Page 1

Ab Crunch-Back Row

Composite

Model # SC1010

Revision 062717

OWNER’S

MANUAL

Page 2

Strength (Composite)

Ab Crunch-Back Row

IMPORTANT:

All products shown are prototype. Actual product delivered may vary.

Product specications, features & soware are subject to change without notice.

For the most up-to-date owner’s manual please visit www.truetness.com.

For documents in additional languages please visit www.truetness.com/resources/document-library/

IMPORTANTE:

Todos los productos mostrados son prototipos. La realidad el producto suministrado puede diferir.

Especicaciones de productos, características y soware están sujetas a cambios sin previo aviso.

Para la más actualizada de este manual del propietario, por favor visite www.truetness.com

Para los documentos en otros idiomas, por favor visite www.truetness.com/resources/document-library/

IMPORTANT: Tous les produits présentés sont prototype. Le produit réel livré peut varier. Spécications du

produit, caractéristiques et logiciels sont sujettes à modication sans préavis. Pour la plus à jour le manuel du

propriétaire s'il vous plaît visitez www.truetness.com. Pour documents dans des langues supplémentaires,

veuillez www.truetness.com/resources/document-library/ de visite

重要提示: 显示所有产品的原型。实际交付的产品可能有所不同产品规格,功能和软件如有更改,恕不另

行通知迄今为止对于大多数的使用说明书,请访问www.truetness.com 对于其他语言的文档,请访问

www.truetness.com/resources/document-library/

ھام:

جمیع المنتجات المعروضة ھي النموذج. قد تختلف المنتج الفعلي تسلیمھا.

مواصفات المنتج، والمیزات والبرامج قابلة للتغییر دون إشعار.

لمعظم ما یصل حتى الآن دلیل المالك یرجى زیارة www.truetness.com.

للمستندات في لغات إضافیة، یرجى زیارة www.truetness.com/resources/document-library/

WICHTIG: Alle hier gezeigten Produkte sind Prototypen. Das tatsächliche Produkt ausgeliefert wird, kann

variieren. Produkt-Spezikationen, Funktionen und Soware können sich ohne vorherige Ankündigung

ändern. In den meisten Fällen bis zu Bedienungsanleitung Bisher besuchen Sie bitte www.truetness.com. Für

Dokumente in weiteren Sprachen nden Sie unter www.truetness.com/resources/document-library/

BELANGRIJK: Alle getoonde producten zijn prototype. Daadwerkelijke product geleverd kan verschillen.

Product specicaties, eigenschappen & soware zijn onderhevig aan verandering zonder kennisgeving. Voor

de meest actuele handleiding van de eigenaar kunt u terecht www.truetness.com. Voor documenten in andere

talen kunt u terecht op www.truetness.com/resources/document-library/

: . , .

,

.

, www.truetness.com

. , , www.truetness.com/resources/document-library/

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 2 of 46

Page 3

Strength (Composite)

Ab Crunch-Back Row

A MESSAGE TO OUR CUSTOMERS

Frank Trulaske began TRUE Fitness® over thirty-ve year ago with the simple philosophy of delivering superior

tness products, service, and support. Today, TRUE is the global leader in premium tness equipment for the

commercial and residential markets. Our goal is to be the leader in technology, innovation, performance, safety

and style. TRUE has received many awards for its product over the years and remains the benchmark for the

industry. Fitness facilities and consumers invest in TRUE products for their durable commercial platforms used

in all its products, both commercial and residential alike.

e proud manufacturing tradition of quality and the culture of innovation at TRUE have given rise to a full line

of extraordinary cardio and strength equipment. As a result, people all over the world are beneting from the

TRUE experience. Innovation across the full product line has made TRUE successful and is a trademark of the

TRUE heritage. TRUE’s patented Heart Rate Control technology is just one of the remarkable ways we deliver

simple and superior performance every user can enjoy, and most importantly, use to achieve personal health and

tness goals.

At the heart of our success is the relentless and systematic life testing of both our products and their components.

We have dedicated employees who understand our philosophy is to deliver the best products in the world.

Our goal is to deliver the world’s best premium equipment for our customers’ health and tness solutions.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 3 of 46

Page 4

Strength (Composite)

Ab Crunch-Back Row

Table of Contents

CHAPTER 1: SAFETY INSTRUCTIONS ..........................................................................................................................5

• COMPLIANCES: ............................................................................................................................ 9

• COMMERICAL MAINTENANCE SCHEDULE: .....................................................................9

CHAPTER 2: ASSEMBLY GUIDE ...................................................................................................................................10

• MACHINE SPECIFICATIONS: .................................................................................................10

• REQUIRED TOOLS: ....................................................................................................................11

• PRE-ASSEMBLY CHECKLIST: ..................................................................................................12

• ASSEMBLY STEPS: ......................................................................................................................14

• CARE & MAINTENANCE: ........................................................................................................36

CHAPTER 3: CARE & MAINTENANCE .......................................................................................................................36

• DAILY INSPECTION & MAINTENANCE: .............................................................................36

• WEEKLY INSPECTION & MAINTENANCE: ........................................................................ 36

• OTHER SCHEDULED PREVENTIVE MAINTENANCE: ...................................................37

• CLEANING THE EQUIPMENT: ..............................................................................................37

• CABLE INSPECTION & MAINTENANCE: ............................................................................38

CHAPTER 4: CUSTOMER SERVICE ..............................................................................................................................40

• CONTACTING SERVICE: ..........................................................................................................40

• CONTACTING SALES: ...............................................................................................................40

• REPORTING FREIGHT OR PARTS DAMAGE: ..................................................................... 41

CHAPTER 5: ADDITIONAL INFORMATION: ............................................................................................................42

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 4 of 46

Page 5

CHAPTER 1: SAFETY INSTRUCTIONS

F

ACILITY AND USER SAFETY PRECAUTIONS

exiting the machine. Be certain members are instructed on how to operate and adjust

S

AFETY

1. Review and understand all of the warning labels affixed to this machine and on the facility

safety sign.

2. Be certain that the machine operation is understood before it is used. Refer to the

instructional procedure label affixed to the machine.

3. Make sure all users are properly trained on how to use this equipment. If this machine is

being used in a commercial setting, end users may not have access to this owners manual. It is

the responsibility of the facility to instruct users as to the proper usage of the equipment as well

as making them aware of potential hazards. Maximum user weight is 300 lbs (136 kg) unless

otherwise stated in the manual.

4. Use each machine only for the intended exercise. Do not allow anyone to invent exercises not

included on the instructional procedure label or the intended use Label.

Strength (Composite)

Ab Crunch-Back Row

5. Do not modify the machine.

6. This equipment meets industry safety standards for stability when used for the intended

exercise. Do not allow straps, resistance bands or other means to be attached to the framework

of this machine to perform stretching or body weight exercises. This can result in machine

instability and lead to serious crushing injuries.

7. Keep children away from this equipment. Adults should closely supervise use by teenagers.

8. It is recommended that users receive a thorough medical exam before commencing an

exercise program. All medical issues should be reviewed to ensure that weight training will not

aggravate pre-existing medical conditions.

9. If the machine appears damaged or inoperable, contact a facility staff member to place an

“OUT OF ORDER, DO NOT USE” sign on the machine until it is repaired. Only use TRUE

supplied replacement components to service this machine.

I

10.

when using this equipment.

11. Do not attempt to free any jammed assemblies by yourself as this may cause injury.

12. On Plate Loaded and Free Weight machines:

12a. Use of spotter(s). Instruct users to seek the advice of the facility staff as to the

nstruct users not to wear loose or dangling clothes or have headphone wires hanging

appropriate use of spotters when lifting. More than one spotter may be required

depending upon the amount of weight being lifted.

12b. Instruct users to load weight plates evenly and carefully to avoid tipping equipment

and crushing injuries.

12c. If the machine is equipped with safety stops or catches, inspect them and verify their

proper operation before use and make sure they are securely in place before using or

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 5 of 46

Page 6

Strength (Composite)

12d. This equipment is designed for standard olympic size weight plates with a 50mm bore

S

AFETY

Ab Crunch-Back Row

CHAPTER 1: SAFETY INSTRUCTIONS

(1.9”).

12e. Do not exceed the maximum weight capacity of the machine. Maximum plate size is

13. On Selectorized and Cable equipped machines:

I

NSTALLATION SAFETY PRECAUTIONS

45 lbs. (25 kg.).

13a. Do not allow users to perform any exercise by holding the end of the cable and/or the

cable end fitting. Use only appropriate handles or attachments properly connected to

the cable end.

13b. Do not high-pin or double-pin the weight stack. Do not allow the machine to be used if

the top plate or weight stack is pinned in a raised position. Use an assistant and

carefully return the machine to the proper position with the cap plate resting on the top

weight. Inspect the entire length of the cable to ensure that it is properly seated in all

of the pulley grooves.

13c. Do not allow the use of weight plates or dumbbells to be used as a means to add

additional weight to the weight stacks. Use only the TRUE adder weight system

specifically designed for the machine.

1. Read this installation manual entirely before assembling this equipment.

2. Verify that there is adequate space surrounding this piece of equipment for safe access and

operation. Installation must meet ADA requirements for accessibility.

3. Install this piece of equipment on a solid level surface that does not deviate more than 1/8”

over a 10’ distance (or as defined and required by local building and architectural codes.)

4. TRUE strongly recommends that all equipment be anchored to the floor to prevent movement

and increase stability.

• Due to the wide variation of flooring on which the unit can be installed, contact a

qualified contractor to determine an appropriate fastening system for your floor.

• Use 3/8” diameter hardware (10 mm) to anchor the machine. Anchors should have a

minimum pull out force of 220 lb (110 kg) for each position.

• When attaching the machine to the floor, if there is a gap between the machine foot

and the floor, do not use the anchor to remove the gap as this can cause the

machine frame to deform. Instead, place a shim between the bottom of the foot and

the floor, then tighten the anchor.

• Anchoring holes are provided on the feet of the frame. All anchoring locations must

be used when anchoring the equipment to the floor.

5. DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion

caused by installation in these locations can lead to premature failure of components.

6. Be sure all hardware is tight before using this machine.

7. Some assembly materials may come preassembled in the carton. Refer to Chapter 2:

Assembly Guide for instructions on disassembling assembly materials where appropriate

before beginning assembly.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 6 of 46

Page 7

S

AFETY

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 1: SAFETY INSTRUCTIONS

M

AINTENANCE SAFETY PRECAUTIONS

1. Refer to the maintenance schedule table in this manual for when to perform maintenance.

2. Check the function of your machine DAILY by verifying the following:

• If equipped with cables, inspect cables and end fittings for any signs of wear.

Replace if worn, frayed, or damaged with TRUE replacement components.

• Verify that all adjustments are possible and carried out with ease. Make sure that

each adjustment pin inserts completely into each position without binding.

• Verify that safety catches and stops are in proper working order and engaged.

• Verify that the exercise is performed smoothly, free of noise, and/or binding.

• If equipped with a weight stack, verify that the proper weight selector pin is in place.

3. Check the function of your machine WEEKLY by verifying the following:

• Nuts, Bolts, and Fasteners: check tightness weekly. If any hardware has become

loose, retighten it, use Loctite

™

Threadlocker 242, or both.

• Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any

component at first signs of wear. Use only TRUE supplied components.

4. Replace any warning label at the first sign of wear. Labels and the facility safety sign may be

obtained from TRUE.

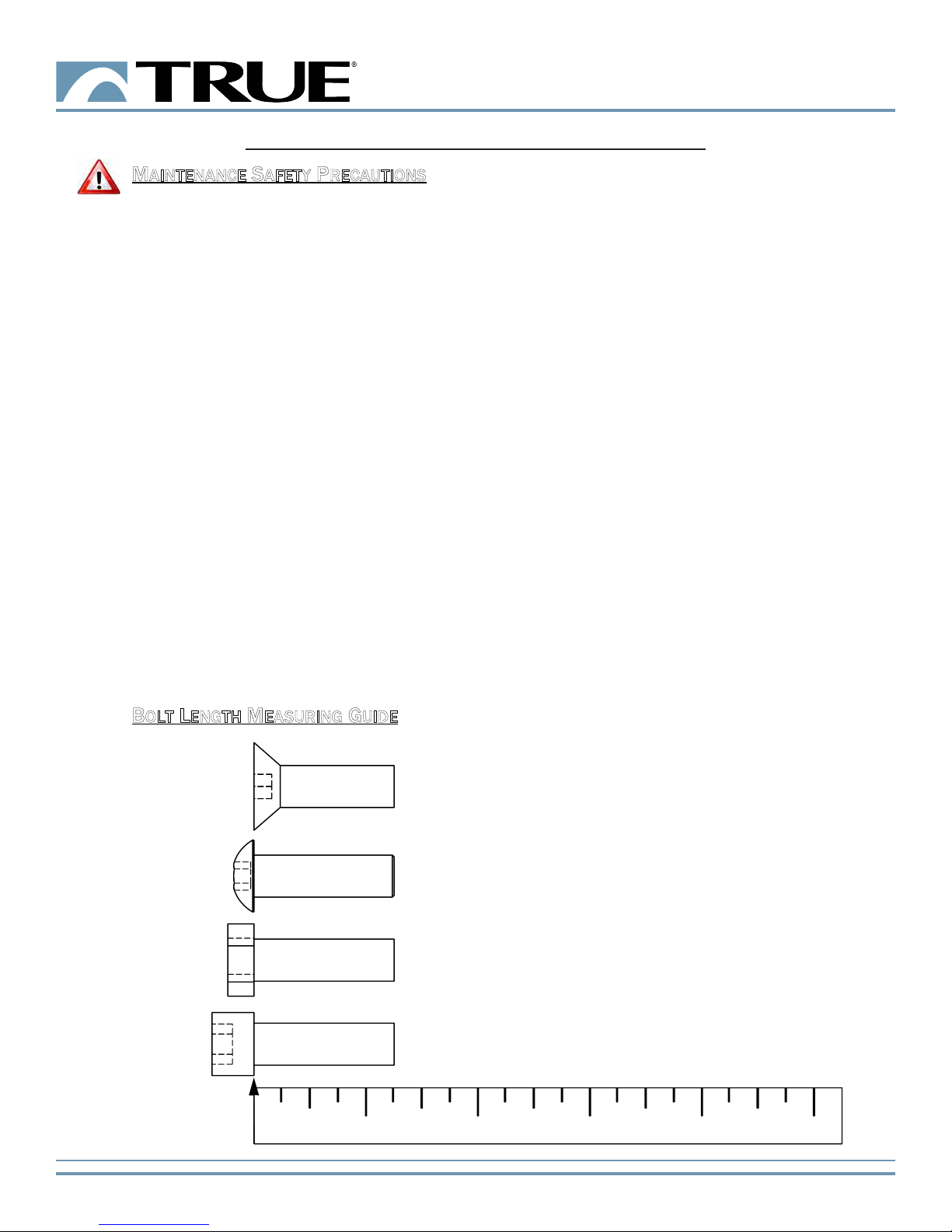

B

OLT LENGTH MEASURING GUIDE

FLAT HEAD SCREW

BUTTON HEAD SCREW

HEX HEAD SCREW

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

SOCKET HEAD SCREW

1

23

4

5

Page # 7 of 46

Page 8

IMPORTANT

Preventative maintenance is crucial to maintaining the function and safety of this equipment. Your

G

ENERAL CARE AND

M

AINTENANCE

facility must establish written guidelines for preventative maintenance and keep written or online

records of the maintenance performed on these products. As a minimum, the items presented in

the SAFETY section of this document and the items that follow here, should be included in your

maintenance program.

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 1: SAFETY INSTRUCTIONS

1. Cables (If equipped): inspect end fittings daily for wear. Inspect the entire length of the

cable weekly. Replace cables at the first sign of wear and on an annual basis. If the cable

tension has been adjusted, be certain that the cable nut is tight.

2. Nuts, Bolts, and Fasteners: check tightness weekly. If any hardware has become loose,

retighten and/or use Loctite

using the machine.

3. Safety Catches: inspect catches, stop rods and their associated fasteners weekly. Tighten

any loose hardware and replace any components at first signs of wear.

4. Frames: sweat, disinfecting sprays and spills can lead to corrosion which may lead to

premature failure of components. Wipe all machines down with a damp cloth and dry

completely each day. This includes painted parts, chrome parts and upholstered pads.

5. Painted and chrome plated parts: use Simple Green with a dilusion of 32:1 or similar

cleaner for light dirt and grime. Use Turtle Wax Polishing Compound or a good car polish to

remove heavier dirt and grease as well as for polishing. DO NOT use solvents, lacquer

thinner, acetone or finger nail polish remover. For scuffs and marks that are not removed

by the above methods use a soft scrub cleanser. Make sure all parts are dry upon

completion.

6. Weight stack enclosures (shrouds)(If Equipped): wipe down with a damp cloth as needed.

7. Exercise instruction labels: clean with soap and water as needed.

8. Guide rods (If equipped): wipe all dirt and dust from th

application of Tri-Flow

then wipe the guide rods with the rag. DO NOT use oil lubricants such as WD-40. Caution: Tri-

TM

Flow

9. Bronze bushings: check monthly for signs of wear and replace as needed.

10. Linear Bearing Shafts: wipe any accumulation of dust or other contaminants from the

shafts on a weekly basis. Apply a thin layer of a Teflon

TRUE recommends Magnalube

11. When replacing any component, use only TRUE supplied parts.

12. Be sure all hardware is tight before using the machine.

will stain carpet and clothing.

TM

brand Threadlocker 242. Be sure all hardware is tight before

TM

or other teflon spray lubricant. Spray the Tri-FlowTM on a rag and

® brand.

e guide rods before applying a light

® (PTFE) grease on a weekly basis.

Retain these instructions for future reference.

If you have any questions, do not hesitate to contact your TRUE dealer or TRUE Fitness Technology

at (800)883-8783 or service@truefitness.com.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 8 of 46

Page 9

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 1: SAFETY INSTRUCTIONS

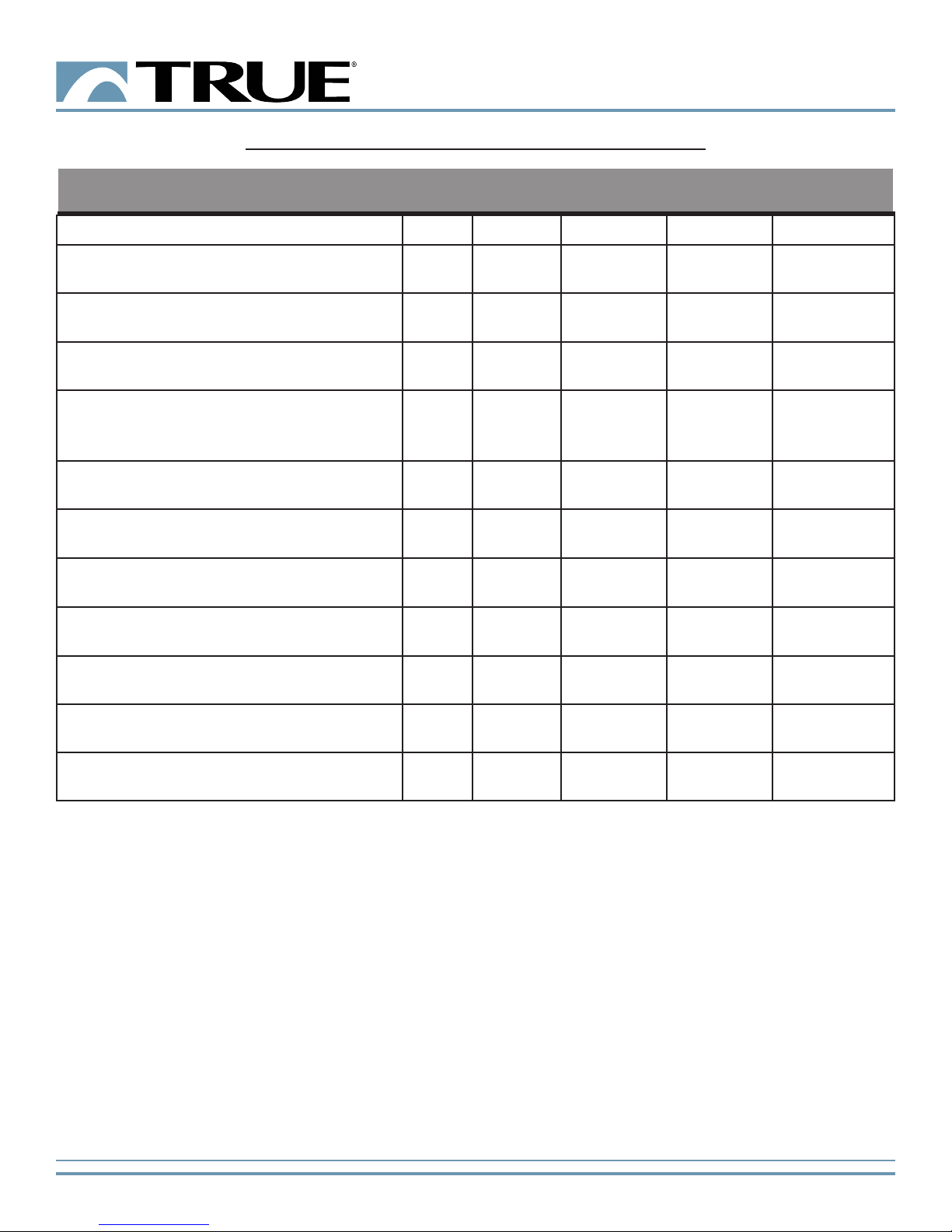

COMMERICAL MAINTENANCE SCHEDULE

DAILY WEEKLY MONTHLY 6 MONTHS ANNUALLY

INSPECT: Cables for wear, tension, and

proper connection if equipped.

INSPECT: All nuts and bolts and tighten if

needed.

INSPECT: All anti-slip surfaces and replace

as needed.

INSPECT: All adjustment pins, weight stack

pins, set screws, gas shocks, snap links, and

pulleys if equipped.

INSPECT: All accessory bars and handles. X

INSPECT: All safety and instructional

decals.

INSPECT: All weight stack shields if

equipped.

CLEAN: Guide rods and lubricate with a

teon lubricant if equipped.

CLEAN: Upholstery X

X

X

X

X

X

X

X

LUBRICATE: Pivot bearings and linear

bearings.

REPLACE: Cables if equipped. X

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

X

Page # 9 of 46

Page 10

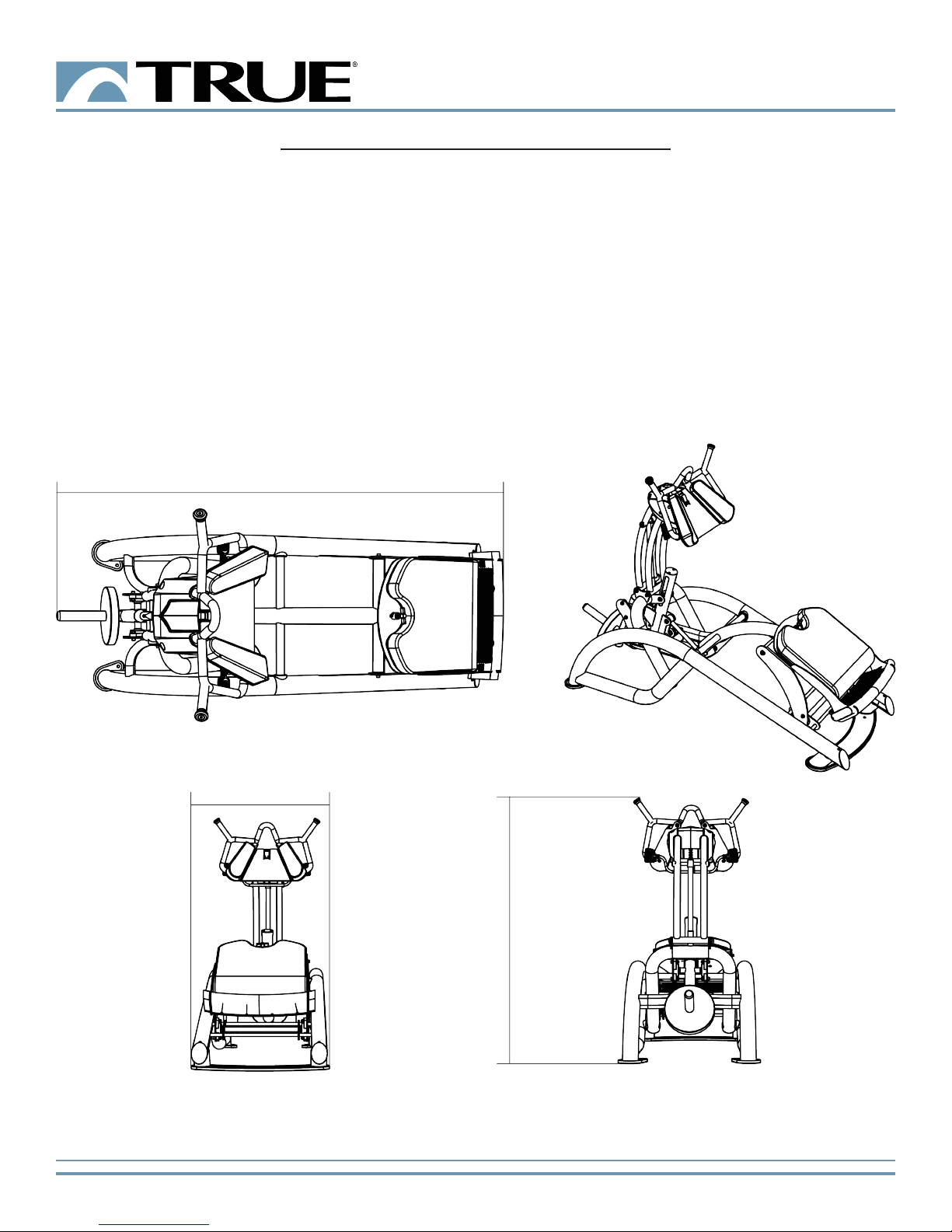

CHAPTER 2: ASSEMBLY GUIDE

MACHINE SPECIFICATIONS:

Features

• Weight of assembled machine: 557 lb. (253 kg.), but without free weights.

• Floor loading:

• For machine weight without counterweights and free weights it is 30 lb/2 (148 kg/m)

• Maximum user weight is 400 lb. (182 kg.)

• Maximum free weight per weight horn is 4 x 45 lb. (25 kg.) weight plates.

85"

Strength (Composite)

Ab Crunch-Back Row

31"

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

61"

Page # 10 of 46

Page 11

CHAPTER 2: ASSEMBLY GUIDE

REQUIRED TOOLS:

Strength (Composite)

Ab Crunch-Back Row

Ratchet Handle

9/16” Socket

6 mm hex bit socket

9/16” & 3/4” wrench

Allen wrench (supplied):

• 3 mm

COMPLIANCES:

is equipment complies with all tness product standards. For a complete list of compliances, please visit www.

TrueFitness.com.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 11 of 46

Page 12

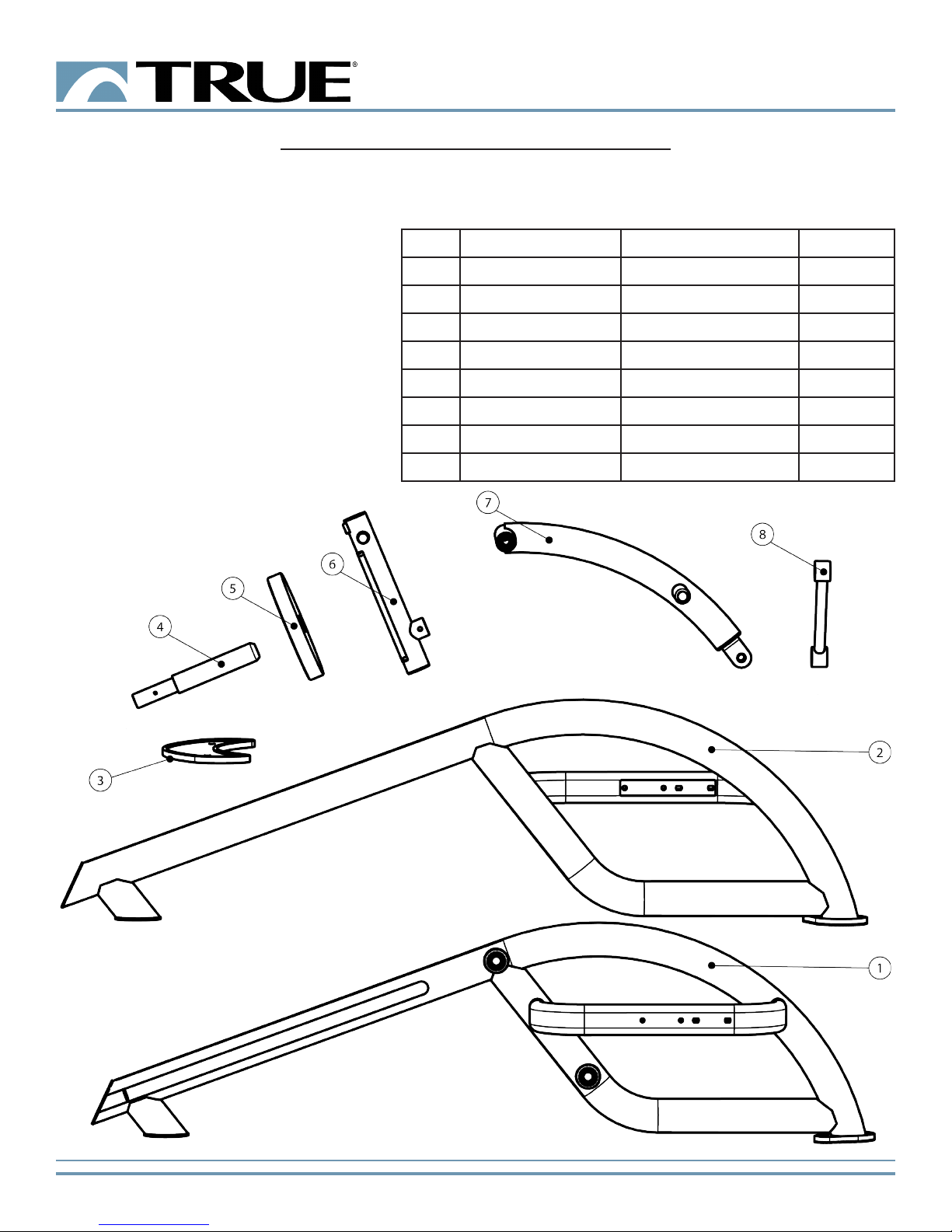

CHAPTER 2: ASSEMBLY GUIDE

PRE-ASSEMBLY CHECKLIST:

Carton One Contents

Strength (Composite)

Ab Crunch-Back Row

Note: Hardware item

numbers on the tooling card

may not match the harware

item numbers shown in the

owner’s manual.

Item Part Number Description Quantity

1 SC10SF000X Le Main Frame 1

2 SC10SF100X Right Main Frame 1

3 SC10MF400X Footplate 1

4 SC10WH000 Weight Horn 1

5 CW35 Counterweight 1

6 SC10MF300X Weight Arm 1

7 SC10LK000X Center Linkage 1

8 SC10LK100X Middle Linkage 1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 12 of 46

Page 13

CHAPTER 2: ASSEMBLY GUIDE

PRE-ASSEMBLY CHECKLIST:

Carton Two Contents

Strength (Composite)

Ab Crunch-Back Row

Note: Hardware item

numbers on the tooling card

may not match the harware

item numbers shown in the

owner’s manual.

Note: Do not remove the zip

tie holding the roller wheels

in place on the seat carriage

assembly until Step 14 (Seat

Carriage Assembly).

Item Part Number Description Quantity

1 SC10HF000X Handle Frame 1

2 SC10PD300 Le Arm Pad 1

3 SC10PD400 Right Arm Pad 1

4 SC10SD000 Le Shroud 1

5 SC10SD002 Right Shroud 1

6 SC10PD200 Knee Pad 1

7 SC10PD000X Arm Pad Assembly 1

8 SC10MF500X Nylon Rod 1

9 SC10LK200X Front 4-Link Assy 1

10 SC10LK300X Rear 4-Link Assy 1

11 SC10CA000X Seat Carriage Assy 1

12 SC10MF000X Pull Arm 1

13 SC10MF200X Frame Brace 1

14 SC10MF100X Lever Arm 1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 13 of 46

Page 14

CHAPTER 2: ASSEMBLY GUIDE

PRE-ASSEMBLY CHECKLIST:

Cartons ree/Four Contents

Strength (Composite)

Ab Crunch-Back Row

Note: Hardware item

numbers on the tooling card

may not match the harware

item numbers shown in the

owner’s manual.

Item Part Number Description Quantity

1 CW35 Counterweight, 35 lb. 1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 14 of 46

Page 15

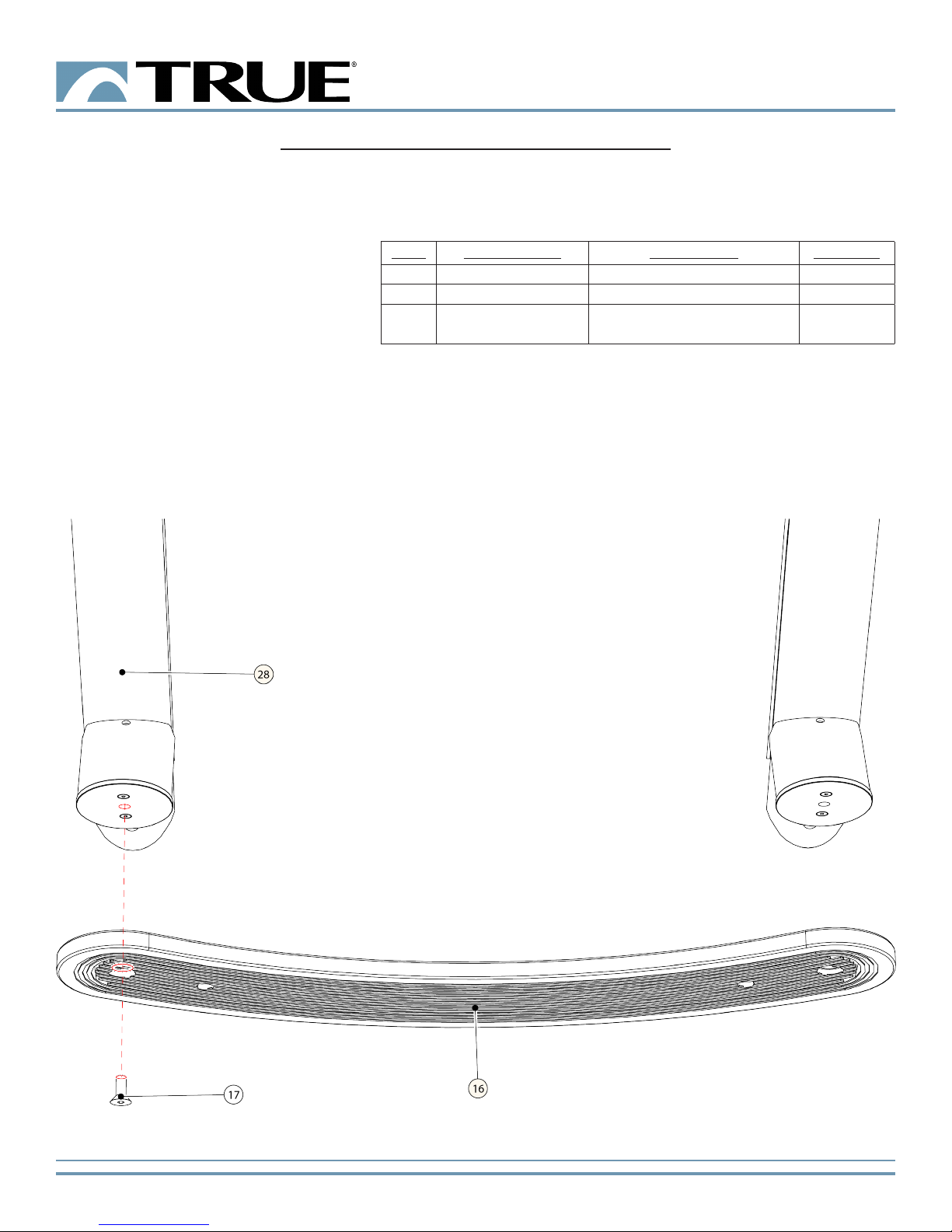

ASSEMBLY STEPS:

Step 1 (Footplate):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Secure the footplate to the right main

frame rail using the identied hardware.

Note: Only the screw for securing the

footplate to the right main frame rail is

used at this time. e screw for the le

main frame rail is used to secure the

footplate in Step 8 (Footplate Assembly

[Cont.])

Item Part Number Description Quantity

28 SC10SF100X RIGHT MAIN FRAME 1

16 SC10MF400X FOOTPLATE ASSEMBLY 1

17 C 658 FLAT HEAD HEX CAP

SCREW 3/8”-16 UNC X 1”

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 15 of 46

Page 16

ASSEMBLY STEPS:

Step 2 (Main Frame):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Insert the pull arm and center linkage

into the right side frame, and then into

the le side frame.

Note: Use caution until the main frame

is secured with the hardware identied

in Step 3 (Frame Brace Assembly) to

prevent injury.

Item Part Number Description Quantity

49 SC10SF000X LEFT SIDE FRAME

ASSEMBLY

54 SC10SF100X RIGHT SIDE FRAME

ASSEMBLY

37 SC10MF000X PULL ARM 1

16 SC10LK000X CENTER LINKAGE

ASSEMBLY

1

1

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 16 of 46

Page 17

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 3 (Frame Brace Assembly):

Strength (Composite)

Ab Crunch-Back Row

Secure the frame brace assembly to

the le and right main frame using the

identied hardware.

Item Part Number Description Quantity

17 C 630 SHCS 3/8”-16 UNC X

2.75”

1 C 754C 3/8 SAE WASHER ZINC 8

13 C1024 NUT CAP 3/8”-16 UNC X

11.5MM

2 SC10MF200X FRAME BRACE ASSY 1

4

4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 17 of 46

Page 18

ASSEMBLY STEPS:

Step 4 (Lever Arm Assembly):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Secure the lever arm to the identied

items and then place inside the frame

brace assembly as shown below.

Note: Ensure the lever arm assembly is

seated behind the pull arm.

Item Part Number Description Quantity

5 SC10MF100X LEVEL ARM ASSEMBLY 1

2 SC10BR003 FLANGE BEARING 2

26 SC10MF200X FRAME BRACE

ASSEMBLY

22 SC10MF000X PULL ARM 1

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 18 of 46

Page 19

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 5 (Frame Brace Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the lever arm assembly to the

frame brace assembly and main frame

using the identied hardware.

Item Part Number Description Quantity

18 C1073 SHCS 3/8”-16 UNC X

3.25”

1 C 754C 3/8 SAE WASHER ZINC 8

13 C1024 NUT CAP 3/8”-16 UNC X

11.5MM

4

4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 19 of 46

Page 20

ASSEMBLY STEPS:

Step 6 (Lever Arm Wheel):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Insert the level arm wheel inside the

lever arm assembly and secure in place

using the identied hardware.

Note: Use caution when securing the

lever arm wheel to ensure it does not

fall down the lever arm assembly.

Item Part Number Description Quantity

34 SC10WL000X BIG WHEEL ASSEMBLY 1

14 SC10SH005 WHEEL SHAFT 0.67” x

4.37”

18 SC10SS001 WHEEL SHAFT SLEEVE 2

25 C1072 FLAT WASHER 10.5 mm x

21 mm x 1.8 mm

27 C1023 HEX SOCKET CAP HEAD

3/8-16 UNC x 1”

7 SC10CP200 CAP O.D. 76 mm 1

21 C1042 FHSCS 10-24 x 5/8” 2

1

2

2

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 20 of 46

Page 21

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 7 (Middle Linkage Assembly):

Strength (Composite)

Ab Crunch-Back Row

Secure the middle linkage assembly to

the lever arm and center linkage using

the identied hardware.

Item Part Number Description Quantity

23 SC10LK100X MIDDLE LINKAGE

ASSEMBLY

26 SC10SH001 SHORT CONNECTING

SHAFT

14 SC10SS000 SHAFT SLEEVE SHORT 4

13 C1072 FLAT WASHER 10.5 mm x

21 mm x 1.8 mm

20 C1023 HSCS 3/8”-16 UNC x 1” 4

1

2

4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 21 of 46

Page 22

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 8 (Footplate Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the footplate to the le main

frame rail using the identied hardware.

Item Part Number Description Quantity

30 SC10SF000X LEFT MAIN FRAME 1

16 SC10MF400X FOOTPLATE ASSEMBLY 1

37 C 658 FLAT HEAD HEX CAP

SCREW 3/8”-16 UNC X 1”

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 22 of 46

Page 23

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 9 (Lower Linkage Assemblies):

Strength (Composite)

Ab Crunch-Back Row

Secure the front and back linkage

assemblies to the pull arm assembly using

the identied hardware.

Note: e connecting shas can only be

inserted in the link assemblies as shown

due to the sha at ends matching up

with the designated holes on the pull arm.

Item Part Number Description Quantity

10 SC10LK200X FRONT FOUR-LINK

ASSEMBLY

13 SC10LK300X REAR FOUR-LINK

ASSEMBLY

23 SC10SH003 CONNECTING SHAFT

233 mm

24 C 754C 3/8” SAE WASHER ZINC 4

5 C1023 HSCS 3/8”-16 UNC x 1” 4

1

1

2

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 23 of 46

Page 24

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 10A (Forearm Pad Assembly):

Inser the forearm pad assembly into the front linkage using the orientation shown below.

Note Ensure the selector pin aligns with one of the selector holes.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 24 of 46

Page 25

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 10B (Forearm Pad Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the forearm pad assembly to

the front and back linkages using the

identied hardware.

Note: Depress the height selector paddles

to engage the selector pin for properly

aligning the top axle holes of the front and

back linkages.

Note: e connecting shas can only be

inserted in the link assemblies as shown

due to the sha at ends matching up

with the designated holes on the pull arm.

Item Part Number Description Quantity

1 SC10SH003 CONNECTING SHAFT

2

233 mm

13 C 754C 3/8” SAE WASHER ZINC 4

20 C1023 HSCH 3/8”-16 UNC x 1” 4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

2013 201 131

Page # 25 of 46

Page 26

ASSEMBLY STEPS:

Step 11 (Forearm Pads):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Secure the forearm pads to the forearm

pad assembly using the identied

hardware.

Note: e forearm pads are le and

right dependent. Only the right pad is

shown for reference, but both forearm

pads must be installed during this step.

20

Item Part Number Description Quantity

14 SC10PD400 RIGHT PAD 1

20 C 658 FLAT HEAD HEX CAP

4

SCREW 3/8”-16 UNC x 1”

Note: The forearm pads are left and right dependent.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

1414

Page # 26 of 46

Page 27

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 12 (Handle Frame Assembly):

Strength (Composite)

Ab Crunch-Back Row

Secure the handle frame assembly to

the forearm pad assembly using the

identied hardware.

Item Part Number Description Quantity

2 C 754C 3/8” SAE WASHER ZINC 4

5 C1023 HSCH 3/8”-16 UNC x 1” 4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 27 of 46

Page 28

ASSEMBLY STEPS:

Step 13 (Housing Cover):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Secure the housing cover to the forearm

pad assembly and the front and back

linkages using the identied hardware.

Note: e housing covers are le and

right dependent.

Item Part Number Description Quantity

1 C1074 PHILLIPS PAN HEAD

SCREW M5 x 0.8 x 10mm

2 SC10SD002 RIGHT SHROUD 1

3 SC10SD000 LEFT SHROUD 1

4 SC10SH002 SHROUD CONNECTING

SHAFT

8

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 28 of 46

Page 29

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 14 (Seat Carriage Assembly):

Strength (Composite)

Ab Crunch-Back Row

Insert the seat carriage assembly into

the main frame rails ensuring proper

alignment inside the rails.

Note: Remove the end caps from the

main frame rails before proceeding with

this step.

Note: Do not use any lubricant inside of

the main frame rails or directly on the

knee seat assembly wheels.

Item Part Number Description Quantity

5 SC10CA000X SEAT CARRIAGE

ASSEMBLY

14 SC10SF100X RIGHT MAIN FRAME

RAIL

17 SC10SF000X LEFT MAIN FRAME RAIL 1

1

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 29 of 46

Page 30

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 15 (Seat Carriage Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the seat assembly to the center

linkage arm using the identied

hardware.

Item Part Number Description Quantity

13 SC10SH004 CARRIAGE

CONNECTING SHAFT

538 mm

14 C1072 FLAT WASHER 10.5 mm x

21 mm x 1.8 mm

17 C1023 HSCH 3/8”-16 UNC x 1” 2

20 SC10SS000 SHAFT SLEEVE SHORT 2

1

2

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 30 of 46

Page 31

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 16 (Seat Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the seat assembly to the center

linkage arm using the identied hardware.

13

1

Item Part Number Description Quantity

1 SC10CA000X SEAT CARRIAGE

1

ASSEMBLY

2 C 658 FLAT HEAD HEX CAP

4

SCREW 3/8”-16 UNC x 1”

13 SC10PD200 KNEE PAD 1

2

2

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

2

2

Page # 31 of 46

Page 32

ASSEMBLY STEPS:

Step 17 (End Caps):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Secure the end caps to the main frame

rails using the identied hardware.

Item Part Number Description Quantity

1 C1017 FLAT HEAD SOCKET

SCREW #10-24 UNC x 1/2”

2 SC00CP000 END CAP 2

4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 32 of 46

Page 33

ASSEMBLY STEPS:

Step 18 (Back Linkage Brace):

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 2: ASSEMBLY GUIDE

Insert the back linkage brace into the

pull arm assembly as shown below and

secure as shown using the identied

hardware .

Item Part Number Description Quantity

19 SC10MF500X BACK LINKAGE BRACE 1

20 SC10CP100 LOCKING CAP 2

21 SC10SH000 STAINLESS STEEL SHAFT

120 mm

22 C1012 SH SCREW 3/8”-16 x 2-3/8” 2

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 33 of 46

Page 34

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 19 (Weight Arm Assembly):

Strength (Composite)

Ab Crunch-Back Row

Secure the weight arm to the identied

items as shown below.

Item Part Number Description Quantity

1 SC10BR003 FLANGE BEARING 2

2 SC10MF300X WEIGHT ARM

ASSEMBLY

1

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 34 of 46

Page 35

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 20 (Weight Arm Assembly [Cont.]):

Strength (Composite)

Ab Crunch-Back Row

Secure the weight arm assembly to

the frame brace assembly using the

identied hardware.

Item Part Number Description Quantity

1 C 754C 3/8” SAE WASHER ZINC 8

5 SC10MF200X FRAME BRACE ASSEMBLY 1

13 C1024 NUT CAP 3/8”-16 UNC x

11.5”

14 C 625 3/8”-16 x 1-1/2” SHCS ZINC 4

4

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 35 of 46

Page 36

CHAPTER 2: ASSEMBLY GUIDE

ASSEMBLY STEPS:

Step 21 (Counterweight & Weight Horn):

Strength (Composite)

Ab Crunch-Back Row

Secure the counterweight and weight

horn to the weight arm assembly using

the identied hardware.

Item Part Number Description Quantity

15 SC10WH000 WEIGHT HORN 1

16 CW35 COUNTER WEIGHT 35 lbs. 1

17 C 754C 3/8” SAE WASHER ZINC 2

18 C 622 3/8”-16 x 3/4” SHCS ZINC 2

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 36 of 46

Page 37

CHAPTER 3: CARE & MAINTENANCE

CHAPTER 4: CARE & MAINTENANCE

CARE & MAINTENANCE:

Preventative maintenance is

written

these products.

follow

IMPORTANT

specifically

warranty.

DAIL

The following items are critical to the safety of users and maintenance staff as well as ensuring the optimum performance

of

not r

WEEKL

The followin

of

scheduling regular maintenance or inspections.

Strength (Composite)

Ab Crunch-Back Row

CARE & MAINTENANCE:

DAILY INSPECTION & MAINTENANCE:

the machines. These inspections should be performed each day before the equipment is subject to use. TRUE Fitness is

esponsible for performing or scheduling regular maintenance or inspections.

• Inspect cables for wear, tension, and proper connection (as described in the cable inspection section below) if equipped.

• Inspect all adjustment pins, weight stack pins, set screws, gas shocks, snap links, and pulleys if equipped.

• Inspect all safety and instructional decals.

• Inspect all weight stack shields if equipped.

• Verify that rubber hand grips are intact and secure.

• Verify that anti-skid foot grips are intact and secure

• Verify that the weight stack selector pin is attached with the coiled lanyard to the top plate if equipped.

crucial to maintaining the function and safety of this equipment. Your facility must establish

guidelines for preventative maintenance and keep written or online records of the maintenance performed on

As a minimum, the items presented in the Safety Instructions section of this document and the items that

here, should be included in your maintenance program.

: Always purchase replacement parts from TRUE Fitness. Many parts are tested and manufactured

for TRUE Fitness equipment. Use of unapproved parts may cause serious injury and/or void the limited

Y INSPECTION & MAINTENANCE:

WEEKLY INSPECTION & MAINTENANCE:

the machines. These inspections should be performed each week. TRUE Fitness is not responsible for performing or

• Check entire length of cable & end fittings for any signs of wear if equipped. Replace immediately as required. (Refer

to Daily Maintenance Section).

• Verify that a minimum of 1/2 inch (12.7mm) of the threaded portion of the cable bolt is threaded into the top plate

and that the nut is tight if equipped with a cable. (See Cable Inspection & Maintenance Section).

• Perform a function test by placing the selector pin in the top plate and cycling the machine through the intended

motion if equipped with a cable. Verify that the machine operates smoothly without binding. Select a moderate weight

and repeat.

• Verify that each pulley rotates freely when performing the exercise if equipped with pulleys. A pulley that does not

rotate will cause extreme cable wear and could lead to cable failure. Determine cause and remedy immediately.

• Verify that the adjustment pop pins retract easily and fully engage (when released) into each adjustment disc hole/slot.

The pop pins are spring loaded so they should return to the engaged position when you release the knob.

• Verify that the adjustment pin disengages and engages freely when actuating the adjustment mechanism. Be sure that

the adjustment pin inserts fully into the adjustment disc.

• Verify that all hardware is tight and that associated frame members are secure. Apply a few small drops of a thread

locking compound such as Loctite on any loose bolts.

• Inspect frame for integrity and function. Replace any components at the first sign of wear with only TRUE

parts.

Y INSPECTION & MAINTENANCE:

g items are critical to the safety of users and maintenance staff as well as ensuring the optimum performance

supplied

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 37 of 46

Page 38

CHAPTER 3: CARE & MAINTENANCE

CHAPTER 4: CARE & MAINTENANCE

OTHER SCHEDULED PREVENTIVE MAINTENANCE:

to dry completely before using.

Strength (Composite)

Ab Crunch-Back Row

OTHER SCHEDULED PREVENTIVE MAINTENANCE:

TRUE recommends that scheduled maintenance be performed by a qualified service technician. Please contact your

dealer or visit www.truefitness.com to contact a local TRUE authorized service technician.

Monthly:

Clean guide rods and lubricate with a Teflon grease if equipped with guide rods.

Every 6 months:

Lubricate pivot bearing and linear bearings with lithium grease.

CLEANING THE EQUIPMENT:

CLEANING THE EQUIPMENT:

Daily Cleaning:

Wipe all machines with a water dampened cloth and dry completely. This includes painted parts, chrome plated parts

(except guide rods), plastic parts, and upholstered pads. It is important not to leave parts damp. This will increase the

potential for corrosion to occur.

CAUTION:

Certain anti-bacterial cleaners and other harsh cleaning agents can induce corrosion on the machine components. These

solutions can also dry out and cause cracking and splitting on the upholstery.

Heavy Duty Cleaning:

Guide Rods (If Equipped): Clean and lubricate with a Teflon Spray. Be sure to coat the entire guide rod. Spraying

lubricant into the cap plate bushings is also recommended.

Chromed Adjustment Tubes: Wipe away dust and dirt before applying a Teflon spray lubricant. TRUE Fitness

recommends using TriFlow or a similar brand.

Linear Bearings: Clean the linear shaft and lubricate (as required) with Teflon based grease. Keeping linear bearings clean

and lubricated is critical to long life and good performance.

Painted Frames: If you have scuff marks, grease or a heavy dirt buildup on frame components, start with a mild soap

solution or a diluted solution of a product such as Simple Green with a dilusion of 32:1. If you cannot remove the marks

using those methods, use a car polish/cleaner. DO NOT use solvents such as lacquer thinner, mineral spirits or acetone.

For deeper scuff marks, use an automobile finish rubbing compound.

Upholstery: For heavy duty cleaning, use a mild soap solution. This method should be sufficient in the majority of

instances. In severe stain cases, you can use a solution of 5-10% household bleach diluted with water. Be sure to test an

inconspicuous area first. DO NOT use chemical cleaners on the vinyl upholstery. You can also use a lanolin based hand

cleaner to clean your upholstery. Wipe off after cleaning with a damp cloth and thoroughly dry. Plastic Parts: use a mild

soap solution to clean dirt and grease marks. Labels: use a mild soap solution to clean dirt and grease marks. Shrouds: use

a mild soap solution to clean dirt and grease marks.

CAUTION:

Do not use any acidic cleaners. Doing so will weaken the paint or powder coatings and may void the TRUE Fitness

Warranty. Never pour or spray liquids on any part of the equipment. Allow the equipment

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 38 of 46

Page 39

Strength (Composite)

CHAPTER 4: CARE & MAINTENANCE

Twisted Cable (Zig-Zag pattern):

Break in the Cable Cover:

Break/Bend in Cable:

Tear in the Cable Cover:

Stretched Cable Covering:

Crimp Connector Dislodged:

Bad

Good

Ab Crunch-Back Row

CHAPTER 3: CARE & MAINTENANCE

CAUTION:

If you determine that the equipment needs service, make sure that the equipment cannot be used inadvertently and ensure

other users know that the machine needs service.

*To order parts or to contact a TRUE Authorized Service representative, please visit www.truefitness.com

CABLE INSPECTION & MAINTENANCE:

CABLE INSPECTION & MAINTENANCE:

One of the most critical areas that require frequent inspection on any weight machine is the cable or belt system that lifts

the weight stack if the machine is equipped with those items. Sudden failure of a worn cable can, in some instances, result

in injury to the user. It is the responsibility of the facility to inspect the cables frequently.

Cables are components that wear over time. This means that the more often a piece of equipment is used, the greater the

likelihood that cable wear will occur. This holds true for equipment made by any manufacturer and applies to urethane

belts as well as wire rope cables. Listed below are the areas of the cable that require inspection.

*TRUE Fitness recommends that all cables be replaced on an annual basis to maintain the safety of all users.

Cable Wear:

Inspect all cables for any signs of wear. Pay close attention to the cable in the area of the end fittings and attachment

points. Inspect the areas around the pulleys and/or cams. Shown below are examples of cables that exhibit signs of

potential failure. If any of these conditions are apparent, the machine should immediately be taken out of service and

repaired. Be sure to use only cables supplied by TRUE Fitness. DO NOT use cables that have fittings attached with hand-

tools.

crimp

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 39 of 46

Page 40

CHAPTER 3: CARE & MAINTENANCE

CHAPTER 4: CARE & MAINTENANCE

CABLE INSPECTION & MAINTENANCE (continued):

Cable Tension:

Cable Bolt

Cable Nut

Top Plate

Strength (Composite)

Ab Crunch-Back Row

Ensure that the cables are adjusted to remove any slack using the threaded end fittings. These are normally located at the

weight stack connection. Depending upon the machine, there may be multiple threaded fitting on multiple cables. You

can determine if there is too much slack by performing the exercise. As you start to move a load arm or handle, the weight

stack should lift immediately. If not, the cable tension needs to be adjusted.

To adjust the cable tension, loosen the cable nut

that is located on the cable bolt connected to the

top plate. Tighten the cable bolt until the top plate

is barely lifted off of the first weight plate and then

re-tighten the cable nut.

CAUTION:

A minimum of 1/2 inch (12.7mm) of the threaded

portion of the cable bolt must be threaded into the

top plate.

*No more than 1 inch (25.4 mm) of the threaded

portion of the cable bolt should be visible.

Handle Fittings (if applicable):

Inspect the cable fittings where any handles are

attached to the end of the cable. The fittings supplied

with this machine are load rated snap-links. Ensure

that the snap-link opens and closes easily and is fully

engaged when closed. Replace the snap-link as

needed.

1” (25.4 mm)

Maximum

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 40 of 46

Page 41

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 4: CUSTOMER SERVICE

CONTACTING SERVICE:

TRUE Fitness recommends that you gather the serial number, model number, and a brief description of the

reason for the request. Aer information has been gathered you may choose to contact your selling dealer or

local service company to set an appointment. (If you are not familiar with who is in your area, you may visit

our website at www.truetness.com and use our dealer locator to obtain the contact information for the closest

dealer).

You may also contact TRUE Fitness’ customer support team by calling 800-883-8783 or emailing us at service@

truetness.com Monday — Friday during normal hours of operation.

TRUE FITNESS SERVICE DEPARTMENT

865 HOFF ROAD

ST. LOUIS, MO 63366

1.800.883.8783

HOURS OF OPERATION: 8:30 A.M. - 5:00 P.M. CST

E-MAIL: service@truetness.com

CONTACTING SALES:

Interested in TRUE products? Please contact us with any sales or product inquires so that we may direct you to

the appropriate sales representative to answer your questions.

TRUE FITNESS HOME OFFICE

865 HOFF ROAD

ST. LOUIS, MO 63366

1.800.426.6570

HOURS OF OPERATION: 8:30 A.M. - 5:00 P.M. CST

E-MAIL: sales@truetness.com

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 41 of 46

Page 42

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 4: CUSTOMER SERVICE

REPORTING FREIGHT OR PARTS DAMAGE:

Unfortunately, sometimes materials can be damaged during shipment. If materials are damaged during

shipment, please follow the guidelines below to determine the appropriate process for you to follow in case of

damages.

Severe Damage:

Obvious damage to external packaging / internal product. Please refuse the shipment and it will be returned to

TRUE Fitness by the carrier. Contact the TRUE Fitness customer support team by calling 800.883.8783 or sales

support team by calling 800.426.6570 Monday-Friday during normal hours of operation to notify us that the

shipment has been refused. Once we have received the damaged shipment, a replacement shipment will be sent

to you. Only refuse the damaged piece if the shipment is multiple boxes.

Slight Damage:

e box may have minimal damages and you are not sure if the actual product is damaged or not. You must

sign the bill of lading as damaged when accepting the shipment. Once you have opened the box and you have

determined something is indeed damaged please gather the serial number, model number, description and

photos of damages. Please make sure the photos include the damaged product as well as the damaged box the

product arrived in. Contact the TRUE Fitness customer support team by calling 800.883.8783 or sales support

team by calling 800.426.6570 Monday-Friday during normal hours of operation.

Concealed Damage:

You may receive a shipment that looks intact and discover once the box has been opened that there are hidden

damages. Please notify the carrier immediately. We will not be able to le a claim if the carrier is not notied

in a timely manner. Once you have called the carrier you will need to gather the serial number, model number,

description and photos of damages. Contact the TRUE Fitness customer support team by calling 800.883.8783 or

sales support team by calling 800.426.6570 Monday-Friday during normal hours of operation.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 42 of 46

Page 43

Strength (Composite)

Ab Crunch-Back Row

AB CRUNCH/

BACK ROW

CHAPTER 5: ADDITIONAL INFORMATION

AB CRUNCH/BACK ROW

Composite Motion® Technology provides the integration of functional exercises using controlled

movement patterns for a safer and more effective workout experience. The Ab Crunch/Back

Row combines the benefits of core conditioning with the simultaneous knee raise and back

row exercises. An easily adjustable, multi-position starting point allows this machine to

accommodate a wide range of users varying in size and flexibility levels. The multi-grip

handle bars provide added user stability during exercise and allow users to find the most

comfortable position for precise exercise execution.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 43 of 46

Page 44

Strength (Composite)

Warranties outside the U.S. and Canada may vary - Please contact your dealer for details. Specications subject to change without notice.

COMPOSITE STRENGTH AB CRUNCH / BACK ROW

• Safer and more eective method of functional training for users of all ability levels

• Incorporates both upper and lower body exercises for a more ecient workout

• Swiveling shin pad unlocks to incorporate oblique muscles for added results

• Enables users to burn more calories and strengthen more muscle groups in less workout time

Light starting weights and heavy load capacities accommodates all ability levels.

CHAPTER 5: ADDITIONAL INFORMATION

Ab Crunch-Back Row

Product Dimensions

85” L x 31” W x 61” H / 216 cm x 79 cm x 155 cm

Product Weight

557 lbs / 253 kg

Warranty

TEN YEAR WARRANTY COMMERCIAL PRODUCTS – Frame Components and Welds excluding Coatings

FIVE YEAR WARRANTY - Bushings, Sealed Rotating Bearings, Pulleys, Weight Plates and Guide Rods excluding Coatings

ONE YEAR WARRANTY - Cables, Linear Bearings and Shafts and all other components not mentioned elsewhere in this warranty

90-DAY WARRANTY - Normal wear parts including but not limited to Labels, Upholstered Pads and Grips

ONE YEAR WARRANTY – Labor

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

truefitness.com | 800.426.6570 | 636.272.7100 ©2017 True Fitness Technology, Inc

Page # 44 of 46

COMPOSITE1601

Page 45

CHAPTER 5: ADDITIONAL INFORMATION

Save Time and Register Online!

Activate Multiple Warranties at truetness.com

Strength (Composite)

Ab Crunch-Back Row

All TRUE® Fitness products are distributed by TRUE and are

warranted to the original registered product purchaser and the

parts of the TRUE product (the “Product”) listed below, under

normal use and service, shall be free of manufacturing defects

in workmanship and materials only for the period of time

beginning from the original date of purchase set forth below:

Frame* 10 Years

Parts

Bearings, Bushings, and Weight Plates

Guide Rods and Pulleys

Cables and Belts

Cosmetics, Coatings, Grips, and Upholstery

Labor

Frame

Bearings, Bushings, Weight Plates

Guide Rods and Pulleys

Cables and Belts

Cosmetics, Coatings, Grips, and Upholstery

NOTE: Warranty valid for USA and Canada only.

NOTE: Failure to register this product will result in no

servicing or authorization of parts to be shipped.

NOTE: Buying after-market products from a 3rd party will

result in voided warranty.

NOTE: This product is intended for Commercial use. If this

product will not be used in this particular setting, please

contact TRUE as is warranty is void.

Frame: The frame is warranted for defects in material and

workmanship for a 10 years. The frame is warranted for labor

and freight (for parts shipped from TRUE) for one year from

date of purchase. * This limited warranty on structural frame

does not include paint or coatings.

5 Years

5 Years

1 Year

3 Months

1 Year

1 Year

1 Year

1 Year

6 Months

Cosmetics: The Composite Strength Line cosmetic parts,

coatings, grips and upholstery are warranted for defects in

material and workmanship for six months with labor warranty

to match the parts warranty period. This limited warranty

does not cover damage or equipment failure resulting from

or caused by improper assembly/installation, failure to follow

instructions and warnings in owner’s manual, accident,

misuse, abuse, unauthorized modication, or failure to provide

reasonable and necessary maintenance. This limited warranty

will apply to, but may not be limited to, plastic covers, shrouds,

caps, badges, overlays, paint, coatings, soft step inserts, and

grips.

Labor: Labor is covered for a period of one year from the

date of purchase unless otherwise expressed within this

limited warranty as long as a TRUE authorized service provider

performs the service. Service that requires over 50 miles of

travel may be subject to additional charges. Reasonable and

necessary maintenance guidelines can be found in the owner’s

manual.

Claims Procedure: TRUE Limited Warranty service may be

obtained by contacting the authorized TRUE dealer from

whom the Product was purchased. If the dealer from whom

the Product was purchased is no longer an authorized TRUE

dealer, then TRUE Limited Warranty service may be obtained

by contacting TRUE directly using the following contact

information:

TRUE Fitness, Service Department

865 Ho Road, St. Louis, MO 63366

1.800.883.8783

Hours of operation 8:30am - 5:00 pm CST

Parts: The Composite Strength Line’s mechanical parts are

warranted for defects in material and workmanship for ve

years with one year labor warranty. Cables and belts are

warranted for defects in material and workmanship for one

year with one year labor warranty.This limited warranty does

not cover damage or equipment failure resulting from or

caused by improper assembly/installation, failure to follow

instructions and warnings in owner’s manual, accident,

misuse, abuse, unauthorized modication, or failure to provide

reasonable and necessary maintenance.

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 45 of 46

Page 46

CHAPTER 5: ADDITIONAL INFORMATION

Save Time and Register Online!

Activate Multiple Warranties at truetness.com

Strength (Composite)

Ab Crunch-Back Row

The above Limited Warranty is subject to and will be in

accordance with the conditions set forth below:

1. THIS LIMITED WARRANTY GIVES YOU SPECIAL LEGAL

RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH

VARY FROM STATE TO STATE.

2. This Limited Warranty can be processed only if the Warranty

Registration Form is completed online, or if the attached form

is lled in, signed by the original purchaser, and mailed to

TRUE within 30 days of purchaser’s receipt of this Product. The

serial number must be intact on the Product for this Limited

Warranty to be valid.

3. This Limited Warranty applies to the product only while the

Product remains in the possession of the original purchaser

and is not transferable

4. This Limited Warranty becomes VALID ONLY if the Product

is initially assembled/installed by a TRUE authorized dealer/

technician (if anyone other than a TRUE authorized dealer/

technician initially assembles and installs the Product, this

Limited Warranty will be void unless the written authorization

of TRUE is rst obtained).

5. This Limited Warranty does not cover damage or equipment

failure resulting from or caused by improper assembly/

installation, failure to follow instructions and warnings in

owner’s manual, accident, misuse, abuse, unauthorized

modication, or failure to provide reasonable and necessary

maintenance (as referenced in thw owner’s manual.)

6. This Limited Warranty applies only to the cost of repair or

replacement of parts and does not include labor (beyond

the above warranty period), transportation, service, return

and freight charges associated therewith except as expressly

specied herein.

7. This Limited Warranty shall not apply to: Service calls to

correct installation of the equipment or instruction to owners

on how to use the equipment; or any labor costs incurred

beyond the applicable labor warranty period.

8. This Limited Warranty, which is given expressely and in lieu

of all other express warranties, constitutes the only warranty

made by TRUE.

9. ANY IMPLIED WARRANTY, INCLUDING WITHOUT

LIMITATION THE WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, IS LIMITED IN

DURATION AND REMEDY TO THE TIME PERIOD COVERED

BY THE LIMITED WARRANTY. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

10. THE REMEDIES DESCRIBED ABOVE ARE YOUR SOLE

AND EXCLUSIVE REMEDIES AND TRUE’S ENTIRE LIABILITY

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

FOR ANY BREACH OF THIS LIMITED WARRANTY. TRUE’S

LIABILITY SHALL UNDER NO CIRCUMSTANCES EXCEED

THE ACTUAL AMOUNT PAID BY YOU FOR THE PRODUCT,

NOR SHALL TRUE UNDER ANY CIRC UMSTANCES BE LIABLE

FOR ANY CONSEQUENTIAL, INCIDENTIAL, SPECIAL, OR

PUNITIVE DAMAGES OR LOSSES, WHETHER DIRECT OR

INDIRECT. SOME STATES DO NOT ALLOW THE EXCLUSION

OR LIMITATION OF INCIDNETIAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU.

NOTE TO AUTHORIZED WARRANTY LABOR PROVIDERS:

Warranty labor reimbursement or warranty parts rights may

not be transferred to, reassigned to, a third party without the

express written consent of TRUE. Even jobbing out warranty

labor requires TRUE’s written approval.

COMPOSITE STRENGTH LINE SERIAL NUMBER:

The Composite SC-1010 comes with one serial number on the

base of the machine. Please write down your serial number

below and keep for your records.

SERIAL NUMBER:

SAMPLE SERIAL NUMBER STICKER:

Keep this page for your records

Page # 46 of 46

Page 47

Strength (Composite)

Ab Crunch-Back Row

CHAPTER 5: ADDITIONAL INFORMATION

Thank you for purchasing a TRUE product. To validate the TRUE product warranty the fast and easy way,

please go on-line now to truetness.com/support and register your product. The information you provide will

never be distributed to any other individuals or agencies for any purpose. If you prefer to mail your warranty

card, have the owner of the product complete the information below and return it to TRUE Fitness within 30

days from the date of equipment installation.

To mail your warranty information, please ll in the information below and mail to: Service Dept., TRUE Fitness,

865 Ho Road, St. Louis, MO 63366 (or save postage and register online at truetness.com)

Commercial Warranty Registration

PLEASE PROVIDE YOUR SERIAL NUMBER BELOW.

REQUIRED FOR WARRANTY REGISTRATION:

SERIAL NUMBER:

Model Type

Date of Purchase

Your Company Name

Contact First Name

Contact Last Name

Address

City State ZIP

Email Address Website

Phone Fax

1. Where did you rst learn about TRUE?

___ a. Dealer ____ b. Website

____ c. Advertisement ____ d. Referral

____ e. Current Customer ____ f. Other_______________

2. Why did you purchase a TRUE product?

___ a. Design/Appearance ___ b. Dealer Suggestion

___ c. Price/Value ___ d. Quality Construction

___ e. Performance ___ f. TRUE Reputation

___ g. Other_________________________

3. Please indicate your type of facility:

___ a. Apartment/Condo ___ b. Corporate Fitness Center

___ c. Municipality ___ d. Health Club/Gym/Spa

___ e. Hotel/Resort ___ f. Military Base

___ g. Student Rec Center ___ h. Other

4. What other types of equipment does your company ly own?

___ a. Treadmill Brand ________________

___ b. Bike Brand ________________

___ c. Elliptical Brand ________________

___ d. Free Weights/Gym Brand ________________

5. How many people use your facility on a daily basis?

___ a. <25 ___ b. 25-75

___ c. 76-150 ___ d. 150+

6. Do you plan to purchase more tness equipment

in the next 6-12 months?

____ Yes ____ No

7. If you answered “yes” to question 6, what type do you

plan to purchase?

____ a. Treadmill ____ b. Elliptical

____ c. Stationary Bike ____ d. Free Weights

____ e. Gym ____ f. Other ______________

8. Would you recommend TRUE to other club owners?

____ Yes ____ No

9. You are a valued TRUE customer and your suggestions

allow us to continually improve your experience. Is there

anything else you would like us to know? Please explain:

True Fitness Technology • O’Fallon, MO • Phone: 800-426-6570/636-272-7100 • Truetness.com

Page # 47 of 46

Loading...

Loading...