Page 1

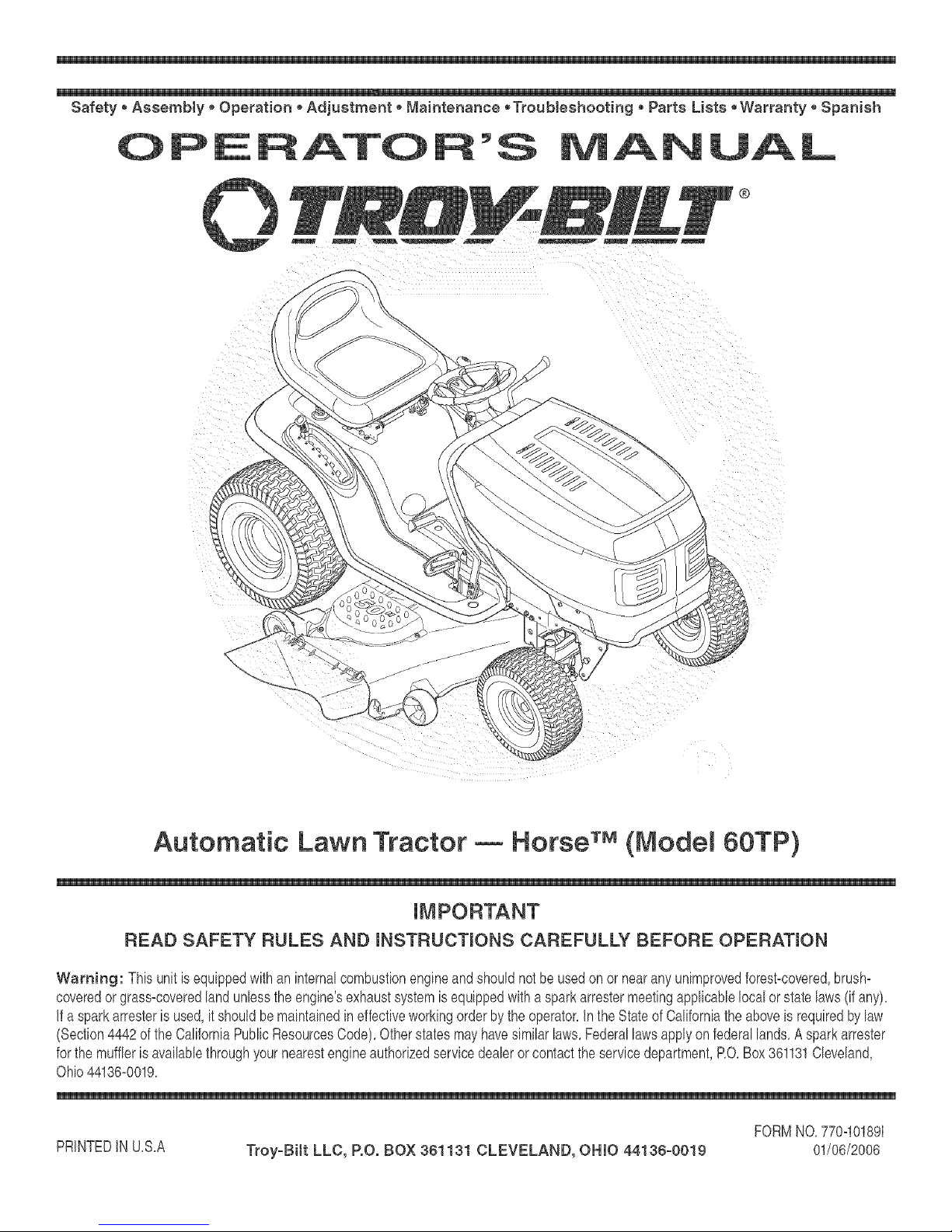

Automatic Lawn Tractor Horse TM(Model 60TP)

READ SAFETY RULES AND mNSTRUCTmONS CAREFULLY BEFORE OPERATmON

Warning: This unitis equippedwithan internalcombustionengineandshouldnotbeusedon or nearanyunimprovedforest-covered,brush=

coveredor grass=coveredlandunlesstheengine'sexhaustsystemis equippedwitha sparkarrestermeetingapplicablelocalorstatelaws(if any),

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbytheoperator,Inthe StateofCaliforniatheaboveis requiredbylaw

(Section4442ofthe CaliforniaPuNicResourcesCode),Otherstatesmayhavesimilarlaws,Federallawsapplyonfederallands,A sparkarrester

forthe mufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO,Box361131Cleveland,

Ohio44136=0019,

PRINTEDIN U,S,A Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 01/06/2006

FORMNO,770=10189I

Page 2

This Operator's Manua_ is an important part of your new lawn tractor, mtwH_ he_p you assemble,

prepare and maintain the unit for best performance. P_ease read and understand what it says.

Table of Contents

Slope Gauge ....................................................... 3

Safe Operation Practices ................................... 4

Setting Up Your Lawn Tractor ............................ 8

Operating Your Lawn Tractor ........................... 10

Adjusting Your Lawn Tractor ............................ 18

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT,

please locatethe modelplate onthe equipmentand copythe

informationto the sample model plate providedto the righL

Youcan locatethe modelplate by looking beneath the seal

Thisinformationwill be necessaryto usethe manufacturer's

web siteand/or obtainassistancefromthe CustomerSupport

Departmentoran authorizedservice dealer.

Maintaining Your Lawn Tractor ........................ 20

Off-Season Storage / Attachments ................. 26

Safety Labels .................................................... 27

TrouMe Shooting .............................................. 28

Parts List ........................................................... 30

Modem Number Seriam Number

0 TR#_H_--T_ TROY=BiLT LLC

P. O. BOX 361131

www.troybiit.com CLEVELAND, ON44136

338=558=7228

,, 856=848=6483_

Customer Support

P_ease do NOTreturn the unitto the retai_er from which it was

purchased, without first contacting Customer Support.

if you havedifficulty assemblingthis productor haveany questions regarding the controls, operation, or maintenanceof this

unit,youcan seek helpfrom the expert& Choosefromthe optionsbelow:

1, Visittroybilt.com for manyusefulsuggestions,Clickon Customer

Supportbuttonandyouwillget theoptionsreproducedin thescreen

shotbelow,CIbk onthe appropriatebuttonandhelpis immediately

availabb,

2, Phonea Customer Support Representativeat 1=866-840=6483,

3, The engine manufacturer isresponsibbforall engine=relatedissues

with regardtoperformance,power=rating,specifications,warrantyand

service,Phaserefertothe enginemanufacturer'sOwner's/Operator's

Manual,packedseparatelywithyour unit,formoreinformation,

Page 3

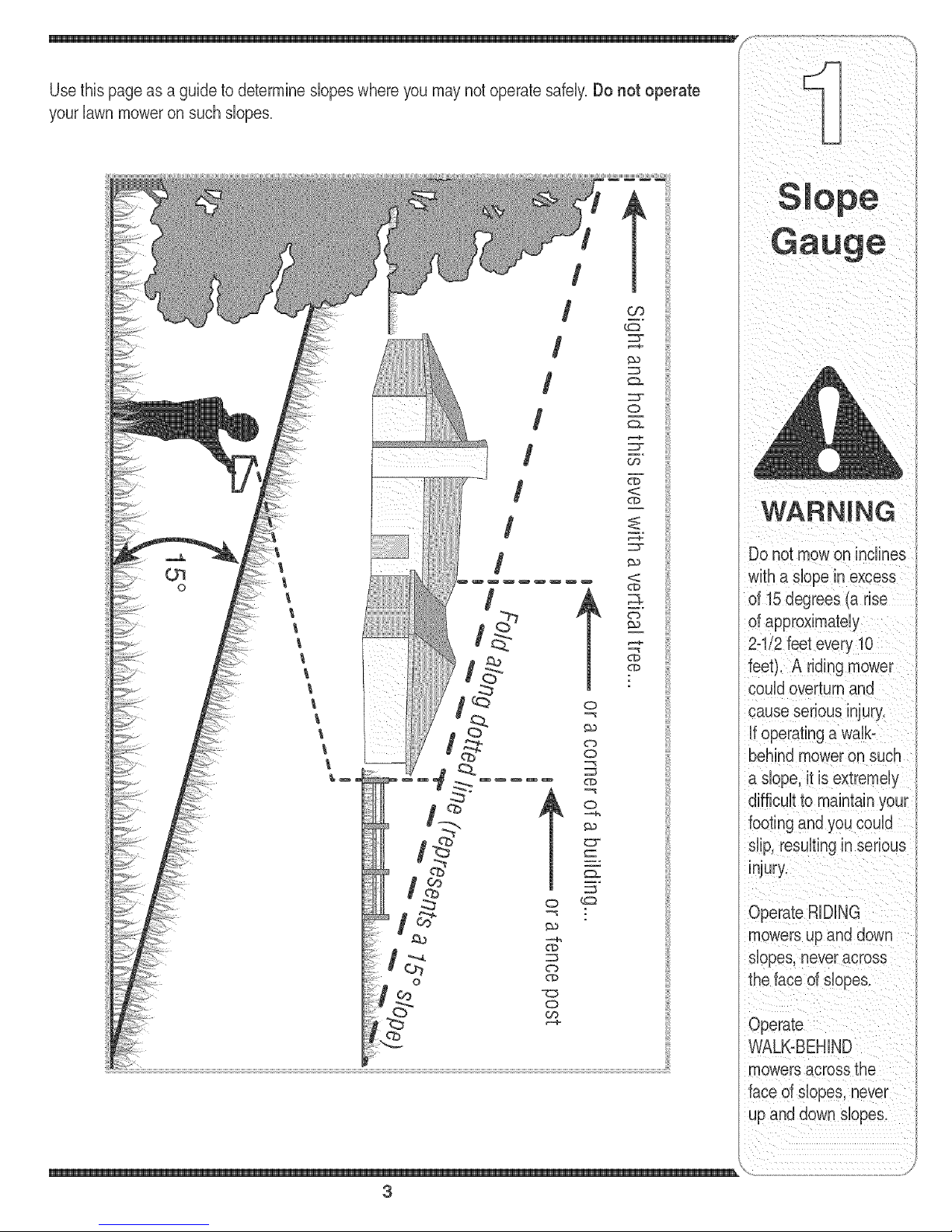

your lawn moweron such slopes.

/

t

/

/

/

/

/

o

WARNING

w_

Do not mowon inclines

with a dope in excess

of 15 degrees (a rise

of approximately

2-"

feet). A riding r

couldoverturnand

cause serious injury.

if operatinga walb

behindmoweron such

a dope, it is extremely

footing and you could

dip, resultinginserious

injury.

OperateRiDiNG

mowersupand down

dopes, neveracross

o

3

theface of dopes.

Operate

WALK-BEHIND

mowersacrossthe

face of dopes, never

up and down slopes.

\

Page 4

_i i _ i _i _ i _ iii _ _

S ale resultin seriousinjury.This machineis capable of amputatinghandsandfeet and throwing objects.

DANGER: This machine wasbuiltto be operatedaccordingto the rubs for safeoperation inthis

manuakAs withany type of powerequipment,carelessnessor erroronthe partof the operatorcan

Failureto observethe followingsafetyinstructionscould resultin serious injury or death.

instructionswhich, if

notfollowed, could

endangerthe personal

safetyand/or property

of yourself and others.

Readandfobowall

instructionsinthis man=

ualbefore attemptingto

operatethis machine.

Failureto complywith

Whenyouseethis

symbol.

HEED ITS WARNING

Your

Responsibility

Restrictthe use

of this power machine

to personswho read.

understand

and followthewarnings

and instructions

in this manual

Children

1. Tragicaccidentscanoccuriftheoperatorisnot

abrt tothepresenceof children.Childrenareoften

attractedto the machineandthemowingactivity.

Theydo notunderstandthe dangers.Neverassume

thatchildrenwillremainwhereyoulastsawthem.

a. Keepchildrenoutofthe mowingareaandin

watchfulcareof a responsibleadultotherthan

theoperator.

b. Bealertandturnmachineoffifachildenters

thearea.

c. Beforeandwhilebacking,lookbehindand

downfor smallchildren.

d. Nevercarrychildren,evenwiththeblade(s)

shutoff.Theymayfalloffandbeseriously

iniuredor interferewithsafemachineoperation.

e. Useextremecarewhenapproachingblind

corners,doorways,shrubs,treesor other

objectsthatmayblockyourvisionofa child

whomayruninto themachine.

f. Toavoid back-overaccidents, always

disengagethe cutting blade(s) before

shifting into Reverse.Ifequipped,the

"ReverseCaution Mode" should not be

usedwhen children or others are around.

g. Keepchildrenawayfromhotor running

engines.Theycansuffer burnsfroma hot

muffler.

h. Removekeywhenmachineisunattendedto

preventunauthorizedoperation.

2. Neverallowchildrenunder14yearsoldto operate

themachine.Children14}'earsoldandovershould

readandunderstandtheoperationinstructionsand

safetyrubs inthis manualandshouldbetrainedand

supervisedbya parent.

Operation

Safe Handlingof Gasoline:

1. Toavoid personal injuryor property damageuse

extremecare in handlinggasoline. Gasoline is

extremely flammableand the vapors areexplo-

sive. Seriouspersonaliniurycanoccurwhengasoline

isspilledonyourselforyourclotheswhichcan ignite.

Washyourskinandchangeclothesimmediately.

a. Useonlyanapprovedgasolinecontainer.

b. Neverfillcontainersinsideavehbb or ona

truckor trailerbedwitha plastb liner.Always

placecontainerson thegroundawayfrom

yourvehble beforefilling.

c. Whenpractbal,removegas-powered

equipmentfromthetruck ortrailerand refuelit

ontheground.Ifthis isnot possibb,then

refuelsuchequipmentona trailerwitha

portabbcontainer,ratherthanfromagasoline

dispensernozzb.

d. Keepthenozzbincontactwiththerimof

thefueltankor containeropeningatall

timesuntilfuelingis complete.Donot usea

nozzleIocbopendevice.

e. Extinguishallcigarettes,cigars,pipesand

othersourcesofignition.

f. Neverfuelmachineindoors.

g. Neverremovegascaporaddfuelwhilethe

engineishot or running.Mow engineto cool

atbast twominutesbeforerefueling.

h. Neveroverfillfueltank.Filltanktonomore

than1/2inchbelowbottomoffilbr neckto

allowspacefor fuelexpansion.

i. Replacegasolinecapandtightensecurely.

i. If gasolineisspilled,wipeitofftheengine

andequipment.Moveunittoanotherarea.

Wait5 minutesbeforestartingthe engine.

k. Toreducefirehazards,keepmachinefreeof

grass,leaves,orotherdebrisbuild-up.Clean

upoil orfuelspillageand removeanyfuel

soakeddebris.

I. Neverstorethemachineorfuelcontainer

insidewherethereis anopenflame,spark

or pilotlightason a waterheater,space

heater,furnace,clothesdryeror othergas

appliances.

m. Allowa machinetocool atbast fiveminutes

beforestoring.

4

Page 5

GeneralOperation:

1. Read,understand,andfollowallinstructionsonthe

machineandinthe manual(s)beforeattemptingto

assembleandoperate.Keepthismanualina safe

placeforfutureandregularreferenceandforordering

replacementparts.

2. Befamiliarwithall controlsandtheirproperoperation.

Knowhowtostopthe machineanddisengagethem

quickly.

3. Neverallowchildrenunder14yearsold to operate

this machine.Children14yearsold andovershould

readandunderstandtheoperationinstructionsand

safetyrubs in thismanualandshouldbetrainedand

supervisedbyaparent.

4. Neverallowadultstooperatethis machinewithout

properinstruction.

5. Tohelpavoidbladecontactora thrownobiectiniury,

keepbystanders,helpers,childrenandpetsat bast

75 feetfromthemachinewhileit is inoperation.8top

machineifanyoneentersthearea.

6. Thoroughlyinspecttheareawheretheequipmentisto

beused.Removeallstones,sticks,wire,bones,toys,

andotherforeignobiectswhichcould bepickedup

andthrownbythe blade(s).Thrownobiectscancause

seriouspersonaliniury.

7, Planyourmowingpatterntoavoiddischargeof

materialtowardroads,sidewalks,bystandersandthe

like.Also,avoiddischargingmaterialagainsta wall or

obstructionwhichmaycausedischargedmaterialto

ricochetbacktowardtheoperator.

8. Alwayswearsafetyglassesorsafetygogglesduring

operationandwhile performingan adiustmentor

repairtoprotectyoureyes.Thrownobiectswhich

ricochetcancauseseriousiniuryto theeyes.

9. Wearsturdy,rough-sobdworkshoesandclose-fitting

slacksandshirts.Loosefittingclothesandiewelry

canbecaughtinmovabbparts. Neveroperatethis

machinein barefeetor sandals.

10.Beawareofthe mowerandattachmentdischarge

directionanddo notpoint itat anyone.Donotoperate

themowerwithoutthedischargecoverorentiregrass

catcherin itsproperplace.

11.Donotput handsorfeetnearrotatingpartsor under

thecuttingdeck.Contactwiththe blade(s)can

amputatehandsandfeet.

12.Amissingor damageddischargecovercan cause

bladecontactor thrownobiectiniuries.

13.8toptheblade(s)whencrossinggraveldrives,walks,

or roadsandwhilenotcuttinggrass.

14.Watchfortrafficwhenoperatingnearorcrossing

roadways.Thismachineisnot intendedforuseon

anypublic roadway.

15.Donotoperatethemachinewhileunderthe influ-

enceof alcoholordrugs.

16.Mowonlyin daylightor goodartificiallight.

17,Nevercarrypassengers.

18.Disengageblade(s)beforeshiftingintoreverse.

Backupslowly.Alwayslookdownandbehindbefore

andwhilebackingto avoida back-overaccident.

19.Slowdownbeforeturning.Operatethe machine

smoothly.Avoiderraticoperationandexcessive

speed. }

20.Dbengageblade(s),setparkingbrake,stopengine

andwaituntilthe blade(s)cometo acompletestop

beforeremovinggrasscatcher,emptyinggrass,

uncloggingchute,removinganygrassor debris,or

makinganyadiustments.

21.Neverleavea runningmachineunattended.Always

turnoff blade(s),placetransmissionin neutral,set

parkingbrake,stopengineand removekeybefore

dismounting.

22.Useextracare whenloadingor unloadingthe

machineintoa trailerortruck.Thisunitshould not

bedrivenupor downramp(s),becausethe unit

couldtip over,causingseriouspersonaliniury.The

unitmustbepushedmanuallyonramp(s)to loador

unloadproperly.

23.Mufflerandenginebecomehotandcan causea

burn.Do nottouch.

24.Checkoverheadclearancescarefullybeforedriving

underlowhangingtreebranches,wires,dooropen-

ingsetc. wheretheoperatormaybestruckorpulled

fromtheunit,whichcouldresultinseriousiniury.

25.Disengageallattachmentclutches,depressthe

brakepedalcompbtelyandshift intoneutralbefore

attemptingtostartengine.

26.Yourmachineisdesignedtocutnormalresidential

grassof aheightno morethan 10".Donotattemptto

mowthroughunusuallytall,dry grass(e.g.,pasture)

or pilesof dryleaves.Drygrassor leavesmay

contacttheengineexhaustand/orbuildup onthe

mowerdeckpresentinga poten%lfire hazard.

27.Useonlyaccessoriesandattachmentsapprovedfor

thismachinebythe machinemanufacturer.Read,

understandandfollowall instructionsprovidedwith

theapprovedaccessoryorattachment.

28.Dataindicatesthatoperators,age60 yearsand

above,areinvolvedin a largepercentageofriding

mower-relatediniuries.Theseoperatorsshould

evaluatetheirabilityto operatetheridingmower

safelyenoughto protectthemselvesandothersfrom

seriousiniury.

29.Ifsituationsoccurwhicharenot coveredinthis

manual,usecareandgoodiudgment.Contactyour

customerservicerepresentativeforassistance.

WARNING

Thissymbol points

instructionswh ch. if

notfollowed,could

endangerthe personal

safety and/or property

of yourself and others.

Readand followall

instructionsin this man-

ual before attemptingto

operatethis machine.

these instructions may

result in personal injury.

When you see this

symbol.

HEED iTS WARNING

Your

Responsibility

Restrictthe use

d this powermachine

to personswho read,

understand

and followthe warninas

and instructions

in this manual

5

Page 6

Slope Operation:

Slopesarea majorfactorrelatedtolossof controland

tip-overaccidentswhichcanresultin severeinjuryor

death,All slopesrequireextracaution,if youcannot

backuptheslopeor ifyoufeeluneasyonit, do notmow

it,

Foryour safety,usetheslopegaugeincludedaspartof

thismanualto measureslopesbeforeoperatingthisunit

ona slopedor hillyarea,if theslopeisgreaterthan15

;_,_ degreesasshownontheslopegauge,do notoperate

,, thisunitonthatareaorseriousinjurycouldresult,

uperal:lon Do:

1, Mowupanddownslopes,notacross,Exercise

racl:lces extremecautionwhenchangingdirectiononsbpes,

2, Watchforhobs, ruts,bumps,rocks,or otherhidden

objects,Uneventerraincouldoverturnthemachine,

Tallgrasscan hideobstacbs,

3, Useslowspeed,Choosea lowenoughspeed

settingso thatyouwill nothaveto stoporshift while

ontheslope,Tiresmaylosetractiononslopeseven

thoughthe brakesarefunctioningproperly,Always

keepmachineingearwhengoingdownslopesto

takeadvantageofenginebrakingaction,

4, Followthemanufacturer'srecommendationsfor

wheelweightsorcounterweightsto improvestability,

5, Useextracarewithgrasscatchersorotherat-

out important safety

instructionswhich,if

notfollowed,could

endangerthe personal

safety and/or property

of yourself and others.

Readand follow all

instructionsin this man°

ual before attemptingto

tachments,Thesecanchangethestabilityof the

machine,

6, Keepall movementon theslopesslowandgradual

Donot makesuddenchangesinspeedor direction,

Rapidengagementor brakingcouldcausethe front

ofthe machineto liftand rapidlyfib overbackwards

whichcouldcauseseriousinjury,

7, Avoidstartingor stoppingon a slope,If tireslose

traction,disengagetheblade(s)andproceedslowly

straightdowntheslope,

Do Not:

1, Donotturnonslopesunlessnecessary;then,turn

slowlyandgraduallydownhill,if possibb,

2, Donotmowneardrop-offs,ditchesorembankments,

Themowercouldsuddenlyturnoverif awheel isover

theedgeof acliff,ditch,or if anedgecavesin,

3, Donottry tostaNlizethemachinebyputtingyourfoot

ontheground,

4, Donotuseagrasscatcheronsteepslopes,

5, Donotmowonwetgrass,Reducedtractioncould

causesliding,

6, DonotshifttoneutralandcoastdownhillOver-speed-

ingmaycausetheoperatortolose controlofthe

machineresultingin seriousinjuryordeath,

7, Donottow heavypullbehindattachments(e,g,loaded

dumpcart, lawnroller,etc,)on slopesgreaterthan

5 degrees,Whengoingdown hill,the extraweight

tendsto pushthetractorand maycauseyouto loose

control (e,g,tractormayspeedup,brakingandsteer-

ingabilityarereduced,attachmentmayjack-knifeand

causetractorto overturn),

Towing:

1, Towonlywitha machinethathasa hitchdesignedfor

towing,Donotattachtowedequipmentexceptatthe

hitchpoint,

2, Followthemanufacturersrecommendationfor weight

limitsfor towedequipmentandtowingonslopes,

3, Neverallowchildrenor othersin oron towedequip-

ment,

4, Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol,

5, Travelslowlyandallowextradistancetostop,

6, Donotshifttoneutralandcoastdownhill

these instructions may

result in personal injury,

When you see this

symbol

HEED ITS WARNING

YOUr

Responsibility

Restrictthe use

ofthis power machine

to personswho read.

understand

and followthe warnings

and instructions

in this manual

6

Page 7

Service lO,Neverattemptto makeadiustmentsor repairstothe

1. Neverrun anengineindoorsorinapoorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorless,anddeadlygas.

2. Beforecleaning,repairing,orinspecting,makecertain

theblade(s)andall movingpartshavestopped.

Disconnectthe sparkplugwireandgroundagainstthe

engineto preventunintendedstarting.

3. Periodicallychecktomakesurethebladescometo

compbtestopwithinapproximately(5) fiveseconds

afteroperatingthebladedisengagementcontrol,ifthe

bladesdonotstopwithinthethis timeframe,yourunit

shouldbeservicedprofessionallybyanauthorized

MTDServiceDealer.

4. Checkbrakeoperationfrequentlyas itissubiectedto

wearduringnormaloperation.Adiustandserviceas

required.

5. Checktheblade(s)andenginemountingboltsat

frequentintervalsforpropertightness.Also,visually

inspectblade(s)fordamage(e.g. excessivewear,

bent,cracked). Replacetheblade(s)withtheoriginal

equipmentmanufacturer's(O.E.M.)blade(s)only,

listedin thismanual."Useof partswhichdonotmeet

theoriginalequipmentspecificationsmaybad to

improperperformanceandcompromisesafety!"

6. Mowerbladesaresharp.Wrapthe bladeor wear

gloves,anduseextracautionwhenservicingthem.

7, Keepall nuts,bolts,andscrewstightto besurethe

equipmentis insafeworkingcondition.

8. Nevertamperwiththe safetyinterlocksystemor other

safetydevices.Checktheir properoperationregularly.

9. Afterstrikingaforeignobiect,stoptheengine,

disconnectthesparkplugwire(s)and groundagainst

theengine.Thoroughlyinspectthe machineforany

damage.Repairthedamagebeforestartingand

operating,

machinewhiletheengineisrunning,

11,Grasscatchercomponentsandthedischarge

coveraresubiectto wearanddamagewhichcould

exposemovingpartsor allowobiectstobethrown,

Forsafetyprotection,frequentlycheckcomponents

andreplaceimmediatelywithoriginalequipment

manufacturer's(O,E,M,)partsonly,listedinthis

manual,"Useof partswhichdo notmeettheoriginal

equipmentspecificationsmaybad toimproper

performanceandcompromisesafety!"

12,Donotchangetheenginegovernorsettingsor

over-speedtheengine,Thegovernorcontrolsthe

maximumsafeoperatingspeedof theengine,

13,Maintainor replacesafetyandinstructionlabels,as

necessary,

14,Observeproperdisposallawsandregulationsfor

gas,oil,etc, toprotecttheenvironment,

ii

i /

This symbol points

instructionswhich, if

safetyand/or property

ofyourself and others,

Readand follow al

ual before attemptingto

operatethis machine.

When you see this

symbol,

NEED roTSWARNING

Your

Responsibility

Restrictthe use

of this power machine

to personswho read,

understand

>wthewarnings

and instructions

in this manual

\

7

Page 8

Use extremecare

gasoline. Gasol!ne is

extremely flammab!e

andtheVaporsare

explos!ve. Never fuel

machine indoors

orwhiletheengine

is hot or running.

Ext ,g, shcigarettes,

Wini Nut

Hex Bolt

Figure 1

Attaching the Battery Cables

NOTE:Thepositivebatteryterminalis markedPos,(+),

The negativebatteryterminalis markedNeg,(-),

Thepositivecable(heavyredwire) issecuredto the

positivebatteryterminal(+)withahexboltandhex

nutat thefactory.Beforeattachingthenegativecable

removethebatterybyremovingthepositivecable

andhold=downstrap.Notethe dateon thesideof the

battery,ifthe batteryis putinto serviceafterthisdate,

chargethebatteryas instructedon page22 ofthis

manualpriorto operatingthetractor.

. Securebatterybackontothetractorwiththehold=

downstrap.Reattachthepositivecable(heavyred

wire)to thepositivebatteryterminal(+)withthebolt

andnut.Makecertainthattherubberbootcoversthe

terminalto helpprotectit fromcorrosion.

• Removethehex boltandhexnutfromthe negative

cable.

• Removetheblackplasticcover,if present,fromthe

negativebatteryterminalandattachthenegative

cable(heavyblackwire)tothe negativebattery

terminal(-) withthe boltandnut.

• Makecertainthehold=downstrapisin positionover

thebattery,securingit inplace,SeeFigure1,

Gas and Oil Fill-up

Thegasolinetankislocatedunderthe hoodandhasa

capacityofthreegallons,Donotoverfill,

WARNING: Use extreme care

when handling gasoline. Gasoline

is extremely flammable and the

vapors are explosive. Never fuel

machine indoorsor while the

engine is hotor running. Extin-

guish cigarettes, cigars, pipes,

and other sources of ignition.

8

Page 9

Servicetheenginewith gasolineandoilasinstructedin f

theseparateKohlerOperator/OwnerManualpackedwith

yourtractor,Readinstructionscarefully,

IMPORTANT:Yourtractorisshippedwithmotoroilinthe

engine,However,you MUSTchecktheoillevel before

operating,Becarefulnotto overfill,

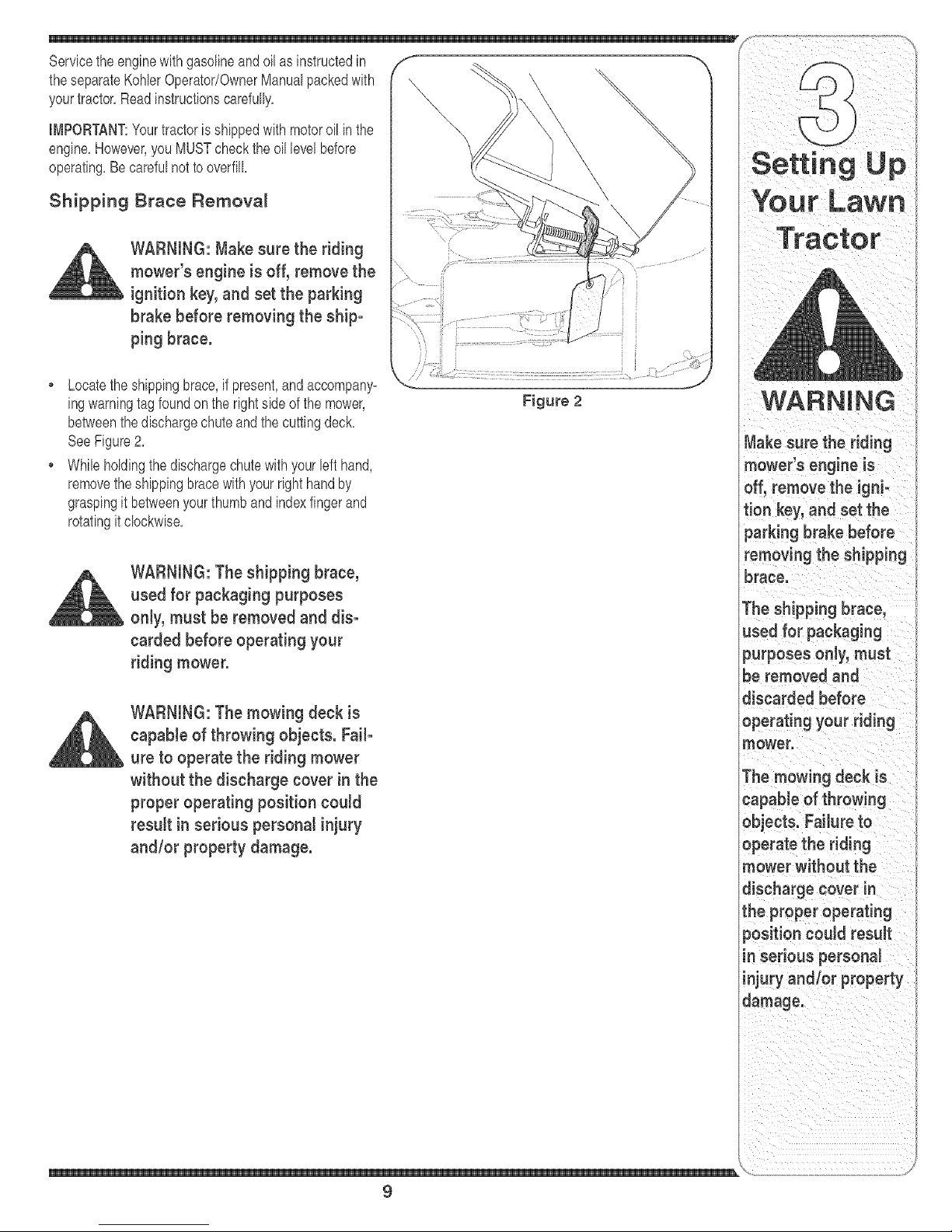

Shipping Brace Remova_

WARNING: Make sure the riding

mower's engine is off, remove the

ignitionkey, and set the parking

brake before removing the ship-

ping brace.

Locatetheshippingbrace,ifpresent,andaccompany-

ingwarningtagfoundon the rightside ofthe mower,

betweenthedischargechuteandthe cuttingdeck,

SeeFigure2,

• While holdingthedischargechutewithyourleft hand,

removetheshippingbracewithyourrighthandby

graspingit betweenyourthumbandindexfingerand

rotatingitclockwise,

WARNING: The shipping brace,

used for packaging purposes

only, must be removed and dis-

carded before operating your

riding mower.

WARNING: The mowing deck is

capable of throwing objects. Fail-

ure to operate the riding mower

without the discharge cover in the

proper operating position could

result in serious personal injury

and/or property damage.

Figure 2

Your Lawn

Tractor

WARNING

Make sure the riding

mower's engine is

off, remove the igni-

tion key, and set the

parking brake before

removing the shipping

brace.

The shipping brace,

used for packaging

purposes only, must

be removed and

discarded before

operating your riding

mower.

The mowing deck is

capable of throwing

objects. Failure to

operate the riding

mower without the

discharge cover in

the proper operating

9

Page 10

NOTE:Anyreference

inthismanualtothe

RIGHTorLEFTsideof

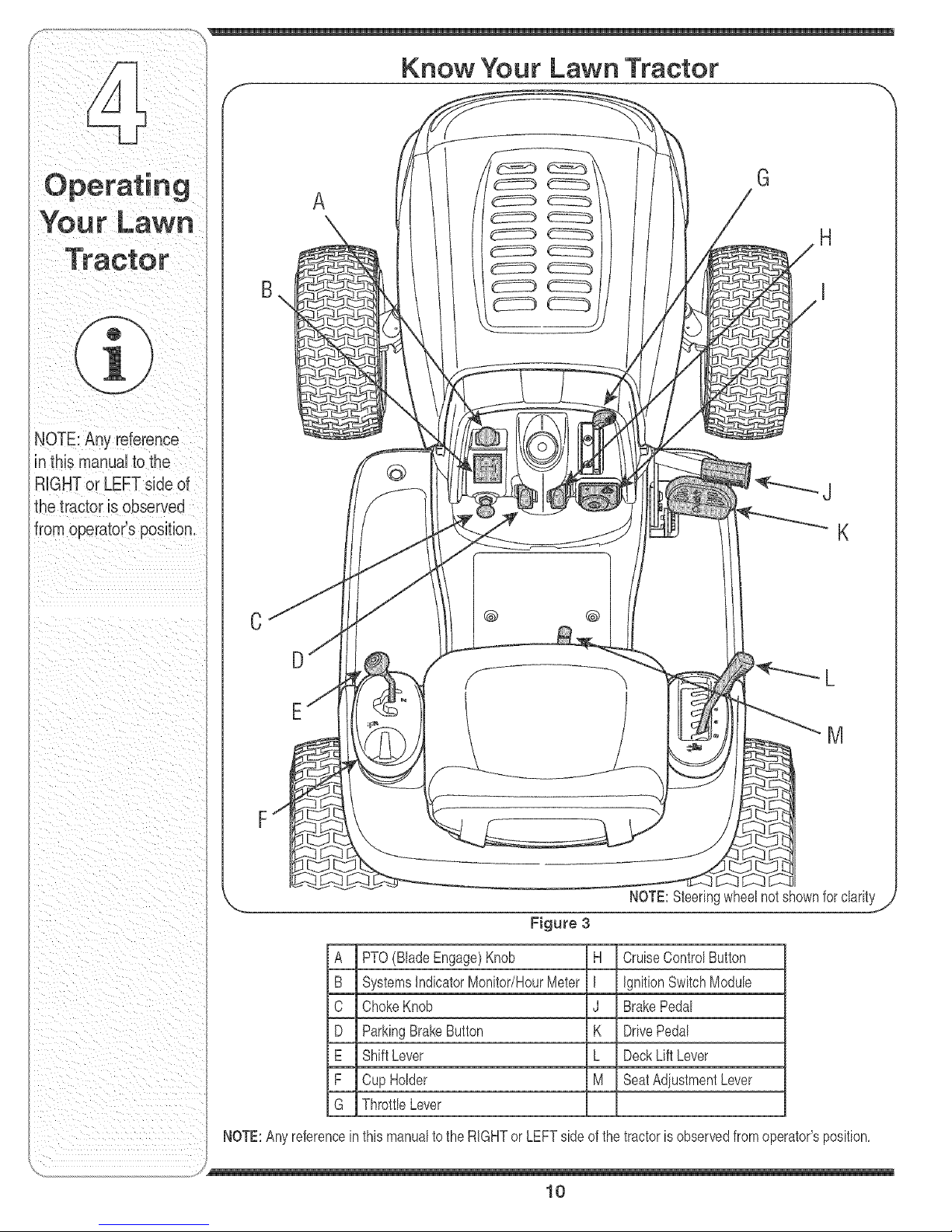

Know Your Lawn Tractor

G

A

@

J

@ @

D

E

A PTO(BladeEngage)Knob H CruiseControISutton

B SystemslndicatorMonitor/HourMeter I ignitionSwitchModule

C ChokeKnob J BrakePedal

D ParkingBrakeButton K DrivePedal

E ShiftLever L DeckLift Lever

F CupHolder M SeatAdiustmentLever

G Throttb Lever

K

M

NOTE:Anyreferencein thismanualtotheRIGHTor LEFTside ofthe tractoris observedfromoperator'sposition,

J

10

Page 11

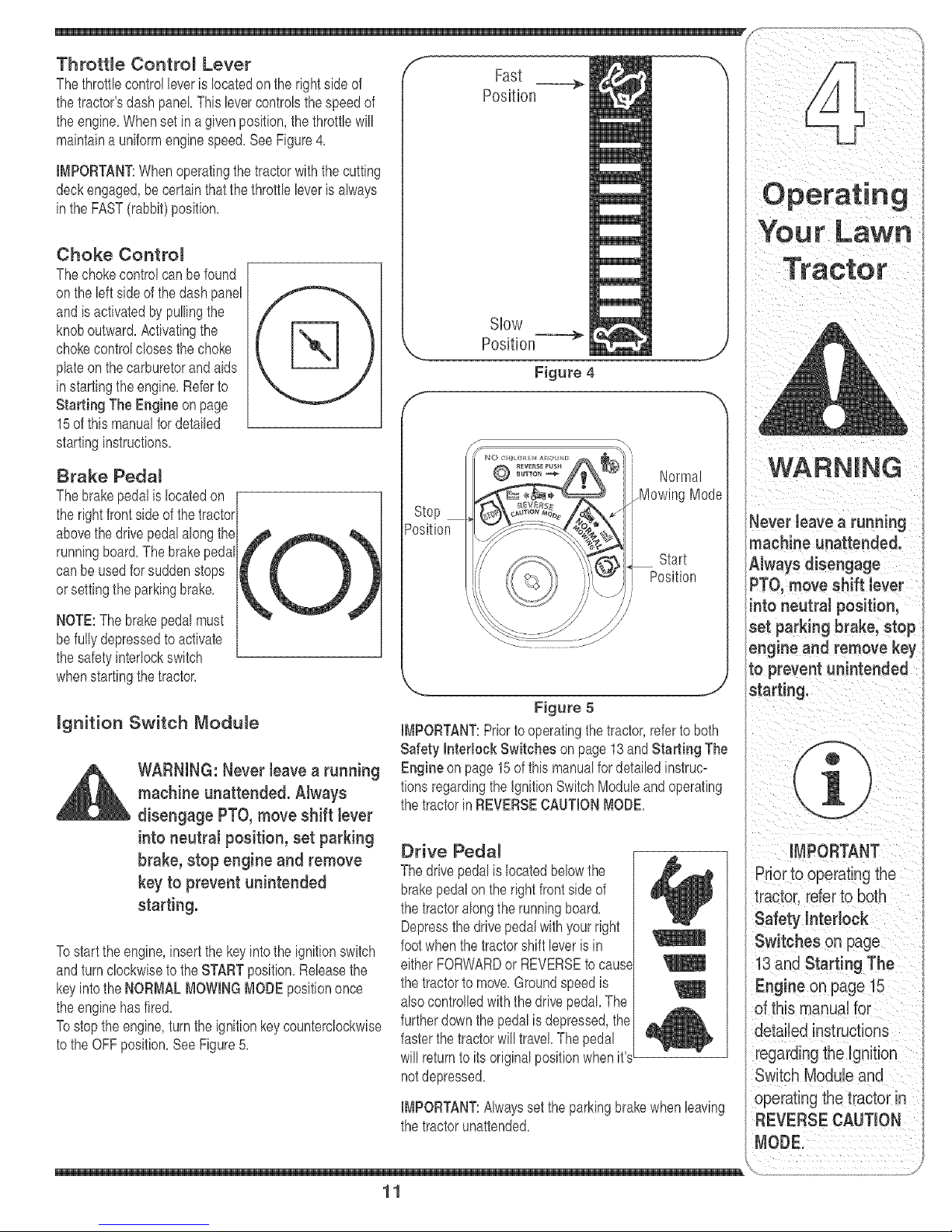

theengine.Whensetin agiven position,thethrottlewill

maintaina uniformenginespeed.SeeFigure4.

IMPORTANT:Whenoperatingthetractorwiththecutting

deckengaged,becertainthatthe throttb bver isalways

inthe FAST(rabbit)position.

Choke Contro_

Thechokecontrolcan befound

onthebft sideofthedashpanel

andisactivatedby pullingthe

knoboutward.Activatingthe

chokecontrolclosesthe choke

plateonthe carburetorandaids

instartingthe engine.Referto

Starting TheEngine onpage

15ofthis manualfordetailed

startinginstructions.

Slow

Position---=_

Figure 4

Brake Pedal

Thebrakepedalislocatedon [

therightfrontsideof thetractor/

abovethedrivepedalalongthe-

runningboard.Thebrakepedal

canbeusedforsuddenstops

orsettingthe parkingbrake.

NOTE:Thebrakepedalmust

befullydepressedtoactivate

thesafetyinterlockswitch

whenstartingthetractor.

mgnition Switch Module

WARNING: Never have a running

machine unattended. AJways

disengage PTO,move shift bver

into neutral position, set parking

brake, stop engine and remove

key to prevent unintended

starting.

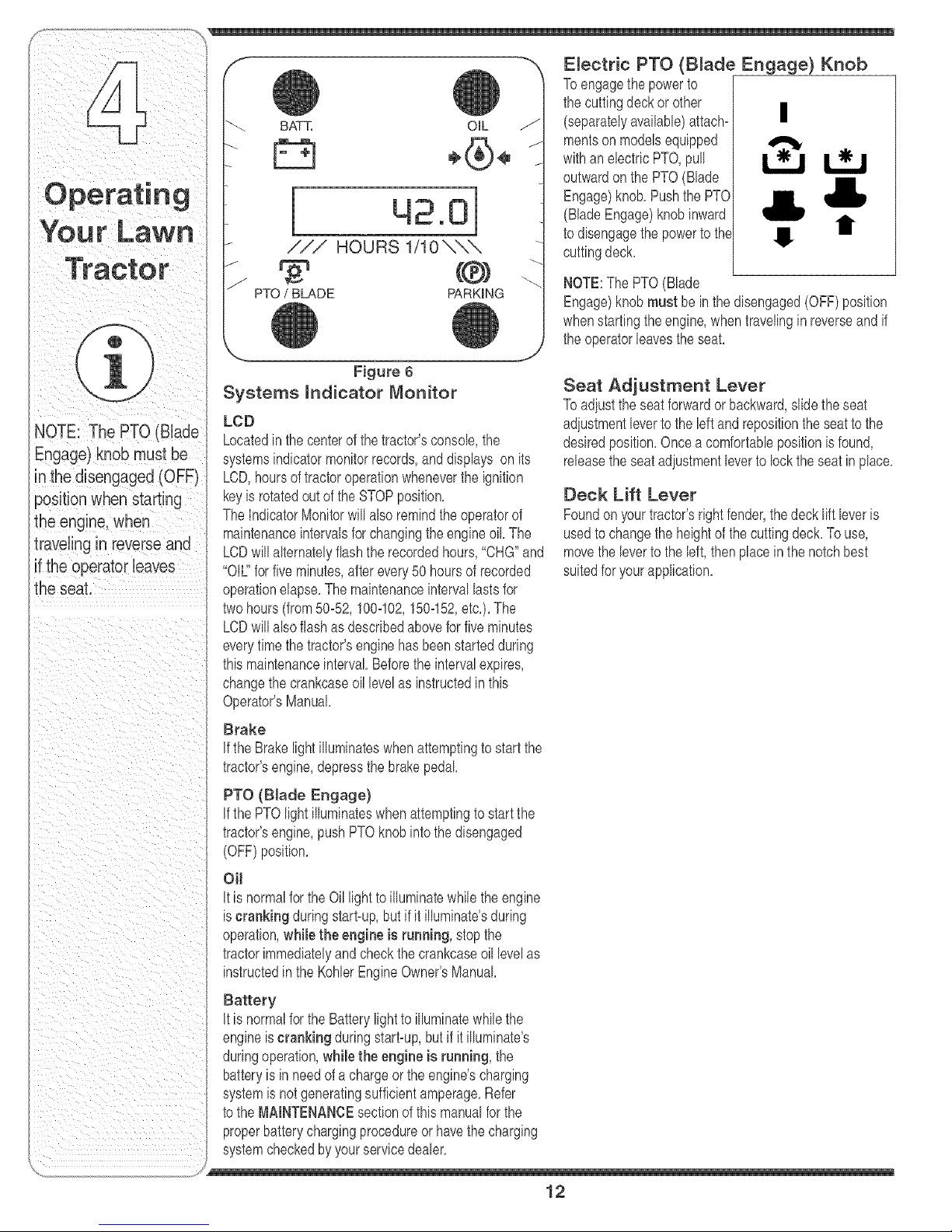

Tostarttheengine,insertthe keyintothe ignitionswitch

andturnclockwiseto theSTARTposition.Rebasethe

keyintothe NORMALMOWINGMODEpositiononce

theenginehasfired.

Tostopthe engine,turnthe ignitionkeycounterclockwise

tothe OFFposition.SeeFigure5.

Normal

_MowingMode

_osition

Start

Position

Figure 5

IMPORTANT:Priortooperatingthetractor,referto both

Safety hterlock Switches on page13andStarting The

Engineon page15ofthis manualfordetailedinstruc=

tionsregardingtheignitionSwitchModuleandoperating

thetractorin REVERSECAUTIONMODE.

Drive Pedal

Thedrivepedalislocatedbelowthe

brakepedalonthe rightfrontside of

thetractoralongtherunningboard.

Depressthe drivepedalwithyourright

footwhenthe tractorshift bver is in

eitherFORWARDor REVERSEtocause

thetractortomove.Groundspeedis

alsocontrolledwiththe drb'epedal.The

furtherdownthe pedalisdepressed,the

fasterthe tractorwilltravel Thepedal

willreturntoits originalpositionwhenit'sL

notdepressed.

IMPORTANT:Alwayssettheparkingbrakewhenleaving

thetractorunattended.

machine unattended.

A ,vaysd sengage

PTO, move Shift lever

into neutral position,

set parking brake;stop

engineandremovekey

to prevent unintended

stai

operating the tractor in

REVERSE CAUTION

11

Page 12

NOTE:The PTo (Biade

Engage)knobmust be

inthedisengaged(OFF)

the seat.

BATT, OIL

/

/

/

.ol

/

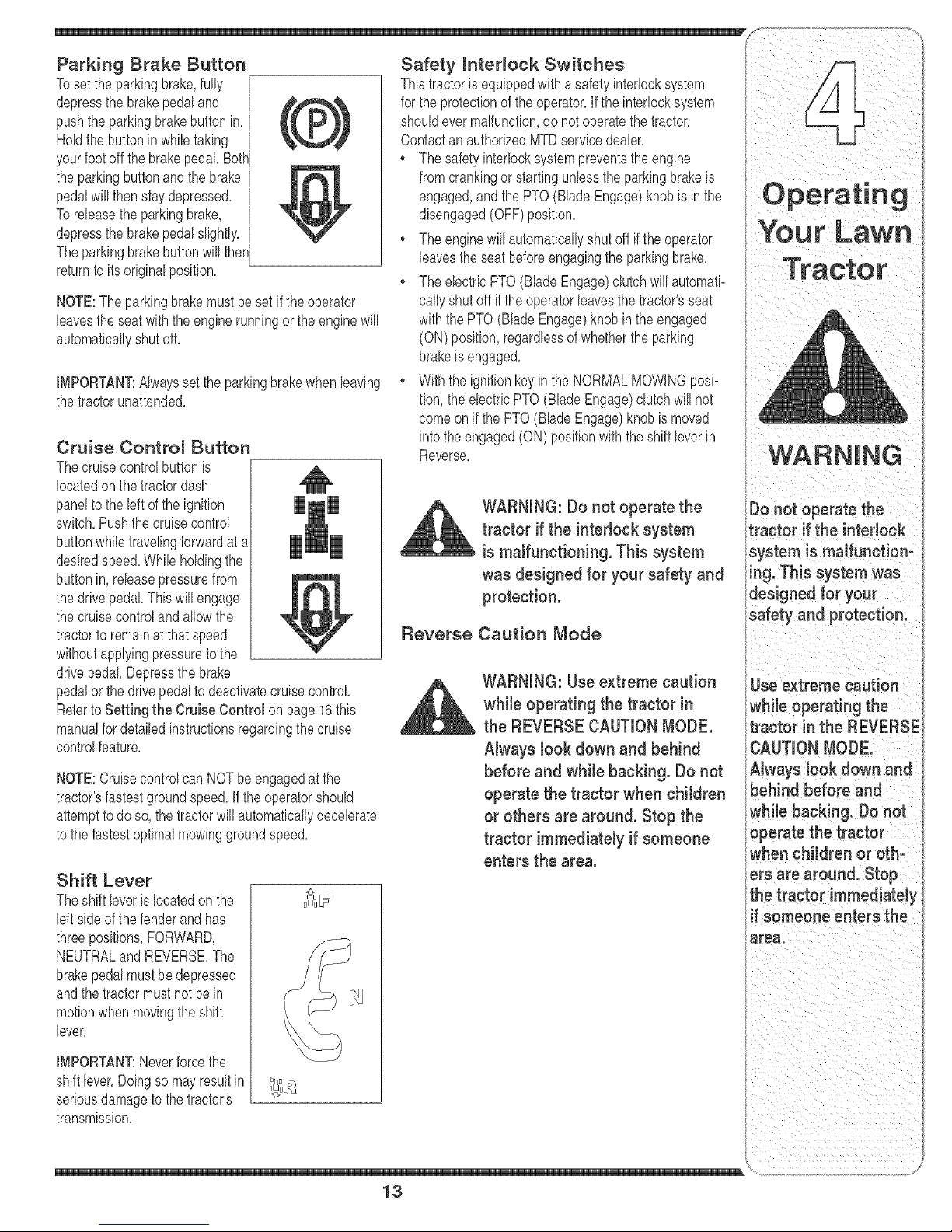

Systems mndicator Monitor

LeD

Locatedinthecenterof thetractor'sconsole,the

systemsindicatormonitorrecords,anddisplays on its

LCD,hoursoftractoroperationwheneverthe ignition

keyb rotatedoutof theSTOPposition,

TheIndicatorMonitorwillalso remindtheoperatorof

maintenanceintervalsforchangingtheengineoil The

LCDwillalternatelyflashtherecordedhours,"CHG"and

"Oil" for fiveminutes,afterevery50 hoursof recorded

operationelapse,The maintenanceintervallastsfor

twohours(from50-52,100-102,150-152,etc,),The

LCDwillalsoflashasdescrbed aboveforfiveminutes

everytimethetractor'senginehasbeenstartedduring

thb maintenanceinterval Beforetheintervalexpires,

changethecrankcaseoil levelas instructedin this

Operator'sManual,

Brake

If theBrakelightilluminateswhenattemptingtostartthe

tractor'sengine,depressthebrakepedal

/// HOURS 1/10\\\

PTO/ BLADE PARKmNG

Figure 6

Electric PTO (B_ade Engage) Knob

Toengagethe powerto

thecuttingdeckor other

(separatelyavailable)attach- |

mentsonmodelsequipped

withanelectricPTO,pull

outwardon thePTO(Blade

Engage)knob,Pushthe PTO

(BladeEngage)knobinward

todisengagethepowertothe t

cuttingdeck,

NOTE:ThePTO(Blade

Engage)knobmust bein thedisengaged(OFF)position

whenstartingtheengine,whentravelinginreverseandif

theoperatorleav'estheseat,

Seat Adjustment Lever

Toadiustthe seatforwardor backward,slidethe seat

adiustmentleverto theleftandrepositiontheseattothe

desiredposition,Oncea comfortabbpositionisfound,

releasetheseatadiustmentleverto locktheseat inplace,

Deck Lift Lever

Foundonyourtractor'srightfender,thedecklift leveris

usedto changethe heightofthecuttingdeck,Touse,

movethebver tothe left,thenplacein the notchbest

suitedforyourapplication,

I!

PTO (Blade Engage)

if the PTOlightilluminateswhenattemptingtostart the

tractor'sengine,pushPTOknobintothedisengaged

(OFF)position,

OH

it is normalfortheOil lighttoilluminatewhiletheengine

iscranking duringstart-up,but ifit illuminate'sduring

operation,while the engine is running, stopthe

tractorimmediatelyandcheckthecrankcaseoillevelas

instructedin theKohlerEngineOwner'sManual

Battery

it is normalfortheBatterylightto illuminatewhilethe

engineiscranking duringstart-up,but if it illuminate's

duringoperation,while the engine is running, the

batteryis in needofa chargeortheengine'scharging

systemis notgeneratingsufficientamperage,Refer

tothe MAINTENANCEsectionofthis manualforthe

properbatterychargingprocedureorhavethecharging

systemcheckedbyyourservmedealer,

/

12

Page 13

Parking Brake Button

Tosetthe parkingbrake,fully

depressthe brakepedaland

pushthe parkingbrakebuttonin,

Holdthe buttoninwhiletaking

yourfootoff thebrakepedal Both"

theparkingbuttonandthe brake

pedalwillthen staydepressed,

Toreleasethe parkingbrake,

depressthe brakepedalslightly,

Theparkingbrakebuttonwill ther

returnto itsoriginalposition,

NOTE:Theparkingbrakemustbesetif theoperator

leavestheseatwiththe enginerunningor theenginewill

automaticallyshutoff,

IMPORTANT:Alwayssettheparkingbrakewhenleaving

thetractorunattended,

Cruise Contro_ Button

Thecruisecontrolbuttonis

locatedonthetractordash

paneltothe leftofthe ignition

switch,Pushthecruisecontrol

buttonwhiletravelingforwardat a

desiredspeed,Whileholdingthe

buttonin,releasepressurefrom

thedrivepedal Thiswillengage

thecruisecontrolandallowthe

tractorto remainatthatspeed

withoutapplyingpressuretothe

drivepedal Depressthebrake

pedalor thedrivepedalto deactivatecruisecontrol

RefertoSetting the Cruise Control on page16this

manualfordetailedinstructionsregardingthecruise

controlfeature,

NOTE:Cruisecontrolcan NOTbe engagedatthe

tractor'sfastestgroundspeed,if theoperatorshould

attempttodoso,the tractorwill automaticallydecelerate

tothe fastestoptimalmowinggroundspeed,

Shift Lever

Theshift leveris locatedon the

leftsideof thefenderand has

threepositions,FORWARD,

NEUTRALand REVERSE,The

brakepedalmustbe depressed

andthetractormustnot bein

motionwhenmovingthe shift

lever,

uu _

Thistractoris equippedwith asafetyinterlocksystem

forthe protectionof theoperator,Ifthe interlocksystem

shouldevermalfunction,do notoperatethetractor,

Contactan authorizedMTDservicedealer,

, Thesafetyinterlocksystempreventstheengine

fromcrankingor startingunlessthe parkingbrakeis

engaged,andthe PTO(BladeEngage)knobisinthe

disengaged(OFF)position,

, Theenginewillautomaticallyshutoff if theoperator

leavestheseatbeforeengagingtheparkingbrake,

• The electricPTO(BladeEngage)clutchwillautomati-

callyshutoff ifthe operatorleavesthetractor'sseat

withthePTO(BladeEngage)knobinthe engaged

(ON)position,regardlessofwhetherthe parking

brakeis engaged,

, WiththeignitionkeyintheNORMALMOWINGposi-

tion,theelectricPTO(BladeEngage)clutchwillnot

comeonif the PTO(BladeEngage)knobismoved

intotheengaged(ON)positionwiththe shiftleverin

Reverse,

WARNING: Do not operate the

tractor if the interlock system

is malfunctioning. This system

was designed for your safety and

protection.

Reverse Caution Mode

WARNING: Use extreme caution

while operating the tractor in

the REVERSECAUTIONMODE.

Always took down and behind

before and while backing. Do not

operate the tractor when children

or others are around. Stop the

tractor immediately if someone

enters the area.

Tractor

l

=aution

while operating the

tractor in the REVERSE

Always look down and

behind before and

whi!e back!rig, Donot

operate the tractor

when children or oth:

ers are around. Stop

the tractor immediately

ifsomeone enters the

IMPORTANT:Neverforcethe

shiftlever,Doingsomayresultin

seriousdamagetothetractor's

transmission,

_,o iiiiiiiiiiiiiii _/

13

Page 14

De not operate the

tractor if the interlock

system is malfunction-

ing. This system was

designed for your

safety and protection.

Position

Start

Position

J

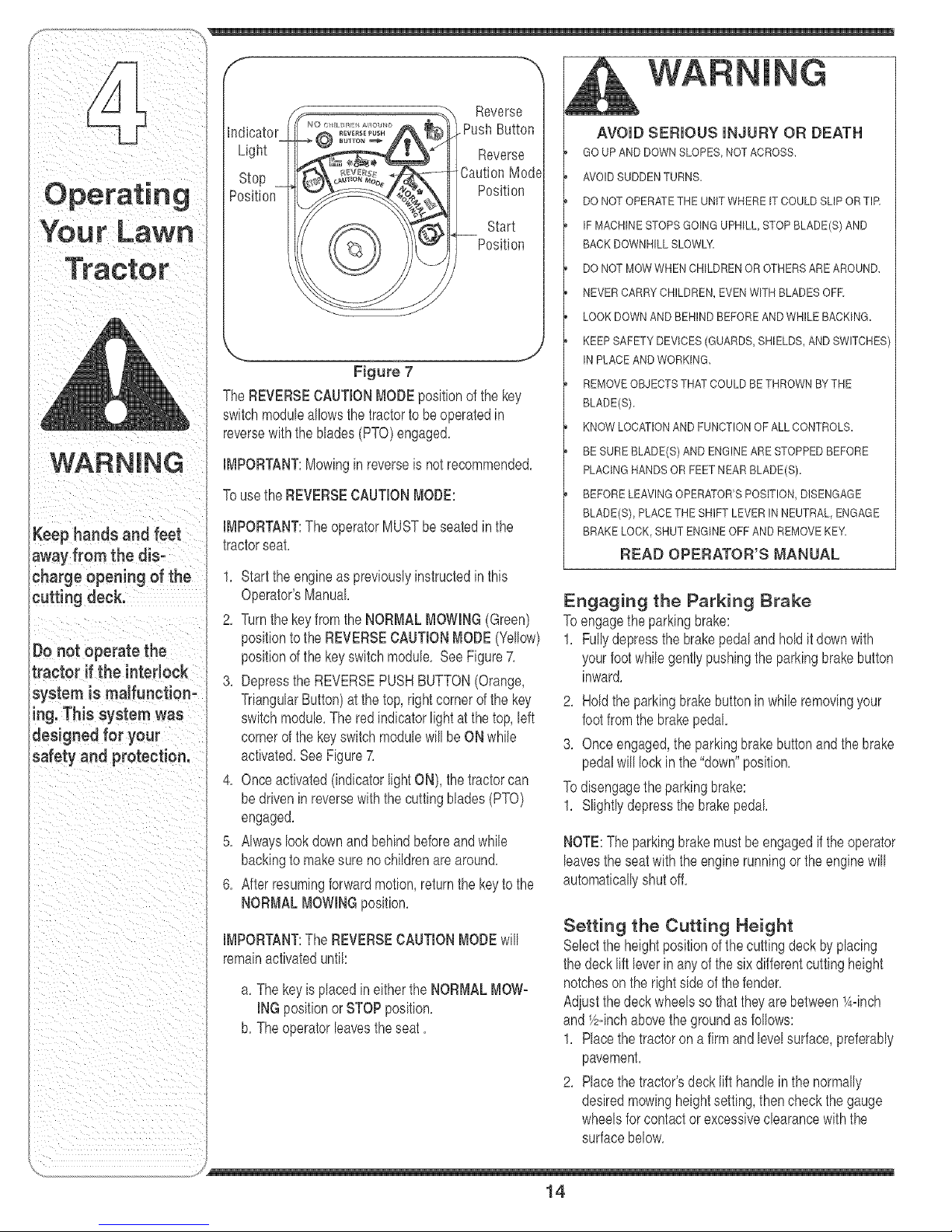

Figure 7

TheREVERSECAUTIONMODEpositionof the key

switchmoduleallowsthe tractorto beoperatedin

reversewiththeblades(PTO)engaged,

IMPORTANT:Mowingin reverseis notrecommended,

Tousethe REVERSECAUTIONMODE:

IMPORTANT:TheoperatorMUSTbeseatedinthe

tractorseat,

1, Startthe engineaspreviouslyinstructedinthis

Operator'sManual

2, Turnthekeyfromthe NORMALMOWING(Green)

positiontothe REVERSECAUTIONMODE(Yellow)

positionofthe keyswitchmodule, SeeFigure7,

3, DepresstheREVERSEPUSHBUTTON(Orange,

TriangularButton)atthetop,rightcornerof thekey

switchmodule,Thered indicatorlightatthe top,left

cornerof thekeyswitchmodulewillbeON wMe

activated,SeeFigure7,

4, Onceactivated(indicatorlightON), thetractorcan

bedrivenin reversewiththe cuttingblades(PTO)

engaged,

5, AMayslookdownandbehindbeforeandwMe

backingtomakesure nocMdrenarearound,

6, Afterresumingforwardmotion,returnthekeyto the

NORMALMOWINGposition,

IMPORTANT:TheREVERSECAUTIONMODEwill

remainactivateduntil:

a, The keyis placedin eitherthe NORMALMOW-

INGpositionorSTOPposition,

b, Theoperatorleavestheseat,

AVOIDSUDDENTURN&

DO NOT OPERATETHEUNITWHEREIT COULDSLIPORTIR

IFMACHINESTOPSGOINGUPHILL,STOPBLADE(S)AND

BACKDOWNHILLSLOWLY

DO NOT MOWWHENCHILDRENOROTHERSAREAROUND,

NEVERCARRYCHILDREN,EVENWITH BLADESOFE

LOOK DOWNAND BEHINDBEFOREAND WHILEBACKING.

KEEPSAFETYDEVICES(GUARDS,SHIELDS,ANDSWITCHES

INPLACEANDWORKING,

REMOVEOBJECTSTHATCOULDBE THROWNBYTHE

BLADE(Sb

KNOWLOCATIONANDFUNCTIONOF ALLCONTROLS.

BE SUREBLADE(S) ANDENGINEARESTOPPEDBEFORE

PLACINGHANDSORFEETNEAR BLADE(Sb

BEFORELEAVINGOPERATOR'SPOSITION,DISENGAGE

BLADE(S), PLACETHESHIFT LEVER IN NEUTRAL,ENGAGE

BRAKELOCK,SHUTENGINEOFFAND REMOVEKEY_

READ OPERATOR'S MANUAL

Engaging the Parking Brake

Toengagethe parkingbrake:

1, Fullydepressthebrakepedaland holdit downwith

yourfootwMe gentlypushingtheparkingbrakebutton

inward,

2, Holdtheparkingbrakebuttoninwhileremovingyour

footfromthe brakepedal,

3, Onceengaged,theparkingbrakebuttonandthebrake

pedalwilllockin the "down"position,

Todisengagetheparkingbrake:

1, Slightlydepressthebrakepedal

NOTE:Theparkingbrakemustbeengagedif theoperator

leavestheseatwiththe enginerunningor theenginewill

automaticallyshutoff,

Setting the Cutting Height

Selecttheheightpositionofthe cuttingdeckbyplacing

thedeckliftleverin anyof thesix differentcuttingheight

notchesonthe rightsideofthe fender,

Adjustthedeckwheelsso thattheyare between_A=inch

and_/zqnchabovethe groundasfollows:

1, Placethetractoronafirmandlevelsurface,preferably

pavement,

2, Placethetractor'sdecklift handleinthe normally

desiredmowingheightsetting,thencheckthegauge

wheelsforcontactorexcessiveclearancewiththe

surfacebelow,

J

14

Page 15

if the wheelscontactthesurfaceadiustasfollows: IMPORTANT:DoNOTholdthekeyintheSTARTpod=

3, Raisethedecklifthandletoits highestsetting,

4, Removethe reargaugewheelsbyremovingthe lock

nutsandshoulderscrewswhichsecurethemto the

deck,

5, Removethe locknutsand shoulderscrewswhich

securethefrontgaugewheelsto thedeck,

6, Race thedecklifthandleinthedesiredmowing

heightsetting,

7, inserttheshoulderscrewwiththereargaugewheel

intothe indexholethatleavesapproximately1/2"

betweenthebottomofthe wheelandthe pavement,

8, Notethe positionoftheindexholeused;theninstall

theotherreargaugewheelandthe frontballwheels

intothe correspondingindexholeof theothergauge

wheelbrackets,

9, if thegaugewheelshaveexcessiveclearancewith

thesurfacebelow,lowerthe wheelstothe index

holethatprovidestheapproximate1/2"clearanceas

describedabove,

tionfor longerthanten secondsatatime,Doingsomay

causedamagetoyourengine'selectricstarter,

6, Afterthe enginestarts,deactivatethechokecontrol

and placethethrottlecontrolinthe FASTposition,

NOTE:DoNOTleavethechokecontrolonwhileoperat=

ingthetractor,Doingsowill resultina "rich"fuelmixture

andcausetheengineto runpoorly,

Stopping the Engine

WARNING: if you strike a foreign

object, stop the engine, discon-

nect the spark plug wire(s) and

ground against the engine.

Thoroughly inspect the machine

for any damage. Repair the

damage before restarting and

operating

iii ii it

WARNING

WARNING: Keep hands and feet

away from the discharge opening

of the cutting deck.

NOTE:Thedeckwheelsarean anti=scalpfeatureofthe

deckandarenotdesignedto supportthe weightofthe

cuttingdeck,

RefertoLeveling the Deck on page18ofthismanual

formoredetailedinstructionsregardingvariousdeck

adiustments,

Starting the Engine

WARNING: Do not operate the

tractor if the interlocksystem is

malfunctioning. This system was

designed for your safety and

protection.

NOTE:Referto theTRACTORSET-UPon page8 ofthis

manualforGasolineandOilfill=upinstructions,

1, insertthetractorkeyintotheignitionswitch,

2, Race thePTO(BladeEngage)knobinthedisem

gaged(OFF)position,

3, Engagethetractor'sparkingbrake,

4, Activatethechokecontrol,

5, TurntheignitionkeyclockwisetotheSTARTposition,

Aftertheenginestarts, releasethekey,Itwill returnto

theON position,

1, Ifthebladesareengaged,placethePTO(Blade

Engage)knobinthe disengaged(OFF)position,

2, TurntheignitionkeycounterclockwisetotheSTOP

position,

3, Removethekeyfromtheignitionswitchto prevent

unintendedstarting,

Driving The Tractor

WARNING: Avoid sudden starts,

ex-cessive speed and sudden

stops.

WARNING: Do not [cave the seat

of the tractor without first placing

the PTO(Blade Engage) knob in

the disengaged (OFF} position,

depressing the brake pedal and

engaging the parking brake. If

leaving the tractor unattended,

also turn the ignition key off and

remove the key.

1, Depressthe brakepedaltoreleasetheparkingbrake

and letthe pedalup,

2, MovethethrottleleverintotheFAST(rabbit)position,

Donotleavetheseat

Ofthetractorwithout

first placingthe PTO

(B!adeEngage)knobin

the disengaged (OFF)

position;depreSs, g

the brake pedal and

engaging the parking

brake. If leaving the

tractor unattended,

als0 turn the igaitio,

key off and remove the

key,

15

Page 16

ii ii i

IMPORTANT:DoNOTusetheshiftlevertochangethe

directionoftravelwhenthetractorisin motion,Always

usethe brakepedalto bringthetractortoa complete

stopbeforeshifting,

3, To moveforward,placetheshift leverinthe

FORWARDposition,thenslowlydepressthedrive

pedaluntilthe desiredspeedisachieved,

4, To movein reverse,placetheshift leverinthe

REVERSEposition,checkthattheareabehindis

clearthenslowlydepressthe drivepedal,

Driving On S_opes

Refertothe SLOPEGAUGEon page3 to helpdeter=

mineslopeswhereyoumayoperatethetractorsafely,

NOTE:Cruisecontrolcan notbeengagedatthetractor's

fastestgroundspeed,If theoperatorshouldattempttodo

so,thetractorwillautomaticallydeceleratetothe fastest

optimalmowinggroundspeed,

Disengagethecruisecontrolusingoneofthe following

methods:

1, Depressthebrakepedaltodisengagethecruise

controlandstopthetractor,

2, Lightlydepressthedrivepedal

Tochangeto the reversedirectionwhenoperatingwith

cruisecontrol,depressthebrakepedalto disengagethe

cruisecontroland bringthetractortoa completestop,

Thenplacetheshift leverinthe REVERSEpositionand

depressthedrive pedal

WARNING

Do not mow on inclines

with a slope in excess

of 15 degrees (a rise

ofapproximately 2-1/2

feet every 10feet). The

tractor could overturn

and cause serious

injury.

To help avoid blade

contact or a thrown

object injury, keep

bystanders, helpers,

children and pets at

least 75 feet from the

machine while it is in

operation.Stop rna=

chine if anyone enters

the area.

WARNING: Do not mow on

inclineswith a stope in excess

of 15 degrees (a rise of approxi-

mately 2-1/2 feet every 10feet).

The tractor could overturn and

cause serious injury.

Mowupanddownslopes,NEVERacross,

Exerciseextremecautionwhenchangingdirection

onslopes,

, Watchforholes,ruts,bumps,rocks,orotherhidden

obiects,Uneventerraincouldoverturnthe machine,

Tallgrasscan hideobstacles,

, Avoidturnswhendrivingonaslope,Ifaturnmust

be made,turndowntheslope,Turningupa slope

greatlyincreasesthechanceof a rollover,

, Avoidstoppingwhendrivingupaslope,Ifitis

necessarytostopwhiledrivingupa slope,start up

smoothlyandcarefullyto reducethepossibilityof

flippingthetractoroverbackward,

Setting The Cruise Control

1, Placetheshiftleverin the FORWARDposition,

thenslowlydepressthedrive pedaluntilthedesired

speedis achieved,

2, Lightlydepressthecruisecontrolbutton,

3, While continuingtoholdthe cruisebuttonin,liftyour

footfromthedrive pedal(youshouldfeelthecruise

latchengage),

Onceengaged,thecruisecontrolbuttonand thedrive

pedalwill lockin the "down"position,and thetractorwill

maintainthesameforwardspeed,

Engaging the B_ades

EngagingthePTO(BladeEngage)transferspowertothe

cuttingdeckor other (separatelyavailaNe)attachments,

Toengagethe blades,proceedasfollows:

1, MovethethrottlecontrollevertotheFAST(rabbit)

position,

2, PullthePTO(BladeEngage)knoboutwardintothe

engaged(ON)position,

3, Keepthethrottleleverinthe FAST(rabbit)position

forthe mostefficientuseofthe cuttingdeckor other

(separatelyavailable)attachments

iMPORTANT:Theelectric PTOclutchwillautomatically

shutoffif the PTOis engagedwiththeshift leverin posi=

tionfor reversetravelwiththeignitionkeyintheNORMAL

MOWINGposition,Referto SafetyInterlockSwitcheson

page13,

Using the Deck Lift Lever

Toraisethecuttingdeck,movethedecklift leverto the

left,thenplaceit inthenotchbestsuitedfor yourapplica-

tion,RefertoSettingThe CuttingHeightearlierin this

section,

Mowing

WARNING: To help avoid blade

contact or a thrown object injury,

keep bystanders, hetpers, children

and pets at least 75 feet from the

machine while it is in operation.

Stop machine if anyone enters the

area.

y

16

Page 17

Thefollowinginformationwillbehelpfulwhenusingthe

cuttingdeckwithyourtractor:

WARNING: Plan your mowing

pattern to avoid discharge of

matedaJs toward roads, side°

waJks,bystanders and the Jike.

Nso, avoid discharging materiaJ

against a wall or obstruction

which may cause discharged

matedaJ to ricochet back toward

the operator.

Donot mowathighgroundspeed,especiallyifa

mulchkit or grasscollectoris installed,

• For bestresultsit isrecommendedthatthefirsttwo

lapsbe cutwiththe dischargethrowntowardsthe

center,Afterthefirsttwolaps,reversethedirectionto

throwthedischargetotheoutsidefor thebalanceof

cutting,Thiswillgivea betterappearancetothe lawn,

• Do notcut thegrasstooshort,Shortgrassinvites

weedgrowthandyellowsquicklyin dryweather,

• Mowingshouldalwaysbedonewiththeengineat full

throttle,

• Underheavierconditionsitmaybenecessarytogo

backoverthecut areaa secondtimetoget a clean

cut,

, DoNOTattempttomowheavybrushandweedsand

extremelytallgrass,Yourtractoris designedtomow

lawns,NOTclearbrush,

• Keepthe bladessharpandreplacethebladeswhen

worn,RefertoCutting Blades onpage22 ofthis

manualforproperbladesharpeninginstructions,

MuJching (If Equipped)

Selectmodelscomeequippedwitha mulchkitwhich

incorporatespecialblades,alreadystandardonthe

tractor,ina processof recirculatinggrassclippings

repeatedlybeneaththecuttingdeck,Theultra-fine

c@pingsarethenforcedbackintothelawnwherethey

actasa naturalfertilizer,

Observethefollowingpointsfor thebestresultswhen

mulching:

, Neverattempttomulchif thelawnisdamp,Wetgrass

tendstostickto the undersideofthe cuttingdeck

preventingpropermulchingofthe c@pings,

• Do NOTattempttomulchmorethan1/3thetotal

heightof thegrassor approximately14/2 inches,

Doingso willcausethe clippingstoclumpup beneath

thedeckandnot bemulchedeffectively,

Figure 8

Maintaina slowgroundspeedto allowthegrass

clippingsmoretimeto effectivelybemulched,

Alwayspositionthethrottlecontrolleverin theFAST

(rabbit)positionandallow itto remaintherewhile

mowing,Failingtokeeptheengineat fullthrottle

placesstrainon thetractor'sengineanddoesnot

allowthebladesto properlymulchgrass,

NOTE:Itis notnecessarytoremovethedischargechute

tooperatethemowerwiththe mulchkit installed,

Tooperatethecuttingdeckwithoutmulching,simply

removethemulchplugby pivotingthedischargechute

upandpullingtheplugoutward,Toreinstallplug:

Locatetworectangularholesonthe cuttingdecksurface,

1, Pivotthedischargechuteuptoaccessthedeck

opening,SeeFigure8,

2, Insertthemulchplug,aligningthetopedgeof the

plugwiththedeckas shownin theFigure8, Make

surethe notchesonthe plugarein theslots onthe

deckopening,

3, Lightlytapontheplugwithyourhandto assurethat

thenotchesfitsnuglyunderthechutetabs,

Headlights

• On somemodels,thelampsareON wheneverthe

tractor'sengineis running,Onothermodels,the

lampsareONwheneverthe ignitionkeyis movedout

of the STOPposition,

, On all models,thelampsturnOFFwhentheignition

keyismovedtothe STOPposition,

Operatin

Your Lawn

tern to avoid discharge

of materials toward

roads, sidewalks, by-

standers and the like.

AJso,avoid discharging

materiaJagainst a wall

or obstruction which

may cause discharged

materiaJto ricochet

back toward the

operator.

17

Page 18

Loosen

lower deck

Figure 9

Figure 10

WARNING:Neverattempt to make

any adjustments whilethe engine is

running, except wherespecified in the

operator's manual.

Leveling the Deck

NOTE:Checkthetractor'stirepressurebeforeperform-

inganydecklevelingadiustments,RefertoTires on

page22 forinformationregardingtirepressure,

Front To Rear

Thefrontof thecuttingdeckissupportedbya stabilizer

barthatcanadiustedtolevelthe deckfromfronttorear,

Thefrontof thedeckshouldbebetween1/4-inchand

3/8-inchlowerthantherearof thedeck, Adjustif

necessaryasfollows:

Thefirst measurementtakenshouldbebetween

1/4"and3/8" lessthanthesecondmeasurement,

Determinethe approximatedistancenecessaryfor

properadiustmentandproceed,ifnecessary,tothe

nextstep,

3, Fromthefrontofthetractor,loosenthehexlock nut

oneachend of thedeck hangerrod,andturnaway

fromtheinnerhex nuts,SeeFigure9,

4, Tightenthe innerhexnutsfrontagainstthefront

hangerbrackettoraisethe frontofthe deck;loosen

thehexnutstolowerthefrontof thedeck,

5, Retightenthetwo locknutsagainsttheinnerhexnuts

whenproperadiustmentisachieved,

Side to Side

if thecuttingdeckappearstobemowingunevenly,aside

tosideadiustmentcanbeperformed,Adiustif necessary

asfollows:

1, Withthetractorparkedonafirm,levelsurface,place

thedeckliftleverin thetop notch(highestposition)

androtatebothbladessothattheyare perpendicular

withthetractor,

2, Measurethedistancefromtheoutsideoftheleftblade

tipto thegroundandthe distancefromtheoutsideof

therightbladetipto theground,Bothmeasurements

takenshouldbeequal If they'renot,proceedtothe

nextstep,

8, Loosen,butdoNOTremove,thehexcapscrewon

theleftdeckhangerbracket,SeeFigure10,

4, Balancethedeckbyusingawrenchto turnthe

adiustmentgear(foundimmediatelybehindthe hex

capscrewiust loosened)clockwise/uporcounter-

clockwise/down,Thedeckis properlybalancedwhen

bothbladetip measurementstakenearlierareequal

5, Retightenthehexcapscrewonthebft deckhanger

bracketwhenproperadiustmentisachieved,

Parking Brake Adjustment

WARNING:Neverattempt to adjust the

brakes while the engine isrunning.

Always disengage PTO,moveshift

lever into neutral position, stop engine

and remove keyto prevent unintended

starting.

18

Page 19

if the tractordoesnotcometo a compbtestopwhenthe

brakepedalis completelydepressed,or if thetractor's

rearwheelscanrollwiththe parkingbrakeapplbd, the

brakeis inneedofadiustment,Thebrakedisccanbe

foundon the rightsideofthe transmissioninthe rearof

thetractor,Adiustif necessaryasfollows:

1, Lookingatthetransmissionfromtherightsideofthe

tractor,locatethecompressionspringand brakedisc,

SeeFigure11,

2, Loosen,butdo NOTremove,the hexnutfoundon the

rightsideofthe brakeassembly,SeeFigure11,

3, Usinga feebr gauge,setthe gapbetweenthebrake

discandthe brakepuckat,011",

4, Reqightenthehexnut loosenedearlier,

Seat Adjustment

_ ARNING:Before operating this

Toadiustthe positionoftheseaton modelsequipped

witha seatadiustmentlever,movethebv'ertotheleft

andslidethe seatforwardor rearward.SeeFigure

3 on page10.Makesureseatis lockedintoposition

beforeoperatingthetractor.

Steering Adjustment

if the tractorturnstighterinonedirectionthan theother,

or ifthe balliointsarebeingreplaceddueto damageor

wear,thesteeringdraglinksmayneedto beadiusted,

Adiustthedraglinksso thatequalbngthsare threaded

intothe balliointon the leftandrightside:

1, Loosentheiamnutfoundonthedraglinkat therear

ofthe ballioint,SeeFigure12,

2, Removehexnuton thetopof ballioint,SeeFigure12,

3, Threadtheballiointtowardtheiam nuttoshortenthe

draglink,Threadthe balliointawayfromtheiamnut

to bngthenthedraglink,

4, Replacehexnutandretightentheiamnut afterproper

adiustmentisachieved,

NOTE:Threadingtheballiointstoo farontothedraglinks

willcausethe fronttiresto"toe4n"too far,Propertoeqnis

between1/16"and5/16",

machine,makesure the seat is engaged

in the seat stop, stand behind the

machine and pull back on seat until fully

engagedinto stop.

Set gap .011

Figure 11

Figure 12

Fronttiretoeqncanbemeasuredasfollows:

1, Placethesteeringwheelinpositionforstraight

aheadtravel

2, Infrontoftheaxle,measurethedistancehorizontally

fromtheinsideof the leftrimto theinsideof the right

rim,Notethedistance,

3, Behindtheaxle,measurethedistancehorizontally

fromtheinsideof the leftrimto theinsideof the right

rim,Notethedistance,

Hex Nut

NOTE: Threading the

4. Themeasurementtakeninfr_nt_ftheaxIe_h_uIdbebetween1/16__and5/16Èbssthanthemeasure_

menttakenbehindtheaxle,Adiustifnecessary, L

19

Page 20

Figure 13

6, Refilltheenginewithnewmotoroilas instructedinthe

KohlerOperator/OwnerManualpackedwithyourunit,

IMPORTANT:Refertothe KohlerOperator/Owner

Manualpackedwithyourunitfor informationregardingthe

quantityandproperweightof motoroil

Air Cleaner

Servicethepre=cbaner,ifsoequipped,andcartridge/air

cbanerelementas instructedin theKohbrOperator/

OwnerManualpackedwithyourunit.

Spark PJug(s)

Thesparkplug(s)shouldbecleanedandthegapreset

oncea season,Sparkplugreplacementisrecommended

atthe startof eachmowingseason,Refertothe Kohbr

Operator/OwnerManualforcorrectplugtypeandgap

specifications,

inorderte rep!acethe

WARNING: Before performing

any maintenance or repairs,

disengage PTO,move shift lever

intoneutral position, set parking

brake, stop engine and remove

key to prevent unintended

starting.

Engine

Referto the Kohler OperatodOwner Manualfor

engine maintenanceinstructions.

Checkengine oil level beforeeachuseas instructed

in theKohbrOperator/OwnerManualpackedwithyour

unit,Follow the instructionscarefully.

Changing Engine Oil

NOTE:Dependingontheenginemodelfoundon your

tractor,itmaybenecessaryto removethetractor'sside

panelinordertoreplacetheoilfilter (if soequipped),

1, Popopenthe protectivecaponthe endofthe oil

drainvalvetoexposethe drainport, SeeFigure13,

2, Removetheoil fillcap/dipstickfromtheoil filltube,

3, Pushtheoildrainhose(packedwiththismanual)

ontothe oildrainport,Routetheoppositeendof the

hoseintoan appropriateoil colbction containerwith

a capacitygreatenoughto colbct the usedoil

4, Aftertheoilhasfinisheddraining,pushtheoildrain

valvebackin,rotateit clockwisetolockthevalve

closedandre=captheendoftheoildrainvalveto

keepdebrisfromenteringthedrainport,

5, Servicetheoilfilter(ifsoequipped)asinstructedin

theseparateKohbrOperator/OwnerManualpacked

withyourunit,

Performtheabovestepsinthe oppositeorderafteroil

hasfinisheddraining,

Lubrication

WARNING: Before lubricating,

repairing, or inspecting,atways

disengage PTO,move shift lever

intoneutral position, set parking

brake, stop engine and remove

key to prevent unintended start-

ing.

Engine

Lubricatetheenginewithmotoroil as instructedinthe

KohlerOwnerManualpackedwith yourunit,

Pivot Points & Linkage

Lubricateall thepivotpointson the drivesystem,parking

brakeandlift linkageatbast oncea seasonwithlightoil

Rear Wheels

Therearwheelsshouldberemovedfromtheaxlesonce

a season,Lubricatethe axlesandtherimswell withan

all=purposegreasebeforere=installingthem,

Front AxJes

Eachendof thetractor'sfrontpivotbarisequippedwith a

greasefitting,Lubricatewitha greasegun afterevery25

hoursof tractoroperation,

Cleaning the Engine And Deck

Anyfuel oroil spilledonthe machineshouldbewiped

off promptly.DoNOTallowdebristo accumulatearound

thecoolingfinsofthe engineoron anyotherpartof the

machine.

IMPORTANT:Theuseofapressurewashertocban your

tractoris NOTrecommended,It maycausedamageto

ebctrbal components,spindles,pulleys,bearingsor the

engine,

2O

Page 21

Deck Wash System TM

Yourtractor'sdeckmay'beequippedwitha waterport on \,

itssurfaceas partof itsdeckwashsystem,

If equipped,usetheDeckWashSystemTM torinsegrass

clippingsfromthedeck'sundersideandpreventthe

buildupofcorrosivechemicals,Completethefollowing

stepsAFTEREACHMOWING:

1, Drivethetractortoalevel,clearspoton yourlawn,

i

i "\

nearenoughtoa watersillcock(spigot)for your

gardenhoseto reach,

IMPORTANT:Makecertainthetractor'sdischargechute

isdirectedAWAYfromyourhouse,garage,parkedcars,

etc,

2, DisengagethePTO(BladeEngage),movetheshift

leverintotheneutralposition,setthe parkingbrake,

andstoptheengine,

Figure 14

3, Threadthehosecoupler(packagedwithyourtractor's

Operator'sManual)ontotheendofyourgardenhose,

4, Attachthehosecouplertothewaterportonyour

deckssurface,SeeFigure14,

5, Turnthewateron,

6, Whilesittingin theoperator'spositionon thetractor,

re=starttheengineandplacethethrottleleverinthe

FAST(rabbit)position,

7, Disengagetheparkingbrake,

8, Movethetractor'sPTO(BladeEngage)intotheON

position,

Support Pin

9, Remaininthe operator's position withthe cutting

deckengagedfora minimumof twominutes,allowing

...... ............. i / / /

theundersideof thecuttingdeckto thoroughlyrinse,

10,Movethetractor'sPTO(BladeEngage)intotheOFF

position,

11,Turntheignitionkeytothe STOPpositiontoturnthe

Figure 15

tractor'sengineoff andengagetheparkingbrake,

12,Turnthewateroff anddetachthe hosecouplerfrom

thewaterport onyourdeckssurface,

13,Repeatsteps4=11on theoppositesideofthecutting

deck,

Cutting Deck Remova_

Toremovethecuttingdeck, proceedasfollows:

1, PlacethePTO(BladeEngage)knobinthedisen=

gaged(OFF)positionandengagetheparkingbrake,

2, Lowerthedeckbymovingthedeck liftleverintothe

bottomnotchon the rightfender,

3, Removethe PTObeltfromaroundthetractor's

enginepulleyandidlerpulley(s),RefertoFigure18

5, Pullthedecksupportpinoutwardto releasethedeck

fromthedecklift arm,

6, Rotatethepinslightlytowardtherearofthetractor

and releasethepinintothe holeprovided,

7, Repeattheabovestepsonthetractor'srightside,

8, Movethedeckliftleverintothetop notchontheright

fenderto raisedeck liftarmsupandout ofthe way,

9, Gentlyslidethecuttingdecktowardthefrontof the

tractorand releasethehooksonthe deckfromthe

deckstabilizerrod,

10,Gentlyslidethecuttingdeck(fromtherightside)out

from underneaththetractor,

onpage24,

4, Lookingatthecuttingdeckfromthe leftsideof the

tractor,locatethedecksupportpinonthe rearleft

sideof thedeck, SeeFigure15,

iMPORTANT

Makecertain the

tractor's dischargechute

is directedAWAYfrom

your house garage,

parkedcars. etc.

21

Page 22

Jump Starting

WARNING

Never exceed the

maximum inflation

_ressureshown on the

sidewall of the tire.

Batteries giveoff an

.=×plosivegas whib

:barging. Charge bat-

tery in a wellventiJated

_reaand keep away

from an open flame

_r pilot light as on a

_vaterheater, space

heater,furnace, clothes

;lryeror other gas

_ppliances.

Be sure to shut the

engine off, remove

ignition key, discon-

nect the spark plug

wire(s) and ground

against the engine to

prevent unintended

starting before remov=

ing the cutting blade(s)

for sharpening or

replacement. Protect

your hands by using

heavy gloves or a rag

tograsp the cutting

blade.

WARNING: Never e×ceed the

ma×imum inflation pressure

shown on the sidewall of tire.

Therecommendedoperatingtire pressureis:

Approximately10psifor thereartires

Approximately14psifor thefronttires

IMPORTANT:Refertothetiresidewallforexacttire

manufacturer'srecommendedormaximumpsi.Donot

overinflate.Uneventire pressurecouldcausethecutting

decktomowunevenly.

Battery

Thebatteryisseabd andis maintenance-free.Acid

bvels cannotbe checked.

. Alwayskeepthebatterycabbs andterminalscban

andfreeof corrosivebuild-up.

. Aftercleaningthebatteryandterminals,applya light

coatofpetroleumielly or greaseto bothterminals.

• Alwayskeepthe rubberbootpositionedoverthe

positiveterminaltopreventshorting.

IMPORTANT:If removingthebatteryforanyreason,

disconnecttheNEGATIVE(Black)wirefromit'sterminal

first,followedbythe POSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthe POSITIVE

(Red)wire itsterminalfirst,followedbythe NEGATIVE

(Black)wire.Becertainthat thewiresareconnectedto

thecorrectterminals;reversingthemcouldchangethe

polarityandresultindamagetoyourengine'salternat-

ingsystem.

Charging

If thetractor hasnot beenputinto usefor anextended

periodoftime,chargethe batterywithanautomotive-

type 12-voltchargerfor a minimumof one hour atsix

ampe.

WARNING: Batteries give off an

explosive gas while charging.

Charge battery in a well venti-

lated area and keep away from

an open flame or pilot light as

on a water heater, space heater,

furnace, clothes dryer or other

gas appliances.

WARNING: When removing or

installingthe battery, follow

these instructions to prevent the

screwdriver from shorting against

the frame.

IMPORTANT:Neveriumpyourtractor'sdeadbatterywith

thebatteryofa runningvehicle,

1. Connectendofoneiumpercabletothepositive

terminalofthegoodbattery,thenthe otherendtothe

positiveterminalofthedeadbattery.

2. Connecttheotheriumpercabletothenegative

terminalofthegoodbattery,thento theframe of the

unit with the dead battery.

WARNING: Failure to use this

procedure could cause sparking,

and the gas in either battery could

explode.

Cleaning

Cban the batterybyremovingit fromthe tractorand

washingwitha bakingsodaandwatersolution,if neces-

sary,scrapethe batteryterminalswitha wirebrushto

removedeposits,CoatterminaBandexposedwiringwith

greaseorpetroleumiellytopreventcorrosion,

Battery Failures

Somecommoncausesforbatteryfailureare:

. incorrectinitialactivation • undercharging

. overcharging •corrodedconnections

"freezing

Thesefailures are NOTcovered byyour tractor's

warranty.

Cutting B_adee

WARNING: Be sure to shut the

engine off, remove ignition

key,disconnect the spark plug

wire(s) and ground against the

engine to prevent unintended

starting before removing the

cutting blade(s) for sharpening or

replacement. Protect your hands

by using heavy gloves or a rag to

grasp the cutting blade.

22

Page 23

WARNING:Periodicallyinspect

the Made spindJes for cracks or

damage, especially if you strike a

foreign object. Replace immedi-

ately if damaged.

Thebladesmayberemovedasfollows,

1, Removethedeckfrombeneaththetractor,(referto

CuttingDeckRemovalon page21)thengentlyflip

thedeckoverto exposeitsunderside,

2, Race a blockofwoodbetweenthecenterdeckhous-

ingbaffleandthecuttingbladetoact asa stabilizer,

SeeFigure16,

3, Usea 15/16"wrenchtoremovethehexflangenut

thatsecuresthebladeto thespindleassembly,See

Figure16,

4, Toproperlysharpenthecuttingblades,removeequal

amountsofmetalfrombothends ofthe bladesalong

thecuttingedges,paralleltothe trailingedge,ata

25°to 30°angle,

I[_tPORTANT:If thecuttingedgeofthebladehasalready

beensharpenedto within15/8" fromtheedge,or ifany

metalseparationis present,replacethebladeswithnew

ones,SeeFigure17,

It isimportantthateachcuttingbladeedgebeground

equallyto maintainproperbladebalance,

• A poorlybalancedbladewillcauseexcessive

vibrationand maycausedamageto thetractorand

resultinpersonalinjury,Thebladecanbetestedby

balancingitona roundshaftscrewdriver,Grindmetal

fromtheheavysideuntilit balancesevenly,

• Whenreplacingthe blade,besuretoinstalltheblade

withthesideofthe blademarked"Bottom" (orwith

a partnumberstampedinit) facingthegroundwhen

themoweris intheoperatingposition,

IMPORTANT:Usea torquewrenchto tightentheblade

spindlehexflangenutto between70foot-poundsand 90

foot-pounds,

Fuses

A fuseisinstalledinyourtractor'swiringharnessto

protectthetractor'selectricalsystemfromdamage

causedbyexcessiveamperage,

Figure 16

Figure 17

If theelectricalsystemdoesnotfunction,or your

tractor'senginewillnotcrank,firstchecktobecertain

thatthefusehas notblown,

• It can eitherbefoundunderthe hoodmountedbehind

thetop ofthe dashpanelon the supportbar,or under

theseatmountedtotheinsideofthe tractorframe

nexttothe batterytray,

Always use a fuse with the same

amperage capacity for replace-

meat.

Periodically inspect

the blade spindles for

cracks or damage,

especially if you strike

aforeign object.

Replace immediately if

damaged.

Always use a fuse with

:hesame amperage

capacity for replace-

meat.

23

Page 24

f_!!_ _i_ _

Your Lawn

-- ", Tochangeorrepace thedeck bet andPTObet onyour

tractor,proceedasfollows:

I Pivoting Idler Pulley Belt Guard 1, Lowerthedeckbymovingthedeck liftbver intothe

\ / bottomnotchon the rightfender,

"Square

Hole

Figure 18

2, Removethe beltguardsbyremovingtheseBtapping

screwsthatfastenthemto thedeck,

3, a,Toeaseinremovingthebeltinlatersteps,loosen,

butdonot remove,theboltwhichsecuresthe

pivotingidlerpulbyto the idlerbracket,

b, inserta 3/8"-driveratchetwrench(settotighten)

intothe squarehob foundintheidlerbracketon the

bft sideof thedeck'ssurface,SeeFigure18,

c, Graspthe ratchet'shandbandpivotittowardthe

rightside ofthe tractorto relbvetensiononthe belt,

d,With belttensionrelbved,carefully removethe

belt from around the bft-hand spindle pulley.

IMPORTANT:Carefullyallowtheratchetto pivotrearward

beforeremovingitfromthesquarehob,

WARNING

Be sure to shut the

engine off, remove ig=

nition key, disconnect

Lhespark pJugwire(s)

and ground against

the engine to prevent

unintended starting

before removing the

beJt(s).

Avoid the possibility of

a pinching injury.Do

not place your fingers

onthe idler spring or

between the belt and a

pulley while removing

the belt.

Changing the Deck Be_t & PTO Be_t

WARNING: Be sure to shut

the engine off, remove ignition

key, disconnect the spark plug

wire(s} and ground against the

engine to prevent unintended

starting before removing the

belt(s).

Allbeltson yourtractorare subiecttowearandshould

bereplacedif anysignsof weararepresent,

IMPORTANT:TheV-beltsfoundon yourtractorare

speciallydesignedtoengageanddisengagesafely,A

substitute(nomOEM)Wbeltcan bedangerousbynot

disengagingcompletely,Fora properworkingmachine,

usefactoryapprovedbelts,

WARNING: Avoid the possibility

of a pinching injury. Do not place

your fingers on the idlerspring

or between the belt and a pulley

while removing the belt.

4, Removethedeckbeltfromaroundallpulbys,including

thedeckidlerpulleysandthe electricPTOclutch,

NOTE: The idlerpulby(s) mayhaveto be loosened,but

notremoved,in orderto removethebeltfromaround

them,

5, Routethenewbelts(deckbeltfirst)asshowninFigure

19,

6, Remountthebeltguardsremovedearlbr,

Changing the Transmission Drive

Be_ta

NOTE:Severalcomponentsmustberemovedand

specialtools(i,e,air/impactwrench)inordertochange

thetractor'sdrivebelts,SeeanauthorizedTroyBilt

ServiceDeabr to haveyourdrivebeltsreplacedor phone

CustomerSupportas instructedonpage2 forinformation

onorderinga ServiceManual

/

24

Page 25

Figure 19

J

25

Page 26

; ofthismanualbeforestoringforanextendedperiod, Manualforproperenginecarepriortostoringyourtractor,

WARNING

Drain fuel only into an

approved container

outdoors, away from

an open flame. Al-

low engine to coon.

Extinguish cigarettes,

cigars, pipes, and

other sources of igni=

tion prior to draining

fuel.

WARNING: Drain fueJonly into

an approved container outdoors,

away from an open flame. Allow

engine to coot. Extinguish

cigarettes, cigars, pipes, and

other sources of ignition prior to

WARNING: Never store the

machine or fuel container indoors

where there is an open flame,

spark or pilot tight such as on

water heater, furnace, clothes

dryer or other gas appliance.

draining fuel.

Attachments & Accessories

Thefollowingattachmentsandaccessoriesare compatiblefor Model60TPHorseLawnTractors,Seetheretailer

fromwhichyoupurchasedyour tractor,an authorizedTroyBiltServiceDealeror phone1-866-840-6483for informa-

tionregardingpriceandavailability,

NOTE:Model60TPLawnTractorsare NOTdesignedforusewithany typeofground_engagingattachments(e,g,

filleror plow),Useofthis typeofequipmentWILLvoidthetractor'swarranty,

MODEL _ DESCRiPTiON

0EM-190-032

OEM-190-i92

OEM-190-193

OEM-190-218

OEM_190_607"

OEM-190-658

OEM_190_672

OEM-190-833

Notcompatiblewithtractorsequippedwitha GrassCollector

42-inchTwo-stageSnowThrower

50-inchBaggerKit

50-inchMulcherKit

BearWheelWeightKit

DeluxeTractorSunshade

GrilleGuard(mountsonfrontof tractor)

46-inchFrontDozerBlade

Never store the ma-

chine or fuel container

indoors where there is

an open flame, spark

or pilot light such

as on water heater,

furnace, clothes dryer

or other gas appliance.

26

Page 27

iiiii_i_iii_ii_i_i_ii_iii_iW_i_!_!_!_i_ii_i_iiiii_iiiii_iH:!:!:!:!i_i_@iiiiiiii

_and instructions

27

Page 28

Problem

Cause

Remedy

1. PlacePTOknob(orlever)in

For repairs beyond

the minor adjust-

ments listed here,

contact an authorized

service dealer.

Engineruns erratic

1, UnitrunningwithCHOKEapplied,

2, Sparkplugwire(s)loose,

3, Blockedfuellineorstab fuel

4, Ventingascapplugged,

5, Waterordirt infuelsystem,

6, Dirtyaircbaner,

1, PushCHOKEcontrol(if so

equipped)in,or movethethrottle

controloutof theCHOKEposition,

2, Connectandtightenspark

plugwire(s),

3, Cban fuelline;filltank withclean,

fresh(lessthan30 daysold)

gasoline,Replacefuelfilter,ifso

equipped,

4, Char ventorreplaceifdamaged,

5, Drainfueltank, Refillwith

freshfuel

6, Replaceaircleanercartridge/eb=

mentor cleanpre=cleaner,ifso

equipped,

28

Page 29

Problem Cause Remedy

. 2, Air flowrestrbted,' 2, CLeangrassclippingsanddebris

, , aroundtheengine:scoe!!ng

• • finsandbbwer housing.

Enginehesitatesat 1, Sparkplug(s)gaptooclose, 1, Removesparkplug(s)and reset

high RPM thegap,

' ..... equipped, ........ .....

Excessive

Vibration

1, Cuttingbladelooseor unbalanced,

2, Damagedor bentcuttingblade,

1, Tightenbladeandspindle,Balanc(

blade,

2, Replaceblade,

For repairs beyond

the minor adjust-

ments listed here,

contact an authorized

service dealer,

Uneven cut

1, Decknotbalancedproperly,

2, Dullblade,

3, Uneventirepressure,

1, Performside-to-sidedeckadiust-

ment,

2, Sharpenor replaceblade,

3, Checktirepressureinall fourtires,

29

Page 30

Model 60TP

Models w/Quick

Adjust Seat

Modelsw/Manually

AdjustingSeat

..... i

t_ ¸¸¸•'(iii_ii_ii_'i!¸ •

3O

Page 31

Ref. Part No. Description

No.

1 710-1268t Screw,#10-16x.375

2 712-04063 Nut, FlangeLock,5/16-18,GrF

3 712-04064f Nut, FlangeLock,1/4-20

4 720-0309At SeatAdiusterGrip

5 726-0201t Nut,Speed,.3125ID

6 731-04074f Spacer

7 732-0499t CompressionSpring.41x 1.5

8 732-1184 Spring,Extension,.84Dia.x 4.6

9 736-0275t Wash,Flat,.344x.688x.065

10 736-3019t Wash,Flat,.531x1.062x.134

11 738-0137At Screw,Shld,.340x.285,1/4-20

12 738-0296 Screw,Shoulder,.437x.268

13 738-0966At Screw,Should,.50x.925,3/8-16

14 783_0209D SeatBracket,Lift

15 783_0611t SeatStop

16 783-0738Ct SeatPivotBracket

17 783-0739At SeatAdiustmentLever

18 783_0753t SeatAdiustmentSelector

19 757-04036 MediumBackSeat

20 726_3046 RatchetClip

21 735-0657 LRFootPad,Rubber

22 735-0656 RHFootPad,Rubber

23 710_0451 Bolt,Carriage,5/16_18.75,Grl

24 710-0599 Screw,1/4-20,0.500

25 710-0604A Screw,5/16-18,0.625

26 710-0895 Screw,1/4-15,0.750

27 731_1990 Cover,LiftLever

28 731-2104C Cover,w/CupHolder

29 736-3078 Washer,Flat,.344x 1.0x.063

Ref. PartNo. Description

No.

30 783-04333A Fender

31 783-0677B Adiust.Brkt.,Lift

32 783-1489B MountingBracket,Seat

33 710_0227 Screw,#8_18x.50

34 726_0279 Plate,Insulator

35 725-1303 SpringSwitch,Outer

36 725-1439 SpringSwitch,inner

37 726-0278 Plate,InsulatorBoss

38 683_04079 ShaftAssembly,Lift

39 712-04065 Nut,FlangeLock,3/8-16,GrF

40 714-0104 Pin,Cotter,.072Dia.x 1.13

41 714-0111 Pin,Cotter,3/32, 1.0

42 716-0106A Ring,EType,.625Dia.

43 720_0311 Grip, Handle,1/2

44 732_0874 Spring,Torsion

45 738-0138A Screw,5/16-18x.620Gr2

46 738-0380 Screw,Shld,.50x.27

47 741-0225 Bearing,RexFlange

48 746-0968 Cable,Lift,16.16

49 747-04155 Handle,Lift

50 756_1154 Pulley,Roller

51 783_0678A Arm,Lift_LH&RH

52 736-0607 LockWasher,5/16

53 710-0726 Screw,5/16-12

54 738-04012At ShoulderScrew

55 720-04061t Knob,3/8-16

56 736-0300t FlatWasher,.406x .875x.059

57 783-04081At SeatPivotBracket,ManualAdi.

58 710-0870t HexHeadWasherScrew,3/8_16

t if Equipped

ustrated

parts,calltheCustomer

Service Line at

NOTE:Tractorfeaturesvaryby model NOTall partslistedaboveandpicturedonthepreviouspagearestandard

equipment.

31

\

Page 32

Model 80TP

32

Page 33

Ref. Part No. Description

No.

1 710-04095 RexScrew,3/8-16,1,00,Gr5

2 710-0514 RexScrew,3/8-16,1,00,Gr5

3 710-0643 HexScrew,5/16-18,1,00,Gr5

4 711-1408 Link,Drag,RH

5 7114409A Link,Drag,LH

6 712-0214 Nut,HexLock,3/8-24

7 712-04065 Nut,FlangeLock,3/8-16,Grf

8 712-0459 Nut,Range Lock,7/16-20

9 712-3004A Nut,FlangeLock,5/16-18,Gr5

10 712-0240 Nut,Jam,7/16-20,Gr2

11 7174550E Gear,Steering,11/90Ratio

12 717-1554 Gear,Pinion,Steering

13 723-0448A BaliJoint,7/16-20,Lock

14 736-3004 Washer,Flat,,406x,875x,105

15 736-3084 Washer,Flat,,51x 1,12x ,06

16 710q260A Screw,5/16-18,0,750

17 738-04154 Spacer,Shoulder,,38x 1,00x ,31

18 738qOO1A Shaft,Steering,,6250Dx 24,25

19 741-0475 PlasticBushing,3801D

20 738-0143 Screw,Shoulder,,498x,340

21 783-0726E PivotBracket,SupportRH

22 783-0727D PivotBracket,SupportLH

23 783-0728 PivotBracket,Bar

24 631-04008 SteeringWheel

25 731-04681 SteeringWheeICap

26 738-04128 ShoulderScrew,,5x2,380,3/8-16

27 734-2290A DeluxeRubCap

28 736-0316 FlatWasher,,78x 1,589x ,06

29 714-04039 CotterPin, 5/32x 1,25

30 719-04105 CastIronPivotBar

parts, call the Customer

Service Line at

or visit

wwW:tioyb t,com:

31 731-04693 RubCap

32 638-04003 LHAxle Assembly,,750

33 638-04004 RHAxb Assembly,,750

34 711-0332 Pin,Clevis,,50x,78

35 714-04023 CotterPin, Internal,,080x 1,5625

36 783-0720A AdiustmentBracket,Front

37 741-0656A RexFlangeBearing