Page 1

Indoor Air Quality Handbook

.

A Practical Guide to Indoor

Air Quality Investigations

ENERGY AND COMFORT

ENERGY AND COMFORT

Indoor Air Quality

TRUST. SCIENCE. INNOVATION

Page 2

Page 3

Indoor Air Quality Handbook

A Practical Guide

to Indoor Air Quality

Investigations

Copyright © 2011 by TSI Incorporated

Page 4

Page 5

Contents

Introduction ..................................................................................................................................................... 1

Building Design and Operation ........................................................................................................................ 2

Effects of Poor Quality Air ............................................................................................................................... 3

Types of Pollutants ......................................................................................................................................... 4

Controlling Sources of Pollutants ..................................................................................................................... 4

Investigating Indoor Air Quality ...................................................................................................................... 5

Measurements Used to Determine Air Quality ............................................................................................... 6

Comfort Issues and Productivity ...................................................................................................................... 6

Temperature ...................................................................................................................... 7

Humidity ............................................................................................................................. 7

Air Movement and Flow ..................................................................................................... 8

Velocity .......................................................................................................................... 8

Volume .......................................................................................................................... 8

Ventilation ..................................................................................................................... 9

Health and Safety Issues .............................................................................................................................. 11

Carbon Monoxide ............................................................................................................ 11

Airborne Particles ............................................................................................................ 11

Ultrafine Particles ............................................................................................................ 13

Bioaerosols ...................................................................................................................... 14

Chemicals in Aerosol Form ............................................................................................. 15

Light, Noise, Vibration, Ergonomics, Odors, etc. ............................................................ 15

Conclusion .................................................................................................................................................. 16

Sources for Information Relating to Indoor Air Quality Evaluations ........................................................... 17

Standards and Guidelines ............................................................................................................................. 18

IAQ Instruments from TSI .............................................................................................................................. 19

Indoor Air Quality Handbook i

Page 6

Page 7

Indoor Air Quality Handbook

Introduction

Concern about indoor air quality (IAQ) and the study of air quality issues is a fairly recent phenomenon. Some of

the earliest documented studies occurred in Scandinavia in the mid-1960s and were focused primarily on

thermal comfort issues. For the first decade or so, IAQ studies primarily involved comparing indoor air to outdoor

air. The level of outdoor pollution was a chief concern and the goal was to ensure that indoor air was of better

quality than the outdoor air subjected to pollutants.

As studies increased in sophistication, other

measurable factors came into play. Building

construction materials and techniques

changed radically. A reduction in natural

ventilation, or "fresh" air, in the interest of

saving energy became a concern and,

finally, people realized that pollutants could

actually originate within a building. The

World Health Organization (WHO) estimated

that more than 30 percent of all commercial

buildings have significant IAQ problems.

For many years, people working in areas

with known exposure to potential hazards have had a number of options available with respect to personal

protection, including equipment such as respirators, hard hats, gloves, goggles, and more. Indoor air quality as

discussed here, however, applies to areas or situations where people are generally unaware of potential hazards.

They normally do not expect to need protection and this is why the subject has become so important.

In some cases, the quality of

indoor air can be critical.

Since the energy crisis of the 1970s, buildings have been constructed much tighter, significantly lowering the

exchange of indoor and outdoor air. The strategy has been to save energy costs by re-circulating internal air and

minimizing the need to heat, cool or condition outdoor air. Although considerable savings are realized with this

strategy, unwanted contaminants can and do become trapped in these tight enclosures.

Recent developments in construction materials have resulted in the use of more synthetics and composites,

which can affect air quality. Radical changes in technology have led to innovations such as computers and

photocopiers that provide greater efficiencies and time savings, but they can also affect the quality of indoor air.

These potentially adverse effects are further complicated by the fact that people are spending more time than

ever indoors, up to 90 percent according to estimates by the U.S. Environmental Protection Agency (EPA). It is

easy to understand why there is a growing concern about the quality of the air we breathe.

Indoor Air Quality Handbook 1

Page 8

Indoor Air Quality Handbook

People are spending more than

90 percent of their time indoors.

As a result of these and other factors, totally new terminology has come into use and the topic is gaining more

attention every day. Some examples include:

• Sick Building Syndrome (SBS)—where more than 30 percent of occupants experience adverse

effects while in the building, but no clinically diagnosed disease is found.

• Building Related Illness (BRI)—general term for a medically diagnosable illness caused by, or

related to, building occupancy.

• Multiple Chemical Sensitivity (MCS) or Environmental Illness (EI)—a controversial condition

where an individual has or develops sensitivity to even low levels of certain chemicals due to extended

exposure.

Bottom line, the quality of indoor air can and does impact productivity, personal comfort, building maintenance

costs and even health and safety, either positively or negatively depending on how air quality is managed.

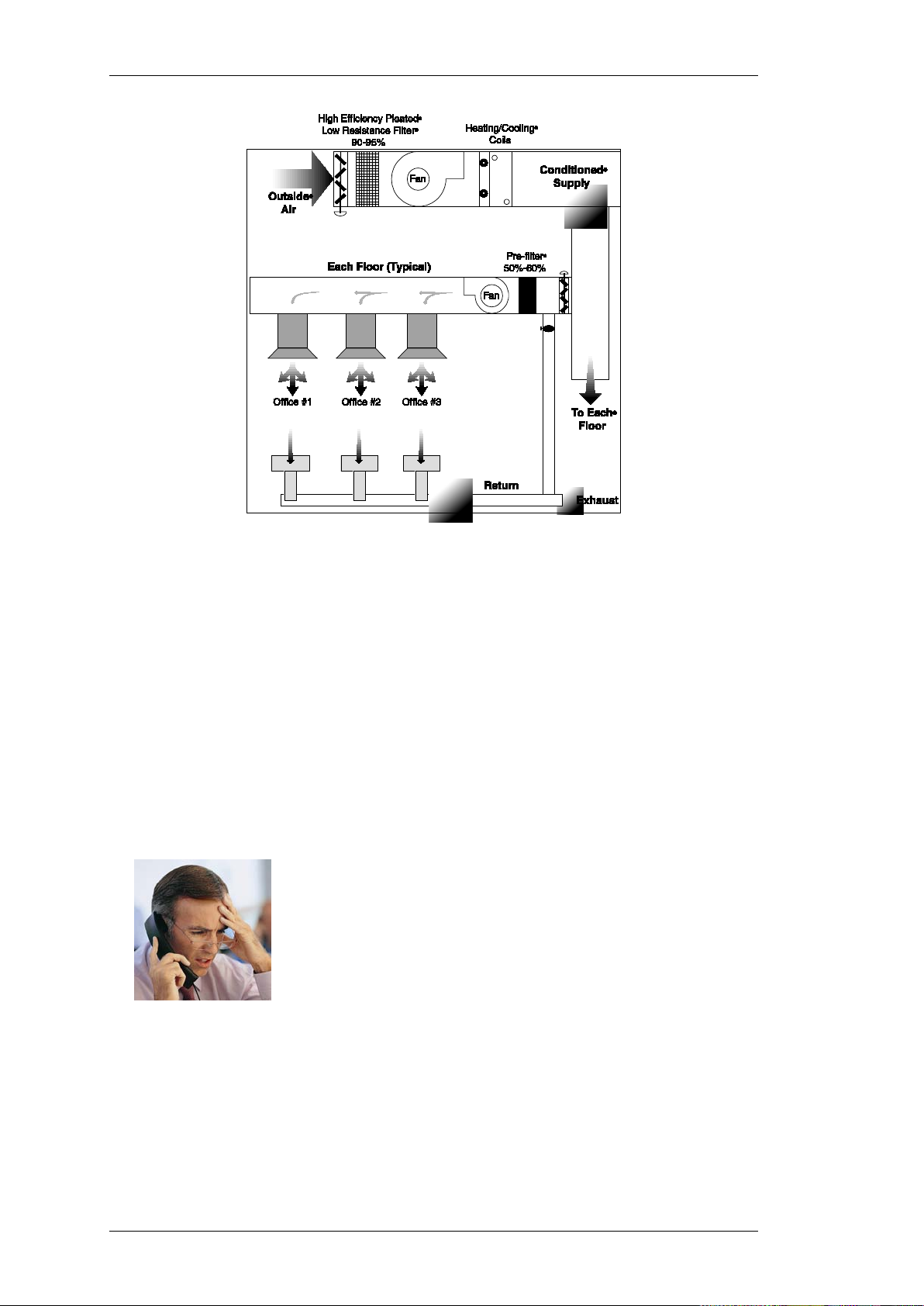

Building Design and Operation

Ensuring satisfactory air quality requires a good understanding of the building itself. The design, physical layout,

mechanical systems, equipment and space usage are all essential elements that can affect air quality. The air

distribution system requires particular attention. How does outdoor air get in? Is the air filtered? How does air

circulate throughout the building?

Understand how spaces are designed and where walls, furnishings and equipment are located. Keep in mind the

building layout can create physical barriers that impede the flow and distribution of air, which can impact the

quality of air in a given area.

2 TSI Incorporated

Page 9

Indoor Air Quality Handbook

Unwanted contaminants move from areas

of relative positive pressure to those of relative negative

pressure through a path of least resistance.

Consider pollutant "pathways" which allow airborne gases and particles to migrate to different areas of the

building. These pathways may not be obvious and are not necessarily physically defined. Pollutants can travel by

air movement or pressure differential where unwanted contaminants move from areas of relative positive

pressure to those of relative negative pressure through a path of least resistance.

Effects of Poor Quality Air

In this handbook, when we talk about factors affecting air quality, we are beyond the already proven hazardous

materials where exposure limits have been set and personal protective equipment prescribed. Here, we address

what would be considered "normal" air in offices, schools, libraries, churches, hospitals and other interior spaces

where we spend time without expecting to face any risks.

Different people react differently to

different levels of different substances.

As bizarre as it sounds, there is no universal reaction to a measured amount of a

particular material. People simply have different tolerance levels. It is difficult to

assign standards or even guidelines to set acceptable versus unacceptable levels of

literally thousands of airborne pollutants.

Many indoor air contaminants are actually new, bred from the ever-changing technology that so many of us are

exposed to daily. From alternative energy sources to photocopiers, we are generating new pollutants at an everincreasing pace.

Indoor Air Quality Handbook 3

Page 10

Indoor Air Quality Handbook

Typical symptoms caused by air quality problems vary greatly according to an individual's sensitivity and may

include chills, sweating, eye irritation, allergies, coughing, sneezing, nausea, fatigue, skin irritation, breathing

difficulty and others. In extreme cases, personal reactions actually reach the point where an individual cannot

function, when exposed to adverse air conditions.

Unfortunately, there are virtually no Federal regulations governing exposure levels in non-industrial indoor

environments. Indoor air quality is a growing concern and gaining attention. It is prudent to take a proactive

approach and address any issues that could potentially have adverse affects on indoor air

quality.

Types of Pollutants

General pollutant types that affect air quality include:

• Biological—bacteria, fungi, viruses, molds, pollen, animal hair, dander and excrement are examples of

common biological pollutants that can impact air quality.

• Chemical—cleaners, solvents, fuels, adhesives, various combustion by-products and emissions from

furnishings and floor and wall coverings are typical examples of airborne chemicals.

• Particles and Aerosols—are solids or liquids that are light enough to be suspended in air. Particles are

classified in three general categories—coarse, fine and ultrafine—and are derived from dust, construction

activities, printing, photocopying, manufacturing processes, smoking, combustion and some chemical

reactions in which vapors condense to form particles. These can be categorized as dust, smoke, mist, fume

and condensates.

Controlling Sources of Pollutants

In a typical building, pollutants fall into two

source categories: those that enter the building

from the outside and those generated within

the building itself. Both include a wide variety

of types and origins. Outdoor sources can

include building stack exhaust, vehicle

emissions, industrial processes and

construction activity as well as many others.

Internal sources include maintenance or

housekeeping activities, chemicals, cleaners,

solvents, building renovations, new furnishings,

new finishes, office equipment and various

occupant activities.

Pollutant sources must be located and controlled to ensure good indoor air quality. Keep in mind that both

sources and pathways are essential components that must be well understood for effective problem remediation.

Pathways are created as pollutants travel by air movement or from relative positive to relative negative pressure

areas through even the smallest of openings. Several methods for managing a pollutant source are available

once the source is identified, including:

• Removing the source

• Repairing the source so it no longer contributes pollutants

• Isolating the source with a physical barrier

• Isolating the source using air pressure differential

• Minimizing the time people are exposed

• Diluting pollutants and removing them from the building with increased ventilation

• Increasing filtration to clean the air and remove pollutants

4 TSI Incorporated

Page 11

Indoor Air Quality Handbook

Investigating Indoor Air Quality

A typical IAQ investigation requires several steps:

• Planning—

∗ Gather background information about the building and its systems.

∗ Interview affected people—understand the complaints and symptoms and check for patterns as to

where and when they occur.

∗ Set objectives.

∗ Determine the strategy to be employed.

• Gathering data—make necessary measurements throughout the building, possibly including temperature,

humidity, CO

• Analyzing the data—check for acceptable measurements to eliminate certain areas or suspected

problems, as well as anomalies that direct you to areas requiring additional focus (remember, there can be

multiple problems).

• Reporting findings—all results indicating a need for corrective action should be reported.

• Offering assistance—prepare an IAQ management plan that includes setting policies and conducting

routine measurements to ensure good air quality is maintained.

Often, it is advisable to consult with an

experienced IAQ professional, health and

safety specialist or industrial hygienist

when devising an IAQ investigation. So

many issues must be considered in a

complete investigation that this

precaution will probably end up saving

time and increasing the likelihood of a

successful outcome.

To help steer an investigation, the

affected occupants should be asked

questions such as:

1) What symptoms are you

experiencing?

2) When did the symptoms begin?

3) Are the symptoms present all the time or just during certain times (hour, day, season of the year, etc.)?

4) Where do the symptoms occur?

5) Do symptoms subside when you leave the affected the area? How soon?

6) Have there been changes to the area—new furniture, carpet, paint, remodeling or construction

projects, etc.?

7) Is there a smoking or parking area nearby?

8) Have you recently moved?

9) Have you had a significant change in your activities?

10) Does anyone else near the affected area have symptoms similar to yours?

, CO, particles, VOCs, chemicals and bioaerosols.

2

Indoor Air Quality Handbook 5

Page 12

Indoor Air Quality Handbook

Measurements Used to Determine Air Quality

Several parameters must be measured and analyzed to determine the quality of indoor air and whether or not

corrective action is appropriate. Remember that once a problem is discovered and corrected, an area should be

routinely monitored to prevent a reoccurrence. This also helps to detect emerging problems early so they can be

remedied before they become difficult and expensive to manage.

Criteria for determining indoor air quality can be separated into two basic categories—comfort and health. The

difference, of course, is the way in which humans are affected, and some criteria may influence both comfort and

health. Measurements associated with each of these categories are covered in the following discussion.

Comfort Issues and Productivity

Comfort is a way of measuring occupant satisfaction which, in turn, can directly affect concentration and

productivity and impact the cost of doing business. Comfort is a phenomenon that is both physical and

psychological, and it varies greatly from person to person. It can depend upon factors like type of clothing worn,

level and type of activity and physical surroundings, including people, furnishings and adjacent spaces. Attaining

optimum comfort is not practical. As a general rule of thumb, the best one can hope to achieve is satisfying

about 80% of the occupants.

Comfort is a way of measuring occupant satisfaction which,

in turn, can directly affect concentration and productivity and

impact the cost of doing business.

Common measurable characteristics of comfort include temperature, humidity, air velocity (draft), ventilation,

vibration and noise. Factors much harder to quantify yet able to impact perceived individual comfort include light

glare, odors, physical space layout, proximity to other areas, clothing, activity, and ergonomics. Even emotional or

psychological stress in the workplace or at home can contribute to a person's feeling of comfort.

The following discussion describes various measurements often used to determine comfort level. When making

a measurement, allow sufficient time for the instrument to capture a “stable” reading. If you move from a hot

area to a cold area and quickly take a temperature measurement, for example, the accuracy of the reading could

be subject to question.

6 TSI Incorporated

Page 13

Indoor Air Quality Handbook

What to Measure—Temperature

Why measure?

Temperature is one of the basic IAQ measurements that has a direct impact on perceived comfort and, in turn,

concentration and productivity. According to ASHRAE Standard 55, the recommended temperature ranges

perceived as "comfortable" are 22.8 to 26.1°C (73 to 79°F) in the summer and 20.0 to 23.6°C (68 to 74.5°F) in

the winter.

How to measure?

Measurements should be taken periodically at many areas of the building to be sure that air is distributed evenly

and temperatures are consistent. TSI offers a number of instruments that measure temperature. These include

IAQ monitors, thermohygrometers and multi-parameter ventilation meters.

What to Measure—Humidity

Why measure?

Too little humidity in a space may create static build-up and people will sense that their skin feels dry. Too much

humidity and people will think it feels “sticky.” According to ASHRAE Standard 55, indoor humidity levels should

be maintained between 30 percent and 65 percent for optimum comfort.

How to measure?

Humidity can be measured in several ways.

Typically, references such as relative

humidity, wet bulb, dry bulb, humidity ratio

and absolute humidity are used. Whichever

method is chosen, measurements should

be taken periodically and spread throughout

the building to ensure that air is distributed

evenly and humidity levels are consistent

and within goals. As with temperature, TSI

offers several portable instruments that

measure humidity, including IAQ monitors,

thermohygrometers and multi-parameter

ventilation meters.

ASHRAE Standard 55 links temperature and

humidity together to provide a measure of

thermal comfort. The objective should be to

set the appropriate temperature and

humidity levels so as to maximize occupant

comfort while controlling energy

consumption. The "comfort zone" shown on

the graph is based on the subjective

response of people tested under a variety of

conditions and their perception of what was

or was not comfortable. Compare the actual

temperature and humidity data collected to

the graph to determine if an area is within

the prescribed comfort zone.

Indoor Air Quality Handbook 7

Page 14

Indoor Air Quality Handbook

What to Measure—Air Movement and Flow The three V’s—Velocity, Volume and Ventilation

Velocity— Why measure?

One of the first checks, often overlooked, in a comfort study is making sure that sufficient air is moving in a

space. Air movement can affect human comfort level in that too much is perceived as “drafty” or “chilly” and too

little may create a sensation of stuffiness.

How to measure?

A quick spot check at the supply diffuser will show if

sufficient air is entering a space. This will assure

there are no unexpected blockages in the air

system, such as a closed damper. Velocity is also a

good indicator that air is being appropriately

distributed or balanced throughout the building and

reaching all the spaces intended. Measurements

should also be taken in the actual occupied “zones”

to assess how air velocity affects individuals. TSI

provides several instruments for making quantitative

air velocity measurements, including air velocity

meters, rotating vane anemometers and the multiparameter ventilation meters.

Volume— Why measure?

ASHRAE Standard 62 lists recommended outdoor air requirements expressed in terms of cubic feet per minute

(cfm) per person depending on the type of space and activity. The Percent Outdoor Air must be calculated (see

ventilation section). This percentage can then be multiplied by the measured airflow to calculate the amount of

outdoor air being supplied. Air volume or flow into an area affects the air change rates or exchange of air

between outdoors and indoors. This results from leakage and natural or mechanical ventilation systems. The

exchange of air can have a large impact on indoor air quality as it may increase the amount of outdoor pollutants

being introduced or, conversely, dilute and help remove contaminants generated indoor.

How to measure?

Air velocity is seldom uniform across any section of an air duct. The

shape of a duct, its turns and branches and friction all affect the

movement of air. In general, air tends to move slower toward the

edges or corners and faster in the center of a duct. The average air

velocity can be determined using a straight average for both round

and rectangular ducts using the log-Tchebycheff method, a method

that accounts for velocity losses due to friction. As the figure below

indicates, velocity measurements should be taken at a minimum of

25 points for rectangular ducts and, for round ducts, symmetrically

disposed diameters with at least 6 points on each should be used.

For the greatest accuracy, take these measurements at least 7.5

diameters downstream or 3 diameters upstream from any disturbance

such as an elbow, venturi or take-off. ASHRAE Standard 111 has

additional details on measuring flow in ducts.

8 TSI Incorporated

Page 15

Indoor Air Quality Handbook

To determine volumetric flow rate, the average measured air velocity is multiplied by the cross-sectional area of a

duct. For example, if a duct is 2 feet by 2 feet (cross-sectional area = 4 square feet) and the average measured

air velocity is 150 feet per minute, the resulting flow rate is 150 ft/min x 4 square feet or 600 cfm (cubic feet per

minute). Multi-parameter ventilation meters are capable of calculating automatically the volumetric flow rate

when the cross-sectional area of a duct is entered.

An air capture hood can also be used to determine air flow. Capture hoods provide quick, direct measurements

of air flow from diffusers, vents or grilles. They are capable of collecting and storing real-time flow measurements

and they are also valuable when balancing the system for proper flow in all areas.

Air velocity meters, multi-parameter ventilation meters and air capture hoods all provide a fast, accurate means

for measuring volumetric airflow.

Ventilation— Why measure?

The introduction of outdoor air helps dilute unwanted pollutants

and gets them out of the building faster. ASHRAE Standard 62

presents recommendations pertaining to ventilation, or the amount

of outdoor air introduced into a given area. It recommends a

minimum volume per person over time, depending on the type of

space and activity being performed, expressed in cubic feet per

minute per person.

How to measure?

A good indicator of proper ventilation is the level of CO2 present in

a space. Carbon dioxide is a normal by-product of respiration,

combustion and other processes. Elevated levels of CO

may

2

indicate that additional ventilation is required. ASHRAE Standard

62 recommends an indoor level not to exceed about 700 ppm

above outdoor ambient air which is typically about 300 to 400

ppm. Under normal conditions, even elevated CO

levels are rarely

2

a health hazard since levels up to 10,000 parts per million can be

tolerated without ill effects by healthy people.

Measurements should be taken between different areas, in air distribution zones, at varying heights and between

indoor and outdoor areas to ensure that the building is properly ventilated.

Indoor Air Quality Handbook 9

Page 16

Indoor Air Quality Handbook

Residential kitchens

25

The amount of outdoor air entering the building can be calculated as a percentage of the total air volume. This

calculation can be done using either temperature or CO

. Three measurements need to be taken: return air,

2

supply air and outdoor air. The equation is as follows:

RAM − SAM

Percent Outdoor Air =

RAM − OAM

____________

× 100

Where: RAM = Return Air Measure

SAM = Supply Air Measure

OAM = Outdoor Air Measure

IAQ monitors can be used to measure both temperature and CO

simultaneously and perform this percent

2

outdoor air calculation automatically when the three measurements are entered. Many monitors are also

equipped with data logging capability so that an area can be monitored over time to see if action needs to be

taken to change ventilation amounts or patterns.

When the volumetric flow rate (cfm) is determined, the amount of outdoor air (OA) entering the space can be

calculated by multiplying the flow rate by the percent outdoor air (see volume section).

Air flow (cfm) × %OA = OA% cfm

The next step is calculating the volume of outdoor air per person.

OA% cfm ÷ no. of people = volume of OA per person (in cfm)

This calculation can then be compared to the table in ASHRAE Standard 62 to determine if an adequate amount

of outdoor air per person is being supplied for a particular type of space. The following table lists a few examples

taken from Table 2 in the standard.

Application

Dining areas 20

Kitchens 15

Hotel/motel rooms 15

Parking garages 1.5 cfm/ft2

Office space 20

Conference rooms 20

Public rest rooms 50

Smoking areas 60

Retail stores (typical) 15

Gymnasium 20

School classroom 15

School laboratories 20

Auditoriums/theaters 15

Libraries 15

Patient rooms 25

Health procedure & recovery rooms 15

Operating rooms 30

Residential living areas 15

cfm/person

(outdoor air)

Residential bath 20

Residential garage 100 cfm/vehicle

Approved in 2004, Addendum 62n to ASHRAE Standard 62 incorporates a number of new variables and

equations for determining more effective dilution and evacuation of pollutants generated by the building and its

occupants. The International Mechanical Code and other organizations that govern design, construction,

commissioning and inspection of buildings have yet to adopt this new standard, and the addendum remains

a guideline.

10 TSI Incorporated

Page 17

Indoor Air Quality Handbook

Health and Safety Issues

While comfort is important in maintaining productivity and concentration, many unwanted airborne contaminants

can actually pose a threat to human health. Unhealthy IAQ conditions occur whenever vapors, gases or airborne

particulates are present in concentrations that adversely affect one or more occupants of a space.

Potentially toxic, infectious, allergenic, irritating or otherwise harmful substances are almost always around us.

Usually they exist in such small concentrations that stay below a “trigger” threshold and get little attention. When

concentrations rise above the threshold, problems can begin. Even at relatively low concentrations, some

individuals are very sensitive to certain substances and may react adversely even though other area occupants

are not bothered. In very extreme cases, concentrations may be high enough to be fatal to all occupants.

Dangerous airborne substances are serious matters and must be dealt with, proactively, before problems get out

of control.

What to Measure—Carbon Monoxide

Why measure?

Carbon monoxide (CO) is a colorless, odorless, poisonous gas that is

a by-product of incomplete combustion. When inhaled, it readily

mixes with hemoglobin in the blood, inhibiting the blood's ability to

carry and exchange oxygen. Carbon monoxide does not readily leave

the body once it enters and treatment in some cases may even

require a blood transfusion. Excessive exposure to carbon monoxide

can starve the body of oxygen and lead to death. Even a few parts

per million is reason to immediately investigate this serious health

concern.

The U. S. EPA has set National Primary Ambient Air Quality

Standards for Outdoor Air to be used in locating ventilation sources

for buildings. Exposure limits for CO are an average of 35 ppm for

one hour, not more than one time per year, or 9 ppm over any eighthour period. The American Conference of Government Industrial

Hygienists (ACGIH) and U.S. Occupational Safety and Health

Administration (OSHA) have also set maximum exposure limits in the

Industrial Workplace Standard. There are no Federal regulations

governing carbon monoxide exposure limits in non-industrial indoor

environments.

How to measure?

Measurements of carbon monoxide should be taken periodically and spread throughout many areas in a building

to be sure that air is being distributed evenly and no dangerous levels of CO are detected. Pay particular attention

to areas in which any form of combustion takes place. Typical examples of outdoor CO sources in a building

include vehicular emissions from traffic or parking areas and building exhaust stacks. Indoor sources include

furnaces, boilers, stoves and smoking areas. Instruments that measure carbon monoxide in real time include the

IAQ monitors and combustion analyzers.

What to Measure—Airborne Particles

Why measure?

Respiration of particles challenges the body’s natural defense mechanisms and overexposure may strain these

mechanisms, causing an adverse reaction. Inhalable particles are typically defined as those with an aerodynamic

diameter of 10 micrometers or smaller, commonly referred to as PM10. Respirable particles, or those that readily

enter the lungs, are usually classified as less than 4 microns in diameter. Sources may include dust, mists,

fumes, smoke, environmental tobacco smoke (ETS) and other particulate by-products of combustion. ASHRAE

Standard 62 recommends a maximum exposure limit for PM10 particles of 0.15 mg/m

and 0.05 mg/m

3

for an annual average exposure. This is consistent with the EPA's National Ambient Air Quality

3

for a 24-hour average

Standards. The industry is moving in the direction of concern for smaller particles since they bypass natural

defense mechanisms more readily and make their way deep into the lungs.

Indoor Air Quality Handbook 11

Page 18

Indoor Air Quality Handbook

Respiration of particles challenges the body’s natural

defense mechanisms and overexposure may strain

these mechanisms causing an adverse reaction.

How to measure?

First, it is important to minimize airborne particles

as much as possible using more routine means

such as good housekeeping practices, upgrading

filters, maintaining a positive pressure relative to

the outdoors and having proper exhaust design.

Even with these practices in place, airborne

particles may enter workspaces.

When it does become necessary to measure

airborne particles, two basic methods typically are

used: air sampling over time and measurements

employing real-time instruments. With air sampling

over time, materials are most often collected on a

filter medium and subsequently analyzed in an

environmental laboratory located away from the

sampling location. With real-time instruments,

measurements are made and results obtained on-site.

Three types of instruments—photometers, optical particle counters and condensation particle counters—

normally are used for real-time measurements. Performance features and applications for the three are

compared in the following charts. The specific instrument of choice depends on the application and the desired

results.

Features

Typical Size Range 0.1 to 10 µm 0.3 to 20 µm 0.02 to 1.0 µm

Measures Particle Mass Yes No No

Measures Particle Size No Yes No

Detects Single Particles No Yes Yes

Typical Mass Concentration Range 0.01 to 100 mg/m3 N/A N/A

Typical Number Concentration, Upper Limit N/A

Applications

Indoor Air Quality – Conventional studies Good Good Excellent

Indoor Air Quality – Ultrafine particle tracking Poor N/A Excellent

Industrial Workplace Monitoring Excellent Poor Excellent1

Outdoor Environmental Monitoring Good Good Excellent1

Emissions Monitoring Excellent Poor Good

Respirator Fit Testing Excellent Poor Excellent

Filter Testing Excellent Excellent Excellent

Clean Room Monitoring Poor Excellent Excellent

1

Health effects of ultrafine particles (below 0.1 µm) are not completely understood, though research suggests that they may cause the

greatest harm. There are currently no established exposure limits or governmental regulations specifically addressing ultrafines.

Most guidelines offered by ASHRAE and the EPA are written in terms of mass concentration per volume rather

than absolute counts. TSI’s product offering in this area includes an aerosol monitor, which is a photometer that

measures particle mass per volume in real-time for particles ranging from 0.1 to 10 micrometers diameter.

Photometer OPC CPC

6

2 x 10

Particles/ft3

70

3

Particles/cm

Photometer OPC CPC

1.5 x 10

Particles/ft3

500,000

Particles/cm

10

3

12 TSI Incorporated

Page 19

Indoor Air Quality Handbook

What to Measure—Ultrafine Particles

Why measure?

Ultrafine particles (UFPs), defined as particles less than

0.1 micrometer diameter, are often produced by combustion

and some chemical reactions. They are so small that they can

pass easily through the body's natural defense mechanisms to

the deepest areas of the lungs. Certain people are extremely

sensitive to ultrafine particles, sometimes regardless of

chemical composition. It is suspected that the sheer number of

particles and their cumulative surface area may trigger a

reaction in these people.

As of this writing, no specific guidelines or standards have been

developed for ultrafine particles. Much research currently is

being done, however, and some initial results have linked UFPs

to potentially adverse health conditions. There are thousands of

case studies where indoor air quality was suspected as the

reason for health complaints and, when a source of UFPs was

located and controlled, the complaints went away. Often, this

happened after conventional IAQ measurements had failed to

identify any serious problems that would likely be the cause.

These very tiny particles migrate on “pathways” driven by air movement or differences in air pressure. Because

of their extremely low mass, they can take days, weeks or even months to settle out of the air. Ultrafine particles

can penetrate even the smallest opening and are not detectable using most conventional particle detection

instruments.

How to measure?

The only practical instrument for detecting ultrafine particles is a condensation particle counter (CPC), a device

that “grows” the small particles to a size large enough to be counted using conventional particle counting

techniques. TSI’s ultrafine particle counter employs CPC technology to detect and track ultrafine particles within

the building environment.

The method for tracking UFPs begins outdoors where several measurements are made with the particle counter

to establish a baseline. If the building’s intake air is filtered, you can subtract from the base-line measurement a

percentage of particulates roughly equal to the efficiency rating of the filter to establish an indoor goal. For

example, a 75% efficient filter effectively removes about three-quarters of all particles leaving 25% of the

outdoor reading as the goal. Inside, measurements are taken and compared to this indoor goal. Seek levels of

ultrafine particles greater than the goal to find sources of particles that might contribute to air quality problems. A

basic understanding of the ventilation system and how outdoor air is introduced, filtered and distributed

throughout the building is necessary for an effective investigation.

If levels of ultrafine particles significantly higher than expected are found anywhere in the building, take steps to

locate and identify the source. Using the particle counter much like a Geiger counter, ultrafines can be traced

quickly and easily directly to their source. Once a source is located, remedial action to control, repair or remove it

is often straightforward.

Remember that in a thorough investigation there may be, and often are, multiple problems or sources of UFPs.

Unmasking and solving one source of particles allows you to search out the next. Continue until no additional

sources are found. Routine, ongoing monitoring helps ensure that problems do not resurface, and new issues

can be dealt with quickly before they become serious or expensive to correct.

Indoor Air Quality Handbook 13

Page 20

Indoor Air Quality Handbook

Studies have shown elusive ultrafine particles

may lead to problems even though other

parameters are within acceptable levels.

Another important parameter to consider along with ultrafine particles is differential air pressure. Airborne

particles travel along seen and unseen pathways and are driven by air movement and pressure differential. Small

particles naturally migrate from areas of higher to lower relative pressure. Even very small differences cause

movement. TSI's micromanometers offer a means for accurately measuring differential pressure to help identify

these pathways.

What to Measure—Bioaerosols

Why measure?

Bioaerosols are defined by the ACGIH as airborne particles, large molecules or

volatile compounds that are living or were released from a living organism. Types of

most concern for IAQ and included in this definition are plants, including fungi,

yeasts, molds, mildews and pollen, as well as bacteria, endotoxins, viruses,

antigens, and animal parts. Bioaerosols range in size from less than 0.1 micrometer

to 100 micrometers in diameter.

Some of these bioaerosols contain dangerous toxins that in extreme cases can

cause a range of adverse health effects, including death. Mechanisms may include

immunologic hypersensitivity, infection and toxic reaction. Diseases typically associated with bioaerosol

dispersion include Legionellosis, Pneumonia, Tuberculosis, Histoplasmosis, Aspergillosis, asthma, cancer and

others. Generally, most healthy people are able to fend off adverse effects from exposure.

Besides serious diseases, some bioaerosols can also cause varying levels of irritation in certain individuals,

including allergic reactions, headaches, eye irritation, sneezing, fatigue, nausea, difficult breathing and more.

About 10 percent of the population is allergic to one or more of the hundreds of thousands of different types of

mold alone. As with other particles, bioaerosols may irritate certain sensitive individuals regardless of the

bioaerosol composition or level of toxicity.

How to measure?

Most biological growth requires some kind of food and water. Condensation, plumbing leaks, roof leaks, or even

improper housekeeping can lead to unwanted moisture which can foster unwanted growth that must be checked

and corrected. At this time, bioaerosols such as molds, fungi and bacteria must be collected, cultured and

analyzed in an environmental microbiology laboratory setting to determine exactly what they are and how large of

a presence they have. Sampling often consists of collecting material through an air sample on different sized

filter media. In commercial and residential environments, “settle plates” and surface swabbing are not viable

means of testing for biologicals. These methods were developed for testing in highly controlled environments and

may grossly understate or overstate the condition in commercial and residential environments. The analysis

portion of the testing may take days or even weeks before results are determined. While there are some large,

expensive research-grade instruments that can be used to assess biological material, there are no practical,

portable “real-time” instruments that reliably measure biologicals.

14 TSI Incorporated

Page 21

Indoor Air Quality Handbook

What to Measure—Chemicals in Aerosol Form (Condensates)

Why measure?

A wide variety of chemicals in gas, vapor or particle form can become

airborne and have potentially adverse health effects in certain individuals. In

cases where exposures are known, personal protective equipment is available

to control contact. It is the unexpected exposure in areas where risk is not

normally assumed that causes concern.

Some common chemicals of special concern include, but are not limited to,

lead, radon, formaldehyde, environmental tobacco smoke and volatile organic

compounds (VOCs). VOCs are a broad class of chemicals containing carbon

atoms that tend to give off high levels of vapor even at room temperature.

They typically are found in building materials, cleaners, solvents, paints,

gasoline and other substances.

Airborne chemicals—particles, vapors or gases—can originate from sources

within a building or enter it by several means. They enter the building on air

currents or by seeking relatively negative pressure areas. Chemicals in the soil

can be tracked in and become airborne. And, finally, the deterioration or disturbance of materials containing

unwanted chemical compounds can introduce airborne particles. For many of the materials that fall into this

category, there do exist established exposure levels for chemicals known to be dangerous that are set by EPA

(National Ambient Air Quality Standards) or OSHA regulations that apply in the industrial workplace.

How to measure?

Some of the tools available include electrochemical and infrared (NDIR) gas sensors designed to identify

particular gases present in industrial settings, from combustions, emissions and other situations that could

impact air quality. Photo-ionization and flame-ionization detectors can be used to identify many VOCs that can

impact IAQ.

In most cases, it is difficult to get an accurate picture of the extent of chemical contaminants in the air using realtime data collection. It is more often a complex mix rather than individual compounds that pose the difficult

challenge. Consequently, sampling is an accepted practice generally conducted using techniques such as

filtration, absorption in another media, or impaction.

What to Measure—Light, Noise, Vibration, Ergonomics, Odors, etc.

Why measure?

It is important here to recognize that a healthy, productive working or living environment consists of more than

just good quality air. The entire picture must be considered in order to optimize occupant

The entire picture must be considered in order to

optimize people’s satisfaction and productivity.

satisfaction and productivity. There are guidelines and standards that pertain to other factors that contribute to

the total working environment, and instrumentation is available that objectively measures some of these

parameters in real time. Further details are outside the scope of this book.

Indoor Air Quality Handbook 15

Page 22

Indoor Air Quality Handbook

Conclusion

While investigating any indoor air quality situation, be aware of the entire picture. Many parameters that may be

contributing to an overall problem must be considered and checked. Also keep in mind that it is not uncommon

to find multi-layered problems, and finding and solving one issue may not get to the root cause. Think of an

investigation as peeling an onion; as each layer is removed, another is exposed.

Be sure to understand the exact time and place that problems are suspected, since many IAQ problems come

and go in a moment. Use common sense along with the proper tools and keep investigating and correcting

problems until complaints stop.

16 TSI Incorporated

Page 23

Indoor Air Quality Handbook

Sources for Information Relating to Indoor Air Quality Evaluations

The following is a partial list of organizations offering information on indoor air quality:

Aerias, LLC—www.aerias.org

Air Conditioning Contractors of America (ACCA)—www.acca.org

Air Conditioning and Refrigeration Institute (ARI)—www.ari.org

Air Diffusion Council (ADC)—www.flexibleduct.org

American Board of Industrial Hygienists (ABIH)—www.abih.org

American Conference of Governmental Industrial Hygienists (ACGIH)—www.acgih.org

American Indoor Air Quality Council (AmIAQ)—www.iaqcouncil.org

American Industrial Hygiene Association (AIHA)—www.aiha.org

American Lung Association (ALA)—www.lungusa.org

American National Standards Institute (ANSI)—www.ansi.org

American Society for Testing and Materials (ASTM)—www.astm.org

American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE)— www.ashrae.org

ASHRAE Fundamentals Handbook—www.ashrae.org

ASHRAE Standard 55, Thermal Environmental Conditions for Human Occupancy

ASHRAE Standard 62, Ventilation for Acceptable Air Quality

ASHRAE Standard 111, Practices for Measuring, Testing, Adjusting, and Balancing of Building Heating, Ventila-

tion, Air-Conditioning, and Refrigeration Systems

American Society of Safety Engineers (ASSE)—www.asse.org

Asthma and Allergy Foundation of America (AAFA)—www.aafa.org

Building Air Quality Alliance

Building Owners and Managers Association (BOMA)—www.boma.org

Center for Disease Control and Prevention (CDC)—www.cdc.gov

Government Information Exchange

Healthy Buildings International (HBI)—www.hbi.com.au

Indoor Air Quality Association (IAQA)—www.iaqa.org

International Facility Management Association (IFMA)—www.ifma.org

National Air Duct Cleaners Association (NADCA)—www.nadca.com

National Air Filtration Association (NAFA)—www.nafahq.org

National Institute for Occupational Safety and Health (NIOSH)—www.cdc.gov/niosh/homepage.html

National Institute of Standards and Technology (NIST)—www.nist.gov

National Institutes of Health (NIH)—www.nih.gov

National Safety Council (NSC)—www.nsc.org

U.S. Department of Health and Human Services (HHS)—www.hhs.gov

U.S. Department of Labor Occupational Health and Safety Administration (OSHA)—www.osha.gov

U.S. Environmental Protection Agency (EPA)—www.epa.gov

U.S. Public Health Service (PHS)—www.hhs.gov/phs

A host of trade publications, books and web sites dedicated to IAQ issues also are excellent sources of information but are far too numerous to mention here.

Indoor Air Quality Handbook 17

Page 24

Indoor Air Quality Handbook

Standards and Guidelines

Parameter Limit/Range Reference TSI Instrument

Temperature

Summer 73 to 79°F

Winter 68 to 74.5°F

Relative Humidity 30% to 65%

Air Movement 0.8 ft/s or 0.25 m/s

Ventilation (outdoor air)

Recommended volume/person

minimum depending on type of

space and activity

Ventilation (CO2)

No more than about 700 ppm

over outdoor ambient

Ultrafine Particles

n.a. n.a. P-T

<1.0 micron

8 hr. TWA 1 hr. TWA

Carbon Monoxide 50 ppm

35 ppm

9 ppm

9 ppm (peak)

25 ppm

9 ppm

–

–

35 ppm

–

–

26 ppm

ASHRAE Standard 55-1992

ISO 7730

ASHRAE Standard 55-1992

ISO 7730

WHO

ISO 7730

ASHRAE Standard 62-2003

(Table 2)

ASHRAE Standard 62-2003

OSHA

NIOSH

EPA

ASHRAE

ACGIH

WHO

Q-T

RAK

ALC

IAQ-C

ALC

TH-C

ELOCICALC

V

Q-T

RAK

ALC

IAQ-C

VELOCICALC

ALC

TH-C

V

ELOCICALC

DP-CALC

CCUBALANCE

A

RAK

Q-T

ALC

IAQ-C

ALC

TH-C

Q-T

RAK

ALC

IAQ-C

RAK

RAK

Q-T

ALC

IAQ-C

CA-CALC

18 TSI Incorporated

Page 25

Indoor Air Quality Handbook

•

CO

RH

IAQ Instruments from TSI

TM

RAK

Q-T

Indoor Air Quality Monitors

Model 7575

• Measures CO

, CO, temperature and humidity simultaneously

2

• Calculates dew point, wet bulb and percent outside air

• Large graphic display

o Displays up to five measurements

o On-screen messages and instructions

o Supports 12 different languages

• One instrument with multiple plug-in probe options including VOC’s and

air velocity

• Stores up to 39 days of data collected at one-minute log intervals

RAKPRO™ data analysis software provided for data logging, analysis and

• T

documenting results

Bluetooth communications for transferring data or remote polling

IAQ CALC

Indoor Air Quality Meters

Models 7515, 7525, 7535, 7545

• Fast and accurate CO

• % outside air calculations

• Statistics including average, maximum, and minimum values

• Downloads to spreadsheet or database using LogDat2

TM

7535, 7545)

, temperature, humidity and CO readings

2

TM

software (7525,

IAQ Monitor Feature Chart

Model

7515

7525

7535

7545

7575

CO

2

Feature

Temp

Datalog

Indoor Air Quality Handbook 19

Page 26

Indoor Air Quality Handbook

Volatile Organic Compounds (VOC)

Indoor Air Quality Probes

Models 984, 985, 986, 987

• Pre-calibrated plug-and-play accessory probes for TSI Model 7575

RAK™ monitor

Q-T

• Compact design with ergonomic handle

• Four versions available with multiple measurement capability

o Model 984 - Low concentration (ppb) VOC and temperature

o Model 985 - High concentration (ppm) VOC and temperature

o Model 986 - Low concentration (ppb) VOC, temperature, CO

2

and humidity

o Model 987 - High concentration (ppm) VOC, temperature CO

2

and humidity

• Calculates VOC exposure in mass concentration

o Requires knowledge of VOC being measured

o Enter specific response factor into meter

• Two-year factory warranty

• Send only the probe back for factory calibration

VELOCICALC®

Air Velocity Meters

Models 9535, 9535-A, 9545, 9545-A

• Wide air velocity range of 0 to 6,000 ft/min (0 to 30 m/s)

• Easy recording of multiple measuring points

• Calculates valuable statistics—average, maximum and minimum values,

and records the number of samples

• Flow rate calculated automatically

• Durable telescoping probe with etched length marks

• Humidity measurement [Models 9545 and 9545-A]

ACCUBALANCE®

Air Capture Hood

Model 8375

• Ergonomic design and ultra light weight for easy one person operation

• Detachable digital manometer for use in other applications with Pitot,

air flow, temperature, velocity matrix, or relative humidity probes

• Back pressure compensated

• Multiple hood sizes available

• Bio-Safety hood kit available

20 TSI Incorporated

Page 27

Indoor Air Quality Handbook

DP-CALCTM

Micromanometers

Models 5815, 5825, 8710

• Accurately measures differential and static pressure

• Wide measurement range of -15 to +15 in. H

O (-3735 to 3735 Pa)

2

• Automatic conversion of actual and standard flows (Model 5825, 8710)

• Flowrate automatically calculated (Model 5825, 8710)

• Measures velocity with Pitot tube in high temperature and

contaminated areas

Auto-zeroing technology (8710)

•

TM

IDEPAK

S

Personal Aerosol Monitors (Photometer)

Model AM510

• Measure aerosol mass concentrations in real time

• Small, lightweight and quiet

• PM10, PM2.5, PM1.0 and respirable fractions

• Belt mounted

• Battery operated

Data logs and downloads to a PC for analysis and reporting

•

USTTRAK

D

TM

II and DRX

Aerosol Monitors

Models 8530, 8532, 8533 and 8534

3

• Measures mass in high concentrations up to 400 mg/m

(Model 8530, 8532)

• Simultaneously measure size-segregated mass fraction concentrations cor-

responding to PM

(Model 8533, 8534)

1, PM2.5, Respirable, PM10, and Total PM size fractions

• Easy to program, easy to operate

• New graphical user interface with color touch-screen

• Perform in-line gravimetric analysis for custom reference calibrations

• Automatic zeroing (with optional zero module) minimizes the effect of

zero drift

• Measure aerosol concentrations corresponding to PM

1, PM2.5, PM10, or

Respirable size fractions

TM

P-TRAK

Ultrafine Particle Counters (CPC)

Model 8525

• Counts ultrafine particles less than 1 micron diameter in real-time

• Tracks to the source

• Portable, battery operated

• Data logs to document results

Indoor Air Quality Handbook 21

Page 28

Indoor Air Quality Handbook

EROTRAK

A

TM

Handheld Particle Counter

Model 9306

• Complies with all requirements of ISO 21501-4

• 0.3 to 25 μm size range

• 0.1 CFM (2.83 L/min) flow rate

• Measures up to six channels of simultaneous data

• Model 9306-V2 provides unique variable binning option

• Integrated handle for one hand operation

• Removable, rechargeable Li-ion battery

• Long life laser diode

• USB and Ethernet output

• 10,000 sample record storage, 250 locations

• Local or remote configuration via web browser

• Provides Pass/Fail reporting on ISO 14644-1, EU GMP, and FS209E

• Compatible with T

RAKPRO™ Lite and FMS 5 software packages

• Optional Temperature/RH sensor available

22 TSI Incorporated

Page 29

Indoor Air Quality Handbook

Notes

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

Indoor Air Quality Handbook 23

Page 30

Indoor Air Quality Handbook

Notes

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

_____________________________________________________________________

24 TSI Incorporated

Page 31

Page 32

TSI Incorporated

.

USA Tel: +1 800 874 2811 E-mail: info@tsi.com Website: www.tsi.com

UK Tel: +44 149 4 459200 E-mail: tsiuk@tsi.com Website: www.tsiinc.co.uk

France Tel: +33 491 11 87 64 E-mail: tsifrance@tsi.com Website: www.tsiinc.fr

Germany Tel: +49 241 523030 E-mail: tsigmbh@tsi.com Website: www.tsiinc.de

India Tel: +91 80 41132470 E-mail: tsi-india@tsi.com

China Tel: +86 10 8251 6588 E-mail: tsibeijing@tsi.com

Singapore Tel: +65 6595 6388 E-mail: tsi-singapore@tsi.com

- 500 Cardigan Road, Shoreview, MN 55126-3996 USA

Contact your local TSI Distributor or visit our website www.tsi.com for more detailed specifications.

P/N 5001020 Rev E (7/2011) Copyright © 2011 by TSI Incorporated Printed in U.S.A.

TRUST. SCIENCE. INNOVATION

Loading...

Loading...