Page 1

o

$7 50

If-BIL

Owner/Operator

Manual

TRAIL BLAZER

Sickle Bar Mower

« Safety

Models

• Assembly

« Controls

• Operation

• Maintenance

3V2 HP

4 HP

Page 2

ADANGER

Awarning

The mower’s cutter bar can cause serious

personal injury. Read this Owner/Operator Manual thoroughly for precautions you must follow

when operating the mower. Always follow these

precautions.

PLEASE NOTE

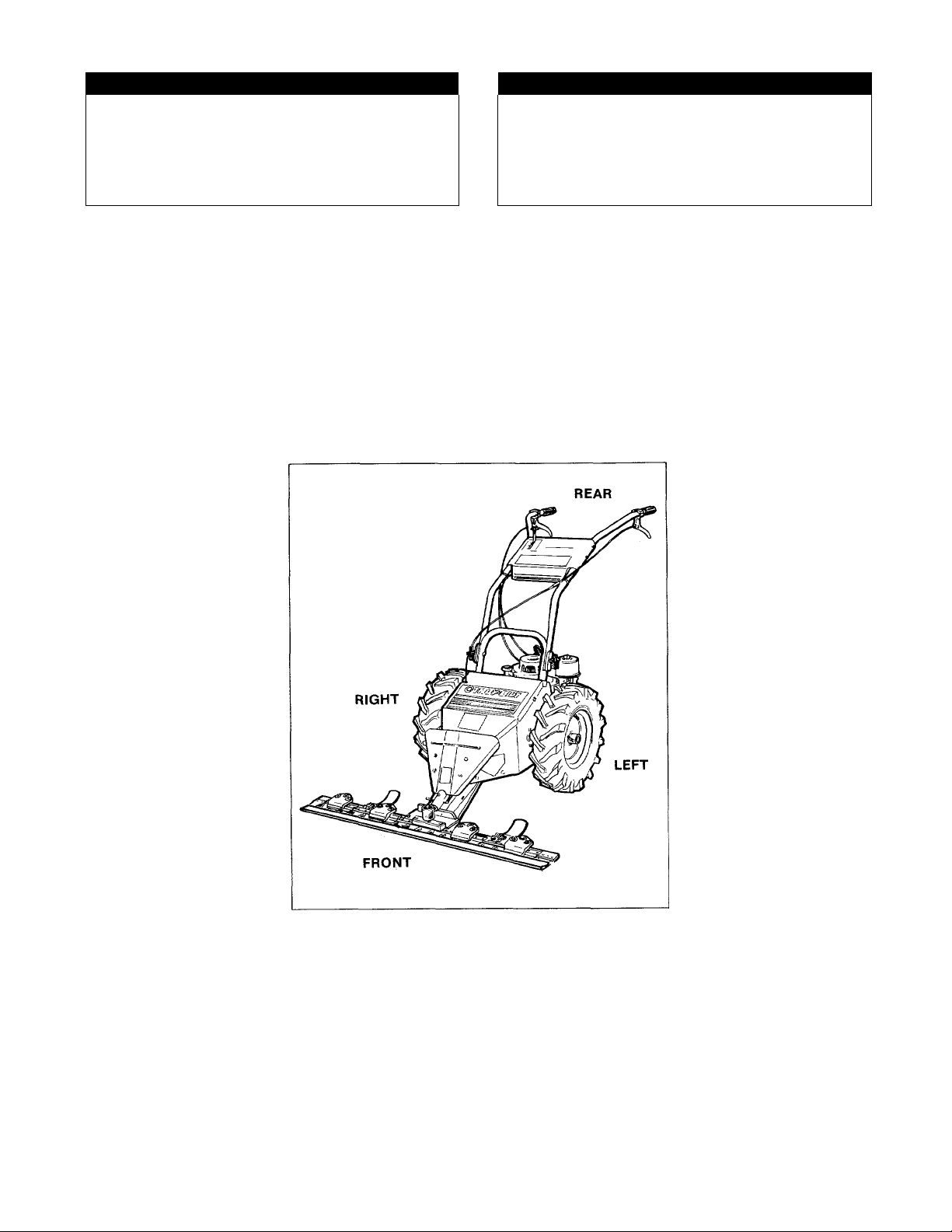

All directions in this Manual are determined from the

operator’s position, standing behind the handlebars

and facing forward. Please refer to the figure below.

Avoid fires due to sparks.

Do not operate engine if spark arrester screen is

loose or damaged.

IMPORTANT!

If you notice any freight damage either at the time of

delivery or later during assembly, make sure that you

notify the truck terminal that delivered your mower that

you intend to file a claim. If you have any problems

with this procedure, please call us so that we can help

you get satisfaction. Our phone numbers are listed on

Page 3 and on the back cover of this manual.

Page 3

TABLE OF CONTENTS

Page

Section 1: Safety.................................................................... 4

Training ............................................................................. 4

Preparation ....................................................................... 4

Operation .......................................................................... 4

Disconnecting the Spark Plug Wire ................................ 5

Maintenance and Storage

Decals ............................................................................... 5

.........................................

Section 2: Easy Assembly

Section 3: Engine and Mower Controls

Blade Drive Lever

Wheel Drive Lever

Cutting Height Adjusters

Handlebar Height Adjustment ........................................13

Engine Throttle Lever .....................................................14

Engine Choke ..................................................................14

Recoil Starter

Engine Ignition Switch

(Electric Start Models)

...........................................................

..........................................................

................................................

...................................................................

.......................................

.........................

... 14

12

12

12

13

14

Section 4: Mower Operation ........................................15

Filling the Engine’s Gas Tank.........................................15

Starting the Mower ..........................................................16

Mowing

Stopping

General Mowing Tips.......................................................17

............................................................................

..........................................................................

16

17

Page

Sections; Maintenance............................................18

Engine Maintenance ...........................................18

Checking the Engine Oil Level and

Adding Oil to the Engine ..............................18

Changing the Engine Oil

5

Air Filter Maintenance

.................................

.....................................

19

19

Spark Arrester .................................................20

Air Cooling System Maintenance

.....................

21

Carburetor Adjustment (Engine

Speed & Mixture) ..........................................21

Engine Ignition System

..................................

21

Spark Plug.......................................................21

Liquid Lock

Mower Maintenance

Lubrication

Removing and Reinstalling the Wheels

.....................................................

...........................................

.......................................................

...........

21

22

22

23

Wheel Drive Belt Removal and

Installation

Wheel Drive Adjustment (General)

...................................................

..................

23

27

Wheel Drive Check.......................................27

Wheel Drive Initial Setting

Wheel Drive Main Adjustment

...........................

.....................

28

28

Cutter Bar Drive Belt Removal and

Installation

Cutter Bar Drive Adjustment (General)

Cutter Bar Drive Check

Cutter Bar Drive Initial Setting

...................................................

...........

...............................

.....................

29

32

32

32

Cutter Bar Drive Main Adjustment ...............33

Cutter Bar Maintenance

...................................

34

Removal and Installation of the

Cutter Bar Assembly.................................34

Blade Guide Maintenance ...........................35

Blade Guide Adjustment...........................36

Removing and Installing the Cutter

Blade Assembly .......................................36

Tightening a Loose Individual Blade

Replacing Individual Blades

.........................

Electric Starting System Maintenance

Battery Charging

.........................................

...........

............

37

38

40

40

Seasonal Charging ......................................40

Battery Removal & Installation

...................

41

Storage....................................................................42

Maintenance Schedule

...........................................

42

Troubleshooting Chart ............................................43

Alphabetical Index

Specifications

.............................

...................................

inside rear cover

inside rear cover

Page 4

Dear Owner:

Congratulations on the purchase of your TROY-BILT TRAIL BLAZER® Sickle Bar Mower. You will find this mower

to be a unique and useful piece of equipment that can be used for many projects on your property. You can

use this mower for numerous tasks, such as taming those unsightly areas on your property that you never had

the time to mow, cleaning up any badly overgrown spots that are threatening to surround your out-buildings,

making an occasional pass over the edges of your property to keep your property lines clear, or making a single

path through head-high weeds and saplings to make a nature trail or a cross country trail that can be enjoyed all

year long.

Because of the TROY-BILT TRAIL BLAZER® Mower’s ease of operation and well-balanced build, you can do all

of the above-mentioned projects easily with little more effort than simply walking behind the mower. The mower’s

cutter bar has induction hardened teeth that slice through weeds and small saplings in a single pass, leaving a

wide swath behind.

To help you get the most value from your mower, we’ve prepared this Owner/Operator Manual for your use.

This Manual will tell you how to easily assemble your mower and operate its controls. It also provides you with

easy-to-follow procedures for performing required maintenance.

And, of course, we are never more than a phone call away. If you should ever have any questions about your

mower, or need to order any parts, please call us. Our phone numbers are listed on Page 3 and on the back cover

of this Manual. One of our helpful, friendly Technical Service people will be glad to assist you.

Sincerely,

Dean Leith, Jr.

Sales Manager

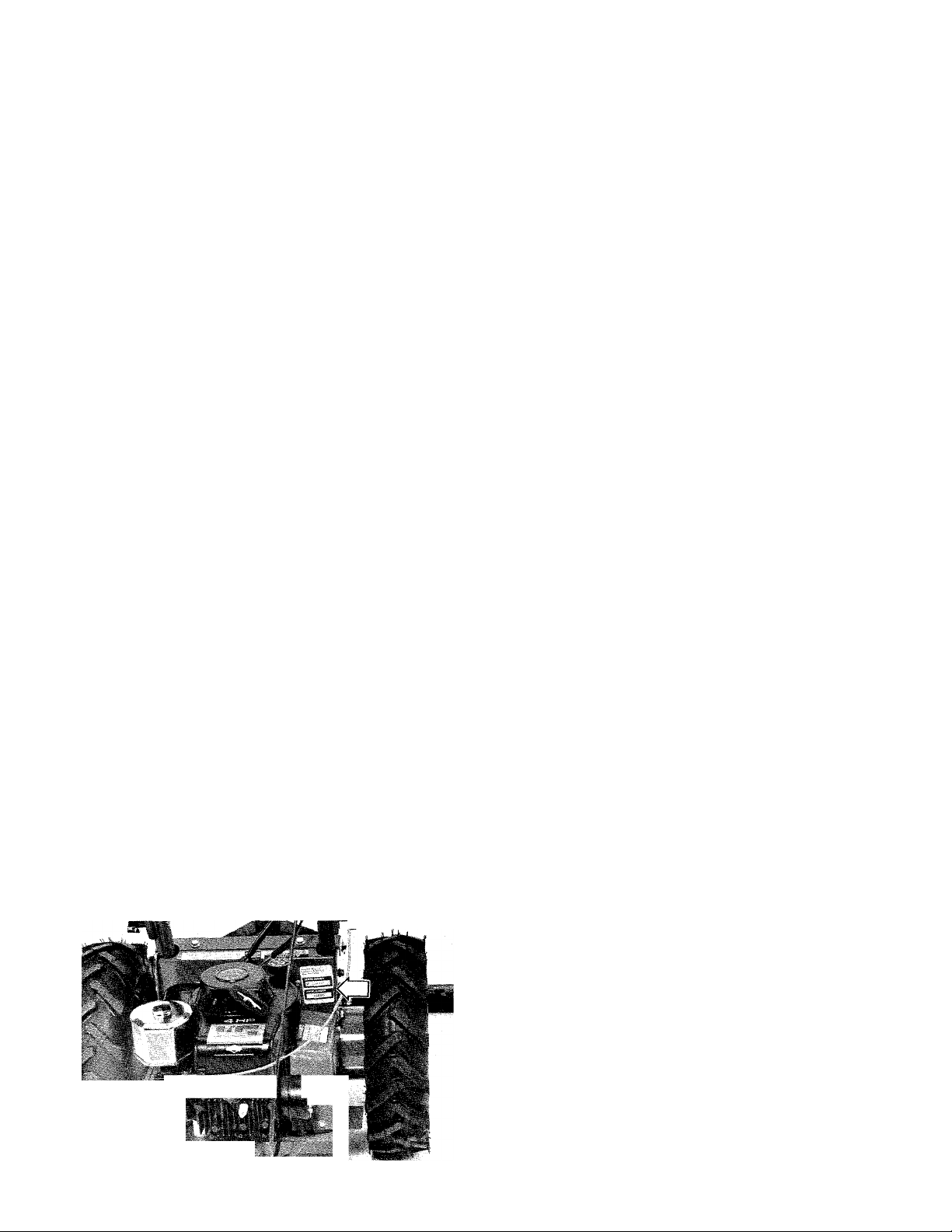

RECORD YOUR MOWER’S SERIAL AND

MODEL NUMBERS

The arrow in the photo shows the location of the

serial number and model number decals on your

TRAIL BLAZER® Mower. Please record these numbers

in the spaces below. If you should ever need any

replacement parts, or if you have any questions for

us, we will need to know these numbers. Also please

be sure to tell us if you have an electric start or a

standard start model.

MY TRAIL BLAZER® MOWER IS (CHECK ONE);

□ AN ELECTRIC START MODEL.

□ A STANDARD START MODEL.

ITS SERIAL NUMBER IS

ITS MODEL NUMBER IS

ITS DATE OF DELIVERY WAS.

_____________________________

_____________________________

RECORD YOUR MOWER ENGINE’S

IDENTIFICATION NUMBERS

Please refer to the Briggs & Stratton Operating and

Maintenance Instructions Manual that was included in

the literature package. This manual will show you the

location of the engine’s identification numbers. If you

ever need any engine parts, you will need to provide

its identification numbers.

To obtain engine parts or service, please look in

the yellow pages of your telephone book under

“ENGINES-GASOLINE” or “GASOLINE ENGINES”.

Then look for the name of the nearest Authorized

Briggs & Stratton Service Center. If you have trouble

finding a service shop, please feel free to call us and

we will provide you with the name, telephone number,

and address of the service center nearest you.

Please record the important engine information in

the blank spaces below. This will give you a handy

reference for later use.

ENGINE HORSEPOWER RATING

ENGINE MODELATYPE/

CODE NUMBER

________

_____________________

Page 5

FOR SERVICE OR PARTS:

If you should ever need service assistance or

replacement parts for your mower, call us at the

numbers listed below:

TROY-BILT MANUFACTURING CO.

102nd St. & 9th Ave., Troy, New York 12180

For Technical Service, call Toll-Free: 1-800-833-6990

For Parts Sales, call Toll-Free: 1-800-648-6776

M-F 8 a.m. to 7 p.m.

Sat. 9 a.m. to 4:00 p.m.

GARDEN WAY BRANCH CANADA

1515 Matheson Blvd. E, Unit B11

Mississauga, Ontario L4W 2P5

Call Toll-Free: 1-800-225-3585

M-F 8 .m. to 4:30 p.m.

If you are ordering parts for your mower, please

give us the following information:

1. The serial number of your mower.

2. Whether you have an electric start model or a

standard start model.

3. The PART NUMBER of the part you need (from

the TRAIL BLAZER® Mower Parts Catalog).

4. The PART DESCRIPTION of the part you need

(from the TRAIL BLAZER® Mower Parts Catalog).

5. The QUANTITY of that particular part that you

need.

(Please remember that you can get many of the

common hardware items from a nearby well-stocked

hardware store as well as from us.)

AWARNING TO ALL CALIFORNIA MOWER OPERATORS

Under California Law, you are not permitted to operate an internal combustion engine using hydrocarbon

fuels on any forest-covered, brush-covered, or grass-covered land, or land covered with grain, hay, or other

flammable agricultural crop, without an engine spark arrester in continuous effective working order. The

engine on your mower, like most lawn or garden equipment, is an internal combustion engine that burns

gasoline (a hydrocarbon fuel); therefore it must be equipped with a spark arrester muffler in proper working

order. The spark arrester must be attached to the engine exhaust system in such a manner that flames or heat

from the system will not ignite flammable material. Failure of the operator to comply with this regulation is a

misdemeanor under California Law. Other states may have similar laws. Federal laws apply on Federal lands.

The TRAIL BLAZER® Mower is equipped with a

screen-type spark arrester on its muffler.

Please refer to Page 20 in this Manual and to the

Briggs & Stratton Operating and Maintenance Instruc

tions Manual for specific inspection and maintenance

procedures for the spark arrester.

Page 6

SECTION 1: SAFETY

IMPORTANT—Safe Operation Practices for Sickle Bar Mowers

When operating or servicing the mower always

follow the safe operating practices described in this

Section. If you should ever lend this mower to another

person, make sure that he or she understands the

safe operation of the mower.

TRAINING

1. Read this Owner/Operator Manual, the separate

engine owner’s manual, and any other literature you

may have received before you use the mower. Be

thoroughly familiar with the controls and proper use

of the mower. Know how to stop the mower and

disengage its controls quickly in case of an emergency.

2. Never allow children to operate the mower. Do not

allow adults to operate the mower without proper

instruction. Do not allow irresponsible adults to oper

ate the mower.

3. Keep the area of operation clear of all persons,

particularly small children, and pets.

PREPARATION

1. Thoroughly inspect the area where the mower is to

be used. Remove all metal debris, limbs, and other

hazards. Also inspect this area for holes, ruts, or

bumps. Uneven terrain could overturn the mower. Be

aware that tall vegetation can hide many hazards.

2. Do not operate the mower when barefoot or when

wearing open sandals. Always wear substantial foot

wear which will protect your feet and help improve

traction.

3. Do not wear loose fitting clothing or jewelry that

could get caught in moving parts. Also be aware that

vines, branches, etc. can snag loose fitting clothing or

jewelry.

4. Remove any rings or other metal jewelry when

working on or near the electric starting system.

5. Before starting the engine, make sure that the

plastic blade protector is removed from the blade and

that both handlebar levers are disengaged (released).

Also check the muffler’s spark arrester screen for

security and damage.

6. Mow only in daylight.

7. Never operate the mower in wet grass. Always be

sure of your footing; keep a firm hold on the handle

bar grips, and walk, never run.

8. Never operate the mower without the weed deflec

tor and all guards in place (except for the plastic

blade protector, which should be removed before

starting the engine).

9. Never attempt to disconnect or remove guards or

other safety devices, or to defeat the purpose of

these safefy devices.

10. Gasoline is highly flammable and its vapors are

explosive. Handle it with extreme care. Use an

4 approved fuel container.

If you should ever have any questions about oper

ating or servicing your TRAIL BLAZER® Mower, please

call us immediately. One of our trained technical

service representatives will be happy to assist you.

Our phone numbers are listed on Page 3 and on the

back cover of this Manual.

11. Check the gas level in the gas tank before starting

the engine. Do not fill the gas tank when the mower is

indoors, when the mower’s engine is running, or when

the mower’s engine is hot. Allow the mower’s engine

to cool for several minutes before filling the gas tank.

Reinstall the gas tank cap securely and clean up any

spilled gasoline before starting the engine.

12. Keep smoking materials, sparks, and flame away

from the gas tank and the fuel container.

13. Move the mower away from gas fumes before

starting the engine.

14. If you are mowing in a dry area, do not smoke.

Do not smoke while mowing.

15. Do not charge the battery (on electric start mod

els) in an airtight space.

16. When charging the (electric start) mower’s bat

tery, do not use a battery charger other than the one

provided with the mower.

17. The electric start mower’s battery contains toxic

materials. Do not damage the battery case. If the case

is broken or damaged, avoid contact with the battery

contents.

18. Dispose of the battery properly. Check with local

authorities for proper disposal methods.

19. Do not operate the mower if the cutter bar assem

bly is not securely installed.

OPERATION

1. Before each use, check the operation of the han

dlebar levers. See Page 16 in this Manual for specific

instructions. Do not use the mower if either handlebar

lever is not functioning properly.

2. Do not put hands or feet near or under any moving

parts. Keep clear of the cutter bar at all times when

the engine is running.

3. Keep the plastic blade protector on the blade until

you are ready to start the engine.

4. Before removing or installing the plastic blade

protector: shut the engine off, disconnect the spark

plug wire and prevent it from touching the spark plug.

On electric start models, also remove the Engine

Ignition key from the keyswitch.

5. Do not change the engine governor settings or

overspeed the engine.

6. Stop the cutter bar blade when crossing gravel

drives, walks, or roads.

7. Watch for traffic when operating near, or when

crossing roadways.

Page 7

SAFETY

8. Stop both the cutter bar blade and the wheel drive

when you are approached by any child, inattentive

person, or pet.

9. Before inspecting, cleaning, adjusting, or repairing

the mower or cutter bar: stop the engine, disconnect

the spark plug wire and prevent it from touching the

spark plug, wait for all moving parts to stop, and

reinstall the plastic blade protector on the blade. On

electric start models, also remove the Engine Ignition

key from the keyswitch.

10. Never leave the operator’s position while the

mower’s engine is running. Stop the engine, discon

nect the spark plug wire and prevent it from touching

the spark plug to help prevent accidental starting. Also,

remove the Engine Ignition key from the keyswitch on

electric start models to help prevent accidental starting

or unauthorized use.

11. If the mower should start to vibrate abnormally,

stop the engine, disconnect the spark plug wire and

prevent it from touching the spark plug. Also, remove

the Engine ignition key from the keyswitch on electric

start models. Wait for ail moving parts to completely

stop and then inspect the mower for damage. Repair

the damage before restarting the engine and operating

the mower.

12. Do not run the engine in an enclosed area.

Engine exhaust contains carbon monoxide gas,

a deadly poison that is odorless, colorless and

tasteless.

13. Do not mow excessively steep slopes.

14. Keep all movements on a slope slow and gradual.

Do not make sudden changes in speed or direction.

15. Do not touch engine parts which may be hot from

operation. Allow parts to cool before inspecting,

cleaning, or repairing.

16. Whenever you pull the mower rearward, release

both handlebar levers. Always check behind you for

hazards when backing up.

17. If you’re not mowing, disengage the blade drive.

18. Do not operate the mower while under the influ

ence of alcohol or drugs.

19. Do not mow near drop-offs, ditches, or embank

ments. If the mower’s wheel goes over the edge, or if

the edge caves in, the mower could suddenly overturn.

20. Keep children out of the mowing area. Keep them

under the watchful eye of an adult other than the

person operating the mower. Never assume that chil

dren will remain where you last saw them.

21. Before you back the mower up, and while you’re

backing it up, be sure to look behind you for small

children.

22. Never attempt to carry children on the mower.

They could fall off and be seriously injured, or they

could interfere with the safe operation of the mower.

23. Use extra care when approaching blind corners,

shrubs, trees, and any other object that may obscure

vision.

24. When removing the cutter bar blade from the

cutter bar assembly, wear sturdy leather gloves to

help prevent the blades from accidentally pinching or

cutting your fingers or hands.

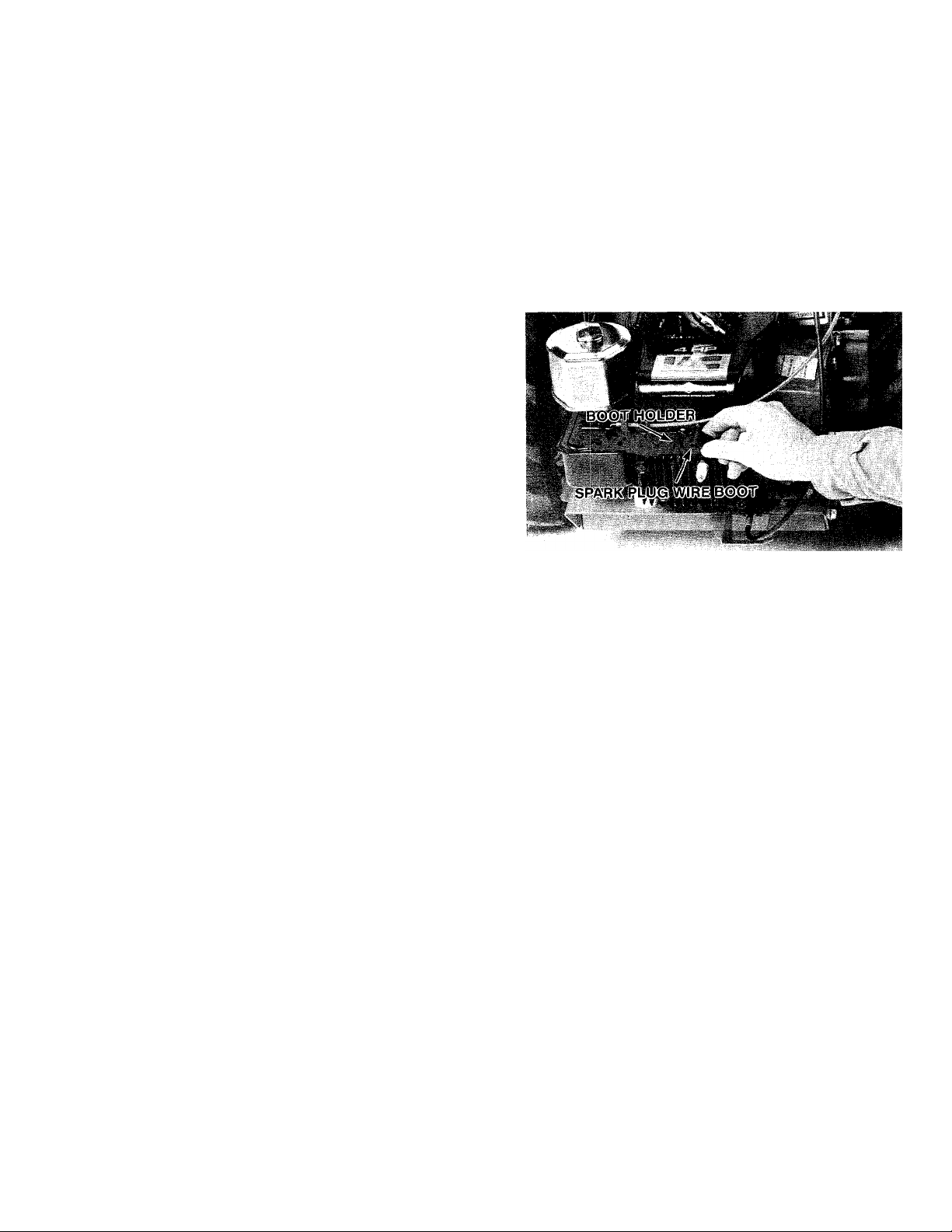

Disconnecting the Spark Plug Wire

Whenever you perform any type of cleaning, inspec

tion, or maintenance on the mower, shut the engine

off and then disconnect the spark plug wire from the

spark plug. Then prevent the wire from touching the

spark plug by placing the spark plug wire’s boot on

the V-shaped holder that is on the rear of the engine.

See the photo below.

Preventing the spark plug wire from touching the

spark plug helps to prevent the engine from being

accidentally started.

Preventing the spark plug wire from touching the spark plug.

MAINTENANCE AND STORAGE

1. Keep all nuts, bolts, and screws tight to be sure

that the equipment is in safe working condition.

2. If the mower has gasoline in its gas tank, do not

store it inside a building where fumes from the gaso

line could reach an open flame or spark.

3. Allow the engine to cool before storing the mower

in any enclosure.

4. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

5. Store gasoline in a cool, well-ventilated area, safely

away from any spark- or flame-producing equipment.

Store gasoline in an approved container, safely out of

the reach of children.

6. Before inspecting, cleaning, adjusting, or repairing

the mower: Stop the engine, disconnect the spark

plug wire and prevent it from touching the spark plug,

wait for all moving parts to stop, and reinstall the

plastic blade protector on the blade. On electric start

models, also remove the Engine Ignition key from the

keyswitch.

7. Do not allow children to be around you when you

are working on the mower.

DECALS

We’ve placed operating and safety decals on the

mower to help you when operating the mower or to

warn you of any hazards. If any of these decals is

missing, iilegible, or damaged, please contact us

immediately for replacements. Please refer to your

TRAIL BLAZER® Parts Catalog for decal location and

replacement information.

Page 8

SECTION 2: EASY ASSEMBLY

Please follow the assembly steps given in this Sec

tion to properly assemble your mower. These steps

will not take very long and they will assure you of

having assembled your mower correctly.

To assemble the mower, you’ll need the following

items:

1. One pair of scissors.

2. One flat-tipped screwdriver.

3. One quart of high quality engine oil. (See “Specifi

cations” on the inside rear cover of this Manual for

recommended types of oil.)

4. One 3/8-inch wrench.

5. A piece of wood (to tap the handle onto the

Throttle Lever).

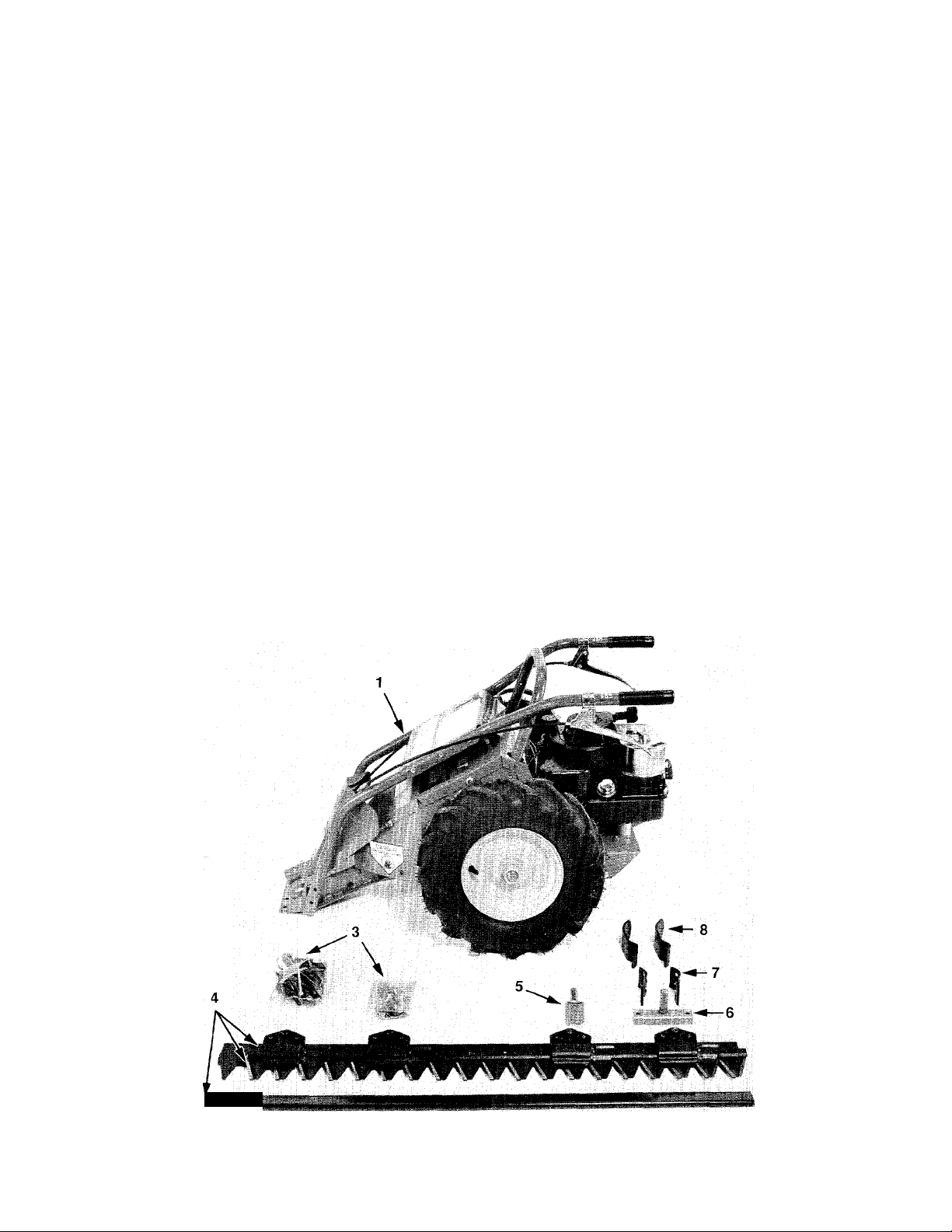

Step 1: Check your Parts

We’ve carefully packed your mower here at the

factory. After unpacking it, compare the contents of

the cartons to Photo 2-1 to make sure that you have

the necessary parts to assemble your mower. If any

parts are missing, please call us for replacements.

The following list of components is keyed to the

callouts in Photo 2-1.

1. The upper handlebar assembly.

2. The mower body/engine assembly.

Before you begin assembly, please read this Sec

tion all the way through to familiarize yourself with the

assembly steps. Then gather the necessary tools.

6.

A 13 MM (millimeter) wrench. (You can substitute

a V2-inch wrench).

7.

A clean funnel.

8.

For electric start mowers, you’ll also need a

13/16-inch wrench (you can substitute a large

adjustable wrench).

9.

An assistant to help steady the mower.

10.

Grease, multi-purpose type.

The mower hardware packages.

3.

4.

The cutter bar assembly, which consists of;

a. The ledger bar.

b. The cutter blade.

c. The plastic blade protector.

5.

The drive socket.

6.

The drive pin.

7.

Two forward height adjuster halves.

Two rear height adjuster halves.

8.

m .

Photo 2-1: The contents of the shipping cartons.

Page 9

Open the hardware packages. Compare their con

tents with Photo 2-2 and the following list. If any

pieces are missing, call us for replacements.

1. Two handlebar lock clamps.

2. Two handlebar knobs.

3. Two handlebar star washers.

4. Tie straps (four for electric start models; two for

standard start models).

5. Two curved head handlebar bolts.

6. Two #10 lockwashers.

7. Two 10-32 nuts.

8. Two 10-32 X Va-inch slotted head screws.

9. One keyswitch (with nut and lockwasher).*

10. One pair of keys.*

11. One battery charger.*

12. Two 8 MM X 20 MM hex head screws.

13. Two 5/16-inch lockwashers.

14. Four 5/16-18 X iy4-inch carriage bolts.

15. Four 5/16-18 locknuts.

16. Throttle Lever knob.

17. Height adjuster hardware (not shown):

a. Two U-bolts.

b. Four U-bolt nuts.

c. Four flat washers for U-bolts.

d. Four 8MM X 30MM carriage bolts.

e. Four 8MM flat washers.

f. Four 8MM lock nuts.

* Electric start models only.

EASY ASSEMBLY

6,8

9

10

^ mm

12

13

O

c>

15

Photo 2-2: The contents of the hardware packages.

14

16

Step 2: Attaching the Handlebars

1. Slide the upper handlebars into position over the

lower handlebars and align the holes.

NOTE

Use the upper set of holes (in the lower handle

bars) for the higher handlebar height position.

Use the lower set of holes for the lower handle

bar height position.

2. From the inner side, push one of the curved head

handlebar bolts through these holes.

3. Place a handlebar lock clamp over the end of this

bolt. The curved side of the lock clamp faces in.

4. Place a lockwasher on the bolt.

5. Install a handlebar knob on the bolt.

6. Repeat Steps 2 through 5 for the other side of the

handlebars. Very securely tighten both handlebar

knobs.

NOTE

The lower handlebars are rubber mounted at

their lower end to help reduce vibration to the

operator. This may make them feel somewhat

loose, however this is normal.

Photo 2-3: Attaching the handlebars.

Page 10

EASY ASSEMBLY

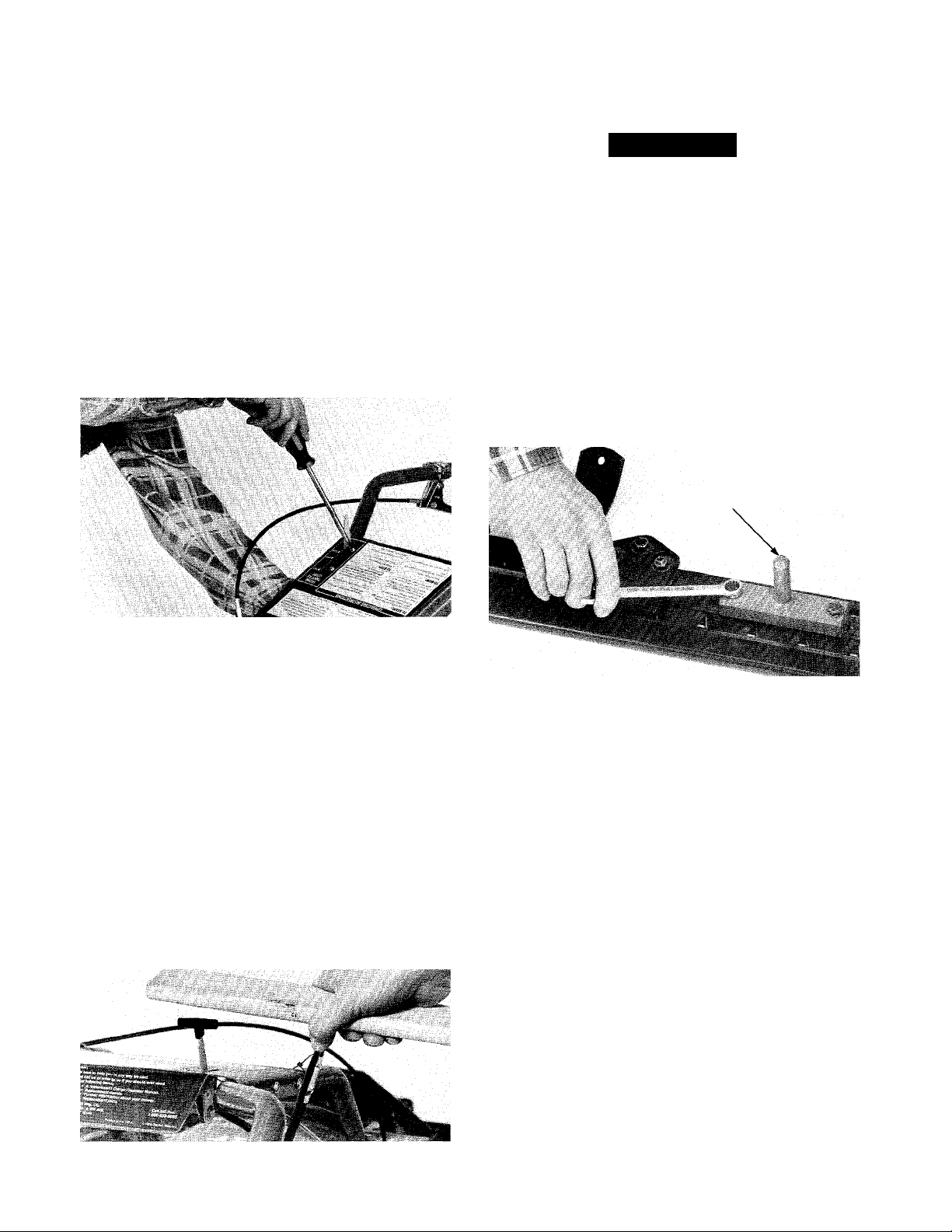

Step 3: Installing the Throttle Lever

1. The throttle cable is already attached to the Throt

tle Lever and the carburetor. Unwrap the throttle cable

and lever from the mower.

2. From underneath the control panel, insert the

Throttle Lever’s handle up, through the small rectan

gular cut-out in the control panel.

3. From above the control panel, insert one of the

#10-32 X Vz-inch screws down through one of the

cut-outs in the control panel decal. Make sure that

this screw goes through the hole in the base of the

Throttle Lever. Loosely install one of the #10 lockwashers and one of the #10-32 nuts on this screw.

4. Install the second screw, lockwasher, and nut in

the remaining hole. Then tighten both nuts with a

%-inch wrench and screwdriver.

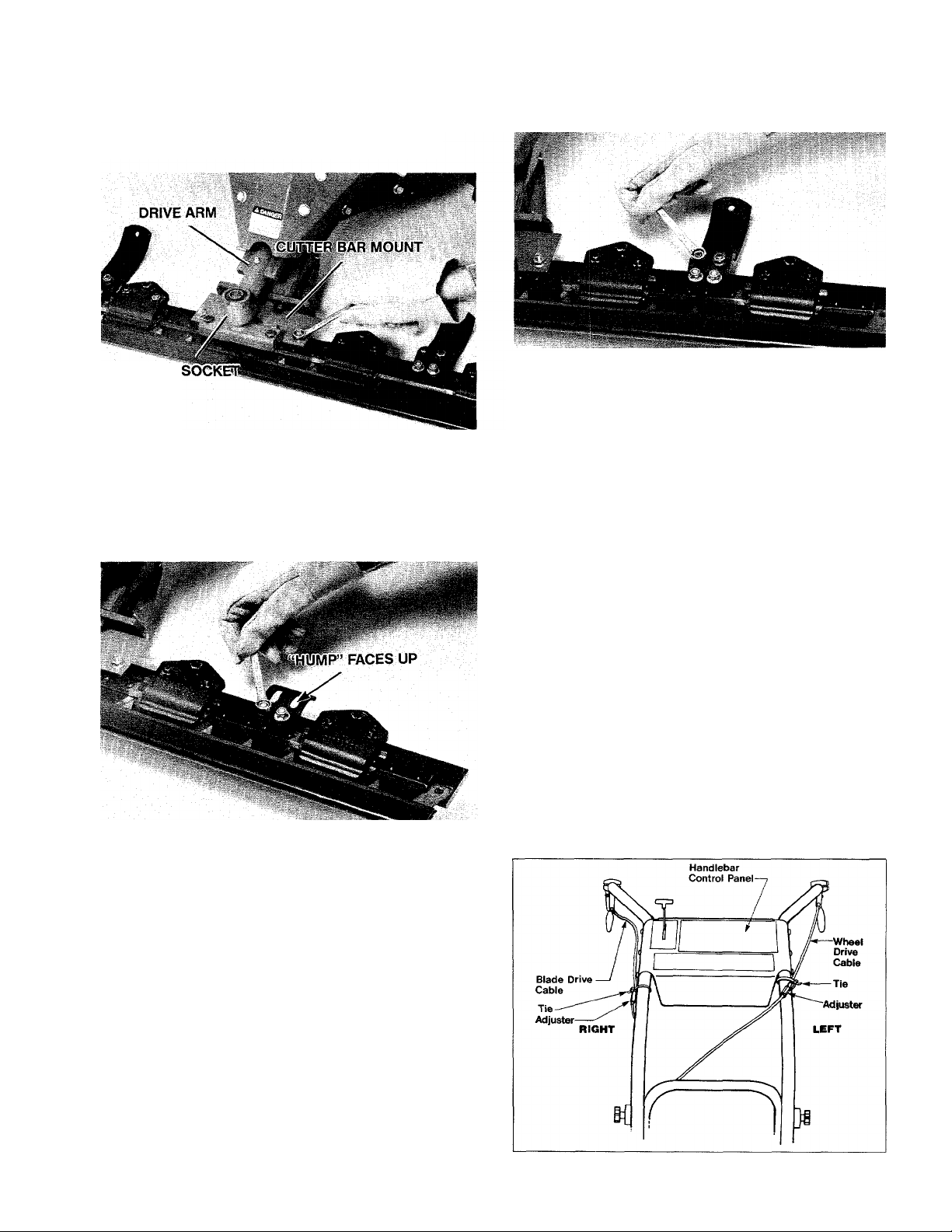

Step 4: Assembling and Installing the Cutter Bar

À CAUTION

The cutter blades are sharp. Keep the plastic

blade protector on the cutter bar when working

on or near the cutter bar.

Failure to do so could result in personal injury

or property damage.

1. If the drive pin is not installed on the cutter blade,

place it on top of the blade. Align the holes in the

base of the drive pin with the holes in the cutter bar.

Secure the drive pin in place with two 8 MM x 25 MM

bolts and two 8 MM lockwashers. Use a 13 MM (or a

Vz-inch) wrench to evenly and securely tighten both

bolts. See Photo 2-6.

APPLY

GREASE

Photo 2-4: Installing the throttle lever.

5. Move the Throttle Lever forward and backward

several times. If the lever binds or does not have full

travel, loosen both nuts that you installed in Steps 3

and 4. From underneath the control panel, push the

base of the Throttle Lever slightly to the right.

Retighten both nuts and again check the Throttle

Lever for free movement. If the Throttle Lever should

still not move, push the carburetor's throttle arm

(where the lower end of the Throttle Lever cable is

secured) to the left. (Occasionally dried paint on the

throttle arm pivot keeps it from moving.)

6. Place the Throttle Lever knob on top of the Throttle

Lever handle. Use a piece of wood to gently tap the

knob onto the Throttle Lever handle.

Photo 2-6: Installing the drive pin.

2. Grasp the drive pin with one hand. Steady the cut

ter bar with your other hand. Try to move the cutter

blade from side to side. Occasionally dried paint will

prevent the blade from moving. If you can’t move the

blade, rap the side of the drive pin with a rubber mal

let to break the cutter blade free of the dried paint.

3. Place the drive socket on the drive pin. Place the

cutter bar assembly in front of the mower's nose

piece.

4. Lubricate the drive pin with multi-purpose grease.

5. Have an assistant push down on the handlebars to

very slightly raise the nose of the mower.

6. Slowly slide the cutter bar assembly rearward.

Make sure that; a) the cutter bar mount rests on top

of the cutter bar and its four holes align with the four

(square) holes in the cutter bar mount, and b) the

shaft on the drive socket enters the hole in the front

of the drive arm.

8 Photo 2-5; Installing the throttle lever knob.

7. From underneath, insert a 5/16-18 x VA-inch car

riage bolt up through one of the holes in the cutter

bar. Loosely install a 5/16-18 nut on this bolt. Repeat

Page 11

this for the remaining three holes. Then tighten ail

four nuts.

EASY ASSEMBLY

DRIVE

Photo 2-7: Installing the cutter bar assembly

8. Place the forward (shorter) half of one of the height

adjusters beneath the rear of the cutter bar. Make sure

that the “hump” on the height adjuster faces up. Align

the two holes in this half of the height adjuster with

the two holes in the rear of the cutter bar. See Photo 2-8.

Photo 2-8: Installing the forward half of the height adjuster.

Photo 2-9: Installing the rear half of the height adjuster.

12. Repeat Steps 8 through 11 for the remaining side

of the cutter bar and height adjuster halves.

13. Flave your assistant lower the nose of the mower.

NOTE

To adjust the height adjusters for blade cutting

height, piease refer to “Cutting Fleight Adjusters”

in Section 3 of this Manual.

Step 5: Attach the Tie Straps (Standard Start

Models Only)

NOTE

If you have an electric start model, the tie straps

wiil be installed in Step 9.

1. On the right-hand handlebar, loop a tie strap

(serrated side faces in) around the handiebar, the

biade drive lever control cable and the throttle cable.

Make sure that the strap is located ABOVE the adjuster

assembly on the control cable. See Figure 2-10.

Tighten the strap and trim off any excess iength.

2. Use a second tie to attach the wheel drive lever

control cable to the left-hand handlebar. Again, make

sure that the strap is located ABOVE the adjuster

assembly on the cable.

9. From underneath, insert two 8MM x 30MM car

riage bolts up through the holes in the height adjuster

and blade. Place an 8MM flat washer and an 8MM

lock nut on each of these carriage bolts. Use a 13MM

(or a Va-inch) wrench to evenly and securely tighten

both of these nuts.

NOTE

Use care to not use the 5/16-18 nuts on the

8MM carriage bolts. Although it is possibie to

make them fit, you will ruin the bolt.

10. Place the rear (longer) half of the height adjuster

(again, with its “hump” facing up) beneath the for

ward half of the height adjuster.

11. From underneath, insert a U-bolt through the two

holes in the height adjuster halves. Place a flat washer

and a locknut on each of the threaded ends of the U-bolt.

Use a Vainch wrench to evenly tighten the nuts.

Figure 2-10: Attaching the tie straps (standard start models

only).

Page 12

EASY ASSEMBLY

Step 6: Add Oil to the Engine

1. Push the mower to a level area.

2. Unscrew the dipstick from the engine. Wipe the

dipstick clean.

3. Insert a clean funnel into the oil fill tube as shown

in Photo 2-11.

4. Pour the oil into the engine. The engine will hold

approximately Vk pints. See Photo 2-11.

NOTE

Please refer to “Specifications” on the inside

rear cover of this Manual to determine the type

of oil to add to the engine.

5. Remove the funnel. Screw the dipstick back into

the oil fill tube. Unscrew the dipstick and check the

oil level. It should be up to the FULL mark on the

dipstick.

If it is not up to this level, re-insert the funnel into

the oil fill tube. Then slowly add more oil until the oil

level is correct. While you’re adding the oil, frequently

pause and check the oil level with the dipstick to

prevent overfilling.

Photo 2-11: Adding oil to the engine.

Step 7: Check Tire Air Pressure

Use an automotive-type tire pressure gauge to

check the air pressure in both tires. The tires may

have been over-inflated for shipping purposes. Make

sure that the air pressure in both tires is the same or

the mower could pull to one side. The correct tire

pressure is from 10 to 20 pounds per square inch (PSI).

If you have a standard start TRAIL BLAZER® Mower, you

have now finished assembling it. Before you begin opera

tion, review Section 1: Safety, and read Sections 3 and 4 to

make sure that you know how to properly and safely operate

your new mower.

If you have an electric start TRAIL BLAZER® Mower, you

will have a few additional assembly steps to complete to

assemble some of the electric starting system parts on the

mower. Please go on to these following steps.

Step 8: Installing the Keyswitch

1. Unscrew the large nut off the keyswitch. Remove

the large toothed lockwasher from the keyswitch.

2. From underneath the mower’s control panel, insert

the threaded end of the keyswitch into the hole in the

rear of the control panel. (The hole for the keyswitch is

marked “ENGINE IGNITION’’.)

3. Place the large toothed lockwasher back onto the

keyswitch. Reinstall the nut on the keyswitch. Use a

13/16-inch wrench (or a large adjustable wrench) to

securely tighten the nut.

NUT LOCKWASHER

10

Photo 2-12: Installing the keyswitch.

Page 13

EASY ASSEMBLY

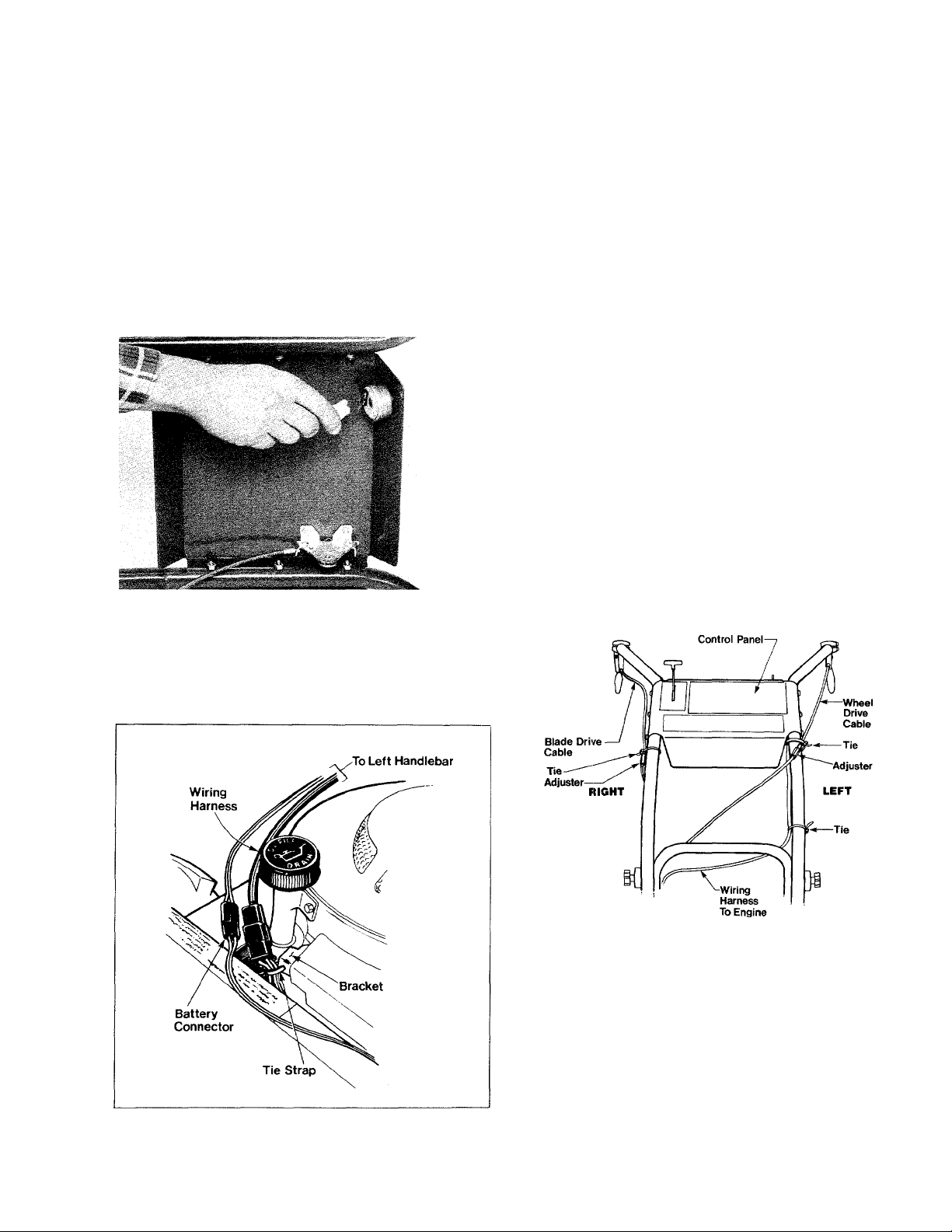

Step 9: Connecting the Wiring Harness

1. Unwrap the wiring harness from the mower.

2. Route the wiring harness beneath the left-hand

handlebar tube. Plug the connector at the top of the

wiring harness into the back of the keyswitch. (You can

attach the connector to the two keyswitch terminals

either way.)

3. For now, leave the plug on the lower end of the

wiring harness disconnected. You’ll connect it later,

after you’ve charged the battery.

5. Move the lower part of the wiring harness to the

right and secure it to the engine’s bracket with the tie

strap as shown in Figure 2-14. Make sure that the

large connector on the wiring harness is ABOVE the tie

strap. Be certain that the battery connector wires are

NOT secured to the engine’s bracket with the tie strap.

6. Secure the upper part of the wiring harness to the

left-hand handlebar tube (above the lock clamp) with

a wide tie strap as shown in Figure 2-15. Make sure

that the serrated side of the strap faces in when you

loop it around the handlebar. After tightening the strap,

snip off any excess length.

7. Use another wide tie strap to secure the Wheel

Drive Cable and the wiring harness to the left-hand

handlebar tube below the handlebar’s control panel

as shown in Figure 2-15. Make sure that the tie strap

is located ABOVE the cable adjuster.

8. Use another wide tie strap to secure the Blade

Drive Cable and the throttle cable to the right-hand

handlebar tube as shown in Figure 2-15. Make sure

that the tie strap is located ABOVE the cable adjuster.

Photo 2-13: Attaching the Wiring Harness to the Keyswitch.

4. Insert the narrow plastic tie strap into the hole in

the bracket that is located on the front part of the

engine housing (to the left of the oil fill tube).

See Figure 2-14.

Figure 2-14: Secure the lower end of the wiring harness to

the engine bracket (electric start models).

Handlebar

Figure 2-15: Attaching the tie straps (electric start models).

Step 10: Charge the Battery

Charge the mower’s battery by following the battery

charging instructions given on Page 40 of this Manual.

After you’ve charged the battery, you’ve finished

assembling the mower. Before operating the mower,

be sure to review Section 1: Safety, and read Sec

tions 3 and 4 to make sure that you know how to

properly and safely operate your new mower.

11

Page 14

SECTION 3: ENGINE AND MOWER CONTROLS

This Section shows the location and describes the

function of the various mower and engine controls

you will need to use when operating the mower.

After reading this Section and familiarizing yourself

with the various controls, please refer to “Section 4:

Operation” for step-by-step engine starting and

mower operation instructions.

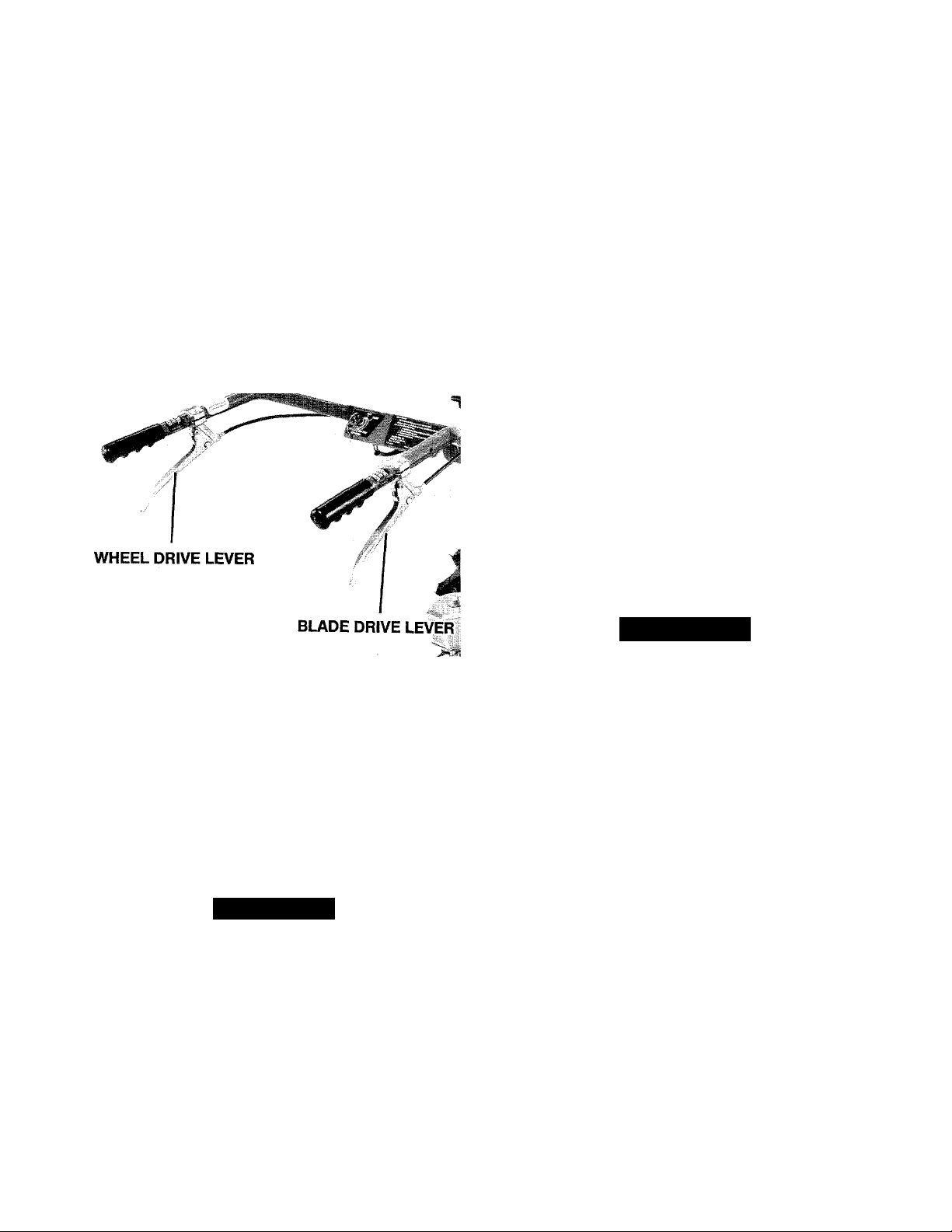

Wheel Drive Lever

This lever is located beneath the left-hand handle

bar grip. To make the mower’s wheels turn (when the

engine is running) you simply rest your left hand on

the left-hand handlebar grip and squeeze the lever

upward. The wheels will begin turning and will

continue to turn as long as you are squeezing the

Wheel Drive Lever.

To stop the wheels from turning, simply release the

Wheel Drive Lever.

Photo 3-1: The handlebar control levers.

Blade Drive Lever

This lever is located beneath the right-hand handle

bar grip. To operate the cutter bar (when the engine is

running) you simply rest your right hand on the

right-hand handlebar grip and squeeze the lever

upward. The cutter bar will begin oscillating (moving

back and forth) and will continue to do so as long as

you are squeezing the Blade Drive Lever.

To stop the cutter bar from oscillating, simply

release the Blade Drive Lever.

ADANGER

If the cutter bar does not stop oscillating when

you release the Blade Drive Lever, or if it oscillates

before you squeeze this lever, shut the mower’s

engine off, wait until it cools, disconnect the spark

plug wire and prevent it from touching the spark

plug. Do not use the mower until the cutter bar

drive mechanism is repaired so that the cutter

bar stops oscillating when the Blade Drive Lever

is released. See “Cutter Bar Drive Adjustment

(General)” in Section 5 of this Manual.

^WARNING

If the wheels do not stop turning when you release

the Wheel Drive Lever, shut the mower’s engine

off, wait until the engine cools, disconnect the

spark plug wire and prevent it from touching the

spark plug. Do not use the mower until the wheel

drive mechanism is repaired so that the wheeis

stop turning when the Wheel Drive Lever is re

leased. See “Wheel Drive Adjustment (General)”

in Section 5 of this Manual.

Failure to do so could result in personal injury or

property damage.

12

Failure to follow this instruction could result in

personal injury or property damage.

Page 15

MOWER CONTROLS

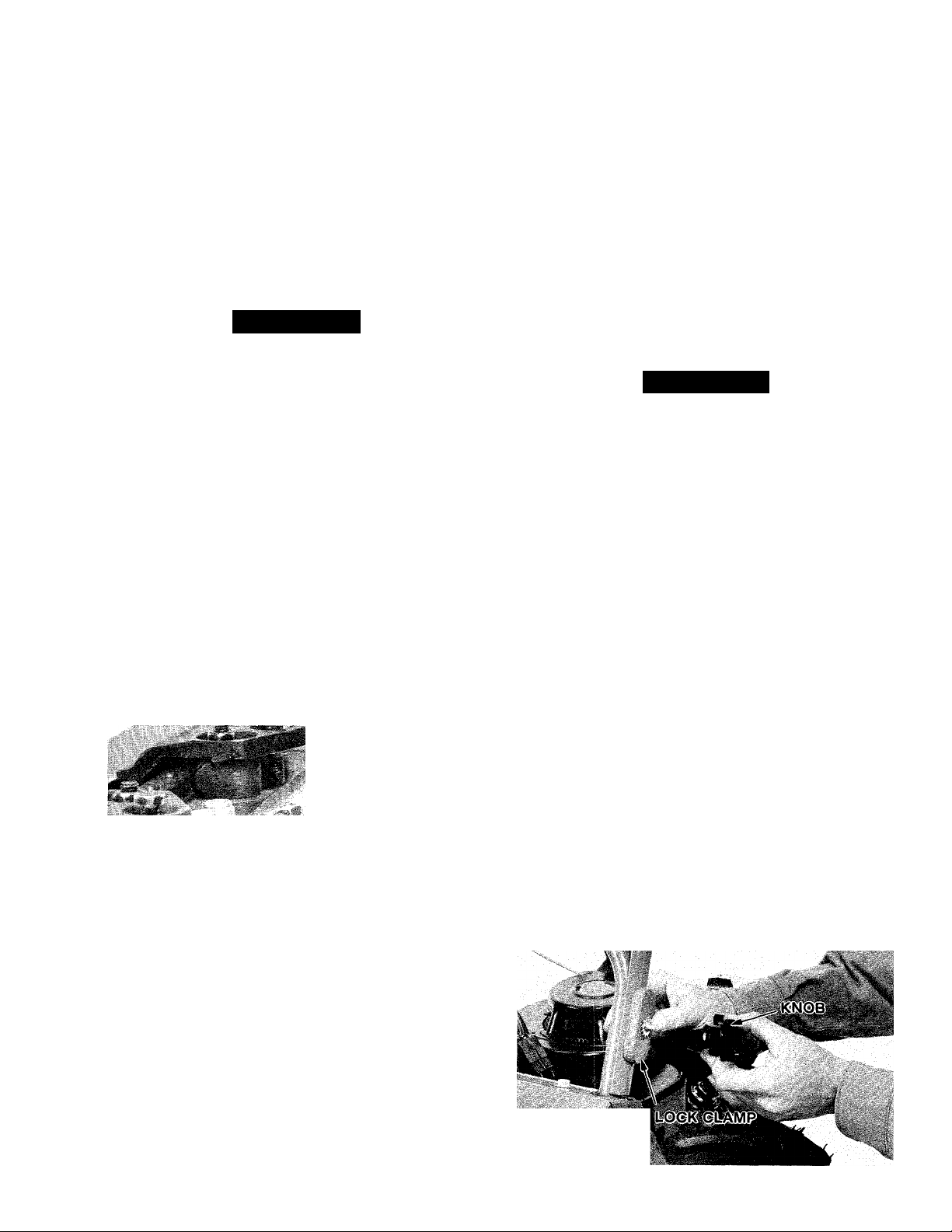

Cutting Height Adjusters

There are two cutting height adjusters, one on each

side of the rear end of the cutter bar. These adjusters

are used to raise or lower the blade’s cutting height.

You can adjust the blade’s cutting height from approx

imately 11/4-inch to 5-inches.

To prevent excessive wear on the blade, set both

height adjusters so that the blade is raised off the

ground and will not dig into the ground.

To change the cutter bar’s cutting height;

A CAUTION

Before changing the cutter bar’s cutting height,

shut the engine off, disconnect the spark plug

wire and prevent it from touching the spark plug,

and reinstall the plastic blade protector on the

front of the cutter bar. On electric start models,

also remove the Engine Ignition key from the

key switch.

Failure to do so could result in personal injury or

property damage.

1. Move the mower to a flat area such as a paved

driveway or a garage floor.

2. Use a 13 MM wrench (or a '/2-inch or an adjustable

wrench) to loosen the two nuts that hold the halves of

the height adjusters together.

3. Move the rear half of the height adjuster rearward

to raise the cutting height. Move the rear half of the

height adjuster forward to lower the cutting height.

Handlebar Height Adjustment

You can adjust the handlebars on your mower to

either of two positions. The lower handlebar height is

approximately 36 inches high and the higher handle

bar height is approximately 38 inches high.

NOTE

The lower handlebars are rubber mounted at

their lower end (to help reduce vibration to the

operator). This may make them feel somewhat

loose, however this is normal.

To adjust the handlebar height:

Acaution

Before adjusting the handlebar height, shut the

engine off, allow it to cool, disconnect the spark

plug wire and prevent it from touching the spark

plug. For electric start models, also remove the

Engine Ignition key from the keyswitch.

Failure to do so could result in personal injury or

property damage.

1. Unscrew the handlebar knobs from both sides of

the lower handlebars. Then remove the lockwashers

and handlebar lock clamps.

2. Remove one of the handlebar bolts by pushing it

inward.

3. Use one hand to hold the upper handlebars while

you push the remaining handlebar bolt inward all the

way.

LOWER CUTTING X

HEIGHT HIGHER CUTTING

HEIGHT

Photo 3-2: Adjusting the blade height

4. Hold the rear half of the height adjuster in place

while you tighten the two nuts that you loosened in

Step 2.

5. Repeat Steps 1 through 4 for the height adjuster

on the other side of the cutter bar. Visually check the

blade to make sure it is parallel to the driveway or

garage fioor. Otherwise the cutting height will be

uneven and you’ll get a sloping cut when you mow.

4. Slide the upper handlebars up or down to align

the holes in their ends with the holes in the lower

handlebar.

5. Reinstall the two handlebar bolts, two handlebar

lock clamps, and the two lockwashers.

6. Place the two handlebar knobs on the handlebar

bolts and very securely tighten them.

&

Photo 3-3: Adjusting the handlebar height

13

Page 16

ENGINE CONTROLS

Engine Throttle Lever

The Engine Throttle Lever is attached to the righthand side of the handlebar control panel. This lever

controls the speed of the engine (which in turn con

trols the speed of both the cutter bar and the wheels

when you have those handlebar levers engaged).

Moving the Engine Throttle Lever forward increases

the engine speed. Moving the Engine Throttle Lever

rearward decreases the engine speed. Moving it all

the way to the rear (to its STOP position) will shut the

engine off.

Recoil Starter

The recoil starter rope is located on top of the

engine. It is used to “pull-start” the engine. To use the

recoil starter rope, stand in back of the mower and

place your left hand on the left handlebar (to stabilize

the mower while you pull the recoil starter rope).

Grasp the black plastic starter rope handle with your

right hand, and slowly pull the rope until you feel

some resistance. Then rapidly pull the rope to start

the engine.

If you have an electric start mower, you can also

use the recoil starter rope to start the engine if the

electric starting system should malfunction. You can

start the electric start mower with the recoil starter

rope regardless of whether or not the Engine Ignition

key is in the keyswitch. [Please refer to “Engine Igni

tion Switch (Electric Start Models)” in this Section for

additional information.]

Photo 3-4: The Engine Throttle Lever.

Engine Choke

The engine on your mower does not have a sepa

rate manually operated choke lever. The START posi

tion of the Engine Throttle Lever automatically sets

the choke on the engine’s carburetor.

Photo 3-5: Starting the engine with the recoil starter rope.

Engine Ignition Switch (Electric Start Models Only)

The Engine Ignition Switch is located on the left

hand side of the rear lip of the handlebar control

panel. This switch enables you to easily start your

mower’s engine by simply turning the key to the

START position. When the engine starts, release the

key and it will automatically return to the RUN positon.

The Engine Ignition key will not shut the mower

engine off. Use the Engine Throttle Lever to stop the

engine.

14

NOTE

You can use the recoil starter rope to start the

engine on your electric start mower. It doesn’t

matter if the Engine Ignition key is in the

keyswitch or not.

Page 17

SECTION 4i MOWER OPERATION

This Section of the Manual provides step-by-step

starting and operating procedures. Before you start

your mower’s engine, please review all of the Safety

Instructions given in “Section 1: Safety”.

When first operating the mower, it is a good idea to

practice using it on a clear, level area. This way you’ll

Filling the Engine’s Gas Tank

Use clean, fresh lead-free gasoline which has a

minimum octane rating of 77.

Do not add any type of oil to the gas.

A DANGER

Gasoline and its fumes are highly flammable.

Before filling the gas tank, shut the engine off,

allow it to cool, disconnect the spark plug wire

and prevent it from touching the spark plug. On

electric start models, also remove the Engine Igni

tion key from the keyswitch.

Failure to do so could result in personal injury or

property damage.

comfortably familiarize yourself with the location and

operation of all the mower’s controls.

If you should ever lend your mower to another

person, please lend him or her this Manual to read.

Make sure that he or she knows how to safely oper

ate, and quickly stop the mower.

To add gas to the mower’s gas tank:

1. Unscrew the cap from the gas tank.

2. Insert a clean funnel into the gas tank (or use a

fuel container that has a flexible pour spout).

3. Very slowly pour gas into the tank. Pause fre

quently while you’re pouring, remove the funnel, and

check the level of the gas in the gas tank. Do not fill

the gas tank to the point of overflowing—allow some

air space in the gas tank for the gas to expand.

4. Securely reinstall the gas tank cap.

5. Wipe any spilled gas off the mower before you

start the engine.

ACAUTION

• Check the gas level in the mower’s gas tank

before starting the engine.

• Do not fill the gas tank indoors, when the engine

is running, or when the engine is hot. Allow the

engine to cool for several minutes before fill

ing the gas tank.

• Reinstall the gas tank cap securely, and clean

up any spilled gas before starting the engine.

• Keep gas and its vapors away from all sources

of sparks and flame.

• Move the mower away from gas fumes before

starting the engine.

• Never run the engine indoors; always run the

engine outdoors and make sure there is ade

quate ventilation.

Failure to follow these instructions could result in

personal injury or property damage.

Photo 4-1: Filling the gas tank.

15

Page 18

OPERATION

ENGINE

THROTTLE

LEVER

BLADE

DRIVE

LEVER

RECOIL

STARTER

ROPE

WHEEL DRIVE

LEVER

ELECTRIC

START

KEYSWITCH

Photo 4-1: Mower Controls.

Starting the Mower

^WARNING

Do not operate the mower when children or others

are around.

Failure to follow this instruction could result in

personal injury or property damage.

1. Before starting the mower, thoroughly inspect the

area where you’ll be using the mower. Remove all

metal debris and other hazards from this area. Aiso

inspect this area for hidden hazards, holes, ruts, or

bumps.

2. Before you start the mower’s engine, be sure to per

form the following pre-start checklist:

a. Check to make sure that there is gas in the

mower’s gas tank. See Page 15 for gas tank filling

instructions and safety cautions.

b. Check the engine oil level.

c. Check the spark arrester screen (on the muffler)

for looseness and damage.

Awarning

Avoid fires due to sparks.

Do not operate engine if spark arrester screen is

loose or damaged.

d. Make sure that both handlebar levers are not

engaged (make sure that they are released).

e. Check to make sure the blade cutting height is

adjusted to the desired cutting height.

f. Remove the plastic cutter bar protector from the

front of the blade.

g. Reconnect the spark plug wire to the spark

plug.

3. Start the engine as follows:

For electric start engines:

a. Stand behind the mower in the operator’s position.

b. Move the Engine Throttle Lever to START.

c. Grasp the right-hand handlebar grip with your

right hand.

d. Turn the Engine Ignition key to START

NOTE

Do not continuously crank the engine with the

Engine Ignition key. Use the key only for 15

seconds. If the engine doesn’t start, allow it to

rest for 45 seconds before again trying to start

the engine.

e. When the engine starts, release the key. It will

automatically return to its RUN position.

For standard start engines:

a. Stand behind the mower in the operator’s posi

tion. (See Photo 3-5 on Page 14.)

b. Move the Engine Throttle Lever to START

c. Place your left hand on the left handlebar to

stabilize the mower when you pull the recoil starter

rope.

d. Grasp the black plastic starter rope handle with

your right hand. Slowly pull the rope until you feel

some resistance. Then rapidly pull the rope to start

the engine. Repeat this step as necessary until the

engine starts.

16

Page 19

OPERATION

Mowing

1. Stand behind the mower in the operator’s position

and place both hands on the handlebar grips.

2. To engage the cutter bar drive, squeeze the righthand handlebar lever (the Blade Drive Lever). The

cutter bar blade should begin to oscillate (move from

side to side) rapidly.

3. To make sure that the cutter bar drive mechanism

is working correctly, release the right-hand handlebar

lever. The cutter bar blade should stop oscillating.

ADANGER

If the cutter bar does not stop oscillating when

you release the Blade Drive Lever, or if it oscillates

before you squeeze this lever, shut the mower’s

engine off, wait until it cools, disconnect the spark

plug wire and prevent it from touching the spark

plug. Do not use the mower until the cutter bar

drive mechanism is repaired so that the cutter

bar stops oscillating when the Blade Drive Lever

is released. See “Cutter Bar Drive Adjustment

(General)’’ in Section 5 of this Manual.

Failure to follow this instruction could result in

personal injury or property damage.

4. To engage the wheel drive, squeeze the left-hand

handlebar lever (the Wheel Drive Lever). The wheels

should begin turning.

5. To make sure that the wheel drive mechanism is

working correctly, release the left-hand handlebar

lever. The wheels should stop turning.

Awarning

If the wheels do not stop turning when you release

the Wheel Drive Lever, shut the mower’s engine

off, wait until the engine cools, disconnect the

spark plug wire and prevent it from touching the

spark plug. Do not use the mower until the wheel

drive mechanism is repaired so that the wheels

stop turning when the Wheel Drive Lever is re

leased. See “Wheel Drive Adjustment (General)’’.

Failure to do so could result in personal injury or

property damage.

6. If both the cutter bar drive mechanism and the

wheel drive mechanism are operating correctly, re

engage the lever(s).

NOTE

If you only want to move the mower (and not

mow), don’t engage the Blade Drive Lever, just

engage the Wheel Drive Lever.

Stopping

To stop the mower:

1. Release both handlebar levers (this will stop the

wheels and cutter bar).

2. Move the engine throttle lever to STOP (to stop

the engine).

3. After the engine cools, disconnect the spark plug

wire from the spark plug. Prevent it from touching the

spark plug by placing the boot on the end of the

spark plug wire onto the V-shaped holder on the

back of the engine (see Page 5).

4. Reinstall the plastic blade protector on the cutter

bar.

General Mowing Tips

1. Before mowing, be sure to inspect the area

thoroughly. Remove all metal debris and other haz

ards. Remember that tall grass or vegetation can hide

these hazards. Also note the location of any hidden

obstacles, such as gullies or brush-covered posts,

holes, bumps, etc.

2. If the area to be mowed has small trees, it is best

to saw down any that are over V2 -inch in diameter.

Make sure that the trees are sawed off low enough so

that the mower’s blade won’t catch on them. This will

prevent excessive cutter bar wear or blade breakage.

3. If the blade should clog, release the handlebar

levers, pull the mower rearward for a few feet, push

down on the handlebars so that the blade is raised

slightly off the ground, and re-engage the Blade Drive

Lever. This should “shake” any excess material off the

cutter bar. Then you can go forward and resume

mowing. Never unclog any part of the mower with

your hands or feet when the engine is running.

4. If you should accidentally hit an object that stops

the forward motion of the mower, immediately disen

gage (release) the Wheel Drive Lever to help prevent

any damage to the wheel drive mechanism.

5. If taller vegetation tends to wrap around the mower

between the wheels and the side frame, shut the

engine off and remove the vegetation by referring to

“Removing and Reinstalling the Wheels”. After remov

ing this excess vegetation, check to make sure that

both weed guards are in place between the rear

inner surface of the tires and the engine deck.

17

Page 20

SECTIONS: MAINTENANCE

Engine Maintenance

Checking the Engine Oil Level and Adding Oil to the Engine

Before starting the mower’s engine, check its oil

level. If you run the engine while it’s low on oil, you

risk causing damage to the engine. While mowing,

frequently stop the engine and check its oil level (at

least every 5 hours of operation).

If you’re mowing slopes, the oil can slant away from

internal engine parts, so it is extremely important to

keep the oil level correct. While mowing slopes, check

the engine oil level every 30 minutes of operation and

keep the oil level up to the FULL mark on the dipstick.

(Be sure to move the mower to a flat area before

checking the engine oil level.)

To check the engine oil level;

A CAUTION

5. Firmly screw the dipstick all the way back into the

oil filler tube.

6. Unscrew the dipstick and check the engine oil level.

The level should be between the ADD and the FULL

marks on the dipstick.

7. If you have to add oil to the engine, please use the

following instructions:

a. Insert a clean funnel into the oil filler tube.

b. Select a clean, high-quality detergent oil using

the viscosity and temperature recommendations

given in “Specifications” on the inside rear cover of

this Manual.

c. Slowly pour the oil into the funnel, pausing fre

quently to check the engine oil level with the dipstick

(see the previous instructions).

Before checking the engine oil level, shut the

mower’s engine off, allow the engine to cool, dis

connect the spark plug wire and prevent it from

touching the spark plug. For electric start mod

els, also remove the Engine Ignition key from the

keyswitch.

Failure to do this could result in personal injury

or property damage.

1. Move the mower to a level area.

2. Shut the engine off.

3. Clean any debris away from the area around the oil

dipstick so that no debris can fall into the engine when

the dipstick is removed.

4. Unscrew the dipstick and use a clean, lint-free rag

to wipe the dipstick clean.

NOTE

DO NOT overfill the engine with oil. Overfilling

the engine with oil could make the engine smoke

excessively or appear to be seized.

d. When the engine oil level is correct, securely

reinstall the dipstick.

18 Figure 5-1: Checking the engine oil level.

Photo 5-2: Adding oil to the engine.

Page 21

MAINTENANCE

Changing the Engine Oii

After the very first five hours that you operate your

new mower, change the engine oil. Thereafter, change

the engine oii every twenty-five hours of operation. If

you operate your mower in very dusty or dirty condi

tions, change the engine oil even more frequently.

Use the following instructions when changing the

engine oil:

1. Run the mower engine until it is warm. Then SHUT

THE ENGINE OFF.

A CAUTION

Before changing the engine oii, shut the engine

off, disconnect the spark plug wire and prevent it

from touching the spark plug. For electric start

models, also remove the Engine Ignition key from

the keyswitch.

Failure to do this could result in personal injury

or property damage.

2. Place a drain pan with a minimum capacity of 2

quarts beneath the engine’s drain plug.

3. Use a pair of pliers to firmly grip the engine oil

drain tube as shown in Photo 5-3. This prevents the

drain tube from accidentally being unscrewed from

the base of the engine when you remove the drain

plug in the next step.

4. Use a 13/16-inch wrench (or a large adjustable

wrench) to unscrew the drain plug from the drain

tube. See Photo 5-3.

Air Cleaner Maintenance

The engine on your mower uses one of two types

of air filters. The 3V2-horsepower engine has a single

element oil foam air cleaner. The 4-horsepower engine

has a dual element air cleaner (a replaceable paper

cartridge with an oiled foam pre-cleaner).

Before each use, always make sure that the air

cleaner is securely attached to the engine. A loose or

ill-fitting air cleaner assembly could allow dust or

dirt into the engine. This could shorten the life of

the engine.

Every 25 hours of engine operation (more frequently

if operating the mower in a very dusty or dirty envi

ronment) clean and inspect the engine’s air cleaner

element(s).

To service the 3V2-horsepower engine air cleaner:

1. Clean any excess dirt, dust, or chaff off the air

cleaner.

2. Remove the screw that secures the air cleaner

assembly to the engine. Lift the air cleaner assembly

up, off the engine.

3. Separate the body halves of the air cleaner assem

bly and remove the foam element.

4. Clean this foam element as follows:

a. Thoroughly wash the element in a solution of

liquid detergent and water.

b. Wrap the element in a clean towel and squeeze

it dry.

c. Apply clean engine oil to the ends and sides of

the foam element. Knead the foam element to

evenly distribute the oil.

d. Squeeze any excess oil out of the foam element.

5. Thoroughly clean both halves of the air cleaner

body.

Photo 5-3: Draining the engine oil.

5. Allow all of the old oil to flow out of the engine.

6. Again grip the drain tube with the pliers and reinstall

the drain plug on the oil drain tube. Very securely

tighten the drain plug.

7. Refill the engine with fresh oil. See “Checking the

Oil Level and Adding Oil to the Engine” on Page 18 for

specific instructions.

6. Reinstall the foam element in the bottom half of the

body.

7. Place the air cleaner’s cup into the foam element

as shown in Figure 5-4.

8. Place the top half of the body onto the bottom half.

Insert the screw into the top half of the air cleaner

and reinstall the air cleaner assembly onto the engine.

Figure 5-4: The 3 %-hor^power engine’s air cleaner as^nbly: 19

Page 22

MAINTENANCE

To service the 4-horsepower engine air cleaner:

1. Clean any excess dirt, dust, or chaff from the air

cleaner and carburetor.

2. Unscrew the knob from the top of the air cleaner

and lift the cover off.

3. Remove the foam pre-cleaner by sliding it upward,

off the paper cartridge.

4. Unscrew the wing nut from the stud in the center

of the paper filter. Lift the cartridge and base plate up,

off the stud.

5. Clean the foam pre-cleaner as follows:

a. Wash it in a solution of warm water and non

sudsing detergent.

b. Wrap it in a towel and squeeze it dry.

c. Apply clean engine oil to it and then knead it to

evenly distribute the oil. Squeeze any excess oil

out of the pre-cleaner.

6. Clean the paper cartridge by tapping it on a flat

surface to remove any loose dirt. If the cartridge is

very dirty, either replace it with a new one or wash it

in a solution of low- or non-sudsing detergent and

warm water. Then rinse the cartridge thoroughly from

the Inside out until the water flowing through the

cartridge is clear. Allow the cartridge to dry very

thoroughly before reinstalling it.

7. Clean the base plate and the inside of the air

cleaner cover.

8. Place the base plate over the stud. Then place the

paper cartridge over the stud and secure it in place

with the wing nut.

9. Slide the foam pre-cleaner down over the cartridge.

10. Place the cover over the stud. Secure the cover

in place with the knob.

Spark Arrester

The muffler on the mower’s engine is equipped

with a screen-type spark arrester to help keep stray

sparks from accidentally escaping.

Before each use, check the spark arrester for

looseness and damage. If the spark arrester is

damaged or missing, do not use the mower until the

spark arrester is replaced with an original-equipment

spark arrester (available from us or your local Briggs

& Stratton dealer).

^WARNING

Avoid fires due to sparks.

Do not operate engine if spark arrester screen is

loose or damaged.

A WARNING TO ALL CALIFORNIA

MOWER OPERATORS

Under California Law, you are not permitted to

operate an internal combustion engine using hy

drocarbon fuels on any forest-covered, brushcovered, or grass-covered land, or land covered

with grain, hay, or other flammable agricultural

crop, without an engine spark arrester in contin

uous effective working order. The engine on your

mower, like most lawn or garden equipment, is an

internal combustion engine that burns gasoline (a

hydrocarbon fuel); therefore it must be equipped

with a spark arrester muffler in proper working

order. The spark arrester must be attached to the

engine exhaust system in such a manner that

flames or heat from the system will not ignite flam

mable material. Failure of the operator to comply

with this regulation is a misdemeanor under Cali

fornia Law. Other states may have similar laws.

Federal laws apply on Federal lands.

L

BASE PLATE FOAM PRECLEANER

20 Photo 5-5: The 4-horsepower engine’s air cleaner assembly

KNOB-

Photo 5-6: The engine spark arrester.

Also, please refer to the Briggs & Stratton Operat

ing and Maintenance Instructions Manual for periodic

spark arrester maintenance information.

Page 23

MAINTENANCE

Air Cooling System Maintenance

As you mow, dry grass or chaff can clog the engine’s

cooling fins and shrouds. Clean any debris from the

engine as often as needed to avoid engine over

heating and damage.

If the accumulation of debris and dirt is especially

heavy, it may be necessary to remove the engine

shroud every few hours and clean the engine parts

located beneath the shroud. When removing and

replacing the engine shroud, be very careful not to

bend or damage the governor vanes, linkages, or

any wires.

After approximately 100 hours of engine operation

(more often if necessary), take the mower to an

Authorized Briggs & Stratton Service Center so that

its cooling fins and shrouds can be properly cleaned.

This will help prevent engine overspeeding, over

heating, or other damage.

Carburetor Adjustment (Engine Speed & Mixture)

We have adjusted the carburetor on your mower’s

engine to give you the best possible performance

from your mower.

The rated speed for the engine is 3100 RPM to

3300 RPM. Do not attempt to make any adjustments to

the carburetor that would allow the engine to exceed

this speed. The idle speed for the engine is 1750

RPM.

If you believe that the engine’s carburetor is out of

adjustment, please refer to the Briggs & Stratton Oper

ating and Maintenance Instructions Manual for the

correct procedure for carburetor adjustments.

After you clean and inspect an old spark plug, or if

you are installing a new spark plug, be sure to set the

gap to 0.030 inch.

Liquid Lock

When a vertical crankshaft engine (such as on your

mower) is tipped so that the spark plug points down

ward for several hours, there is a chance that oil can

leak into the space between the top of the piston and

the cylinder head. If the piston is on its compression

stroke, the oil can prevent it from moving. This situa

tion is called “liquid lock’’, because the oil isn’t com

pressible and it “locks” up the engine.

You will notice when you have an engine in this

condition. You will be able to pull the recoil starter

rope out only a short distance. Then you won’t be

able to pull it out any farther. If you’re using the

Engine Ignition key to try to start the engine and you

think the engine is locked up, don't turn the key to

start until you’ve cleared the engine as follows, or you

could damage the starter.

Liquid lock is corrected as follows;

1. Remove the spark plug from the cylinder.

2. Slowly pull the recoil starter rope by hand until no

more oil comes out of the spark plug hole.

3. Thoroughly clean the spark plug. Reinstall the

spark plug. Reconnect the spark plug wire to the

spark plug.

4. Check the engine oil level.

Engine Ignition System

Your mower’s engine is equipped with an electronic

ignition system. This type of system eliminates the

traditional set of points and condenser. With this

newer type of electronic ignition system, you no

longer have to perform any scheduled ignition system

maintenance (other than cleaning or replacing the

spark plug as discussed next).

If you ever suspect that the engine’s ignition sys

tem is malfunctioning, contact an Authorized Briggs &

Stratton Service Center for repairs.

Spark Plug

Every 100 hours of engine operation you should

remove, clean, and inspect (or simply replace) the

spark plug.

Inspect the spark plug for stripped threads, exces

sive combustion deposits on the electrodes and the

interior of the spark plug, cracked porcelain, or other

damage. If the spark plug is damaged, replace it.

Refer to “Specifications” on the inside back cover of

this Manual for replacement types of spark plugs.

Whenever you clean a spark plug, don’t blast clean

it. Scrape it or wire brush it clean.

5. Again try to start the engine.

21

Page 24

Mower Maintenance

Lubrication

Please refer to Photo 5-7 and the list of items that

follow it to see which items on your mower should be

lubricated. Keeping these items lubricated helps your

mower to perform better.

Photo 5-7: Mower lubrication points.

NOTES

• Use fresh automotive grease when grease is

called for.

• Use clean automotive type oil when oiling the

blade.

1. Lubricate the handlebar levers’ pivot points—

Approximately every 25 hours of mower operation (or

if either handlebar lever should bind or if the lever's

action should become rough) apply oil or a silicone

spray to the pivot points of both handlebar levers.

Use care not to get any lubricant on the levers, so

that your fingers won’t slip off the lever during

operation.

2. Grease the wheel shaft and clevis pin-Whenever

you remove the wheels (or every 25 hours of engine

operation, whichever comes first), you should apply a

thin coating of grease to both the wheel shaft and

clevis pin. This helps prevent corrosion from forming

and allows you to more easily remove the clevis pin

and wheel.

3. Grease the back channel of the drive arm—Every

25 hours of engine operation, clean any dirt from the

top of the flywheel and from the back channel of the

drive arm. Disconnect the spark plug wire and rotate

the flywheel by hand until the bearing is all the way

forward in the back channel. (The hole in the flywheel

will be underneath the drive arm.) Then use your

finger to apply fresh grease to the inside of the back

22

channel.

•

4. Grease the cutter bar mount and the drive arm—

Every 25 hours of operation use a grease gun to

apply grease to the three fittings shown in Photo 5-7.

Each fitting will require four or five complete pumps

with the grease gun to make sure that it is lubricated

properly. This ensures that your blade will easily pivot

to follow the contours of the land you’re mowing. It

also ensures that cutter bar removal will be easier.

5. Oil the cutter bar—Every 5 hours of operation you

should liberally apply oil to the cutter bar. Liberally

apply oil to all the friction points on the cutter bar

blades, the blade guides, and the ledger bar. You can

use a squirt-type oil can, or you can simply pour oil

onto the cutter bar directly from the can.

6. Oil the jackshaft chain—Every 25 hours of opera

tion use a squirt-type oil can to sparingly oil the

jackshaft chain. Use care not to get any oil on the

cutter bar drive belt.

7. Grease the drive pin—Every 10 hours of operation

remove the drive socket and apply fresh grease to

the drive pin.

Page 25

MAINTENANCE

Removing and Reinstaliing the Wheels

The mower’s wheels are secured to the wheel shaft

by a clevis pin and a clinch pin. Removing the wheels

is a simple matter. Occasionally, especially when

you’re mowing taller vegetation, you might find that

this vegetation tends to wrap around the wheels. To

remove this vegetation, take the wheel off by following

the instructions below. Then pull the vegetation off

and reinstall the wheel.

A CAUTION

Before removing or reinstalling a wheel, shut the

engine off, allow it to cool, disconnect the spark

plug wire and prevent it from touching the spark

plug, and reinstall the plastic blade protector on

the front of the blade. For electric start models,

also remove the Engine Ignition key from the keyswitch.

Failure to do this could result in personal injury

or property damage.

To remove a wheel;

NOTE

If you had a difficult time removing the clevis pin

or the wheel, inspect the wheel shaft, clevis pin,

and inside surface of the wheel hub for corro

sion or dirt. Clean any dirt away from these

areas. If there is any corrosion, use a fine grade

of sandpaper to remove it. Then apply grease to

the wheel shaft and clevis pin to prevent further

corrosion and to make future wheel removal

easier.

To reinstall the wheel:

1. Align the wheel hub with the wheel shaft and slide

the wheel onto the wheel shaft.

2. Rotate the wheel on the wheel shaft until the holes

in the wheel hub align with the hole in the wheel

shaft.

3. Insert the quick release pin through these holes.

4. Move the quick release pin’s round wire bail over

the wheel hub.

Removing and Installing the Wheel Drive Beit

1. Prop up the mower so that the wheel is supported

off the ground. Do this by placing a 5 or 6-inch thick

block of wood beneath the mower.

Photo 5-8: Removing the wheel.

2. Move the quick release pin’s round wire bail over

the wheel hub.

3. Insert your finger in the round wire bail. Pull the

pin out of the wheel hub. A small twisting motion

while you pull is helpful.

4. Carefully slide the wheel outward until it is off the

wheel shaft.

A CAUTION

Before removing or installing the wheel drive belt,

shut the engine off, allow it to cool, disconnect

the spark plug wire and prevent it from touching

the spark plug, and reinstall the plastic blade pro

tector on the front of the blade. For electric start

models, also remove the Engine Ignition key from

the keyswitch.

Failure to do so could result in personal injury or

property damage.

You’ll need the following items to change the wheel

drive belt:

1.

A replacement original equipment wheel drive

belt (if the old belt is bad).

2.

(Recommended) A new IVz-inch long by 3/16inch thick cotter pin.

Several 6-inch thick blocks of wood (used to

raise both wheels off the ground).

4.

Two V2-inch wrenches.

5.

A Yi6-inch wrench.

A hammer.

6.

7.

A V4-inch straight punch.

8.

A %2- or Vs-inch straight punch.

9.

A pair of water pump or channel lock pliers.

10.

A medium-sized flat tip screwdriver (long or

medium length).

11.

A soft-faced hammer may be needed.

12.

A large straight punch may be needed.

13.

Safety glasses or goggles.

23

Page 26

MAINTENANCE

To remove the wheel drive belt:

1. Use the V2 -inch wrench to remove the two bolts

that attach the top of the hood to the rear hood. Then

loosen the four bolts (two on each side) that attach