Page 1

EFIS

Installation & Operation Manual

8300-056 Rev B

TRUTRAK FLIGHT SYSTEMS

1500 S. Old Missouri Road

Springdale, AR 72764

Ph. 479-751-0250 Fax 479-751-3397

www.trutrakflightsystems.com

Page 2

INSTALLATION MANUAL

FOR

EFIS

TABLE OF CONTENTS

OPERATION OF THE BASIC FLIGHT INSTRUMENT ..............1

THE DISPLAY .................................................................................2

MECHANICAL INSTALLATION CONSIDERATIONS ..............3

PITOT AND STATIC CONNECTIONS.......................................... 3

RFI/EMI ............................................................................................3

OPERATING CONTROLS .............................................................. 4

GPS INFORMATION.......................................................................5

SL 30 INFORMATION ....................................................................5

AUTOMATIC ARRIVAL TRANSITION.......................................6

SETUP SCREENS ............................................................................7

EFIS SOFTWARE UPDATES.......................................................10

ELECTRICAL PIN-OUT................................................................11

EFIS WIRING DIAGRAM.............................................................13

EFIS PILOT’S GUIDE ...................................................................19

RETURN MERCHANDISE POLICY AND PROCEDURE.........21

Revision Date Description Page #

A 07/0/1/2008 Initial Release

B 02/12/2009 Updated pictures & added SL 30 All

Page 3

OPERATION OF THE BASIC FLIGHT INSTRUMENT

As with our autopilot products, extensive attention has been given to providing the

simplest operation. No sequential pressing of buttons is required to reach basic control functions

and no additional button pressing is required to set values. Starting with a clean sheet of paper the

layout of controls (two knobs and five soft keys) is sufficient to handle all EFIS and built in

autopilot control functions.

On the basic flight instrument the right hand knob is primarily dedicated to setting the

barometer and the left hand knob is primarily dedicated to setting the direction bug. Pressing the

ALT soft key sets the altitude bug to the 100 foot mark nearest the present altitude. This setting

is entered into the active state by pressing the right hand knob. If the intent is to select an altitude

the ALT button is pressed and the right hand knob is rotated to select the desired altitude. (with

the knob out steps are 500 feet and with the knob depressed steps are 100 feet.) When the altitude

has been set press the knob to ENTER the value. It will be noted that when any value is to be set

a screen showing the selection to be made will appear above the appropriate knob.

When the aircraft is within 30 miles of the destination fix the CRS labels the soft key at the

far left. To select an arrival course different from the enroute course on the HSI press CRS and

then rotate the left hand knob. When the course is set press the knob to ENTER. A computer

generated arrival procedure in which steering from the enroute course to the selected runway is

described in the special functions section.

Just above the left knob is the label [DIM] in small print. To set the dimmer press and

hold the knob in for approximately one second, then rotate to set the desired light intensity.

When this is done press the knob to exit the set mode.

When there is NO GPS FIX the directional gyro operates in the free gyro mode, and the

label above the far left soft key is SET DG. When this button is pressed the left knob is used to

set the DG to the magnetic compass. As is the case with any free gyro this procedure is to be

repeated periodically as required.

TruTrak Flight Systems 1 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 4

THE DISPLAY

Consider first the pitch display. Motion of the pitch display short term is gyroscopic as it must be to fly in

IMC. Long term it is VSI. This is a special case of a presentation used in the military called VELOCITY VECTOR.

This display has two advantages. The first is that it provides an instantaneous vertical speed presentation. The

second is that when the reference airplane is on the horizon the aircraft is neither climbing nor descending. This

eliminates the need for adjusting the position of the pitch reference airplane to compensate for the angle the

fuselage is flying. The resulting benefit of this concept is that it makes holding altitude easier (not only in straight

flight but also in turns). It is a fact that next to AOA, airspeed provides the best warning of approaching a stall. For

this reason the airspeed pointer flashes red when a pre-set minimum airspeed safely above a stall is reached.

There are critics of this concept who believe that attitude is an indicator of approaching a stall. NOT SO, attitude

alone is not at all such an indicator.

The HSI is

placed below the

horizon as in the larger

more expensive

displays. It is in the

form of an ellipse for

two reasons. First, an

ellipse when compared

with a circle of the

same height provides a

broader scale at the top

where it is read.

Second, it looks as a

circle would when laid

out on the ground

ahead of the aircraft.

When a DIRECT TO or

FLIGHT PLAN is set

into the GPS this

display becomes an

HSI. The boldness of

this high quality display

in combination with its

location enhances the

flyability of the overall

instrument. Finally, the

HSI contains features that make functions available that are not found in other low cost systems. These are

described in other sections.

better. It will be noted that after having tried other presentations the automobile industry is back to round

instruments. Nothing in the modern world of vertical tapes compares with the dynamic effect of a white needle

moving around a black altimeter dial. As a target altitude is approached it is natural for the pilot to slow the needle

velocity so as to arrive at the altitude without overshoot. The difference is that in this system the dials rotate about

fixed pointers, but the relative motion retains the same effect as the moving pointer. In addition, the rotating

altimeter dial further enhances the motion factor. To satisfy personal preference the display can be switched back

and forth between round and rectangular, even in flight. Of those who have tried both the choices have been

almost unanimous in favor of the round.

indicators move outward on the bank angle scale as airspeed increases. Placed above the bank angle scale is an

inclinometer that looks just like a conventional ball in a curved tube.

Still another convenient feature is the optional presentation of important engine data in the pilot’s direct field

of vision displayed across the top of the instrument.

The analog presentations of airspeed and altitude are based on the belief that in some cases round is

Within the bank angle scale indicators are inserted which show the angle for a standard rate turn. These

TruTrak Flight Systems 2 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 5

Mechanical Installation Considerations

PROGRAMMER INSTALLATION

Mounting Considerations

The EFIS Series unit is designed to mount in the aircraft instrument panel within view and reach of the

pilot. The primary unit location should minimize pilot head movement when transitioning between

looking outside of the cockpit and viewing/operating the EFIS Series unit. Maximum recommended

viewing angle should be no more than 20 deg. The maximum mounting angle the EFIS can accommodate

is 12 degrees longitudinal axis and 0 degrees lateral axis. The location should be such that the EFIS Series

unit is not blocked by the glare shield on top, or by the throttles, control yoke, etc. on the bottom. Use

aircraft installation standards for mounting and support of the EFIS programmer.

Wiring Considerations

Use AWG #24 or larger wire for all connections unless otherwise specified. The standard solder pin

contacts supplied in the connector kit are compatible with up to AWG #18 wire. In cases where some

installations have more than one component sharing a common circuit breaker, sizing and wire gauge is

based on, length of wiring and current draw on units. In these cases, a larger gauge wire such as AWG

#20 may be needed for power connections. Do not attach any wires to the outside of the EFIS or route

high current wires within six (6) inch of the programmer. Ensure that routing of the wiring is not exposed

to sources of heat, RF or EMI interference. Check that there is ample space for the cabling and mating

connectors. Avoid sharp bends in cabling and routing near aircraft control cables. Do not route the COM

antenna coax near any EFIS components.

RFI/EMI considerations

The EFIS programmer is shielded and does not generate any appreciable level of electromagnetic

interference. The EFIS itself has been internally protected from RF interference and has been tested

under fairly extreme conditions, such as close proximity to transmitting antennas. However, it is always

good practice to insure that such antennas are properly shielded and not routed directly over or under

sensitive panel-mounted electronic equipment. Most problems in this area are the result of improper RF

shielding on transmitting antennas, microphone cables, and the like.

Pitot and Static Connections

The TruTrak EFIS require connections to the Pitot and

static lines. The preferred method of this connection

would be tee fittings near the aircraft’s airspeed indicator.

The importance of a good static port and line cannot be

overstated. In some cases, problems can be caused by

having a large number of devices connected to a single,

insufficient, static port. In other cases, the static line itself

is adequate but there are one or more devices connected to

the same line, one of which has a large static reservoir. A

simple remedy for this problem if it occurs is a tee-fitting

near the static port, and a dedicated line to the EFIS only or

a dedicated static port close to the autopilot. Obviously, an

insufficiently-large orifice coupled with large static

reservoirs can aggravate the problems associated with lag. PITOT STATIC

TruTrak Flight Systems 3 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 6

Operating Controls

As with our autopilot products, extensive attention has been given to providing the simplest operation.

No sequential pressing of buttons is required to reach basic control functions and no additional button

pressing is required to set values.

BARO & TRK SELECTION

In the TruTrak EFIS display,

both barometer BARO and

direction TRK, the green

triangle bug, are directly set

by rotation of dedicated

knobs.

DIMMING

Dimming of the display is

accomplished by press and

release of the left knob

[DIM] and then rotating the

knob Counter Clock wise to

reduce the display

illumination. External

dimmer input will only

control the button

illumination.

DIRECTION GYRO

Normally this adjustment will not be necessary as the HSI will be slaved to a GPS NMEA source. If there

is a loss of the GPS source then the internal gyro backup will maintain the DG. Depressing the soft key

beneath SET DG provides a screen for correction any drift in the DG that may occur. Natural progression

will be reduced with repeated DG SET.

TruTrak Flight Systems 4 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 7

ALTITUDE BUG

Depressing the soft key beneath ALT provides a screen for

selecting the altitude bug. The bug will move to the closes 100

ft mark of the current altitude. Then rotating the right hand

knob SELECT ALT will allow the altitude to be selected.

Each step of the rotary encoder moves the bug 500ft. while

depressing the knob provides 100ft. steps. The altitude bug will

never move out of view but will remain ether at the top of the

altimeter to indicate selected altitude is above current altitude or

the bottom to indicate selected altitude is below current altitude.

The selected altitude can always be seen above the ALT on the

display.

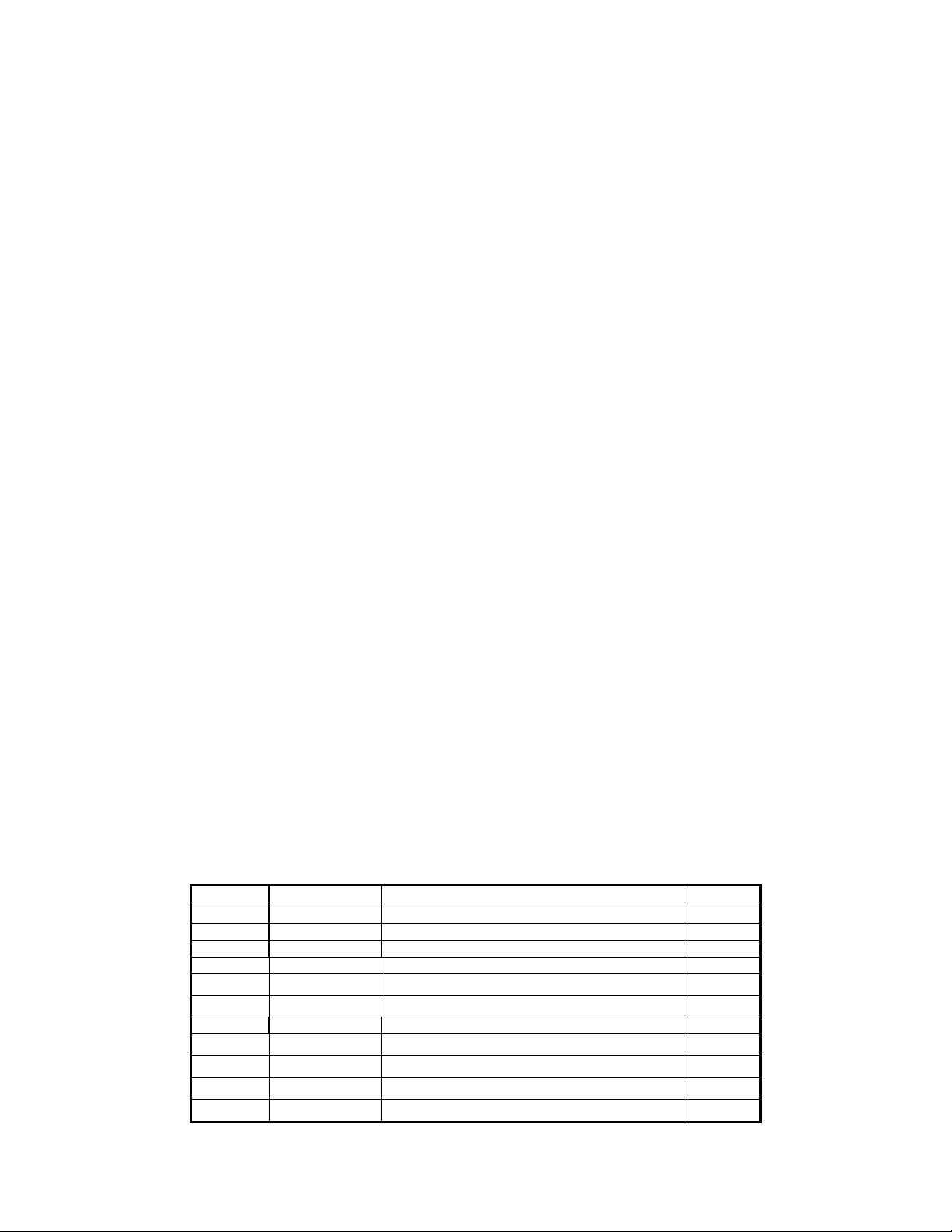

GPS INFORMATION

The HSI requires GPS NMEA information to function correctly.

If the primary serial connection and communication protocols

have been setup correctly, the EFIS screen will display NO GPS

FIX until the GPS unit has acquired satellites. Then the display

will show GPS/HSI information as shown. If not then the

Display will show NO GPS and only the DG will be operational.

When a flight plan has been entered into the GPS the HSI will

display a Course to the first way point. The deviation bar will

offset to show the aircraft present position compared to the

desired track. The yellow diamond bug shows bearing to

waypoint. Setting the HSI CRS pointer is accomplished by

pressing the soft key beneath CRS to enter the set up screen.

Rotation of the left knob selects the course.

SL 30 INFORMATION

If the serial wires are connected from a SL 30 NAV/COM. The

EFIS will have VOR or ILS above the CRS label. Press and

HOLD the button to display this information on the HSI.

TruTrak Flight Systems 5 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 8

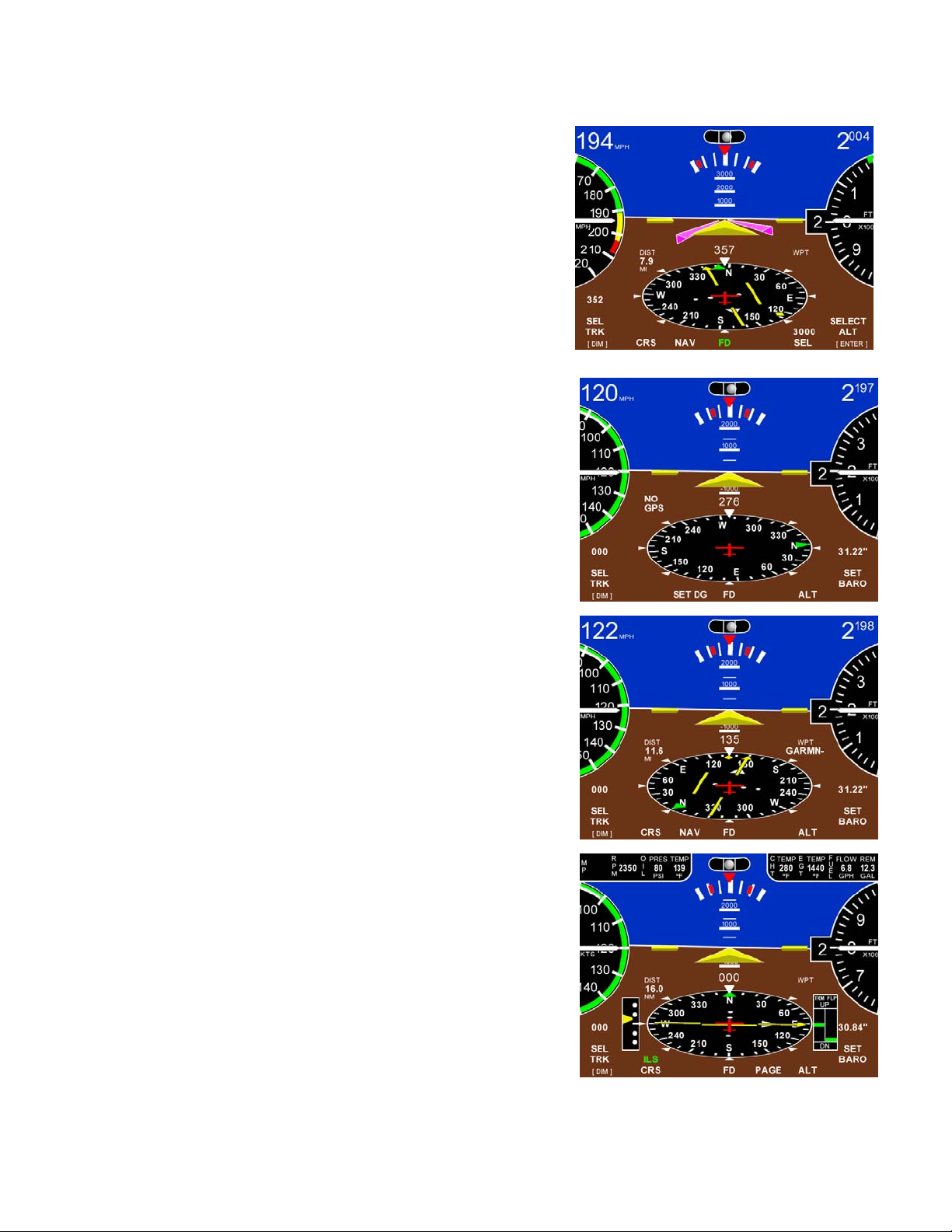

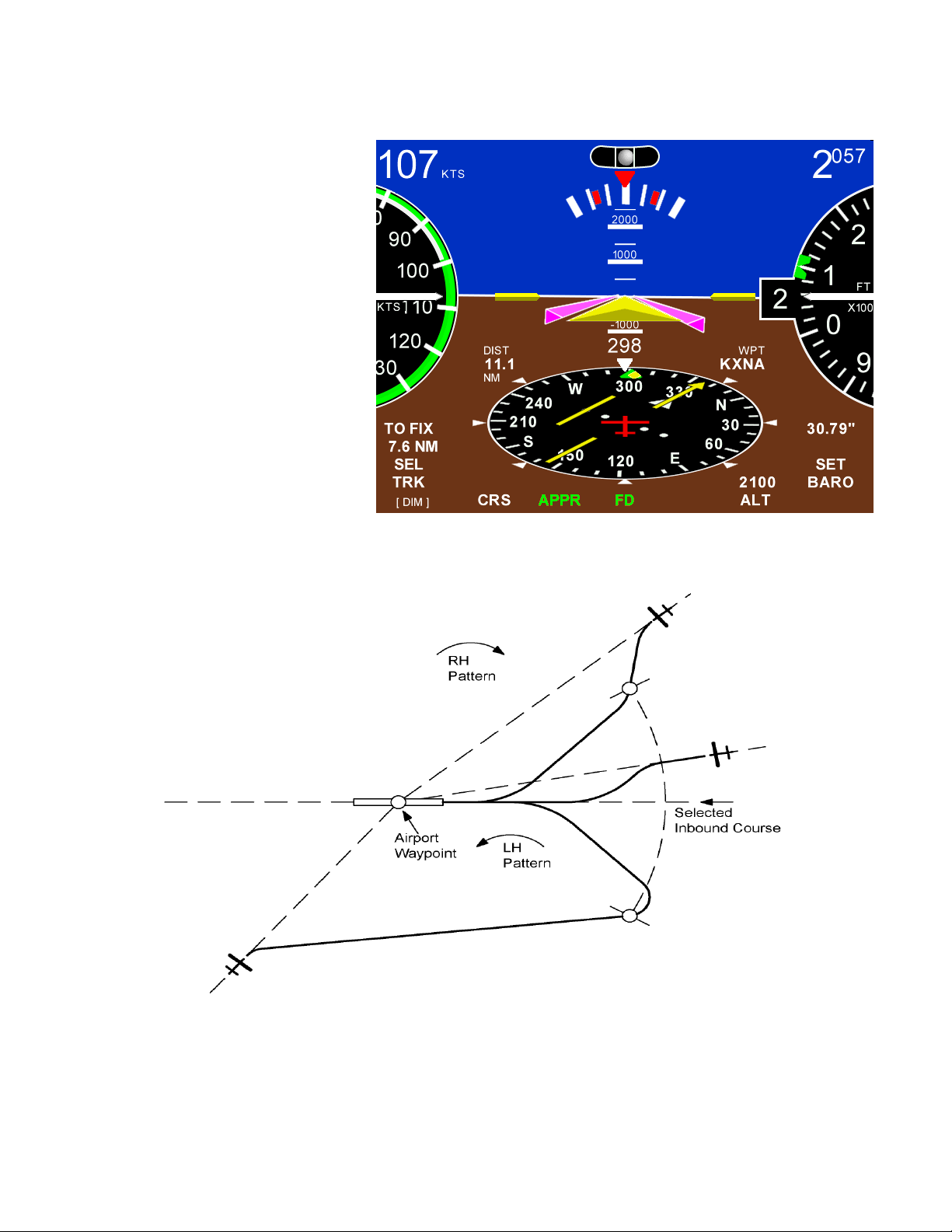

AUTOMATIC ARRIVAL TRANSITION

In an aircraft tracking a course

inbound to a destination airport, the

letters CRS will appear above the far

left soft key when the distance

becomes less than 30 miles. When

CRS is showing the autopilot can be

programmed to fly a transition from

the enroute arrival course to a

selected arrival course set into the

HSI. This is not intended to be used

in an IFR approach but instead as a

convenience for the low time pilot in

arriving at an un-familiar airport or

for the over loaded pilot in marginal

VFR weather.

To initiate the automatic

arrival mode, press CRS, select the

desired inbound runway course, and press APPR. The autopilot will now fly the entire arrival path to

the desired runway. An additional feature of the automatic arrival mode can be used to position the

aircraft according to the desired right or left hand pattern. After setting the inbound course press ENTER

instead of APPR to remain in track mode. Once the desired aircraft position is established, press CRS

then APPR to initiate the automatic arrival. This procedure works regardless of the direction of the

inbound course and that of the selected approach course to the airport.

PRESS CRS – SELECT COURSE – PRESS APPR

TruTrak Flight Systems 6 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 9

SETUP SCREENS

To enter the setup screen the right knob must be pressed and held until the SETUP shows then press and

release the soft key below SETUP before releasing the right knob. This is the location that the STYLE,

ATT & ZERO, INFO, UNITS, BALL, ALERTS, SPEEDS, & SERIAL Baud rate are set at.

Press and release the right knob to return to the main screen.

STYLE

Select ether ROUND gauge or

RECT tape style airspeed and

altimeter gauges.

Press and release the right knob to

return to the SETUP screen if no

selection pressed.

ATT & ZERO

Click ATT on or off to show aircraft attitude indication on the EFIS

horizon. The attitude can be zeroed for different aircraft by clicking

the ZERO soft key button.

INFO

This button will display the information about all the components that

are connected to the EFIS communication buss, Serial numbers,

Software version, and Model type.

The LEFT KNOB must be clicked to return to the main page.

TruTrak Flight Systems 7 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 10

UNITS

Under this button the UNIT of

Measure for the BARO ( IN HG,

MBAR) or DIST (NM, MI, KM)

readouts can be set.

BALL

After the EFIS is installation in the aircraft, center the ball by rotating

the right knob.

Press and release the right knob to return to the SETUP screen.

ALERTS

LOW AS

Setting the airspeed to 0 will disable

the warning.

When an airspeed is selected by the

right knob, the arrow on the airspeed

gauge will flash red at your selected

airspeed. The flight director bar, if

engaged, will flash red and drop to

indicate an airspeed increase is needed.

Press and release the right knob to return to the SETUP screen if no selection pressed.

TruTrak Flight Systems 8 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 11

SPEEDS

VSO Bottom of the white arc. The stall speed or the

minimum steady flight speed in the landing configuration.

VS Bottom of the green arc.

minimum steady flight speed clean configuration.

The stall speed or the

VFE

Top of the white arc. Maximum flap extended

speed.

VNO

Top of the green arc. Maximum structural

cruise speed.

VNE

Red line, Top of yellow arc. Never exceed speed.

Press and release the right knob to return to the SETUP screen if no

selection pressed.

SERIAL

Select ether 4800 or 9600 Baud for correct GPS communications.

Press and release the right knob twice to return to the MAIN screen.

TruTrak Flight Systems 9 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 12

ENGINE INFORMATION

If the Engine Data Module is installed, connecting the TCB A & B

will display engine information at the top of display. More detailed

information is available under the page button. You must return to the

MAIN page to enter the setup pages.

FLIGHT DIRECTOR

The magenta wings that come up when the FD button is pressed will

show the aircraft flight positioning to follow and maintain TRK, VSI,

NAV, etc commands. All the pilot has to do is keep the triangle in the

wings as they move to follow the commands the pilot commanded the

EFIS to perform. A change in TRK will command the wings to bank

in the direction to acquire the new TRK. (AS SHOWN) A command to

climb to a new altitude will cause the wings to move up on the

horizontal plane to acquire the new altitude. When there is not enough

airspeed to perform a climb. The FD wings will not rise above the

horizon.

EFIS SOFTWARE UPDATES

COMPACT FLASH SLOT

The EFIS software can be updated by inserting a Compact

Flash card (CE), with the face down, in the top slot on the

back. Software updates are available from TruTrak Then

apply power to the EFIS, monitor the screen. Follow the

instructions on the screen. When power is applied to the

EFIS again the new software will be installed. Confirm the

update by watching the display lower left side on startup

for the version number change or in the INFO page..

TruTrak Flight Systems 10 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 13

Electrical Pin-out

The table below provides a brief explanation of each pin function on the main 37-pin connector P101.

P101 EFIS Rear Connector (Viewed from rear of EFIS) or wire side of connector.

P101

Pin

Function Notes

1 Dedicated ground connection for Pitch Reverse Jumper.

2

Pitch Reverse Jumper

3 SL-30 RS-232 OUTPUT.

4 BUTTON DIMMER connection

5

NO CONNECTION

6

NO CONNECTION

7

ALERT

8

NO CONNECTION

9

10 Pitch Servo Torque Control. A signal from the autopilot to the pitch servo which sets the

amount of torque to be delivered by the servo.

11 Pitch Servo Trim Sensor. A signal from the pitch servo to the autopilot which indicates an

out-of-trim condition and its direction.

12 AIRCRAFT POWER (+12 to +28 V DC). The EFIS itself draws less than 3 ampere.

13 Audio signal Out. This pin may be wired to an unswitched input of an audio panel. The

autopilot uses various voice or tones to denote specific events (loss of GPSS, capture

Glideslope, etc). Volume is adjustable within a setup screen of the autopilot.

14

Pitch Servo control lines. These lines cause the stepping motor in the pitch servo to run in the

appropriate direction at the desired velocity. They are small-signal lines and do not have any

15

substantial current-carrying capability or require any special shielding. Connect to pitch servo

16

as shown on wiring diagram.

17

18

AOA

19 GROUND CONNECTION. Provide #20 AWG to common ground ing point.

Direction of servo arm / capstan rotation

EFIS autopilot only

EFIS autopilot only

Not used at this time

Not used at this time

EFIS autopilot only

EFIS autopilot only

EFIS autopilot only

Not used at this time

TruTrak Flight Systems 11 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 14

Autopilot Rear Connections to P101 (Continued)

P101

Function Notes

Pin

20 Control Wheel Switch. Connect as shown in wiring diagram to a SPST momentary sw itch

EFIS autopilot only

located remotely to the autopilot for convenient engage/disengage function.

21

FLAP SW.

22

ALT RS-232 Output

23

SPARE SWT

24

No Connection

25 PRIMARY SERIAL INPUT. Baud rate selectable 1200, 2400, 4800 or 9600 baud.

Not used at this time

Not used at this time

Not used at this time

Automatically decodes NMEA-0183, Garmin Aviation Format, or Apollo/UPSAT MovingMap or GPSS format. Provides directional reference to the autopilot.

26

ARINC-A

27

ARINC-B

28 Roll Servo Torque Control. A signal from the autopilot to the roll (aileron) servo which sets

Digital differential signals from Garmin, Sierra, or other panel-mount receiver

which provide directional steering commands (GPSS) to autopilot

EFIS autopilot only

EFIS autopilot only

the amount of torque to be delivered by the servo.

29

30

SL 30 RS232 IN

31

AP Power

Roll (aileron) Servo control lines. These lines cause the stepping motor in the roll servo to run

in the appropriate direction at the desired velocity. They are small-signal lines and do not have

any substantial current-carrying capability or require any special shield ing. Connect to roll

32

servo as shown on wiring diagram.

33

34

35

Wiring to roll servo J201

Direction of servo arm / capstan rotation

(as viewed from face of the servo body)

J101 Pin 32 Pin 33

for RIGHT aileron

Not used at this time

No Connection

EFIS autopilot only

Reverse servo

direction if necessary

by swapping wires on

pin 32 and 33. See

note 3 on wiring

diagram.

Standard J201-4 J201-5 Servo CCW (counter-clockwise) Î RIGHT

Reversed J201-5 J201-4 Servo CW (clockwise) Î RIGHT

36

37

TCB-B

TCB-A

Not used at this time

Not used at this time

EFIS

P1 pins

RS 232 25 11 Data out Data out Blue wire Blue wire Blue wire Blue wire Blue wire Blue wire Data out

ARINC

A

ARINC

B

EFIS

P1 pins

RS 232 25 19 19 19 5 / 22 P1- 22 56 56

ARINC

A

ARINC

B

King

KMD 150

26 N/C N/C N/C N/C N/C N/C N/C N/C N/C N/C

27 N/C N/C N/C N/C N/C N/C N/C N/C N/C N/C

Garmin 155XL Garmin 200XL Garmin 300XL Garmin GX 50-65 Garmin GNS 480 Garmin 430

26 16 16 16 N/C P5 - 4 46 46

27 15 15 15 N/C P5 - 24 47 47

Garmin III Garmin 92 Garmin 195 Garmin 196 Garmin 295 Garmin 296 Garmin 396 Garmin 496 AvMap

EKP IV

Garmin 530

P4001

P5001

EFIS or

EFIS AP SERIES

ALL

CURRENT DRAW

LOW BRIGHT

1.07 Amps @ 12v

0.65 Amps @ 24v

CURRENT DRAW

HIGH BRIGHT

2.02 Amps @ 12 v

1.15 Amps @ 24v

WEIGHT

2.33 lbs High bright

6.375W x 5.75H x 3.625D

1.95 lbs Low bright

DIMENSIONS

Behind panel

TruTrak Flight Systems 12 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 15

EFIS Basic Wiring Diagram

The connector ( P1) view is as if you are looking at the connector on the unit. This is the same view of the wire connector on

the wire side for pin placement.

NOTE: Some pins are not used at this time, see pin out page 11 & 12.

TruTrak Flight Systems 13 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 16

TruTrak Flight Systems 14 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 17

TruTrak Flight Systems 15 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 18

TruTrak Flight Systems 16 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 19

TruTrak Flight Systems 17 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 20

TruTrak Flight Systems 18 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 21

EFIS Pilot’s Guide

Button labels – White - mode is OFF, Green - mode is ON

Click – Momentarily push and release any knob or button

Press – Push and hold any knob or button for 2 seconds and release

Enter – Click knob labeled

[ Enter ]

Basic Operation

Barometer adjust – Rotate right knob

Track bug adjust – Rotate left knob

Altimeter bug adjust – Click ALT button, bug will synchronize to nearest 100 feet

Rotate right knob to select new altitude (Depress knob for 100 ft resolution)

Click

[ Enter ]

Altimeter bug cancel – Click ALT button

Dimmer function – Click left knob to enter setup mode Rotate left knob to set desired brightness

Click

[ Enter ]

Nav mode – Click NAV button

Nav mode cancel – Click NAV button or rotate left knob (Track bug adjust)

Flight Director Operation

Flight Director on / off – Press FD button – on,

Press FD button – off

Track select – Rotate left knob

Nav mode – Click NAV button

Nav mode cancel – Click NAV button or rotate left knob (Track select)

Altitude select – Click ALT button, bug will synchronize to nearest 100 feet

Rotate right knob to select new altitude (Depress knob for 100 ft resolution)

Click

[ Enter ] (VS is fixed at +/- 500 FPM)

Barometer adjust – Rotate right knob

Dimmer function – Click left knob to enter setup mode, Rotate left knob to set desired brightness

Click

[ Enter ]

Arrival Transition

(Note: Operation is the same regardless of FD being on or off)

Arrival Transition – Click CRS

Rotate left knob to set HSI course pointer to selected runway direction

Click APPR

TruTrak Flight Systems 19 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 22

TruTrak Flight Systems No Penalty Upgrade Policy

As the product line continues to grow, it becomes increasingly difficult to maintain a simple upgrade policy. We do

want to reward our repeat customers by allowing a lower cost upgrade from one system to another; however we

are not able to offer this across the board on all products. If you are considering an upgrade, please call and we

will give you a quote on what this would cost. Many products that we sell today are upgradeable for only the

difference in system price. Because we continually strive to have the most up to date products possible, we

occasionally have to discontinue products. We will continue to offer discounted upgrades even for our discontinued

products.

TruTrak Flight Systems 20 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 23

RETURN MERCHANDISE POLICY AND PROCEDURE

Under no circumstances should products be returned to TruTrak without first obtaining a Return of Merchandise

Authorization number (RMA #) from TruTrak. An RMA# may be obtained by contacting us at 866-878-8725.

Products that do not have an RMA # will not be processed.

Please include documentation stating the reason for the return and describing any symptoms, failure modes,

suspected causes of damage, diagnostics performed, data collected, etc.

Product(s) should be packaged in their original shipping containers. In lieu of this, they should be very carefully

packaged in containers suitable to protect them during transit. For your protection, items should be insured for the

full value. Note that damage caused during shipping will not be repaired under warranty.

The outside of the box must be clearly marked with the RMA # issued by TruTrak and the RMA # must also be

noted on the return documents.

Products will be returned to the customer at no charge via FedEx Ground or UPS Ground. If customer requests

expedited shipping (2

number.

INTERNATIONAL SHIPMENTS:

Trutrak sends all International shipments with an insurance value on all products. Trutrak pays for shipping only.

The customer is responsible for any and all additional fees, duties, taxes associated with the shipment.

When sending products to Trutrak for repair or otherwise please be advised that the customer is responsible for all

charges and fees associated with shipment. For your protection, items should be insured for the full value.

Trutrak states on all product returns “WARRANTY REPAIR AT NO CHARGE TO CUSTOMER. A COMMERCIAL

INVOICE VALUE OF $___ GIVEN FOR INSURANCE PURPOSE S ONLY”

Please keep in mind that your government or another entity in your country may impose a charge for custom and/or

brokerage fees, duties and taxes on items received from the US. These charges do not originate from our company nor do

we benefit from them in any way. You are responsible for payment of all custom and brokerage fees, duties and taxes that

may be imposed when these goods are imported into your country.

Send ALL return shipments to:

TruTrak Flight Systems, Inc., 1500 South Old Missouri Road, Springdale, AR 72764 USA

Attention: Returns Dept. RMA#

Warranty On TruTrak Flight Systems Products

We here at TruTrak Flight Systems know how important it is to feel as though the customer is purchasing a product

that the manufacturer is going to stand behind. For this reason we want offer more than the basic one year warranty

that is standard to this industry. The warranty on all TruTrak products will be three years from the date of

purchase. Abuse and misuse of a product are not covered under this warranty. Modification to a product may void

the warranty, as well as carry a penalty when upgrading to another product. This three year warranty will be for all

products except the Pictorial Turn & Bank, which will continue to have a warranty of one year from the date of

purchase.

nd

Day or Overnight) they will be charged the shipping cost and must supply a credit card

TruTrak Flight Systems 21 EFIS Installation Manual

February 2009 8300-056 Rev B

Page 24

TruTrak Flight Systems, Inc.

1500 S. Old Missouri Rd.

Springdale AR 72764

(479) 751-0250

FAX (479) 751-3397

www.trutrakap.com

Loading...

Loading...