Trynex 261390 User Manual

866-5TURFEX

© Trynex International 2009 L1302 (REV 002)

1 —

1

© Trynex International

Owner / Operator’s Manual

The Commercial Turf Choice

SPREADERS

This Manual Must Be Read Before Operating The Equipment

CUSTOMER COPY

Warren, Michigan 48089

Protected by the following patents, #6,089,478, #6,088,865, #Des.425,915

and

other pending U.S. and foreign patent applications.

R

TS-300

TS-300-EG

TS-700-E

TS-700-GR

TS-1200-GR

TS-1200-P

TS-700-P

TS-1200-E

Table of Contents

R

Spreader Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

Adjustable Spinner Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Spreader Calibration Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52-53

Warranty & Warranty Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54-55

TS-700-E / GR / P & TS-1200-E / GR / P Gate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

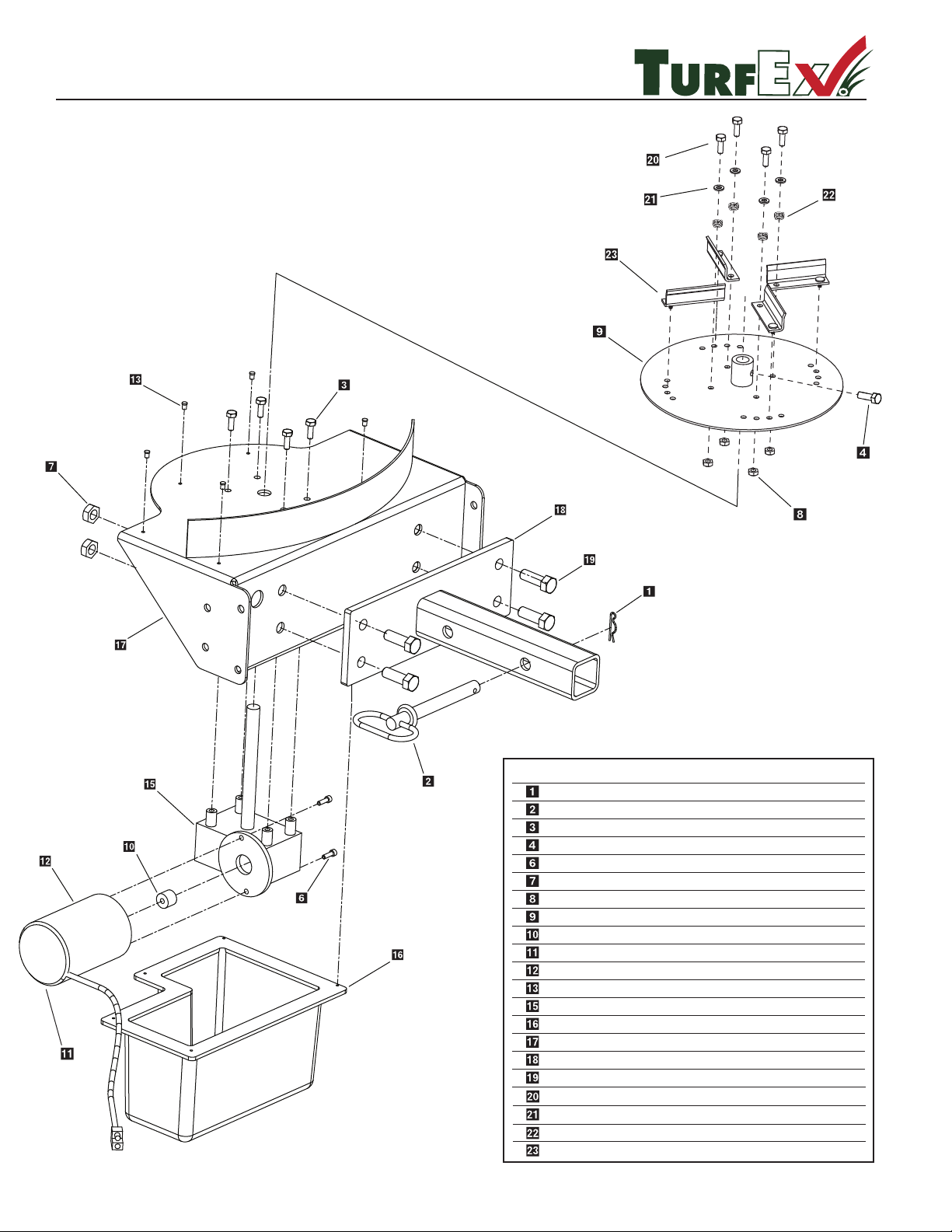

TS-700-GR / TS-1200 GR Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

TS-700-GR & TS-1200-GR Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30-31

Calibration Speed Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

Calibration Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

. TPM-175 Three Point Mount

Blank Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40-41

Blank Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34-35

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information and Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

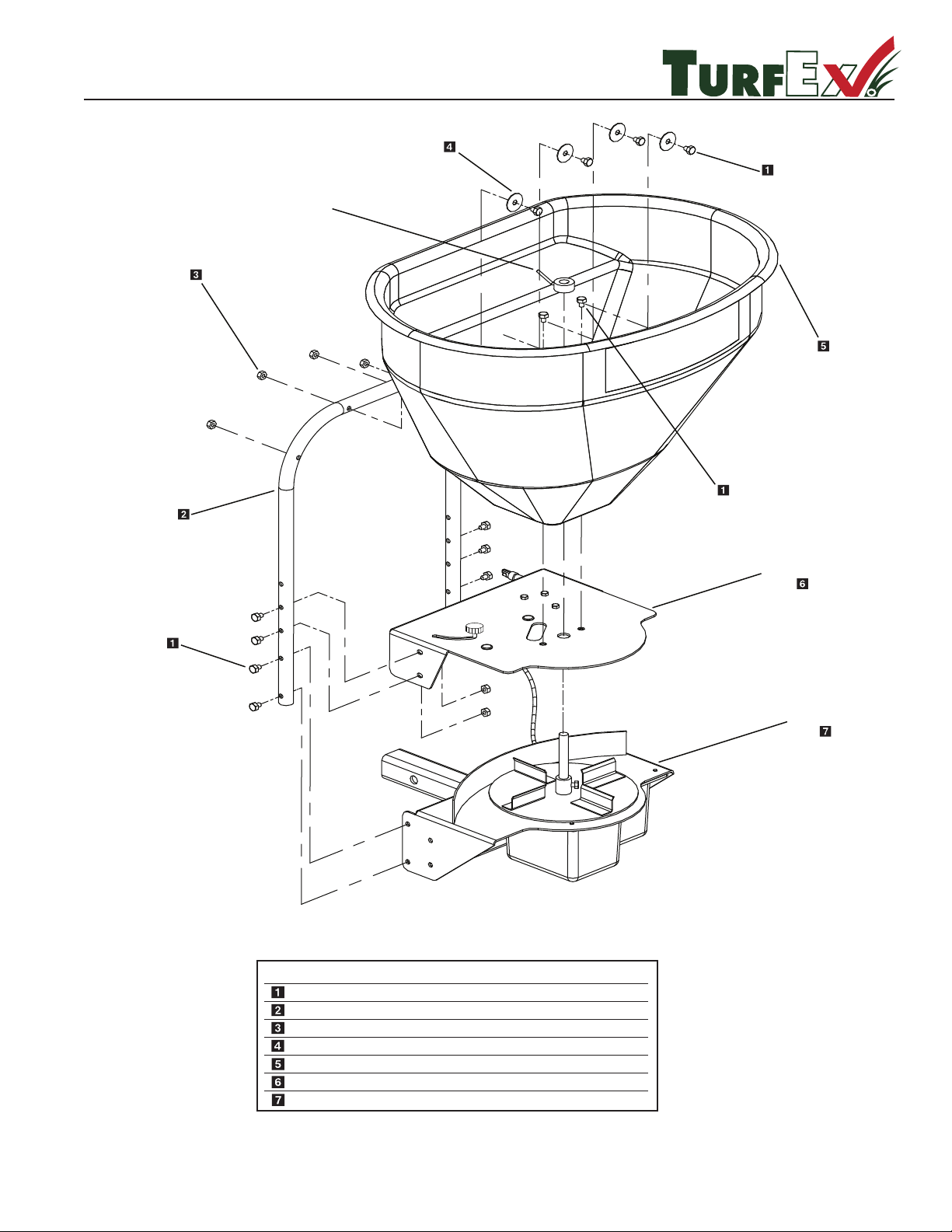

TS-300-E / TS-300-EG Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TS-700-E / P Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

TS-1200-E / P Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

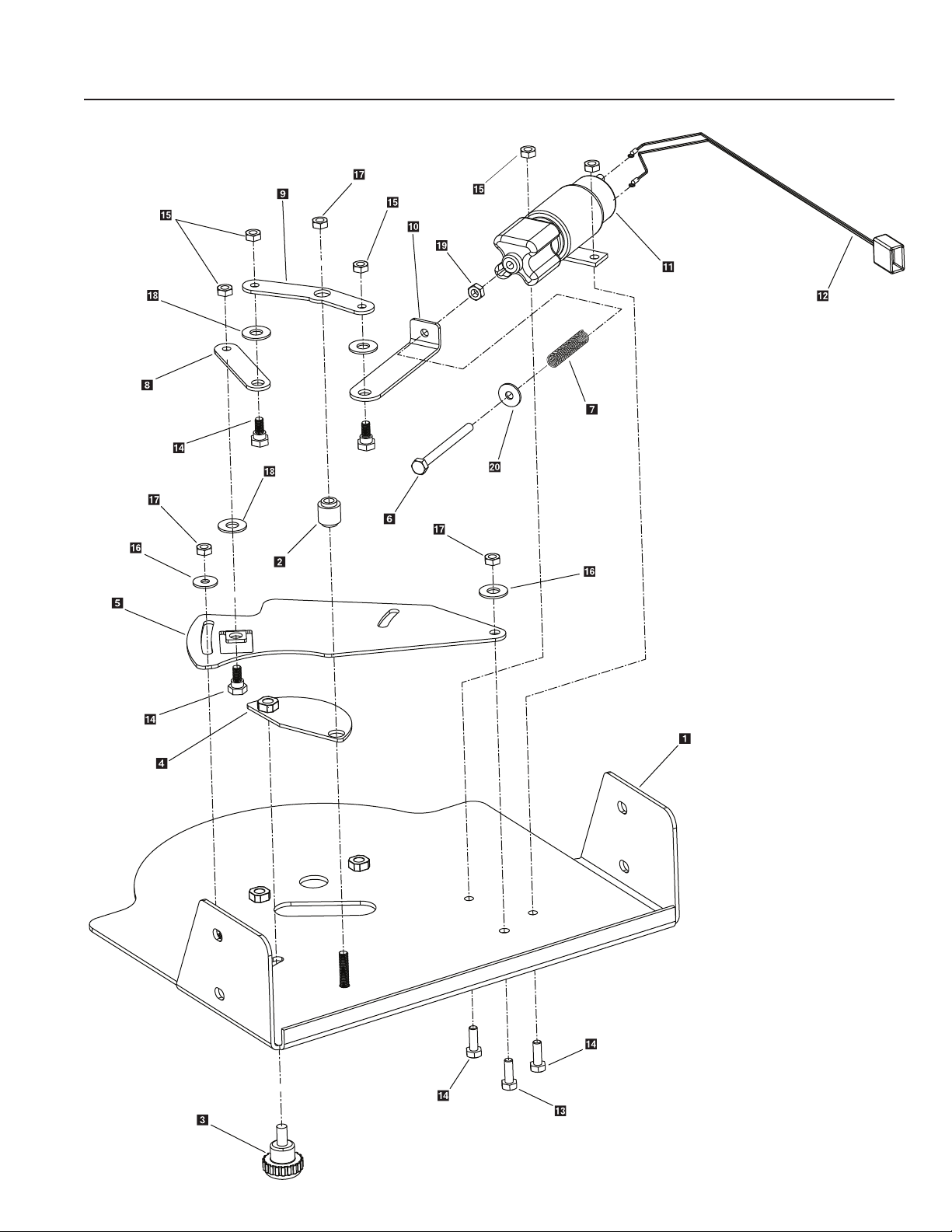

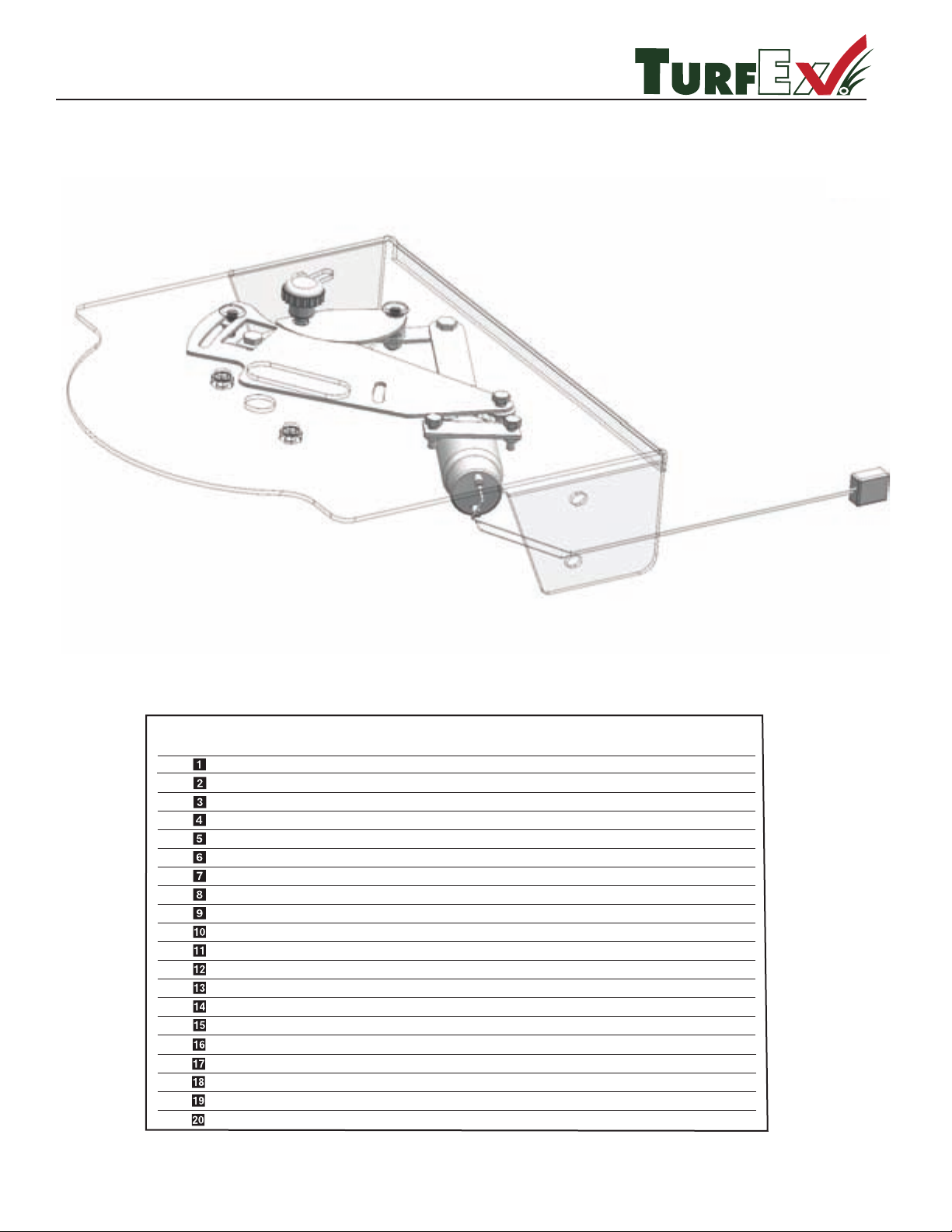

TS-700-E / P & TS-1200-E / P Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TS-700-E & TS-1200-E Electrical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7

8-21

26-27

28-29

33

Accssories & Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. SDK-020 Side Deector Kit

. ADF-020 Adjustable Deector Kit

. DRM-175 Drop Mount Receiver

. TLR-175 Trailer Mount

. UTM-175 Utility Mount

. VAR-020 Variable Speed Control Kit (TS-300,TS-700-E & TS-1200-E Only)

. ZTR-175 Zero Turn Radius Mower Mount

42-50

1 — 2

© Trynex International 2009 L1302

1 — 3

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and use of

this spreader.

Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information) before

attempting any procedure contained herein.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this SAFETY ALERT SYMBOL to pinpoint characteristics

that, if NOT carefully followed, can create a safety hazard. When you see this symbol in this manual or on the

machine itself, BE ALERT! Your personal safety and the safety of others is involved

.

Dened below are the SAFETY ALERT messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment.

R

© Trynex International 2009 L1302

© Trynex International 2009 L1302

1 — 4

General Information

CONGRATULATIONS!

The Turfex product you have purchased is an example of turf management product at its nest! Your Turfex product’s, self

contained design is a trademark of all Turfex products. Here’s why...

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your Turfex product.

RELIABILITY:

High impact linear low density polyethelyne hopper, state-of-the-art electronic dual variable speed control, custom engineered

powder coated frame, maximum torque 12 volt motor coupled to a custom engineered transmission found only on Turfex products.

VERSATILITY:

Multi-use capabilities allows spreading of a variety of materials.

WARRANTY:

Two years parts and labor from date of installation.

The benets you are about to recognize are that of time, money and eort.

We welcome you to the world of Turfex Performance.

Registration

Record the following information in this manual for quick reference.

Spreader

Model Number _____________________________________________________________________________________

Serial Number ________________________________ Controller Serial Number ____________________________________

Date of Purchase ___________________________________________________________________________________________

Dealer Where Purchased _____________________________________________________________________________________

When ordering parts, the above information is necessary. This will help to insure

that you receive the correct parts.

At the right is a diagram of the ID tag. This tag is located on the frame

(where applicable).

Please ll out the warranty card with all the necessary information to validate it. This will also give us a record so that

any safety or service information can be communicated to you.

SER. NO.______________________

TRYNEX INTERNATIONAL

Warren, MI 48089 (800) 725-8377

R

R

1 — 5

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who

ha

ve any part in the preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety precautions.

If anything happens to mark or destroy the decals, please request new ones from Trynex.

Unit must be strapped down and locked into position before operating vehicle.

Never exceed the Gross Vehicle Weight Rating of vehicle. Failure to do so may limit a vehicles

handling characteristics.

Never attempt to take a unit o with material in it.

Do not drive at excessive speeds when loaded spreader is attached to vehicle. Braking distances may

be decreased and handling characteristics may be impaired at higher speeds.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on spreader or mount.

Always shut o vehicle and power source before attempting to attach or detach or service spreader

unit. Be sure vehicle/power source is properly braked or chocked.

Always keep hands, feet, and clothing away from power-driven parts.

Remember

it is the owner’s

responsibility to communicate information on safe usage and proper maintenance of all equipment.

Always make sure personnel are clear of areas of danger when using equipment. Maintain 60'

distance from all bystanders when operating the spreader.

Inspect the unit periodically for defects. Parts that are broken, missing, or worn out must be replaced

immediately. The unit, or any part of it should not be altered without prior written permission from

the manufacturer.

Never use with foreign debris in the spreader. These units are designed to handle clean,

free-owing material.

Note: Can not spread water softner salt.

R

© Trynex International 2009 L1302

© Trynex International 2009 L1302

1 — 6

Safety

(continued)

Al

ways inspect pins and latches whenever attaching or detaching spreader, and before traveling.

Never leave material in hopper for long periods of time. Be aware that all ice melters and fertilizers

are hygroscopic and will attract atmospheric moisture and harden up.

Remember, most accidents are preventable and caused by human error.

Exercising of care and

precautions must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medication that might alter your

judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this could result in

serious injury to the eyes.

R

© Trynex International 2009 L1302

1— 7

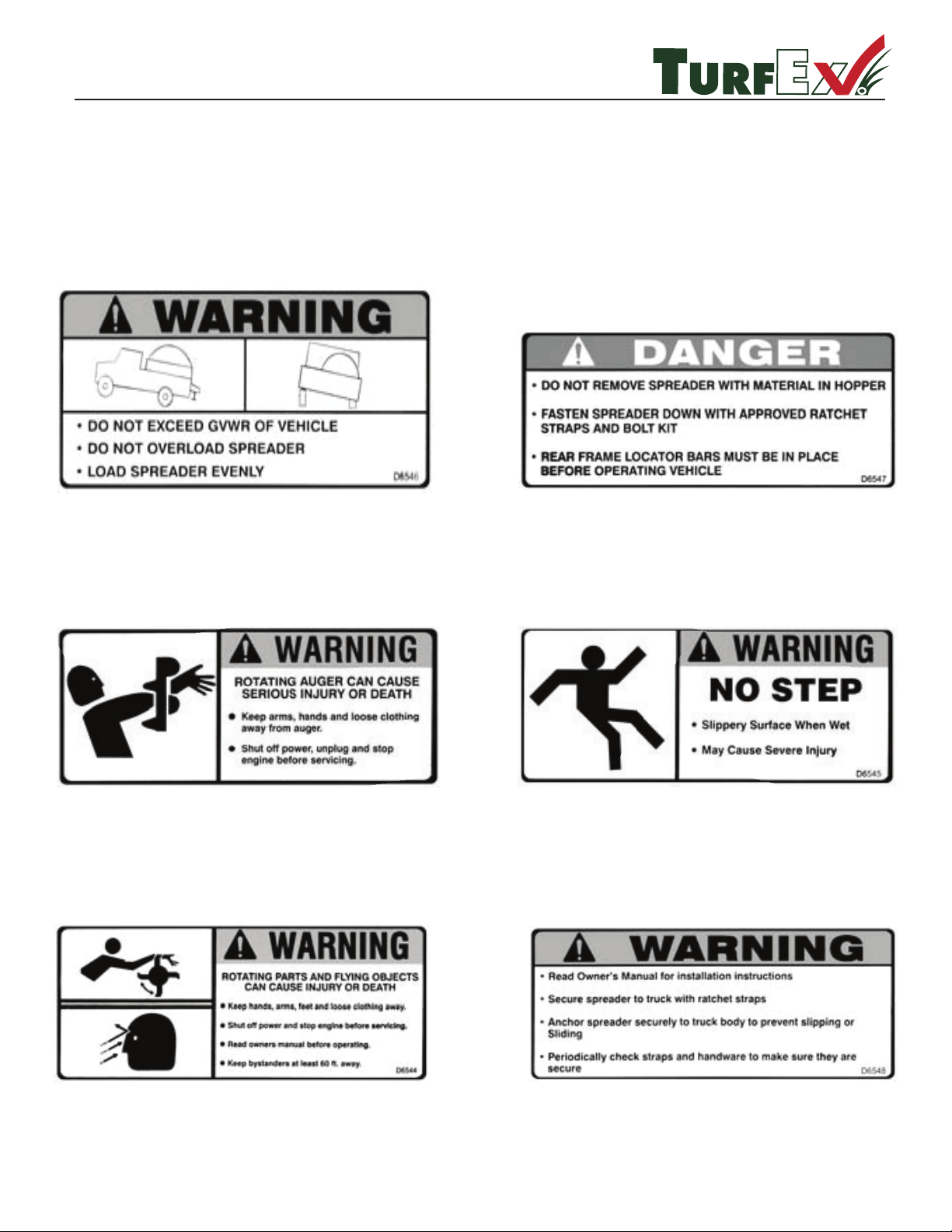

Safety and Warning Labels

D 6546

D 6548

D 6335

D 6544

D 6545

D 6859

All Turfex products have warning labels instructing you about certain safety issues you should be aware of. Below are

examples of what to look for and familiarize yourself with. In the event that a label is lost or removed for renishing

reasons, you may obtain new ones from Turfex.

R

© Trynex International 2009 L1302

1 — 8

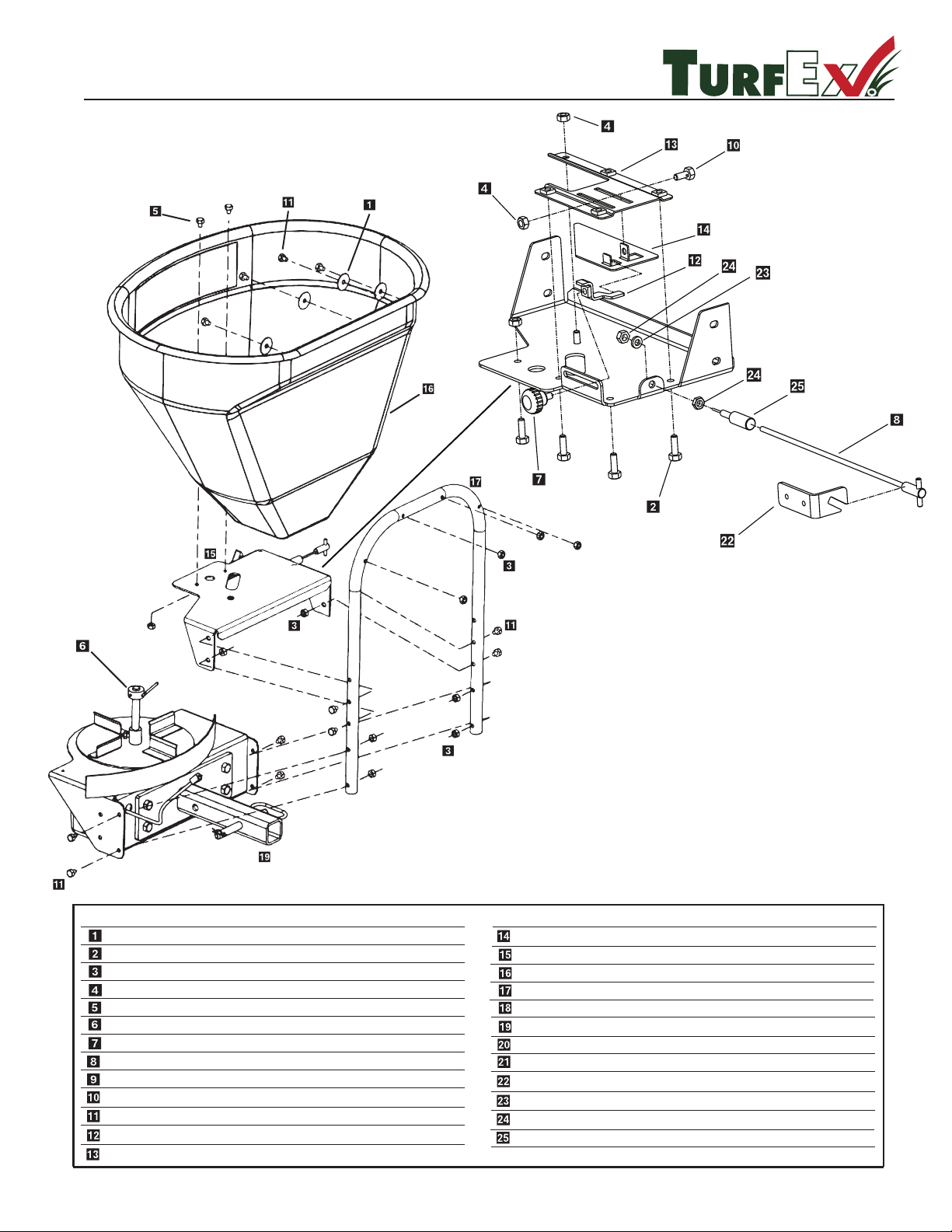

TS-300

Main Assembly Views

R

© Trynex International 2009 L1302

1 — 9

TS-300

Exploded View

R

.ytQ noitpircseD .oN traP yeK

D 4318 3/8" Fender Washer 4

T 15049 5/16-18 x 1/2” Hex Bolt SS 2

14 utnkcoL "61/5 8316 D

1 t SSuN xeH 61 - "61/5 8616 D

1 bonK etaG 2036 D

.ytQ noitpircseD .oN traP yeK

1

kcarT etaG redeeS

e 1dilS etaG redeeS 5076 D

4076 D

1 reppoH redeeS 051 9076 D

D 6418 5/16" - 18 x 1" Hex Bolt SS 2

D 6304 T-Handle Cable - 10' 1

D 6305 Bulkhead Cable Fitting 1

D 6308 5/16" - 16 x 3/4" Bolt w/Hole SS 1

D 6462 5/16" - 18 x 1-3/4" HHCS 12

D 6703 Gate Indicator / Stop 1

D 6706 Seeder 400 Gate Deck 1

D 6712 Hopper Tube Support 1

D 6480 Transmission Weldment 1

D 6485 Light Duty Receiver Mount 1

D 4116 1/2"-13 x 1-1/2" Hex Bolt 4

4 tuN kcoL "2/1 0214 D

1 T 15036

Cable Mounting Bracket

T 15051

T 15052

T 15050

3/8 Internal Star Lock Washer

3/8-24 Jam Nut SS

C

able Fitting

1

1

1

D 6705 Agitator 1

© Trynex International 2009 L1302

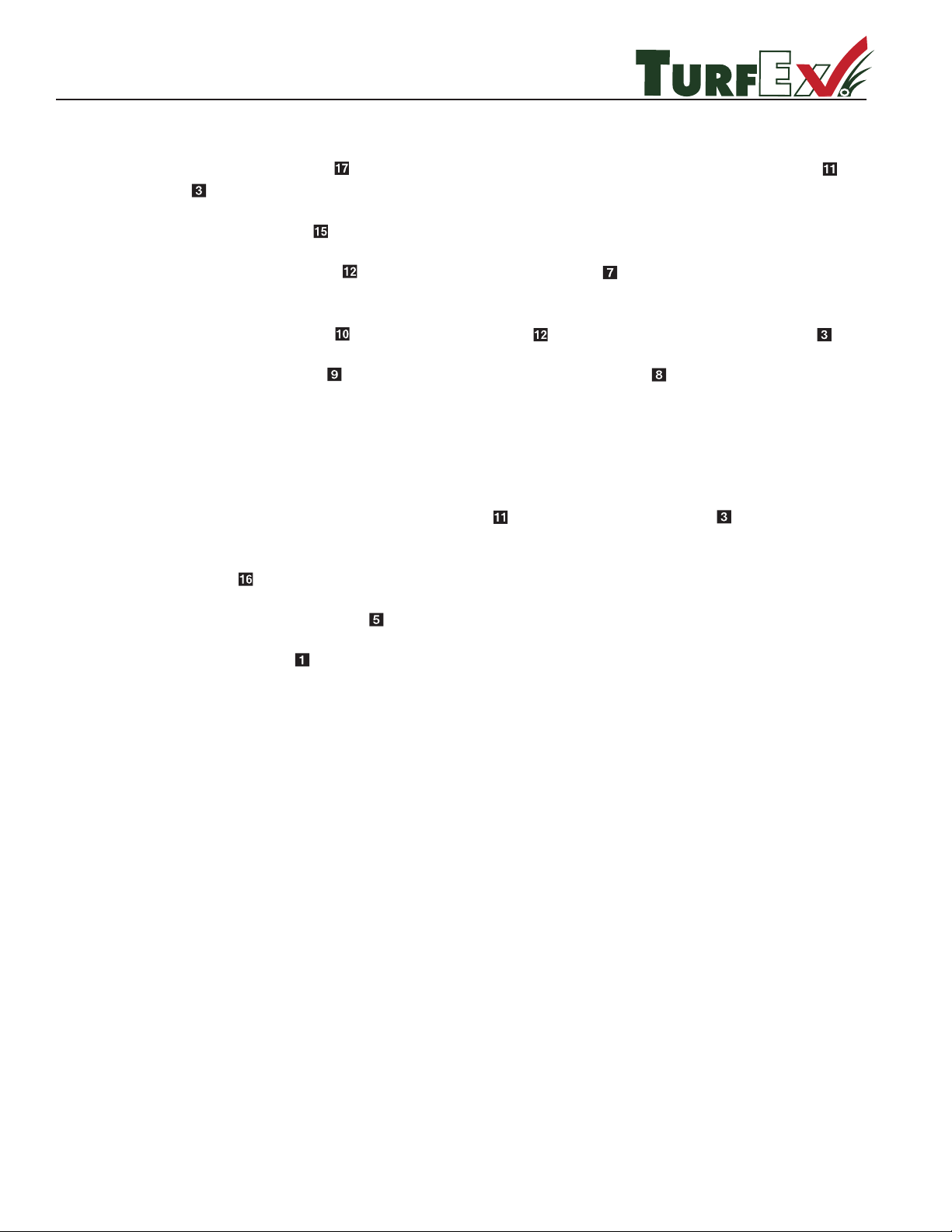

Assembly Instructions (refer to digram on page 1-9)

Step

1: Attach hopper tube support (D 6712)

to complete drive assembly using (4) 5/16"-18 x 1-3/4" hex bolt (D 6462)

and (4)

5/16" lock nut (D 6138)

. Use (2) holes at bottom end of tube.

Step 2: Place spreader gate deck (D 6706) upside down on table.

Step 3: Assemble gate indicator/stop (D 6703)

on stop slide with gate knob (D6302)

. Gate stop must be on the inside of deck where

it will stop the track.

Step 4: Insert (1) 5/16 bolt with hole (D 6308)

through gate slide (D 6705)

. Finger tighten (1) 5/16" locknut (D 6138)

on bolt.

Step 5: Take bulkhead cable tting (D 6305)

and screw it onto T-handle cable - 10' (D 6304)

rubber coating.

Step 6: Place assembly through tab on gate deck. Tighten down with supplied washer and nuts.

NOTE: There should be a nut on either

side of tab.

Step 7: Lower gate assembly over spinner shaft. Spinner shaft must go through 5/8" hole on deck. Shaft to be centered in hole.

Step 8: Fasten deck to hopper tube using (4) 5/16" hex bolts (D 6462)

and (4) 5/16" locknuts (D 6138)

NOTE: You must rst

tighten bottom bolts, pull front of deck up, then tighten top set of bolts.

Step 9: Place hopper (D 6709)

on deck. 5/8" hole must be used for spinner shaft.

Step 10: Finger tighten (2) 5/16 x 1" bolts (D 6166)

through bottom of hopper.

Step 11: Place (4) at washers (D 4318)

over hex bolts (D 6462). Place bolts through hopper back and in through tube support.

Tighten with (4) 5/16" locknuts.

Step 12: Tighten bolts in bottom of hopper.

Step 13: Place agitator (D 6405) on spinner shaft. Tighen to middle of at with short allen key.

Step 14: Attach receiver mount (D 6485) to transmission weldment (D 6480) using (4) 1/2" hex bolts (D 4116) and (4) 1/2" lock

nuts (D 4 120).

CABLE INSTALLATION

Step 1: Place unit on vehicle where it will be permanently used. Place hitch pin in hitch so unit does not move.

Step 2: Route T-handle to desired operating location. There cannot be any bends or sharp corners.

Step 3: Take T-handle out of sleeve. Take nuts and washer o of sleeve.

Step 4: Drill holes to mount T-handle mounting bracket. Mount T-Handle to bracket.

Step 5: Close gate slide all the way.

Step 6: Re-insert cable handle and wire all the way. Aim through bolt with hole and tighten bolt.

1 — 10

TS-300

R

© Trynex International 2009 L1302

1 — 11

TS-300

Wiring Diagram

R

TS-300 Wiring Instructions

Step 1: First, install switch at desired location.

Step 2: Run spreader/vehicle harness from the rear of vehicle to switch area. Attach the female spade red wire to the switch. Leave the

black wire for Step 5.

Step 3: Route the power harness from the battery to the switch/control.

Step 4: Attach the red lead to the positive side of the battery and the black lead to the negative side of the battery.

Step 5: Attach the female spade red wire on switch terminal. Using 3" double female black wire jumper attach the black wire from the

power harness to the black wire of the vehicle harness.

Step 6: Install rubber weatherproof boot on switch before nishing installation.

Step 7: Insert dielectric grease on terminals of SAE plug at rear of vehicle.

20

AMP

BATTERY

REMOVE JUMPER FOR USE

WITH VC-020 VARIABLE

SPEED CONTROLLER

DOUBLE FEMALE

3" JUMPER

Key Part No. Description Qty.

D 6184 On/O Switch 1

D 6406 Rubber Switch Boot 1

D 6716 Wiring Harness 1

D 6425 Fuse Holder 1

D 6482 20 Amp Fuse 1

D 7105 3/8" Ring Terminal 1

© Trynex International 2009 L1302

1 — 12

TS-300-EG

Main Assembly Breakdown

R

.ytQ noitpircseD .oN traP yeK

D 4318 3/8" Fender Washer

14

14

8316 D

D 6462 5/16" - 18 x 1-3/4" HHCS

5/16" Lock Nut

1 2.7 Cu/Ft Seeder Hopper Yellow 6753 D

1

Electric Gate Assembly

Drive Assembly

1

D 6712 Hopper Tube Support 1

4

SEE DRIVE EXPLODED

VIEW

SEE GATE EXPLODED

VIEW

SEE DRIVE EXPLODED

VIEW

TS-300-EG / TS-300

R

Drive Assembly

Key Part No. Description Qty.

D 4135 2-5/16" Hair Pin Clip 1

D 4136 5/8" x 5-1/2" Hitch Pin 1

D 6131 1/4"-20 x 1/2" Serr. Flange Bolt 4

D 6133 5/16-18 x 1/2 HHCS 1

D 6172 #10-32 x 5/8" Serr Flange Bolt 2

10 Inch Spinner Plate 1

D 6232 Motor Drive Coupler 1

D 6410 Motor 12 Volt DC (TS-300 Motor) 1

D 6487 #8 x 1/2" Hex Head Sheet Screw 5

D 6715 Transmission 14.5 to 1 1

D 7153 Plastic Bottom Cover 1

D 6480 Transmission Weldment 1

D 6485 Light Duty Receiver Mount 1

D 4116 1/2"-13 x 1-1/2" Hex Bolt 4

1/4-20 x 1-1/4 Panhead MSSS 4

D 4120 1/2" Lock Nut 4

T 30218

T 15014

T 30217

T 15031

T 15016

1/4 Flat Washer SS 4

Tension Spring 4

Adjustable Flite 4

1/4-20 Nylock Nut SS 4

D 6106

Motor 12 Volt (TS-300-EG) 4

T 15030

Complete Drive Assembly Part Number A-4039

( Note: Does Not Include Hich Mount )

© Trynex International 2009 L1302

1 — 13

TS-300-EG

Electric Gate Control System

1 — 14

© Trynex International 2009 L1302

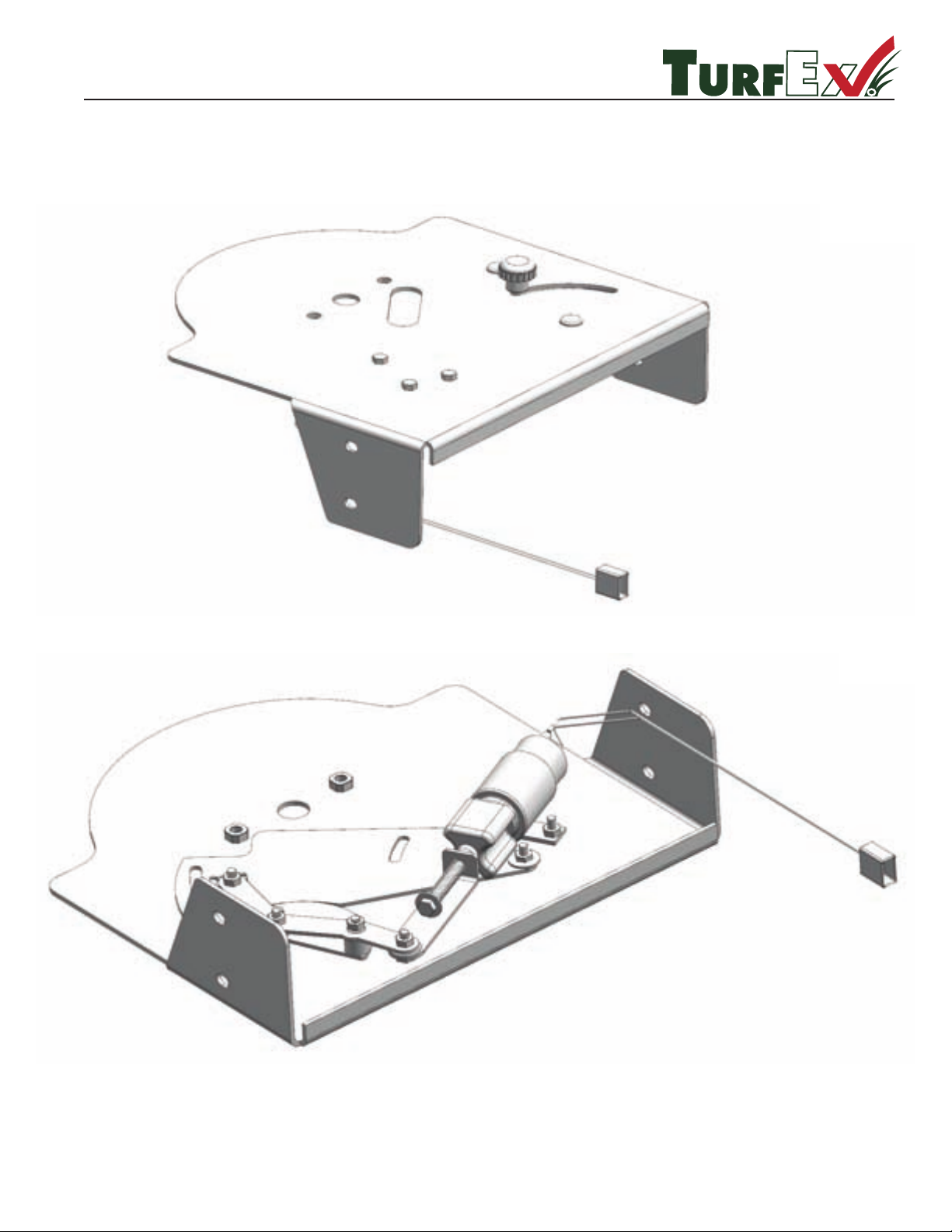

TS-300-EG GATE

R

.ytQ noitpircseD .oN traP yeK

1

T-15029 Gate Stop Knob

T-15001 Gate Deck

T-15003 Gate Stop

T-15002 Gate Slide

T-15012 1/4-28 x 3 SHCS SS

T-15009 Stainless Spring

T-15007 Stainless Arm #3

T-15006 Stainless Arm #2

T-15005 Stainless Arm #1

T-15008 12 Volt Actuator

T-15020 Actuator Power Cord

D 6166 5/16-18 x 1 Hex Bolt

T-15021 1/4-20 x 3/4 PPH MS Stainless

T-15016 1/4-20 Nylock Stainless

1

1

1

1

1

1

1

1

1

1

1

1

5

4

T-15017 5/16 Nylon Flat Washer

T-15018 5/16-18 Nylock Stainless

T-15023 1/4” Nylon Flat Washer

T-15013 1/4-28 Jam Nut Stainless

T-15014 1/4” Flat Washer Stainless

2

4

3

1

1

T-15037 Gate Stop Spacer

Parts Breakdown

© Trynex International 2009 L1302

1 — 15

TS-300-EG

R

Gate Assembly Views

1 — 16

© Trynex International 2009 L1302

TS-300-EG

R

Front & Rear Assembly Views

© Trynex International 2009 L1302

1 — 17

Loading...

Loading...