Page 1

For Parts Call 606-678-9623 or 606-561-4983

Professional Shop Manual

78/83/90 Series Horizontal Shaft Engines

(277/357/420 cc Engines)

NOTE: These materials are for use by trained technicians who are experien ced in th e service an d re pair of outdoo r po wer

equipment of the kind described in this publication, a nd are n ot intende d for use by un trained or ine xper ien ced individu als.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and tr ained p rofessional. Read, understan d, and follo w all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as co mpl ete and accu rate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2010 MTD Products Inc. All Rights Reserved

www.mymowerparts.com

Page 2

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

Page 3

For Parts Call 606-678-9623 or 606-561-4983

Table of Contents

Chapter 1: Introduction

Professional Service Manual Intent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Model and serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Air filter (summer engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Oil type and capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Changing the oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fuel filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Valve lash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General torque specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Frequently used specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Chapter 2: Basic Troubleshooting

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Steps to troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Define the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identify factors that could cause the problem . . . . . . . . . . . . . . . . . . . . . . . . 18

Repairing the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Prime test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Leak-down test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Compression test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PCV testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3: Air Intake systems

Heat box (snow engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Air filter (summer engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Air filter base and control panel (summer engines) . . . . . . . . . . . . . . . . . . . 32

Carburetor and Insulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

www.mymowerparts.com

I

Page 4

For Parts Call 606-678-9623 or 606-561-4983

Chapter 4: The Fuel System and Governor

Inspecting the fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Test fuel for alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Fuel tank vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

The fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Inspect the fuel lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

The fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Evaporative (EVAP) emissions system . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Troubleshooting the EVAP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Charcoal canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Roll over valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Primers (snow engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Carburetors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Inspecting the carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Disassembly and rebuilding of the carburetor . . . . . . . . . . . . . . . . . . . . . . .52

Fuel shut-off valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Governor arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Governor shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Governor cup and the governor gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Governor adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 5: Lubrication

Oil type and quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Oil dip stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Dip stick tube removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Positive crankcase ventilation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 6: Starter and Charging Systems

Recoil Starter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Starter Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Starter Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Starter pulley and recoil spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Electric starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Charging system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Charging system testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

II

www.mymowerparts.com

Page 5

For Parts Call 606-678-9623 or 606-561-4983

Chapter 7: Ignition System

Troubleshooting the ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Stop switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Remote (ignition) stop switch (snow engines) . . . . . . . . . . . . . . . . . . . . . . . 83

Test for ignition that won’t turn off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

The module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Module removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Installing the module and setting the air gap . . . . . . . . . . . . . . . . . . . . . . . . 87

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

About the spark plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cleaning the spark plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Inspection of the spark plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Spark plug removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 8: Exhaust

Summer engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Spark arrestor (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Muffler removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Muffler removal/replacement (snow engines) . . . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 9: Cylinder Head

Cylinder head removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Cylinder head installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Chapter 10: Crankshaft, piston and Connecting Rod

Crankshaft inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Piston Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Connecting rod inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Cylinder inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Balance Shaft (483 & 490) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Engine specifications chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Engine torque values chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Chapter 11: Failure Analysis

Abrasive Ingestion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Insufficient lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Engine Overspeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Overheated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Mechanical Breakage/ Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Detonation/preignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

www.mymowerparts.com

III

Page 6

For Parts Call 606-678-9623 or 606-561-4983

IV

www.mymowerparts.com

Page 7

For Parts Call 606-678-9623 or 606-561-4983

Introduction

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent

This manual is intended to provide service dealers with an introduction to proven diagnostic and repair proce-

dures for 78/83/90 series MTD horizontal shaft engines.

Disclaimer: The information contained in this manual is correct at the time of writin g. Both the prod u ct an d th e inf or -

mation about the product are subject to change without notice.

About the text format:

NOTE: Is used to point out information that is relevant to the procedure, but does not fit as a step in the proce -

dure.

• Bullet points: indicate sub-steps or points.

! CA UTION! CA UTION

! WA RNI NG! WA RNI NG

! DANGER! DANGER

1. Numbered steps indicate specific things that should be done, and the order in which they should be done .

1a. Substeps will be lettered and nested within steps. Two or more substeps may be combined to describe

the actions required to complete a step.

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD be liable for poor text interpretation or poor execution of the pro cedures described

in the text.

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

Warning indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury.

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or MTD Technical Suppor t.

Safety

This Service Manual is meant to be used along with the Operator’s Manual. Read the Operator’s Manual and

familiarize yourself with the safety and operational instructions for the equipment being worked on. Keep a copy of

the Operator’s Manual for quick reference. Operator’s manuals may be viewed for free at the brand support website.

It will be necessary to have the complete model and serial number for the equipment.

www.mymowerparts.com

1

Page 8

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

• Be prepared in case of emergency:

! CAUTION! CAUTION

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Grooming and attire:

! WARNING! WARNING

! CAUTION! CAUTION

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

! DANGER! DANGER

2

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all power

equipment. All the labels in the world cannot protect a technician from an instant of

carelessness.

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

www.mymowerparts.com

Page 9

For Parts Call 606-678-9623 or 606-561-4983

Introduction

Fasteners

• Most of the fasteners used on the MTD engine are metric. Some are fractional inches. For this reason,

wrench sizes are frequently identified in the text, and measurements are given in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners, like cotter pins, are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summa-

rized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manual is handy as a quick-r eference g uide as we ll as a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary pr ocedures. Th is avoids repeating

the same procedure two or three times in the manual.

www.mymowerparts.com

3

Page 10

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

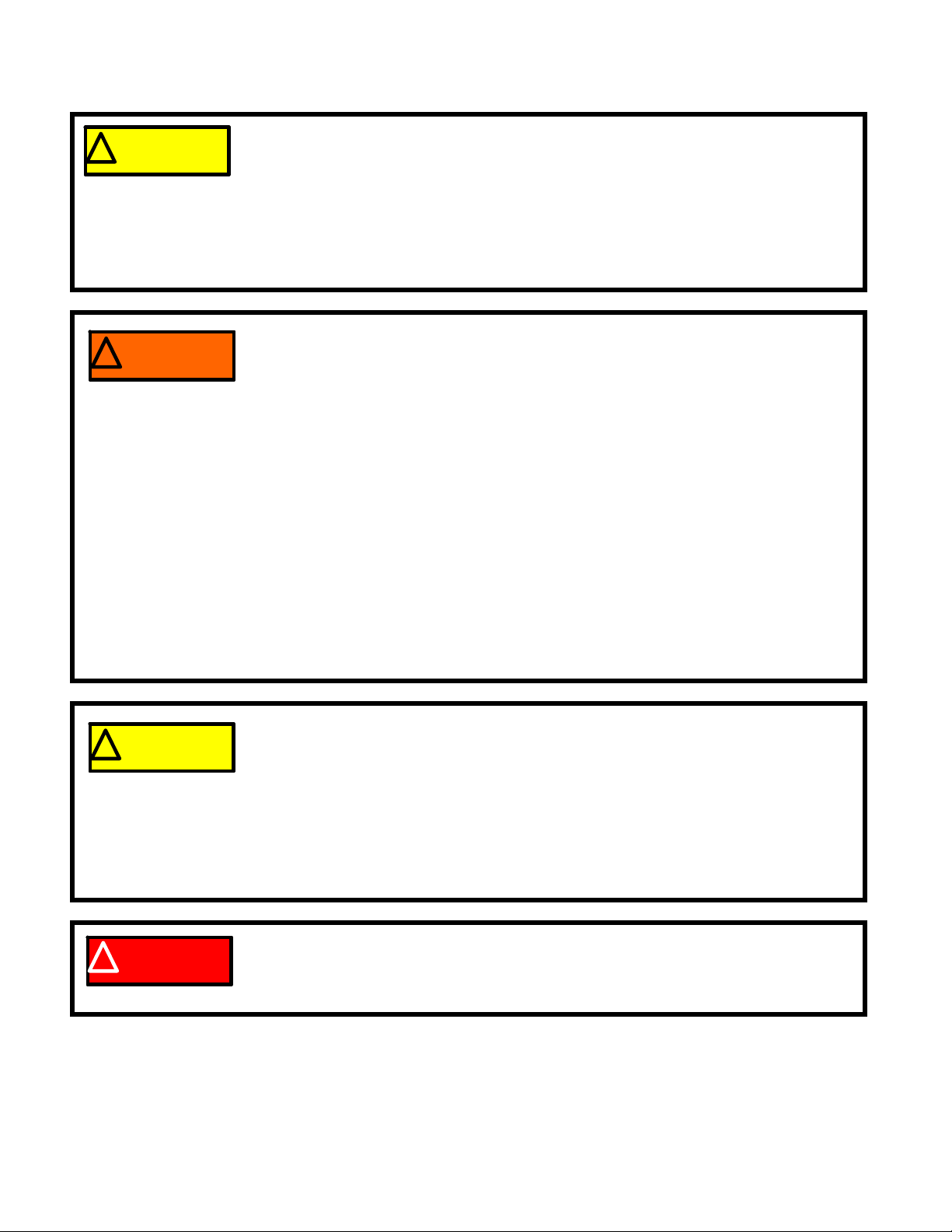

Model and serial number

The model and serial number can be found on a white

sticker with a bar code. The sticker is located on the right

side of the engine at the bottom of the block.

See Figure 1.1.

NOTE: The serial number will always start with the

model number.

MTD H oriz ontal Engine Model Desi gna tors

Front of engine

Model /serial number

Figure 1.1

Starter/Alternators

1=Recoil st art

2=Electric start

3=E. start/alt. 20W/20W

4=E. start/alt. 3A DC/5A

Bore Dia. (mm)

MTDEngineSerialNumbers

1P65FH/0510271A0023

1 6 1 - S H A

Major Revision

Change

Compliance

U United States (50 State)

H Europe

C California

0 (Zero) 49 State

G U .S.(49) and Europe

W U.S.(50) and Europe

End Product

C Chipper/Shredder

J Snow/No tank

L L ogsplitter

R T iller (slow reverse)

SSnow

T Tiller

V Verticutter

Modelnu m b er

Mont hYea r

ProducingLine #

Date

Engi ne

number

A=1stshift

nd

sh i f t

B=2

4

www.mymowerparts.com

Page 11

Maintenance

For Parts Call 606-678-9623 or 606-561-4983

The information in this manual applies to the MTD

engine. Some basic principles may apply to engines produced by other manufacturers.

As the saying goes “an ounce of prevention is worth a

pound of cure”. The same can be said about preventive

maintenance on outdoor power equipment. By changing

the spark plug and oil at recommended intervals many failures can be avoided.

NOTE: Please refer to Chapter 7: Ignition for the complete

service instructions on spark plugs.

1. The spark plug used in the MTD engine is a F6RTC

gapped to 0.026” - 0.030” (0.65 - 0.75 mm).

See Figure 1.2.

Introduction

Figure 1.2

2. Wear rate will vary somewhat with severity of use. If the edges of the center electrode are rounded-off, or any

other apparent wear / damage occurs, replace the spark plug befo re operating failure (no start) occurs.

3. Cleaning the spark plug:

NOTE: MTD does not recommend cleaning spark plugs. Use of a wire brush may leave metal deposits on the

insulator that causes the spark plug to short out and fail to spark. Use of abrasive blast for cleaning

may cause damage to ceramic insulator or leave blast media in the recesses of the spark plug. When

the media comes loose during engine operation, severe and non-warrantable engine damage may

result.

4. Inspection of the spark plug can provide indications of th e op er a ting c on di tion of th e en gine .

• Light tan colored deposits on insulator and electrode s is nor mal.

• Dry , black deposits on the insulator and electrodes indicate an over-rich fuel / air mixture (too much fuel or

not enough air)

• Wet, black deposits on the insulator and electrodes indicate the presence of oil in the combustion cham-

ber.

• Heat damaged (melted electrodes / cracked insulator / metal transfer deposits) may indicate detonation.

• A spark plug that is wet with fuel indicates that fuel is present in the combustion chamber, but it is not

being ignited.

NOTE: The F6RTC plug is the only plug that is EPA certi-

fied for the MTD engine.

www.mymowerparts.com

5

Page 12

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

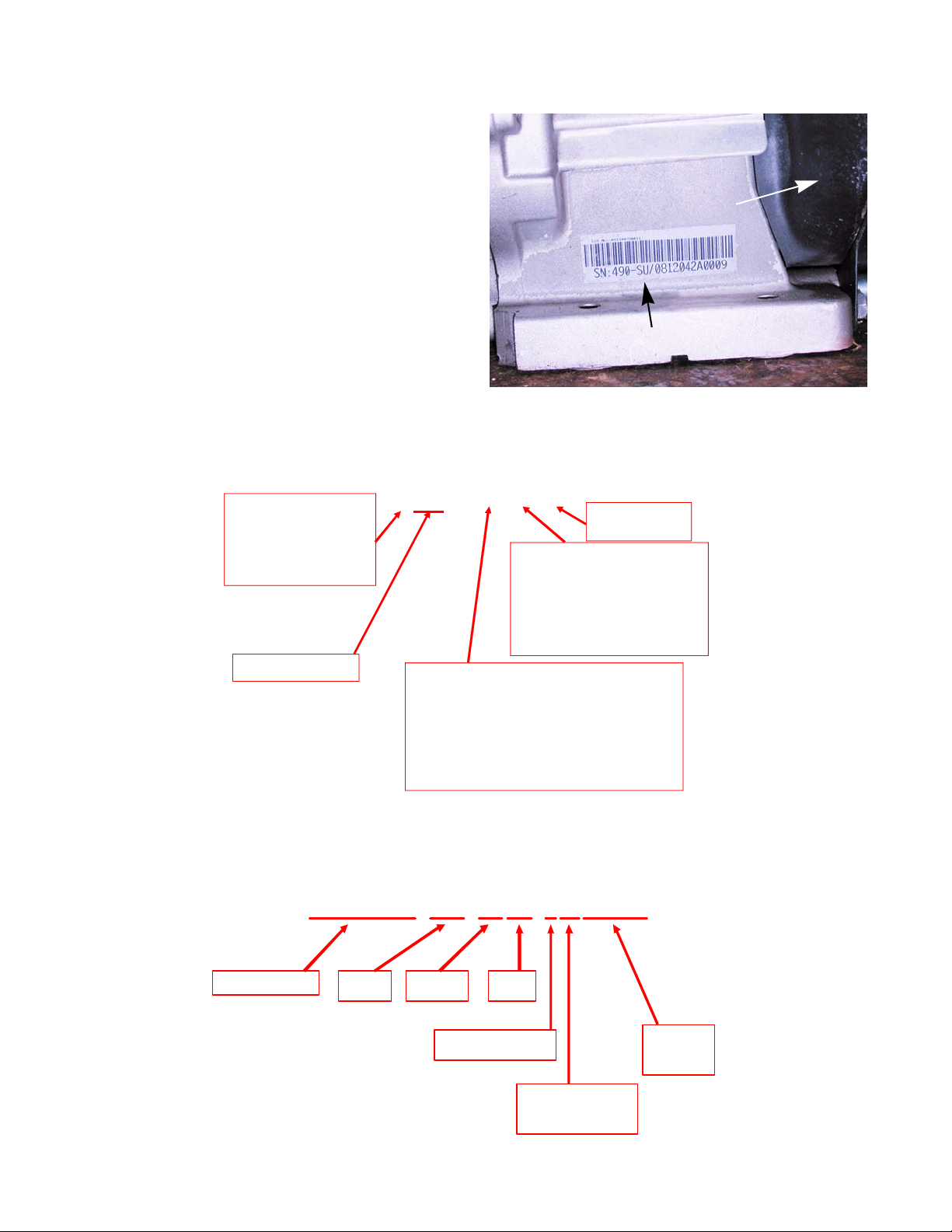

Air filter (summer engines)

Generally air filters come in two different types, a

pleated-paper element or foam. A combination of the two

are

used on the MTD engine. See Figure 1.3.

1. The main function of the air filter is to trap air borne

particles before they enter the engine . Dirt ingestion

can cause serious internal engine damage.

NOTE: Snow engines do not have air filters

because the snow will plug up the filter . Gen

erally the air is clean enough that there is

minimal risk of dirt ingestion when the

ground is covered with snow.

2. Air filters used on the MTD engine are designed to

prevent particles larger than 3-5 micron from pass

ing through into the engine.

3. The filter should be checked on a regular basis pos-

sibly several times in a season.

4. Typically an air filter should be changed before every season.

5. If a foam air pre-cleaner is dirty, but not in bad of condition it can be cleaned and reused. The paper pleate d fil-

ters can be shaken or lightly tapped to free the debris from the filter.

NOTE: Never use compressed air on a paper air filter . Compressed air will remove the tiny fibers that are used

to catch the dirt in the air. Without these fibers the filter is useless.

-

-

Paper-pleated element

Foam pre-filter

Figure 1.3

6. Foam pre-filters can be washed in warm soapy water.

NOTE: When drying a foam filter either squeeze it in side of a paper towel or let it air dry DO NOT wring it

because the filter will tear.

7. Before installing any foam filter, after it has been washed, it needs to be free of moisture.

NOTE: Always check with factory specification prior to servicing/replacing any engine components.

NOTE: Do not oil the foam pre-filter. The paper filer will absorb the oil and it will become plugged.

6

www.mymowerparts.com

Page 13

For Parts Call 606-678-9623 or 606-561-4983

Introduction

Oil type and capacity

MTD engines use oil with a SF/SG API rating or better is the recommended oil for this engine. The winter

engines use SAE 5W-30 oil and the summer engines use SAE 10W-30 oil. The oil capacity for all of the 78/83/90

series engines is 37 fl.oz (1.1 liters).

• Check the oil level frequently and change the oil more frequently in severe operating conditions such as

exceptionally deep snow falls.

• Synthetic oil is a suitable alternative, but it does not extend service interva ls.

NOTE: MTD recommends the use of petroleum oil during the break in period to ensure the piston rings cor-

rectly break in.

• Synthetic vs. Petroleum based oil: To simply look at synthetic oil and to compare it with Petroleum based

oil there is very little difference. However, when you look at the two thro ugh a microscope it is easy to see

the difference. Synthetic is made up of smaller molecules. This allows the oil to get into areas that petroleum based oil cannot.

• No oil additives or viscosity modifiers are recommended. The performance of a good oil meeting the API

specifications will not be improved by oil additives.

NOTE: Some oil additives may cause severe and non warrantable engine damage, constituting a lubrication

failure.

NOTE: If the oil is noticeably thin, or smells of gasoline, a carburetor repair may be needed before the engine

can be run safely.

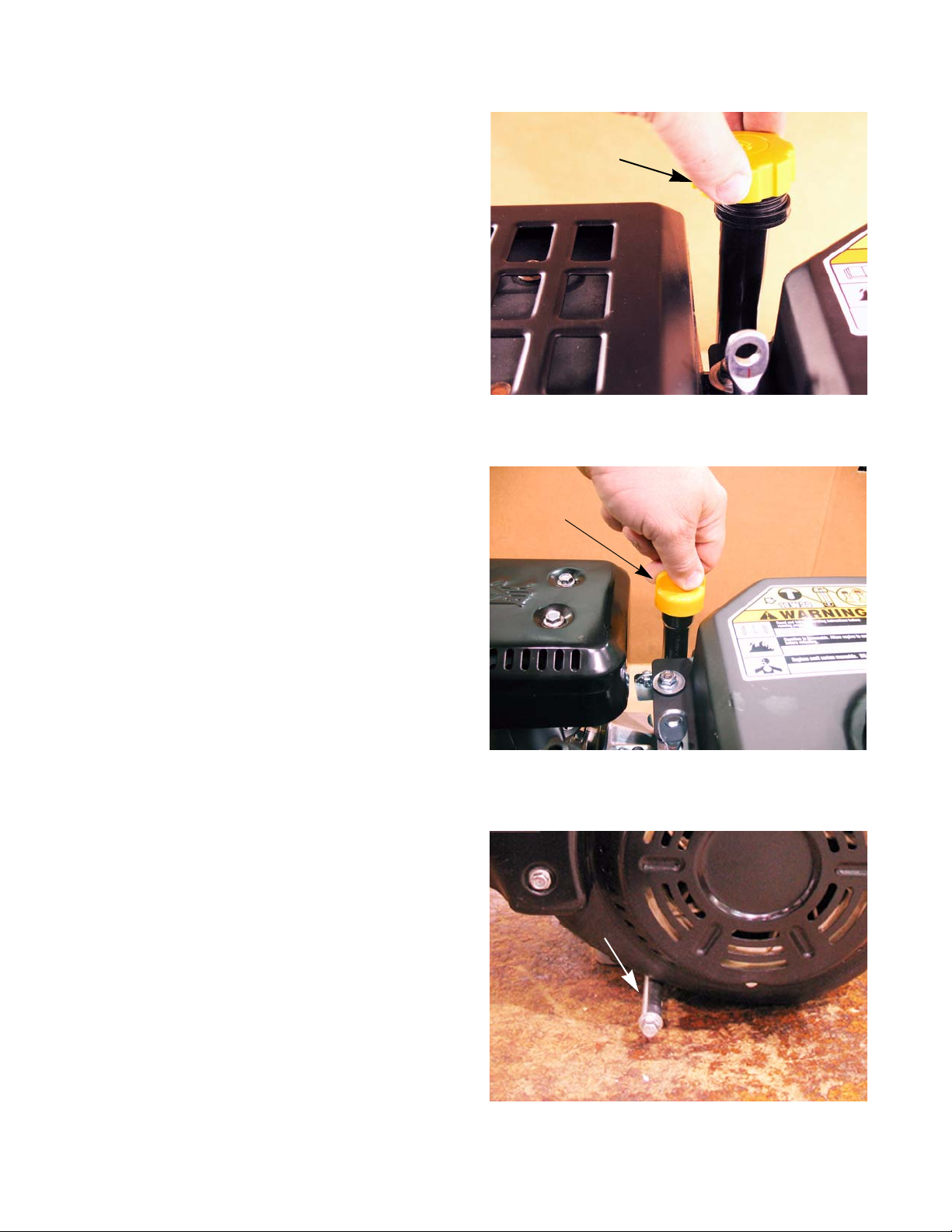

NOTE: There are two types of dip sticks that can be found

on MTD engines; a threaded dip stick that was

used on older engines and a quarter turn dip stick

that is used on engines currently being produced.

See Figure 1.4.

1/4 turn

Figure 1.4

Threaded

www.mymowerparts.com

7

Page 14

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

To check the oil with a threaded dip stick:

1. Twist and remove the dip stick from the engine.

2. Clean the oil off of the tip of the dipstick.

3. Re-insert the dipstick without threading it in to get

the oil level reading.

4. The oil level is determined by the lowest point on

the dipstick that is completely covered with oil.

To check the oil with a 1/4 turn dip stick:

1. Twist and remove the dip stick from the engine.

2. Clean the oil off of the tip of the dipstick.

See Figure 1.5.

Do not thread

dipstick in to check

the oil level

Figure 1.5

Fully seat the

dip stick before

reading it

3. Re-insert the dipstick and turn it until it is fully

seated to get the oil level reading.

4. The oil level is determined by the lowest point on

the dipstick that is completely covered with oil.

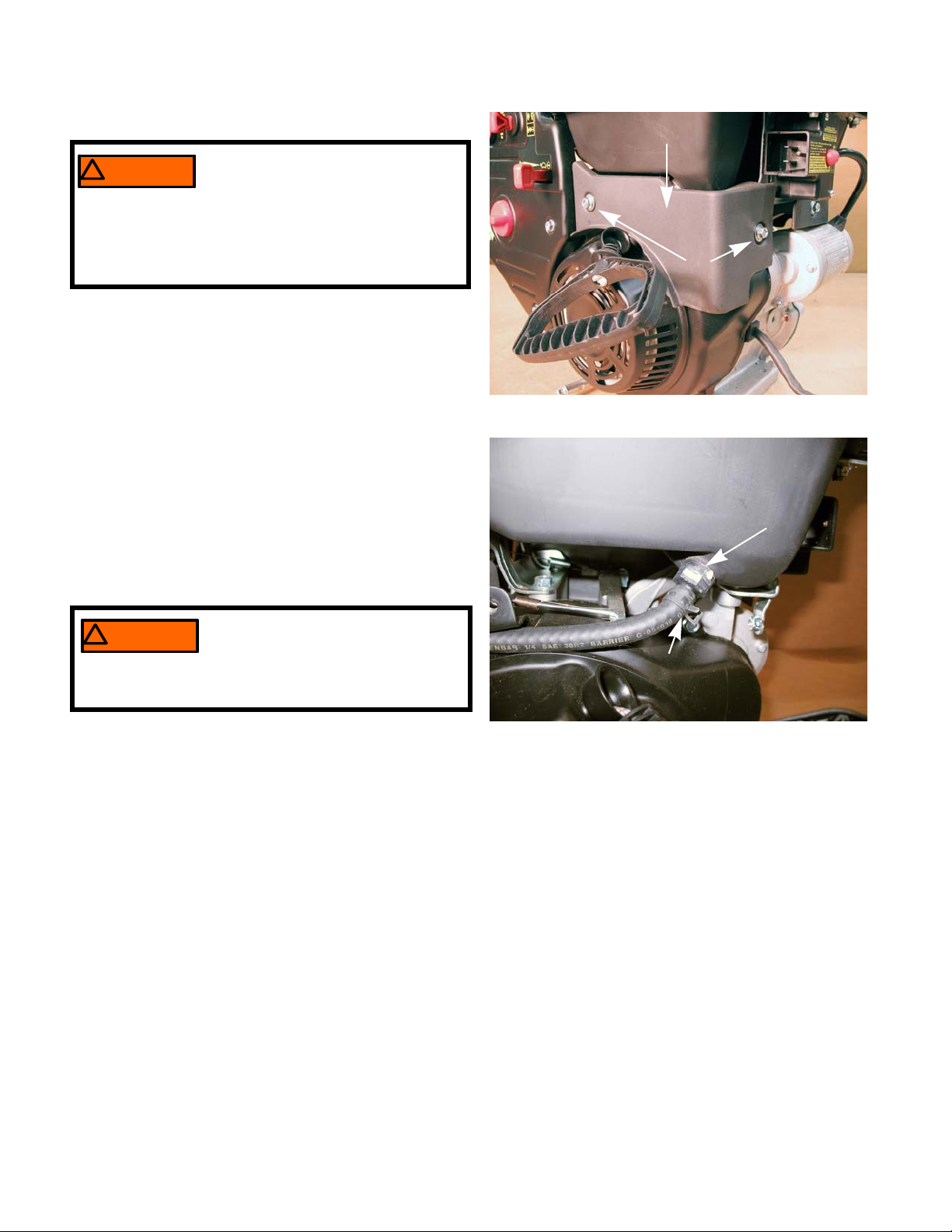

Changing the oil

NOTE: If the engine has been running, allow the

engine to cool before doing any mainte

nance work.

NOTE: The oil should be changed after the first 5 hours of operation and every 50 hours there after.

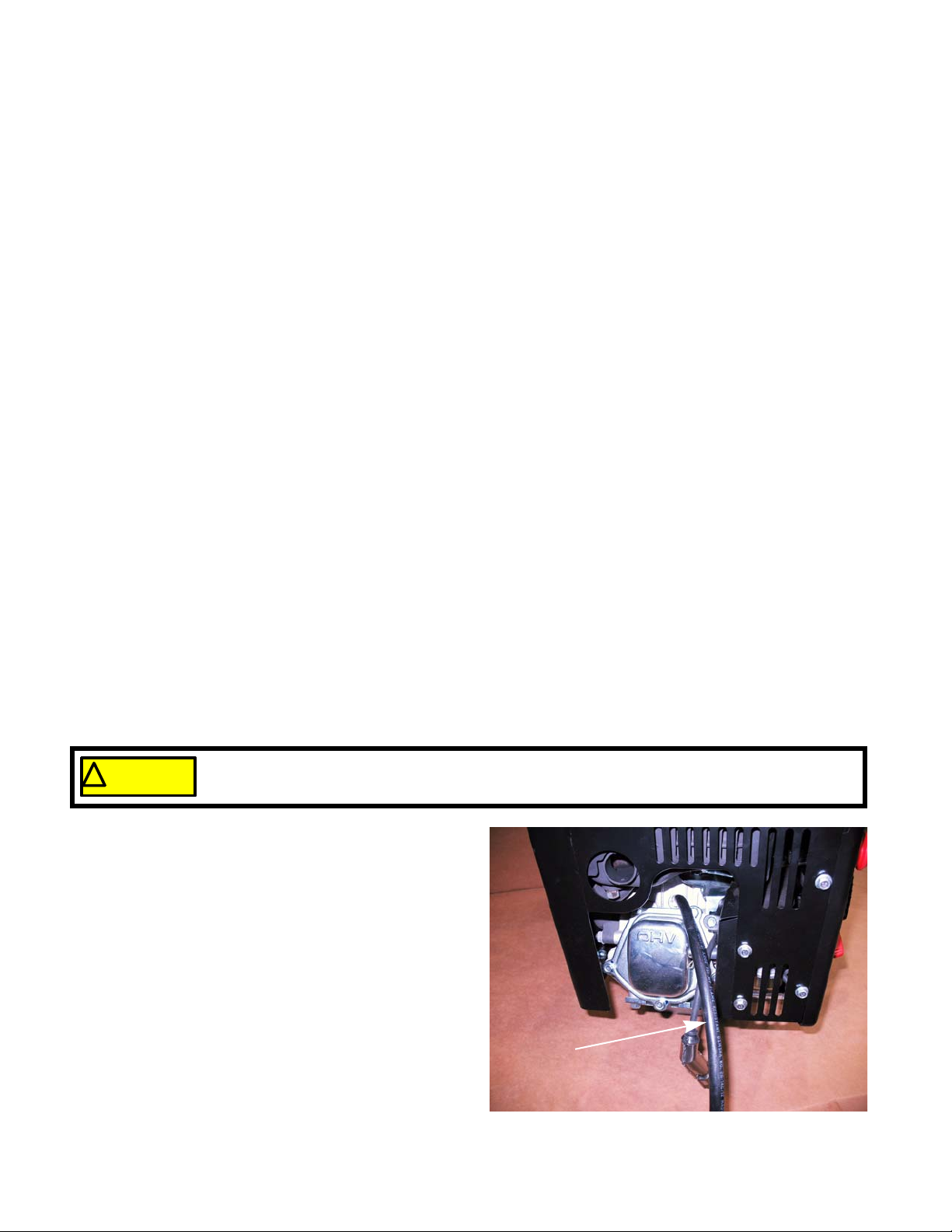

1. Place a suitable drain pan under the drain plug to

collect the oil.

2. Drain the oil by removing the drain plug located at

the end of the extension pipe threaded into the base

of the engine, using a 10mm wrench.

See Figure 1.7.

3. When all of the oil has drained out, reinstall the

drain plug. Tigh te n the d rain p l ug to a torq ue of 1 06124 in-lbs (12-14 Nm).

See Figure 1.6.

-

Figure 1.6

Oil drain

4. Fill the engine with 37 fl.oz (1.1 liters) of fresh, clean

oil that is the appropriate weight for the application.

5. Safely dispose of the used oil according to the local

laws and regulations.

8

www.mymowerparts.com

Figure 1.7

Page 15

For Parts Call 606-678-9623 or 606-561-4983

Introduction

Fuel

Gasolines currently on the market are not pur e gasoline. Today’s fuels have alcohol and other additives in them to

reduce emissions. The fuel make up can vary seasonally and geographically.

Fuel with alcohol added to it is sometimes referred to as “oxygenated fuel”. The extra oxygen carried by the ethanol increases the oxidation of the fuel. This speeds up the process that causes the fuel to go bad.

Excessive alcohol in fuel creates a lot of problems for gasoline engines. One of the biggest problems is that alcohol attracts and holds water. This corrodes the metal components of the fuel system, especially the carburetor. Alcohol also does not produce as much heat as gasoline when burnt. This results in less power for the en gine.

A 10% alcohol mix (E10) is acceptable for MTD engines. Anything higher than that will result in performance

issues.

NOTE: E85 and E20 fuels are not to be used in any MTD engines.

NOTE: Use clean, fresh fuel with a pump octane rating of 87 or greater.

• Stale or out-of-date fuel is the leading cause of hard starting issues.

• In areas that have high amounts of alcohol in their fuel, high oct ane fuel may imp rove engine performance

and startability.

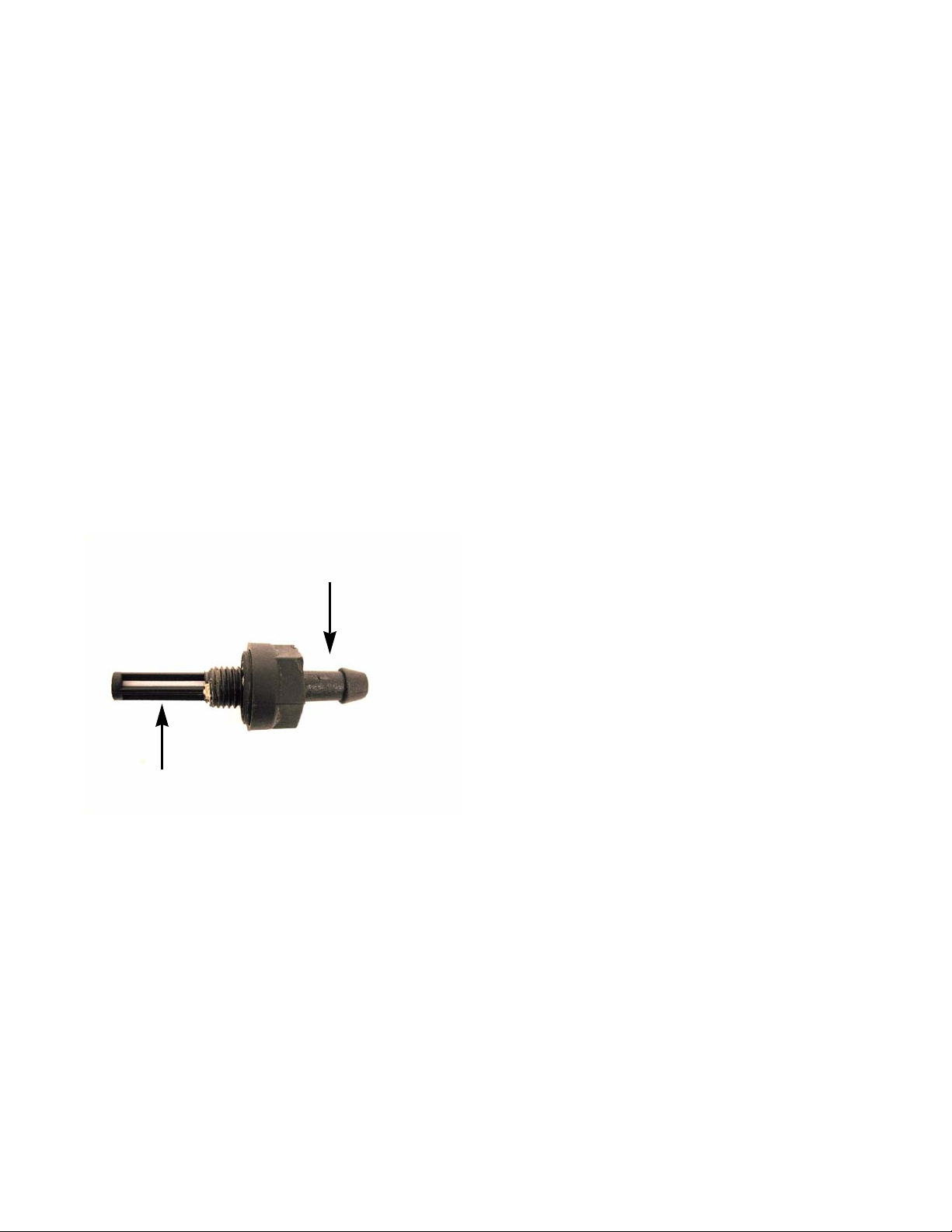

Fuel filters

fuel filter

Nipple

Figure 1.8

Dirty fuel can clog the carburetor and introduce abrasive materials into the engine. To help prevent that, MTD

engines are equipped with a fuel filter . The fuel filter is p art

of the fuel tank nipple.

See Figure 1.8.

www.mymowerparts.com

9

Page 16

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

To replace the fuel filter:

To avoid personal injury or property

! WARN IN G! WARN IN G

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled

on yourself and/or your clothes which can ignite.

Wash your skin and change clothes immediately.

1. Siphon the fuel out of the fuel tank.

2. Remove the front fuel tank shroud using a 10 mm

wrench.

3. Remove the fuel line from the fuel tank nipple:

3a. Squeeze the tabs on the fuel line clamp with a

pair of pliers while sliding the clamp down the

fuel line away from the nipple.

1.10.

damage, use extreme care in handling gasoline. Gasoline is extremely

See Figure 1.9.

See Figure

Front fuel tank shroud

Remove these

screws

Figure 1.9

Fuel filter

3b. Gently work the fuel line off of the nipple.

Residual fuel in the fuel tank will

! WARN IN G! WARN IN G

mended to help prevent gasoline from splashing

into your eyes.

4. Remove the fuel tank nipple using a 17 mm wrench.

5. Install a new filter by following the above steps in

reverse order.

NOTE: Apply a small amount of releasable thread locking compound such as Loctite® 242 (blue ) an d tigh ten

come out when the fuel line is

removed. Safety goggles are recom-

the filter by hand and then an additional 3/4 to 1 full turn to compress the gasket.

Fuel line clamp

Figure 1.10

10

www.mymowerparts.com

Page 17

r

For Parts Call 606-678-9623 or 606-561-4983

Introduction

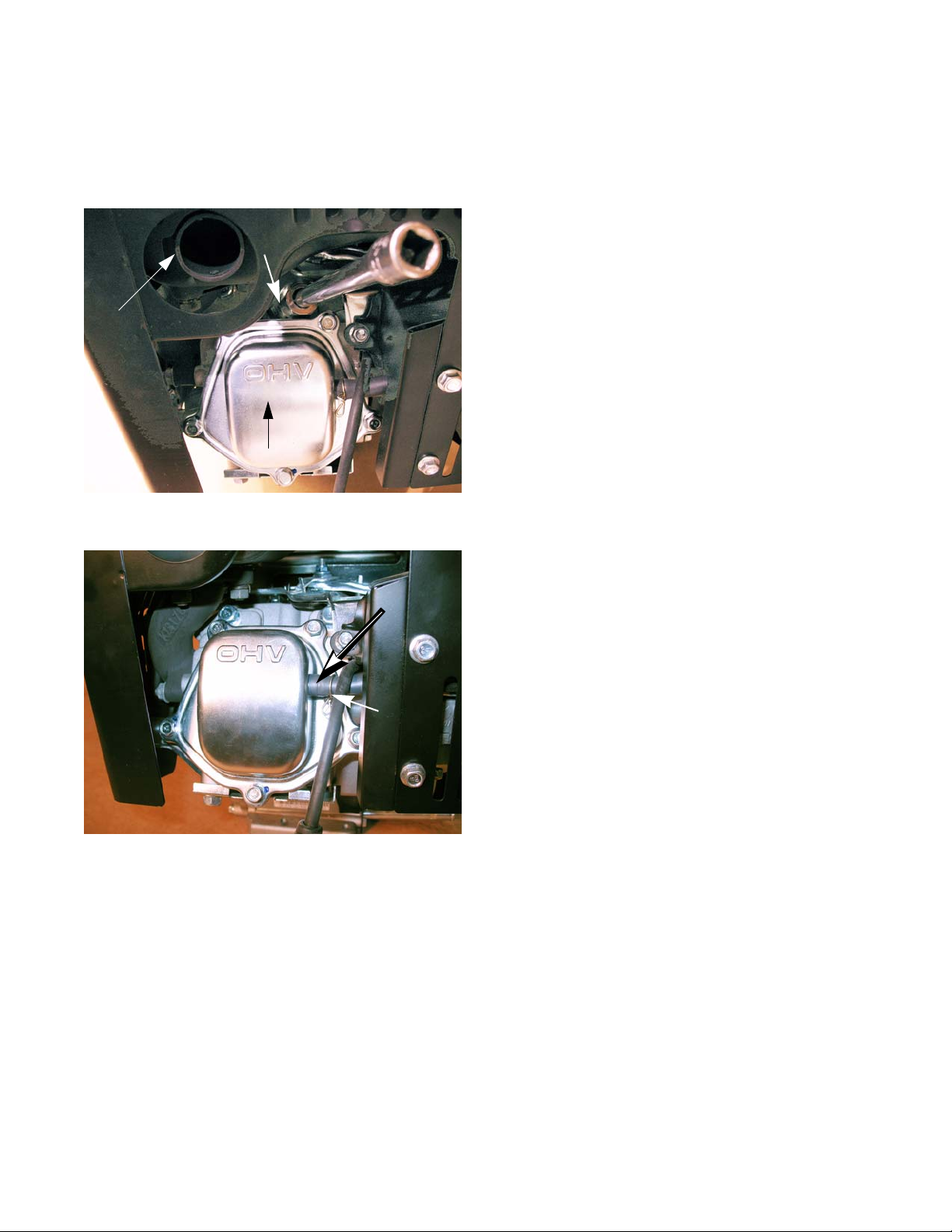

Valve lash

V alve lash is the clearance between the top of the valve stem and the rocker arm. The valve lash should be

checked after the first 25 hours of use and ever y 100 hour s a f ter th at. Valve lash can be checked and adjusted using

the following steps:

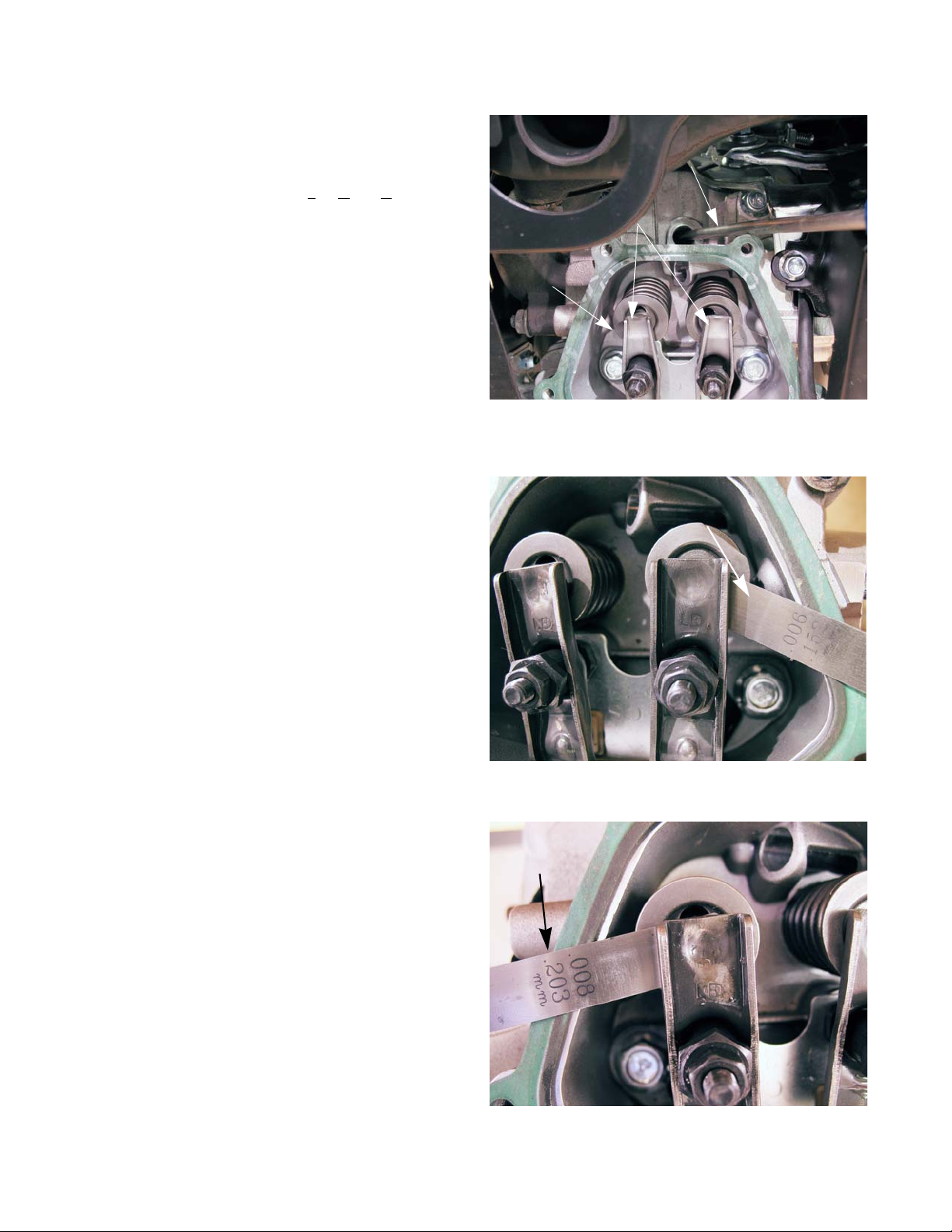

Muffle

Spark plug socket

Valve cover

Figure 1.11

Breather

hose

spring

clamp

1. If the engine has been run, allow it to cool thoroughly.

Position the equipment for easy access to the cylin

der head.

2. Disconnect the high-tension lead from the spark plug

and ground it well away from the spark plug hole.

3. Remove the spark plug using a 13/16” or 21mm

wrench. A flexible coupling or “wobbly” extension

may help.

4. Disconnect the breather hose from the valve cover.

See Figure 1.12.

5. Remove the five bolts that secure the valve cover

using a 10mm wrench. Remove the valve cover from

the engine.

NOTE: If care is taken not to damage the valve cover gas-

ket, it can be re-used.

See Figure 1.11.

-

Figure 1.12

11

www.mymowerparts.com

Page 18

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

6. Slowly pull the starter rope until air can be heard

coming out of the spark plug hole.

7. Confirm that the piston is at Top-Dead-Center on

the compression stroke.

• The compression stroke can be distinguished

from the overlap stroke by the presence of air

pressure at the spark plug hole and the fact that

neither of the valves should move significantly

on the compression stroke.

• There is an automatic compression release

mechanism that “bumps” the exhaust valve as

the piston rises on the compression stroke. At

TDC, the exhaust valve should be fully closed.

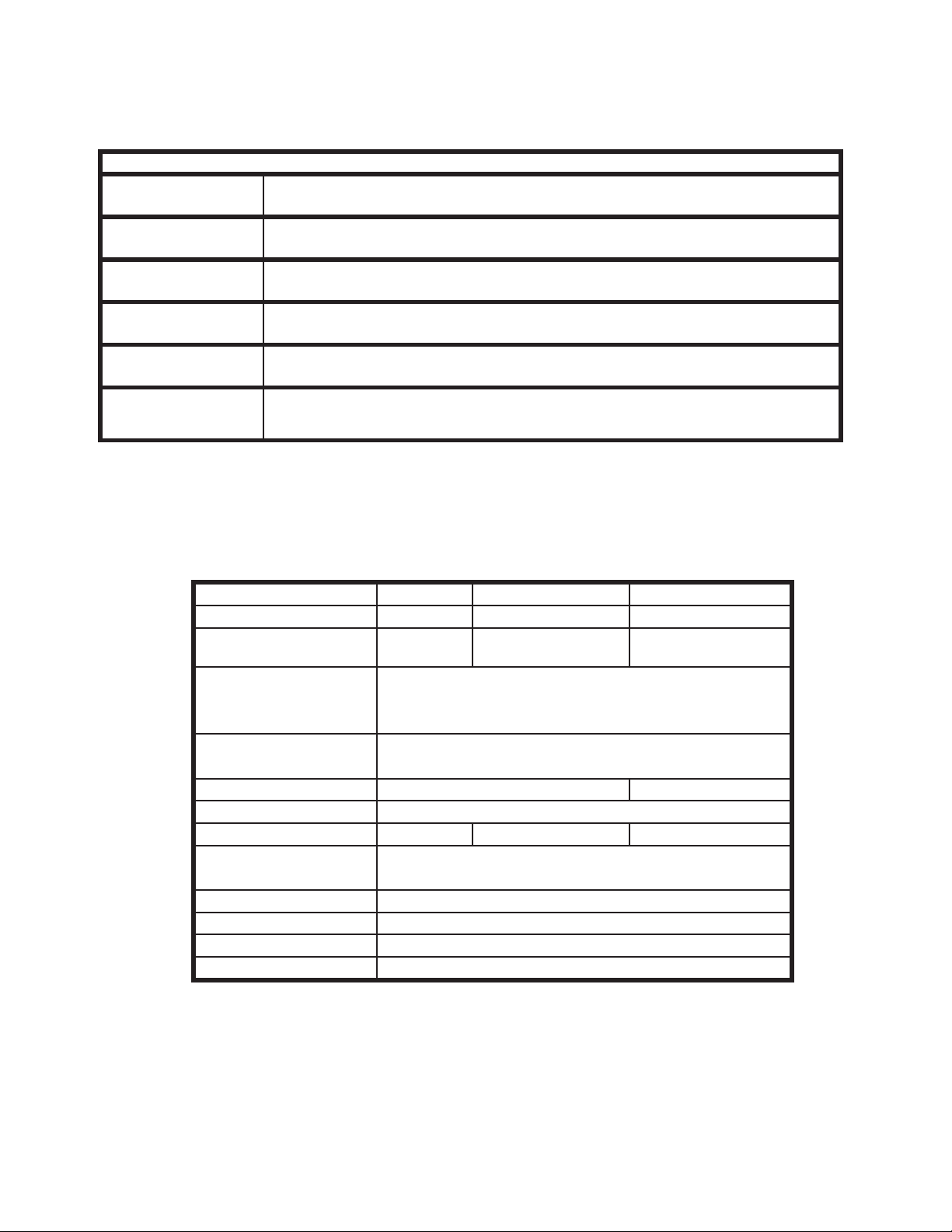

8. Check valve lash between each valve stem and

rocker arm using a feeler gauge.

9. Intake valve lash (carburetor side) should be 0.004”-

0.006” (0.10 - 0.15mm).

See Figure 1.13.

See Figure 1.14.

Probe to confirm piston

is at top of travel

Valves closed

(push rods slack)

Push rods

relaxed

Figure 1.13

.006” feeler

gauge

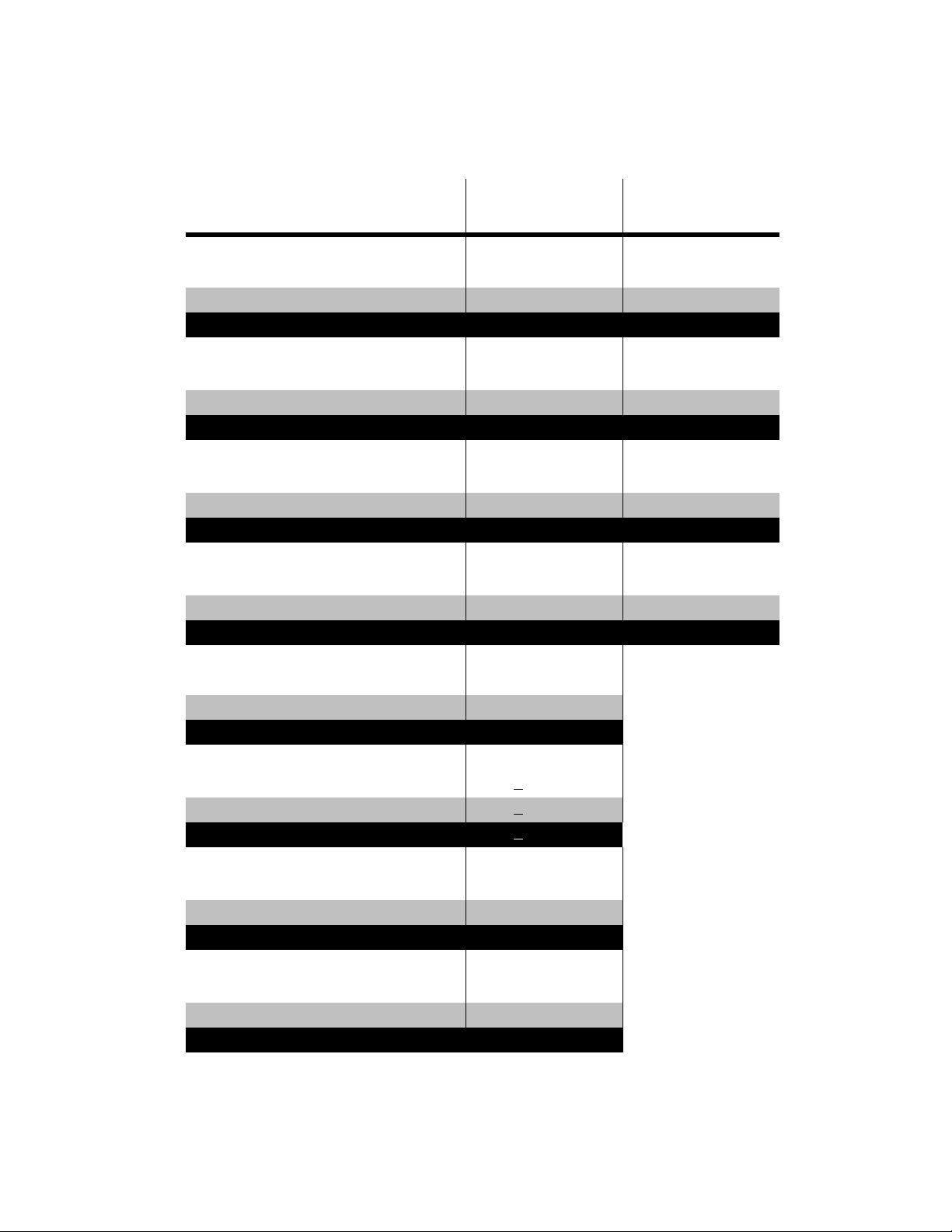

10. Exhaust valve lash (muffler side) should be 0.006-

0.008” (0.15 - 0.20mm).

11. Use a 10mm wrench to loosen the jam nut, and a

14mm wrench to adjust the rocker arm fulcrum nut.

See Figure 1.15.

• Tighten the rocker arm fulcrum nut to close-up

the clearance between the end of the valve

stem and the contact point on the rocker arm.

• Loosen the rocker arm fulcrum nut to open-up

the clearance between the end of the valve

stem and the contact point on the rocker arm.

12. Hold the fulcrum nut with a 14mm wrench, tighten

the jam nut to a torque of 80 - 106 in-lb. (9-12 Nm)

using a 10mm wrench.

12

See Figure 1.15.

www.mymowerparts.com

Figure 1.14

.008” feeler

gauge

Figure 1.15

Page 19

For Parts Call 606-678-9623 or 606-561-4983

Introduction

13. Double-check the clearance after tightening the jam nut, to confirm that it did not shift. Re-adjust if necessary.

14. Rotate the engine through several compression cycles:

• Observe the movement of the valve gear.

• Return the piston to TDC compression stroke and re-check the valve lash to confirm consistent movement

of the valve gear, including the slight bump to the exhaust valve from the automatic compression release.

15. Clean-up any oil around the valve cover opening, clean the valve cover, replace the valve cover gasket if necessary.

16. Install the valve cover, tightening the valve cover screws to a torque of 62 - 80 in-lbs (7-9 Nm).

IMPORTANT: Over tightening the valve cover will cause it to leak.

17. Install the spark plug.

Cleaning the engine

1. To maintain a proper operating temperature and to keep the equipment looking good; all debris should be

removed from the engine.

2. It is recommended to use compressed air to blow all of the debris off of the engine.

NOTE: A pressure washer may be used to clean outdoor power equipment but only after the unit has been

allowed to properly cool.

NOTE: Mice and other critters tend to build nests inside the engine shrouds while the snow blower is stored

during the long off season.

www.mymowerparts.com

13

Page 20

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

General torque specifications

1

)

ODFLWLUFQR

QLVUHQHWVD

PXQLPXO$

Maintenance Chart

&KHFNRLO

&KHFNDLUILOWHU

,IDSSOLFDEOH

1RWHRQDLUILOWHU

1RWHRQSUHILOWHU

&KHFNJDSVSDUNSOXJ

&KHFNFRROLQJILQV

&KDQJHRLO

1RWHRQRLO

9DOYHODVK

'UDLQRUSUHVHUYHIXHO

)RJRUOXEHF\OLQGHU

5RWDWHHQJLQHWR7'&

0H]LV

VEOQLHGDU*

P1

VEOQL

P1

P1

P

1

P1

00

0

VEOQL

I

VEOW

VEOWI

0DLQWHQDQFHLWHP (DFKXVH (DFKKUVXVH (DFKKUVXVH

'LUWPD\EHVKDNHQRUWDSSHGRXWRIWKHDLUILOWHUEXW

FRPSUHVVHGDLULVQRWWREHXVHGIRUFOHDQLQJ'RQRW

ZDVKRURLOSDSHUILOWHUHOHPHQW

)RDPSUHILOWHUPD\EHZDVKHGLQZDWHUDQGPLOG

GHWHUJHQWDQGUHXVHG'RQRWRLO

5HSODFHLIZRUQ

$IWHUSURORQJHGVWRUDJH

&KDQJHRLODIWHUILUVWKUVRIXVHDQGEHIRUHSURORQJHG

VWRUDJH

$IWHUWKHILUVWKUVRIXVHDQGHYHU\KUVDIWHUWKDW

%HIRUHSURORQJHGVWRUDJH

%HIRUHSURORQJHGVWRUDJH

%HIRUHSURORQJHGVWRUDJH

000H]LV

VEOWI

P1P1

P1

P1

VEOWIVEOQL

P1

VEOWIVEOQL

P1

VEOWIVEOQL

P1

14

www.mymowerparts.com

Page 21

For Parts Call 606-678-9623 or 606-561-4983

Frequently used specifications

Intake valve lash

Exhaust valve lash

Spark plug gap

Introduction

Minimum Maximum

in. mm in. mm

78 0.004 0.10 0.006 0.15

83 0.004 0.10 0.006 0.15

90 0.004 0.10 0.006 0.15

78 0.006 0.15 0.008 0.20

83 0.006 0.15 0.008 0.20

90 0.006 0.15 0.008 0.20

78 0.026 0.65 0.030 0.75

83 0.026 0.65 0.030 0.75

90 0.026 0.65 0.030 0.75

Module air gap

78 0.016 0.40 0.024 0.60

83 0.016 0.40 0.024 0.60

90 0.016 0.40 0.024 0.60

Displacement

78 16.9 cid (277 cc)

83 21.8 cid (357 cc)

90 25.6 cid (420 cc)

Governed engine RPM

78 3500 + 100

83 3500 + 100

90 3500 + 100

Oil capacity

78 37 oz 1.1 L

83 37 oz 1.1 L

90 37 oz 1.1 L

Fuel tank capacity

78 1.3 gal 5.0 L

83 1.3 gal 5.0 L

90 1.3 gal 5.0 L

www.mymowerparts.com

15

Page 22

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

16

www.mymowerparts.com

Page 23

For Parts Call 606-678-9623 or 606-561-4983

BASIC TROUBLESHOOTING

CHAPTER 2: BASIC TROUBLESHOOTING

Definitions

Troubleshooting - The act of gathering information by preforming tests and direct observations.

Diagnosis

shooting.

Introduction

Diagnosing an engine is an art form that is built upon several factors. First and most importantly is a good understanding of how the engine works. The second is skills that have been honed by experience. Finally the use of visual

observations and a structured, systematic approach to troubleshooting a problem.

The first part of this chapter will outline the steps of troubleshooting an engine so a technician can form a proper

diagnosis. The second half of this chapter will describe specific procedures and tests to perform while troubleshooting.

Steps to troubleshooting

Define the problem

The first step in troubleshooting is to define the problem:

- Developing and testing theories of what the problem is, based on the information gathered in trouble-

The first two rules in troubleshooting is to cause no further harm to the engine and prevent

! CA UTION! CAUTION

NOTE: The steps and the order of the steps that follow are a suggested approach to troubleshooting the MTD

• Crankshaft will not turn.

injuries. Always make sure to check the oil for level and condition before starting an engin e.

Also check attachments for damage and make sure they are firmly mounted.

engine. The technician does not necessarily have to follow them as described in this chapter

A. Hard to pull rope, steady pressure

B. Rope jerks back

C. Rope will not pull at all

• Crankshaft turns, no start

• Starts, runs poorly

A. Starts, then dies

B. Runs with low power output

C. Makes unusual smoke when running

I. Black smoke, usually heavy

II. White smoke, usually heavy

III. Blue smoke. usually light

D. Makes unusual sounds when running

I. Knock

II. Click

III. Chirp

www.mymowerparts.com

17

Page 24

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

IV. Unusual exhaust tone

There are tools that the technician can use in order to define the problem, such as:

1. Interview the customer.

1a. Get a good description of their complaint.

1b. If it is an intermittent problem, verify what conditions aggravate the problem as best as possible.

1c. Get an accurate service history of the equipment.

1d. Find out how the customer uses and stores the equipment.

2. Direct observation:

2a. Do not automatically accept that the customer is correct with their description of the problem. Try to

duplicate the problem.

2b. Check the general condition of the equipment (visually).

I. Cleanliness of the equipment will indicate the level of care the equipment has received.

II. Make sure the engine and attachments are securely fastened.

III. The tune-up factors.

NOTE: Most hard starting and poor running conditions can be solved by performing a tune-up.

a. Check the condition and amount of oil in the crankcase.

b. Check the level and condition of the fuel.

c. Check the ignition and “read” the spark plug.

d. Look for obvious signs of physical damage, exhaust system blockage or cooling system block-

age.

3. Broken starter rope.

3a. Usually means the engine was hard to start.

3b. Makes it impossible to confirm any running or hard starting symptoms by direct observation.

3c. Some inference can be made from checking other factors of the general condition of the equipment.

Identify factors that could cause the problem

This is the second step in the troubleshooting process.

1. Crankshaft will not turn.

A. Hard to pull rope, steady pressure. This usually indicates a mechanical bind of some sort. The likely

suspects are:

I. A slightly bent crankshaft. In some cases the drag may increase and decrease as the crankshaft

rotates. This produces a pulsing feeling that is different than a jerk back.

II. A parasitic load from a drive belt that is not releasing or an implement that is jammed.

III. An internal drag from a scored or seized piston.

18

www.mymowerparts.com

Page 25

For Parts Call 606-678-9623 or 606-561-4983

BASIC TROUBLESHOOTING

D. Rope jerks back. This usually indicates that the piston is stopping before top dead center on the com-

pression stroke and is being driven back down by compression or combustion. The likely suspects are:

I. Compression that is unusually high.

a. valve lash.

b. a partial hydraulic lock.

III. Ignition timing is advanced.

a. Improper air gap.

b. Sheared or missing flywheel key.

c. The wrong flywheel or module is installed on the engine.

IV. Insufficient inertia to over-come normal compression .

a. Loose implement.

b. A light flywheel used on a heavy flywheel application.

C. Rope will not pull at all. This is usually either a quick fix or a catastrophic failure. The likely suspects

are:

I. A broken starter recoil (easy fix).

II. Complete hydraulic lock (easy fix).

III. External binding/jammed implement (easy fix).

IV. Bent crankshaft (unrepairable)

V. Internal binding, crankshaft, connecting rod or piston (unrepairable)

2. Crankshaft turns, no start.

2a. Most gasoline engine diagnosis involves isolating problems in the four critical factors an engine needs to

run properly:

I. Ignition- sufficient spark to start combustion in the cylinder, occurring at the right time.

II. Compression- enough pressure in the cylinder to convert combustion into kinetic motion. It also

needs sufficient sealing to generate the vacuum needed to draw in and atomize the next intake

charge.

III. Fuel- correct type and grade of fr esh gasoline; in sufficient quantity, atomized (tiny droplets) and in

correct fuel/air proportions.

IV. Flow- if all of the above conditions are met but the flow of air is constricted on the inlet or exhaust

side, it will cause the engine to run poorly or not at all. This also includes ensuring the valves are

timed to open at the proper time.

2a. Isolate the ignition system and compression from the fuel system by preforming a prime test.

I. Burns prime and dies. This would indicate a fuel system issue.

II. Does not burn prime. Not a fuel system issue. Check for an ignition, compression or flow problem.

2c. Compression or ignition problem

I. Check the engine stop and safety switch.

II. Test the ignition system using a proper tester.

III. Replace the spark plug with a new one or a known go od one.

IV. Check compression or leak down.

V. Check valve lash.

www.mymowerparts.com

19

Page 26

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

VI. Check valve timing/actuation.

VII. Check exhaust.

3. Starts, runs poorly

3a. Starts, then dies

I. Run the engine with a spark tester in-line between the sp ark plug wire and the sp ark plug or use an

oscilloscope and see if the spark goes away at the same time the engine dies.

II. Check choke operation.

a. Black smoke?

b. Wet plug?

III. Prime test immediately after engine dies. If it restarts; this may indicate a problem with fuel flow to

the carburetor. Check the gas cap, fuel line, fuel filter, and the float in the carburetor.

3b. Runs with low power output.

I. Look for unusual exhaust color (smoke).

II. Unusually hot muffler (may glow red).

a. Retarded ignition

b. Exhaust valve opening early (lash too tight)

III. Mechanical bind

a. A slightly bent crankshaft. In some cases the drag may incr ease and decrease a s the crankshaf t

rotates. This produces a pulsing feeling that is different than a jerk back.

b. Parasitic external load. A bind in the equipment the engine is powering.

c. Internal drag from a scored piston or similar damage.

IV. Low governor setting or stuck governor.

a. Check RPMs using a tachometer.

b. RPMs should not droop under moderate to heavy loads.

V. Low compression

a. Check valve lash

b. Check compression

c. Check leak down to identify the source of the compression loss.

VI. Flow blockage

a. Exhaust blockage, usually accompa nied by an unusual exhaust sound.

• Just as a throttle on the carburetor controls the engine RPMs by limiting the amount of air an

engine can breathe in, an exhaust blockage will limit engine performance by constricting the

other end of the system.

• The muffler itself my be blocked.

• The exhaust valve may not be opening fully, possibly because of extremely loose valve lash

settings.

• The exhaust valve seat may have come loose in the cylinder head. This may cause a loss of

compression, a flow blockage or it may randomly alternate between the two.

NOTE: The cause of an exhaust valve coming loose is usually over heating.

20

www.mymowerparts.com

Page 27

For Parts Call 606-678-9623 or 606-561-4983

BASIC TROUBLESHOOTING

b. Intake blockage

• An intake blockage up-stream of the carburetor will cause a rich fuel/air mixture and constrict

the amount of air that the engine can draw in, limiting performance.

• The intake valve not fully opening. A possible cause of this is loose valve lash.

V. Makes unusual smoke when running

a. Black smoke, usually heavy, usually indicates a rich air fuel mixture

• Not enough air: air flow blockage or a partially closed choke.

• Too much fuel: carburetor float or float valve stuck or metering / emulsion issues with the carburetor.

b. White smoke, usually heavy

• Oil in muffler, usually the result of improper tipping. The engine will “fog” for a minute or so,

then clear-up on its own.

• Massive oil dilution with gasoline. It may be caused by improper tipping. It can also be caused

by leaky carburetor float valve, if there is a down-hill path from the carburetor to the intake port.

Check oil for gasoline smell, repair carburetor.

c. Blue smoke, usually light.

PCV system

• May be blocked or unplugged.

• May be over-come by massive over-filling or oil dilution with gasoline.

• Will cause oil to exit the engine via any low-resistance paths.

Piston rings

• Confirm with leak-down test.

• Smoke will be more pronounced under load.

• Repair may not make economic sense.

Valve guides (and intake valve stem seal).

• Smoke will be more pronounced on over-run.

VI. Makes unusual noise when running

a. Knock

• Check for loose mounting of engine or driven implement

• Rotate crankshaft back-and-forth to check for loose connecting rod.

b. Click

• Clicks and pops on engine shut-down: Compression release coming into play as the engine

RPMs cross the activation threshold. This will have no ill effects on engine performance.

• Half-engine speed clatter: loose valve lash.

• Half-engine speed clatter, slightly heavier: wrist-pin.

• Rhythmic heavy-light engine speed click: piston slap

c. Spark-knock

• Advanced ignition timing

www.mymowerparts.com

21

Page 28

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

• Low octane fuel

• Over-heating engine (check for blocked cooling air flow)

• Carbon build-up in cylinder: glowing carbon chunks pre-igniting air fuel mix.

d. Chirp

• Compression, blowing-by the fire-ring of a damaged head gasket will sometimes produce a

chirping noise.

• Confirm with a compression test and leak-down test.

e. Unusual exhaust tone

Splashy or blatty

• Splashy idle usually indicates a slight rich condition.

• May indicate an exhaust blockage, usually slightly muffled.

Backfire

• On over-run: unburned fuel igniting past exhaust valve. Mixtu re not b urnin g completely in combustion chamber. It may be too rich or it may be spark-plug or ignition problem.

• Occasional, under load: engine momentarily runs lean, usually will cycle with float bowl level or

governor pull-in, sometimes sounds like a slight stumble. Ethanol content exceeding 10% will

make the engine run artificially lean.

Skip

• Usually ignition related.

• Run the engine with a spark tester in-line between the spark plug wire and the spark plug or

use an oscilloscope and see if the spark goes away at the same time the engine dies.

4. Engine over-speed

A. Continual over-speed

• Binding or damaged external governor linkage or carburetor throttle.

• Mis-adjusted governor arm.

• Internal governor failure.

B. Momentary over-speed

• Intermittent bind (very unusual).

• Interference: This is fairly common when debris can fall on the governor linkage duri ng normal

operations.

5. Engine RPMs surge (hunting)

A. Over-governed condition- Return spring replaced with wron g part or hooked into wrong hole.

NOTE: This is an extremely rare condition, usually created by tampering.

B. Lean Air-fuel mixture condition- When AFR (Air Fuel Ratio) is significantly below stoichiometric ratio

(14.7:1) engine RPMs sink until they reach a po int tha t can be su pp or te d by the availa b l e fuel . Th is

causes a momentary surge in power until the available fuel is consumed, then the RPMs fall again,

repeating the cycle.

• Too much air: look for an air leak in the intake tract

• Not enough fuel: look for fuel supply or carburetor problems

22

www.mymowerparts.com

Page 29

For Parts Call 606-678-9623 or 606-561-4983

BASIC TROUBLESHOOTING

Repairing the problem

The third step in the troubleshooting process is to repair the problem. This step consists of:

A. Form a diagnosis by using all of the information gathered fro m the tro ubl eshooting th at was per forme d.

B. Physically perform the repair.

The fourth, and hopefully final, step in the troubleshooting process is the follow through. This step consists of:

A. Thoroughly test the repaired equipment: confirmin g that the initial diagnosis was correct. If it was

wrong, start the troubleshooting process over again.

NOTE: Sometimes the engine will have multiple problems at the same time. By performing one repair, other

issues may show up that are unrelated to the first repair.

B. Delivery to customer: We are not just repairing equipment, we are repairing customers.

• Inoculate against recurring problem with education, e.g.: if the problem was caused by stale

fuel, make sure the customer is aware that fuel go es bad ove r tim e.

• Make sure the customer understands th e repair , preventing “superstitious” come-backs.

www.mymowerparts.com

23

Page 30

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Prime test

To perform a prime test:

1. Prime the engine through the carburetor throat using a squirt bottle, filled with clean fresh gasoline.

2. Make sure the throttle is in the run position and the safety key if fully inserted.

3. Attempt to start the engine.

4. If the engine starts and runs long enough to burn the prime, the problem is effectively isolated to the fuel system. proceed to Chapter 4: The Fuel System and Governor.

5. Check ignition system as described in Chapter 7: Ignition System.

6. If the ignition system is working, check the compression or perform a leak down test.

Leak-down test

A leak-down test is the preferred method to test the engine’s ability to compress the charge. It will also show

where pressure is leaking from.

To perform a leak-down test:

NOTE: A leak down test pressurizes the combustion chamber with an external air source and will allow the

technician to listen for air “leaking” at the valves, piston rings and the head gasket.

NOTE: These are general instructions. Read and follow the instructions that came with the tester before

attempting to perform this test.

• If possible, run the engine for 3-5 minutes to warm up the engine.

• Remove the spark plug and air filter.

• Find top dead center of the compression stroke.

! CA UTION! CAUTION

1. Find top dead center by following the steps

described in the valve lash section of Chapter 1:

Introduction

2. Thread the leak down tester adapter into the spark

plug hole.

If the engine is not centered at top dead center, the engine will rotate when compressed air is

introduce to the combustion chamber.

See Figure 2.1.

3. Connect tester to compressed air.

4. Adjust the regulator knob until the needle on the

gauge is in the yellow or set area of the gauge.

5. Connect the tester to the adapter.

NOTE: If the engine rotates it was not at top dead

center.

6. Check the reading on the gauge.

24

www.mymowerparts.com

Leak-down

tester adapter

Figure 2.1

Page 31

For Parts Call 606-678-9623 or 606-561-4983

7. Compare the results to the following chart.

Leak-down Testing Results

Symptom Possible cause

BASIC TROUBLESHOOTING

Air escaping from

the breather

Air escaping from

the exhaust

Air escaping from

the carburetor

Gauge reading

low

Gauge reading

moderate

Gauge reading

high

Worn cylinder or piston rings.

Possible blown head gasket

Leaking exhaust valve

Leaking intake valve

Cylinder and piston rings are in

good condition

There is some wear in the

engine, but it is still usable

excessive wear of cylinder and/

or piston rings. Engine should

be short blocked or it could be a

blown head gasket.

www.mymowerparts.com

25

Page 32

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Compression test

To perform a compression test:

NOTE: Compression should be in the range of 40-75 PSI (2.8-5.2 Bar).

• Disconnect the high-tension lead from the spark plug and ground it well away from the spark plug hole.

• Remove the spark plug using a 13/16” or 21mm wrench. A flexible coupling or “wobbly” extension may

help.

• Pull the starter rope several times to purge any fuel or oil from the combustion chamber.

NOTE: Air compresses readily, liquid does not. Liquid in the combustion chamber will result in an artificially

high compression reading.

1. Install a compression gauge in the spar k pl ug hole.

2. Confirm that the gauge is “zeroed”, then pull the

starter rope repeatedly, until the needle on the

gauge stops rising.

3. Interpreting compression readings.

See Figure 2.2.

Compression Readings

Readings in

psi

<20

(1.4 Bar)

Most likely a stuck valve or

too tight of a valve lash,

provided the starter rope

pulls with normal effort.

Compression gauge

Reading ~

Figure 2.2

Possible causes

40 PSI

26

20 - 40

(1.4-2.8 Bar)

Valve seat damage or piston ring and/or cylinder

wear.

40 - 75

Normal readings

(2.8-5.2 Bar)

>75

(>5.2 Bar)

Excessive valve lash, a

partial hydraulic lock, a bad

cam or a bad automatic

compression relief.

www.mymowerparts.com

Page 33

For Parts Call 606-678-9623 or 606-561-4983

BASIC TROUBLESHOOTING

PCV testing

The PCV (Positive Crankcase Ventilation) valve is located in the valve cover and allows the crankcase pre ssure to

escape.

Leakage and blockage are the two failure modes for a PCV system. Either mode will cause crankcase pressure to

build-up, though the effects of a blocked PCV are generally more dramatic. Increased case pressure will result in oil

entering the combustion chamber.

crankcase

air chamber

Figure 2.3

• Oil will be forced by the rings and valve guides, being burnt in the combustion chamber.

• The cause of this oil burning can be mistaken for a worn-out engine, if proper diagno sis (compression, leakdown, and case pressure) is not performed.

4. Experimentation by MTD’s Training and Education Department has revealed the following characteristics of

MTD engines:

1. The PCV chamber is vented to the heat box through a

molded rubber hose. The rubber hose directs crank

case fumes to the heat box assembly.

See Figure 2.3.

2. When functioning properly, the PCV valve works with

the inherent pumping action of the piston in the bore

to expel pressure from the crankcase.

NOTE: Normally, small engines run with slightly negative

case pressure. This case pressure can be mea

sured using a slack-tube water manometer, or an

electronic version of the same tool. Less than -3”

to -4” (-7.6 - 10.2cm) of water is a typical reading at

idle.

3. An engine that fails to purge extra case pressure in a

controlled manner will build case pressure. The pres

sure will find it’s own way out of the engine in undesirable ways.

-

-

-

• A leaky PCV system will not build-up substantial case pressure.

• A leaky PCV system will allow the engine to ingest contaminants through the system, accelerating engine

wear.

• A blocked PCV system will allow crankcase pressure to build very rapidly . Noticeable oil fumes will be evident

in the exhaust within several minutes of normal operation.

27

www.mymowerparts.com

Page 34

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

28

www.mymowerparts.com

Page 35

For Parts Call 606-678-9623 or 606-561-4983

AIR INTAKE SYSTEMS

CHAPTER 3: AIR INTAKE SYSTEMS

MTD builds horizontal crank engines for snow blowers and chore performers. The differences between snow

engines and chore engines are the muffler and the air intake system. Therefore the air intake system for the snow

and chore engines will be discussed separately, as will the mufflers in a later chapter.

Heat box (snow engines)

One of the big differences between snow engines and all other small engines is that the air intake of the snow

engine does not have an air filter. This is because air filters tend to freeze, cutting off air flow to the engine. The snow

engine however does have a heat box to preheat the intake air.

The bottom of the heat box is open to draw in a large volume of cold air. The top of the heat box has a small

opening were the choke rod connects to the ca rburetor . Th is draws in just enough warm air from the top of the engine

to heat the cold air to the desired temperature as it enters the carburetor.

To remove/replace the heat box:

1. Pull off the choke and throttle knobs.

Remove these

screws

Remove the

breather hose

Figure 3.1

2. Remove the control panel by taking off the five

screws secures it using a 10 mm wrench.

See Figure 3.1.

3. Disconnect the wire from the ignition switch and the

primer line from the primer button.

4. Slide the breather hose out of the heat box.

See Figure 3.2.

5. Remove the two carburetor nuts using a 10 mm

wrench.

See Figure 3.2.

NOTE: When installing, tighten the carburetor nuts to a

torque of 80 - 106 in-lbs. (9-12 Nm)

Remove these

nuts

Figure 3.2

6. Remove the choke selector assembly.

7. Slide the heat box off of the carburetor studs.

8. Install the heat box by following the previo us steps in

reverse order.

NOTE: There is no gasket between the heat box and the

carburetor.

www.mymowerparts.com

29

Page 36

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Air filter (summer engines)

Generally air filters come in two different types, a

pleated-paper element or foam. A combination of the two

are

used on the MTD engine.

• Air filters used on the MTD engine are designed

to prevent particles larger than 3-5 micron from

passing through into the engine.

• The filter should be checked on a regular basis

possibly several times in a season.

NOTE: Never use compressed air on a paper air fil-

ter. Compressed air will remove the tiny

fibers that are used to catch the dirt in the

air. Without these fibers the filter is useless.

NOTE: Refer to Chapter 1: Introduction for the

maintenance interval and cleaning instruc

tions for the air filter.

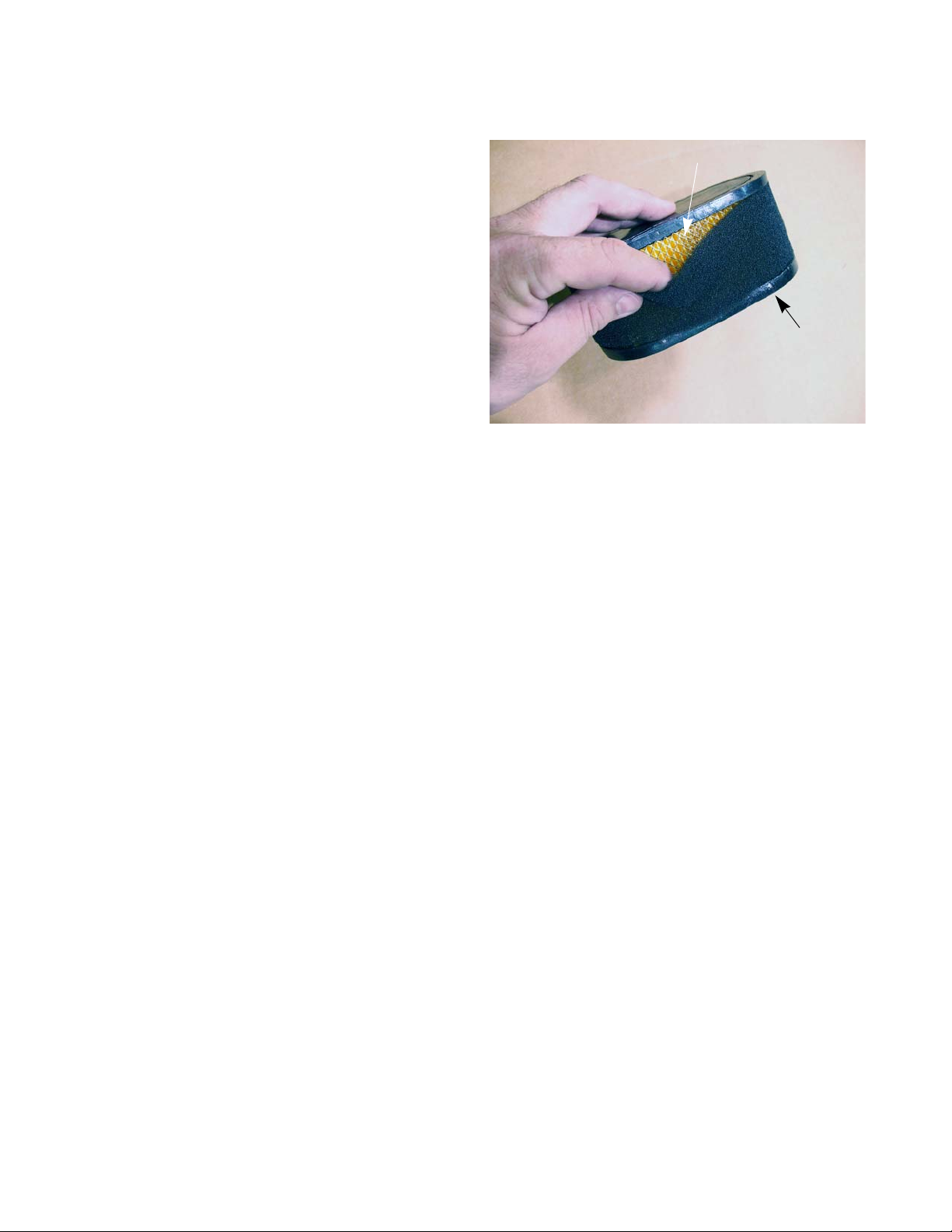

To replace an air filter:

1. Wipe down the air filter housing to prevent any

debris from getting into the engine.

2. Unthread the two wing nuts in the air filter cover.

See Figure 3.4.

-

Paper-pleated element

Foam pre-filter

Figure 3.3

Wings nuts

NOTE: The wing nuts are part of the filter housing

and do not come off.

3. Swing the housing away from the fuel tank.

See Figure 3.5.

4. Remove the air filter assembly.

Figure 3.4

Air filter

housing

Air filter assembly

30

Figure 3.5

www.mymowerparts.com

Page 37

For Parts Call 606-678-9623 or 606-561-4983

AIR INTAKE SYSTEMS

5. Install the air filter by following the previous steps in

reverse order.

NOTE: When installing the air filter, the hole in the bottom

of the paper element must fit over the riser in the

air filter base.

Riser

Air filter base

Figure 3.6

See Figure 3.6.

www.mymowerparts.com

31

Page 38

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Air filter base and control panel (summer engines)

To remove/replace the air filter base and control panel:

1. Remove the air filter following the steps described in

the previous section.

2. Remove the three screws that hold the air filter base

to the intake elbow.

See Figure 3.7.

3. Pull off the throttle lever knob. See Figure 3.8.

4. Remove the two carburetor nuts using a 10 mm

wrench.

5. Remove the bolt from the front of the control panel

using a 10 mm wrench.

6. Align the throttle lever, choke lever and the fuel

shut-off lever in the middle of their slots.

7. Remove the bolt that holds the rear of the control

panel to the throttle bracket.

See Figure 3.9.

Air filter base

Control

panel

Carburetor nuts

Screws

Figure 3.7

Throttle lever

Choke lever

Bolt

Fuel shut-off

Figure 3.8

Throttle bracket

Bolt

8. Disconnect the breather hose.

32

www.mymowerparts.com

Breather hose

Figure 3.9

Page 39

For Parts Call 606-678-9623 or 606-561-4983

AIR INTAKE SYSTEMS

NOTE: All summer engines built on or after January 1,

2011 will have a hose from the evaporative emis

sions (EVAP) system att ached to the control panel

Breather hose

above the breather hose.

9. Pull the control panel straight off the front of th e

engine.

10. Install the control panel by following the previous

steps in reverse order.

See Figure 3.10.

-

EVAP hose

Figure 3.10

NOTE: tighten the carburetor nuts to a torque of 80 - 106

in lbs (9 - 12 Nm).

11. Test run the engine before returning it to service.

www.mymowerparts.com

33

Page 40

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Carburetor and Insulator

1. Siphon the fuel out of the fuel tank.

To avoid personal injury or prop-

! WAR N IN G! WAR N IN G

extremely flammable and the vapors are explosive. Keep away from sources of ignition.

Serious personal injury can occur when gasoline is spilled on yourself and/or your clothes which

can ignite. Wash your skin and change clothes

immediately

NOTE: Dispose of drained fuel in a safe and

responsible manner.

2. Remove the fuel tank front bezel using a 10 mm

wrench.

NOTE: The bezel may get stuck on the cup for the

See Figure 3.11.

recoil starter. If it does, the recoil starter is

easily removed with an 8 mm wrench.

erty damage, use extreme care in

handling gasoline. Gasoline is

Remove these screws

Figure 3.11

3. Disconnect the fuel line from the fuel tank.

See Figure 3.12.

Residual fuel in the fuel tank will

! WAR N IN G! WAR N IN G

help prevent gasoline from splashing into your

eyes.

come out when the fuel line is

removed. Wear safety goggles to

Remove the fuel line

from the fuel tank

Figure 3.12

34

www.mymowerparts.com

Page 41

For Parts Call 606-678-9623 or 606-561-4983

AIR INTAKE SYSTEMS

4. Remove the Heat box (snow engines) or the control

panel (summer engines) by following the steps

described in appropriate section of this chapter.

5. Disconnect the throttle linkage and spring.

See Figure 3.13.

6. Slide the carburetor off of the mounting studs.

7. Remove the carburetor.

NOTE: The barb on the carburetor inlet is very sharp. If

Throttle linkage

Throttle spring

Figure 3.13

The fuel line is pulled off of it, the line will be dam

aged and must be replaced.

-

Engine model number

Ignition wires

Figure 3.14

NOTE: The carburetors are not inter -changeable from one

engine model to another. To help prevent carbure

tor mix-ups, the engine model number is stamped

on the carburetor by the fuel nipple.

See Figure 3.14.

8. Unhook the ignition wires from the clip molded into

the insulator plate.

See Figure 3.15.

-

Spark plug wire

Clip

Figure 3.15

www.mymowerparts.com

35

Page 42

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

NOTE: An insulator block separates the carburetor

from the cylinder head. There is a gasket on

each side of the insulator.

NOTE: The gaskets are different, and there is an

orientation to the insulator.

See Figure 3.16.

• The bowl vent channel in the insulator faces the

carburetor, with the exit toward the bottom.

• There is a small hole in the insulator to carburetor gasket. The hole should be aligned to allow

passage of air through the bowl vent channel to

the throttle side bowl vent in the carburetor

body.

9. Install the insulator and carburetor by following the

above steps in reverse order.

NOTE: Tighten the carburetor mounting nuts to a

torque of 80 - 106 in-lbs (9-12 Nm).

10. Test run the engin e befo re returning to service.

Insulator block

Gaskets

Figure 3.16

36

www.mymowerparts.com

Page 43

For Parts Call 606-678-9623 or 606-561-4983

FUEL SYSTEM AND GOVERNOR

CHAPTER 4: THE FUEL SYSTEM AND GOVERNOR

The function of the fuel system is to store fuel, mix the fuel with air in the correct ratio and deliver it to the intake

port. The fuel system consists of the following components:

• Fuel tank

• Fuel lines

• Fuel filter

• Carburetor

NOTE: When working on the fuel systems, look at the whole system. A problem will rarely be isolated to one

component.

Inspecting the fuel

NOTE: Fuel is the maintenance item most often overlooked by consume rs. A lot of f uel systems prob lems are

caused by gas that is out of date or fuel with too much alcohol in it. When inspecting the fuel:

• Look for water.

• Look for dirt.

• Look for discoloration.

• Sniff carefully to see if it smells like varnish or kerosene.

• Save the fuel to show to customer.

• Look for oil in the fuel.

• Test the fuel for alcohol content if there is a reason to suspect it.

NOTE: Save a sample of the fuel collected to show the customer.

NOTE: Customers pouring engine oil into the fuel tank seems to be a growing problem.

www.mymowerparts.com

37

Page 44

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

Test fuel for alcohol

Fuels currently on the market contain a wide array of additives. Some of these additives oxygenate the fuel. Oxygenated fuel reduces emissions, and is required in some parts of the United States. Fuel make-up varies seasonally

and geographically. Ethanol is the primary additive used to oxygenate fuel.

Ethanol in fuel creates a lot of problems for gasoline engines. The biggest problem is that alcohol attracts and

holds water. Th is corrod es the met a l components of the fuel system, especially the carburetor. Alcohol also does not

produce as much heat as gasoline when burnt. This results in less power for the engine.

A 10% ethanol (E10) mix is acceptable for MTD engines. Anything higher than that will result in performance

issues.

NOTE: E20 and E85 fuels are not to be used in any

MTD engines.

There are several alcohol test kit available commercially. See Figure 4.1.

Generally these kits involve mixing a measured

amount of water and gas together and seeing were the

boundary layer is.

The test kit should come with a chart to compare the

boundary layer height to alcohol percentage.

See Figure 4.2.

Figure 4.1

Figure 4.2

38

www.mymowerparts.com

Page 45

For Parts Call 606-678-9623 or 606-561-4983

FUEL SYSTEM AND GOVERNOR

Fuel tank vent

The fuel tank vent performs the important task of allowing air into the fuel tank. As fuel is being used by the

engine, the fuel level in the tank drops. The dropping fuel level then create s a vacuum in the tank. If the fuel tank

could not draw air through the vent, the vacuum would prevent the fuel from getting to the carburetor. The vent is

located in the fuel cap.

See Figure 4.3.

Fuel cap

Vent

Figure 4.3

NOTE: All summer engines built on or after January 1, 2011 will have an evaporative emissions (EVAP) sys-

tem that the fuel tank vents through, not the fuel cap. Refer to the evaporative emissions section of this

chapter to understand how this system works and how to test it.

To test the cap vent:

1. Remove the fuel cap.

2. Clean off the vent.

3. Blow air into the vent hole. The air should blow throw the vent with little back pressure.

4. Suck air through the vent hole. Air should freely enter through the vent.

• Replace the cap if the vent builds pressure or restricts air movement.

• A cap that maintains pressure will cause the engine to run rich as the fuel in the tank heats and expands,

forcing it’s way past the float valve in the carburetor.

• A cap that maintains vacuum will cause the engine to run lean as the fuel is depleted and no air comes in

to replace it.

• The two conditions may both be present, but the symptoms vary with fuel, fuel level, and operating conditions.

• A bad fuel cap vent usually presents as a “Runs and quits” scenario.

www.mymowerparts.com

39

Page 46

I

For Parts Call 606-678-9623 or 606-561-4983

78/83/90 Series Horizontal Shaft Engines

The fuel filter

The fuel filter is located in the fuel tank nipple. It can be remove d and cl eaned with a can of ca rb cleaner or it can

be replaced.

See Figure 4.4.

NOTE: If cleaning a filter, back-flush it by spraying the carb cleaner through the barb end and out of the

screen. Also make sure the fuel tank is clean.

nset:

Fuel filter/barb

Filter

Figure 4.4

NOTE: To replace the fuel filter follow the steps described in Chap ter 1: Introduction.

Inspect the fuel lines

• Are they cracked?

• Are they clogged?

• Are they brittle?

NOTE: If the answer to any of the above is yes, replace the fuel lines. When replacing fuel lines, low perme-

able fuel line must be used in order to meet EPA and CARB standards.

NOTE: The nipple has a sharp edge that will damage the inner lining of the fuel line. Replace the fuel line

every time it is removed from the carburetor fuel nipple.

! WARN IN G! WARN IN G

• Drain the fuel tank before starting work to prevent spillage.

• Dispose of drained fuel in a safe and responsible manner.