Page 1

Alnor

Air Volume Instruments

®

LoFlo Balometer® Capture Hood

Owner’s Manual

Page 2

LIMITATION OF WARRANTY AND LIABILITY

Seller warrants the goods sold hereunder, under

normal use and service as described in the operator's

manual, shall be free from defects in workmanship

and material for twenty-four (24) months, or the length

of time specified in the operator's manual, from the

date of shipment to the customer. This warranty

period is inclusive of any statutory warranty. This

limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research

anemometers, and certain other components

when indicated in specifications, are warranted

for 90 days from the date of shipment.

b. Parts repaired or replaced as a result of repair

services are warranted to be free from defects in

workmanship and material, under normal use, for

90 days from the date of shipment.

c. Seller does not provide any warranty on finished

goods manufactured by others or on any fuses,

batteries or other consumable materials. Only the

original manufacturer's warranty applies.

d. Unless specifically authorized in a separate

writing by Seller, Seller makes no warranty with

respect to, and shall have no liability in

connection with, goods which are incorporated

into other products or equipment, or which are

modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and

is subject to the LIMITATIO N S stated herein. NO

OTHER EXPRESS OR IMPLIED WARRANTY OF

FITNESS FOR PARTICULAR PURPOSE OR

MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE

EXCLUSIVE REMEDY OF THE USER OR BUYER,

AND THE LIMIT OF SELLER'S LIABILITY FOR ANY

AND ALL LOSSES, INJURIES, OR DAMAGES

CONCERNING THE GOODS (INCLUDING CLAIMS

BASED ON CONTRACT, NEGLIGENCE, TORT,

STRICT LIABILITY OR OTHERWISE) SHALL BE

THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE

OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN NO EVENT

SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES.

SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR

REINSTALLATION COSTS OR CHARGES. No

Action, regardless of form, may be brought against

Seller more than 12 months after a cause of action

has accrued. The goods returned under warranty to

Seller's factory shall be at Buyer's risk of loss, and will

be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this

LIMITATION OF WARRANTY AND LIABILITY, which

contains the complete and exclusive limited warranty

of Seller. This LIMITATION OF W A RRA NTY AND

LIABILITY may not be amended, modified or its term s

waived, except by writing signed by an Officer of

Seller.

Service Policy

Knowing that inoperative or defective instruments are

as detrimental to TSI as they are to our customers ,

our service policy is designed to give prompt attention

to any problems. If any malfunction is discovered,

please contact your nearest sales office or

representative, or call Customer Service at

(800) 874-2811 (USA) and (1) 651-490-2811

(International).

Trademarks

®

TSI

, TSI logo, Alnor®, and Balometer® are

trademarks of TSI Incorporated.

.

Page 3

iii

iii v

Page 4

Page 5

TABLE OF CONTENTS

Section 1 General Description ......................................................... 1

Section 2 Theory of Operation ........................................................ 1

Section 3 Safety ............................................................................... 2

Section 4 Instrument Setup and Storage.......................................... 2

Section 5 About the Instrument Display ......................................... 4

Section 6 Getting Started ................................................................. 5

Section 7 Detailed Operation .......................................................... 5

Section 8 Troubleshooting .............................................................. 8

Section 9 Maintenance .................................................................... 9

Section 10 Service Information ....................................................... 10

Appendix A Correction Factors for Standard

Flow Rate to Actual Flow Rate ..................................... 11

®

Appendix B Model 6200 LoFlo Balometer

Setting Instruction for User Programmable

Correction Factors ......................................................... 12

Capture Hood Field

Page 6

Page 7

SECTION 1

General Description

The Alnor® LoFlo Balometer® Capture Hood is a

compact instrument that measures very low air flow

rates in HVAC systems. It measures from 10 to 500

cfm (17 to 850 m

Balometer

3

®

/h, 4.7 to 236 l/s). The LoFlo

Capture Hood displays standard air volume

rate when placed at supply or return diffusers, registers,

or grilles located on the ceiling, wall, or floor.

®

The LoFlo Balometer

Capture Hood has a vent

mechanism which reduces the restriction of air flow

caused by the instrument. This unique venting system

(patent pending) allows the instrument to remain

compact while still measuring a wide range of volume

rates. The LoFlo Balometer

®

Capture Hood should be

SECTION 2

Theory of Operation: Capture Hoods

and Thermo-anemometry Sensing

As air exits a diffuser, it is captured in the hood or base

and directed over a manifold. The manifold averages

the velocity pressure and directs air over the sensors.

The velocity and temperature of the air passing through

the manifold are sensed, using a constant temperature

thermo-anemometer principle. The voltage output from

the sensor is then calibrated for the entire volume rate

passing through the LoFlo Balometer

All capture hoods are susceptible to “odd” air flow

patterns. “Odd” could refer to any air flow pattern

different from the pattern where it was calibrated.

Substantial negative effects can be observed when

®

Capture Hood.

used with the vents closed at lower volume rates, but

higher volume rates should be measured with the vents

open to minimize any resistance effects. A 2-point

measurement may be taken to compensate for the

resistance effect of the instrument at higher volume

rates.

®

The LoFlo Balometer

Capture Hood is battery

powered and may be used with or without optional

hoods. It weighs just over 6 pounds with the 2' x 2'

hood, helping to reduce worker fatigue.

using a large hood on a small diffuser. For example,

using a 2' x 2' hood on a 10" x 10" diffuser. This creates

large recirculation regions on the sides of the fabric

hood and causes an “odd” air flow pattern as it passes

over the manifold. It is recommended to match the

hood closely to the size of the diffuser.

3

NOTE: Throughout this manual, the units cfm, m

and l/s are used for simplicity. Note, howeve r , that

the LoFlo Balometer

in standard cubic feet per minute (scfm), standard

cubic meters per hour (std. m

®

Capture Hood actually reads

3

/h), or standard liters

/h

per second (std. l/s).

1

Page 8

SECTION 3

Safety

When using the LoFlo Balometer® Capture Hood to

check air flow at ceiling diffusers, make certain that

you can safely raise and hold the unit while making

measurements. Be especially careful when working on

a ladder.

WHILE USING THE LOFLO BALOMETER

MAY COME INTO CONTACT WITH OR BE EXPOSED TO DUST

OTHER AIRBORNE CONTAMINANTS

, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS, ALWAYS USE AN APPROPRIATE

MOLD

MASK OR RESPIRATOR WHILE EMPLOYING THE

SECTION 4

Instrument Setup and Storage

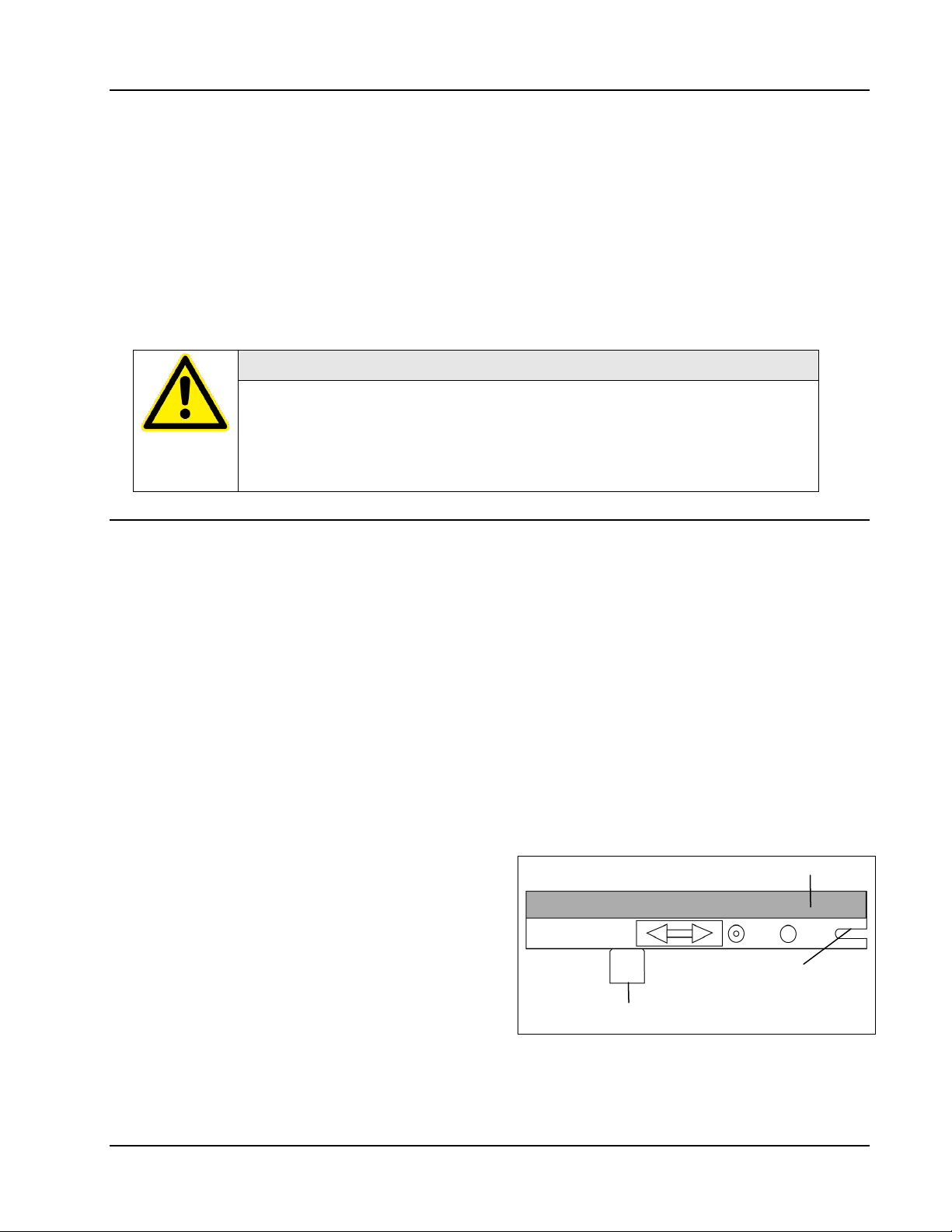

Hood Setup

1. Locate the four (4) aluminum channels for the

hood and position them into a square with the foam

facing up. Slide the “U” opening on the channel

end (Fig. 1) and corner bracket toward the brass

eyelets until you feel it latch.

2. Continue with the other two channels until you

have a square frame that is locked tightly in all

four corners.

3. Locate the hood for the frame size you have

assembled.

4. Position a corner seam of the hood onto the corner

of the frame. Stretch the nylon hood to an adjacent

corner until the hood corner meets the frame

corner.

Observe all necessary precautions so that the unit does

not become caught in moving machinery or touch any

exposed electrical wiring.

®

The LoFlo Balometer

Capture Hood is not designed

for gas mixtures other than air. Use with corrosive or

other dangerous or explosive gas mixtures is not

recommended and is at the user’s risk.

CAUTION

®

INSTRUMENT TO TEST AIR FLOW IN DUCTS, YOU

, POLLEN, MOLD, FUNGUS, OR

. IF YOU ARE OR MAY BE SENSITIVE TO DUST, POLLEN,

LOFLO BALOMETER

®

INSTRUMENT.

Rotate the hood assembly until the metal cups are

above the spring-loaded pins.

8. Locate the hood support rods. Extend the hood so

it is taut and insert one support rod onto the springloaded pin closest to you.

9. Push the support rod down and insert the top end

of the rod into the metal cup on the hood frame.

Fig 1.

10. Install the rod on the opposite side, then install the

last two rods.

Foam

5. Push the elastic cord into the channel along the

“U” Opening

side of the frame.

6. Repeat steps 4 and 5 until the hood assembly is

complete and ready to mount onto the base.

7. Place hood on a table or clean floor with the base

inside the opening. Pull the hood over the base.

2

Metal Cup

Figure 1

Hood Frame Channel

Page 9

Instrument Storage

The hood and frame assemblies can be detached from

the instrument base and placed inside their own

carrying case without disassembly.

®

The LoFlo Balometer

turned off before re-packing the instrument. If storing

the LoFlo Balometer

Capture Hood should always be

®

Capture Hood for an extended

period of time, remove the batteries to prevent damage

due to leakage.

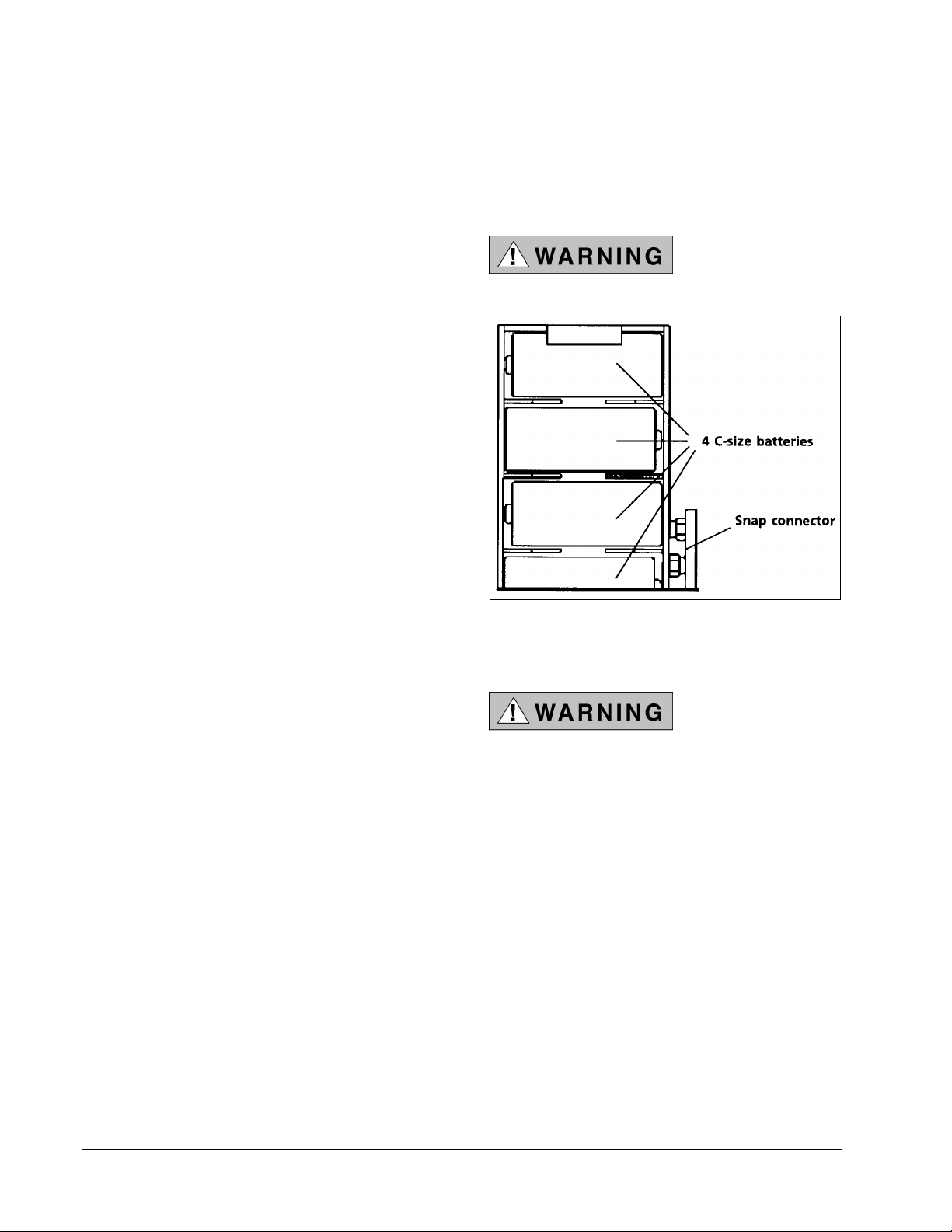

Battery Installation

3

®

2. Turn the LoFlo Balometer

3. Reconnect the fully charged battery holder to the

LoFlo Balometer

®

Capture Hood and slide battery

Capture Hood off.

holder into the battery compartment.

4. Replace battery cover.

Do not try to charge

alkaline batteries.

To install the 4 C-size batteries that ship with the LoF lo

Balometer

1. Make sure the LoFlo Balometer

®

Capture Hood:

®

Capture Hood

switch is off.

2. Remove the battery cover located on top of the

meter.

3. Slide the battery holder up until the snap connector

is exposed.

4. Disconnect the battery holder from the LoFlo

Balometer

®

Capture Hood.

5. Install the 4 C size batteries in the holder.

6. Reconnect the snap connector and slide the battery

holder into the battery compartment.

7. Replace battery cover.

To use and install rechargeable batteries:

NOTE: As an alternative to alkaline batteries, four

Nickel Cadmium (NiCd) rechargeable batteries are

available from TSI for use in the LoFlo Balometer

®

Capture Hood.

1. Connect the battery holder loaded with

rechargeable NiCd batteries to the charger and

charge for 12–14 hours.

Figure 2

Battery Holder

Do not use the

charger as a battery

substitute. Damage

to the instrument

will result.

3

Page 10

About the Instrument Display

This display is an analog display, simulated with 26

LCD segments to give the user the response of a

mechanical Balometer

an exact digital number, using 3½ digit numeric

section. The LCD has indicators for supply, return,

manual range, vent modes, and low battery.

Figure 3 shows the front of the LoFlo Balometer

Capture Hood.

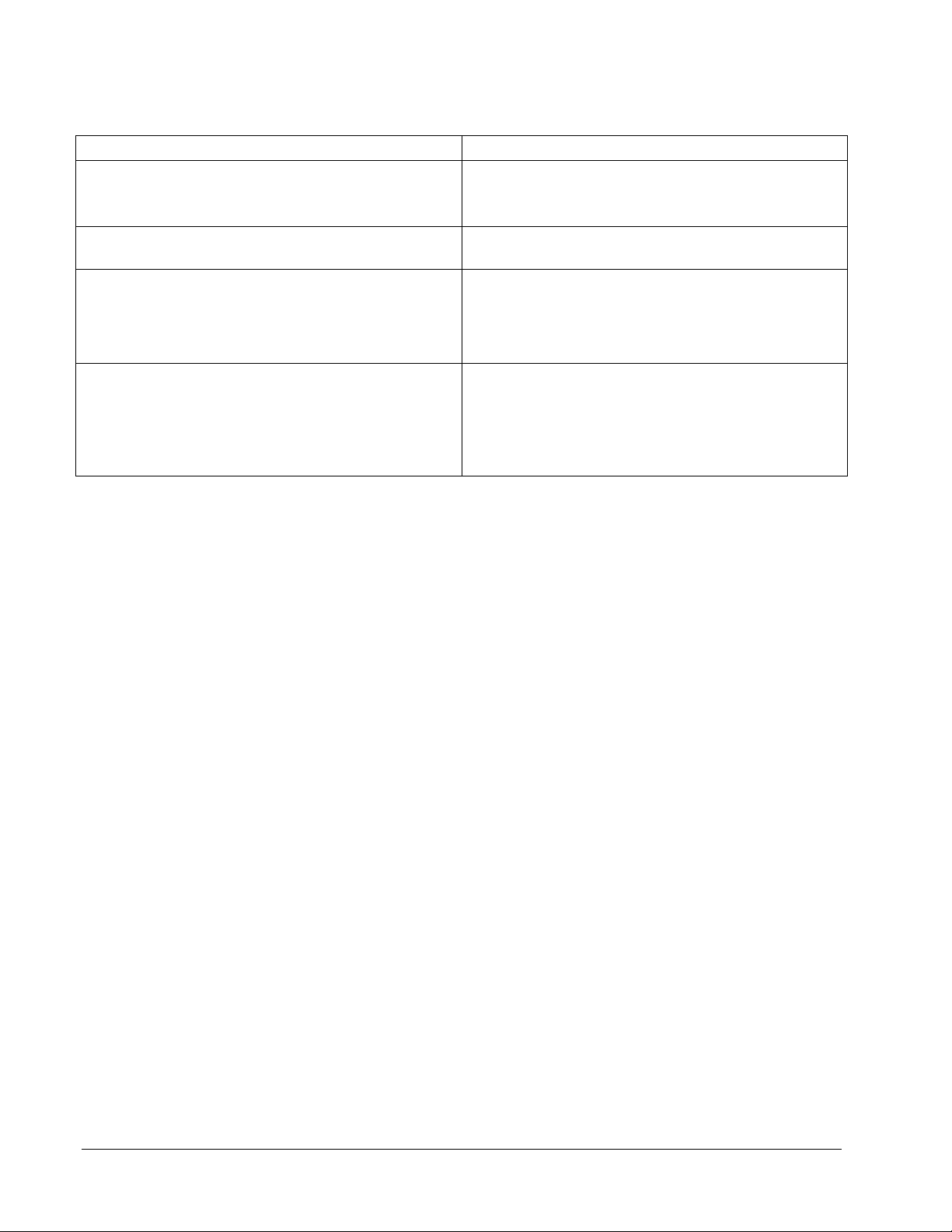

Index No. Name

1 LCD

2 On/Off Switch

3 Supply/Return Button

4 Manual Range Button

5 Handle Button

6 Battery Holder

7 Vents

8 Vent Open/Close Slide

®

Capture Hood. It also displays

®

SECTION 5

Front View of LoFlo Balometer

Figure 3

®

Capture Hood

Figure 4 shows the LCD.

Index No. Name

1 Digital Readout

2 Simulated Analog Display

3 Manual Range Indicator

4 Supply/Return Indicator

5 2-Point Mode Indicator

6 Vent Indicator

7 Units Indicator

8 Low Battery Indicator

4

LoFlo Balometer

Figure 4

®

Capture Hood LCD

Page 11

SECTION 6

Getting Started

NOTE: The instrument should be allowed to

stabilize to room conditions in order to achieve

specified accuracy.

1. If you are using a hood with the unit, assemble

the LoFlo Balometer

in Section 4, “Instrument Setup and Storage.”

2. Turn on the unit using the slide switch located on

the right side of the meter.

3. When turned on, the LoFlo Balometer

Hood displays the vent closed indicator. Close the

vent on the base by turning the top baffle counter

clockwise.

4. Select the proper mode for air flow direction,

supply or return.

5. Place the LoFlo Balometer

the diffuser or grille to be measured.

®

Capture Hood as described

®

Capture

®

Capture Hood over

5

6. The auto range feature of the LoFlo Balometer

Capture Hood will choose the correct scale and

display the volume rate in the digital readout

section. A quick press on the handle switch will

freeze the display.

7. Another quick press will unfreeze the display.

8. For volume rates above 150 cfm (255 m

71 l/s), it is recommended to use the vent open

mode to minimize air flow resistance effects. See

Section 7, “Detailed Operation.”

NOTE: Make sure that there are no gaps between

the LoFlo Balometer

®

Capture Hood and the

surface around the diffuser or grille. Also, make

sure that your body or other objects are not

blocking or diverting the air flow where the a ir is

exiting (supply) or entering (return). This will affect

the reading.

3

/h,

®

SECTION 7

Detailed Operation

Handle Button

In 1-point mode, the handle button will freeze the

digital reading and flash the value when it is pressed for

less than three seconds. When the handle button is

pressed for more than three seconds, it switches the

LoFlo Balometer

mode and vent open mode.

In 2-point mode, the handle button cycles the

instrument through the 2-point measurement process.

See 2-point mode section for detail.

Auto/Manual Ranging Button

When turned on, the instrument is in auto-range mode.

The user can switch to manual range mode by pressing

the range button. The manual range indicator will

show. By pressing the range button, the meter display

switches to the next volume range. To return to autorange mode, press and hold the range switch until the

manual range indicator disappears.

®

Capture Hood between vent closed

Changing Measurement Units

To change measurement units:

1. Turn the instrument off.

2. Press and hold the supply/return button and switch

the instrument on at the same time.

3. The display will flash one of the three available

measurement units: cfm, m

4. Press and hold the supply/return button or the

range button to scroll through the measurement

units.

5. When the units you desire are displayed, switch the

instrument off.

6. When you turn the instrument on again, your

chosen units will be displayed.

3

/h, l/s.

5

Page 12

Supply/Return Button

The LoFlo Balometer® Capture Hood is in supply mode

when turned on. This is indicated on the display with

the supply indicator

. To take return air

measurements, press the supply/return button on the

front of the meter. Return air mode will be indicated on

the display with the return indicator

.

Significant errors may result if:

• Instrument is not in proper mode.

• Fabric hood is not used with vent open

mode.

Vent Closed/Vent Open Modes

When the instrument is turned on, it is in the vent

closed mode

. When the vent closed indicator is on,

the vents must be closed to take the measurement.

Close the vents by loosening the thumbscrew and

sliding the vent baffle to the fully closed position and

locking the vent in place again.

The vent open mode is indicated with the vent open

indicator on the LCD

. Open the vents by loosening

the thumb screw and sliding the vent baffle to the fully

open position and locking it into place again. Then

press and hold the handle switch for more than 3

seconds to switch the LoFlo Balometer

®

Capture Hood

to the open vent mode.

The vent open mode was developed for higher volume

rates on larger diffusers; the 2' x 2' or 650 mm x

650 mm hood should always be used with vent open

mode.

1-Point Measurement Mode

The default mode of the LoFlo Balometer® Capture

Hood is the 1-point measurement mode. If you are in 2point measurement mode, simply turn the instrument

off and turn back on.

The 1-point measurement mode is described in the

Getting Started section earlier in this manual. This is

the faster, simpler way to take measurements.

Use Vent Closed Mode for measurements between:

3

10–150 cfm (17–255 m

/h, 4.7–71 l/s).

NOTE: In Vent Closed Mode, volume rates below

8 cfm (13 m

rates above 517 cfm (879 m

3

/h, 3.6 l/s) are displayed as 0; volume

3

/hr, 244 l/s) are

displayed as Or.

Use Vent Open Mode for measurements between:

150–500 cfm (255–850 m

NOTE: In Vent Open Mode, volume rates below

150 cfm (255 m

volume rates above 517 cfm (879 m

3

/h, 71–236 l/s)

3

/h, 71 l/s) are displayed as Ur;

3

/h, 244 l/s) are

displayed as Or.

2-Point Measurement Mode—Supply

Only

To activate the 2-point measurement mode, turn the

instrument off. While pressing the handle button, turn

the instrument back on. The 2-point mode indicator will

show.

The 2-point measurement mode takes both vent open

and vent closed measurements to calculate a resistancecompensated volume flow rate.

The process starts with the vents closed and the display

showing the vent closed indicator.

®

1. Place the LoFlo Balometer

diffuser to be measured and press the handle

switch once to take the vent closed measurement.

2. The instrument stores that reading.

3. The display will now show the open vent indicator

and you should open the vents.

NOTE: Make certain you are using a fabric hood

when in 2-point mode.

4. Again place the LoFlo Balometer

over the diffuser to be measured and press the

handle switch to take the vent open measurement.

5. The instrument calculates and displays the

compensated reading.

6. The numeric display will flash; press the handle

switch again and the instrument will display the

vent closed indicator. Close the vents.

7. Return to Step 1 to take another resistance

compensated reading.

NOTE: Return to 1- point measurement mode at

any time by turning the power off and on.

Capture Hood over the

®

Capture Hood

6

Page 13

7

When “–––” is displayed at the last step of the 2-point mode, the calculation fo r th e r esistan ce ef f ect can not be made. It

can be caused by any of the conditions listed here.

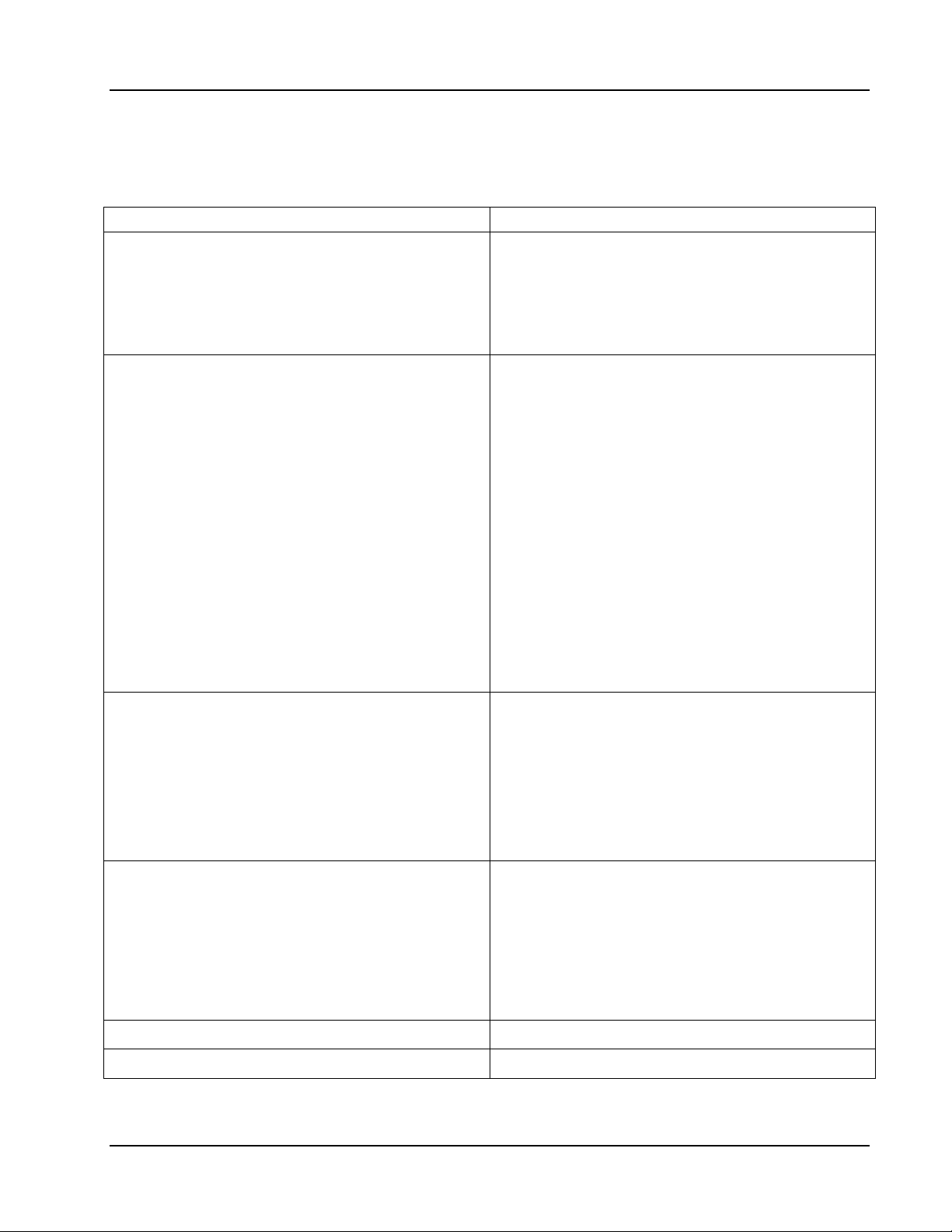

Condition Reason

The vent closed or vent open measurement is less than 150

3

cfm (70 l/s, 255 m

/h).

• Calculations are not made at the low end since the

effect is small and can generally be neglected. Use 1point mode.

The vent closed or vent open measurement is greater than

3

500 cfm (235 l/s, 850 m

/h).

The vent open measurement minus the vent closed

measurement is too small (< 0).

• Calculations are not made beyond the calibrated range.

• A mistake has occurred in the process. Repeat the

two-point measurement.

• The resistance effect is small and was overwhelmed

by natural fluctuations. Use single-point mode.

The vent open measurement minus the vent closed

measurement is too large.

• A mistake has occurred in the process. The vent may

not have been open for the open vent measurement.

Repeat the two-point measurement.

• The effect is beyond the range of the compensation

equation. Perform a traverse of the system instead.

NOTE: The display will also show “–––” when th e retu rn mode is selected. The 2-point measurement mode is for

supply only.

7

Page 14

SECTION 8

Troubleshooting

Symptom Possible Cause and Corrective Action

Meter does not turn on.

Meter reading lower than expected.

• Battery holder snap connector not connected. Connect

battery holder to instrument.

• Batteries may be discharged. Charge or replace them.

• Switch failure, wiring failure, or cir c uit failure. Call

TSI.

• Wrong vent mode chosen. Choose correct vent mode,

open or closed.

• Wrong air direction mode chosen. Choose correct

direction, supply or return.

• Back pressure effects could be significant. Use 2-

point measurement mode.

• Hood frame not sealing properly around diffuser or

grill. Press hood evenly against diffuser.

Meter reading higher than expected.

Meter not at zero at zero flow.

Meter displays Er.

Handle button not working.

• Odd air flow pattern present. Perform traverse and use

proportional balancing.

• Hood torn. Replace, or repair tear with duct tape or

other non-porous material.

• Meter out of calibration. Call TSI.

• Damage to manifold. Call TSI.

• Wrong vent mode chosen. Choose correct vent mode,

open or closed.

• Wrong air direction mode chosen. Choose correct

direction, supply or return.

• Odd air flow pattern present. Perform traverse and use

proportional balancing.

• Meter out of calibration. Call TSI.

• Instrument not at room temperature. Allow instrument

to acclimate before turning on the power.

• The LoFlo Balometer

room air currents. Place on floor with a piece of

cardboard over the top to determine if it is measuring

real air currents.

®

Capture Hood is reading real

• Meter out of calibration. Call TSI.

• Self test failed. Call TSI.

• Call TSI.

8

Page 15

9

SECTION 9

Maintenance

Hoods

Hoods may be cleaned in cool water with a mild

detergent.

Sensing Manifold

The manifold should be checked visually before using

to be certain that the sensing holes have not become

clogged with dirt or dust particles. Do not immerse the

manifold in water. It is recommended that cleaning be

done with extreme care with the manifold in place. Do

not use highly compressed air to clean the manifold

tubes.

Calibration

It is recommended that your LoFlo Balometer® Capture

Hood be returned to the factory once a year for a

calibration check. When shipping the LoFlo

Balometer

®

Capture Hood for factory calibration, pack

it carefully, and follow the Instructions for Return in

this manual.

Vent Operation

If the vent becomes difficult to operate, remove both

thumbscrews from the vent mechanism and spray the

contacting surfaces with silicone spray lubricant. Wipe

off excess and reassemble vent mechanism.

Performance Check

If the calibration is to be checked, the best way is to use

a reference flow standard more accurate than the LoFlo

Balometer

used for this purpose include orifice plates, venturis,

nozzles, and laminar flow elements. These devices

require accurate differential pressure, barometric

pressure, and temperature reading instruments to

measure either actual or standard volume rate.

If the LoFlo Balometer

against a velocity instrument such as a pitot

probe/manometer or thermo-anemometer, there may be

errors. If a velocity standard is used, the average

velocity must be obtained by taking a traverse.* The

accuracy of the traverse is dependent on the flow

uniformity, the number of readings taken, the accuracy

of the velocity instrument, and operator expertise. This

average velocity reading must then be multiplied by the

area over which the traverse was taken.

Finally, air flow instrumentation is dependent on

environmental conditions such as temperature,

atmospheric pressure, humidity, and even turbulence.

These conditions can have very different effects on

various instrument types. Caution must be exercised

when making comparisons.

*A traverse is a set of velocity readings taken in a prescribed

pattern which will provide an overall velocity value when

averaged together. Any of the Alnor velocity measuring

instruments can be used for this purpose.

®

Capture Hood. Flow standards that may be

®

Capture Hood is checked

9

Page 16

SECTION 10

Service Information

Service and Repair

Please return your Product Registration Card

immediately. This allows us to send you service

reminders, special offers, and important information

about your product.

Before sending your instrument for calibration or

repair, you should call TSI Customer Service. The

Service Department will provide you with the cost of

service or calibration, Return Material Authorization

(RMA) number, and shipping instructions.

Please have the following information available when

you call:

Owner’s name, address, and phone number

Billing address, if different and applicable

Instrument name or model

Serial number

Date of purchase

Where purchased

TSI recommends that you keep a “calibration log” and

keep all records of service on your instrument.

Instructions for Return

two inches (5 cm) of suitable shock-absorbing material.

Include the Purchase Order showing instrument model

number, cost of service and/or calibration, and the

RMA number. Mark the outside of the shipping

container with the RMA number. This will expedite

processing of your instrument when we receive it.

Damaged in Transit

All orders are carefully packed for shipment. On

receipt, if the shipping container appears to have been

damaged during shipment, the instrument should be

thoroughly inspected. The delivering carrier’s papers

should be signed noting the apparent damage. DO NOT

DISCARD THE BOX.

If the instrument itself has been damaged, a claim

should be promptly filed against the carrier by the

customer. The selling agent will assist the customer by

supplying all pertinent shipping information; however,

the claim must be filed by the insured. If the instrument

is damaged beyond use, a new order should be placed

with TSI while awaiting reimbursement from the

carrier for the damaged instrument.

Call TSI directly for assistance if necessary.

Send the instrument prepaid. Securely package your

instrument in a strong container surrounded by at least

10

Page 17

11

APPENDIX A

Correction Factors for Standard Flow Rate to Actual Flow Rate

The LoFlo Balometer® Capture Hood measures

standard volumetric flow rate. Standard flow is defined

as the flow rate at standard conditions, 70°F (21.1°C)

and 14.7 psia (29.92 inHg, 760 mmHg). Actual flow

rate is the true volumetric rate of air at the local

temperature and barometric pressure. If you desire

standard flow rate, use the displayed reading.

However, if the actual flow rate is desired, use the

information below.

To correct the standard flow rate to actual flow rate use

the equation below.

V

= V

act

V

= Actual flow rate

act

V

= Standard flow rate (this is displayed by

std

std

x CF

the instrument)

T

= Actual Temperature

act

ρ

= Actual barometric pressure

act

3

ρ

= Standard density 0.075 lb/ft

std

(at 70°F and 14.7 psia)

ρ

= Actual density in lb/ft

a

3

CF = ρ

(Correction Factor)

std/ρa

Using the equations or chart below, you can bypass the

full density calculation.

Calculations in imperial units

CF = (14.7/ ρ

Where ρ

is in psia and T

act

)*(460+ T

act

act

is in °F

act

)/530

Calculations in imperial units

CF = (29.92/ ρ

Where ρ

is in inHg and T

act

)*(460+ T

act

act

is in °F

act

)/530

Calculations in metric units

CF = (760/ ρ

Where ρ

act

)*(273.15+ T

act

is in mmHg and T

act

is in °C

act

)/294.25

For your convenience, we have made a chart for

determining the correction factor given temperature and

pressure.

NOTE: The atmospheric pressure as reported by

the National Weather Service is corrected to sea

level and cannot be used if measurements are not at

sea level.

11

Page 18

APPENDIX B

Model 6200 LoFlo Balometer® Capture Hood Field Setting Instructions for

User Programmable Correction Factors

HISTORY:

It is well known that capture hoods are susceptible to

diffuser styles that are different from that upon which

they were calibrated. Understanding that these

productivity tools may require adjustment in the field,

the LoFlo Balometer

®

Capture Hood is equipped with

two separate sets of field programmable correction

factors, “FLD A” and “FLD B”, that allow for a field

calibration of the instrument to different diffusers.

DETERMINING FIELD PROGRAMMABLE

CORRECTION FACTORS:

Correction factors are simply the relation between the

actual volume flow rate and that which is displayed on

the LoFlo Balometer

®

Capture Hood. The actual

volume flow rate is most accurately established through

performing a duct traverse. The correction factor is then

determined as the ratio of the actual volume flow rate

divided by the volume flow displayed on the LoFlo

Balometer

®

Capture Hood set in the factory calibration

setting (default from factory). The number obtained is

used as the multiplier for that particular diffus e r.

Example:

Duct Traverse yields 120 CFM

®

LoFlo Balometer

Capture Hood in Supply Mode

with Vents Closed yields 107 CFM

Correction Factor = 120/107 = 1.121

Because there are no decimal points available for the

correction factor values, this number will be

programmed into the LoFlo Balometer

®

unit as 1121.

If all available operating modes of the LoFlo instrument

are to be used, a separate multiplier must be determined

for each mode. The four available modes are:

• Supply, Vent Closed (10-150 CFM)

• Supply, Vent Open (150-500 CFM)

• Return, Vent Closed (10-150 CFM)

• Return, Vent Open (150-500 CFM)

PROGRAMMING THE CORRECTION

FACTORS TO THE INSTRUMENT:

Once the multipliers have been determined, the

correction factors are programmed to the LoFlo

instrument using the following steps:

1. Turn the instrument off.

2. Press and hold the range selector button

while

simultaneously switching the instrument on. The

display will show “FAC” with the seven segment

characters, indicating the unit is in its defau lt fa ctory

setting.

3. Use the supply/return button

to cycle through

the available storage fields, “FLD A”, “FLD B” or

“FAC”. Use the handle hold switch to select the

desired field. If “FLD A” or “FLD B” are selected,

the field letter chosen will be displayed at the upper

right of the LCD throughout the programming

cycle. Note that the factory calibration setting,

“FAC”, cannot be altered.

4. Once the desired storage field has been selected, the

unit will display the symbols for the Supply, Vent

Closed mode, along with the current correction

factor programmed for that mode. The factory

default coefficient for each mode within both of the

programmable storage fields is 1000 (recall that

decimal points are not available, and thus the stored

value of 1000 is actually 1.000). Use the

supply/return button to increase the coefficients

value, or the range selector button to decrease the

value as desired. When the correct multiplier is

displayed, press the handle hold switch to store the

value. The display will then cycle to the Supply,

Vent Open mode (indicated by the appropriate

symbols), again allowing for increasing/decreasing

of the multiplier to the desired set-point as described

above. This process will repeat for the remaining

two operating modes (Return, Vent Closed; and

Return, Vent Open).

5. Once a correction factor has been selected and

stored for each of the four operating modes, the unit

will proceed into operation using the programmed

coefficients of the storage field that was selected.

Once again, use of “FLD A” or “FLD B” will be

indicated by the field letter chosen being displayed

at the upper right of the LCD throughout the

operating cycle. The selected storage field will

12

Page 19

remain as the start-up default setting unless changed

by the user.

6. To return to the factory calibration setting, “FAC”,

press and hold the range selector button while

simultaneously switching the instrument on. Select

the “FAC” setting by depressing the handle hold

switch. The factory calibration has just been

restored as the default operating setting. Stored

coefficients in “FLD A” and “FLD B” will remain

for future use.

NOTES:

• Always use the factory calibration setting, “FAC”,

in determining the correction factors.

• Correction factors must be in the range of 0.250 to

1.999 (0250 to 1999 without the decimal point).

• Use of correction factors greater than 1.000 may

cause the display to indicate a flow value at zero

flow (typically 12-13 CFM at zero flow) . This is

normal and will limit the use of correction factors at

the extreme low-end of the operating range.

• Do not use measurements which are less than

10 CFM * correction factor. For example, if you

program a correction factor of 1.5, do not use

measurements less than 15 CFM (10 * 1.5 = 15).

13

13

Page 20

Page 21

INDICE

Seccion 1 Descripción General ...................................................... 17

Seccion 2 Teoría de Operación ......................................................

Seccion 3 Seguridad .......................................................................

Seccion

Seccion

Seccion

Seccion

Seccion

Seccion

Seccion

4 Montaje y Almacenamiento del Instrumento ................ 18

5 Visualización del Instrumento ....................................... 20

6 Comienzo ...................................................................... 21

7 Operación Detallada ...................................................... 21

8 Resolución de Problemas .............................................. 24

9 Mantenimiento .............................................................. 25

10 Información Sobre Servicio........................................... 26

Apéndice A Factores de Ajuste para Nivel de Flujo

Estándar a Nivel de Flujo Real ......................................

17

18

27

15

Page 22

Especificaciones* Sobre El LoFlo Balometer®

Nivel de

Volumen: 10–500 cfm o pies cúbicos por

minuto (17–850 m

3

/h) (4,7–236 l/s)

Exactitud: ±(3% + 5 cfm)

(±(3% + 8,5 m3/h, 2,4 l/s))

Altura: 15,5 pulgadas, base solamente

(394 mm)

22 pulgadas, con cubierta 16 x 16

pulgadas (559 mm)

34,5 pulgadas, con cubierta 2 x 2 pies

(876 mm)

Peso: aproximadamente 6 libras (2,7 kg)

con cubierta 4,6 libras (2,1 kg) base

solamente

Diámetro de la

Apertura de la

Base: 13,3 pulgadas de diámetro (338 mm)

Tamaños de 16 x 16 pulgadas, 2 x 2 pies, o

26 x 26

las Cubiertas: pulgadas (406 x 406 mm, |

610 x 610 mm, o 650 x 650 mm)

Visualización: Dígitos 3,5. 0,44 pulgadas (11 mm)

de alto, visualización digital con

visualización analógica simulada de

26 segmentos

Resolución: 1 cfm desde 10–500 cfm

(Abastecimiento 0,1 l/s desde 4,7 a 9,9

o Retorno) 1 l/s desde 10 a 236 l/s

Fuente de 4 pilas alcalinas tamaño C de 1,5V

Alimentación: (Níquel Cadmio opcional)

Vida Útil de

las Pilas: Mínimo de 10 horas de uso continuo

*Las especificaciones están sujetas a cambio sin previo aviso.

16

Page 23

17

SECCION 1

Descripción General

El LoFlo Balometer® de Alnor es un instrumento

compacto que mide niveles muy bajos de flujo de aire

en sistemas HVAC. Puede medir valores de 10–500

cfm, (17–850 m

3

/h, 4,7–236 l/s). El LoFlo Balometer®

visualiza un nivel de volumen de aire estándar cuando

se sitúa en los difusores de abastecimiento o retorno,

los registros o las rejillas ubicadas en techos, paredes o

suelos.

®

El LoFlo Balometer

tiene un mecanismo de

ventilación que reduce la restricción de flujo de aire

causada por el instrumento. Este excepcional sistema de

ventilación (con patente pendiente) permite al

instrumento permanecer compacto cuando se encuentra

en el proceso de medición de una gran cantidad de

SECCION 2

Teoría de Operación: Cubiertas de Captura

y Medición Termo-Anemométrica

Al salir el aire del difusor, el mismo queda capturado

en la cubierta o en la base y se transporta hacia un

distribuidor. El distribuidor regula la presión de

velocidad y dirige el aire hacia los sensores. Entonces

se mide la velocidad y la temperatura del aire a su paso

por el distribuidor, utilizando un termo-anemómetro de

temperatura constante. El voltaje de salida proveniente

del sensor es entonces calibrado para el nivel de

volumen total que pasa a través del LoFlo Balometer

Todas las cubiertas de captura son susceptibles a

patrones de flujo de aire “extraños”. El término

“extraño” puede referirse a cualquier patrón de flujo de

aire que sea diferente del patrón donde fue calibrado.

Podrían observarse efectos negativos substanciales si se

®

.

®

niveles de volumen. El LoFlo Balometer

deberá tener

los respiraderos cerrados cuando los niveles de

volumen sean bajos pero, cuando sean más altos, los

niveles de volumen deberán medirse con los

respiraderos abiertos para así minimizar cualquier

efecto de resistencia. Puede tomarse una medición de 2

puntos para compensar el efecto de resistencia del

instrumento a niveles altos de volumen.

®

El LoFlo Balometer

funciona con pilas y puede

utilizarse con o sin las cubiertas opcionales. El peso

sobrepasa ligeramente las 6 libras con la cubierta de 2 x

2 pies, ayudando a reducir la fatiga del operario.

utiliza una cubierta grande en un difusor pequeño, por

ejemplo, si se utiliza una cubierta de 2 x 2 pies en un

difusor de 10 x 10 pulgadas. Esto crearía grandes

regiones de recirculación en los lados de la cubierta de

tela y podría ocasionar un patrón de flujo de aire

“extraño” a su paso por el distribuidor. Se recomienda

que los tamaños de la cubierta y del distribuidor

correspondan entre sí.

3

NOTA: Las unidades cfm, m

este manual por motivos de simplicidad. Observe,

sin embargo, que el LoFlo Balometer

mediciones en pies cúbicos por minutos estándar

(scfm), metros cúbicos por hora estándar (std. m

/h y l/s se usan en

®

muestra las

3

/h)

o litros por segundo estándar (std. l/s).

17

Page 24

®

SECCION 3

Seguridad

Cuando vaya a utilizar el LoFlo Balometer® para

comprobar el flujo de aire en los difusores para techos,

asegúrese de que pueda elevar y mantener fija la unidad

mientras está haciendo las mediciones. Sea

especialmente precavido cuando esté trabajando en una

escalera.

Tome todas las precauciones necesarias de manera que

la unidad no se quede atrapada al mover maquinaria o

MIENTRAS USE EL INSTRUMENTO LOFLO BALOMETER

DE AIRE EN CONDUCTOS

POLEN

AIRE

CANTAMINANTES

MIENTRAS EMPLEA EL INSTRUMENTO

, MOHO, HONGOS, U OTROS CONTAMINANTES T RANSPORTADOS POR EL

. SI ERES ALERGICO AL POLVO, POLEN, MOHO, HONGOS O OTROS

, USE SIEMPRE UN RESPIRADOR O MASCARA APROPIADO

, PUEDE ESTAR EN CONTACTO O EXPUESTO A POLVO,

SECCION 4

Montaje y Almacenamiento del Instrumento

que no toque ningún cable eléctrico que esté al

descubierto.

®

El LoFlo Balometer

tipo de mezclas gaseosas que no sean aire. No se

recomienda el uso de mezclas gaseosas corrosivas u

otras que sean explosivas o peligrosas. De hacerlo así,

las posibles consecuencias serán responsabilidad del

usuario.

CAUTION

no está diseñado para ningún otro

PARA PROBAR CAUDAL

.

1. Localice los cuatro (4) canales de aluminio para la

cubierta y sitúelos dentro de un cuadrado con la

espuma hacia arriba. Deslice la abertura en “U” en

el extremo del canal (Fig. 1) y la repisa angular

hacia los ojales de chapa hasta que sienta que está

asegurada.

2. Continúe con los otros dos canales hasta que tenga

una estructura cuadrada fijada firmemente en las

cuatro esquinas.

3. Localice la cubierta correspondiente al tamaño de

la estructura que ha ensamblado.

4. Sitúe una junta angular de la cubierta en la esquina

de la estructura. Estire la cubierta de nilón a una

esquina adyacente hasta que la esquina de la

cubierta encuentre a la esquina de la estructura.

5. Empuje el cordón elástico dentro del canal a lo

largo del lado de la estructura.

6. Repita los pasos 4 y 5 hasta que se complete el

ensamblaje de la cubierta y esté listo para montarlo

sobre la base.

7. Sitúe la cubierta sobre una mesa o suelo limpios

con la base en el interior de la abertura. Sitúe la

cubierta sobre la base. Gire el ensamblaje de la

cubierta hasta que las cubetas metálicas queden por

encima de los pasadores de muelle.

8. Localice las varillas de soporte de la cubierta.

Extienda la cubierta de manera que quede tensa e

inserte una varilla de soporte en el pasador de

muelle más cercano a usted.

9. Empuje la varilla de soporte hacia abajo e inserte el

extremo superior de la varilla dentro de la cubeta

metálica en la estructura de la cubierta. Fig.1.

10. Instale la varilla en el lado opuesto y, luego, instale

las dos varillas restantes.

18

Page 25

19

Espuma

Abertura en “U”

Cubeta metálica

Figura 1

Canal de la estructura de la cubierta

Almacenamiento del Instrumento

Los montajes de la cubierta y de la estructura pueden

retirarse de la base del instrumento y guardarse dentro

de su estuche de transporte sin necesidad de ser

desmontados.

®

El LoFlo Balometer

antes de volverlo a empaquetar. Si se va a almacenar el

LoFlo Balometer

retire las pilas para evitar daños por fugas.

deberá estar siempre apagado

®

por un período largo de tiempo,

Para usar e instalar pilas recargables:

NOTA: Como alternativa a las pilas alcalinas, TSI

dispone de 4 pilas recargables de Níquel Cadmio

(NiCd) para el LoFlo Balometer

®

.

1. Conecte el contenedor de las pilas cargado con las

pilas recargables NiCd al cargador y cárguelas

durante 12–14 horas.

2. Apague el LoFlo Balometer

3. Vuelva a conectar el contenedor con las pilas

cargadas al LoFlo Balometer

®

.

®

e introduzca el

contenedor en el compartimento de las pilas.

4. Vuelva a colocar la tapa de las pilas.

No intente cargar

baterías alcalinas

Instalación de las Pilas

Para instalar las 4 pilas tamaño C incluidas con el

LoFlo Balometer

1. Asegúrese de que el interruptor del LoFlo

Balometer

2. Retire la tapa de las pilas ubicada encima del

medidor.

3. Deslice el contenedor de las pilas hacia arriba hasta

que el conector de ajuste rápido quede al

descubierto.

4. Desconecte el contenedor de las pilas del LoFlo

Balometer

5. Instale las 4 pilas tamaño C en el contenedor.

6. Vuelva a conectar el conector de ajuste rápido e

introduzca el contenedor de las pilas en el

compartimento de las pilas.

7. Vuelva a colocar la tapa de las pilas.

®

:

®

esté apagado.

®

.

4 pilas tamaño C

Conector de

ajuste rápido

Figura 2

Contenedor de pilas

No utilice el

cargador como

sustituto de las

baterías. Esto

podría ocasionar

daños al

instrumento.

19

Page 26

SECCION 5

Visualización del Instrumento

Este instrumento utiliza visualización analógica,

simulada con 26 segmentos en Diodo de cristal líquido

(LCD) para proporcionar al usuario la respuesta del

balómetro mecánico. También visualiza un número

digital exacto, utilizando una sección numérica digital

de 3 +. El LCD dispone de indicadores para

abastecimiento, retorno, nivel manual, modos de

respiradero e indicador de pila baja.

La Figura 3 muestra la parte frontal del LoFlo

Balometer

®

.

Indice No. Nombre

1 Diodo de cristal líquido (LCD)

2 Interruptor de encendido/apagado

(On/Off)

3 Botón de abastecimiento/retorno

4 Botón de nivel manual

5 Botón de la empuñadura

6 Contenedor de las pilas

7 Respiraderos

8 Corredera de apertura/cierre del

respiradero

La Figura 4 muestra la pantalla LCD.

Indice No. Nombre/Descripción

1 Lectura digital

2 Visualización analógica simulada

3 Indicador de nivel manual

4 Indicador de abastecimiento/retorno

5 Indicador de modo de 2 puntos

6 Indicador de respiradero

7 Indicador de unidades

8 Indicador de pila baja

Figura 3

Vista frontal del LoFlo Balometer

®

Figura 4

Pantalla LCD del LoFlo Balometer

®

20

Page 27

21

SECCION 6

Comienzo

NOTA: Deberá dejarse que el instrumento se

estabilice a las condiciones ambientales normales

para que pueda así alcanzar la exactitud

especificada.

1. Si está utilizando la cubierta con la unidad, monte

el LoFlo Balometer

®

tal y como se describe en la

Sección 4, Montaje y almacenamiento del

instrumento.

2. Encienda la unidad utilizando el interruptor

corredizo ubicado en el lado derecho del medidor.

®

3. Una vez encendido, el LoFlo Balometer

muestra

el indicador de respiradero cerrado. Cierre el

respiradero situado en la base girando la placa de

desviación en el sentido de las agujas del reloj.

4. Seleccione el modo apropiado para establecer la

dirección, el abastecimiento o el retorno del flujo

de aire.

®

5. Sitúe el LoFlo Balometer

sobre el difusor o el

enrejado que va a ser medido.

6. La característica de auto nivel del LoFlo

Balometer

®

elegirá la escala correcta y mostrará el

nivel de volumen en la sección de lectura digital.

Una simple presión en el interruptor de

empuñadura hará que se congele la visualización.

7. Otra simple presión activará de nuevo la

visualización.

8. Para niveles de volumen superiores a 150 cfm (255

3

/h, 71 l/s), se recomienda el uso del modo de

m

respiradero abierto para así minimizar los efectos

de resistencia del flujo de aire. Vea la Sección 7,

Operación detallada.

NOTA: Asegúrese de que no haya espacios vacíos

entre el LoFlo Balometer

®

y la superficie que rodea

al difusor o a la rejilla. Asimismo, asegúrese de que

su cuerpo u otros objetos no estén bloqueando ni

desviando el flujo de aire allá donde esté saliendo

el aire (abastecimiento) o donde esté entrando

(retorno). De ser así, la lectura podría verse

afectada.

SECCION 7

Operación Detallada

Botón de la Empuñadura

En el modo de 1 punto, el botón de la empuñadura hará

que la lectura digital se congele y que destelle el valor

cuando se le presiona durante menos de tres segundos.

Cuando se presiona el botón por más de tres segundos,

cambiará el LoFlo Balometer

respiradero cerrado y el modo de respiradero abierto.

En el modo de 2 puntos, el botón de la empuñadura

lleva a cabo el ciclo del instrumento a través del

proceso de medición de 2 puntos. Para información más

detallada, vea la sección de modo de 2 puntos.

Botón de Nivelado Auto/Manual

Una vez encendido, el instrumento estará en el modo de

selección de nivel automático. El usuario puede

cambiar al modo de selección manual presionando el

botón de nivel. Al hacerlo, aparecerá el indicador

manual de nivel. Si se presiona el botón de nivel, la

®

entre el modo de

pantalla del medidor cambia al siguiente nivel de

volumen. Para volver al modo automático, presione y

mantenga presionado el botón de nivel hasta que

desaparezca el indicador de nivel manual.

Cambio de las Unidades de Medición

Para cambiar las unidades de medición:

1. Apague el instrumento.

2. Presione y mantenga presionado el botón de

abastecimiento/retorno y encienda el instrumento

al mismo tiempo.

3. La pantalla destellará una de las tres unidades de

medición disponibles: cfm, m

4. Presione y mantenga presionado el botón de

abastecimiento/retorno o el botón de nivel para

seleccionar las unidades de medición.

3

/h o l/s.

21

Page 28

5. Cuando aparezcan en pantalla las unidades

deseadas, apague el instrumento.

6. Cuando encienda el instrumento de nuevo, las

unidades elegidas aparecerán en pantalla.

Botón de Abastecimiento/Retorno

El LoFlo Balometer® estará en el modo de

abastecimiento cuando esté encendido. Esto se indica

en la pantalla con el indicador

. Para tomar

mediciones de aire de retorno, presione el botón

abastecimiento/retorno de la parte frontal del medidor.

El modo de retorno de aire se indicará en la pantalla

con el indicador

.

Podrían obtenerse errores significativos si:

• El instrumento no está en el modo

apropiado.

• La cubierta de tela no se usa con el modo

de respiradero abierto.

Modos de Respiradero Abierto/Cerrado

Al encenderse, el instrumento estará en el modo de

respiradero cerrado

respiradero cerrado esté encendido, los respirader os

deberán estar cerrados para poder tomar las mediciones.

Para cerrar los respiraderos, afloje el tornillo de orejetas

y deslice el deflector del respiradero a su posición de

completamente cerrado, y asegure de nuevo el

respiradero en su lugar.

El modo de respiradero abierto se indica con el

indicador correspondiente en el Diodo de cristal líquido

(LCD)

. Para abrir los respiraderos, afloje el tornillo

de orejetas y deslice el deflector del respiradero a su

posición de completamente abierto, y asegure de nuevo

el respiradero en su lugar. Luego, presione y mantenga

presionado el botón de la empuñadura durante más de 3

segundos para cambiar el LoFlo Balometer

respiradero abierto.

. Cuando el indicador de

®

al modo de

modo de medición de 2 puntos, simplemente apague y

vuelva a encender el instrumento.

El modo de medición de 1 punto se describe en la

sección Comienzo incluida en este manual. Esta es la

forma más rápida y sencilla de tomar mediciones.

Utilice el modo de respiradero cerrado para mediciones

entre los valores:

3

10–150 cfm (17–255 m

NOTA: En el Modo de respiradero cerrado, los

niveles de volumen inferiores a 8 cfm (13 m

l/s) aparecen en pantalla como 0; los niveles de

volumen superiores a 517 cfm (879 m

/h, 4,7–71 l/s).

3

/h, 3,6

3

/h, 244 l/s)

aparecen en pantalla como Or

Utilice el Modo de respiradero abierto para mediciones

entre los valores:

150–500 cfm (255–850 m

NOTA: En el Modo de respiradero abierto, los

niveles de volumen inferiores a 150 cfm (225 m

71 l/s) aparecen en pantalla como Ur; los niveles de

volumen superiores a 517 cfm (879 m

3

/h, 71–236 l/s)

3

/h, 244 l/s)

3

/h,

aparecen en pantalla como Or;

Modo de Medición de 2 Puntos—

Abastecimiento Solamente

Para activar el modo de medición de 2 puntos, apague

el instrumento. Vuelva a encender el instrumento

mientras presiona el botón de la empuñadura. Deberá

aparecer el indicador de modo de 2 puntos.

El modo de medición de 2 puntos toma las mediciones

con el respiradero abierto y cerrado para así poder

calcular el nivel de volumen de flujo de resistencia

compensada.

El proceso empieza con los respiraderos cerrados y con

la pantalla mostrando el indicador de respiradero

cerrado.

®

1. Ubique el LoFlo Balometer

va a medirse y presione el botón de la empuñadura

una vez para tomar las mediciones con respiradero

cerrado.

2. El instrumento almacena la lectura.

sobre el difusor que

El modo de respiradero abierto fue diseñado para altos

niveles de volumen en difusores grandes; deberán

utilizarse siempre las cubiertas de 2 x 2 pies o de 650 x

650 mm cuando se use el modo de respiradero abierto.

Modo de Medición de 1 Punto

3. La pantalla mostrará ahora el indicador de

respiradero abierto y, por tanto, deberá abrir los

respiraderos.

NOTA: Asegúrese de que esté utilizando una

cubierta de tela cuando esté en el modo de 2 puntos.

®

4. Ubique de nuevo el LoFlo Balometer

sobre el

difusor a medir y presione el botón de empuñadura

l modo preestablecido del LoFlo Balometer® es el

para tomar la medición con respiradero abierto.

modo de medición de 1 punto. Si se encuentra en el

22

Page 29

23

5. El instrumento calculará y mostrará la lectura

compensada.

6. El resultado numérico destellará en la pantalla;

presione el botón de empuñadura de nuevo y el

instrumento mostrará el indicador de respiradero

7. Vuelva al paso 1 para tomar otra lectura de

resistencia compensada.

NOTA: Vuelva al modo de medición de 1 punto en

cualquier momento simplemente presionando el

botón de encendido y apagado.

cerrado. Cierre los respiraderos.

Cuando “—-” aparezca en pantalla en el último paso del modo de 2 puntos, no podrá realizarse el cómputo del efecto de

resistencia. Esto podría ser a causa de cualquiera de las condiciones que se en umeran a continuación

Condición Razón

La medición con respiradero abierto o cerrado es inferior a

3

150 cfm (70 l/s, 255 m

/h).

• Los cómputos no se hacen en el extremo inferior

puesto que el efecto es pequeño y, generalmente,

pueden ignorarse. Use el modo de 1 punto.

La medición con respiradero abierto o cerrado es superior

3

a 500 cfm (235 l/s, 850 m

/h).

• Los cómputos no se hacen más allá del nivel

calibrado. Utilice un balómetro estándar o eléctrico

(Nivel de volumen: 50–200 cfm), o lleve a cabo una

traversa del sistema.

El valor de la medición de respiradero abierto menos el

valor de la medición de respiradero cerrado es demasiado

• Se produjo un error durante el proceso. Repita la

medición de 2 puntos.

pequeño (< 0).

• El efecto de resistencia es pequeño y fue rebasado por

las fluctuaciones naturales. Use el modo de 1 punto.

El valor de la medición de respiradero abierto menos el

valor de la medición de respiradero cerrado es demasiado

grande.

• Se produjo un error durante el proceso. El respiradero

podría no haber estado abierto para la medición de

respiradero abierto. Repita la medición de 2 puntos.

• El efecto va más allá del nivel de la ecuación de

compensación. Lleve a cabo una traversa del sistema.

NOTA: la pantalla también mostrará “—-” cuando se seleccione el modo de retorno. El modo de medición de 2

puntos es para abastecimiento solamente.

23

Page 30

SECCION 8

Resolución de Problemas

Síntoma Posible Causa y Acción Correctiva

El medidor no se enciende.

La lectura del medidor es más baja de lo esperado.

• El conector de ajuste rápido del contenedor de las

pilas no está conectado. Conecte el contenedor de las

pilas al instrumento.

• Las pilas podrían estar descargadas. Cárguelas o

reemplácelas.

• Fallo del interruptor, fallo del cableado, o fallo del

circuito. Llame a TSI.

• Se ha elegido un modo de respiradero equivocado,

abierto o cerrado.

• Se ha elegido un modo de dirección del aire

equivocado. Elija la dirección correcta, abastecimiento

o retorno.

La lectura del medidor es más alta de lo esperado.

• Los efectos de contrapresión podrían ser

significativos. Utilice el modo de medición de 2

puntos.

• La estructura de la cubierta no cierra correctamente

alrededor del difusor o de la rejilla. Presione la

cubierta de manera uniforme contra el difusor.

• Se encuentra presente un patrón de flujo de aire

irregular. Haga una traversa y utilice un balance

proporcional.

• La cubierta esta rasgada. Reemplácela, o repare el

daño con cinta aislante u otro material no poroso.

• El medidor necesita calibración. Llame a TSI.

• Se ocasionaron daños al distribuidor. Llame a TSI.

• Se ha elegido un modo de respiradero equivocado,

abierto o cerrado.

• Se ha elegido un modo de dirección del aire

equivocado. Elija la dirección correcta, abastecimiento

o retorno.

• Se encuentra presente un patrón de flujo de aire

irregular. Haga una traversa y utilice un balance

proporcional.

• El medidor necesita calibración. Llame a TSI.

24

Page 31

25

Síntoma Posible Causa y Acción Correctiva

El medidor no está a cero cuando hay flujo cero.

• El instrumento no está a temperatura ambiente.

Permita que se aclimate el instrumento antes de

encenderlo.

• El capo de captura LoFlo

corrientes reales de aire de la sala. Sitúelo en el suelo

con un pedazo de cartón en la parte superior para

determinar si se están midiendo corrientes reales de

aire.

Balometer® está leyendo

• El medidor necesita calibración. Llame a TSI.

El medidor muestra Er.

El botón de la empuñadura no funciona.

• La autoverificación no ha funcionado. Llame a TSI.

• Llame a TSI.

SECCION 9

Mantenimiento

Cubiertas

Las cubiertas deberán limpiarse en agua fría con un

detergente suave.

Distribuidor Sensor

Deberá revisarse visualmente el distribuidor antes de su

uso para asegurase de que los agujeros sensores no se

quedan atascados con partículas de suciedad o de

polvo. NO sumerja el distribuidor en agua. Se

recomienda que la limpieza se lleve a cabo con cuidado

extremo y con el distribuidor en su lugar. No utilice

aire muy comprimido para limpiar los tubos del

distribuidor.

Calibración

Se recomienda devolver el LoFlo Balometer® a la

fábrica una vez al año para una comprobación de la

calibración. Embale el LoFlo Balometer

cuidadosamente cuando vaya a enviarlo para su

calibración, y siga las instrucciones de devolución

incluidas en este manual.

®

Operación del Respiradero

Si se dificulta la operación del respiradero, retire los

tornillos de orejetas del mecanismo del respiradero y

rocíe las superficies de contacto con lubricante de

silicona. Limpie el exceso y vuelva a montar el

mecanismo del respiradero.

Comprobación de Rendimiento

Si se va a comprobar la calibración, la mejor manera es

usar un estándar de flujo de referencia más preciso que el

LoFlo Balometer

utilizarse para este propósit o incl uyen i nstrum ent os com o

placas perforadas, tubos Venturi , boquill as y ele m entos de

flujo laminar. Estos di sposit ivos re quiere n inst rum entos

precisos de lectura de presión diferencial, de pres ión

barométrica y de temperatura para la medición de niveles

de volumen estándar o reales.

Si se comprueba el LoFlo Balometer

de velocidad como, por ejem plo, un tubo de

Pitot/manómetro o termo-anemómetro, podría haber

errores. Si se utiliza la velocidad estándar, la velocidad

media deberá obtenerse tomando una traviesa*. La

exactitud de la travie sa depe nde de l a uniform i dad del

flujo, del número de lectur as que se han tom a do, de la

exactitud del instrumento de velocidad, y de la pericia del

operador. Esta lectura de la velocidad media deberá

entonces multiplicarse por el área sobre la cual se ha

tomado la traversa.

Finalmente, la ins trum ent aci ón del fl ujo de ai re depe nde

de las condiciones ambientales como la temperatura, la

presión atmosférica, l a hum eda d e, inc luso, l a turbul enci a.

Estas condiciones pueden tener diferentes efectos en los

diversos tipos de instrum entos. Se debe rá tene r preca ución

al hacer comparaciones.

*Una traversa es un conjunto de lecturas de velocidades

tomadas en una pauta determinada que proporcionarán el

valor de la velocidad media una vez hecho el promedio. Para

este propósito pueden utilizarse cualquiera de los

instrumentos de medición de velocidad de

®

. Los estándares de flujo que pueden

®

con un instrumento

Alnor.

25

Page 32

SECCION 10

Información Sobre Servicio

Servicio y Reparación

Sírvase devolver su Tarjeta de registro del producto

inmediatamente. Esto nos permitirá enviarle

recordatorios de servicio, ofertas especiales e

información importante sobre su producto.

Antes de enviar el producto para su calibración o

reparación, deberá llamar al Servicio de atención al

cliente de TSI. El Departamento de servicio le

proporcionará el valor del costo del servicio o de la

calibración, el número de Autorización de devolución

de material (RMA, por sus siglas en inglés) y las

instrucciones de envío.

Sírvase tener la información siguiente disponible al

realizar la llamada:

Nombre del propietario, dirección y número de

teléfono

Dirección de envío de la factura, si fuera

diferente

y applicable

Nombre del instrumento o modelo

Número de serie

Fecha de compra

Lugar de compra

TSI le recomienda que mantenga un ‘registro de

calibración’ y que guarde todos los documentos de

servicio del instrumento.

Instrucciones de Devolución

Envíe el instrumento con el franqueo pre-pagado.

Embale el instrumento con seguridad en un contenedor

resistente envuelto en, al menos, 2 pulgadas (5 cm) de

material de protección contra golpes apropiado. Incluya

la Orden de compra con el número de modelo del

instrumento, el costo del servicio y/o calibración, y el

número de Autorización de devolución de material

(RMA). Marque el exterior del contenedor de envío con

el número de RMA. Esto acelerará el procesamiento de

su instrumento cuando lo recibamos.

Daños en Tránsito

Todos los pedidos son embalados cuidadosamente para

su envío. Una vez recibido, si el contenedor de envío

aparenta haber sido dañado durante su envío, el

instrumento deberá ser inspeccionado meticulosamente.

Los documentos de la compañía transportista deberán

firmarse haciendo constar el daño aparente. NO SE

DESHAGA DE LA CAJA.

Si el instrumento ha sufrido daños, el cliente deberá

presentar una queja inmediatamente contra la compañía

transportista. El agente vendedor asistirá al cliente

proporcionando toda la información de envío

pertinente; sin embargo, la reclamación deberá ser

presentada por la parte asegurada. Si el instrumento

está dañado sin remedio, se deberá hacer un nuevo

pedido a TSI mientras se espera el reembolso por parte

de la compañía transportista por el instrumento dañado.

Llame a TSI directamente si necesita asistencia.

26

Page 33

27

APENDICE A

Factores de Ajuste para Nivel de Flujo Estandar a Nivel de Flujo Real

El LoFlo Balometer® mide el nivel de flujo volumétrico

estándar. El flujo estándar se define como el nivel de

flujo en condiciones normales, 70°F (21, 21°1C) y 14,7

psia (29,92 inHg, 760 mmHg). El nivel de flujo real es

el nivel volumétrico real de aire a la temperatura y

presión barométrica local. Si desea conocer el nivel de

flujo estándar, utilice la lectura qu e ap arece en pantalla.

Sin embargo, si desea conocer el nivel de flujo real,

utilice la siguiente información:

Para cambiar de flujo de aire estándar a flujo de aire

real, utilice la siguiente ecuación:

= V

V

act

= Nivel de flujo r eal

V

act

= Nivel de flujo estándar

V

std

x CF

std

(la que aparece en pantalla)

T

= Temperatura real

act

= Presión barométrica real

P

act

= Densidad estándar 0/075 lb/ft3

P

std

(a 70°F y 14,7 psia)

P

= Densidad real en lb/ft3

a

CF = P

(Factor de ajuste)

std/Pa

Al utilizar las ecuaciones o la gráfica que se ilustra más

adelante, podrá pasar por alto el cómputo de densidad

total.

Cómputos en unidades inglesas

CF = (14,7/P

Donde P

act

)*(460+ T

act

act

aparece en psia y T

)/530

aparece en °F

act

Cómputos en unidades inglesas

CF = (29,92/P

Donde P

aparece en inHg y T

act

)*(460+ T

act

)/530

act

aparece en °F

act

Cómputos en unidades métricas

CF = (760/P

Donde P

act

)*(273,15+ T

act

act

aparece en mmHg y T

)/294,25

aparece en C

act

Para mayor conveniencia, hemos dibujado una gráfica a

modo de determinar el factor de ajuste dada la

temperatura y la presión.

NOTA: La presión atmosférica de acuerdo al

Servicio Nacional de Meteorología ha sido ajustada

al nivel del mar y no puede utilizarse si las

mediciones no se encuentran a dicho nivel.

TEMPERATURA DEL AIRE (°F)

LoFlo Balometer® con cubierta de 16 x 16 pulgadas.

TEMPERATURA DEL AIRE (°C)

PRESIÓN DEL AIRE (en Hg)

27

Page 34

[THIS PAGE INTENTIONALLY LEFT BLANK]

28

Page 35

TABLE DES MATIÈRES

Section 1 Description Générale ..................................................... 31

Section 2 Principe de Fonctionnement .......................................... 31

Section 3 Sécurité .......................................................................... 32

Section 4 Préparation et Entreposage de l’In strument .................. 32

Section 5 Caractéristiques d’Affichage ......................................... 34

Section 6 Mise en Marche ............................................................. 35

Section 7 Détails de Fonctionnement ............................................ 35

Section 8 Dépannage ..................................................................... 38

Section 9 Entretien ........................................................................ 39

Section 10 Renseignements de Service ........................................... 40

Annexe A Facteurs de Correction Entre

le Débit Normal et le Débit Réel ................................... 41

29

Page 36

Fiche Technique Du Débitmètre LoFlo Balometer®

Plage: 17–850 m

(10–500 pi

Précision: ±(3 % + 8,5 m

±(3 % + 5 pi3/mn)

Hauteur: 394 mm (15,5 po), base seul.

559 mm (22 po) avec hotte 406 mm

876 mm (34,5 po) avec hotte 610 mm

Poids: env. 2,7 kg (6 lb) avec hotte

2,1 kg (4,6 lb) base seul.

Diamètre

d’Ouverture

de la Base: 338 mm (13,3 po) de diamètre

Dimensions 406 x 406 mm, 610 x 610 mm ou

de Hottes: 650 x 650 mm (16 x 16 po, 24 x 24

po ou 26 x 26 po)

3

/h ou 4,7–236 L/s

3

/mn)

3

/h ou 2,4 L/s)

3

Plage: 0,1 L/s entre 4,7 et 9,9 L

(Alimentation 1 L/s entre 10 et 236 L/s

ou Retour) 1 pi

3

/mn entre 10 et 500 pi3/mn

/s

Dimensions haut. (base seul.): 394 mm (15,5 po)

Hors Tout: haut av. hotte 610 mm: 876 mm

(34,5 po)

haut av. hotte 406 mm: 559 mm

(22 po) ouverture supér: 338 mm

(13,3 po) dia.

Bloc

d’Ali-Mentation: 4 piles C alcalines 1,5 V

(nickel-cadmium en option)

Durée des Piles: 10 heures minimum en utilisation

constante

Affichage: affichage numérique 3+ chiff r es ,

11 mm (0,44 po) haut., avec affichage

analogique simulé à 26 segments.

3

Résolution/ 1 m

/h entre 17 et 850 m3/h

*Spécifications peuvent subir des changements sans préavis

30

Page 37

31

SECTION 1

Description Générale

Le débitmètre LoFlo Balometer® Alnor est un

instrument compact capable de mesurer des niveaux

très bas de débit d’air dans les systèmes CVC. Sa plage

de mesure est entre 17 et 850m

236L/s (10–500 pi

Balometer

®

3

/mn). Le débitmètre LoFlo

affiche le volume d’air normal lorsqu’il est

3

/h ou entre 4,7 et

placé contre les diffuseurs, les registres ou les g rilles

d’alimentation ou de retour montés au plafond, au mur

ou au plancher.

®

Le débitmètre LoFlo Balometer

est pourvu d’un

mécanisme à évents qui réduit l’obstruction du courant

d’air causée par l’instrument. Ce système à évents

SECTION 2

Principe de Fonctionnement: Hottes de Captage et Détection par

Anémomètre Thermique

À la sortie d’un diffuseur, l’air est capté dans la hotte

ou dans la base et dirigé vers un collecteur. Le

collecteur distribue la pression de vitesse et fait passer

l’air sur les capteurs. La vitesse et la température de

l’air passant dans le collecteur sont détectées selon le

principe de l’ anémomètre thermique à température

constante. La tension de sortie de l’anémomètre

thermique est alors calculée en fonction du débit total à

l’intérieur du débitmètre LoFlo Balometer

Une hotte de captage est toujours susceptible

d’engendrer des courbes de débit irrégulières, On peut

considérer comme « irrégulière » toute courbe de débit

différente de la courbe d’étalonnage. Des effets négatifs

considérables peuvent découler de l’utilisation d’une

hotte trop grande par rapport au diffuseur comme, par

®

.

exclusif (brevet en instance) permet à cet instrument

compact de mesurer une vaste plage de débits. Il est

préférable d’utiliser le débitmètre LoFlo Balometer

®

avec les évents fermés aux débits plus faibles, mais les

débits plus élevés doivent être mesurés avec les évents

ouverts afin de réduire les effets de résistance. On peut

effectuer une mesure en deux points pour compenser

l’effet de résistance à débit élevé de l’instrument.

®

Le débitmètre LoFlo Balometer

est alimenté par piles

et peut être utilisé avec ou sans les hottes offertes en

option. Il pèse un peu plus de 2,7kg avec une hotte de

610mm en place, ce qui réduit la fatigue de l’opérateur.

exemple, une hotte de 610 x 610 mm (24 x 24 po) avec

un diffuseur de 254 x 254 mm (10 x 10 po). Cela crée

d’importantes zones de recirculation le long des côtés

de la hotte de toile et engendre une courbe de débit

irrégulière au passage dans le collecteur. Il est

recommandé d’utiliser une hotte de dimensions

équivalentes à celles du diffuseur.

NOTE: Pour simplifier le présent manuel, on

a utilisé les unités « m

Prière de noter, cependant, que le débitmètre LoFlo

Balometer

®

affiche des valeurs en mètres cubes par

heure standard—m

standard—L/s (std)—et en pieds cubes par minute

standard—pi

3

/mn (std).

3

/h », L/s » et « pi+/mn ».

3

/h (std)—, en litres par seconde

31

Page 38

®

SECTION 3

Sécurité

En utilisant le débitmètre LoFlo Balometer® pour

contrôler le débit d’air de diffuseurs de plafond,

s’assurer qu’il est possible d’élever et de maintenir

l’appareil en toute sécurité pendant la mesure. Être

particulièrement prudent en travaillant dans une

échelle.

LORS DE L'UTILISATION DU LOFLO BALOMETER

'AIR DANS LES CONDUITES, VOUS POUVEZ ÊTRE EN CONTACT OU Ê TRE

D

EXPOSE

CHAMPIGNONS

VOUS ETES POTENTIELLEMENT

LA MOISISSURE

TOUJOURS UN MASQUE RESPIRATOIRE APPROPRIE

'INSTRUMENT LOFLO BALOMETER®.

L

A DE LA POUSSIERE, DU POLLEN, DE LA MOISISSURE, DES

OU À D'AUTRES CONTAMINANTS TRANSPORTÉS DANS L'AIR. SI

, AUX CHAMPIGNONS OU À D'AUTRES CONTAMINANTS, UTILISER

Prendre toutes les précautions nécessaires pour éviter

d’accrocher l’appareil dans la machinerie en

mouvement ou de toucher des fils électriques exposés.

Le débitmètre LoFlo Balometer

®

les mélanges gazeux autres que l’air. L’utilisation en

présence de mélanges gazeux corrosifs, explosifs ou

autrement dangereux est contre-indiqué et aux risques

de l’utilisateur.

CAUTION

POUR MESURER LE DÉBIT

ALLERGIQUES A LA POUSSIERE, AU POLLEN, A

PENDANT L'UTILISATION DE

SECTION 4

n’est pas conçu pour

Préparation et Entreposage de l’Instrument

Préparation de la Hotte