TruTrak 380-385 Install manual

Vizion 380/385 Series Autopilots

Installation Manual

8300-086 Rev IR

TRUTRAK FLIGHT SYSTEMS

1500 S. Old Missouri Road

Springdale, AR 72764

POSTAL SERVICE ADDRESS

Springdale, AR 72765-0189

Ph: 479-751-0250 Fax: 479-751-3397

www.trutrakap.com

P.O. Box 189

INSTALLATION MANUAL

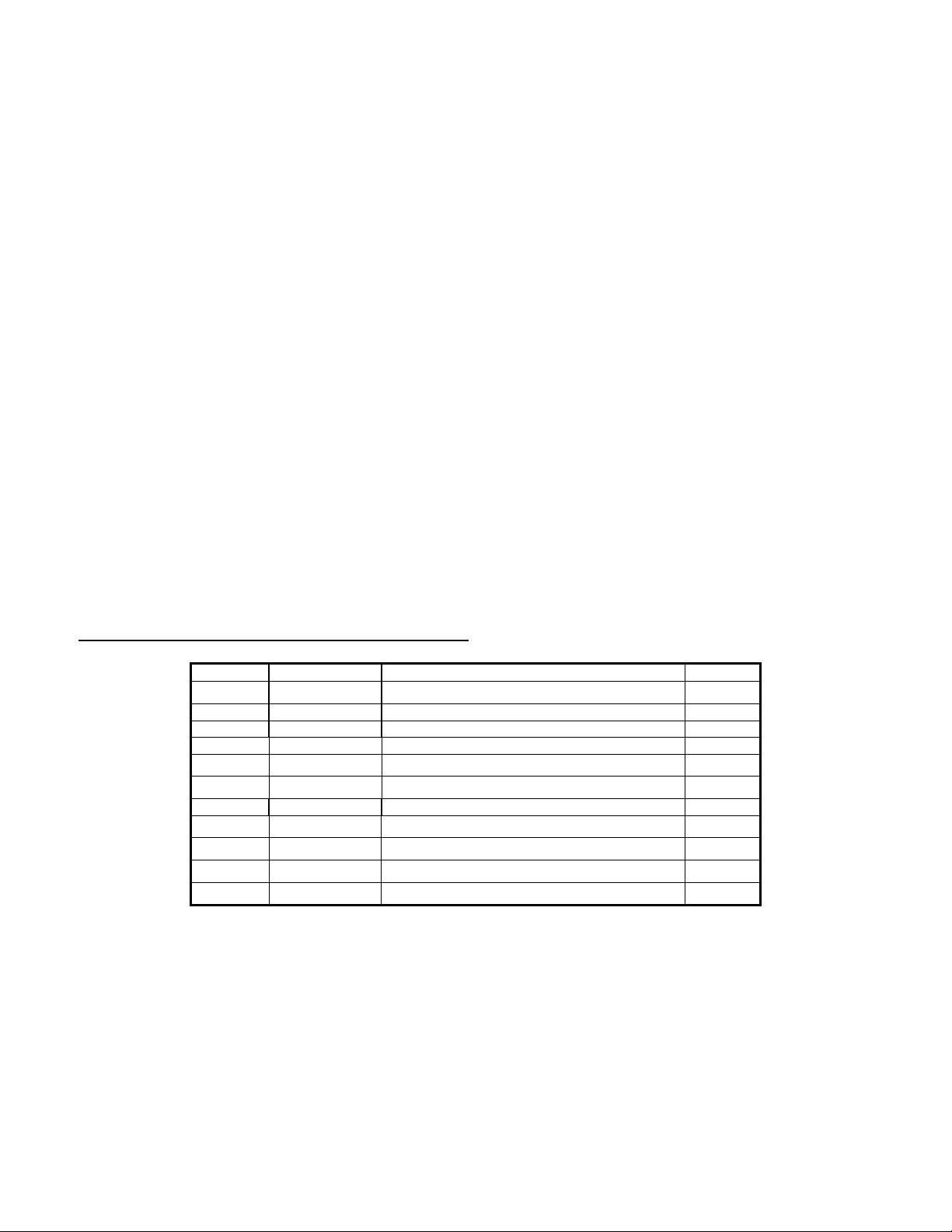

Revision

Date

Description

Page #

IR

12/18/2013

Initial Release

For

Vizion 380/385 Series Autopilots

TABLE OF CONTENTS

Mechanical Considerations ..................................................................................................................................................................... 1

Pitot / Static Connections ........................................................................................................................................................................ 2

RFI / EMI Considerations ........................................................................................................................................................................ 2

Vizion Series Ground Checkout ............................................................................................................................................................. 3

Electrical Pin-out ......................................................................................................................................................................................... 4

Vizion Wiring Diagram ............................................................................................................................................................................. 5

Controller Dimensions/Panel Cut-outs ............................................................................................................................................. 6

GPS Setup Guide........................................................................................................................................................................................ 91

Garmin 430W and 530W ........................................................................................................................................................................................ 113

Warranty Information/Upgrade Policy .......................................................................................................................................... 17

RETURN MERCHANDISE POLICY AND PROCEDURE ........................................................................................................... 18

Mechanical Considerations

The installation information in this section is extremely important and must be clearly

understood by the installer. Improper servo installation or failure to observe and

diagnose installation problems prior to flight can result in extremely serious

consequences, including loss of ability to control the aircraft. If there are any

questions on the part of the installer it is mandatory to resolve these questions prior to

flight of the aircraft.

Most modern experimental aircraft use push-pull tubes to drive the primary controls. These tubes generally have a

total travel of 3” or less; therefore, it is best to connect the autopilot servo to the primary control by the same method.

This connection consists of an arm on the servo connected by a push-pull rod to the primary control. Rod-end bearings

are required on each end of the push-pull rod.

The servo arm must not rotate even near to the point called OVER CENTER, the point at which the

primary aircraft control would lock up. Some aircrafts mechanical primary control installations will not

allow this to occur and do not need the servo stops.

This is a condition that would result from the servo being back driven when the pilot operates the controls,

or from the servo itself driving the controls to a stop. To protect against this mechanical stops are supplied

with the servos. These stops are drilled so that they can be mounted at different angles as required (18

intervals).

In addition to the proper use of the stop it is important to know the amount of travel on the primary

control that the servo can handle. With the push rod connected to the outermost hole (1 ½”) the travel on

the primary cannot exceed 2 ½”, the intermediate hole 2 1/16”, and the inner hole 1 5/8”.

It is important to note that at the neutral point of the control the SERVO ARM must be PERPENDICULAR to

the push rod, and that the stop must be mounted so as to limit travel as near as possible to equal amounts

in both directions. In certain factory-designed installations there may be well-proven exceptions.

There will be installations in which space does not permit the use of the stop. When this is done the aircraft’s primary

control stops must be positive and care must be taken to be sure that at the neutral point the servo arm is

perpendicular to the push rod, and that the travel limits of the servo arm are not exceeded.

There are installations in which the travel of the push-pull tube exceeds the allowable 2 ½”. For such installations, the

drive can be applied to a bell crank at a radius point that moves the desired 2 ½” of maximum allowed travel in the

outermost hole of the arm.

When there is no way to have a drive point of less than 2 ½” or when the primary control is cable-driven it is necessary

to use the capstan-cable servo drive. When this is done the servo should be mounted so that the 1/16” diameter cable

which wraps around the capstan when extended parallel to the primary cable is approximately 3/16” from the primary

cable. If the primary control travel does not exceed 5” the cable locking pin will be 180 away from the point at which

the cable leaves the capstan. When the primary control is at the neutral point this means the total cable wrap around

the capstan is 360 . If the primary control travel is greater than 5” the cable wrap is 720 and the pin is adjacent to the

output point when the primary control is at the neutral point.

The cable clamps when properly installed will not slip and thus get loose, but it is desirable to NICO press or swedge a

fitting on to the cable so as to provide added assurance that the cable will not become slack. If the bridle cable is not

sufficiently tight there will be lost motion in the autopilot drive. This will result in hunting (oscillation).

TruTrak Flight Systems 1 Vizion 380/385 Series Autopilot Installation Manual

December 2013 8300-086 Rev IR

Controller Installation

Mounting Considerations

The Vizion controller unit is designed to mount in the aircraft instrument panel within view and reach of the pilot.

Maximum recommended viewing angle should be no more than 20 deg. The maximum mounting angle the Vizion can

accommodate is 10 degrees longitudinal (pitch) axis and 0 degrees lateral (roll or yaw) axis. The location should be

such that the controller unit is not blocked by the glare shield on top, or by the throttles, control yoke, etc. on the

bottom. Use aircraft installation standards for mounting and support of the controller.

Wiring Considerations

Use AWG #24 or larger wire for all connections unless otherwise specified. The standard solder pin contacts supplied in

the connector kit are compatible with up to AWG #18 wire. In cases where some installations have more than one

component sharing a common circuit breaker, sizing and wire gauge is based on length of wiring and current draw on

units. In these cases, a larger gauge wire such as AWG #20 may be needed for power connections. Do not attach any

wires to the outside of the programmer or route high current wires within six (6) inch of the programmer. Ensure that

routing of the wiring is not exposed to sources of heat, RF or EMI interference. Check that there is ample space for the

cabling and mating connectors. Avoid sharp bends in cabling and routing near aircraft control cables. Do not route the

COM antenna coax near any autopilot components.

Pitot and Static Connections

All multi-servo TruTrak autopilots require connections to the pitot and static lines. The preferred method of this

connection would be tee fittings near the aircraft’s altimeter. The static line for the autopilot requires due care in its

construction, as excessive lag or insufficient static orifices can cause the autopilot to oscillate (hunt) in pitch. Although

there is compensation within the autopilot sufficient to handle moderate amounts of lag, the importance of a good static

port and line cannot be overstated. In some cases problems can be caused by having a large number of devices

(including the autopilot) connected to a single, insufficient, static port. In other cases, the static line itself is adequate

but there are one or more devices connected to the same line, one of which has a large static reservoir. A simple remedy

for this problem if it occurs is a tee-fitting near the static port, and a dedicated line to the autopilot only. Obviously, an

insufficiently-large orifice coupled with large static reservoirs can aggravate the problems associated with lag.

RFI/EMI considerations

The autopilot controller is shielded and does not generate any appreciable level of electromagnetic interference.

Moreover, the servo lines (except for power and ground) are low-current and cannot contribute to RF interference. The

servo power and ground lines do have switching currents through them, but so long as there are no parallel runs of

servo power and ground lines with such things as poorly-shielded antenna lines or strobe light power lines, there is no

need to shield the servo harnesses.

The autopilot itself has been internally protected from RF interference and has been tested under fairly extreme

conditions, such as close proximity to transmitting antennas. However, it is always good practice to insure that such

antennas are properly shielded and not routed directly over or under sensitive panel-mounted electronic equipment.

Most problems in this area are the result of improper RF shielding on transmitting antennas, microphone cables, and

the like. The most sensitive input to the autopilot is the Control Wheel Switch input. This line should not be routed in

parallel with transmitting antennas or other sources of known RF interference. If necessary, it can be shielded with the

shield connection to pin 13 of the autopilot connector.

TruTrak Flight Systems 2 Vizion 380/385 Series Autopilot Installation Manual

December 2013 8300-086 Rev IR

Vizion Ground Checkout

Once installation and setup of the autopilot are complete (see Operation Manual for setup and operation instructions), a

ground checkout is a good idea before the first flight of the system. This is a simple procedure to verify that the servos

move in the correct direction. Follow the steps below to verify this:

-1) Center both the aileron and elevator control surfaces.

-2) Engage the autopilot.

-3) Turn the knob clockwise, make sure the controls move to the right (stick) or clockwise (yoke).

-4) Turn the knob counter-clockwise. It must be turned enough to select a left bank angle. Make sure the controls move

to the left (stick) or counter-clockwise (yoke).

-5) Push the knob to move the cursor to SVS and turn the knob clockwise to select a climb rate. Make sure the controls

move aft. The cursor will return to the Bank selection after three seconds.

-6) Push the knob to move the cursor to SVS and turn the knob counter-clockwise. It must be turned enough to select a

rate of descent on the autopilot display. Make sure the controls move forward.

If steps 2-6 are all verified then the Vizion is ready to be engaged in flight.

*For instructions on accessing the setup menus and adjusting autopilot settings, please see section 5 of the

Vizion 380/385 Operating Manual.

*For recommended settings of common Experimental-Amateur Built aircraft, please see section 8 of the Vizion

380/385 Operating Manual.

TruTrak Flight Systems 3 Vizion 380/385 Series Autopilot Installation Manual

December 2013 8300-086 Rev IR

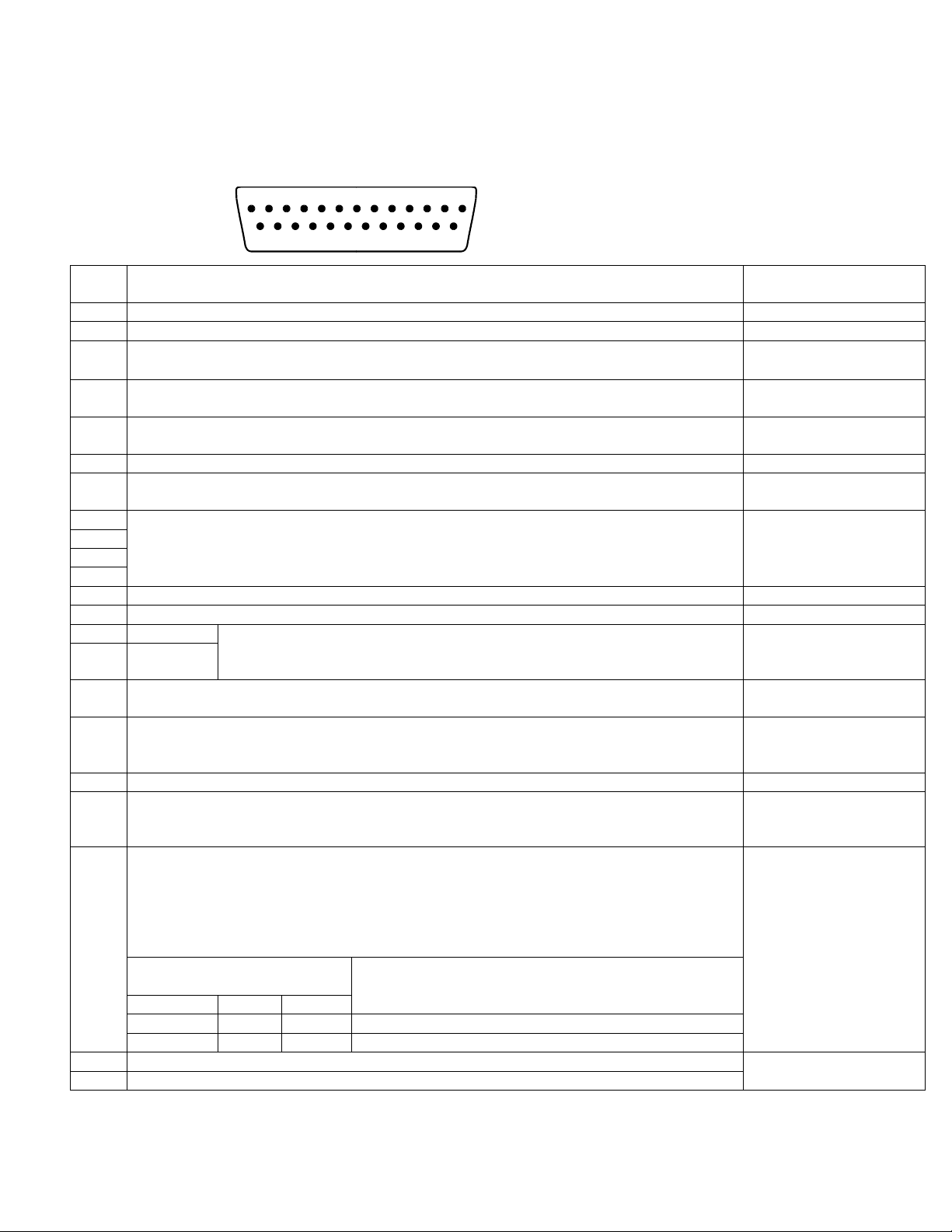

Electrical Pin-out

P101

Pin

Function

Notes

1

Used for external Emergency AP Level button connection.

2 Used for external Emergency AP Level button connection.

3

Control Wheel Switch. Connect as shown in wiring diagram to a SPST momentary switch

located remotely to the autopilot for convenient engage/disengage function.

4

Pitch Servo Torque Control. A signal from the autopilot to the pitch servo which sets the

amount of torque to be delivered by the servo.

5

Pitch Servo Trim Sensor. A signal from the pitch servo to the autopilot which indicates

an out-of-trim condition and its direction.

6

Unused.

7

RS-232 Output. Output to G3X/AFS-5000 series

Required for integrated

control mode.

8

Pitch Servo control lines. These lines cause the stepper motor in the pitch servo to run in

the appropriate direction at the desired velocity. They are small-signal lines and do not

have any substantial current-carrying capability or require any special shielding. Connect

to pitch servo as shown on wiring diagram.

9

10

11

12

Yaw Damper option.

13

Ground Connection. Provide #20 AWG to common grounding point.

14

ARINC-A

Digital differential signals from Garmin, Sierra, or other panel-mount

receiver which provide directional steering commands (GPSS, GPSV) to

autopilot

Vizion 385 Only

15

ARINC-B

16

Roll Servo Torque Control. A signal from the autopilot to the roll (aileron) servo which

sets the amount of torque to be delivered by the servo.

17

Primary Serial Input. Baud rate selectable 1200, 2400, 4800 or 9600 baud.

Automatically decodes NMEA-0183, Garmin Aviation Format, or Apollo/UPSAT MovingMap or GPSS format. Provides directional reference to the autopilot.

18

Auxiliary RS-232 Input. Presently unused.

19

Autopilot Master (+12 to +28 V DC). The autopilot itself draws less than 0.5 ampere.

Most of the current required by the autopilot system is used by the servos (up to 2A per

servo).

20

21

22

23

Roll (aileron) Servo control lines. These lines cause the stepping motor in the roll servo

to run in the appropriate direction at the desired velocity. They are small-signal lines and

do not have any substantial current-carrying capability or require any special shielding.

Connect to roll servo as shown on wiring diagram.

Reverse servo direction

if necessary by

swapping wires on pins

20 and 21. See note 2 on

wiring diagram.

Wiring to roll servo J201

Direction of servo arm / capstan rotation

(as viewed from face of the servo body)

for RIGHT aileron

J101

Pin 20

Pin 21

Standard

J201-4

J201-5

Servo CCW (counter-clockwise) RIGHT

Reversed

J201-5

J201-4

Servo CW (clockwise) RIGHT

24

TCB-A

Unused at this time, for

future expansion.

25

TCB-B

Rear 25-Pin Connector P101

viewed from rear of unit

1

20 21 22 23 24 25

2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19

All TruTrak Vizion 380 and 385 autopilots have consistent wiring requirements. Therefore, this manual covers all such

units, with special notations covering any differences between the units. The table below provides a brief explanation

of each pin function on the main 25-pin connector P101.

TruTrak Flight Systems 4 Vizion 380/385 Series Autopilot Installation Manual

December 2013 8300-086 Rev IR

Loading...

Loading...