Page 1

46 Series

3

21

4

5

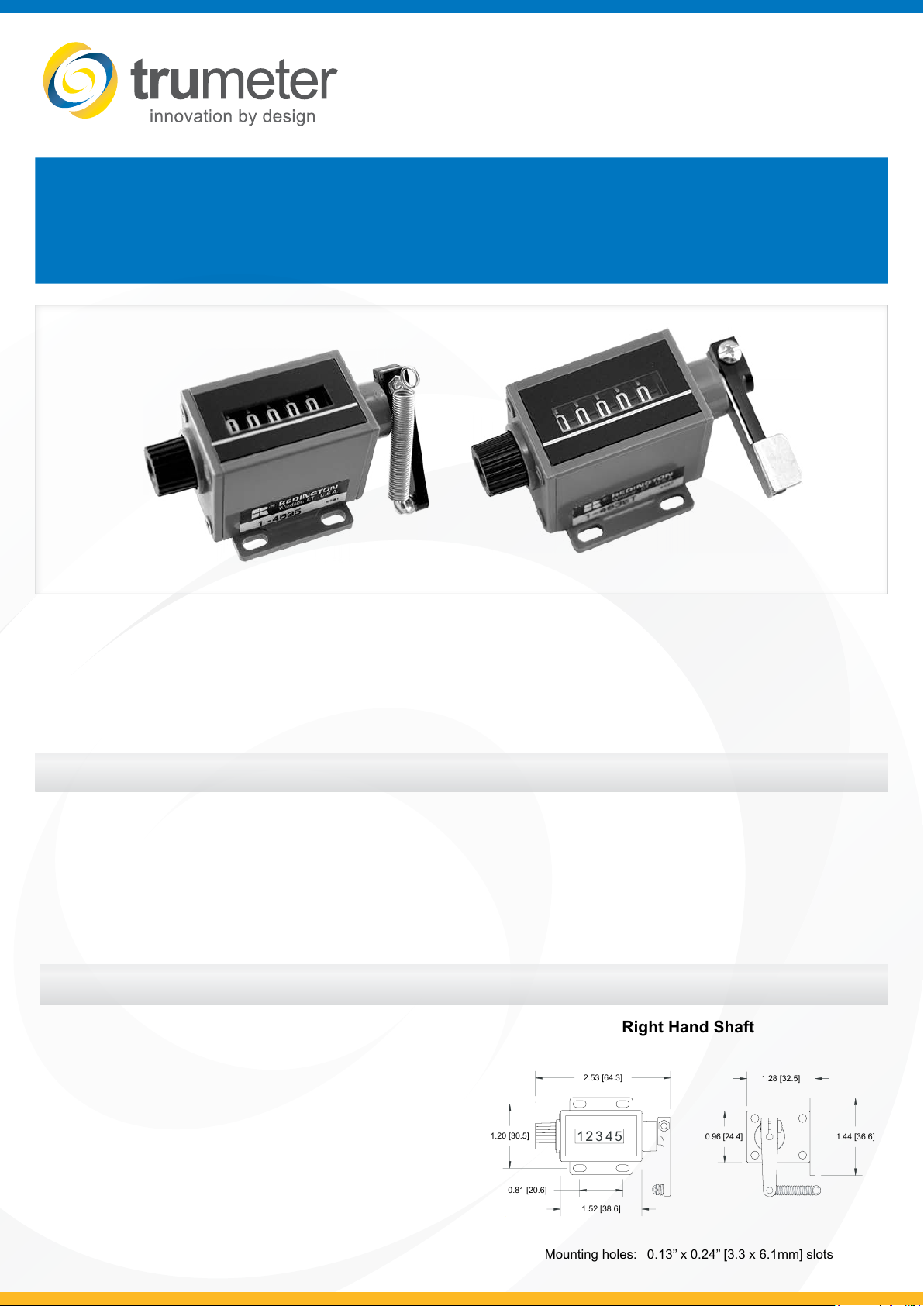

0.81 [20.6]

1.52 [38.6]

2.53 [64.3]

1.20 [30.5]

1.44 [36.6]

1.28 [32.5]

0.96 [24.4]

Right Hand Shaft

Mounting holes: 0.13’’ x 0.24’’ [3.3 x 6.1mm] slots

Mechanical Stroke Counter

These 5 gure stroke counters are especially designed for limited space and high count life

applications. The advanced drive system translates into exceptionally high operating speeds,

extended operating life, for fast and accurate readings. Ideal for copiers, printing presses, cut-o

machines, and piece-part counting applications. Also available with a thumb lever for use as a tally

counter

Key Features

• Compact size

• Reliability

• Low cost

• Optional special levers

• Special Metal Lever

• Lever and spring

• Optional non-reset – consult factory

Specication

Figures 5 gures, white on black, 0.19’’

Reset Standard knob

Speed 1,000 counts/minute

Rotation Top-coming or top-going

Count Stroke 40° Min. - 45° Max.

Shaft Extension Right-hand or left-hand

Shaft Diameter 0.156’’ [4.0mm]

Operating Life Beyond 5 million counts

Temp. Range -15°F to +140°F [-25°C to +60°C]

Weight 2 oz. [57g]

[5mm] high

Applications

• Copiers

• Printing press

• Farm equipment

• Piece-part counting

• Shearing/cut-off machines

Dimensions

Page 2

Mechanical Rotation

Totalizing counters are used to sum the total number of cycles or inputs to a device. These counters have no “outputs”.

Totalizers can be Mechanical, Electromechanical or Electronic.

Totalizers are typically used to total cycle count, piece count, and linear length or to indicate position. Displays for

Mechanical & Electromechanical Totalizers are molded gure wheels usually displaying 0-9 digits on a contrasting

background and have a count capacity of 3-8 gures.

Mechanical Totalizers

The input for Mechanical Totalizers can be Rotary, Stroke or Rotary Ratchet. Mechanical Totalizers require no operating

power or sensor and are easy to install. For hand operated applications you need to consider our Model 46 with thumb

lever option.

Z

Basic operation of a mechanical stroke counter

The illustration (right) shows the lever in the rest position with a total shaft

rotation of X+Y+Z. Although these angles may dier from model to model,

the total shaft rotation contains a pre-travel (X), a count stroke (Y), and

an over-travel (Z). The lever must start in the pre-travel area and continue

through to the over-travel area to register a count. It is recommended that

the spring furnished with the counter be used to simplify adjustment of

count stroke to drive mechanism.

Y

X

SHAFT ROTATIONS:

Arrows indicate shaft rotation to increase count:

Left-hand top-coming:

(rotation #1)

Right-hand top-coming:

(rotation #3)

Part Numbers:

Note: This illustrates rotations 2 and 3 only.

Left-hand top-going:

(rotation #2)

Right-hand top-going:

(rotation #4)

1-4615 Left-hand, top-coming, standard reset knob

1-4625 Left-hand, top-going, standard reset knob

1-4635 Right-hand, top-coming, standard reset knob

1-4645 Right-hand, top-going, standard reset knob

1-4635T Right-hand, top-coming, std. reset knob,

with thumb lever

10007-001 Special Metal Lever

10007-009S Spring and Lever Kit

46-series-DS.v.2.2 04/2017

Loading...

Loading...