batteries

have leaked.

The chemical in batteries could cause burns or other health hazards.

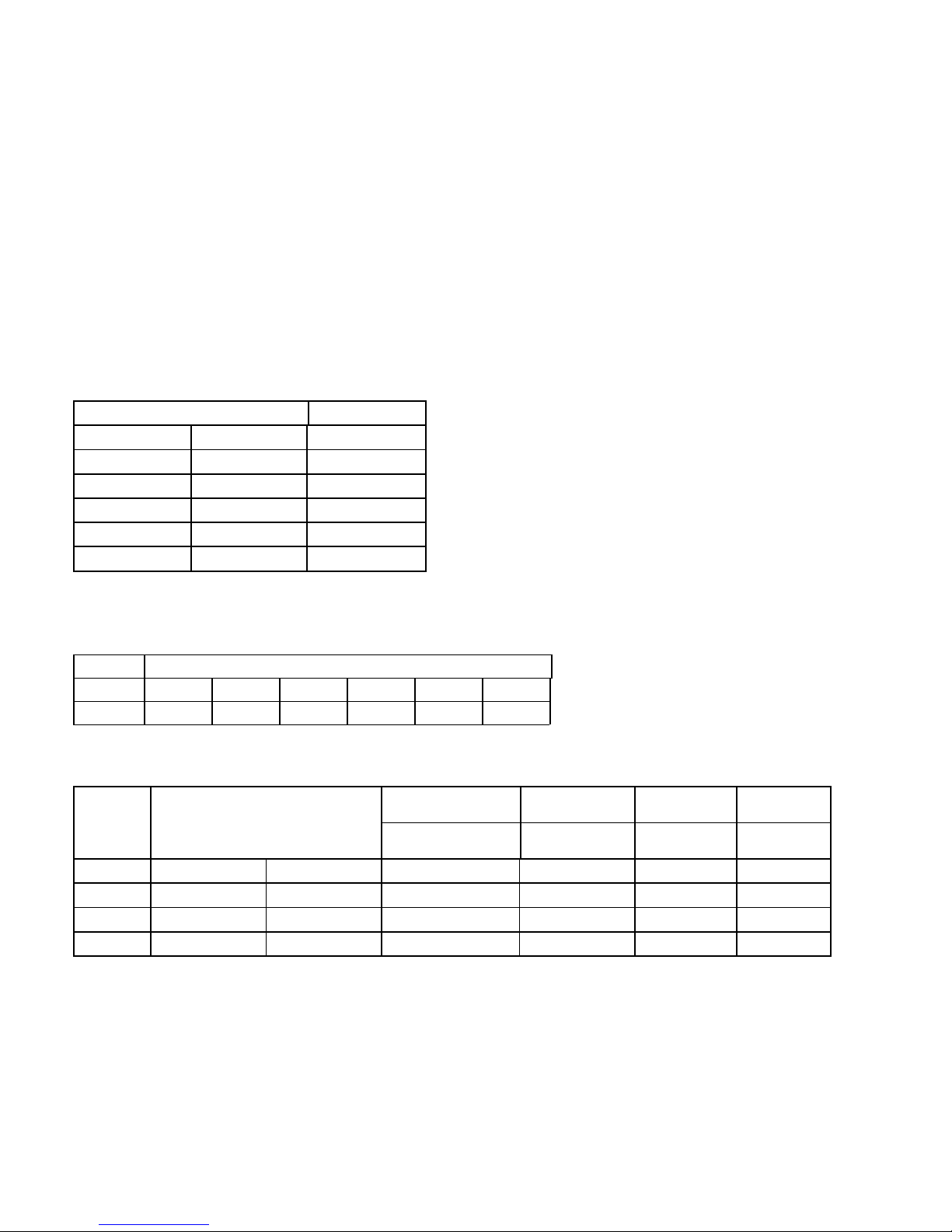

3.3 Installation details

■

Wrench torque sheet for installation

Outside diameter Torque

mm inch Kg.m

φ6.35 1/4 1.8

φ9.52 3/8 4.2

φ12.7 1/2 5.5

φ15.88 5/8 6.6

φ19.05 3/4 6.6

■

Connecting the cables

The power cord of connect should be selected according to the following specifications sheet.

Grade

Unit 7K 9K 12K 18K 24K 28K

mm2 1.0 1.0 1.5 2.5 2.5 2.5

■

Pipe length and the elevation

Standard length

Max. Max. Additional

Capacity Pipe size

(m) Elevation Elevation refrigerant

Btu/h GAS LIQUID

B (m) A (m) (g/m)

9K-12K 3/8’’ (φ9.52) 1/4’’ (φ6.35) 3.5 5 10 30

18K-22K 1/2’’ (φ12.7) 1/4’’ (φ6.35) 4 10 15 30

24K-28K 5/8’’ (φ15.88) 3/8’’ (φ9.52) 5 15 20 65

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Lo Hi

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

8

Caution:Capacity is base on standard length and maximum allowance length is base of reliability.Oil

trap should be install per 5-7 meters.

4、

Indoor unit and outdoor unit explosion diagram and spare parts list(see explosion diagram file)

5. Refrigerant cycle diagram (working principle)

Page 21

19

9. PCB function:

NOTE: Ts is the set temperature, Tr is indoor room temperature, TP1 is indoor coil pipe temperature, TP2 is outdoor

coil pipe temperature.

Display panel

[1]only two LED

①running lamp(green):power on light, flash one time/ one second during anti cooled wind.

②timer lamp(yellow):only light at timer state.

[2]eleven LED

① running lamp(green):power on light, flash one time/ one second during anti cooled wind.

②temperature lamp(green):16~31℃ set temp. and room temp. display, light is set temp. flash is set temp.

[3]two LED and two 8LED

① running lamp(green):power on light, flash one time/ one second during anti cooled wind.

② timer lamp(yellow):only light at timer state.

running

Page 22

20

③8LED display set temp., also it can display timer time and failure code.

[4]LED multi-colour panel

①according to display mode: dehumidification, cooling, ventilation, heating, auto, sleep, fan speed, swing, timer, indoor

fan running.

Cooling

● Start up the compressor: when the room temperature is more than Ts+1℃, compressor → start-up

● Shut down the compressor: when the room temperature is less than or equal to the set temperature Ts-1℃,

compressor → shutdown

● When the temperature of coil pipe of the indoor units is less than or equal to 1℃ for one minute and the

compressor has continuous run for more than ten minutes, the compressor and outdoor blower fan shut down

through the electric control board and the indoor blower fan is running at low speed.

● When the temperature of coil pipe of the indoor units is more than or equal to 7℃ and the compressor has

shutdown for more than three minutes, the compressor and outdoor blower fan start to run and the indoor blower

fan is running at set speed.

● When the temperature of coil pipe of the indoor units is equal to or less than -10℃ for three minutes in the

compressor has continuous run for three minutes, the compressor, indoor and outdoor blower fans and swinging

wind shut down. Restart up six minutes later; if the above situations appear again within six minutes, all the

outputs are shut down through the electric control board and display failure.

● When you press turbo button of remote, the air conditioner enter turbo running, compressor and outdoor blower

fan turn on all along, indoor blower fan run at high speed, turbo indication is light.

● After the compressor runs five minutes, the lamp flashes 4 times per six seconds or display E4 if the temperature

of indoor coil pips is more than 25℃ in the continuous 20 minutes. The controller will automatically shut down if

the temperature of indoor coil pips is more than 25℃ in another continuous 20 minutes, that is the abnormality

protection of outdoor units and the indicator lamp keeps its former state of flashing. If the temperature of indoor

coil pips is less than 25℃ in the second 20 minutes or the compressor shuts down, the electric control board will

store to the normal display and the time is restarted when starting up the compressor next time.

Page 23

21

1° C

7° C

Tr

-10° C

compresso

r

outdoor

blower fan

door

blower fan

compresso

r

door

blower fan

Tr

Heating (only applicable to heat pump units)

● Start up the compressor: when the room temperature is less than Ts-1℃, compressor → start-up

● Shut down the compressor: when the room temperature is more than or equal to the set temperature Ts+3℃,

compressor → shutdown

● The electric heating start-up in the heating mode shall meet the following conditions: ① start up the compressor

Page 24

22

and indoor blower fan ② none defrost ③ TP1< 49℃ ④Tr ≤20℃.

● The electric heating shutdown in the heating mode shall meet one of the following conditions: ① shutdown

indoor blower fan ② Tr ≥ 23℃ ③ TP1≥50℃.

● In the heating mode, the indoor flower fan can be set as high/ medium/ low /automatic running mode by remote

control however the anti cool air function is prior. In the heating mode, the anti cool air control function is to

control shutdown of the indoor blower fan by detecting the temperature of coil pipe of evaporator so as to attain

the purpose of preventing cold air from blowing.

● For the waste heat emission function in the heating mode, in principle, the indoor blower fan shall be on for

fifteen seconds after the electric heating is closed.

● When the temperature of coil pipe of indoor units is more than or equal to 56℃, the outdoor blower fan shuts

down and it enters the overload protection; when the temperature of coil pipe of indoor units is less than or equal

to 52℃, the outdoor blower fan starts up and it exit the overload protection.

● When the temperature of coil pipe of indoor units rises to 63℃, the compressor and outdoor blower fan are closed

and two minutes later, the change valve is closed. The indoor blower fan is running at the set speed. Restart up six

minutes later; if the above situations appear again within ten minutes, all the outputs are shut down through the

electric control board and display failure.

● When you press turbo button of remote, the air conditioner enter turbo running, compressor ,outdoor blower fan

and four-way valve turn on all along, indoor blower fan run at high speed and it must meet start condition, turbo

indication is light.

● After the compressor runs five minutes, the lamp flashes 4 times per six seconds or display E4 if the temperature

of indoor coil pips is less than 30℃ (heating) in the continuous 20 minutes. The controller will automatically shut

down if the temperature of indoor coil pips is less than 30℃ in another continuous 20 minutes, that is the

abnormality protection of outdoor units and the indicator lamp keeps its former state of flashing.

Page 25

23

+

3

-

1

COMPRESSOR

start-up

start-up

outdoor

blower fan

start-up start-up

start-up

start-up

blower fa

n

lower

speed

low

speed

low

speed

lower

speed

low

speed

start-up

2

MIN

2

MIN

start-up

start-up

over 6 MIN

four-way

valve

Tr

Tr

Page 26

24

compresso

r

door

blower fan

Tr

36

Defrost (only applicable to the heating mode)

1. the intelligent defrost

In the heating mode, the electric control board checks and compares the temperature of indoor room and indoor coil

pipe after the compressor works for a while; judge whether the outdoor heat exchanger part is frosted or not according to

conditions such as the change of indoor coil pipe temperature; if it is judged as frosted, it automatically enters defrosting

process. When defrosting, close the indoor and outdoor blower fan and four-way valve.

2. Outdoor PCB for defrost.

In the heating mode, the unit defrost by outdoor control board:

①unit start defrost shall all meet the following conditions:

a、compressor continuous running over 7 minutes;

b、defrost relay shut off;(-5℃)

c、compressor cumulate running time over 50 minutes.;

②first defrost interval time is 50 minutes, later defrost interval time decided by last defrost time.

Defrost time(minute) Next defrost interval time(minute)

15 30

10--15 40

7--10 60

3--7 70

≤3 80

(2)end defrost condition(meet one of follows)

a、defrost time have fifteen minutes.

b、defrost relay turn on;(>8℃)

c、press ON/OFF key in defrost process.

3. Outdoor sensor for defrost

Page 27

25

① unit start defrost shall meet one of the following conditions:

a. compressor cumulate running time over 30 minutes and it continuous running over 3 minutes, the

temperature of coil pipe of the outdoor units is equal to or less than -15℃ for one minutes (Tp2≤-15℃).

b. compressor cumulate running time over 40 minutes and it continuous running over 3 minutes, the

temperature of coil pipe of the outdoor units is equal to or less than -5℃ for one minutes (Tp2≤-15℃).

c. Air conditioner first power on or it wait over 30 minutes ,the temperature of coil pipe of the outdoor units is

equal to or less than -2℃ (Tp

2

≤-15℃)

②end defrost condition(meet one of follows)

a. the temperature of coil pipe of the outdoor units is more than 15℃ (Tp

2

≥-15℃).

b. defrost time have fifteen minutes.

compresso

r

outdoor

blower fan

door

blower fan

TP2

Tr

Page 28

26

compresso

r

outdoor

blower fan

door

blower fan

TP2

Tr

Tr

compresso

r

outdoor

blower fan

door

blower fan

TP2

Page 29

27

outdoor

blower fan

door

blower fan

TP2

defrost time over 15 MIN or TP2 >15° C

Tr

compresso

r

■ Sequence chart in defrosting mode

end defrost

start-up

shutdown start-up

shutdown

start-up

start-up

start-up

shutdown

defrost

our-way

valve

door

blower fa

n

start-up

start-up

start-up

start-up

shutdown

shutdown

outdoor

blower fan

compressor

start defrost

Dehumidification

Dehumidification running is to eliminate the water vapor in the air by using the cool circulating capacity, but the

dehumidification will not decrease the indoor temperature in great deal. The air conditioner automatically repeats on

and off circulation according the room temperature, which is shown in the following figure.

Page 30

28

indoor

blower fan

°C

°C

door

blower fa

n

Tr

shutdown

shutdown shutdown shutdown shutdown

shutdown

shutdownshutdownshutdownshutdown

low speed

Tr≤10℃

shutdown

start-up

start-up

start-up

start-up start-up

start-up

start-up

start-up

forbid

dehumidify

● In the dehumidification mode, the indoor fan is running at the low speed for twenty seconds at first, then it select

working mode.

Ventilation working mode (only applicable to single cooling unit)

In the ventilation mode.When ventilating, the compressor, outdoor blower fan, four-way valve and electric heating are

all closed and the indoor blower fan is running at the set speed.

compresso

r

outdoor

blower fan

door

blower fan

Tr

Automatic mode

● Conditions for entering the automatic running mode are: After power-up for the first time, start up and select the

automatic operating mode of remote or press emergency key, the working mode depends on Tr and if the working

Page 31

29

mode had set , it doesn’t change by Tr and the default set temperature is 25 ℃.

2

5

T

r

2

1

26° C

mode

Time on and time off

When the time on or time off is used, the clock of remote controller shall be corresponding to the current clock and the

timing times is less than or equal to 24 hours, when the timing time is reached, unit will start-up or shutdown.

Sleep function

When the sleep key is press, air conditionerenter sleep state, indoorblower fan running at low speed, only sleep

indication display.

Emergency key function

There is a forcible execution key on the panel of indoor units and the air conditioner can run by pressing the key when

the remote control is out of work or missing.

When pressing down the forcible execution key, then power up and enter the self-check program.

Failure display

LED lamp display

code explain code explain

failure

The reason of fault and solution

DF

display at

on state

flicker 1/1

SEC

defrost

indication

Normal, the defrost state is removed, it will return to

normal condition automatically

display at

off state

flicker 1/3

SEC

anti cold wind

1、 Normal (during heating mode )

2、It will be removed when the coil pipe temperature

sensor reaches certain temperature.

E2 display at flicker 1/1 display room temp. 1、Check whether the resistance of the sensor is normal

Page 32

30

off state SEC at on/off

state

sensor fault

(the resistance is 5КΩ in the normal temperature

25 )℃ , when it is abnormal the sensor should be

replaced.

2、Check whether there is short circuit or open circuit in

the wire of the sensor, and whether the plug is

connected well, whether there is welding off or

rosin joint on the electric control board, if there is

any, it should be repaired.

3、When the 1 and 2 are both normal, then the

components or integrated circuit is damaged, the

electric control board should be replaced.

E3

display at

off state

flicker 3/5

SEC

display

at on/off

state

coil temp.

sensor fault

1、Check whether the resistance of the sensor is normal

(the resistance is 5КΩ in the normal temperature

25 )℃ , when it is abnormal the sensor should be

replaced.

2、Check whether there is short circuit or open circuit in

the wire of the sensor, and whether the plug is

connected well, whether there is welding off or

rosin joint on the electric control board, if there is

any, it should be repaired.

3 、 When the 1 and 2 are both normal, then the

components or integrated circuit is damaged, the

electric control board should be replaced.

E4

display at

on/off

state

flicker 4/6

SEC

display

at off

state

outdoor unit

abnormal

1、 Check whether the winding resistance and

operation current of the compressor are normal.

2、Check whether the high and low pressure is normal

when the unit is running.

3、Check (whether the coil pipe sensor is normal)

whether the contact of the inserter on the circuit

board is well, the coil pipe temperature sensor is

fixed, the evaporation of the indoor unit is well,

the key is to check the evaporator temperature

detected by the coil pipe temperature sensor has

reached the cooling or heating temperature.

4、Check whether the surface of the condenser is too

dirty, it should be cleaned when it is too dirty.

5、Check whether the capacitance of the outdoor motor

and the fan is damaged, it should be replaced when

it is damaged.

6、If the above items are normal, the electric control

board should be replaced.

E5

PG motor

display at

off state

flicker 5/7

SEC

display

at off

state

no feedback

signal of indoor

fan

1、Check whether two sets of plugs on the outlet end of

the motor have loosed from the socket of the

electric control board, insert it firmly when loosing.

2、Check whether the indoor motor has damaged, the

motor should be replaced when it is damaged

3、 Check whether the controllable silicon and other

components on the electric control board have

Page 33

31

damaged, replace the controllable silicon or electric

control board when they are damaged.

E6

PG motor

display at

off state

flicker 6/8

SEC

display

at off

state

no over zero

signal

1、Firstly check whether the indoor fan is normal.

2、Check whether the signal outputting from the

integrated chip of the electric control board is

normal, the electric control board should be

replaced when the signal is abnormal.

E7

display at

off state

flicker 7/9

SEC

display

at off

state

outdoor

feedback fault

1、Check whether the winding resistance and operation

current of the compressor are normal

2、Check whether the high and low pressure is normal

when the unit is running.

3、Check whether the indoor and outdoor wiring is

right; when it is wrong, connect them again

according to the circuit diagram

4、 Check whether the contact of the inserter on the

circuit board and the connection are well, otherwise

repair.

5、Check whether the signal feedback wire is

disconnected, replace or connect the feedback

signal wire.

6、Check whether the supply power is phase-lacking or

phase opposition.

7、Check whether the AC electromagnetic contactor is

well.

E8

display at

off state

flicker 8/10

SEC

display

at off

state

frost

protection/over

heat protection

1、Check whether the filter of the indoor unit is dirty or

blocked, and clean if it is dirty.

2、Check whether the indoor fan is running normally,

and replace the motor if it is abnormal.

3、Check whether indoor pipe temperature sensor is

normal, and replace the sensor if it is abnormal.

4、Check whether the system pressure is normal, if

abnormal, should check whether there is leakage,

and fill the refrigerant again.

Page 34

32

10. TROUBLE SHOOTING

Is CN (Tr sensor connector)

connected properly?

Is Tr sensor resistance value

(5KO at 25? ) normal?

Indoor P. C. board is defective. Replace P. C. board.

Connect CN properly.

Replace TA sensor.

Is CN (TP1 sensor connector)

connected properly?

Is TP1 sensor resistance value

(5KO at 25? ) normal?

Indoor P. C. board is defective. Replace P. C. board.

Connect CN properly.

Replace TC sensor.

YES

YES

YES

YES

NO

NO

NO

NO

Indoor Tr sensor

error

Indoor TP1 sensor

error

Page 35

33

Turn off power

supply once, and

turn it on again.

Does

compressor

continue to

operate?

Start to operate indoor

unit in cooling

operation at airflow

level “LOW”,wait

three minutes..

Does indoor

fan operate?

Fan motor

operates

normally.

Is it possible to detect AC

220V between

pin(high/middle/low) and

pin(common) of motor

connector .

Replace indoor

fan motor.

Replace main

P.C. board.

Replace

bearing.

YES

YES

YES

NO

NO

NO

Turn off indoor unit and rotate

cross-flow fan by hand when the

unit is on standby.Is it possible to

rotate cross-flow fan by hand

properly?

Only indoor fan motor does not operate.

Is capacitor of indoor fan ok?

YES

NO

YES

Replace

capacitor

NO

<Primary check>

(1) Is it possible to detect the power supply voltage (200-240V) between L and N on the terminal

block?

(2) Does the indoor fan motor operate in cooling operation?

Page 36

34

Compressor does not operate.

Turn on power supply.

Does compressor delay

three minutes by

temperature changes or

others?

Does OPERATION

indication indicate?

Is it possible to detect AC

220-240V on terminal

block or contactor of

compressor?

Are all of compressor

cords normal?

Is compressor motor

winding normal?(Check

winding resistor.)

Is capacitor for

compressor normal?

Is overload relay normal?

Does compressor start?

Does compressor stop

after a while?

Is gas quantity normal?

(Check gas pressure.)

Microcontroller is defective or

miniature relay is defective..

Is resistance value of room

sensor (Tr) and heat exchanger

sensor (TP1) normal?

Room sensor or heat

exchanger sensor is

defective.

Replace room sensor

or heat exchanger

sensor.

Compressor is defective.

Capacitor is defective.

Overload relay is defective.

Compressor is defective.

Gas shortage (Gas leak)

Compressor is defective.

Replace P.C. board.

Rewire or replace

defective cords.

Replace compressor.

Replace capacitor.

Replace overload

relay.

Supply gas.

Replace compressor.

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO NO

NO

NO

NO

NO

NO

NO

NO

Check power supply.

Replace compressor.

Wait three minutes

<Primary check>

(1) Is the room temperature higher than the preset temperature in cooling operation?

(2) Is the crossover cable connected properly?

Page 37

35

Replace

P.C. board.

Is receiver on

indoor unit exposed

to direct sunlight?

Batteries are

exhausted.

Press START/STOP

button.

Is there any thyristor

fluorescent light

nearby?

Does indoor unit

operate when

moving remote

control near receiver

or indoor unit?

P.C. board is

defective.

Is transmission

mark indicated?

Press RST button

on remote control

with tip of pencil.

Press START/STOP

button.

Does radio sound is

affected by remote

control when a

signal is transmitted

at distance of 5 cm

from radio?

Does indoor unit

start to operate by

automatic restart

function?

Is transmission

mark indicated?

Does indoor unit

beep and operate?

Remote control is

defective.

Keep indoor unit

away from

thyristor

fluorescent light.

Avoid direct

sunlight.

Replace

batteries.

Normal

operation

Replace remote

control.

The unit does not beep at all.

OPERATION indication on

indoor unit is not indicated.

NO

NO

NONO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

YES

YES

Page 38

36

Trouble

Is the power

applied to the unit?

Check power supply mains or

interconnection wires

Is the power normal? check

the voltage between L&N of

terminal block

Check the wiring of indoor and

outdoor

Press the power ON/OFF button

of wire control or remote control

YES

YES

NO

NO

Does the beeper

beep?

Is the display all

off?

Check the connector on display

PCB connected to control PCB

Check the display PCB itself

Is the unit display

normal?

Does outdoor unit run?

Does the

compressor run

normally?

Check the failure code

according to the failure

table

Normal

Check the

compressor ,wires

and it’s

capacitor.

YES

YES

YES

YES

YES

YES

NO

NO

NO

Does the control

ok?

Does the control

PCB ok?

Control failure

Control PCB failure

NO

NO

YES

NO

Trouble shooting

NO

Does the indoor

unit run?

Page 39

37

Indoor unit and outdoor unit don’t operate

Indoor and outdoor unit

don’t operate

Press emergency key, does

the air conditioner

running?

Replace fuse of

indoor PCB.

YES

YES

YES

NO

NO

NO

NO

Make the power

supply ok.

Replace remote

control.

YES

NO

Replace remote

receiver or display

panel.

NO

YES

YES

Replace transformer.

Does the transformer has

output?

Does the fuse of indoor

PCB burn out?

Change a good remote,

does the air conditioner

running?

Is the power supply no

problem?

Does the 12V and 5V of

indoor PCB have?

Replace PCB.

normal

Does the electric switch

cut off?

Does the electric switch

cut off after a few

nimutes?

Is the wires of indoor

unit and outdoor unit no

problem?

YES

Reconnect the wires.

NO

Is the insulation of

indoor unit and outdoor

unit no problem?

YES

Find the reason and

replace the failure

componet.

NO

Is the resistance of each

main component no

problem?

Rreplace the failure

componet.

NO

YES

YES

YES

Loading...

Loading...