True 15 Series, Professional 15 Series Installation Manual

15 Series Installation Guide

ALL REFRIGERATOR

WINE CABINET

BEVERAGE DISPENSER

Thank You

For

Your Purchase

Thank you for purchasing your new True Professional Series unit. For over

65 years, True® has been a leader in commercial refrigeration. No other

refrigeration company has the reputation for being the industry’s best when

it comes to superior quality and service. And while our reputation for quality

reaches across the globe, all of our products are proudly made in the USA.

Respected by the culinary world, True’s unmatched performance is proven

—Our products are carried in some of the most prestigious restaurants and

hotels around the world.

And now, we are pleased to bring this performance to you —crafting products

for your home of the same quality that the world’s best chefs demand in their

kitchens.

This guide will answer most of your questions about the installation of your True

Professional unit. If you have questions that are not answered here, contact

True customer service at 800-325-6152 or info@true-residential.com. Or you

may also visit our website at true-residential.com.

67 Y E AR S of TRUE INNOVATION, EXPERTISE and PERFORMANCE.

WWW.TRUE-RESIDENTIAL.COM

True Professional 15 Series

ALL REFRIGERATOR

(Overlay Panel)

TUR-15-R/L-OP-A

TUR-15-R/L-OG-A

WINE CABINET

(Overlay Panel)

BEVERAGE DISPENSER

(Overlay Panel)

TWC-15-R/L-OP-A

TWC-15-R/L-OG-A

TUR-15BD-R/L-OP-A

Solid Panel Ready

(OP)

Glass Framed Panel Ready

(OG)

www.true-residential.com

15 Series

ALL REFRIGERATOR

TUR-15-R/L-SS-A

TUR-15-R/L-SG-A

WINE CABINET

TWC-15-R/L-SG-A

BEVERAGE DISPENSER

TUR-15BD-R/L-SS-A

Stainless Solid Door

(SS)

Stainless Glass Door

(SG)

15 Series Installation Guide

INDEX

Ownership 1

Safety Precautions 1

Disposal of Old Refrigerator 1

CFC Disposal 1

Uncrating 2

Electrical Specications 3

Leveling Refrigerator 4

Installing Anti-Tip Brackets 5

Installing the Door Stop 6

Installation Specications 8-12

Installation Specications for 15 Series Solid Panel Ready (OP)

and Glass Framed Panel Ready (OG) 13-20

Installation Specications for Beverage Dispenser Units 23-30

Installation of Castors 31

15 Series Cabinet Components and

True Precision Control Operation 33-37

TM

Wine Shelving Adjustment 38

Stacking Kit Instructions 40-44

General Maintenance, Replacement Parts, Installation Checklist, FAQs and

Warranty 45

OWNERSHIP

To insure that your unit works properly from the

rst day, it must be installed properly. (We highly

recommend a trained refrigeration mechanic and

electrician install your True Professional Cabinet.) The

cost of a professional installation is money well spent.

Before you start to install your True Professional

Cabinet, carefully inspect it for freight damage. If

damage is discovered, immediately le a claim with

the delivery freight carrier. True is not responsible for

damage incurred during shipment.

Any questions about the installation please contact

your True dealer or True Technical Service Department

at 1-800-325-6152 (Please have your model and

serial numbers available when you call our Service

Department).

SAFETY PRECAUTIONS

• This refrigerator must be properly installed

and located in accordance with the installation

instructions before it is used.

NOTE: WE STRONGLY RECOMMEND THAT ANY

SERVICING BE PERFORMED BY A QUALIFIED

INDIVIDUAL

PROPER DISPOSAL OF THE OLD

REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous... even if they will sit for “just a few

days”. If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

Before You Throw Away Your Old Refrigerator or

Freezer:

• Take off the doors.

• Leave the shelves in place so that children may not

easily climb inside.

• Do not allow children to climb, stand or hang on

the shelves in the refrigerator. They could damage

the refrigerator and seriously injure themselves.

• Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

• Keep hands away from the “pinch point” areas

(gaps between the doors and between the doors

and cabinet) small areas are not necessarily safe.

• Unplug the refrigerator before cleaning and

making repairs.

NOTE: We strongly recommend that any

servicing be performed by a qualied individual.

• Setting temperature control to OFF only removes

power from the refrigeration system, it does not

remove power from other circuits. For example,

temperature control and lights.

DANGER!

RISK OF CHILDREN

ENTRAPMENT

CFC DISPOSAL

Your old refrigerator may have a cooling system that

used CFC’s (chlorouorocarbons). CFCs are believed

to harm stratospheric ozone. If you are throwing away

your old refrigerator, make sure the CFC refrigerant is

removed for proper disposal by a qualied service. If

you intentionally release this CFC refrigerant you can

be subject to nes and imprisonment under provisions

of the environment legislation.

True Professional 15 Series Installation Guide

1

UNCRATING

Tools Required:

• Cutting utensil (utility knife)

• Hammer

• Crowbar

• Phillips head screwdriver

The following procedure is recommended for

uncrating the unit:

MOVE YOUR UNIT AS CLOSE TO THE FINAL

LOCATION AS POSSIBLE BEFORE REMOVING

THE WOODEN SKID.

A. Remove nails securing cardboard box to the

wooden skid. Then discard any outer packaging

(cardboard, clear plastic).

A

Inspect for concealed damage. Again, immediately le

a claim with the freight carrier if there is damage.

B. IMPORTANT: Remove styrofoam block before

removing refrigerator from pallet.

C. Remove skid by carefully lifting the refrigerator off

and place skid aside.

D. Open the unit and remove any packing material.

Styrofoam, tape, and any other material used

for shipping purposes.

NOTE: KEYS FOR UNIT ARE PROVIDED WITH

THIS PACKET

B

C

2

True Professional 15 Series Installation Guide

packing material

Grill is attached to

D

back of unit

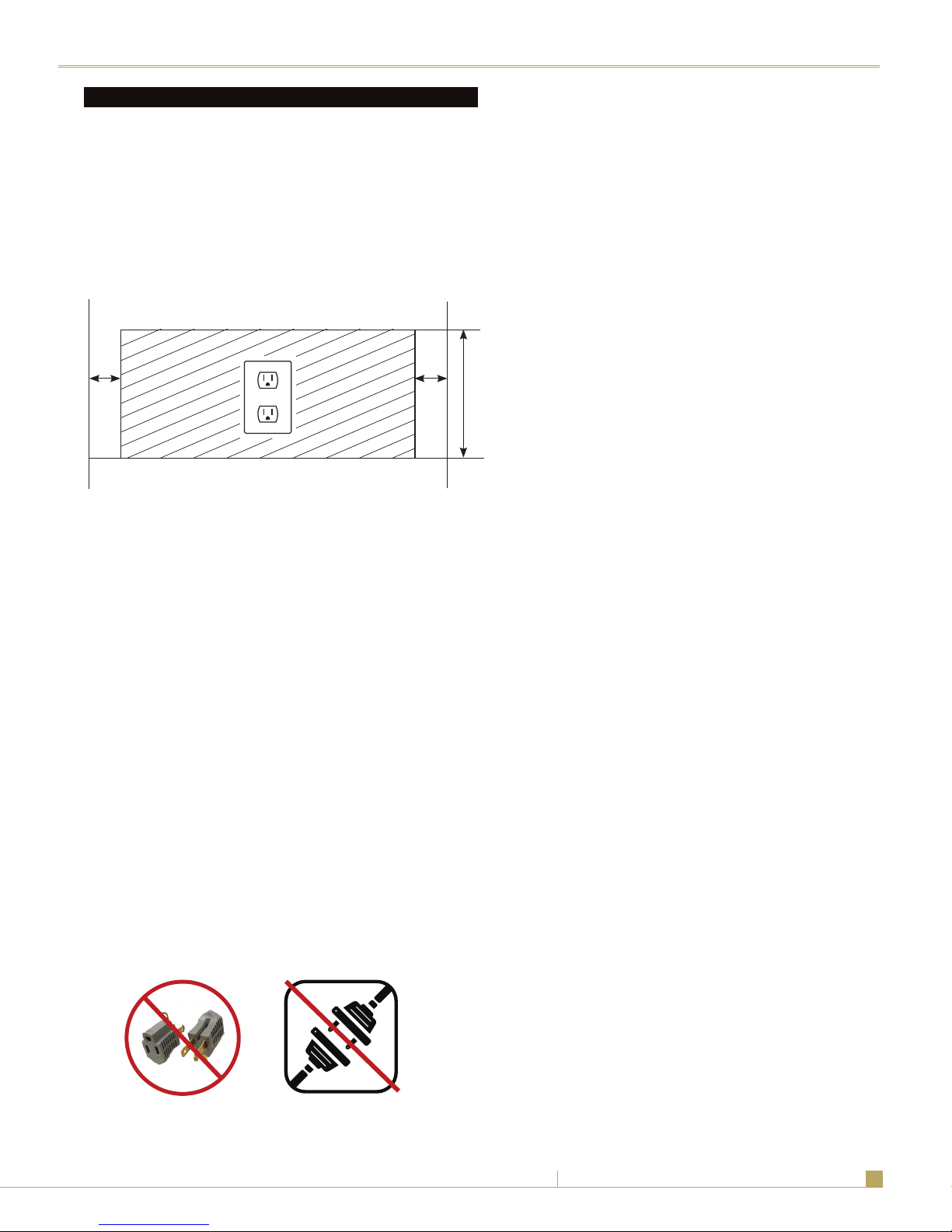

ELECTRICAL SPECIFICATIONS

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord. For personal

safety, this appliance must be properly grounded.

To minimize the depth of the cutout opening, the

electrical outlet must be positioned as shown below.

Outlet must be ush with wall.

Rear wall of cut out

2” 2” 8”

Before your new unit is connected to a power supply,

check the incoming voltage with a volt meter. If anything

less than 100% of the rated voltage for operation is

noted, correct immediately.

The unit should always be plugged into its own

individual electrical outlet, which has a voltage rating

that matches the rating plate. This provides the best

performance and also prevents overloading house

wiring circuits which could cause a re hazard from

overheated wires. Never unplug your refrigerator by

pulling on the power cord. Always grip plug rmly

and pull straight out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end. When moving the

refrigerator away from the wall, be careful not to roll

over or damage the power cord.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall outlet to minimize the

possibility of electric shock hazard from this appliance.

A 115V AC, 60 Hz, 15 amp circuit breaker and electrical

supply are required.

Have the wall outlet and circuit checked by a qualied

electrician to make sure the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your

personal responsibility and obligation to have it replaced

with the properly grounded 3 prong wall outlet.

Do not use an extension cord or two prong adaptor.

Electrical ground is required on this appliance.

True Professional 15 Series Installation Guide

3

LEVELING REFRIGERATOR

1. Set unit in its nal location. Be sure there is adequate ventilation in

your room.

2. Proper leveling of your True unit is critical to operating success

(for non-mobile models). Effective condensate removal and door

operation will be effected by leveling. Adjust leg levelers on the front

and back of the cabinet if it needs to be lowered or raised.

3. The unit should be leveled from the interior of the unit front to back

and side to side with a level. If the refrigerator is not level adjust the

stainless steel leg levelers. The leg levelers can be adjusted by turning

to reach the desired leveling height as shown in the illustration below.

4. Free plug and cord from back of cooler (do not plug in).

5. The unit should be placed close enough to the electrical supply so

that extension cords are never used.

6. Once installed in nal location, inser t toe kick by clipping in place.

WARNING: COMPRESSOR WARRANTIES ARE VOID IF

THE UNIT IS MORE THAN 7 FT. (2.1M) FROM PLUG-IN

CONNECTION OR IF AN EXTENSION CORD IS USED.

4

True Professional 15 Series Installation Guide

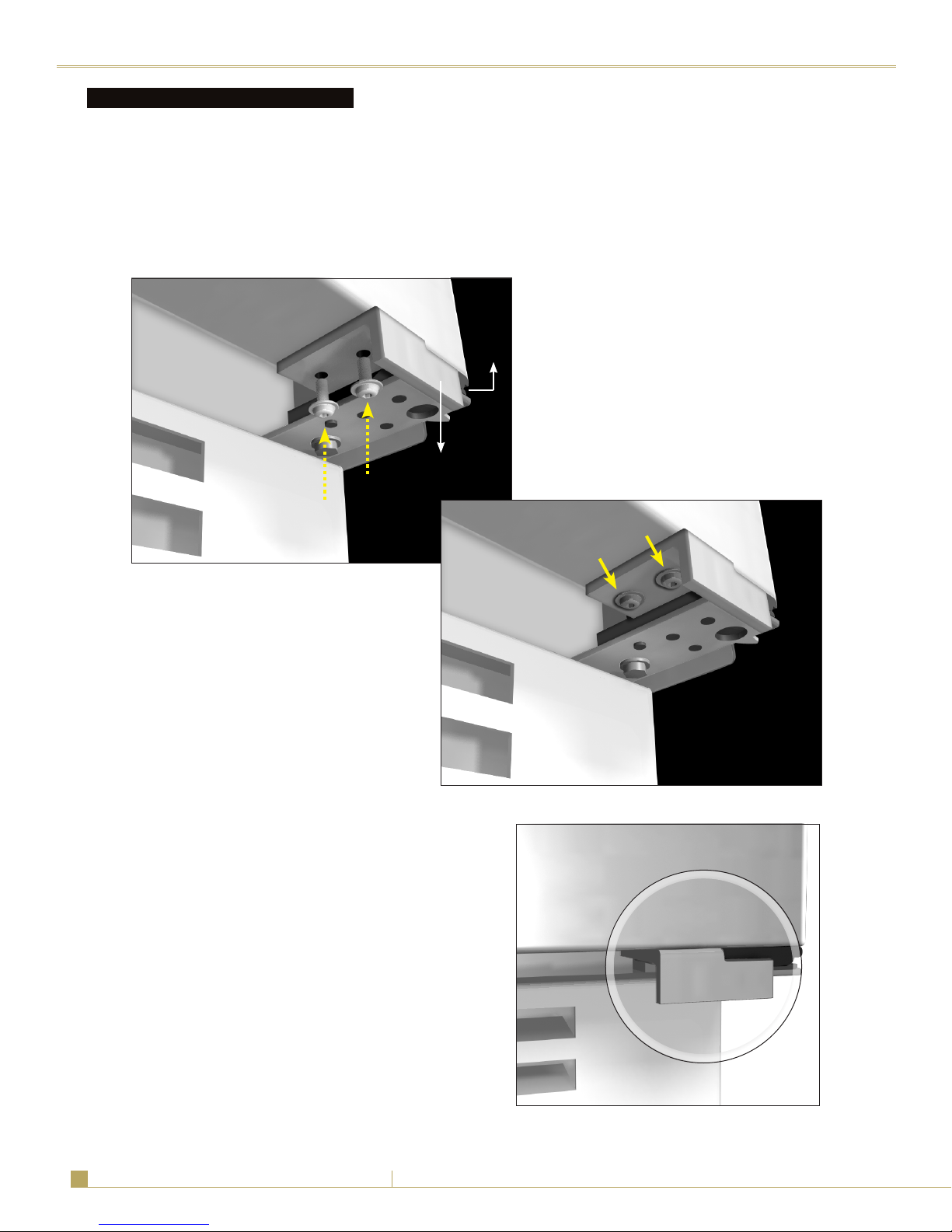

INSTALLING ANTI-TIP BRACKETS

ALL STACKED UNITS MUST HAVE THE ANTI-TIP BRACKETS INSTALLED.

TIP OVER HAZARD: A CHILD OR ADULT CAN TIP THE REFRIGERATOR

AND MAY CAUSE PROPERTY OR BODILY HARM.

To prevent this the anti-tip brackets need to be installed.

Reconnect the anti-tip bracket if the product is moved.

Failure to follow these instructions can result in property

or bodily harm.

Read all installation instructions rst. Install the anti-tip

brackets to hold both rear legs of the unit. Follow these

steps to secure the brackets to the oor before moving

the unit into nal operating position.

Contact a qualied oor covering installer for the best

procedure of drilling mounting holes through your type

of oor covering.

BEFORE MOVING UNIT TAKE PRECAUTIONS TO

PROTECT THE FLOOR COVERING.

A

ANTI-TIP BRACKET LOCATOR - TOP VIEW

27/32” 27/32”

Back of the unit

A. Determine the location of the unit. From the front

of the determined location of the lower louver grill

measure back 20

1/2

”. From the determined side of

the unit measure over 27/32”. This is where the back

and outer side of the bracket should sit. Using the

bracket as a template mark the holes for drilling.

B. To mount the anti-tip bracket to wood oor, drill

pilot holes for each of the bracket holes. To mount

the anti-tip bracket to concrete or ceramic oor

use a masonry bit to drill pilot holes. Align anti-tip

bracket holes with the holes in the oor. Fasten antitip bracket with screws provided using the brass

colored screw for wood, or blue colored masonry

screw for concrete.

C. Move unit into nal position making sure rear leveling

legs slide into the anti-tip brackets.

Overlay Panel

22 1/32”

22 25/32”

20 1/2”

13 3/16”

Cabinet Front

B

C

True Professional 15 Series Installation Guide

5

INSTALLING THE DOOR STOP

All units are provided with an optional door stop. When installed, the door stop will restrict the door from

opening past approximately 120º to prevent damage to surrounding cabinets. To install the door stop, use the

2 screws provided and secure the bracket to the bottom of the door on the same side as the hinge.

Hinge

Door stop

6

True Professional 15 Series Installation Guide

Cabinet door

Door stop

installed

Cabinet grill

NOTES

True Professional 15 Series

Installation Specifications

8

True Professional 15 Series Installation Guide

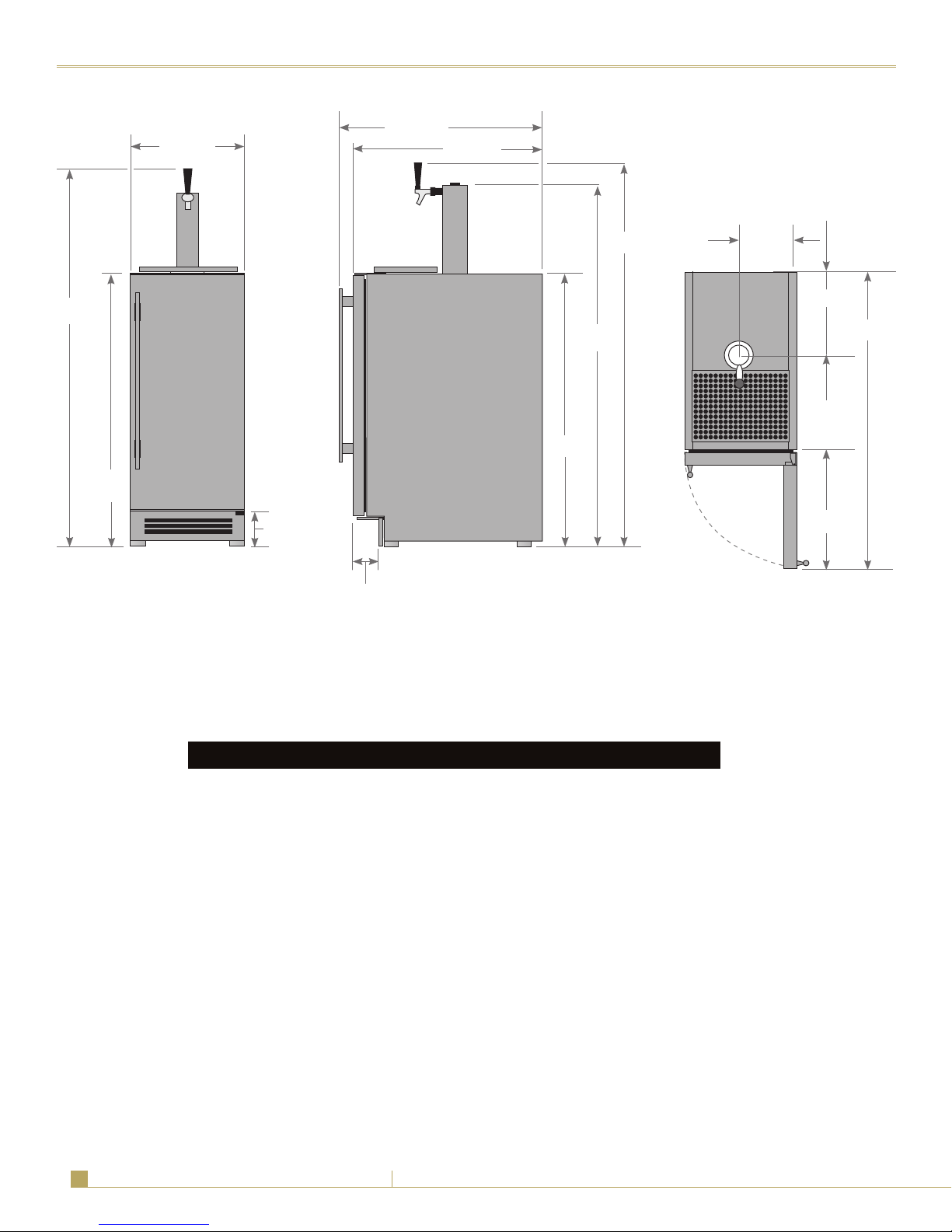

BEVERAGE

DISPENSER

INSTALLATION SPECIFICATIONS-STAINLESS SOLID & GLASS DOOR

ALL REFRIGERATOR

WINE CABINET

TUR-15-R/L-SS-A TUR-15-R/L-SG-A TWC-15-R/L-SG-A TUR-15BD-R/L-SS-A

7/8

”

FRONT

VIEW

1/8

4

”

29

3/4

”

3/4

3

”

Dimensions may vary by ± 1/8”

7/8

23

SIDE

VIEW

”14

34

1/4

TOP

VIEW

”

5/8

21

”

1/4

16

”

7/8

1

”

True Professional 15 Series Installation Guide

9

14 7/8"

25 3/4"

23 7/8"

49 7/8"

34 1/4"

FRONT

VIEW

4 1/8"

SIDE

VIEW

3 3/4"

Dimensions may vary by ± 1/8”

46 3/8"

34 1/4"

49 7/8"

TOP

VIEW

7 1/2"

10 1/4"

37 7/8"

16 1/4"

15” Single tap unit accommodates (1) slim 1/4 barrel or (1) 1/6 barrel.

10

True Professional 15 Series Installation Guide

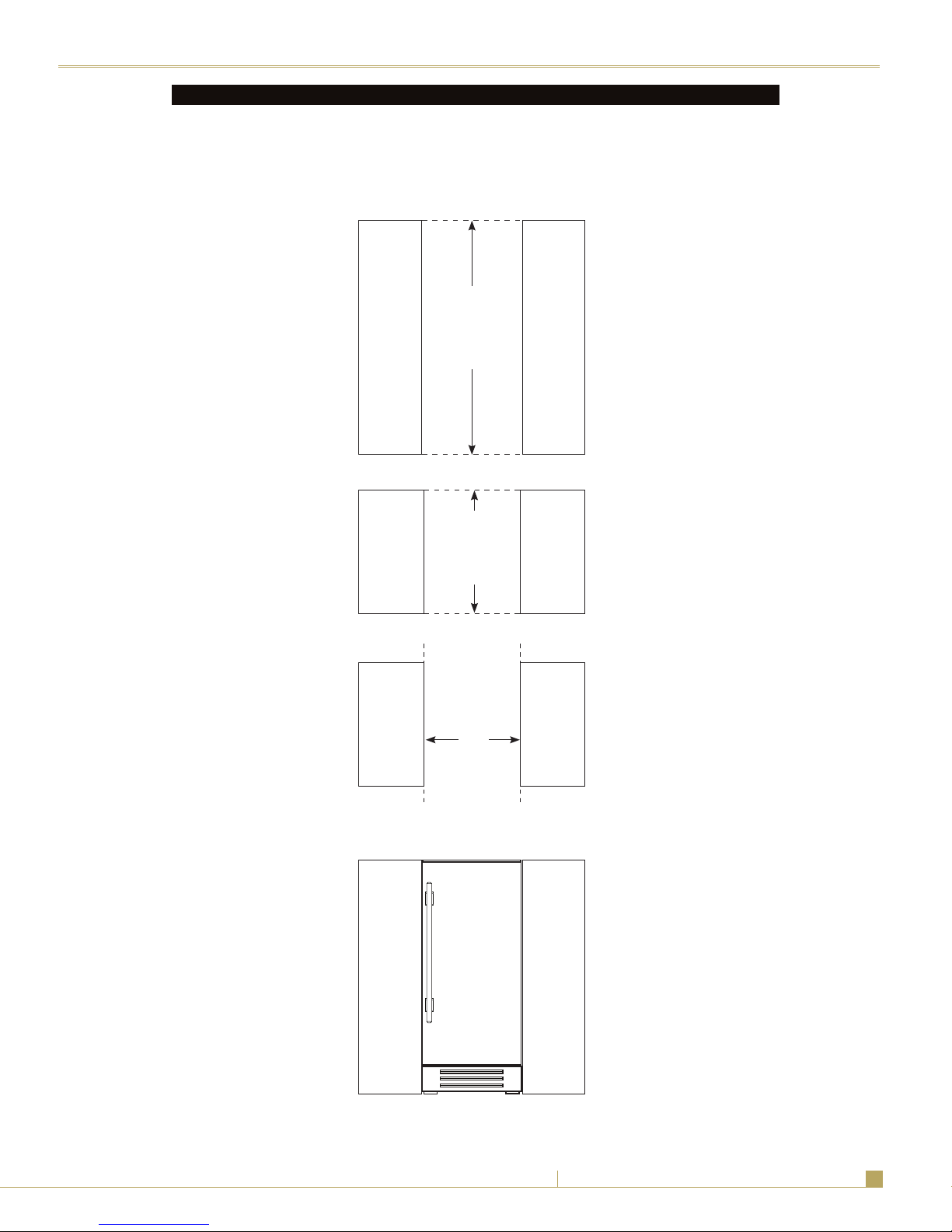

INSTALLATION SPECIFICATIONS-STAINLESS SOLID & GLASS DOOR

True’s Stainless Solid and Glass Door units are designed to be inserted into a cabinet

opening or free standing. Below are recommended dimensions for rough opening.

ROUGH

OPENING

HEIGHT

1/2

34

”

ROUGH

OPENING

DEPTH

24”

ROUGH

OPENING

WIDTH

15”

Front view

of unit

between

cabinets

True Professional 15 Series Installation Guide

11

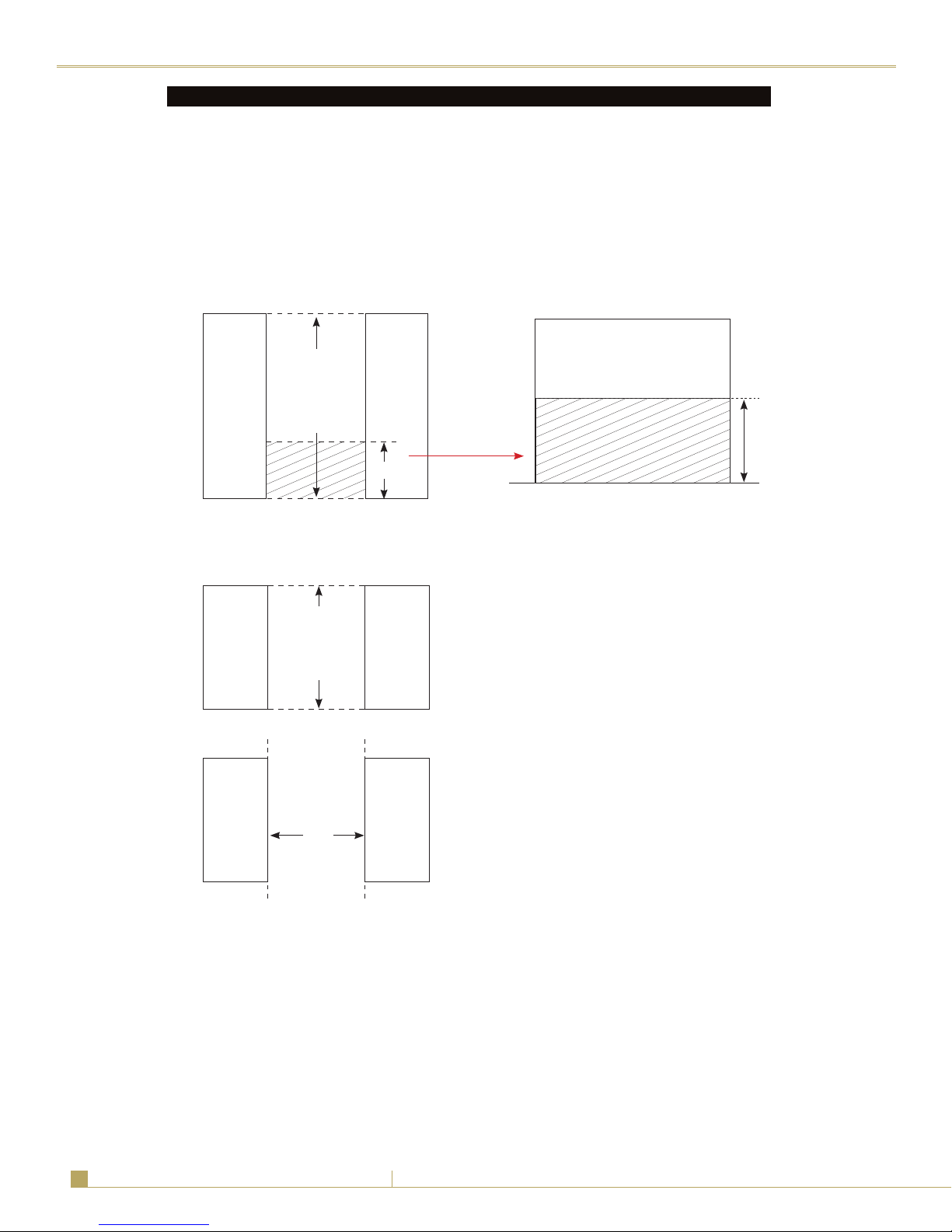

INSTALLATION SPECIFICATIONS - OUTDOOR

True’s stainless steel cabinets are UL rated for use in outdoor settings.

In outdoor locations where the ambient temperature regularly exceeds 95˚F, it is recommended

to vent the rear of the cut out opening in the area shown below for optimum performance. The

recommended cut out size is 4” x 10”.

ROUGH

OPENING

HEIGHT

1/2

34

”

8”

8”

ROUGH

OPENING

DEPTH

24”

ROUGH

OPENING

WIDTH

15”

1212

True Professional 15 Series Installation Guide

Loading...

Loading...