Page 1

Commercial

Refrigerator & Freezer

Service Manual

Solid Door

Model No. : MSR-23NM

MSR-49NM

MSF-23NM

MSF-49NM

Glass Door

Model No. : MSR-23G-1

MSR-49G-2

Page 2

TABLE OF CONTENTS

1. FEATURE CHART

1-1. FRONT VIEW(MSF-49NM)

1-2. SIDE VIEW(MSF-49NM)

1-3. FRONT VIEW(MSR-49G-2)

1-4. SIDE VIEW(MSR-49G-2)

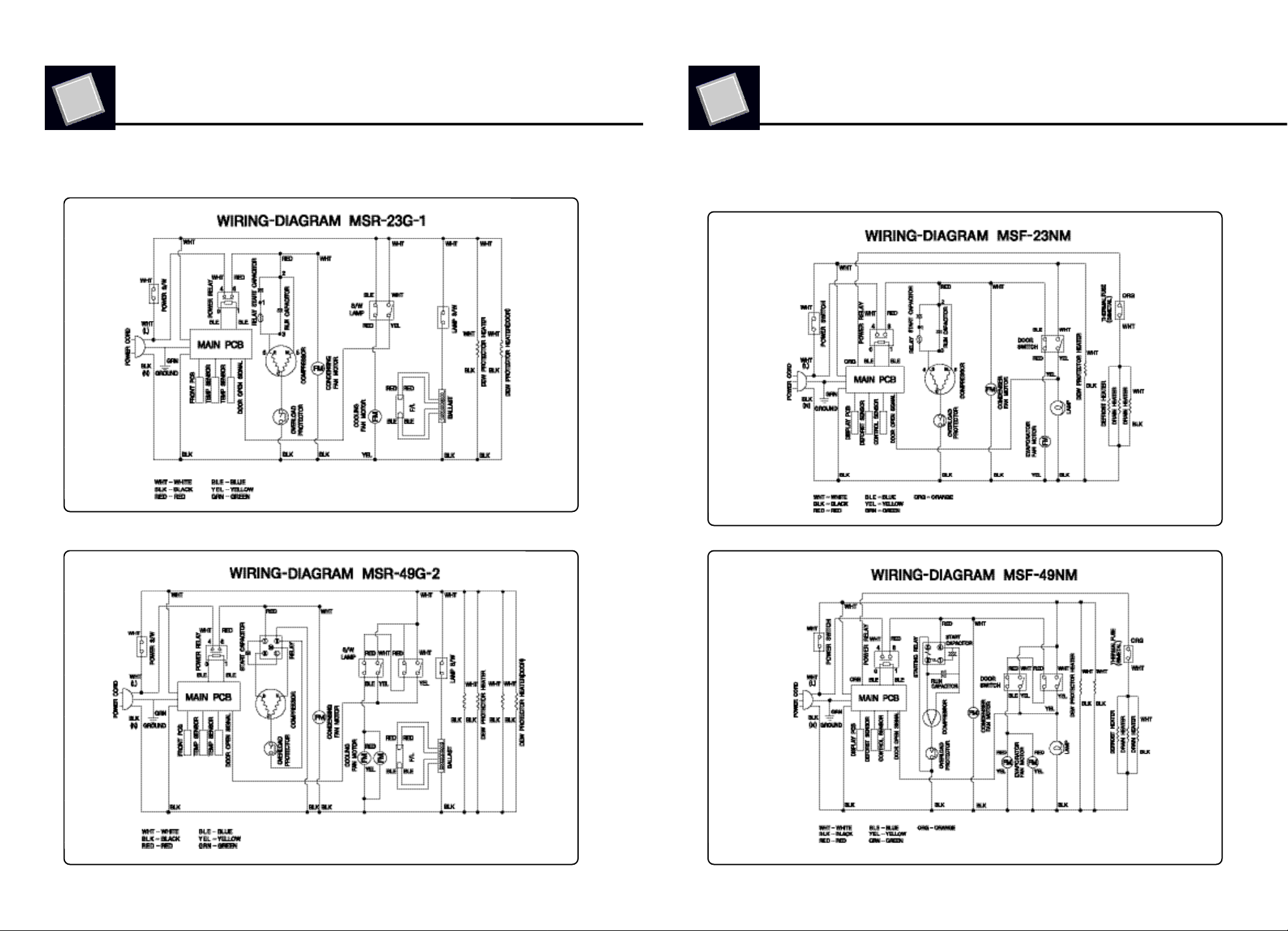

2. WIRING DIAGRAM

2-1. REFRIGERATOR : MSR-23NM, MSR-49NM

2-1. REFRIGERATOR : MSR-23G-1, MSR-49G-2

2-2. FREEZER : MSF-23NM, MSF-49NM

3. PART DETAILS

3-1. TOP PANEL

3-2. COMPRESSOR COMPARTMENT

3-3. DOOR

3-4. COOLING COMPARTMENT

4. MAIN COMPONENTS

4-1. COMPRESSOR

4-2. POWER RELAY(COMP. RELAY)

4-3. CONDENSER DRYER

4-4. COMPRESSOR CAPACITOR

4-5. EVAPORATOR FAN MOTOR

4-6. CONDENSER FAN MOTOR

4-7. EVAPORATOR DEFROST HEATER

4-8. LAMP BULB

4-9. MAIN PCB

4-10. DISPLAY PCB

4-11. BALLAST

1. FEATURE CHART

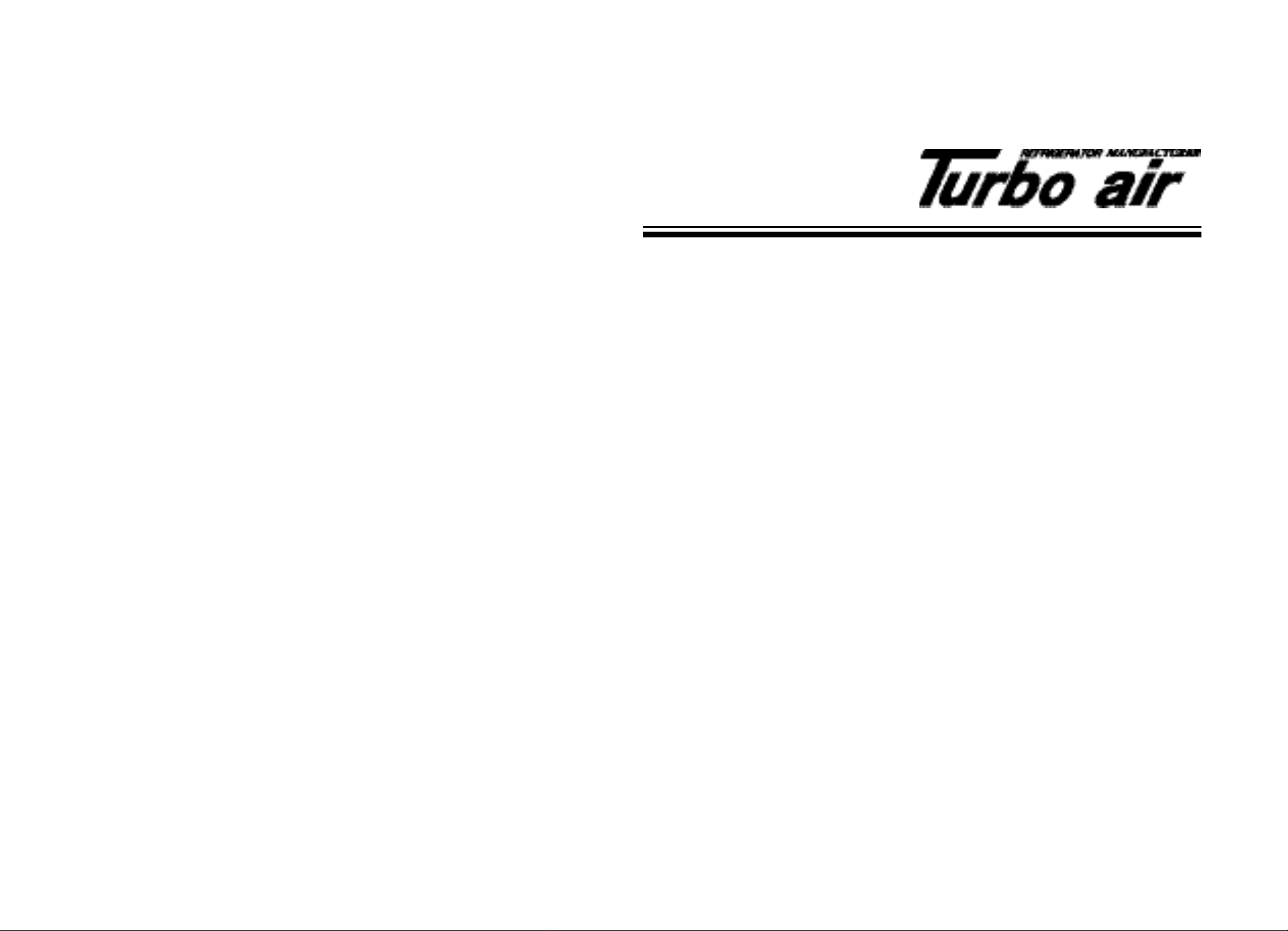

1-1. FRONT VIEW(MSF-49NM)

①

⑨

③

⑥

⑤

②

④

⑦

⑧

⑩

⑪

⑫

5. ELECTRONIC CONTROL INSTRUCTIONS

5-1. FREEZER CONTROL

5-1-1. HOW TO USE THE DISPLAY PCB PANEL

5-1-2. MANUAL DEFROST

5-1-3. FUNCTION TABLE

5-1-4. ERROR CODE TABLE

5-2. REFRIGERATOR CONTROL

5-2-1. HOW TO USE THE DISPLAY PCB PANEL

5-2-2. FUNCTION TABLE

5-2-3. ERROR CODE TABLE

6. REPLACEMENT OF MAIN COMPONENTS

6-1. TOP PANEL PARTS

6-2. REPLACING DOOR

6-3. DOOR SPRING ADJUSTMENT

6-4. REVERSIBLE-DOOR ASSEMBLING METHOD

6-5. REFRIGERATION COMPARTMENT PARTS

6-6. CONDENSING UNIT

6-7. LIGHTING-PARTS

7. PART-LIST

2

⑯

①TOP PANEL

②DOOR SWITCH

③POWER SWITCH

④DOOR LOCK

⑤MAIN PCB

⑥POWER RELAY(COMP.RELAY)

⑦DISPLAY PCB

⑧CONTROL BOARD HOUSING

⑬

⑭

⑮

⑨FREEZER BRAND LOGO

⑩DOOR HINGE TOP

⑪DOOR

⑫DOOR HANDLE

⑬DOOR HINGE BOTTOM

⑭BOTTOM GRILLE

⑮CASTER

⑯DRAIN PAN

3

Page 3

FEATURE CHART

FEATURE CHART

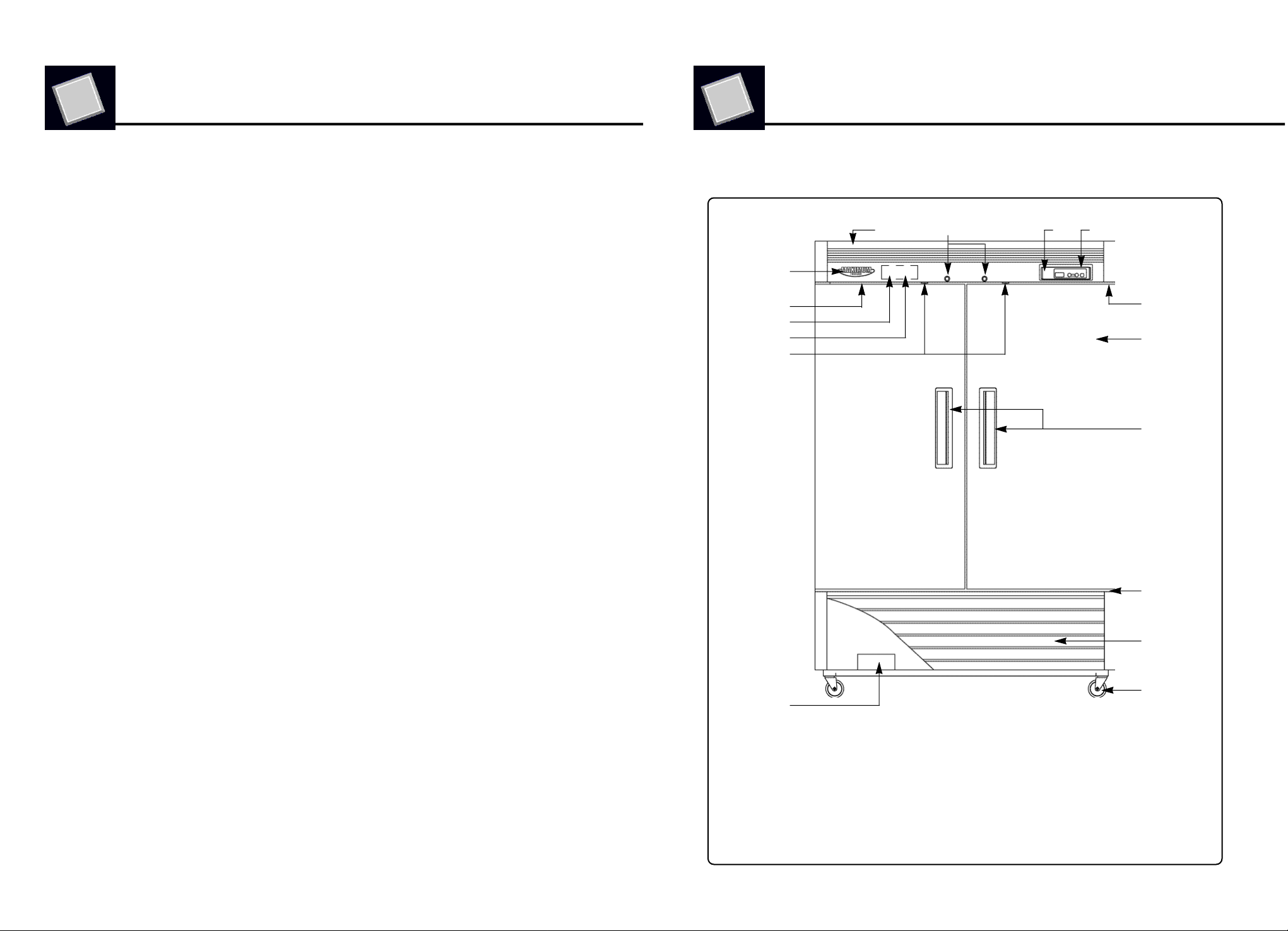

1-2. SIDE VIEW(MSR-49NM)

③

②

①

⑦

⑨

⑧

⑬

⑥-②

④

⑭

⑯

⑤

⑥-④

⑥-③

⑩

⑥-①

⑪

⑫

⑮

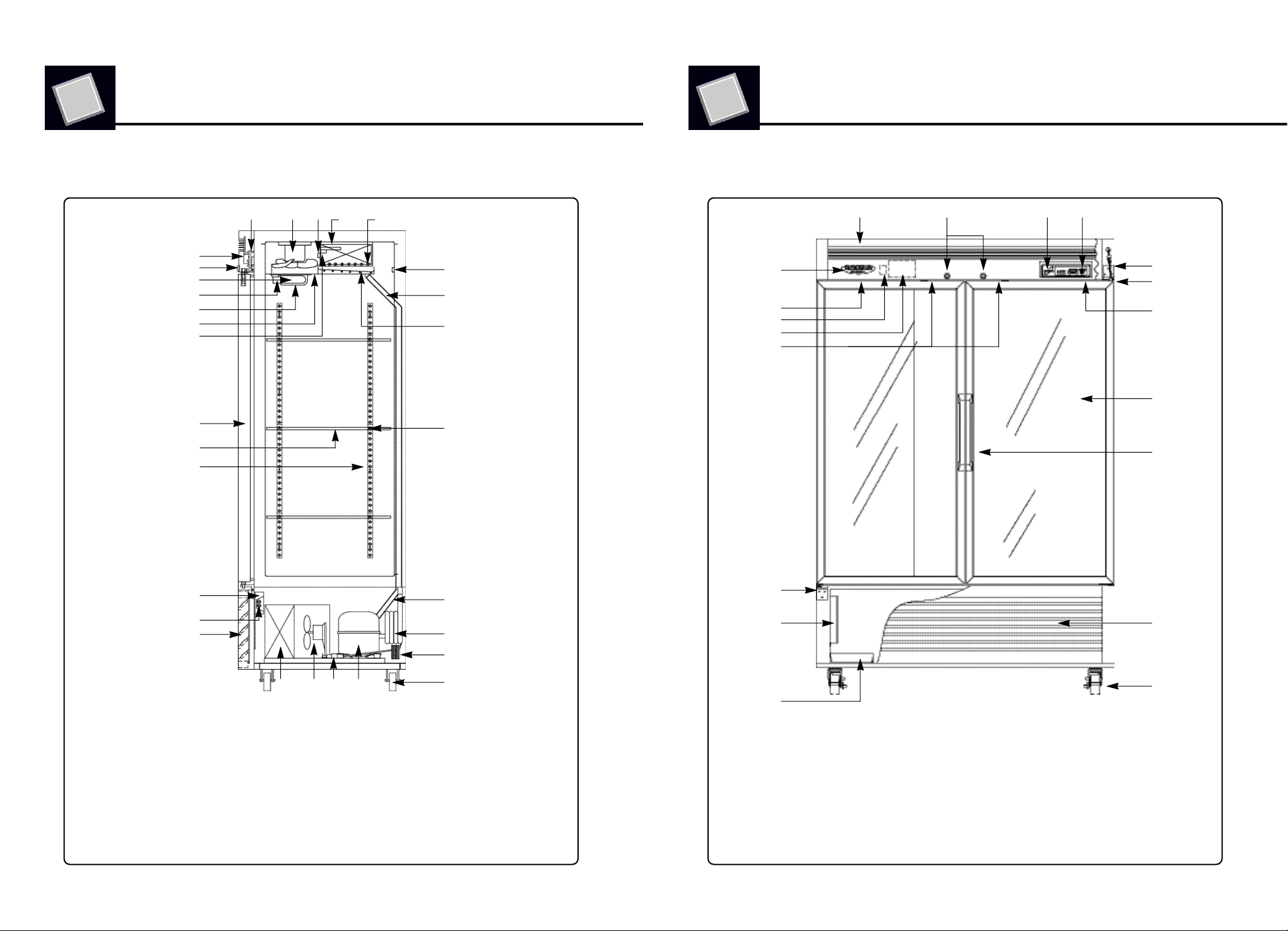

1-3. FRONT VIEW(MSR-49G-2)

① ⑦ ⑧ ⑨

⑲

③

⑥

⑤

②

⑩

⑪

④

⑱

⑰

⑱

⑲

⑰

①TOP PANEL

②POWER RELAY

③MAIN PCB

④DOOR

⑤EVAPORATOR FAN MOTOR

⑥SENSOR

⑥-① FREEZER C SENSOR

⑥-② DEFROST SENSOR

⑥-③ REFRIGERATOR C SENSOR

⑥-④ REFRIGERATOR T SENSOR

⑦LAMP BULB

⑳

⑧LAMP SHIELD

⑨LAMP SOCKET

⑩

EVAPORATOR DEFROST HEATER

⑪EVAPORATOR DRAIN HOSE

⑫

EVAPORATOR DRAIN PAN HEATER

⑬

EVAPORATOR FAN MOTOR GUARD

⑭SHELF

⑮SHELF CLIPS

⑯SHELF STANDARD

⑰BOTTOM GRILLE

⑱

COMPRESSOR CAPACITOR COVER

⑲COMPRESSOR CAPACITOR

⑳CONDENSOR COIL

CONDENSOR FAN MOTOR

CONDENSOR DRYER

COMPRESSOR

CAPILLARY TUBE

SUCTION LINE

DRAIN-HOSE

CASTER

4

⑫

⑬

⑭

①TOP PANEL

②DOOR SWITCH

③POWER SWITCH

④LAMP SWITCH

⑤MAIN PCB

⑥POWER RELAT(COMP RELAY)

⑦DOOR LOCK

⑧DISPLAY PCB

⑨CONTROL BOARD HOUSING

⑩DOOR HEATER HARNESS

⑯

⑮

⑪DOOR HINGE TOP

⑫DOOR HINGE BOTTOM

⑬BALLAST

⑭DRAIN PAN

⑮CASTER

⑯BOTTOM GRILLE

⑰DOOR HANDLE

⑱GLASS DOOR

⑲REFRIGERATOR BRAND LOGO

5

Page 4

FEATURE CHART

2. WIRING DIAGRAM

1-4. SIDE VIEW(MSR-49G-2)

①

⑦

⑧

⑨

⑩

⑪

⑫

⑦

② ③ ④

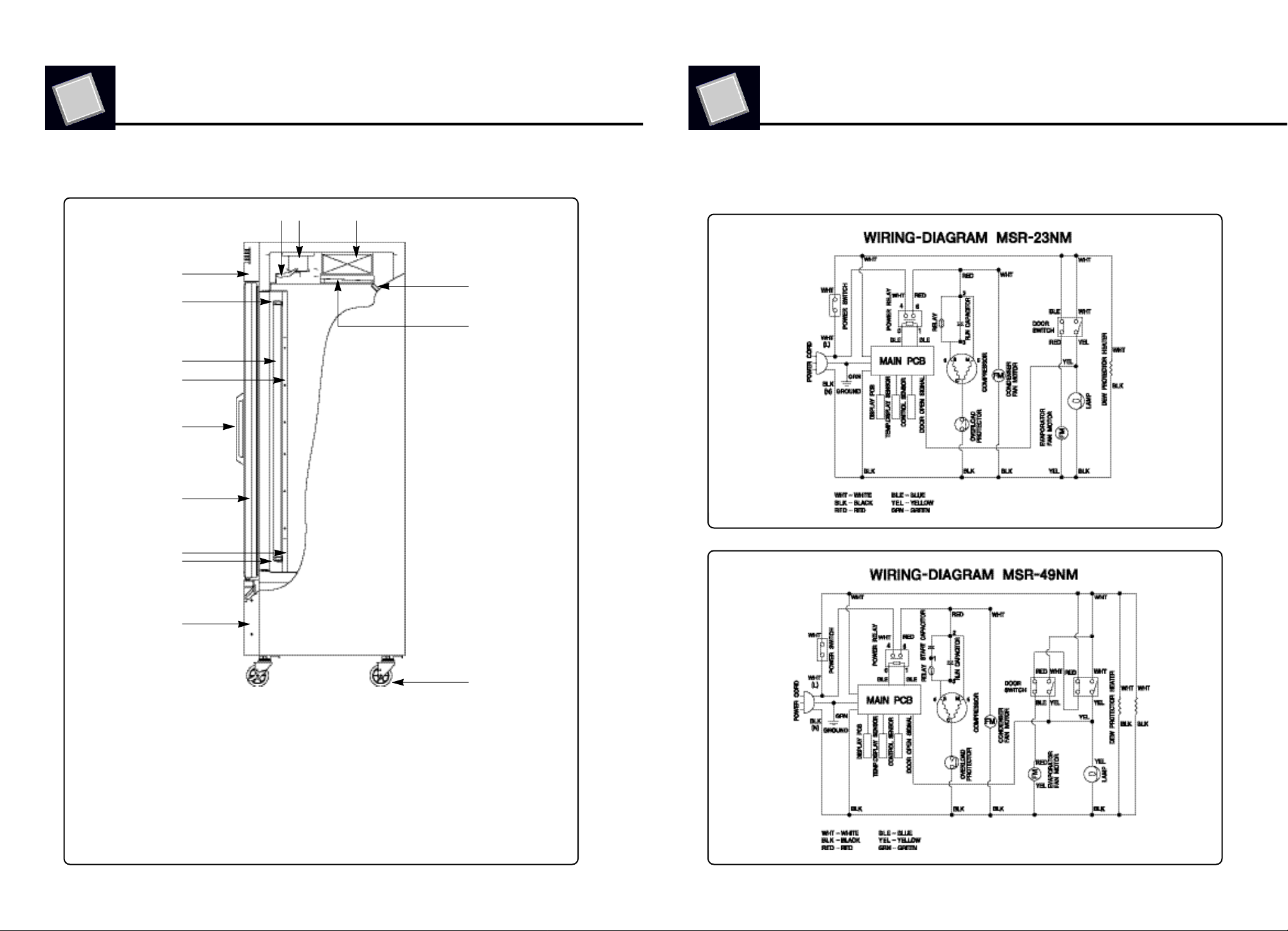

2-1. REFRIGERATOR

● MSR-23NM

⑤

⑥

● MSR-49NM

⑬

①TOP PANEL

②EVAPORATOR FAN BLADE

③EVAPORATOR FAN MOTOR

④EVAPORATOR COIL

⑤EVAPORATOR TOP DRAIN HOSE

⑥EVAPORATOR DRAIN FAN

⑦LAMP SOCKET

⑧FLUORESCENT LAMP

⑨SHELF STANDARD

⑩DOOR HANDLE

6

⑭

⑪DOOR FRAME

⑫FLUORESCENT LAMP ASSEMBLY

⑬BOTTOM GRILLE

⑭CASTER

7

Page 5

WIRING DIAGRAM

WIRING DIAGRAM

● MSR-23G-1

● MSR-49G-2

2-2. FREEZER

● MSF-23NM

● MSF-49NM

8

9

Page 6

3. PART DETAILS

PART DETAILS

3-1. TOP PANEL

Display PCB

Power SwitchPower SwitchPower Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power Switch

Power SwitchPower Switch

Power SwitchPower Switch

Power Switch

Power SwitchPower Switch

POWER SWITCHPOWER SWITCHPOWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

Door LockDoor LockDoor Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door Lock

Door LockDoor Lock

Lamp SwitchLamp SwitchLamp Switch

Lamp SwitchLamp Switch

Lamp SwitchLamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp Switch

Lamp SwitchLamp Switch

3-2. COMPRESSOR COMPARTMENT

Condensing Unit

MSR-49NM

Main PCB

POWER RELAYPOWER RELAYPOWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

10

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCBMAIN PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCB

DISPLAY PCBDISPLAY PCB

MSF-49NM

MSF-23NM, MSR-23NM

11

Page 7

3-3. DOOR

Door Gasket

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKET

GASKETGASKET

PART DETAILS

Drain Pan

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

WICKING

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

PAD

DRAIN PANDRAIN PANDRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

DRAIN PAN

PART DETAILS

3-4. COOLING COMPARTMENT

Evaporator Housing (Duct) (MSF-49NM)

DRAIN HOSEDRAIN HOSEDRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

DRAIN HOSE

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

Freezer Evaporator(MSF-49NM)

FREEZER C SENSORFREEZER C SENSORFREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMP

LAMPLAMP

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COIL

EVAPORATOR COILEVAPORATOR COIL

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

Condenser Fan Motor Assembly

Compressor Capacitor(Running & Starting Capacitor)

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

12

13

Page 8

PART DETAILS

4. MAIN COMPONENTS

4-1. COMPRESSOR

Evaporator Housing (Duct) (MSF-23NM, MSR-23NM Type)

Freezer Evaporator (MSF-23NM)

MODEL

Refrigerant

Voltage

Comp. Model

Part code

Starting type

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

SK182C-L2U

R7439-010

RSCR

4-2. COMP. RELAY

MODEL

Voltage

Relay Model

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

4-3. DRYER

MODEL

Refrigerant

Spec

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

R-134a R-404a R-134a

115 V / 60 Hz

SK1A1C-L2W

R7439-110

CSR

R-134a

36GR

R2183-032

AJA2425ZXA

R7439-030

-

115 V / 60 Hz

G7L-1A-TUB

R7253-040

R-404a

36GR

R2183-043

SK1A1C-L2W

R7439-110

CSR

R-134a

36GR

R2183-032

AKA4476YXA

R7439-150

-

Evaporator Defrost Heater (MSF-49NM, MSF-23NM)

14

MSF-49NMMSF-49NMMSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-49NM

MSF-23NMMSF-23NMMSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

MSF-23NM

4-4. CAPACITOR

MODEL

Voltage

Running

Part code

Starting

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

250VAC 12uF

R7543-030

─

250VAC 12uF

R7543-110

125VAC 125uF

R7543-100

4-5. EVAPORATOR FAN MOTOR

MODEL

Voltage

Motor Model

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

115 V / 60 Hz

115 V / 60 Hz

IS-4420DADY

R7423-031

15

250VAC 12uF

─ ─

R7543-110

125VAC 125uF

R7543-100

Page 9

MAIN COMPONENTS

5. ELECTRONIC CONTROL INSTRUCTIONS

4-6. CONDENSER FAN MOTOR

MODEL

Voltage

Motor Model

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

4-7. DEFROST HEATER

MODEL

Voltage

Spec

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

─

4-8. LAMP

MODEL

Voltage

Spec

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

25 W

R7494-010

4-9. MAIN PCB

115 V / 60 Hz

SR-043

R7423-020

115 V / 60 Hz

445 W

R7303-400

115 V / 60 Hz

600 W

R7303-410

─

FLUORESCENT 32W/865RS

R7494-150

5-1. FREEZER CONTROL

5-1-1. How to use the display PCB panel

- 88 LED

- It indicates setting temperature,

except defrost function

-Door Open LED

-Temperature can be controlled by the user.

-Factory setting is at level "2 ℉". Setting can

be changed by pressing up/down button.

MODEL

Voltage

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

R7103-260 R7103-250 R7103-260

4-10. DISPLAY PCB

MODEL

Voltage

Part code

MSR-23NM MSR-49NM MSF-23NM MSF-49NM MSR-23G-1 MSR-49G-2

4-11. BALLAST

MODEL

Voltage

Spce

Part code

115 V / 60 Hz

115 V / 60 Hz

R7113-190

MSR-23G-1 MSR-49G-2

120V / 60Hz

32W

R7553-011

16

5-1-2. Manual Defrost Function

Press temperature setting UP/DOWN key for 2 seconds at

the same time, manual defrost mode will start.

If you press UP/DOWN key for 2 seconds again on defrosting

manual defrost will be cancelled and it will revert to nomal

mode after 10 minutes of pause(Display panel indicates “DF”

for pause period)

17

Page 10

ELECTRONIC CONTROL INSTRUCTION

ELECTRONIC CONTROL INSTRUCTION

5-1-3. FUNCTION TABLE

Function

No

1

2

Initial

Operation

Temperature

Control

Controlled

Part

Compressor

LED

Description

1. 88 LED displays inside temperture

2. Begin to run immediately on the higher than 50℉ and

begin to run after 5 minutes pause on the lower

than 50℉.

1. The temperature can be changed by pushing up/down

buttons.

2. 88 LED displays inside temperture

3. Buzzer buzzes 1time whenever a button is pressed

4. Compressor automatically turns on and off by C-sensor

(Except error mode)

5. Comp. on/off temperature (℉)

Setting 5.0 3.0 1.0 -1.0 -2.0

Comp On 5.3 3.5 0.8 -1.3 -1.8

Comp OFF -2.5 -4.7 -7.4 -9.4 -10.6

-------------------------------------------------------Setting -3.0 -5.0 -7.0 -9.0

Comp On -3.1 -4.9 -5.8 -7.6

Comp OFF -11.2 -13.0 -13.9 -15.7

No

4

Function

MAIN PCB

Controlled

Part

FREEZER /

R E F R I G E R A T O R

DEFROST TIME

Description

1. It can be set as below according to the connection of

JUMPER (J1,J2,J3)in the main PCB.

P. C . B

D I S C O N N E C T I

- O N

Indicated to ℉

T e m p e r a t u r e

The controller

of Refrigerator

REMARKS

Applied to the

Freezer model

only.

TRANSFORMER

JUMPER

NO.

JP1

JP2

JP3

JUMPER

FUNCTION

Unit of the

Temperature

Mode of the

control to

Refrigerator

/ Freezer

Control of

Defrost cycle

JUMPER

1,2,3

C O N N E C T I O N

Indicated to ℃

T e m p e r a t u r e

The controller

of Freezer

8 Hr 6 Hr

ERROR CODE (FREEZER)

1. Defrost Cycle : It can be set 8Hr or 6Hr by OPTION

JUMPER (JP3)

TRANSFORMER

JUMPER

1,2,3

P. C . B

2. The condition of DEFROST operation

3

Defrost

Function

Heater

Compressor

-It runs regularly according to the defrost cycle with

adding up the plug in time.

-When the defrost starting time comes, COMPRESSOR

must be turned off and the defrost operation cycle

begins to run according to the conditions as the

below 1 and 2 after checking the temperature by

DEFROST SENSOR.

Cond ition 1(In case the temperature checked by

DEFROST SENSOR is low than 23℉); Defrost Heater

(Max. 40Min. running) runs by that time DEFROST-SENSOR

sensor 53℉ and COMPRESSOR runs after 10minutes

pauses.

18

Code

─

c S

c O

c S

c O

Content Perception Method Refrigeration state

D-sensor

- short circuit

- wire disconnection

- Normal operation

- Defrost

Heater ON : 20 MINUTES

- short circuit

C-sensor

- wire disconnection

- Time control

Comp ON : 10 MINUTES

C-sensor

D-sensor

- short circuit

- wire disconnection

Comp OFF : 6 MINUTES

19

Page 11

SENSOR DESCRIPTION

ELECTRONIC CONTROL INSTRUCTION

ELECTRONIC CONTROL INSTRUCTION

Sensor

D-sensor

C-sensor

T-sensor

Model Role Wire Color

Freezer

Freezer

Refrigerator

Refrigerator

Detect Eva coil’s temp. to terminate

defrosting

Detect inside air temp. to operate comp and to

indicate the inside temp. on the display PCB

Detect Eva coil’s temp. to operate comp

Detect inside air temp. to indicate the inside temp

on the display PCB

5-2. REFRIGERATOR CONTROL

5-2-1. HOW TO USE THE DISPLAY PCB PANEL

- 88 LED

- It indicates setting temperature,

except defrost function

WHT

BLK

BLK

WHT

-Door Open LED

5-2-2. FUNCTION TABLE

1

Temperature

2

Function

Initial

Operation

Control

No

Controlled

Part

Compressor

LED

Description

1. 88 LED displays inside temperture

2. Begin to run immediately on the higher than 41℉ and

begin to run after 5 minutes pause on the lower

than 41℉.

1. The temperature can be changed by pushing up/down

buttons.

2. 88 LED displays inside temperture

3. Buzzer buzzes 1time whenever a button is pressed

4. Compressor automatically turns on and off by C-sensor

(Except errer mode)

5. Comp. on/off temperature (℉)

Setting 39 38 37 36 35

Comp On 39.0 39.0 39.0 39.0 39.0

Comp OFF 30.2 28.4 27.5 27.0 25.0

----------------------------------------------------------------Setting 34 32 30 28

Comp On 39.0 39.0 39.0 39.0

Comp OFF 23.0 21.2 19.0 17.6

-Temperature can be controlled by the user.

-Factory setting is at level "35 ℉". Setting can

be changed by pressing up/down button.

20

ERROR CODE

Code

ㄱS

ㄱO

─

ㄱS

ㄱO

Content Perception Method Refrigeration state

T-sensor

C-sensor

C-sensor

T-sensor

- short circuit

- wire disconnection

- short circuit

- wire disconnection

- short circuit

- wire disconnection

- Normal operation

- Time control

Comp ON : 10 MINUTES

Comp OFF : 20 MINUTES

21

Page 12

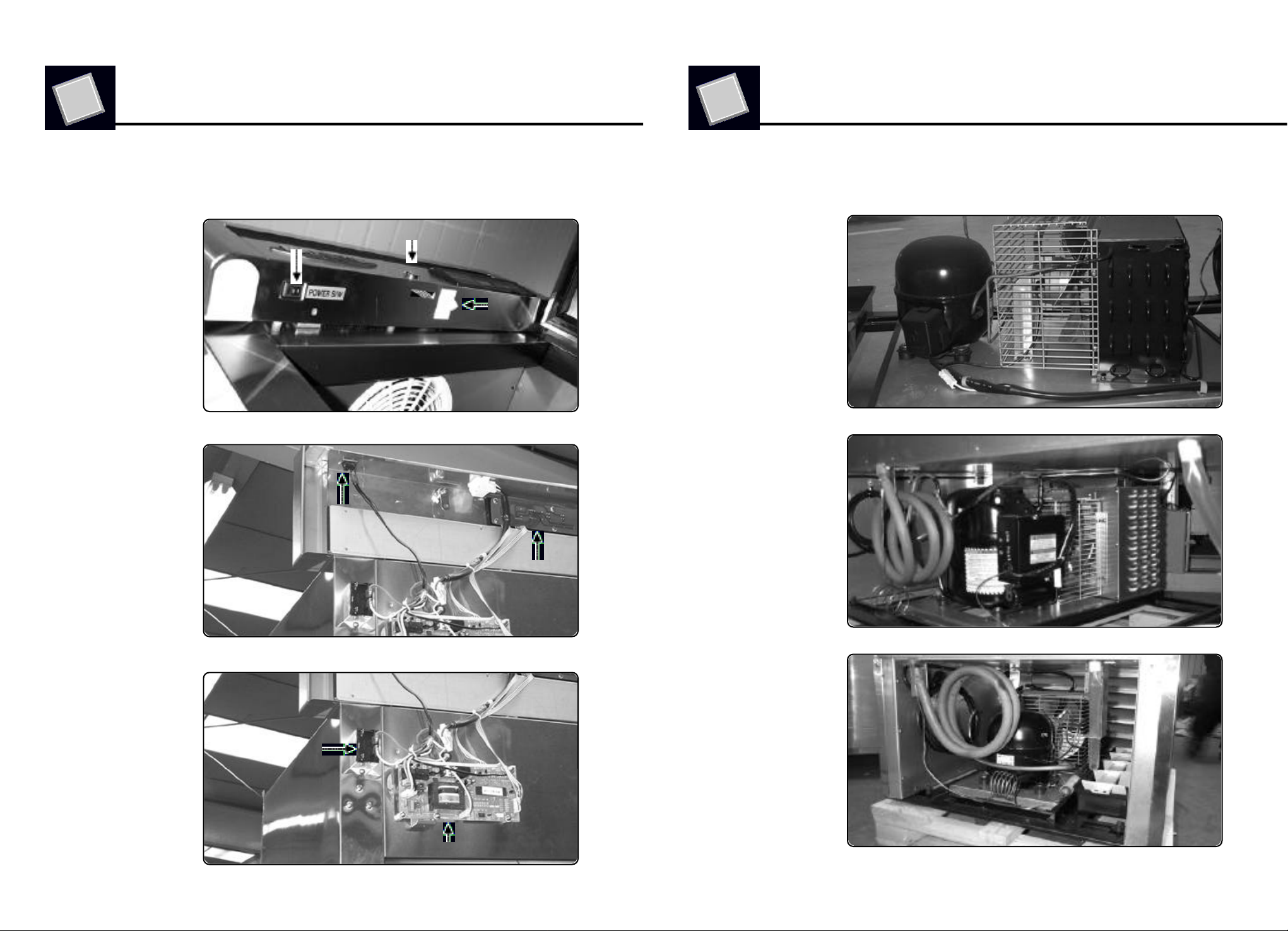

6. REPLACEMENT OF MAIN COMPONENTS

6-1. TOP PANEL PARTS

REPLACEMENT OF MAIN COMPONENTS

- MAIN PCB

- LOCK ASSEMBLY or POWER SWITCH

- DOOR SWITCH

A. Untie the screws located on top grille panel.

B. Untie the screws located on bottom of top panel.

# caution : When unscrewing, hold the top panel.

Panel may fall & cause injury.

C. Place the top panel on top of the cabinet.

D. You can replace POWER-RELAY and MAIN PCB

22

POWER RELAYPOWER RELAYPOWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

POWER RELAY

23

MSF-23NM

MAIN PCBMAIN PCBMAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

MAIN PCB

Page 13

REPLACEMENT OF MAIN COMPONENTS

REPLACEMENT OF MAIN COMPONENTS

6-2 REPLACING DOOR

E. Pull out the harness located back of top panel.

You can separate top panel out of the unit.

You can replace power switch, lamp switch and display PCB.

A. Disassemble top panel as described section 6-1 A,B

B. Remove bottom grille by unscrewing the four screws located on each side

of bottom grille.

C. Open the capacitor cover.

Disconnect the Mullion Heater

24

25

Page 14

REPLACEMENT OF MAIN COMPONENTS

REPLACEMENT OF MAIN COMPONENTS

6-3 DOOR SPRING ADJUSTMENT

D. Untie the hinge.

A. Detailed structure of DOOR-HINGE

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREWSCREW

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGE

HINGEHINGE

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

SPRING

B. Coordinated principle of DOOR TENSION

After putting Tool for revolving DOOR-HINGE STOP-PIN HOLE, Insert DOOR-HINGE

STOP-PIN into the hole after revolving up to the requested TENSION.

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

DOOR HINGE

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

STOP PIN

DOORDOORDOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

DOOR

26

TOOLTOOLTOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

REMOVEREMOVEREMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

REMOVE

DOOR-HINGE SHAFT-UPPERDOOR-HINGE SHAFT-UPPERDOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR-HINGE SHAFT-UPPER

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PIN

DOOR HINGE STOP PINDOOR HINGE STOP PIN

DOOR HINGE UPPERDOOR HINGE UPPERDOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

DOOR HINGE UPPER

27

Page 15

C. Remove the door hinge stop pin

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

TOOLTOOL

REPLACEMENT OF MAIN COMPONENTS

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

DOOR-HINGE STOP-PIN

REPLACEMENT OF MAIN COMPONENTS

6-4. REVERSIBLE-DOOR ASSEMBLING METHOD

APPLIED MODEL : MSF-23NM, MSR-23NM

1. Taking apart TOP GRILL and GRILL ASSEMBLY

1) Take apart TOP GRILL

after eliminating screw connected

Upper or downward located ①

in the PICTURE (A)

2) Take apart GRILL

after eliminating the screw connected

Left and right side located ②

in the PLCTURE (A)

# Attention : Heed not to damage Electricity

wire and not to fall top-grill

from the upper.

Also be careful the sharp

edges during working.

②

①

TOP GRILL

GRILL

ASSEMBLY

PICTURE A

B. Place the door hinge stop pin and adjust the strength of the door spring.

REMOVE

28

2. Taking apart of DOOR-ASSEMBLY

1) Take apart ①~⑩ in order at the PICTURE (B)

# Attention : Heed the elasticity

when eliminating the

PIN and the weight

during taking apart

DOOR ASSEMBLY.

29

②M5✽27 SCREW

④DOOR-HINGE

SHAFT-UPPER

⑨M5✽27 SCREW

PICTURE B

③DOOR-HINGE

UPPER

①DOOR-HINGE

STOP PIN

⑤DOOR-HINGE

BUSHING

⑥DOOR

ASSEMBLY

⑦DOOR-HINGE

BUSHING

⑧DOOR-HINGE

SHAFT-LOWER

⑩DOOR-HINGE

LOWER

Page 16

3. Assembling method of REVERSIBLE DOOR

1) After reversing 180 degree

DOOR ASSEMBLY of ⑥,

③DOOR-HINGE

LOWER

have the HANDLE be the

requested side.

2) Assemble as the following

⑧DOOR-HINGE

SHAFT-LOWER

order

⑥DOOR ASSEMBLY

⑤DOOR-HINGE BUSHING

①DOOR-HINGE STOP PIN

③DOOR-HINGE UPPER

REPLACEMENT OF MAIN COMPONENTS

⑨M5✽27 SCREW

⑦DOOR-HINGE

BUSHING

④DOOR-HINGE

SHAFT-UPPER

②M5✽27 SCREW

REPLACEMENT OF MAIN COMPONENTS

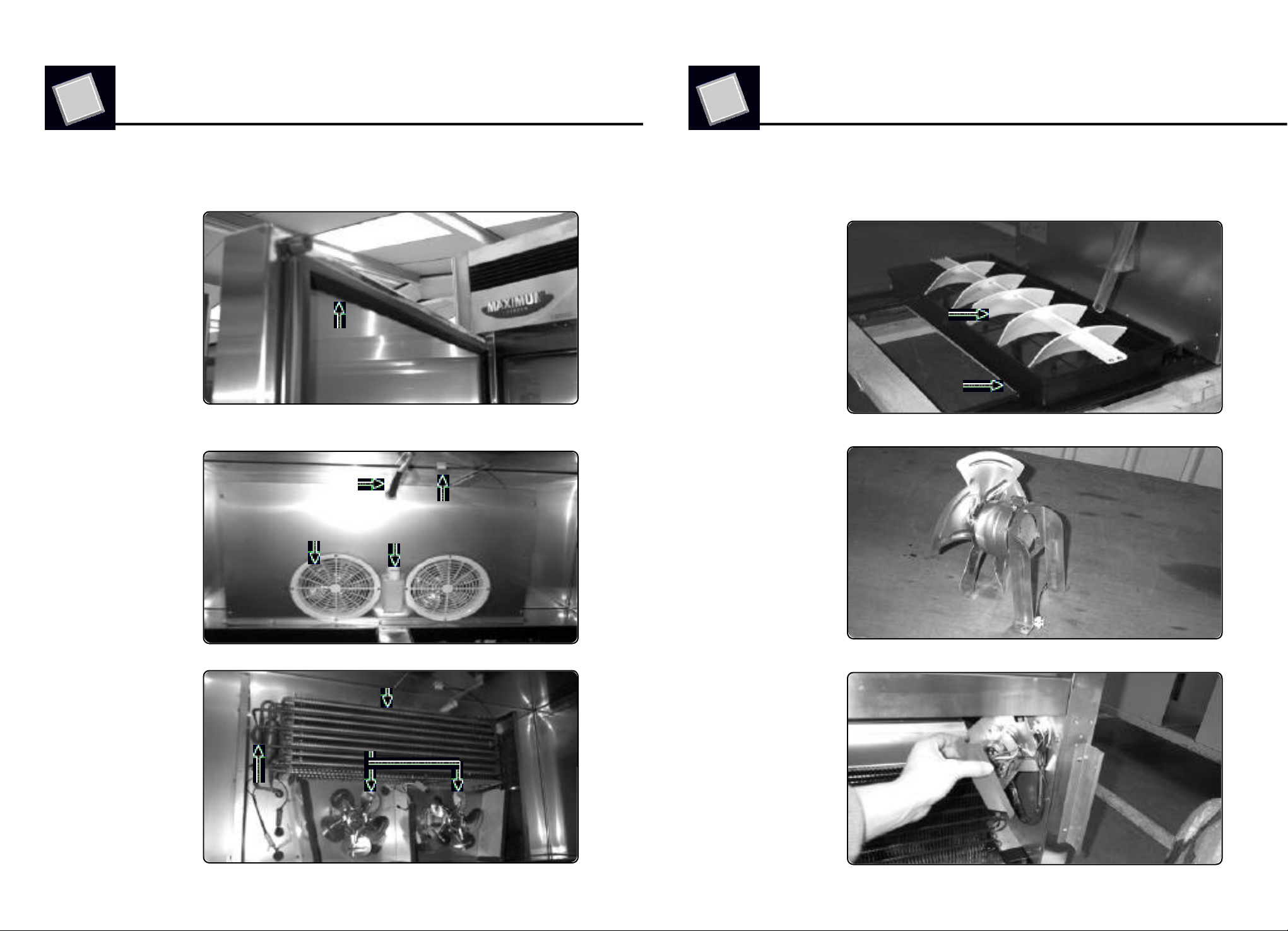

6-5. REFRIGERATION COMPARTMENT'S PARTS

- LAMP BULB, LAMP SHIELD

- EVAPORATOR FAN MOTOR

- D-SENSOR, C-SENSOR, T-SENSOR

- EVAPORATOR COIL

- EVAPORATOR DEFROST HEATER

A. Disassemble lamp shield

LAMP BULBLAMP BULBLAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP BULB

LAMP SHIELDLAMP SHIELDLAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

LAMP SHIELD

B. Disassemble duct

LAMP SOCKETLAMP SOCKETLAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

LAMP SOCKET

-After assembling ③②, assemble ④⑤

PICTURE C

-Insert ④ into ⑥

-After inserting ⑦⑧, fix ③⑨

-Insert reversly for suitable spring elasticity

# Attention : When screw connected, should well be connected to maintain sufficient sustain

4. Assembling TOP GRILL and GRILL ASSEMBLY

1) Connect the screw at the

①

location ① on the top

and bottom of the top grill

2) Connect the screw at the

location ② on the left and

right side of the grill assembly.

②

PICTURE D

C. Pull out the lamp

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

EVAPORATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

DEFROST HEATOR

EVAPORATOR DRAIN PAN HEATEREVAPORATOR DRAIN PAN HEATEREVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR DRAIN PAN HEATER

EVAPORATOR FAN MOTOREVAPORATOR FAN MOTOREVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

30

31

Page 17

REPLACEMENT OF MAIN COMPONENTS

REPLACEMENT OF MAIN COMPONENTS

D. Replacing evaporator fan motor

D-1. Disconnect the fan motor's harness.

D-2. Untie the four screws which located on bottom of fan motor

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOR

EVAPORATOR FAN MOTOREVAPORATOR FAN MOTOR

E. Replacing sensor

E-1. FREEZER C-sensor of

Untie as illustrated below and pull-out the FREEZER C-sensor from the cover.

E-2. DEFROST-sensor of Freezer

Disassemble the DEFROST-sensor from the evaporator

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSOR

DEFROST SENSORDEFROST SENSOR

E-3. C-sensor of Refrigerator

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSORFREEZER C SENSOR

32

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

FREEZER C SENSOR

33

C SENSORC SENSORC SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

C SENSOR

Page 18

REPLACEMENT OF MAIN COMPONENTS

E-4. T-Sensor (Temperature Display Sensor) of Refrigerator

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSORDISPLAY T-SENSOR

REPLACEMENT OF MAIN COMPONENTS

6-6. CONDENSING UNIT

- Condensing units : Compressor, Condenser Fan Motor, Condenser Coil,

Condenser Dryer.

- Others : Power-cord, Drain pan

A. Untie two screws as below.

REFRIGERATOR C-SENSORREFRIGERATOR C-SENSORREFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

REFRIGERATOR C-SENSOR

DISPLAY T-SENSORDISPLAY T-SENSORDISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

DISPLAY T-SENSOR

34

B. Pull-out the condensing unit (MSF-49 NM)

35

Page 19

6-7. LIGHTING-PARTS

A. MSR-23G-1

REPLACEMENT OF MAIN COMPONENTS

REPLACEMENT OF MAIN COMPONENTS

B. MSR-49G-2

2. Separate the Lamp Reflection

1. Untie three screws seciromg the Lamp

Reflection.

3. Separate the Lamp out of the Lamp

socket and replace it.

1. Separate the Shelves

2. Separate the Lamp Socket

3. Take out the Doors and separate the

Lamp from the Lamp Holder.

36

4. Separate the Lamp shield End Cap

37

Page 20

REPLACEMENT OF MAIN COMPONENTS

7. PART-LIST

C. BALLAST

1. Untie four screws securing the sign frame End separate Sign Frame End.

2. Separate connector of the ballast

3. Untie two screws for separating the Ballast.

Part name Code Description

CASTER

CASTER R3323-010 SPCC 4" 2 2 2 2 2 2

CASTER BRAKE R3323-020 SPCC 4" 2 2 2 2 2 2

COMPRESSOR

COMPRESSOR R7439-030 AJA2425ZXA 1

COMPRESSOR R7439-110 SK1A1C-L2W 1 1 1

COMPRESSOR R7439-010 SK182C-L2U 1

COMPRESSOR R7439-150 AKA4476YXA 1

COMPRESSOR RUN CAPACITOR R7543-110 250VAC 12UF 1 1

COMPRESSOR START CAPACITOR R7543-100 125VAC 125UF 1 1

COMPRESSOR RUN CAPACITOR R7543-030 250VAC 12UF 1

COMPRESSOR RELAY HARNESS R7373-770 AWG18 1

COMPRESSOR RELAY HARNESS R7373-780 AWG18 1

COMPRESSOR RELAY HARNESS R7373-790 AWG18 1

COMPRESSOR RELAY HARNESS R7373-800 AWG18 1

COMPRESSOR RELAY HARNESS R7283-070 AWG18 1

COMPRESSOR RELAY HARNESS R7283-080 AWG18 1

POWER-CORD R7363-060 3000MM 1 1 1 1 1 1

CONDENSER

CONDENSER COIL R2272-012 1

CONDENSER COIL R2202-030 4.7613340 1

CONDENSER COIL R2202-031 4.7618960 1 1 1

CONDENSER COIL R2273-021 1

CONDENSER DRYER R2183-032

CONDENSER DRYER R2183-043

CONDENSER FAN

CONDENSER FAN MOTOR R7423-020 SE-043

CONDENSER FAN MOTOR BLADE R3729-020

CONDENSER FAN MOTOR BRACKET

DRAIN

DRAIN PAN R3743-060 ABS BLK 1 1 1

DRAIN PAN R3742-070 ABS BLK 1 1 1

DRAIN WICKING BAR R3853-230 PP

DRAIN WICKING BAR R3853-240 PP

DRAIN WICKING PADS R1154-101 PP T2.599103 1 1 1

DRAIN WICKING PADS R1154-020 PP T2.583180 1 1 1

R3313-260 SBHG1-0 T2.0164 1 1 1 1 1 1

25.41690.635

25.41300.635

9W CCW 1550RPM

AL3004H14

WHT T2.040569

WHT T2.040657

9" CCW T1.0 1 1 1 1 1 1

Solid Glass

R23 R49 F23 F49 R23 R49

1 1 1 1 1

1

1 1 1 1 1 1

1 1 1

1 1 1

38

39

Page 21

PART-LIST

PART-LIST

Part name Code Description

EVAPORATOR

EVAPORATOR COIL R2263-044 CU+AL 1 1

EVAPORATOR COIL R2263-034 CU+AL 1

EVAPORATOR COIL R8613-342 CU+AL 1 1

EVAPORATOR COIL R8613-353 CU+AL 1

EVAPORATOR DEFROST HEATER R7303-410 SUS304 ¢8 600 W 22.0Ω 1

EVAPORATOR DEFROST HEATER R7303-400 SUS304 ¢8 445 W 29.7Ω 1

EVAPORATOR DRAIN PAN HEATER R7303-180 PVC 105℃ 90W 147Ω 1

EVAPORATOR DRAIN PAN HEATER R7303-170 PVC 105℃ 90W 147Ω 1

SENSOR BRACKET R3314-190 P.P, WHT 1 1 1 1 1 1

EVAPORATOR THERMAL FUSE (BIMETAL)

EVAPORATOR FAN MOTOR R7423-031 IS-4420 1650±150RPM 1 1 1 2 1 2

EVAPORATOR FAN MOTOR BLADE R3729-010 8" C.C.W 1 1 1 2 1 2

EVAPORATOR FAN MOTOR BRACKET R3204-360 STS-304 T1.012090 1 1 1 2 1 2

FREEZER SENSOR R7213-081 YELLOW 1 1

DEFROST SENSOR R7213-101 WHITE 1 1

REFRIGERATOR SENSOR R7213-091 BLACK 1 1 1 1

DISPLAY SENSOR R7213-111 WHITE 1 1 1 1

TOP PANEL

TOP PANEL ASSEMBLY R8182-130 1 1

TOP PANEL ASSEMBLY R8182-120 1 1

TOP PANEL ASSEMBLY R8182-120 1

TOP PANEL ASSEMBLY R8182-130 1

FREEZER BRAND LOGO R5133-150 1 1

REFRIGERATOR BRAND LOGO R5133-140 1 1 1 1

FREEZER MAIN PCB R7103-250 1 1

REFRIGERATOR MAIN PCB R7103-260 1 1 1 1

CONTROL BOARD HOUSING R7113-190 1 1 1 1 1 1

DISPLAY PCB R7113-190 20220 T1.5 1 1 1 1 1 1

DISPLAY PCB FILM R4113-370 PC-SHEET 1 1 1 1 1 1

SUPPORTER PCB R3084-010 NYLON66 6 6 6 6 6 6

POWER RELAY R7253-040

DOOR SWITCH R7203-020 125V 1.5A 1 2 1 2 1 2

DOOR SWITCH HARNESS R7373-423 AWG18 1 1

DOOR SWITCH HARNESS R7373-433 AWG18 1 1

DOOR LOCK R3739-010 1 2 1 2 1 2

R7253-050 80℃±4 G4A00 1 1

OMRON G7L-1A-TUB

Solid Glass

R23 R49 F23 F49 R23 R49

1 1 1 1 2 2

Part name Code Description

BOTTOM GRILLE

BOTTOM GRILLE ASSEMBLY R8182-080 1 1 1

BOTTOM GRILLE ASSEMBLY R8182-092 1 1 1

SHELF

SHELF CLIP R3313-151 12 24 12 24 12 24

SHELF R3233-072 3 3

SHELF R3233-063 6 6

SHELF (GLASS) R3233-180 3

SHELF L (GLASS) R3233-160 3

SHELF R (GLASS) R3233-170 3

SHELF STANDARD R3373-121 4 8 4 8 4 8

DOOR

DOOR ASSEMBLY R8272-220 1 1

DOOR ASSEMBLY R8272-170 2 2

GLASS DOOR ASSEMBLY L R8172-650 1

GLASS DOOR ASSEMBLY R R8172-630 1

GLASS DOOR ASSEMBLY R8172-640 1

DOOR GASKET R3903-354 RD-PVC BLACK 1 2 1 2

MULLION R8163-031 30W PINK 1

MULLION R8163-121 38W YELLOW 1

DOOR HINGE TOP R3394-120 AL 1 2 1 2

DOOR HINGE BOTTOM R3394-130 AL 1 2 1 2

DOOR HINGE WASHER R3034-020 18 T2.2 2 4 2 4

DOOR HINGE STOP PIN R3044-040 330 1 2 1 2

LAMP

LAMP BULB R7394-010 25W, E26 1 1 1 1

LAMP SHIELD R3813-130 MIPS (HR-3370) 1 1 1 1

LAMP SOCKET R7393-020 660W 250V 1 1 1 1

FLUORESCENT LAMP

FLUORESCENT R7394-150 PHILIPS 32W/865RS 1 1

BALLAST R7553-010 ADVANCE (R-1P32-TP) 1 1

LAMP GUARD R3894-030 PP 1 1

GUARD SOCKET R3814-550 ABS V0 2 2

LAMP SOCKET R7393-180 ABS V0 2

LAMP SOCKET R7393-170 ABS V0 2

Solid Glass

R23 R49 F23 F49 R23 R49

40

41

Loading...

Loading...