FITTED EQUIPMENT

93

FITTED EQUIPMENT

Truma Combination Boiler ...................................................................................................... 94

Truma heating system and air flow .......................................................................................... 95

Truma CP 25 digital timer control ........................................................................................... 95

Truma CP Plus digital timer control ........................................................................................ 99

Truma Combination Boiler fault finding .................................................................................. 107

Truma Combi heating system function description ................................................................ 108

ALDE Compact 3010 .......................................................................................................... 112

ALDE Compact 3010 Control Panel ...................................................................................... 117

Thetford refrigerators ............................................................................................................ 125

Dometic absorption refrigerators ........................................................................................... 133

Cooker 3 burner and hotplate ............................................................................................... 154

Cooker 3 burner gas hob (Sprite only) ................................................................................... 159

Microwave oven .................................................................................................................. 162

Thetford C260 cassette toilet ................................................................................................ 165

Caravans with external BBQ point ........................................................................................ 172

Caravans with TV inlet in battery box .................................................................................... 173

Status 550 directional TV and FM radio antenna .................................................................. 175

Bedding ................................................................................................................................ 176

Softrollo Blinds (Seitz) ........................................................................................................... 177

Doorscreen ........................................................................................................................... 177

Roof lights ............................................................................................................................ 178

Exterior Door Key ................................................................................................................. 178

Windows .............................................................................................................................. 178

Heki-2 roof light (Seitz) .......................................................................................................... 179

Mini Heki rooflight ................................................................................................................. 179

Care of laminate tops, tables, furniture and doors ................................................................. 179

Doors ................................................................................................................................... 179

Tables ................................................................................................................................... 180

Table storage ........................................................................................................................ 180

12V reading lamp ................................................................................................................. 180

Trigger shower heads ............................................................................................................ 180

Fixing of awnings .................................................................................................................. 180

Paint colour reference ............................................................................................................ 181

Drop down TV mechanism .................................................................................................... 181

Front locker and sunroof ........................................................................................................ 181

Bonded Roof ......................................................................................................................... 181

Step on hitch cover ............................................................................................................... 181

Cycle racks ........................................................................................................................... 182

Caravan motor mover ............................................................................................................. 182

Omni-vent ............................................................................................................................. 183

Rear view camera .................................................................................................................. 185

FITTED EQUIPMENT

94

TRUMA COMBI BOILER

The instructions covering fitted equipment to

your caravan were correct at the time of going to print. Owners handbooks are updated

annually and we take great care to try and

ensure their accuracy. However, the Swift

Group Limited cannot accept responsibility for any changes that may be made in

specification or operating instructions to the

equipment described in this section after the

time of going to press.

Every care is taken to ensure that the information provided in this handbook is correct

and easy to understand.

Separate manufacturers’ leaflets on many

of the components are also included in the

Owner’s Pack provided with this caravan

and we recommend that you compare the

instructions in the handbook with the component manufacturers literature, to ensure

the information provided is as accurate as

possible.

If you are in any doubt as to how to operate the equipment in your caravan, please

contact the component manufacturer’s

service department on the telephone number shown on their component leaflet. If you

remain in any doubt, please contact your

supplying dealer.

Notice: In the interest of safety, replacement

parts for an appliance shall conform to the

appliance manufacturer’s specifications and

should be fitted by them or their authorised

agents.

Truma Combination Boiler

The Truma Combination boiler has been

designed to run on gas or electric power and

the optimum performance is obtained when

used in dual fuel mode, that is running on

gas and electric at the same time.

Running in dual mode has the following

benefits:

• Fastest possible heat up time, the gas burner

combines with an electric element to provide

energy to heat your hot water and warm your

caravan.

• The intelligent heat management system

automatically senses when the water and

room are nearing the required temperature

and then automatically turns off your gas

burner and operates solely on electric power,

conserving your gas.

• As hot water is used or the room cools the

Truma combination heater will continue to

operate on electric only until a point where

the demands necessitate that additional

gas power is required. An example for

such a demand could be for instance if the

exterior door was left open and the room

temperature dropped by 10 degrees in the

space of a few minutes, in this case the

intelligent heat management system would

decide the best way to get the room back

to the required temperature would be to use

both gas and electric at the same time.

Operating the Truma Combination system on

electric or gas only will result in longer heat up

times for hot water and the room temperature

in comparison to operating on dual fuel.

Operating on electric only may not in all cases

maintain a comfortable room temperature

especially in colder conditions.

The intelligent heat management system in

dual fuel mode allows the Truma Combination

boiler to prioritize the electric power source

over your gas, this will conserve your gas

supply.

FITTED EQUIPMENT

95

Truma Heating System

and Air Flow

The Swift Group undertakes considerable

testing of our products in cold chambers to

ensure they meeting the BS EN 1649 Grade 3

standard and are usable in cold temperatures.

During this testing, the air flow on the blown air

outlets is defined and set by us.

Butterfly outlets

Blown air

The air ducting outlets on some models are

of the butterfly type, and if fitted these may be

opened or closed by adjusting the butterfly

valves. Twisting the disc in its housing directs

the flow in the direction required. One outlet

on each leg of the air ducting layout must

be kept open at all times, and when high

specification (Combi 6) heating systems are

fitted, depending on the number of blown air

outlets in the layout, butterfly fittings may not

be present.

Under no circumstances should the air ducting

outlets be blocked.

Note: The next instructions detail the

operation of the Combi Control Panel

- for further details of the Truma Combi

appliance, please see the following section.

Truma Heating System

Control Panels

Depending on the specification of your

caravan, when the Combi heating is fitted,

either a CP25 Controller or CP Plus Controller

will be fitted.

Truma CP 25

Digital Timer Control

Operating instructions

Depending on the specification of your

caravan, the CP25 controller may be fitted

to control the operation of the Truma Combi

appliance.

Please be sure to read the instructions for

installation and use before attempting to

connect and use this device!

Symbols used

! Symbol indicates a possible hazard.

Comment including information and tips.

Safety instructions

! To protect you from electrical shocks,

injury or burns the following basic safety

principles must be observed when using

electrical devices. Please read and follow these

instructions before using the device.

Installation

Ensure that the devices are positioned safely

and cannot fall down or over. Always position

the cables to ensure they do not pose a

tripping hazard. Do not expose electrical

devices to rain. Do not operate electrical

devices in damp or wet environments. Do not

operate electrical devices close to flammable

liquids or gases. Position the devices so that

they are out of the reach of children.

Protection against an electrical shock

Only operate devices whose casings and

cables are undamaged . Ensure the cables are

installed safely. Do not pull on the cables.

TRUMA DIGITAL TIMER CONTROLS

FITTED EQUIPMENT

96

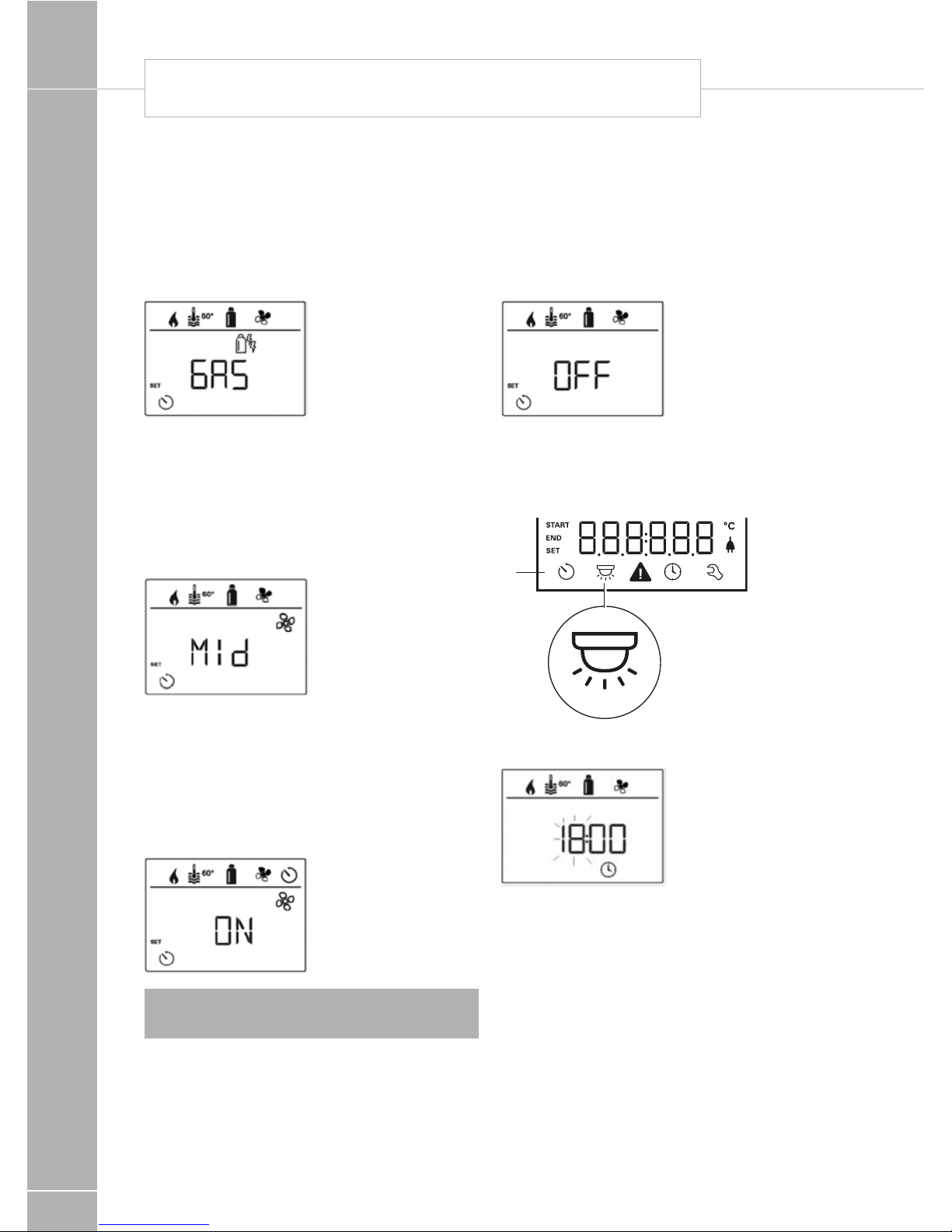

TRUMA CP 25 DIGITAL TIMER CONTROL

Use

Do not use electrical devices for purposes

other than those stated by the manufacturer.

Repairs

Do not repair or modify the device. Please

contact your dealer or the Truma Service (see

service manual or www.truma.com).

Accessories

Only use accessories and additional devices

that are supplied or recommended by the

manufacturer.

Intended use

The CP 25-UK is a digital operating / display

and control unit for the Combi Boiler.

The device is designed to be installed in

caravans and motorcaravans.

Initial operation or activation after a

power cut

After the operating voltage has been

connected , the unit will beep and the display

remains dark. To switch on, press the key 4

and the main screen will appear.

Function description

Note: More details regarding the operating

modes can be found in the operating

instructions of your Combi.

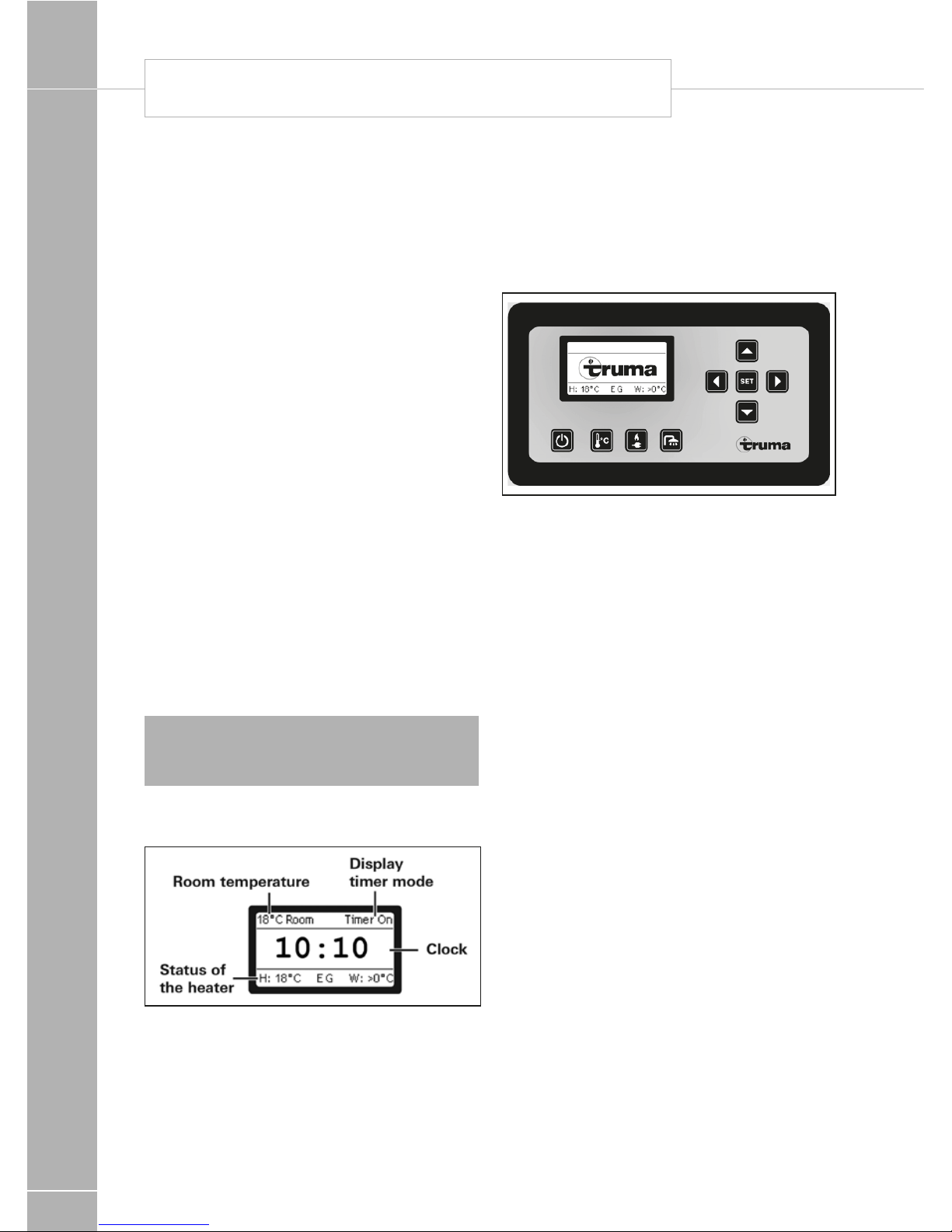

Main Screen

Room temperature: Display on when the

heater is active

Timer: Display on when the timer is active

Clock: Only if the clock has been set,

otherwise the Truma logo will appear

in the display

Status of the heater :

H: Set room temperature (e.g. 18°C)

EG: Energy selection (E = Electro, G = Gas)

W: Set water temperature

Selection Key upwards to select functions

or set values

Selection key downwards to select

functions or set values

Selection key backwards to select values

Selection key forwards to select values

On / Off

• Display and heater is switched on and /

or off

• The clock is shown when the time is set

• After an interruption in the operating

voltage, the display and the heater are

switched off. If the time is shown, this

needs to be set.

Green LED shines when the heater is on

Greed LED flashes when the heater is

after-running

Red LED shines when there is a malfunction

Manual mode

• In manual mode, the heater is controlled

via the 4 keys below the display.

• It is not necessary to set the time because

the Truma logo is shown in the display

instead of the time.

FITTED EQUIPMENT

97

Note: A pre-selection between summer

/ winter operation must be made via the

set-up.

Room Temperature

When the menu is selected the yellow LED

shines.

The current set room temperature is displayed

and can be changed.

Key increases the room temperature (max

30°C) by 1°C.

Key reduces the room temperature (min

5°C) by 1°C.

A change in the room temperature needs to be

confirmed with SET.

Energy selection

When the menu is selected the yellow LED

shines.

Depends on summer / winter operation

(see setup)

• Use key or to select the energy

source and confirm with SET.

• Bar shows current mode.

Summer operation

230 V - 4 A (electro mode 230 V, 900 W)

230 V - 8 A (electro mode 230 V, 1800 W)

Gas powered

Winter operation

230 V - 4 A (electro mode 230 V, 900 W)

230 V - 8 A (electro mode 230 V, 1800 W)

Gas powered

230 V - 4 A and gas (mixed operation gas and

electro mode 900 W)

230 V - 8 A and gas (mixed operation gas and

electro mode 1800 W)

Note: If electro or mixed operations are

selected and there is no 230 V power

supply, the heating will not function.

Water temperature

When the menu is selected the yellow LED

shines. During the heating-up phase, the set

water temperature flashes in the main screen.

• Use key or to select the water

temperature and confirm with SET.

• Bar shows current mode

Depends on summer / winter operation

(see setup)

Summer operation

Water 40°C

Water 60°C

Winter operation

Water > 0°C (heating without controlled water

temperature, heating has priority)

Water > 60°C

Timer mode

• The heater runs in timer mode as soon

as one or both timers have activated in

the setup.

• ‘Timer On’ appears in the main screen.

• The heater is only active in the set time

window (active timer)

• Only the energy selection can be changed

in the case of an active timer

• A change in the room or water

temperature will automatically switch the

control system into manual mode.

Set up

In the main screen display you can enter the

setup menu via the setup key.

The following settings can be made:

Back (return to main screen)

Timer 1 on / off (select SET on / off)

Timer 2 on / off (select SET on / off)

Summer / Winter (select SET summer /

winter)

FITTED EQUIPMENT

98

Set clock

Set timer 1

Back (Return to main screen)

Start (Set start time)

Stop (Set stop time)

Water (Set water temperature)

Temp (Set room temperature)

The timer settings can be made every day until

the timer is switched off. If the room or water

temperature is changed outside the timer

menu, the timer is automatically switched off.

Trouble shooting list

Fault Rectification / Cause

Clock is not shown Set clock

Activated timer is not shown anymore Power supply was interrupted

Room temperature is not shown Heater not active

Device does not react anymore Interrupt power supply for 10 seconds

Heater / display does not react Check 12 V supply voltage

If these measures do not rectify the problem,

please contact the next Truma service point

(See Truma service book or www.truma.com)

Set timer 2

Back (Return to main screen)

Start (Set start time)

Stop (Set stop time)

Water (Set water temperature)

Temp (Set room temperature)

The timer setting can be made every day until

the timer is switched off. If the room or water

temperature is changed outside the timer

menu, the timer is automatically switched off.

Buzzer on / off (select SET on / off)

Backlight (brightness levels 0-9)

Note: If no action is taken, the display

switches back to the main screen after a few

seconds. The lighting switches off after a

short delay.

TRUMA CP 25 DIGITAL TIMER CONTROL

FITTED EQUIPMENT

99

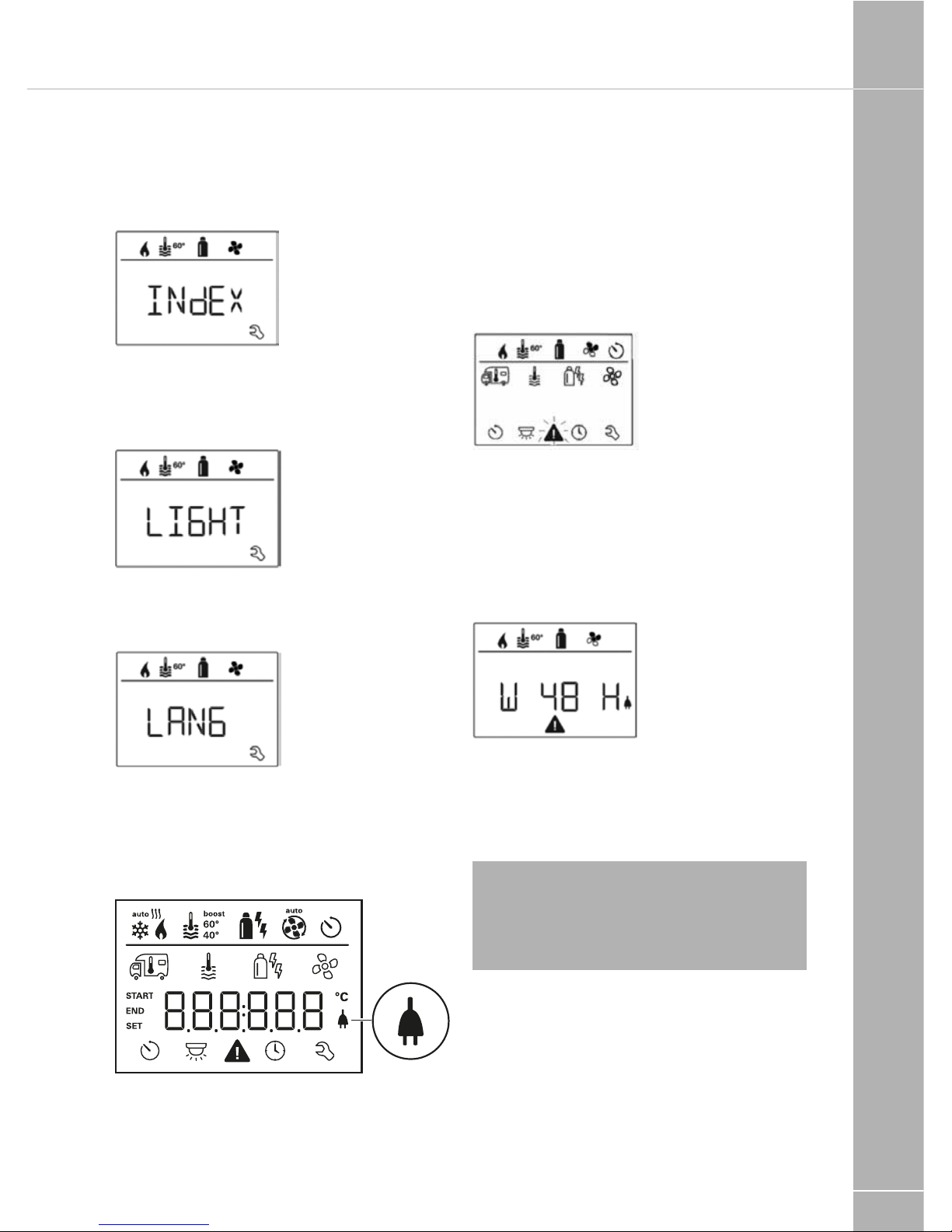

Truma CP Plus

Digital Timer Control

Depending on the specification of your

caravan, the Truma CP-Plus controller may

be fitted to control the operation of the Truma

Combi appliance.

Safety instructions

• The device may only be operated if it is in

perfect working order.

• Arrange for malfunctions to be rectified

immediately. Only rectify malfunctions

yourself, if the remedy is outlined in the

troubleshooting information in these

Operating Instructions.

• Do not repair or modify the device!

• Only allow the manufacturer or its customer

service to repair a faulty device.

Note: If the power supply to the systems is

interrupted for longer than 20 minutes, the

time and date need to be entered again.

Important note

If the power supply to the systems is

interrupted for longer than 20 minutes, the

time and date need to be entered again.

Intended use

The control panel Truma CP plus serves to

control and monitor a Combi heater and /

or a Truma air conditioning unit. The device

is designed for installation in caravans and

motor-caravans.

For clarity only the instructions relevant to

combi heating are included in this guide.

Instructions relevant to air conditioning should

be requested if an appropriate air conditioner

is fitted.

FITTED EQUIPMENT

100

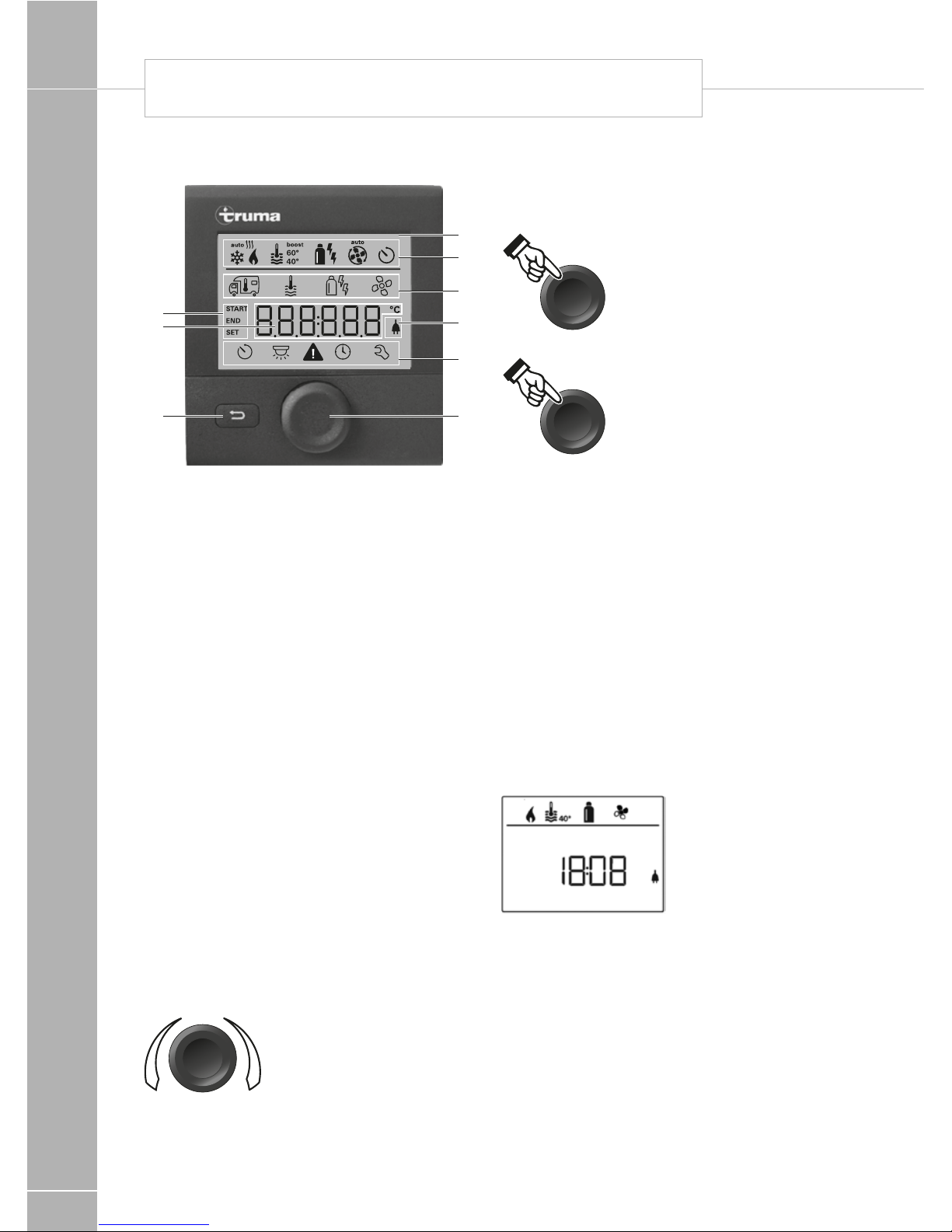

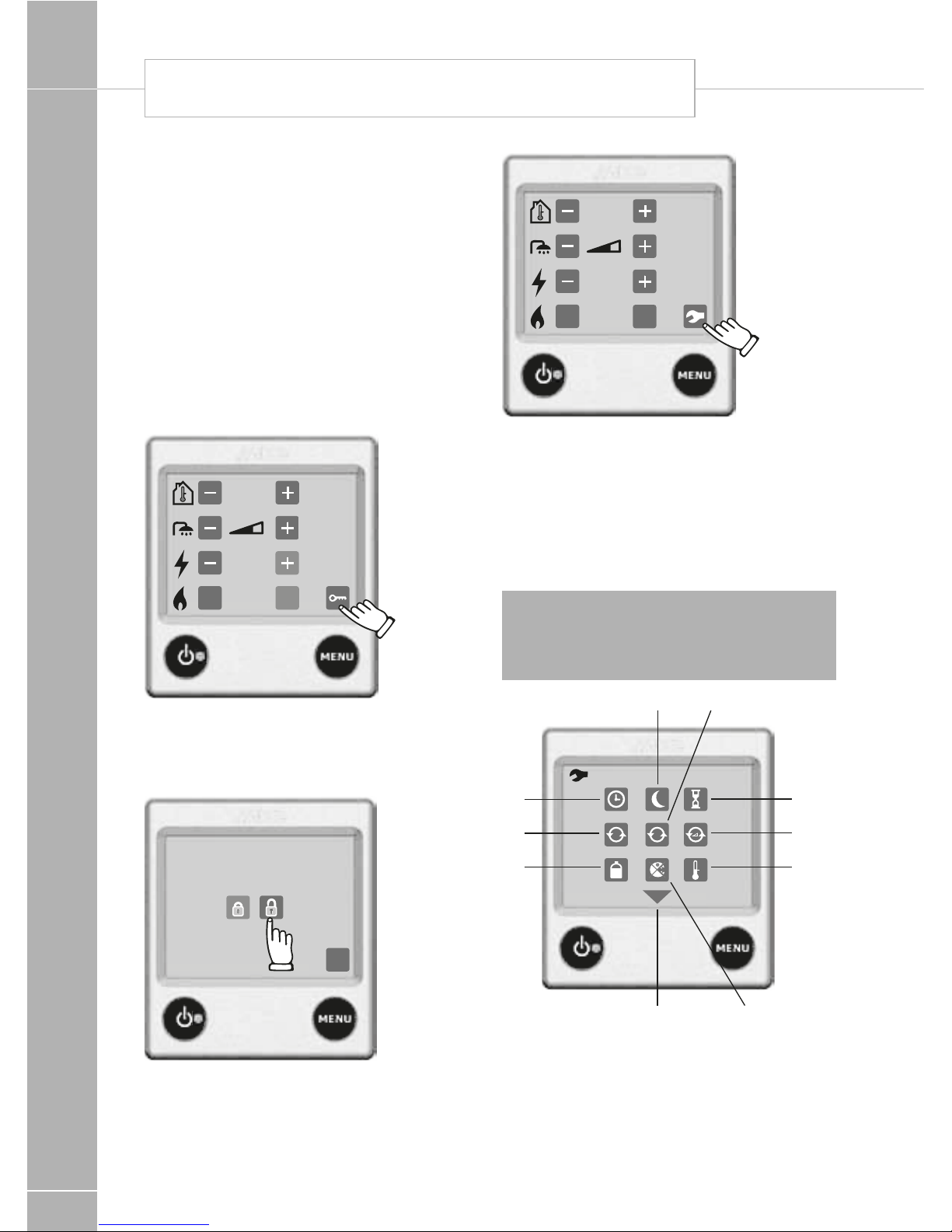

Display and control elements

2

3

5

4

8

6

7

9

1

1 - Display

2 - Status line

3 - Menu line (above)

4 - Menu line (below)

5 - Display of mains voltage 230 V

(shore power)

6 - Display timer

7 - Settings / values

8 - Control knob / push button

9 - Back button

The control knob / push button (8) is used to

select menus in the lines (3 + 4) and configure

the settings. These are shown via a display (1)

with a lighted background. Pressing the Back

button (9) takes the user back out of the menu

again.

Control knob / push button

The control knob / push button (8) is used to

select and change set values and parameters;

these can be saved by clicking the control

knob / push button. Selected menu items will

flash.

+

-

Turn to the right (+)

• Menu is paged from left

to right.

• Increase values.

Turn to the left (-)

• Menu is paged from right to left.

• Reduce values.

Clicking

• Accept (save) a selected

value.

• Select a menu item, change

to the setting level.

3 sec

Press (3 seconds)

• Main switch function

ON / OFF

Back button

Pressing the Back button (9) takes the user

back out of the menu again and discards the

settings. This means that the previous values

are retained.

Functions

The functions in the menu lines (3, 4) of the

control panel can be selected in any sequence.

The operating parameters are shown in the

status line (2) or the displays (5, 6).

Start / stand-by screen

After connecting the control panel to the

power supply, a start screen is shown after a

few seconds.

If no entry is made within a few minutes, the

standby screen is automatically shown again.

The display shows the time and current room

temperature alternately.

TRUMA CP PLUS DIGITAL TIMER CONTROL

FITTED EQUIPMENT

101

Switch on / return to setting level

• Press the control knob / push button for

longer than 3 seconds or the

• Back button.

The display shows the setting level. The first

symbol flashes.

Note: Previously set values / operating

parameters become active again after the

system is switched on.

Switch off

• Press the control knob / push button for

longer than 3 seconds.

Change the room temperature

• Use the control knob / push button to select

the symbol in menu line (3).

• Click to change to the setting level.

• Depending on the connected device, use the

control knob / push button to select between

the heater or air conditioning unit.

• Use the control knob / push button to select

the required temperature.

• Click the control knob / push button to

confirm the value.

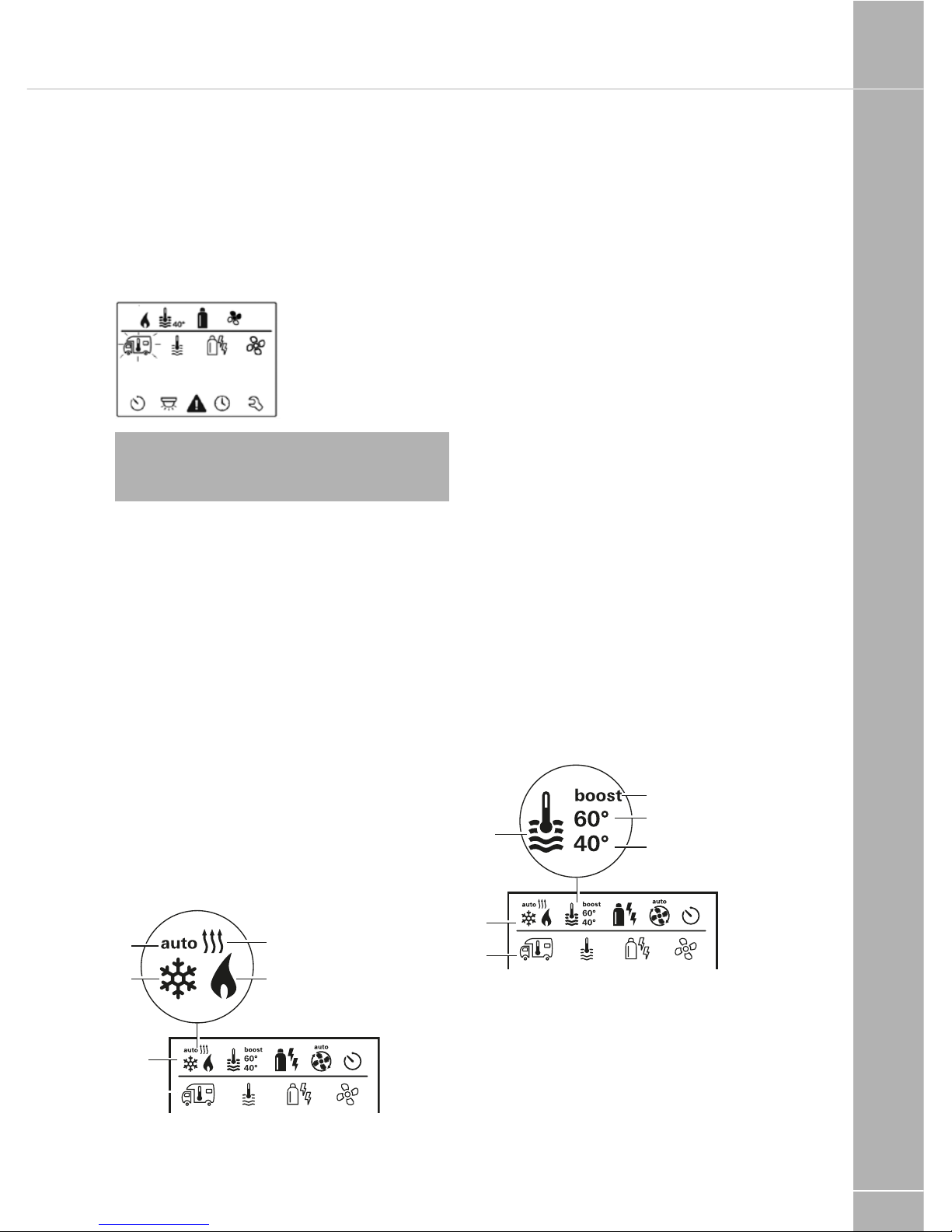

2

3

a

d

b

c

Heater

Settable temperature range 5 - 30 °C (1 °C

steps)

a = heater * – Heater is switched on.

Air conditioning unit (not normally fitted)

Settable temperature range 16 - 31 °C (1 °C

steps)

b = cool *

( Air conditioning unit is switched on)

c = auto

(Air conditioning unit is set to automatic)

d = hot

(Air conditioning unit is in heating mod.)

* This symbol will flash until the required room

temperature is reached.

Change the warm water level

• Use the control knob / push button to select

the symbol in menu line (3).

• Click to change to the setting level.

• Use the control knob / push button to select

the required level.

• Click the control knob / push button to

confirm the value.

2

3

a

b

c

d

a = Boiler *

(Warm water boiler is switched on)

b = 40°

(Warm water temperature 40 °C)

c = 60°

(Warm water temperature 60 °C)

FITTED EQUIPMENT

102

d = boost *

(Targeted, fast heating of the content of the

boiler [boiler priority]. The water temperature

is kept at the higher level [around 62 °C] – Not

Combi Diesel. Once the water temperature is

reached, the room is heated again.)

* This symbol will flash until the required water

temperature is reached.

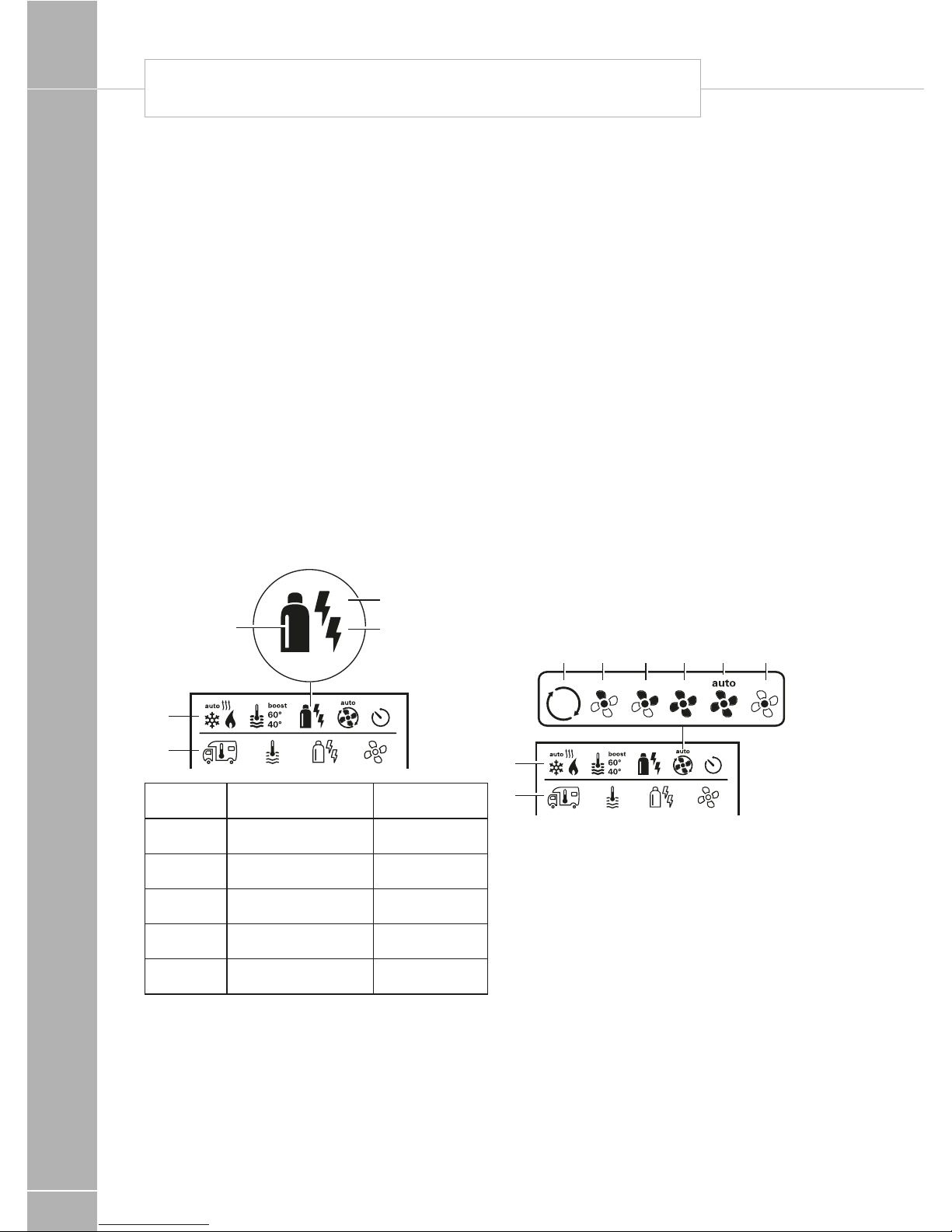

Select power type

• Use the control knob / push button to select

the symbol in menu line (3).

• Click to change to the setting level.

• Use the control knob / push button to select

the required power type.

• Click the control knob / push button to

confirm the value.

2

3

a

b

c

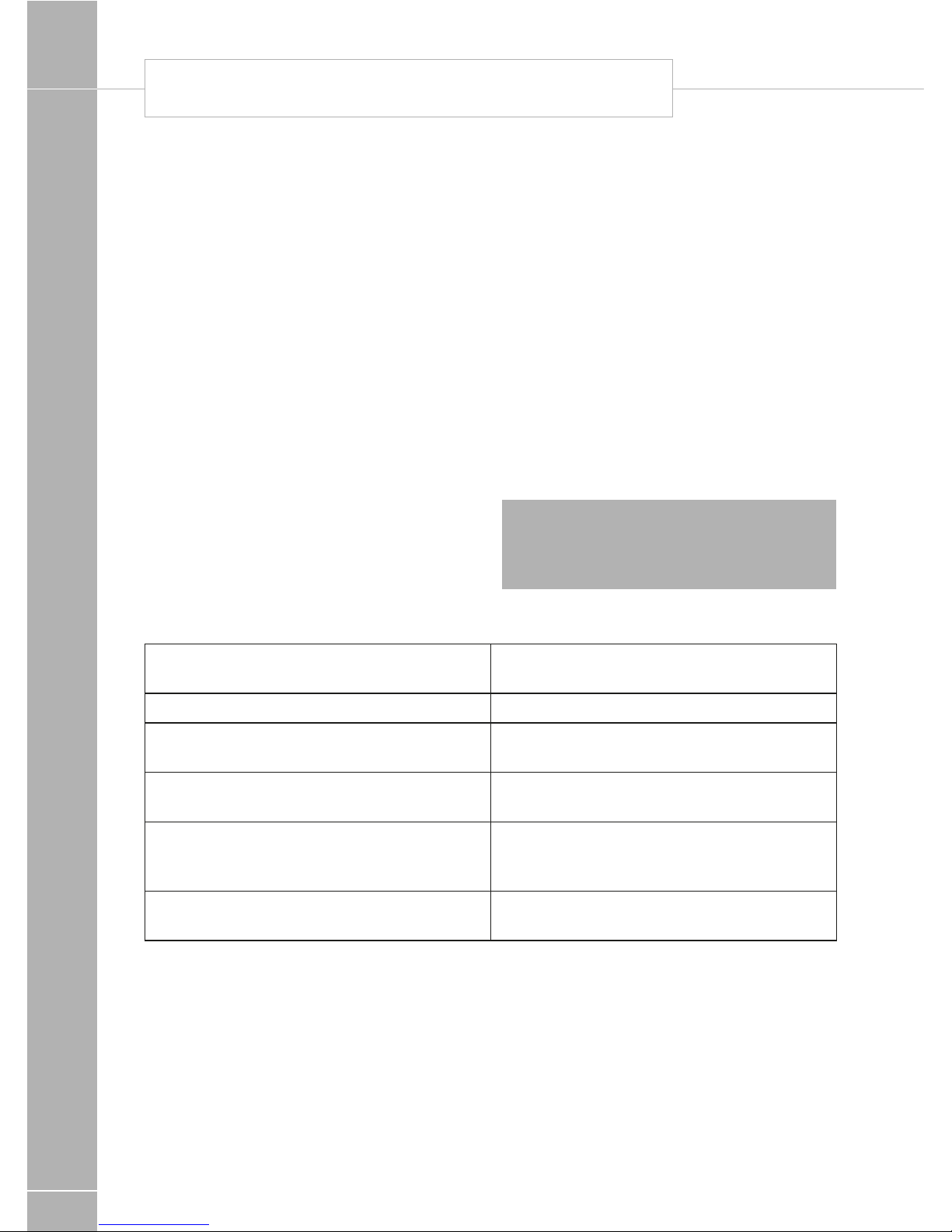

Symbol Operating mode Power type

a Gas Gas

b EL 1 Electro

b + c EL 2 Electro

a + b Mix 1* Gas + Electro

a + b + c Mix 2* Gas + Electro

* Mixed mode

Special aspects in the mixed mode

Interruption of the power supply 230 V

Combi Gas

The heater automatically switches to the gas

mode. As soon as the 230 V power supply is

reconnected, the heater automatically switches

back to the mixed mode.

Malfunction in the combustion process

(e.g. lack of fuel)

Combi Gas

The heater automatically switches to the

electro mode. If the heater should operate

in the mixed mode again, the cause of the

malfunction needs to be rectified. Switch the

heater off and on again on the control panel.

Select fan level

When the heater / air conditioning unit is

connected.

• Use the control knob / push button to select

the symbol in menu line (3).

• Click to change to the setting level.

• Use the control knob / push button to select

the required fan level.

• Click the control knob / push button to

confirm the value.

2

3

a b c d e f

TRUMA CP PLUS DIGITAL TIMER CONTROL

FITTED EQUIPMENT

103

Symbol Operating mode Description

– Off Fan is switched off

a Vent

Circulating air, if no device is in operation. 9 speed levels can

be selected.

b Eco Low fan level

c Mid High fan level (only Combi Gas)

d High

Fast heating of the room. Available, if the difference between

the selected and current room temperature is >10 °C.

Set timer

• Use the control knob / push button to select

the symbol in menu line (4).

• Click to change to the setting level.

Note: If the timer is activated (ON), the timer

in the menu is shown as deactivated (OFF).

Enter start time

• Use the control knob / push button to set the

hours, then the minutes.

Enter end time point

• Use the control knob / push button to set the

hours, then the minutes.

Note: If the start / end times are exceeded

when entered, the operating parameters are

only taken into consideration when the next

start / end times are reached. Until then, the

operating parameters set outside the timer

remain valid.

Set the room temperature

• Click to change to the setting level.

• Use the control knob / push button to select

the required room temperature.

• Click the control knob / push button to

confirm the value.

Set the warm water level

• Click to change to the setting level.

• Use the control knob / push button to select

the required warm water level.

• Click the control knob / push button to

confirm the value.

FITTED EQUIPMENT

104

Select power type

• Click to change to the setting level.

• Use the control knob / push button to select

the power type.

• Click the control knob / push button to

confirm the value.

Select fan level

• Click to change to the setting level.

• Use the control knob / push button to select

the required fan level.

• Click the control knob / push button to

confirm the value.

Activate the timer (ON)

• Click to change to the setting level.

• Use the control knob / push button to

activate the timer (ON)

• Click the control knob / push button to

confirm the value.

Note: The timer remains active, even for

several days, until it is deactivated (OFF).

Deactivate the timer (OFF)

• Click to change to the setting level.

• Use the control knob / push button to

deactivate the timer (OFF)

• Click the control knob / push button to

confirm the value.

Switch lighting on/off

Available if an air conditioning unit is connected

4

Set time

• The hour display flashes.

• Use the control knob / push button to set the

hours (24 h mode).

• After clicking the control knob / push button

again, the minute display will flash.

• Use the control knob / push button to set the

minutes.

• Click the control knob / push button to

confirm the value.

TRUMA CP PLUS DIGITAL TIMER CONTROL

FITTED EQUIPMENT

105

Service menu

Query the index status of a

connected device

Change the background lighting of the

control panel

There are 5 background lighting levels to

choose from.

Change language

Select the required language from those

available (e.g. English, German, French, Italian).

Display mains voltage 230 V

The symbol indicates that 230 V mains voltage

(shore power) is available.

Warning

In the event of a warning, a warning symbol

appears to indicate that an operating

parameter has reached an undefined status.

In this case, the affected device continues

to run. As soon as the operating parameter

returns to the set range, this symbol will turn

off automatically.

Read out the warning code

• Use the control knob / push button to select

the symbol.

• Click the control knob / push button. The

current warning code is shown. The cause of

the warning can be identified and rectified via

the error list.

Cause rectified / return to setting level

• Click the control knob / push button.

Cause not rectified / return to setting level

• Press the Back button

Note: In this case, the warning is not

acknowledged on the control panel and the

warning symbol remains. The control panel

remains in the warning status. Devices connected to the control panel can be operated.

FITTED EQUIPMENT

106

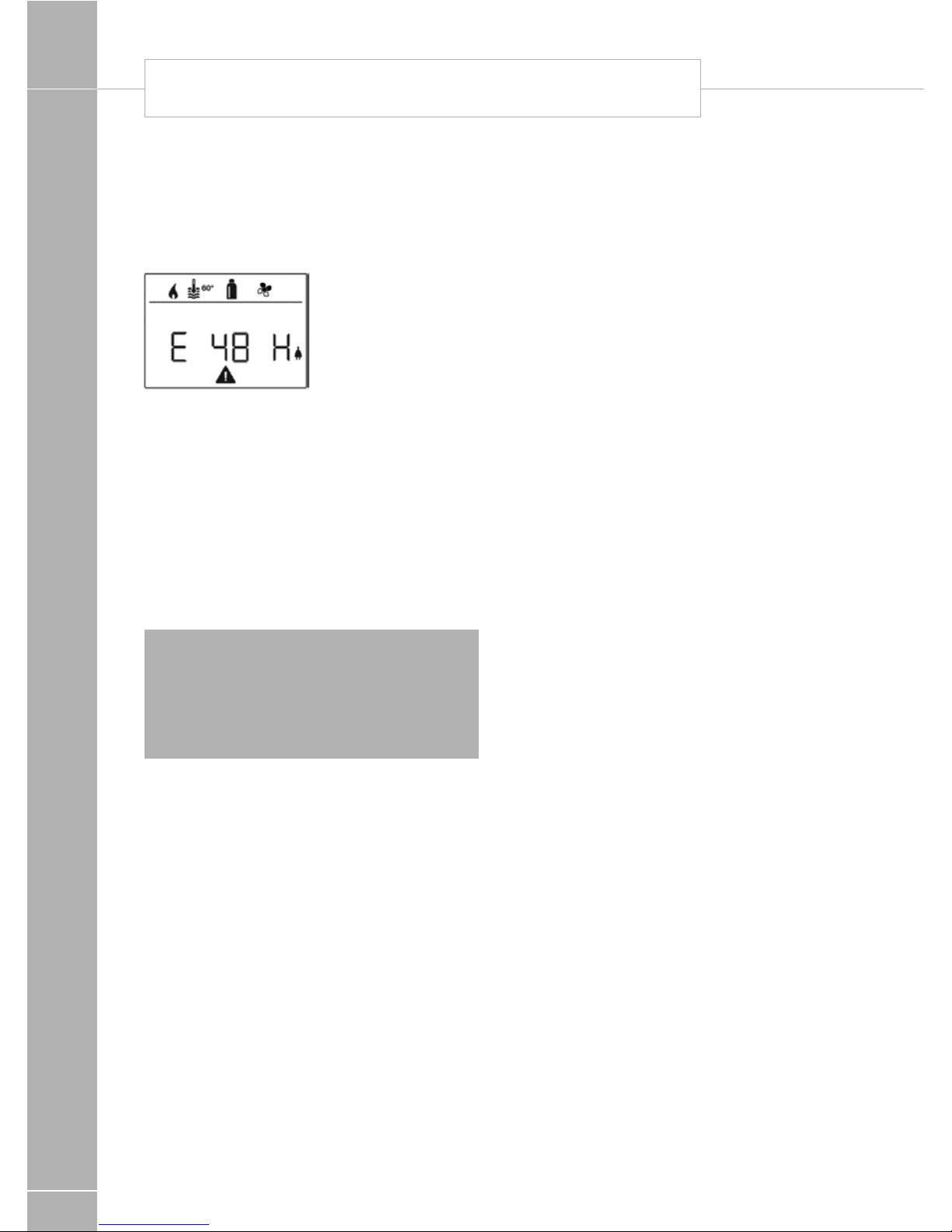

Malfunctions

In the case of a malfunction, the control

panel immediately jumps to the menu level

“malfunction” and shows the error code of the

malfunction:

Cause remedied / return to setting level

• Click the control knob / push button.

• The respective device is restarted.

If the cause is not remedied, the malfunction

will occur again and the control panel will jump

again to the menu level “malfunction”.

Cause not remedied / return to

setting level

• Press the Back button.

Note: In this case, the malfunction is not

acknowledged in the control panel and the

warning symbol remains on. The device

remains in the malfunction status. Other

devices connected to the control panel can

be operated.

Maintenance

This device is maintenance-free. Use a nonabrasive damp cloth to clean the front. If this

proves inadequate, use a neutral detergent.

Disposal

The device must be disposed of in compliance

with the administrative provisions of the

respective country in which it is used. The

national regulations and laws (in Germany

these are e.g. the End-of-Life Vehicle

Regulations) must be observed.

TRUMA CP PLUS DIGITAL TIMER CONTROL

FITTED EQUIPMENT

107

Troubleshooting instructions

(Combi Gas heater)

Error code Cause Remedy

#17 • Summer mode with empty water

container

• Warm air outlet blocked

• Circulated air intake blocked

• Switch device off and allow to cool.

Fill boiler with water

• Check each of the outlet openings

• Remove the blockage from the

circulated air intake

#18 • Gas pressure regulator frozen

• Too much butane in the gas

cylinder

• Use the regulator heating (EisEx)

• Use propane (Butane is unsuitable

for heating, especially at temperatures below 10

o

C

#21 • Room temperature sensor or

cable faulty

• Please contact the Truma Service

#24 • Potential under-voltage battery

voltage too low <10.4V

• Charge battery

#29 • Heating element for FrostControl

has a short circuit

• Disconnect the heating element

plug on the electronic control unit.

Replace heating element

#41 • Electronics are blocked • Please contact the Truma Service

#42 • Window above the cowl is open

(window switch)

• Close the window

#43 • Over-voltage > 16.4V • Check the battery voltage and volt-

age sources eg. the charger

#44 • Under-voltage battery voltage too

low < 10.0V

• Charge battery. Replace any

old batteries

#45 • No 230V operating voltage

• Faulty 230V fuse

• Overheating protection has

triggered

• Reconnect the operating

voltage 230V

• Replace the 230V fuse

• Reset the overheating protection.

Allow the heating to cool down,

remove the connection cover and

press the reset button

#112 • Gas cylinder or quick-acting valve

in the gas line closed

• Check the gas supply and open

the valves

#212 • Combustion air intake or exhaust

outlet closed

• Check the openings for soiling

(snow, ice, leaves etc) and remove

#255 • No connection between the heater

and the control panel

• Control panel cable faulty

• Please contact the Truma Service

If these steps do not rectify the malfunction,

please contact the Truma Service.

TRUMA COMBI BOILER FAULT FINDING

FITTED EQUIPMENT

108

Truma Combination Heating

System Function Description

The liquid gas heater Combi E is a warm-air

heater with integrated hot water boiler (10 liter

volume). The burner operates fan-supported,

which ensures trouble-free function even

when on the move. The unit also has heating

elements for electrical operation.

In winter operation the heater can be used to

heat the room and simultaneously warm water.

3 different options are available for operating

the unit.

– gas operation only Propane / Butane for

autonomous use

– electrical operation only 230 V for stationary

use on camp sites

– or gas and electrical operation – mixed

operation only possible in winter mode.

Winter operation (Space heating with

water heating)

In winter operation, the unit automatically

selects the required power setting according

to the temperature difference between the

temperature set on the control panel and the

current room temperature. When the boiler

is filled, the water is automatically heated as

well. The water temperature depends on the

selected operational mode and the heater

output. All 3 energy selection options can be

used for winter deployment.

With gas operation the unit automatically

selects the output level that is required.

Depending on the fuse protection at the

camping site, power of 900 W (3.9 A) or

1800 W (7.8 A) can be manually selected for

electrical operation.

If more output is required (e.g. heating up

or low outside temperatures) gas or mixed

operation should be selected so that enough

heating power is always available. With

mixed operation, 230 V electrical operation

is preferred if the power requirement is low

(e.g. for maintaining the room temperature).

The gas burner is not enabled until the power

requirement is higher, and is the first to switch

off during heat-up operations.

Summer operation (Water heating only)

Gas operation or 230 V electrical operation

is used for hot water preparation. The water

temperature can be set to 40 °C or 60 °C.

With gas operation the water is heated at

the lowest burner setting. Once the water

temperature is reached, the burner switches

off. Depending on the fuse protection at the

camping site, power of 900 W (3.9 A) or

1800 W (7.8 A) can be manually selected for

electrical operation. Mixed operation is not

possible. With this

setting the unit automatically selects electrical

operation. The gas burner is not enabled.

Repairs may only be carried out by

an expert

Guarantee claims, warranty claims and

acceptance of liability will be ruled out in the

event of the following:

– modifications to the unit

(including accessories),

– modifications to the exhaust duct and

the cowl,

– failure to use original Truma parts as

replacement parts and accessories,

– failure to follow the installation and operating

instructions.

It also becomes illegal to use the appliance,

and in some countries this even makes it illegal

to use the vehicle.

During the initial operation of a brand new

appliance (or after it has not been used for

some time), a slight amount of fumes and

smell may be noticed for a short while. It is a

good idea to heat the device up several times

in summer operation (60 °C) and to make sure

that the area is well ventilated. Heat-sensitive

objects such as spray cans

or flammable liquids may not be stored in

the same compartment where the heater is

installed because, under certain conditions,

this area may be subject to elevated

temperatures.

Important operating notes

The integrity and tight fit of the exhaust gas

TRUMA COMBI BOILER

FITTED EQUIPMENT

109

double duct must be checked regularly,

particularly at the end of long trips. Also check

the mounting of the appliance and the cowl.

Following a blow-back (misfire) always have

the exhaust gas system checked by an expert!

Always keep the cowl for the exhaust duct and

combustion air intake free of contamination

(slush, ice, leaves etc.). A number of hot air

outlets and the recirculated air intake openings

must be free so that the unit does not

overheat. The integrated temperature limiter

blocks the gas supply when the unit becomes

too hot.

Operating Instructions

Always observe the operating instructions and

“Important operating notes” prior to starting!

The vehicle owner is responsible for the correct

operation of the appliance. Before using for the

first time, it is essential to flush the entire water

supply system through with clean water. If

the heater is not being used, always drain the

water contents if there

is a risk of frost. There shall be no claims under

guarantee for damage caused by frost!

Room thermostat

To measure the room temperature, a room

temperature sensor is fitted to the furniture.

The exact location is determined by the layout

of the vehicle.

Taking into operation

Heating is possible without restrictions with

gas, electrical and mixed operation, with or

without water. Check to make sure the cowl is

unobstructed. Be sure to remove any covers

that may be present.

For operating on gas turn on gas cylinder and

open the shut off valve at the manifold. For

operating on electric operate the water heater

switch on the power supply unit. See page 71.

Filling the water heater

Switch on power for water pump (main or

pump switch) to prime the water system. Open

hot water taps in kitchen and bathroom, (set

preselecting mixing taps or single-lever fittings

to “hot”). Leave the fittings open for as long as

it takes for the boiler to displace the air and fill

up, and the water to flow without interruption.

If just the cold water system is being operated,

without using the water heater, the heater tank

also fills up with water. To avoid frost damage,

the boiler must be drained through the drain

valve, even if the boiler was not operated.

When connecting to a central water supply

(rural or city mains), a pressure reduction valve

must always be installed to prevent pressures

above 2.8 bar from developing in the water

heater.

Draining the water heater

Switch off power to water pump (main or

pump switch). Open hot water taps in kitchen

and bathroom. In order to check the water that

is flowing out, place an appropriate container

(capacity 10 litres) beneath the drain valve.

Open the drain valve which is situated next to

the boiler by lifting the yellow handle into the

vertical position.

Check whether all of the water in the boiler (10

itres) has been drained into the container via

the drain valve.

There shall be no claims under guarantee

for damage caused by frost!

Maintenance

Only original Truma parts may be used for

maintenance and repair work! Materials in the

device which come into contact with water

are suitable for use with drinking water (see

manufacturer‘s declaration: www.truma.com /

downloads / manufacturer‘s declaration).

Bio-film, deposits and limescale must be

removed using chemicals to protect the

unit from infestation by microorganisms.

Only chloride-free products must be used

in order to prevent damage to the unit. The

effectiveness of the use of chemicals to

combat microorganisms in the unit can be

increased by heating the water in the boiler to

70 °C at regular intervals. The unit must stay

switched on for at least 30 minutes and no

warm water may be removed. The residual

heat in the heat exchanger will heat the water

up to 70 °C.

FITTED EQUIPMENT

110

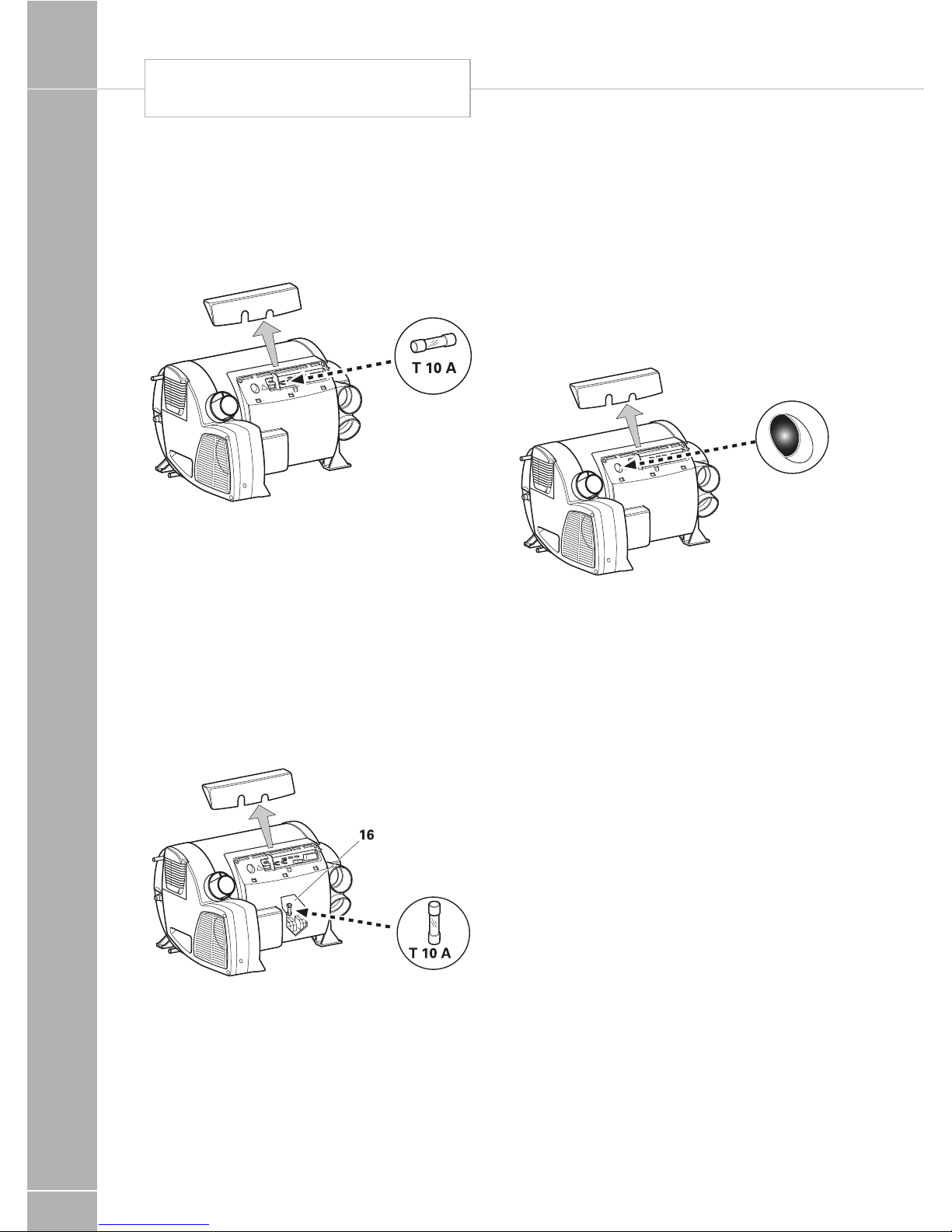

Fuses 12 V

The fuse is in the electronics beneath the

connection cover. Replace the unit’s fuse only

with an identical fuse.

Device fuse: 10 A – slow – (T 10 A)

Fuses 230 V

The fuse and the power supply lines must only

be replaced by an expert! The unit must be

disconnected from the mains (all poles) before

opening the electronic housing lid.

The fuse is in the power electronics (16)

beneath the electronic housing lid.

This fine fuse must always be replaced with a

fuse of the same type: 10 A, slow, interrupting

capacity “H”.

Overheating protection 230 V

The 230 V heating facility has a mechanical

overheating switch. If the 12 V power supply

is interrupted during operation or during the

after-run period, for example, the temperatures

within the unit could activate the overheating

protection. To reset the overheating protection,

allow heater to cool, remove connection cover

and press red reset button.

TRUMA COMBI BOILER

FITTED EQUIPMENT

111

Technical data

determined in accordance with EN 624 or

Truma test conditions

Device category

I

3 B/P

in accordance with EN 437

Type of gas

Liquid gas (propane/butane)

Operating pressure

30mbar (see type plate)

Water contents

10 litres

Heating up time from approx 15

O

C to 60OC

Boiler approx 20 minutes (measure according

to EN15033)

Heater + boiler approx 80 min

Water pressure

max 2.8 bar

Rated thermal output

(automatic output levels)

Gas operation

Combi 4 E: 2000 W / 4000 W

Combi 6 E: 2000 W / 4000 W / 6000W

Electrical operation

Combi 4 E / Combi 6 E: 900 W / 1800 W

Mixed operation (gas and electrical)

Combi 4 E: max. 3800 W

Combi 6 E: max. 5800 W

Gas consumption

Combi 4 E: 160-320 g/h

Combi 6 E: 160-480 g/h

Readiness-heat power requirement Combi 4 E

/ Combi 6 E:

Gas operation 5.2 g/h

Air delivery volume

(free-blowing without hot-air pipe)

Combi 4 E:

with 3 hot-air outlets max. 249 m3/h

with 4 hot-air outlets max. 287 m3/h

Combi 6 E:

with 4 hot-air outlets max. 287 m3/h

Current input at 12 V

Heater +boiler

Combi 4 E: Short-term max. 5.6 A

(average power consumption 1.1 A)

Combi 6 E: Short-term max. 5.6 A

(average power consumption 1.3 A)

Heating up of boiler: 0.4 A

Stand-by: 0.001 A

Heating element FrostControl (optional):

maximum 0.4 A

FITTED EQUIPMENT

112

Alde Compact 3010

Challenger and Eccles SE, Conqueror,

Elite and Cameo based models

Please read these instructions carefully

before using the boiler.

These instructions are approved for The Alde

Compact 3010 boiler fitted in caravans, motor

caravans and buildings in accordance with CE

no. EMC e5 02 0138, 845 BP-0003.

Installation and repairs may only be carried out

by a professional. National regulations must be

adhered to.

Boiler design

The boiler consists of three eccentrically- fitted

cylinders (heat exchanger, water jacket for the

heating system and, outermost, water jacket

for hot water). The two outer pipes, and their

ends and connections, are made of stainless

steel, while the heat exchanger is made of

aluminium.

The heat exchanger is divided into two semicircles. The burner is located in the upper

half, being the combustion chamber, and

the combustion gases are expelled through

the lower half. The burner unit is fitted on the

end of the heat exchanger. It consists of a

combustion fan, burner, solenoid valve and

intake/exhaust connections. Two heating

cartridges are fitted to the water jacket of the

heating system. Maximum output is 2 or 3 kW,

depending on model.

Description of functions

Using LPG

When LPG operation is selected on the control

panel, the combustion fan starts. When the

fan speed is correct, it signals the circuit

board that the boiler can be lit. The circuit

board sends ignition sparks to the spark plug

at the same time as it sends electricity to the

solenoid valve, which opens to allow gas in.

The burner ignites, and a sensor transmits a

signal back to the circuit board that the boiler

is lit, and the ignition spark stops. The burner

keeps burning until the boiler thermostat or the

room thermostat reaches the set temperature

reading.

Should the boiler go out for any reason, the

sensor is activated and a new attempt is made

to start the boiler (in about 10 seconds).

ALDE HEATING OPERATING INSTRUCTIONS

FITTED EQUIPMENT

113

Using the heating cartridge

Electrical operation is selected on the control

panel, the 12-volt relays on the circuit board

trip, allowing the 230 volt supply to reach the

electrical elements.

The heating cartridge is controlled in the same

way as the gas boiler.

Warm water

When only warm water is required, for example

during the summer, no settings need to be

made, the boiler will look after this function

automatically.

The pump will only start when the temperature

in the vehicle is lower than the set temperature

(see item 4, Control Panel). If the vehicle

temperature is higher, the pump will not start.

Important information

• The boiler must not be started if there is no

glycol in the system.

• The LPG boiler and heating cartridge may be

operated in parallel.

• The heating system may be heated up

without the warm water heater being filled

with fresh water.

• Always switch off the main isolator for the

boiler when the vehicle is not being used.

• Always drain the warm water heater of fresh

water if there is a risk of frost.

• The LPG boiler must not be operated when

refuelling the vehicle.

• When washing the vehicle, take care not to

get water in the venting.

! WARNING: Care should be taken

to ensure adequate ventilation of the flue

at all times. Its is inadvisable to inhale

exhaust fumes.

The Domestic hot water heater

The boiler is fitted with a built-in warm water

heater with a volume of approx. 8.5-litres fresh

water. The warm water heater can produce

around 12 litres of 40°C water per half-hour

(at a cold water temperature of 10°C). If the

heating cartridges are used instead of gas

for heating the boiler, the capacity is slightly

reduced. Always rinse out the heater before

it is used, particularly if it has not been in

operation for some time.

Note: The hot water is not intended for

drinking or cooking.

When the heater is in continuous use, it should

be emptied approx. once a month, to ensure

that a new air cushion is formed in the heater.

The air cushion is essential for absorbing

pressure surges in the heater.

Note: The warm water heater should

always be drained of fresh water when there

is a risk of frost and when the caravan is not

in use.

The warranty does not cover frost damage.

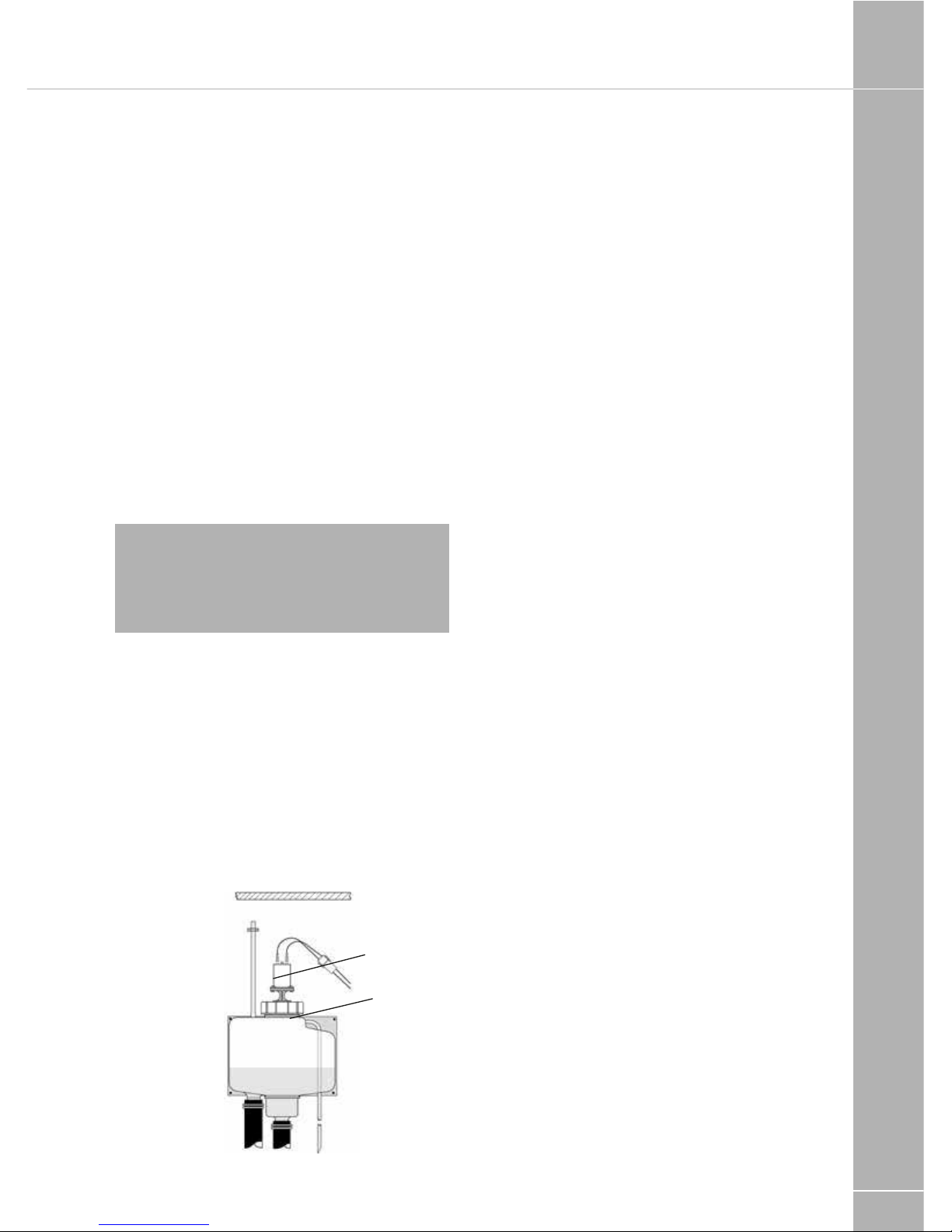

Draining the heater using the combined

safety/drain valve:

1. Switch off the freshwater pump

2. Open all water taps.

3. Then open the safety/drain valve by raising

the yellow lever (M) to a vertical position.

4. The heater will now drain directly below

the vehicle through the safety/drain valve

hose. Check that all the water is emptied out

(about 7-10 litres). Leave the valve in the open

position until the next time the heater is used.

Note: Check that the automatic check valve

(N) is open and is allowing air to enter the

heater when it is being drained, and that the

hose (O) is not blocked.

FITTED EQUIPMENT

114

Closed Open

M

N

The heating cartridges

All Compact 3010s are fitted with two 230V

heating cartridges with a maximum output

of either 2100 or 3150W. Select the heating

cartridge output on the control panel.

Always check that the input supply of the

vehicle has the correct amperage in relation to

the selected output.

Note these ratings are for the boiler only.

1050W requires a 6 amp fuse/supply.

2100W requires a 10 amp fuse/supply.

3150W requires a 16 amp fuse/supply.

The circulation pump

A circulation pump is required to circulate the

heated glycol fluid. A 12V circulation pump is

fitted in the expansion tank.

An optional 230V circulation pump can be

fitted on the boiler. Selection of circulation

pump is made with a switch on the control

panel. The room thermostat on the control

panel controls the circulation pump, i.e.

switches it on or off according to the amount

of heat required.

System temperature

The boiler is set to a system temperature of

80°C, i.e. the temperature of the glycol fluid as

it circulates in the heating system.

Air circulation

In order to achieve the best possible result

from the principle of convected heat, it is

important to allow air to circulate freely under

bunks, and behind backrests and wallmounted cabinets.

If the vehicle has a fitted carpet, ensure that

the carpet does not obstruct the air supply to

the radiators.

It is just as important that cushions or

blankets do not interrupt the flow of air behind

backrests and wall cabinets.

Note: During the first weeks of ownership

customers may notice a drop in the glycol

level and/or blocked radiators. This is normal

as the system settles.

Maintaining the heating system

Winter camping

While camping during the winter, ensure that

the flue is kept clear of snow and ice, since the

inlet air to the LPG boiler enters through the

flue. Do not start the LPG boiler until the flue

is completely free of snow. A flue extension

(part no. 3000 320) for fitting on the roof is

recommended for winter camping.

Air stream

Convectors

The heating system

Regularly check the heating system’s fluid level

in the expansion tank. The level should be

about 1cm above the minimum indicator in a

cold tank. The heating system should be filled

with a mixture of water and glycol.

For preference, use high quality ready mixed

glycol (with inhibitor) intended for use in

aluminium heating systems.

If using concentrated glycol, the mixture

should consist of 50% water and 50% glycol.

If the heating system will be exposed to

temperatures below -25°C, the glycol content

must be increased, but not to more than

50%. Any vessels used for the liquid must be

spotlessly clean, and the pipes in the heating

system must be free of contamination. This will

prevent the growth of bacteria in the system.

ALDE HEATING OPERATING INSTRUCTIONS

FITTED EQUIPMENT

115

The glycol mixture should be changed every

second year, since its ability to protect against

corrosion, for example, will deteriorate. The

glycol content should be checked before

topping up with new liquid. This will ensure

that the concentration of glycol in the mixture

is not too high.

If the fluid level in the expansion tank falls for

reasons other than evaporation, please check

all joints, drain cocks and bleeder screws to

ensure that they are not leaking. If the glycolwater mixture leaks out, rinse with water and

wipe up.

Never allow the heating system to stand empty

of glycol.

Filling the system with glycol fluid

Note: Any vessels used to carry the fluid

must be spotlessly clean and the pipes in

the system must be free of contamination.

This will prevent the growth of bacteria in the

system.

The system is filled through the expansion

tank, either manually or using the Alde filling

pump which both tops up and bleeds the

system. For manual filling, unfasten the

circulation pump nut (R) and lift the pump (S)

out of the tank. Slowly pour the glycol mixture

into the tank. Bleed the system.

Top up with more liquid if the level has fallen

after bleeding. Bleed a newly filled system

regularly during the first days the heating

system is in operation.

- MAX

- MIN

R

S

Types of glycol

Various types of antifreeze (as used in car

radiators) are available from service stations,

car accessory shops and on line retailers and

these types of antifreeze can be used to top

up or replace the heating system fluid in the

Alde heating system.

Frost and corrosion damage are not covered

under warranty, so it is important that the

type purchased contains corrosion inhibitors

suitable for use with aluminium systems.

Always check the label, ask the retailer for

advice, or check with your supplying dealer

if unsure. Please note the corrosion inhibitor

will have a limited life, and after it expires, the

system will have no corrosion protection.

The fluid will usually be named as Ethylene

glycol, but may also be described as

monoethylene glycol, MEG, ethanediol, or

G12++. There is no industry standard for

the colour of the antifreeze, but as a general

guideline it indicates the type of corrosion

inhibitor:

Blue, Green - Silicate inhibitor, usually offering

2-year corrosion protection

Red, Orange - OAT inhibitor, usually offering

5-year corrosion protection

Purple, Magenta - G12++ Silicated OAT

inhibitor, usually offering 5 year corrosion

protection

It is important that antifreeze containing Silicate

inhibitor (Blue or Green) is not mixed with

antifreeze containing OAT inhibitor (Red or

Orange). To guarantee compatibility, there are

two options:

1. Match the colour, taking care to also check

the label on the antifreeze bottle, i.e. if the

system is filled with blue silicate-containing

antifreeze, top up with blue silicatecontaining antifreeze.

2. Use G12++ antifreeze which is compatible

with any of the other types of inhibitor

described.

FITTED EQUIPMENT

116

Bleeding the system

Depending on how the pipes have been fitted,

air pockets may form when the system is filled

with glycol fluid.

A sign that there is air trapped in the system

is that the heat released into the pipes only

extends a metre or so from the boiler even

though the circulation pump is operating.

In newly-filled systems, small air bubbles

can form in the expansion tank, creating a

murmuring sound. If the circulation pump is

stopped for a few seconds, the bubbles will

disappear.

Bleeding:

If a bleeder screw is fitted to the outgoing pipe,

open this bleeder screw and leave it open until

it starts to discharge water.

If the boiler is fitted with an automatic bleeder,

there is no need to bleed it manually. Start the

LPG boiler. The circulation pump should be

switched off.

Open the remaining bleeder screws in the

system (please refer to the instruction manual

of the vehicle for their locations). Leave

the bleeder screws open until they start

discharging fluid, and then close them. Start

the circulation pump and let it run for a while.

Check that the pipes and radiators around the

vehicle are heating up.

If there are still issues, try the following:

Single-axle caravan:

Stop the circulation pump. Lower the front

of the caravan as far as possible. Leave it in

this position for a few minutes to allow the

air to travel upwards in the system. Open the

bleeder screw at the highest point. Leave it

open until it discharges glycol fluid. Raise the

front of the caravan as far as possible and

repeat the procedure in this position.

Then position the caravan horizontally and

start the circulation pump. Check that the

pipes and radiators around the vehicle are

heating up.

Twin-axle caravan:

The easiest way to bleed the heating system is

to place the vehicle on a sloping surface or to

raise one end of the vehicle using a jack. Bleed

the system as described above.

Fault finding

The boiler does not start

1. No LPG? Incorrect type for conditions?

2. Is the main tap fully open?

3. If the boiler has not been operated for

some time, or if the gas cylinder has been

changed, it may take longer than normal to

light the boiler.

4. Check that the boiler is connected to the

electricity supply (> 11V).

5. Check that the fuse (T) for the boiler

is intact.

6. Check whether the electric connections on

the boiler are securely in position.

If none of the above helps, contact a

service workshop.

The heating cartridge is not working

1. Check that there is an electricity supply

(230V ~) to the heating cartridge.

2. Check that the relays fitted to the boiler

come on (a slight click can be heard from

the relays when the heating cartridge is

switched on at the control panel).

If none of the above helps, contact a

service workshop.

ALDE HEATING OPERATING INSTRUCTIONS

FITTED EQUIPMENT

117

Operating instructions control

panel 3010 613

Please read these instructions carefully before

using the boiler. For Operating and Installation

Instructions of boiler, please see separate

instruction. These instructions are for the Alde

Compact 3010 boiler fitted in vehicles, boats

and buildings in accordance with CE no. 0845

BP0003, installation in vehicles e500 00005

and EMC e5 03 261.Installation and repairs

may only be carried out by a professional.

National regulations must be adhered to.

1. Starting the boiler

1. The control panel and the boiler are

switched off.

2. To start the boiler, press the On/Off button

and the start-up display is displayed. The

boiler starts with the last selected setting.

A green LED comes on beside the On-/Off

button when the panel/boiler is on.

2. The control panel in standby mode

Note: if “Standby Brightness” is set to Off,

the display goes out when it enters standby

mode, but lights up if you press the screen.

See settings under 9.12.

A. Clock

The clock shows day and time. Theclock is set

under section 9 point 2.

B. Outdoor temperature

The outdoor temperature is displayed

only if an outdoor temperature sensor is fitted.

C. Indoor temperature

The indoor temperature is displayed

automatically.

D. Circulation pump

This symbol is displayed when circulation of

the central heating is called for.

E. LPG bottle full/empty

This symbol is displayed when the sensor on

the cylinder changeover is connected and

activated in accordance with section 9 point 8.

F. 230 volts

This symbol is displayed when 230V is

connected to the boiler.

G. MENU button

Button for setting menu.

FITTED EQUIPMENT

118

H. On/Off button

Shut down / turn on the boiler

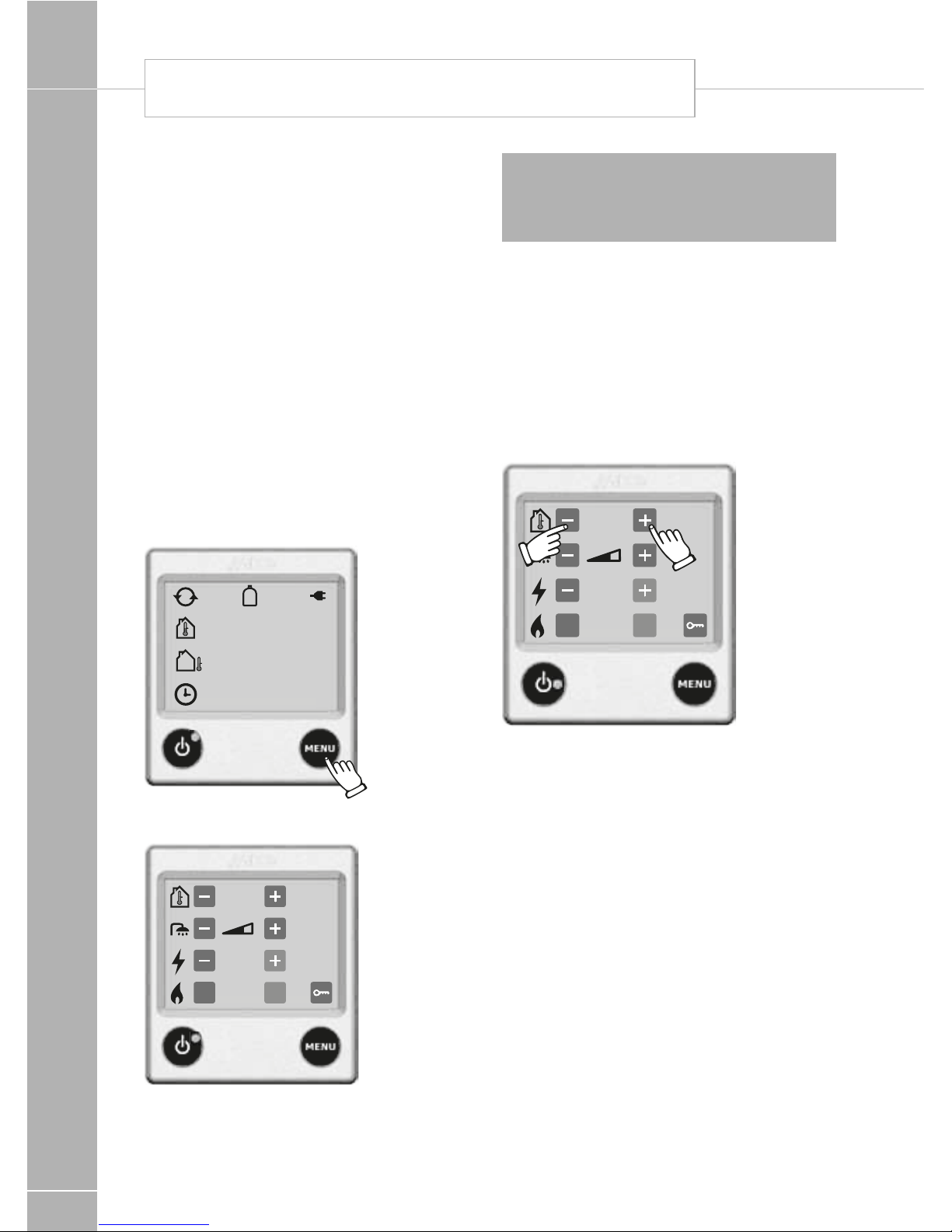

3. From standby mode to setting menu

When on standby, the indoor temperature is

displayed, and the outdoor temperature is

displayed if an outdoor temperature sensor

has been connected. The background lights

up when you press the screen or the MENU

button. Start the setting menu by pressing

the MENU button. The background lights up

and those functions which can be set are

displayed. The settings are automatically saved

after 10 seconds. The control panel reverts to

standby automatically after 30 seconds if no

buttons are pressed (or if the MENU button in

the setting menu is pressed).

1. The control panel in standby.

+22°C

+6°C

Fri 18.30

2. The control panel in setting menu.

+22°C

ON

2 kW

OnOf

f

Note: if “Standby Brightness” is set to Off,

the display goes out when it enters standby

mode, but lights up if you press the screen.

See settings under 9.12.

4. Set the required temperature

The temperature can be set from +5°C to

+30°C in steps of 0.5°C. Warm water is

always available (50°C) when the boiler is on

and running on LPG and/or electricity. During

summer, when only warm water is required,

adjust the temperature setting to well below

the surrounding temperature so that central

heating circulation is not called for.

+22°C

ON

2 kW

OnOf

f

1. The temperature displayed is the

temperature which is set at present (in this

case 22.0°C).

2. Raise the temperature by pressing the +

button. Lower the temperature by pressing

the – button.

3. The settings are ready and the central

heating will circulate at the set temperature.

5. Hot water boost

If you need more warm water, you can raise

the water temperature temporarily from 50°C

to 65°C. After 30 minutes, the boiler reverts

to normal operation. While hot water boost is

activated, the circulation pump is stopped.

ALDE HEATING OPERATING INSTRUCTIONS

FITTED EQUIPMENT

119

+22°C

ON

2 kW

OnOf

f

1. Increase the quantity of warm water by

pressing the + button. When activated the

plus symbol changes colour to green.

2. The settings are ready.

If you wish to revert to the basic warm water

settings before 30 minutes have expired.

+22°C

ON

2 kW

OnOf

f

1. Reset the warm water by pressing

the – button.

2. The settings are ready.

6. Heating with electricity

Do as follows to active heating with electricity.

The greater the power, the better the heating

performance. In choosing between electricity

and gas, electricity is given priority.

+22°C

ON

2 kW

OnOf

f

1. Start and step between the various power

steps (Off, 1kW, 2kW or 3kW) with the

+ button or – button. The set value is

displayed on the screen. When activated

the plus symbol changes colour to green.

(Certain boilers are equipped with max 2

kW, selecting 3kW is not possible in these

cases.)

2. The settings are ready and the boiler is

working at set temperature.

3. To switch off the electrical operation, step

with the – button to Off.

7. Heating with gas

Do as follows to activate heating with gas. If

both electricity and gas are selected, electricity

is given priority.

+22°C

ON

2 kW

OnOf

f

1. Start the gas operation by pressing On. The

On symbol is activated and changes colour

to green.

FITTED EQUIPMENT

120

2. The settings are ready and the boiler is

working at set temperature.

3. In order to switch off gas operation,

press Off.

8. Unlocking the tool menu

It is possible to go from the setting menu to

the tool menu. Under the tool menu you can

access the other functions of the control panel,

described in section 9.

1. The control panel in setting menu.

Press the unlock symbol.

+22°C

ON

2 kW

OnOf

f

2. The control panel in unlocking menu. Press

on open padlock, then OK or MENU to

unlock the tools menu. When activated the

symbol changes colour to green.

OK

3. The control panel in setting menu with

unlocked tool menu. In order to get to the

tool menu, press the symbol.

+22°C

ON

2 kW

OnOf

f

9. The tool menu - functions

When you are in the tool menu (see section 8),

you can use the tools described below. Step

between the various tool fields by pressing the

up or down arrow symbols. You can always

leave the tool menu with the MENU button.

Note: Functions marked with * indicate

that the symbol for the function is displayed

on the control panel even if the accessory is

not installed!

5

A

7

4

5

2

8

1

9

36

10

ALDE HEATING OPERATING INSTRUCTIONS

FITTED EQUIPMENT

121

Ext

Lan

Amp

11

14 16

15

13

12

1. Arrow symbols

Step between the various tool fields

by pressing the up or down arrow

symbols. You can always leave the tool

menu with the MENU button.

2. Clock

The clock must be set if automatic

nighttime mode or automatic start is to

be used. If 12V voltage is lost, the clock

will be reset and correct time will no

longer be displayed. This is prevented

with an optional AA battery backup.

3. Automatic night-time mode

This function is used when you want

to programme the central heating to

automatically lower the temperature

at night and raise the temperature in

the morning.

4. Starting the boiler automatically

This function is used to start the boiler

automatically at a later point of time.

With automatic start, the boiler works

for 24 hours and then stops. After that,

it repeats the automatic start once a

week; at the same day and time, as

long as the function is activated. For

automatic start to function, the On/Off

button must be set in the OFF position.

5. Constant pump operation

Cont.: With this function selected the

pump is permanently on. (NB., this

function limits the supply of hot water,

particularly when there is a low heating

requirement) Therm: With this function

selected the pump is controlled by the

panel/room sensor. This is the normal

operating mode for heating the vehicle

and obtaining a normal supply of hot

water. Factory setting is Therm.

A

6. *Pump Auto / 12V

In the Auto mode, the 230V pump

operates, and when 230V is

disconnected, the 12V pump starts. In

12V mode, the 12V pump is used even

if 230V is connected. The Auto function

is activated in the factory setting.

7. *Pump speed

The circulation pump’s capacity can be

remote controlled from the panel.

Note: A pump with remote control must be

installed in order that this function can be

used (see the manual for the vehicle, boat

or building).

8. *LPG bottle full/empty

This function is used in combination

with the cylinder changeover

(DuoComfort or DuoControl) and

indicates if the LPG bottle is full or

empty. This function can also be

used to control defroster heating of

the cylinder changeover using an

EisEx defroster.

Note: The cylinder changeover (DuoComfort

or DuoControl) must be installed in order for

this function to work (see the manual for the

vehicle, boat or building).

9. Automatic anti-bacterial mode

(legionella)

At 02.00 at night (if the clock is set)

the boiler starts and works according

to “Hot water boost” (see section 5).

This is in order to reduce the risk of

legionella. The function is deactivated in

the factory setting.

Loading...

Loading...