Page 1

XENION® HELION® Surgical Lighting System

Service Manual

Page 2

To the Service technician,

Please read through this service manual with great care and comply with the safety information and requirements for servicing.

CE markingCE marking

CE marking

CE markingCE marking

This item of equipment is a Class I medical device as defined by

the European Medical Device Directive (MDD) 93/42/EEC, June

1993, Appendix IX.

Conformity

The manufacturer declares that this product conforms to the fundamental requirements according to MDD Appendix I and documents this by means of the CE marking.

What equipment forms the subject of this service manual?What equipment forms the subject of this service manual?

What equipment forms the subject of this service manual?

What equipment forms the subject of this service manual?What equipment forms the subject of this service manual?

The surgical lighting system with the following variants:

• 1 to 4-fold suspension with the following types of lamp:

HELION

®

with halogen lamp:

• HELION S; HELION M/M+; HELION L/L+.

XENION

®

with metal vapour lamp:

• XENION M/M+; XENION L/L+.

And the following optional equipment:

• TFT flat screens 15

“ and 19“,

• HELION M/M+; L/L+; XENION M+ with fixed focus camera.

• TruVidia camera system.

TT

echnical Customer Service is at your disposal,echnical Customer Service is at your disposal,

T

echnical Customer Service is at your disposal,

TT

echnical Customer Service is at your disposal,echnical Customer Service is at your disposal,

• if you have any questions on disassembly, repairs or settings,

or

• if you would like to re-order spare parts.

2

Sales

Service

Visit us on the Internet

How to contact usHow to contact us

How to contact us

How to contact usHow to contact us

• TRUMPF KREUZER Medizin Systeme GmbH + Co. KG

• Benzstrasse 26

• 82178 Puchheim, Germany

• Telephone: +49 / (0)89 / 8 09 07 - 0

• Fax: +49 / (0)89 / 8 09 07 - 2 22

• Telephone: +49 / (0) 180 / 2 25 41 35

• Fax: +49 / (0) 36 71 / 58 61 75

© TRUMPF KREUZER, 2004

• Edition: 03/2005, Version 1 (15.03.2005)

www.Trumpf-med.com

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 3

Notes relating to this documentation

Copyright

We reserve the right to

make changes

Copyrights

Translations

Trademarks

• The information contained in this service manual and parts

thereof are the intellectual property of TRUMPF KREUZER

Medizin Systeme GmbH + Co. KG and is protected by national and international copyright and other laws for the protection of intellectual property.

• Any duplication, reproduction, translation, microfilming storage - in either electronic or magnetic form - processing as

electronically or magnetically stored data, copying or distribution of these documents and/or the information contained

herein or parts thereof without the prior written approval of

TRUMPF KREUZER Medizin Systeme GmbH + Co. KG is hereby

strictly prohibited.

TRUMPF KREUZER Medizin Systeme GmbH + Co. KG shall

assume no liability whatsoever on the basis of, or in association with, the use of said information prohibited in this manner

by any person or company.

• TRUMPF KREUZER Medizin Systeme GmbH + Co. KG reserves

the right to amend, delete or modify in any other manner all

information contained herein at any time and on any grounds

without prior notice.

We are constantly engaged on the further development of our

products and reserve the right to make changes to the scope

of supply in terms of design, equipment or technology.

• TRUMPF KREUZER Medizin Systeme GmbH + Co. KG explicitly reserves all rights under the copyright laws.

• The German-language version of this service manual shall be

binding as regards translations into foreign languages.

• The HELION

®

and XENION® lamps are registered trademarks

of TRUMPF KREUZER Medizin Systeme GmbH + Co. KG.

• All trademarks mentioned in this service manual are the sole

property of the respective manufacturers.

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 3

Page 4

Contents

11

Important Information for the Service TImportant Information for the Service T

1

Important Information for the Service T

11

Important Information for the Service TImportant Information for the Service T

1.1 Information for the service technician .......................... 8

1.2 Tools and equipment required .................................... 8

1.3 Proper servicing ........................................................ 9

1.4 Warranty and liability ................................................. 9

1.5 Disposal ................................................................... 9

22

YY

our Safety is Important to Usour Safety is Important to Us

2

Y

our Safety is Important to Us

22

YY

our Safety is Important to Usour Safety is Important to Us

2.1 Symbols used in this service manual ......................... 10

2.2 Symbols on the equipment ....................................... 10

2.3 Overview of the most important safety information ..... 11

33

Observe these WObserve these W

3

Observe these W

33

Observe these WObserve these W

44

TT

able - Table - T

4

T

able - T

44

TT

able - Table - T

55

Changing the LChanging the L

5

Changing the L

55

Changing the LChanging the L

roubleshooting and Proubleshooting and P

roubleshooting and P

roubleshooting and Proubleshooting and P

ork Rork R

ulesules

ork R

ules

ork Rork R

ulesules

ampamp

..........................................................................................

amp

.............................................

ampamp

..........................................................................................

..............................................................

...............................

..............................................................

........................................................................

....................................

........................................................................

ossible Rossible R

ossible R

ossible Rossible R

echnicianechnician

echnician

echnicianechnician

emediesemedies

emedies

emediesemedies

............

......

............

............

......

............

1010

10

1010

1313

13

1313

1414

14

1414

1717

17

1717

88

8

88

5.1 Changing the lamp of the HELION S ........................ 17

5.2 Changing the lamp of the HELION M/M+ / L/L+ ..... 17

5.3 Changing the lamp of the XENION M/M+ ...............18

5.4 Changing the lamp of the XENION L/L+ ..................19

66

Setting the LSetting the L

6

Setting the L

66

Setting the LSetting the L

6.1 Setting the luminous field for the

HELION M/M+ / L/L+ ........................................... 20

6.2 Setting the luminous field for the XENION M/M+ ...... 21

6.3 Setting the luminous field for the XENION L/L+ ......... 22

6.4 Setting the luminous field for the XENION M

with fixed focus camera ........................................... 22

77

RR

eplacing the Feplacing the F

7

R

eplacing the F

77

RR

eplacing the Feplacing the F

88

TT

esting the Servomotor for theesting the Servomotor for the

8

T

esting the Servomotor for the

88

TT

esting the Servomotor for theesting the Servomotor for the

HELION M/M+ L/L+HELION M/M+ L/L+

HELION M/M+ L/L+

HELION M/M+ L/L+HELION M/M+ L/L+

8.1 Testing the polarity of the servomotor ........................ 24

8.2 Testing the servomotor ............................................. 25

99

TT

esting the Input Vesting the Input V

9

T

esting the Input V

99

TT

esting the Input Vesting the Input V

uminous Fuminous F

uminous F

uminous Fuminous F

ilter Glass Assemblyilter Glass Assembly

ilter Glass Assembly

ilter Glass Assemblyilter Glass Assembly

ieldield

........................................................................

ield

....................................

ieldield

........................................................................

....................................................................................

..........................................

....................................................................................

oltagesoltages

oltages

oltagesoltages

..........................................................................

.....................................

..........................................................................

............................................

......................

............................................

2020

20

2020

2323

23

2323

2424

24

2424

2626

26

2626

4

9.1 Testing the input voltage of the transformer ............... 26

9.2 Testing the mains fuse for the building

power supply .......................................................... 26

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 5

Contents

1010

TT

esting the Electrics of the Support Systemesting the Electrics of the Support System

10

T

esting the Electrics of the Support System

1010

TT

esting the Electrics of the Support Systemesting the Electrics of the Support System

10.1 Testing the voltage at the sliding contact in the extension

arm........................................................................ 27

10.2 Replacing the sliding contact in the extension arm/

Testing the slip ring on the central column ................. 28

10.3 Dismantling the light head ....................................... 29

10.4 Testing the cables in the spring arm that lead to the

contact block

in the extension arm ................................................29

10.6 Testing the cables in the extension arm...................... 30

10.7 Replacing the cables in the extension arm .................31

10.8 Dismantling the central column ................................31

10.9 Replacing the slip ring ............................................. 32

1111

TT

esting the Electrics of theesting the Electrics of the

11

T

esting the Electrics of the

1111

TT

esting the Electrics of theesting the Electrics of the

..........................

.............

..........................

2727

27

2727

HELION M / L LHELION M / L L

HELION M / L L

HELION M / L LHELION M / L L

11.1 Testing the voltage at the focus unit .......................... 33

11.2 Testing the voltages and cables in the lamp ............... 34

1212

TT

esting the Electrics of theesting the Electrics of the

12

T

esting the Electrics of the

1212

TT

esting the Electrics of theesting the Electrics of the

HELION M+ / L+ LHELION M+ / L+ L

HELION M+ / L+ L

HELION M+ / L+ LHELION M+ / L+ L

12.1 Testing the voltage at the focus unit .......................... 36

12.2 Testing the operating voltages, fuse and

cables in the lamp ................................................... 37

12.3 When the dimmer is defective .................................. 39

1313

TT

esting the Electrics of theesting the Electrics of the

13

T

esting the Electrics of the

1313

TT

esting the Electrics of theesting the Electrics of the

XENION M/M+ / L/L+ LXENION M/M+ / L/L+ L

XENION M/M+ / L/L+ L

XENION M/M+ / L/L+ LXENION M/M+ / L/L+ L

13.1 Testing the operating voltages, fuses and

cables in the lamp ................................................... 40

13.2 When the dimmer is defective .................................. 42

1414

FF

unctional Check, Hand-unctional Check, Hand-

14

F

unctional Check, Hand-

1414

FF

unctional Check, Hand-unctional Check, Hand-

ampamp

........................................................................................

amp

............................................

ampamp

........................................................................................

ampamp

............................................................................

amp

......................................

ampamp

............................................................................

ampamp

............................................................

amp

..............................

ampamp

............................................................

Over and CustomerOver and Customer

Over and Customer

Over and CustomerOver and Customer

3333

33

3333

3636

36

3636

4040

40

4040

InstructionInstruction

Instruction

InstructionInstruction

14.1 Important Information .............................................. 43

14.2 Inspection intervals and authorised staff ....................43

14.3 Monitoring activities ................................................ 44

14.4 Testing the function of the lamps............................... 48

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 5

......................................................................................................................

...........................................................

......................................................................................................................

4343

43

4343

Page 6

Contents

15 T15 T

15 T

15 T15 T

15.1 Data sheets ............................................................ 50

15.2 Circuit diagrams and set values ................................ 52

echnical Descriptionechnical Description

echnical Description

echnical Descriptionechnical Description

15.2.1 HELION M/M+; HELION L/L+; HELION XL+ ..52

15.2.2 XENION M/M+; XENION L/L+........................ 53

15.2.3 XENION M / M+ ............................................ 54

15.2.4 XENION L/L+ ................................................. 55

15.2.5 HELION M+; HELION L+

with wall control panel ..................................... 56

15.2.6 XENION M/M ; XENION L/L+

with wall control panel ..................................... 57

15.2.7 24 V power supply AC/DC HELION M/M+;

HELION L/L+ ; HELION XL+;

XENION M/M+; XENION L/L+........................ 58

15.2.8 TruVidia combination

with HELION M/M+; HELION L/L+; HELION XL+;

XENION M/M+; XENION L/L+ lamps ...............59

15.2.9 7-pole plug -> cardanic suspension

TruVidia 8-pole DIN socket ...............................60

15.2.10 5-pole plug TFT LCD monitor with cardanic suspen-

sion; (optional DC/DC converter) ...................... 61

15.2.11 TFT LCD monitor .............................................. 62

15.2.12 TFT LCD monitor

with monitor power supply unit .......................... 63

15.2.13 Plug connector -> TruVidia spring arm .............. 64

15.2.14 Plug connector -> spring arms

3-pole / 5-pole / 7-pole................................... 65

15.2.15 HELION M/L light head ....................................66

15.2.16 HELION M/L light head

with fixed focus camera .................................... 67

15.2.17 HELION M/L light head

with TruVidia .................................................... 68

15.2.18 HELION M+/L+ light head .............................. 69

15.2.19 HELION M+/L+ light head

with wall control panel ..................................... 70

15.2.20 HELION M+/L+ light head

with fixed focus camera .................................... 71

15.2.21 HELION M+/L+ light head

with TruVidia .................................................... 72

15.2.22 HELION M+/L+ light head

with fixed focus camera and wall control panel... 73

....................................................................................

..........................................

....................................................................................

5050

50

5050

6

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 7

Contents

15.2.23 XENION M light head ...................................... 74

15.2.24 XENION M light head

with wall control panel ..................................... 75

15.2.25 XENION M light head

with fixed focus camera .................................... 76

15.2.26 XENION M light head

with TruVidia .................................................... 77

15.2.27 XENION L light head ........................................78

15.2.28 XENION L light head

with wall control panel ..................................... 79

15.2.29 XENION L light head

with TruVidia .................................................... 80

15.2.30 XENION M+ light head.................................... 81

15.2.31 XENION M+ light head

with wall control panel ..................................... 82

15.2.32 XENION M+ light head

with fixed focus camera .................................... 83

15.2.33 XENION M+ light head

with TruVidia .................................................... 84

15.2.34 XENION M+ light head

with fixed focus camera and wall control panel... 85

15.2.35 XENION L+ light head .....................................86

15.2.36 XENION L+ light head

with wall control panel ..................................... 87

15.2.37 XENION L+ light head

with TruVidia .................................................... 88

15.2.38 HELION/XENION transformer connector ........... 89

15.3 Test report .............................................................. 90

16 T16 T

16 T

16 T16 T

echnical Dataechnical Data

echnical Data

echnical Dataechnical Data

........................................................................................................

....................................................

........................................................................................................

9191

91

9191

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 7

Page 8

1 Important Information for the Service Technician

Only for trained and authorised

fitters

Servicing in accordance with

this service manual

Use original parts only

In case of problems

Defective parts

Repairs outside the scope of

the repair order

No unauthorised or

temporary repairs

1.11.1

1.1

1.11.1

This service manual is intended only for service technicians

trained and authorised by TRUMPF KREUZER Medizin Systeme GmbH + Co. KG.

Information for the service technicianInformation for the service technician

Information for the service technician

Information for the service technicianInformation for the service technician

• Servicing must be carried out in steps according to this service

manual.

• The safety, reliability and performance of the equipment is only

ensured where TRUMPF KREUZER original parts are used.

• If, when dismantling, making repairs or settings, you encounter problems which are not covered by this service manual or

not covered in sufficient detail, you should immediately contact your nearest TRUMPF KREUZER Customer Service Centre

for your own safety and that of the hospital staff and patients.

Only carry out repairs that you are familiar with from your

training and which are included in this service manual.

• Replace any defective parts with TRUMPF KREUZER original

parts.

If it should be necessary to replace parts outside the scope of

the repair order, discuss this work with the customer first.

• Unauthorised or temporary repairs are not permitted even if

requested by the customer.

Comply with all the requirements from the current laws, regulations and standards.

• For information and to order spare parts please contact

TRUMPF KREUZER Service

(Telephone: +49 / (0) 180 / 225 4135).

1.21.2

1.2

1.21.2

TT

ools and equipment requiredools and equipment required

T

ools and equipment required

TT

ools and equipment requiredools and equipment required

• Basic equipment:

- fitter’s tool set,

- cordless screwdriver

• Measuring instruments:

- luxmeter (for measuring light intensity),

- voltmeter (for making electrical measurements).

• For fitting/dismantling heavy components:

- Lifting equipment with a permitted load of at least 200 kg. The

lift must correspond at least to the height of the ceiling.

- Ladder with necessary length.

• Accessories:

- cable ties

8

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 9

1 Important Information for the Service Technician

Check the installation position

of the cables

Installing safety devices

Before the functional check

Check the PE connections

Carry out functional check

1.31.3

1.3

1.31.3

Observe the following rules when carrying out service work:

• Put the cables back in their original installation position.

• Install or renew all safety devices such as covers, cable ties,

• Check cables that have been detached or been renewed against

• Check that the earth connections comply with the current stand-

• Carry out a functional check according to Chapter 14:

1.41.4

1.4

1.41.4

TRUMPF KREUZER Medizin Systeme GmbH + Co. KG assumes

no liability for the reliable and proper functioning of the

surgical lighting system if:

• installation, modifications and repairs are not performed by

• The electrical installation of the respective equipment does not

• The surgical lighting system is used other than for its intended

PP

roper servicingroper servicing

P

roper servicing

PP

roper servicingroper servicing

Check the cables when positioning the lamp etc. to ensure

they are not severed or squashed.

cable holders, cable shields, ground, equipotential bonding

and earth connections.

the circuit diagrams in this service manual to ensure they have

been properly connected.

ards in your country.

“Functional Check, Hand-Over and Customer Instruction”.

WW

arranty and liabilityarranty and liability

W

arranty and liability

WW

arranty and liabilityarranty and liability

TRUMPF KREUZER service technicians or persons authorised

by TRUMPF KREUZER.

comply with the regulations currently applicable.

purpose as stated in the operating instructions.

1.51.5

1.5

1.51.5

• Please dispose of the packaging materials according to the

• Observe that it is compulsory to recycle removed components,

DisposalDisposal

Disposal

DisposalDisposal

applicable guidelines for disposal.

particularly electronic components and cables.

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 9

Page 10

2 Your Safety is Important to Us

DANGER

WARNING

CAUTION

NOTE

2.12.1

2.1

2.12.1

Important information is shown in this service manual and

on the equipment using symbols and key words.

Signal words such as DANGER, WARNING or CAUTION indicate the level of risk. This is visually emphasised by the

different triangle symbols.

The signs have the following meanings:

Symbols used in this service manualSymbols used in this service manual

Symbols used in this service manual

Symbols used in this service manualSymbols used in this service manual

Failure to comply will certainly result in

severe or even fatal injury.

Failure to comply may result in

severe or even fatal injury.

Failure to comply may result in

minor or moderate injury or damage to property.

Offers tips on usage and handy information.

Electric shock

Falling load

Sudden release

of spring arm

Biohazard

Laser radiation

Danger of

tripping

Danger of an electric shock which may result in severe or even

fatal injury.

Danger of a falling load when in the installation area under a light

system or following incorrect installation.

Danger of sudden release of the spring arm when dismantling the

lamps.

Danger of infection due to the lighting system not being cleaned

and disinfected.

Danger of eye damage due to the optional laser (Class 2) in the

central hand grip.

Danger of tripping and falling over tools or components in the

hospital staff’s path.

2.22.2

2.2

2.22.2

Symbols on the equipmentSymbols on the equipment

Symbols on the equipment

Symbols on the equipmentSymbols on the equipment

10

ATTENTION! Comply with operating instructions.

CE conformity marking with

number 0123 of notified body.

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 11

2 Your Safety is Important to Us

2.32.3

2.3

2.32.3

Hazards from electric shockHazards from electric shock

Hazards from electric shock

Hazards from electric shockHazards from electric shock

DANGER – power supply and emergency power supply:

During all servicing the building power supply and the emergency

power supply must be de-energised all-pole disconnection and

prevented from being switched back on again.

DANGER – Electric shock - High voltage 300 V:

The ballast in XENION lamps produces a starting voltage of

300 V:

When carrying out measurements in the lamps and when the power

is switched on:

• cordon off the installation site,

• avoid all contact with conductive parts.

Overview of the most important safety informationOverview of the most important safety information

Overview of the most important safety information

Overview of the most important safety informationOverview of the most important safety information

FF

alling lighting system partsalling lighting system parts

F

alling lighting system parts

FF

alling lighting system partsalling lighting system parts

DANGER – Falling lighting system parts:

During servicing it is not permitted to stand under the lighting system.

Sudden release of spring armSudden release of spring arm

Sudden release of spring arm

Sudden release of spring armSudden release of spring arm

WARNING - Sudden release of spring arm:

• The spring arm is under high tension. If the lamp is not removed in the uppermost spring arm position, the spring arm

releases suddenly, springing upwards, and can cause serious

injury.

• Only dismantle the lamp when the spring arm is in the uppermost position.

Eye damage due to the optional laserEye damage due to the optional laser

Eye damage due to the optional laser

Eye damage due to the optional laserEye damage due to the optional laser

WARNING – Laser radiation (LASER CLASS 2) -

Do not look directly at the beam from the central hand grip:

Laser radiation does not constitute a danger to persons who are

not anaesthetised, due to the blink reflex.

Nevertheless, to avoid damaging your eyes you should not look

directly at the laser beam.

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 11

Page 12

2 Your Safety is Important to Us

2.32.3

2.3

2.32.3

FF

F

FF

WARNING – Failure of the spare lamp:

Always change both lamps. When replacing the lamp always replace the entire lamp unit.

In the case of HELIUM models, the lamp base must also be replaced.

Damage to components of the lighting systemDamage to components of the lighting system

Damage to components of the lighting system

Damage to components of the lighting systemDamage to components of the lighting system

CAUTION – Damage to lamps:

Handle and insert new lamps by the packaging film/using a soft

cloth only.

Overview of the most important safety informationOverview of the most important safety information

Overview of the most important safety information

Overview of the most important safety informationOverview of the most important safety information

(cont(cont

’d)’d)

(cont

’d)

(cont(cont

’d)’d)

ailure of the lamps during an operationailure of the lamps during an operation

ailure of the lamps during an operation

ailure of the lamps during an operationailure of the lamps during an operation

Before initial operation of the lighting systemBefore initial operation of the lighting system

Before initial operation of the lighting system

Before initial operation of the lighting systemBefore initial operation of the lighting system

WARNING – Malfunction:

Before the initial operation of the lighting system the electrical

supply has to be checked and approved by qualified staff.

12

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 13

3 Observe these Work Rules

WARNING – Risk of infection:

Ask a doctor about the possible risks (e.g. hepatitis B) of

being a service technician.

After consulting a doctor, get yourself vaccinated against

hepatitis B. A booster is required every 10 years.

Disinfection of the equipment must be organised in good

time before servicing and must be carried out by the operator.

• Servicing must only be carried out on lighting systems which

have been cleaned and disinfected,

• Comply with hygiene guidelines concerning cleaning, disinfection and clothing,

• Only work in the operating theatre with the permission of the

user,

• Observe the code of practice in force at the medical facility,

particularly in the operating theatre,

• If you have any symptoms, consult a doctor immediately.

Inform your doctor that you have worked in hazardous areas –

even after several months.

WARNING – Wear protective eyewear:

Wear protective eyewear in case of a possible risk to eyes,

in particular when carrying out the following work:

• hammering pins or similar components in/out,

• removing tensioned springs and fuses,

• when drilling,

• when soldering,

• when using solvents, cleaning agents or other chemicals.

CAUTION – Tripping and falling:

• Put dismantled components or tools somewhere that nobody

can trip and fall over them.

• Keep your work place clean and tidy during and after servicing.

7200791 Service Manual for the HELION® XENION® Surgical Lighting System GB 13

Page 14

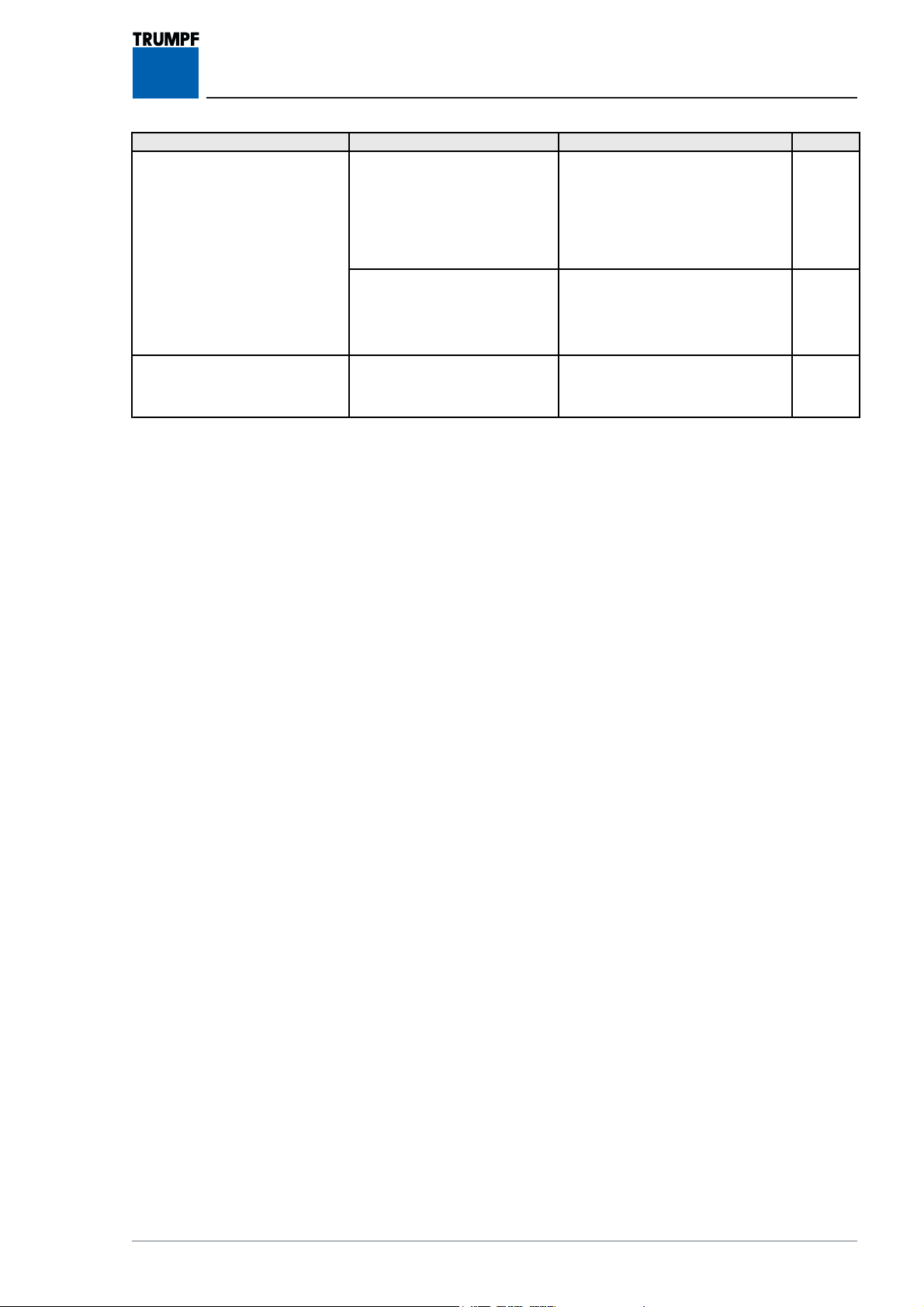

4 Table – Troubleshooting and Possible Remedies

Fault Possible causes Possible remedy Section

LED lamp indicator lit up Lamp defective Change lamp 5

Luminous field too small/

luminous intensity too low

Noises in the light head Loose parts in the light

HELION light head Possible causes Possible remedy Section

Inconsistent, off-centre luminous

field with HELION

M / M+/ L / L+ only

No light No input voltage Check building power supply 9.1

Maladjusted limit stops Adjust luminous field 6

Check light head/focus unit/ replace

head/focus unit

Servomotor polarity incorrect/

servomotor defective

Mains fuse of building power

supply defective

Electrical connections for lamp,

cardanic suspension, spring arm

or extension arm interrupted

Defective sliding contact in

extension arm

Defective cable in light

head/cardanic suspens ion

Defective cable in spring arm Check/replace internal electrical

filter glass assembly or defective

parts

Check polarity of

servomotor/replace focus unit

Check mains fuse at automatic circuit

breaker

Check internal electrical supply lines

of lamp, cardanic suspension, spring

arm or extension arm

Replace sliding contact in extension

arm/check slip ring on central column

Check/replace internal electrical

supply line in light head/

replace cardanic suspension

supply line in spring arm

7 ff.

8

9.2

10

10.1

10.2

10.3

10.4

10.4

10.5

Defective cable in extension arm Check/replace internal electrical

supply line in extension arm

Defective slip ring on central

column

Contact areas burnt/damaged HELION M / M+ / L / L+:

Line contact on PCB in light head

defective/

PCB defective/fuse on PCB

defective/cables in light head

defective

Line contact on PCB in light head

defective/

PCB defective/fuse on PCB

defective/cables in light head

defective

Replace slip ring on central column 10.8

Check operating voltage on focus

unit/replace unit

HELION M / M+ / L / L+:

Check positioning of cables on PCB

and control panel/

replace PCB/replace lamp supply

lines

HELION M / L:

Check positioning of cables on PCB

and control panel/

replace PCB/replace cables in light

head

10.6

10.7

10.9

11.1

12.1

11.1

12.1

11.2

14

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 15

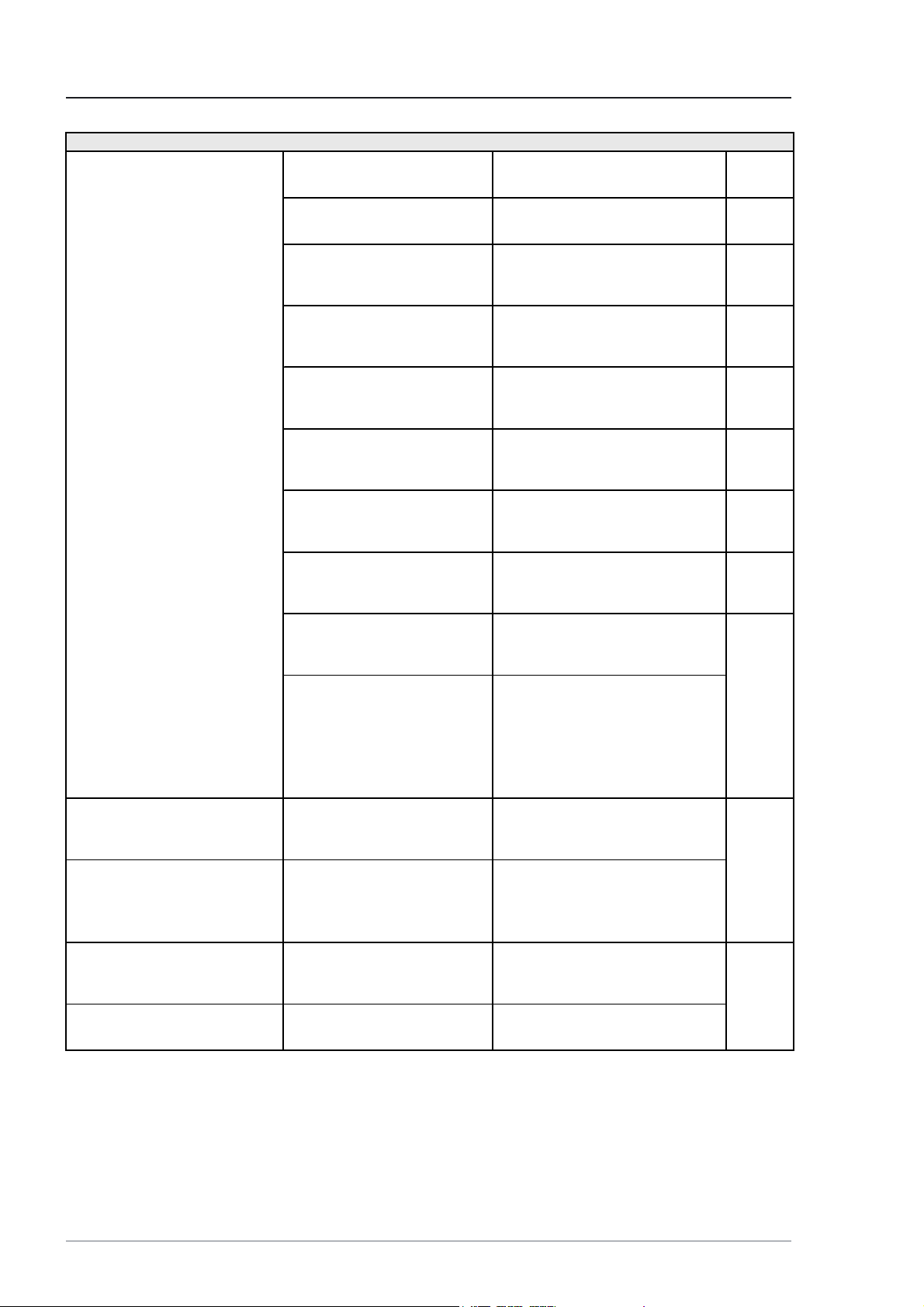

4 Table – Troubleshooting and Possible Remedies

Fault Possible cause Possible remedy Section

No light Line contact on PCB in light head

defective/

PCB defective/

fuse on PCB defective

Check positioning of cables on PCB

and control panel/

replace PCB/replace fus e/

replace cables in light head

12.2

Line contact on PCB in light head

defective/

PCB defective/

fuse on PCB defective

No dimmer function Line contact on PCB/control

panel in light head defective

Check positioning of cables on PCB

and control panel/

replace PCB/replace fus e

Check positioning of cables on PCB

and control panel

13.1

13.2

®

XENION® Surgical Lighting System GB

157200790 Service Manual for the HELION

Page 16

4 Table – Troubleshooting and Possible Remedies

XENION light head

No light No input voltage Check building power supply 9.1

Mains fuse for building power

supply defective

Electrical connection for lamp,

cardanic suspension, spring arm

or extension arm interrupted

Defective sliding contact in

extension arm

Defective cable in light

head/cardanic suspension

Defective cable in spring arm Check/replace internal electrical

Defective cable in extension arm Check/replace internal electrical

Defective slip ring on central

column

Contact areas burnt/damaged Check operating voltage at focus

Check mains fuse at automatic circuit

breaker

Check internal electrical supply lines

for lamp, cardanic suspension, spring

arm or extension arm

Replace sliding contact in extension

arm/check slip ring on central column

Check/replace internal electrical

supply line in light head/

replace cardanic suspension

supply line in spring arm

supply line in extension arm

Replace slip ring on central column 10.8

unit/replace unit

9.2

10

10.1

10.2

10.3

10.4

10.4

10.5

10.6

10.7

10.9

13.1

Line contact on PCB in light head

defective/

PCB defective/fuse on PCB

defective/cables in light head

defective/ballast defective

The halogen lamp does not light

up when switched on

Only the halogen lamp lights up Metal vapour lamp

No dimmer function Line contact on

Dimmer functioning incorrectly Reversed potentiometer polarity Change potentiometer polarity

Halogen lamp defective/no

power supply available

defective/power supply to

electronics too low/high

PCB/potentiometer/ballast in

light head defective

Check positioning of cables on PCB

and control panel/replace PCB/

replace fuse on PC B/

replace cables in light head

XENION L / L+ only:

Replace lamp/check voltage of

electronics

XENION L / L+ only:

Replace lamp/check LED indicator on

the electronics/check voltage

Check positioning of cables on

PCB/potentiometer/control

panel/replace potentiometer

13.1

5.4

13.2

16

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 17

5 Changing the Lamp

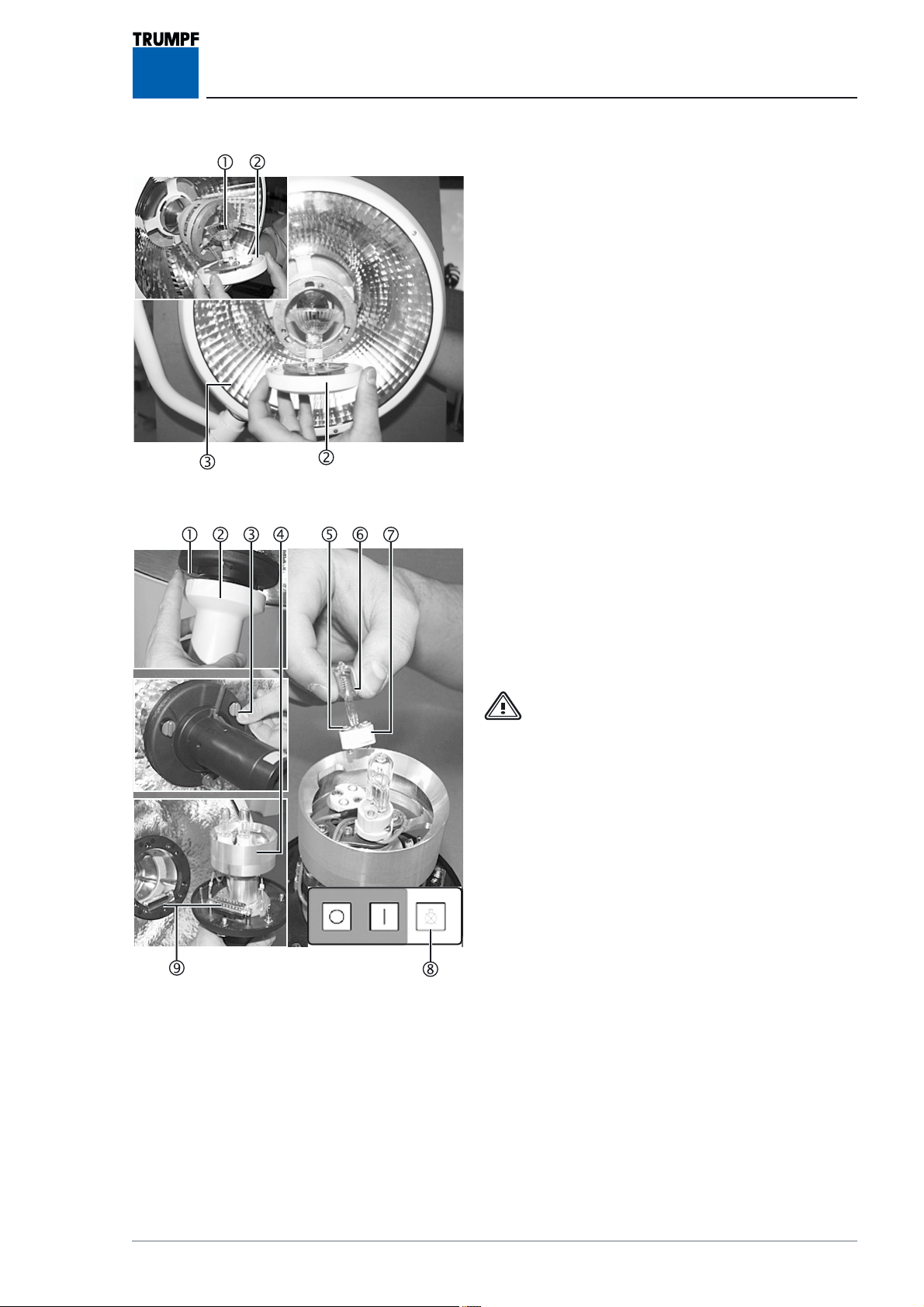

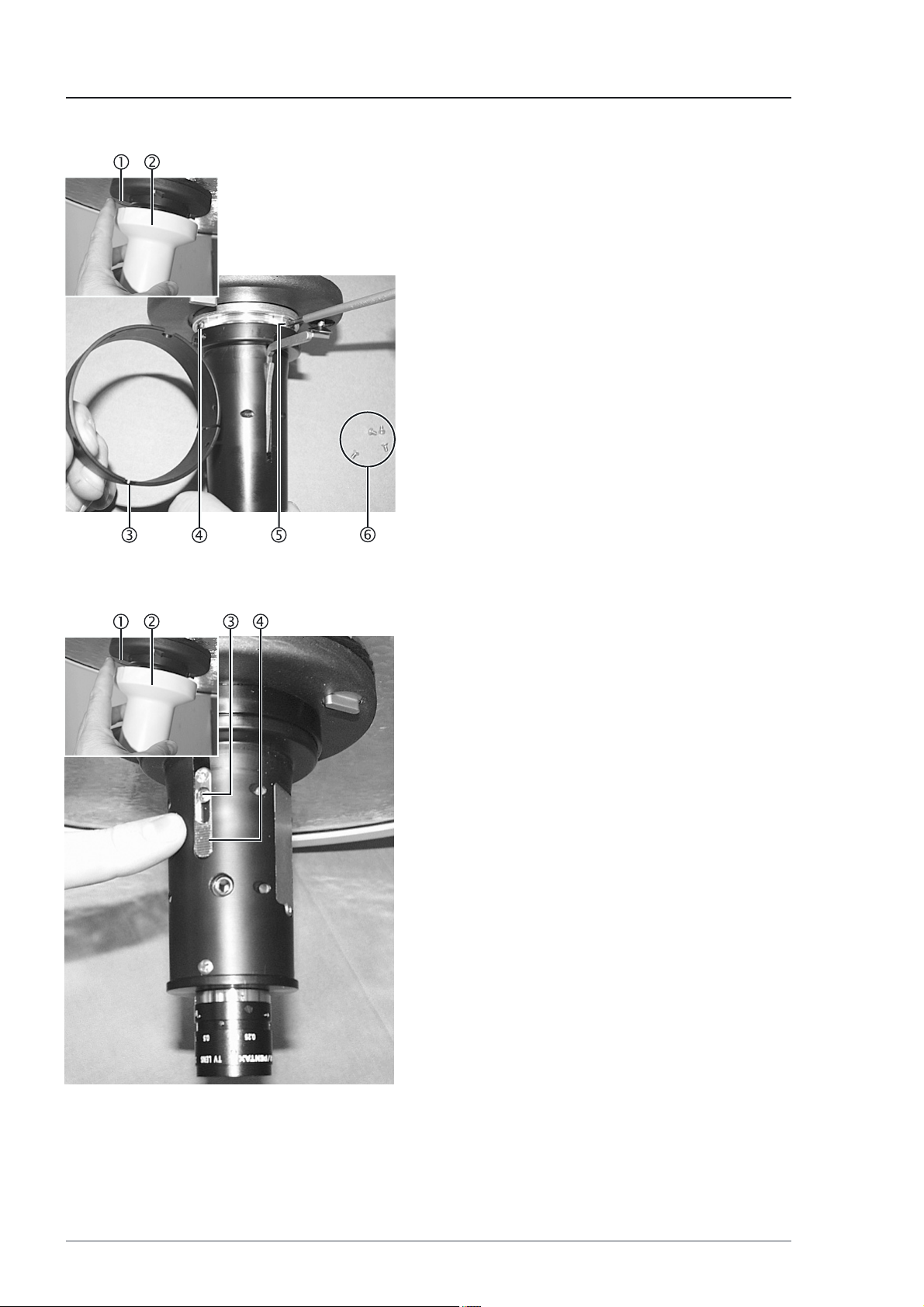

Figure 01

Figure 02

5.15.1

5.1

5.15.1

Changing the lamp of the HELION SChanging the lamp of the HELION S

Changing the lamp of the HELION S

Changing the lamp of the HELION SChanging the lamp of the HELION S

The lamp does not light up.

Removal:

1. Carefully turn the lamp holder 2 and remove it

from the HELION S lamp 3.

2. Carefully remove the old lamp 1 from the lamp

holder 2 and dispose of it in the appropriate

manner.

Installation:

3. Fit the new lamp 1 holding it by the packaging

film/using a soft cloth and fit the components as

described above, but in the reverse order.

5.25.2

5.2

5.25.2

Changing the lamp of the HELION M/Changing the lamp of the HELION M/

Changing the lamp of the HELION M/

Changing the lamp of the HELION M/Changing the lamp of the HELION M/

M+ / L/L+M+ / L/L+

M+ / L/L+

M+ / L/L+M+ / L/L+

The display 8 is lit up. The lamp is defective.

Removal:

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

WARNING – Failure of the spare lamp:

• Always change both lamps.

• When replacing the lamp always replace the

lamp base too.

2. Undo the three screws 3 and remove the focus

unit 4.

3. Unscrew the two cross-recessed head screws 5

and remove the old lamp 6 together with the

base 7 by pulling it upwards and dispose of it in

an appropriate manner.

Installation:

4. Fit the new lamp 6 together with the base 7

holding it by the packaging film/using a soft cloth

and fit the components as described above, but

in the reverse order.

5. Insert the focus unit 4 into the lamp so that both

the plug connectors 9 are aligned.

6. Tighten the three screws 3 by hand.

7. Attach the central hand grip 2.

®

XENION® Surgical Lighting System GB

177200790 Service Manual for the HELION

Page 18

5 Changing the Lamp

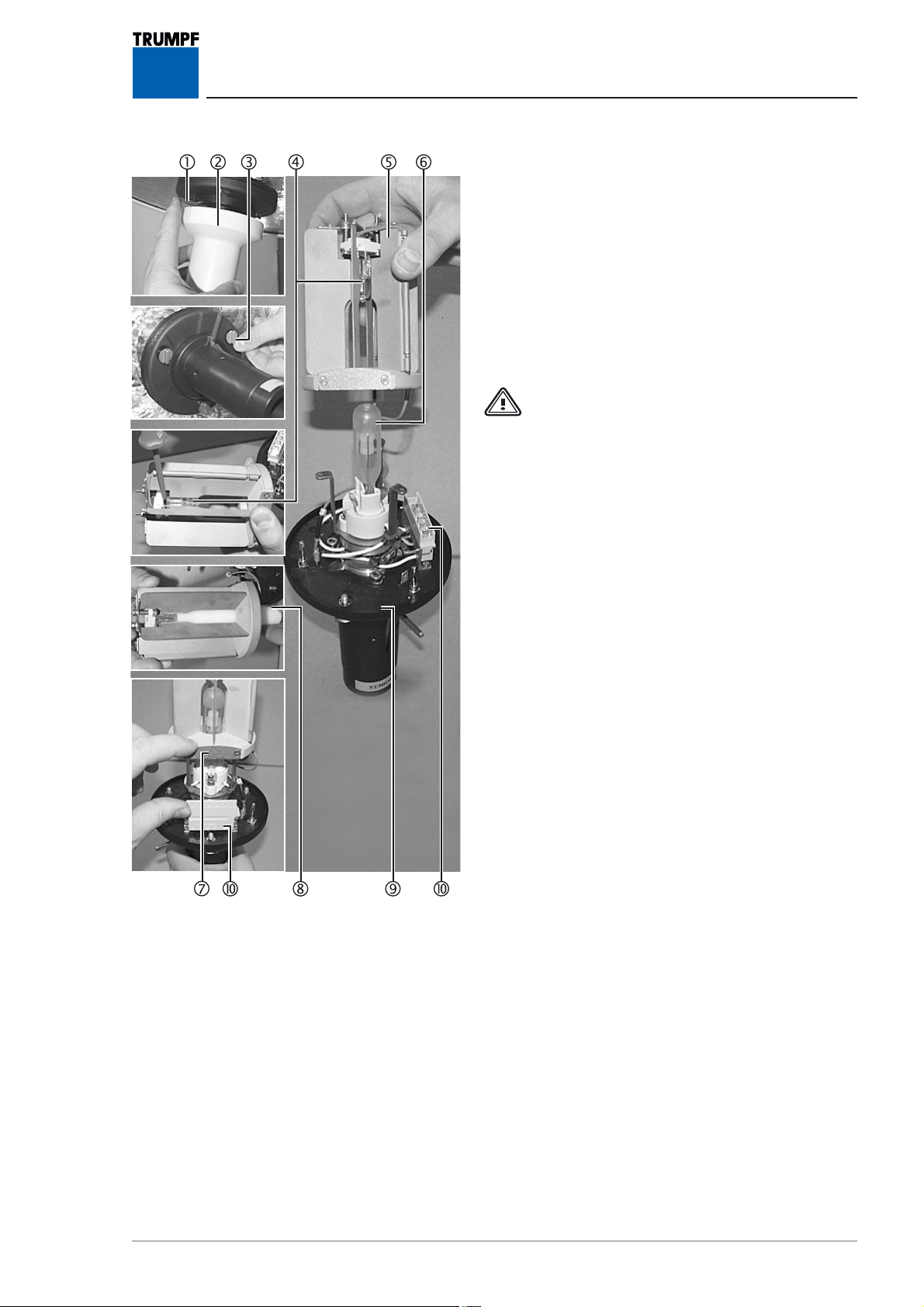

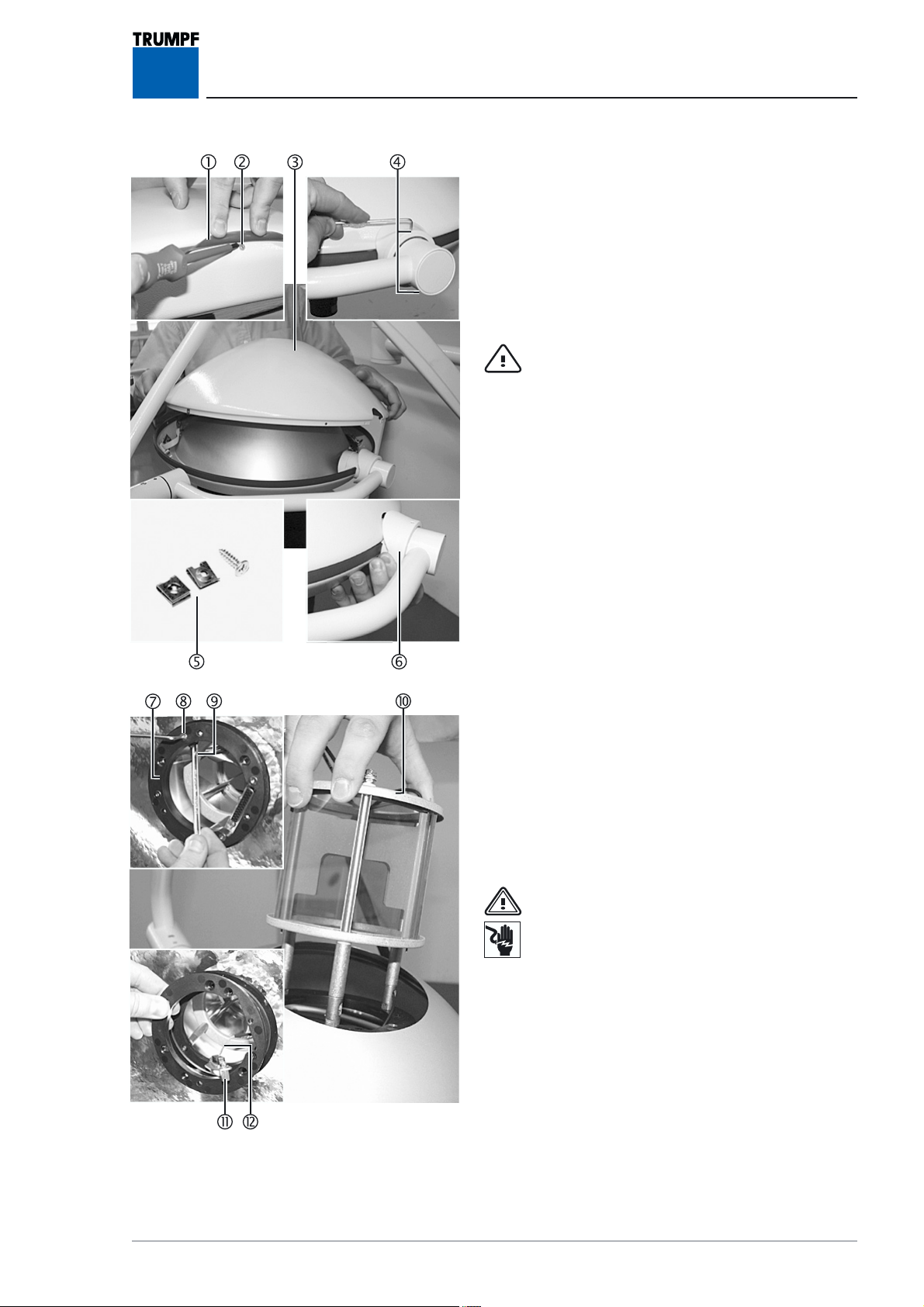

Figure 03

5.35.3

5.3

5.35.3

Removal:

1. Unlock the central hand grip 2 by means of the

2. Undo the three screws 3 and remove the focus

3. Remove the old metal vapour lamp 4 by pulling

Installation:

4. Fit the new metal vapour lamp 4 holding it by

5. Insert the focus unit 5 into the lamp so that both

6. Tighten the three screws 3 by hand.

7. Attach the central hand grip 2.

Changing the lamp of the XENION M/Changing the lamp of the XENION M/

Changing the lamp of the XENION M/

Changing the lamp of the XENION M/Changing the lamp of the XENION M/

M+M+

M+

M+M+

unlocking device 1 and remove it.

unit 5.

it upwards and dispose of it in an appropriate manner.

the packaging film/using a soft cloth and assemble

the components as described above, but in the

reverse order.

the plug connectors 6 are aligned.

18

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 19

5 Changing the Lamp

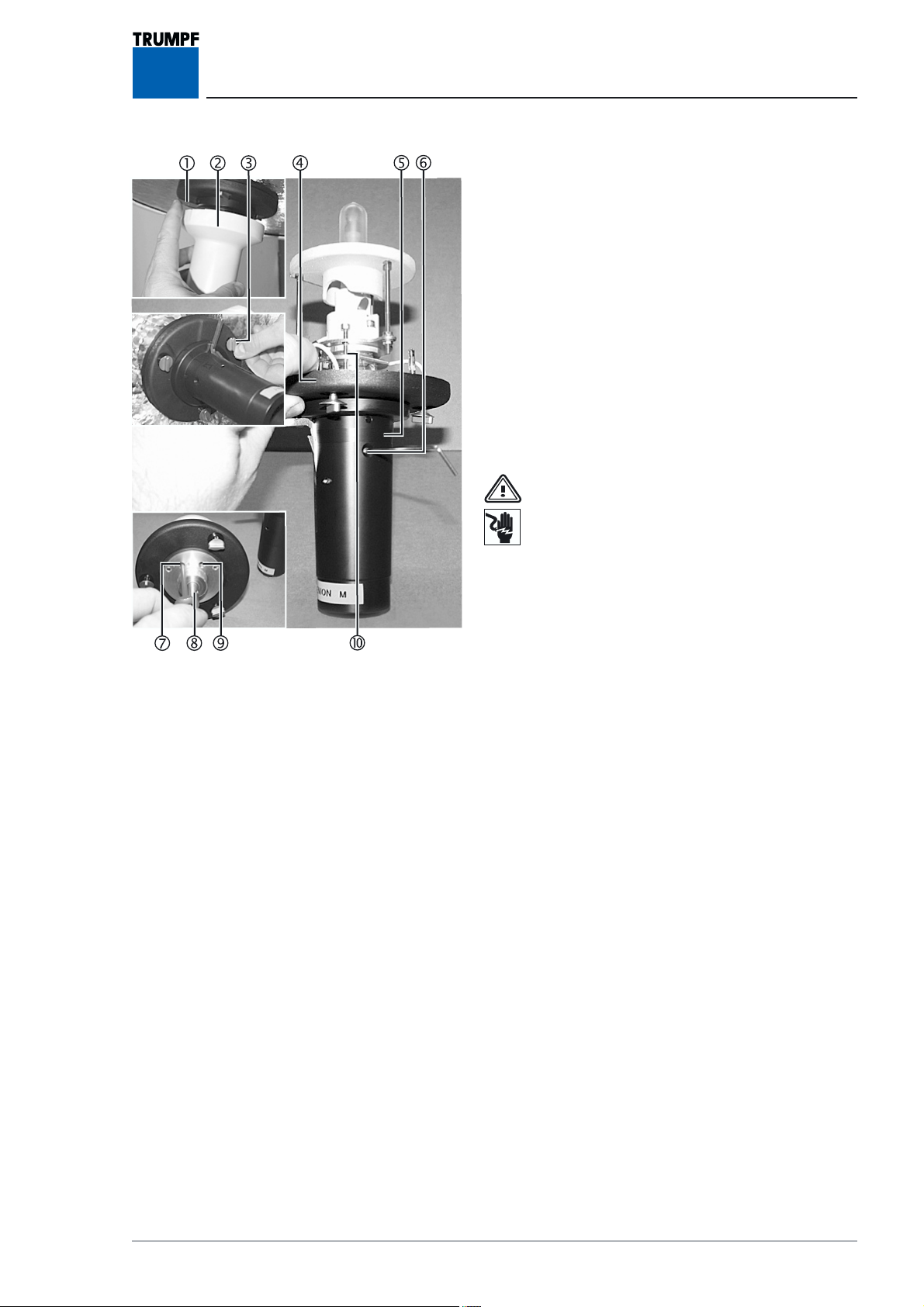

Figure 04

5.45.4

5.4

5.45.4

Removal:

Changing the lamp of the XENION L/Changing the lamp of the XENION L/

Changing the lamp of the XENION L/

Changing the lamp of the XENION L/Changing the lamp of the XENION L/

L+L+

L+

L+L+

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 9.

3. Turn the aperture attachment 5 45 degrees to

the left (anti-clockwise) and remove by pulling upwards.

WARNING – Failure of the spare lamp:

• Always change both lamps (supplied as a

set).

4. Using a screwdriver, push out the old halogen lamp

4, remove it from the aperture attachment 5

and dispose of it in an appropriate manner.

5. Remove the old metal vapour lamp 6 by pulling

it upwards and dispose of it in an appropriate manner.

Installation:

6. Insert the halogen lamp 4 together with the accompanying plastic mount 8 into the aperture

attachment 5.

7. Insert new metal vapour lamp 6 holding it by the

packaging film/using a soft cloth.

8. Insert the aperture attachment 5 so that the surface 7 and the connector A are aligned.

9. Assemble the components as described above, but

in the reverse order.

10.Insert the focus unit 9 so that both the plug connectors A are aligned.

11.Attach the central hand grip 2.

®

XENION® Surgical Lighting System GB

197200790 Service Manual for the HELION

Page 20

6 Setting the Luminous Field

Figure 01

6.16.1

6.1

6.16.1

Setting is described using the HELION L as an example.

Removal:

Setting the luminous field for the HELI-Setting the luminous field for the HELI-

Setting the luminous field for the HELI-

Setting the luminous field for the HELI-Setting the luminous field for the HELION M/M+ / L/L+ON M/M+ / L/L+

ON M/M+ / L/L+

ON M/M+ / L/L+ON M/M+ / L/L+

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 9.

3. Using an Allen key size 25 6:

- unscrew the long cheese head screw 5 a short

way,

- screw the short cheese head screw 7 in a short

way.

Installation:

4. Fit the components as described above, but in the

reverse order.

WARNING – Electric Shock:

The following adjustments must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

5. Switch on the power supply and the lamp.

6. Mark the maximum and minimum luminous field

diameters on the hand grip according to the lamp

specification 8.

Removal:

7. Switch on the power supply and the lamp.

8. Undo the three screws 3 and remove the focus

unit 9.

9. With an Allen key size 2.5 6 adjust the long cheese head screw 5 and the short cheese head screw

7 according to the markings.

Installation:

10.Fit the components as described above, but in

reverse order.

20

Functional test:

11. Carry out functional test.

12. Repeat procedure if necessary.

13. Fix the long cheese head screw 5 and the short

cheese head screw 7 with screw-locking varnish.

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 21

6 Setting the Luminous Field

Figure 02

6.26.2

6.2

6.26.2

Removal:

Setting the luminous field for the XENI-Setting the luminous field for the XENI-

Setting the luminous field for the XENI-

Setting the luminous field for the XENI-Setting the luminous field for the XENION M/M+ON M/M+

ON M/M+

ON M/M+ON M/M+

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Unscrew the set screw 6 and remove the focus

hand grip 5.

3. Using a screwdriver for cross-recessed head

screws:

- unscrew the recessed head screw 7 a short way,

- screw the cross-recessed head screw 9 in a short

way.

Setting:

WARNING – Electric Shock:

The following test must be carried out with

the power supply switched on.

Cordon off installation site and proceed

with great care.

4. Switch on the power supply and the lamp.

5. Set the maximum and minimum luminous field diameters according to the lamp specification (see

Technical Data), and pull the pivot 8 outwards

while turning it.

6. Attach the focus hand grip 6 and tighten the set

screw 5.

Functional test:

7. Carry out functional test.

8. Repeat procedure if necessary.

Removal:

9. Switch on the power supply and the lamp.

10.Undo the three screws 3 and remove the focus

unit 4.

11.Fix set screws 7/9 in each of the threads of the

adjusting plate A with screw-locking varnish.

Installation:

12.Fit the components as described above, but in

reverse order.

Functional test:

13.Carry out functional test.

®

XENION® Surgical Lighting System GB

217200790 Service Manual for the HELION

Page 22

6 Setting the Luminous Field

Figure 03

Figure 04

6.36.3

6.3

6.36.3

Removal:

1. Unlock the central hand grip 2 by means of the

2. Unscrew the four cross-recessed head screws 6

3. Set the maximum and minimum luminous field

Functional test:

4. Carry out functional test.

5. Repeat procedure if necessary.

6. Fix the cross-recessed head screws 4/5 with

Installation:

7. Fit the components as described above, but in

6.46.4

6.4

6.46.4

Setting the luminous field for the XENI-Setting the luminous field for the XENI-

Setting the luminous field for the XENI-

Setting the luminous field for the XENI-Setting the luminous field for the XENION L/L+ON L/L+

ON L/L+

ON L/L+ON L/L+

unlocking device 1 and remove it.

and remove the trim ring 3.

diameters on the two cross-recessed head screws

according to the lamp specification 4/5.

screw-locking varnish.

reverse order.

Setting the luminous field for the XENI-Setting the luminous field for the XENI-

Setting the luminous field for the XENI-

Setting the luminous field for the XENI-Setting the luminous field for the XENION M with fixed focus cameraON M with fixed focus camera

ON M with fixed focus camera

ON M with fixed focus cameraON M with fixed focus camera

Removal:

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Unscrew the cross-recessed head screw 3.

3. Set the maximum and minimum luminous field

diameters according to the lamp specification by

adjusting the ribbed surface 4.

4. Tighten the cross-recessed head screw 3.

Functional test:

5. Carry out functional test.

6. Repeat procedure if necessary.

7. Fix the cross-recessed head screw 3 with screwlocking varnish.

Installation:

8. Fit the components as described above, but in

reverse order.

22

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 23

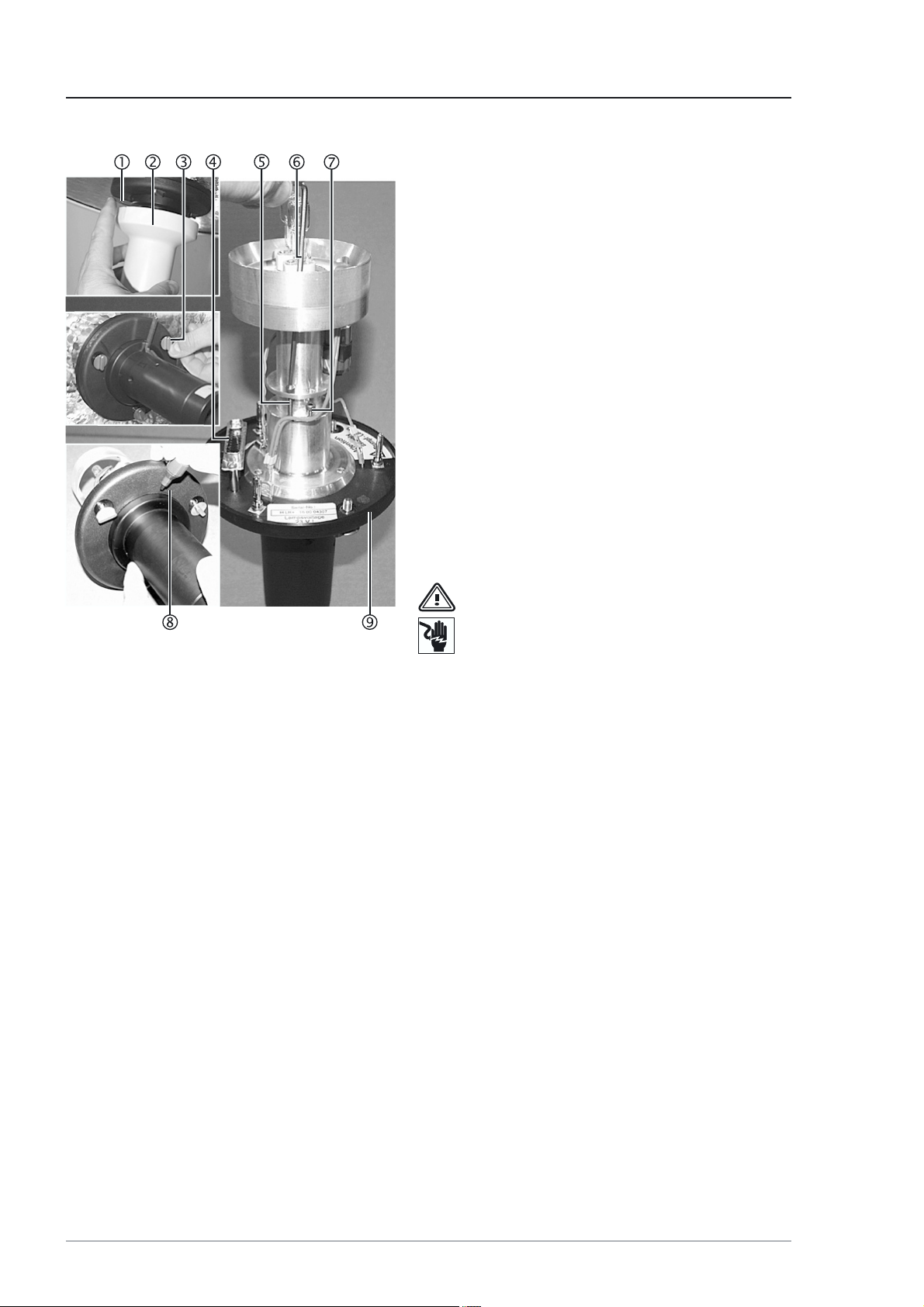

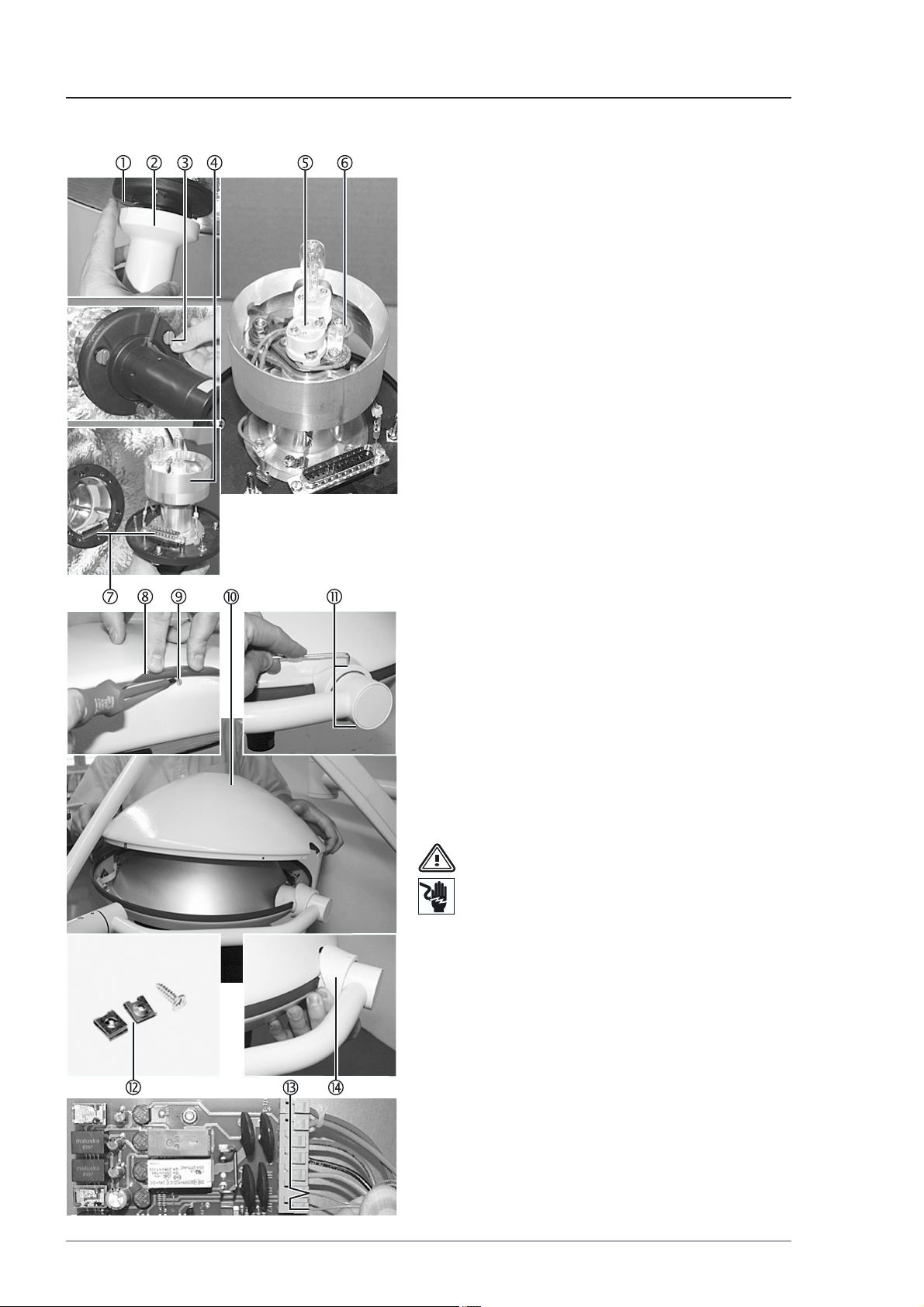

7 Replacing the Filter Glass Assembly

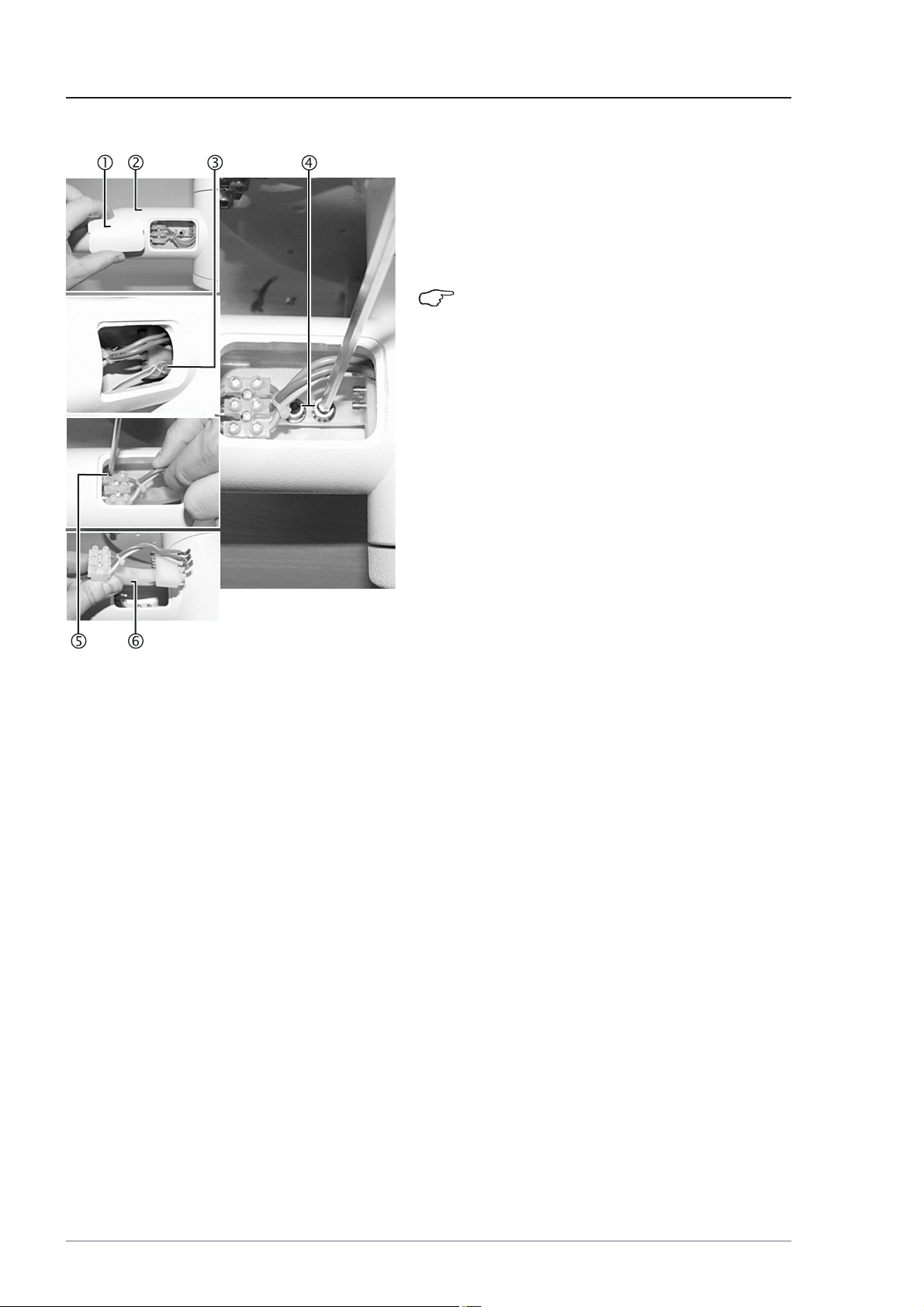

Figure 01 Dismantling the lamp cover:

1. Lift the sealing lip 1, unscrew the sheet-metal

screws 2 and put the sheet-metal clips 5 in a

safe place.

2. Unscrew the two set screws 4 and push back the

plastic cover 6 from the lamp.

3. Remove the lamp cover 3.

Dismantling the filter glass assembly:

CAUTION – Damage to reflector:

• Do not touch the reflector on the inside of

the lamp,

• When unscrewing the four countersunk Allen screws 8 hold on to the SUB-D connector (HEL)/high-voltage contact plug

(XEN) B.

4. Hold the internal hexagon nut 9 securely with a

fork wrench and unscrew the four countersunk Allen screws 8.

5. Remove the plastic ring 7.

6. Lift the filter glass assembly A and SUB-D connector (HEL)/high-voltage contact plug (XEN) B

carefully up and out of the lamp.

7. Disconnect the connecting lines C from the electronics.

Installing the filter glass assembly:

8. Fit the new filter glass assembly (the connecting

lines are also supplied) as described above, but

in reverse order.

Functional test:

WARNING – Electric Shock:

The following test must be carried out with

the power supply switched on.

Cordon off installation site and proceed

with great care.

9. Switch on the power supply and the lamp.

10.Carry out functional test.

Installing the lamp cover:

11.Insert the sheet-metal clips 5 into the lamp cover

3 and install the lamp cover 3 as described

above, but in reverse order.

12.Check the secure positioning of the lamp cover

3.

®

XENION® Surgical Lighting System GB

237200790 Service Manual for the HELION

Page 24

8 Testing the Servomotor for the HELION M/M+ / L/L+

Figure 01

8.18.1

8.1

8.18.1

Dismantling the focus unit:

TT

esting the polarity of the servomotoresting the polarity of the servomotor

T

esting the polarity of the servomotor

TT

esting the polarity of the servomotoresting the polarity of the servomotor

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 4.

3. Remove the central lamp 5 using a soft cloth.

Fitting the focus unit:

4. Insert the focus unit 4 into the lamp so that both

the plug connectors 7 are aligned.

5. Switch on the power supply and the lamp.

Functional test:

6. Remove the focus unit 4 from the lamp again.

If the remaining lamp 5 is not in the centre:

• check if the position of the cables 6 is preventing

the lamp 5 from swivelling,

• change the polarity of the servomotor.

Changing the polarity:

7. Lift the sealing lip 8, unscrew the sheet-metal

screws 9 and put the sheet-metal clips C in a

safe place.

8. Unscrew the two screws B and push back the

plastic cover E from the lamp.

9. Remove the lamp cover A.

10.Change the cables of the servomotor D on the

PCB.

Functional test:

WARNING – Electric Shock:

The following test must be carried out with

the power supply switched on.

Cordon off installation site and proceed

with great care.

11.Switch on the power supply and the lamp.

12.Carry out functional test. If the remaining lamp 5

is not in the centre:

• test the servomotor according to Chapter 8.2:

24

Installing the lamp cover:

13.Insert the sheet-metal clips C into the lamp cover

A and fit the lamp cover A as described above,

but in reverse order.

14.Check the secure positioning of the lamp cover

A

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 25

8 Testing the Servomotor for the HELION M/M+ / L/L+

Figure 02

8.28.2

8.2

8.28.2

Dismantling the focus unit:

TT

esting the servomotoresting the servomotor

T

esting the servomotor

TT

esting the servomotoresting the servomotor

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 4.

3. Swivel the two lamps 5 onto the middle axis represented by the dashed line.

Fitting the focus unit:

4. Insert the focus unit 4 into the lamp so that both

the plug connectors 7 are aligned, then activate

the lamp.

Functional test:

5. Remove the focus unit 4 from the lamp again.

If the two lamps 5 are still on the middle axis

represented by the dashed line:

• check if the position of the cables 6 is preventing

the lamps 5 from swivelling,

• Test the connection of the servomotor to the electronics.

Replacing the focus unit (servomotor):

6. If the two lamps 5 are still on the middle axis

represented by the dashed line:

• the servomotor is defective.

• Replace the entire focus unit 4.

®

XENION® Surgical Lighting System GB

257200790 Service Manual for the HELION

Page 26

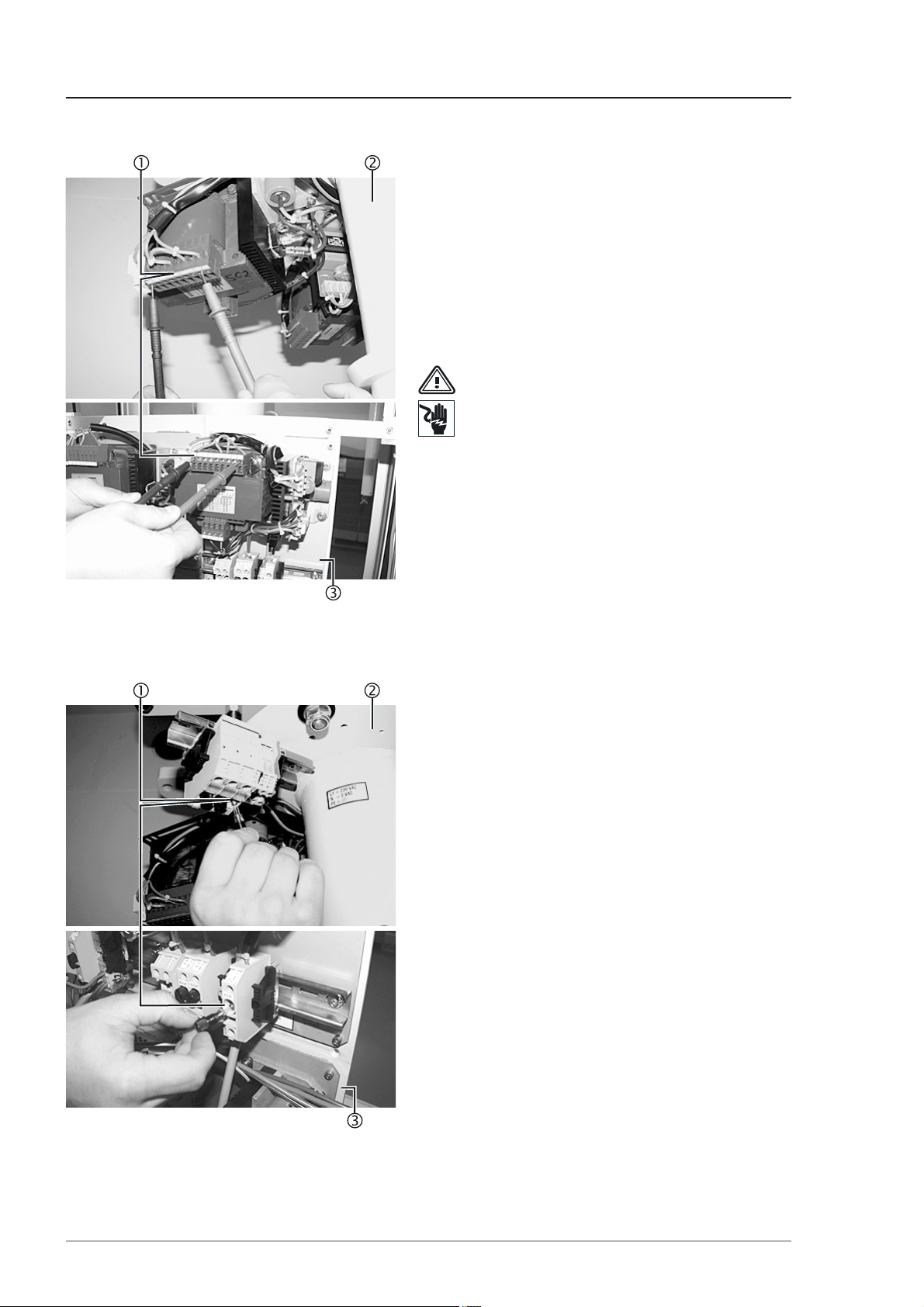

9 Testing the Input Voltages

Figure 01

9.19.1

9.1

9.19.1

The input voltage is measured at the transformer terminal 1. Depending on the installation location, the

transformer is installed on the ceiling tube 2, in the

control cabinet or on a mounting plate 3.

Testing the input voltage:

1. Remove covers etc, open the control cabinet.

2. Switch on the power supply.

3. Using a voltmeter, measure the input voltage at

• If there is no input voltage, inform the customer’s

TT

esting the input voltage of the transesting the input voltage of the trans

T

esting the input voltage of the trans

TT

esting the input voltage of the transesting the input voltage of the trans

formerformer

former

formerformer

WARNING – Electric Shock:

The following test must be carried out with

the power supply switched on.

Cordon off installation site and proceed

with great care.

the transformer terminal 1:

technicians.

--

-

--

Figure 02

9.29.2

9.2

9.29.2

The mains fuse is tested at the fuse terminal 1. Depending on the installation location, the fuse terminal

1 is installed on the ceiling tube 2, in the control

cabinet or on a mounting plate 3.

Testing the mains fuse:

1. Switch off the power supply.

2. Remove covers etc, open the control cabinet.

3. Remove the mains fuse at the fuse terminal 1,

TT

esting the mains fuse for the buildingesting the mains fuse for the building

T

esting the mains fuse for the building

TT

esting the mains fuse for the buildingesting the mains fuse for the building

power supplypower supply

power supply

power supplypower supply

test it and replace if necessary.

26

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 27

10 Testing the Electrics of the Support System

Figure 01

10.110.1

10.1

10.110.1

TT

esting the voltage at the sliding con-esting the voltage at the sliding con-

T

esting the voltage at the sliding con-

TT

esting the voltage at the sliding con-esting the voltage at the sliding con-

tact in the extension armtact in the extension arm

tact in the extension arm

tact in the extension armtact in the extension arm

The input voltage is measured at the contact block 3

in the extension arm 2.

1. Remove the cover 1 from the extension arm 2.

Testing the input voltage at the contact block:

WARNING – Electric Shock:

The following adjustments must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

2. Switch on the power supply and the lamp.

3. Using a voltmeter, measure the input voltage at

the contact block 3:

• check the proper positioning of the cables,

• if there is still no input voltage, the sliding contact

in the extension arm 2 must be tested according

to Section 10.2 and replaced if necessary.

®

XENION® Surgical Lighting System GB

277200790 Service Manual for the HELION

Page 28

10 Testing the Electrics of the Support System

Figure 02

10.210.2

10.2

10.210.2

Removal:

1. Remove the cover 1 from the extension arm 2.

2. Unscrew the two socket head cap screws size 5 4

3. Disconnect the cables at the terminal block 5

Testing the slip ring on the central column:

4. Before fitting a new sliding contact 6 check that

5. Carry out a contact resistance test between the

• If the resistance is infinite, the slip ring must be

- 10.3 Dismantling the light head,

- 10.5 Dismantling the spring arm,

- 10.8 Dismantling the central column,

- 10.9 Changing the slip ring.

RR

eplacing the sliding contact in the exeplacing the sliding contact in the ex

R

eplacing the sliding contact in the ex

RR

eplacing the sliding contact in the exeplacing the sliding contact in the ex

tension arm/testing the slip ring on thetension arm/testing the slip ring on the

tension arm/testing the slip ring on the

tension arm/testing the slip ring on thetension arm/testing the slip ring on the

central columncentral column

central column

central columncentral column

NOTE – in the case of 7-pole sliding contacts:

Disconnect the low-voltage plug connection

3.

and put them in a safe place.

and remove the sliding contact 6.

the slip ring on the central column is functioning

properly:

terminal block on the transformer and the slip ring

in the extension arm:

replaced in accordance with the following sections:

--

-

--

28

Installation:

5. Fit the new sliding contact 6 as described above,

but in reverse order.

6. Fit the cover 1.

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 29

10 Testing the Electrics of the Support System

Figure 03

10.310.3

10.3

10.310.3

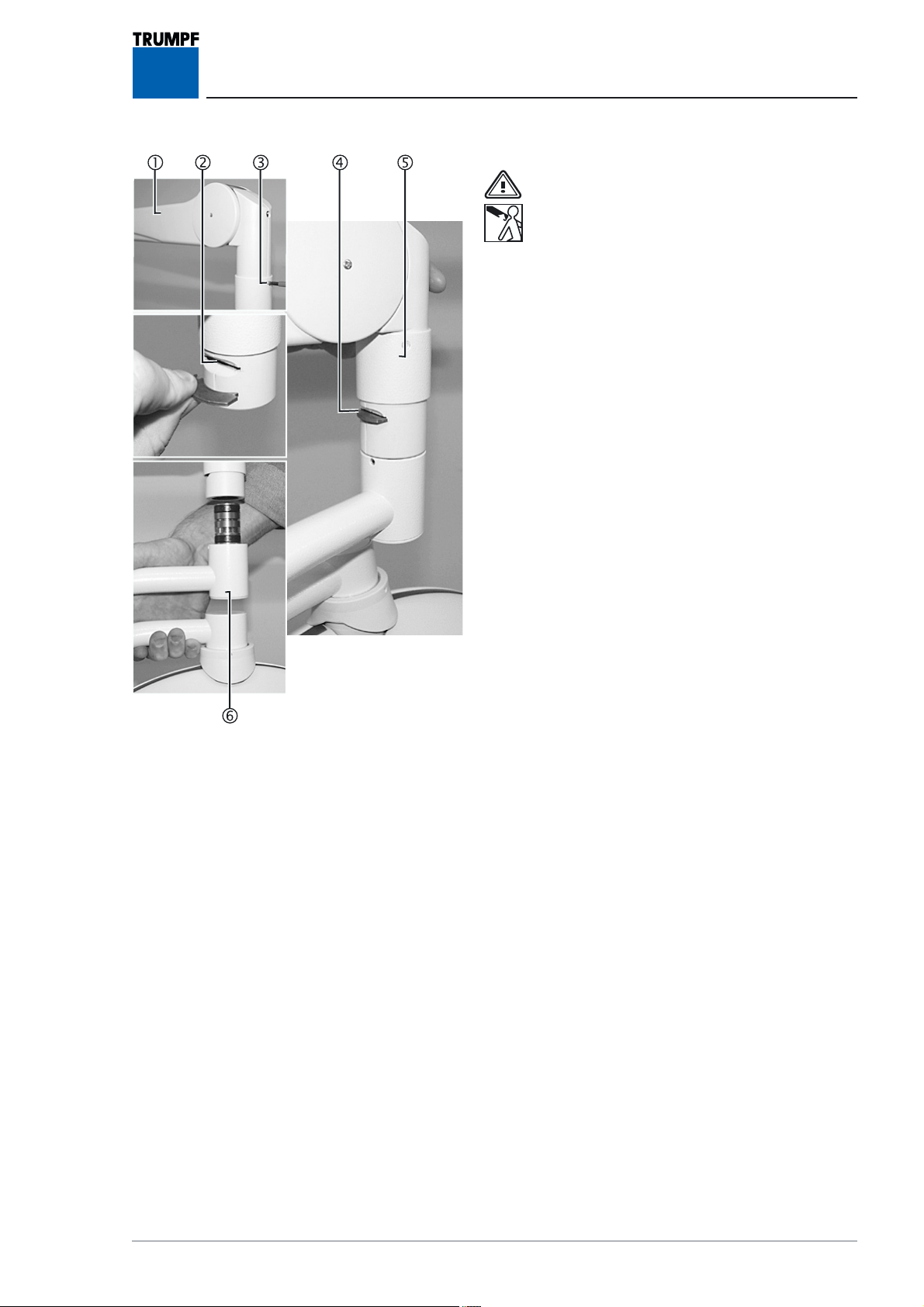

1. Place the spring arm 1 (in the example: Acrobat

2. Unscrew the cross-recessed head screw 3 and

3. Using a small screwdriver, remove the locking seg-

4. Remove the light head 6 with cardanic suspensi-

Dismantling the light headDismantling the light head

Dismantling the light head

Dismantling the light headDismantling the light head

WARNING - Sudden release of spring arm:

• The spring arm 1 is under high tension. If

the lamp 6 is not removed in the uppermost spring arm position, the spring arm

1 releases suddenly, springing upwards,

and can cause serious injury.

• Only dismantle the lamps 6 when the spring arm 1 is in the uppermost position.

2000) in the uppermost position.

push the sleeve 5 up.

ment 4 from the slot 2 and put it in a safe place.

on from the spring arm 1 and carefully put it

aside.

10.410.4

10.4

10.410.4

1. Carry out an all-pole contact resistance test bet-

• If the resistance is infinite, the spring arm must be

• If the resistance is almost zero, the cables in the

- Carry out a contact resistance test between the

TT

esting the cables in the spring armesting the cables in the spring arm

T

esting the cables in the spring arm

TT

esting the cables in the spring armesting the cables in the spring arm

that lead to the contact block in the exthat lead to the contact block in the ex

that lead to the contact block in the ex

that lead to the contact block in the exthat lead to the contact block in the ex

tension armtension arm

tension arm

tension armtension arm

ween the spring arm (sliding coupling) and the

contact block in the extension arm:

replaced in accordance with Section 10.5.

light head and the cardanic suspension must be

tested:

input terminal of the electronics and the sliding

connector on the cardanic suspension (replace

entire cabled cardanic suspension if necessary).

--

-

--

®

XENION® Surgical Lighting System GB

297200790 Service Manual for the HELION

Page 30

10 Testing the Electrics of the Support System

Figure 04

10.510.5

10.5

10.510.5

1. Unscrew the four recessed countersunk head

2. Carefully remove the spring arm 5 from the ex-

Only if there are additional cables in the spring

arm:

3. Remove the lateral covering on the spring arm.

4. Undo the cable fixtures and carefully remove the

5. Unscrew the two cross-recessed head screws 1

6. Carefully put the spring arm 5 aside.

10.610.6

10.6

10.610.6

Dismantling the spring armDismantling the spring arm

Dismantling the spring arm

Dismantling the spring armDismantling the spring arm

screws M5 x 8 mm 3.

tension tube 2.

cables from the spring arm.

and carefully remove the plug-in connector 4

from the spring arm 5.

TT

esting the cables in the extension armesting the cables in the extension arm

T

esting the cables in the extension arm

TT

esting the cables in the extension armesting the cables in the extension arm

1. Carry out an all-pole contact resistance test between the extension arm (sliding connector) and

the contact block in the extension arm:

• If the resistance is infinite, the cables in the exten-

sion arm must be replaced in accordance with

Section 10.7.

• If the resistance is almost zero, the cables in the

spring arm must be tested:

- Carry out an all-pole contact resistance test between the two sliding couplings of the spring arm

(replace the entire cabled spring arm if necessary).

30

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 31

10 Testing the Electrics of the Support System

Figure 05

10.710.7

10.7

10.710.7

RR

eplacing the cables in the extensioneplacing the cables in the extension

R

eplacing the cables in the extension

RR

eplacing the cables in the extensioneplacing the cables in the extension

armarm

arm

armarm

After the lamp and the spring arm have been dismantled, the cables in the extension arm can be replaced.

Removal:

1. Remove the cover 1 from the extension arm 2.

NOTE – in the case of 7-pole sliding contacts:

Disconnect the low-voltage plug connection

3.

2. Unscrew the two socket head cap screws size 5 5

and put them in a safe place.

3. Disconnect the cables at the terminal block 6

and remove the sliding contact 7.

4. Provide the cables 4 with a wire pull and pull

them through the extension arm 2.

Installation:

5. Install the new cables 4 with pre-assembled sliding connector as described above, but in reverse

order.

6. Fit the spring arm and the lamp in accordance

with the current assembly instructions.

7. Carry out functional test.

Figure 06

10.810.8

10.8

10.810.8

Dismantling the central columnDismantling the central column

Dismantling the central column

Dismantling the central columnDismantling the central column

WARNING – Heavy weight:

Two people are needed to dismantle a cen-

tral column with 2 - 4 extension arms.

1. Unscrew the six recessed countersunk head screws

M8 x 15 mm 4.

2. Carefully remove the central column 1 from the

ceiling tube 2.

3. Undo the plug connections 3 and carefully lay

down the central column 1.

®

XENION® Surgical Lighting System GB

317200790 Service Manual for the HELION

Page 32

10 Testing the Electrics of the Support System

Figure 07

10.910.9

10.9

10.910.9

RR

eplacing the slip ringeplacing the slip ring

R

eplacing the slip ring

RR

eplacing the slip ringeplacing the slip ring

1. Unscrew the cross-recessed head screw 3 and

remove the cover 4 of the central column 5.

2. Unscrew the two brake screws 2.

3. Dismantle the sliding contact in accordance with

Section 10.2.

4. Undo the self-locking groove nut 1 with a hook

spanner and twist off from the central column 5.

5. Remove the extension arm 9 from the central column 5.

6. Disconnect all electrical cables of the slip ring 8

concerned.

7. Unscrew the cross-recessed head screw 6 on the

slip ring 8.

8. Remove the slip ring 8 from the central column

by feeding the electrical cables 7 into the central

column 5.

Installation:

WARNING – Falling lighting system:

The self-locking groove nut 1 must be replaced with a new one.

9. Fit the new slip ring 8 as described above, but in

reverse order.

10.Fit the extension arm as described above, but in

reverse order.

Functional check:

WARNING – Electric Shock:

The following adjustments must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

11.Switch on the power supply.

12.Testing the voltage at the contact block in the extension arm.

32

Installation:

13.Fit the spring arm and the lamp in accordance

with the current assembly instructions.

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 33

11 Testing the Electrics of the HELION M / L Lamp

Figure 01

11.111.1

11.1

11.111.1

The test is described using the HELION L as an example.

Removal:

TT

esting the voltage at the focus unitesting the voltage at the focus unit

T

esting the voltage at the focus unit

TT

esting the voltage at the focus unitesting the voltage at the focus unit

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 5.

Preparing for measurement:

3. Place three test prods 4 on the contacts of the

focus unit 5.

4. Insert the focus unit 5.

Carrying out measurement.

WARNING – Electric Shock:

The following adjustments must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

5. Switch on the power supply and the lamp.

6. Measure the voltage with a voltmeter:

• The voltage must be 23 V +/- 0.3 V.

• In the case of voltage deviations, reset the voltage on the transformer in accordance with the specified values in the table.

7. Remove the three test prods 4.

Installation:

8. Insert the focus unit 5 into the lamp so that both

the plug connectors 6 are aligned, then activate

the lamp.

Functional test:

9. Carry out functional test.

®

XENION® Surgical Lighting System GB

337200790 Service Manual for the HELION

Page 34

11 Testing the Electrics of the HELION M / L Lamp

Figure 02

11.211.2

11.2

11.211.2

Dismantling the lamp cover:

1. Lift the sealing lip 1, unscrew the sheet-metal

2. Unscrew the two set screws 4 and push back the

3. Remove the lamp cover 3.

Check the cables on the PCB and control panel:

4. Check the secure positioning of the cables 7/8

Checking the voltages at the PCB:

TT

esting the voltages and cables in theesting the voltages and cables in the

T

esting the voltages and cables in the

TT

esting the voltages and cables in theesting the voltages and cables in the

lamplamp

lamp

lamplamp

screws 2 and put the sheet-metal clips 5 in a

safe place.

plastic cover 6 from the lamp.

on the PCB and the control panel.

WARNING – Electric Shock:

The following measurements must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

5. Switch on the power supply and the lamp.

6. Testing the input voltage on the electronics with a

voltmeter.

7. Using a voltmeter, measure the voltage of:

- 5.1 V DC (designated +5.1 V to GNDB) and

- 12 V DC (designated +12 V to GNDB) and

measure at the measuring points 9 on the PCB:

• If there is no voltage to measure:

- test the cables according to Chapter 10:

• If the voltage is correct, change the PCB:

- remove all cable connectors from the PCB,

- take off the hexagon nut A and remove the PCB,

- fit the PCB as described above, but in reverse order, and attach the cable connector.

Continued on next page.

34

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 35

11 Testing the Electrics of the HELION M/M+ / L/L+ Lamp

Figure 03

11.211.2

11.2

11.211.2

TT

esting the voltages and cables in theesting the voltages and cables in the

T

esting the voltages and cables in the

TT

esting the voltages and cables in theesting the voltages and cables in the

lamps (cont.)lamps (cont.)

lamps (cont.)

lamps (cont.)lamps (cont.)

WARNING – Electric Shock:

The following measurements must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

8. Switch on the power supply and the lamp and, if

necessary, set the lamp to maximum brightness.

Measure the voltage at the contacts of the filter glass

assembly:

9. Using a voltmeter, measure the voltage at the contacts B:

• The voltage must be 23 V +/- 0.3 V.

- In the case of voltage deviations, set the voltage

in accordance with Section 11.1.

If there is no voltage:

• Check the proper positioning of the cables:

• Check the cables for breaks:

- Replace defective cables/components and fit as

described above, but in reverse order.

Installing the lamp cover:

10.Insert the sheet-metal clips 5 into the lamp cover

3 and fit the lamp cover 3 as described above,

but in reverse order.

11.Check the secure positioning of the lamp cover

3.

®

XENION® Surgical Lighting System GB

357200790 Service Manual for the HELION

Page 36

12 Testing the Electrics of the HELION M+ / L+ Lamp

Figure 01

12.112.1

12.1

12.112.1

The test is described using the HELION L+ as an example.

Removal:

TT

esting the voltage at the focus unitesting the voltage at the focus unit

T

esting the voltage at the focus unit

TT

esting the voltage at the focus unitesting the voltage at the focus unit

1. Unlock the central hand grip 2 by means of the

unlocking device 1 and remove it.

2. Undo the three screws 3 and remove the focus

unit 5.

Prepare for measurement:

3. Place three test prods 4 on the contacts of the

focus unit 5.

4. Insert the focus unit 5.

Carry out measurement.

WARNING – Electric Shock:

The following adjustments must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

5. Switch on the power supply and the lamp.

6. Measure the voltage with a voltmeter:

• The voltage must be 23 V +/- 0.3 V.

• In the case of voltage deviations, reset the voltage on the transformer in accordance with the specified values in the table.

7. Remove the three test prods 4.

Installation:

8. Insert the focus unit 5 into the lamp so that both

the plug connectors 6 are aligned, then activate

the lamp.

Functional test:

9. Carry out functional test.

36

7200790 Service Manual for the HELION® XENION® Surgical Lighting System GB

Page 37

12 Testing the Electrics of the HELION M+ / L+ Lamp

Figure 02

12.212.2

12.2

12.212.2

The test is described using the HELION L+ as an example.

Dismantling the lamp cover:

TT

esting the operating voltages, fuseesting the operating voltages, fuse

T

esting the operating voltages, fuse

TT

esting the operating voltages, fuseesting the operating voltages, fuse

and cables in the lampand cables in the lamp

and cables in the lamp

and cables in the lampand cables in the lamp

1. Lift the sealing lip 1, unscrew the sheet-metal

screws 2 and put the sheet-metal clips 5 in a

safe place.

2. Unscrew the two set screws 4 and push back the

plastic cover 6 from the lamp.

3. Remove the lamp cover 3.

Check the cables on the PCB and control panel:

4. Unscrew the four recessed countersunk head

screws 7 and remove the housing on the control

panel.

5. Check the secure positioning of the cables 8/

C/D on the PCB and the control panel.

Checking the fuse and the voltage at the PCB:

6. Check the fuse A and replace if necessary.

Fuse type: T1L 250 V (1 A slow-blow)

WARNING – Electric Shock:

The following measurements must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

7. Switch on the power supply and the lamp and set

the lamp to maximum brightness.

8. Using a voltmeter, measure the voltage at the terminal strip 9:

• The voltage must be between 23 V and 30 V DC.

- In the case of voltage deviations, reset the voltage on the transformer in accordance with the

specified values in the table.

• If there is no voltage to measure:

- Test the cables according to Section 10.

• If the voltage is correct, change the PCB:

- remove all cable connectors from the PCB,

- unscrew the two Allen screws B and remove the

PCB,

- fit the PCB as described above, but in reverse order, and attach the cable connector.

Continued on next page.

®

XENION® Surgical Lighting System GB

377200790 Service Manual for the HELION

Page 38

12 Testing the Electrics of the HELION M+ / L+ Lamp

Figure 03

12.212.2

12.2

12.212.2

9. Switch on the power supply and the lamp and, if

Measure the voltage at the contacts of the filter glass

assembly:

10.Using a voltmeter, measure the voltage at the con-

• The voltage must be 23 V +/- 0.3 V.

- In the case of voltage deviations, reset the volta-

• If there is no operating voltage:

- Check the proper positioning of the cables:

- Check the cables for breaks:

- Replace defective cables/components and assem-

TT

esting the operating voltages, fusesesting the operating voltages, fuses

T

esting the operating voltages, fuses

TT

esting the operating voltages, fusesesting the operating voltages, fuses

and cables in the lamp (cont.)and cables in the lamp (cont.)

and cables in the lamp (cont.)

and cables in the lamp (cont.)and cables in the lamp (cont.)

WARNING – Electric Shock:

The following measurements must be made

with the power supply switched on.

Cordon off installation site and proceed

with great care.

necessary, set the lamp to maximum brightness.

tacts E:

ge on the transformer in accordance with the specified values in the table.

ble as described above, but in reverse order.

Installing the lamp cover:

11.Insert the sheet-metal clips 5 into the lamp cover

3 and fit the lamp cover 3 as described above,

but in reverse order.