Page 1

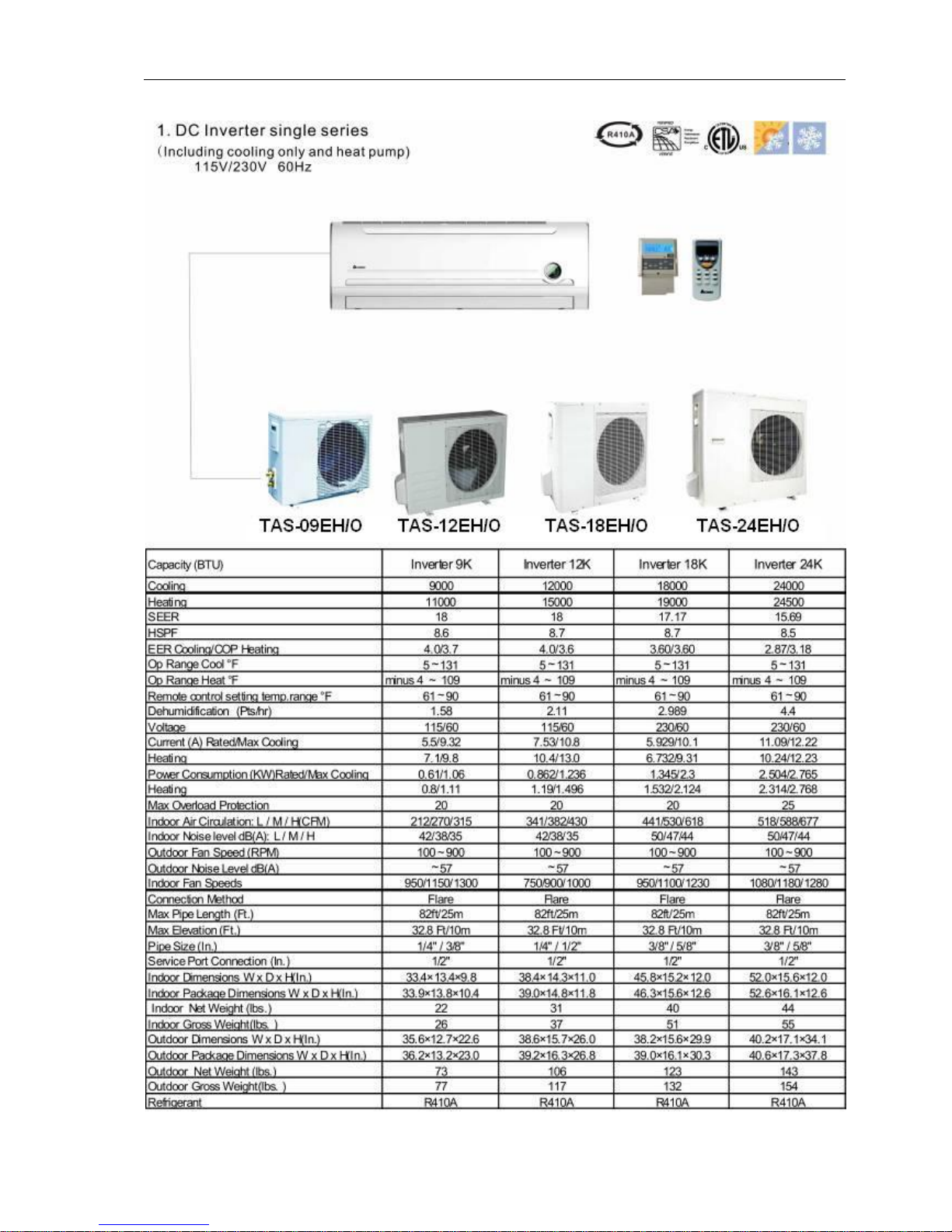

DC Inverter Split Air-Condition Unit

SERVICE MANUAL

Page 2

2

Contents

1. Main parameter........................................................................................................................1-1

2. Working temperature range .................................................................................................2-1

3. Characteristic feature ...........................................................................................................3-1

4. Outline dimension .................................................................................................................4-1

5. Explosion View ......................................................................................................................5-1

6. Error code ...............................................................................................................................6-1

7. DC Invert multi-split series faulty code manual...................................................................7-1

Page 3

3

Page 4

4

2 RATING CONDITIONS and Operating Limits

2.1 RATING CONDITIONS

Standard conditions in accordance with ANSI/AHAM RAC-1-2003, and UL 484.

Cooling:

Indoor: 80oFDB 67oF WB

Outdoor: 95oF DB 75oF WB

Heating:

Indoor: 70 oF DB 60 oF WB

Outdoor: 47

o

F DB 43 oF WB

2.2 Operating Limits

Outdoor

Upper limit (DB)

110 oF

Cooling

Lower limit (DB) 5oF

Upper limit (DB) 75 oF

Heating

Lower limit (DB) 5oF

2PH 198–264V/115V

Voltage

3PH N/A

Page 5

5

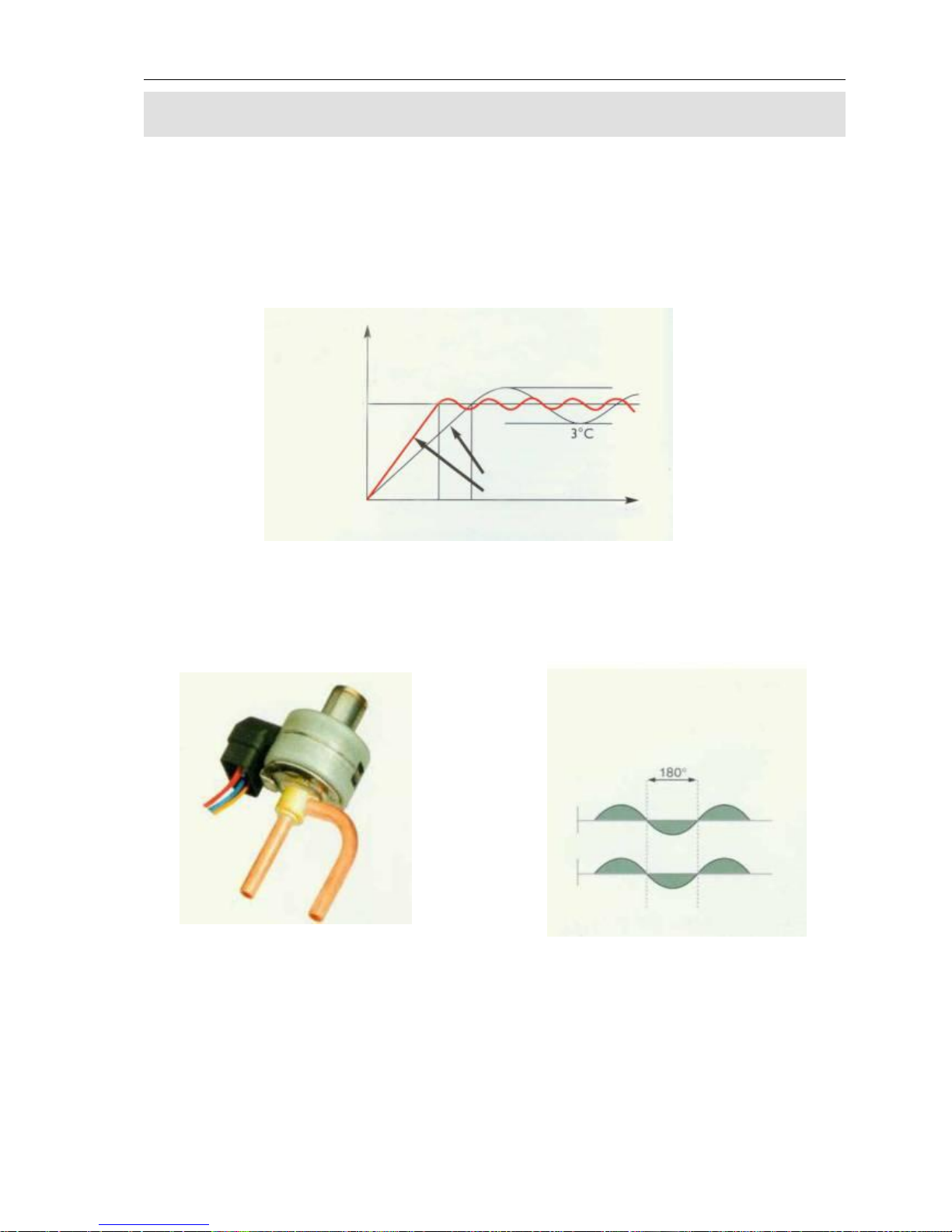

3、 Units characteristic

☆ Wide operating range with outdoor air temperatures up to -15℃ in cooling for the Heat pump

☆ High efficiency and energy saving

☆ Auto-restart after a power supply blackout

☆ Single-phase power supply thanks to DC inverter technology low consumption

☆ Dynamic refrigerant control by DC inverter compressor and circuit, electronic valve and fuzzy logic

managed by a powerful micro program

☆ EEV for each indoor unit

We leaded to adapt 180°sine wave with permanently magnetic and synchronized

Brushless motor, compressor motivated from 120°square wave control to 180°

sine wave. These contribute higher efficiency, lower power consumption and noise.

Compressor motivated

by 180°sine wave

High precision of flow control valve, Compared with the on/off unit, DC inverter

with large range of flow, accurate has the advantage of fast refrigeration of

control, these could implement calefaction, accurate temperature control,

automatically control to refrigerant reliable system, high efficiency and so on.

and help system always run at the

best condition..

Page 6

6

Page 7

7

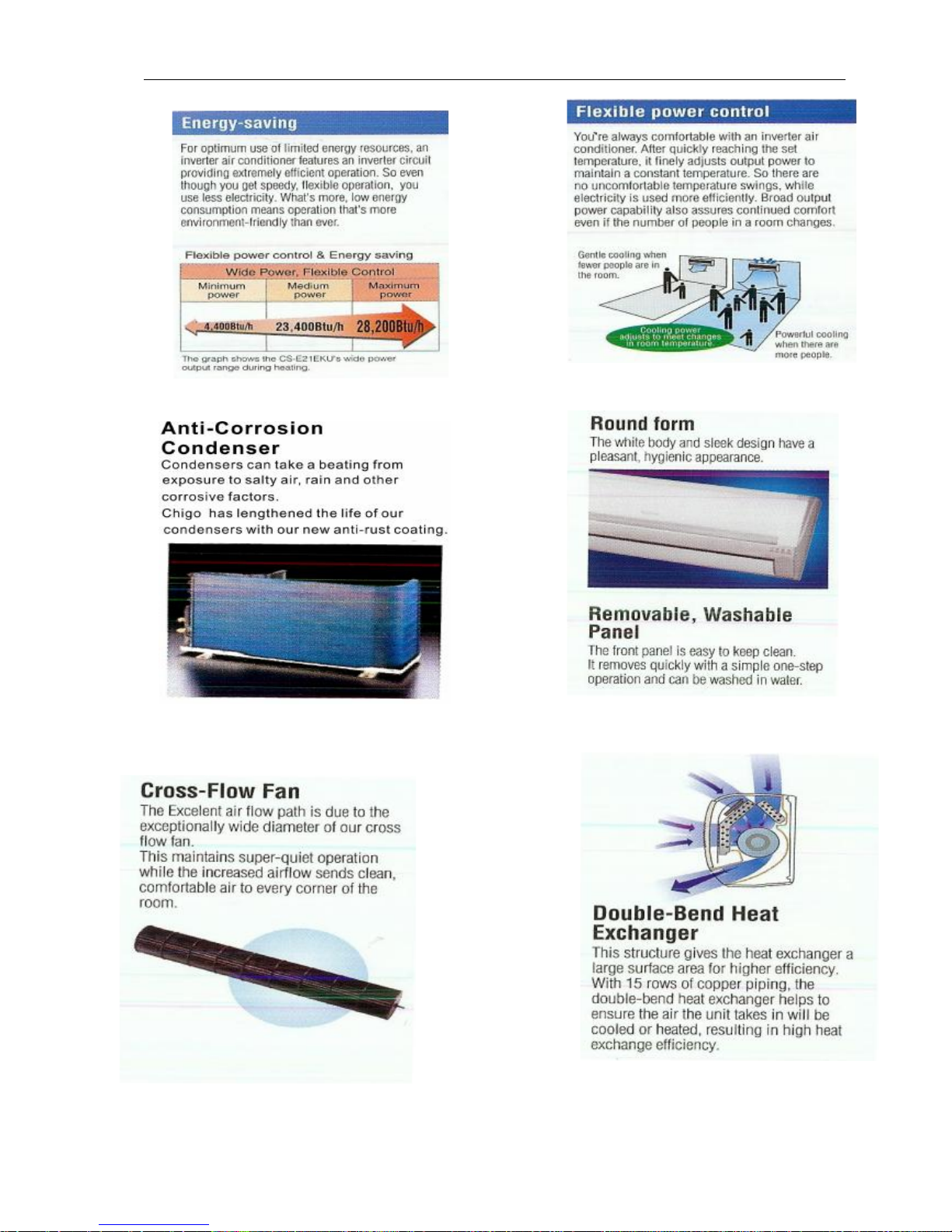

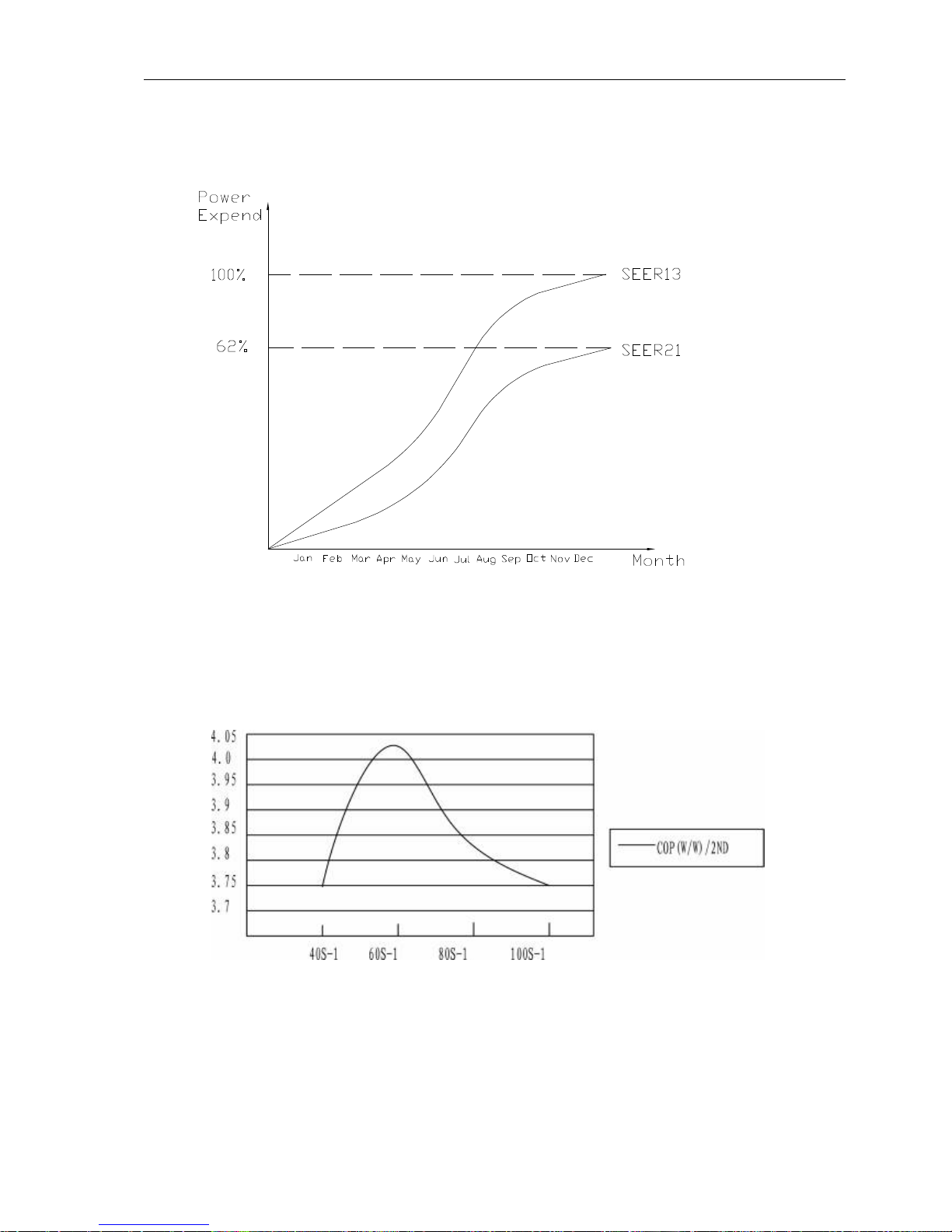

In fact , the new CS is a high efficiency DC inverter technology outdoor unit,its

SEER is as high as 21 for the 12K unit。 when compared to SEER13 , it can

save electricity 38℅ in a year.

Compressor Energy Consumption Diagram

COP (W/W)/2ND

Page 8

8

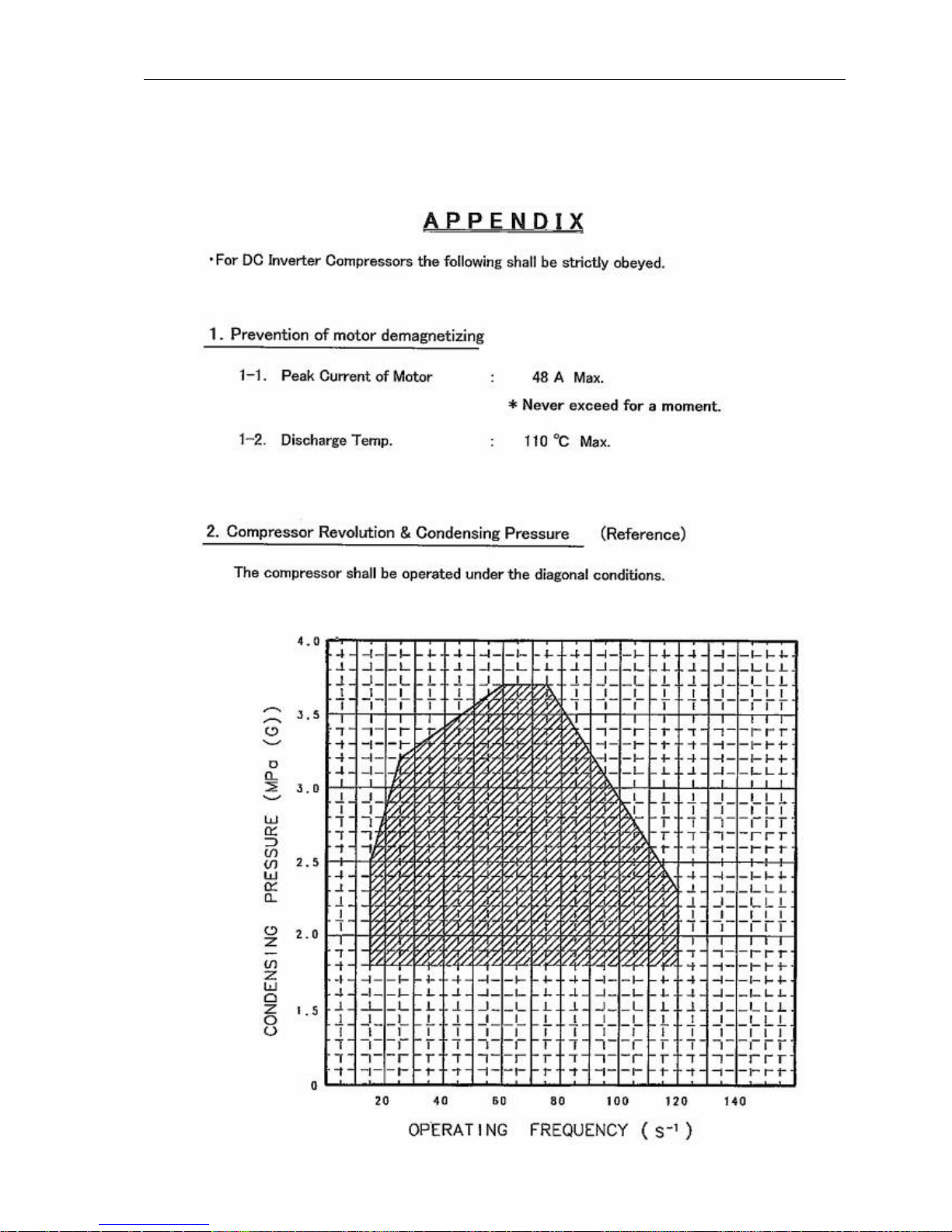

Compressor Condensing Pressure Diagram

Page 9

9

Cooling Capacity (BTU)---Run Model,230/115V,Indoor fan at high speed

INDOOR ENTERING AIR DB/WB TEMPERATURE [0F]

OUTDOOR

ENTERING AIR DB

TEMPERATURE[0F]

DATA 72/59 75/63 81/66 84/70 90/73

TC 80 - 110 % of nominal

SC 80 - 105 % of nominal

14~68

(protection range)

PI 25 - 50 % of nominal

TC

11616

12336

13104

13872

14640

SC

10421

10603

10845

11027

11269

77

PI

0.72

0.73

0.75

0.76

0.77

TC

11040

11808

12576 1

3296

14064

SC

10118

10361

10542

10785

10966

86

PI

0.81

0.82

0.83

0.85

0.86

TC

10464

11232

12000

12768

13536

SC

9876

10058

10300

10542

10724

95

PI

0.88

0.90

0.92

0.93

0.94

TC

9936

10704

11424

12192

12960

SC

9634

9815

10058

10239

10482

104

PI

0.97

0.98

0.99

1.01

1.02

TC

9264

10032

10752

11520

12288

SC

9270

9512

9694

9936

10118

115

PI

1.07

1.08

1.09

1.11

1.13

Page 10

10

Heating Capacity (KW)---Run Model,230V,Indoor fan at high speed

ID COIL ENTERING AIR DB TEMPERATURE [0F]

OD COILENTERING

AIR DB/WB TEM

PERATU RE[0F]

DATA 59 68 77

TC 8960 8260 7700

5/3

PI 0.66 0.73 0.80

TC 9940 9240 8680

14/10

PI 0.80 0.87 0.95

TC 10640 10080 9380

20/18

PI 0.91 0.97 1.04

TC 11060 10500 9800

30/28

PI 0.96 1.02 1.08

TC 11340 10640 10080

36/34

PI 0.99 1.06 1.12

TC 14560 14000 13440

45/43

PI 1.04 1.11 1.18

TC 15400 14840 14140

50/48

PI 1.11 1.18 1.25

TC 16240 15680 14980

59/54

PI 1.16 1.22 1.30

TC 85 - 105 % of nominal

59~75

(Protection Range)

PI 80 - 120 % of nominal

LEGEND

TC – Total Cooling Capacity, BTU SC – Sensible Capacity, BTU PI – Power Input, kW

WB – Wet Bulb Temp., (

0

F) DB – Dry Bulb Temp., (0F) ID – Indoor OD – Outdoor

Page 11

11

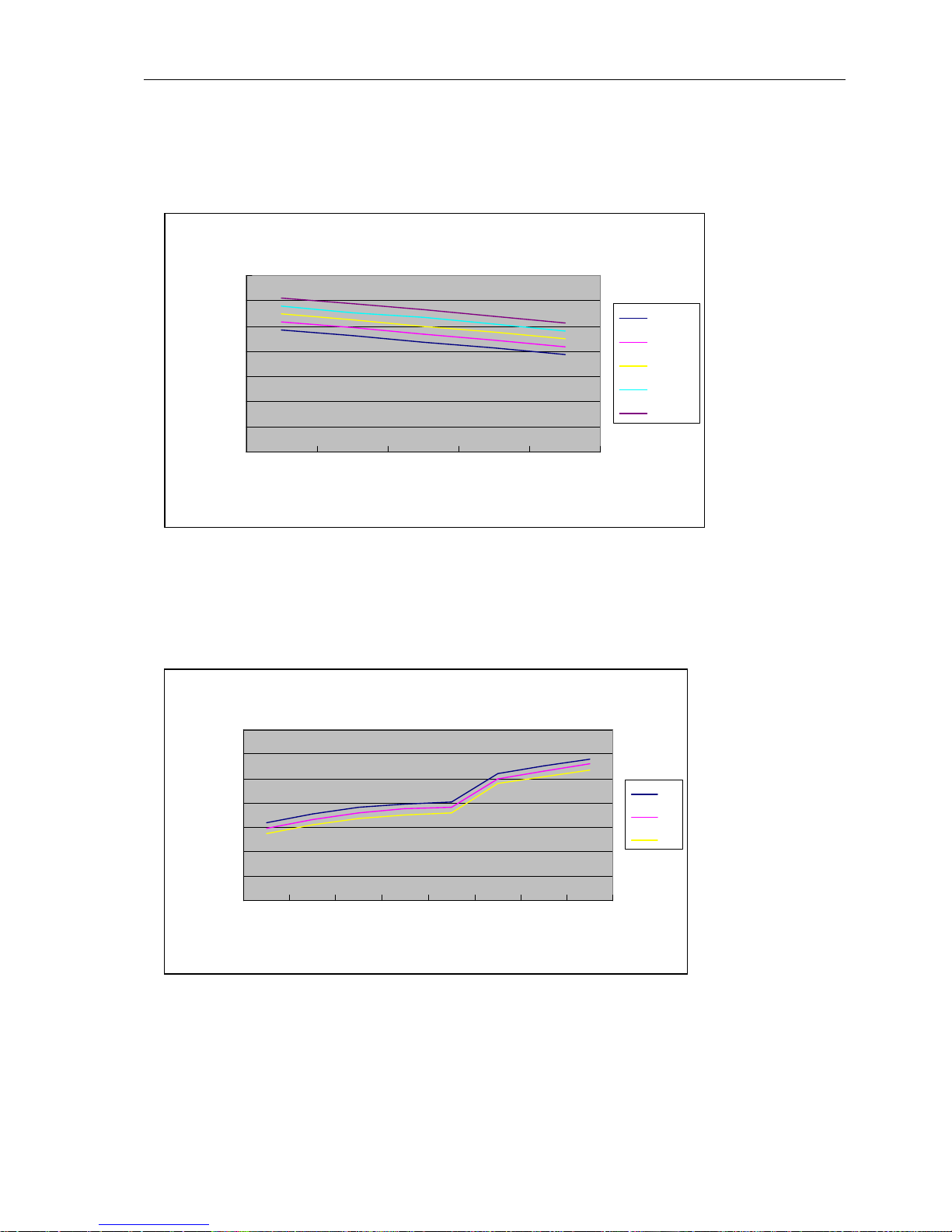

Capacity Correction Factors

Cooling Capacity Ratio Vs. Outdoor Temperature

Heating Capacity Ratio Vs. Outdoor Temperature

Cooling Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

77 86 95 104 115

Outdoor Temp.(deg F)

Capacity Ratio

90/73

84/70

81/66

75/63

72/59

Heating Capacity Correction Factor

0

0.2

0.4

0.6

0.8

1

1.2

1.4

5 14 20 30 36 45 50 59

Outdoor Temp.(deg F)

Capacity Ratio

59

68

77

Page 12

12

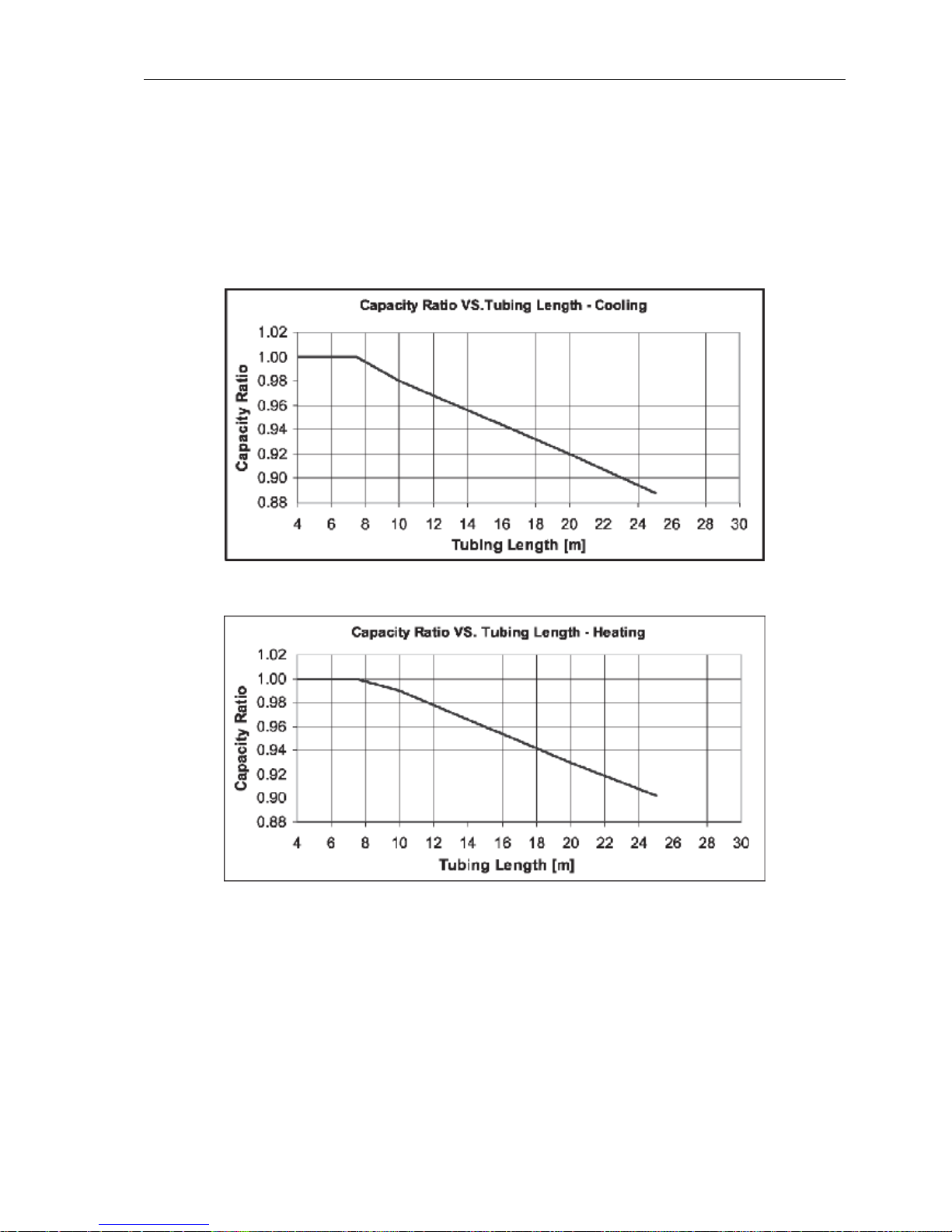

Capacity Correction Factor Due to Tubing Length (One Way)

Cooling

Heating

Page 13

13

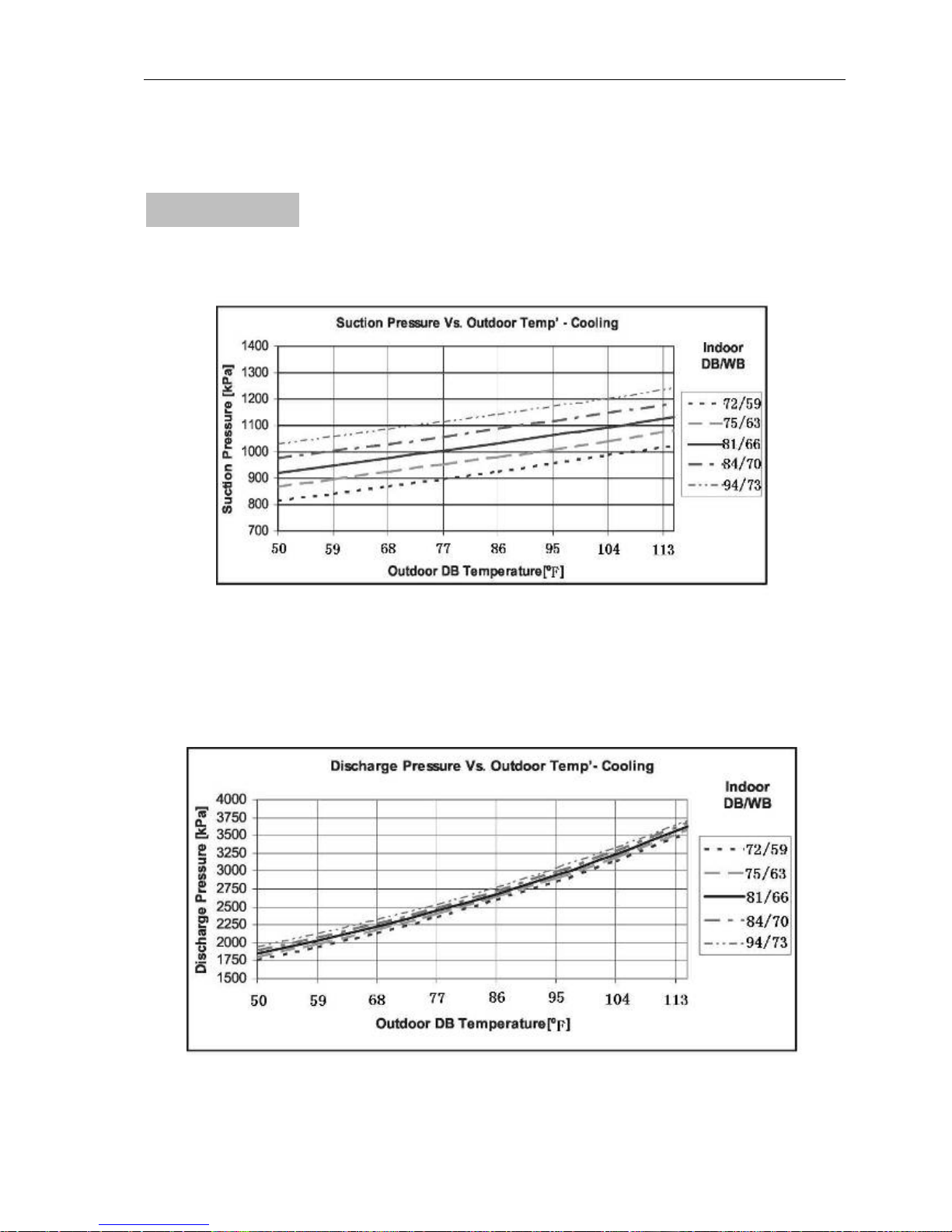

Pressure Curve

Suction Pressure Curve

Discharge Pressure Curve

Page 14

14

ELECTRICAL DATA

Model

TAS-09EH/O

Power Supply 1 PH, 115 VAC,60Hz

Connected to Outdoor

Maximum Current 9.3A

Inrush Current 40A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

2 X 4 X 1 mm2

Model

TAS-12EH/O

Power Supply 1 PH, 115 VAC,60Hz

Connected to Outdoor

Maximum Current 10.8A

Inrush Current 40A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

2 X 4 X 1 mm2

Model

TAS-18EH/O

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 10.1A

Inrush Current 40A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

2 X 4 X 1 mm2

Model

TAS-24EH/O

Power Supply 1 PH, 230 VAC,60Hz

Connected to Outdoor

Maximum Current 12.2A

Inrush Current 35A

Starting Current 1A

Circuit breaker 20A

Power supply wiring - No. x cross section 1 X 3 X 2.5 mm2

Interconnecting cable - No. x cross section

2 X 4 X 1 mm2

Page 15

15

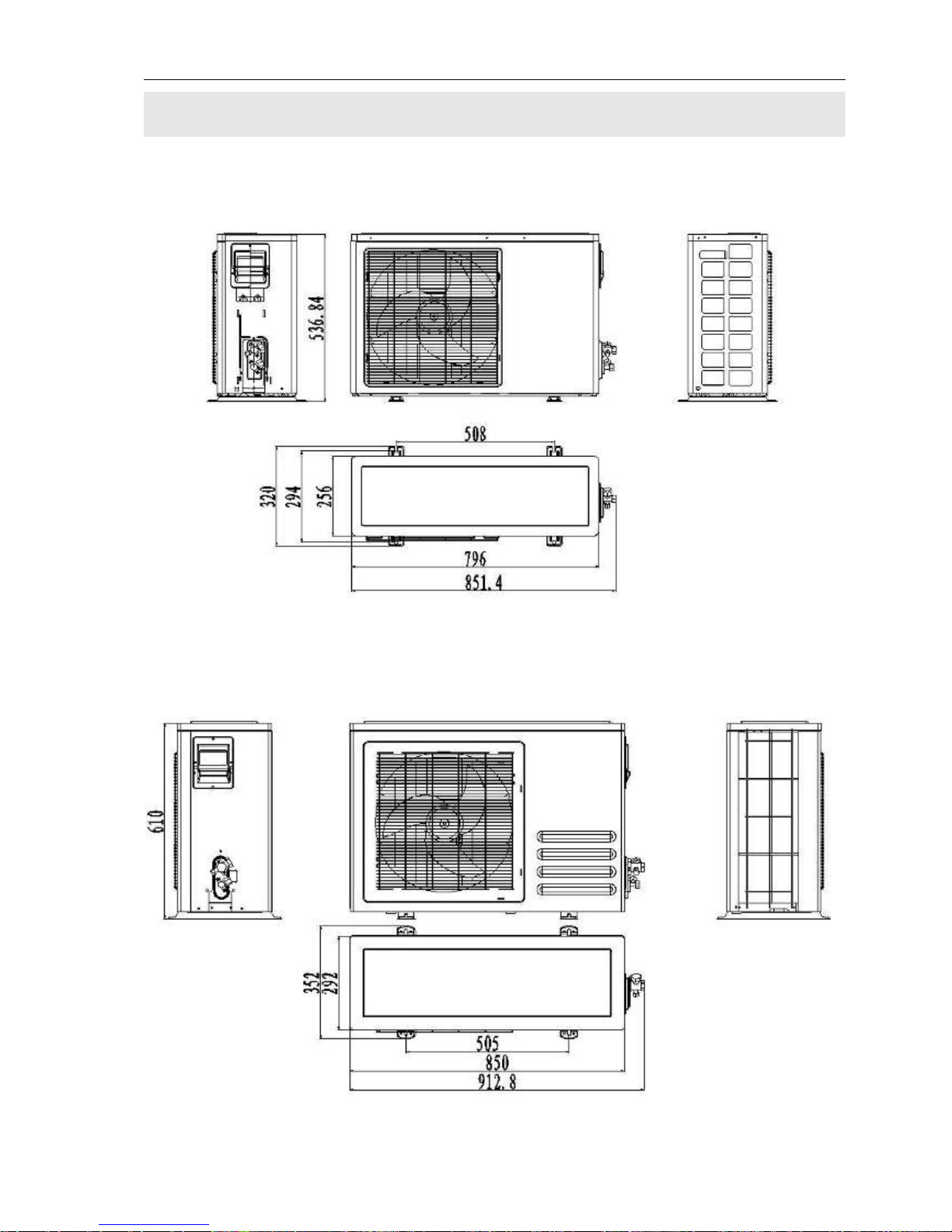

4. OUTLINE DIMENSIONS

4.1 outdoor Unit: TAS-12EH/O

4.2 outdoor Unit: TAS-12EH/O

Page 16

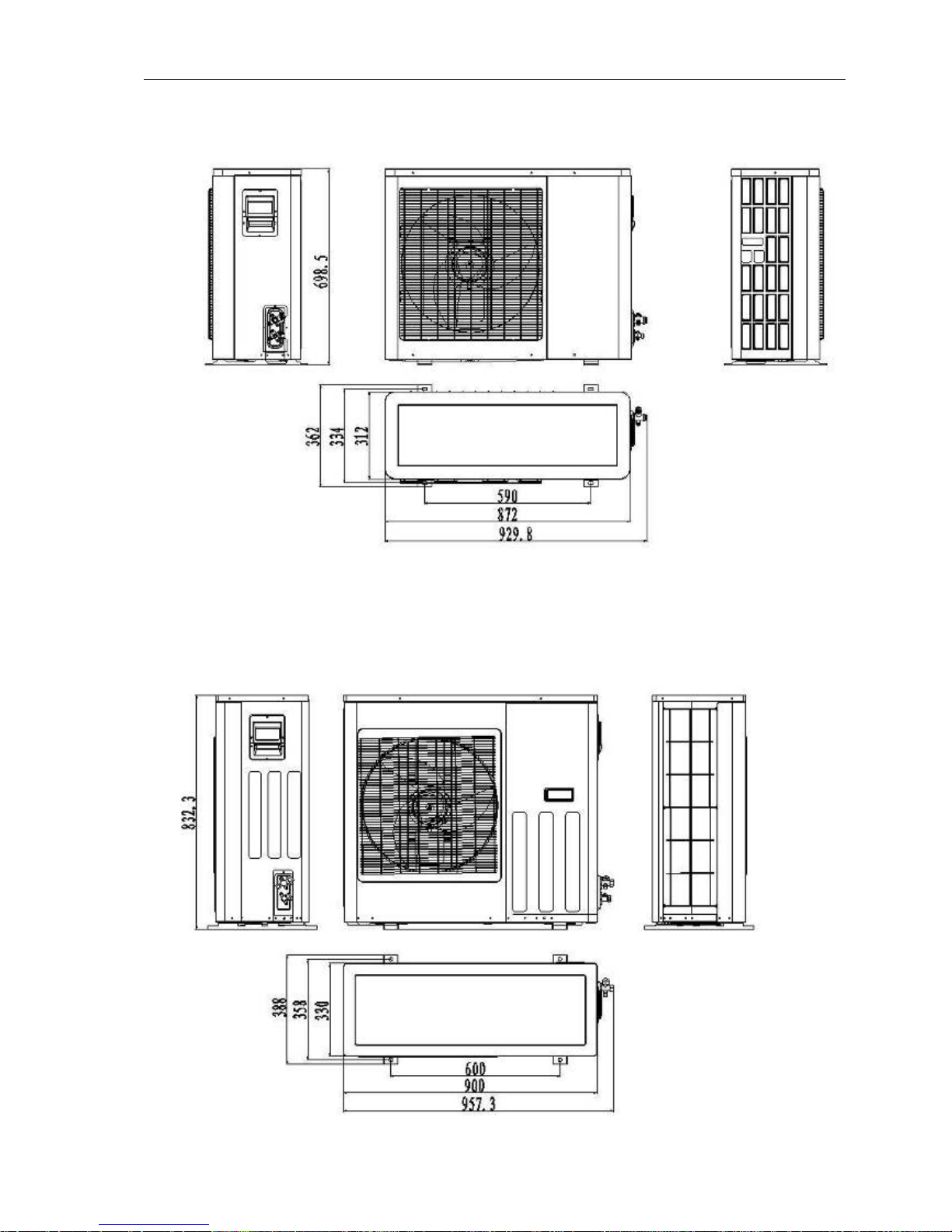

16

4.3 outdoor Unit: TAS-18EH/O

4.4 outdoor Unit: TAS-24EH/O

Page 17

17

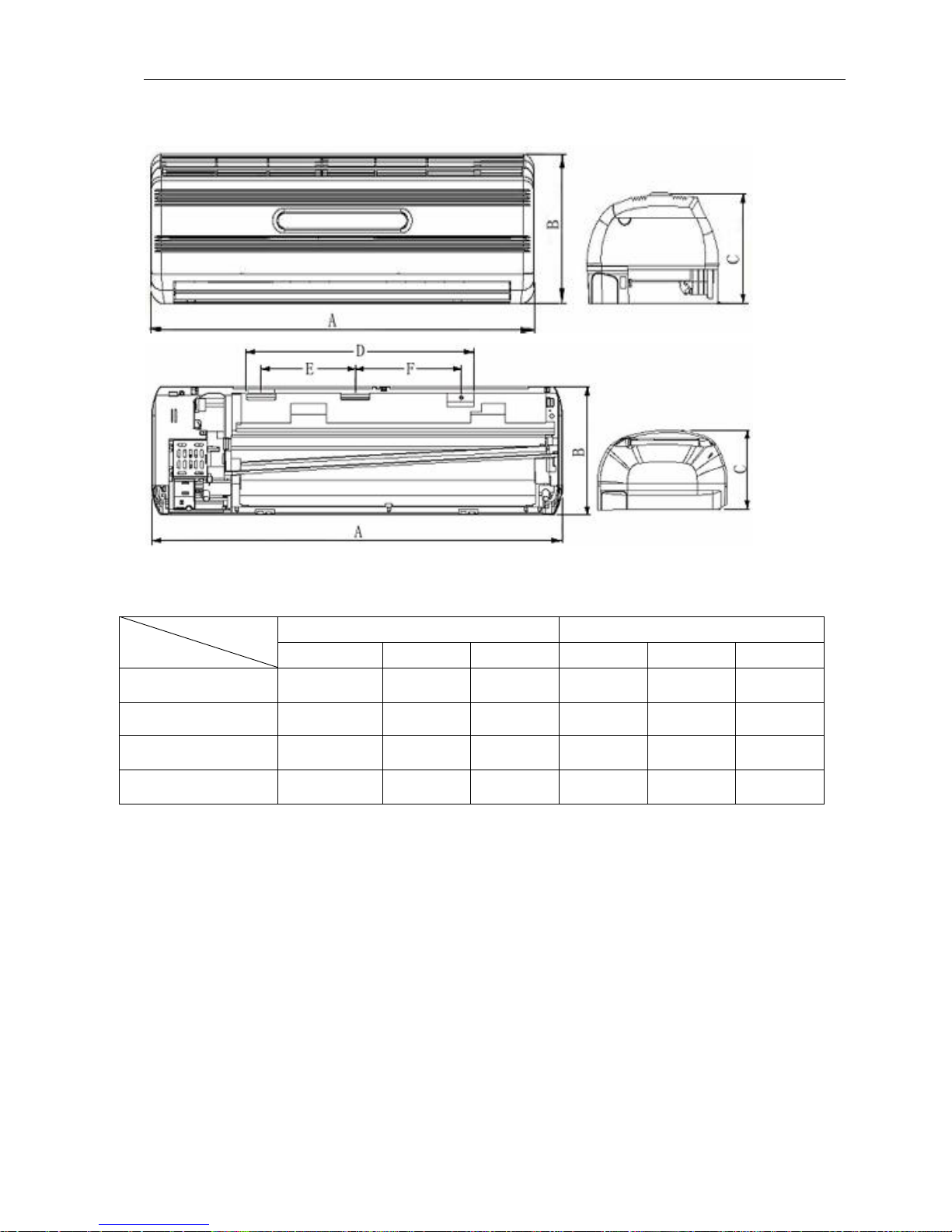

4.5 INDOOR UNIT OUTLINE SIZE AND INSTALLATION SIZE

单位:mm

OUTLINE SIZE INSTALLATION SIZE

SIZE CODE

MODEL

A B C D E F

TAS-09EH

800 280 195 490 / /

TAS-12EH

900 296 220 583 257.5 257.5

TAS-18EH (W)

1068(1080) 325(305) 240(214) 700(696) 305(305) 315(315)

TAS-24EH

1225 325 245 685 311.5 311.5

Page 18

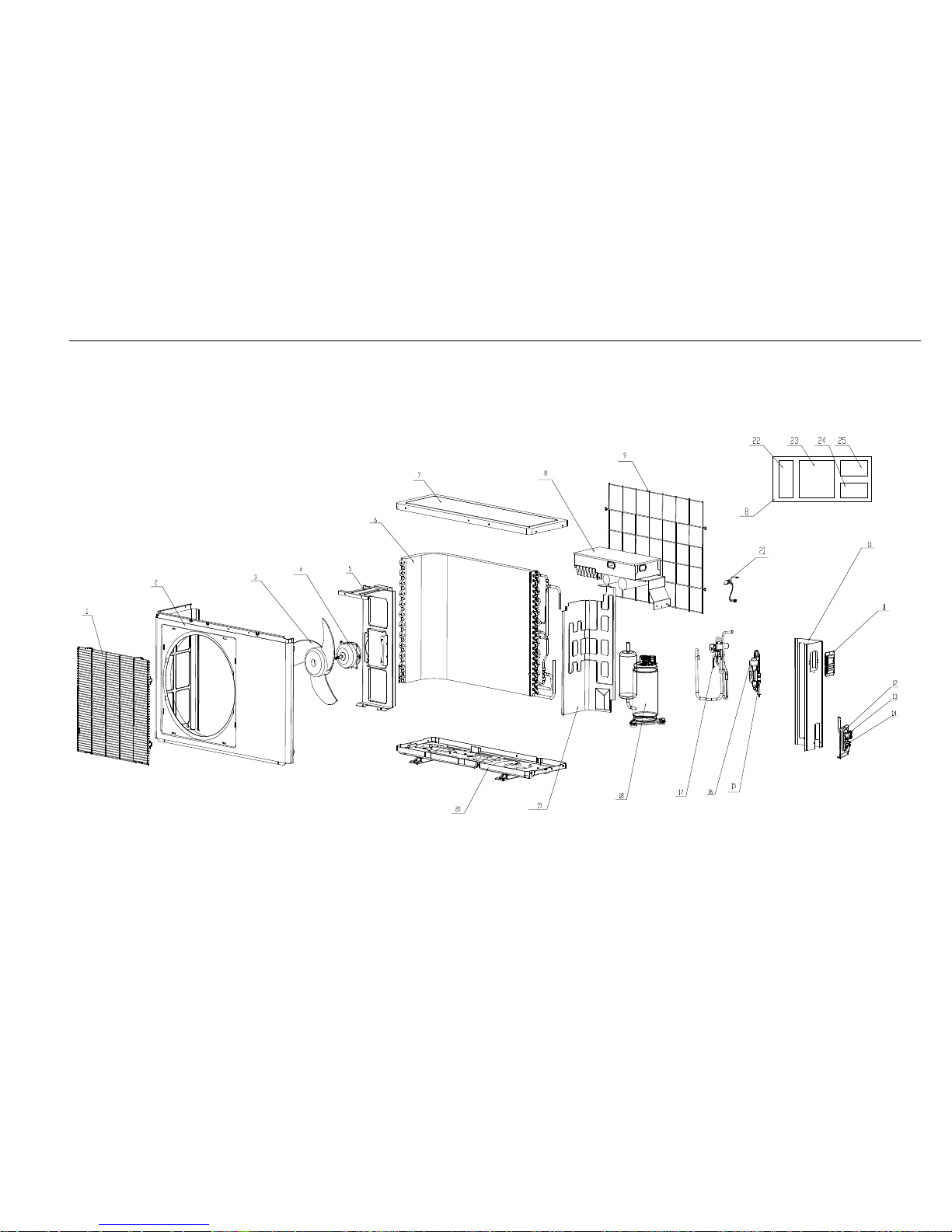

18

5、 EXPLOSION VIEW

5.1、TAS-09EH/O

Page 19

19

Page 20

20

5.2 、TAS-09EH

ON

OFF

Page 21

21

Page 22

22

5.3、TAS-12EH/O

Page 23

23

Page 24

24

5.4、TAS-12EH

ON

0FF

F

Page 25

25

Page 26

26

5.5、TAS-18EH/O

Page 27

27

Page 28

28

5.6、TAS-18EH

ON

0FF

F

Page 29

29

Page 30

30

5.7 TAS-24EH/O

Page 31

31

Page 32

32

5.8、TAS-24EH

Page 33

33

Page 34

34

6、The analysis of indoor malfunction code(internal wiring get loose,

which will cause malfunction.)

Ⅰ、indoor detailed malfunction

1.when indoor unit live wire is disconnected,its lamp panel can’t display.

Live wire is off。

2.when the transformer’s secondary and primary disconnect or indoor fuse is off,the indoor unit lamp

panel can’t display.

Transformer secondary is off

Transformer primary is off

The relevant transfomer primary

socket

Page 35

35

Indoor unit fuse is off.

The indoor unit fuse

The condition that the lamp panel

can’t display。

3.(1)when the indoor null line is off,the system displays F1 code 。

(2)when indoor communication wire is off,the system also displays F1 code 。

The inserted slice to null line

The indoor unit null line is off。

Page 36

36

(2)the indoor communication wire is

off.

Communication wire socket.

the indoor lamp panel displays F1 code.

4. when indoor fan mainline or feedback wire is off,the indoor lamp panel displays F4 code. After directly

insert it well,To restart the unit to recover normal .

Indoor fan mainline is off。

The relevant socket with indoor fan mainline

Page 37

37

indoor fan feedback wire is off。

the relevant socket with indoor feedback

wire 。

The lamp panel displays F4 code.

5.when indoor sensor has the problem, the lamp will display F

2 、 F3

code. When indoor coil outlet , inlet

and middle temperature sensor appear malfunction, the lamp panel displays F3 code; when indoor

temperature sensor appears fault, the lamp panel shows F2 fault code.

Indoor temperature sensor plug

the relevant socket of indoor temperature

sensor plug

Page 38

38

The lamp panel alternately displays F2,F3

fault code.

6.when outdoor temperature sensor is off or loose contact,the indoor lamp panel displays F6 fault

code.

the relevant socket of outdoor temp.

sensor.

The outdoor temperature sensor is

off or loose contact.

Page 39

39

The indoor lamp panel displays F6

fault code.

7.when the system appears mode conflict,the indoor lamp panel shows d1 code.

the indoor lamp panel shows d1 code.

8.when the system is in the defrosting condition,The lamp panel displays dF code.

The lamp panel displays dF code.

Page 40

40

Ⅱ.The outdoor electrical control fault code of the America 12K model .

1.the outdoor module temperature sensor is off or loose contact,the lamp panel shows F6 code.

the outdoor module temperature sensor

is off or loose contact .

the relevant socket with the outdoor

module temperature sensor plug .

The lamp panel shows F6 code .

2.The outdoor unit DC busbar voltage is abnormal,the lamp panel shows F7code.

The P、N power wire are off .

Page 41

41

The lamp panel shows F7code.

3.the outdoor module drive wire is off ,the lamp panel shows FC code .

The outdoor module drive wire is off .

The matching socket with the outdoor

module drive wire

The matching socket with the outdoor

module drive wire .

The outdoor module drive wire is

off .

Page 42

42

The lamp panel shows FC code .

4、the wave filtering board and mainboard power wire is off or loose contact,the lamp panel shoes F1 code .

the wave filtering board and mainboard power

wire is off or loose contact

The matching socket with the wave

filtering board and mainboard power wire

the lamp panel shoes F1 code .

Page 43

43

5. the evaporator middle temperature and condenser middle temperature sensor is off ,the lamp panel

displays P8 code .

the evaporator middle temperature

and condenser middle temperature sensor is

off

the lamp panel displays P8 code

Page 44

44

The 67th style indoor lamp panel

The timing lamp The turbo lamp The running lamp

The indoor unit faulty display:

Faulty contents Trouble display

Communication fault

The running lamp lightens all the time,the turbo lamp

lightens 2 times ,and then extinguish 2 seconds。

Indoor fan fault

The running lamp lightens all the time,the turbo lamp

lightens 5 times,and then extinguish 2 seconds。

Indoor temp. sensor fault

The running lamp lightens all the time,the turbo lamp

lightens 3 times ,and then extinguish 2 seconds。

Indoor coil outlet temp. sensor fault

The running lamp lightens all the time,the turbo lamp

lightens 4 times,and then extinguish 2 seconds。

Indoor coil inlet temp. sensor fault

The running lamp lightens all the time,the turbo lamp

lightens 4 times ,and then extinguish 2 seconds。

Indoor coil middle temp. sensor fault

The running lamp lightens all the time,the turbo lamp

lightens 4 times ,and then extinguish 2 seconds。

Mode conflict

The running lamp lightens 1 time ,and then extinguish

1 second。

Defrosting or anti cold air

The timing lamp lightens 1 time ,and then extinguish

1 second。

The outdoor unit faulty display:

Faulty contents Trouble display

the outdoor unit transducer module

protection faulty

The timing lamp lightens all the time,the turbo lamp

lightens 2 times ,and then extinguish 2 seconds。

over current of outdoor unit

The timing lamp lightens all the time,the turbo lamp

lightens 3 times ,and then extinguish 2 seconds。

discharge temp. of compressor too high,

outside ambient temp. too high, switch

temp. of compressor crust cut off, temp.

of module too high

The timing lamp lightens all the time,the turbo lamp

lightens 4 times ,and then extinguish 2 seconds。

The outdoor unit DC busbar voltage is

abnormal

The timing lamp lightens all the time,the turbo lamp

lightens 7 times ,and then extinguish 2 seconds。

lack refrigerant or reverse valve fault

The timing lamp lightens all the time,the turbo lamp

lightens 8 times ,and then extinguish 2 seconds。

outdoor sensor fault

The running lamp lightens all the time,the turbo lamp

lightens 7 times ,and then extinguish 2 seconds。

outdoor unit drive fault, start compressor

failure

The running lamp lightens all the time,the turbo lamp

lightens 6 times ,and then extinguish 2 seconds。

Page 45

45

The 85th style indoor lamp panel

The timing lamp The sleeping lamp The running lamp

Faulty contents Trouble display

Communication fault

The timing lamp lightens all the time,the sleeping lamp

lightens 2 times ,and then extinguish 2 seconds。

Indoor fan fault

The timing lamp lightens all the time,the sleeping lamp

lightens 5 times ,and then extinguish 2 seconds。

Indoor temp. sensor fault

The timing lamp lightens all the time,the sleeping lamp

lightens 3 times ,and then extinguish 2 seconds。

Indoor coil outlet temp. sensor fault

The timing lamp lightens all the time,the sleeping lamp

lightens 4 times ,and then extinguish 2 seconds。

Indoor coil inlet temp. sensor fault

The timing lamp lightens all the time,the sleeping lamp

lightens 4 times ,and then extinguish 2 seconds。

Indoor coil middle temp. sensor fault

The timing lamp lightens all the time,the sleeping lamp

lightens 4 times ,and then extinguish 2 seconds。

Mode conflict

The timing lamp lightens 1 time ,and then extinguish

1 second。

Defrosting or anti cold air

The running lamp lightens 1 time ,and then extinguish

1 second。

Faulty contents Trouble display

the outdoor unit transducer module

protection faulty

The running lamp lightens all the time,the sleeping lamp

lightens 2 times ,and then extinguish 2 seconds。

over current of outdoor unit

The running lamp lightens all the time,the sleeping lamp

lightens 3 times ,and then extinguish 2 seconds。

discharge temp. of compressor too high,

outside ambient temp. too high, switch

temp. of compressor crust cut off, temp.

of module too high

The running lamp lightens all the time,the sleeping lamp

lightens 4 times ,and then extinguish 2 seconds。

The outdoor unit DC busbar voltage is

abnormal

The running lamp lightens all the time,the sleeping lamp

lightens 7 times ,and then extinguish 2 seconds。

lack refrigerant or reverse valve fault

The running lamp lightens all the time,the sleeping lamp

lightens 8 times ,and then extinguish 2 seconds。

outdoor sensor fault

The timing lamp lightens all the time,the sleeping lamp

lightens 7 times ,and then extinguish 2 seconds。

outdoor unit drive fault, start compressor

failure

The timing lamp lightens all the time,the sleeping lamp

lightens 6 times ,and then extinguish 2 seconds

Page 46

46

DC inverter multi-split series faulty code manual

Malfunction code:F1 ( the communication faulty)

Y

Turn off the power

1、 Refer to the connecting diagram (Fig. 1),

check whether the wire is connected

correctly.

2、 Pls screw again to make the wire firm.

Whether the communication wire is

connected wrongly or disentwined.

N

The indoor PCB fault,check whether the communication

circuit on the indoor PCB has been damaged, check

especially some important electric parts ,such as the

Y

If the indoor PCB has been

damaged, pls changed it.

N

The outdoor PCB fault,check whether the communication circuit on the outdoor PCB has been

damaged,check especially some important electric parts ,such as the optical coupler、voltage

stabilizing diode、resistor、PTC,and so on ;Pls replace the PCB if being abnormal (Fig. 3).

The faulty cause:

1、the communication wire is broken off or

connected wrongiy;、

2、the power ground wire is connected

unfirmly;、

3、the indoor PCB’s hardware has been damaged

;

Page 47

47

The voltage of the cross flow

fan feedback end will be

increased gradually from 0 to

+2.4VDC when turning on

the

indoor

unit

PTC1 resistance value:

1.02KΩ(25℃)

The limited current resistance

value:14.8 kΩ

Note:there are two kinds of connecting technics for the indoor and

outdoor connecting cable,Fig 2 shoed the technics before 2007,and

Fig 3 showed the technics after 2007

Fig.

2

the indoor and outdoor connecting

cable’s technics before 2007

Fig. 3

the indoor and outdoor connecting

cable’s technics after 2007

The voltage stabilizing diode

ZD1 、ZD2 reference value:

Forward resisitance :713 Ω

Page 48

48

Fig. 4: the indoor PCB Note:the above parameter is tested when there is the power in the PCB, so is the following 。

Fig. 5:the outdoor PCB

Malfunction code:F2 (the indoor temp sensor fault)

Turn off the power

Take out the temperature sensor from the indoor PCB,

then check whether the indoor temperature sensor’s

resistance is normal.(the range of normal

resistance :1~40 KΩ)

N

Please replace it .when the indoor

temperature sensor has problem.

Y

Connect the sensor renewedly to the indoor PCB,,then

check the resistance between the sensor and indoor

PCB terminal. The normal resistance value is 0Ω

N

The indoor temperature sensor adapter

connector breaks off, pls replace the

indoor PCB or restore the adapter

connector.

Y

The indoor PCB is bad,please change it

PTC1 resistance value:

The limited current

resistance value: R54:

Faulty cause:1、maybe the indoor temp sensor’s

bnc connector plugs is loose or contact ill;

2

、

the sensor is bad or the down-lead is

circuit-break、circuit-short

3、the indoor PCB’s hardware has been damaged

The voltage stabilizing diode ZD1 、

ZD2 reference value:

Forward resisitance :713 Ω reverse

resistance:∞

Please test the DC motor

end to N terminal voltage

value: VCC-N +15VDC、P-N

+340VDC、Vsp -N 0~+5VDC

Page 49

49

Malfunction code :F3 ( the indoor coil temp sensor fault)

Malfunction code:F4 (the indoor fan motor fault)

Shut off the power

Take out the temperature sensor from the indoor PCB, then

check whether the indoor coil temperature sensor’s

resistance is normal.(the range of normal resistance

:1~40 K

N

Replace it .when the indoor coil

temperature sensor has problem.

Y

Connect the sensor with the indoor PCB

again. Check the sensor and the indoor PCB

terminal resistance. The normal value is 0Ω

N

If the indoor coil temperature

sensor adapter connector is loose.

Change this indoor PCB or repair

this adapter connector

Y

The indoor PCB is bad. please change it .

Shut off the power

Take out the plug from the indoor PCB. Then test the

every winding resistance (the normal value: the main

winding is 273Ω. the auxiliary winding is 343Ω) Fig. 6

fi

N

The indoor fan motor is bad,

then please change it

Y

connect the motor plug with the indoor PCB again and

turn on. Then test the feedback terminal to ground

wire voltage whether it is normal (the normal voltage

is increased gradually from 0 to +2.4VDC)

N

The indoor fan motor is bad, then

please change it

Y

The indoor PCB is bad. please

change it

Check the indoor fan whether it is smooth

N

1.If the fan is bad and change it

2.The bolt what fix the indoor fan

is loose. Pls screw it again

3.There are any dirt in the indoor

fan. Pls clean it

Y

Faulty cause:1、maybe the indoor coil temp sensor’s

bnc connector plugs is loose or contact ill;

2

、

the sensor is bad or the down-lead is

circuit-break、circuit-short

3、the indoor PCB’s hardware has been damaged

The faulty cause:

1、the fan motor is blocked or turns

abnormally;

2、the motor wire is loose or contacts ill

3、the indoor fan motor has been damaged

4、the indoor PCB is bad

Page 50

50

Malfunction code:F6 (the outdoor temp sensor fault)

T

urn off the power

Take out the temperature sensor from outdoor PCB. Then

test this outdoor temperature sensor resistance whether ii

is normal (the normal: discharge sensor is 3K~200K the

other sensor is 1K~40K

).

N

The outdoor temp sensor is

bad ,please change it.

Y

Connect the sensor with the indoor PCB

again. Check the sensor and the indoor PCB

terminal resistance. The normal value is 0Ω

N

The indoor temperature sensor adapter

connector is loose. Change this indoor PCB

or repair this adapter connector

Y

The indoor PCB is bad. please

change it

Faulty cause: 1、 maybe the indoor coil

temp sensor’s bnc connector plugs is loose

or contact ill;

2、the sensor is bad or the down-lead is

circuit-break、circuit-short

3、the indoor PCB’s hardware has been

damaged

Fig. 6、the indoor fan motor

The main winding resistance(the motor wire:

black-white 273) the

auxiliary winding resistance(the motor

wire: red-white 343Ω)

Page 51

51

Malfunction code :FA ( the communication fault between the wire controller to the indoor PCB)

]

Y

Y

N

N

Y

N

N

Electrify and turn on the unit

Check the connecting line、wire controller、PCB

whether they are loose or have a bad contact.

Please change the connecting

line or repair the loose

terminal

Check the indoor PCB、diode、triode

whether they are normal. Fig. 8

The wire controller’s

hardware is bad ,please

change it .

The wire controller’s hardware is

bad ,please change it .

Test the wire controller

to the ground wire

voltage whether it is

+5VDC. Fig. 7

Whether the light of the

wire controller is bright

The indoor PCB is

bad ,then change it

The indoor PCB is bad ,then

change it

The faulty cause:

1、the wire controller’s connecting plug is loose

or contacts ill

2、the wire controller’s hardware has been

damaged ;

3、the indoor PCB has been damaged.

Y

The voltage between the red

wire and white wire

:

+5VDC

The power indicator lamp:the

lamp is bright when the wire

Page 52

52

Fig. 7 the wire controller

Fig.8 the indoor PCB

Malfunction code:P2 (the outdoor unit transducer module protection faulty)

The dynatron Q3 reference value:

be pole :The positive pole resistance:660Ω

the negative pole resistance:961Ω;

bc pole :The positive pole resistance:659Ω

the negative pole resistance :1439Ω

The clamping diode’s parameter:

VD15 The positive pole resistance:389Ω the

negative pole resistance:392Ω

VD16 The positive pole resistance:497Ω the

negative pole resistance:1012Ω

Page 53

53

The malfunction code: P3 (The indoor input current is large)

Turn off the power

1、whether the compressor’s connecting wiring is loose

2、check whether the module and radiator are firm

N

1、pls make the compressor’s

connecting wiring firm。

2 、 pls fixup the IPM and

radiator together

Y

Check whether the compressor’s winding value is normal

(refer to SNYO C-6RZ146H1A winding value:T-R 0.452Ω

T-S0.452Ω R-S0.452Ω)

N

The compressor is bad, then

change it.

The intelligent power module is bad , and

then change it.

Y

Y

N

N

Y

Y

The faulty cause:

1 、 the compressor’s connecting wiring is

loose;

2、the IPM module and radiator are not firm

3、the IPM board has the fault.

The faulty cause:

1、the ambient temp exceed the temp range

of the A/C’s running

2、the outdoor PCB’s hardware is bad

Turn on the unit

Check the ambient temperature whether it is more

than the running temperature(cooling:10~46℃,

Pls wait the conditions returned to

normal then run it if the operating

conditions is very bad.。

Whether the current is normal? the

normal current:18K<13A. 24K, <

15A. 28K<17A

The refrigerant is more than

usual. Pls let it out.

The outdoor PCB is bad. Pls

change it

Whether the pressure is

normal? (the normal

value : the high is

2.4~3.06MPa. the low is

1.2~1.6MPa

Check the compressor

phase current whether it

is large. Pls change it if

the value is large.

N

Page 54

54

Annotation 1:The normal value of the phase current:18K<11A;24K<13A;28K<15A

The malfunction code:P4 (compressor discharge temp is overhigh、outdoor ambient temp go beyond the limited、compressor

crustal temp switch is disconnected、module temp go beyond the limited)

The malfunction code: P7 (The outdoor unit DC generatrix voltage is abnormal)

Turn off the power

Check whether the compressor crustal temp

switch is disconnected.

Y

Compressor crustal temp switch has

been damaged,then change it。

N

Check whether the outdoor ambient temp is

overhigh or overlow.

Y

The fault will disappear when the outdoor

ambient temp is beyond minus 20℃ and

under plus 55℃.

N

Pls Charge the refrigerant.

N

Check whether the A/C units’ pressure is normal(the

normal value : high pressure 3.06Mpa low pressure

1.6Mpa)when the A/C unit operate

Y

2、 check whether module temp sensor’resistance is

normal (the normal value range:1~40KΩ);

3、 check whether the module and radiator are firm;

4、 check whether the disperse heat silica gel is

short or dry;

5、 check whether the module has been damaged.

N

1、Change the temp sensor;

2、Firm the module and radiator;

3 、 Append anew the disperse heat

silica gel;

4、Change the module。

Y

Please change the outdoor PCB

Turn off the supply

Check whether the power voltage is in the

normal voltage range “150V~270V”。

Ensure the power voltage is in the

normal voltage range“150V~270V”

Y

The IPM basic board hardware has been

damaged,pls change the IPM basic board。

The faulty cause:

2、 the compressor crustal temp switch has been

damaged

3、 、outdoor ambient temp go beyond the limited

4、 compressor discharge temp is overhigh

5、 module temp go beyond the limited

The faulty cause:

1、 The power voltage is abnormal

2、 The IPM basic board hardware

has been damaged

Page 55

55

The malfunction code:P8 (lack the refrigerant or reverse valve fault)

Turn off the power

Check whether the high and low pressure

N

Open the high and low

pressure valve

正常

Check whether the system pressure is normal

(the normal value:high pressure3.06Mpa low

pressure

1.6Mpa

)

N

Due to refrigerant leakage ,

kook for the leak to weld it,then

charge anew the refrigerant to

the system.Fig.9~17

Pls change it if the sensor wire is short circuit

or open circuit.

N

Y

Check whether the indoor and outdoor pipe

temp sensor are loose or hang in the air.

Y

Pls arrange the indoor and

outdoor sensor correctly and

change it if the probe spring

piece is damaged.

Refer to Fig.18~25

Y

The faulty cause

1、 the high and low pressure valve are closed

2、 the refrigerant leaks from the A/C system

3、 the indoor and outdoor pipe temp sensor are

loose or hang in the air.

4、 the indoor and outdoor pipe temp sensor has

been damaged.

Page 56

56

Fig. 11、the bell-mouth

should aim at the valve

port

Fig. 12、the bell-mouth

should aim at the valve

port

Fig. 9、 please make

sure that there is

enough soap bubble.

Warning:please connecting the indoor and outdoor units according to the correct installing method,Fig. 11~15

show the right operating way;( Note:the indicator pictures aren’t the real photos about the DC inverter dual

zone unit)

Fig. 10、Pls daub the bubble to

four terminals, then observe them

for five minutes! If there are

some bubbles that grow slowly

and broke around the terminal,. it

Page 57

57

The following pictures are the

wrong operation. such as Fig. 16、

Fig. 17

Fig. 14、please screw the nut until can’t move

by hand,refer to the picture’s position。If not

move when screwing the nut about 3~4 circles

by hand, it is possible that the bell-mouth

doesn’t aim at the valve port ,and then operate

it again from scratch 。

Fig. 13、screw down

the nut gradually by

hand

Fig. 15、 Next please

screw the nut by the

Fig. 16、screw the nut to this place by

hand , and it can’t be moved ; then

force to screw the nut by the spanner。

Fig. 17 、 forcing to screw the nut by

spanner results in the rupture of the

bell-mouth.

Page 58

58

The spring gasket

The spring gasket

Note: Apart from the ambient temperature sensor, all sensors must be equipped with spring washer, please check it by pic. If the

angle is similar to Fig. 24, means that spring has lost its elasticity .please bend it to an angle of 135 degrees, Re. Fig. 8; Please

ensure to install them if no spring washer,.

Fig. 24 The damaged spring gasket Fig. 25 The spring gasket is in good condition.

The malfunction code: P3 (The outdoor unit fault)

Fig. 20 the outdoor condensing temp

sensor(pipe number:3)in the U-type

pipe at the middle of the condenser.

Fig. 21 the outdoor ambient temp

sensor(pipe number:2)locating

on the condenser’s back,

Fig. 18 the compressor’s discharge

temp sensor (no pipe No. ) locating

on the compressor’s outlet gas about

5 CM

Fig. 19 the compressor’s suction

temp sensor(pipe number:4)

locating on the Shock Absorbers

piece above 5CM.

Fig. 20 the outdoor condensing

temp sensor(pipe number:3)

in the U-type pipe at the middle

Fig. 23 The indoor ambient

temp sensor(pipe number:1)

Fig. 22.1 The indoor

evaporator’s middle temp

sensor (pipe number: 3)

Fig. 22.2 The indoor

evaporator’s inlet temp

sensor (pipe number: 4)

Fig. 22.3 The indoor

evaporator’s inlet temp

sensor (pipe number: 2)

Page 59

59

Fig. 26 the DC motor

The malfunction code: FC (outdoor unit drive fault, start compressor failure)

Turn off the power

Check the resistance value of the motor each port are normal.

The reference resistance value of motor port.(Vm-GND

N

The motor is bad or there

is trouble in the

Y

Test the very port resistance value whether the

VCC Vm is normal(the normal

value:VCC:15Vdc.Vm/P:340Vdc.Vsp:0~5V)

The outdoor PCB is

bad.Pls change it

The motor circuit is bad.

pls change this motor

Turn on the unit

Knock the compressor around by crabstick. Let

the rotor become be loose then turn on it again

The start-up moment isn’t

enough because of the first

running.

T

his is a normal

Check the contacting wire of compressor whether

it is right or

credible

N

Pls contact the wire exactly again

according to picture if there is a

mistake

The component of IPM board is

bad. Pls change it

Pls connect the IPM board to the PCB

exactly.

W

hether is running after

turning

on.

Y

The wire connecting the IPM board

to the PCB is loose. Pls change the

wire or PCB board.

N

The faulty cause:

1、 The motor is bad or there is

trouble in the indoor PCB

2、 The outdoor PCB is bad

The faulty cause:

1、 The start-up Moment doesn’t reach the

requirement when the compressor runs

firstly.

2、 The contacting wire of the compressor is

connected wrongly;

3、 The wire connecting the IPM board to the

PCB is loose

4、

The component of IPM board is bad.

The reference resistance value of motor

port.(Vm-GND ∞、 Vcc-GND 125kΩ、

Vsp-GND 200kΩ、PG-GND ∞)

N

Loading...

Loading...