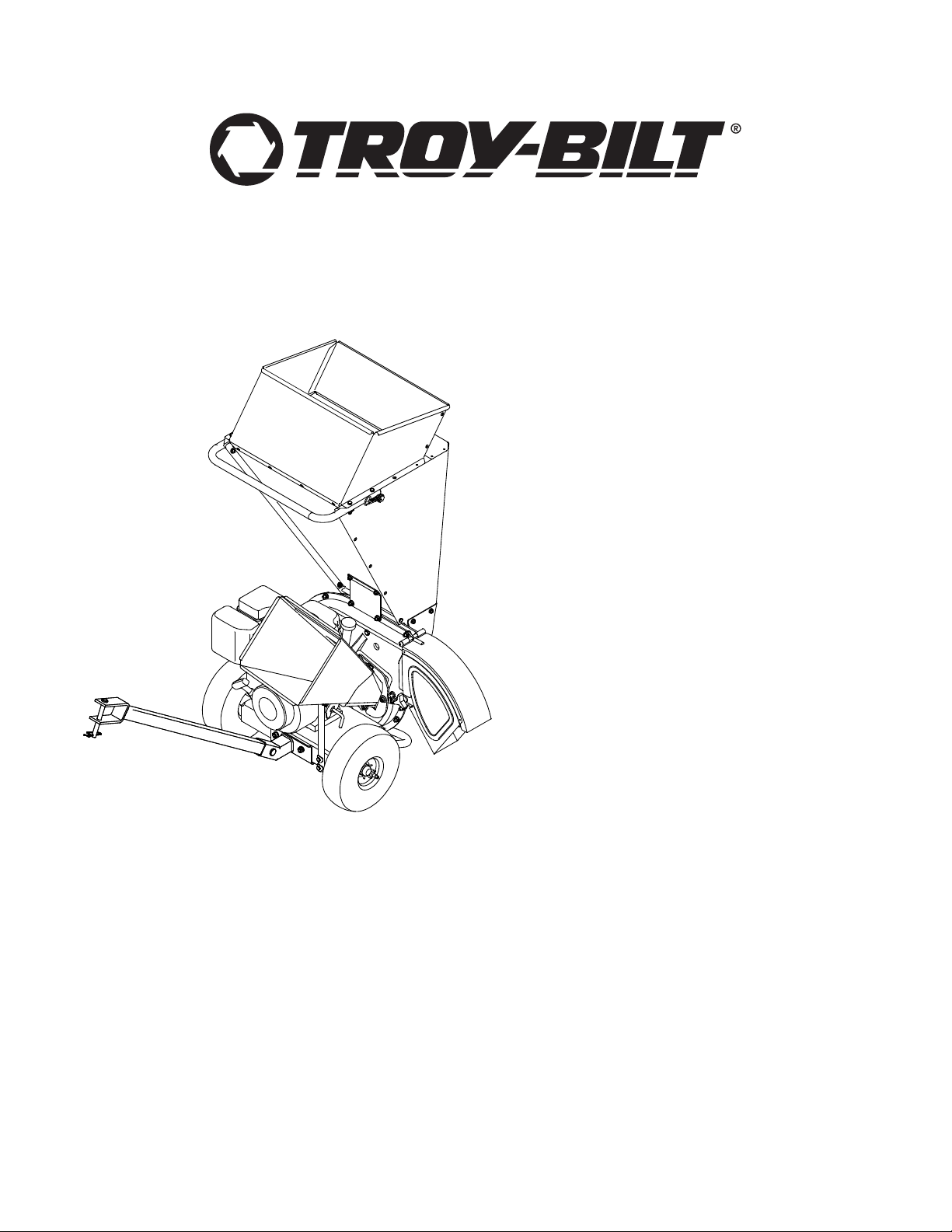

Page 1

Operator’s Manual

Chipper / Shredder

Models CS4210

CS4265

Model CS4210 Shown

IMPORTANT: Read safety ru les and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

TROY-BILT LLC. P.O. BOX 361131, CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO.

769-00830A.fm

(4/15/04)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices 3

Assembling Your Chipper Shredder 5

Know Your Chipper Shredder 6

Operating Your Chipper Shredder 7

Content Page

Maintaining Your Chipper Shredder 9

Trouble Shooting 12

Illustrated Parts List 13

Warranty 16

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new chipper shredder. It will help you assemble,

prepare and maintain the unit for best perfor mance. Please read and understa nd what it says.

Before you start assembling your new equipment, please locate the model plate on t he

equipment and copy the information from it in the space pr ovided below. A sample model plate is

also given below. You can locate the model plate by standing behin d the unit and looking down at

the frame below the engine. This information will be necessary to use the manufacturer’s

web site and/or help from the Customer Support Departme nt or an authorized service dealer.

Copy the model number here:

Copy the serial number here:

www.troybilt.com

TROY-BILT LLC

P. O. BOX

361131

CLEVELAND, OH 44136

330-558-7220

1-800-520-5520

CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from where it was purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, opera tion or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

Visit troybilt.com for many useful suggestions. Click on Customer Support button and you will

get the four options reproduced here. Click on the appropriate button and help is immediately

available.

The answer you are

looking for could be just

a mouse click away!

If you prefer to reach a Customer Support Representat ive, please call 1-800-520-5520.

The answer you are

looking for could be just

a mouse click away!

Engine

Manual

The engine manufactur er is responsible for all engine-related issu es with regards to

performance, power-rating, specifica tions, warranty and service. Please re fer to the engine

manufacturer’s Owner’s/Operator’s Manual, packed separately with your unit, for more

information.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of your self and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failur e to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

WARNING: The Engine Exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe oper ation in this

manual. As with any type of power equipment, carelessne ss or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and thro wing objects.

Failure to observe the following safety instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regu lar reference a nd for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to operate

this machine. Children 16 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this m achine without

proper instruction.

5. Keep bystanders, helpers, pets, and childre n at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharg e opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either th e feed intake or

discharge opening, remove or empty bag, or

inspect and repair the machine while the engine is

running. Shut the engine off and wait until all

moving parts have come to a complete stop.

Disconnect the spark plug wire and ground it

against the engine.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all rocks, bottles, cans, or

other foreign objects which could be picked up or

thrown and cause personal injury or damage to the

machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes a nd closefitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear

leather work gloves when feeding material in the

chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5. Maintain or replace safety and instructions labels,

as necessary.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline containe r.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait five (5) minutes before starting the

engine.

3

Page 4

i. Never store the machine or fuel container

inside where there is an open flame, spar k,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

k. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharg e opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure t he chipper

chute, feed intake, and cutting chamber are empt y

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If it becomes necessary to push material through

the shredder hopper, use a small diameter stick. Do

not use your hands or feet.

5. If the impeller strikes a foreign object or if your

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnect

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

6. Do not allow an accumulation of processed

material to build up in the reduction chamber. This

can prevent proper discharge and result in kickback

of material through the feed opening.

7. Do not attempt to shred or chip material larger than

specified on the machine or in this manual.

Personal injury or machine damage could re sult.

8. Never attempt to unclog either th e feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

9. Never operate without the shredder hopper ,

chipper chute, or chute deflector properly atta ched

to the machine. Never empty or change discharge

bag while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoid accidental kickback injuries.

12. Never operate this machine without good visibility

or light.

13. Do not operate this machine on a paved, gravel or

non-level surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the mach ine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, sto p the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoor s.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

WARNING: - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this man ual and on the machin e.

4

Page 5

SAFETY LABELS FOUND ON YOUR UNIT

SECTION 2: ASSEMBLING YOUR CHIPPER SHREDDER

IMPORTANT:

in the engine. Be certain to service engine wi th gasoline

and oil as instructed in the Briggs & Stratton Owner/

Operator manual packed with your unit. before

operating your machine.

Loose Parts In Carton

•Tow Bar (Model CS4210 Only)

• Debris Collection Bag

• Safety Glasses

• Engine Oil

Lowering the Chipper Chute

For shipping reasons, the unit is crated with its chipper

chute in a raised position. To pivot it downward,

proceed as follows:

• Pull the spring latch upward and gently pivot the

chipper chute down until it clicks into the lock rod.

See Figure 1.

This unit is shipped without gasoline or oil

WARNING: Never operate the chipper

shredder with the chipper chute in the raised

position. Doing so may result in property

damage or serious injury to the operator or

bystanders.

1.

Spring Latch

2.

Lock Rod

Figure 1

5

Page 6

Attaching The Debris Collection Bag

• To attach the bag, place the opening of the bag

completely over the chute deflector.

• Position the bag so that the wing knobs which

secure the chute deflector to the impeller housing

are completely covered.

• Pull on the drawstrap until the b ag is tight around

chute deflector opening.

Debris Collection Bag

Figure 2

Attaching The Tow Bar (Model CS4210 Only)

• To attach the tow bar, remove the spri ng pin and

clevis pin from the end of the tong ue.

See Figure 3.

Spring Pin

Tongue

Base

Clevis Pin

Figure 3

• Insert the tongue into the base. Reinsert th e clevis

pin through aligning holes in both the tongue and

the base.

• Fasten with the spring pin to se cure.

SECTION 3: KNOW YOUR CHIPPER SHREDDER

Read this operator’s manual and safety rules before

operating your chipper shredder. Compare the

illustrations in Figure 4 with your unit to familiarize

yourself with the location of various controls and

adjustments. Save this manual for future reference.

Engine Controls

See the Briggs & Stratton Owner/Operator manual

packed with your unit. for the location and function of

the controls on the engine.

Starter Handle

The starter handle is located on the engine. Pull the

starter handle to start engine. See Figure 4.

Spring Latch

The spring latch is located on the top of the hopper. It is

used to release or lock the chipper chute in a raised

position for storage or for transporting. See Figur e 4.

WARNING: Never operate the chipper

shredder with the chipper chute in the raised

position. Use the spring latch to lower the

chipper chute into the operating position

before starting the engine.

Lock Rod

The lock rod is located on the chipper chute support. It

is used to release or lock the chipper chute in a lowered

position for operation. See Figure 4.

Chipper Chute

Branches up to 3” in diameter may be fed into the

chipper chute for chipping. See Figure 4.

Hopper

Leaves, twigs and branches up to 1/2-inch in

diameter may be placed into the hopper for shredding.

See Figure 4.

IMPORTANT:

greater than 1/2-inch in the hopper. Doing so can result

in serious damage to your unit’s shredder blade, flails

or impeller.

Handle

Use the handle when manually transporting the chippe r

shredder.

Never place branches with a diameter

6

Page 7

Handle

Chipper Chute

Starter Handle

Hopper

Spring Latch

Chute Deflector

Wing Knob

Two Bar

(Model CS4210 Only)

Figure 4

Lock Rod

SECTION 4: OPERATING YOUR CHIPPER SHREDDER

WARNING: The operation of any chipper

shredder can result in foreign objects being

thrown. Always wear the safety glasses

provided with this unit or eye shields before

chipping or shredding and while performing

any adjustments or repairs.

Gas And Oil Fill-Up

Service the engine with gasoline and oil as instr ucted in

the separate engine manual packed with your chipper

shredder. Read instructions carefully.

WARNING: Never fill fuel tank indoors with

engine running or until the engine has been

allowed to cool for at least two minutes after

running.

• Open fuel shut-off valve

(Model CS4210).

• Move choke control lever to

CHOKE position (Models

CS4210 & CS4265).

NOTE: (A warm engine may no t require choking).

• Move throttle control lever to FAST (r abbit) position

(Model CS4265).

OPEN

Starting Engine

• Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug is

fastened securely over the metal tip on the spark

plug.

7

Page 8

• Grasp the starter handle and pull the rope out

slowly until resistance is felt. When it becomes

slightly harder to pull the rope, slowly allow the rope

to recoil. Then pull rope with a rap id, continuous,

full arm stroke. Keep a firm g rip on starter h andle.

NOTE: A “clanking” noise may be heard when pulling

the starter rope. It is completely normal and does NOT

indicate a malfunction of any kind.

• Maintain a grip on the starter handle and allow the

rope to recoil slowly.

• Repeat the previous steps until engine starts.

When engine starts, move choke control gradually

toward the RUN position until the engine is running

smoothly.

WARNING: Never run the engine indoors or

in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and

deadly gas.

Stopping Engine

• Move throttle control lever to STOP position (Model

CS4265) or push rocker switch to OFF (Model

CS4210). See Figure 5.

Observe the following guidelines when shredding yard

debris:

• Never attempt to shred material ot her than normal

yard debris (leaves, twigs, pine cones, etc.).

• Avoid shredding fibrous plants such as tomato

vines until they are thoroughly dried out. Fresh

vines do not shred well and tend to wrap

themselves around the impeller and flails.

• Place reasonable amounts of debris into the

hopper at a time. Do not overload the hopper .

• Allow the material in the hopper to be drawn into

the blades and shredded before adding additional

debris to the hopper. Failure to due so may result in

a clogged hopper, clogged chute deflector or a

stalled engine.

• Avoid placing twigs longer than 24 inches into the

hopper. Twigs longer than 24 inches may result in a

clogged hopper.

IMPORTANT:

greater than 1/2-inch in the hopper. Doing so can result

in serious damage to your unit’s shredder blade, flails

or impeller.

Never place branches with a diameter

Clearing the Hopper

Should the hopper become clogged with debris during

operation, proceed as follows:

• Grasp the handle with both hands and gently

agitate the chipper shredder to help loosen debris,

drawing it into the impeller.

If the clog does not clear, proceed as follows:

• Stop engine.

• Use your hands to remove any debris found near

the top of the hopper.

• Use a branch (or other available device, i.e.

broomstick) to dislodge debris locate d toward the

base of the hopper.

• Restart engine.

Figure 5

NOTE: See your engine manual packed with your unit

for more detailed instructions.

CAUTION: Never stop the engine by moving

the choke lever into the CHOKE position.

Backfire, fire or engine damage could result.

Operating the Chipper Shredder

Shredding

Yard waste such as leaves and pine needles can be

placed in the hopper for shreddin g. After material h as

been processed by the shredder blade and flails, it will

be forced out of the chute deflector, and, if attached,

into a debris collection bag.

NOTE: If you’re unable to pull the starter rope as a

result of accumulated debris near the impeller, follow

instructions under the heading Cleaning the Reduction

Chamber.

Chipping

WARNING: Nev er operat e the chipper

shredder without chipper chute lowere d into

the operating position.

Branches up to 3” in diameter can be fed into the

chipper chute. See Figure 4. Observe the following

guidelines when chipping branches:

• Keep both hands firmly on the branch as you feed it

into the chipper chute.

• Never feed more than one branch into the chipper

chute at a time.

• Never feed anything other than branches (or wood)

into the chipper chute.

8

Page 9

• Apply intermittent pressure (force, in short pulses)

while feeding larger (2- 3-inch diameter) branches

into the chipper chute, to avoid bogging or stalling

the engine.

IMPORTANT:

Never feed branches with a diameter

greater than three (3) inches into the chipper chute.

Doing so can result in serious damage to your unit’s

chipper blades, flails or impeller.

NOTE: For best performance, always operat e the unit

with sharp chipper blades. If a noticeable loss in

performance is encountered while chipping branches,

the chipper blades should be replaced.

Emptying the Debris Collection Bag

• Stop engine.

• Squeeze the locking buckle release the bag’s

drawstrap before loosening it from the chute

deflector. See Figure 6.

• Empty the bag and reattach to the chute def lector

opening. Refer to Figure 2.

Locking Buckle

Figure 6

SECTION 5: MAINTAINING YOUR CHIPPER SHREDDER

Customer Responsibilities

s

r

s

o

h

0

0

1

y

r

e

v

n

u

s

a

e

s

a

e

c

n

O

e

o

g

a

r

o

t

s

e

r

o

f

e

B

MAINTENANCE

SCHEDULE

Lube Spring Latch

T

Lube Chipper Chute Hinge

C

U

Lube Chute Deflector

D

O

R

Inspect Chipper Blades

P

Inspect Shredder Blade

Inspect for Loose Hardware

Check Oil Level

Change Oil

E

N

I

Clean Air Filter Precleaner

G

N

Clean Engine

E

Check Spark Plug

e

s

s

r

u

h

c

a

e

e

r

o

f

e

B

r

u

u

o

o

h

h

0

5

5

2

y

y

r

r

e

e

v

v

E

E

E

SERVICE

DATES

WARNING: Always stop engine, disconnect

spark plug, and ground against engine before

cleaning, lubricating or doing any kind of

maintenance on your machine.

Lubrication

Chipper Chute Hinge: Lubricate the hinge a with light

oil once a season.

9

Page 10

Chute Deflector: Lubricate the pivot points on the

chute deflector with light oil once a sea son.

Engine: Refer to the Briggs & Stratton Owner/Operator

manual packed with your unit for lubricat ion

instructions.

Maintenance

Engine

Refer to the Maintenance section of the Briggs &

Stratton Owner/Operator manual packed with your unit .

Read and follow instructions carefully

• Check engine oil level be fore each use as

instructed in the separate engine manual.

• Clean air cleaner’s pr ecleaner every 25 hours

under normal conditions. Clean every few hours

under extremely dusty conditions. Replace the air

cleaner cartridge once a season. To service the

air cleaner, refer to the separate engine manual.

• The spark plug should be cleaned and the gap

reset once a season. Refer to the separate engine

manual for correct plug type and gap specifications.

Chipper Shredder

Before each use, visually inspect your chipper shredder

for loose (or missing) nuts and bolts. Securely tighten

(or replace) all hardware before op erating the chipper

shredder.

Chute

Deflector

Shredder

Hairpin

Clip

Wing Knobs

Figure 8

• Confirm that the spark plug wire is disconnected

and away from spark plug.

• Pull on the starter rope two-to-three times to purge

any remaining debris from the reduction cham ber

• When the area is cleaned, pivot the shredder

screen downward and re-secure with the clevis pin

and hairpin clip removed earlier.

• Reattach the debris collection bag to the chute

deflector, if desired.

Screen

Housing

Clevis

Pin

Reduction

Chamber

Cleaning the Reduction Chamber

WARNING: The impeller’s shredd er blade

and chipper blades are sharp. Wear leather

work gloves to protect your hands when

cleaning out the reduction chamber.

If the reduction chamber becomes clogged with debris,

the shredder screen can be pivoted upward so that you

can clean the surrounding area. To do so, proceed as

follows:

• Stop the engine and wait until all moving parts have

come to a complete stop.

• Disconnect spark plug wire and keep away from

spark plug.

WARNING: The muffler and surrounding area

will be hot if the engine has been running. Use

caution and protect your hands if working

near the muffler.

• Remove the two wing knobs on either side of the

chute deflector and pivot the chute deflector

upward. See Figure 8.

• Remove the hairpin clip from the clevis pin which

extends through the housing and shredder screen.

See Figure 8. Retain the clevis pin and hairpin clip.

• Pivot the shredder screen upward and clean th e

surrounding area by scraping away debris.

Replacing the Chipper Blades

WARNING: Th e impeller’s chipper blades are

sharp. Wear leather work gloves to protect

your hands.

• Stop the engine and make certain the chipper

shredder has come to a complete stop.

• Disconnect spark plug wire and keep away from

spark plug.

• Pivot the shredder screen upward as instructed

under the heading Cleaning the Reduction

Chamber.

• Remove the chipper chute support brace from the

frame by removing the two hex bolts and saddle

washers which secure it. See Figure 9.

• Remove the chipper chute by removing three hex

nuts and washers which secure it to the impeller

housing. See Figure 9.

• Rotate the impeller by hand until one of the two

chipper blades is visible through the impeller

housing opening.

• Remove the blade by removing the internal hex

screws, lock washers and hex nuts which secure it

to the impeller. Retain the hardware.

10

Page 11

Chipper Blade

Lock Washer & Nut

Support Brace

Impeller

Hex Bolts &

Saddle Washers

Internal

Hex Screw

Figure 9

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the blade and a 1/2” box (or socket) wrench

on the inside of the impeller. See Figure 9. Hold the

Allen wrench stationary and rota te the box (or so cket)

wrench to loosen the nut.

• Install a replacement blade (Part No. 742-0544)

with the hardware removed earlier.

IMPORTANT:

Make certain blades are reassembled with

the sharp edge outward (toward the chipper chute).

Torque hardware to between 20 ft.-lbs and 25 ft. -lbs.

• To replace the other blade, rotate the impeller to

expose the second blade and repeat the steps

above.

Replacing the Shredder Blade

Support

Bracket

Hex Screws

Impeller

Weld Studs

Flange Nuts

Figure 10

Chute Deflector

Shredder

Blade

Internal

Flange

Nuts

Inlet

Guide

Hex Bolt, Lock Washer

& Flat Washer

WARNING: The impeller’s chipper blades are

sharp. Wear leather work gloves to protect

your hands.

• Stop the engine and make certain that all moving

parts have come to a complete stop.

• Remove the two flange nuts (and hex bolts) which

secure the hopper support bracket to the impeller

housing. Retain the hardware. See Figure 10.

• Pivot the shredder screen upward as instru cted

under the heading Cleaning the Reduction

Chamber.

• Remove the six flange nuts which secure the

hopper inlet guide to the impeller ho using. See

Figure 11.

• Carefully separate the hopper a ssembly from the

impeller housing and set it aside.

• Insert a piece of wood into t he chute deflector

opening to stabilize the impeller and prevent it fr om

rotating when removing the shredder blade.

Figure 11

• Remove the two internal hex screws which secure

the shredder blade to the impeller. See Figure 11.

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the shredder blade and a 1/2” box (or socket)

wrench on the inside of the shredder blade. See Figure

11. Hold the Allen wrench stationary and rotate th e box

(or socket) wrench to loosen the nut.

• Remove the hex bolt, lock washer, and flat washer

to completely free the shredder blade.

IMPORTANT:

If sharpening the blade for reuse, follow

the original angle of grind as a guide. Make certain

each cutting edge receives an equal amount of grinding

to prevent an unbalanced blade. Remove metal from

the heavy side until it is balanced evenly.

IMPORTANT:

When reassembling the blade, tighten

center bolt to between 45 ft.-lbs and 60 ft.-lbs an d the

two out bolts to between 20 ft.-lbs and 25 ft.-l bs.

11

Page 12

Storing Your Chipper Shredder

• Clean the equipment thoroughly.

• Wipe equipment with an oiled rag to prevent rust.

• Refer to engine manual for correct engine storage

instructions

• Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilizer.

SECTION 6: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever (if equipped)

not in correct starting position.

4. Choke not in CHOKE position.

(If Equipped)

5. Blocked fuel line.

6. Faulty spark plug.

Engine runs erratic 1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Too much vibration 1. Loose parts or damaged impeller. 1. See authorized service dealer.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

Occasional skip (hesitates)

at high speed

Unit does not discharge 1. Chute deflector clogged.

Rate of discharge slows

considerably or

composition of discharged

material changes

NOTE: For repairs beyond the minor adjustments listed ab ove, contact your neares t authorized service dealer.

1. Spark plug gap too close. 1. Adjust gap to.030” (0.76 mm).

2. Foreign object lodged in impeller.

3. Low engine RPM.

1. Low engine RPM.

2. Chipper blade dull.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to FAST position.

4. Move choke to CHOKE position.

5. Clean fuel line.

6. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline.

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See authorized service dealer.

1. Stop engine immediately and

disconnect spark plug wire. Clean flail

screen and inside of discharge opening.

2. Stop engine and disconnect spark plug

wire. Remove lodged object.

3. Always run engine at full throttle.

1. Always run engine with the throttle (if so

equipped) in the FAST position.

2. Replace chipper blade or see your

authorized service dealer.

12

Loading...

Loading...