Page 1

iLED Lighting System

Installation Instructions

Page 2

To the Service Technician

Conformity The manufacturer declares that this product conforms to the

Please read through these Installation Instructions with great care

and comply with the safety information and requirements for

installation.

CE marking

This item of equipment is a Class I medical device as defined by the

European Medical Device Directive (MDD) 93/42/EEC, June 1993,

Appendix IX.

fundamental requirements according to MDD Appendix I and

documents this by means of the CE marking.

What equipment forms the subject of these Installation

Instructions?

iLED Lighting System:

• single luminaire version:

with one iLED 3 or iLED 5 light head,

• surgical lighting system version:

with a combination of 2 to 3

iLED 3 or iLED 5 light heads,

• plus optional extra equipment.

Customer Service is at your disposal

• if you have any questions on the equipment or its installation,

• if you would like to re-order spare parts,

• for servicing or warranty claims.

How to reach us

• TRUMPF KREUZER Medizin Systeme GmbH + Co. KG

Benzstrasse 26

82178 Puchheim, Germany

Sales • Telephone: ++49 / (0)89 / 8 09 07 - 0

• Fax: ++49 / (0)89 / 8 09 07 - 2 22

Service • Telephone: 0 180 / 2 25 41 35

Telephone: ++49 / (0)36 71/ 5 86 - 0

• Fax: ++49 / (0)36 71 / 58 61 75

© TRUMPF KREUZER, 2007

• Edition: 07/2007, Version 2 (Index 01)

As on: 07.03.2007

Visit us on the Internet www.Trumpf-med.com

2

7200681 Installation Instructions iLED Lighting System US – 07/07

Page 3

Notes relating to this documentation

Applicability • These Installation Instructions are only valid in conjunction with

the iLED planning specification.

Copyright • The information contained in these Installation Instructions and

parts thereof are the intellectual property of TRUMPF KREUZER

Medizin Systeme GmbH + Co. KG, hereinafter TRUMPF, and is

protected by national and international copyright and other laws

for the protection of intellectual property.

• Any duplication, reproduction, translation, microfilming, storage

– in either electronic or magnetic form – , processing as

electronically or magnetically stored data, copying or distribution

of these documents and/or the information contained herein or

parts thereof without the prior written approval of TRUMPF is

hereby strictly prohibited.

We reserve the right to make changes • TRUMPF shall assume no liability whatsoever on the basis of, or

in association with, the use of said information prohibited in this

manner by any person or company.

TRUMPF reserves the right to amend, delete or modify in any

other manner all information contained herein at any time and

on any grounds without prior notice.

We are constantly engaged in the further development of our

products and reserve the right to make changes to the scope

of supply in terms of design, equipment or technology.

Copyrights • TRUMPF expressly reserves all rights in accordance with

copyright law.

Protection laws • All printed material corresponds to the version of the iLED lighting

system and to the status of the safety standards that it is based on

at the time of printing. All protection rights are reserved for

devices, circuits, processes, software programs and names

specified therein.

Translations • The German-language version of these Installation Instructions

shall be binding as regards translations into foreign languages.

Trademarks • All trademarks mentioned in these Installation Instructions are the

exclusive property of the respective suppliers and/or

manufacturers.

7200681 Installation Instructions iLED Lighting System US – 07/07

3

Page 4

Contents

1 Important Information ....................................................................................................7

1.1 Delivery .......................................................................................................................7

1.2 Identification of Components with Serial Numbers ..........................................................7

1.3 Equipment Required for Installation................................................................................8

1.4 Service Technician Qualification Requirements ...............................................................8

1.5 Installation Site Requirements ........................................................................................9

1.6 Intended Use................................................................................................................9

1.7 Warranty and Liability .................................................................................................10

2 Customer Requirements ...............................................................................................11

2.1 Secure Attachment to Ceiling ......................................................................................11

2.2 Ceiling Attachment Equipment Specifications................................................................11

2.3 Customer's Electrical Installation ..................................................................................12

3 Your Safety is Important to Us .......................................................................................13

3.1 Symbols used in these Installation Instructions...............................................................13

3.2 Symbols used on the iLED Lighting System....................................................................14

3.3 Overview of the Most Important Safety Information .......................................................15

4 Identification with Serial Numbers ................................................................................16

4.1 Use of Serial Numbers................................................................................................16

4.2 Position of Serial Numbers ..........................................................................................16

5 Installing the Ceiling Anchor Plate ................................................................................17

5.1 Installation using Heavy Load Anchors .........................................................................17

5.2 Installation using Counterplates...................................................................................18

6 Installing Threaded Bolts or Spacers ..............................................................................19

6.1 Installing Threaded Bolts on the Ceiling Anchor Plate....................................................19

6.2 Installing Optional Spacers on the Ceiling Anchor Plate ................................................19

7 Installing the Ceiling Flange .........................................................................................20

7.1 Preparing for Installation .............................................................................................20

7.2 Installing Components on the Ceiling Flange for the Power Supply

using Control Box Plates .............................................................................................20

7.3 Installing the Ceiling Flange ........................................................................................25

8 Installing an Interface Plate or Canopy Retainer Plate ...................................................26

8.1 Installing an Interface Plate..........................................................................................26

8.2 Installing a Canopy Retainer Plate................................................................................27

9 Installing the Central Axis with Extension Arm ...............................................................28

9.1 Routing Five-pole Cables for Light Heads without Camera through the Ceiling Tube.......28

9.2 Routing Seven-pole Cables for Light Heads with Camera through the Ceiling Tube.........29

9.3 Installing the Central Axis ............................................................................................29

4

7200681 Installation Instructions iLED Lighting System US – 07/07

Page 5

Contents

10 Connecting the Cables .................................................................................................30

10.1 Connection Variants for Light Heads without Camera ...................................................30

10.2 Connection Variants for Light Heads with Camera ........................................................32

10.3 Connection Variant for Camera on Separate Pendant...................................................33

11 Installing a Spring Arm ................................................................................................. 34

11.1 Spring Arm Versions ...................................................................................................34

11.2 Preparing for Installation for all Spring Arm Variants......................................................35

11.3 Installing Spring Arm for Light Head without Camera ....................................................36

11.4 Installing Spring Arm for Light Head with Camera.........................................................37

11.5 Installing Spring Arm for vidiaPORT Monitor Installations...............................................38

11.6 Adjusting Arm Stop on the Acrobat Space Spring Arm ..................................................38

11.7 Installing the Cover.....................................................................................................39

12 Installing the Horizontal Bar on the iLED 5 Light Head .................................................. 40

12.1 Installing the Horizontal Bar on the iLED 5 Light Head without Camera ..........................40

12.2 Installing the Horizontal Bar on the iLED 5 Light Head with Camera...............................40

13 Installing the Light Head .............................................................................................. 41

13.1 Installing the Light Head without Camera on the Acrobat 2000/3000 Spring Arm ..........41

13.2 Installing the iLED 3 Light Head without Camera on the Acrobat 2000 LCH Spring Arm..42

13.3 Installing the iLED 5 Light Head without Camera on the Acrobat 3000 LCH Spring Arm..43

13.4 Installing the Light Head with Camera on the Acrobat 2000/3000 Spring Arm...............44

13.5 Installing the Light Head iLED 3 with Camera on the Acrobat 2000 LCH Spring Arm ......45

13.6 Installing the Light Head iLED 5 with Camera on the Acrobat 3000 LCH Spring Arm ......46

14 Installing Camera on Separate Pendant ....................................................................... 47

14.1 Installing Camera on Separate Pendant on the Acrobat 2000 Spring Arm......................47

15 Connecting/Disconnecting Counterweight .................................................................... 48

15.1 Connecting the Counterweight ....................................................................................48

15.2 Disconnecting the Counterweight ................................................................................49

16 Installing the vidiaPORT Monitor Attachments ............................................................... 50

16.1 Special Features .........................................................................................................50

16.2 vidiaPORT Versions ....................................................................................................50

16.3 Routing Cables through the vidiaPORT Monitor Adapter ...............................................51

16.4 Routing Cables through the VESA 100 Adapter ............................................................53

16.5 Installing the vidiaPORT Monitor Adapter on the Acrobat 2000/3000 Spring Arm ..........53

16.6 Installing the vidiaPORT Duo Monitor Attachment on the Acrobat Space Spring Arm.......55

16.7 Grounding the Acrobat Space Spring Arm ...................................................................57

16.8 Feeding in Cables ......................................................................................................58

16.9 Installing the Rotating Canopy.....................................................................................59

16.10 Installing the Ceiling Tube Cover.................................................................................60

16.11 Installing the Flat-Screen Monitor.................................................................................61

7200681 Installation Instructions iLED Lighting System US – 07/07

5

Page 6

Contents

17 Installing the Wall-Mounted Control Panel ....................................................................62

17.1 Installing the Flush-Mounted Version of the Wall-Mounted Control Panel .......................62

17.2 Installing the Surface-Mounted Version of the Wall-Mounted Control Panel....................65

18 Adjustments ..................................................................................................................68

18.1 Adjusting Spring Force on the Acrobat 2000/3000 and

Acrobat 2000/3000 LCH Spring Arms.........................................................................68

18.2 Adjusting Spring Force on the Acrobat Space Spring Arm..............................................68

18.3 Adjusting Height Stop on the Acrobat 2000/3000 Spring Arms .....................................69

18.4 Adjusting Height Stop on the Acrobat Space Spring Arm ...............................................69

18.5 Adjusting Height Stop on the Acrobat 2000 LCH Spring Arm.........................................70

18.6 Adjusting Height Stop on the Acrobat 3000 LCH Spring Arm.........................................70

18.7 Adjusting Brake Force on the Acrobat 3000 Spring Arm................................................71

18.8 Adjusting Brake Force on the Acrobat 2000 LCH Spring Arm ........................................71

18.9 Adjusting Brake Force on the Acrobat 3000 LCH Spring Arm ........................................72

18.10 Adjusting Brake Force on the vidiaPORT Monitor Adapter .............................................73

18.11 Adjusting Brake Force on the VESA 100 Adapter ..........................................................73

18.12 Adjusting Brake Force on the Camera Adapter of the Separate Camera.........................74

18.13 Adjusting Brake Force on the iLED Lighting System........................................................75

19 Installing the Canopy ....................................................................................................76

19.1 Installing Brackets on the Interface Plate.......................................................................76

19.2 Installing Brackets on the Canopy Retainer Plate ...........................................................77

19.3 Installing the Canopy..................................................................................................78

20 Functional Check and Customer Instruction ..................................................................79

21 Technical Data ..............................................................................................................80

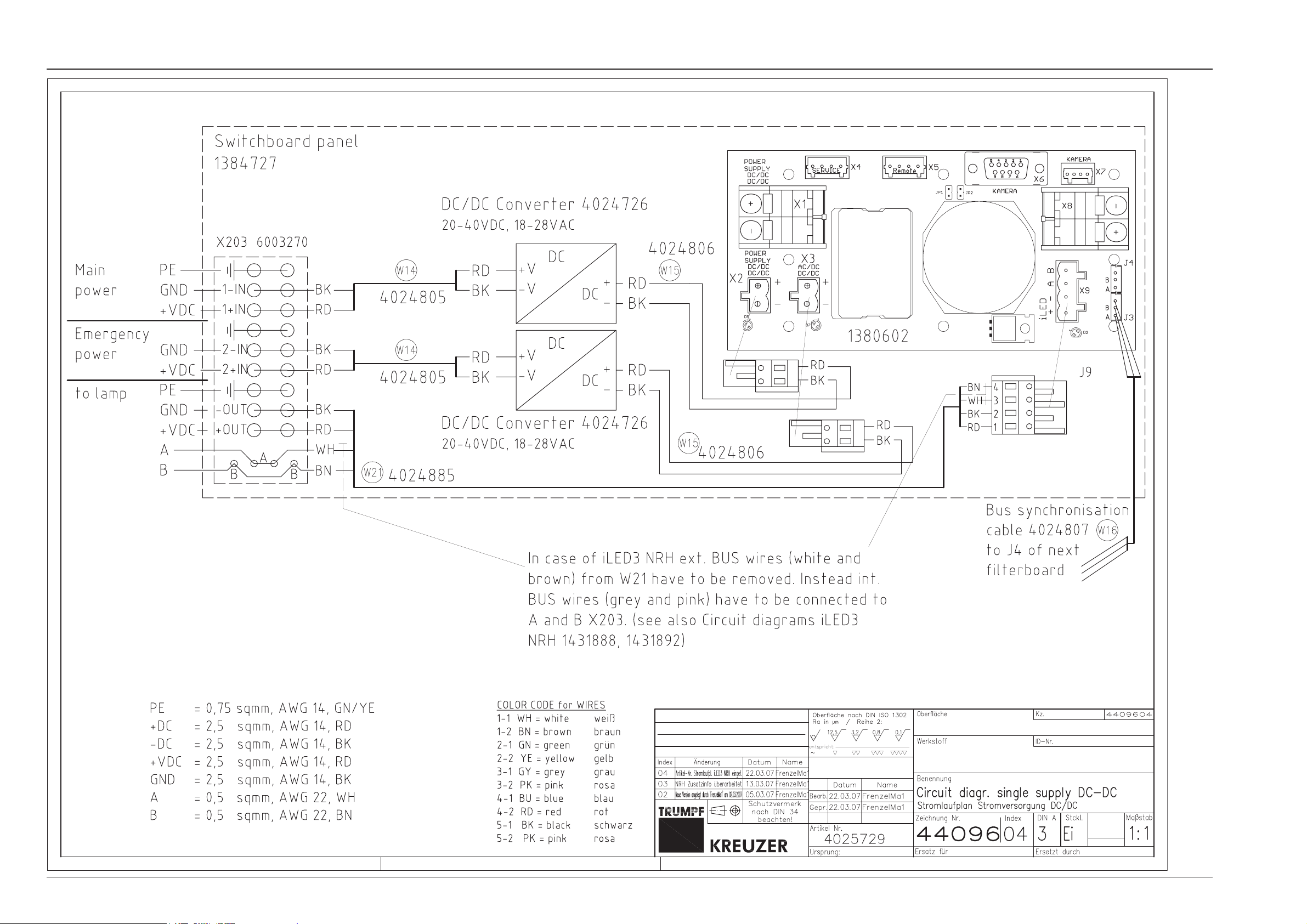

22 Circuit Diagrams ..........................................................................................................84

22.1 Interface Plate Circuit Diagram (Maximum Equipment)..................................................84

22.2 Circuit Diagram – Control Box Plates...........................................................................89

22.3 Circuit Diagram Distance 1-20m (Maximum Equipment)...............................................94

22.4 Circuit Diagram Distance 21-50m (Maximum Equipment).............................................95

22.5 Circuit Diagram – iLED 3 LCH.....................................................................................96

22.6 Circuit Diagram – Camera on Separate Pendant........................................................100

22.7 Circuit Diagram – System with Camera......................................................................102

22.8 Circuit Diagram – vidiaPORT ....................................................................................104

22.9 Circuit Diagram – Wall-Mounted Control Panel .........................................................105

6

7200681 Installation Instructions iLED Lighting System US – 07/07

Page 7

1 Important Information

1.1 Delivery

Damage during transport • Before installation, check the consignment for any damage that

may have occurred during transport.

- In the event of any damage please contact TRUMPF.

Damage claims - Damage claims can only be considered if TRUMPF is notified

immediately.

Damage report - Please complete a damage report as soon as possible and send

it in to TRUMPF to enable damage claims to be validated.

Returns - If you need to return an item or items, please use the original

packaging if possible.

Accompanying documents • To enable us to deal with the matter speedily, please provide the

following details:

- Name and address of customer,

- Consignee,

- Primary serial number of the iLED lighting system or of the

component concerned (see “Section 4.2”, page 16),

- Description of fault (form: Service Advice Form).

1.2 Identification of Components with Serial

Numbers

• The components of the iLED lighting system are identified with

serial numbers:

- The serial numbers define the components of a specified iLED

lighting system without any risk of confusion.

- The components of an iLED Lighting System must be installed in

the relevant position in accordance with the serial numbers.

• An overview of the identification of a iLED lighting system with

serial numbers can be found in “Section 4”, page 16.

7200681 Installation Instructions iLED D Lighting System – 07/07

7

Page 8

1 Important Information

1.3 Equipment Required for Installation

• Vermette 512 lifting equipment or forklift with a load rating of at

least 250kg.

The lift must correspond at least to the height of the

intermediate ceiling.

• Standard drill equipment or

- Core drill HILTI DD-EC 1,

- with appropriate drill,

- and drilling template (# 4019364).

• Spirit level.

• Torque wrench,

• Calibrated luxmeter,

• Multimeter,

• Standard toolkit,

• Two ladders of the necessary length.

1.4 Service Technician Qualification Requirements

Only for trained service technicians • These Installation Instructions are written for trained service

technicians.

Carrying out installation • The iLED lighting system may only be installed by TRUMPF

Technical Service or by authorized service personnel who have

been trained by TRUMPF.

• When installing the equipment, you must follow the steps given in

these installation instruction in the correct order.

• In the event of damage to the iLED lighting system, installation

must cease.

In the event of problems • If you encounter problems which are not covered by these

Installation Instructions or not covered in sufficient detail, you

should immediately contact your nearest TRUMPF Customer

Service Center for the safety of operators and patients.

8

7200681 Installation Instructions iLED D Lighting System – 07/07

Page 9

1 Important Information

1.5 Installation Site Requirements

• The installation site must satisfy the requirements stated in the

iLED planning specification.

• The iLED lighting system, as a surgical lighting system, must only

be installed in rooms that are used for medical purposes and are

set up in accordance with DIN VDE 0100 - 710 or

IEC 60364-710.

• The ambient temperature during operation must be between

10°C and 40°C.

• The relative humidity must be between 30% and 75%.

• The air pressure must be between 700 and 1060 hPa.

1.6 Intended Use

Proper use • The iLED lighting system is for illuminating an examination and

surgical site on the patient in a hospital or doctor's surgery.

Operating range • It operates at a distance of between 70 cm and 150 cm from the

intervention site.

Single luminaire:

Definition: Small surgical luminaire • One iLED 3 / iLED 5 single luminaire is classified as a small

surgical luminaire under IEC 60601-2-41, and may only be

used for operations where light failure will not put the patient at

risk.

Surgical lighting system:

• A surgical lighting system with multiple light heads can be used

without restriction.

Improper use • The iLED lighting system is not suitable for operation in potentially

explosive atmospheres.

• The iLED lighting system must not be used in environments in

which combustible mixtures of anesthetics with air, oxygen or

laughing gas are used.

• To avoid the possibility of the light heads overheating, never

cover them whilst the lighting system is in operation.

• To avoid any risk of dazzling, never look directly at the light

coming from the light heads.

• It is not permitted to place additional loads on the lamp

suspension.

• Do not expose the iLED lighting system to extreme vibrations.

7200681 Installation Instructions iLED D Lighting System – 07/07

9

Page 10

1 Important Information

1.7 Warranty and Liability

TRUMPF guarantees the safety and functionality of the iLED lighting

system only on condition that:

• installation, modifications and repairs are carried out by TRUMPF

service technicians or other persons expressly authorized by

TRUMPF,

• requirements for secure ceiling attachment have been met,

• the electrical installation of the iLED lighting system complies with

the currently applicable regulations,

• only original components from TRUMPF have been used,

• only approved accessories or those that have been tested for

suitability are installed,

• the iLED lighting system is being used for its intended purpose, in

the proper manner,

• it is commissioned and the equipment is released for operation

with a delivery note.

10

7200681 Installation Instructions iLED D Lighting System – 07/07

Page 11

2.1 Secure Attachment to Ceiling

Acceptance certificate of structural

engineer

Holes drilled incorrectly • In the event that a hole is drilled incorrectly, coming up against a

Ceiling anchor plate • To make sure that the load is distributed correctly, the ceiling

Building regulations must be

observed.

2 Customer Requirements

• It must be ensured during planning that all circumstances

involved in the specific case have been given proper

consideration, the specific approval from the competent building

authorities has been obtained and all installation work has been

performed in the proper manner using suitable tools.

• The structural design of the ceiling must ensure that the loads

imposed by the iLED lighting system and other existing ceiling

loads are absorbed and transferred safely.

• The load-bearing capacity must be calculated and checked by a

structural engineer and confirmed by means of proof

calculations. This structural proof for the load-bearing capacity

of the ceiling must be drawn up and submitted prior to

installation of the iLED Lighting System.

reinforcement rod for instance, the responsible structural

engineer should be consulted to make sure that the load is still

adequately distributed over the ceiling area.

anchor plate

• The national and regional building regulations currently

applicable must be observed.

must be installed flush with the ceiling.

2.2 Ceiling Attachment Equipment Specifications

Reinforced concrete ceilings

Class C20/25

Observe instructions from the

manufacturer of the attachment

equipment

Counterplate set For all other ceilings we recommend the use of a counterplate set for

With properly constructed Class C20/25 (or better) reinforced

concrete ceilings, the following attachment equipment (not included

in scope of supply) should be used (see “Section 5.1”, page 17):

• 4 through-wall anchors,

• HILTI make,

• approval no. ETA-98/0001,

• model HST M16/25,

• minimum thickness of raw ceiling 160 mm.

In order to secure the iLED lighting system correctly to the ceiling you

must observe the instructions from the manufacturer of the

attachment equipment.

ceiling attachment (see “Section 5.2”, page 18):

• 4 counterplates with threaded rods M16 (# 4021131),

• 4 M16 hexagon nuts – DIN 934 (# 5200031),

• 4 washers 19.00 – DIN 125 (# 5301901).

7200681 Installation Instructions iLED D Lighting System – 07/07

11

Page 12

2 Customer Requirements

2.3 Customer's Electrical Installation

Installation by specialist external

contractors

Work must be carried out by qualified

electricians

National regulations must be

observed

Device for disconnecting all poles from

the power supply

The electrical connections on the customer's premises must be

implemented by a specialist company commissioned by the

customer as per the iLED planning specification. The following

requirements must be observed:

• Planning, execution and checking of the electrical installation

must be carried out at the customer's premises by competent

electrical engineers and licenced electrical contractors.

• If the applicable regulations in the country concerned require the

device to be connected to the power supply by authorized

specialist engineers, it is important to ensure that they are

observed.

• A device must be installed on the customer's premises which

disconnects all poles of the power supply cables from the power

supply network.

• The terminal blocks must be freely accessible for installation of

the iLED lighting system and performance of the required

electrical safety checks.

• The electrical installations of the room concerned must comply

with the applicable national regulations. DIN VDE 0100 part

710 is applicable in the Federal Republic of Germany.

The requirements of NFPA 70 and NFPA 99 are applicable in

the USA.

12

7200681 Installation Instructions iLED D Lighting System – 07/07

Page 13

3 Your Safety is Important to Us

3.1 Symbols used in these Installation Instructions

Important information is shown in these Installation Instructions

using symbols and signal words.

Signal words such as DANGER, WARNING or CAUTION indicate the

level of risk. This is visually emphasized by the different triangle

symbols.

DANGER

1WARNING

1CAUTION

NOTICE

NOTE

DANGER alerts you to an immediate dangerous situation, which –

unless avoided – will result in death or serious injury.

WARNING alerts you to a potentially dangerous situation, which –

unless avoided – may result in death or serious injury.

CAUTION alerts you to a potentially dangerous situation, which –

unless avoided – may result in minor or slight injury.

NOTICE indicates a potentially dangerous situation, which – unless

avoided – will lead to damage to property.

NOTE gives you additional information and helpful tips for the safe

and efficient use of the appliance.

The following symbols and signal words define the potential threat

more precisely.

Explosion hazard

combustible mixtures of anesthetics with air, oxygen or laughing gas.

warns against use of the iLED lighting system in

Electric shock warns of the danger of electric shock, which

may result in serious injury or even death.

Sudden release of spring arm warns of the sudden release of the

spring arm if the light head is removed without firstly putting the

spring arm in the highest possible limit stop position.

Falling lighting system warns of equipment suddenly falling if

additional loads are placed on the lighting system.

7200681 Installation Instructions iLED D Lighting System – 07/07

13

Page 14

3 Your Safety is Important to Us

3.2 Symbols used on the iLED Lighting System

CE conformity marking

Device tested by Underwriter Laboratories Inc. for USA and Canada.

UL/cUL Classification with respect to electric shock, fire, and

mechanical hazards only in accordance with UL 60601-1 and

CAN/CSA C22.2 No. 601.1 22TF.

14

7200681 Installation Instructions iLED D Lighting System – 07/07

Page 15

3 Your Safety is Important to Us

3.3 Overview of the Most Important Safety

Information

Please also comply with the safety information in the individual

sections.

Installation site

DANGER

Gas explosion

Combustible mixtures of anesthetics with air, oxygen

or laughing gas may not be used in environments in

which the iLED lighting system is operated.

Danger of the lighting system falling

DANGER

Parts falling from overhead

Make sure that no-one is standing below the

lighting system whilst it is being installed.

1WARNING

Danger of the lighting system falling

Comply with the torques for the fixing screws

specified in these Installation Instructions.

Hazards from electric shock

1WARNING

Switch off the building power supply

During all installation work the building power

supply must be de-energized and prevented from

being switched back on again.

7200681 Installation Instructions iLED D Lighting System – 07/07

15

Page 16

4 Identification with Serial Numbers

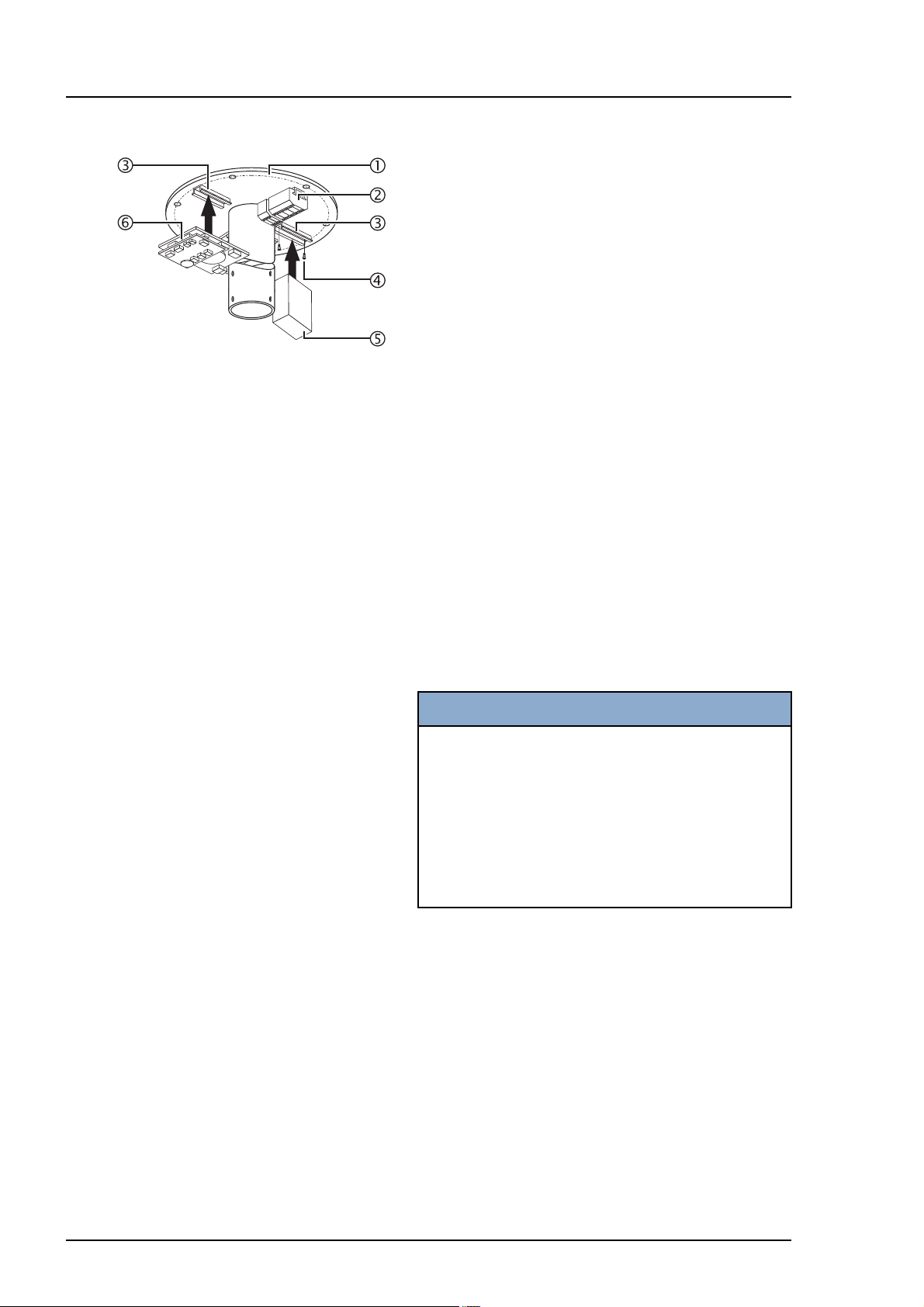

Figure 1 4.1 Use of Serial Numbers

The components of the iLED lighting system are

identified with serial numbers:

• The serial numbers define the components of a

specified iLED lighting system without any risk of

confusion.

• The components of an iLED Lighting System must

be installed in the relevant position in accordance

with the serial numbers.

4.2 Position of Serial Numbers

• The main serial number can be found on the

packaging and also on the top of the uppermost

extension arm 1.

• The positions of the serial numbers are shown in

“Figure 1”, page 16.

16

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 17

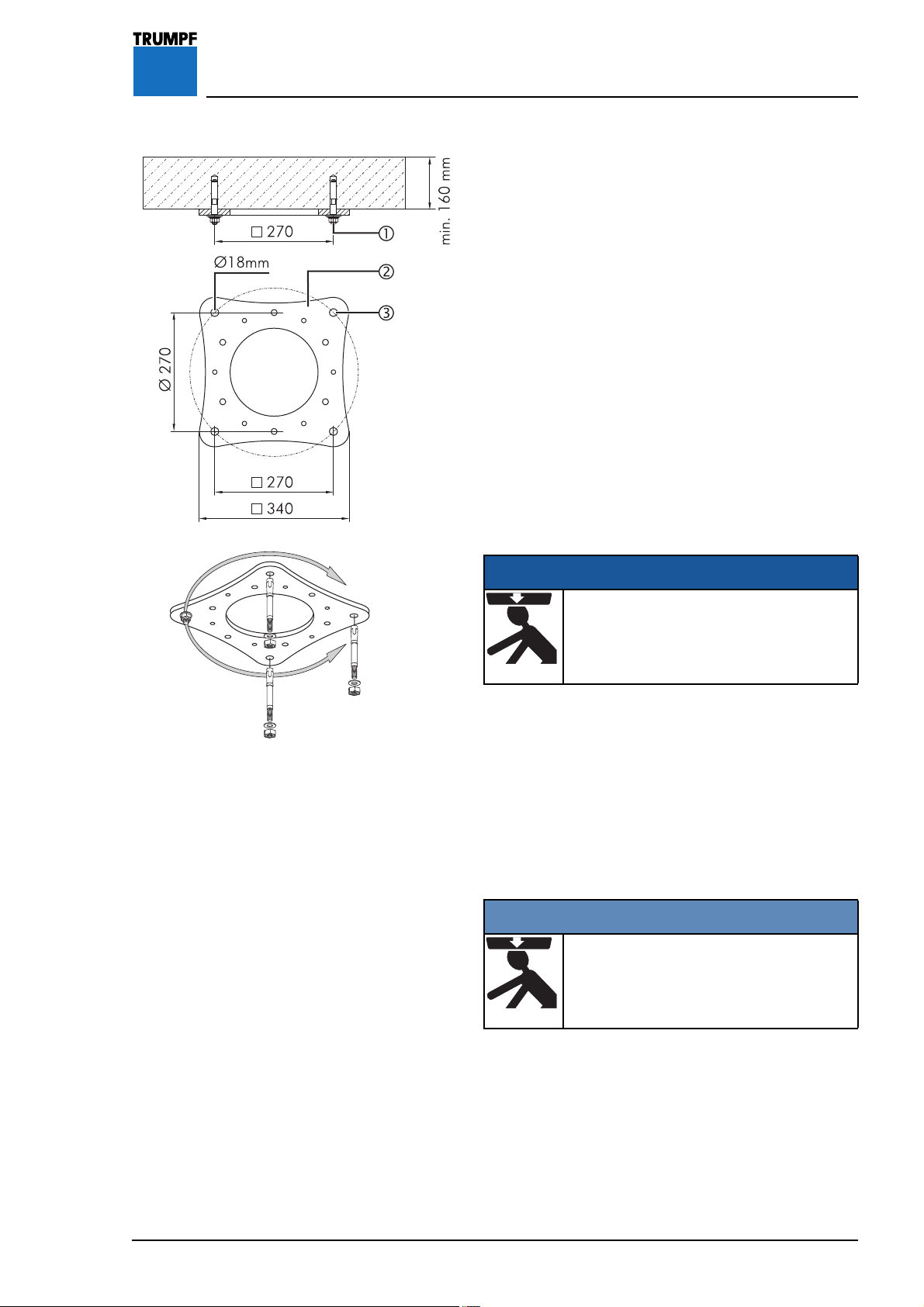

5 Installing the Ceiling Anchor Plate

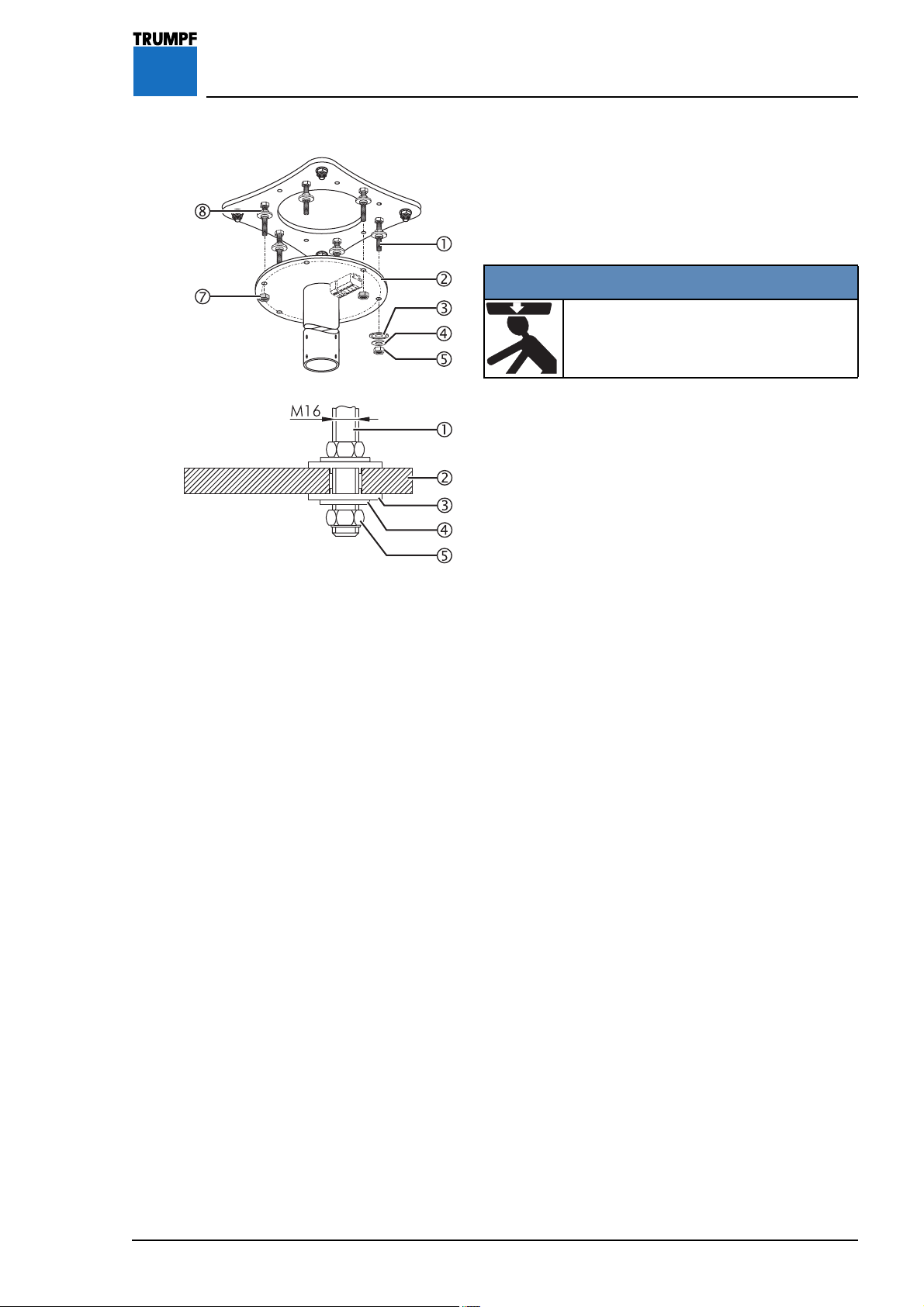

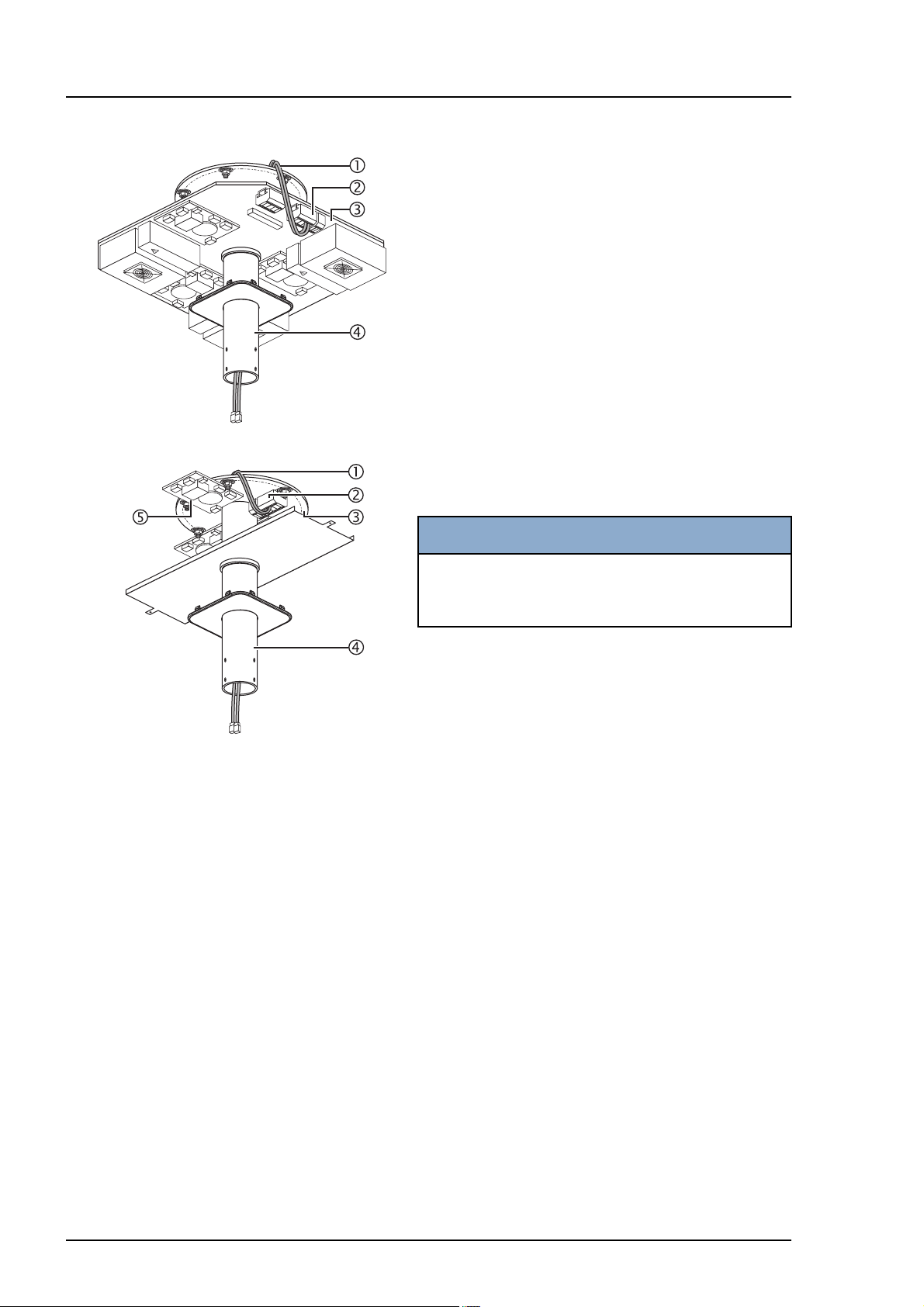

Figure 2 5.1 Installation using Heavy Load Anchors

Check the requirements for secure ceiling attachment

as specified in “Section 2.1”, page 11.

The attachment equipment is described in

“Section 2.2”, page 11.

1. Mark the position of the ceiling anchor plate 2 on

the ceiling in accordance with the plan drawing

using the drilling template (#4019364).

Drill holes:

2. Drill four holes 3 in accordance with the

instructions from the manufacturer of the fixtures.

• Blow out the holes thoroughly.

3. Knock a heavy load anchor 1 into the raw ceiling

as far as the mark in accordance with the

instructions from the manufacturer of the fixtures.

Installing the ceiling anchor plate:

DANGER

Falling ceiling panel

Make sure that no-one is standing

below the ceiling anchor plate 2 whilst

it is being installed.

4. Loosely screw the ceiling anchor plate 2 to the

heavy load anchor 1 that was installed first.

5. Align the ceiling anchor plate 2 with the

remaining drill holes 3.

6. Knock the three remaining heavy load anchors 1

into the raw ceiling through the drill holes 3 in the

ceiling anchor plate 2 as far as the mark.

Tightening the heavy load anchors:

1WARNING

Danger of the lighting system falling

Tighten the heavy load anchors 1 in

accordance with the instructions from

the manufacturer of the fixtures.

7200681 Installation Instructions iLED US Lighting System – 07/07

7. Tighten the heavy load anchors 1 uniformly in

accordance with the instructions from the

manufacturer of the fixtures.

8. Check that the ceiling anchor plate 2 is securely

in place.

• The ceiling anchor plate 2 must lie flush with the

raw ceiling.

17

Page 18

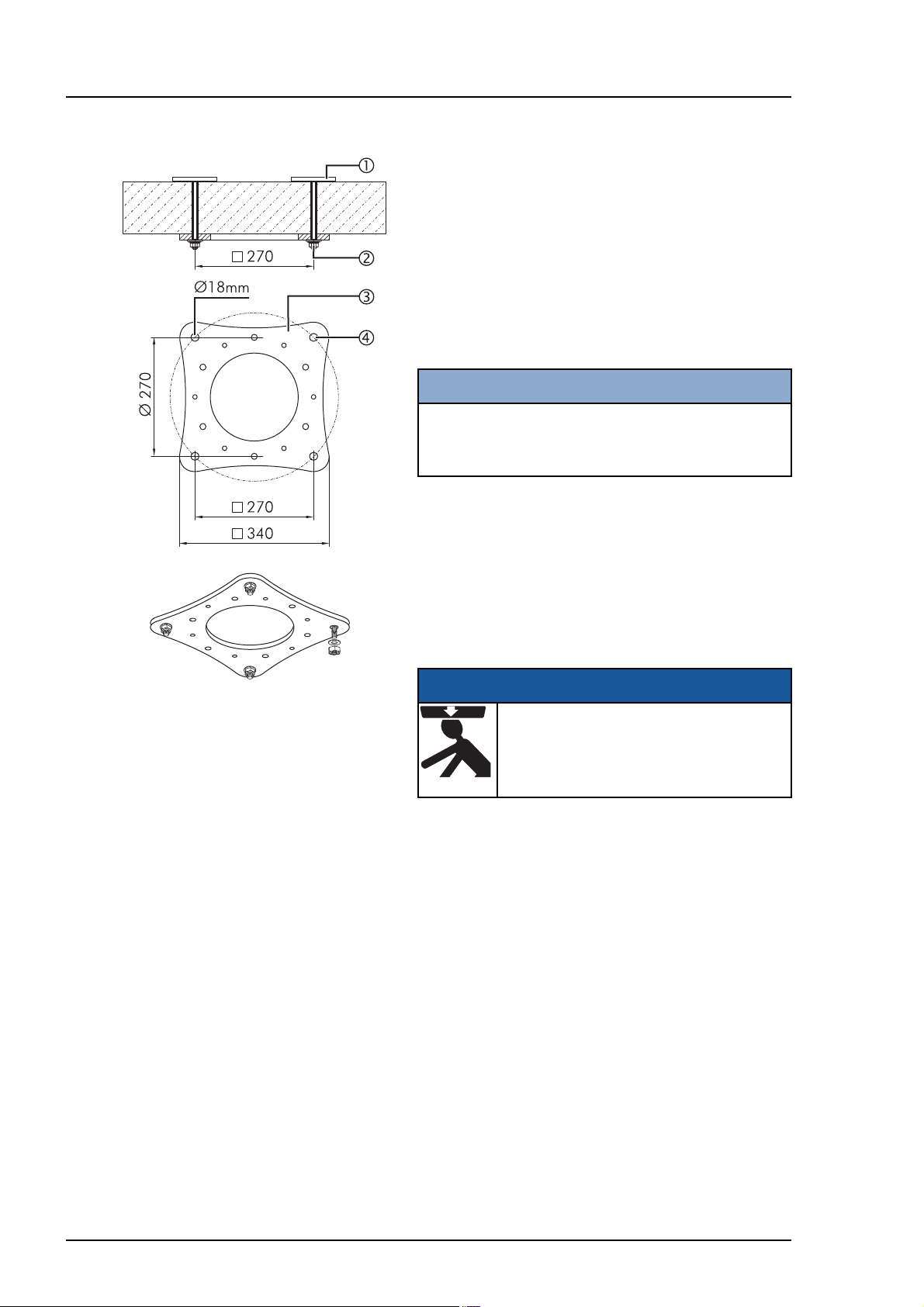

5 Installing the Ceiling Anchor Plate

Figure 3 5.2 Installation using Counterplates

Check the requirements for secure ceiling attachment

as specified in “Section 2.1”, page 11.

The fixtures are described in

“Section 2.2”, page 11.

1. Mark the position of the ceiling anchor plate 3 in

accordance with the plan drawing using the

drilling template (#4019364).

Drilling holes:

NOTE

Faulty, misaligned drill holes

Drill the holes 4 from the

ceiling.

underside of the raw

2. Drill four holes 4, with a 20mm diameter, and

always from the underside of the raw ceiling.

3. Push four counterplates with threaded bolts 1

(#4021131) through the drill holes from the top

side of the raw ceiling.

Installing the ceiling anchor plate:

DANGER

Falling ceiling anchor plate

Make sure that no-one is standing

below the ceiling anchor plate 3 whilst

it is being installed.

4. Position the ceiling anchor plate 3 on an M16

threaded bolt 1 and screw on loosely with a

washer and M16 hexagon nut 2.

5. Push the three remaining threaded bolts 1 into

the ceiling anchor plate 3 and screw each one

firmly in place using 1 washer and hexagon

nut 2.

18

Tightening the hexagon nuts:

6. Tighten the hexagon nuts 2 uniformly to 195Nm.

• At the same time, prevent the counterplates 1 from

turning.

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 19

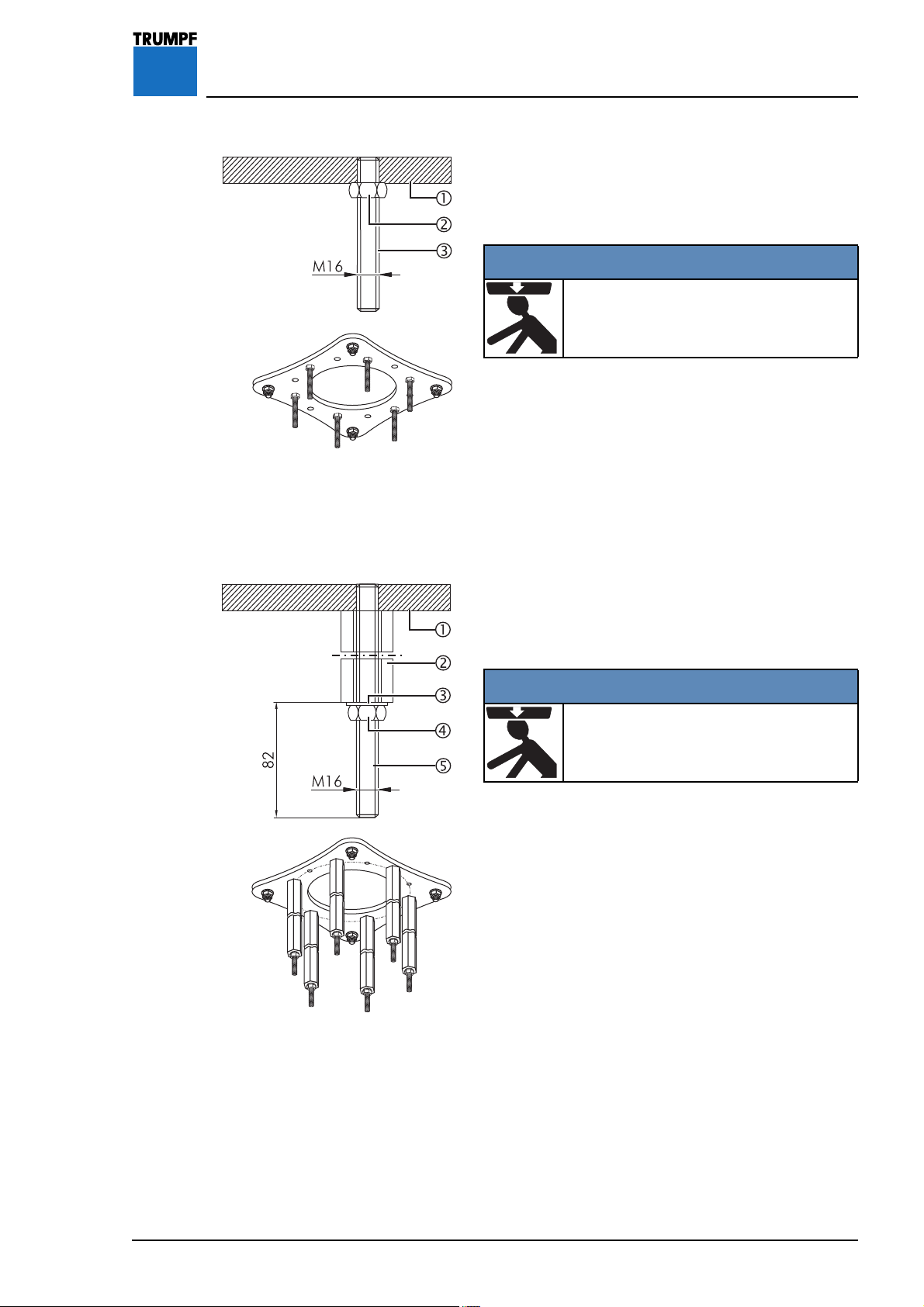

6 Installing Threaded Bolts or Spacers

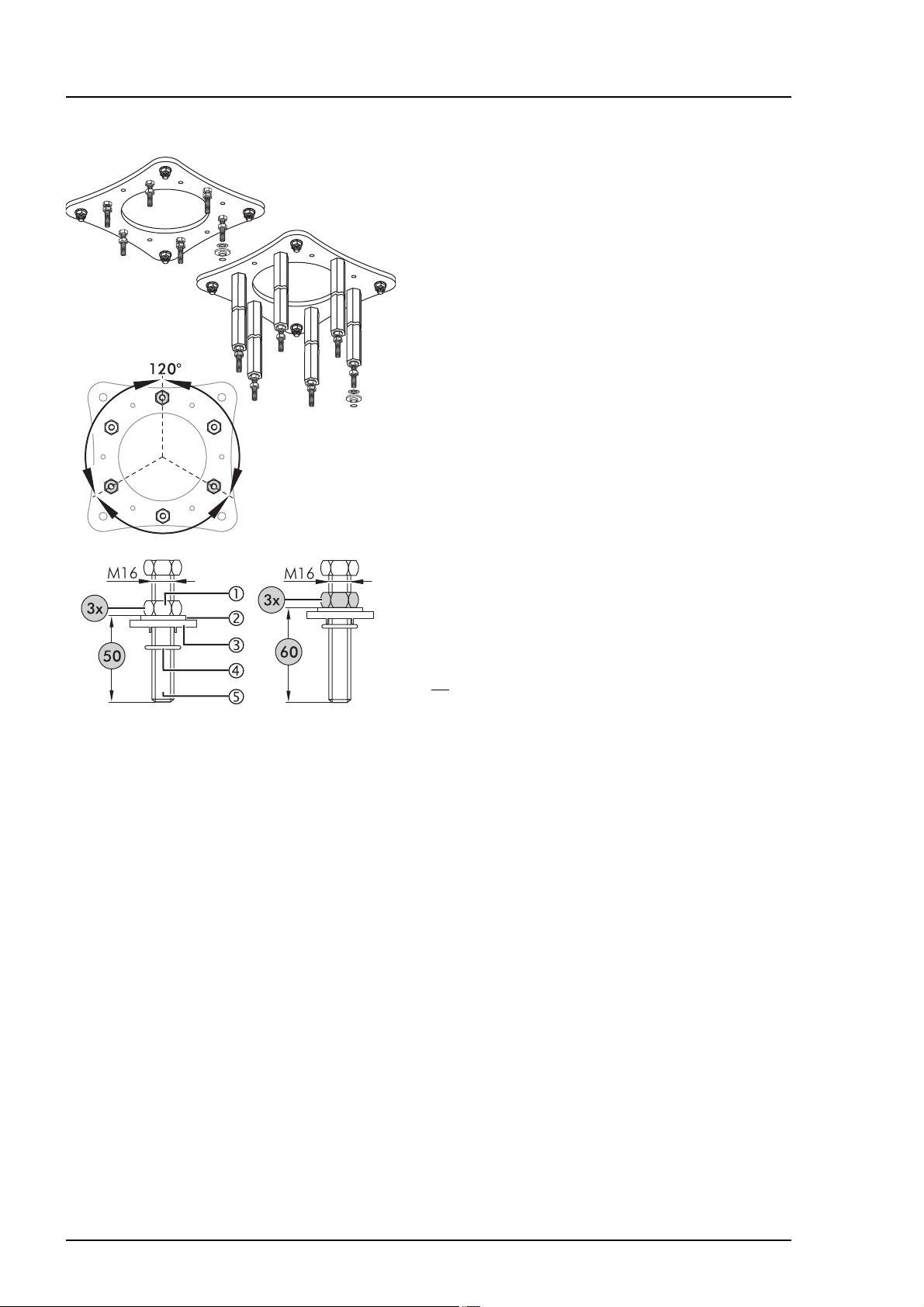

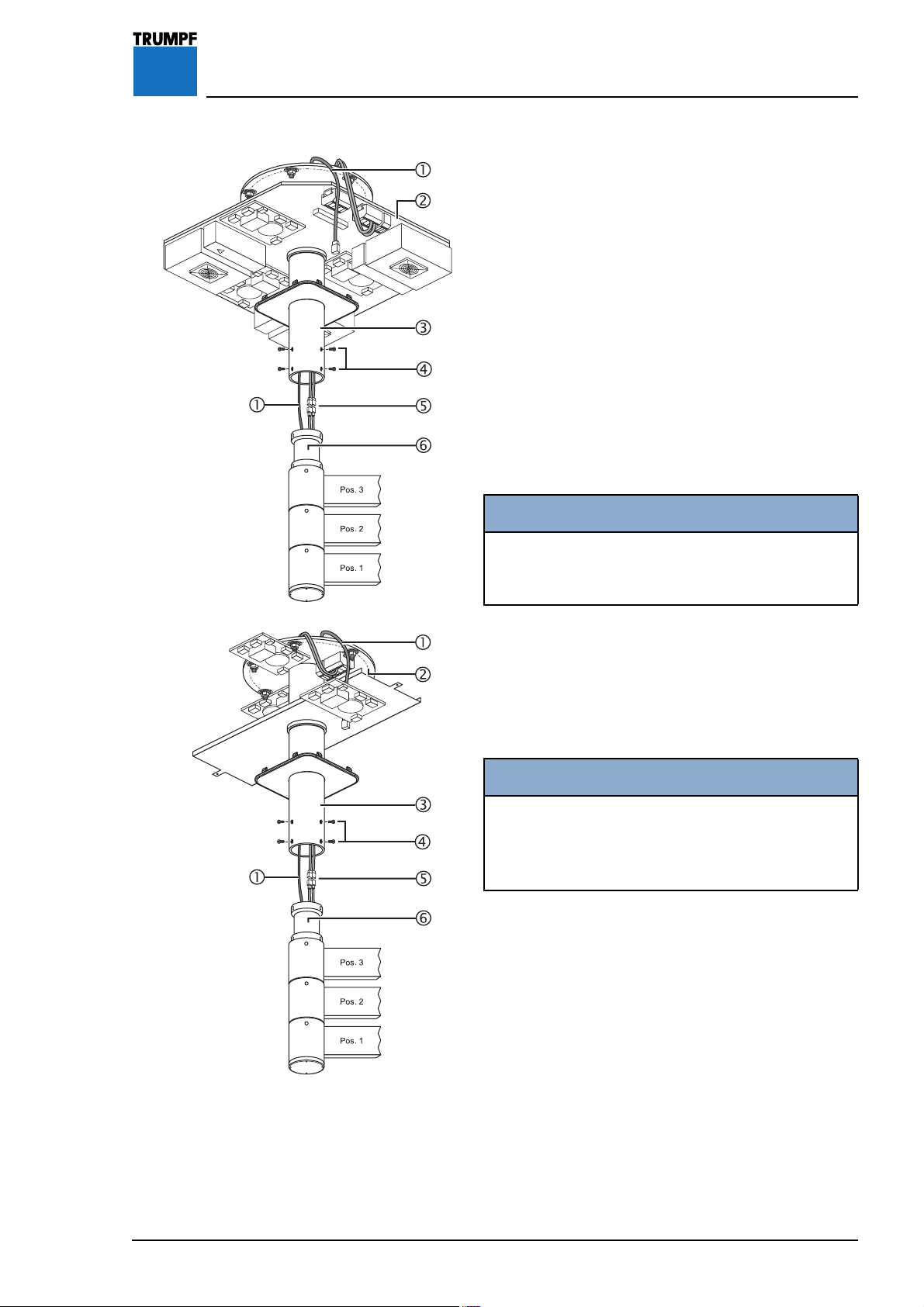

Figure 4 6.1 Installing Threaded Bolts on the

Ceiling Anchor Plate

1. Screw the hexagon nuts 2 onto the threaded bolts

3 (length 110mm) at intervals of min. 25mm.

1WARNING

Danger of the lighting system falling

Screw threaded bolt 3 into the ceiling

anchor plate 1 as far as it will go.

2. Screw six threaded bolts 3 as far as they will go

into the ceiling anchor plate 1.

Tightening the hexagon nuts:

3. Tighten the hexagon nuts 2 uniformly to 195Nm.

Figure 5

6.2 Installing Optional Spacers on the

Ceiling Anchor Plate

The length of the six spacers depends on the specific

order.

1WARNING

Danger of the lighting system falling

Screw threaded bolt 3 into the ceiling

anchor plate 1 as far as it will go.

1. Screw six threaded bolts 5 as far as they will go

into the ceiling plate 1.

2. Push the spacers 2 onto the threaded bolts 5

and put a washer 3 and a hexagon nut 4 on

each of them.

Tightening the hexagon nuts:

3. Tighten the hexagon nuts 4 to 195Nm.

• Check that the spacers 2 are securely in place.

7200681 Installation Instructions iLED US Lighting System – 07/07

19

Page 20

7 Installing the Ceiling Flange

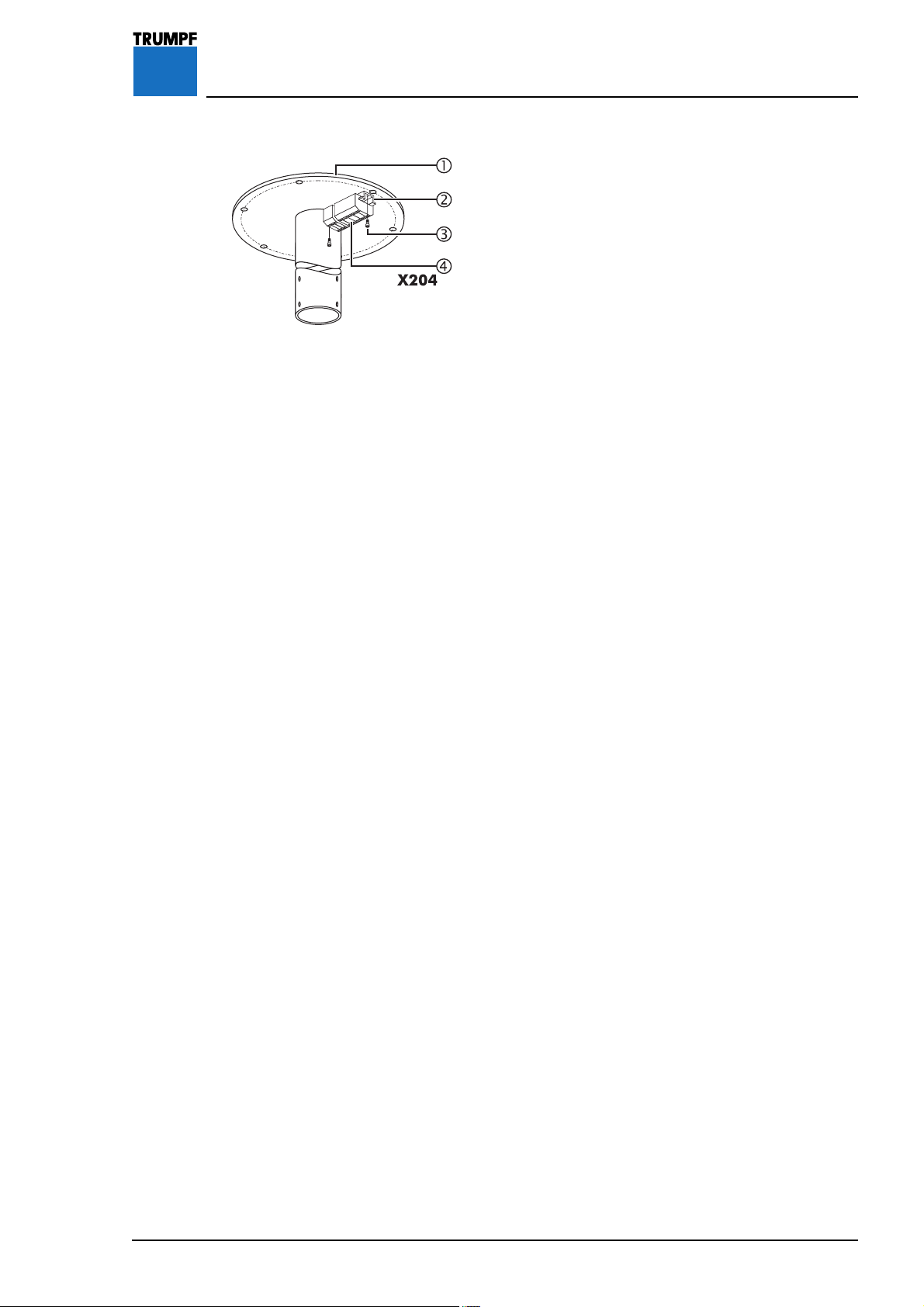

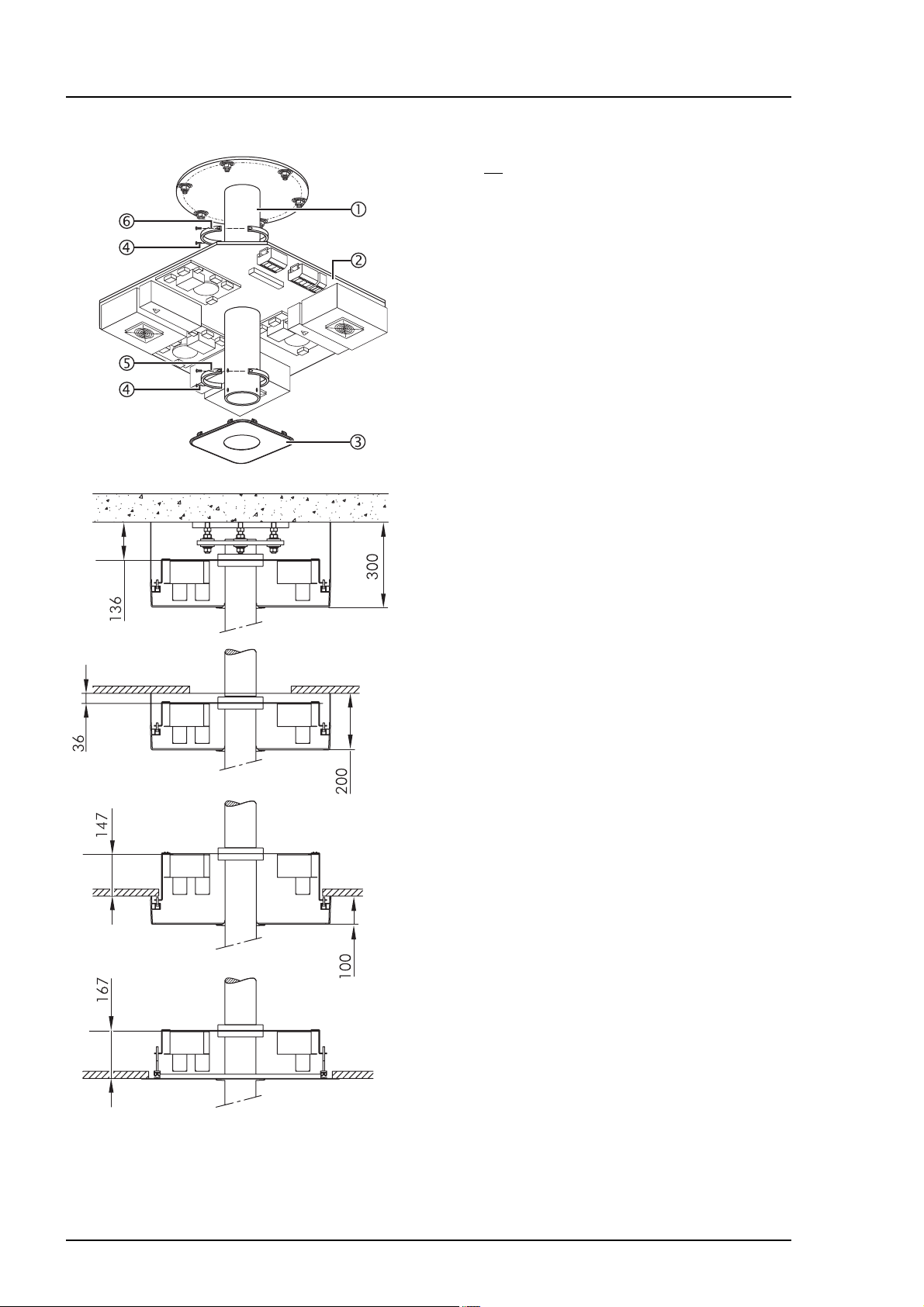

Figure 6 7.1 Preparing for Installation

Irrespective of the attachment elements specified in

“Section 6”, page 19, the following settings always

remain the same.

1. Screw three hexagon nuts 1, offset by 120° and

spaced 50mm, onto 3 threaded bolts 5.

• Screw the remaining 3 hexagon nuts 1 a little

higher e.g. 60 mm.

Aligning the hexagon nuts horizontally:

2. Horizontally align the three lower hexagon nuts 1

(spaced 50mm) using a spirit level.

Installing upper insulation:

3. Put a washer 2 and plastic insulating disk 3 on

the M16 threaded bolt 5 and secure using an

O-ring 4.

4. Repeat this procedure for the remaining 5

threaded bolts 5.

7.2 Installing Components on the Ceiling

Flange for the Power Supply using

Control Box Plates

If no interface plate is installed on the ceiling tube of

the ceiling flange, further components must be

installed on the ceiling flange depending on the

particular iLED lighting system variant.

Install the components on the floor beforehand

according to the following sections and then install

the ceiling flange as described in

page 25

.

“Section 7.3”,

20

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 21

7 Installing the Ceiling Flange

Figure 7 7.2.1 Variant: Light head without camera and

cable lengths of 1 - 20 m

Components to be installed:

• 1 top-hat rail and 1 terminal

1. Screw the top-hat rail 2 to the ceiling flange 1

using two M5 x 16mm socket head cap

screws 3.

2. Push the terminal 4 onto the top-hat rail 2 and

check that it is securely in place.

Electrical connection for iLED 5 / iLED 5 LCH / iLED 3

light heads:

• Route the cables into the control box plate in the

control box and connect according to circuit

diagram #4025890.

Electrical connection for iLED 3 LCH light head:

• Route the cables into the control box plate in the

control box and connect according to circuit

diagram #1431888.

7200681 Installation Instructions iLED US Lighting System – 07/07

21

Page 22

7 Installing the Ceiling Flange

Figure 8 7.2.2 Variant: Light head without camera and

cable lengths of 21 - 50 m

Components to be installed:

• 1 top-hat rail and 1 terminal

• 1 top-hat rail and 1 filter board per light head

Installing the top-hat rails 3:

1. For each component, screw one top-hat rail 3 to

the ceiling flange 1 using two M5 x 16mm socket

head cap screws 4.

Installing the terminal 2:

2. Install one terminal 2 as described in “Section

7.2.1”, page 21, point 2et seqq.

Installing the filter board(s) 5:

NOTE

Filter boards:

• The filter board 5 (without Powerline additional

board) is required to boost the control signals

from the light head where the cables are

between 21 - 50 m in length.

3. For each light head, fit one filter board 5 on the

top-hat rail 3 and check that it is securely in

place.

Electrical connection for iLED 5 / iLED 5 LCH / iLED 3

light heads:

• Route the cables into the control box plate in the

control box and connect according to circuit

diagram #4025743.

Electrical connection for iLED 3 LCH light head:

• Route the cables into the control box plate in the

control box and connect according to circuit

diagram #1431892.

• Remove the jumpers in A and B on terminal X204.

22

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 23

7 Installing the Ceiling Flange

Figure 9 7.2.3 Variant: Light head with camera and cable

lengths of 1 - 50 m

Components to be installed:

• 1 top-hat rail and 1 terminal

• 1 top-hat rail and 1 filter board per light head

without camera

• 1 top-hat rail and 1 filter board with Powerline

additional board per light head with camera

Installing the top-hat rails 3:

1. For each component, screw one top-hat rail 3 to

the ceiling flange 1 using two M5 x 16mm socket

head cap screws 4.

Installing the terminal 2:

2. Install one terminal 2 as described in “Section

7.2.1”, page 21, point 2et seqq.

Installing the filter board(s) 5:

NOTE

Filter boards:

• The filter board with Powerline additional board

6 is required to boost the video signal from the

camera and the control signals from the light

head.

• The filter board 5 (without Powerline additional

board) is required to boost the control signals

from further light heads without camera where

the cables are between 21 - 50 m in length.

3. For each light head, fit one filter board 5 on the

top-hat rail 3 and check that it is securely in

place.

Install filter board with Powerline additional board 6:

4. Fit one filter board with Powerline additional board

6 for the camera connection on the top-hat rail

2 and check that it is securely in place.

7200681 Installation Instructions iLED US Lighting System – 07/07

Electrical connection for iLED 5 light head:

5. Route the cables into the control box plate in the

control box and connect according to the relevant

circuit diagram #4025895.

Electrical connection for iLED 3 LCH light head:

6. Route the cables into the control box plate in the

control box and connect according to circuit

diagram #1442682.

23

Page 24

7 Installing the Ceiling Flange

Figure 10 7.2.4 Variant with camera on separate pendant

Components to be installed:

• 1 top-hat rail and 1 terminal

• 1 top-hat rail and 1 power supply unit

• 1 top-hat rail and 1 filter board with Powerline

additional board

Installing the top-hat rails 3:

1. For each component, screw one top-hat rail 3 to

the ceiling flange 1 using two M5 x 16mm socket

head cap screws 4.

Installing the terminal 2:

2. Install one terminal 2 as described in “Section

7.2.1”, page 21, point 2et seqq.

Install power supply unit 5 for 230 V building power

supply:

3. Fit the power supply unit 5 for the camera on the

top-hat rail 3 and check that it is securely in

place.

Installing filter board with Powerline additional

board

6:

NOTE

Filter boards:

• The filter board with Powerline additional board

6 is required to boost the video signal from the

camera.

• If there are more light heads and cable lengths

of 21- 50m (an)other filter board(s) (without

Powerline additional board) must be installed to

boost the control signals from the light head.

4. Fit one filter board with Powerline additional board

6 for the camera connection on the top-hat rail

3 and check that it is securely in place.

Electrical connection for 230 V:

5. Connect cables for 230 V building power supply

according to circuit diagram #1432289.

24

Electrical connection for 24 V:

6. Connect cables for 24 V building power supply

according to circuit diagram #1440162.

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 25

7 Installing the Ceiling Flange

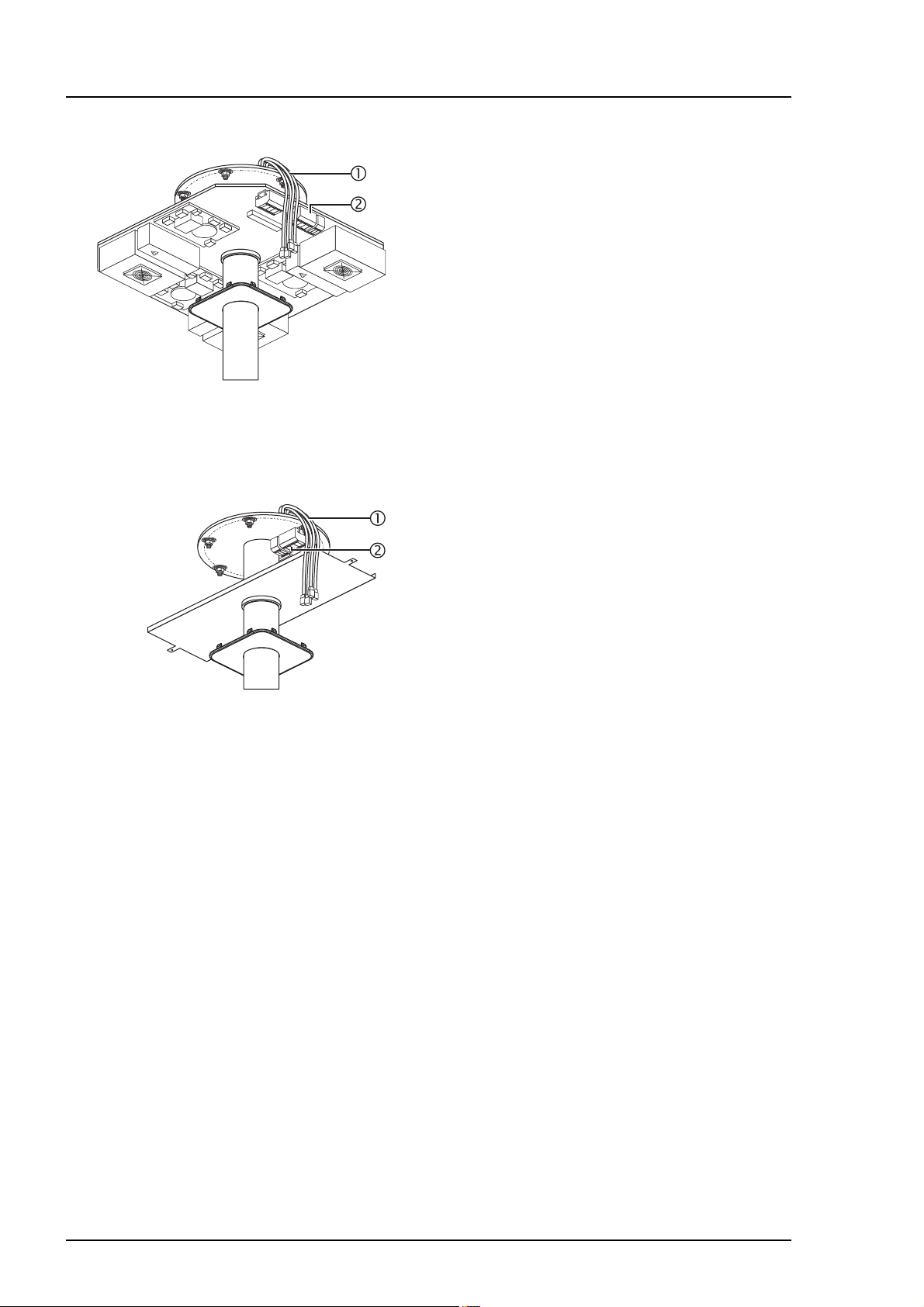

Figure 11 7.3 Installing the Ceiling Flange

1. Place the ceiling flange 2 on the 6 threaded bolts

1 and, using three hexagon nuts 7, turn and

move to the position of the non-aligned hexagon

nuts (spaced 60mm).

1WARNING

Danger of the lighting system falling

Screw the hexagon nuts 6 onto the

threaded bolts 1 as far as they will go.

Installing lower insulation:

2. Fit a plastic insulating disk 3, washer 4 and selflocking hexagon nut 5 on the three aligned

threaded bolts 1.

3. Gently tighten the three hexagon nuts 5.

Checking horizontal alignment:

4. Check the horizontal alignment of the ceiling

flange 2 and tighten the 3 self-locking hexagon

nuts 5 to 70Nm.

5. Screw the three upper hexagon nuts 8 downward

(spaced 60mm).

6. Remove the three hexagon nuts 7 (that were

previously fitted) from the threaded bolts 1, fit

them as described in point 2, and tighten to

70Nm.

• Check that the ceiling flange 2 is securely in

place.

7200681 Installation Instructions iLED US Lighting System – 07/07

25

Page 26

8 Installing an Interface Plate or Canopy Retainer Plate

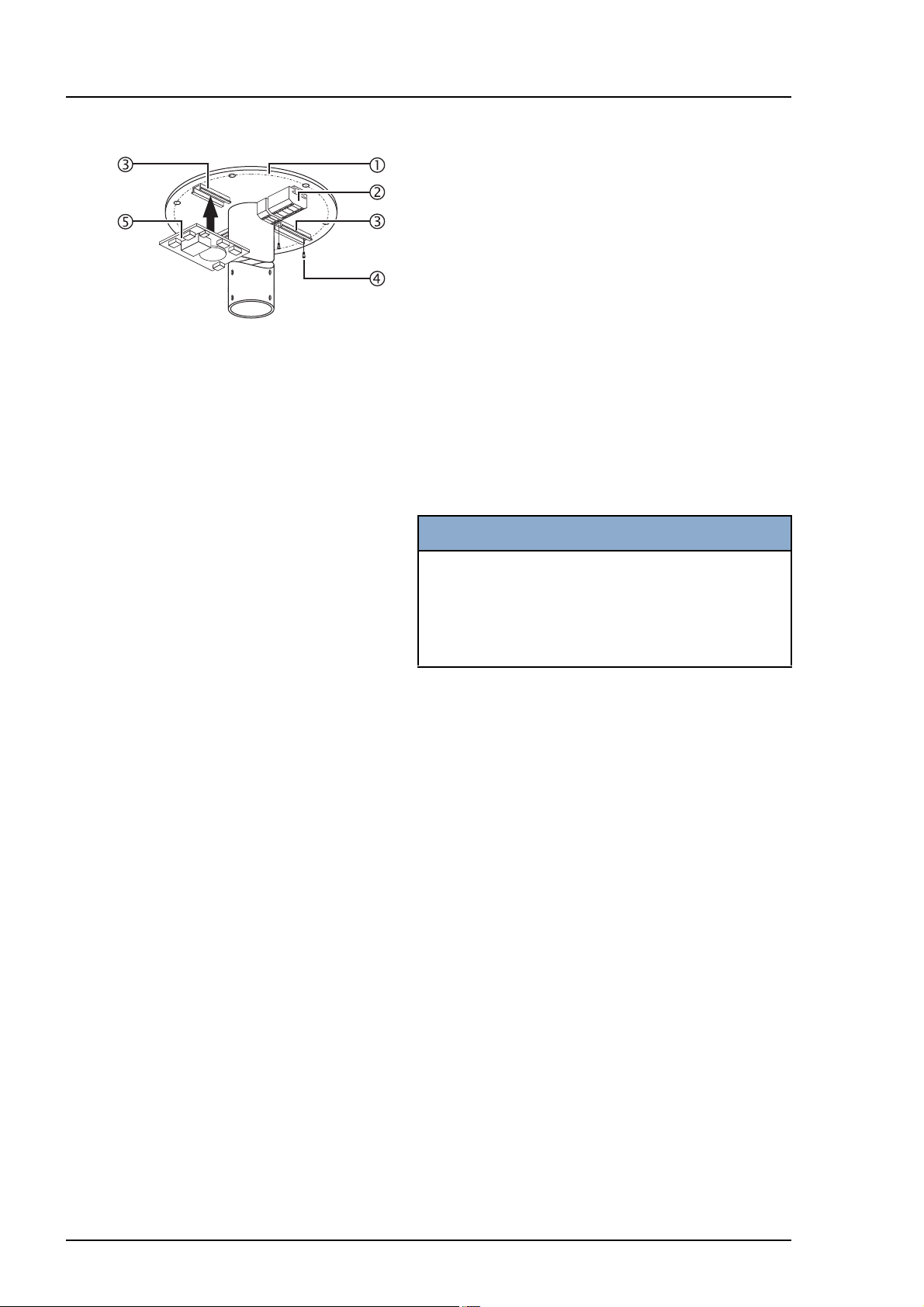

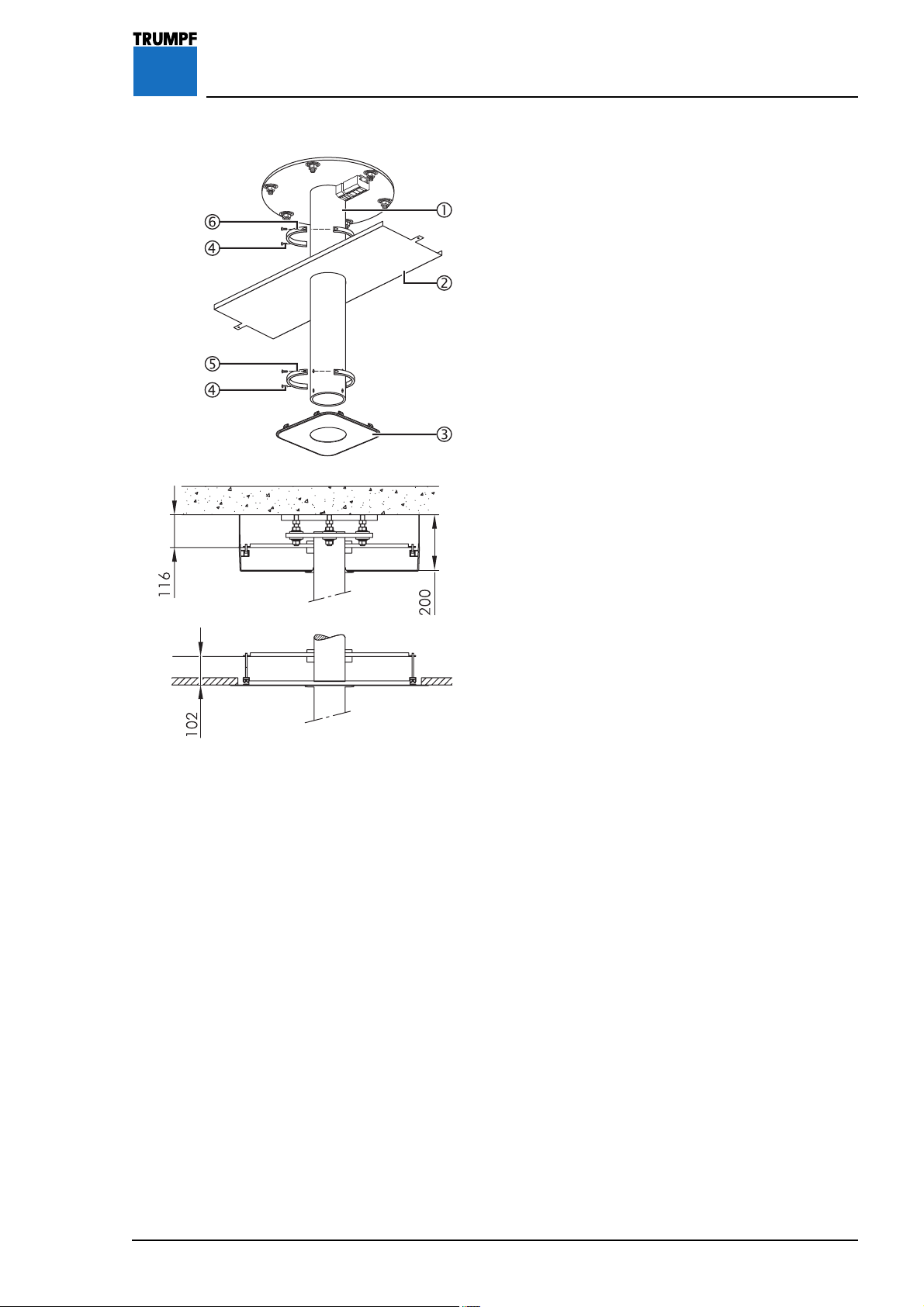

Figure 12 8.1 Installing an Interface Plate

If there is no interface plate installed, then the canopy

retainer plate must be installed as described in

“Section 8.2”, page 27.

Preparing to install the split rings

5/6:

1. Prepare two split rings 5/6 by screwing 2 socket

head cap screws and M8 x 40mm retaining

washers 5.

Adjusting the height of the interface plate:

2. Slide the split ring 6 onto the ceiling tube 1.

3. Adjust the height on the lower edge of the split ring

6 on the ceiling tube 1:

• With canopy:

- Canopy 300 = 136mm

- Canopy 200 = 36mm

- Canopy 100 = 147mm

• With ceiling screen:

- Ceiling screen = 167mm

4. Tighten the M8 x 40mm socket head cap screws

4 on the split ring 6.

Installing the interface plate:

5. Slide the interface plate 2 and the second split

ring 5 onto the ceiling tube 1 and align in

accordance with the ceiling recess.

6. Tighten the M8 x 40mm socket head cap screws

4 on the split ring 5.

7. Check that the interface plate 2 is securely in

place.

Installing the canopy cover 3:

8. Slide the canopy cover 3 onto the ceiling tube 1.

9. Prevent the canopy cover 3 from falling down

until the canopy or ceiling screen is installed.

26

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 27

8 Installing an Interface Plate or Canopy Retainer Plate

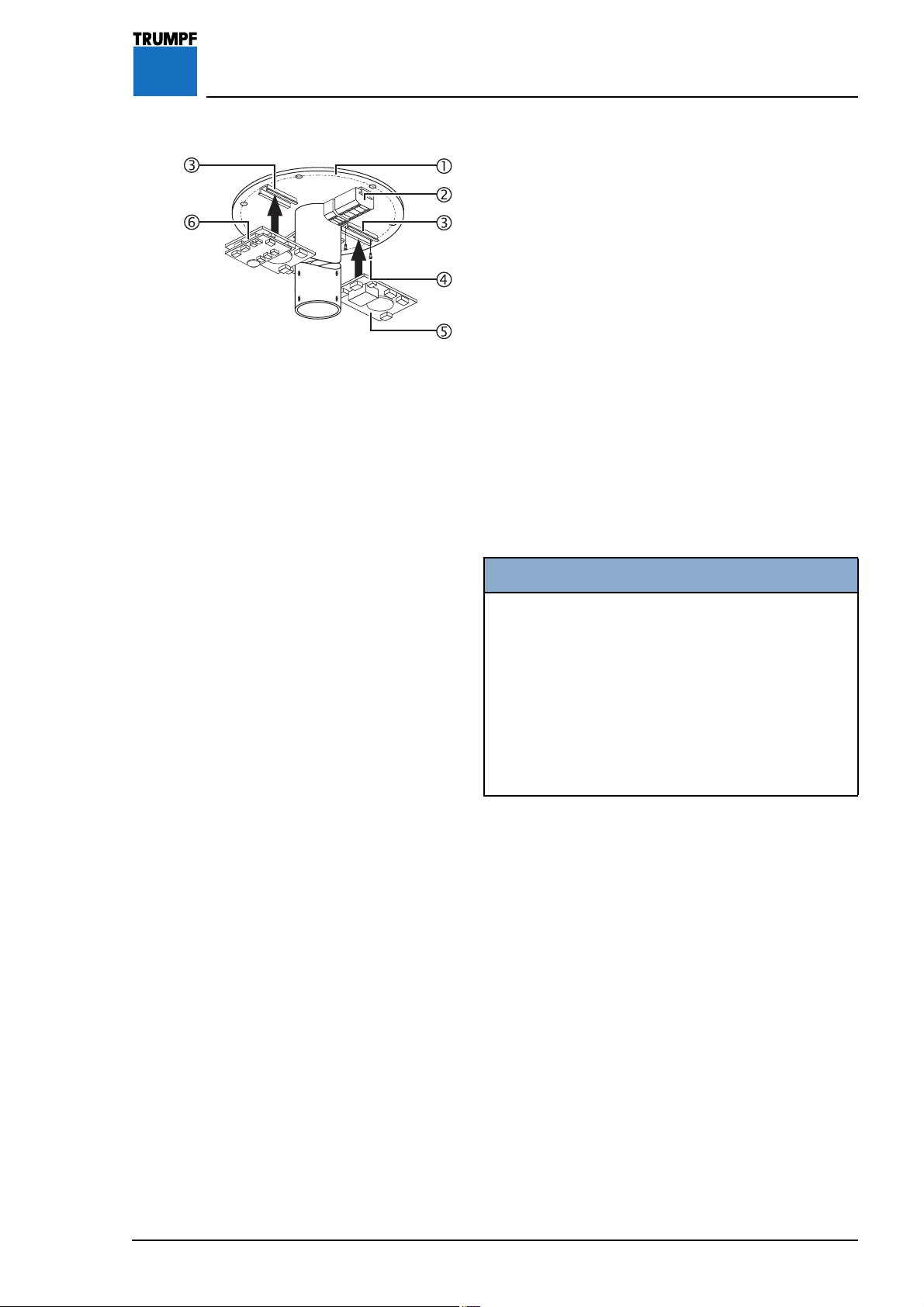

Figure 13 8.2 Installing a Canopy Retainer Plate

In order to later install the canopy and/or a ceiling

screen, the canopy retainer plate must be installed.

Preparing to install the split rings

5/6:

1. Prepare two split rings 5/6 by screwing 2 socket

head cap screws and M8 x 40mm retaining

washers 5 into each.

Adjusting the height of the canopy retainer plate:

2. Slide the split ring 6 onto the ceiling tube 1.

3. Adjust the height on the lower edge of the split ring

6 on the ceiling tube 1:

• With canopy:

- Canopy 200 = 116mm

• With ceiling screen:

- Ceiling screen = 102mm

4. Tighten the M8 x 40 mm socket head cap screws

4 on the split ring 6.

Installing the canopy retainer plate:

5. Slide the canopy retainer plate 2 and second split

ring 5 onto the ceiling tube 1 and align in

accordance with the ceiling recess.

6. Tighten the M8 x 40 mm socket head cap screws

4 on the split ring 5.

7. Check that the canopy retainer plate 2 is securely

in place.

7200681 Installation Instructions iLED US Lighting System – 07/07

Installing the canopy cover 3:

8. Slide the canopy cover 3 onto the ceiling tube 1.

9. Prevent the canopy cover 3 from falling down

until the canopy or ceiling screen is installed.

27

Page 28

9 Installing the Central Axis with Extension Arm

Figure 14 9.1 Routing Five-pole Cables for Light

Heads without Camera through the

Ceiling Tube

The separate 5-pole cables for light heads without

camera must first be routed through the ceiling tube

to the terminal on the interface plate or the ceiling

flange.

The 5-pole cables must be labeled to enable the light

heads without camera to be connected without any

risk of confusion.

Labeling five-pole cables:

1. Label the five-pole cables 1 with numbers on the

ends of the cable (depending on the number of

light heads without camera).

Routing five-pole cables through the ceiling tube:

NOTICE

Take care not to damage the cables

Carefully, without using a great deal of force,

route the cables 1 through the central tube 4.

2. Route the five-pole cables 1 through the ceiling

tube 4 to terminal (X201) 2 on the interface

plate or route them directly to the filter board (X9)

5 on the ceiling flange 3.

Connecting the five-pole cables to the interface plate:

• Connect the five-pole cables 1 in accordance with

the circuit diagrams:

- 230/24 V supply voltage #1431878,

- 24/24 V supply voltage) #1431885,

- 24 V supply voltage #1431887,

- 230 V supply voltage #1431882,

- 230/230V supply voltage #1431884,

and your cable labeling to terminal Klemme 2

on the interface plate.

28

Connecting five-pole cables to the ceiling flange:

1. Connect the five-pole cables 1 in accordance

with the circuit diagrams:

- connection lengths 1 - 20 m #4025890,

- connection lengths 21 - 50 m #4025743,

and your cable labeling to terminal 2 on the

ceiling flange 3.

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 29

9 Installing the Central Axis with Extension Arm

Figure 15 9.2 Routing Seven-pole Cables for Light

Heads with Camera through the

Ceiling Tube

The 7-pole cables from the central axis must be

routed through the ceiling tube to the interface plate

or the ceiling flange.

The 7-pole cables from the central axis must be

labeled to enable the light heads with camera to be

connected without any risk of confusion.

Labeling seven-pole cables:

1. Label the seven-pole cables 1 with numbers on

the ends of the cable (depending on the number of

light heads without camera).

Routing seven-pole cables through the ceiling tube:

NOTICE

Take care not to damage the cables

Carefully, without using a great deal of force,

route the cables 1 through the central tube 3.

2. Route the seven-pole cables 1 through the ceiling

tube 3 to the interface plate or the ceiling

flange 3.

9.3 Installing the Central Axis

NOTICE

Make sure that the central axis is not tilted.

• It should be possible to install the central axis 6

without using a great deal of force.

• Take care not to damage the cables.

1. Using the lifting device, raise the central axis 6.

2. Connect 5-pole cable plugs 5 (see “Section 9.1”,

page 28).

3. Insert the central axis 6 into the ceiling tube 3

and screw it in place using 8 M6 x 10mm

countersunk head screws 4.

4. Tighten the eight M6 x 10mm countersunk head

screws 4 to 10Nm.

5. Check that the central axis 6 is securely in place.

6. Fit the eight M6 x 10 mm countersunk head screws

4 with plastic caps.

7200681 Installation Instructions iLED US Lighting System – 07/07

29

Page 30

10 Connecting the Cables

Figure 16 10.1 Connection Variants for Light Heads

without Camera

10.1.1 Connection to the interface plate

1. Connect the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and the circuit diagrams:

- 230/24 V supply voltage #1431878,

- 24/24 V supply voltage #1431885,

- 230 V supply voltage #1431882,

- 230/230 V supply voltage #1431884,

- iLED 3 LCH for all supply voltages #1431896

to terminal 2.

2. Connect the connecting cables (to be laid by

customer) to the terminals 2.

Figure 17 10.1.2 Connection via interface plate(s) where

cables are between 1 - 20m in length

1. Disconnect the connecting cable plugs 1.

2. Connect the connecting cables 1 in accordance

with your cable labeling in “Section 9.1”, page 28

and the

- circuit diagram #4025890,

- for iLED 3 LCH in accordance with circuit diagram

#1431888 to the terminals 2 on the ceiling

flange.

3. Connect the ground conductor to the terminal 2.

4. Connect the connecting cables (to be laid by

customer) from the control box plate(s) to the

terminals 2.

30

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 31

10 Connecting the Cables

Figure 18 10.1.3 Connection via interface plate(s) where

cables are between 21 - 50m in length

1. Connect the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and in accordance with the circuit

diagram

- #4025743,

- for iLED 3 LCH in accordance with circuit diagram

#1431892,

to the filter board(s) 4 on the ceiling flange.

2. Connect the ground conductor to the terminal 2.

3. For each light head, connect one of the

connecting cables (W18) 3 supplied to the

terminal 2 and connect the plug to the

corresponding

4. Connect the connecting cables (to be laid by the

customer) from the control box plate(s) to the

terminals 2.

filter board 4.

7200681 Installation Instructions iLED US Lighting System – 07/07

31

Page 32

10 Connecting the Cables

Figure 19 10.2 Connection Variants for Light Heads

with Camera

10.2.1 Connection to the interface plate

1. Insert the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and the circuit diagram

- #1434128,

- for iLED 3 LCH in accordance with circuit diagram

#1442682,

into the Powerline additional board 4 on the

interface plate.

2. Connect the connecting cables (to be laid by

customer) to the terminals 2.

3. Plug the video signal cable for the camera into the

Powerline additional board 4.

4. Plug the connecting cable (Type RJ45) from the

controller (TruVidia) into the Powerline additional

board 4.

Figure 20 10.2.2 Connection via control box plate(s)

1. Insert the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and the circuit diagram

- #4025895,

- for iLED 3 LCH in accordance with circuit diagram

#1442682,

into the Powerline additional board 4 on the

ceiling flange.

2. Connect the connecting cables (to be laid by

customer) to the terminals 2.

3. For each light head, connect one of the

connecting cables (W18) 3 supplied to the

terminal 2 and connect the cable to the

corresponding filter board(s) 5.

4. Connect the ground conductor from the Powerline

additional board 4 to the terminal 2.

5. Plug the video signal cable for the camera

Powerline additional board 4.

6. Plug the connecting cable (Typ RJ 45) from the

controller (TruVidia) into the Powerline additional

board 4.

into the

32

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 33

10 Connecting the Cables

Figure 21 10.3 Connection Variant for Camera on

Separate Pendant

10.3.1 Connection to the interface plate

1. Insert the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and the circuit diagrams:

- 230 V camera on separate pendant #1432289,

- 24 V camera on separate pendant #1440162,

- 230/24 V supply voltage #1431878,

- 24/24 V supply voltage #1431885,

- 230 V supply voltage #1431882,

- 230/230 V supply voltage #1431884,

into the Powerline additional board 4 on the

interface plate.

2. Connect customer's connecting cables to the

terminals 2.

3. Plug the video signal cable for the camera into the

Powerline additional board 4.

4. Plug the connecting cable (Type RJ45) from the

controller (TruVidia) into the Powerline additional

board 4.

Figure 22 10.3.2 Connection via control box plate(s)

1. Insert the connecting cable plugs 1 in

accordance with your cable labeling in “Section

9.1”, page 28 and the circuit diagrams:

- 230V camera on separate pendant #1432289,

- 24 V camera on separate pendant #1440162,

- connection lengths 1 - 20m #4025890,

- connection lengths 21 -50m #4025743,

into the Powerline additional board 6 on the

ceiling flange.

2. For 24 V building power supply: connect the

connecting cable (W18) 3 supplied to the

terminal 2 and connect the plug to the

corresponding

filter board 5.

3. For 230 V building power supply: connect the

power supply unit 4 with the connecting cable

(W24) to the terminal 2.

Connect the filter board with the connecting

cable (W25) to the power supply unit.

4. Plug the video signal cable for the camera into the

Powerline additional board 6.

5. Plug the connecting cable (Type RJ45) from the

controller (TruVidia) into the Powerline additional

board 6.

6. Connect the ground conductor from the Powerline

additional board 6 to the terminal 2.

7200681 Installation Instructions iLED US Lighting System – 07/07

33

Page 34

11 Installing a Spring Arm

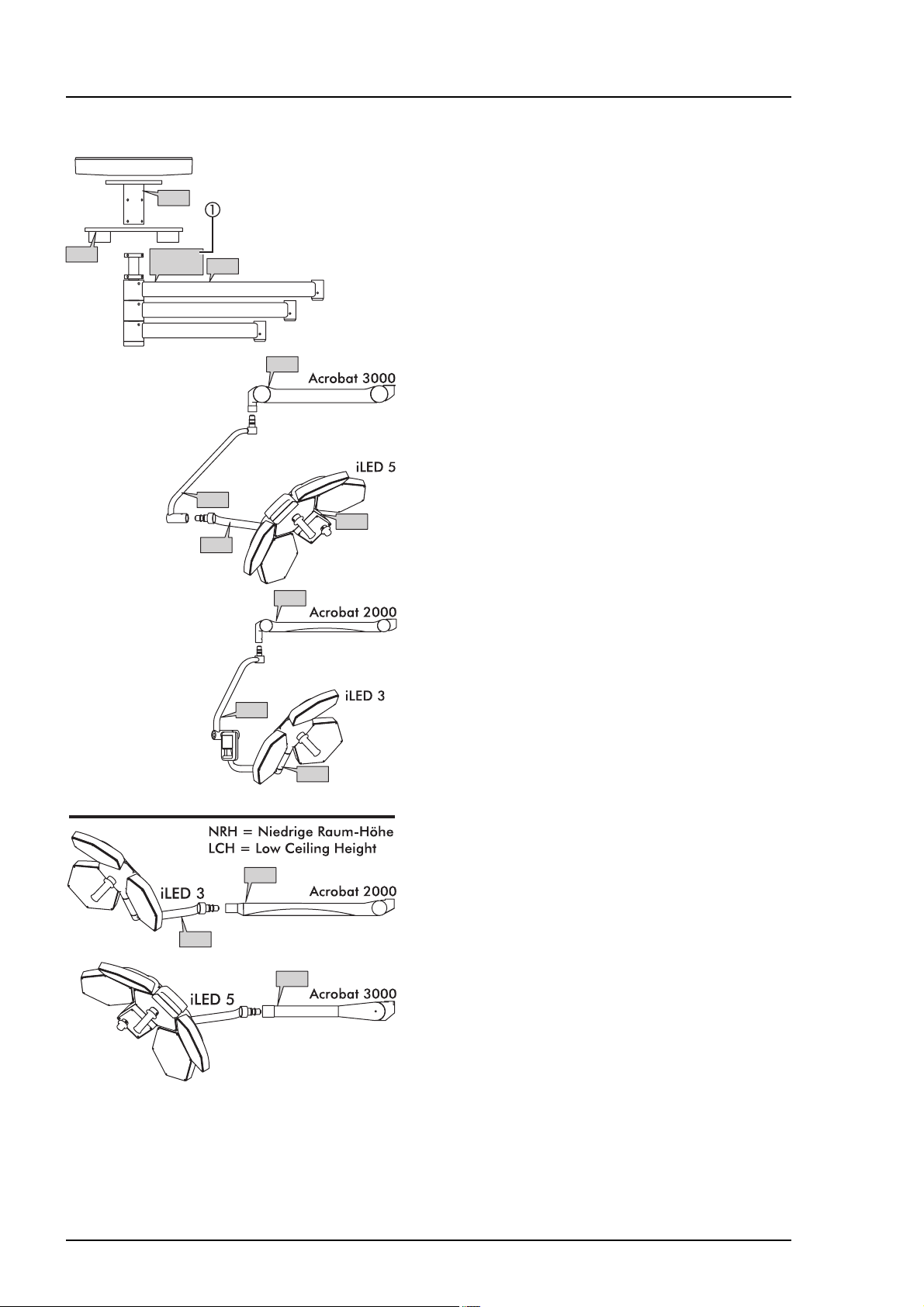

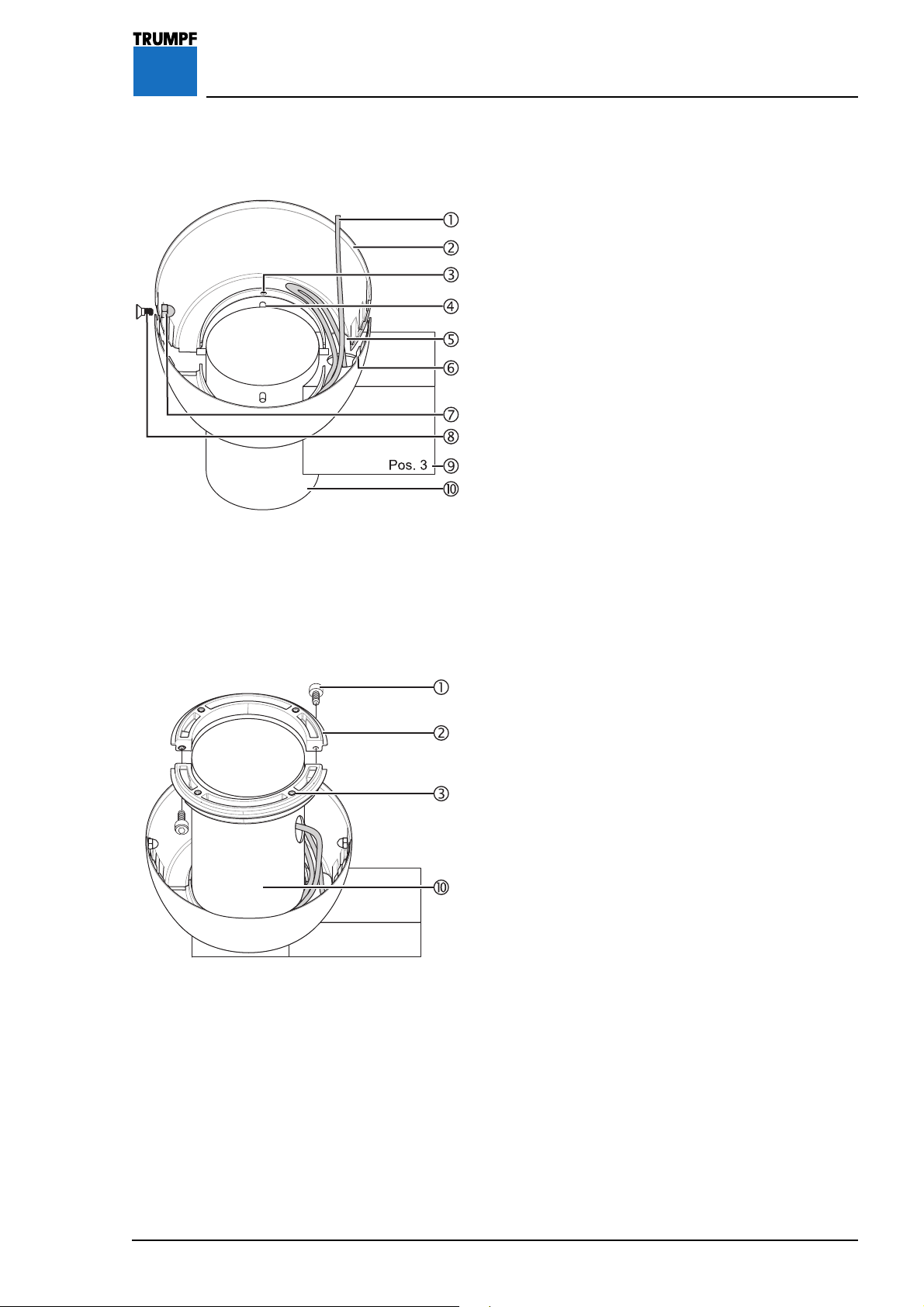

Figure 23 11.1 Spring Arm Versions

In general:

• one iLED 5 light head is installed on a

- Acrobat 3000 spring arm or

- Acrobat 3000 LCH spring arm (

Height),

• one iLED 3 light head is installed on a

- Acrobat 2000 spring arm or

- Acrobat 2000 LCH spring arm (

Height).

• the camera on the separate pendant is mounted on

the Acrobat 2000 spring arm,

• the vidiaPORT monitor holders are mounted on an

Acrobat 2000, Acrobat 3000 or Acrobat Space.

11.1.1 Spring arm equipment

For the different versions of the iLED lighting system,

e.g.: light head with/without camera or for the

vidiaPORT monitor installations, the spring arms

come with different equipment.

Low Ceiling

Low Ceiling

The simplest way of telling the application is to look at

the connecting spigot of the spring arm:

1. Spring arm with 5-pole rotating commutator 1 for

the installation of light heads (see “Section 11.3”,

page 36).

2. Spring arm with 7-pole cabling 2 for the

installation of light heads with camera or camera

on a separate pendant (see “Section 11.4”,

page 37).

3. Hollow spring arm 3 for routing cables for

monitor installations, e.g. vidiaPORT (see “Section

16”, page 50).

• The hollow spring arms 3 are rotation-limited to

approx. 330 degrees, to prevent the routed cables

from twisting.

• The range of the Acrobat Space spring arm can be

adjusted.

11.1.2 Spring arm adjustments

The tension for counterbalancing the weight of the

light head or monitor, the brake force and how to

adjust the spring arm height limit can be found in

“Section 18”, page 68.

34

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 35

11 Installing a Spring Arm

Figure 24 11.2 Preparing for Installation for all Spring

Arm Variants

1. Undo the two screws 1 and remove the cover 2

on the extension arm 3.

1WARNING

Danger of the lighting system falling

Tak e ca r e

4 when removing.

2. Remove the circlip 4 from the spring arm 6.

3. Remove the disk 5 from the spring arm 6.

not to overextend the circlip

7200681 Installation Instructions iLED US Lighting System – 07/07

35

Page 36

11 Installing Spring Arms

Figure 25 11.3 Installing Spring Arm for Light Head

without Camera

Feature of the spring arms:

• 5-pole rotating commutator 6 in the connecting

spigot of the spring arm (see “Section 11.1”,

page 34).

Installing the spring arm:

1. Carefully pull the 5-pole plug 6 out of the

extension arm 3.

NOTICE

Raising the spring arm

Figure 26

• Only raise the spring arm 5

illustrated by the arrow

•

Never lift the spring arm by the cover panels 4.

2. Raise the spring arm 5 at the point

the arrow

and insert it into the extension arm 3.

at the point

.

indicated by

1WARNING

Danger of the lighting system falling

The circlip 1 must be fully engaged

with the groove in the pivot of the

spring arm.

3. Position the disk (1 piece) 2 and install the

circlip 1.

4. Check that the spring arm 5 is securely in place.

Connecting the plug:

NOTE

36

Using the grooves to position the plug

• The plug connector 9 has one narrow groove 7

and one wide groove 8.

• When connecting the plug 9, the grooves 7/8

must be aligned with the corresponding grooves

in the counterpart.

5. Carefully insert the plug 6 from above.

6. Check that the plug 6 is securely in place.

7. Install the cover as described in “Section 11.7”,

page 39.

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 37

11 Installing Spring Arms

Figure 27 11.4 Installing Spring Arm for Light Head

with Camera

Feature of the spring arms:

• 7-pole cabling consisting of three threaded

connectors and a 6-pole plug in the connecting

spigot of the spring arm (see “Section 11.1”,

page 34).

Connecting the cables:

1. Carefully route the cables 7 into the extension

arm 3 out the top of the extension arm 3.

NOTICE

Raising the spring arm

• Only raise the spring arm 5

illustrated by the arrow.

Never lift the spring arm by the cover panels 4.

•

2. Raise the spring arm 5 at the point indicated by

the arrow and carefully route the cables 6 into

the spring arm 5 through the extension arm 3.

Installing the spring arm:

3. Insert the spring arm 5 into the extension arm 3.

at the point

1WARNING

Danger of the lighting system falling

The circlip 1 must be fully engaged

with the groove in the pivot of the

spring arm.

4. Position the disk (1 piece) 2 and install the

circlip 1.

5. Check that the spring arm 5 is securely in place.

Figure 28

7200681 Installation Instructions iLED US Lighting System – 07/07

Connecting the plugs:

6. Connect up the three threaded connectors 8

according to the color code.

7. Connect the 6-pole plug 9.

8. Carefully push the threaded connectors 8 and

6-pole plug 9 back into the extension arm 3

from above.

9. Install the cover as described in “Section 11.7”,

page 39.

37

Page 38

11 Installing Spring Arms

Figure 29 11.5 Installing Spring Arm for vidiaPORT

Monitor Installations

Feature of the spring arms:

• Hollow connecting spigot for routing cables (see

“Section 11.1”, page 34).

1WARNING

Sudden release of the Acrobat Space

spring arm

• If no monitor is mounted when the lock

is disengaged, the spring arm will

jump upward.

• Do not take out the locking pin 5

until the monitor is fully mounted.

Installing the spring arm:

1. Insert the spring arm 4 into the extension arm 3.

Only Acrobat Space spring arm: Adjust the arm

2.

stop as described in “Section 11.6”, page 38.

Figure 30

1WARNING

Danger of the lighting system falling

The circlip 1 must be fully engaged

with the groove in the pivot of the

spring arm.

3. Position the disk (1 piece) 2 and install the

circlip 1.

4. Check that the spring arm 4 is securely in place.

11.6 Adjusting Arm Stop on the Acrobat

Space Spring Arm

The arm stop limits Acrobat Space spring arm rotation

of the extension arm to approx. 330 degrees.

The range can be further limited by installing an extra

stop pin.

1. Check the arm stop of the spring arm in the

extension arm.

• The spring arm must not collide with nearby walls

or objects.

38

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 39

11 Installing Spring Arms

Figure 31 11.7 Installing the Cover

Only for spring arms for vidiaPORT monitor

installations:

• Before installing the cover 2 push the cables into

the spring arm and extension arm.

Only for spring arms with 5-pole plug:

• The grub screws 3 in the cover 2 keep the 5-pole

plug 5 in place:

1WARNING

Electric shock

When installing the cover 2, make

sure that the grub screws 3 do not

damage the internal cables!

1. Position the cover 2 in such a way that the two

grub screws 3 are located in the cut-outs in the

plug 4.

Only for spring arms with 5-pole plug:

2.

Carefully turn the cover 2 with 5-pole plug 5

until the two screws 1 can be screwed in.

3. Screw on the cover 2 using two screws 1.

4. Check that the cover 2 is securely in place.

7200681 Installation Instructions iLED US Lighting System – 07/07

39

Page 40

12 Installing the Horizontal Bar on the iLED 5 Light Head

Figure 32 12.1 Installing the Horizontal Bar on the

iLED 5 Light Head without Camera

1. Unscrew one securing screw 3.

2. Unscrew two brake screws 2/4.

Connecting the plug:

NOTE

Using the grooves to position the plug

• The plug connector 5 has one narrow groove 7

and one wide groove 8.

• When connecting the plug 5, the grooves 7/8

must be aligned with the corresponding grooves

in the counterpart.

Installing the horizontal bar:

3. Precisely insert the horizontal bar 1 axially into the

light head's gimbal joint 6.

4. Screw in a securing screw 3.

5. Screw in two brake screws 2/4.

6. Check that the horizontal bar 1 is securely in

place.

7. Continue installation as described in “Section

13.1”, page 41.

Figure 33

12.2 Installing the Horizontal Bar on the

iLED 5 Light Head with Camera

1. Unscrew one securing screw 3.

2. Unscrew two brake screws 2/4.

Connecting the plug:

3. Connect the 6-pole plug 6.

4. Connect up the three threaded connectors 7

according to the color code.

5. Carefully push the 6-pole plug 6 and threaded

connectors 7 into the gimbal joint 1.

Installing the horizontal bar:

6. Precisely insert the horizontal bar 1 axially into the

light head's gimbal joint 5.

7. Screw in a securing screw 3.

8. Screw in two brake screws 2/4.

9. Check that the horizontal bar 1 is securely in

place.

10. Continue installation as described in “Section

13.4”, page 44.

40

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 41

13 Installing the Light Head

Figure 34 13.1 Installing the Light Head without

Camera on the Acrobat 2000/3000

Spring Arm

The iLED 3 and iLED 5 light heads must be installed

on different spring arms.

1. Only Acrobat 3000 spring arm: unscrew the M10

x 8.6mm slotted brake screw 1.

2. Unscrew the M3 x 8 mm countersunk screw 7

and slide the sleeve 8 upward.

3. Screw the M3 x 8mm countersunk screw 7 back

in again to secure the sleeve 8.

4. Remove the locking segment 2.

Connecting the plug:

NOTE

Using the grooves to position the plug

• The plug connector 6 has one narrow groove 3

and one wide groove 4.

• When connecting the plug 5 the grooves 3/4

must be aligned with the corresponding grooves

in the counterpart.

5. Precisely insert the light head 5 axially into the

spring arm 9.

1WARNING

Danger of the light head falling

• If the wrong locking segment 2 is

fitted, the light head may fall.

• Only use an original locking segment

2 for the spring arm in question.

6. Insert the locking segment 2, unscrew the M3 x

8 mm countersunk screw 7 and slide the sleeve

8 downward.

1WARNING

7200681 Installation Instructions iLED US Lighting System – 07/07

Danger of the light head falling

• Secure the sleeve 8 with an M3 x

8 mm countersunk screw 7.

7. Screw in the M3 x 8mm countersunk screw 7.

Only Acrobat 3000 spring arm: screw in the M10

8.

x 8.6mm slotted brake screw 1.

9. Check that the light head 5 is securely in place.

10. Adjust the spring arm as described in “Section

18”, page 68.

41

Page 42

13 Installing the Light Head

Figure 35 13.2 Installing the iLED 3 Light Head

without Camera on the Acrobat 2000

LCH Spring Arm

1. Unscrew the brake screw 7 on the underside of

the sleeve 4.

2. Turn the sleeve 4 90 degrees and unscrew the

first end device securing screw 2.

3. Turn the sleeve 4 180 degrees and unscrew the

second end device securing screw 2.

Connecting the plug:

NOTE

Using the grooves to position the plug

• The plug connector 3 has one narrow groove 8

and one wide groove 9.

• When connecting the plug 3 the grooves 8/9

must be aligned with the corresponding grooves

in the counterpart.

Installing the light head:

4. Precisely insert the light head 1 axially into the

spring arm 5.

1WARNING

Danger of the light head falling

• Secure the light head 1 with two end

device securing screws 2.

5. Screw in two end device securing screws 2.

6. Screw in one brake screw 7.

7. Check that the light head 1 is securely in place.

8. Adjust the spring arm as described in “Section

18”, page 68.

42

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 43

13 Installing the Light Head

Figure 36 13.3 Installing the iLED 5 Light Head

without Camera on the Acrobat 3000

LCH Spring Arm

1. Carefully take out the sleeve securing screw 7

and slide the sleeve 5 backward.

2. Unscrew the two end device securing screws 4.

3. Unscrew the two brake screws 3.

Connecting the plug:

NOTE

Using the grooves to position the plug

• The plug connector 2 has one narrow groove 8

and one wide groove 9.

• When connecting the plug 2, the grooves 8/9

must be aligned with the corresponding grooves

in the counterpart.

Installing the light head:

4. Precisely insert the light head 1 axially into the

spring arm 6.

5. Screw in two end device securing screws 4.

6. Screw in the two brake screws 3.

1WARNING

Danger of the light head falling

• Secure the sleeve 5 with the sleeve

securing screw 7.

7. Carefully slide the sleeve 5 forward and screw in

the sleeve securing screw 7.

8. Check that the light head 1 is securely in place.

9. Adjust the spring arm as described in “Section

18”, page 68.

7200681 Installation Instructions iLED US Lighting System – 07/07

43

Page 44

13 Installing the Light Head

Figure 37 13.4 Installing the Light Head with Camera

on the Acrobat 2000/3000 Spring Arm

The iLED 3 and iLED 5 light heads must be installed

on different spring arms.

1. Only Acrobat 3000 spring arm: unscrew the M10

x 8.6mm slotted brake screw 1.

2. Unscrew the M3 x 8mm countersunk screw 6

and slide the sleeve 7 upward.

3. Screw the M3 x 8mm countersunk screw 6 back

in again to secure the sleeve 7.

4. Remove the locking segment 2.

Connecting the plug:

5. Connect up the three threaded connectors 3

according to the color code.

6. Connect the 6-pole plug 4.

7. Carefully push the screw connectors 3 and the

6-pole plug 4 into the spring arm 8.

Installing the light head:

8. Precisely insert the light head 1axially into the

spring arm 8.

9. Insert the locking segment 2, unscrew the M3 x

8mm countersunk screw 6 and slide the

sleeve 7 downward.

1WARNING

Danger of the light head falling

• Secure the sleeve 7 with an M3 x

8 mm countersunk screw 6.

10. Screw in the M3 x 8mm countersunk screw 6.

Only Acrobat 3000 spring arm: screw in the M10

11.

x 8.6mm slotted brake screw 1.

12. Check that the light head 5 is securely in place.

13. Adjust the spring arm as described in “Section

18”, page 68.

Mounting the counterweight for the camera:

14. Connect the counterweight for the camera as

described in “Section 15.1”, page 48.

44

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 45

13 Installing the Light Head

Figure 38 13.5 Installing the iLED 3 Light Head with

Camera on the Acrobat 2000 LCH

Spring Arm

1. Unscrew the brake screw 6 on the underside of

the sleeve 3.

2. Turn the sleeve 3 90 degrees and unscrew the

first end device securing screw 2.

3. Turn the sleeve 3 180 degrees and unscrew the

second end device securing screw 2.

Connecting the plug:

4. Connect the six-pole plug 7.

5. Connect up the three threaded connectors 8

according to the color code.

6. Carefully push the six-pole plug 7 and threaded

connectors 8 into the spring arm 4.

Installing the light head:

7. Precisely insert the light head 1 axially into the

spring arm 4.

1WARNING

Danger of the light head falling

• Secure the light head 1 with two end

device securing screws 2.

8. Screw in two end device securing screws 2.

9. Screw in one brake screw 6.

10. Check that the light head 1 is securely in place.

11. Adjust the spring arm as described in “Section

18”, page 68.

Mounting the counterweight for the camera:

12. Connect the counterweight for the camera as

described in “Section 15.1”, page 48.

7200681 Installation Instructions iLED US Lighting System – 07/07

45

Page 46

13 Installing the Light Head

Figure 39 13.6 Installing the iLED 5 Light Head with

Camera on the Acrobat 3000 LCH

Spring Arm

The iLED 3 and iLED 5 light heads must be installed

on spring arms with different tension. See

4.1”, page 16

which.

for which serial number goes with

1. Carefully take out the sleeve securing screw 6

and slide the sleeve 4 backward.

2. Unscrew the two brake screws 2.

Connecting the plug:

3. Connect the six-pole plug 7.

4. Connect up the three threaded connectors 8

according to the color code.

5. Carefully push the six-pole plug 8 and threaded

connectors 7 into the spring arm 5.

“Section

Installing the light head:

6. Precisely insert the light head 1 axially into the

spring arm 5.

7. Screw in two end device securing screws 3.

8. Screw in the two brake screws 2.

1WARNING

Danger of the light head falling

• Secure the sleeve 4 with the sleeve

securing screw 6.

9. Carefully slide the sleeve 4 forward and screw in

the sleeve securing screw 6.

10. Check that the light head 1 is securely in place.

11. Adjust the spring arm as described in “Section

18”, page 68.

Mounting the counterweight for the camera:

12. Connect the counterweight for the camera as

described in “Section 15.1”, page 48.

46

7200681 Installation Instructions iLED US Lighting System – 07/07

Page 47

14 Installing Camera on Separate Pendant

Figure 40 14.1 Installing Camera on Separate

Pendant on the Acrobat 2000

Spring Arm

1. Unscrew the M3 x 8mm countersunk screw 5

and slide the sleeve 6 upward.

2. Screw the M3 x 8mm countersunk screw 5 back

in to secure the sleeve 6.

3. Remove the locking segment 1.

Connecting the plug:

4. Connect up the three threaded connectors 2

according to the color code.

5. Connect the six-pole plug 3.

6. Carefully push the threaded connector 2and the

6-pole plug 3 into the spring arm 7.

Installing the light head:

7. Precisely insert the camera yoke 4 axially into the

spring arm 7.

8. Insert the locking segment 1, unscrew the

M3 x 8mm countersunk screw 6 and slide the

sleeve 6 downward.

1WARNING

Danger of the camera system falling

• Secure the sleeve 6 with an M3 x

8mm countersunk screw 5.

9. Screw in the M3 x 8mm countersunk screw 5.

10. Check that the camera 5 is securely in place.

11. Adjust the spring arm as described in “Section

18”, page 68.

Mounting the counterweight for the camera:

12. Connect the counterweight for the camera as

described in “Section 15.1”, page 48.