Troybilt 31AS6R72063, 31AE6S73063 Owner’s Manual

0 TRoKRILT

Operator's Manu

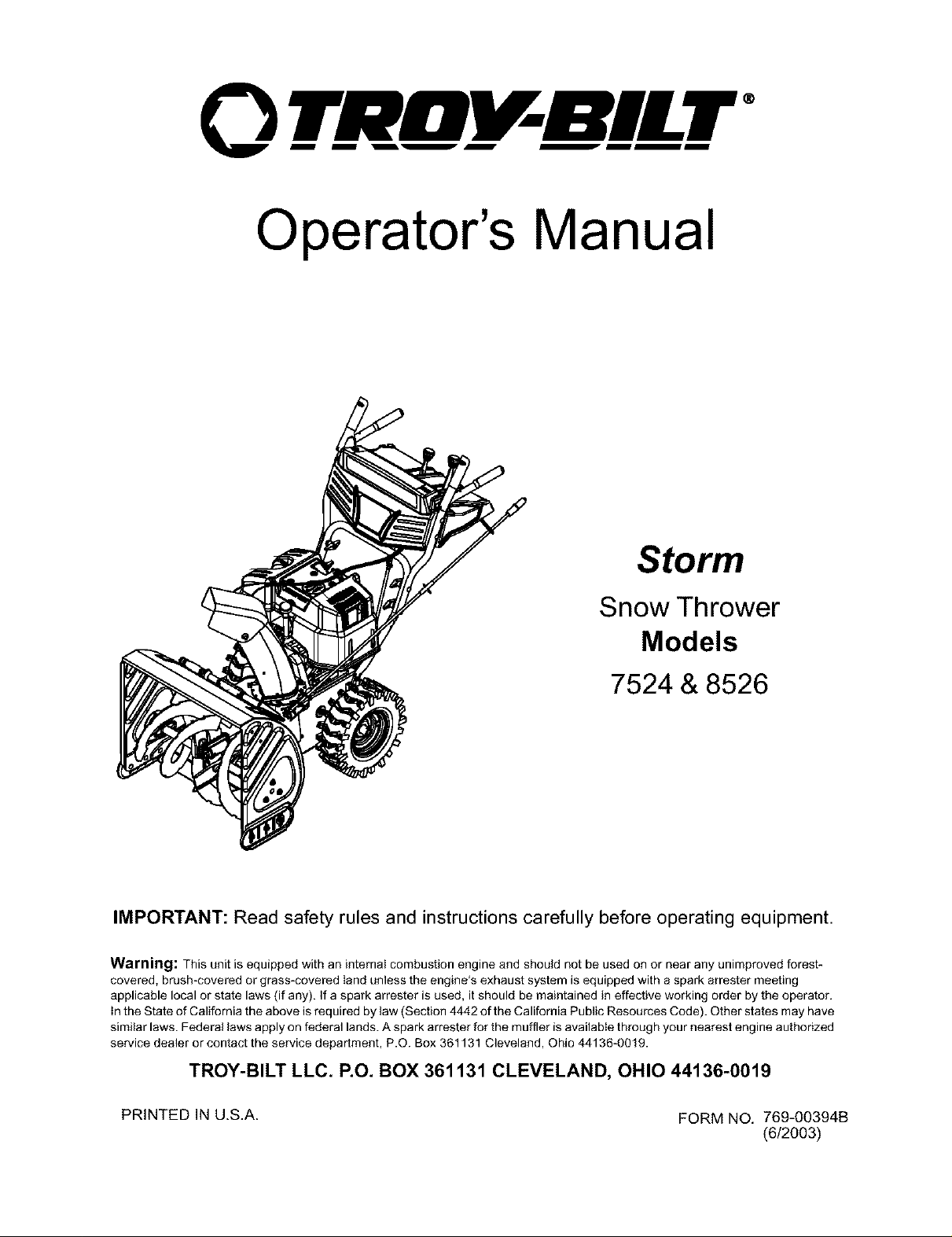

Storm

Snow Thrower

Models

7524 & 8526

I

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit isequipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered Iand unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is availabIe through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A. FORM NO. 769-00394B

(6/2003)

TABLEOFCONTENTS

Content Page

Important Safe Operation Practices ................................................................................... 3

Assembling Your Snow Thrower ........................................................................................ 5

Know Your Snow Thrower ................................................................................................. 7

Operating Your Snow Thrower ........................................................................................... 8

Making Adjustments ........................................................................................................... 10

Maintaining Your Snow Thrower ........................................................................................ 12

Servicing Your Snow Thrower ............................................................................................ 13

Off-Season Storage .......................................................................................................... 15

Troubleshooting ................................................................................................................. 16

Parts List ........................................................................................................................... 17

FINDINGMODELNUMBER

This Operator's Manual isan important part of your new snow thrower. It will help you to assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

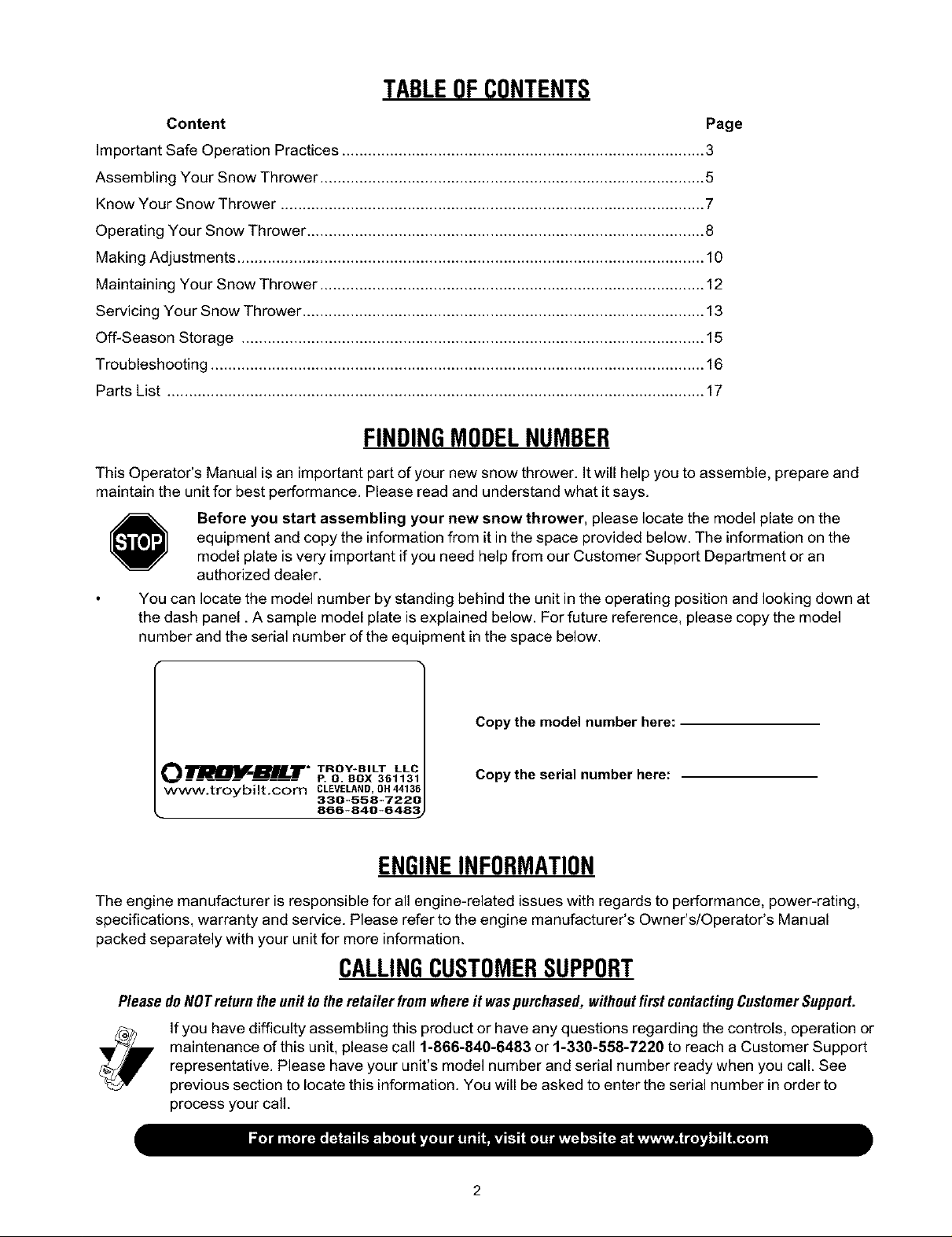

Before you start assembling your new snow thrower, please locate the model plate on the

equipment and copy the information from it inthe space provided below. The information on the

model plate is very important if you need help from our Customer Support Department or an

authorized dealer.

You can locate the model number by standing behind the unit in the operating position and looking down at

the dash panel. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

Copy the model number here:

O_l_B_lr. TROY_BILT LLC

www.troybilt.com CLEVELAND,OH44136

P. O. BOX 361131

330_558_7220

866_840_6483

Copy the serial number here:

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating,

specifications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual

packed separately with your unit for more information.

CALLINGCUSTOMERSUPPORT

Please doNOTreturntheun# totheretailer fromwhereit waspurchased,withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call 1-866-840-6483 or 1-330-558-7220 to reach a Customer Support

representative. Please have your unit's model number and serial number ready when you call. See

previous section to locate this information. You will be asked to enter the serial number in order to

process your call.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol--heed its warning.

,_ WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to State of California to cause cancer and birth defects or other

reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This

machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

Training 7.

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place 8.

for future and regular reference and for ordering

replacement parts. 9.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used. Remove all doormats, newspapers, sleds,

boards, wires and other foreign objects, which could be

tripped over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during j.

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes. Operation

3. Do not operate without wearing adequate winter outer 1.

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on 2.

slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines. 3.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all clutch levers before starting the engine. 4.

Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual.

Let engine and machine adjust to outdoor temperature

before starting to clear snow.

To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes, which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than

½ inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

Allow machine to cool at least 5 minutes before

storing.

Do not put hands or feet near rotating parts, in the auger/

impeller housing or discharge chute. Contact with the

rotating parts can amputate hands and feet.

The auger/impeller clutch lever is a safety device. Never

bypass its operation. Doing so makes the machine

unsafe and may cause personal injury.

The clutch levers must operate easily in both directions

and automatically return to the disengaged position when

released.

Never operate with a missing or damaged discharge

chute. Keep all safety devices in place and working.

5. Neverrunanengineindoorsorinapoorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

6. Donotoperatemachinewhileundertheinfluenceof

alcoholordrugs.

7. Mufflerandenginebecomehotand can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operating on slopes.

10. Plan your snow4hrowing pattern to avoid discharge

towards windows, walls, cars etc. Thus, avoiding

possible property damage or personal injury caused by a

ricochet.

11. Never direct discharge at children, bystanders and pets

or allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or

light. Always be sure of your footing and keep a firm hold

on the handles. Walk, never run.

14. Disengage power to the auger/impeller when

transporting or not in use.

15. Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when in reverse.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage.

Repair any damage before starting and operating.

17. Disengage all clutch levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the discharge chute, making any

adjustments, or inspections.

18. Never put your hand in the discharge or collector

openings. Always use the clean4ool provided to unclog

the discharge opening. Do not unclog discharge chute

while engine is running. Before unclogging, shut off

engine and remain behind handles until all moving parts

have stopped completely.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. Ifsituations occur which are not covered in this manual,

use care and good judgment. Contact your dealer or

telephone 1-866-840-6483 for assistance and the name

of your nearest servicing dealer.

Maintenance& Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine

disengage all clutch levers and stop engine. Wait until the

auger/impeller come to acomplete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer's (HEM) parts only. "Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety.

6. Check clutch controls periodically to verify they engage

and disengage properly and adjust, if necessary. Refer to

the adjustment section in this operator's manual for

instructions.

7. Maintain/replacesafety/instruction labels, as necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

, i.

YourResponsibility

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine. The

safety labels are shown below for your reference.

SECTION2: ASSEMBLINGYOURSNOWTHROWER

Unpacking

Remove staples from the top, sides, and ends of

the shipping crate.

Set panels aside to avoid tire punctures or personal

injury.

Remove and discard plastic bag that covers unit.

Roll the unit out of the crate.

Check the crate for loose parts before discarding.

LooseParts

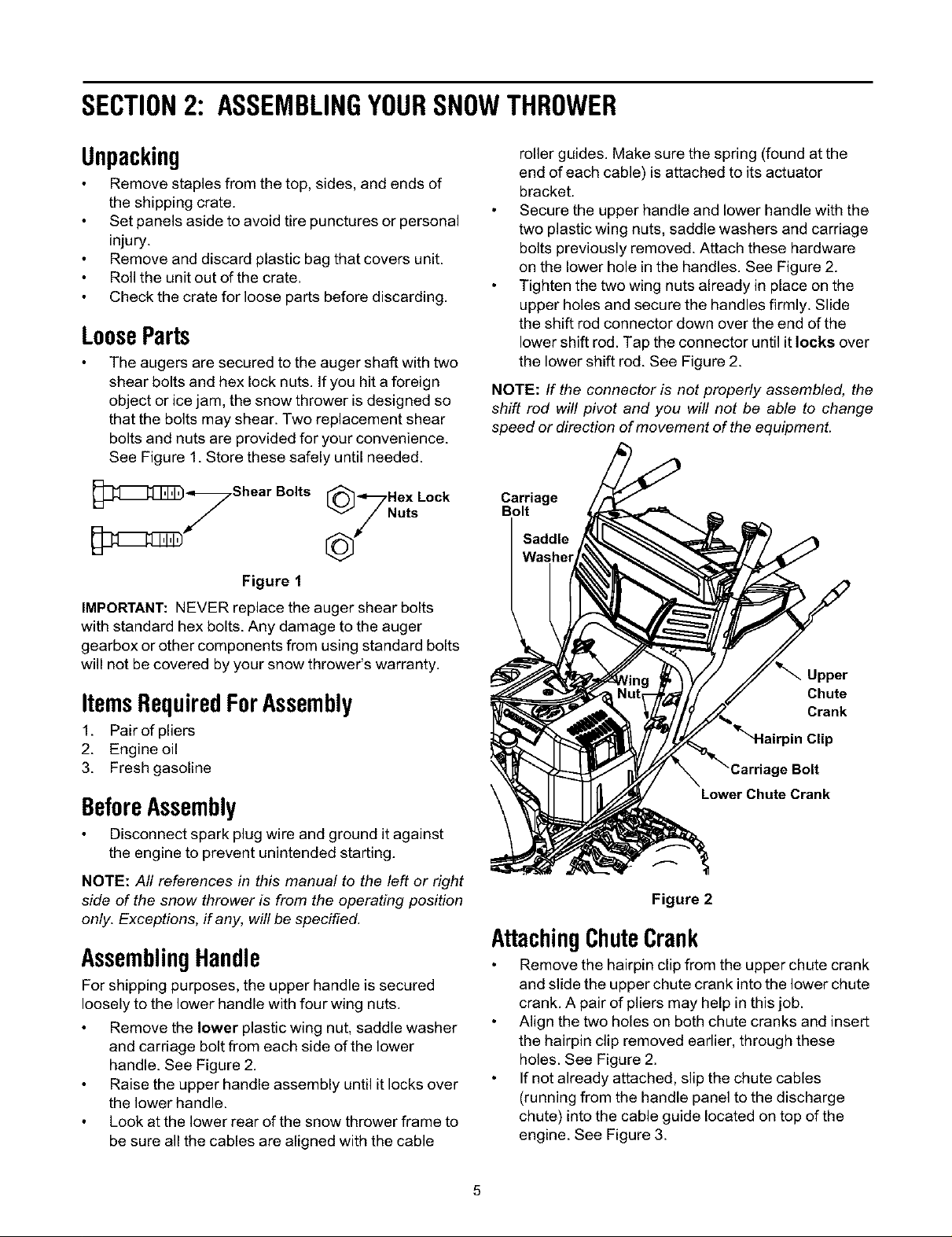

The augers are secured to the auger shaft with two

shear bolts and hex lock nuts. If you hit a foreign

object or ice jam, the snow thrower is designed so

that the bolts may shear. Two replacement shear

bolts and nuts are provided for your convenience.

See Figure 1. Store these safely until needed.

[_ _Hex Lock

__Shear Bolts

iv/ Nuts

Figure 1

IMPORTANT: NEVER replace the auger shear bolts

with standard hex bolts. Any damage to the auger

gearbox or other components from using standard bolts

will not be covered by your snow thrower's warranty.

ItemsRequiredForAssembly

1. Pair of pliers

2. Engine oil

3. Fresh gasoline

BeforeAssembly

Disconnect spark plug wire and ground it against

the engine to prevent unintended starting.

roller guides. Make sure the spring (found at the

end of each cable) is attached to its actuator

bracket.

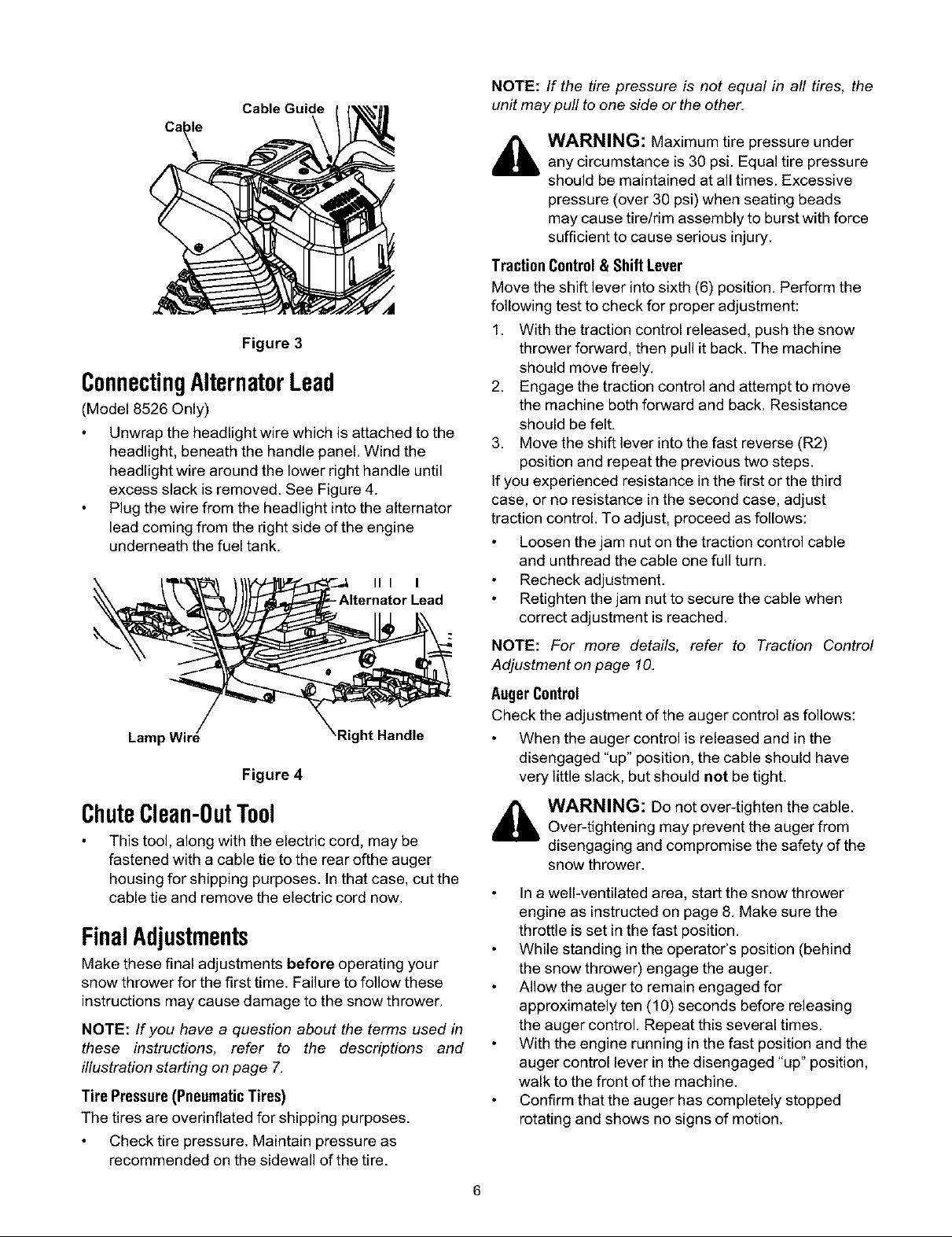

Secure the upper handle and lower handle with the

two plastic wing nuts, saddle washers and carriage

bolts previously removed. Attach these hardware

on the lower hole in the handles. See Figure 2.

Tighten the two wing nuts already in place on the

upper holes and secure the handles firmly. Slide

the shift rod connector down over the end of the

lower shift rod. Tap the connector until it locks over

the lower shift rod. See Figure 2.

NOTE: If the connector is not properly assembled, the

shift rod will pivot and you will not be able to change

speed or direction of movement of the equipment.

Carriage

Bolt

Saddle

Upper

Chute

Crank

"pin Clip

ge Bolt

Lower Chute Crank

NOTE: All references in this manual to the left or right

side of the snow thrower is from the operating position

only. Exceptions, if any, will be specified.

AssemblingHandle

For shipping purposes, the upper handle is secured

loosely to the lower handle with four wing nuts.

Remove the lower plastic wing nut, saddle washer

and carriage bolt from each side of the lower

handle. See Figure 2.

Raise the upper handle assembly until it locks over

the lower handle.

Look at the lower rear of the snow thrower frame to

be sure all the cables are aligned with the cable

Figure 2

AttachingChuteCrank

Remove the hairpin clip from the upper chute crank

and slide the upper chute crank into the lower chute

crank. A pair of pliers may help in this job.

Align the two holes on both chute cranks and insert

the hairpin clip removed earlier, through these

holes. See Figure 2.

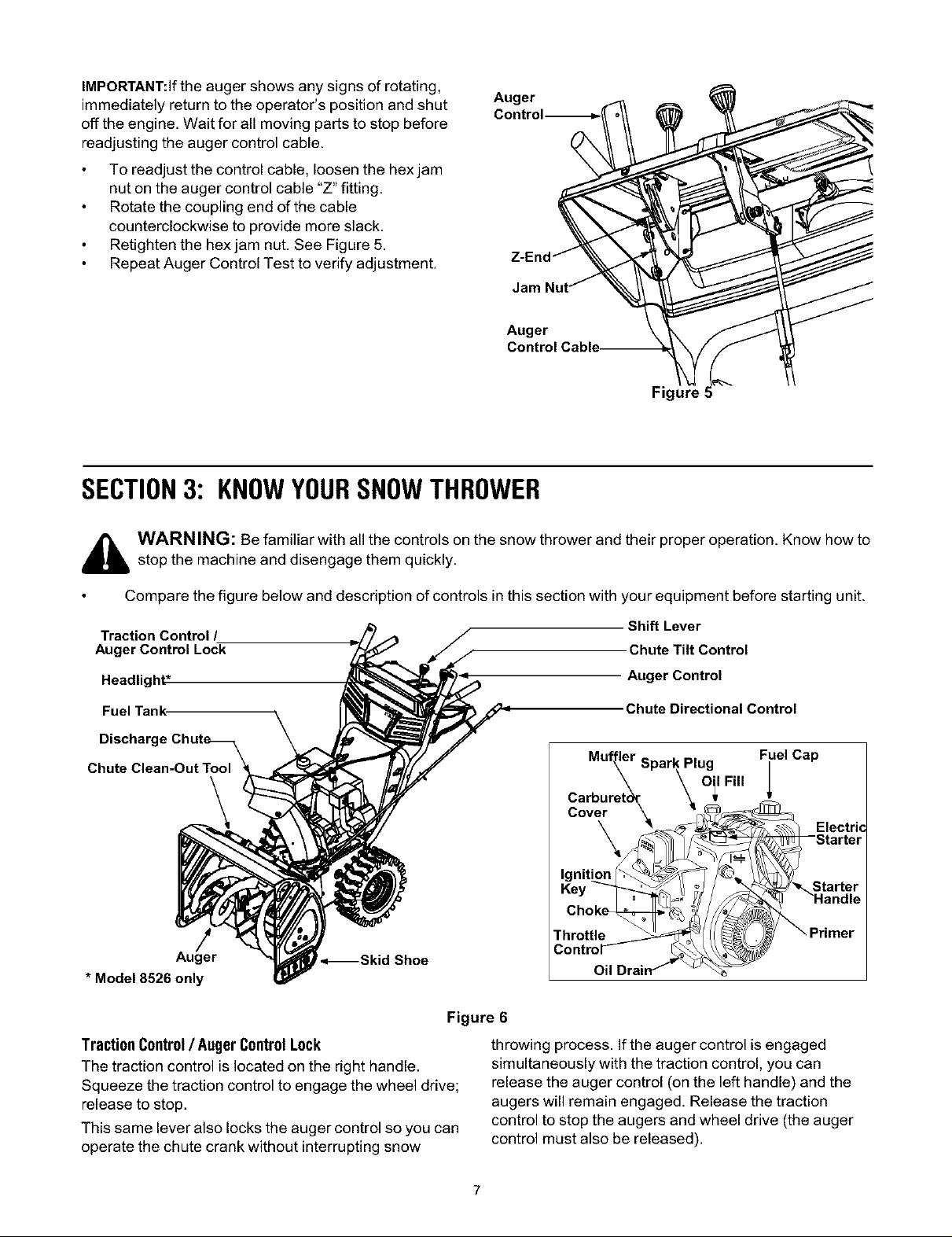

If not already attached, slip the chute cables

(running from the handle panel to the discharge

chute) into the cable guide located on top of the

engine. See Figure 3.

Cable Guide

NOTE: If the tire pressure is not equal in all tires, the

unit may pull to one side or the other.

Figure 3

ConnectingAlternatorLead

(Model 8526 Only)

Unwrap the headlight wire which is attached to the

headlight, beneath the handle panel. Wind the

headlight wire around the lower right handle until

excess slack is removed. See Figure 4.

Plug the wire from the headlight into the alternator

lead coming from the right side of the engine

underneath the fuel tank.

III I

- Alternator Lead

_ WARNING: Maximum tire pressure under

any circumstance is 30 psi. Equal tire pressure

should be maintained at all times. Excessive

pressure (over 30 psi) when seating beads

may cause tire/rim assembly to burst with force

sufficient to cause serious injury.

Traction Control & Shift Lever

Move the shift lever into sixth (6) position. Perform the

following test to check for proper adjustment:

1. With the traction control released, push the snow

thrower forward, then pull it back. The machine

should move freely.

2. Engage the traction control and attempt to move

the machine both forward and back. Resistance

should be felt.

3. Move the shift lever into the fast reverse (R2)

position and repeat the previous two steps.

If you experienced resistance in the first or the third

case, or no resistance in the second case, adjust

traction control. To adjust, proceed as follows:

Loosen the jam nut on the traction control cable

and unthread the cable one full turn.

Recheck adjustment.

Retighten the jam nut to secure the cable when

correct adjustment is reached.

NOTE: For more details, refer to Traction Control

Adjustment onpage 10.

Lamp Wire Right Handle

Figure 4

ChuteClean-OutTool

This tool, along with the electric cord, may be

fastened with a cable tie to the rear ofthe auger

housing for shipping purposes. In that case, cut the

cable tie and remove the electric cord now.

FinalAdjustments

Make these final adjustments before operating your

snow thrower for the first time. Failure to follow these

instructions may cause damage to the snow thrower.

NOTE: If you have a question about the terms used in

these instructions, refer to the descriptions and

illustration starting on page 7.

Tire Pressure (Pneumatic Tires)

The tires are overinflated for shipping purposes.

Check tire pressure. Maintain pressure as

recommended on the sidewall of the tire.

AugerControl

Check the adjustment of the auger control as follows:

When the auger control is released and in the

disengaged "up" position, the cable should have

very little slack, but should not be tight.

_ WARNING: Do not over-tighten the cable.

Over-tightening may prevent the auger from

disengaging and compromise the safety of the

snow thrower.

In a well-ventilated area, start the snow thrower

engine as instructed on page 8. Make sure the

throttle is set in the fast position.

While standing in the operator's position (behind

the snow thrower) engage the auger.

Allow the auger to remain engaged for

approximately ten (18) seconds before releasing

the auger control. Repeat this several times.

With the engine running in the fast position and the

auger control lever in the disengaged "up" position,

walk to the front of the machine.

Confirm that the auger has completely stopped

rotating and shows no signs of motion.

IMPORTANT:Iftheaugershowsanysignsofrotating,

immediatelyreturntotheoperator'spositionandshut

Auger

offtheengine.Waitforallmovingpartstostopbefore

readjustingtheaugercontrolcable.

Toreadjustthecontrolcable,loosenthehexjam

nutontheaugercontrolcable"Z"fitting.

Rotatethecouplingendofthecable

counterclockwisetoprovidemoreslack.

Retightenthehexjamnut.SeeFigure5.

RepeatAugerControlTesttoverifyadjustment.

Auger

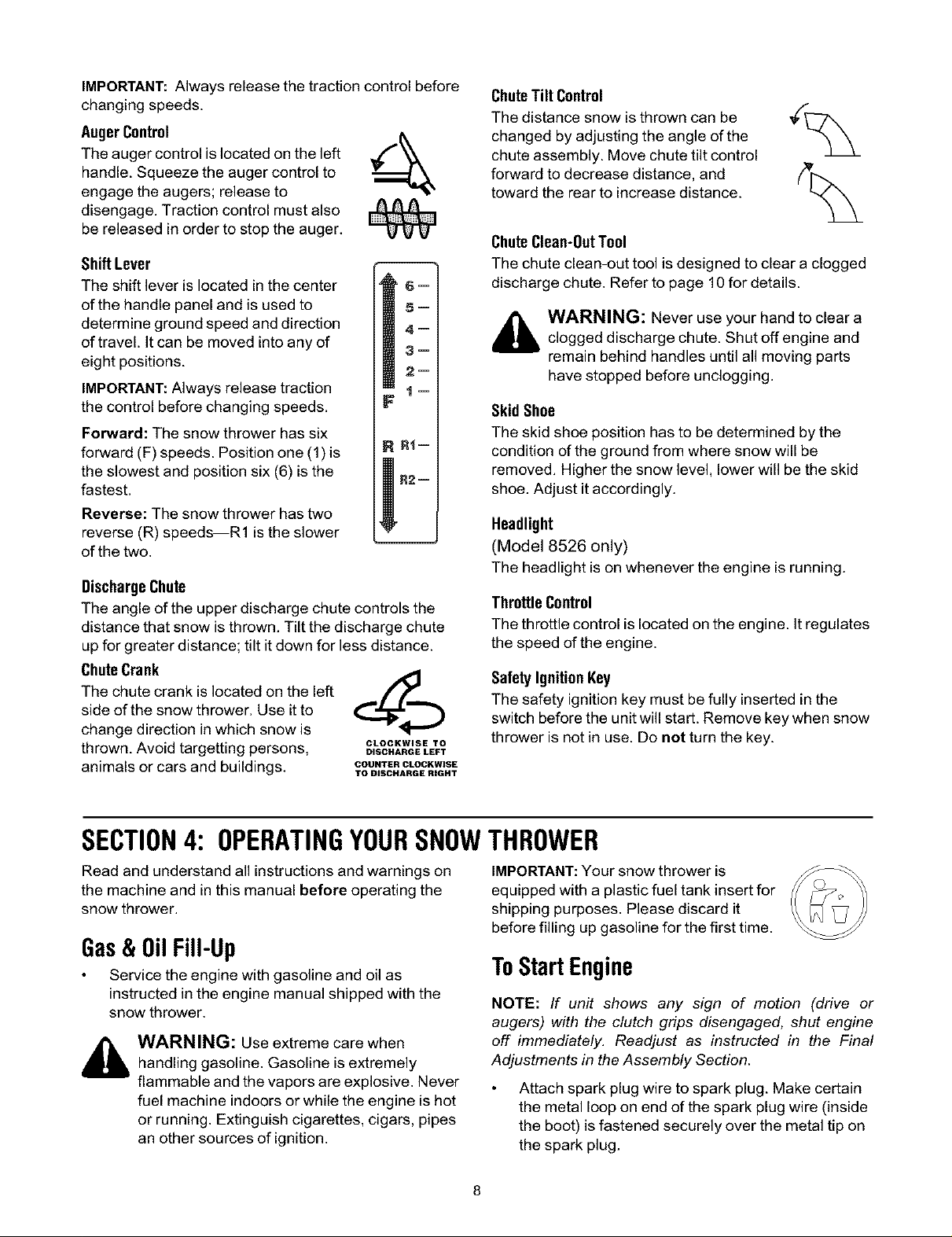

SECTION3: KNOWYOURSNOWTHROWER

Figure 5

_ WARNING: Be familiar with all the controls on the snow thrower and their proper operation. Know how to

Chute Clean-Out Tool

* Model 8526 only

stop the machine and disengage them quickly.

Compare the figure below and description of controls in this section with your equipment before starting unit.

Traction Control /

Auger Control Lock

Headlight*

Fuel Tank

Au/r

_Skid Shoe

Shift Lever

Chute Tilt Control

Auger Control

Chute Directional Control

Fuel Cap

P Iugil Fill 1

Electric

_Starter

Handle

TractionControl/Auger ControlLock

The traction control is located on the right handle.

Squeeze the traction control to engage the wheel drive;

release to stop.

This same lever also locks the auger control so you can

operate the chute crank without interrupting snow

Figure 6

throwing process. If the auger control is engaged

simultaneously with the traction control, you can

release the auger control (on the left handle) and the

augers will remain engaged. Release the traction

control to stop the augers and wheel drive (the auger

control must also be released).

IMPORTANT:Alwaysreleasethetractioncontrolbefore

changingspeeds.

AugerControl

The auger control is located on the left

handle. Squeeze the auger control to

engage the augers; release to

disengage. Traction control must also

be released in order to stop the auger.

Shift Lever

The shift lever is located in the center

of the handle panel and is used to

determine ground speed and direction

of travel. It can be moved into any of

eight positions.

IMPORTANT:Always release traction

the control before changing speeds.

Forward: The snow thrower has six

forward (F) speeds. Position one (1)is

the slowest and position six (6) is the

fastest.

Reverse: The snow thrower has two

reverse (R) speeds--R1 is the slower

of the two.

DischargeChute

The angle of the upper discharge chute controls the

distance that snow is thrown. Tilt the discharge chute

up for greater distance; tilt it down for less distance.

ChuteCrank

The chute crank islocated on the left

side of the snow thrower. Use itto

change direction in which snow is

thrown. Avoid targetting persons,

animals or cars and buildings.

COUNTERCLOCKWISE

TO DISCHARGERIGHT

6m

5=

4=

3=

2=

1=

Rt--

R2--

CLOCKWISE TO

DISCHARGELEFT

ChuteTilt Control

The distance snow is thrown can be

changed by adjusting the angle of the

chute assembly. Move chute tilt control

forward to decrease distance, and

toward the rear to increase distance.

ChuteClean-0utT001

The chute clean-out tool is designed to clear a clogged

discharge chute. Refer to page 10 for details.

_ WARNING: Never use your hand to clear a

clogged discharge chute. Shut off engine and

remain behind handles until all moving parts

have stopped before unclogging.

SkidShoe

The skid shoe position has to be determined by the

condition of the ground from where snow will be

removed. Higher the snow level, lower will be the skid

shoe. Adjust it accordingly.

Headlight

(Model 8526 only)

The headlight ison whenever the engine is running.

ThrottleControl

The throttle control is located on the engine, it regulates

the speed of the engine.

SafetyIgnition Key

The safety ignitionkey must be fully inserted in the

switch before the unit will start. Remove key when snow

thrower is not in use. Do not turn the key.

SECTION4: OPERATINGYOURSNOWTHROWER

Read and understand all instructionsand warnings on

the machine and in this manual before operating the

snow thrower.

Gas& OilFill-Up

Service the engine with gasoline and oil as

instructed in the engine manual shipped with the

snow thrower.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Never

fuel machine indoors or while the engine is hot

or running. Extinguish cigarettes, cigars, pipes

an other sources of ignition.

IMPORTANT:Your snow thrower is

equipped with a plastic fuel tank insert for

shipping purposes. Please discard it

before filling up gasoline for the first time.

ToStartEngine

NOTE: If unff shows any sign of motion (drive or

augers) with the clutch grips disengaged, shut engine

off immediately. Readjust as instructed in the Final

Adjustments in the Assembly Section.

Attach spark plug wire to spark plug. Make certain

the metal loop on end of the spark plug wire (inside

the boot) is fastened securely over the metal tip on

the spark plug.

Loading...

Loading...