Page 1

EMS BU / EDM

Installation & Operation Manual

8300-065 Rev D

TRUTRAK FLIGHT SYSTEMS

1500 S. Old Missouri Road

Springdale, AR 72764

Ph. 479-751-0250 Fax 479-751-3397

www.trutra

kflightsystems.com

Page 2

INSTALLATION MANUAL

TABLE OF CONTENTS

MECHANICAL INSTALLATION....................................................................................1

PITOT AND STATIC CONNECTIONS...........................................................................1

RFI/EMI .............................................................................................................................1

OPERATING CONTROLS................................................................................................2

SETUP SCREENS .............................................................................................................4

UNITS................................................................................................................................4

CONFIG.............................................................................................................................5

GAUGES ............................................................................................................................6

SWITCHES........................................................................................................................7

GAUGES ............................................................................................................................7

CALIB................................................................................................................................7

SNSRS................................................................................................................................8

EFIS SOFTWARE UPDATES...........................................................................................9

SENSORS AND INPUTS..................................................................................................9

EMS ELECTRICAL PIN-OUT........................................................................................15

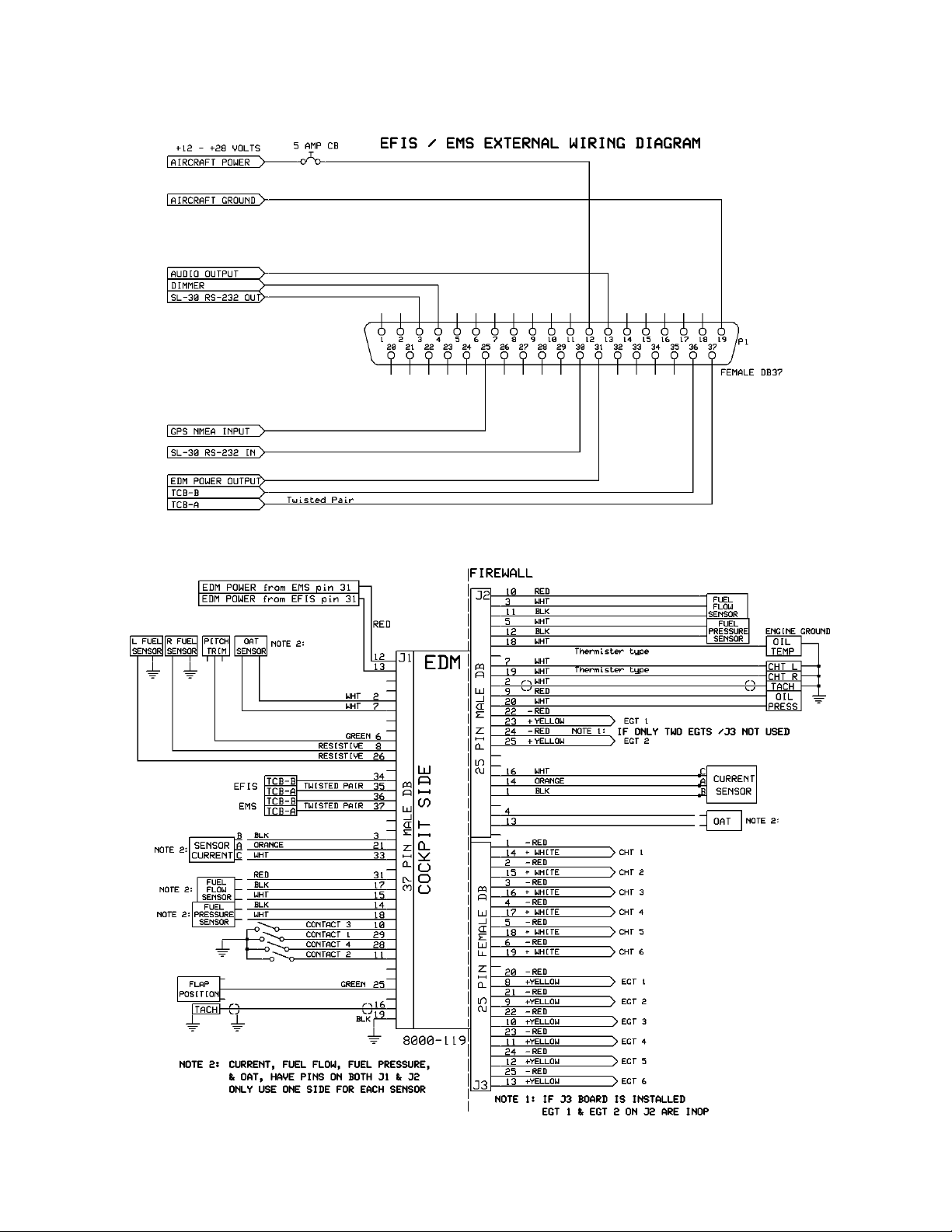

EMS / EDM BASIC WIRING DIAGRAM......................................................................17

EVEKTOR WIRING DIAGRAM....................................................................................20

EDM ELECTRICAL PIN-OUT.......................................................................................21

ROTAX WIRING DIAGRAM.........................................................................................21

EFIS AP / EMS / EDM BLOCK DIAGRAM..................................................................22

NINE CYLINDER EDM BLOCK DIAGRAM...............................................................23

RETURN MERCHANDISE POLICY AND PROCEDURE...........................................29

FOR

EMS / EDM

Revision Date Description Page #

A 1/1/2009 Initial Release

B 03/23/09 Schematic corrections 15, 18, 19

C 04/14/2009 Updated installation & display options ALL

D 06/16/2009 Added nine cylinder option 6, 18, 19, 23, 24

Page 3

Mechanical Installation Considerations

PROGRAMMER INSTALLATION

Mounting Considerations

The EMS Series unit is designed to mount in the aircraft instrument panel within view and reach of the

pilot. The primary unit location should minimize pilot head movement when transitioning between

looking outside of the cockpit and viewing/operating the EMS Series unit. Maximum recommended

viewing angle should be no more than 20 deg. The maximum mounting angle the EMS can accommodate

is 12 degrees longitudinal axis and 0 degrees lateral axis. The location should be such that the EMS Series

unit is not blocked by the glare shield on top, or by the throttles, control yoke, etc. on the bottom. Use

aircraft installation standards for mounting and support of the EMS programmer.

EDM should be mounted on the firewall so that both sides can be accessed for service. Do not run

wire along fuel lines for support. All wiring should be mounted above fuel and hydraulic line for safety.

Never mount wiring directly on support structures, use Adel clamps or wire stand-offs.

Wiring Considerations

Use AWG #24 or larger wire for all connections in the interior of the aircraft unless otherwise specified.

Engine wiring should not be smaller than AWG #22. The standard crimp pin contacts supplied in the

connector kit are compatible with up to AWG #20 wire. In cases where some installations have more than

one component sharing a common circuit breaker, sizing and wire gauge is based on length of wiring and

current draw on units. In these cases, a larger gauge wire such as AWG #20 may be needed for power

connections. Do not attach any wires to the outside of the EMS or route high current wires within six (6)

inches of the programmer. Ensure that routing of the wiring is not exposed to sources of heat, RF or EMI

interference. Check that there is ample space for the cabling and mating connectors. Avoid sharp bends in

cabling and routing near aircraft control cables. Do not route the COM antenna coax near any EMS

components.

RFI/EMI considerations

The EMS programmer is shielded and does not generate any appreciable level of electromagnetic

interference. The EMS itself has been internally protected from RF interference and has been tested

under fairly extreme conditions, such as close proximity to

transmitting antennas. However, it is always good practice

to insure that such antennas are properly shielded and not

routed directly over or under sensitive panel-mounted

electronic equipment. Most problems in this area are the

result of improper RF shielding on transmitting antennas,

microphone cables, and the like.

Pitot and Static Connections

The TruTrak EMS requires connections to the Pitot and

static lines. The preferred m

ethod of this connection would

be tee fittings near the aircraft’s airspeed indicator.

PITOT STATIC

TruTrak Flight Systems 1 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 4

Operating controls

As with our autopilot products, extensive attention has been given to providing the simplest operation.

No sequential pressing of buttons is required to reach basic control functions. Active descriptions of Knob

or Button functions are labeled on display above. If there is a second EFIS connected by way of the TCBA & B wires, information will be communicated between the two units.

BARO Selection (Backup Gauges only)

In the TruTrak EMS display, barometer BARO is

set by rotation of the right dedicated knob. The

Baro reading is displayed in the Altimeter. The

yellow band along with the numerical VS

displayed above indicates VSI direction and speed.

GPS Information

The T&B DG requires GPS NMEA information to

function correctly. If the primary serial connection

and communication protocols have been setup

correctly, the EMS T&B gauge will display the

DG. Also, the timer is updated with GPS NMEA

information.

Dimming

Dimming of the display is accomplished by rotating the left knob, DIM rotating the knob Counter Clock

Wise to reduce the display illumination. External dimmer input will control the button illumination.

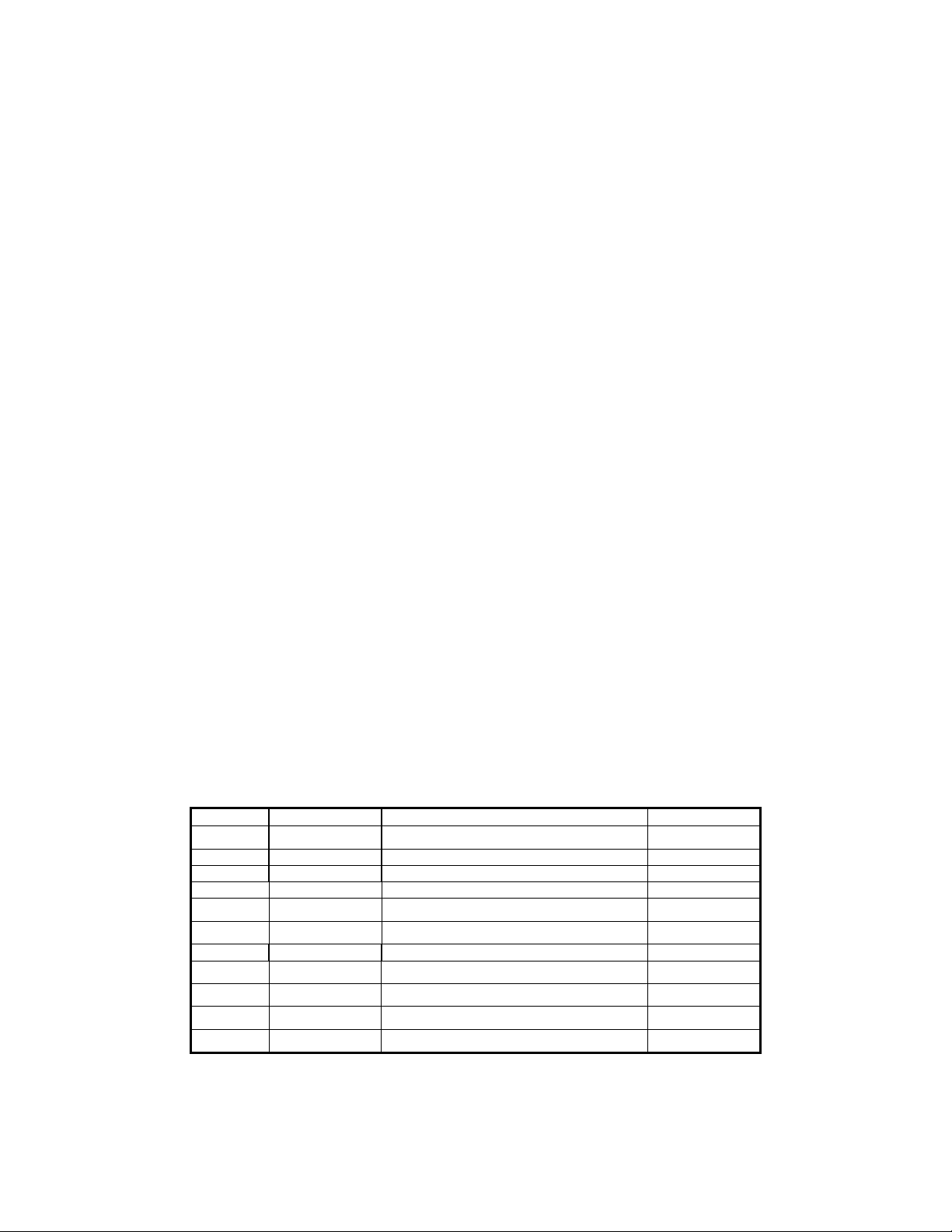

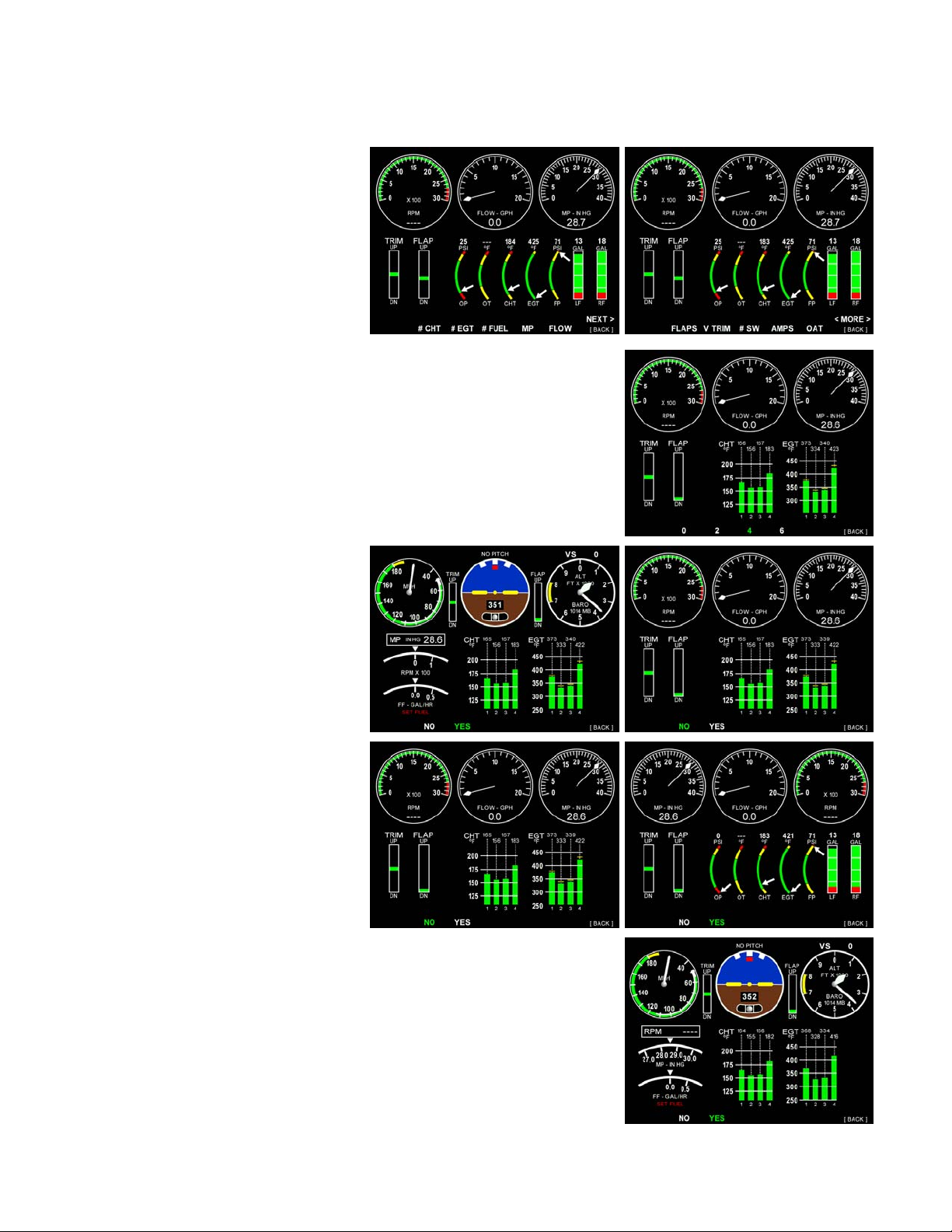

MAIN Page

MAIN page display are shown to the right top of

page picture showing Back Up instrument and the

picture to the right without Back Up.

TruTrak Flight Systems 2 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 5

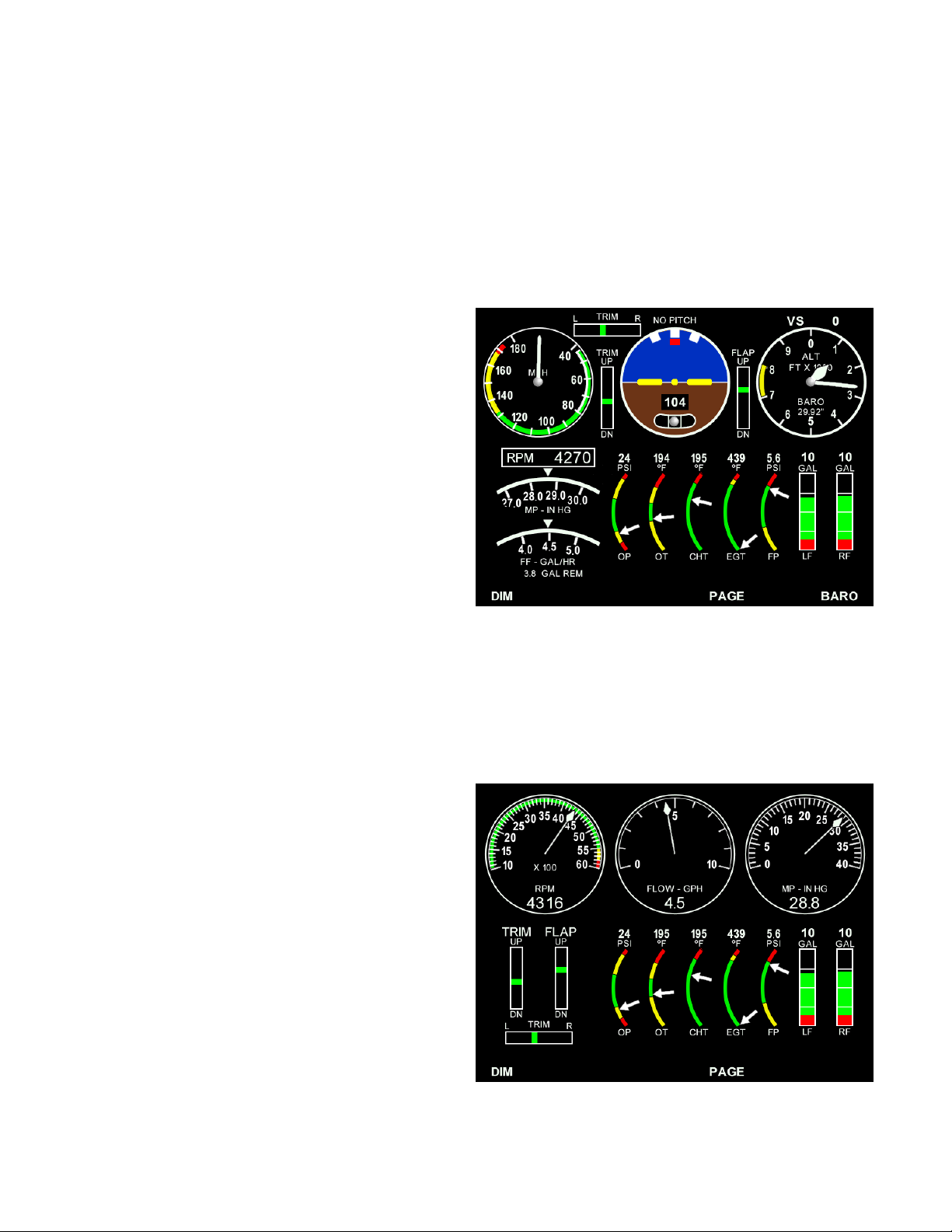

CHT /EGT Page

This page displays a detailed readout of all the CHT and EGT

sensors. Also, PEAK readings will be marked on this page. The

highest reading will be the CHT and EGT that is displayed on

the MAIN page.

TIMER Page

This page displays all the timers that are tracked. Detailed fuel

information and contact switch position along with voltage and

amp indications if installed.

The TIMER Page will be displayed on power up so that fuel

information can be updated. Also, the trip and leg timers can be

reset if needed.

Any parameter that enters a yellow ARC will change the reading displayed to yellow. See VOLTS. If the

parameter progresses to the red position the EMS / EFIS will display a warning box at the bottom of the

screen.

WARNINGS

There will be a warning box that will be displayed at the bottom

of the screen when a parameter first enters the red arc.

See OIL PRESSURE.

Pressing the button below ACK will remove the warning box

and the button below VIEW will change the page to the detailed

view page if different than the current page.

bottom picture oil pressure indication.

See

TruTrak Flight Systems 3 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 6

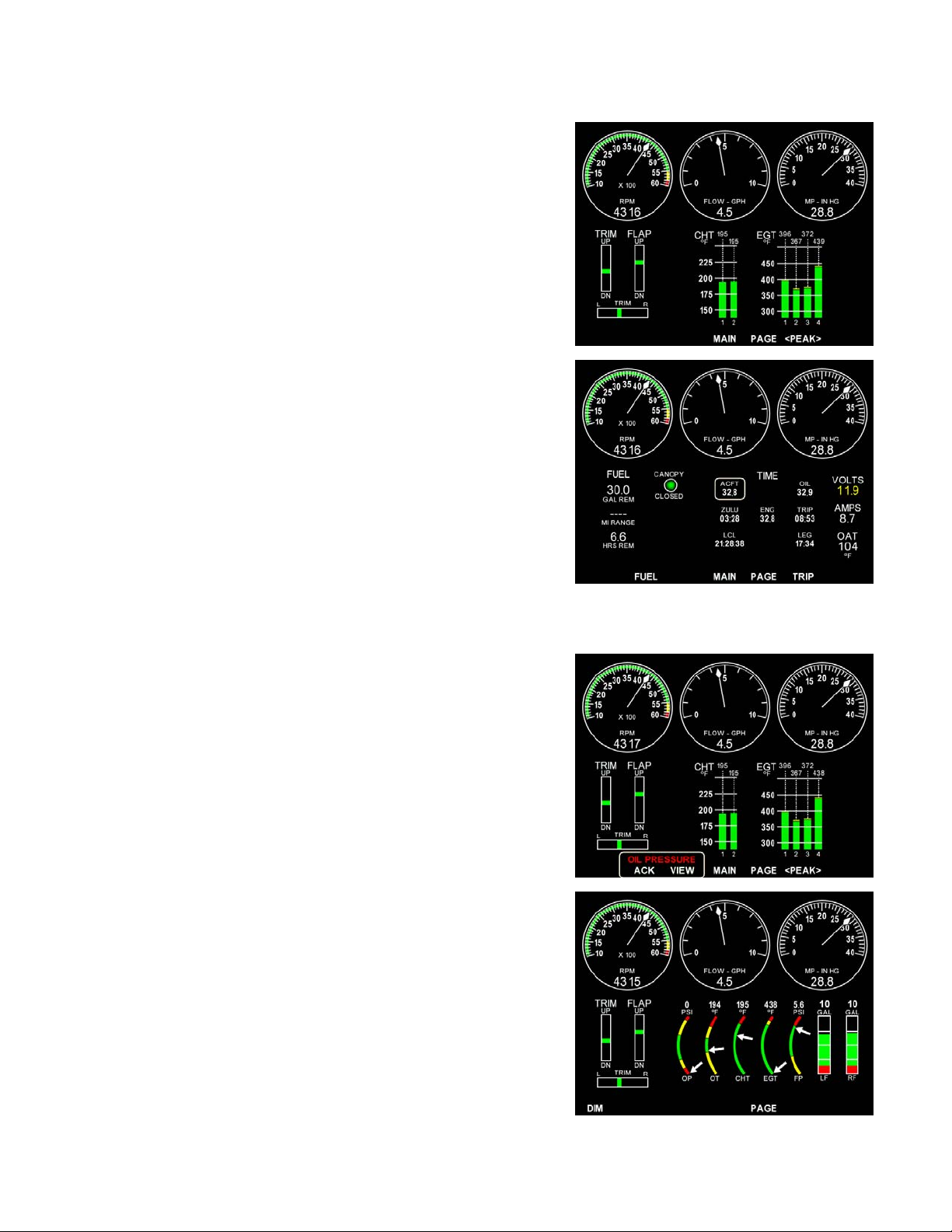

SETUP SCREENS

INFO, UNITS, TIME, CONFIG, GAUGES, CALIB

To enter the setup screen the right

knob must be pressed and held until

the SETUP shows then press and

release the button below SETUP

before releasing the right knob.

Rotate the right knob to step to the

next page.

Press and release the right knob

[EXIT] to step back a page or to

return to the main screens.

INFO

Displays serial numbers and software version and model type of all

units connected to the TruTrak communication wires (TCB-A, TCBB).

Exit by press and release of left knob.

UNITS

BARO, IN HG or MBAR

DIST, NM, MI or KM

PRESS, PSI, IN HG or KPA

MANIFLD, IN HG or MMHG

TEMP, F or C

VOLUME, GALLON or LITER

These pages will allow the setting of

UNITS of Measure for the different

display readouts listed.

Example: Press and release BARO to select IN HG or MBAR as shown.

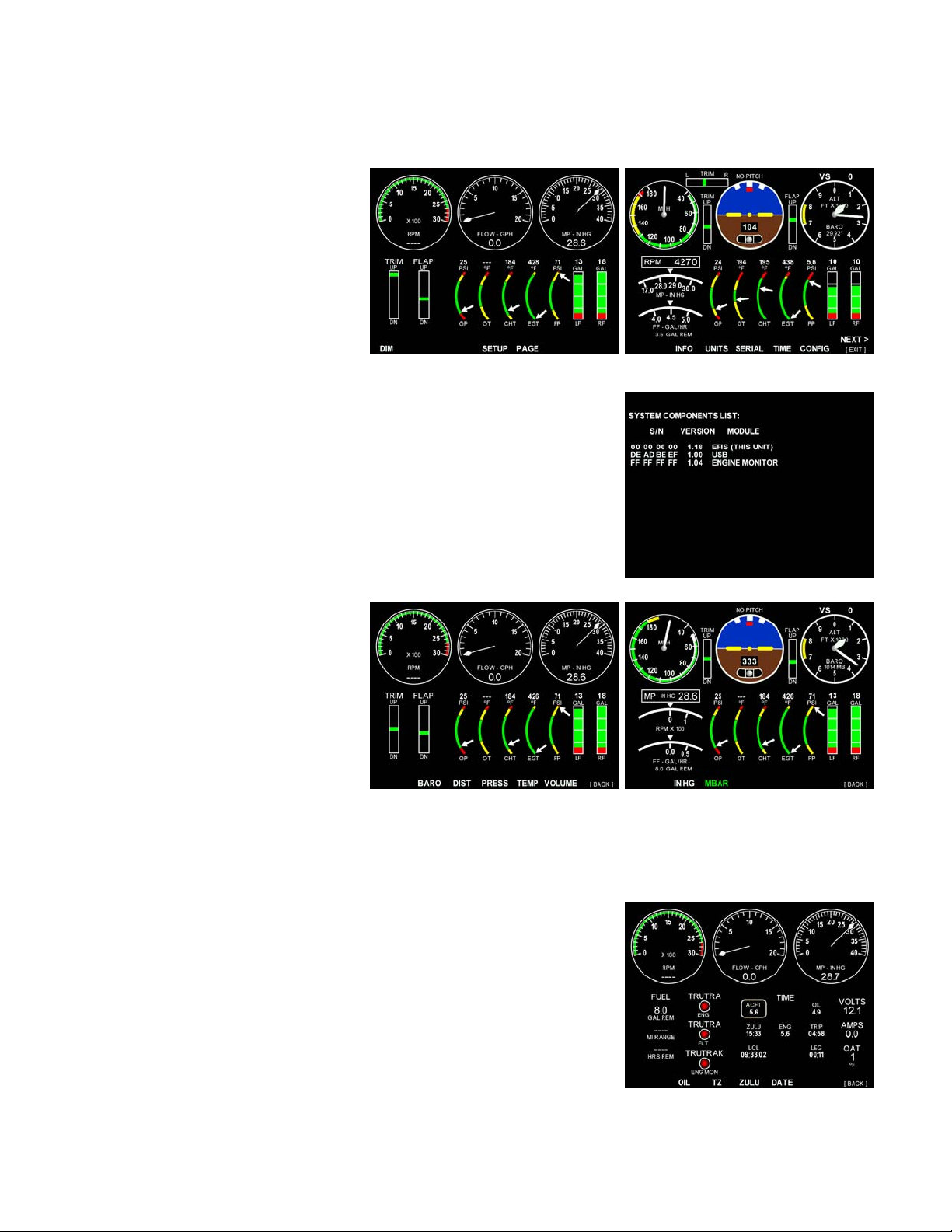

TIME

OIL, TZ, ZULU, DATE

Pressing the OIL button will reset the OIL, TRIP, & LEG timers.

LEG timer will reset with zero oil pressure for @ 5 min.

TRIP is reset with button.

The TZ (time zone) button sets your time zone by +/- from GMT

(Standard Central TZ = -6).

Set ZULU time with this button.(GMT)

Set the DATE with this button. The next screen allows the selection

of MONTH, DAY, and YEAR. Rotate the right knob to change

setting.

TruTrak Flight Systems 4 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 7

CONFIG

#CHT, #EGT, #FUEL, MP, FLOW, FLAPS, V TRIM, H TRIM, #SW, AMPS, OAT, CARB, BKUP,

COMPLX.

These pages will allow the selection

of the different type and quantity of

indicators displayed. Select the

sensors that are installed and the

quantity as needed.

Example: Press and release # CHT to select number of CHT

probes installed, 4 as shown to the right.

BKUP displays the engine

instrument with Airspeed, T&B,

Altimeter/VSI in upper part of

display. (right)

The far right picture is shown

without BKUP selected

As shown on the right pictures, the

COMPLX engine dial instruments

will move the MP to the left side.

COMPLX will also switch the MP to a more detailed display in the

BKUP mode. RPM (digital)and MP (analog display) swap for more

detailed information.

TruTrak Flight Systems 5 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 8

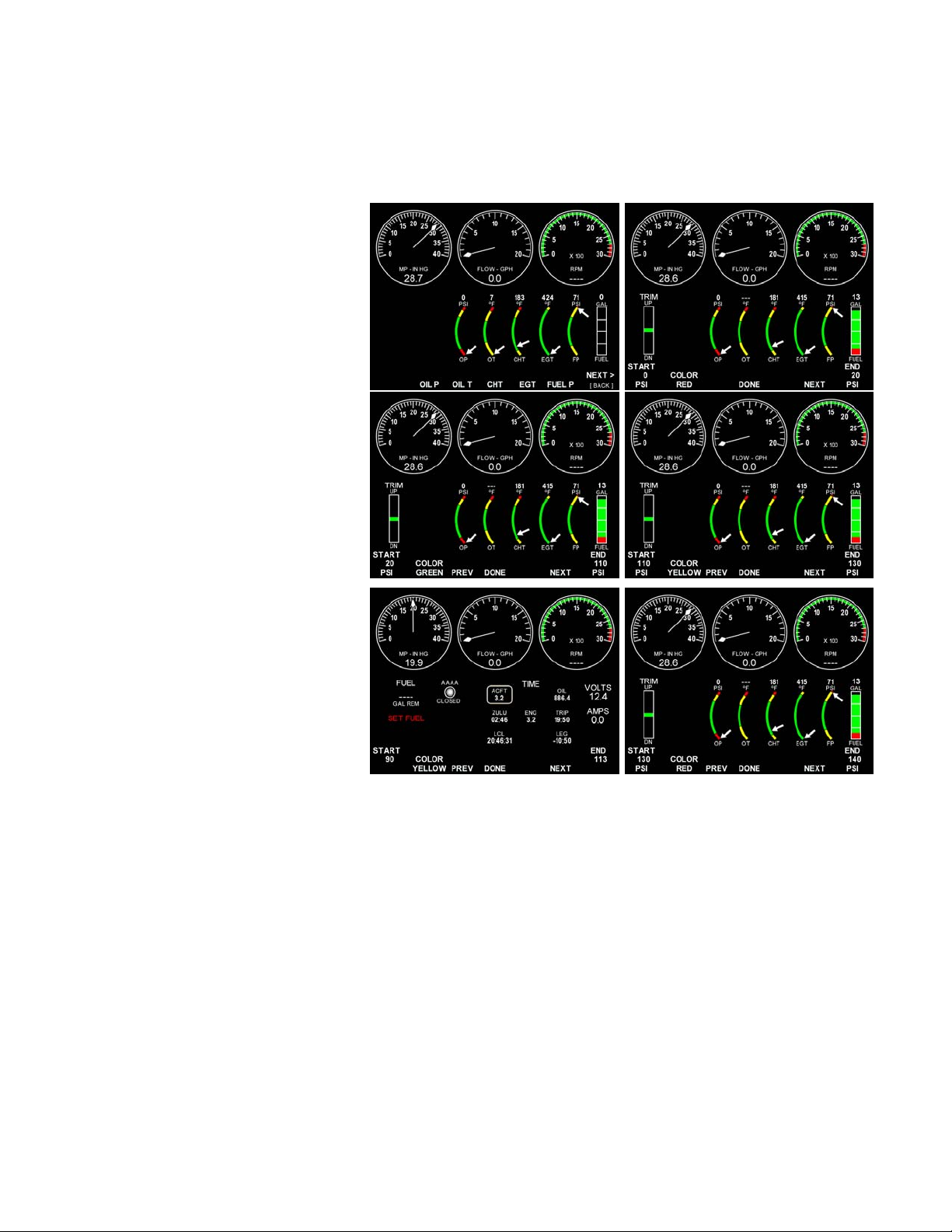

GAUGES (ARC COLOR BAND SETTING)

OIL P, OIL T, CHT, EGT, FUEL P, TANK1, TANK2, RPM, FFLOW, MP, VOLTS, SW #1-3

These pages allow the different colored arcs to be set for the gauge selected. Also, changing Switch

labeling and color. Some gauge arcs are preset at factory.

Select the type gauge to adjust (OIL

P), (upper right picture) the left knob

sets the START position or the

bottom color setting for that part of

the arc, adjust as needed.

Pressing the button below the

COLOR will step through the

available colors for that section of

arc.

The right side knob will adjust the

END or top setting for this arc color.

Adjust as needed.

Press and release NEXT.

Set the next color in the arc (left

middle). Step through all the setting

for all the arc colors, adjust as

needed. Press and release DONE

when finished. Oil Pressure is

shown from 0 to 140 PSI with four

(4) colors in the arc.

NOTE: VOLTS ARC numbers are

1 volt = 10 digit. Exp. 12V = 120

Pressing PREV or NEXT will step

to the previous or next screen as needed to correct or set.

NINE CYLINDER EDM

To have a nine (9) cylinder EDM system the EDM must be setup using the PC TruTrak software.

With a nine (9) cylinder system pin 29 (Contact #1) of the 37 pin DB connector (J1) MUST be grounded to show

cylinder # 7, 8, 9. When the switch is open the EMS display will show CHT/EGT #1-6. When the switch is closed the

display will show CHT/EGT 7-9 in place of 1-3. #4,5,6 will NOT be reported

#1 on the third display page.

FOR AIR PRESSURE OPERATION

The EDM is designed to use a 0-1000 PSI sensor that has a 4-20 ma output. This sensor output must be connected to

pin 32 on the 37 pin DB (J1) connector. Sensor power can be connected to pin 31 if aircraft voltage.

Currently, Air pressure will be displayed under the CARB temp Heading. The display will read in degrees F, BUT, in

actuality it will be in PSI. If the UNITS are changed to Celsius the air pressure will be wrong, the display MUST be in

Fahrenheit.

Unless there is access to the TruTrak setup programming software from the PC, the user MUST NOT change the

CARB, TACH, EGT#, CHT# settings. Doing so will result in the unit not functioning properly.

TruTrak Flight Systems 6 EMS Installation Manual

JUNE 2009 8300-065 Rev D

. This will also change the state of Contact

Page 9

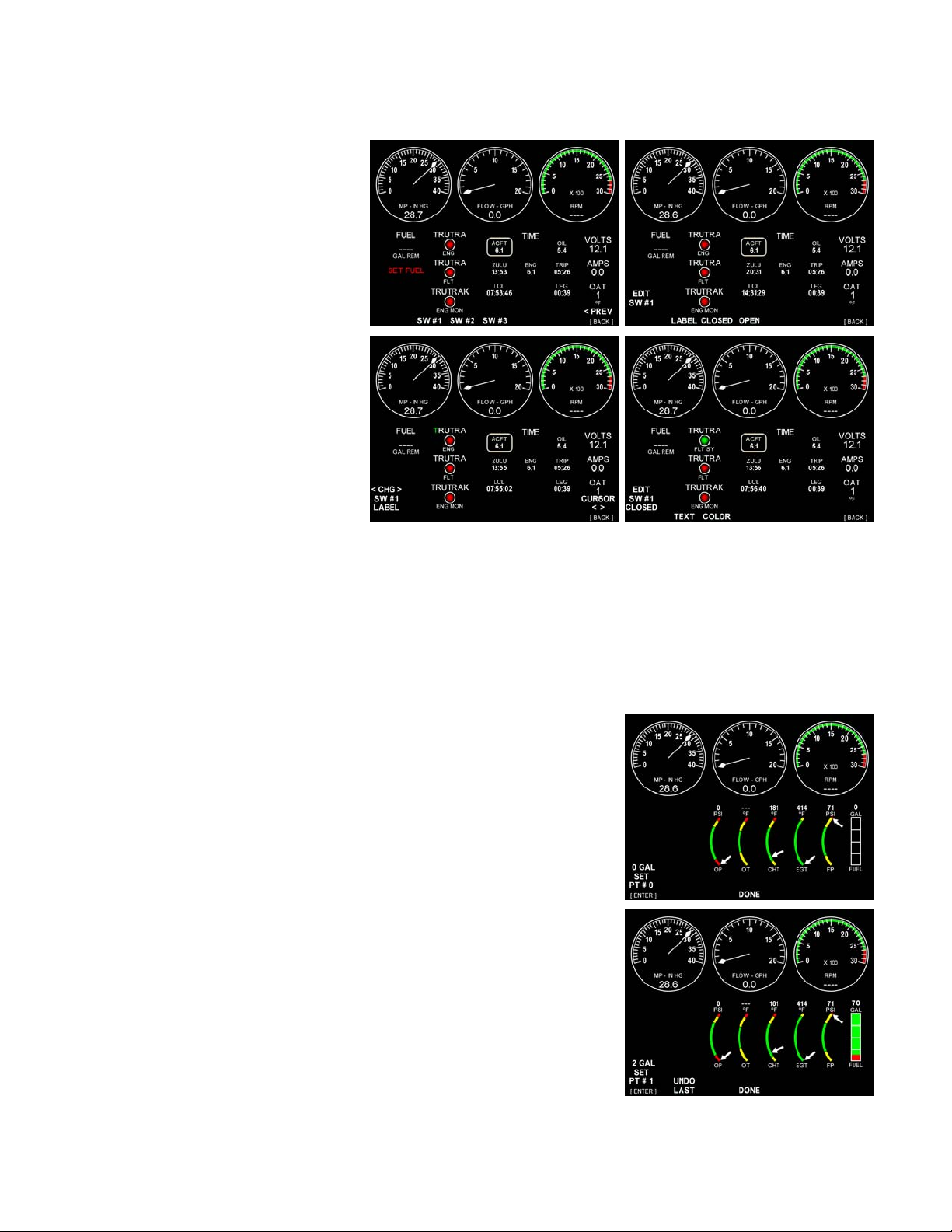

SWITCHES (CONTACTS)

Select the switch (SW # 1) to change

the label on. Select LABEL, now

the left knob will select the

alphanumerical digits and the right

knob will move the cursor position

(green). Select the name for this

switch, there are seven (7) digits

available. Press and release the right

knob (back) to return to the last

page. Select OPEN or CLOSED,

select TEXT to change the label

displayed when the contact is open

or closed. Select COLOR to change

the color that is displayed in ether

switch position.

Press and release the right knob

(back) repeatedly to return to the

beginning.

CALIBRATION

FUEL, TACH, SNSRS, FLAPS, TRIM, SPEEDS, & BALL

These pages allow the selection and calibration of the Fuel level, Tach, Sensors, Flaps and Trim

indicators. Also to set the Baud rate and center the ball in the T&B after installation.

FUEL

The type of and # of fuel sensors MUST be selected first (see CONFIG & SNSRS).

Calibration of tank / guages, there are a total of 15 PTs (calibration

points) possible, not all are necessary.

Select the tank to calibrate, with the tank empty, the first PT #0 is 0

GAL, press [enter]. Add fuel, in whole gallons until the number of

GAL over the displayed gauge just starts to move. Wait until the

number stabalizes. Enter the gallons added by rotating the left knob

and press [enter], PT #1. The gauge colors and number of GAL are not

correct until the calibration are complete. Continue adding fuel, each

PT# should have the total amount of fuel in the tank at that time and

wait until the number stabalizes. When the number displayed STOPS

changing when adding fuel, STOP. This is the last PT # even if the

tank is not full, enter the total gallons in the tank by rotating the left

knob, wait until the number stabalizes. Press DONE.

The sender can not measure fuel past this point. This is NOT to total

fuel used in calcuating remaning fuel. Only the @ amount of fuel in

the tanks.

TruTrak Flight Systems 7 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 10

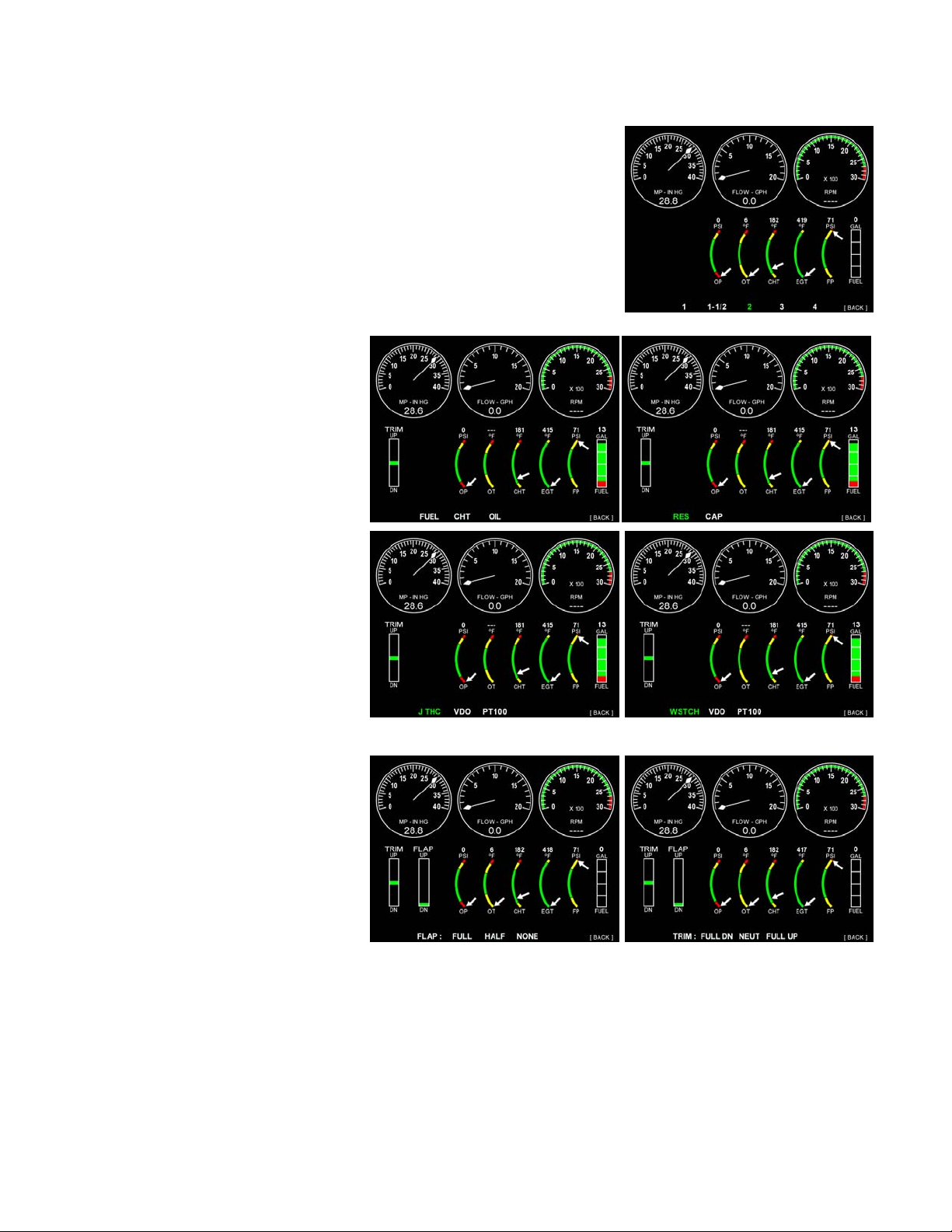

TACH

Select the pulses per revolution,

Lycoming 4 cyclinder = 2

Rotax = 1

SNSRS

FUEL, CHT, OIL;

FUEL Select the type of sender,

Resistive or Capacitance

CHT Select type of Sensor, J type

(J THC), Resistive (VDO), PT100

OIL Select type of Sensor,

Honeywell (WSTCH), Resistive

(VDO), PT100

FLAPS and TRIM

Select the gauge to calibrate,

exp: FLAP, move the flap to full up

and press and release the button

labeled NONE. Continue to HALF

and FULL down positions, pressing

the button for each.

SPEEDS

Select the Baud rate for your GPS input, 9600 or 4800.

BALL (SLIP)

Center the BALL in the T&B after EFIS installation.

TruTrak Flight Systems 8 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 11

EMS Software Updates

The EMS software can be updated by inserting a Compact Flash card (CF), with software acquired from

TruTrak Flight Systems. The CF card must be face down, in the top slot on the back. Then apply power

to the EMS, monitor the screen. Follow the instructions on the screen. When power is reapplied to the

EMS the new software version will be installed and displayed at the bottom of the screen.

SENSORS AND INPUTS

TruTrak Fight Systems can provide engine kits for all known engine types when an EMS / EDM order is

placed. The kit provides for all sensors / harnesses /pins needed.

All sensors ordered from TruTrak Flight Systems have a twisted, color coded, harness attached with

correct connections to the sensor. The EDM pin of the harness is not installed to provide easier routing of

the harness. Wires routed on the engine should be routed away from the exhaust system and above fuel

and hydraulic lines per standard aircraft wiring procedures, AC 43. See the installation manual from the

engine manufacture if possible. Engine wiring harnesses route better together where possible and should

be supported on the engine every 6 inches, Adel clamps work best for this, and tied together every 3

inches. All wire on the engine side of the firewall should be 22 gauge (bundle only) or larger with high

temperature insulation (Teflon) . Any connection from the engine to the firewall should have a service

loop to accommodate the movement of the engine.

TACH wires produce a lot of RF and should be shielded to reduce this as much as possible, only ground

one end. This is NOT the MAG wire, that uses the shield as part of the grounding system.

USE PIN OUT PAGES 18 & 19 FOR WIRING REFERENCES

Color codes:

RED------------------------12V (to EDM)

ORANGE-------------------5V (to EDM)

WHITE--------------SENSOR (to EDM)

BLACK------------ GROUND (to EDM)

Cylinder Head Temperature (J TYPE CHT) Probes (8250-036)

Lycoming / Continental engines use the bayonet J type CHT probes.

Rotax 912 engines use two resistive CHT probes that are included with the

engine. These probes are preinstalled, but you need to route the wire connections

(8220-019) from them to the EDM.

Oil Temperature Sensor

Lycoming / Continental engines must install the 399S9 resistive type. OT sensor

PN (8250-038). One black wire to ground (J2 pin 11, 12, 13) the other black wire

to J2 pin 18

Rotax 912 engines use one resistive OT probe that is included with the engine.

This probe is preinstalled, but you need to route the wire (8220-019)

TruTrak Flight Systems 9 EMS Installation Manual

JUNE 2009 8300-065 Rev D

connection to the EDM.

Page 12

Tachometer

Connect a shielded pick-off from the Magneto or electronic ignition box, ground the shield at the ignition

source. See installation manual for the installed electronic ignition box.

The Rotax 912 engines have a 5th trigger coil for the purposes of electrically monitoring rev counts. This

trigger coil outputs to a two-wire harness. Connect either of the two wires to ground. Connect the other

wire to the TACH input on the EDM.

Manifold Pressure Sensor HOSE (82509-047)

The pressure port on the manifold pressure sensor input requires 1/8” inner diameter tubing for a secure

fit. You may need to use adapters to convert up to larger inner diameter tubing for your specific engine. It

is recommended that you use clamps at every transition point

Oil Pressure Sensor (8250-032)

Lycoming / Continental engines must install the TruTrak OP sensor supplied.

Note that if you are installing on a Jabiru or Rotax engine, your engine comes with a

pre-installed oil pressure sensor. You will need to replace this sensor with TruTrak

supplied sensor assembly.

Fuel Pressure Sensor (8250-040)

First, mount the fuel pressure sensor to a fixed location using an Adel clamp or other

secure method. The fuel pressure sensor must not be installed directly to the engine due

to potential vibration problems. Next, connect the fuel sensor to the engine using

appropriate hoses and fittings. Its pressure port has a 1/8-27 NPT pipe thread fitting;

you may need adapters to connect to the pressure port on your engine. Locate the

correct fuel pressure port for your engine. This port must have a pressure fitting with a

restrictor hole in it. This restrictor hole ensures that, in the event of a sensor failure,

fuel leakage rate is minimized, allowing time for an emergency landing.

Carbureted engines: Use the supplied sensor and harness.

WARNINGS:

Due to vibration issues, never connect the sensor directly to engine.

TruTrak Flight Systems 10 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 13

Fuel Flow Sensor (8250-041)

The FloScan fuel flow transducer has ¼” female NPT threads at both

the inlet and outlet. Only use ¼” NPT fittings to match. When

installing, do not screw fittings more than two full turns past hand

tightened. The torque should not exceed 180 inch-lbs.

WARNINGS:

Due to vibration issues, never connect the sensor directly to engine.

Do NOT use Teflon tape when screwing in any of the fittings.

Make note of the K factor number on the tag attached to the fuel flow sensor. You will need it in the Fuel

Flow Configuration section. Do not lose this number, the fuel flow calibration will not be correct without

this setting.

Setting K factor:

Press and hold the right knob, wait for “SETUP” to show in center lower display press button below at the

same time you are holding the knob. Press and release “CONFIG” press and release “FLOW”, then

“YES”, set K factor by rotating right knob. Press and rotate to step in 100 increments.

General Placement Recommendations

When placing the sensor, ensure that the three wire leads are pointed straight up. Ensure that the

transducer has 6” of straight fuel line before and after it. Placement of the fuel flow sender relative to

other items in the fuel system like fuel pumps is left to the builder. The manufacturer of the fuel flow

sender does not make strong recommendations on this point. It is not uncommon, though, to place the

sender downstream of any auxiliary electric boost pumps but upstream of the engine driven fuel pump.

For best measuring performance, the fuel should travel uphill by one to two inches after leaving the fuel

flow sender.

Fuel Level Sensor

The EDM supports both resistive type sensors as well as capacitive sensors, which output a voltage (e.g.,

Princeton). Once you have installed your fuel level sensors, you will need to calibrate each of them, as

described in Fuel Level Calibration.

Resistive Fuel Level Sensor

You may connect up to two resistive fuel level sensors to the EDM. Simply connect the output of the

sensor you would like to be Fuel Level 1 (right tank) to pin 26 and the sensor you would like to be Fuel

Level 2 (left tank) to pin 8, perform calibration.

TruTrak Flight Systems 11 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 14

Trim and Flaps Position Potentiometers

Most flap and trim sensors are potentiometers (variable resistors) which require power and ground inputs,

and supply an output that is a function of position. These potentiometers come in a variety of resistance

ranges. A typical trim sensor connection, +5 volts (pin 22) to one side of position potentiometer. The

other side is Ground (pin 4), and the center is the output signal (pin 6).

Ray Allen sensor, If the Ray Allen indicator is not used, connect the white/orange wire to the (5V)

excitation line (pin 22), the white/blue wire to (GND) (pin 4), and its white/green wire (signal output) to

(pin 6) on the J1, 37 pin connector. If the display is used, splice off the green/white wire connect to the

EDM (pin 6). Either installation must be calibrated.

Current Sensor (8250-044)

The ammeter transducer can be installed in your electrical system in one of three

locations as shown in the (simplified) electrical diagram below.

Position A-C: Ammeter indicates current flow into or out of your battery. In these

positions, it will show both positive and negative currents.

The current transducer is not

affected by high current levels.

Position transducer so that the

attaching arm points toward the

positive battery post.

TruTrak Flight Systems 12 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 15

Exhaust Gas Temperature (K type EGT) Probes

Correct placement of EGT probes on the exhaust manifold is critical to obtaining accurate readings.

Placement differs between engine types, and even specific models. Consult your specific engine’s manual

for proper EGT locations.

ROTAX ENGINES (8250-034)

For Rotax 912 engines, only two of the four

cylinders need to be monitored for EGT.

Unlike the CHT probes, which are mounted

on diagonal cylinders, the EGT probes

should be mounted on the two rear

cylinders’ exhaust manifolds. It is critical

that the EGT probes be mounted to parallel

cylinders’ exhaust manifolds for proper temperature comparison. Recommended distance from exhaust

flange is 100 mm.

LYCOMING / CONTINENTAL ENGINE (8250-035)

Consult your specific engine’s manual for proper EGT locations.

WARNINGS:

A loose probe could allow exhaust to leak. This can lead to carbon monoxide poisoning in the cabin

and/or a potential fire. Have a knowledgeable mechanic inspect the installation.

The probe can come lose during flight, and could potentially come in contact with rotating engine parts or

the propeller. We suggest safety wire to keep the probe in place.

TruTrak Flight Systems 13 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 16

Outside Air Temperature Sensor (8250-042)

It is important that the OAT probe be mounted somewhere on the skin of the

airplane where it will not be affected by heat sources (sun, engine, airplane interior,

etc). The ideal location would receive no heat from the aircraft engine or any other

source in the airplane body. While this may be impractical, it is a good idea to

mount the probe as far away from heat sources as possible. Generally, avoid these

locations:

Engine exhaust paths

The engine itself

Where the sensor will be in direct sunlight

Where the sensor mounting is exposed to a heated cabin

Transducer Installation

After the mounting location has been determined, drill a 5/16” hole in the skin at the desired location.

Install the OAT probe through the skin make sure that the flange nut is on the outside of the skin. Then

tighten the two nuts with the lock washer on the inside of the skin in place against the skin. Use some

Loctite around the threads of the OAT probe. Twist the nuts onto the threads of the OAT probe and

tighten. Once you have physically mounted the OAT probe, route the attached wires to the EDM. Connect

one of the white wires to ground, at a supplied connection on the 37-pin harness. The other white wire on

the OAT probe to the OAT input on the 37-pin connector pin 25.

Carburetor Air Temperature Sensor

TruTrak can accommodate an additional air temperature sensor for the carburetor or manifold. Westgate

makes carburetor air temperature probes for the different carburetors on an engine. The sensor must be a

399S9 resistive type. Use the TruTrak OAT Sensor (8250-042) if there is room in the manifold plenum

for a Manifold sensor. This sensor MUST be installed in pin 7 of J2 and the CARB must be ON to

function. The selection of the CARB will not allow a second resistive type CHT sensor.

TruTrak Flight Systems 14 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 17

EMS ELECTRICAL PIN-OUT

The table below provides a brief explanation of each pin function on the main 37-pin connector J1.

J1 EMS Rear Connector (Viewed from rear of EMS) or wire side of connector.

J1 Pin Function Notes

1 Dedicated ground connection for Pitch Reverse Jumper.

2

Pitch Reverse Jumper

3 SL-30 output. SL-30 NAV pin 4 RX

4 DIMMER (buttons) connection

5

NO CONNECTION

6

NO CONNECTION

7

ALERT

8

NO CONNECTION

9

AUX 2 RS-232 IN

10 Pitch Servo Torque Control. A signal from the autopilot to the pitch servo which sets the

amount of torque to be delivered by the servo.

11 Pitch Servo Trim Sensor. A signal from the pitch servo to the autopilot which indicates an

out-of-trim condition and its direction.

12

AIRCRAFT POWER MAIN BUSS (+12 to +28 V DC).

13 Audio signal Out. This pin may be wired to an unswitched input of an audio panel. The

autopilot uses various voice or tones to denote specific events (loss of GPSS, capture

Glideslope, etc). Volume is adjustable within a setup screen of the autopilot.

Pitch Servo control lines. These lines cause the stepping motor in the pitch servo to run in

14

the appropriate direction at the desired velocity. They are small-signal lines and do not have

15

any substantial current-carrying capability or require any special shield ing. Connect to pitch

16

servo as shown on wiring diagram.

17

18

19

AIRCRAFT GROUND CONNECTION.

Direction of servo arm / capstan rotation

EMS autopilot only

EMS autopilot only

Not used at this time

Not used at this time

EMS autopilot only

EMS autopilot only

Not used at this time

EMS autopilot only

Not used at this time

TruTrak Flight Systems 15 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 18

EMS Rear Connections to J1 (Continued)

J1 Pin Function Notes

20 Control Wheel Switch / AP Level Button. Connect as shown in wiring diagram to a SPST

momentary switch located remotely to the autopilot for convenient engage/disengage function.

AP Level Button option should be located in easy reach of Copilot and Pilot.

21

EMS Switch

22

NO CONNECTION

23

SPARE SWT

24

No Connection

25 PRIMARY SERIAL INPUT. Baud rate selectable 1200, 2400, 4800 or 9600 baud.

Automatically decodes NMEA-0183, Garmin Aviation Format, or Apollo/UPSAT MovingMap or GPSS format. Provides slaved directional reference to the autopilot.

gital differential signals from Garmin, Sierra, or other panel-mount receiver

26

27

ARINC-A

ARINC-B

Di

which provide directional steering commands (GPSS) to autopilot

28 Roll Servo Torque Control. A signal from the autopilot to the roll (aileron) servo which sets

the amount of torque to be delivered by the servo.

29

No Connection

30 SL 30 input. SL-30 NAV pin 5 TX

31

EDM power

Roll (aileron) Servo control lines. These lines cause the stepping motor in the roll servo to run

in the appropriate direction at the desired velocity. They are small-signal lines and do not have

any substantial current-carrying capability or require any special shield ing. Connect to roll

32

servo as shown on wiring diagram.

33

34

35

Wiring to roll servo J201

Direction of servo arm / capstan rotation

(as viewed from face of the servo body)

J101 Pin 32 Pin 33

for RIGHT aileron

Standard J201-4 J201-5 Servo CCW (counter-clockwise) Î RIGHT

Reversed J201-5 J201-4 Servo CW (clockwise) Î RIGHT

36

TCB-B

37

TCB-A

EMS

J1 pins

RS 232 25 11 Data out Data out Blue wire Blue wire Blue wire Blue wire Blue wire Blue wire Data out

ARINC

A

ARINC

B

EMS

J1 pins

RS 232 25 19 19 19 5 / 22 P1- 22 56 56

ARINC

A

ARINC

B

King

KMD 150

26 N/C N/C N/C N/C N/C N/C N/C N/C N/C N/C

27 N/C N/C N/C N/C N/C N/C N/C N/C N/C N/C

Garmin 155XL Garmin 200XL Garmin 300XL Garmin GX 50-65 Garmin GNS 480 Garmin 430

26 16 16 16 N/C P5 - 4 46 46

27 15 15 15 N/C P5 - 24 47 47

Garmin III Garmin 92 Garmin 195 Garmin 196 Garmin 295 Garmin 296 Garmin 396 Garmin 496 AvMap

P4001

EMS autopilot only

Not used at this time

Not used at this time

EMS autopilot only

EMS autopilot only

Not used at this time

Power to EDM

EMS autopilot only

Reverse servo

direction if necessary

by swapping wires on

pin 32 and 33. See

note 3 on wiring

diagram.

EKP IV

Garmin 530

P5001

EMS or

EMS AP SERIES

ALL

CURRENT DRAW

LOW BRIGHT

1.07 Amps @ 12v

0.65 Amps @ 24v

CURRENT DRAW

HIGH BRIGHT

2.02 Amps @ 12 v

1.15 Amps @ 24v

WEIGHT

2.33 lbs High bright

1.95 lbs Low bright

6.375W x 5.75H x 3.625D

DIMENSIONS

Behind panel

TruTrak Flight Systems 16 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 19

EMS / EDM Basic Wiring Diagram

TruTrak Flight Systems 17 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 20

EDM ELECTRICAL PIN-OUT

J1 Pin

EDM Function / interior

1 Ground

2 Ground

3 Ground

4 Ground

5 Future Alert Lamp Not used at this time

6 Vertical Trim Position (PITCH) input Pitch Trim Input

7 OAT Thermister OAT Input

8 Fuel level Resistive in 2 Left tank Input

9 Fuel level Capacitance in 2 Left tank Input

10 Switch Contact 3 Input

11 Switch Contact 2 Input

12

MAIN EDM POWER

13

MAIN EDM POWER from second EFIS (optional)

14 Fuel Pressure Transducer Fuel Pressure Input

15 Fuel Flow Transducer Fuel Flow Input

16 TACH RPM Input

17 Ground

18 Ground

19

MAIN EDM AIRCRAFT GROUND

20 Sensor 5 volt supply

21 Sensor 5 volt supply

22 Sensor 5 volt supply

23 Sensor 5 volt supply

24 Lateral Trim Position Roll Trim Input

25 Flap Position Flap Position Input

26 Fuel level Resistive in 1 Right tank Input

27 Fuel level Capacitance in 1 Right tank Input

28 Switch Contact 4 Input

29 Switch Contact 1 / NINE CYLINDER SELECT SWITCH Input

30 Not used at this time

31 Sensor 12 volt supply

32 Air Pressure sensor

33 Current Transducer Battery Current Input

34

TCB-B (2)

35

TCB-A (2)

36

TCB-B

37

TCB-A

Notes

Sensor use only

Sensor use only

Sensor use only

Sensor use only

From EMS

From EFIS

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Nine Cylinder EDM

TruTrak Comm. Buss

TruTrak Comm. Buss

TruTrak Comm. Buss

TruTrak Comm. Buss

EDM CURRENT DRAW WEIGHT

Engine Data

Monitor

TruTrak Flight Systems 18 EMS Installation Manual

JUNE 2009 8300-065 Rev D

0.65 Amps @ 12v

0.65 Amps @ 24v

.5 lb 5.25L x 3.4W x 1. 5D

DIMENSIONS

Page 21

J2 Pin

EDM Function / Fire wall

1 Sensor Ground

2 TACH

3 Fuel Flow

4 OAT Thermister

5 Fuel Pressure

6 OIL pressure Sensor (Resistive type) Factory setup only

7 CHT 2 Thermister or Second OAT sensor (CARB TEMP)

8 Sensor 12 volt supply

9 Sensor 12 volt supply

10 Sensor 12 volt supply

11 Sensor Ground

12 Sensor Ground

13 Sensor Ground

14 Sensor 5 volt supply

15 Sensor 5 volt supply

16 Current Transducer

17 Not used at this time

18 Oil Temperature Thermister

19 CHT 1 Thermister

20 Oil Pressure

21 Not used at this time

22 - EGT 1 RED K type / # Nine EGT

23 + EGT 1 YELLOW K type / # Nine EGT

24 - EGT 2 RED K type / # Nine CHT

25 + EGT 2 YELLOW K type / # Nine CHT

Notes

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

Sensor use only

J3 Pin

TruTrak Flight Systems 19 EMS Installation Manual

JUNE 2009 8300-065 Rev D

EDM Function / Fire Wall

1 - CHT 1 J Type RED

2 - CHT 2 J Type RED

3 - CHT 3 J Type RED

4 - CHT 4 J Type RED

5 - CHT 5 J Type RED

6 - CHT 6 J Type RED

7

NO CONNECTION

8 + EGT 1 K type YELLOW

9 + EGT 2 K type YELLOW

10 + EGT 3 K type YELLOW

11 + EGT 4 K type YELLOW

12 + EGT 5 K type YELLOW

13 + EGT 6 K type YELLOW

14 + CHT 1 J Type WHITE

15 + CHT 2 J Type WHITE

16 + CHT 3 J Type WHITE

17 + CHT 4 J Type WHITE

18 + CHT 5 J Type WHITE

19 + CHT 6 J Type WHITE

20 - EGT 1 K type RED

21 - EGT 2 K type RED

22 - EGT 3 K type RED

23 - EGT 4 K type RED

24 - EGT 5 K type RED

25 - EGT 6 K type RED

NOT NINE CYL

NN OPTION

Page 22

EVEKTOR WIRING DIAGRAM

TruTrak Flight Systems 20 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 23

ROTAX WIRING DIAGRAM

TruTrak Flight Systems 21 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 24

EFIS AP / EMS / EDM BLOCK DIAGRAM

TruTrak Flight Systems 22 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 25

NINE CYLINDER EDM BLOCK DIAGRAM

TruTrak Flight Systems 23 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 26

J3 Pin

EDM Function / Fire Wall NINE CYLINDER OPTION

1 + EGT 7 K Type YELLOW

2 - EGT 6 K Type RED

3 + EGT 4 K Type YELLOW

4 - EGT 3 K Type RED

5 + EGT 1 K Type YELLOW

6

7

8

9

10 + CHT 7 J type WHITE

11 - CHT 6 J type RED

12 + CHT 4 J type WHITE

13 - CHT 3 J type RED

14 + CHT 1 J Type WHITE

15

16 + EGT 8 K Type YELLOW

17 - EGT 7 K Type RED

18 + EGT 5 K Type YELLOW

19 - EGT 4 K Type RED

20 + EGT 2 K type YELLOW

21 - EGT 1 K type RED

22

23

24

25 + CHT 8 J type WHITE

26 - CHT 7 J type RED

27 + CHT 5 J type WHITE

28 - CHT 4 J type RED

29 + CHT 2 J type WHITE

30 - CHT 1 J type RED

31 - EGT 8 K type RED

32 + EGT 6 K type YELLOW

33 - EGT 5 K type RED

34 + EGT 3 K type YELLOW

35 - EGT 2 K type RED

36

37

38

39

40 - CHT 8 J type RED

41 + CHT 6 J type WHITE

42 - CHT 5 J type RED

43 + CHT 3 J type WHITE

44 - CHT 2 J type RED

TruTrak Flight Systems 24 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 27

TruTrak Flight Systems 25 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 28

TruTrak Flight Systems 26 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 29

TruTrak Flight Systems 27 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 30

TruTrak Flight Systems No Penalty Upgrade Policy

As the product line continues to grow, it becomes increasingly difficult to maintain a simple upgrade policy. We do

want to reward our repeat customers by allowing a lower cost upgrade from one system to another; however we

are not able to offer this across the board on all products. If you are considering an upgrade, please call and we

will give you a quote on what this would cost. Many products that we sell today are upgradeable for only the

difference in system price. Because we continually strive to have the most up to date products possible, we

occasionally have to discontinue products. We will continue to offer discounted upgrades even for our discontinued

products.

TruTrak Flight Systems 28 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 31

RETURN MERCHANDISE POLICY AND PROCEDURE

Under no circumstances should products be returned to TruTrak without first obtaining a Return of Merchandise

Authorization number (RMA #) from TruTrak. An RMA# may be obtained by contacting us at 866-878-8725.

Products that do not have an RMA # will not be processed.

Please include documentation stating the reason for the return and describing any symptoms, failure modes,

suspected causes of damage, diagnostics performed, data collected, etc.

Product(s) should be packaged in their original shipping containers. In lieu of this, they should be very carefully

packaged in containers suitable to protect them during transit. For your protection, items should be insured for the

full value. Note that damage caused during shipping will not be repaired under warranty.

The outside of the box must be clearly marked with the RMA # issued by TruTrak and the RMA # must also be

noted on the return documents.

Products will be returned to the customer at no charge via FedEx Ground or UPS Ground. If customer requests

expedited shipping (2

number.

INTERNATIONAL SHIPMENTS:

Trutrak sends all International shipments with an insurance value on all products. Trutrak pays for shipping only.

The customer is responsible for any and all additional fees, duties, taxes associated with the shipment.

When sending products to Trutrak for repair or otherwise please be advised that the customer is responsible for all

charges and fees associated with shipment. For your protection, items should be insured for the full value.

Trutrak states on all product returns “WARRANTY REPAIR AT NO CHARGE TO CUSTOMER. A COMMERCIAL

INVOICE VALUE OF $___ GIVEN FOR INSURANCE PURPOSE S ONLY”

Please keep in mind that your government or another entity in your country may impose a charge for custom and/or brokerage

fees, duties and taxes on items received from the US. These charges do not originate from our company nor do we benefit from

them in any way. You are responsible for payment of all custom and brokerage fees, duties and taxes that may be imposed

when these goods are imported into your country.

Send ALL return shipments to:

TruTrak Flight Systems, Inc., 1500 South Old Missouri Road, Springdale, AR 72764 USA

Attention: Returns Dept. RMA#

Warranty On TruTrak Flight Systems Products

We here at TruTrak Flight Systems know how important it is to feel as though the customer is purchasing a product

that the manufacturer is going to stand behind. For this reason we want offer more than the basic one year warranty

that is standard to this industry. The warranty on all TruTrak products will be three years from the date of

purchase. Abuse and misuse of a product are not covered under this warranty. Modification to a product may void

the warranty, as well as carry a penalty when upgrading to another product. This three year warranty will be for all

products except the Pictorial Turn & Bank, which will continue to have a warranty of one year from the date of

purchase.

nd

Day or Overnight) they will be charged the shipping cost and must supply a credit card

TruTrak Flight Systems 29 EMS Installation Manual

JUNE 2009 8300-065 Rev D

Page 32

TruTrak Flight Systems, Inc.

1500 S. Old Missouri Rd.

Springdale AR 72764

(479) 751-0250

FAX (479) 751-3397

www.trutrakap.com

Loading...

Loading...