Page 1

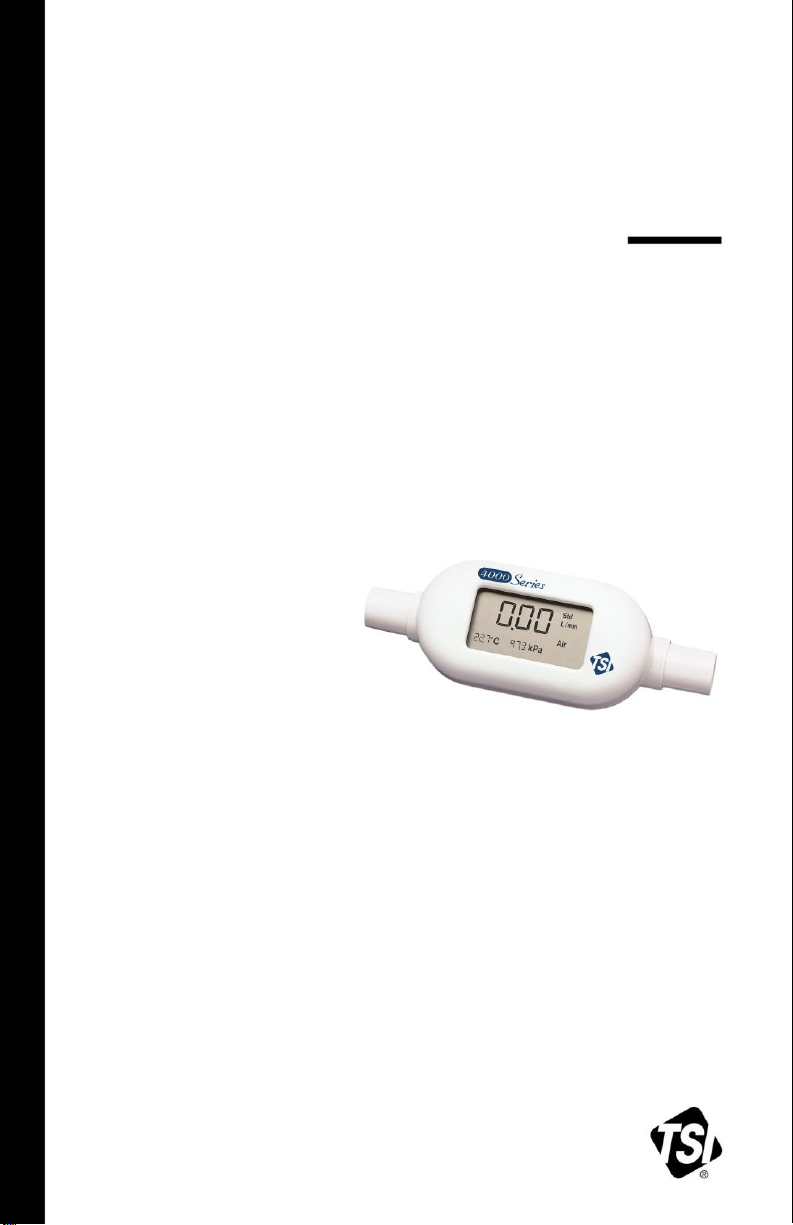

GENERAL PURPOSE

THERMAL MASS FLOWMETER

MODEL 4040/4043/4045

OPERATION AND SERVICE MANUAL

P/N 1980339, REVISION J

FEBRUARY 2016

Page 2

Page 3

GENERAL PURPOSE

THERMAL MASS FLOWMETER

MODEL 4040/4043/4045

OPERATION AND SERVICE MANUAL

P/N 1980339, REVISION J

FEBRUARY 2016

U.S. & INTERNATIONAL TSI Instruments Ltd. (UK)

Sales and Customer Service: Sales and Customer Service:

(800) 874-2811 / +1(651) 490-2811 +44 (0) 1494 459200

Fax: Fax:

+1(651) 490-3824 +44 (0) 1494 459700

Page 4

Page 5

WARNING

TSI flowmeters employ a heated platinum sensor. They

should not be used with flammable or explosive gasses

or mixtures.

Caution

TSI flowmeters are not medical devices under FDA

510k and in no situation should they be utilized for

human respiration measurements.

Copyright

TSI Incorporated / 2002-2016 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 USA

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and

service as described in the operator's manual, to be free from defects in workmanship

and material for 12 months, or if less, the length of time specified in the operator's

manual, from the date of shipment to the customer. This warranty period is inclusive of

any statutory warranty. This limited warranty is subject to the following exclusions and

exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the date

of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s

manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from

defects in workmanship and material, under normal use, for 90 days from the date of

shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on

any fuses, batteries or other consumable materials. Only the original manufacturer's

warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that

the instrument or product is properly calibrated at the time of its manufacture.

Instruments returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory

authorized service center with the one exception where requirements set forth in the

manual allow an operator to replace consumables or perform recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to

accidental or intentional damage, or is not properly installed, maintained, or cleaned

according to the requirements of the manual. Unless specifically authorized in a

separate writing by Seller, Seller makes no warranty with respect to, and shall have no

liability in connection with, goods which are incorporated into other products or

equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO

SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID

WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES

CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S

i

Page 6

EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE PRICE

DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT SELLER’S OPTION

REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS

BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE)

SHALL BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE

PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE, SELLER WILL

REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO DO SO, WILL

REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO EVENT SHALL

SELLER BE LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR ANY

SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER

SHALL NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR

REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be

brought against Seller more than 12 months after a cause of action has accrued. The

goods returned under warranty to Seller's factory shall be at Buyer's risk of loss, and will

be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of Seller.

This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its

terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI attention to

any problems. If any malfunction is discovered, please contact your nearest sales office

or representative, or call TSI's Customer Service department at (800) 874-2811 (USA)

or (001 651) 490-2811 (International) or visit www.tsi.com.

ii

Page 7

CONTENTS

CHAPTERS

1 UNPACKING AND PARTS IDENTIFICATION ............................. 1

2 SETTING-UP ................................................................................. 3

Supplying Power ............................................................................ 3

Connecting Filter and Flow Tubes ................................................. 4

RS232 Configuration and Operation ............................................. 4

Configuration Software .................................................................. 5

3 OPERATION ................................................................................. 7

Overview ........................................................................................ 7

ON/OFF Switch ............................................................................. 7

Warm-up Time ............................................................................... 7

Flow Rate Measurement ............................................................... 7

Temperature Measurement ........................................................... 8

Pressure Measurement ................................................................. 8

Volume Measurement ................................................................... 8

4 MAINTENANCE ............................................................................ 9

Flow Sensor ................................................................................... 9

Re-certification ............................................................................... 9

Cases ............................................................................................ 9

Storage .......................................................................................... 9

5 TROUBLESHOOTING ................................................................ 11

APPENDIXES

A SPECIFICATIONS* ..................................................................... 13

B STANDARD FLOW RATE VS. VOLUMETRIC FLOW RATE.... 17

iii

Page 8

(This page intentionally left blank)

iv

Page 9

Qty

Item Description

Part/Model

1

Mass Flowmeter, 22 mm ISO tapered inlet/outlet

Mass Flowmeter, 0.50 inch inlet/outlet

Mass Flowmeter, 0.75 inch inlet/outlet

4040

4043

4045

1

Computer Cable

1303583

1

Analog Cable

1303584

1

Filter

22 mm ISO-taper (for Model 4040)

3/8” Female NPT (for Model 4043/45)

1602292

1602300

1

AC Adapter

100 to 240 V, N. America NEMA 5-15 plug, grounded

100 to 240 V, Europlug, CEE 7/16, grounded

100 to 240 V, Great Britain, grounded, fused

100 to 240 V, Australia/NZ

8918-NA

8918-EC

8918-GB

8918-AT

1

Operation and Service Manual

1980339

1

RS232 Serial Command Set manual

1980340

1

Carrying Case (optional accessory)

1319176

Chapter 1

Unpacking and Parts Identification

Carefully unpack the instrument and accessories from the shipping

container. Check the individual parts against the list of components in

Table 1. If any parts are missing or damaged, notify TSI immediately.

Table 1. List of Components

1

Page 10

2

1. On/Off Switch

4. DC Power Input

2. Display

5. Flow Inlet

3. Mounting Inserts (2)

6. Computer Serial Interface and

Analog Output and Optional

Power Input Connector

Parts Identification

Figure 1-1 Model 4040/4043/4045 Mass Flowmeter

Chapter 1

Page 11

Table 2. List of Connector Pin-outs and

Cable Color Code Designations

Pin

Function

Cable Color

Code

1

Power Input (+)

Black

2

Power Ground (-)

Green

3

Analog Output (+)

Red 4 Analog Ground (-)

Brown

5

(no connection)

Blue

6

RS232 Receive (in)

White

7

RS232 Transmit (out)

Yellow

8

Logic Ground

Gray

Chapter 2

Setting-Up

Supplying Power

The flowmeter can be powered in one of two ways: through the power

jack using the supplied AC adapter or through the mini-DIN

connector. The DC power input connector is shown below along with

the power requirements.

Power Supply: 7.5 VDC ± 1.5 V, 300 mA maximum

When supplying power through the TSI-supplied interface cable, line

up the arrow on the connector with the bottom side of the flowmeter.

Flowmeter connector pin-out designations are shown below.

3

Page 12

4

Ca u ti o n

Always use a filter on the inlet of the flowmeter.

Failure to filter the gas flow may change the

calibration and/or permanently damage the

sensor.

Function

Command

Select Gas Calibration (air, oxygen, mixture)

SG

Select Oxygen Concentration in Air (21% to 99%)

SGM

Select Standard or Volumetric Flow Measurement

SU

LCD Display Update Rate (controls averaging)

SUR

Select Data Update Rate for Analog Output

SSR

Set Analog Output Full-Scale Flow Rate Value

SAS

Set Analog Output Zero Value

SAZ

Connecting Filter and Flow Tubes

The Models 4040/4043/4045 have an exposed thermal flow sensor,

which must be protected from foreign matter and particles in the gas

flow. TSI has supplied a filter, which should be connected to the inlet

of the flowmeter; however, any filter will work as long as it has a

minimum efficiency of 99.9%.

Note: Flow direction is identified by the large arrow printed on the

bottom side of the flowmeter.

After attaching the filter, connect the flow tube, to the inlet, of the

filter. Connecting a tube to the outlet of the flowmeter will create back

pressure. See Appendix A for flowmeter accuracy specifications when

operating at various pressures. In general, minimize back pressure on

the flowmeter to maintain higher accuracy.

RS232 Configuration and Operation

Many flowmeter operating parameters can be easily configured

through the RS232 serial port. Likewise, the flow rate, temperature,

pressure, and volume can be read through the serial port. Refer to

the Series 4000/4100 RS232 Serial Command Set manual for a

detailed description of the commands and command syntax.

RS232 Settings: Baud Rate ........ 38.4 k

Data Bits .......... 8

Parity ................ None

Stop Bits .......... 1

Flow Control ..... None

Table 3. Changeable Operating Parameters

Chapter 2

Page 13

5

Configuration Software

TSI has several software utilities to help you communicate with your

flowmeter to change parameters and to obtain flow data. You can

download the latest versions of these at no charge from our web site:

http://flowmeters.tsi.com

1. If you only want to change one or more of the operating

parameters shown in Table 3 (above), the easiest way is to use

the software utility called “TSI setup.” This uses convenient dropdown menus to help change these parameters. After you have

made your changes, be sure to click on “Send” to store the

changes in the flowmeter’s memory.

2. If you want to communicate directly with the flowmeter using the

basic RS232 commands shown in the Serial Command Set

Manual, you can use a terminal program. HyperTerminal is a

common terminal program that is included with most versions of

the Microsoft operating system. You can download a document

from our web site that helps you configure HyperTerminal.

Download the document called “Using HyperTerminal to

communicate with TSI Flowmeters.”

Operation

Page 14

6

3. If you plan to develop a more sophisticated program for data

collection and control using LabVIEW, you can download a

demonstration program called “Real-time Demo Program” and

the source code “Source Code for Real-time Demo Program.”

This program is intended to be a basic demonstration program and

not a practical laboratory tool. It does, however, have a convenient

implementation of the VOLUME measurement function that can be

useful for basic tests.

Chapter 2

Page 15

Ca u ti o n

TSI flowmeters are not medical devices under

FDA 510k and in no situation should they be

utilized for human respiration measurements.

Chapter 3

Operation

Overview

The Models 4040/4043/4045 Flowmeters measure mass flow rate,

temperature and absolute pressure of the gas inside the flow tube. All

measurements made by the Model 4040/4043/4045 are NIST

traceable.

ON/OFF Switch

Slide the switch to the ON position. The power switch is marked in the

international symbols '|' for on and 'O' for off. The flowmeter will begin

to simultaneously display flow rate, temperature and pressure.

Warm-up Time

The flowmeter will provide readings immediately upon power-up.

Recommended warm-up time of the flowmeter is 5 minutes.

Flow Rate Measurement

Flow rate data can be obtained from the Models 4040/4043/4045

through the LCD display, RS232 serial port or the linearized analog

output. The analog output is a 0 to 10 volt DC linear signal

representing 0 to 300 Std L/min (Model 4043: 200 Std. L/min) (analog

output scaling is user selectable). Refer to the RS232 Serial

Command Set manual for instructions on how to obtain flow data

through the serial port.

Gas calibrations (air, 100% nitrogen, 100% oxygen, or air/oxygen

mixtures) can be selected through the RS232 serial port. Refer to the

RS232 Serial Command Set manual for instructions on how to select

gas calibrations. The LCD display will indicate the calibration being

utilized, air or O2. When air/oxygen mixtures are being measured, the

LCD display will illuminate both the air and oxygen symbols. When

nitrogen is selected no gas type is displayed on the LCD.

7

Page 16

8

Flow can be displayed in units of standard liters per minute

(Std L/min*) or in volumetric units of liters per minute (L/min). Refer to

Appendix B for a description between the two measurements.

Selecting between the two measurements is accomplished through

the serial port. Refer to the RS232 Serial Command Set manual for

instructions on how to select between flow units.

Temperature Measurement

The Models 4040/4043/4045 have an independent temperature

transducer in the flow tube to measure the gas temperature. The

temperature sensor is used for temperature compensation of flow rate

and for converting flow from standard to volumetric units.

Temperature is displayed on the LCD and is available through the

RS232 serial port in the units of degrees Celsius (°C).

Note: At low flow rates, the temperature inside of the flow tube will

increase because of the heat generated by the thermal flow

sensor. This effect is normal and the temperature of the

incoming gas will be measured once flow resumes.

Pressure Measurement

The Models 4040/4043/4045 measure absolute pressure near the

outlet of the flowmeter in the SI units of kilo-Pascals (kPa). Pressure

measurements are required when converting from standard to

volumetric flow. Absolute pressure measurements are displayed on

the LCD display and are available through the RS232 serial port.

Volume Measurement

The Models 4040/4043/4045 measure total volume by integrating flow

over time. This is a calculated measurement performed by the

flowmeter and is only available using the RS232 serial port. Volume is

not displayed on the LCD display. Refer to the Models

4040/4043/4045 RS232 Serial Command Set manual for instructions

on using the volume function.

*

TSI instruments defines standard conditions as 21.1°C (70° F) and 101.3 kPa (14.7

psia, 1 bar).

Chapter 3

Page 17

Ca u ti o n

The flowmeter must be switched off for cleaning.

Only use clean, dry, compressed air when

attempting to remove contamination from the

sensor.

Chapter 4

Maintenance

Flow Sensor

Periodically inspect the flow sensor by looking into the outlet of the

flowmeter. Remove dust, particles and fibers from the sensor, with

clean, dry compressed air. The flow sensor will break if touched.

Never run liquids through the flowmeter and never touch the

sensor with a brush. Dust or other deposits on the flow sensor will

degrade the 4040/4043/4045 flowmeter’s flow accuracy.

Re-certification

To maintain a high degree of confidence in the measurements made

by the Models 4040/4043/4045, TSI recommends that you return the

instrument to TSI every 12 months for re-certification. For a nominal

fee, we will recalibrate the unit and return it to you with a certificate of

calibration and US National Institute of Standards Technology (NIST)

traceability. This “annual checkup” assures you of consistently

accurate readings; it is especially important in applications where

strict calibration records must be maintained.

Cases

If the instrument case or storage case needs cleaning, wipe it off with

a soft cloth dipped in isopropyl alcohol or mild detergent. Never

submerge the flowmeter.

Storage

When storing the flowmeter, always cover the ends of flow tubes with

the provided caps to prevent dust or other foreign matter from

entering the tube.

9

Page 18

(This page intentionally left blank)

10 Chapter 4

Page 19

Symptom

Possible Causes

Corrective Action

No display.

Unit not switched on.

Switch on the unit.

No power to

instrument.

Plug in AC adapter or

check power source on

mini-DIN connector.

Temperature

reads high at

low or zero

flows.

Temperature sensor is

being heated from the

flow sensor.

This is normal. Once

flow exceeds 1 Std

L/min, the temperature

will track the flowing gas

temperature.

Flow readings

fluctuate badly.

The flow is fluctuating.

Improve inlet conditions

or increase display

averaging time.

Display shows

flows over-range

with no flow

passing through

flow tube.

The sensor may be

damaged or broken.

Return flowmeter to TSI

for service.

Chapter 5

Troubleshooting

Table 4 lists the symptoms, possible causes, and recommended

solutions for common problems encountered with the flowmeter. If the

symptom is not listed, or if none of the solutions solves the problem,

please contact TSI Customer Support at 1-800-874-2811 or

651-490-2811.

Table 4. Troubleshooting

11

Page 20

(This page intentionally left blank)

12 Chapter 5

Page 21

Flow Measurement

Measurement Range

Models 4040/4045 .........

Model 4043 only ............

Accuracy

Air, O2 ...........................

N2, Air/O2 mixtures ........

Resolution (Display) ..........

Response .........................

0 to 300 Std L/min.

0 to 200 Std L/min.

2% of reading or 0.05 Std L/min, whichever is

greater

3% of reading or 0.1 Std L/min, whichever is

greater

Accuracy stated at standard conditions: 21.1°C

and 101.3 kPa)

See notes 1 through 6 below.

0.01 Std L/min between 0 and 90 Std L/min

0.1 Std L/min between 90 and 300 Std L/min

Less than 4 msec, 63% of final value at full

scale flow

Temperature Measurement

Measurement Range ........

Accuracy ...........................

Resolution (Display) ..........

Response .........................

0 to 50°C

±1°C, at flows greater than 1 L/min. See note 2

below.

0.1°C

Less than 75 msec, 63% of final value for 20°C

step change in temperature at full scale flow

Static Pressure Measurement (Measured inside flow tube near the exit)

Measurement Range ........

Accuracy ...........................

Resolution (Display) ..........

Response .........................

Over Pressure ..................

50 to 199 kPa Absolute

±1 kPa, See note 7 below

0.1 kPa

Less than 4 msec.

63% of final value for 30 kPa step change

620 kPa

Burst Pressure

Tested to 690 kPa without rupture. Do not exceed 690 kPa.

Pressure Drop

See Chart.

Volume

Measurement Range ........

Accuracy ...........................

0.001 to 99.99 Liters

2% of Reading at flows greater than 2.5 Std

L/min

See notes 1 through 6 below.

Appendix A

Specifications*

Specifications 13

Page 22

Instrument Temp. Range

Operation, Ambient ..........

Storage, Ambient ..............

0 to 50°C

-20 to 60°C

Physical Dimensions

External Dimensions ........

Tube Adapters ..................

(Inlet & Outlet)

Weight ..............................

Flow Body Material ...........

See Diagram

Model 4040: 22 mm male ISO Taper

Model 4043: ½ inch straight

Model 4045: ¾ inch straight

180 grams

PolyCarbonate

Computer Interface

Connector .........................

Type .................................

Baud Rate ........................

Data Bits ...........................

Parity ................................

Stop Bits ...........................

Flow Control .....................

8 pin mini-DIN

RS232 Serial

38.4 k

8

None

1

None

Analog Output (Flow Only)

Range ...............................

Resolution ........................

Maximum Current .............

Flow Accuracy ..................

0 to 10 V

13 bit

5 mA

See note 6 below.

Power

AC adapter or power supplied through mini-DIN

7.5 VDC ± 1.5 V, 300 mA maximum

Notes:

1 Accuracy stated at standard conditions of 21.1°C and 101.3 kPa.

Add an additional 0.075% of reading per 1°C away from standard

conditions when operating within the range of 0°C to 50°C.

Add an additional 0.015% of reading per 1 kPa above 101.3 kPa or

Add an additional 0.022% of reading per 1 kPa below 101.3 kPa

when operating within the pressure range of 70 kPa to 170 kPa.

2 Accuracy stated with gas temperature and flow body temperature within

±10°C of one another.

3 Accuracy stated measuring dry gas (less than 10% R.H.).

4 Includes ±0.5% of reading repeatability.

5 Volumetric flow rate is calculated from the mass flow measurement. Add

an additional 0.25% of reading to the flow accuracy to account for the

uncertainty in measuring gas temperature and pressure.

6 For analog output, accuracy offset increases from 0.05 to 0.1 Std L/min.

7 Add uncertainty of 0.2 kPa for every 10°C away from 21.1°C.

*Specifications subject to change without notice.

14 Appendix A

Page 23

Specifications 15

Page 24

16 Appendix A

Page 25

m

m

P

3.101

11.2115.273

T15.273

)FlowStandard(FlowVolumetric

min/L78.84

117

3.101

11.2115.273

1515.273

)100(FlowVolumetric

Appendix B

Standard Flow Rate vs. Volumetric Flow Rate

Since thermal flow sensors are sensitive to changes in air density and

air velocity, all thermal flowmeters indicate flow rates with reference to

a set of standard conditions. For TSI instruments, standard conditions

are defined as 21.1° C (70° F) and 101.3 kPa (14.7 psia). Other

manufacturers may use different values.

Standard flow rate is the flow rate the air would be moving if the

temperature and pressure were at standard conditions. It is usually

the most useful measure of airflow because it defines the heatcarrying capacity of the air.

Volumetric flow rate is the true volume flow of the gas exiting the

flowmeter.

In some instances, volumetric flow rate rather than standard flow rate

may be of interest. To display volumetric flow rate, the Models

4040/4043/4045 will multiply the standard flow measurement by the

following density correction factor:

Where

Tm = Gas temperature measured in flow tube in units of degrees

Celsius

Pm = Absolute pressure measured in flow tube in units of kPa

To demonstrate the difference in output, consider the following.

Measured flow displays 100 Std L/min at 15C and 117kPa. The

volumetric flow as calculated by the Models 4040/4043/4045 would

be as follows.

17

Page 26

USA Tel: +1 800 874 2811

UK Tel: +44 149 4 459200

France Tel: +33 1 41 19 21 99

Germany Tel: +49 241 523030

India Tel: +91 80 67877200

China Tel: +86 10 8219 7688

Singapore Tel: +65 6595 6388

TSI Incorporated – Visit our website www.tsi.com for more information.

P/N 1980339 Rev J ©2016 TSI Incorporated Printed in U.S.A.

*1980339*

Loading...

Loading...