Page 1

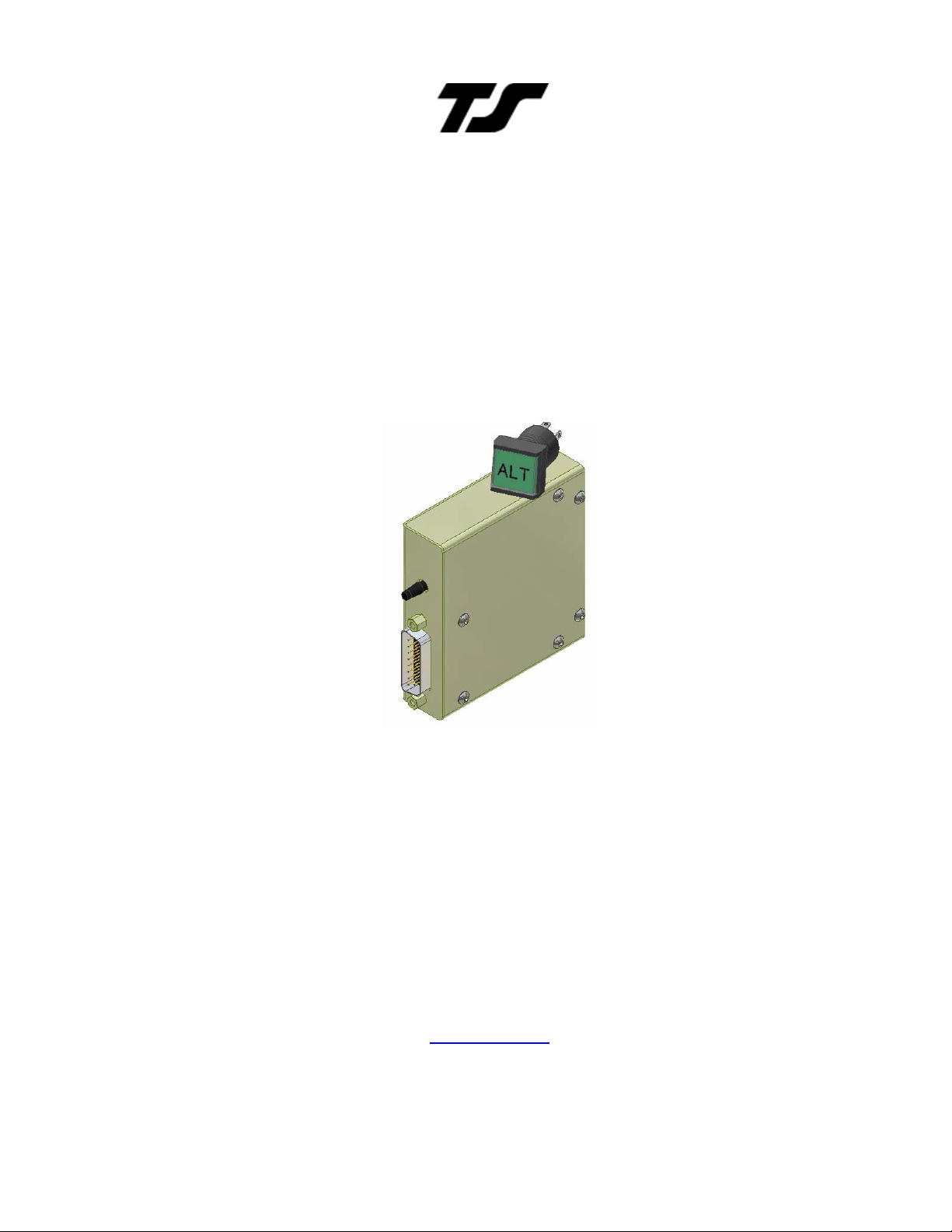

Altrak Altitude Hold &

Altrak VS Altitude Hold

Installation & User Guide

8300-014 Rev B

TRUTRAK FLIGHT SYSTEMS

1500 S. Old Missouri Road

Springdale, AR 72764

Ph. 479-751-0250 Fax 479-751-3397

www.trutrakap.com

Page 2

Revision

Date Description

Page #

INSTALLATION MANUAL

For

Altrak VS & Altrak Altitude Hold

TABLE OF CONTENTS

Mechanical Considerations ...................................................................................... 1

RFI/EMI considerations ........................................................................................... 2

Altrak Programmer Mounting / Setup / Ground Test ............................................ 2

Altrak VS control panel installation ........................................................................ 3

Power Up ................................................................................................................... 3

Basic Altrak Operation ............................................................................................. 4

Altrak VS Operation................................................................................................. 5

Electrical Pin out ....................................................................................................... 6

Altrak Wiring Diagram ............................................................................................ 7

Altrak VS Wiring Diagram ...................................................................................... 8

Trouble Shooting ...................................................................................................... 9

Installation Diagram ................................................................................................11

Assembly Diagram ...................................................................................................12

RETURN MERCHANDISE POLICY AND PROCEDURE ... Error! Bookmark not

defined.

A

B 01/10/2009 New schematics & Installation notes 7 - 12

07/01/2008 Initial Release

Page 3

Mechanical Considerations

The installation information in this section is extremely important and

must be clearly understood by the installer. Improper servo installation

or failure to observe and diagnose installation problems prior to flight

can result in extremely serious consequences, including loss of ability

to control the aircraft. If there are any questions on the part of the

installer it is mandatory to resolve these questions prior to flight of the

aircraft.

Most modern experimental aircraft use push-pull tubes to drive the primary controls. These tubes generally

have a total travel of 3" or less; therefore, it is best to connect the autopilot servo to the primary control by the

same method. This connection consists of an arm on the servo connected by a push-pull rod to the primary

control. Rod-end bearings are required on each end of the push-pull rod.

The servo arm must not rotate even near to the point called OVER CENTER, the point at which the

primary aircraft control would lock up. Some aircrafts mechanical primary control installations will not

allow this to occur and do not need the servo stops.

This is a condition that would result from the servo being back driven when the pilot operates the

controls, or from the servo itself driving the controls to a stop. To protect against this mechanical

stops are supplied with the servos. These stops are drilled so that they can be mounted at different

angles as required (18° intervals).

In addition to the proper use of the stop it is important to know the amount of travel on the primary

control that the servo can handle. With the push rod connected to the outer most hole (1 1/2") the

travel on the primary can not exceed 2 1/2", the intermediate hole 2 1/16", and the inner hole 1 5/8".

It is important to note that the servo travel should be very nearly the same in both directions. In most

cases this means that the servo arm needs to be perpendicular to the push rod but there are

exceptions such as the RV-4 and RV-8 installations.

There will be installations in which space does not permit the use of the stop. When this is done the

aircraft's primary control stops must be positive and care must be taken to be sure that the servo

drives the push rod the same distance in both directions, and that the travel limits of the servo arm

are not exceeded.

There are installations in which the travel of the push-pull tube exceeds the allowable 2 1/2". For such

installations, the drive can be applied to a bell crank at a radius point that moves the desired 2 1/2" of

maximum allowed travel in the outer most hole of the arm.

When there is no way to have a drive point of less than 2 1/2" or when the primary control is cable-driven it is

necessary to use the capstan-cable servo drive. When this is done the servo should be mounted so that the

1/16" diameter cable which wraps around the capstan when extended parallel to the primary cable is

approximately 3/16" from the primary cable. If the primary control travel does not exceed 5" the cable-locking

pin will be 180° away from the point at which the cable leaves the capstan. When the primary control is at the

neutral point this means the total cable wrap around the capstan is 360°. If the primary control travel is

greater than 5" the cable wrap is 720°and the pin is adjacent to the output point when the primary control is at

the neutral point. The cable clamps when properly installed will not slip and thus get loose, but it is desirable

to nico press or swedge a fitting onto the cable so as to provide added assurance that the cable will not

become slack. If the bridle cable is not sufficiently tight there will be lost motion in the autopilot drive. This

will result in hunting (oscillation).

TruTrak Flight System 1 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 4

RFI/EMI considerations

The autopilot programmer is shielded and does not generate any appreciable level of electromagnetic

interference. More over, the servo lines (except for power and ground) are low-current and cannot contribute

to RF interference. The servo power and ground lines do have switching currents through them, but so long

as there are no parallel runs of servo power and ground lines with such things as poorly-shielded antenna

lines or strobe light power lines, there is no need to shield the servo harnesses.

The autopilot itself has been internally protected from RF interference and has been tested under fairly

extreme conditions, such as close proximity to transmitting antennas. However, it is always good practice to

insure that such antennas are properly shielded and not routed directly over or under sensitive panel-mounted

electronic equipment. Most problems in this area are the result of improper RF shielding on transmitting

antennas, microphone cables, and the like. The most sensitive input to the autopilot is the Control Wheel

Switch input. This line should not be routed in parallel with transmitting antennas or other sources of known

RF interference. If necessary, it can be shielded with the shield connection to pin 15 of the autopilot

connector.

Altrak Programmer Mounting / Setup / Ground Test

Must be performed before first flight

After the servo is installed check to see which direction the servo turns to move the elevator up. If the servo

turns counter-clockwise (when looking at the servo arm or capstan) to drive the elevator up then no jumper is

necessary on the programmer. If the servo turns clockwise for elevator up then the pitch servo reverse

jumper must be installed. See Pin 4 on the wiring table for instructions on how to wire the pitch servo reverse

jumper.

The programmer has a static port located next to the connector. The static port can be connected to the

static system. For pressurized aircraft it is necessary that the static system be connected to the Altrak static

port. For most other aircraft the static connection is optional.

Before mounting the Altrak it should be tested for proper operation. After the servo installation and wiring are

complete and the Altrak programmer is plugged in, the test can be performed. When the Altrak is powered-up

it is necessary that the Altrak be stationary. The attitude of the programmer is not important during the

power-up phase. With the Altrak programmer secured turn on the master switch and avionics master so the

Altrak has power. During the power-up phase of operation (the first ten seconds that the Altrak has power)

the ALT button will flash. Next engage the Altrak by pressing the ALT button. With the THIS SIDE RIGHT

sticker facing you rotate the programmer module clockwise to simulate a nose down attitude. The servo

should cause the elevator to move up to correct for the simulated nose down attitude. Rotating the

programmer counter-clockwise should drive the elevator down.

Mounting the programmer module of the Altrak can be done in any location; the only requirement that must be

met is that the side of the unit label "This side right" must face the right side of the aircraft. This is also the

side that has six (6) screws on the surface. The rotational position is not important as long as the right side is

facing right. The side with the sticker also must be parallel with the direction of flight. The mounting holes on

the programmer are 1-1/2 inches apart, and are tapped for a 6-32 thread, use any screw length up to 1" in

length. The engage/disengage pushbutton which also serves as the enunciator can be mounted anywhere in

the panel.

The activity setting (activity is the amount of servo movement for a given amount of programmer movement)

in all RV type aircraft will be at medium activity setting. If more or less activity is required, it is necessary to

use a jumper as per the wiring diagram to change the activity setting.

MOVE TAIL UP AT LEAST A FOOT AND ELEVATOR MUST

MOVE UP AT SAME TIME. MOVE TAIL DOWN AT LEAST A

FOOT AND ELEVATOR MUST MOVE DOWN AT SAME TIME.

TruTrak Flight System 2 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 5

Altrak VS control panel installation

The Altrak VS comes with a reversible control panel, which can be mounted either horizontally or vertically.

The engage/disengage button requires a 5/8” diameter hole; the same size hole can be used for the mounting

of the VS control knob. A template for the two holes is included with this manual. When putting the knob on

the VS control potentiometer, the pointer must be pointing at the larger white mark on the control panel. This

is shown below for both the horizontal and vertical mounting orientations.

Power Up

When powering up the autopilot ensure that the aircraft is still

for 10 seconds.

The power up of the autopilot takes approximately ten seconds. During the power up cycle it is very

important that the aircraft be as still as possible for the initialization of the internal gyro. While the

autopilot is in the power up phase, the enunciator will flash rapidly for approximately ten seconds. Once the

power up phase is completed, the enunciator will remain unlit.

TruTrak Flight System 3 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 6

Basic Altrak Operation

Once the aircraft is at the desired altitude, and trimmed for level flight, the altitude hold can be engaged.

Pushing the ALT button will engage the Altitude hold. If in severe turbulence or when the aircraft is out of trim

and the servo may run out of torque, in this case the current altitude and the selected altitude may be

different. When the difference between the current altitude and the initial selected altitude is more than

approximately 50 feet the light in the switch will flash, rapid flashing of the light for below altitude and slow

flash of the light for above altitude. If an out of trim condition is suspected, disengage the altitude hold, re-trim

the aircraft, and re-engage the altitude hold. If turbulence is the cause for the altitude departure the Altrak will

fly back to the desired altitude automatically.

Changing the desired altitude can be done by simply disengaging the altitude hold, flying to the desired

altitude and re-engaging by pushing the ALT button. If on a long flight setting the barometer to the local

setting will result in a difference in indicated altitude and the altitude selected by the Altrak. To correct the

altitude error, disengage the altitude hold, fly to the new desired altitude and re-engage the altitude hold.

If the optional trim sensing pitch servo has been purchased, the Altrak will enunciate the need to trim the

aircraft, with a rapid flash of the light in the switch for the need to trim up, and a slow flash of the light in the

enunciator for the need to trim down. If the Altrak is coupled with a Digitrak / Pictorial Pilot, the Altrak can only

be engaged if the Digitrak / Pictorial Pilot are engaged. When the control wheel switch is pushed, the Digitrak

/ Pictorial Pilot will enter control wheel steering mode as normal, but the Altrak will remain engaged and

holding altitude while the pilot manually flies the aircraft to the desired track. Upon release of the control

wheel switch the Digitrak / Pictorial Pilot will re-engage and synchronize to the track being flown at the time,

and the Altrak will remain engaged throughout the maneuver. It should be noted that the Altrak will lose some

altitude while the aircraft is turning. The altitude loss could be as much as 50 to 100 feet depending upon the

bank angle. The Altrak will recover the lost altitude on it's own after the turn is completed, or if the aircraft is

in a sustained turn.

Because Altrak does not receive bank angle information, it will lose some

altitude in turns. If the bank angle is less than 30 degrees the altitude loss will

be less than 50 feet, for this reason it is recommended that the bank angle be

kept below 30 degrees.

TruTrak Flight System 4 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 7

Altrak VS Operation

Note: Zero vertical speed (Altitude hold) must be selected or Altrak VS will NOT engage.

To engage the Altrak VS, ensure that zero vertical speed is selected on the VS control knob (The VS control

knob should be at the center detent.) Push the ALT button to engage the Altrak VS. When Altrak VS is

engaged it will be in altitude hold mode. If the aircraft is out of trim the light in the Altrak engage/disengage

button will enunciate the need for trim, with a rapid flashing of the light for trim up, and a slow flashing of the

light for trim down.

If Altrak is coupled with the Digitrak / Pictorial Pilot, the Altrak can only be engaged if the Digitrak / Pictorial

Pilot are engaged. When the control wheel switch is pushed, the Digitrak / Pictorial Pilot will enter control

wheel steering mode as normal, but the Altrak will remain engaged while the pilot manually flies the aircraft to

the desired track. Upon release of the control wheel switch the Digitrak / Pictorial Pilot will re-engage and

synchronize to the track being flown at the time, Altrak will remain engaged throughout the maneuver. It

should be noted that if Altrak is in altitude hold during this maneuver, it will lose some altitude while the

aircraft is turning. The altitude loss could be as much as 50 to 100 feet depending upon the bank angle. The

Altrak will recover the lost altitude on its own after the turn is complete.

Changing the desired altitude can be done by simply rotating the VS control knob to the right to command a

vertical speed climb, or to the left to command a vertical speed descent. The maximum possible vertical

speed in either direction is approximately 800 feet per minute. As when in the altitude hold mode, the Altrak

VS will always enunciate the need for trim, with a rapid flashing for trim up, and a slow flashing for trim down.

TruTrak Flight System 5 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 8

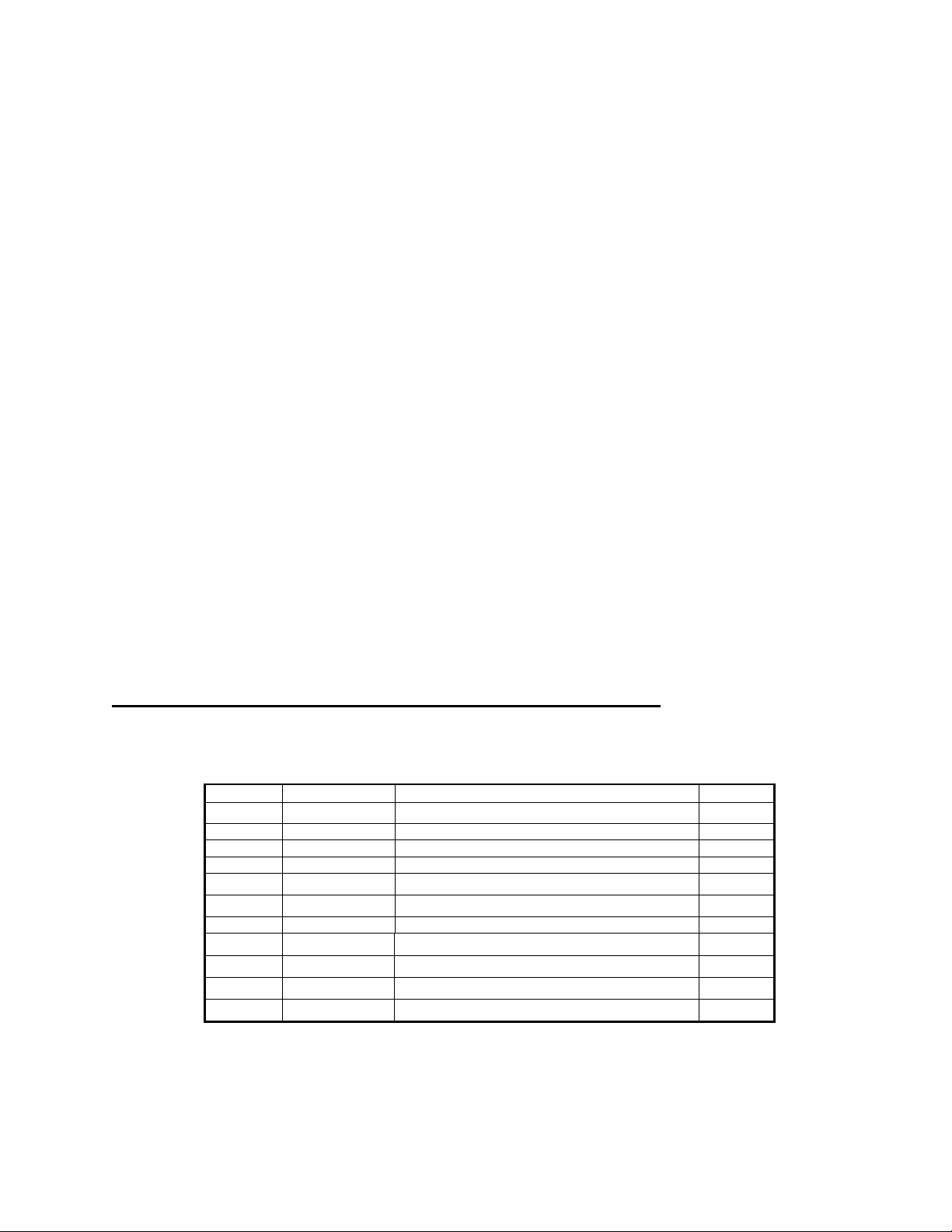

Electrical Pin-Out

P101

Function

Notes

1 Autopilot Master

(+12 to +14 V DC). The autopilot itself draws less than 0.3 ampere.

See note 3 on wiring

2 Control Wheel Switch

. Connect as shown in wiring di

See note 3 on wiring

3 On / Off Switch

. Connects to the illuminated push button module

4 Pitch Reverse Jumper

,

Direction of the servo arm / capstan rotation

See note 2 on wiring

5 Pitch Servo Trim Sensor.

A signal from the pitch servo to the autopilot which indicates

6 Engage Lamp /

LED

Connects to

LED which connects to

470 ohm resistor

. See Module Rear View

7 Pitch Servo Torque Control

. A signal from the autopilot to the pitch servo which sets

8 VS control

inpu

t from button assembly on panel.

VS Option only

9 AP On

. Connect to pin 7 on

Digitrak / Pictorial Pilot

/Pictorial Pilot (This function is

See note 3 on wiring

10

Activity Select

. Connect to ground for low activity, leave open for medium activity, and

See note 4 on wiring

11

Pitch Servo control lines

. These lines cause the stepping motor in the pitch servo to run

Do

NOT

attempt to

15 Ground Connection

. Provide #20 AWG to common grounding point.

The table below provides a brief explanation of each pin function on the main 15-pin connector P101.

Pin

Most of the current required by the system is used by the servo (up to 1Amp depending

on torque setting).

agram to a SPST momentary

switch located remotely to the autopilot for convenient disengage function.

present or absent, as follows:

Pin 4 open ( no connection) Servo CCW (counter-clockwise) → UP

Pin 4 Jumpered to pin 15 Servo CW (clockwise) → UP

an out-of-trim condition and its direction. (For use with trim sensing servo upgrade)

the amount of torque to be delivered by the servo.

only to be used if Altrak is coupled to Digitrak / Pictorial Pilot/Pictorial Pilot.)

connect to 12v for high activity

( as viewed from face of the servo body) for

UP elevator

diagram

diagram

diagram

on wiring diagram

diagram

diagram

in the appropriate direction at the desired velocity. They are small-signal lines and do not

12

have any substantial current-carrying capability or require any special shielding. Connect

13

to pitch servo as shown on wiring diagram.

14

TruTrak Flight System 6 Altrak Installation & User Guide

January 2009 8300-014 Rev B

reverse servo direction

by swapping wires

Page 9

BASIC ALTRAK WIRING DIAGRAM

TruTrak Flight System 7 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 10

ALTRAK VS WIRING DIAGRAM

TruTrak Flight System 8 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 11

ALT

ALT

Trouble Shooting

Problem Cause Corrective Action

LED will not blink

when power applied

LED blinks but will

not light up when pressed

ALT VS will not engage (

ALT LED light up)

No aircraft voltage and/or

ground to system

Engage signal not received

at module or DT/PP not

engaged if connected pin 9

Engage signal not received

at module or VS knob not

Correct power, ground

wiring

Check for low (ground) at

pin 3 when ALT switch

depressed

See above and/or check for

2.5 v at pin 8 at module

centered (2.5 v)

Aircraft pitches up or

down rapidly

Aircraft hunts up and

down

Weight of Module, switches, wires: .5 lb

Weight of servo 2.5 lb

Max voltage 14 volts

Max current with servo engaged 2 amps

Pitch servo is reversed Install or remove jumper to

ground pin 4

Activity not correct See note 3 (slow hunt

increase activity)

TruTrak Flight System 9 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 12

This page unintentionally left blank

TruTrak Flight System 10 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 13

Installation Diagram

TruTrak Flight System 11 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 14

Assembly Diagram

TruTrak Flight System 12 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 15

RETURN MERCHANDISE POLICY AND PROCEDURE

Under no circumstances should products be returned to TruTrak without first obtaining a Return of

Merchandise Authorization number (RMA #) from TruTrak. An RMA# may be obtained by contacting us at

866-878-8725.

Products that do not have an RMA # will not be processed.

Please include documentation stating the reason for the return and describing any symptoms, failure modes,

suspected causes of damage, diagnostics performed, data collected, etc.

Product(s) should be packaged in their original shipping containers. In lieu of this, they should be very

carefully packaged in containers suitable to protect them during transit. For your protection, items should be

insured for the full value. Note that damage caused during shipping will not be repaired under warranty.

The outside of the box must be clearly marked with the RMA # issued by TruTrak and the RMA # must also

be noted on the return documents.

Products will be returned to the customer at no charge via FedEx Ground or UPS Ground. If customer

requests expedited shipping (2nd Day or Overnight) they will be charged the shipping cost and must supply a

credit card number.

INTERNATIONAL SHIPMENTS:

Trutrak sends all International shipments with an insurance value on all products. Trutrak pays for shipping

only. The customer is responsible for any and all additional fees, duties, taxes associated with the shipment.

When sending products to Trutrak for repair or otherwise please be advised that the customer is responsible

for all charges and fees associated with shipment. For your protection, items should be insured for the full

value.

Trutrak states on all product returns “WARRANTY REPAIR AT NO CHARGE TO CUSTOMER.

A COMMERCIAL INVOICE VALUE OF $___ GIVEN FOR INSURANCE PURPOSES ONLY”

Please keep in mind that your government or another entity in your country may impose a charge for custom and/or

brokerage fees, duties and taxes on items received from the US. These charges do not originate from our company nor do

we benefit from them in any way. You are responsible for payment of all custom and brokerage fees, duties and taxes

that may be imposed when these goods are imported into your country.

Send ALL return shipments to:

TruTrak Flight Systems, Inc., 1500 South Old Missouri Road, Springdale, AR 72764 USA

Attention: Returns Dept. RMA#

Warranty On TruTrak Flight Systems Products

We here at TruTrak Flight Systems know how important it is to feel as though the customer is purchasing a

product that the manufacturer is going to stand behind. For this reason we want offer more than the basic one

year warranty that is standard to this industry. The warranty on all TruTrak products will be three years from

the date of purchase. Abuse and misuse of a product are not covered under this warranty. Modification to a

product may void the warranty, as well as carry a penalty when upgrading to another product. This three year

warranty will be for all products except the Pictorial Turn & Bank, which will continue to have a warranty of

one year from the date of purchase.

TruTrak Flight System 13 Altrak Installation & User Guide

January 2009 8300-014 Rev B

Page 16

TRUTRAK FLIGHT SYSTEMS

1500 S. Old Missouri Road

Springdale, AR 72764

POSTAL SERVICE ADDRESS

P.O. Box 189

Springdale AR 72765-0189

Ph: 479-751-0250 Fax: 479-751-3397

www.trutrakap.com

Loading...

Loading...