Page 1

ENERGY AND COMFORT

Combustion Analysis

CA-CALC™

Combustion Analyzers

Series CA-6100

Operation and Service Manual

P/N 1980451 Revision G

August 2010

Page 2

Page 3

3

Copyright ©

TSI Incorporated / 2002–20010 / All rights reserved.

Part Number

1980451 / Revision G

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, M N 55126 / USA

Fax No.

(651) 490-3824

LIMITATION OF WARRANTY AND LIABILITY (effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as described in the

operator's manual, shall be free from defects in workmanship and material for twenty-four (24)

months, or the length of time specified in the operator's manual, from the date of shipment to the

customer. This warranty period is inclusive of any statutory warranty. This limited warranty is

subject to the following exclusions:

a. Batteries are warranted for 90 days from the date of shipment to the customer.

Electrochemical gas sensors are warranted for a period of twelve (12) months from the date

of shipment to the customer.

b. Parts repaired or replaced as a result of repair services are warranted to be free from defects

in workmanship and material, under normal use, for 90 days from the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or on any

fuses, batteries or other consumable materials. Only the original manufacturer's warranty

applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with

respect to, and shall have no liability in connection with, goods which are incorporated into

other products or equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR

BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS

OR CHARGES. No Action, regardless of form, may be brought against Seller more than 12

months after a cause of action has accrued. The goods returned under warranty to Seller's

factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms

waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our

customers, our service policy is designed to give prompt attention to any problems. If any

malfunction is discovered, please contact your nearest sales office or representative, or call TSI's

Customer Service department at (651) 490-2811 or (800) 874-2811.

Page 4

4

(This page intentionally left blank)

Page 5

i

Contents

Introduction ........................................................................................ 1

Manual Purpose ............................................................................ 1

Using This Manual ......................................................................... 1

Warnings and Cautions ................................................................. 1

Chapter 1 Instrument Description ................................................... 3

Chapter 2 Unpacking ........................................................................ 5

List of Standard Components ........................................................ 5

Accessories and Replacement Parts ............................................ 5

Chapter 3 Component Identification ............................................... 7

The Gas Sensors .......................................................................... 9

The Sampling Probe ...................................................................... 9

Flue Probe Thermocouple (CA-6120, CA-6130, CA-6140) .......... 9

On-Board Temperature Measurement (CA-6120, CA-6130,

CA-6140) .................................................................................... 9

Diaphragm Pump .......................................................................... 9

Draft Sensor (CA-6110, CA-6140) .............................................. 10

Water Trap ................................................................................... 10

Optional Combustion Supply Air Thermocouple Probe

(CA-6120, CA-6130, CA-6140) ................................................ 10

Optional Protective Boot .............................................................. 10

Schematic Representation of Series CA-6100 CA-CALC

Analyzer ................................................................................... 11

Chapter 4 Getting Started .............................................................. 13

Supplying Power ......................................................................... 13

Connecting the Sampling Probe ................................................. 13

Connecting the Optional Combustion Supply Air

Temperature Probe (CA-6120, CA-6130, CA-6140) ............... 14

Connecting the Optional Portable Printer .................................... 14

Connecting to a Computer .......................................................... 15

Default Instrument Settings ......................................................... 15

Factory Defaults and Language Selection .................................. 15

Chapter 5 Basic Operation ............................................................. 17

Buttons and Button Operations ................................................... 17

Startup ......................................................................................... 18

Characters and Display Icons ..................................................... 19

Measurements and Calculations ................................................. 20

Page 6

ii

Chart of Measurements for Series CA-6100 CA-CALC

Instrument Models .................................................................... 20

Data Display, Viewing Measurements and Calculations ............. 22

Using the Sampling Probe ........................................................... 23

Draft Measurement (CA-6110, CA-6140) .................................... 24

Printing to the Portable Printer and to a Computer

(All Models)............................................................................... 25

Handling Data .............................................................................. 27

Chapter 6 MENU Options ............................................................... 31

LITE Menu Option........................................................................ 32

FUEL Menu Option ...................................................................... 32

UNIT Menu Option (Changing Units) .......................................... 33

INT.S MENU Option .................................................................... 34

TIME MENU Option (Set Time and Date) ................................... 34

CAL MENU Option ...................................................................... 34

CAL.F MENU Option—Setting the Calibration Factor ................. 39

BAUD Rate MENU option ............................................................ 40

COMM MENU Option—Set the Output Communications

Device ....................................................................................... 41

FP MENU Option—Fuel Parameters (CA-6120, CA-6130,

CA-6140) .................................................................................. 42

Fuel Parameter Descriptions for U.S. Fuels ................................ 43

FP Fuel Parameters for Siegert Calculation—Siegert Fuel

Parameters ............................................................................... 43

LANG MENU Option .................................................................... 44

Chapter 7 Setup for Gas Calibration ............................................. 45

The Calibration Setups ................................................................ 45

Chapter 8 Maintenance and Troubleshooting .............................. 49

Emptying Water Trap ................................................................... 49

Changing the (optional) Water Trap Filter ................................... 49

Cleaning the Sample Probe ......................................................... 50

Installing a Gas Sensor ............................................................... 50

Adding a CO Sensor to the Model CA-6120 ............................... 52

Disabling CO Sensor Recognition by a Model CA-6130 ............. 52

Appendix A Error Codes ................................................................ 53

Appendix B Calculations ................................................................ 55

COu Undiluted CO Concentration Calculation ............................ 55

Excess Air Calculation ................................................................. 55

Calculating Combustion Efficiency for U.S. Fuels ....................... 55

Siegert Formula ........................................................................... 56

Determining CO2 Using the O2 Concentration ............................ 57

Page 7

iii

A General Equation for the Combustion of a Simple

Hydrocarbon in Air ................................................................... 57

Calculating CO2 Max From the Carbon Content ......................... 57

Calculation of Combustion Air Requirement ............................... 57

Appendix C Series CA-6100 CA-CALCTM Combustion

Analyzer Specifications ............................................................ 59

Page 8

iv

(This page intentionally left blank)

Page 9

1

!

!

Introduction

Manual Purpose

This manual describes the operation and maintenance of TSI Series

CA-6100 CA-C

6130, and 6140).

Using This Manual

ALC™ portable combustion analyzers (Models 6110, 6120,

Before using your CA-C

its entirety.

Much of the information in this manual is applicable for all Series CA-6100

instruments. Where information is applicable to a particular model, notation

is made.

Warnings and Cautions

The manual assumes that you have a basic understanding of combustion

safety concerns and are thoroughly familiar with the fuel burning equipment

being tested. If you are using measurements as the basis for equipment

adjustments, rely on your good judgment and experience together with the

measured data. This is especially important where safety issues are of

concern. Equipment adjustments must always coincide with the fuel burning

equipment manufacturer’s recommendations.

ALC™ Combustion Analyzer, review this manual in

WARNING

High temperatures and toxic gases are produced when

fossil fuels are burned. Only qualified individuals,

thoroughly familiar with operating and adjusting fuelburning equipment, should use gas measurements for

the purpose of making equipment adjustments.

Note

The CA-CALC™ analyzer is not intended for use as a

continuous monitor.

Page 10

2

Notes: Best results are obtained if the CA-CALC™ combustion analyzer is

allowed to stabilize at the temperature of the test environment before

using.

To reduce sensor exposure to gas and to reduce build up of water

vapor in the sampling lines and water trap, turn the pump off when

not making measurements.

Page 11

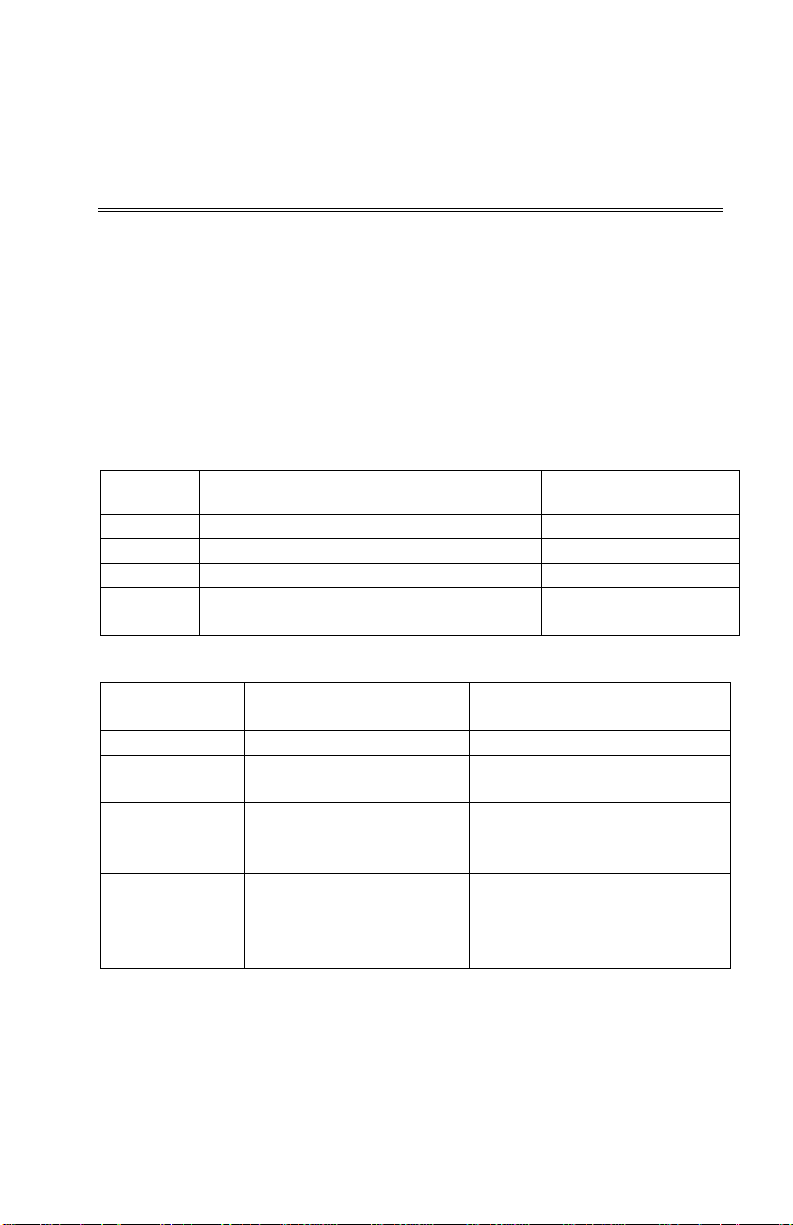

Model

Description

Measurements

CA-6110

Safety Monitor, CO and Draft,

CO, Draft

CA-6120

Boiler and Furnace Efficiency Monitor

O

2,

Temperature

CA-6130

Boiler and Furnace Tune-up Monitor

CO, O

2,

Temperature.

with Draft

Draft

CA-6110

CO and Draft

n/a

2

CA-6130

O2, CO, Flue/stack and

Excess air, Fuel Efficiency,

CO, CO ratio

CA-6140

O2, CO, Flue and Supply

Excess air, Fuel Efficiency,

Chapter 1

Instrument Description

The Series CA-6100 CA-CALC™ Combustion Analyzers are portable

instruments designed for measuring combustion gases, combustion gas

temperatures and draft pressure. These measurements are used to evaluate

the performance of burners in boilers, furnaces, and hot water tanks. From

the measured data, the CA-C

of combustion parameters including CO concentration, excess air, CO

combustion efficiency and draft. Measurements for your CA-C

analyzer will depend upon its Model number designation.

Series CA-6100 CA-C

ALC™ combustion analyzers calculate a variety

ALC™

TM

ALC

Combustion Analyzer Models

level,

2

CA-6140 Boiler and Furnace Tune-up Monitor

Series CA-6100 CA-C

Model

Number

CA-6120 O2, Flue/stack and

The Series CA-6100 CA-C

probe having an in-line water trap and particulate filter. For instruments

measuring temperature, the sample probe has an integral thermocouple.

The Series CA-6100 CA-C

power supply or AA-size batteries.

CO, O

ALC™ Measurements and Calculations

Measured with

Sensor

Calculations

Excess air, Fuel Efficiency,

Supply Air Temperature

Supply Air Temperature

Air Temperature, Draft

Loss, qA, %CO

Loss, qA, %CO2, undiluted

Loss, qA, %CO2, undiluted

CO, CO ratio, draft and

differential pressure.

ALC™ Analyzers are supplied with a sampling

ALC™ Analyzers operate using either an AC

Temperature,

2,

3

Page 12

4

The Series CA-6100 CA-CALC™ Analyzers can store individual data

samples (up to 24), and print the data to a portable printer or computer.

Stored data can be saved over a user-defined interval and averaged if

required.

The Series CA-6100 CA-C

ALC™ Analyzers (not CA-6110) have a variety of

standard fuels, and enable you to modify the fuel parameters, or to install

your own user defined fuel. Loss and efficiency are calculated from standard

heat-loss calculations or using the Siegert formula (refer to Appendix B

).

Chapter 1

Page 13

1

Sample probe with water trap, draft line and

801991

Sample probe with water trap and draft line

801992

4

AA cell alkaline batteries

1 Operation and Service manual

1980451

1

Combustion Supply Air thermocouple Type K

3013003

1

Portable printer kit

801994

1

Universal Power supply 7.2 V with assorted plug

2182003

1

Boot with magnet and carrying strap

801995

1

Computer cable

8940

1

Hard side Carrying case

1500134

1

Replacement pump

801996

1

CO replacement sensor

802006

1

O2 replacement sensor

802012

1

Water trap filters

1602309

1

Lithium battery

1208028

1

Calibration kit O2 (N2 gas) and CO

802003

Chapter 2

Unpacking

Carefully unpack your CA-CALC™ combustion analyzer and accessories

from the carrying case. Check the individual parts against the list of

components in the table below. If items are missing or damaged, notify TSI

immediately.

List of Standard Components

Qty. Item Component Part/ Model

1 Series CA-6100 CA-CALC combustion analyzer,

carrying case, and boot (case and boot not

included with Model CA-6110)

temperature

Sample probe with water trap and temperature

Accessories and Replacement Parts

Item Part/Model

types

801990

5

Page 14

6

(This page intentionally left blank)

Chapter 2

Page 15

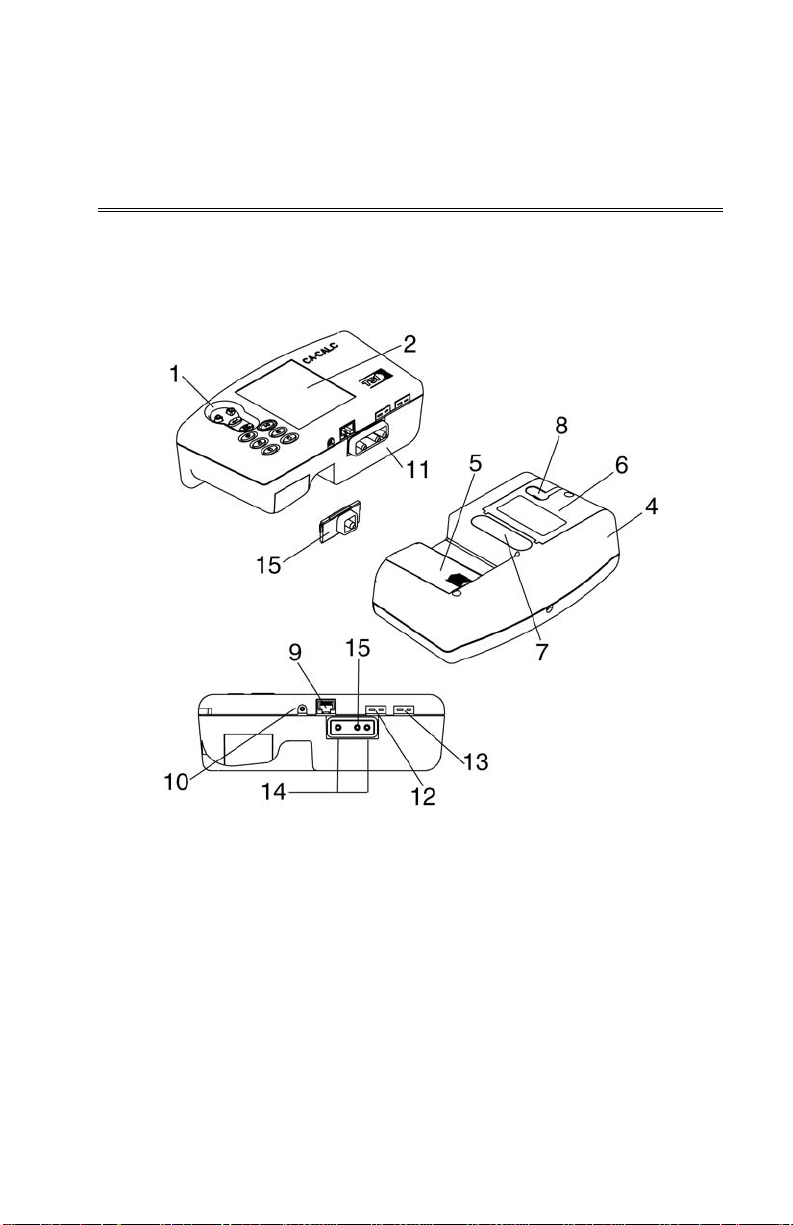

Chapter 3

Component Identification

Key components of the CA-CALC™ combustion analyzer and sampling

probe are identified in Figures 1 and 2, and under section headings in the

text that follows.

1. Buttons 9. RS-232 interface connector

2. Display 10. AC power input connector

3. Top cover 11. Sample port*

4. Case bottom 12. Flue/stack thermocouple port*

5. Battery cover 13. Port for supply Air temperature probe*

6. Sensor cover 14. Optional draft measurement ports [left

side (reference), right side (stack)]*

7. Damping chamber 15. Sample port Models CA-6120, CA-6130*

8. Gas vent

Figure 1. Series CA-6100 CA-CALC™ Combustion Analyzer

*For 11–15 see Figure 4 for Model details.

7

Page 16

8

1. Tube retaining fitting

(some models)

2. Probe handle 7. Flexible sample line

3. Position collar 8. Water Trap

4. Sample tube 9. Water trap filter

5. Probe tip with thermocouple

Figure 2. CA-C

ALC™ Sampling Probe Components

6. Thermocouple connector

(some models)

Chapter 3

Page 17

9

CA-6110

CO and Draft, Safety Monitor

CO

CA-6120

Boiler and Furnace Efficiency Monitor

O2

CA-6130

Boiler and Furnace Tune-up Monitor

CO, O2

CA-6140

Boiler and Furnace Tune-up Monitor with

Draft

CO, O2

The Gas Sensors

Your CA-C

ALC™ analyzer has the following electrochemical gas sensors.

Model

Description

Gas

Sensor

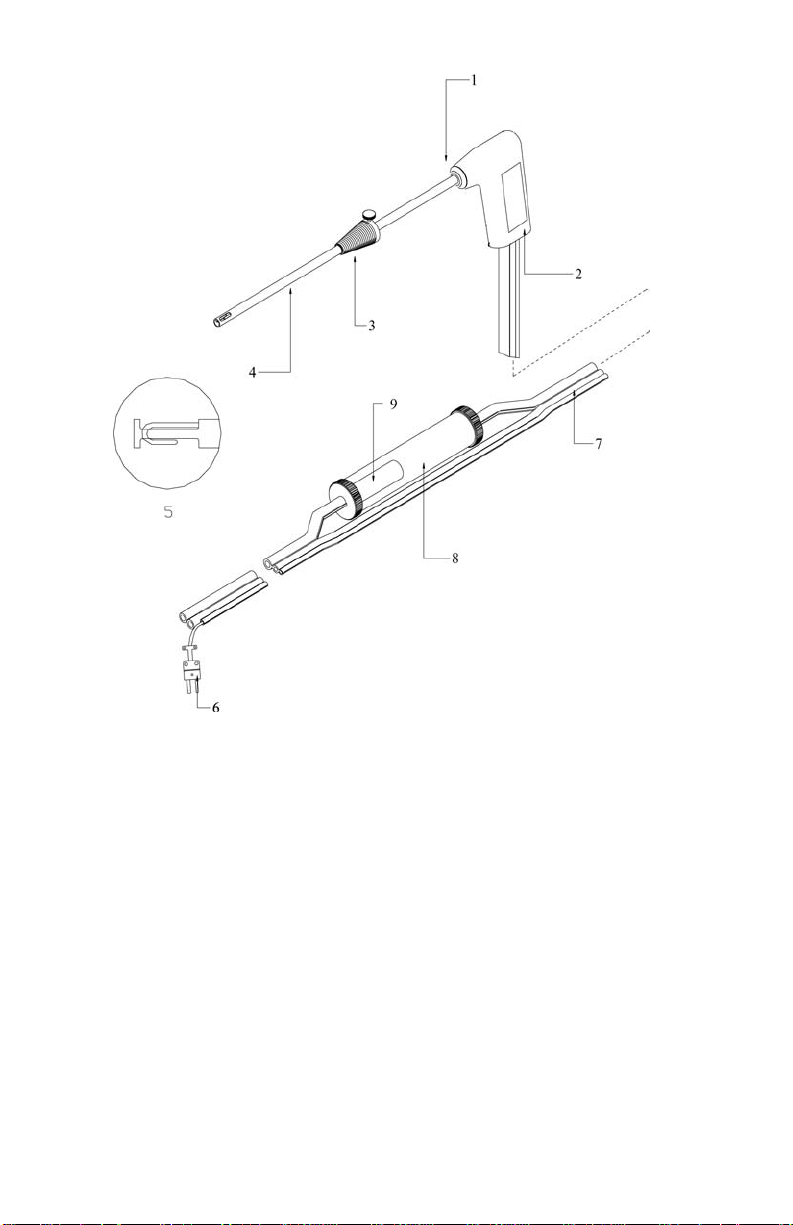

The Sampling Probe

Your combustion analyzer comes equipped with a sampling probe similar to

that depicted in Figure 2. If the model has temperature measurement

capability (Models 6120, 6130, 6140), a thermocouple is present and

extends to the end of the stainless sampling tube. For Model CA-6140

instruments, the probe tube is removable for cleaning. For instruments

measuring draft (Models 6110 and 6140), a draft sampling line is present.

Flue Probe Thermocouple (CA-6120, CA-6130, CA-6140)

For instruments measuring temperature (Models 6120, 6130, 6140), a

Type K thermocouple probe extends through the SS sampling tube on the

probe to its tip, where flue temperatures are measured. The thermocouple

probe measures temperatures up to 700 degrees C (1300 degrees F).

The Type K thermocouple connector plugs into the flue (stack)

thermocouple port (see Figure 1).

On-Board Temperature Measurement (CA-6120, CA-6130, CA-6140)

Your CA-C

ALC™ analyzer uses an on-board temperature detector to provide

the combustion supply air temperature when no supply-air accessory probe

is present.

Diaphragm Pump

The CA-C

ALC™ analyzer, samples exhaust gases from the flue, and delivers

them to the electrochemical sensors using a diaphragm sampling pump. The

pump is accessed through the sensor cover (see Figure 1), and can be

removed for cleaning or for replacement. Typical pump life is 1000 hours.

Component Identification

Page 18

10

Draft Sensor (CA-6110, CA-6140)

A differential pressure transducer in CA-C

ALC™ analyzer models CA-6110

and CA-6140 is used to measure draft pressure. The transducer has a

measurement range of ±30” of H

O (7.47 kPa).

2

Water Trap

The water trap shown in Figure 2 is used to remove moisture that collects in

the sample tubing when combustion gases are sampled. The water trap uses

two chambers and a hydrophobic coalescing filter to maximize water

removal.

Optional Combustion Supply Air Thermocouple Probe (CA-6120, CA-6130, CA-6140)

A measurement of the Combustion Supply Air temperature is made using a

Type K thermocouple probe having a “miniature” type connector. The probe

is plugged into the receptacle identified in Figure 1, reference 13.

When a Supply Air temperature probe is not used, the supply air temperature

is assumed to be the instrument temperature, and is measured automatically

by an on-board temperature sensor.

Optional Protective Boot

An optional protective boot is available for your instrument. The boot

provides drop protection for the instrument and is supplied with a magnet,

enabling the instrument to be mounted on a flat, vertical metal surface. The

boot is equipped with a carrying strap.

Chapter 3

Page 19

11

Schematic Representation of Series CA-6100 CA-CALC™ Analyzer

Figure 3. Schematic Representation of Series CA-6100

Component Identification

ALC™ Analyzer

CA-C

Page 20

12

(This page intentionally left blank)

Chapter 3

Page 21

Chapter 4

Getting Started

Supplying Power

The CA-C

or an AC adapter. Quality alkaline batteries enable the in s tr ument to operate

for at least 10 hours. Use of the plug-in AC adapter conserves battery life,

and can be substituted for batteries.

Connecting the Sampling Probe

The sampling probe depicted in Figure 2, is connected to the instrument by

pushing the sample and draft tube over the ports on the instrument. Refer to

the figures below showing the proper connection of the probe tubes to the

instrument sample ports. Note that the Type K thermocouple connector can

be inserted only one way. The thermocouple connector is oriented with the

large spade to the left. Do not force the connector.

ALC™ portable combustion analyzer operates using 4 AA batteries

Installing Batteries

Turn the combustion analyzer over and remove the battery cover by

pushing down on the cover latch tab with your thumb and sliding the

cover back, away from the instrument case. Remove the battery holder

from the battery compartment. Note the orientation of the contacts on

the holder and in the instrument. Replace the used batteries with new

batteries, matching the + and – terminals, as indicated on the battery

holder. Replace the battery cover.

Connecting the Optional AC Adapter

Connect the corresponding connector plugs to the AC wall source and

instrument power connection located on case bottom (see Figure 2).

When using the power supply, the batteries are bypassed.

Note: The CA-C

batteries.

ALC™ analyzer does not charge rechargeable

13

Page 22

14

Figure 4. Sampling Probe Connections

Connecting the Optional Combustion Supply Air Temperature Probe (CA-6120, CA-6130, CA-6140)

For Models CA-6120, 6130 and 6140 an optional Type K thermocouple

probe (TSI PN 3013003) may be used to measure the temperature of the air

supplied to the burner; the Combustion Supply air. Connect the optional

supply air thermocouple (see “Optional Accessories”) to the supply air

thermocouple port depicted in Figure 1. The thermocouple connector can be

inserted only one way—large spade to the left. Do not force the connector.

Connecting the Optional Portable Printer

Find the printer interface cable included with the optional portable

printer. For the serial printer, connect the large 9-pin connector on the

cable to mating connector on the printer. Connect the opposite end to the

instrument’s RS-232 communications and printer port. See Figure 1 for

port location.

The printer and CA-C

ALC™ combustion analyzer have both been factory

set for a baud rate of 1200. If baud rates are not matched, the printer will

print random characters, question marks or asterisks. Printer settings are

described in the printer manual, along with illustrations identifying the

correct DIP-switch configuration. You will also need to set your

communication device (COM) to PRN for printer. To set the CA-C

baud rate and device settings, refer to Chapter 6, “MENU Options

ALC™

.”

Chapter 4

Page 23

15

2

Fuel parameters

Time

Connecting to a Computer

Use the optional computer interface cable, Model 8940, to transfer

(download) data serially from the CA-C

ALC™ analyzer to a computer.

Connect the large 9-pin connector on the computer interface cable to the 9pin serial connector on your computer. Connect the opposite end to the

instrument’s RS-232 communications and printer port. See Figure 1 for port

location. Set the baud rate of the CA-C

described in Chapter 6, “MENU Options

ALC™ to that of your computer, as

.” The factory preset baud rate is

1200. Set the COMM option to COMP so serial data is formatted for output

to the computer. The alternative is PRN, indi cating output formatted for

printer output. Press the Print button to send data to the computer.

Default Instrument Settings

The CA-C

ALC™ combustion analyzer uses a number of parameter settings

for presenting measured data, performing calculations, and controlling

instrument operation. These include the measurement units, the fuel used,

the baud rate, and so on. When shipped, your instrument has factory preset

parameter settings and the selection of E (English) as the Default language.

When another language is chosen from the language MENU option,

different settings are automatically installed. These are indicated in the table

below. Specific settings are easily changed as described in Chapter 6,

“MENU Options

”; however, settings are reset to those listed below if the

language is changed.

Factory Defaults and Language Selection

Language Selection

O2

CO

Draft units

Temp units

Excess Air

Effc./Loss basis

Effc./loss units

Fuel list

Fuel

Baud Rate

Sampling interval

Communications

E (Default) D, FI, S, N, I

% %

PPM (parts per million) PPM

Inches H

Degrees Fahrenheit Degrees Centigrade

%EA λ = %EA/100 +1

ASME Siegert formula

% (net) % qA

C, H, H2O, HHV, CO2max A2 B

U.S. Fuels Siegert Fuels

Natural Gas Natural Gas

1200 1200

1 second 1 second

Printer format Printer format

MM / DD / YY DD / MM / YY

O mbar

Getting Started

Page 24

16

(This page intentionally left blank)

Chapter 4

Page 25

Chapter 5

Basic Operation

Buttons and Button Operations

ON-OFF Control Button

Turns the instrument on and off.

The ENTER Control Button

Press the ENTER button to execute a command,

such as selecting a menu item.

The ESC Control Button

Used to return to the previous screen or cancel a

process.

ARROW Control Buttons

Use the arrow buttons to step between items and

change values.

The PUMP On-Off Button

Turns the pump on or off.

The PRINT Button

Send data to a printer or computer through the serial

port.

The SAVE Data Button

Save current data. Up to 20 samples.

The REVIEW Data Button

Review currently saved data samples.

The CLEAR Data Button

Clear currently saved data samples.

17

Page 26

18

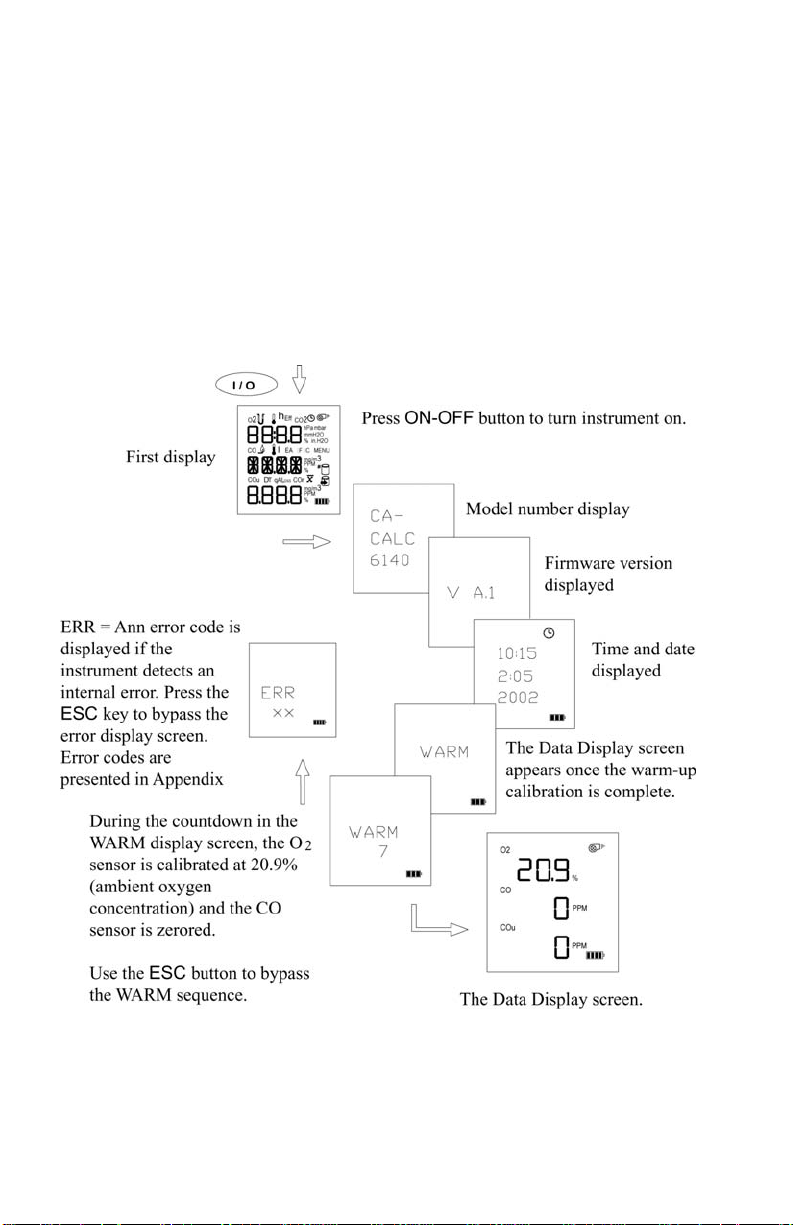

Startup

Remove the sampling probe from the flue or disconnect the sample tubing

from the sampling port. Press the ON-OFF button. The following is a

diagram of the start-up sequence, and shows screens displayed during start

up. If no errors are detected, the Data Display screen is displayed when the

sequence is complete.

While the WARM screen is displayed, the O

sensor is automatically

2

calibrated using ambient air, and the CO sensor is zeroed. At the end of the

WARM sequence (30 seconds), the pump stops and the draft sensor is

zeroed.

Figure 5. Startup Sequence

Chapter 5

Page 27

19

Characters and Display Icons

Refer to F below to identify the icons and characters that comprise the main

Data Display screen. The display icons indicate measurements made, units,

or functions performed. The icons that appear depend on the instrument

model, measurement and calculation capabilities. Refer to Chapter 1

for a

general description of your instrument model. Also refer to the next section,

“Measurements and Calculations

.”

Figure 6. LCD Display and Description of Icons

Basic Operation

Page 28

20

Measurements and Calculations

Chart of Measurements for Series CA-6100 CA-C

ALC™

Instrument Models

Measurement CA-6110 CA-6120 CA-6130 CA-6140

O2 oxygen

CO carbon

monoxide

CO2

Flue (stack) temp

TS

Air temp TA

ΔT

Excess air or

lambda

Loss (ASME)

qA (Siegert)

Efficiency

Efficiency (Siegert)

COu

COr

Draft

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X

X X

X X

Oxygen Measurement (CA-6120, CA-6130, CA-6140)

Models equipped with an O

electrochemical sensor oxygen (see table

2

above) measure oxygen concentration in the range of 0 to 25%, and

perform calculations to determine the concentration of %CO

in the

2

exhaust.

All Models with O

temperature. O

sensor are also equipped for measuring flue

2

and temperature measurements together, enable the

2

calculation of flue heat loss and efficiency.

Carbon Monoxide Measurement (CA-6130, CA-6140)

Models equipped with the CO electrochemical sensor measure carbon

monoxide in the range of 0 to 9999 PPM. Models with an O

sensor

2

too, calculate undiluted CO and CO ratio.

Measurement

CO

2

Models with an O

Flue/stack Temperature, T

sensor calculate %CO2.

2

S (CA-6120, CA-6130, CA-6140)

Flue temperature measured with sampling probe.

Chapter 5

Page 29

21

Combustion Air Temperature, TA (CA-6120, CA-6130, CA-6140)

Measurement of combustion air is determined using the temperature

probe accessory, TSI PN 3013003. In the absence of this probe, the

combustion air temperature is determined from a temperature sensor in

the instrument case.

ΔT, Temperature Difference (CA-6120, CA-6130, CA-6140)

The flue/stack temperature minus the combustion air temperature.

Excess Air or Lambda (λ) (CA-6120, CA-6130, CA-6140)

Calculations of these values are found in Appendix B

.

Loss (CA-6120, CA-6130, CA-6140)

Heat loss from the hot gases exiting the flue/stack. Includes latent heat

loss from the formation of water vapor. See Appendix B

.

qA (CA-6120, CA-6130, CA-6140)

Heat loss using the Siegert formula. See Appendix B

.

Efficiency (CA-6120, CA-6130, CA-6140)

Combustion efficiency: 100 percent minus Loss above. See

Appendix B

.

η Siegert Efficiency (CA-6120, CA-6130, CA-6140)

Combustion efficiency: 100 percent minus qA above. See Appendix B

COu, Undiluted carbon monoxide concentration (CA-6130, CA-6140)

Calculation of the CO concentration, undiluted by excess air. This

calculation requires a measurement of the O

measurement. Not available with models CA-6110 and CA-6120. Refer

to Appendix B

.

COr, CO ratio (CA-6130, CA-6140)

Ratio of CO to CO

Basic Operation

. See Appendix B.

2

concentration and CO

2

.

Page 30

22

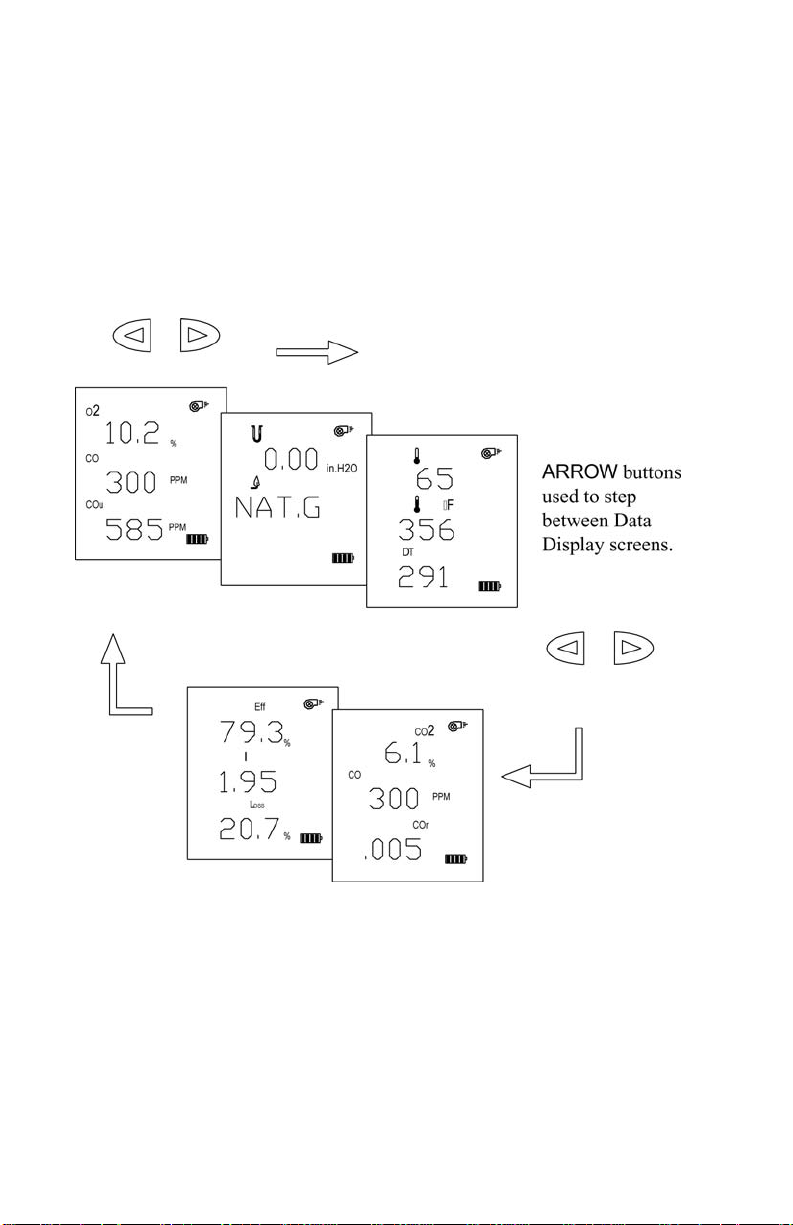

Data Display, Viewing Measurements and Calculations

Measurements and calculations are presented in the Data Display screens.

The Data Displays appear once the Startup sequence is complete as

illustrated earlier in Figure 5.

Refer to Figure 7 below. The appropriate character or icon appears above

the data shown. Select the appropriate data display using the arrow buttons.

For the Model CA-6110, only one data display screen is used, displaying

the CO concentration and Draft.

Figure 7. Example Data Displays for a

ALC Model CA-6140

CA-C

Chapter 5

Page 31

23

2. Draft regulator

4. Hot exhaust gases

Using the Sampling Probe

Gas and Temperature Measurements

Connect the sampling probe to the CA-C

Chapter 4

.

ALC™ analyzer as described in

Place the Sampling probe through a hole in the exhaust flue, following

recommendations presented below. Placement of the probe is

important, and certain considerations must be given when choosing a

sampling location.

To ensure that the gas measurements are not diluted or cooled by

outside air, place the probe before any draft damper or regulator as

illustrated in Figure 8. Tilt the probe tip up slightly so vapor

condensing in the sampling tube does not run back to the probe tip and

cool the thermocouple tip.

Important: Orient the sampling tube to ensure that the

thermocouple tip is exposed directly to exhaust flow (see

Figure 8 below).

1. Sampling probe 3. Exhaust flue

Basic Operation

Figure 8. Sampling Probe Location

Page 32

24

!

The sampling probe tip should be placed at the point of highest exhaust

gas temperature. This means at the base of the flue, before heat is lost

to the flue sidewalls, and towards the center, especially for small ducts.

If the flue/stack gas temperature is underestimated, the operating

efficiency will be overstated. When an economizer or air heater is used,

the flue/stack temperature is measured after these devices.

Cautions

Hot probe! When removed, the sampling probe will

be extremely hot. Avoid touching the probe tip, and

avoid placing the probe on or near plastic materials

such as the instrument case. These will melt.

Maintain a minimum 2” (5 cm) clearance between

the probe handle and position collar when the probe

is mounted in flue.

Empty Water Trap! Watch the water trap and

empty it frequently to prevent the possibility of

flooding the instrument. See Chapter 8

instructions.

Draft Measurement (CA-6110, CA-6140)

Whenever the pump is turned OFF, the display screen changes to display

the draft reading and the draft icon appears. Turning the pump on with the

ON/Off button again causes the draft reading to disappear.

for

Zeroing the Draft Sensor

For the most accurate draft reading, the draft sensor must be zeroed

prior to the draft measurement. To zero the draft sensor, remove the

sampling probe from the flue, or separate the sampling tube or tubes

from the draft port. Press and hold the PUMP ON/OFF button until

the display says “ZERO.” Release the button.

Saving Draft

Whenever a sample is saved using the SAVE DATA button, a draft

reading is automatically taken. For this to occur, the pump is

automatically turned off and a few seconds are allowed for th e d raft

reading to stabilize. Draft is recorded at the end of the d ata-sampling

interval.

Differential Measurement

Instruments with draft measurement capability have two ports to enable

differential pressure measurements. The left-side port is the reference

Chapter 5

Page 33

25

port. When no tube is connected, the draft measurement is referenced

to the ambient (room) pressure.

Printing to the Portable Printer and to a Computer

(All Models)

Printing to the Portable Printer

Instrument data can be output through the RS-232 serial port to the

optional portable printer. First refer to “Connecting the Optional

Portable Printer” in Chapter 4. Make sure the baud rate is set correctly.

To print the information on the Data Display, press the PRINT button.

The printer responds immediately once the button is pressed, producing

a printout of the current data. An example of this printout is shown in

Figure 9.

Saved data can be printed too. Hold the Print button down until a

countdown from three (3) begins. Release the button at zero (0), and all

saved data is printed.

Printing individual saved data samples is described in the next section,

“Handling Data

.”

Printing to a Computer

Use the PRINT button to output data to a computer as well as to the

portable printer. Refer to “Connecting to a Computer

” in Chapter 4.

Data transferred to a computer is the same as that output to a printer

(see Figure 9); however, it is formatted differently and uses the

®

Windows

character set rather than DOS characters. You will need to

set appropriate COMM MENU option before sending data to the

computer. Refer to the Chapter 6, “MENU Options

.”

Data can be downloaded to a terminal emulator program such as the

HyperTerminal, which accompanies the Windows

®

operating system

program. Look for HyperTerminal in the Accessories folder. In

HyperTerminal, use the Capture Text option from the Transfer

menu for recording instrument data.

Your instrument comes configured with the following communications

protocol.

®

Windows is a registered trademark of Microsoft Corporation.

Basic Operation

Page 34

26

Communications Protocol

Baud rate 1200 (default)

Data bits 8

Parity None

Stop bit 1

Flow None

-------------------------------MODEL: 6130

SERIAL: 55030026

---------------------------------Current Data

--------------------------------DATE: 01/16/06

TIME: 15:00:18

Fuel: Nat G

Fuel Parameters:

Carbon wt.: 75.0 %

Hydrogen wt.: 25.0 %

CO2 max vol.: 11.8 %

Sulfur wt.: 0.0 %

kBTU/lb: 23.8

Moisture: 0.0 %

O2: 6.0 %

CO: 5 PPM

COu: 7 PPM

CO2: 8.4 %

COr : NA

TA: 70 °F

TS: 300 °F

TS-TA: 230

EA: 16 %

Loss: 16 %

Effc: 84 %

Figure 9. Example Printout

Chapter 5

Page 35

27

Handling Data

Saving Data

Up to twenty (20) separate measurements can be made and saved to the

instrument memory. Data is saved from the Data Display screen by

pressing the SAVE DATA button. When SAVE DATA is pressed,

measurements are sampled and averaged over the interval set in the

INT.S MENU option

described in Chapter 6. As data is sampled, the

sample number is displayed, and the save data icon blinks.

Note: The pump turns off while the draft is measured and saved.

Figure 10. Saving Data Diagram

Basic Operation

Page 36

28

CLEAR Data

Press the CLEAR DATA button, from the Data Display screen, to erase

data Samples saved in instrument memory. To prevent accidentally

erasing all your data, the CLEAR DATA button must be held while the

instrument counts down from three (3). When the instrument displays

zero, release the button and the all data cleared. If the button is held

longer, nothing is cleared.

To erase the last Sample only, release the CLEAR data button before

zero is displayed, during 3, 2, or 1.

Figure 11. Clearing Saved Data

Chapter 5

Page 37

29

REVIEW Data Samples

Press the REVIEW DATA button briefly to recall saved Samples. The

number of the last Sample appears. Select the specific data Sample you

wish to view using the ARROW buttons and press ENTER. When the

Sample is displayed, use the ARROW buttons to step through the

measurement screens. Review the diagram in Figure 12. You can

average data Samples as described in the next section.

Printing

To print individual saved Samples, press the print button while the

saved Sample is shown. To print all saved Samples, hold the PRINT

button down until a countdown from three (3) begins. Release the

button at zero, (0) and all saved Samples are printed.

Figure 12. Review Saved Data

Basic Operation

Page 38

30

Averaging Saved Samples

To average all your saved Samples, press and hold the REVIEW DATA

button while in the Data Display screen. Hold the button for three seconds.

The screen blanks during this interval. The X-bar icon which appears

indicates that the data presented is an average of all Samples. See

Figure 13.

Figure 13. Display of Average of Samples

Chapter 5

Page 39

Chapter 6

MENU Options

The Series CA-6100 CA-CALC™ instrument has a variety of user selectable

parameters, available as MENU options. The user-selectable MENU options

are shown in the schematic below. Press ENTER to access the MENU

options from the Main Data Display screen. View the MENU options by

pressing using the ARROW buttons. Once the screen of interest is

displayed, press the ENTER button again to choose the MENU option.

Refer to Figure 14, which shows the MENU options.

Figure 14. Menu Option

31

Page 40

32

LITE Menu Option

Select the backlight option as ON, OFF or AUTO. Auto turns the backlight

on for 60 seconds whenever a button is pressed. Refer to Figure 14, which

shows the LITE menu option.

FUEL Menu Option

Use the FUEL option to select from seven preset U.S. fuels or six Siegert

fuels, or select the USER fuel. The fuels parameter list presented (U.S. or

Siegert), is determined by the LOSS selection (Loss or qA respectively). For

more on fuels, refer to the fuel parameters, FP MENU option in this chapter,

and information in Appendix B

. Refer to Figure 15, which shows the FUEL

menu options.

Figure 15. FUEL Options

Chapter 6

Page 41

33

UNIT Menu Option (Changing Units)

It is possible to display data in different measurement un its as indicated in

the table below.

Optional Units

Measurement UNIT Options

TEMP (temperature) Degrees F Degrees C

GAS (*CO concentration) PPM mg/m3

PRES (draft pressure) In. H2O mbar hPa mm H2O

EA (excess air) % EA λ (Lambda = %EA/100 + 1)

LOSS (flue gas heat loss) Loss (ASME) qA (Siegert)

DECI Period, or comma f or decimals

DATE Month/day or day/month format option

To change units, press the ENTER button from the Data Display screen.

Using the ARROW buttons, find UNIT from the MENU options. Continue

using the ARROW buttons to find an option and ENTER to activate it.

Refer to the example below which diagrams changing units. In this example,

CO units are changed.

Figure 16.

Choosing Units.

Example; Setting

the GAS Display

Units.

Menu Options

Page 42

34

INT.S MENU Option

This option enables you to change the sampling interval over which data is

averaged and saved. Use the ENTER button to select. Use the ARROW

buttons to choose the sampling interval from the following options 1, 5, 10,

15, 20, 25, and 30. These represent the number of discrete data values taken

each second and averaged. Use the SAVE DATA button to begin sampling.

TIME MENU Option (Set Time and Date)

Press the ENTER button when the TIME MENU item is displayed. Use the

ARROW buttons to select the field to be changed. The field will blink as it

is highlighted by the ARROW button. To change, press ENTER again. Use

the ARROW buttons to increase or decrease the value selected. Press

ENTER to install the new value. Press ESC to abort and return to the

previous screen.

Time or

and Date

fields

HR:MN

MM.DD

2 0 Y Y

HR:MN

DD.MM

2 0 Y Y

CAL MENU Option

The CAL option is used for performing calibrations of the on-board sensors.

When this option is chosen using the ENTER button, characters and icons

associated with the installed sensor will be displayed, one at a time. Press an

ARROW button and scroll through the options until the desired sensor for

calibration appears. Press ENTER to begin the calibration process. Refer to

Figures 17, 18, and 19, for schematic representations for calibration of the

electrochemical sensors, draft sensor and temperature sensors.

Gas Sensor Calibration (CA-6120, CA-6130, CA-6140)

O

2

Select CAL from the MENU options using the ENTER button. Select

icon from the icons displayed using an ARROW button and

the O

2

press ENTER. Attach the zero gas (nitrogen, N

as described in Chapter 7, “Setup for Gas Calibration

press ENTER to begin the zero calibration. Once complete, the SPAN

calibration screen appears. The O

the ARROW buttons. If room air is used as the calibration gas, do not

change the 20.9% value displayed.

concentration can be adjusted using

2

) to the sampling probe

2

.” When ready,

Chapter 6

Page 43

35

Use the ARROW buttons to match the calibration gas concentration. If

the ambient air is used, make sure the setting is 20.9% as shown.

Press ENTER button to begin the SPAN calibration.

Figure 17. O2 Sensor Calibration Sequence

Menu Options

Page 44

36

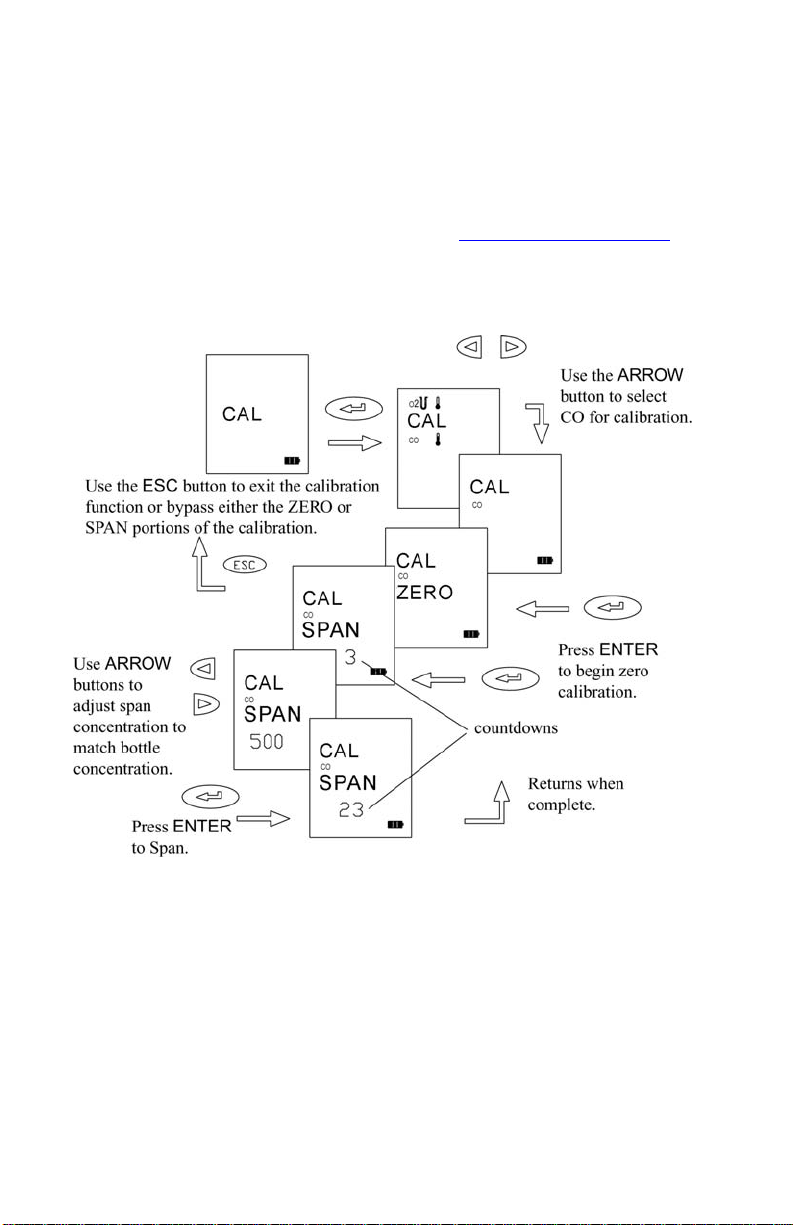

CO Sensor Calibration (CA-6110, CA-6130, CA-6140)

Select CAL from the MENU options by pressing ENTER. Select the

CO icon from the icons displayed using an ARROW button and press

ENTER. For the zero calibration, find a location free of CO. When

ready, press ENTER to begin the zero calibration. Once complete, the

SPAN calibration screen appears. Connect your calibration gas to the

sampling probe as described in Chapter 7, “Setup for Gas Calibration.

Adjust the CO concentration in the span screen, using the ARROW

buttons, so it matches your calibration gas bottle concentration. Press

the ENTER button to start the calibration.

”

Figure 18. CO Calibration

Chapter 6

Page 45

37

Draft Calibration (CA-6110, CA-6140)

Span calibration of the draft sensor is normally not required. The draft

sensor should be routinely zeroed however, to compensate for the

effects of temperature on sensor signal, and to correct for normal drifts

in sensor zero voltage over time. As described earlier in the manual,

zeroing the sensor is achieved simply by holding the pump ON/OFF

button down for three seconds. This should be done prior to any

pressure measurement. This is especially important when the draft

pressure is small.

The schematic below outlines the steps in performing a draft calibration.

As with other calibrations, select the draft icon using the arrow buttons.

Begin the calibration by pressing the ENTER button to perform a

calibration zero. When the zero is complete, use the arrow buttons to

select your supply reference pressure. Press ENTER to initiate the Span

calibration. Both plus and minus pressures are calibrated by applying

the same positive pressure to both the right then left draft sample ports

in turn.*

Figure 19. Draft Calibration

Menu Options

Page 46

38

Temperature Calibration (CA-6120, CA-6130, CA-6140)

Calibration of the thermocouple temperature sensors is not

recommended. Thermocouple sensors are very repeatable, so even if a

replacement is required, or a combustion air temperature probe is

purchased as an accessory, it is unnecessary to calibrate it. Calibration

of a thermocouple probe has value if a narrow temperature range is

used, and calibration is preformed in that range. The burden is left to

you to provide an accurate temperature reference. Refer to the steps

diagramed below if calibration of a thermocouple is desired.

Figure 20. CO Calibration

Chapter 6

Page 47

39

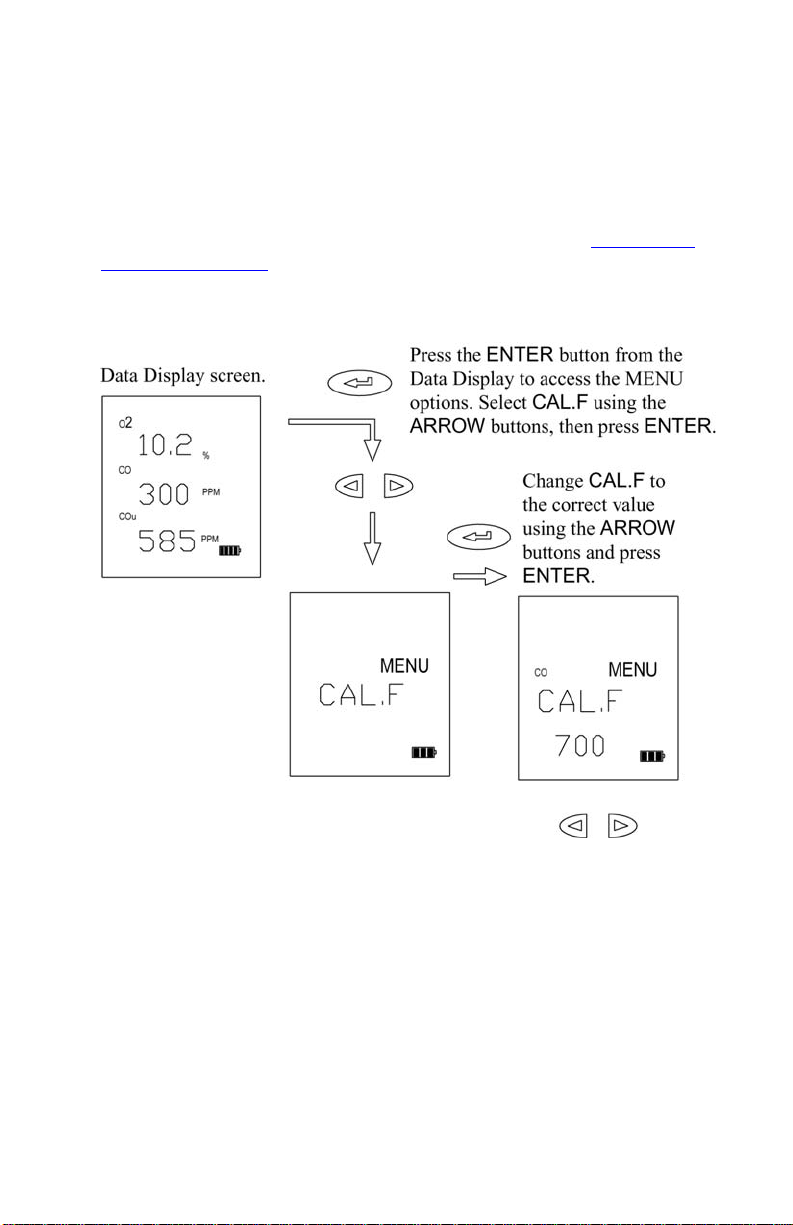

CAL.F MENU Option—Setting the Calibration Factor

When you install a replacement CO sensor from TSI, you will enter a new

calibration factor. This factor is determined by a sensor calibration at the

factory.

After installing your new sensor, as described in Chapter 8, “Maintenance

and Troubleshooting,” find the calibration factor sheet. Use the MENU

option CAL.F, and enter calibration factor provided. Refer to the details

outlined in the schematic below.

Figure 21. Setting the Calibration Factor

Menu Options

Page 48

40

BAUD Rate MENU option

Baud rate can be set to match your computer or portable printer. Your

instrument is delivered with a default baud rate of 1200.

Baud rate values are displayed in the BAUD rate option divided by 1000.

The following baud rates can be set. 1.2 (1200), 2.4 (2400), 4.8 (4800),

9.6 (9600), 19.2 (19200).

To set the baud rate follow the steps outlined in the schematic shown below

in Figure 22.

Figure 22. Setting the Baud Rate

Chapter 6

Page 49

41

COMM MENU Option—Set the Output Communications Device

Your CA-C

ALC™ analyzer transfers current or saved data to a serial printer

or computer The COMM MENU option is used to select the device that you

want to communicate with.

To set the device, follow the steps outlined in the schematic shown below in

Figure 23.

Figure 23. Setting the Data Output Device

Menu Options

Page 50

42

FP MENU Option—Fuel Parameters (CA-6120, CA-6130, CA-6140)

U.S. Fuel Parameters

For U.S. fuels, and U.S. Fuel Parameters to be displayed, the fuel heat

LOSS selection must be set to Loss, not qA. Refer to the section

“UNIT Menu Option (Changing Units)

” in this chapter.

For calculations of flue losses, maximum %CO

, fuel composition and

2

fuel heat content are used. These are the Fuel Parameters. In your CA-

ALC™ analyzer, U.S. fuel parameters are the carbon and hydrogen

C

content, moisture content, sulfur content, and maximum %CO

, C2MX.

2

Refer to the diagrams (Figures 24 and 25) and table below, for

information on viewing and changing fuel parameters.

Figure 24. Fuel Parameters for U.S. Fuels

Chapter 6

Page 51

43

Your CA-CALC™ analyzer has parameters for seven common U.S. fuels

in instrument memory. Fuel parameters for these fuels can be changed,

if you know, for example, that your fuel has a different composition

than that stored. The instrument fuel parameters values are presented in

Appendix B, with additional technical information.

Fuel Parameter Descriptions for U.S. Fuels

Fuel Parameter Description

C % carbon by weight

H % hydrogen by weight

H2O % water content by weight

S % sulfur by weight

C2MX CO2 max %

KBTU Heating value in kiloBTUs/lb

FP Fuel Parameters for Siegert Calculation—Siegert Fuel Parameters

For the Siegert fuels and Siegert Fuel Parameters to be displayed, the fuel

heat LOSS selection must be set to qA, not Loss. Refer to the section UNIT

Menu Option (Changing Units)” in this chapter.

The Siegert value for flue loss, given the designation qA, is used

widely in Europe. Two coefficients are used in the Siegert formula for

flue loss, derived from typical fuel compositions. These are given the

designations, A2 and B.

The default Siegert coefficient values in your CA-C

ALC™ analyzer, are

those used in Germany. Siegert coefficients used in other countries

may be different, reflecting differences in local fuel compositions.

Note: A2 is sometimes defined differently. A2 values entered by the user

must be appropriate for the Siegert equation presented in

Appendix B

.

Figure 25 diagrams the steps in changing the Siegert fuel parameters.

Menu Options

Page 52

44

Figure 25. Changing Fuel Parameters for

Siegert Fuels

LANG MENU Option

Use this option to select between the following languages: E English,

D German, N Dutch, FI Finish, I Italian or S Swedish. English is the

language (default) initially installed on the instrument.

When the language is changed, instrument settings are automatically

changed too. Refer to Chapter 4 “Default Instrument Settings

” for more

information on this feature.

Chapter 6

Page 53

Chapter 7

Setup for Gas Calibration

The Calibration Setups

Note: To perform your gas sensor calibration, you will also need to refer

back to Chapter 6, and the section, “CAL MENU Option

CO and O

accuracy of these gas measurements. Gas sensors do drift over time,

depending upon the operating environment and gas exposure history.

With the proper equipment, such as that shown in the figures below, it is

easy to calibrate your CA-C

wish, you may also return your instrument to TSI for a new factory

calibration.

The equipment needed to calibrate individual gas sensors can be purchased

from TSI as calibration kits. Model numbers for these kits are found in

Chapter 2, “Unpacking

calibration system. Two calibration setups are presented in Figures 26 and

27. A brief discussion of these calibration setups is presented in the

following section.

gas sensors can be calibrated periodically to maintain the

2

ALC™ analyzer gas sensors. However, if you

.” You may also elect to put together your own

.”

45

Page 54

46

Figure 26. Calibration with TSI Calibration Kit

A TSI supplied calibration kit (Figure 26) uses a demand flow regulator to

supply gas to the CA-C

ALC™ analyzer in response to the draw of the

instrument sampling the pump. If a conventional regulator and valve are

used (Figure 27), the setup supplies gas to the instrument using a tee to a

bleed-off extra gas. This prevents a forced flow at the instrument inlet. The

bead-type flow meter depicted in the figure is used to verify there is extra

flow (.5 to 2 L/min recommended). Extra flow is required to prevent room

air from being drawn in, diluting the sample.

Chapter 7

Page 55

47

Figure 27. Alternative Calibration Setup

Setup for Gas Calibration

Page 56

48

(This page intentionally left blank)

Chapter 7

Page 57

Chapter 8

Maintenance and Troubleshooting

For additional troubleshooting information, please visit TSI’s website

http://combustion.tsi.com.

Emptying Water Trap

Refer back to Figure 2 showing the water trap in the sample line, and to

Figure 28 below. Liquid water forms in the first chamber of the water trap as

gases are sampled from the flue. The water trap is designed so even when

shaken, or when its orientation is changed, water does not pass to the second

chamber. The water level must remain below the level depicted in the figure,

however.

To empty the water trap:

1. First separate it from the sampling tube by pulling the tube ends off the

barbs on the end caps.

2. Remove the probe side end cap by pulling outward with a twisting

motion.

3. Pour out the water.

4. Replace the end cap and re-install the trap.

Important: Make sure the water trap is oriented so that end-cap 1

below is toward the instrument.

Changing the (optional) Water Trap Filter

Identify the water trap filter (refer to Figure 28). This filter is designed to

remove soot particles before they contaminate the instrument. The filter can

be removed for cleaning or replacement by following these steps:

1. Remove the instrument side end cap by pulling it out with a twisting

motion.

2. Grasp the filter using a needle-nose pliers and pull it out.

3. To clean the filter, remove the bulk of the soot by tapping the filter. The

soot may be removed by rinsing with water or isopropyl alcohol. The

effectiveness of the rinse depends on the soot composition—is it dry or

oily. Avoid rubbing, which may drive contaminates into the filter

causing permanent plugging.

49

Loading...

Loading...