Page 1

Owner/Operator

Manual

PTO HORSE

Tiller

• Safety

50

V.

7 HP

• Controls

• Operation

• Maintenance

8 HP

Page 2

factory in Troy, N.Y, where tillers have been made since 1937. Please come and visit us.

fe call your machine the PTO HORSE Model

•BILT® Roto Tiller-Power Composter

hout this Owner/Operator Manual and in

r literature, we refer to your machine as the

RSE Model”. The name aptly describes its

3e ruggedness, and it distinguishes this

m the smaller ECONO-HORSE, PONY® and

models, as well as from other models that

n available in the past or that might be

I in the future.

;tory dates back to the old Rototiller Corpo-

5 company that introduced rear-tine rotary

WARNING TO ALL CALIFORNIA AND OTHER POWER EQUIPMENT OPERATORS

California law, and under the laws of several other states, you are not permitted to operate an

I combustion engine using hydrocarbon fuels on any forest covered, brush covered, or grass

dl land, or on land covered with grain, hay, or other flammable agricultural crop, without an

spark arrester in continuous effective working order.

gine on your power equipment, like most outdoor power equipment, is an internal combustion

that burns gasoline, a hydrocarbon fuel. Therefore, your power equipment must be equipped

spark arrester muffler in continuous effective working order. The spark arrester must be

id to the engine exhaust system in such a manner that flames or heat from the system will not

lammable material. Failure of the owner / operator of the equipment to comply with this

ion is a misdemeanor under California law, and may also be a violation of other state and / or

regulations, laws, ordinances, or codes. Contact your local fire marshal or forest service for

; information about what regulations apply in your area.

tillage to America in 1930. The first rear-tine tillers

Rototiller, Inc. built in Troy were manufactured in 1937,

in the same building where Garden Way built its first

HORSE Model in 1961. We’re still building our tillers

at the same location.

Over the years, the PTO HORSE Model has been

continually refined and improved. Its performance

and reliability have long been recognized by many

thousands of serious vegetable gardeners as being

unmatched by any othertiller of its size or design.

Page 3

Off to a Safe Start!

The PTO HORSE Model TROY-BILT® Tiller meets

voluntary safety standard B71.8-1986, which is

sponsored by the Outdoor Power Equipment insti

tute, Inc. and is published by the American National

Standards Institute, Inc.

Your new tiller is basically a simple machine to

operate. However, as with all new and unfamiliar

powered equipment, you should thoroughly read

and understand this Owner/Operator Manual and

any other literature you received with your tiiler

before you attempt to start the engine. Please care

ful iy follow recommended operating instructicns

and safety practices closely at ail times. Failure to

do so could result in injury or property damage.

ASSEMBLY INSTBUCTIONS ^

NOTICE!

Included in your literature package is an As

sembly Instructions Manual that provides stef:>

by-step instructions on how to assemble your

new tilier. if you purchased your tiller un

assembled, then be sure to read and follow the

assembly instructions carefully.

Cali our Technical Service Department imme

diately (see page 4) if the Assembly Instructions

Manual is missing from your literature package,

or if you have any questions about assembly.

Please don’t attempt to assemble your tiller with

out proper instructions.

CONTENTS

Introduction

If You Need Service............................................

Section 1; Safety Instructions

Section 2: Controls and Functions

Section 3: Operation of Tiiler

Section 4: Tilling in the Garden ..........................

Section 5: The PTO Power Unit

Section 6: Maintenance and Service ....

Section 7: Troubleshooting

Section 8: Specifications

............................

..............................

.........................

...............................

....................................

4

6

16

25

32

36

65

70

?

I

»

A CAUTION

TO AVOID INJURY:

Read the Owner/Operator Manual.

Know location and function of all controls.

Keep all safety devices and shields in place.

Never allow children or uninstructed adults to

operate tiller.

Shut off engine and disconnect spark plug

wire before unclogging tines or making repairs.

Keep bystanders away from machine.

Keep away from rotating parts.

Section 9: Attachments and Accessories

Index .................................................................

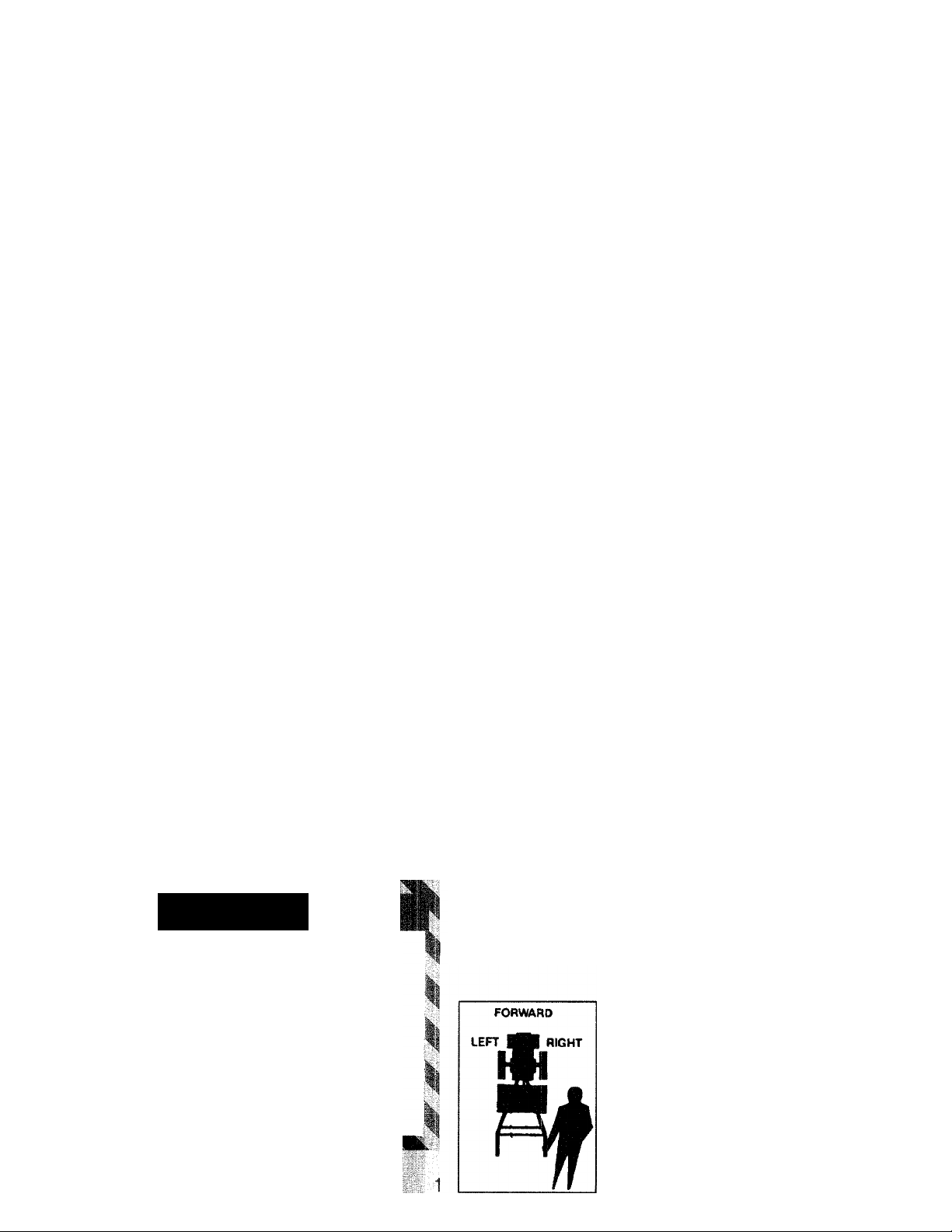

“OPERATOR’S POSITION”

All references to LEFT and

RIGHT sides of the tiller

are given from the opera

tor’s position behind the

handlebars (unless speci

fied otherwise).

72

79

Page 4

Introduction

i-

Welcome to “Power gardening

the TROY-BILT® Tiller way.” Your

new PTO HORSE Model Tiller is a

useful, productive gardening tool

that, with proper care, should last

for many years.

Your tiller was designed to easily

chop up, shred and bury all sorts

of vegetation and organic matter in

the garden in addition to preparing

seedbeds and cultivating. With op

tional tiller attachments it can also

be used for furrowing and hilling,

as well as light earthmoving and

snow removal chores.

The PTO HORSE Model’s design,

with powered wheels ahead of the

separately geared Bolo Tines in

the rear, gives it an outstanding

combination of tilling and com

posting capabilities that allows you

to enrich your soil far beyond your

abilities to do so by hand. This soil

enhancement is gained by tilling in

and burying organic materials such

as leaves, mulches, crop residues,

sod, green manure cover crops

and even standing cornstalks! By

using this method, you will soon

experience better yields in your

garden than ever before. This is

said to be the greatest single

benefit of power gardening “the

different, better, and so much more

enjoyable TROY-BILT® Tiller way.”

We have tried our best to build

your tiller as strong and trouble-

free as we know how. This, of

course, is to our mutual benefit. We

have fewer service problems and

you have a truly reliable machine.

VERY IMPORTANT!

Before trying to operate your tiller or PTO Power Unit

for the first time, please make sure that you:

Complete all of the tiller

assembly steps that are de

scribed in the separate As

sembly Instructions Manual

that came packaged with

this Manual.

Completely familiarize your

self with all of the operating

controls as described in Sec

tion 2 of this Manual.

REMEMBER ... PRACTICE SAFETY AT ALL TIMES!

Read and understand all of

the Safety Instructions in

Section 1 of this Manual.

Read and understand all of

the operating procedures for

the tiller and the PTO Power

Unit, as described in Sections

3, 4 and 5 of this Manual.

Page 5

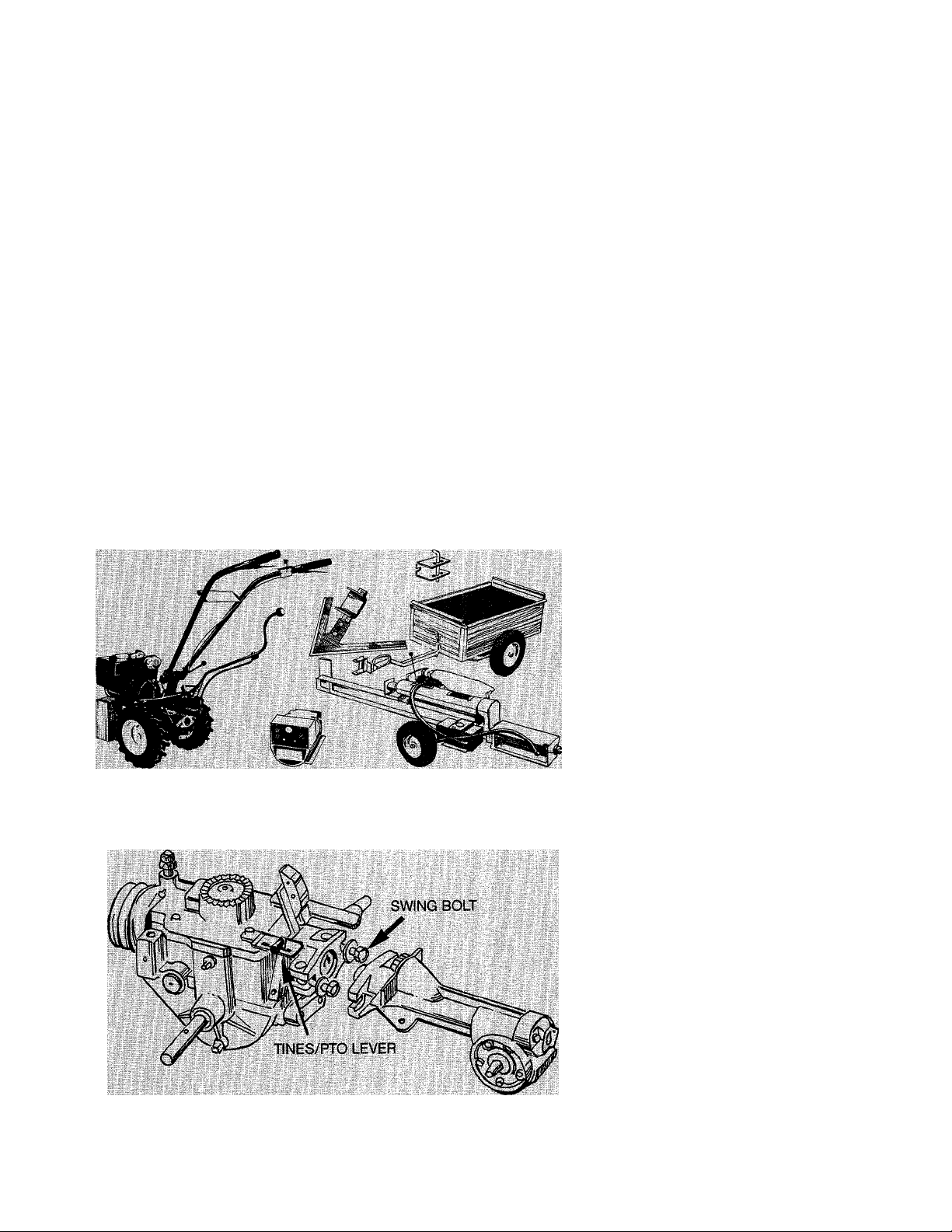

You also have a versatile PTO Power Unit...

In addition to being an incredibiy efficient tiller, your machine can

be quickly converted into a seifcontained PTO (Power Take-Off)

Power Unit that is capable of tow

ing or powering various TROY-BILT

PTO attachments (see Figure 2).

This ability to convert the tiller

into a PTO Power Unit is made

possible by the unique design of

the Horse Modei’s transmission.

As shown in Figure 3, the trans

mission is made up of two sepa

rate cast-iron housings that are

held together by a locking collar, a

dowel pin and two swing-bolts.

Figure 2: The tine attachment can be removed and various powered or nonpowered attachments can be connected to the Power Unit.

Each housing has separate drive

shafts that are joined by a tine

ciutch. This clutch can be engaged

or disengaged by moving the Tines/

PTO Ciutch Lever that is located

on the left side of the PTO Power

Unit transmission.

When the tine attachment is in

place, the lever allows you to

operate the tiller with the tines

disengaged, even when the wheeis

are in motion. This tine disconnect

feature provides added conven

ience when transporting, loading,

or unioading the tiller. When the

lever is in the engaged position.

the tine ciutch connects the two

drive shafts together, transmitting

power to the tines.

If the tine attachment is removed

(by ioosening the two swing-bolts

and sliding the attachment off), the

PTO Power Unit can be used to

tow moderate loads or drag-

behind implements, or to provide

engine power to powered station

ary attachments such as the TROYBILT® Generator, TROY-BILT® PTO

Log Splitter and TROY-BILT® PTO

Chipper/Shredder. This PTO capa

bility truly makes your tiller an allaround, all-season work horse.

For detailed instructions on how

to convert your tilier into a PTO

Power Unit piease refer to Section

5 in this Manual.

A word about

maintenance...

You can help ensure long-lasting

and proper performance from your

PTO HORSE Model by always re

membering to perform the sched

uled maintenance services that are

presented in Section 6 of this

Manual, and in the accompanying

engine manufacturer’s Owner’s

Manual.

By treating your machine with

good care in the manner described

in those pages, your efforts will be

returned many times over in the

form of a more satisfying and

easier operating machine, and

with much more bountiful garden

ing resuits.

Figure 3: The transmission consists of two housings, held together by swingbolts. Separate “dog” clutches on each drive shaft are engaged and disengaged

with the Tines/PTO Clutch Lever.

Page 6

We’re here to serve you!

The whole idea behind TROYBILT® Tiller Factory Service is to

get parts, attachments and service

advice out to you just as quickly

as possible and to answer any

questions you may have about tilling

or gardening, by phone or by letter,

depending upon what is needed.

If you have a question

or problem ...

If you have a question or prob

lem that Is not answered In this

Manual, then please get in touch

with our Technical Service Depart

ment by phone or by letter. One of

our friendly, helpful tiller experts

will gladly help you out.

Nothing is more important to all

of us here at the factory than mak

ing sure that every owner is com

pletely satisfied 1JD0-percent of the

time. You’re always entitled to firstrate service. Please be assured

that we will do our very best to see

that you get it at all times.

Thank you.

Dean Leith, Jr., Sales Manager

For the fastest service, DIAL FREE from:

In the U.S.A..........................................(Toll-Free) 1-800-833-6990

In Canada (Garden Way Canada).... (Toll-Free) 1-800-225-3585

Our business hours are (Eastern Time):

In the U.S.A.: M-F 8 a.m. to 7 p.m.; Sat. 9 a.m. to 4 p.m.

In Canada: M-F 8 a.m. to 5 p.m.

If you need a tiller part...

If you need to order a part for

your tiller, please refer to the sepa

rate Parts Catalog that came with

this Manual. There, you will find

detailed instructions on how to

identify parts and how to place

your order.

Our mailing address Is:

In the U.S.A. In Canada

Troy-Bilt Mfg. Co.

102nd St. & 9th Ave.

Troy, New York 12180

Garden Way Canada

1515 Matheson Blvd. E.

Mississauga, Ontario L4W 2P5

NOTE: When calling or writing, please provide us with your Tiller

Serial Number (See page 5).

If you need engine service or

For engine service or parts, con

tact your nearest engine service

dealer who is authorized to service

the particular make of engine that

is on your tiller. Look in the Yellow

Pages of your telephone directory

under “Engines—Gasoline” for

the name of your nearest service

dealer. The service dealer can

handle all parts, repairs and war

ranty service concerning the en

gine alone.

It is important to remember that

your engine is covered by the en-

parts...

gine manufacturer’s Limited War

ranty and any unauthorized work

done on the engine during the war

ranty period may void your engine

warranty. For full details on the

engine’s Limited Warranty, please

see the separate engine manufac

turer’s Owner’s Manual that came

with this Manual.

If you have any difficulty in find

ing an authorized service dealer

or in obtaining warranty service,

please contact our Technical Serv

ice Department for assistance.

Page 7

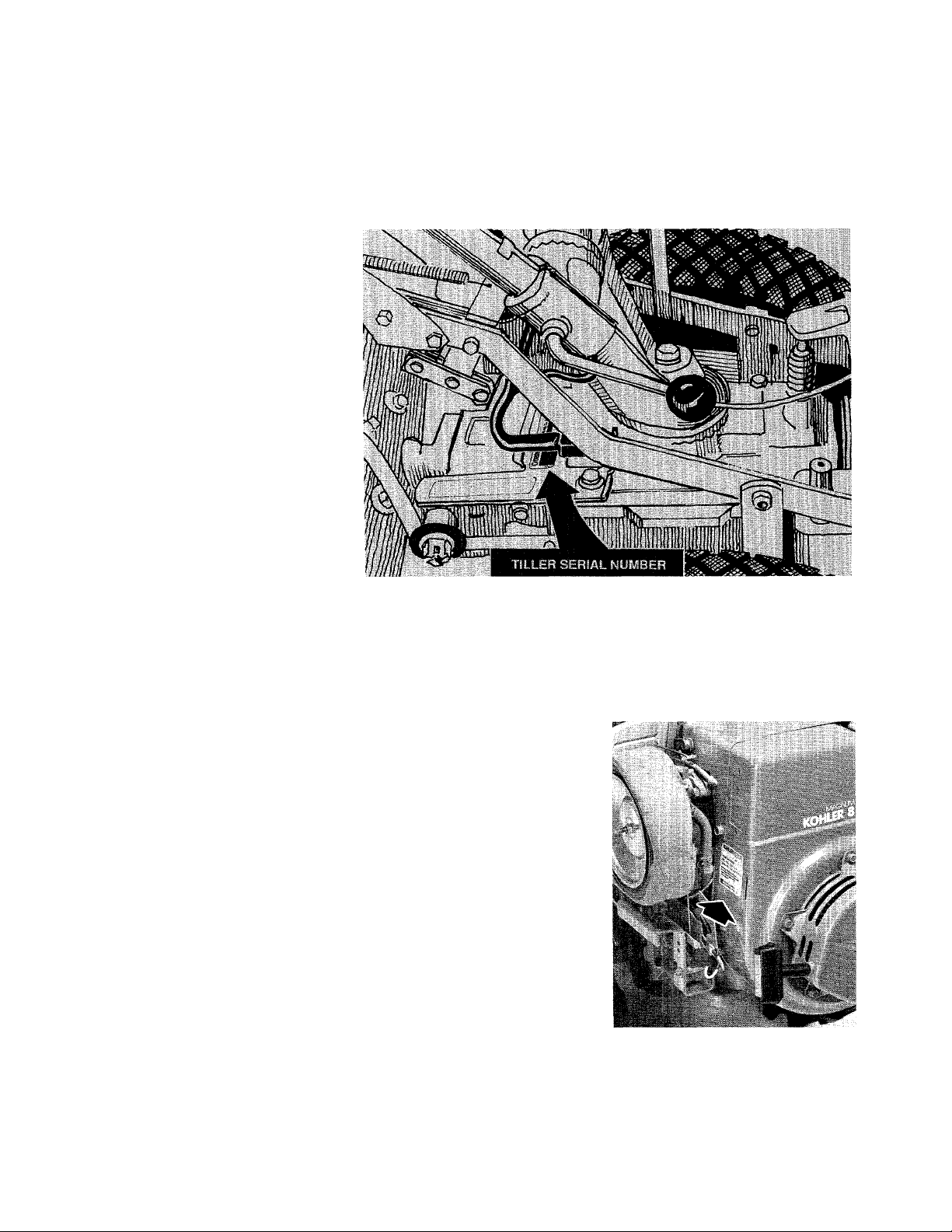

RECORD YOUR TILLER SERIAL NUMBER

To help you as quickly as possi

ble when you write or call for serv

ice or parts, we will need to know

your Tiller Serial Number.

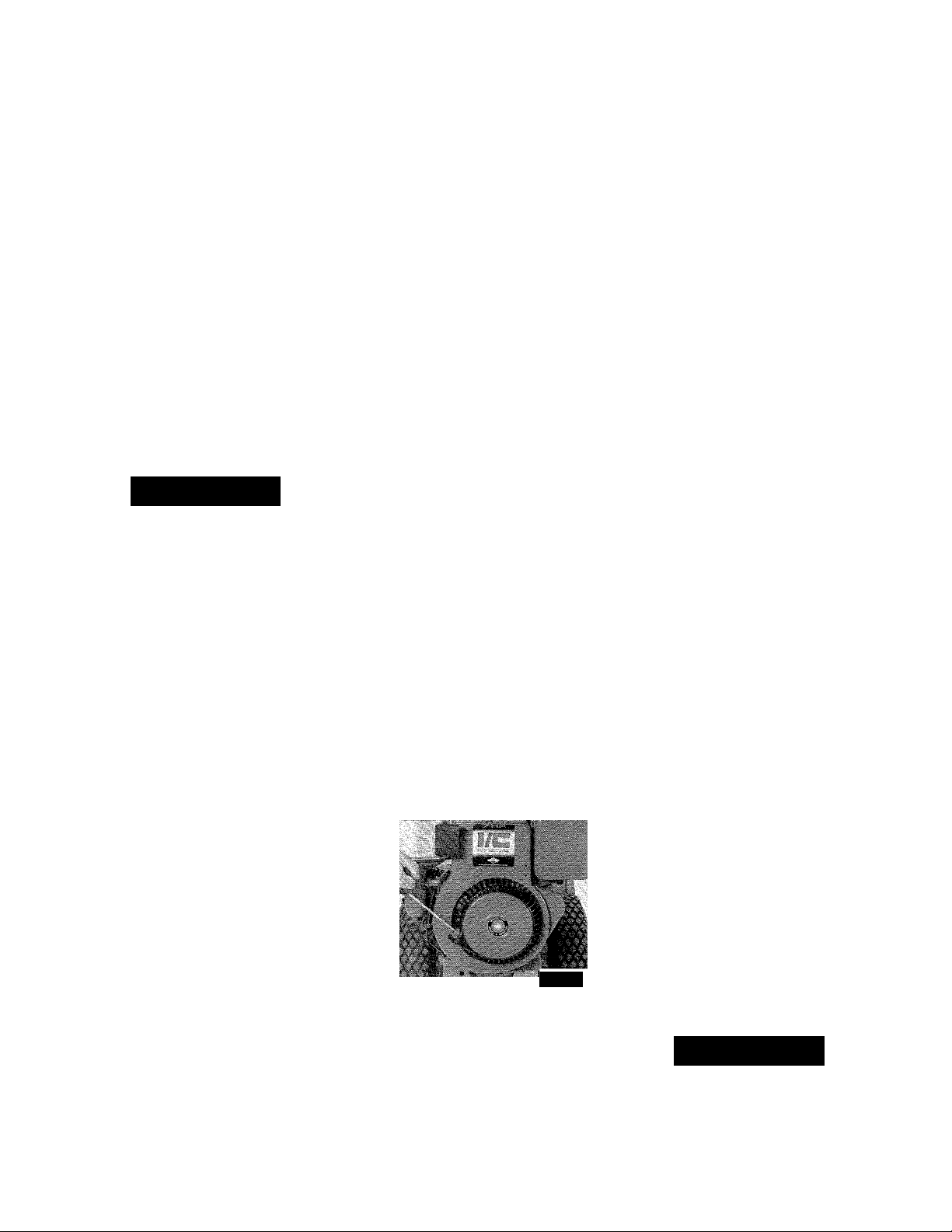

The arrow in the Figure at the

right points to a iocation on the

transmission where the serial

number is located. For ready

reference, please record this

number, aiong with the delivery

date of your tiiier, in the spaces

provided beiow.

Serial Number:

Date of Delivery:

RECORD YOUR ENGINE MODEL NUMBER

Should you ever need engine

service or parts, you may be asked

for the engine model code number.

On the 7HP Briggs & Stratton

engine, the number is stamped on

the top of the blower housing

cover, as shown in Photo 6.

On the 8HP Kohler engine, the

number is located on the right side

of the blower housing cover, be

hind the air cleaner cover (remove

wing nut to remove air cleaner

cover). See Photo 7.

Engine Code:

________________

PHOTO 6: Code number location on

7HP Briggs & Stratton engine.

... .

PHOTO 7: Code number location on

8HP Kohler engine.

Page 8

SECTION 1:

The PTO HORSE Model Tiller

has been designed with many

safety features to help protect indi

viduals from harm and property

from being damaged. However, as

with any type of power equipment,

it is necessary for you and any

TRAINING

1. Read both this Owner/Operator

Manual and the separate engine

Owner’s Manual carefully. Be

thoroughly familiar with the con

trols and the proper use of the

tiller and its engine. Know how to

stop the unit and disengage the

controls quickly.

2. Read the Owner/Operator Man

operator to follow safe operating

practices at all times. Failure to do

so can result in personal injury or

damage to equipment or property.

Before operating or servicing the

tiller or the PTO Power Unit, care

fully read and follow all of the

A

SAFETY ALERT SYMBOL

This symbol is used to alert you to

important safety messages in this

Manual and on your tiller. When

you see this symbol, carefully read

and follow its safety message.

uals provided with any optional

accessories or attachments before

operating. The manuals provide a

detailed description of proper use

Safety Instructions found in this

Owner/Operator Manual and in the

separate Owner’s Manual provided

by the engine manufacturer. If you

have any questions, please call or

write us.

and operation, and point out other

important Safety Instructions.

3. Never allow children to operate

the tiller. Never allow adults to

operate the tiller without proper

instruction.

4. Keep the area of operation clear

of all persons (particularly small

children), and pets.

PREPARATION

1. Thoroughly inspect the area

where the tiller is to be used and

remove all foreign objects before

tilling.

2. Put the Wheels/Tines/PTO Drive

Lever in “NEUTRAL” before starting

the engine.

3. Do not operate the tiller without

wearing suitable outer garments.

Avoid loose garments or jewelry

that could get caught in moving

parts of the tiller or its engine.

4. Do not operate the tiller when

barefoot or wearing sandals,

sneakers, or similar lightweight

footwear. Wear footwear which will

improve footing on slippery sur

faces.

5. Do not till near underground

electric cables, telephone lines,

pipes, or hoses. If in doubt, contact

your telephone or utility company

to locate underground services.

6. Handle fuel with care; it is highly

flammable and its vapors are

explosive.

(a) Use an approved fuel con

tainer.

(b) Never remove gas cap or add

fuel to a running engine or to a

hot engine. Engine shall be al

lowed to cool before refueling.

(c) Keep matches, cigarettes,

cigars, pipes, open flames, or

sparks away from the fuel tank

and fuel container.

(d) Fill fuel tank outdoors with

extreme care. Never fill fuel

tank indoors. Use a funnel or

spout to prevent spilling.

(e) Replace fuel cap securely and

clean up spilled fuel before

restarting.

7. Never attempt to make any ad

justments while the engine is

running or the spark plug wire is

connected, except where specifi

cally instructed to do so.

Page 9

OPERATION

1. Do not put hands or feet near or

under rotating parts.

2. Exercise extreme caution when

operating on or crossing gravel

drives, walks, or roads. Stay alert

for hidden hazards or traffic.

3. After striking a foreign object,

stop the engine, remove the key on

electric start models, disconnect

the spark plug wire, and thoroughiy

i nspect the ti I ier for any damage.

Repair the damage before restart

ing and operating the tiller.

4. Exercise caution to avoid slip

ping or falling.

5. If the machine should start to

vibrate abnormally, stop the engine,

remove the wire from the spark

plug, and check immediately for

the cause. Vibration is generally a

warning of trouble.

6. Stop the engine, remove the key

on electric start models, and dis

connect the spark plug whenever

you leave the operating position,

before unclogging the tines, and

when making any repairs, adjust

ments, or inspections.

7. Take all possible precautions

when leaving the tiller unattended.

Shift into “NEUTRAL”, stop the en

gine, remove the key on electric

start models, and disconnect the

spark plug wire to prevent acci

dental starting.

8. Before cleaning, repairing, or in

specting, stop the engine, remove

the key on electric start models,

and make certain all moving parts

have stopped. Disconnect the

spark plug wire and keep the wire

away from the plug to prevent ac

cidental starting. For electrical

saftey, always remove the cable

from the negative (-) side of the

battery (on electric start models)

before attempting any repairs or

maintenance.

9. Always keep the flap on the tine

hood down when operating the

tiller, except when using the hiller/

furrower attachment.

10. Never operate the tiller without

proper guards, shields, plates, or

other safety protective devices in

place.

11. Do not run the engine in an en

closed area; exhaust fumes con

tain carbon monoxide gas, a deadly

poison that is odorless, colorless

and tasteless. Always make sure

there is adequate ventilation when

the engine is running.

12. Keep children and pets away.

13. Never operate the tiller under

engine power if the Wheel Speed

Lever is in the “FREEWHEEL”

position. In “FREEWHEEL”, the

wheels will not hold the tiller back

and the revolving tines could pro

pel the tiller rapidly, possibly caus

ing loss of control. Always engage

the Wheel Speed Lever in either

the “FAST” or “SLOW” wheel

speed position before starting the

engine or engaging the tines with

the Wheeis/Tines/PTO Drive Lever.

14. Be aware that the tiller may

unexpectedly bounce upward or

jump forward and be propelled

away from you if the tines should

strike or catch extremely hardpacked soil, sod, frozen ground, or

buried obstacles such as large

stones, roots, or stumps. If you are

in doubt about the tiling condi

tions, always use the following

operating precautions to assist you

in maintaining control of the tiller.

(a) Walk behind and to one side of

the tiller, using just one hand

on the handlebars. Relax your

arm, but use a secure hand grip.

(b) Use shallower depth regulator

SAFETY INSTRUCTIONS

settings, gradually working

down deeper with each tilling

pass.

(c) Use slowerwheel, tine and en

gine throttle speeds.

(d) Clearthetillingareaof all

large stones, roots, and other

debris.

(e) Avoid applying downward

pressure on the handlebars. If

necessary, apply slight upward

pressure to prevent the tines

from digging too deeply.

(f) Always avoid contacting hard-

packed soil or sod at the end

of a row by reducing the en

gine speed and lifting the han

dlebars to raise the tines out of

the soii.

(g) In an emergency, stop the tines

and wheels by shifting the

Wheels/Tines/PTO Drive Lever

into “NEUTRAL”. If you cannot

reach the lever or have lost

control of the tiller, LET GO of

the handlebars and all controls

and do not attempt to restrain

the tiller.

15. Do not overload the machine

capacity by attempting to till too

deeply at too fast a rate.

16. Never operate the tiller at high

transport speeds on slippery sur

faces.

17. Do not operate til Ier on a slope

that is too steep for safety. When

on slopes, slow down and make

sure you have good footing. Never

permit the tiller to free-wheel down

slopes.

18. Clear the area of bystanders

before tilling.

Page 10

19. Use only attachments and

accessories that are approved

by Garden Way Manufacturing

Company.

20. Use tiller attachments and

accessories when recommended.

21. Never operate the tilier without

good visibility or light.

22. Never operate the tilier when

fatigued, or whiie under the in

fluence of alcohol, drugs, or

medication.

23. Do not change the engine

governor settings or overspeed

the engine.

24. Do not touch engine parts that

may be hot from operation. Allow

parts to cool before inspecting,

cleaning, or repairing.

25. POISON/DANGER-CAUSES

SEVERE BURNS. The battery on

electric start models contains

sulfuric acid. Avoid contact with

skin, eyes or clothing. Antidote:

EXTERNAL—Flush immediately with

lots of water.

INTERNAL—Drink large quantities

of water or milk. Follow with milk of

magnesia, beaten eggs or vegetable

oil. Call physician immediately.

EYES—Flush with water for 15 min

utes and get prompt medical atten

tion. Keep out of reach of children.

26. DANGER-BATTERIES PRO

DUCE EXPLOSIVE GASES. Keep

sparks, flame, or smoking materi

als away. Ventilate when charging

or using in an enclosed space.

Always shield eyes when working

near batteries.

27. Please Remember: You can al

ways stop the tines and wheels by

putting the Wheels/Tines/PTO Drive

Lever in “NEUTRAL”, or by moving

the Throttle Lever to the “STOP”

position. If you have lost control of

the tiller, and cannot reach the

levers, LET GO of the handlebars

and all controls and do not attempt

to restrain the tiller. The Forward

Interlock Safety System will stop

the engine.

28. Look behind and use care

when backing. For added safety,

put Wheel Speed Lever in “SLOW”

before reversing.

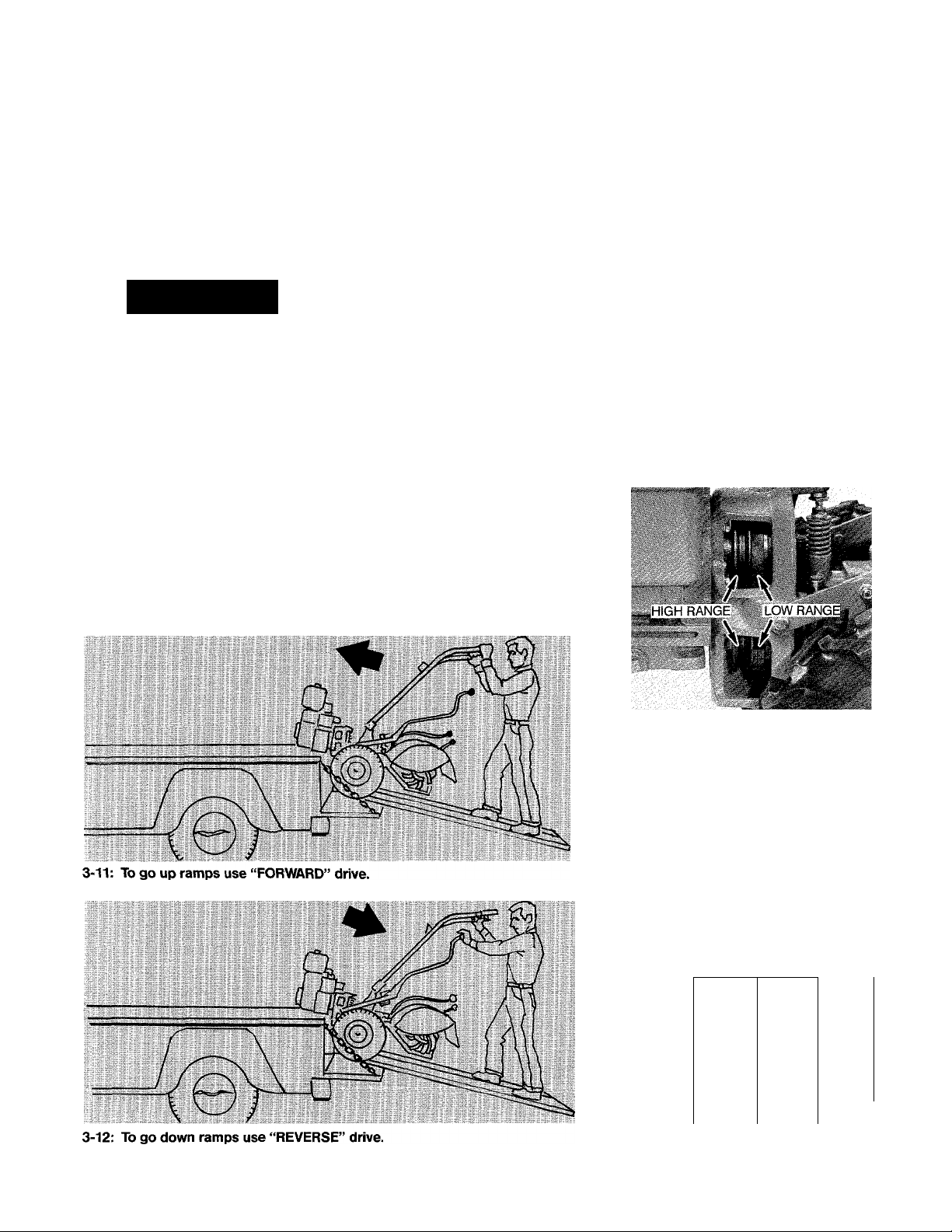

29. When loading or unloading

unit, always disengage the tines

and use slower wheel and engine

throttle speeds. Use sturdy ramps

that are wide and strong enough

to support both the tiller and oper

ator (tiller weighs between 280 and

325 lbs.). Never go down ramps in

“FORWARD” drive as the tiller

could tip forward, exposing you to

the tines (which should be disen

gaged). Always use “REVERSE”

drive and back down ramps. To go

up ramps, use “FORWARD” drive

and follow tiller up ramps.

30. The Forward Interlock Safety

System should first be tested for

proper functioning every time the

tiller or PTO Power Unit is used.

See Section 3 in this Manual for

the testing procedure to follow.

31. When snowplowing with the

optional dozer blade, either remove

the tines completely, or disengage

the tines with the Tines/PTO Clutch

Lever. Revolving tines could be

dangerous on slippery sidewalks

or driveways.

MAINTENANCE AND STORAGE

1. Never perform any maintenance

while the engine is running or the

spark plug wire is connected, ex

cept where specifically instructed

to do so.

2. Keep machine, attachments

and accessories in safe working

condition.

3. Check all nuts, bolts, and screws

at frequent intervals for proper tight

ness and to be sure the equipment

is in safe working condition.

4. Never store the machine with

fuel in the fuel tank inside a build

ing where fumes may reach an

open flame or spark, or where igni

tion sources are present (such as

hot water and space heaters, fur

naces, clothes dryers, stoves, elec

tric motors, etc.).

5. Allow the engine to cool before

storing in any enclosure.

6. To reduce fire hazard, keep the

engine free of grass, leaves or ex

cessive grease.

7. Store gasoline in a cool, wellventilated area, safely away from

any spark or flame-producing

equipment. Store gasoline in an

approved container, safely out of

the reach of children.

8. Refer to the Maintenance and

Service Section of this Manual if

the tiller is to be stored for an

extended period.

8

DECALS

Safety decals and operating in

struction decals are located on the

handlebars, the operator control

panel, the tine hood, the engine,

and the transmission. Contact us

immediately for replacement decals

if any are missing, illegible, or

damaged. See your Parts Catalog

for the exact location and part

number of each decal. Do not at

tempt to operate machine if any

decals are illegible or missing.

Page 11

SECTION 2:

Before using your tiller or PTO

Power Unit for the first time, be

come thoroughly familiar with the

operation of the controls by mov

ing them to their various positions

Tiller and PTO Power Unit Controls

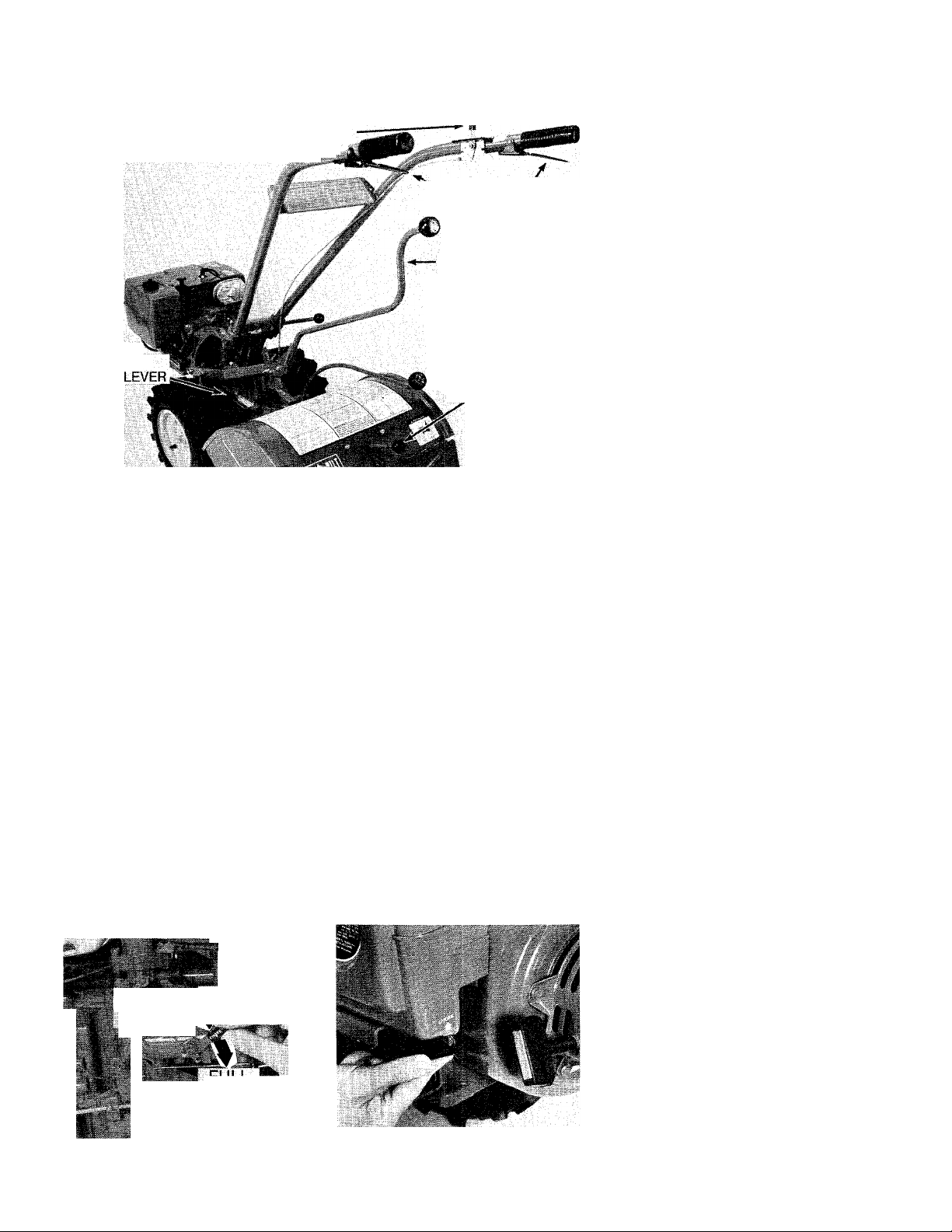

1. Wheels/Tines/ PTO Drive Lever

This lever engages power from

the engine to the transmission

(see Photos 2-1, 2-2, and 2-3).

There are three positions of this

lever: "FORWARD”, “NEUTRAL”

and “REVERSE”.

When you move the lever down

to the “FORWARD” position, it

raises the engine upward and tight

ens the drive belt located between

the engine pulley and the transmis

sion pulley. The transmission then

while the engine is not running.

Taking the time now to fully under

stand the location, function, and

operation of these controls will

greatly add to the productive use,

drives the wheels and tines in a

forward direction. (If the tines are

removed and replaced with a PTO

driven attachment, the lever will

apply power to the attachment.)

The lever will remain in “FOR

WARD” until you tap or lift it

upward and let it go.

When you move the lever all the

way up to the “REVERSE” position,

it lowers the engine and causes

the drive belt to go slack. At the

same time, the rubber reverse disc

on the engine pulley comes into

contact with the transmission pul

ley, causing the transmission to

rotate the wheels and tines (or any

PTO driven attachment) in a re

verse direction. The reverse oper

ation will continue as long as you

hold the lever up. When you re

lease the lever, it will automatically

return to “NEUTRAL”. This is a

safety feature for your protection.

When the lever is in “NEUTRAL”,

the engine will continue to run, but

power will not be transferred to the

transmission.

safe operation, and full enjoyment

of your new machine. The proper

operation of each control is dis

cussed in detail in this Section.

To operate the Wheels/Tines/

PTO Drive Lever:

A. Practice shifting the lever as

described next. As you do, note in

the accompanying photos the vari

ous positions that the clutch roller

takes on the belt adjustment block.

Your roller should be similarly po

sitioned when you shift the lever.

B. For forward motion of the wheels

and tines (or to apply power to any

PTO driven attachment), push the

iever all the way down and release

it. See Photo 2-1. To return to

“NEUTRAL”, tap or lift the lever up

and let it go (Photo 2-2).

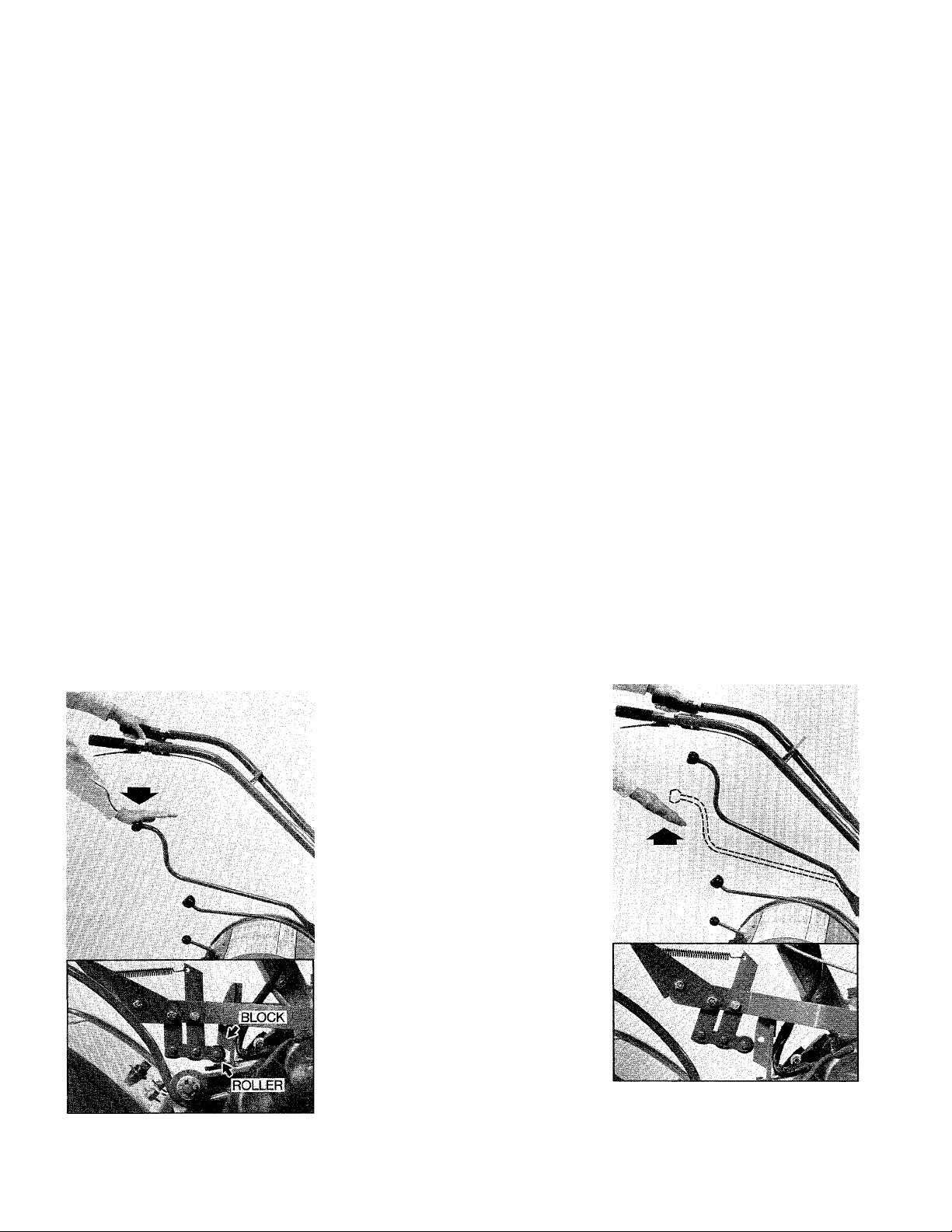

2-1: Push lever down for “FORWARD”.

The clutch roller (lower photo) will be

engaged below the adjustment block.

IMPORTANT

Moving the lever to the “NEUTRAL”

position will stop all wheel and tine

motion, or power to any PTO driven

attachment.

2-2: Tap or lift lever up to return to

“NEUTRAL”. The clutch roller (lower

photo) will rest anywhere on the face

of the adjustment block, depending

upon drive belt length and tension.

Page 12

C. Before shifting into “REVERSE”,

always look behind you to make

sure there are no obstacles in the

way. Then raise the tines out of the

soil by lifting up on the handlebars,

and slowly lift the lever all the

way up. See Photo 2-3. To return

to “NEUTRAL”, simply let go of

the lever.

Please remember that you should

never till when in “REVERSE” (al

ways disengage the tines with the

separate Tines/PTO Clutch Lever

before reversing). You should also

avoid using “REVERSE” with any

PTO driven attachments as they are

not designed for reverse operation.

Until you are completely com

fortable with handling the machine

when it is moving backward, it is a

good idea to use “REVERSE” only

at slower wheel and engine throttle

speeds. Many people never shift

into “REVERSE” when the separate

Wheel Speed Lever is in the “FAST”

wheel speed position. This is a

good rule to follow.

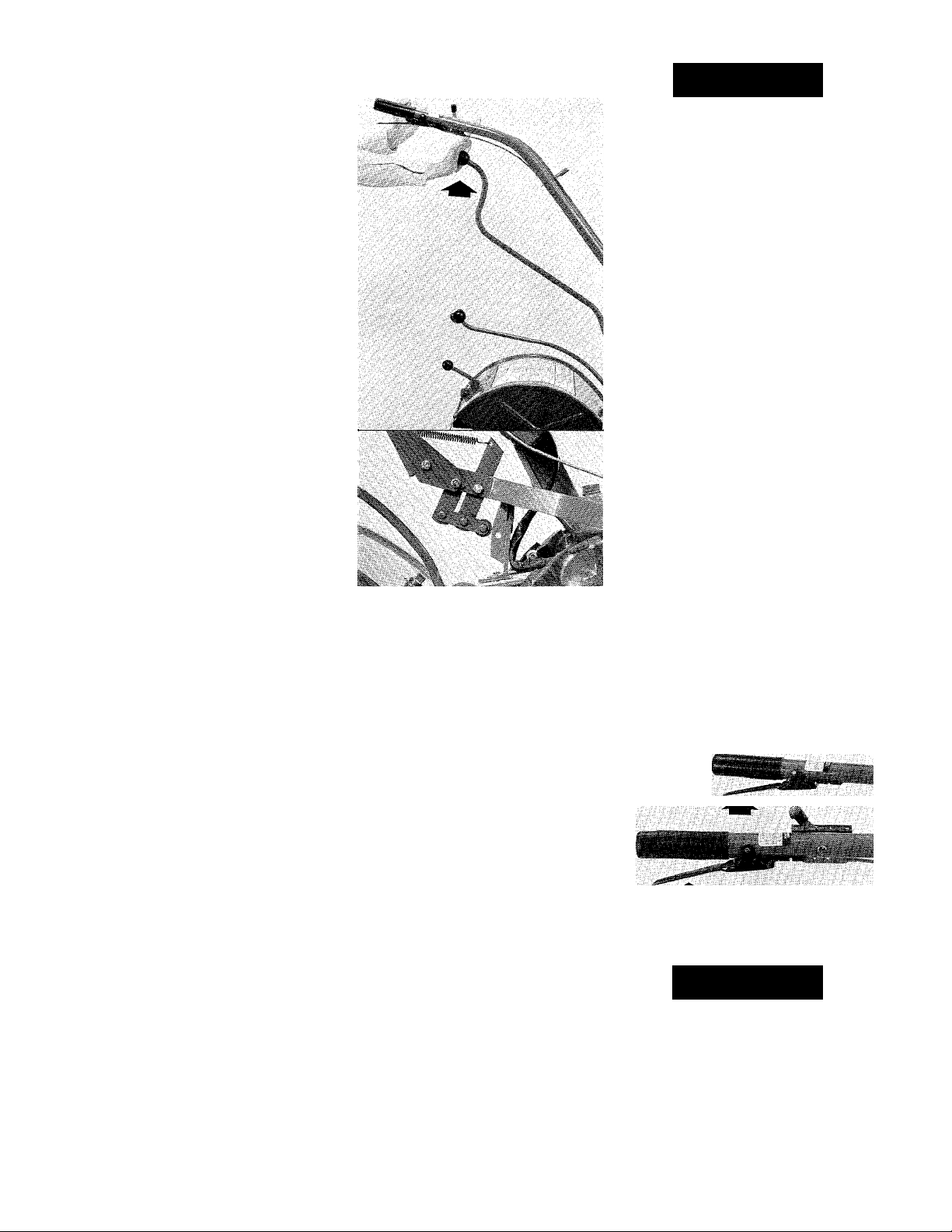

2-3: Lift handlebars, then lift and hold

lever up to go in reverse. Let go of

lever to stop reverse motion. (Note

that the clutch roller doesn’t move very

far from “NEUTRAL” to “REVERSE”.)

A CAUTION

TO AVOID PERSONAL INJURY OR

DAMAGE TO EQUIPMENT:

• Always place the Wheeis/Tines/

PTO Drive Lever in “NEUTRAL” be

fore starting the engine, and before

engaging the wheels, tines or other

PTO driven attachments.

• Always make sure there are no

obstacles behind you before oper

ating in “REVERSE”.

• The Wheels/Tines/PTO Drive

Lever should automatically return

to “NEUTRAL” when you release it

from the “REVERSE” position. If it

fails to do so, push it down into

“NEUTRAL”. Then, immediately re

fer to Section 6 of this Manual

for adjustment instructions.

• There should not be any reverse

motion if the Wheels/Tines/PTO

Drive Lever is not held in the “RE

VERSE” position. If there is, the

machine is badly out of adjustment

and it should not be operated until

the condition is corrected. See Sec

tion 6 for adjustment instructions.

• Always return to “NEUTRAL”

and allow all motion to stop before

shifting into “FORWARD” or “RE

VERSE”. This pause between shift

ing will protect the drive belt,

reverse disc, and other transmis

sion components from undue wear

and damage.

2. Forward Interlock Levers

There are two Forward Interlock

Levers, one located directly below

each handlebar grip. See Photo

2-4. One or both of the interlock

levers must be kept squeezed

against the handlebar grip(s) when

ever the Wheels/Tines/PTO Drive

Lever is engaged in “FORWARD”.

If you release both interlock

levers before first returning the

Wheels/Tines/PTO Drive Lever to

“NEUTRAL”, the engine will shut

off. This is a safety feature for your

protection should you ever lose

control of the machine and cannot

stop forward motion by moving the

Wheels/Tines/PTO Drive Lever into

“NEUTRAL”.

NOTE: The interlock levers do

not affect operation when the

Wheels/Tines/PTO Drive Lever is

in “REVERSE”.

To operate the

Forward interlock Levers:

A. Squeeze one of the interlock

levers against the handlebar grip

before engaging the Wheeis/Tines/

PTO Drive Lever in “FORWARD”.

Continue to squeeze one or both

of the interlock levers during all

forward operation.

B. To stop forward operation in

normal use, first shift the Wheels/

Tines/PTO Drive Lever into “NEU

TRAL” and then release BOTH in

terlock levers. All forward motion

will stop, but the engine will con

tinue to run.

C. To stop forward motion in an

emergency, release BOTH interlock

levers. This will cause the engine

to shut off, stopping all forward

motion.

10

2-4: The Forward Interlock Levers.

A WARNING

To help avoid personal injury, the

Forward Interlock Safety System

should first be tested for proper

functioning every time the tiller or

PTO Power Unit is used. See Sec

tion 3 in this Manual for the easy

testing procedure to follow.

Page 13

CONTROLS mo FUUCTIONS

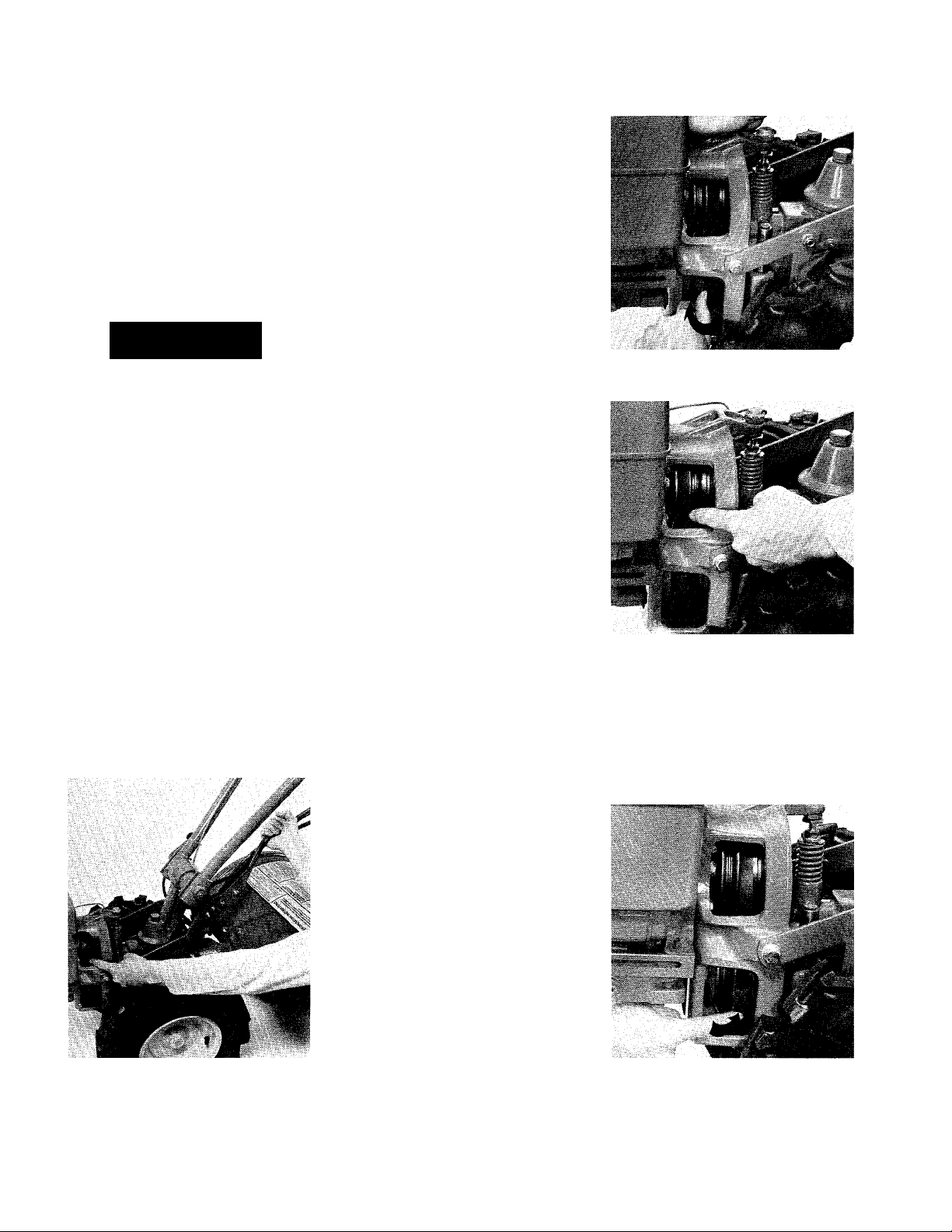

3. Wheel Speed Lever

This lever allows you to choose

between two different wheel

ground speeds: “SLOW” or

“FAST”. It also has a “FREE

WHEEL” position, in which the

wheels are free to turn without the

engine running. See Photo 2-5.

When the lever is engaged in

either “SLOW” or “FAST” and the

Wheels/Tines/PTO Drive Lever

is in either “FORWARD” or

“REVERSE”, the wheels will turn

under engine power.

When the lever is in the “FREE

WHEEL” position and the Wheels/

Tines/PTO Drive Lever is in “NEU

TRAL”, the machine can be moved

(on level ground) by pushing or

pulling on the handlebars. The

“FREE WHEEL” position is also

used when you are operating a

PTO driven stationary attachment,

in which case you would not want

the wheels to move when the

Wheels/Tines/PTO Drive Lever is

engaged in “FORWARD”.

IMPORTANT

By moving the forward drive belt

(see “Changing Belt Speeds” in

Section 3) into one of two different

belt ranges, you can obtain a total

of fod-' different forward wheel

ground speeds. There are, however,

only two reverse wheel ground

speeds (“SLOW” or "FAST”), be

cause the rubber reverse disc, not

the drive belt, drives the wheels in

the reverse direction.

the selected wheel gear. When the

clutch goes into gear, you will no

longer be able to roll the wheels.

When you shift the lever into

“FREE WHEEL”, the sliding clutch

is disengaged from both wheel

gears and the wheels will roll freely.

Note that there should not be any

“clicking” noise when you’re in

“FREE WHEEL”. If there is, shift the

lever a little more (either up or

down) to eliminate the noise—and

the rubbing of the clutch and gear

that causes it.

To operate the Wheel Speed

Lever:

A. With the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”, roll the

wheels a few inches in either di

rection while you push the Wheel

A WARNING

Never put revolving tines in the soil

when the Wheel Speed Lever is in

“FREE WHEEL”. Doing so can

cause the tiller to be propelled rap

idly by the tines, possibly causing

loss of control and serious per

sonal injury. Always engage the

Wheel Speed Lever in either

“SLOW” or “FAST” wheel speed

before putting the tines in the soil.

FREE WHEEL

Speed Lever down to the “SLOW”

position, or up to the “FAST” posi

tion. See Photo 2-5. When the lever

is in gear, you will no longer be

able to roll the wheels.

B. With the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”, move

the Wheel Speed Lever in between

the “SLOW” and “FAST” wheel

speed positions to place the wheels

in “FREE WHEEL”.

A CAUTION

TO AVOID PERSONAL INJURY OR

DAMAGE TO EQUIPMENT:

• Use the “SLOW” wheel speed

position when first learning to op

erate the machine and whenever

you operate in “REVERSE”.

• Do not shift the Wheel Speed

Lever when heading up or down a

slope. If the lever is accidentally

placed in “FREE WHEEL”, the ma

chine could roll out of control.

• Place the Wheels/Tines/PTO

Drive Lever in “NEUTRAL” before

shifting into “SLOW” or “FAST”.

This will prevent damage to the

clutch or wheel speed gears.

• Do not attempt to stop the

wheels by shifting the Wheel Speed

Lever. Always put the Wheels/

Tines/PTO Drive Lever in “NEU

TRAL” to stop the wheels.

When you shift the lever into

“SLOW” or “FAST”, it moves a slid

ing clutch inside the transmission

to the left or right to engage the

slow speed wheel gear or the fast

speed wheel gear. When engag

ing the clutch, you should roll the

wheels forward or backward a few

inches to help align the clutch with

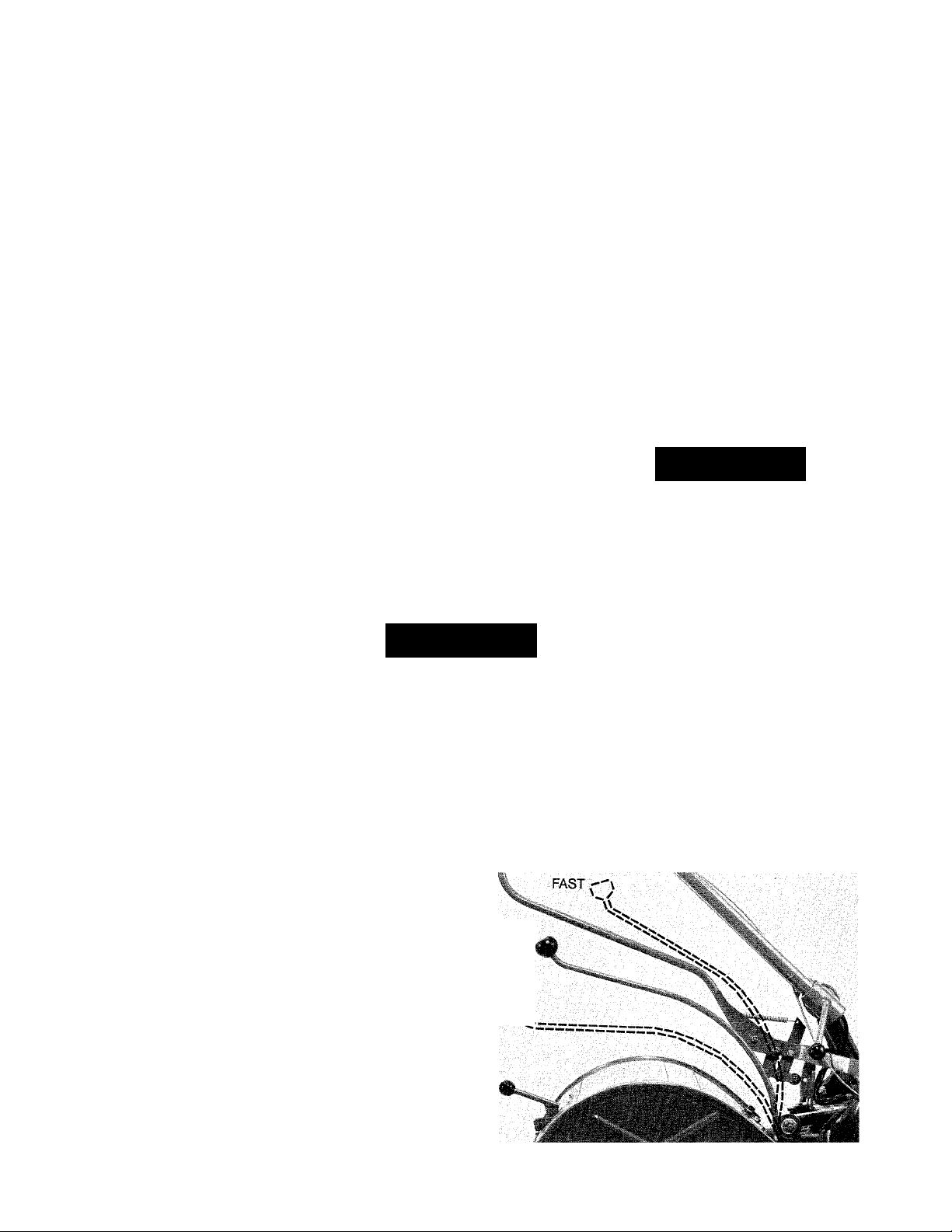

SLOW /s

2-5: The Wheel Speed Lever.

11

Page 14

4. Tines/PTO Clutch Lever

5. Depth Regulator Lever

This lever is located on the

left side of the transmission, just

forward of the tiller tine hood.

There are two operating positions:

“ENGAGE” and “DISENGAGE”.

See Photo 2-6.

When you move the lever to the

“ENGAGE” position, it moves the

“dog” clutch on the PTO Power ^

Unit drive shaft backward until it

engages the “dog” clutch on the

tine attachment drive shaft. (If the

tines are removed and replaced

with a PTO driven attachment, the

“dog” clutch on the power unit will

engage with the “dog” clutch on

the PTO driven attachment). Engine

power will then be applied to the

tines or PTO driven attachment

when the separate Wheels/Tines/

PTO Drive Lever is engaged in

“FORWARD” or “REVERSE”.

In the “DISENGAGE” position, the

“dog” clutches are disengaged,

and power will not be applied to

the tines or PTO attachment.

When operating the tiller, the

“DISENGAGE” position allows you

to stop the tines while the sep

arately controlled wheels continue

to rotate. You should use this fea

ture whenever you are transport

ing, loading or unloading, turning

around, or backing the tiller up.

You should also disengage the

lever before towing or transporting

any attachment.

When the tines are removed and

a PTO driven attachment that oper

ates from a stationary position is

installed, the “ENGAGE” position

allows you to power the attachment

while the wheels on the PTO Power

Unit are not moving.

Always place the Wheels/Tines/

PTO Drive Lever in “NEUTRAL” be

fore shifting the Tines/PTO Clutch

Lever. Doing so will help prevent

damage to the transmission that

could occur if you try to engage or

disengage the separate drive shaft

clutches while they are turning

under power.

To operate the Tines/PTO Clutch

Lever:

A. Put the Wheels/Tines/PTO Drive

Lever in “NEUTRAL”.

B. Pull the Tines/PTO Clutch Lever

out and then slide it into the “EN

GAGE” or the “DISENGAGE” slot.

C. After selecting the “ENGAGE”

position, do not immediately shift

the Wheels/Tines/PTO Drive Lever

into “REVERSE”. Always use “FOR

WARD” first, to help align the drive

shaft clutches inside the transmis

sion. NOTE: The lever should move

easily. If it doesn’t, then the “dog”

clutch inside the PTO Power Unit

transmission may need to be lubri

cated. See “Tiller Lubrication” in

Section 6 of this Manual.

A CAUTION

TO AVOID PERSONAL INJURY OR

DAMAGE TO EQUIPMENT:

• Always disengage the Tines/

PTO Clutch Lever before reversing,

transporting, turning around, or

loading or unloading the tiller or

PTO Power Unit.

• Do not attempt to stop the tines

or any PTO driven attachment by

disengaging the Tines/PTO Clutch

Lever. Always put the Wheels/

Tines/PTO Drive Lever in "NEU

TRAL” to stop all motion.

• Read the Owner/Operator Man

ual provided with any attachment

before attempting to operate the

attachment.

2-6: The Tines/PTO Clutch Lever.

This lever is located at the rear

of the tine hood—see Photo 2-7. It

is used to regulate the tilling depth

of the tines.

To operate the lever, pull it straight

back and then slide it up or down

to any of eight different notched

settings.

When the lever is moved all the

way down until it engages the high

est notch in the lever, it places the

tines in the “TRAVEL” position. In

this position the tines will clear the

ground by approximately 2-inches,

allowing you to transport the tiller

without the tines—which should be

disengaged—scraping your lawn

or driveway.

For shallow tilling and cultivat

ing, you should place the lever in

the second or third notch from the

top. These positions will allow the

tines to dig just a few inches into

the soil. The remaining notches

are used for deeper tilling (up to

8-inches deep, depending on the

soil conditions), and for turning

under organic matter.

Further details regarding the

proper use of this lever will be

found in Section 4 of this Manual

(see “Tilling Depths”).

A WARNING

To help avoid personal injury,

always place the tines in the

“TRAVEL” position before starting

the engine. This prevents the tines

from touching the ground until you

are ready to begin tilling.

2-7: The Depth Regulator Lever.

I

12

Page 15

FüMCTiOMS

6. Handlebar Height

Adjustment Lever

This lever is located near the

bottom of the handlebars, on the

right side of the tiller. See Photo

2-8. It allows you to adjust the han

dlebars up or down to any of four

different settings.

As a general rule, the handlebars

should be adjusted to approxi

mately waist level when the tines

are 3 to 4-inches in the soil, but

you should try different settings to

find the one that is most comforta

ble for you.

» s

N

1

2-8: Handlebar Height Adjustment

Lever.

To operate the Height Adjustment

Lever:

A. Stop the engine before adjust

ing the handlebars.

B. Support the handlebars with

one hand while unwinding the lever

enough so that the teeth in the

ratchets are disengaged.

C. Move the handlebars up or

down to either of two preset height

adjustment settings and then re

tighten the lever securely.

D. Two additional height settings

can be obtained by switching the

inside handlebar ratchets, as

shown in Figure 2-9. This will

change the handlebar height a few

inches higher or lower than the

lowest setting obtained in Step C.

2-9: Switch ratchets to obtain two

more height settings.

A WARNING

For use with the PTO Chipper/

Shredder Attachment only, the

handlebars can be swung 30° to

the right side by loosening the

mounting bolt at the bottom of the

handlebar base. NEVER OPERATE

THE TILLER OR OTHER ATTACH

MENTS WITH THE HANDLEBARS

SWUNG OUT TO THE RIGHT SIDE.

Doing so could result in unsafe

handling and personal injury.

ENGINE CONTROLS

The following are descriptions of

the controls on your 7 HP Briggs &

Stratton Engine or 8 HP Kohler

Engine. Additional information on

the safe, efficient operation of your

engine is given in the engine man

ufacturer’s Owner’s Manual which

was included in your literature

package. Please read that literature

carefully and save it for future

reference.

A WARNING

To avoid personal injury or dam

age to equipment, do not attempt

to start your engine at this time.

Complete starting instructions for

the engine are given in Section 3,

“Operation of Tiller.”

1. Engine Throttle Lever

This lever is located on the right

side handlebar (see Photo 2-10). It

is used to regulate engine speeds

as well as to start and stop the

engine.

In general, faster engine speeds

will be required when breaking new

ground or tilling under heavy crop

residues, but remember to use

only as fast an engine speed as is

needed to do the job. Try to judge

when the engine is providing the

proper amount of power—not too

little, but not too much. The sound

of the engine running will be your

best guide.

IMPORTANT

Factory settings of the throttle cable

should be satisfactory for most con

ditions. If adjustments are needed,

refer to Section 6 of this Manual.

To operate the Engine Throttle Lever:

A. When starting the engine, first

make certain that the Wheels/

Tines/PTO Drive Lever is in “NEU

TRAL”. Then, place the lever ap

proximately halfway between the

“SLOW” and “FAST” throttle set

tings. This position should provide

the carburetor with sufficient gas

oline flow to start the engine. How

ever, you may need to experiment

the first few times to find that “just

right” starting position.

B. For faster engine speeds move

the lever forward toward the

“FAST” setting; for slower speeds

......

.

2-10: The Engine Throttle Lever.

move it backward toward the

“SLOW” setting.

C. To stop the engine, move the

lever all the way back to the

“STOP” position (during normal

operation you would first place the

Wheels/Tines/PTO Drive Lever in

“NEUTRAL” and then release both

Forward Interlock Levers before

stopping the engine).

13

Page 16

2. Engine Choke Control

Your erigine is equipped with a

manually operated choke control

as shown in Photo 2-11 or 2-12.

The choke makes starting a cold

engine easier by decreasing the

amount of air in the carburetor’s

air-fuel ratio, thus creating a richer

fuel mixture. The use of the choke

for starting will vary, depending on

air temperature and altitude.

To operate the Choke Control:

A. Before starting a cold engine,

set the choke in the “FULL CHOKE”

position. On the 7 HP Briggs &

Stratton Engine, move the lever all

the way down. On the 8 HP Kohler

Engine, move the lever all the

way up.

B. When the engine starts, slowly

move the lever to the “CHOKE

OFF” position (all the way up for

the 7 HP Briggs & Stratton Engine;

all the way down for the 8 HP

Kohler Engine).

C. If the engine should falter with

the choke at “CHOKE OFF”, return

the lever to a position halfway be

tween “FULL CHOKE” and “CHOKE

OFF”. As soon as the engine runs

smoothly, return the lever to

“CHOKE OFF”.

D. When restarting an already

warm engine, you may not have to

use the choke at all. However, if

the engine falters or hesitates, try

using a “HALF CHOKE” position

until it runs smoothly, and then

return the lever to “CHOKE OFF”.

A CAUTION

Never operate the engine under a

load (tines, wheels, or PTO attach

ments engaged) without first return

ing the choke control to “CHOKE

OFF”. Failure to do so can quickly

build up carbon deposits that can

harm the engine.

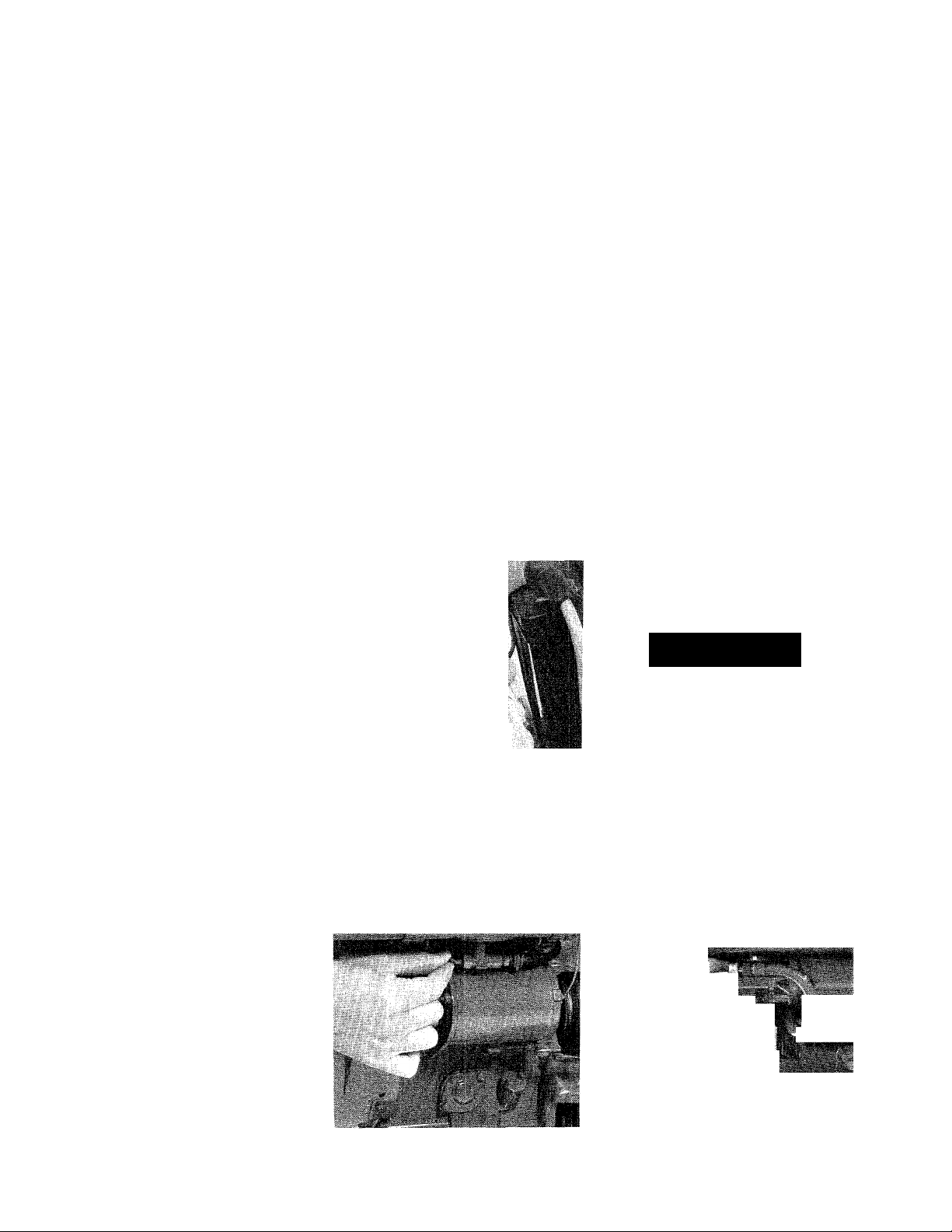

3. Engine Recoil Starter

The recoil starter is located at

the front of the engine, as shown

in Photo 2-13 or 2-14. It is used to

start engines that are not equipped

with the optional key switch start

ing feature.

To operate the Engine Recoil

Starter:

A. When starting the engine, first

make certain that the Wheels/

Tines/PTO Drive Lever is in

“NEUTRAL”.

B. Place your free hand in the lo

cation shown in Photo 2-13 or 2-14

to help stabilize the machine.

C. Grasp the starter rope handle

with your other hand and pull the

CHOKE

OFF

H'

FULL

CHOKL-

2-11 : Choke control on 7 HP Engine. 2-12: Choke control on 8 HP Engine.

* '-A ■

?

FULL CHOKE

L -'

.if-

%

2-13: Starting the 7 HP Briggs &

Stratton Engine.

2-14: Starting the 8 HP Kohler Engine.

handle out slowly until it is harder

to pull because of engine compres

sion. Then pull the handle with a

rapid, continuous, full-arm stroke.

Let the starter rope rewind slowly

after each start attempt.

To help avoid personal injury, be

sure that the area behind you is

clear before pulling the starter rope.

A WARNING

14

Page 17

CONTROLS AND FUNCTIONS

4. Key Switch Starter

The key switch starter for the

optional electric start engine is

located on the right side of the

battery hold-down clamp, as shown

in Photo 2-15. There are three op

erating positions identified on the

switch: “OFF”, “RUN” and “START”.

When the key is turned to the

“START” position, the battery sup

plies an electrical current to the

engine’s starter motor which then

cranks the engine over at a fast

enough speed for starting.

During engine operation, the bat

tery is recharged automatically via

a small recharging current that the

engine sends back to the battery

through the electrical system’s re

charging line.

. If the electrical system should

ever fail to start or stop the engine,

IMPORTANT

If the battery will not be used for

oxlondcd periods of time, it should

be fully charged before placing it

in storage. Before reinstalling the

battery after storage, give it a thor

ough recharge. See “Battery Care

and Maintenance” in Section 6 for

charging instructions.

refer to the “Electric Start Trouble

shooting” instructions found in

Section 6 of this Manual.

To operate the Key Switch Starter:

A. When starting the engine, first

make certain that the Wheels/

Tines/PTO Drive Lever is in “NEU

TRAL”. Also remember to set the

Engine Throttle Lever in the start

ing position and the Choke Control

in the “FULL CHOKE” position (for

cold starts).

B. Insert the key firmly into the key

switch slot and turn it all the way

to the right, to the “START” po

sition. When the engine starts,

release the key and it will auto

matically return to the “RUN” posi

tion. Do not hold the key in the

"START” position for longer than a

‘tti a::.l Lij: ftt,

2-15: The Key Switch Starter.

few seconds. Prolonged cranking

can damage the starter motor if it

is cranked more than 15 seconds

per minute.

C. There are two ways to stop the

engine:

(1) Put the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”, re

lease both Forward Interlock

Levers, and then pull the throt

tle lever all the way back to the

“STOP” position. Turn the key

to “OFF” and remove the key.

(2) Put the Wheels/Tines/PTO

Drive Lever in “NEUTRAL”, re

lease both Forward Interlock

Levers, and then turn the key

to “OFF”. Put the throttle lever

in the “STOP” position and re

move the key.

NOTE: To stop forward motion in an

emergency, release both Forward

Interlock Levers. This will cause

the engine to shut off.

A WARNING

To avoid injury due to accidental

or unauthorized engine starting,

always remove the key from the

switch when leaving the machine

unattended.

5. Fuel Tank Shut-Off

Valve

Your engine is equipped with a

fuel tank shut-off valve. It is located

underneath the gasoline tank. See

Photo 2-16 or 2-17.

This valve stops the flow of gas

oline from the fuel tank to the car

buretor. Before starting, make sure

that the valve is in its OPEN posi

tion (rotate counterclockwise sev

eral turns) or the engine will quit

from lack of fuel shortly after you

start it.

NOTE: Close fuel shut-off valve

when engine is transported to pre

vent fuel leakage from carburetor.

2-16: Fuel shut-off valve on 7 HP

Briggs & Stratton Engine.

15

, 'pr;, m

2-17: Fuel Shut-off valve on 8 HP

Kohler Engine.

Page 18

SECTION 3:

Before you attempt to operate

your tiller make sure that you’ve

read and fully understand all of the

Safety instructions in Section 1

and the Controls information in

Section 2. You should also read

this Section carefully before start

ing your engine.

You should practice with your

tiller in an open, level area before

you use it in your garden. While

practicing, do so without the tines

revolving (disengage the tines with

the Tines/PTO Clutch Lever).

When you’ve become completely

familiar with your tiller, you can

begin using it in your garden.

A WARNING

To avoid personal injury or damage

to equipment, read the Owner/Operator Manuals provided with any

optional accessories or attach

ments before operating the tiller or

PTC Power Unit. The Manuals pro

vide a detailed description of proper

use and operation, and point out

other important Safety Instructions.

Break-in operation

During the first few hours of new

machine operation, you must per

form the following maintenance.

For subsequent required mainte

nance, and the procedures to fol

low, please refer to Section 6 in

this Manual.

1. CHANGE ENGINE OIL. The en

gine oil must be changed after the

first 5 hours of new engine opera

tion. Thereafter, change the oil after

each 10 operating hours. Change

the oil more frequently when oper

ating in extremely dusty or dirty

conditions.

2. CHECK TRANSMISSION GEAR

OIL LEVEL. The gear oil levels must

be checked after the first 2 hours

of new tiller operation. Thereafter,

check the oil levels after every 30

operating hours.

■a

3. CHECK DRIVE BELT TENSION.

The tension on the drive belt may

need to be adjusted after the first 2

or 3 hours of new operation due to

initial belt wear and seating of the

belt with its pulleys. Thereafter,

check the tension after every 10

operating hours.

4. CHECK BOLTS AND NUTS.

Check for loose bolts and nuts

after the first 2 hours of new tiller

operation. Thereafter, check after

every 10 operating hours.

Preparation before starting

Make the following checks and

perform the services as required

before starting the engine.

1. CHECK ENGINE OIL LEVEL.

Check the oil level in the engine

crankcase. Do not run the engine

unless the proper oil level is

maintained.

2. SERVICE AIR CLEANER. Make

sure that the air cleaner elements

are not dirty.

3. CHECK SAFETY GUARDS. Make

sure that all safety guards and cov

ers are securely in place.

4. ATTACH SPARK PLUG WIRE. Be

sure that the spark plug wire is

securely attached to the spark

plug.

5. CHECK ENGINE COOLING

SYSTEM. The cooling fins and air

intake screen must be clean to

ensure adequate cooling.

■

1 I

mW

bWÜ

■'.a.', ■

............

.................................

6. ADJUST HANDLEBARS. Set the

handlebars to a comfortable oper

ating height.

7. CHECK BATTERY (Eiectric Start

Models). Make sure that the bat

tery is properly filled and that all

electrical connections are clean

and tight.

8. FiLL FUEL TANK WITH GASO

LINE. Avoid using gasoline that is

not fresh, as stale fuel can cause

gum deposits to form in the carbu

retor and fuel lines. Fuel should

not be stored for more than six

months. The use of unleaded gas

oline is recommended as it resuits

in fewer combustion deposits and

longer engine life. DO NOT MIX OIL

WITH THE GASOLINE.

(a) Clean the fuel cap and its sur

rounding area before removing the

cap.

(b) Use a clean funnel to add fuel

to the fuel tank.

(c) Do not fill the tank to the point of

overflowing. Fill to within Ta-inch of

the top of the tank to prevent spiils

and to allow for fuel expansion.

(d) For 7 HP Briggs & Stratton

Engines: use clean, fresh, lead-free

automotive gasoline (leaded gas

oline may be used if unleaded is

unavailable). Use gasoline that has

a minimum octane rating of 77. Do

not use gasoline containing Meth

anol. The use of gasoline which

contains alcohol (such as gasohol)

is not recommended. If you are

....

16

Page 19

using gasohol, refer to the Briggs

& Stratton Operating and Mainte

nance Instructions booklet for

specific cautions and recommen

dations for this type of fuel.

(e) For 8 HP Kohler Engines: use

fresh, clean, unleaded regular auto

motive gasoline with a pump sticker

octane rating of 87 or higher.

(Leaded “Regular” grade gasoline

is an acceptable substitute). The

fuel tank capacity is Vk gallons.

(f) Replace the fuel cap securely

before starting the engine.

A DANGER

GASOLINE IS HIGHLY FLAMMABLE

AND ITS VAPORS ARE EXPLOSIVE.

FOLLOW THESE SAFETY PRAC

TICES TO PREVENT INJURY FROM

FIRE OR EXPLOSION!

• Never fill tank when engine is

running or still hot from operation.

Allow engine and muffler to cool at

least 2 minutes before refueling.

• Do not allow open flames,

sparks, matches or smoking in the

area.

• Fill fuel tank outdoors in a wellventilated area. Wipe up any spills

and move tiller away from gasoline

fumes before starting engine.

• Use only an approved gasoline

container and store safely out of

reach of children.

• Store gasoline and tiller in a

well-ventilated area. Do not store

where vapors may reach an open

flame or spark, or where ignition

sources are present (such as hot

water and space heaters, furnaces,

clothes dryers, stoves, electric

motors, etc.)

• Allow engine to cool before stor

ing in any enclosures.

• Never bring a gasoline can near

the battery posts on electric start

model tillers. A short circuit caused

by touching the positive (+) post

and any metal could cause an ex

plosion of the gasoline or of bat

tery gases.

Test operation of Forward Interlock Safety System

The Forward Interlock Safety

System consists of an electrical

grounding system that connects

the two Forward Interlock Levers

on the handlebars to the ignition

system of the engine. One or both

of the Forward Interlock Levers

must be kept squeezed against the

handlebar grip(s) whenever the

Wheels/Tines/PTO Drive Lever is

engaged in “FORWARD”. If you

release BOTH interlock levers be

fore first moving the Wheels/Tines/

PTO Drive Lever to “NEUTRAL”, the

interlock system will ground out the

engine’s ignition system and stop

the engine. The interlock system

also prevents the engine from start

ing if the Wheels/Tines/PTO Drive

Lever is engaged in “FORWARD”.

Because the interlock system is

an electrical/mechanical device, it

is subject to wear or possible fail

ure. Therefore, the interlock sys

tem should be checked for proper

operation each time the tiller or

PTO Power Unit is used.

^ DANGER

The Forward Interlock Safety Sys

tem is designed for your safety.

Never attempt to disconnect or to

otherwise defeat the purpose of

this system. If the interlock system

fails to operate properly, immedi

ately contact the TROY-BILT Tiller

Technical Service Department. Do

not operate the tiller or PTO Power

Unit until the system has been re

paired and is functioning properly.

Always test the system prior to

each use.

How to check the interlock system:

1. Move the machine outdoors and

park it on level ground. Make sure

the area around you is clear of any

obstacles.

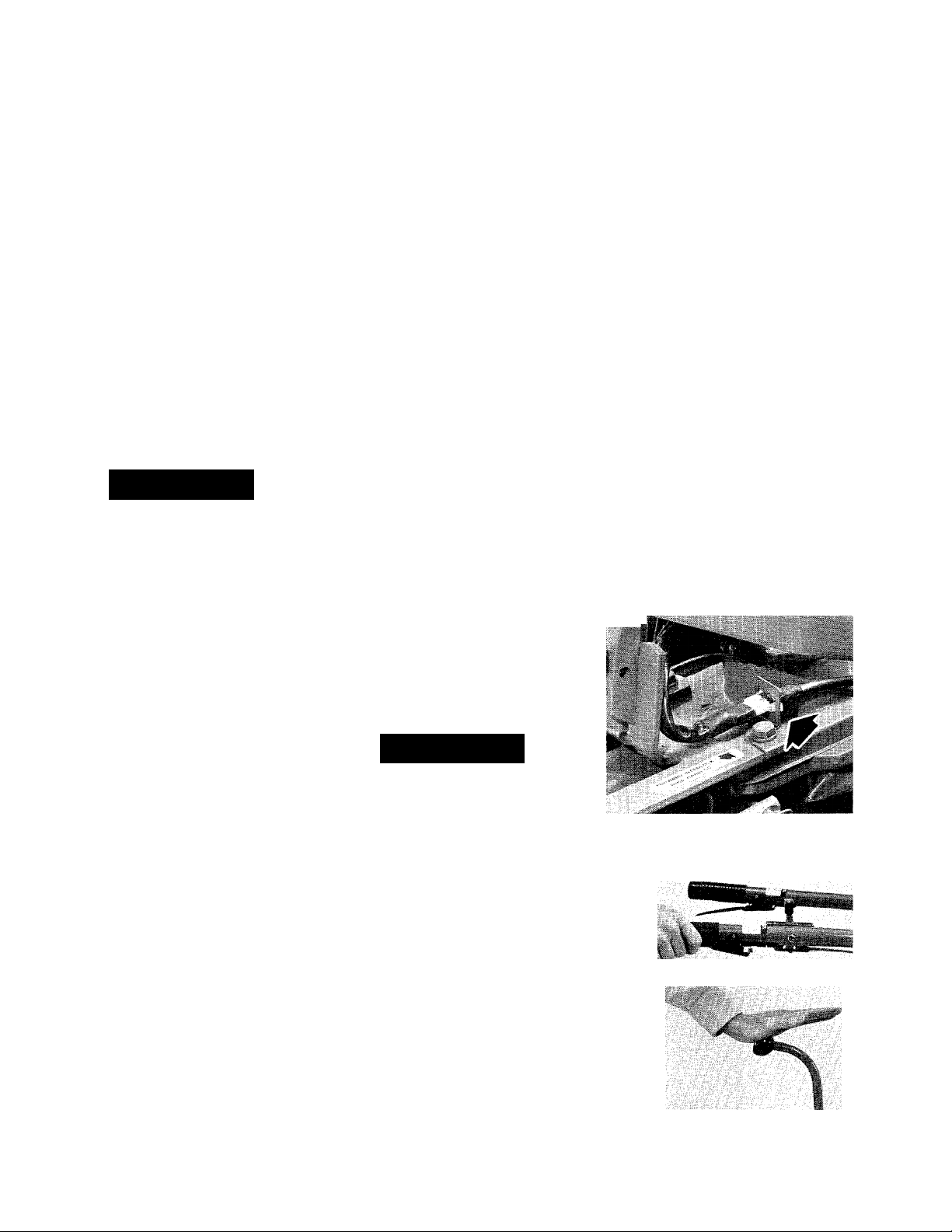

2. Check to make sure that the

Forward Interlock Wire Harness

OPERATION OF TILLER

plug at the bottom of the handle

bars is firmly connected to the wire

harness receptacle located on the

top, right side of the transmission.

See Photo 3-2.

3. Place the Wheel Speed Lever in

“SLOW” and the Tines/PTO Clutch

Lever in “DISENGAGE”.

4. Start the engine as described

on Pages 18-19. Set the throttle

lever in a “SLOW” running position

and ailow the engine to warm up.

5. Squeeze one of the Forward

Interlock Levers against the handle

bar grip and then push the Wheels/

Tines/PTO Drive Lever all the way

down to “FORWARD”. See Photo

3-3. As the tiller starts to move

r

3-2: Check for good connection be

tween plug and receptacle of Forward

Interlock Safety System.

3-3: Squeeze one Forward Interlock

Lever and then move Wheels/Tines/

PTO Drive Lever down to “FORWARD”.

17

Page 20

Starting and stopping the engine

forward, release the Forward Inter

lock Lever briefly. If the system

is working properly, the engine

should start to shut off when you

release the lever. If It does, quickly

squeeze the lever against the han

dlebar grip and then return the

Wheels/Tines/PTO Drive Lever to

the “NEUTRAL” position (tap or lift

the lever up and release It). Repeat

this test using the other Forward

Interlock Lever.

6. If the engine does not start to

shut off when the Fonward Inter

lock Levers are released, the sys

tem is not functioning correctly,

and you should stop the engine.

Cold weather operation

Before operating the machine in

cold weather (below 40 °F) you

should take the following steps to

protect your engine and transmis

sion from possible damage.

1. Use a lighter weight oil in the

engine crankcase. See “Engine Oil

Maintenance” in Section 6.

2. Allow the engine to warm up

thoroughly before putting it under

a load.

3. Use fresh, winter grade fuel

(gasoline suppliers change the

fuel blend seasonally).

4. Use the correct weight gear oil

in the PTO Power Unit transmis

sion. See “Transmission Gear Oil

Maintenance” in Section 6.

5. While the engine is warming,

place the Wheel Speed Lever in

“FREE WHEEL”, block the wheels

to prevent them from moving, and

remove the key (on electric start

models) and disconnect the spark

plug wire from the spark plug. Do

not operate the tiller or PTO Power

Unit again until the system is again

functioning properly. See Section 6

in this Manual for some simple

troubleshooting checks you can do

to correct a faulty Interlock system.

IMPORTANT

To avoid possible damage to the

Forward Interlock Safety System,

do not use high-pressure sprays

around the wire harness recepta

cle or neutral plunger assembly.

put the Tines/PTO Clutch Lever in

“DISENGAGE”. Then squeeze one

of the Forward Interlock Levers

against the handlebar grip and shift

the Wheels/Tines/PTO Drive Lever

into “FORWARD”. This will rotate

the drive shaft inside the transmis

sion and help to warm the trans

mission gear oil.

6. Do not try to move the machine

if the wheels are frozen to the

ground. First melt the ice with

warm water.

A DANGER

To avoid personal injury, do not run

engine in an enclosed or poorly

vented area. Engine exhaust con

tains carbon monoxide, an odor

less and deadly gas.

To start the engine:

IMPORTANT

Use the following steps to practice

starting and stopping the engine

ONLY. Do not attempt to drive the

tiller or PTO Power Unit until you

have read ALL of the operating

instructions in this Section and in

Section 5.

1. Place the Wheels/Tines/PTO

Drive Lever in “NEUTRAL” (Photo

3-4). To find “NEUTRAL” (while the

engine is not running), push the

lever down until it engages in

“FORWARD”. Then tap or lift the

lever up and release it.

2. Lower the Depth Regulator

Lever until the tines are off the

ground (Photo 3-4).

3. Put the Wheel Speed Lever in

either “SLOW” or “FAST” (Photo

3-4). Be sure to roll the wheels

while shifting the lever until the

wheels are engaged.

NOTE: If using a PTO driven sta

tionary attachment, put lever in

“FREEWHEEL” and place blocks

around all wheels to prevent

equipment from moving.

4. Move the engine throttle lever

forward, away from the “STOP”

position (Photo 3-4).

5. Put the Tines/PTO Clutch Lever

in the “DISENGAGE” position—

Photo 3-4. (Use the “ENGAGE” po

sition if you want the tines to turn

or if you want to apply power to a

PTO driven stationary attachment).

6. Move the choke control to the

“FULL CHOKE” position (Photo 3-5

or 3-6). NOTE: A warm engine may

start without choking.

18

Page 21

ENGINE THROTTLE

FORWARD INTERLOCK

LEVERS

OPERATION OF TILLER

2. Move the engine throttle lever

to the “STOP” position (and turn

the key to “OFF” on electric start

models). Remove the key for

safekeeping.

TINES/PTO

CLUTCH

3-4: Tiller and engine controls.

NOTE; Be sure that fuel tank shut

off valve (see Page 15) is in “OPEN”

position.

7. For recoil start engines;

(a) Stabilize machine by placing

your free hand on the fuel tank

of the Briggs & Stratton Engine

or on the air cleaner cover of

the Kohler Engine.

(b) Use your other hand to slowly

pull the starter rope until you

feel resistance. Then rapidly

pull the rope. (Look behind you

before pulling rope out.) Let

the rope rewind slowly after

each start attempt.

8. For electric start engines;

(a) Turn the key to the “START”

position. Do not hold the key at

“START” for longer than a few

seconds as prolonged crank

ing can damage the starter

chok'éI

i

OFF

FULL ^

■ 'CHOKEpP^

3-5: Choke control on 7 HP Engine.

WHEELS/TINES/PTO

DRIVE LEVER

WHEEL SPEED LEVER

/

DEPTH REGULATOR

LEVER

motor if cranked more than 15

seconds per minute.

(b) When the engine starts, release

the key and it will return to the

“RUN” position.

9. If the engine fails to start in four

or five tries, let the engine set for

10 minutes and repeat the start

ing procedure.

10. When the engine starts, slowly

move the choke control (if used) to

the “HALF CHOKE” and then to

the “CHOKE OFF” positions.

11. Move the throttle lever to the

“SLOW” position and let the engine

warm up.

STOPPING THE ENGINE:

1. To stop the wheels and tines at

any time, move the Wheels/Tines/

PTO Drive Lever into the “NEU

TRAL” position and then release

both Forward Interlock Levers.

3-6: Choke control on 8 HP Engine.

IMPORTANT

If turning the key to “OFF” or mov

ing the throttle lever to “STOP"

does not shut the engine off, you

can move the choke control to the

“FULL CHOKE” position. This will

flood the engine and cause it to

stall. Use this procedure only in

emergencies, as continued use can

be harmful to your engine.

Starting the Electric Start Engine with the recoil starter rope

If necessary, the electric start

engine can be started with the re

coil rope. However, before doing

so be sure to follow the procedure

below that applies to your particu

lar situation.

1. If the battery is in good condi

tion (not “dead” or damaged), you

can leave it on the tiller which

allows it to be recharged during

engine operation. But, before start

ing the engine with the recoil rope,

make sure that the battery is filled

to the correct level with electrolyte

and that all of the cables and wires

are properly connected.

2. If the battery is “dead” or dam

aged, then it should be removed

from the tiller and tested by a qual

ified battery mechanic. While the

battery is removed, keep the loose

terminal on the positive (+) battery

cable (if cable is still attached to

solenoid) covered with a wrapping

of electrical tape and secure the

cable to the frame of the battery

bracket. This will prevent any pos

sibility of sparking from the cable

terminal.

3. Before starting the engine with

the recoil starter rope, place the

key switch in the “RUN” position,

the engine throttle lever in the

“START” position, and the choke

control in the “FULL CHOKE” posi

tion (for cold starts).

19

Page 22

To operate the tiller

Now that you are familiar with

the operation of your engine, foilow these steps for operating your

tiller. When first practicing with

your tiller, please leave the Tines/

PTO Clutch Lever in the “DISEN

GAGE” position and put the Wheel

Speed Lever in the “SLOW” wheel

speed position.

A WARNING

To avoid personal injury, keep

hands, feet, legs and clothing away

from the revolving tines.

To begin tilling:

1. Start the engine by following

the previous engine starting in

structions. Be certain that the

Wheels/Tines/PTO Drive Lever is

in “NEUTRAL” before starting the

engine.

2. Test operation of Forward Inter

lock Safety System. See page 17.

3. Set the Depth Regulator Lever

to the desired digging depth and

increase the engine throttle speed

(when practicing with the tiller

leave the tines in the “TRAVEL”

position).

4. Move the Tines/PTO Clutch

Lever to the “ENGAGE” position

(when practicing with the tiller

leave the tines in the “DISEN-

GAGE” position).

5. For FORWARD MOTION of the

wheels and tines, squeeze and hold

one of the Forward Interlock Levers

(see Photo 3-7) against the handle

bar grip and then move the Wheels/

Tines/PTO Drive Lever down into

“FORWARD”.

6. As the tiller moves forward, re

lax and let the wheels pull the tiller

along while the tines do the dig

ging. Walk behind and to one side

of the tiller (walk on the side that is

not yet tilled to avoid making foot

prints in the freshly tilled soil),

and lightly, but securely, grip the

handlebars with one hand. See

Photo 3-8.

Allow the machine to work at its

own pace. Pushing it forward in an

attempt to make it go faster will

only make the tiller harder to con

trol. Also, please do not push down

on the handlebars in an attempt to

force the tiller to dig deeper. Doing

so takes the weight off the wheels,

reduces traction, and causes the

tines to attempt to propel the tiller

instead of just digging. This can

if / :/

' " V / ■ ■ '' ■ ’'■ '***■

1- 1

cause the tiller to hop and skip

rapidly across the garden.

7. TO STOP FORWARD MOTION:

Tap or lift the Wheels/Tines/PTO

Drive Lever up to “NEUTRAL” and

then release BOTH Forward Inter

lock Levers.

8. TO STOP FORWARD MOTION

IN AN EMERGENCY: Let go of ALL

handlebar control levers (this will

shut off the engine).

9. For REVERSE MOTION:

(a) Do not till while in “REVERSE”.

(b) Put the Wheels/Tines/PTO

Drive Lever in “NEUTRAL” and

reduce the engine throttle

speed. Make sure the area be

hind you is clear.

Put the Wheel Speed Lever in

(c)

the “SLOW” position.

Put the Tines/PTO Clutch Lever

(d)

in “DISENGAGE”.

Lift the handlebars until the

(e)

tines clear the ground and then

lift and hold the Wheels/Tines/

PTO Drive Lever all the way up

(you do not need to squeeze a

Forward Interlock Lever while

in “REVERSE”).

V

. £

■

3-7: Squeeze one Forward Interlock

Lever before engaging Wheels/Tines/

PTO Drive Lever in “FORWARD”.

3-8: Guide tiller with one hand.

20

Page 23

A CAUTION

TO HELP AVOID PERSONAL INJURY

OR DAMAGE TO EQUIPMENT:

• Always make sure there are no

obstacles behind you before oper

ating in “REVERSE”.

• Disengage the tines, reduce the

engine throttle speed and move

the Wheel Speed Lever into the

“SLOW” position before operating

in “REVERSE”. Avoid using “FAST”

wheel speed until you are sure

you can control the machine at

this faster speed.

10. TO STOP REVERSE MOTION:

Release the Wheels/Tines/PTO

Drive Lever and it will automatically

return to the “NEUTRAL” position.

(The Forward Interlock Levers will

not stop “REVERSE” motion.)

TO STOP THE ENGINE: