Page 1

TRnV BILT

Operator's Manual

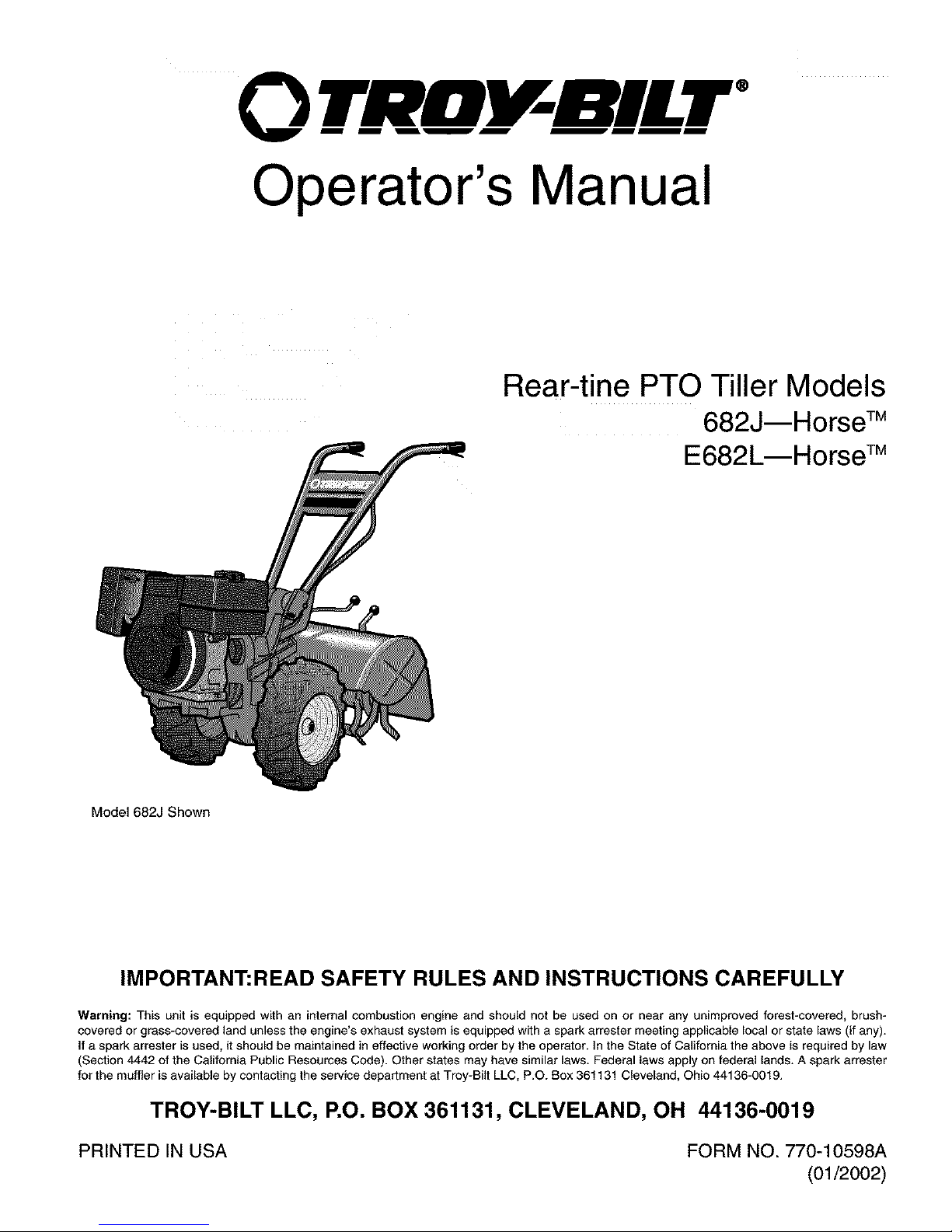

Rear-tine PTO Tiller Models

E682L--Horse TM

682J--Horse TM

Model 682J Shown

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FORM NO. 770-10598A

(01/2002)

Page 2

TABLE OF CONTENTS

Content Page

Calling Customer Support .................................................... 2

Safety ................................................................... 3

Assembly ................................................................. 6

Features and Controls ....................................................... 11

Operation ................................................................ 14

Maintenance .............................................................. 28

Troubleshooting ........................................................... 41

Attachments & Accessories .................................................. 43

Parts List ................................................................. 44

Warrany Information ........................................................ Back Cover

FINDING MODEL NUMBER

This Operator's Manual is an important part of your new Rear-tine Tiller. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the infor-

mation from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment

in the space below

Copy Model Number Here

O BILT" TROY-BILT LL(

www.troybilt.com CL_E_ND, OH_136

• 866-840-648_

P. O. BOX 361131

330-558-7220

Copy Serial Number Here

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, speci-

fications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual packed sepa-

rately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

your unit's model number and serial number ready when you call. See previous section to locate this

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

information. You will be asked to enter the serial number in order to process your call.

2

Page 3

n

Safety

SafetyAlert Symbol

,_ This is a safetyalertsymbol. It is used inthis

Failureto obey safety messagescould result in personal

injury or propertydamage.

Training

1. Carefullyreadthis Owner's Manual,the

separateEngineOwner's Manual,and any

other literature you may receive.Bethor-

oughly familiar with the controls and the

proper useof the tiller and itsengine.

Know howto stopthe unit and disengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe areaof operation clearof all

persons, particularly children andpets.

4. Keepin mind that the operator or user

is responsible for accidents or hazards

occurring to other people,their property,

andthemselves.

Preparation

1. Thoroughly inspect theareawherethe

tiller isto beusedand remove all foreign

objects.

2. Putthe Wheels/Tines/PTODrive Lever

into NEUTRALbefore starting theengine.

3. Do not operatethe tiller without

wearingadequate outergarments. Avoid

loose garmentsor jewelry that could get

caught in moving parts.

4. Do not operatethe tiller when barefoot

or wearingsandals,sneakers,or light

footwear. Wear protectivefootwear that

will improve footing on slippery surfaces.

5. Do not till nearunderground electric

cables,telephone lines,pipes or hoses. If

in doubt, contact your telephoneor utility

company.

manualand on the unit to alertyou to

potential hazards. Whenyou seethis symbol,

readand obey the messagethat follows it.

6. Warning:Handlefuel with care; it is

highly flammable andits vapors are

explosive. Besureto takethe following

precautions:

a. Store fuel in containersspecifically

designedfor this purpose.

b. The gascapshall neverbe removed

or fuel addedwhile the engineis

running. Allow the engine to cool

for severalminutes beforeadding

fuel.

c. Keepmatches,cigarettes, cigars,

pipes, openflames,andsparks

awayfrom the fuel tank and fuel

container.

d. Fillfuel tankoutdoors with extreme

care. Neverfill fuel tank indoors.

Usea funnel or spout to prevent

spillage.

e. Replaceall fuel tankand container

caps securely.

f. If fuel is spilled,do not attempt to

start the engine, but move the

machine awayfrom the areaof

spillageand avoid creatingany

source of ignition until fuel vapors

havedissipated.

7. Never makeadjustmentswhen engine

is running (unlessrecommendedby

manufacturer).

Operation

1. Do not put hands or feet nearor under

rotating parts. Donot allow handsor any

other part of the bodyor clothing nearthe

rotating tines or nearanyother moving

part. Thetines beginto rotate forward

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

WARNING

Theengineexhaustfromthis productcontains

chemicalsknowntotheStateofCaliforniatocause

cancer, birth defects or other reproductive harm.

oncethe enginestarts, the Tines/PTO

ClutchLever is in the ENGAGEposition,

the Forward Interlock Leversaresqueezed

closedand the Wheels/Tines/PTODrive

Leveris shiftedto FORWARD.Thetines

rotate in Reversewhether the Interlock

Leversare closedor open.

2. Exerciseextreme caution when on or

crossing graveldrives, walks, or roads.

Stayalert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking aforeign object, stop the

engine,removethe wire from the spark

plug wire and preventit from touching the

spark plug. Thoroughly inspectthe

machinefor anydamage and repairthe

damagebefore restarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor-

mally,stop the engine, disconnectthe

spark plugwire and preventit from

touching the spark plug, and check imme-

diatelyfor the cause.Vibration is

generallya warning of trouble.

6. Stopthe engine,disconnect the spark

plug wire and preventit from touching the

spark plugwheneveryou leavethe

operatingposition, before unclogging the

tines, or when making any repairs,adjust-

ments or inspections.

7. Takeall possible precautionswhen

leavingmachine unattended.Stopengine.

Disconnectspark plug wire and move it

away from spark plug. Removeignition

keyon electric start models

Page 4

Section1: Safety

8. Beforecleaning, repairing, or inspect-

ing, stop the engine and make certain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching thespark plugto preventacci-

dentalstarting.

9. Theflap onthe tine hood must be

down when operatingthetiller, unless

using the Hiller/Furrowerattachment.

10. Neverusethe tiller unlessproper

guards, plates,or other safety protective

devicesare in place.

11. Donot runenginein anenclosed

area.Engineexhaustcontains carbon

monoxide gas,adeadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren and pets away.

13. Neveroperatethe tiller underengine

power if the WheelSpeedLeveris in the

FREEWHEELposition. In FREEWHEEL,

thewheels will not hold the tiller backand

the revolving tines could propel thetiller

rapidly, possibly causing lossof control.

Alwaysengagethe Wheel SpeedLeverin

either FASTor SLOWposition before

starting the engineor engaging thetines

with theWheels/Tines/PTODrive Lever.

14. Beaware thatthe tiller mayunex-

pectedlybounceupwardor jump

forwardifthe tines shouldstrike

extremelyhardpackedsoil, frozen

ground,or buried obstacleslike large

stones,roots, orstumps. If in doubt

aboutthe tilling conditions,alwaysuse

thefollowingoperatingprecautionsto

assistyouin maintainingcontrolofthe

tiller:

a. Walk behindandto oneside of the

tiller, usingonehandonthe han-

dlebars.Relax yourarm, butusea

securehandgrip.

b. Use shallowerdepthregulator

settings,workinggraduallydeeper

with eachpass.

c. Use slowerwheel, tine and engine

speeds.

d. Clearthe tilling areaof all large

stones,rootsand otherdebris.

e. Avoidusingdownwardpressureon

handlebars.If needbe, useslight

upwardpressureto keepthe tines

fromdiggingtoo deeply.

f. Beforecontactinghardpackedsoil

at the endof arow, reduceengine

speedand lift handlebarsto raise

tines outofthe soil.

g. In an emergency,stoptines and

wheels byshiftingthe

Wheels/Tines/PTODriveLever

intoNEUTRAL.If youcan not

reachthe lever or havelostcontrol

ofthe tiller, let go of thehandle-

barsand all controls. Do not

attemptto restrainthetiller.

15. Do not overloadthe tiller's capacity by

attempting to till too deeply at too fast a

rate.

16. Never operatethe tiller at high

transport speedson hardorslippery

surfaces. Look behindand usecare when

backing up.

17. Do not operatethe tiller on aslope

that is too steep for safety. When on

slopes, slow downand makesure you

havegood footing. Never permit the tiller

to freewheel down slopes.

18. Neverallow bystandersnear the unit.

19. Onlyuse attachments andaccessories

that areapproved bythe manufacturerof

the tiller.

20. Usetiller attachments and acces-

sories when recommended.

21. Never operatethe tiller without good

visibility or light.

22. Never operatethe tiller if you are

tired, or under the influenceof alcohol,

drugs or medication.

23. Operatorsshall nottamper with the

engine-governorsettings on the machine;

the governor controls the maximum safe

operating speedto protect the engineand

all moving parts from damagecaused by

overspeed. Authorized serviceshall be

sought if a problem exists.

24. Do not touch engineparts which may

be hot from operation. Let parts cool

down sufficiently.

25. POISON/DANGER--CAUSES

SEVEREBURNS.The batteryon electric

start models contains sulfuric acid. Avoid

contact with skin, eyesor clothing. Keep

out of reach of children.

Antidotes:

External- Flushimmediately with lots of

water.

Internal- Drink largequantities of water

or milk. Followwith milk of magnesia,

beateneggs orvegetableoil. Calla

doctor immediately.

Eyes- Flushwith water for 15 minutes.

Getprompt medical attention.

26. DANGER-BATTERIESPRODUCE

EXPLOSIVEGASES. Keepsparks,flame

or smoking materialsaway. Ventilate

when charging battery or using inan

enclosed space. Alwayswear safety

goggles when working near battery.

27. Pleaseremember:You canalways

stop the tines andwheelsby releasingall

controls, or by moving the ignition switch

and/or throttle control leveronthe engine

to OFFor STOP.

28. To load or unloadthe tiller, seethe

instructions in Section 4 of this Manual.

29. Useextremecautionwhen backingor

pulling the machinetowards you.

30. Startthe enginecarefully accordingto

instructions and with feet well awayfrom

the tines.

31. Neverpick upor carry a machine

while the engineis running.

32. When loading or unloadingthe tiller,

alwaysdisengage tinesand use slower

wheel and enginethrottle speeds. Use

sturdy ramps wide and strong enoughto

easily support the tiller (280-to-325 Ibs.,

depending on model) andoperator.

Nevergo down ramps in FORWARD

drive--the tiller could tip forward,

exposing you to the tines (which should

be disengaged). Alwaysuse REVERSE

drive and backdown ramps. Togo up

ramps, useFORWARDdrive and follow

the tiller.

33. TheForward Interlock SafetySystem

should betested for correct functioning

every time thetiller or PTOpowerunit is

used. SeeSection 4 in this Manual.

34. If using the optional Dozer Blade,

either removethe tine attachment,or

disengagethe tineswith the Tines/PTO

ClutchLever. Revolvingtines are

dangerous.

Page 5

Section1: Safety

MaintenanceandStorage

1. Keepthe tiller, attachmentsandacces-

sories insafe working condition.

2. Checkall nuts, bolts, andscrews at

frequent intervalsfor proper tightness to

be surethe equipment is insafe working

condition.

3. Neverstore the tiller with fuel in the

fuel tank insidea building where ignition

sources are presentsuch ashot water

and spaceheaters,furnaces, clothes

dryers, stoves, electric motors, etc.).

Allow engine to cool beforestoring in any

enclosure.

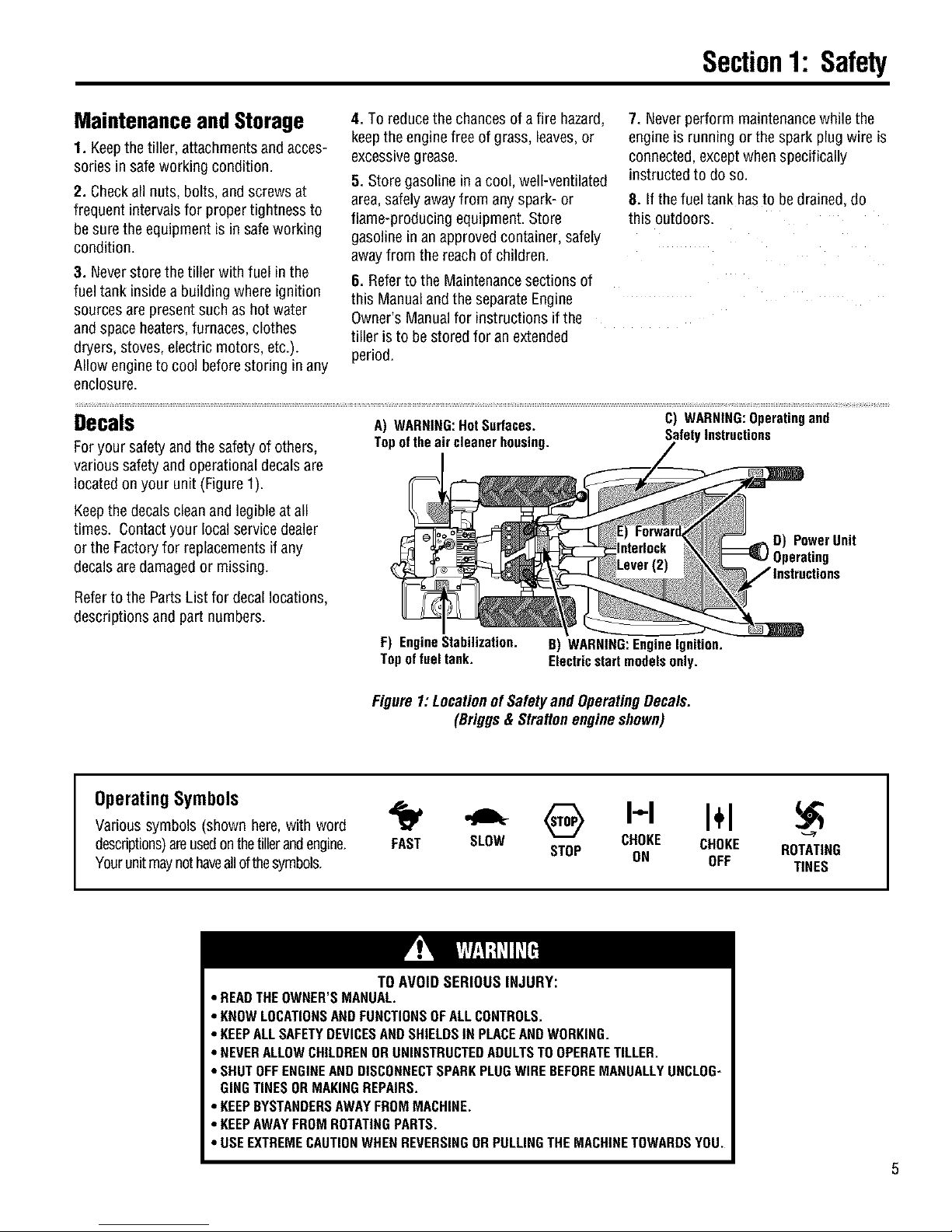

Decals

Foryour safetyand the safetyof others,

various safetyand operational decalsare

located onyour unit (Figure 1).

Keepthe decalscleanandlegibleat all

times. Contactyour local servicedealer

or the Factoryfor replacementsif any

decalsare damagedor missing.

4. To reducethe chancesof afire hazard,

keepthe enginefree of grass, leaves, or

excessivegrease.

5. Store gasolinein acool, well-ventilated

area,safely awayfrom any spark-or

flame-producing equipment. Store

gasolinein an approvedcontainer, safely

away from the reachof children.

6. Referto the Maintenancesections of

this Manualand the separateEngine

Owner's Manualfor instructions if the

tiller is to be stored for an extended

period.

A) WARNING:HotSurfaces.

Topoftheaircleanerhousing. SafetyInstructions

7. Neverperform maintenancewhile the

engine is running orthe spark plugwire is

connected, exceptwhen specifically

instructed to do so.

8. If thefuel tank hasto bedrained,do

this outdoors.

C) WARNING:Operatingand

D) PowerUnit

Referto the Parts List for decal locations,

descriptions andpart numbers.

OperatingSymbols

Varioussymbols (shown here,with word

descriptions)areusedonthetillerandengine.

Yourunitmaynothaveallofthesymbols.

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSANDFUNCTIONSOFALL CONTROLS.

• KEEPALL SAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINES ORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHE MACHINETOWARDSYOU.

F) EngineStabilization.

Topof fueltank.

Figure1:LocationofSafetyand OperatingDecals.

(Briggs& Stratton engineshown)

B) WARNING:EngineIgnition.

Electricstartmodelsonly.

I I I÷I

FAST SLOW CHOKE CHOKE

STOP ON OFF

TO AVOID SERIOUS INJURY:

ROTATING

TINES

Page 6

I1

Assembly

To prevent personal injury or property

damage, do not start the engine until

all assembly steps are complete and

you have read and understand the

safety and operatinginstructionsin this

manual.

Introduction

Carefullyfollow these assembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety beforebeginning assembly.

NOTE:Varioustiller models are presented

in this Manual. Useonly the information

appropriatefor your tiller model.

InspectUnit

Inspectthe unitand carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protectyour rights, put your

claim inwriting and mail acopy to the

carrier within 15 days after the unit has

beendelivered. Contactusat the Factory

if you needassistance inthis matter.

STEP1: UnpackingInstructions

NOTE:Do not severelybendany of the

control cableson the unit.

1. Thetiller is heavy. Do not attemptto

remove it from the shipping platform until

instructed to do so in theseAssembly

steps.

2. Removeall unassembledpartsfrom

the carton. Thehardwarebag is included

in your literature packaging.

3. Checkthat you havethe items listed

below (contact your local dealeror the

Factory if any items are missing or

damaged).

NOTE: Usethe screw lengthtemplate

(Figure2-1) to identify screws.

LoosePartsList

Qty. Description

1 HandlebarAssembly

1 Wheels/TinesPTODriveLever

Thefollowing items

are in the hardwarebag:

2 20 oz.Bottles SAE30W Oil

1 Clutch PawlSpring

1 BeltAdjusting Tool

2 PlasticCableTies

1 CurvedHeadScrew, 1/4-20 x 2

1 FlangedLock Nut, 1/4-20

1 PanHeadScrew,#10-32 x 1/2

Thefollowing parts (electric start models

only), packagedseparately.

2 Nuts,1/4-20

(for battery terminals)

2 Screws,1/4-20 x 5/8

(for battery terminals)

2 Keys

(in ignition switch)

NOTE:LEFTand RIGHTsides of the

tiller are as viewed from the

operator's position behind the han-

dlebars(unless otherwise noted).

Tools]MaterialsNeeded

for Assembly

(1) 3/8" open-endwrench*

(2) 7/16"open-end wrench*

(2) 1/2" open-endwrench*

(1) 9/16"open-end wrench*

(1) 3/4"open-end wrench*

(1) Flatblade screwdriver

(1) Scissors (to trim plastic ties)

(1) Tire pressuregauge

(1) 4-1/2" highwood block to prop unit

* Adjustable wrenchesmay be used.

Figure2-1: Toidentifylengthofscrew,

placescrewontemplateasshownand

measuredistancebetweenbottomofscrew

headandtipofscrew.

STEP 2: Attach Handlebar

IMPORTANT: When disassembling

handlebar assembly, keep left-side clamp

and ratchet separatedfrom the right-side

clamp andratchet.

1. Disassemblethe handlebarassembly.

To do this, remove the height adjustment

leverby turning the leverin a counter-

clockwise direction (Figure2-2).

2. Placethe handlebarendson either side

ofthe base,with thewire harnesstoward

the rear ofthe base(Figure2-2).

3. Installthe heightadjustment lever

through the right-side clamp, handlebar

end, ratchet, and base;then out through

the left-side ratchet, handlebarend,and

clamp (Figure2-2). Securewith nut, but

don't fully tighten.

IMPORTANT:Do notforce the height

adjustment leverthrough the handlebars.

The interlock wires may be blocking the

leverand could bedamaged.You may

gently movethe wiresaside if this

condition occurs.

6

Page 7

Section2: Assembly

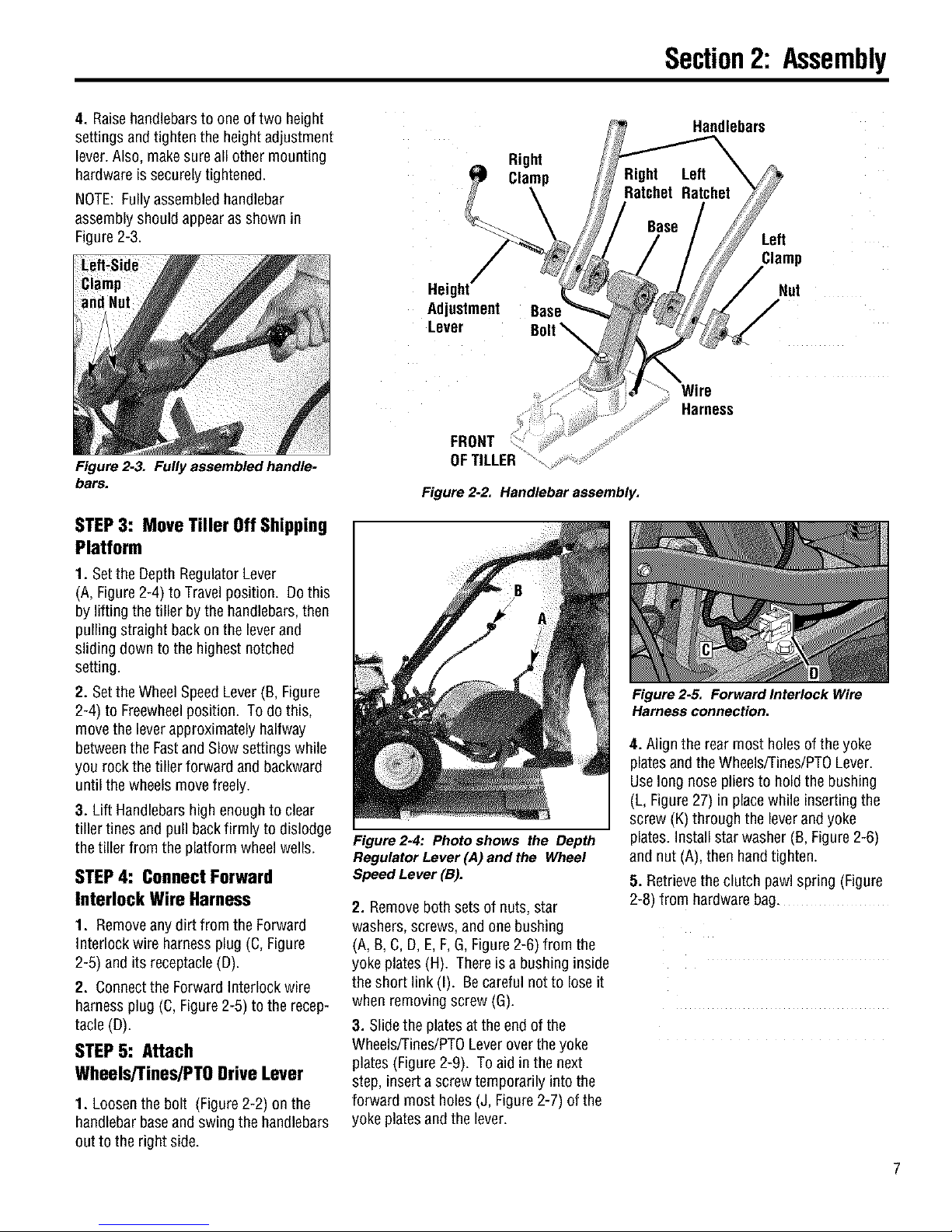

4. Raisehandlebarsto oneof two height

settings andtighten the heightadjustment

lever. Also, makesure all other mounting

hardware issecurely tightened.

NOTE: Fully assembledhandlebar

assembly should appearas shown in

Figure2-3.

Figure 2-3. Fully assembled handle-

bars.

STEP3: MoveTiller OffShipping

Platform

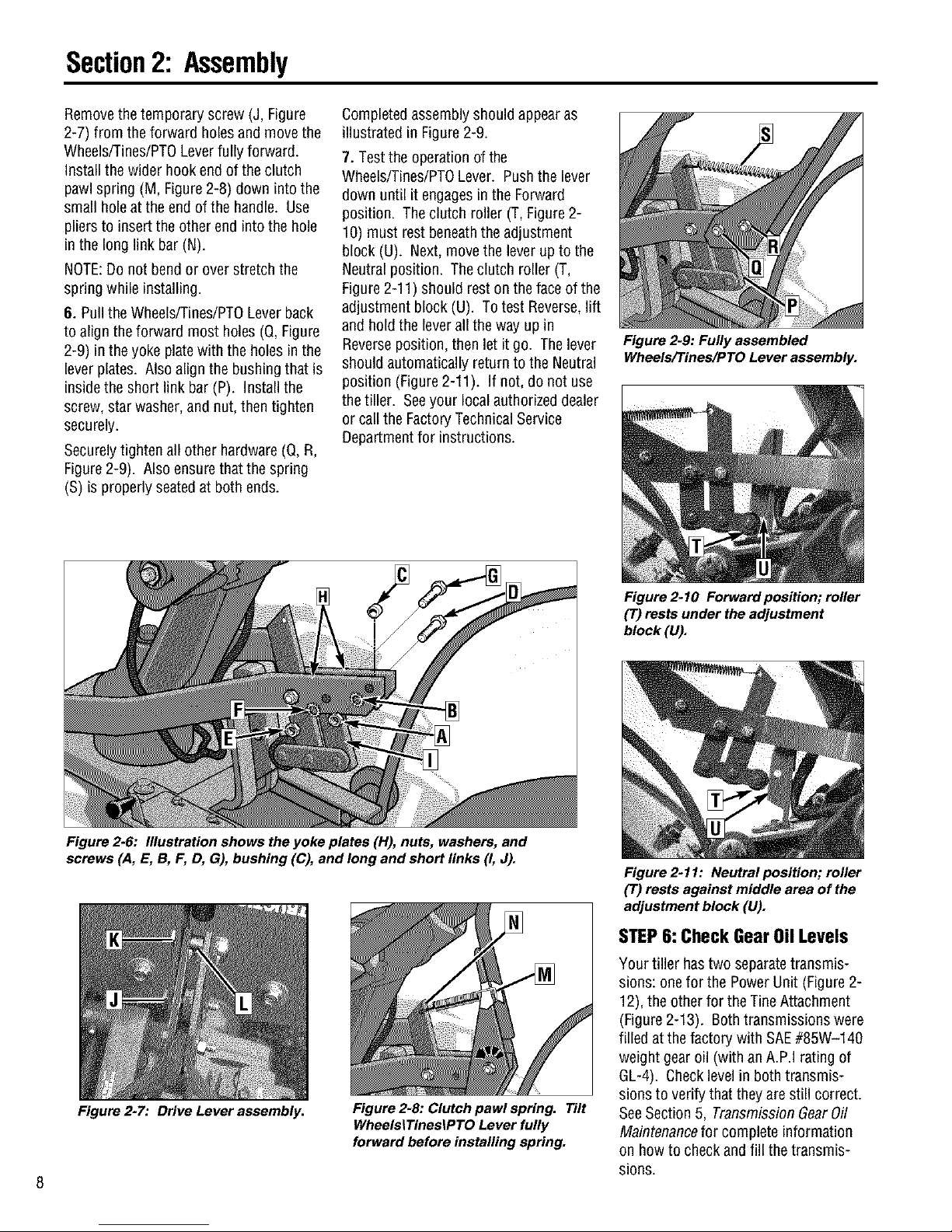

1. Setthe DepthRegulatorLever

(A, Figure2-4) to Travel position. Dothis

by lifting the tiller by the handlebars,then

pulling straight backonthe leverand

sliding down to the highest notched

setting.

2. Setthe WheelSpeedLever(B, Figure

2-4) to Freewheelposition. To do this,

move the leverapproximately halfway

betweenthe Fastand Slow settings while

you rock the tiller forward andbackward

until thewheels movefreely.

3. Lift Handlebarshighenoughto clear

tiller tines and pull backfirmly to dislodge

the tiller from the platform wheel wells.

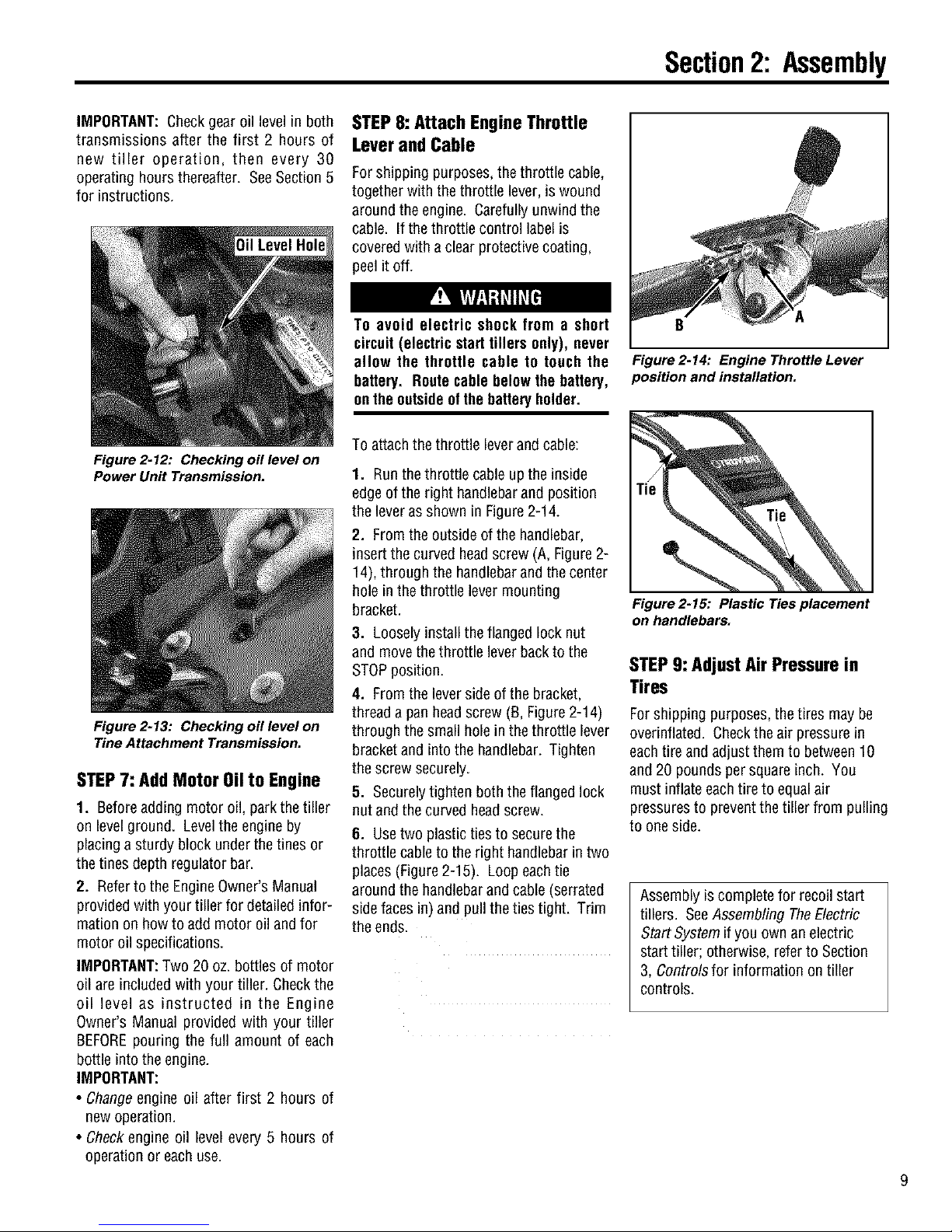

STEP4: ConnectForward

InterlockWire Harness

1. Removeany dirt fromthe Forward

Interlock wire harnessplug (C, Figure

2-5) andits receptacle(D).

2. Connect the Forward interlock wire

harness plug (C,Figure2-5) to the recep-

tacle (D).

STEP5: Attach

WheelsiTines/PTODriveLever

1. Loosenthe bolt (Figure2-2) on the

handlebar baseand swing the handlebars

out to the right side.

Right

Clam

Height

Adjustment

Lever

FRONT

OFTILLER

Figure 2-2. Handlebar assembly.

Figure 2-4: Photo shows the Depth

Regulator Lever (A) and the Wheel

Speed Lever (B).

2. Removeboth sets of nuts, star

washers, screws, and one bushing

(A, B, C,D, E,F,G,Figure2-6) from the

yoke plates(H). There is a bushing inside

the short link (I). Becareful not to loseit

when removing screw (G).

3. Slidethe platesat the endof the

Wheels/Tines/PTOLeveroverthe yoke

plates (Figure2-9). To aid in the next

step, insert a screwtemporarily into the

forward most holes (J, Figure2-7) of the

yoke platesandthe lever.

Base

Handlebam

Base

Left

Clamp

Nut

Wire

Harness

Figure 2-5. Forward Interlock Wire

Harness connection.

4. Align the rear most holes of theyoke

platesand the Wheels/Tines/PTOLever.

Uselong nose pliersto hold the bushing

(L, Figure27) in placewhile insertingthe

screw (K)through the leverand yoke

plates.Install star washer (B, Figure2-6)

and nut (A),then handtighten.

5. Retrievethe clutch pawl spring (Figure

2-8) from hardware bag.

Page 8

Section2: Assembly

Removethe temporary screw (J, Figure

2-7) from the forward holes andmove the

Wheels/Tines/PTOLeverfully forward.

Install the wider hook end of the clutch

pawl spring (M, Figure2-8) down into the

small holeat the end of the handle. Use

pliers to insert the other endinto the hole

in the long link bar (N).

NOTE:Do not bend or over stretch the

spring while installing.

6. Pull the Wheels/Tines/PTOLeverback

to align the forward most holes (Q,Figure

2-9) inthe yoke platewith the holes in the

lever plates. Also alignthe bushing that is

insidethe short link bar (P). Install the

screw, starwasher, and nut, then tighten

securely.

Securelytighten allother hardware(Q,R,

Figure2-9). Alsoensure that the spring

(S) is properly seatedat both ends.

Completedassembly should appearas

illustrated in Figure2-9.

7. Testthe operation of the

Wheels/Tines/PTOLever. Pushthe lever

down until it engages in the Forward

position. The clutch roller (T, Figure2-

10) must rest beneaththe adjustment

block (U). Next,move the lever upto the

Neutral position. Theclutch roller (T,

Figure2-11) should rest on theface of the

adjustment block (U). To test Reverse,lift

and holdthe leverall the way up in

Reverseposition, then let it go. Thelever

should automatically return to the Neutral

position (Figure2-11). If not, do not use

the tiller. Seeyour localauthorized dealer

or call the FactoryTechnicalService

Departmentfor instructions.

Figure 2-9: Fully assembled

Wheels/Tines/PTO Lever assembly.

Figure 2-6: Illustration shows the yoke plates (H), nuts, washers, and

screws (A, E, B, F, D, G), bushing (C), and long and short links (I, J).

Figure 2-7: Drive Lever assembly.

Figure 2-8: Clutch pawl spring. Tilt

WheelsiTinesiPTO Lever fully

forward before installing spring.

Figure 2-10 Forward position; roller

(T) rests under the adjustment

block (U).

Figure 2-11: Neutral position; roller

(7) rests against middle area of the

adjustment block (U).

STEP6: CheckGearOilLevels

Your tiller hastwo separatetransmis-

sions: one for the PowerUnit (Figure 2-

12), the otherfor the Tine Attachment

(Figure2-13). Both transmissions were

filled atthe factory with SAE#85W-140

weight gearoil (with anA.P.I rating of

GL-4). Checklevelin both transmis-

sions to verify that they are still correct.

SeeSection 5, TransmissionGearOil

Maintenancefor complete information

on howto check andfill the transmis-

sions.

Page 9

Section2: Assembly

IMPORTANT: Checkgearoil level in both

transmissions after the first 2 hours of

new tiller operation, then every 30

operating hours thereafter. SeeSection 5

for instructions.

OilLevel Hole

Figure 2-12: Checking oil level on

Power Unit Transmission.

Figure 2-13: Checking oil level on

Tine Attachment Transmission.

STEP7: AddMotor0il to Engine

1. Beforeadding motor oil, park thetiller

on levelground. Levelthe engineby

placinga sturdy block under thetines or

the tines depth regulator bar.

2. Referto the EngineOwner's Manual

provided with your tiller for detailed infor-

mation onhow to add motor oil andfor

motor oil specifications.

IMPORTANT:Two 20 oz. bottles of motor

oil are included with your tiller. Checkthe

oil level as instructed in the Engine

Owner's Manual provided with your tiller

BEFOREpouring the full amount of each

bottle into the engine.

IMPORTANT:

• Change engine oil after first 2 hours of

newoperation.

• Check engine oil levelevery 5 hours of

operation or eachuse.

STEP8: AttachEngineThrottle

LeverandCable

Forshipping purposes, the throttle cable,

together with the throttle lever, is wound

around the engine. Carefully unwindthe

cable. If the throttle control label is

coveredwith a clear protectivecoating,

peel it off.

To avoid electric shock from a short

circuit (electric starttillers only), never

allow the throttle cable to touch the

battery. Routecable belowthe battery,

onthe outsideof thebatteryholder.

To attachthe throttle leverandcable:

1. Runthethrottle cableup the inside

edge of the right handlebarand position

the leverasshown in Figure2-14.

2. Fromthe outside of the handlebar,

insert the curved headscrew (A, Figure 2-

14), through the handlebarand the center

hole inthe throttle levermounting

bracket.

3. Looselyinstallthe flanged lock nut

and movethe throttle leverbackto the

STOPposition.

4. Fromthe lever side of the bracket,

threada pan headscrew (B, Figure2-14)

through the small hole in the throttle lever

bracketand intothe handlebar. Tighten

the screw securely.

5. Securelytighten boththe flanged lock

nut and the curved headscrew.

6. Usetwo plastic tiesto securethe

throttlecableto the right handlebarin two

places (Figure2-15). Loop eachtie

around the handlebarand cable (serrated

sidefaces in) and pull the ties tight. Trim

the ends.

B

Figure2-14: Engine ThrottleLever

position and installation.

Figure 2-15: Plastic Ties placement

on handlebars.

STEP9: Adjust Air Pressure in

Tires

Forshipping purposes,the tires may be

overinflated. Checkthe air pressurein

eachtire andadjust them to between10

and 20 pounds persquare inch. You

must inflate eachtire to equalair

pressuresto preventthe tiller from pulling

to one side.

Assembly is complete for recoilstart

tillers. SeeAssembling TheElectric

Start Systemif you own anelectric

start tiller; otherwise, refer to Section

3, Controlsfor information on tiller

controls.

Page 10

Section2: Assembly

ASSEMBLINGTHEELECTRICSTARTSYSTEM

Thefollowing steps explain howto install and chargethe batteryon electric start tillers. For your safety,follow all steps and observe

all accompanyingsafety messages. Section 5 contains othergeneralbattery maintenanceand recharginginstructions.

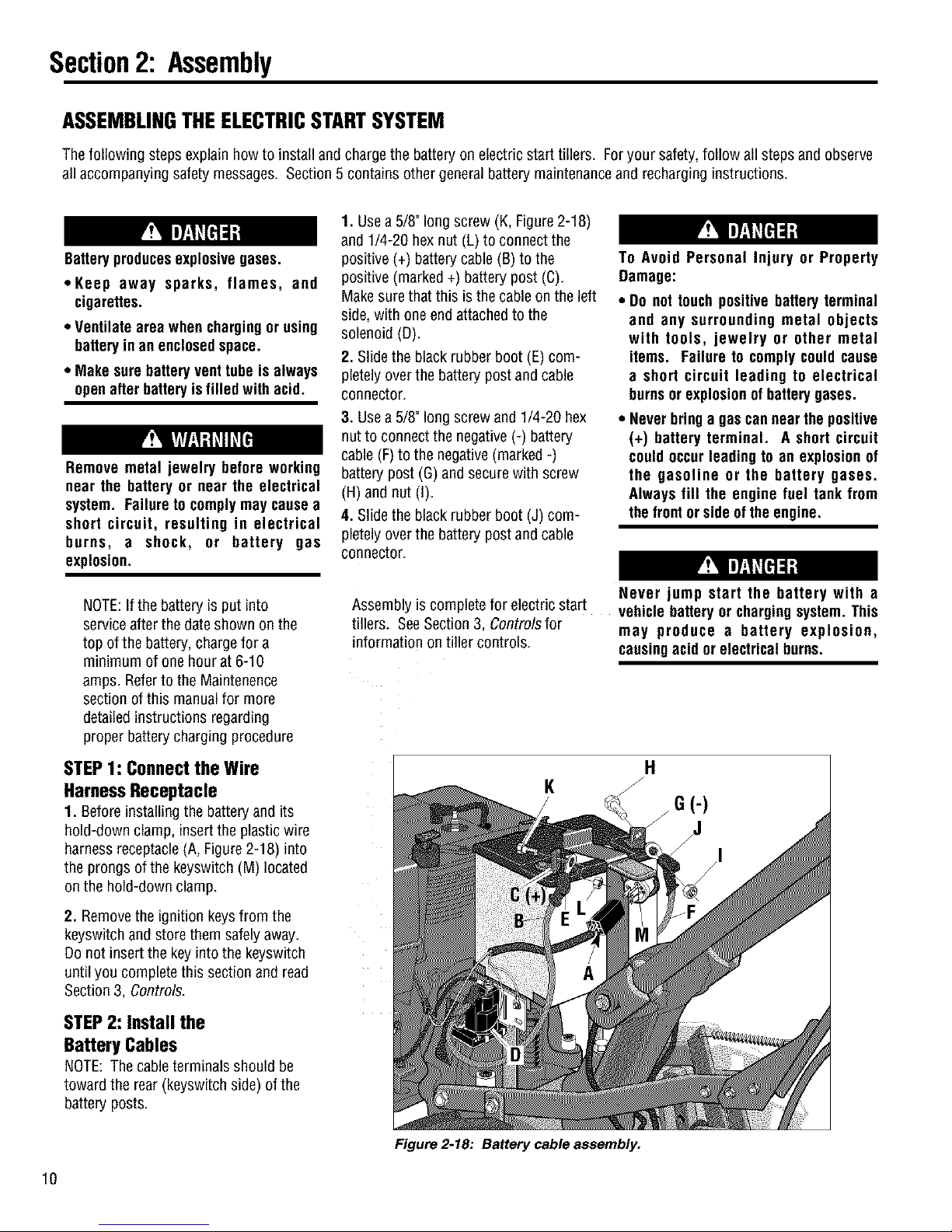

1. Usea 5/8" long screw (K,Figure2-18)

and 1/4-20 hexnut (L) to connect the

Batteryproducesexplosivegases.

*Keep away sparks, flames, and

cigarettes.

. Ventilate area whenchargingor using

batteryin anenclosedspace.

. Make surebatteryvent tube is always

openafter batteryis filled with acid.

Remove metal jewelry before working

near the battery or near the electrical

system. Failureto complymay cause a

short circuit, resulting in electrical

burns, a shock, or battery gas

explosion.

positive (+) batterycable(B)to the

positive (marked +) battery post (C).

Make surethat this is the cableonthe left

side, with oneend attachedto the

solenoid (D).

2. Slidethe black rubber boot (E) com-

pletely over the battery postandcable

connector.

3. Usea 5/8" long screw and 1/4-20 hex

nut to connect the negative (-) battery

cable (F)to the negative(marked -)

battery post (G) andsecurewith screw

(H) and nut (I).

4. Slidethe black rubber boot (J) com-

pletely over the battery postandcable

connector.

To Avoid Personal Injury or Property

Damage:

* Do not touch positive batteryterminal

and any surrounding metal objects

with tools, jewelry or other metal

items. Failure to complycould cause

a short circuit leading to electrical

burnsor explosionof batterygases.

* Neverbringa gascannearthe positive

(+) battery terminal. A short circuit

could occurleading to an explosionof

the gasoline or the battery gases.

Always fill the engine fuel tank from

thefront or sideof theengine.

NOTE:Ifthe battery is put into

serviceafter the dateshown onthe

top of the battery, chargefor a

minimum of one hour at 6-10

amps. Referto the Maintenence

section of this manualfor more

detailedinstructions regarding

proper batterycharging procedure

STEP1: Connectthe Wire

HarnessReceptacle

1. Beforeinstalling the battery and its

hold-down clamp, insert the plastic wire

harness receptacle(A, Figure2-18) into

the prongs of the keyswitch (M)located

on the hold-down clamp.

2. Removethe ignition keysfrom the

keyswitch andstore them safely away.

Do not insertthe key into the keyswitch

until you complete this section andread

Section 3, Controls.

STEP 2: Install the

BatteryCables

NOTE:The cableterminals should be

toward the rear (keyswitchside) of the

battery posts.

Assembly is complete for electric start

tillers. SeeSection 3, Controlsfor

information on tiller controls.

K

Never jump start the battery with a

vehicle battery or chargingsystem. This

may produce a battery explosion,

causingacid orelectrical burns.

G(-)

J

10

Figure 2-18: Battery cable assembly.

Page 11

n

FeaturesandControls

Before operating your machine,

carefully read and understand all

safety, controls, operating instructions

in this Manual, the separate Engine

Owner's Manual and on the decals on

themachine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

Introduction

This section describesthe location and

function of the controls and features on

your tiller. Referto Section 4, Operation

for detailedoperating instructions.

Practice usingthesecontrols, with the

engine shut off, until you completely

understand the operation of the controls

and feelconfident with eachof them.

IMPORTANT:Referto the separateengine

manufacturer's Engine Owner's Manual

for information about the controls on the

engine.

NOTE:All referencesto left,right, front

and rearof themachineare basedon a

position behindthe handlebarsandfacing

forward.

PTOAttachmentsFeature

In addition to powerfultilling capability,

you canquickly convert your machine

into a PTO(Power Take-Off)PowerUnit

that iscapableof towing or powering

various TROY-BILTattachments.

You canaccessthis capability by

removing the tines attachment (powered

by the PTOPower Unit). The PTOPower

Unit isthen availablefor engine powered

attachments,or for pulling ortowing non-

poweredattachments. SeeSection 4,

PTOPower Unitfor detailedinformation

on installingand operating TROY-BILT

PTOattachments.

WheelsiTines/PTODriveLever

Usethe Wheels/Tines/PTODriveLever(A,

Figure3-1) to engageand disengage

powerto the transmission.

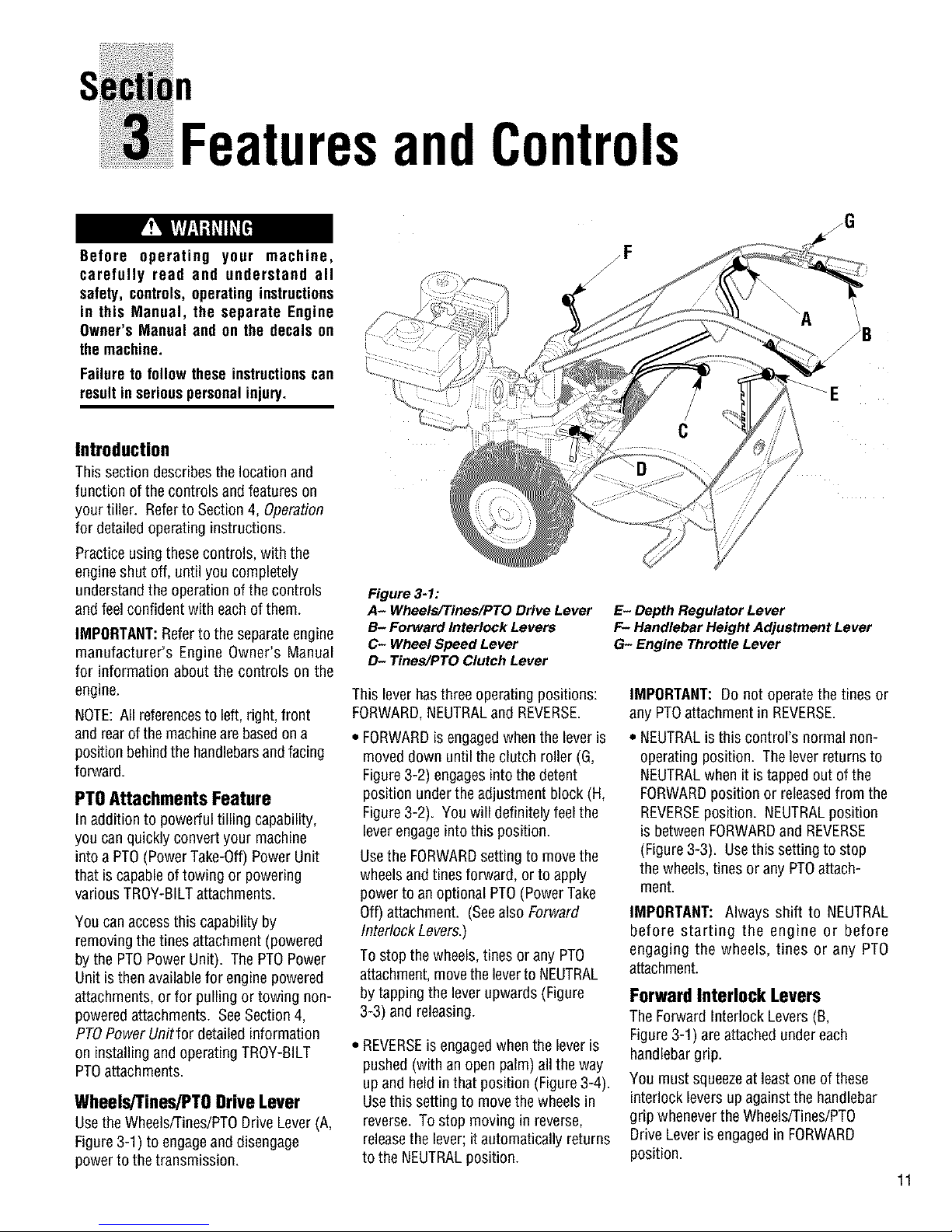

Figure 3-1:

A- Wheels/Tines/PTO Drive Lever

B- Forward Interlock Levers

C- Wheel Speed Lever

D- Tines/PTO Clutch Lever

This leverhasthree operatingpositions:

FORWARD,NEUTRALand REVERSE.

FORWARDisengagedwhen the leveris

moved down until the clutch roller (G,

Figure3-2) engagesinto the detent

position underthe adjustment block (H,

Figure3-2). You will definitely feelthe

leverengageinto this position.

Usethe FORWARDsetting to movethe

wheels andtines forward, orto apply

power to anoptional PTO(PowerTake

Off) attachment. (Seealso Forward

Interlock Levers.)

To stop the wheels, tines orany PTO

attachment,movetheleverto NEUTRAL

by tapping the leverupwards (Figure

3-3) and releasing.

• REVERSEis engagedwhen the lever is

pushed(with an openpalm)all the way

up and heldin that position (Figure3-4).

Usethis setting to movethe wheels in

reverse. To stop moving inreverse,

releasethe lever;it automatically returns

to the NEUTRALposition.

zG

E- Depth Regulator Lever

F- Handlebar Height Adjustment Lever

G- Engine Throttle Lever

IMPORTANT: Do not operatethe tines or

any PTOattachment in REVERSE.

• NEUTRALis this control's normal non-

operating position. Thelever returns to

NEUTRALwhen it is tappedout of the

FORWARDposition or releasedfrom the

REVERSEposition. NEUTRALposition

is betweenFORWARDand REVERSE

(Figure3-3). Usethis setting to stop

the wheels,tinesor any PTOattach-

ment.

IMPORTANT: Always shift to NEUTRAL

before starting the engine or before

engaging the wheels, tines or any PTO

attachment.

Forward Interlock Levers

The Forward Interlock Levers (B,

Figure3-1) are attachedundereach

handlebargrip.

You must squeezeat least one of these

interlock levers up against the handlebar

grip wheneverthe Wheels/Tines/PTO

Drive Leveris engagedin FORWARD

position.

11

Page 12

Section3: FeaturesandControls

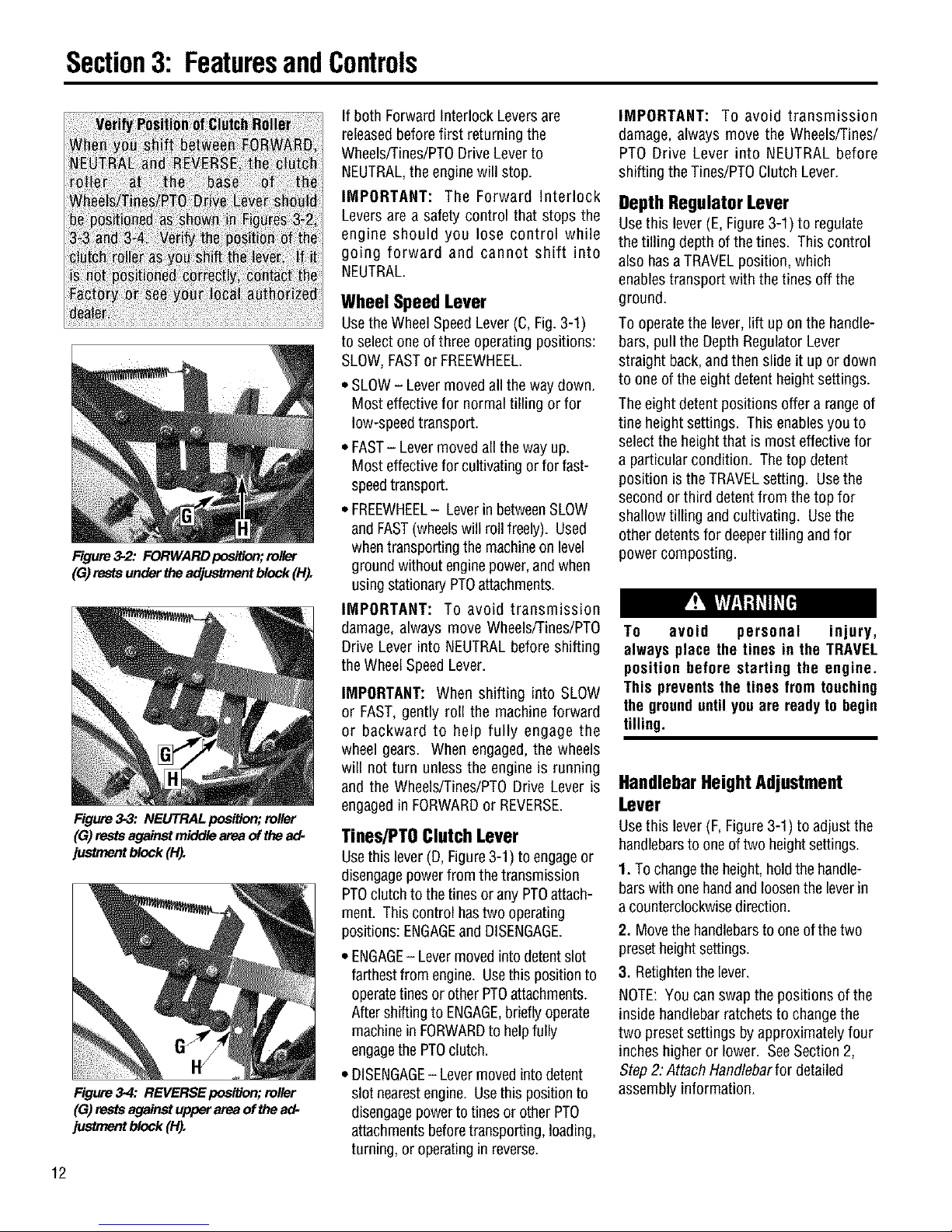

Figure 3-2: FORWARD posiUon;roller

(G)rests under lhe adj_t block (H_

Figure 3-3: NEUTRAL position; roller

(G) rests against middle area of the ad-

justment block (H).

Figure 3-4: REVERSE position; roller

(G) rests against upper area ofthe ad-

justment block (H).

12

If both Forward Interlock Leversare

releasedbefore first returning the

Wheels/Tines/PTODriveLever to

NEUTRAL,the enginewill stop.

IMPORTANT: The Forward Interlock

Levers are a safety control that stops the

engine should you lose control while

going forward and cannot shift into

NEUTRAL.

Wheel Speed Lever

Usethe Wheel SpeedLever (C,Fig.3-1)

to selectone of threeoperating positions:

SLOW,FASTor FREEWHEEL.

- SLOW- Levermovedall the waydown.

Most effectivefor normaltilling or for

low-speedtransport.

., FAST- Levermovedall theway up.

Most effectivefor cultivatingorfor fast-

speedtransport.

- FREEWHEEL- Leverin betweenSLOW

and FAST(wheelswill roll freely). Used

whentransporting the machineon level

groundwithout enginepower,andwhen

usingstationaryPTOattachments.

IMPORTANT: To avoid transmission

damage, always move Wheels/Tines/PTO

Drive Lever into NEUTRALbefore shifting

the WheelSpeedLever.

IMPORTANT: When shifting into SLOW

or FAST, gently roll the machine forward

or backward to help fully engage the

wheel gears. When engaged,the wheels

will not turn unless the engine is running

and the Wheels/Tines/PT0 Drive Lever is

engagedin FORWARDor REVERSE.

Tines/PTOClutchLever

Usethis lever(D, Figure3-1) to engageor

disengagepower fromthe transmission

PTOclutchto the tinesor any PTOattach-

ment. Thiscontrol hastwo operating

positions: ENGAGEand DISENGAGE.

- ENGAGE- Levermovedintodetentslot

farthestfrom engine. Usethis positionto

operatetinesor otherPTOattachments.

Aftershifting to ENGAGE,brieflyoperate

machinein FORWARDto helpfully

engagethe PTOclutch.

• DISENGAGE- Lever movedinto detent

slot nearestengine. Usethis positionto

disengagepowertotines or otherPTO

attachmentsbeforetransporting, loading,

turning, oroperatingin reverse.

IMPORTANT: To avoid transmission

damage, always move the Wheels/Tines/

PTO Drive Lever into NEUTRAL before

shifting the Tines/PTOClutch Lever.

DepthRegulatorLever

Usethis lever(E, Figure3-1) to regulate

the tilling depth of the tines. This control

also hasaTRAVELposition, which

enablestransport with thetines off the

ground.

To operatethe lever, lift up on the handle-

bars, pull the DepthRegulatorLever

straight back,and then slide it up or down

to one of the eightdetent heightsettings.

Theeight detent positions offer a range of

tine heightsettings. This enablesyou to

select the heightthat is most effectivefor

a particularcondition. The top detent

position is theTRAVELsetting. Usethe

second orthird detentfrom the top for

shallow tilling andcultivating. Usethe

otherdetents for deepertilling and for

powercomposting.

To avoid personal injury,

always place the tines in the TRAVEL

position before starting the engine.

This preventsthe tines from touching

the grounduntil youare ready to begin

tilling.

HandlebarHeightAdjustment

Lever

Usethis lever(F, Figure3-1) to adjust the

handlebarsto oneof two heightsettings.

1. Tochangetheheight,hold the handle-

barswith one handand loosenthe leverin

a counterclockwisedirection.

2. Movethe handlebarsto oneof the two

presetheightsettings.

3. Retightenthe lever.

NOTE:You can swapthe positions of the

inside handlebarratchetsto change the

two presetsettings by approximately four

inches higheror lower. SeeSection 2,

Step2: Attach Handlebarfor detailed

assembly information.

Page 13

The tiller handlebarscan be swungout

30°to the rightside for use onlywith the

PTOChipper/Shredderattachment. This

is doneby looseningthe mountingbolt

on the handlebarbase. Never operate

yourtiller orattachments,otherthanthe

PTO Chipper/Shredder,with the handle-

bars in the right side position. Doingso

could result in unsafe handling and

personalinjury.

EngineThrottleLever

Usethe throttle lever(G, Figure3-1) to

adjust enginespeedaswell asto start

and stopthe engine.

Move the leverawayfrom the STOP

position before starting the engine.

Enginespeedsare variableand range

betweenthe FASTand SLOW. Usethe

STOPposition to turn the engineoff.

NOTE: A secondarythrottle leveris

located onthe front of the 8HPandIOHP

engines. AseparateOn/Offsw_chmay

alsobeavailableontheengine. (See

EngineOwner'sManualfor information.)

KeyswitchStarter

Thekeyswitch starter on electricstart

models (A, Figure3-5) hasthree

positions: OFF,RUNand START.Turn

the keyto STARTto start the engine.

Releasethe keyand

it will returnto the

RUNposition. Turn

the keyto OFFto

stop the engine.

(Anotherway to

stop the engine is to

move the engine

throttle leverto the Figure 3-5

STOPposition.)

Section3: FeaturesandControls

Engine Controls

Referto the engine manufacturer's Engine

Owner's Manual (included inthe tiller lit-

erature package)to identify the controls

on your engine.

IMPORTANT:An engine On/Offswitch, a

secondary throttle control, a choke lever

and a fuel line shut-off control may be

located on the engine. Refer to your

Engine Owner's Manual for detailed

information.

To avoid serious personal injury or

damageto equipment, do not startyour

engine at thistime. Complete starting

instructionsare describedin Section4,

Operation.

13

Page 14

n

Op

Before operating your machine,

carefully read andunderstandall safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner's Manual, and on the decals on

the machine.

Failureto follow these instructionscan

resultin seriouspersonalinjury.

ration

INTRODUCTION

Readthis Section ofthe manual

thoroughly before you start the engine.

Then,take the time to familiarizeyourself

with the basic operation of the tiller

beforeusing it inyour garden. Find an

open, levelareaandpractice usingthe

tiller controls without the tines engaging

the soil (put tines inTravelsetting--

Section 3, DepthRegulator Lever). Only

after you've becomecompletelyfamiliar

with the tiller should you beginusing it in

the garden.

Your tiller and its optional PTO Power

Unit attachments are capable of

causing serious injury to untrained or

carelessoperators.

To avoid serious personal injury or

property damage, read the Owner's

Manual that is provided with any

optional accessories or attachments

before using the tiller or PTO Power

Unit.

Break-InOperation

Perform the following maintenanceduring

thefirst hours of new operation (see

MaintenanceSection in this Manualand

maintenanceinformation inthe Engine

Owner's Manual).

1. Changeengine oil afterfirst 2 hours of

newengine operation.

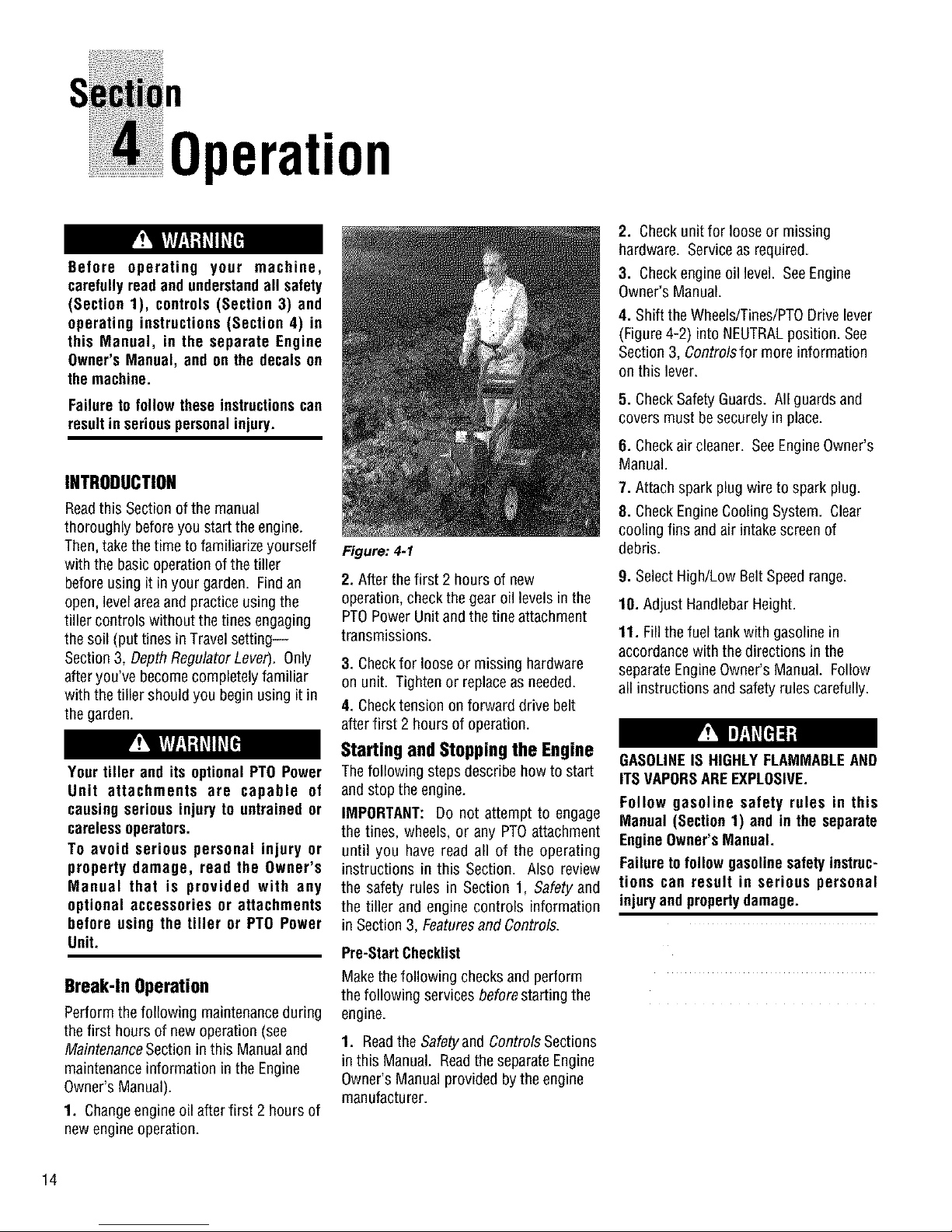

Figure: 4-1

2. After the first 2 hours of new

operation, checkthe gearoil levels inthe

PTOPower Unitandthe tine attachment

transmissions.

3. Checkfor loose or missing hardware

on unit. Tighten or replaceas needed.

4. Checktension on forward drive belt

after first 2 hours of operation.

StartingandStoppingthe Engine

Thefollowing stepsdescribehow to start

and stopthe engine.

IMPORTANT: Do not attempt to engage

the tines, wheels, or any PTOattachment

until you have read all of the operating

instructions in this Section. Also review

the safety rules in Section 1, Safety and

the tiller and engine controls information

in Section3, Featuresand Controls.

Pre-StartChecklist

Make thefollowing checks and perform

the following services before starting the

engine.

1. Readthe Safetyand ControlsSections

in this Manual. Readthe separate Engine

Owner's Manual provided by the engine

manufacturer.

2. Checkunit for looseor missing

hardware. Serviceas required.

3. Checkengine oil level. SeeEngine

Owner's Manual.

4. Shift the Wheels/Tines/PTODrivelever

(Figure4-2) into NEUTRALposition. See

Section3, Controlsfor more information

on this lever.

5. CheckSafety Guards. All guards and

covers must besecurely in place.

6. Checkair cleaner. SeeEngineOwner's

Manual.

7. Attach spark plug wire to spark plug.

8. CheckEngineCooling System. Clear

cooling fins andair intake screen of

debris.

9. Select High/Low Belt Speedrange.

10. Adjust HandlebarHeight.

11. Fillthe fueltank with gasolinein

accordancewith the directions in the

separate EngineOwner's Manual. Follow

all instructions andsafetyrules carefully.

GASOLINEIS HIGHLYFLAMMABLEAND

ITS VAPORSAREEXPLOSIVE.

Follow gasoline safety rules in this

Manual (Section 1) and in the separate

EngineOwner'sManual.

Failureto followgasolinesafety instruc-

tions can result in serious personal

injuryandpropertydamage.

14

Page 15

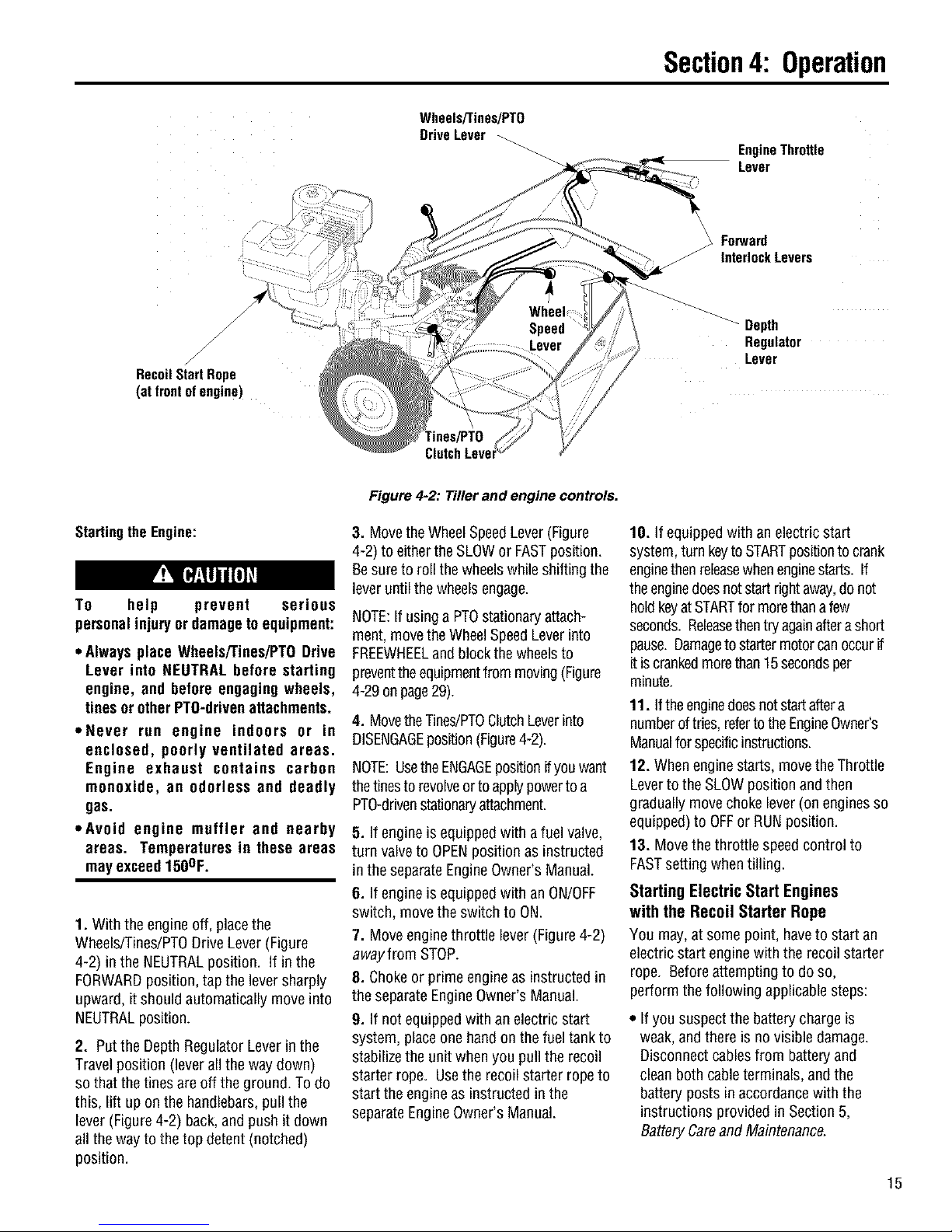

RecoilStartRope

(atfrontofengine)

Wheels/Tines/PTO

DriveLever

Tines/PTO

Figure 4-2." Tiller and engine controls.

Section4: Operation

EngineThrottle

Lever

\

_ Forward

J

Depth

InterlockLevers

Regulator

Lever

Startingthe Engine:

To help prevent serious

personalinjury or damagetoequipment:

• Always place Wheels/Tines/PTODrive

Lever into NEUTRAL before starting

engine, and before engaging wheels,

tinesor otherPTO-drivenattachments.

• Never run engine indoors or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas.

• Avoid engine muffler and nearby

areas. Temperatures in these areas

mayexceed150OF.

1. With the engineoff, placethe

Wheels/Tines/PTODriveLever (Figure

4-2) in the NEUTRALposition. If inthe

FORWARDposition, tap the lever sharply

upward, it should automatically moveinto

NEUTRALposition.

2. Putthe DepthRegulator Leverinthe

Travel position (leverall the way down)

so that the tines are off the ground. To do

this, lift uponthe handlebars,pull the

lever (Figure4-2) back,andpush it down

all the way to the top detent (notched)

position.

3. Move theWheel SpeedLever(Figure

4-2) to eitherthe SLOWor FASTposition.

Besureto roll the wheelswhile shifting the

leveruntil thewheelsengage.

NOTE:If usingaPTOstationary attach-

ment, movetheWheelSpeedLeverinto

FREEWHEELand block thewheelsto

preventthe equipmentfrom moving(Figure

4-29 onpage29).

4. MovetheTines/PTOClutchLeverinto

DISENGAGEposition(Figure4-2).

NOTE:Usethe ENGAGEpositionifyouwant

thetinesto revolveor toapplypowertoa

PTO-drivenstationaryattachment.

5. If engineis equippedwith afuel valve,

turn valveto OPENposition as instructed

in theseparate EngineOwner's Manual.

6. If engineis equippedwith an ON/OFF

switch, move theswitch to ON.

7. Move engine throttle lever(Figure 4-2)

awayfrom STOP.

8. Chokeor prime engine asinstructed in

the separateEngineOwner's Manual.

9. If not equipped with anelectric start

system, placeone handon thefuel tank to

stabilizethe unit when you pull the recoil

starter rope. Usethe recoil starter rope to

start the engineas instructedin the

separateEngineOwner's Manual.

10. If equipped with anelectric start

system,turn keyto STARTpositionto crank

enginethen releasewhenenginestarts. If

theenginedoesnotstart rightaway,donot

holdkeyatSTARTfor morethan afew

seconds.Releasethentry againaftera short

pause.Damageto startermotorcanoccurif

itis crankedmorethan15secondsper

minute.

11. Iftheenginedoesnotstart aftera

numberoftries,refertothe EngineOwner's

Manualforspecificinstructions.

12. Whenenginestarts, move theThrottle

Leverto the SLOWposition andthen

graduallymovechoke lever(on enginesso

equipped)to OFFor RUNposition.

13. Movethe throttle speed control to

FASTsettingwhen tilling.

Starting Electric Start Engines

with the Recoil Starter Rope

You may,at some point, haveto start an

electricstart enginewith the recoil starter

rope. Beforeattempting to do so,

perform the following applicablesteps:

• If you suspectthe battery chargeis

weak,and there is novisible damage.

Disconnectcables from batteryand

cleanboth cableterminals, andthe

battery posts inaccordance with the

instructions providedin Section 5,

BatteryCareand Maintenance.

15

Page 16

Section4: Operation

Reconnectthe cables andsecurely

tighten to batteryposts. Theenginewill

rechargethe battery if the battery is still

good.

• If you suspectthe batter is "dead", or if

the batteryis damaged,disconnect, and

remove it. Haveit checkedby a

qualifiedtechnician.

• If battery has beenremoved,wrap cable

terminals atend of positive cablewith

electricaltape andsecurethecableto

the batterybracket. This will prevent

electricaldischarge.

• Before pulling the recoil starter rope,

turn the keyswitch to the RUNposition.

Move theThrottle Lever awayfrom

STOPposition and set the chokeas

applicable. SeeEngineOwner's Manual.

Stopping the Engine and Tiller

1. Tostop the wheelsand tines, movethe

Wheels/Tines/PTODriveLever into

NEUTRALposition andthen releaseboth

ForwardInterlock Levers.

16

2. Move the engineThrottle Leverto the

STOPposition. Thenonelectric start

models, turn the keyto OFF. Removethe

key for safekeeping.

NOTE: Theenginemayhavea separate

Throttle Control Leverand ON/OFFswitch

on the engine. Thesecontrols can also be

usedto stop the engine. Seethe Engine

Owner's manualfor information specific

to your engine.

Operating the Tiller

Whenfirst practicing,keeptheTines/PTO

ClutchLeverin DISENGAGEpositionand

theWheelSpeedLeverinSLOWposition.

To avoid serious personal injury or

damageto equipment:

• Alwaysplace Wheels/Tines/PTODrive

Lever in NEUTRAL before starting

engine, and before engagingwheels,

tinesor otherPTOattachments.

• Be sure thereare no obstaclesbehind

youbeforemovingin reverse.

• Wheels/Tines/PTODriveLever should

automatically return to NEUTRAL

when released from REVERSE

position. If it doesnot, movelever to

NEUTRALmanually and discontinue

use until you adjust the lever. See

Section 5, Checking and Adjusting

ReverseDrive System.

• No reverse motion should occur if

Wheels/Tines/PTODrive Lever is not

held up in REVERSE. SeeSection 5,

Checking and Adjusting Reverse

Drive System for adjustment steps.

Do not use tiller unless properly

adjusted.

• Alwaysreturn to NEUTRALand let all

motion stop before shifting to

FORWARDor REVERSE.

Thefollowing pagesprovide guidelines

for using your tiller effectivelyandsafely

in variousgardening applications. Be

sure to read Tilling Tips& Techniques,in

this Section, beforeyou actually putthe

tines into the soil.

This isa traditional standard-rotating-tine

(SRT) tiller with forward rotating tines. It

operates inacompletelydifferent manner

than counter-rotating-tine (CRT)tillers, or

from front-tine tillers.

Movingthe Tiller ForwardandTilling

1. Start the engine and gradually increase

engine speedto FAST(see Startingthe

Engine,this Section).

The ForwardInterlock Safety System is

designedfor the operator'ssafety. Do

not disconnector attempt to defeat the

purpose of the system. If the system

malfunctions,immediately contactyour

local authorized dealer or the

TROY-BILT Technical Service Depart-

ment for assistance. Do not use the

tiller or the PTO power unit until the

Forward Interlock Safety System is

functioning properly. Always test the

system before using the tiller or PTO

powerunit.

2. Testthe ForwardInterlock Safety

System. See TestingForward Interlock

System,this Section.

Keepaway fromrotatingtines. Rotating

tineswill causeinjury.

3. When practicing, setthe Depth

Regulator Leverto Travel position.

Otherwise,set the Depth Regulator Lever

to a desireddepth.

4. Move Tines/PTOClutch Leverto

ENGAGEposition if you want the tines to

turn. If practicing, leavein DISENGAGE.

IMPORTANT: Do not move Tines/PTO

Clutch Lever to ENGAGE unless

Wheels/Tines/PTO Drive Lever is in

NEUTRAL.Tiller damagemay occur!

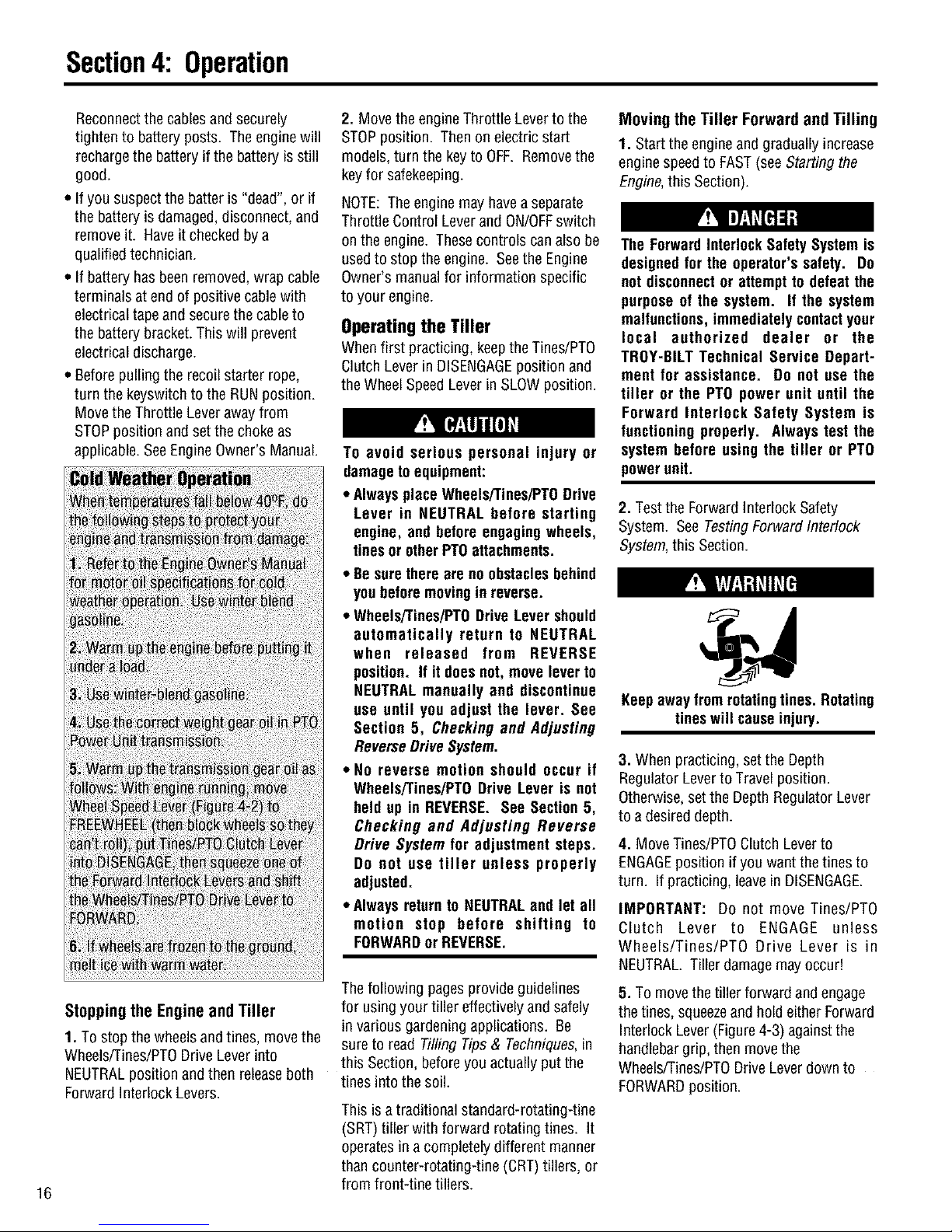

5. To movethe tiller forward andengage

the tines,squeezeandholdeither Forward

Interlock Lever(Figure4-3)againstthe

handlebargrip, thenmove the

Wheels/Tines/PTODriveLeverdownto

FORWARDposition.

Page 17

Figure 4-3: Moving tiller forward:

squeeze one Forward Interlock Lever

and then move Wheels/Tines/PTO

Drive Lever down to FORWARD.

6. Whenthe tiller movesforward, relax

and let thewheels power thetiller along

while thetines dig. Walk behindand to

one sideof the tiller. Walk on the side

that is not yet tilled (Figure4-4). Usea

firm grip on the handlebarsbut keepyour

arm relaxed.

IMPORTANT: Letthe tiller move aheadat

its own pace. Do not push it ahead--this

reduces operator control and tilling effi-

ciency. Do not push handlebars down in

an attempt to dig deeper-- this takes

weight off the wheels, reduces traction,

and causes the tines to try to propel the

tiller.

StoppingForwardMotionandTines

1. Tostop forward motion, tap

Wheels/Tines/PTODriveLever upward

into NEUTRAL.Then releasethe Forward

Interlock Levers. Thewheels and tines

will stop and the engine will continue

running.

2. In an emergency,releaseall of the

control levers. Thisstops forward motion

and shuts-off the engine.

To Help Avoid Personal Injury or

Damageto Equipment:

• Be sure no obstaclesare behindyou

beforeoperatingthe tiller in REVERSE.

• Disengagethe tines, reduce engine

speed, and move the Wheel Speed

Lever to SLOW position before

operating in REVERSE. Avoid using

FAST wheel speed until you are

familiar withbackingthe tiller.

Figure 4-4: Guide tiller with one hand.

Moving the Tiller in Reverse

IMPORTANT: Do not till while in

REVERSE.

1. Shift theTines/Wheels/PTODriveLever

(Figure4-2) into NEUTRALand movethe

WheelSpeedLever to the SLOW position.

2. Move Tines/PTOClutch Lever(Figure

4-2) into DISENGAGEposition.

3. Verify that the area behindyou is clear.

4. Lift upthe handlebarsuntil the tines

are off theground, thenshift the

Wheels/Tines/PTODriveLever allthe way

up and hold. You do not needto squeeze

the Forward Interlock Leversto use

mve_e.

5. Theunit immediatelyengagesin

reverse. Periodicallycheck behindyou

while holding the handlebarsupandthe

Wheels/Tines/PTOLeverin its upper-most

position.

Stopping Reverse Motion

Releasethe Wheels/Tines/PTODrive

Lever- the lever automatically returns to

the NEUTRALposition. This stops the

wheels immediately.(TheForward

Interlock Leverswill notstop REVERSE

motion.)

ToStopthe Engine

Move the engineThrottle Leverto the

STOPposition. Then, on electric start

models, turn keyto OFF. Removethe key

for safekeeping.

Section4: Operation

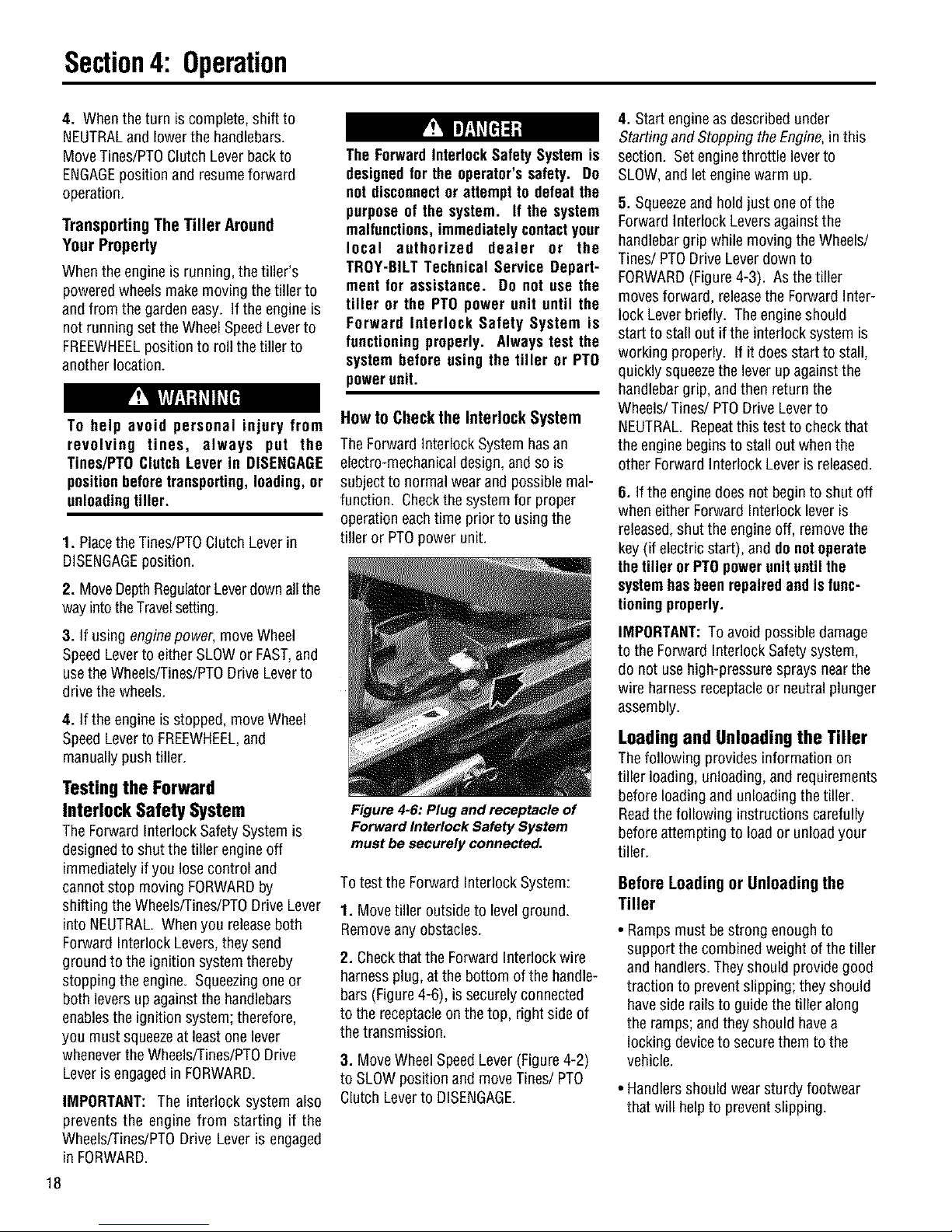

MakingTurns

Turningthe tiller is easyand just requires

practice. First find the balance point

betweenthe engine and thetines by lifting

upthe handlebars(Figure4-5). Onceyou

find the balancepoint, then letthe

poweredwheelsdo theturning as you

pushsidewayson the handlebarsin the

direction of theturn. Practice theturning

maneuverdescribed herein alarge open

area. Oncecomfortableturning the tiller,

you canthen take it to the gardenarea.

1. Atthe endof a row, movethe Wheels/

Tines/PTODrive Lever(Figure4-2)to

NEUTRALpositionand reducethe engine

speed.

2. Move the Tines/PTOClutch Lever

(Figure4-2) into the DISENGAGE

position.

3. Resumeforward operation, and lift

handlebarsuntil tines are off theground

(Figure4-5). Findthe balancepoint

betweenthe engine and thetines. Then

pushthe handlebarsin the direction of the

turn. Be very careful to keepfeetandlegs

away fromthe tines (which should bedis-

engaged). Letthe poweredwheels do the

hardwork. The insidewheelwill pivotin

placewhile the outsidewheel drives the

tiller around inthe direction ofthe turn.

Figure 4-5: Turning the tiller.

NOTE:Use REVERSEif necessaryto turn

in alimited space.

17

Page 18

Section4: Operation

4. Whenthe turn is complete,shift to

NEUTRALand lowerthe handlebars.

Move Tines/PTOClutch Leverbackto

ENGAGEposition and resumeforward

operation.

Transporting The Tiller Around

Your Property

When the engineis running, thetiller's

poweredwheels make moving the tiller to

and from the gardeneasy. If the engine is

not running set the WheelSpeedLever to

FREEWHEELposition to roll the tiller to

another location.

To help avoid personal injury from

revolving tines, always put the

Tines/PTOClutch Lever in DISENGAGE

positionbeforetransporting,loading,or

unloadingUiler.

1. Placethe Tines/PTOClutch Leverin

DISENGAGEposition.

2. MoveDepthRegulatorLeverdownall the

way intotheTravelsetting.

3. If using enginepower, moveWheel

SpeedLeverto either SLOWor FAST,and

usethe Wheels/Tines/PTODrive Leverto

drivethe wheels.

4. If theengine is stopped, moveWheel

SpeedLeverto FREEWHEEL,and

manually push tiller.

Testing the Forward

Interlock SafetySystem

The Forward Interlock SafetySystem is

designedto shut thetiller engine off

immediately if you losecontrol and

cannot stop moving FORWARDby

shifting theWheels/Tines/PTODrive Lever

into NEUTRAL. Whenyou releaseboth

Forward Interlock Levers,they send

ground to the ignition system thereby

stopping theengine. Squeezingoneor

both levers up against the handlebars

enablesthe ignition system;therefore,

you must squeezeat leastone lever

whenever the Wheels/Tines/PTODrive

Leveris engagedin FORWARD.

IMPORTANT: The interlock system also

prevents the engine from starting if the

Wheels/Tines/PTODrive Lever is engaged

in FORWARD.

18

The ForwardInterlockSafetySystem is

designedfor the operator's safety. Do

not disconnector attempt to defeat the

purpose of the system, if the system

malfunctions, immediately contactyour

local authorized dealer or the

TROY-BILT Technical Service Depart-

ment for assistance. Do not use the

tiller or the PTO power unit until the

Forward Interlock Safety System is

functioning properly. Always test the

system before using the tiller or PTO

powerunit.

HowtoCheckthe Interlock System

The Forward Interlock System hasan

electro-mechanicaldesign, and so is

subject to normal wearand possiblemal-

function. Checkthe system for proper

operationeach time prior to using the

tiller or PTOpower unit.

Figure 4-6: Plug and receptacle of

Forward Interlock Safety System

must be securely connected.

To test the ForwardInterlockSystem:

1. Movetiller outside to levelground.

Removeany obstacles.

2. Checkthat the ForwardInterlockwire

harnessplug, at the bottom ofthe handle-

bars (Figure4-6), is securelyconnected

to the receptacleon the top, right sideof

the transmission.

3. MoveWheel SpeedLever(Figure4-2)

to SLOWposition and moveTines/PTO

ClutchLever to DISENGAGE.

4. Start engine asdescribed under

Starting andStopping the Engine,in this

section. Setengine throttle lever to

SLOW,and let enginewarm up.

5. Squeezeand hold just one of the

Forward Interlock Leversagainst the

handlebargrip while movingthe Wheels/

Tines/PTO DriveLever down to

FORWARD(Figure4-3). As the tiller

movesforward, releasethe ForwardInter-

lock Leverbriefly. The engineshould

start to stall out if the interlock system is

working properly. If it does start tostall,

quickly squeezethe lever up againstthe

handlebargrip, andthen return the

Wheels/Tines/PTO Drive Leverto

NEUTRAL. Repeatthis test to checkthat

the engine beginsto stall out when the

other ForwardInterlock Leveris released.

6. If the enginedoes not beginto shut off

when either ForwardInterlock leveris

released,shut theengine off, removethe

key (if electric start), and donotoperate

the tiller or PTOpowerunituntil the

systemhasbeenrepaired and isfunc-

tioningproperly.

IMPORTANT:To avoid possible damage

to the ForwardInterlock Safetysystem,

do not use high-pressure sprays nearthe

wire harnessreceptacleor neutralplunger

assembly.

Loading and Unloading the Tiller

Thefollowing provides information on

tiller loading, unloading, andrequirements

before loading and unloading the tiller.

Readthe following instructions carefully

beforeattempting to load or unloadyour

tiller.

BeforeLoadingorUnloadingthe

Tiller

• Ramps must be strong enoughto

support the combined weight of thetiller

and handlers.Theyshould providegood

traction to prevent slipping; they should

haveside railsto guide thetiller along

the ramps;and they should havea

locking deviceto securethemto the

vehicle.

• Handlersshould wear sturdy footwear

that will helpto preventslipping.

Page 19

Section4: Operation

• Turnthe vehicle's engineoff and apply

its parkingbrake.

• Positionthe loading vehicleso that the

ramp angle isas flat aspossible (the

less incline to the ramp,the better).

Loadingthe Tiller

1. Use loading rampsthat arestrong and

wide enough to safely holdthe weight of

the tiller andthe operator combined--

your tiller weighs between280 and 325

Ibs.

2. Move the Tines/PTOClutch Lever

(Figure4-2) into DISENGAGEposition.

3. Setthe DepthRegulatorlever (Figure

4-2) to the Travel position.

4. Move WheelSpeedLever (Figure4-2)

into SLOWposition and reducethe

enginethrottle speed.

5. Shift the Wheels/Tines/PTOLever

(Figure4-2) into FORWARDposition and

follow the tiller up the ramps (Figure4-7).

Checkthe wheelsas you move the tiller

forward. Ensurethat they moveupthe

center of eachramp.

6. Preventtiller from rolling in vehicle.

LeaveWheel SpeedLeverin FASTor

SLOWposition, chock wheels with blocks

and tie down the tiller.

Figure 4-7: To go up ramps, use

FORWARD drive.

Unloading the Tiller

IMPORTANT:Neverunload thetiller in

FORWARDdrive. Thetiller could tip

forward andexposeyou to the tines

(which should bedisengagedas

instructed).

1. Use loading rampsthat arestrong and

wide enough to safely holdthe weight of

the tiller andthe operator combined--

your tiller weighs between280 and 325

Ibs.

2. Move the Tines/PTOClutch Lever

(Figure 4-2) to DISENGAGEposition.

3. Setthe DepthRegulatorLever (Figure

4-2) to the Travel position.

4. Move WheelSpeedLever (Figure4-2)

to SLOWposition and reducethe engine

throttle speed.

IMPORTANT: Look behind you before

you backdown the ramp to ensurethat all

is clear. While descending, keepchecking

for obstacles behindyou.

5. Move and holdthe Wheels/Tines/PT0

Lever into REVERSEdrive and backdown

the ramps (Figure4-8). Checkthewheels

asyou move the tiller backward. Ensure

that they movedown the center of each

ramp.

Figure 4-8: TOgo down ramps, use

REVERSE drive.

Changing Speed Belts

Your tiller hastwo belt-driven speed

ranges- HIGH RANGEand LOWRANGE

- you pick one or the other by deciding

which setof pulleygrooves to movethe

forward belt into. Bymoving the belt

from onespeed rangeinto the other, in

combination with the FASTand SLOW

wheel speeds,you obtain a choice of four

different forward wheel speedsandtwo

different tine speeds.

To help avoid serious personal injury,

stop the engine, remove the ignition

key, disconnect spark plug wire and

move the wire away from the spark

plug, and let engine and muffler cool

downbeforechangingbelt speeds.

Changingthe beltfrom LOWrange into

HIGHrange (or backagain) isa matter of

moving the belt from one setof pulley

grooves to a second set of pulleygrooves.

This changeis done quickly andwithout

tools (Figures4-9 through 4-13).

Pulley

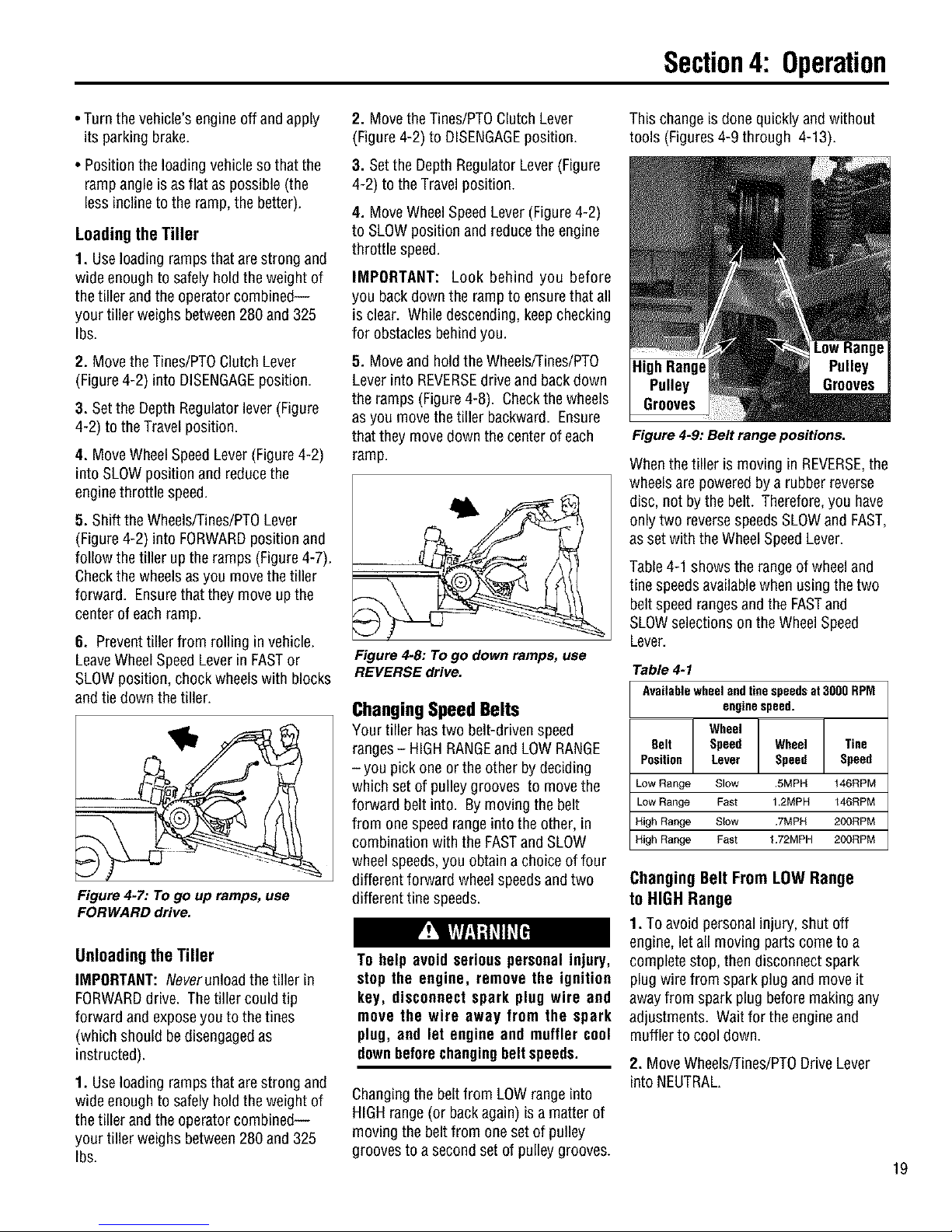

Figure 4-9: Belt range positions.

Whenthe tiller is moving inREVERSE,the

wheels arepowered bya rubber reverse

disc, not bythe belt. Therefore,you have

onlytwo reversespeedsSLOWand FAST,

as set with the WheelSpeedLever.

Table4-1 showsthe rangeof wheeland

tine speedsavailablewhen using the two

beltspeed rangesand the FASTand

SLOWselectionson theWheel Speed

Lever.

Table 4-1

AvailablewheelandUnespeedsat 3000RPM

enginespeed.

Belt WheelSpeedWheel Tine

Lever _ Speed _ Speed

Low Range Slow .5MPH _46RPM

Low Range Fast 1.2MPH 146RPM

High Range Slow .7MPH 200RPM

High Range Fast 1.72MPH 200RPM

ChangingBeltFromLOWRange

to HIGHRange

1. To avoid personalinjury, shut off

engine,let all moving parts come to a

completestop, then disconnect spark

plug wire from spark plug andmove it

away from spark plug beforemaking any

adjustments. Wait for the engineand

muffler to cool down.

2. MoveWheels/Tines/PTODriveLever

into NEUTRAL.

19

Page 20

Section4: Operation

The HIGH speed belt range position

combined with a FAST wheel speed

setting propelsthe tiller at the fastest

pace. Reducethe enginethrottle speed

whenstartingoutto help avoidpersonal

injury or propertydamage if using this

speedcombination.

3. Kneelon left side of tiller. Tocreate

belt slack, reachoverto right side of the

pulleys and push inatthe center of the

belt with a finger. At the sametime, use

your left hand to work the belt part-way

onto the lower-front transmission pulley

groove (Figure4-10).

4. Goto right side of tiller and finish

seatingthe belt.

5. Still holding the lever up in REVERSE

position, and working from the left side of

thetiller, movethe beltfrom the lower-

front transmission grooveto the lower-

rear transmission groove.

6. Goto the right side of the tiller and

finish seatingthe belt (Figure4-13).

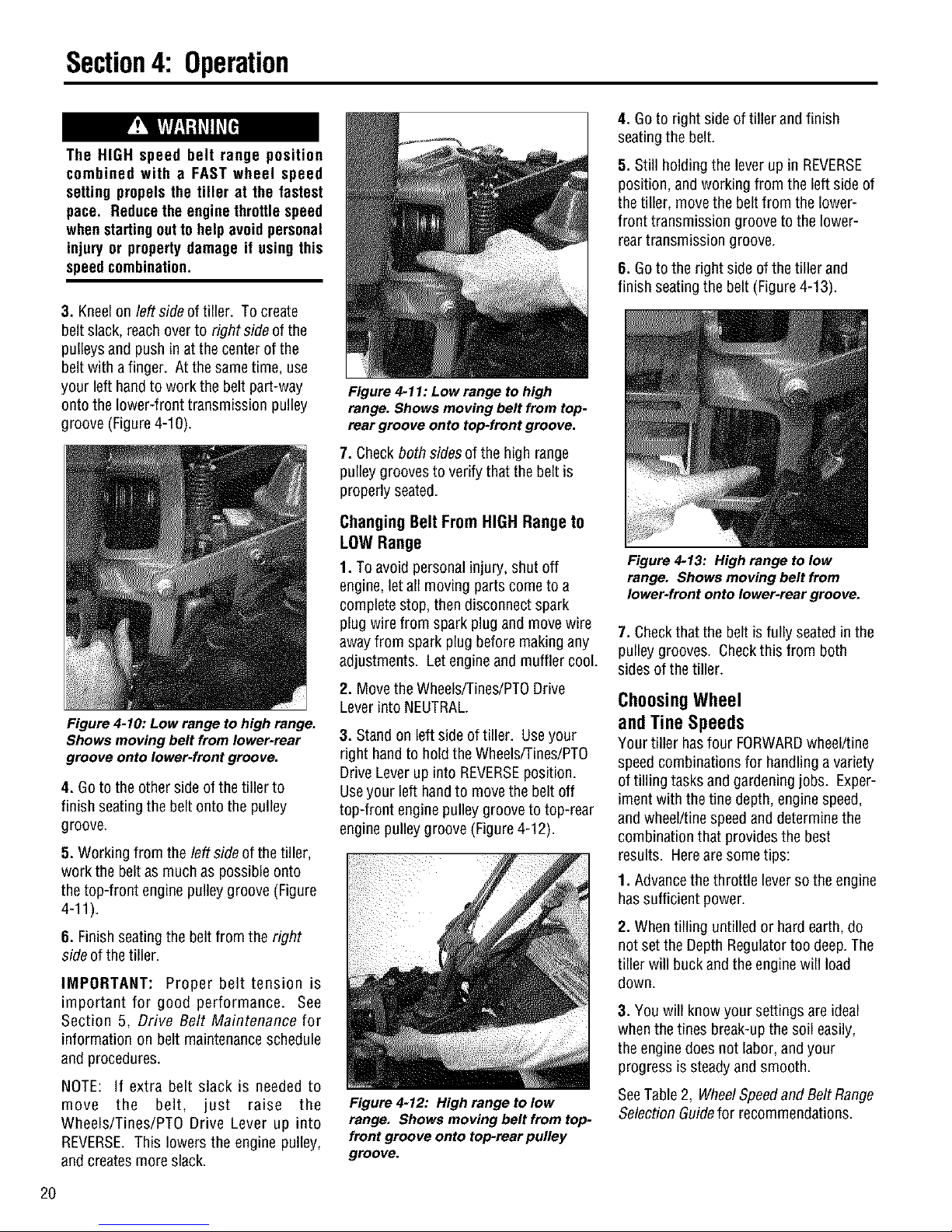

Figure 4-11: Low range to high

range. Shows moving belt from top-

rear groove onto top-front groove.

7. Checkboth sidesof the high range

pulley groovesto verify that the belt is

properly seated.

Figure 4-10: Low range to high range.

Shows moving belt from lower-rear

groove onto lower-front groove.

4. Goto the other side of the tiller to

finish seatingthe belt onto the pulley

groove.

5. Working from the left side of the tiller,

work the beltas muchas possibleonto

the top-front engine pulley groove (Figure

4-11).

6. Finish seatingthe beltfrom the right

side of thetiller.

IMPORTANT: Proper belt tension is

important for good performance. See

Section 5, Drive Belt Maintenance for

information on belt maintenanceschedule

and procedures.

NOTE: If extra belt slack is needed to

move the belt, just raise the

Wheels/Tines/PTO Drive Lever up into

REVERSE.This lowers the engine pulley,

and createsmore slack.

Changing Belt From HIGH Range to

LOW Range

1. To avoid personalinjury, shut off

engine,let all moving parts come to a

complete stop, thendisconnect spark

plug wire from spark plug and move wire

awayfrom spark plug before makingany

adjustments. Let engineand muffler cool.

2. Move theWheels/Tines/PTODrive

Lever into NEUTRAL.

3. Standon left side of tiller. Useyour

right hand to hold the Wheels/Tines/PTO

Drive Lever up into REVERSEposition.

Useyour left handto movethe belt off

top-front engine pulley grooveto top-rear

engine pulleygroove (Figure4-12).

Figure 4-12: High range to low

range. Shows moving belt from top-

front groove onto top-rear pulley

groove.

Figure 4-13: High range to low

range. Shows moving belt from

Iower-frent onto lower-rear groove.

7. Checkthat the belt isfully seatedinthe

pulley grooves. Checkthis from both

sides of thetiller.

ChoosingWheel

and Tine Speeds

Your tiller hasfour FORWARDwheel/tine

speedcombinations for handling a variety

of tilling tasks and gardening jobs. Exper-

iment with the tine depth, enginespeed,

and wheel/tinespeedanddeterminethe

combination that provides the best

results. Herearesome tips:

1. Advancethe throttle leverso the engine

hassufficient power.

2. When tilling untilled or hard earth, do

not set the Depth Regulatortoo deep.The

tiller will buckand the enginewill load

down.

3. You will know your settings are ideal

whenthe tines break-up the soil easily,

the enginedoes not labor, and your

progress issteadyand smooth.

SeeTable2, WheelSpeedand BeltRange

Selection Guidefor recommendations.

2O

Page 21

Section4: Operation

SLOWGEAR,LOWBELTRANGE

For:

• Tillinginsod.

• Tillingin hardclay,

• Tilling understandingcorn-

stalks intoughsoil conditions.

• Tilling undercovercrops.

• Preparingadeepseedbed,

• Tilling instonysoil.

• Tilling underresiduesand

organicmatter,

• Mixingin fertilizers,manure.

SLOWGEAR,NIGHBELTRANGE

For:

• Tillingin sodor hardclay.

• Tillingunderstandingcorn-

stalks(slow,steadyspeed

allowstime to shredstalks).

• Tillingundercovercrops

(bestwheelspeedand belt

speedrangein mostsoils).

• Preparingseedbeds(best

speedchoicein most soils).

• Tillingin stonyground.

• Buildingraisedgardenbeds.

• Mixingin fertilizer.

• Usinghiller wingsin hard

soil.

• Mixingfertilizer andmanure.

• Tillingresiduesandorganics.

TillingTips& Techniques

Letthetiller dothework

• While tilling, relax and letthe wheels

pull the tiller along while the tinesdo

the digging. Walk on theside that is not

yet finished (to avoid making footprints

inthe freshly tilled soil) and lightly, but

securelygrip the handlebarwith just

one hand(Figure4-4).

• Avoid pushingdown on the handlebars

inan attempt to forcethe tiller to dig

deeper. Doing so takesthe weight off

the poweredwheels, causingthem to

losetraction. Without thewheels

helping to hold the tiller back,the tines

will attempt to propel thetiller - often

causingthe tiller to skip rapidly across

the ground. (Sometimes, slight

downward pressureonthe handlebars

will helpget through aparticularly

tough section of sod or unbroken

ground, but inmost casesthis won't be

necessary.)

Tilling depths

• Avoid trying to dig too deeplytoo

quickly, especiallywhenbusting sod or

tilling soil that hasn't beentilled for

some time. Useshallow depth settings

(only an inchor two deep)for the first

passesthrough the gardenarea.

FASTGEAR,LOWBELTRANGE

For:

Goingoverseedbedfor the

lasttime beforeplantingcrops.

Coveringoverseedsinwide

row or plot planting(lift han-

dlebarsto avoidgoingtoo

deep).

Hillingandfurrowing.

Makingraisedbeds.

Cultivating(lift handlebarsto

avoidgoingtoo deep).

•Tilling largeareas.

•Tillingorganicmatterin.

Cultivatingbetweenraised

bedswith optional

hiller/furrowerattachment.

With eachsucceeding pass,adjust the

depth regulatorto diganother inchor

two deeper. (Wateringthe gardenarea

afew daysprior to tilling will make

tilling easier,aswill letting the newly

worked soil set for a day or two before

making afinal, deeptilling pass.)

• Whencultivating (breakingup the

surfacesoil aroundplantsto help

destroyweeds), usevery shallowdepth

settingsto preventinjuryto plantswhose

rootsoften growcloseto thesurface. If

needed,lift uponthe handlebarsslightly

to preventthetinesfrom diggingtoo

deeply. Cultivatingon aregularbasisnot

onlyeliminatesweeds,it alsoloosensand

aeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.

Avoidtillingwet, soggysoil

Tilling wet soil often results in large,hard

clumps of soil thatcan interferewith

planting. Iftime permits, waitaday or

two after heavy rainsto allow the soil to

dry beforetilling. Testthe soil by

squeezingit into a ball. If it compresses

too easily,it istoo wet to till.

FASTGEAR,HIGHBELTRANGE

For:

Preparingseedbedsfor

planting.

Coveringseedswith lessneed

to holdup thehandlebars.

• Cultivating(tillertravelsfaster,

rideshigheron thesoil;allows

engineRPMto bereduced;

handlebarsdon't haveto be

raised).

• Keepinglargeareastilledand

cultivatedin thesummer.

•Tilling organicmatter under.

• Movingtiller quickly.

• Cultivatingbetweenraised

bedsusing theoptional

hiller/furrower.

To helpavoid personalinjury, beaware

that the tiller can unexpectedlybounce

up orjumpaheadand propelawayfrom

you if the tines strike hard or frozen

ground, or buried obstacles like large

stones, roots or stumps. Always use

the following precautions to help

maintaincontrolofthetiller:

• Walk behind and to the side of the

tiller. Useonehand onthe handlebars,

relaxing your arm but with a secure

handgrip.

• Use shallow depthregulatorsettings.

Till graduallydeeper.

• Use slower wheel, tine and engine

speeds.

• Clear the tilling area of all large

stones,rootsandotherdebris.

• Do not putdownwardpressureon the

handlebars. If needed, apply slight

upwardhandlebarpressureto keep the

tinesfromdiggingtoodeeply.