Page 1

INTRODUCTION

Thank you for buying the Horse Tiller Dozer/Snow Blade. This

blade is a versatile tool that helps to make your tiller an “all-season” machine. To ensure safe and proper installation of the

blade, please read and carefully follow all instructions.

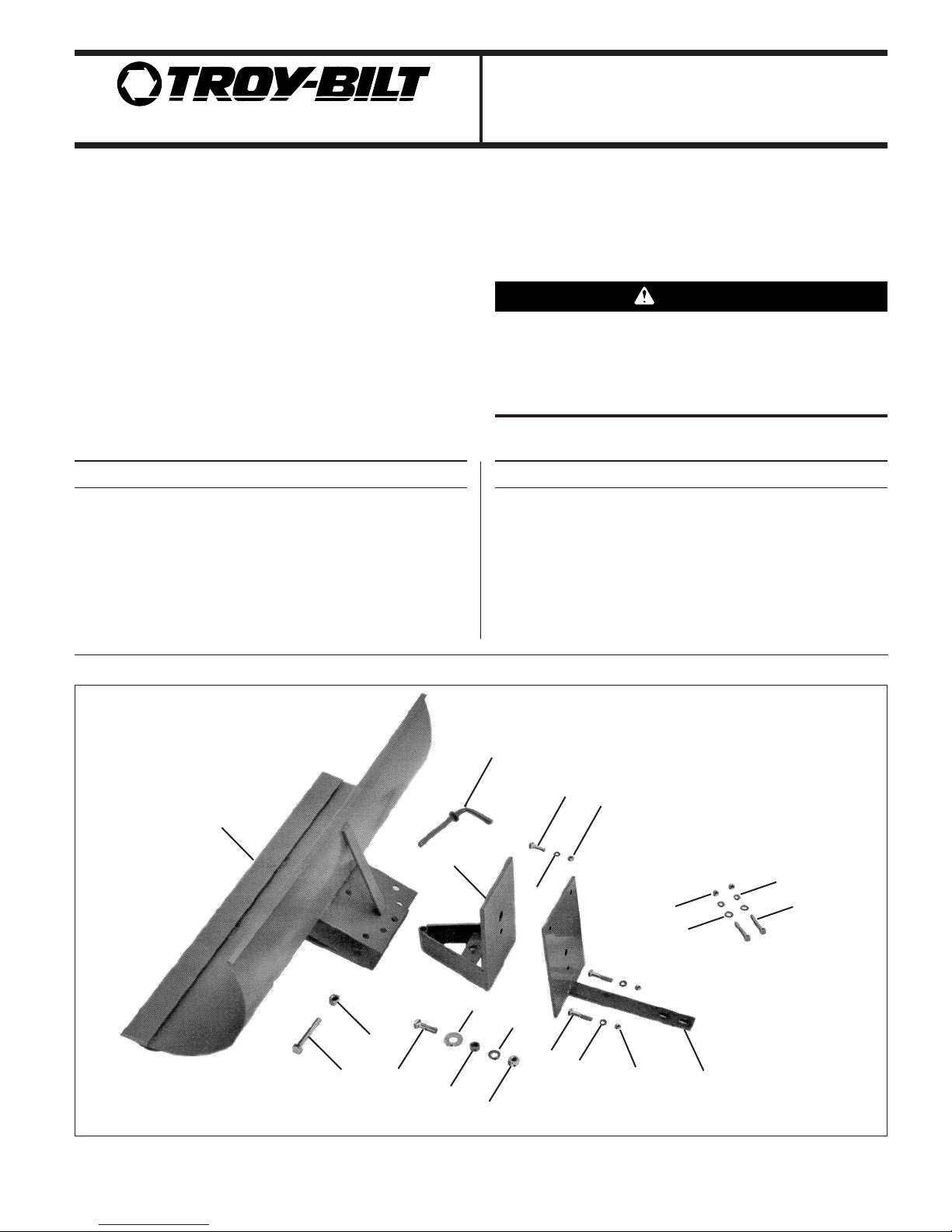

UNPACK AND CHECK PARTS

Check the contents of the shipping carton against the Parts List

below.

ASSEMBLY STEPS

NOTE: Your unit must have the Bumper/Guard attachment

(OEM-290-255/290-255-081) installed before installing the

Dozer/Snow Blade. Refer to the separate Bumper/Guard Attachment kit for installation instructions.

To prevent personal injury or property damage, do not

start the engine until all assembly steps are complete and

you have read and understand the safety and operating

instructions in this Instruction and in the tiller Owner’s

Manual.

Ref. Part No. Description Qty.

1 GW-1157 Dozer/Snow Blade. . . . . . . . . . . . . . . . 1

2 1909773 Swivel Bracket, (A-Frame) . . . . . . . . . 1

3 736-0921 Lockwasher, 1/2". . . . . . . . . . . . . . . . . 1

4 710-3181 Hex Head Bolt, 1/2--13 x 1-1/2, . . . . . 1

5 1909774 Blade Mounting Brack. . . . . . . . . . . . . 1

6 712-0267 Hex Head Nut, 5/16-18 . . . . . . . . . . . . 5

7 736-0119 Lockwasher, 5/16 . . . . . . . . . . . . . . . . 5

8 736-0275 Washer, Plain, 5/16. . . . . . . . . . . . . . . 2

Ref. Part No. Description Qty.

9 1100779 Hex Head Screw, 5/16-18 x 1-3/4. . . . 4

10 1186233 Hex Nut, 1/2". . . . . . . . . . . . . . . . . . . . 1

11 GW-1416 Bushing . . . . . . . . . . . . . . . . . . . . . . . 1

12 1100257 Flat Washer, 1/2". . . . . . . . . . . . . . . . . 1

13 710-0874 Hex Head Screw, 5/16-18 x 1-1/4. . . . 1

14 1100057 Hex Head Screw, 1/2-13 x 3 . . . . . . . . 1

15 712-0384 Hex Locknut, 1/2 x 13. . . . . . . . . . . . . 1

16 GW-1158 Index Pin. . . . . . . . . . . . . . . . . . . . . . . 1

Dozer/Snow Blade Attachment

Model 290-259-081 / OEM-290-259

HORSE TILLER

®

1

13

16

15

4

5

6

7

9

8

7

6

12

3

11

10

9

7

10

14

2

Figure 1: PARTS LIST

WARNING

Page 2

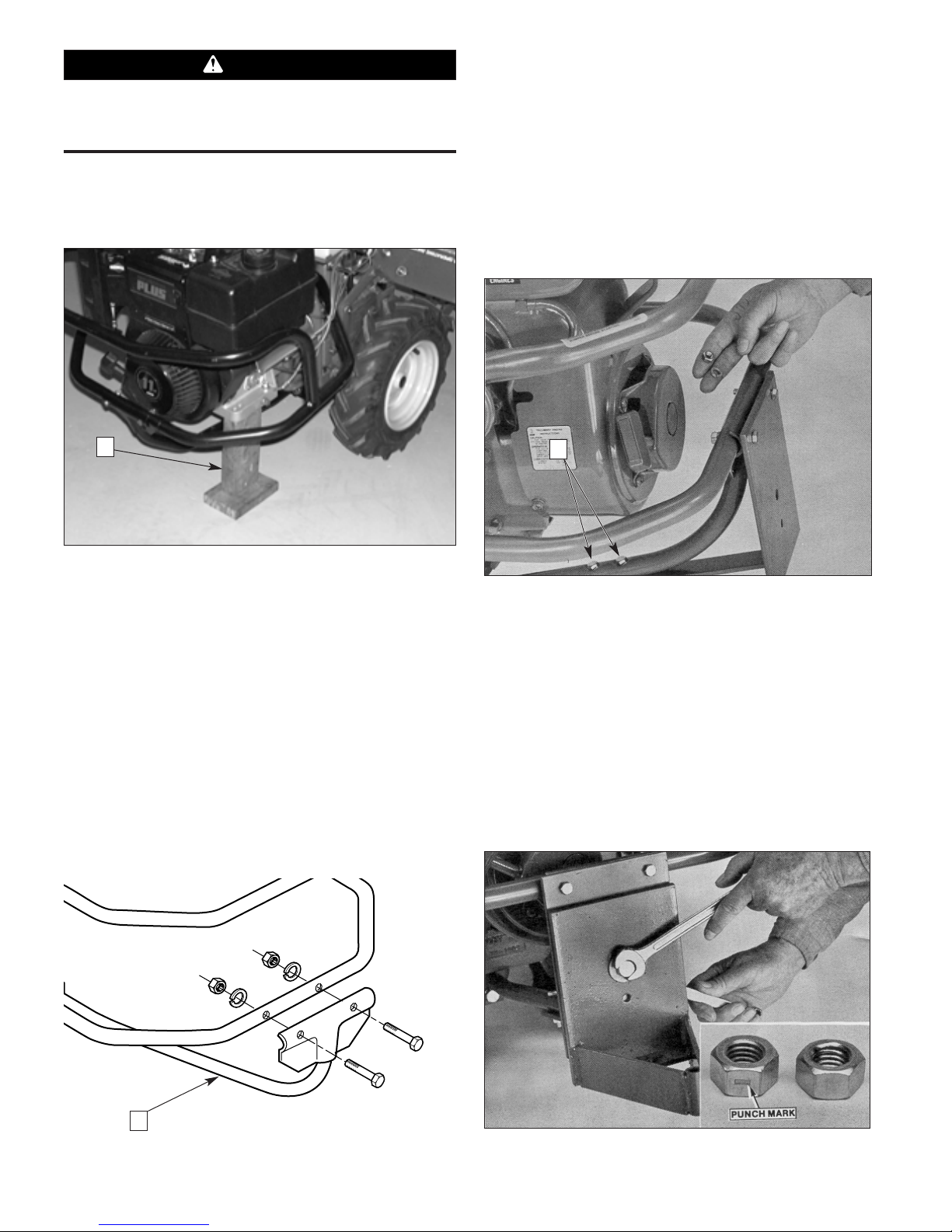

Step 1: Block the Tiller

Move the tiller to a level, hard surface. Place a block under the

engine (A, Figure 2) to prevent the tiller from tipping forward.

Step 2: Remove the Tines

Removing the tines has a functional purpose as well as a safety

purpose. Tine removal makes it possible to bank snow and dirt

because the rear of the tiller sets down further and the blade

can be raised higher off the ground.

Leave the tine holders on.

Their weight helps maintain tiller balance. Also, leave the drag

bar on–it prevents the bottom of the transmission from scraping the ground. Please refer to your Horse Tiller Operator’s

Manual for tine removal instructions.

Step 3: Install Blade Mounting Bracket

1. Remove and discard the two nuts, lock washers and 5/16"-18

x 1-1/2" screws which secure the bumper brace to the lower

bumper (B, Figure 3).

2. Using the hardware included in this attachment, install the

Blade Mounting Bracket (5, Figure 1) to the lower bumper

with two nuts (6, Figure 1), two lock washers (7, Figure 1),

two flat washers (8, Figure 1) and two 5/16"-18 x 1-3/4"

screws (9, Figure 1) included with this attachment.

NOTE: Place the flat washers between the Blade Mounting

Bracket and the Bottom Brace.

3. Secure the bottom portion of Blade Mounting Bracket to the

Bottom Brace with with two nuts (6, Figure 1), two lock washers (7, Figure 1) and two 5/16"-18 x 1-3/4" screws (9, Figure 1)

included with this attachment (C, Figure 4).

Step 4: Install Swivel Bracket (A-Frame)

1. Position the Swivel Bracket (2, Figure 1) in front of the Blade

Mounting Bracket and align the two large holes in each.

2. Secure the brackets together by inserting a 1/2-13 x 1-1/2"

screw (4, Figure 1) with flat washer (12, Figure 1) and bushing (11, Figure 1) through both large holes and fastening with

a lock washer (3, Figure 1) and a

plain 1/2” hex nut (10, Fig-

ure 1), and tighten securely. See Figure 5.

NOTE: Two different 1/2” nuts are included with this attachment

(10 & 15, Figure 1). One is a lock nut (with a punch mark) and

the other is a plain hex nut. See inset of Figure 5.

-2-

To help avoid serious personal injury, disconnect the spark

plug wire and move the wire away from the spark plug.

Remove isgnition key on units so equipped.

WARNING

Figure 2: TILLER BLOCKED (ELECTRIC-START MODEL SHOWN)

Figure 3: REMOVE BOTTOM BRACE HARDWARE

Figure 4: ATTACHING THE BLADE MOUNTING BRACKET

Figure 5: ATTACHING THE SWIVEL BRACKET (A-FRAME)

A

C

B

Page 3

-3-

3. Insert a 1-1/4" screw (13, Figure 1) through the lower, smaller hole in the swivel bracket. Add a lock washer (7, Figure 1)

and hex nut (6, Figure 1) and tighten securely. See Figure 6.

Step 7: Attach Blade to Swivel Bracket

Lift the blade onto the swivel bracket. and position the blade to

align the hole in the blade mounting bracket (D, Figure 7) with

the hole in the swivel bracket. Insert a 3" screw (14, Figure 1)

down through the holes then add a 1/2”

lock nut. Tighten

securely.

Step 8: Set Blade Angle

Move the blade to the desired angle, then align the holes in the

two blade mounting plates (E, Figure 8) with the hole in the

swivel bracket. Insert the index pin (16, Figure 1) down

through the three holes.

BEFORE USING THE DOZER/SNOW BLADE

Adjust Handlebars

When plowing or dozing, your handlebars should be set slightly

less than waist high. This enables more leverage when raising

the blade for banking, clearing obstacles and backing up.

Please refer to the Horse Tiller Owner’s Manual for handlebar

height setting instructions.

Wheel Traction

Good traction is essential when dozing dirt–and especially snow

plowing. Bar Tread tires are a tremendous help for moving dirt.

If you have standard tread tires, we highly recommend using

tire chains (Model OEM-390-991 / 390-991-081). Chains are

also very helpful for winter snowplowing jobs. They can be left

on year-round (for muddy or sandy conditions), or they can be

removed and replaced in minutes, as needed.

Winterize Before cold weather Use

When using your tiller during temperatures below 32o F, you

must drain the #30 weight motor oil and change to a lighter

weight oil. Consult the separate Engine Owner’s Manual for the

specific weight motor oil recommended by the engine manufacturer for lower temperatures. You should also change from

#140 to #90 weight gear oil in the tiller transmission before

operating your tiller in below freezing temperatures.

USING THE DOZER/SNOW BLADE

Snowplowing Tips

Your Dozer/Snow Blade can move large amounts for snow

quickly. Here are some snowplowing techniques to speed up

the job with a minimum of reverse maneuvering and blade

angle changing. Use the patterns described below and shown in

Figure 9 as a guide.

IMPORTANT: Winterize your tiller before using it in cold

weather. See Before Using the Dozer/Snow Blade, above.

Never run the engine indoors or in enclosed, poorly ventilated areas. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

Figure 6: ATTACHING THE SWIVEL BRACKET (A-FRAME)

Figure 7: ATTACHING THE BLADE TO THE SWIVEL BRACKET

D

Figure 8: SETTING THE BLADE ANGLE

E

CAUTION

Page 4

Figure 1

●

Warmup - In cold weather, always allow the engine five or 10

minutes to warmup before plowing (See the Horse Tiller

Operator’s Manual for starting and operating instructions.).

Running the engine before use heats the oil so that it flows

for proper engine lubrication. While warming up the engine,

leave the Wheel Speed Shift Lever in Free Wheeling position

and put the Forward/Reverse Lever in Forward position for

five minutes or more. This rotates the tine shaft and warms

the transmission gear oil. Before doing this, make sure that

the tines have been removed and that the Depth Regulator

Lever is pushed all the way down to the travel setting (top

notch engaged on lever). Later, when removing snow, pull

the drag bar all the way up to allow you to raise the blade as

high as possible for banking.

●

Plowing Deep Snow - It is best to remove a top layer several

inches thick in the first passes before attempting to remove

all the snow. Start near the end of the drive and gradually

work back up.

●

Plowing Light Snow - Make the first pass in the center of the

area being plowed, with the blade angled right (A, Figure 9).

The blade can remain in this position, until the last pass,

when the blade is angled away from the center for this portion

of the plowing operation. When you reach the end of the last

pass down the center, begin to follow the pattern for light

snow (A).

●

Wheel Speed When Banking Snow - Use the Slow Wheel

Speed and High Belt Range, throttle back the engine about 25

percent when banking snow. The slower throttle speed

enables better control and protect the wheel shaft and gears

from damage if the tiller should strike a hidden immovable

object.

NOTE: When using the High Speed Belt Range and Fast Wheel

Speed, throttle back the engine to approximately 70%.

IMPORTANT: Throttling back is very important! The resulting

slow down prevents too much build-up of momentum. If the

blade strikes an immovable object , the resulting shock could

damage the wheel shaft or transmission gears.

Dirt Dozing Tips

Your Dozer/Snow Blade is also handy during spring, summer

and fall for various dirt moving jobs. You can fill ditches,

spread mulch and manure over the garden, do light grading,

prepare land for a small swimming pool to name a few applications. Again, you’ll get the most work from your Blade if you

use these hints... then carefully experiment.

●

Hard Packed Soil - The Blade should be used for moving

loose dirt... it can’t dig into unbroken soil or hard-packed

piles like a bulldozer. Thoroughly loosen the soil with the

tines (before you take them off for safety) or use hand tools

to break-up hard-packed piles.

●

Soil Condition - The soil (or mulch, or manure) is best

moved when it’s dry. If it’s very wet, it can stick to the blade,

and the moisture’s extra weight means you’ll move less per

pass. Also, when the material is nearly dry, you can spread

the material more evenly–it doesn’t clump up.

●

Dozing Dirt Piles - Avoid trying to take too big a bite from a

pile at once Angle the blade away from the pile and start at

one side. Then, spread the load evenly, with the blade

straight ahead. In this manner, when you “cut away” at a pile,

the pile breaks itself up for you.

IMPORTANT: Check engine oil level frequently during snowplowing or earth dozing.

For customer assistance, visit www.troybilt.com, contact your nearest authorized dealer or:

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OHIO 44136-0019, 1-866-840-6483

Printed in U.S.A. Form 769-00134 (03/2002)

Loading...

Loading...