Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OperatOr’s Manual

LS 27 TB — Log Splitter

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-09000

(May 20, 2013)

Page 2

To The Owner

Thank You

Thank you for purchasing a Troy-Bilt Log Splitter. It was carefully

engineered to provide excellent performance when properly

operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. We reserve

the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 7

Controls & Features ................................................ 11

Operation ................................................................12

Maintenance & Adjustment .................................15

1

If applicable, the power testing information used to establish

the power rating of the engine equipped on this machine can be

found at www.opei.org or the engine manufacturer’s web site.

If you have any problems or questions concerning the machine,

phone a authorized Troy-Bilt service dealer or contact us directly.

Troy-Bilt’s Customer Support telephone numbers, website

address and mailing address can be found on this page. We want

to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

The engine manufacturer is responsible for all engine-related

issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer’s

Owner’s/Operator’s Manual, packed separately with your

machine, for more information.

Service .....................................................................17

Troubleshooting .....................................................18

Replacement Parts ................................................ 20

Warranty ................................................................ 24

Record Product Information

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate

the model plate by looking at the side flange of the engine

mounting plate. This information will be necessary, should you

seek technical support via our web site, Customer Support

Department, or with a local authorized service dealer.

Model NuMber

Serial NuMber

Customer Support

Please do NOT return the machine to the retailer or dealer without first contacting the Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

◊ Visit us on the web at www.troybilt.com

See How-to Maintenance and Parts Installation Videos at www.troybilt.com/tutorials

◊ Call a Customer Support Representative at (800) 828-5500 or (330) 558-7220

◊ Write to Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

2

Page 3

Important Safe Operation Practices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

DANGER! This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating hands and feet

and throwing debris. Failure to observe the following safety instructions could result in

serious injury or death.

2

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quick ly.

3. Never allow children under 16 years of age to operate this

machine. Children 16 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4. Never allow adults to operate this machine without proper

instruction.

5. Many accidents occur when more than one person

operates the machine. If a helper is assisting in stacking

logs, never activate the control until the helper is a

minimum of 10 feet from the machine.

6. Keep bystanders, pets, and children at least 10 feet from

the machine while it is in operation.

7. Never allow anyone to ride on this machine.

8. Never transport cargo on this machine.

9. Hydraulic log splitters develop high fluid pressures during

operation. Fluid escaping through a pin hole opening can

penetrate your skin and cause blood poisoning, gangrene,

or death. Give attention to the following instructions at all

times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked,

cracked, or damaged hoses, fittings, or tubing.

c. Stop the engine and relieve hydraulic system

pressure by cycling the valve control lever from

forward to reverse several times while engine is

not running; returning to neutral before repairing

or adjusting fittings, hoses, tubing, or other system

components.

d. Do not adjust the pressure settings of the pump or

valve.

10. Leaks can be detected by passing cardboard or wood,

while wearing protective gloves and safety glasses, over

the suspected area. Look for discoloration of cardboard or

wood.

11. If injured by escaping fluid, see a doctor immediately.

Serious infection or reaction can develop if proper medical

treatment is not administered immediately.

12. Keep the operator zone and adjacent area clear for safe,

secure footing.

3

Page 4

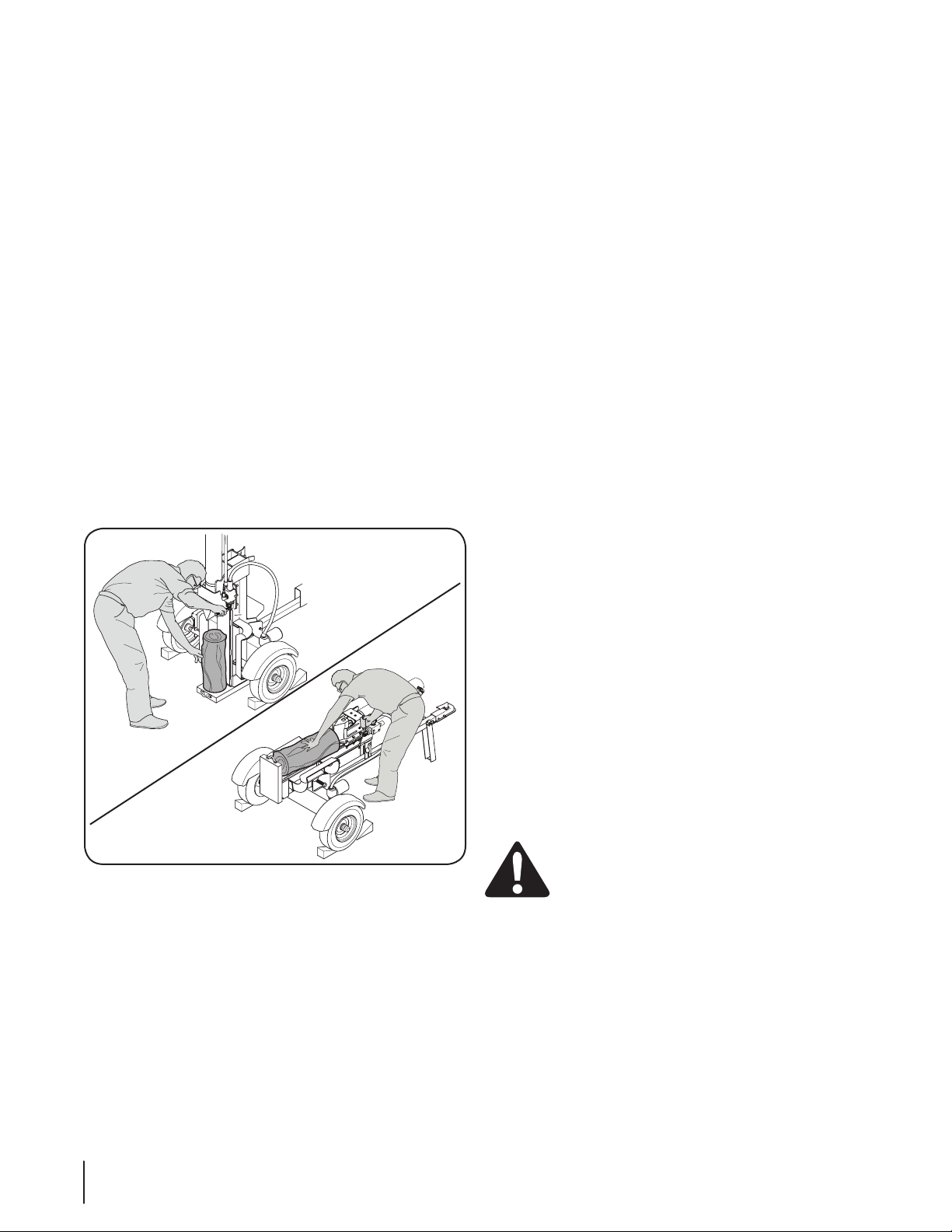

Horizontal

Vertical

13. If your machine is equipped with an internal combustion

engine and is intended for use near any unimproved forest,

brush, or grass covered land, the engine exhaust should be

equipped with a spark arrestor. Make sure you comply with

applicable local, state, and federal codes. Take appropriate

firefighting equipment with you.

14. This machine should be used for splitting wood only, do

not use it for any other purpose.

15. Follow the instructions in the manual(s) provided with any

attachment(s) for this machine.

Preparation

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles when

operating this machine.

3. Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

4. Make sure machine is on a flat, dry, solid ground before

operating.

5. Always block wheels to prevent unintended movement,

and lock beam in either the horizontal or vertical position.

6. Always operate this machine from the operator zone(s)

specified in the manual. See Fig. 2-1.

Figure 2-1

7. Logs should be cut with square ends prior to splitting.

8. Use log splitter in daylight or under good artificial light.

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never overfill the fuel tank. Fill tank to no more than

1/2 inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment and move machine to another area. Wait

five (5) minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

j. Allow machine to cool at least five (5) minutes

before storing.

Operation

1. Before starting this machine, review the “Safe Operation

Practices”. Failure to follow these rules may result in serious

injury to the operator or bystanders.

2. Never leave this machine unattended with the engine

running.

3. Do not operate machine while under the influence of

alcohol, drugs, or medication.

4. Never allow anyone to operate this machine without

proper instruction.

5. Always operate this machine with all safety equipment in

place and working. Make sure all controls are operating

properly for safe operation.

6. Operator Zone

a. Horizontal Operating Position: Stand on the control

lever side of the log splitter and stabilize log as

shown, if needed. See Fig. 2-1.

b. Vertical Operating Position: Stand in front of the log

splitter and stabilize log as shown, if needed. See

Fig. 2-1.

WARNING! When stabilizing log with left hand,

remove your hand when the wedge just contacts

the log or serious injury may occur.

7. When loading a log, always place your hands on the side

of the log, not on the ends, and never use your foot to help

stabilize a log. Failure to do so, may result in crushed or

amputated fingers, toes, hand, or foot.

8. Use only your right hand to operate the controls.

9. Never attempt to split more than one log at a time.

10. For logs which are not cut square, the least square end of

the log should be placed toward the beam and wedge, and

the square end placed toward the end plate.

4 Section 2 — important Safe operation practiceS

Page 5

11. When splitting in the vertical position, stabilize the log

before moving the control handle. Split as follows:

a. Place log on the end plate and turn until it leans

against the beam and is stable.

b. When splitting extra large or uneven logs, the log

must be stabilized with wooden shims or split wood

placed between the log and end plate or ground.

12. Always keep fingers away from any cracks that open in

the log while splitting. They can quickly close and pinch or

amputate your fingers.

13. Keep your work area clean. Immediately remove split wood

around the machine so you do not stumble over it.

14. Do not change the engine governor settings or overspeed

the engine. The governor controls the maximum safe

operating speed of the engine.

15. Never move this machine while the engine is running.

16. This machine should not be towed on any street, highway

or public road without checking the existing federal,

state, or local vehicle requirements. Any licensing or

modifications such as taillights, etc., needed to comply, is

the sole responsibility of the purchaser. If a “Statement of

Origin” is required in your state, see your local dealer.

17. Do not tow machine over 45 mph.

18. See Transporting the Log Splitter section in this manual for

proper towing instructions once all federal, local, or state

requirements are met.

9. Do not alter this machine in any manner, alterations such

as attaching a rope or extension to the control handle, or

adding to the width or height of the wedge may result in

personal injury.

10. According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 130 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Spark Arrestor

WARNING! This machine is equipped with an

internal combustion engine and should not be used

on or near any unimproved forest-covered, brush

covered or grass-covered land unless the engine’s

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in

effective working order by the operator. In the State of California

the above is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

Maintenance and Storage

1. Stop the engine, disconnect the spark plug and ground

it against the engine before cleaning, or inspecting the

machine.

2. Stop the engine and relieve hydraulic system pressure by

cycling the valve control lever from forward to reverse

several times while engine is not running; returning to

neutral before repairing or adjusting fittings, hoses, tubing,

or other system components.

3. To prevent fires, clean debris and chaff from the engine

and muffler areas. If the engine is equipped with a spark

arrestor muffler, clean and inspect it regularly according to

manufacturers instructions. Replace if damaged.

4. Periodically check that all nuts and bolts, hose clamps, and

hydraulic fittings are tight to be sure equipment is in safe

working condition.

5. Check all safety guards and shields to be sure they are in

the proper position. Never operate with safety guards,

shields, or other protective features removed.

6. The pressure relief valve is preset at the factory. Do not

adjust the valve.

7. Never attempt to move this machine over hilly or uneven

terrain without a tow vehicle or adequate help.

8. For your safety, replace all damaged or worn parts

immediately with original equipment manufacturer’s

(O.E.M.) parts only. Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!

5Section 2 — important Safe operation practiceS

Page 6

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

WARNING— CRUSHING HAZARD

Keep hands away from wedge, end plate, partially split wood and moving parts.

BYSTAN DER S

Keep bystanders, helpers and children at least 10 feet away.

SINGLE OPERATOR

Only one person should operate the machine at a time. The adult who loads and stabilizes the

log must be the person who operates control handle.

WARNING— PRESSURIZED FLUID

Never check for hose leaks with your hands. High pressure fluid can escape through a pin hole

leak and cause serious injury by puncturing the skin and causing blood poisoning.

EYE PROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING— MOVING WEDGE

Keep hands away from wedge and moving parts.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING— HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING! Your Responsibility—Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 Section 2 — important Safe operation practiceS

SAVE THESE INSTRUCTIONS!

Page 7

Assembly & Set-Up

Spring Clip

Clevis Pin

Jack Stand

Hex Nuts

Hex Bolts

Tongue

Tank Brackets

Contents of Carton

• One Log Splitter • One Tongue Assembly • One Operator’s Manual

• One Engine Operator’s Manual

3

NOTE: This Operator’s Manual covers several models. Log splitter

features may vary by model. Not all features in this manual are

applicable to all log splitter models and the log splitter depicted

may differ from yours.

WARNING! Use extreme caution unpacking this

machine. Some components are very heavy and will

require additional people or mechanical handling

equipment.

NOTE: All references in this manual to the left or right side and

front or back of the log splitter are from the operating position

only. Exceptions, if any, will be specified.

Unpacking & Assembling the Log Splitter

TOOLS NEEDED: Safety glasses, leather gloves, wire cutters, pry bar,

adjustable and/or socket wrench set and/or claw hammer.

1. Use a pry bar or claw hammer to loosen and remove the top

of the crate.

2. Use a pry bar or claw hammer to remove the sides of the crate,

beginning with the short sides (or left and right side of the log

splitter). Set the sides of the crate aside to avoid injury.

3. On the front side of the crate the tongue assembly is attached

on the inside of the crate with a cable tie. Cut the cable tie to

remove the tongue.

4. Remove the large plastic cover and discard.

WARNING! Do NOT remove any wood or cut any

straps securing the log splitter or its components to

the log splitter or the crate at this time. Only remove

straps and/or wood when instructed to do so.

5. Inspect the bottom of the crate for any protruding staples

or wood splinters and remove.

6. Remove any loose parts included with the log splitter (i.e.

operator’s manual, etc.).

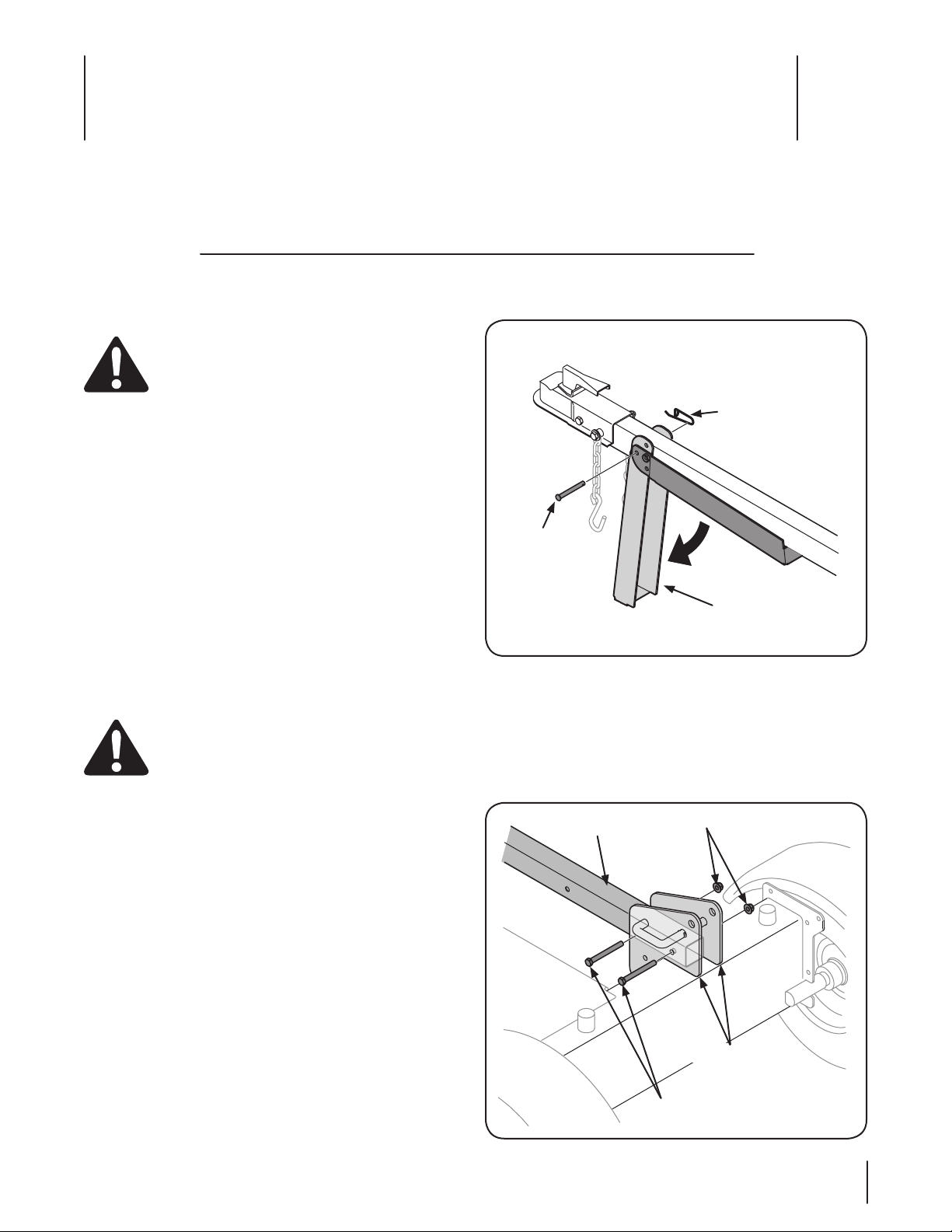

7. Remove the spring clip and clevis pin from the jack stand

on the tongue and then pivot the jack stand towards the

ground into the operating position. See Figure 3-1.

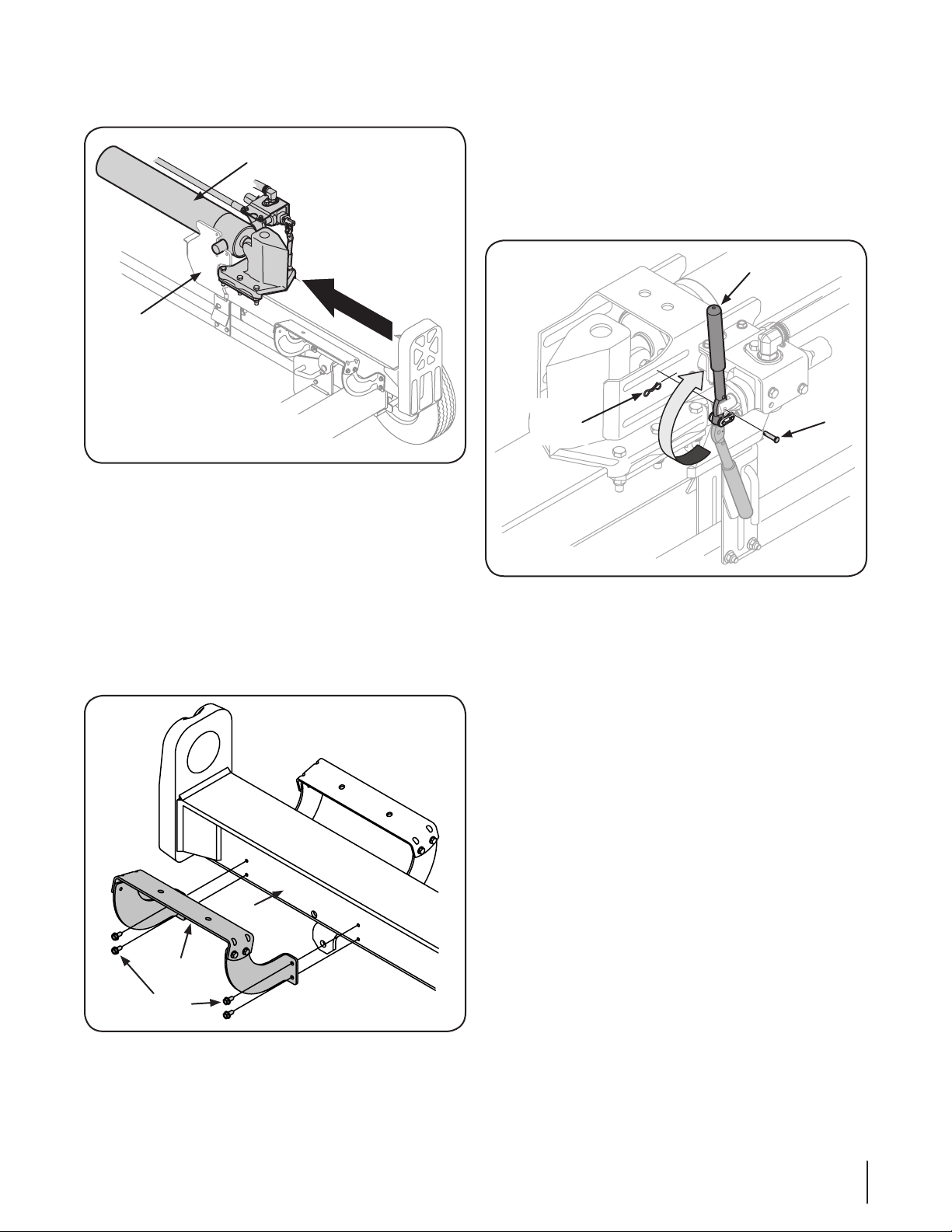

Figure 3-1

8. Secure the jack stand in position with the clevis pin and

spring clip. See Figure 3-1.

9. With the log splitter still secured to the bottom of the crate,

remove two hex bolts and hex nuts from the tank bracket

and remove the piece of wood inside the tank brackets. See

Figure 3-2.

Figure 3-2

7

Page 8

Hex Screws

Hex Screws

Dislodger

Hex Washer

Screw

Log Tray

Beam

10. Align the holes in the tongue with the holes in the tank

Vertical Beam Lock

bracket and secure with the hardware just removed. See

Figure 3-2.

NOTE: The high pressure hose, which runs from the gear

pump to the bottom of the control valve, must be above

the tongue assembly.

11. The log splitter is shipped with the beam in a vertical

position. Remove any bolts or straps securing the end plate

to the bottom of the crate.

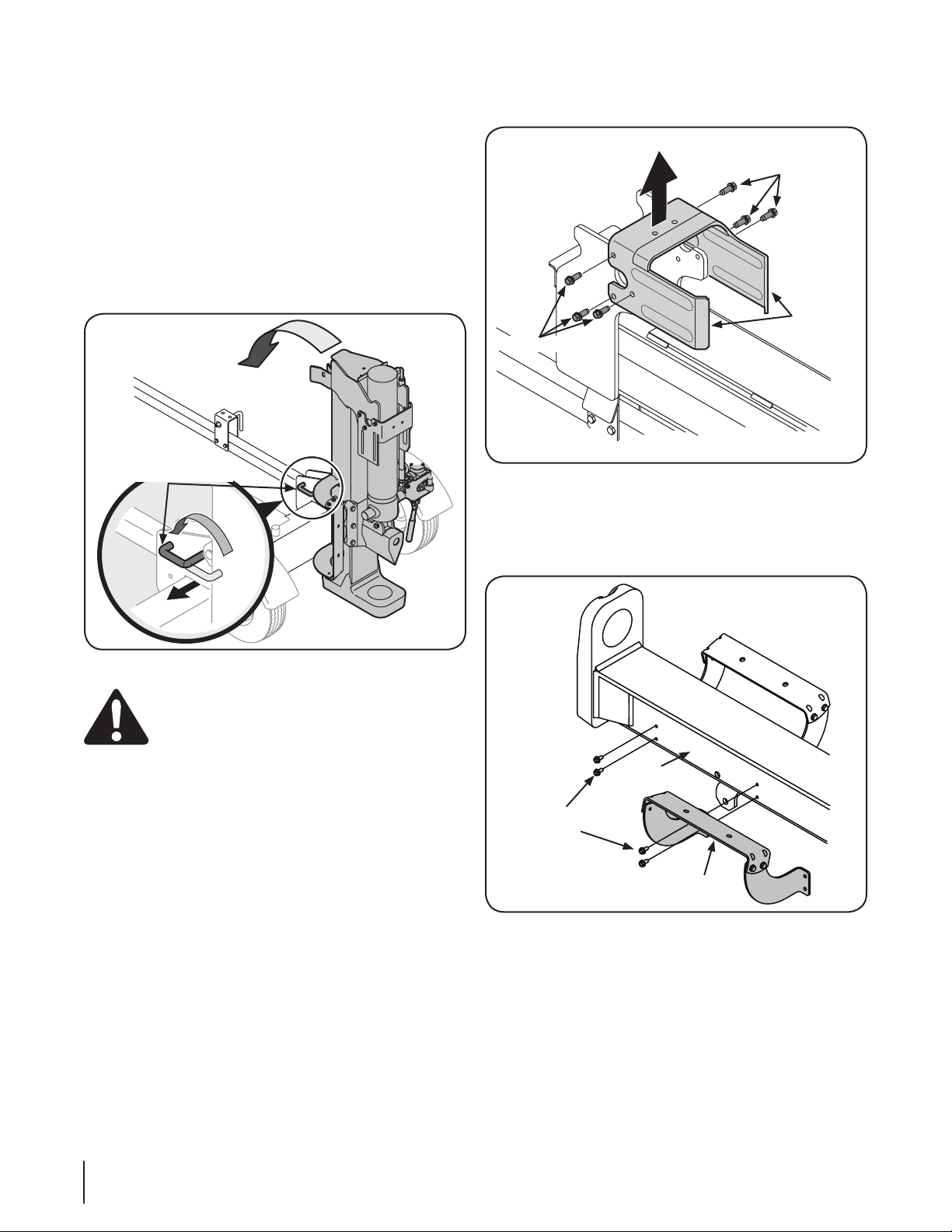

12. Pull out the vertical beam lock, rotate it back, and pivot the

beam to the horizontal position until it locks being sure to

avoid any possible pinch points. See Figure 3-3.

14. Disconnect the dislodger from the beam weld bracket by

removing the six hex screws. See Figure 3-4.

Figure 3-4

15. Disconnect the log tray from the beam on the side of the

control valve by removing the two hex washer screws that

secure it to the beam and the two hex washer screws in the

beam. See Figure 3-5.

WARNING! Take extra care when raising and

lowering the beam as it is fairly heavy. Having a

second person assist with raising or lowering the

beam is recommended. Be sure to keep hands away

from any possible pinch points.

13. Remove the wood between the wedge and the end plate

by cutting the cable tie that secures it. Cut the strap near

the hose on the front of the cylinder that secures it to the

beam weld bracket. Be careful not to damage the hose.

8 Section 2— ASSembly & Set-Up

Figure 3-3

Figure 3-5

Page 9

16. Lift and slide the cylinder up to the top of beam and into

Cylinder

Weld Brackets

Hex Washer

Screw

Log Tray

Beam

Bow-Tie

Cotter

Pin

Control Handle

Clevis

Pin

the weld brackets. See Figure 3-6.

Figure 3-6

17. Attach the dislodger over the wedge assembly and secure

it to the weld brackets with the previously removed

hardware. See Figure 3-4.

NOTE: Lift up on the cylinder when installing the hex screws.

NOTE: Once the six hex screws are tightened, there may be

a slight gap between the dislodger and the weld brackets.

This gap is normal.

18. Reattach the log tray to the side of the beam with the

control valve, aligning the holes in the tray with the holes

in the beam. See Figure 3-7.

20. Cut the metal strap securing the log splitter to the bottom

of the crate and remove the wood under the engine and/or

any other wood, then roll the log splitter off the bottom of

the shipping crate.

21. The control handle is shipped hanging from the valve on

the handle link.

22. Remove the clevis pin and bow-tie cotter pin from the

control handle. See Figure 3-8.

Figure 3-8

23. Rotate the control handle into the operating position and

secure with the clevis pin and bow-tie cotter pin removed

in step 1. See Figure 3-8.

19. Check for and remove any staples on the bottom of the

crate that may puncture the tire.

Figure 3-7

9Section 2 — ASSembly & Set-Up

Page 10

Set-Up

Dipstick

Reservoir

Tank

Gas and Oil Fill-Up

Service the engine with gasoline and oil as instructed in the engine

manual packed with your log splitter. Read the instructions carefully.

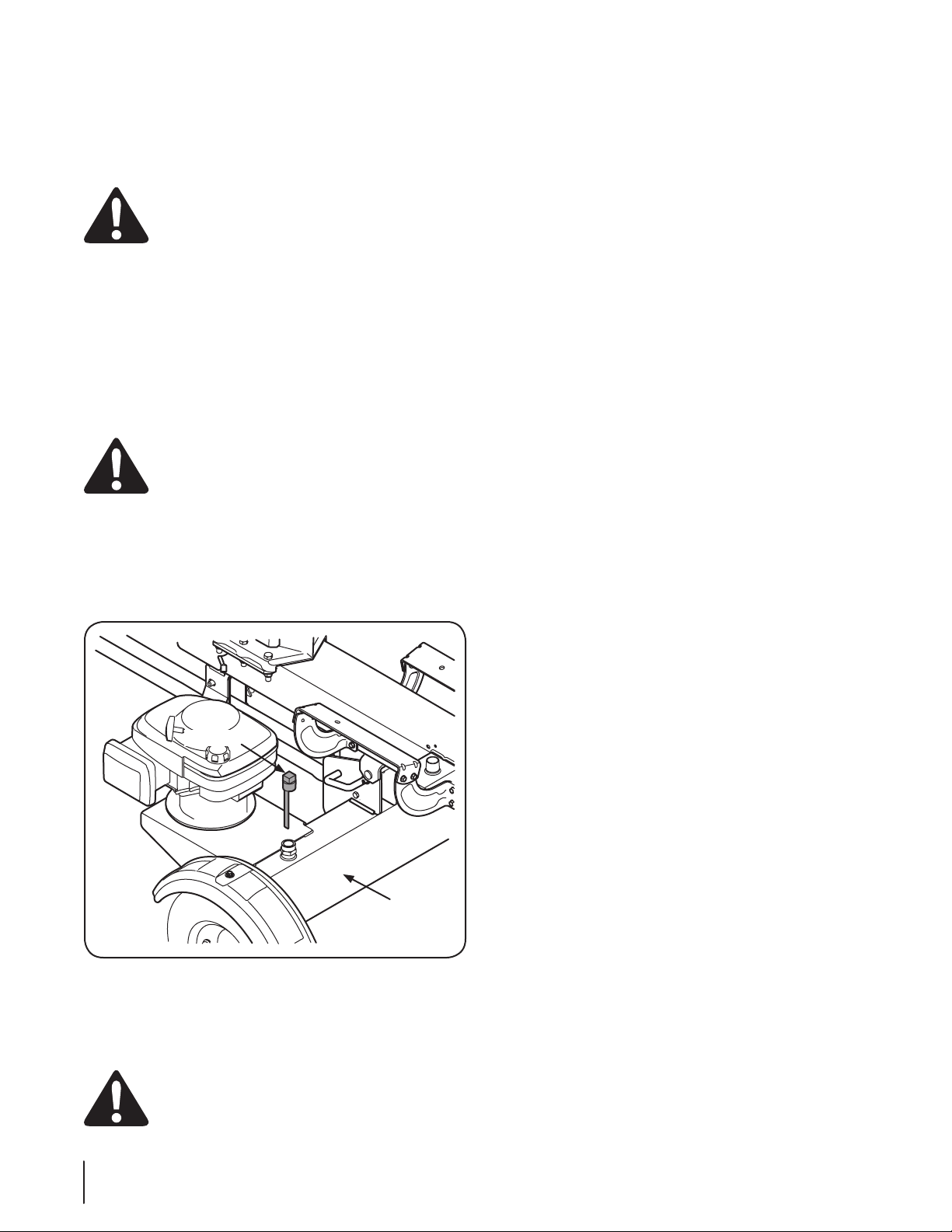

WARNING! Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

NOTE: Your log splitter may be shipped with motor oil in the

engine. You MUST check the oil level before operating. Be careful

not to overfill. Gasoline can be added to the engine when the log

splitter is in either the horizontal or vertical position. However, it

may be easier when the splitter is in the vertical position.

Tire Pressure

The max recommended operating pressure is 30 psi. Under any

circumstances do not exceed the manufacturer’s recommended

psi. Maintain equal pressure on all tires.

WARNING! Excessive pressure when seating beads

may cause tire/rim assembly to burst with force

sufficient to cause serious injury.

Preparing the Log Splitter

1. Lubricate the beam area (where the splitting wedge will

slide) with engine oil. Do not use grease.

2. Remove the vented reservoir dipstick, which is located in front

of the engine on top of the reservoir tank. See Figure 3-9.

3. Check the fluid level using the dipstick. See Figure 3-9. Do

not overfill.

NOTE: Approved fluids include Shell Tellus® S2 M 32 Hydraulic

Fluid, Dexron® III/Mercon® automatic transmission fluid, Pro-

Select™ AW-32 Hydraulic Oil or 10WAW-ISO viscosity grade 32

hydraulic oil. It is not recommended that fluids be mixed, to

top off the reservoir tank during initial set-up use Shell Tellus®

S2 M 32 Hydraulic Fluid only.

4. Replace the vented dipstick securely, tightening it until the

top of the threads are flush with top of the pipe.

5. Disconnect the spark plug and prime the pump by pulling the

recoil starter as far as it will go. Repeat approximately 10 times.

6. Reconnect the spark plug wire and start the engine

following instructions in the Engine Operator’s manual.

7. Use the control handle to engage the wedge to the farthest

extended position. Then retract the wedge.

8. Refill the tank as specified on the dipstick if necessary.

NOTE: Failure to refill the tank will void the splitter’s

warranty.

9. Extend and retract the wedge 12 complete cycles to

remove any trapped air in the system (the system is “selfbleeding”).

10. Refill the reservoir within the range marked on the dipstick

if necessary.

NOTE: Some fluid may overflow from the vent plug as

the system builds heat and the fluid expands and seeks a

balanced level.

Figure 3-9

NOTE: The log splitter is filled to the proper operating level

from the manufacturer with Shell Tellus® S2 M 32 Hydraulic

Fluid. However, you MUST check the fluid level before

operating. If not filled, proceed with the following steps:

WARNING! Much of the original fluid has been drawn

into the cylinder and hoses. Make certain to refill the

reservoir to prevent damage to the hydraulic pump.

10 Section 2— ASSembly & Set-Up

Page 11

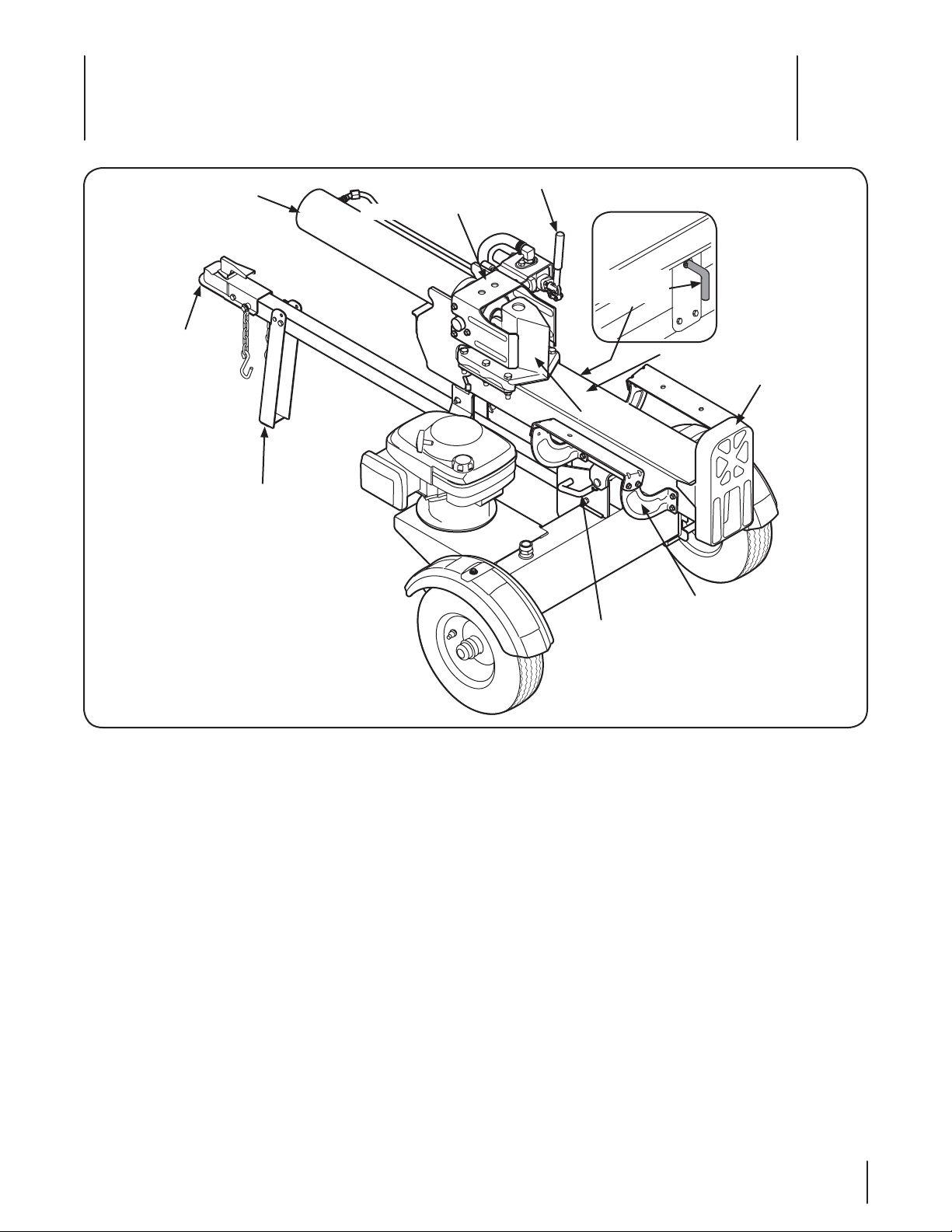

Controls & Features

Cylinder

Log Dislodger

Control Handle

Wedge

Beam Assembly

Log

Tray

Vertical

Beam

Lock

Jack Stand

Tongue

Horizontal

Beam Lock

End Plate

4

NOTE: This Operator’s Manual covers several models. Log splitter

features may vary by model. Not all features in this manual are

applicable to all log splitter models and the log splitter depicted

may differ from yours.

Engine Controls

See the Engine Operator’s Manual for the location and function

of the controls on the engine.

Beam Locks

These two locks, as their name suggests, are used to secure the

beam in the horizontal or the vertical position. The vertical beam

lock is located next to the engine. The horizontal beam lock is

located on the beam support latch bracket.

Control Handle

The control handle has three positions; Forward, Neutral and

Reverse. See the Operation section for instructions.

Figure 4-1

Wedge

The wedge is used to split the wood.

Log Dislodger

The log dislodger is designed to remove any partially split wood

from the wedge. This may occur while splitting large diameter

wood or freshly cut wood.

Log Tray

The log tray is designed to catch the log after it is split.

Tongue

The tongue is used to attach to a towing vehicle for transportation.

End Plate

The end plate holds the log in place while the wedge splits the log.

11

Page 12

Operation

Horizontal

Vertical

Vertical Beam Lock

1

2

1

2

Horizontal Beam Lock

5

Starting & Stopping the Engine

Refer to the Engine Operator’s manual packed with your log

splitter for instructions on starting and stopping the engine.

Using the Log Splitter

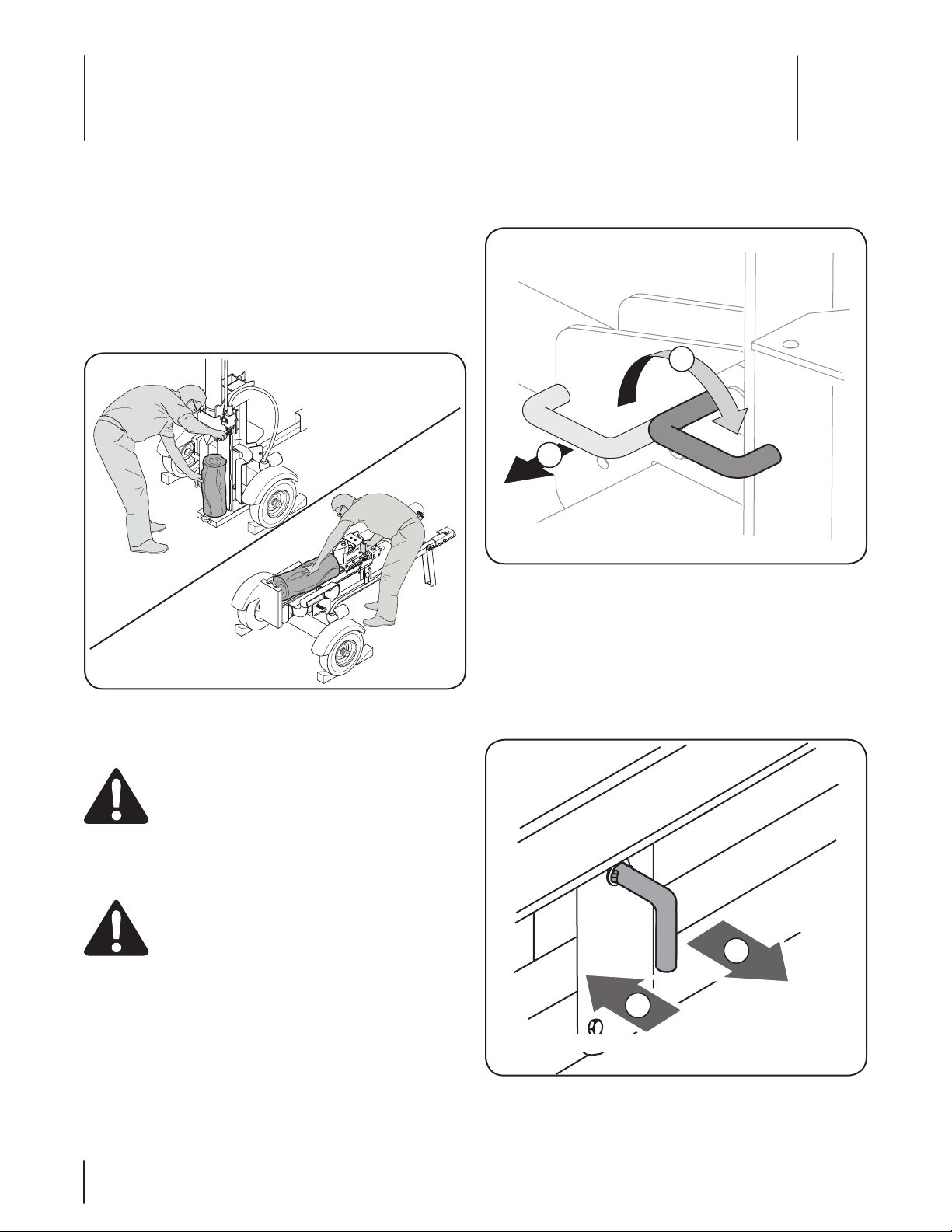

Operating Positions

1. Place the log splitter on flat, dry, solid ground.

2. Block the front and back of both wheels. See Figure 5-1.

Figure 5-1

3. Place the beam in either the horizontal or vertical position

and lock into place.

WARNING! Take extra care when raising and

lowering the beam as it is fairly heavy. Having a

second person assist with raising or lowering the

beam is recommended. Be sure to keep hands away

from any possible pinch points.

4. To place the beam in the vertical position proceed as

follows:

WARNING! Always use the log splitter in the

vertical position when splitting heavy logs.

b. To lock the beam in the vertical position, pull out on the

vertical beam lock and rotate it to secure the beam. See

Figure 5-2 .

Figure 5-2

5. To place the beam in the horizontal position proceed as

follows:

a. Pull the vertical beam lock out and rotate it down.

Pivot the beam to the horizontal position.

b. The horizontal beam lock is self-locking. The spring

loaded lock will snap into place when the beam is

lowered into position. See Figure 5-3.

a. Pull the horizontal beam lock out to release the

beam and pivot the beam to the vertical position.

Figure 5-3

12

Page 13

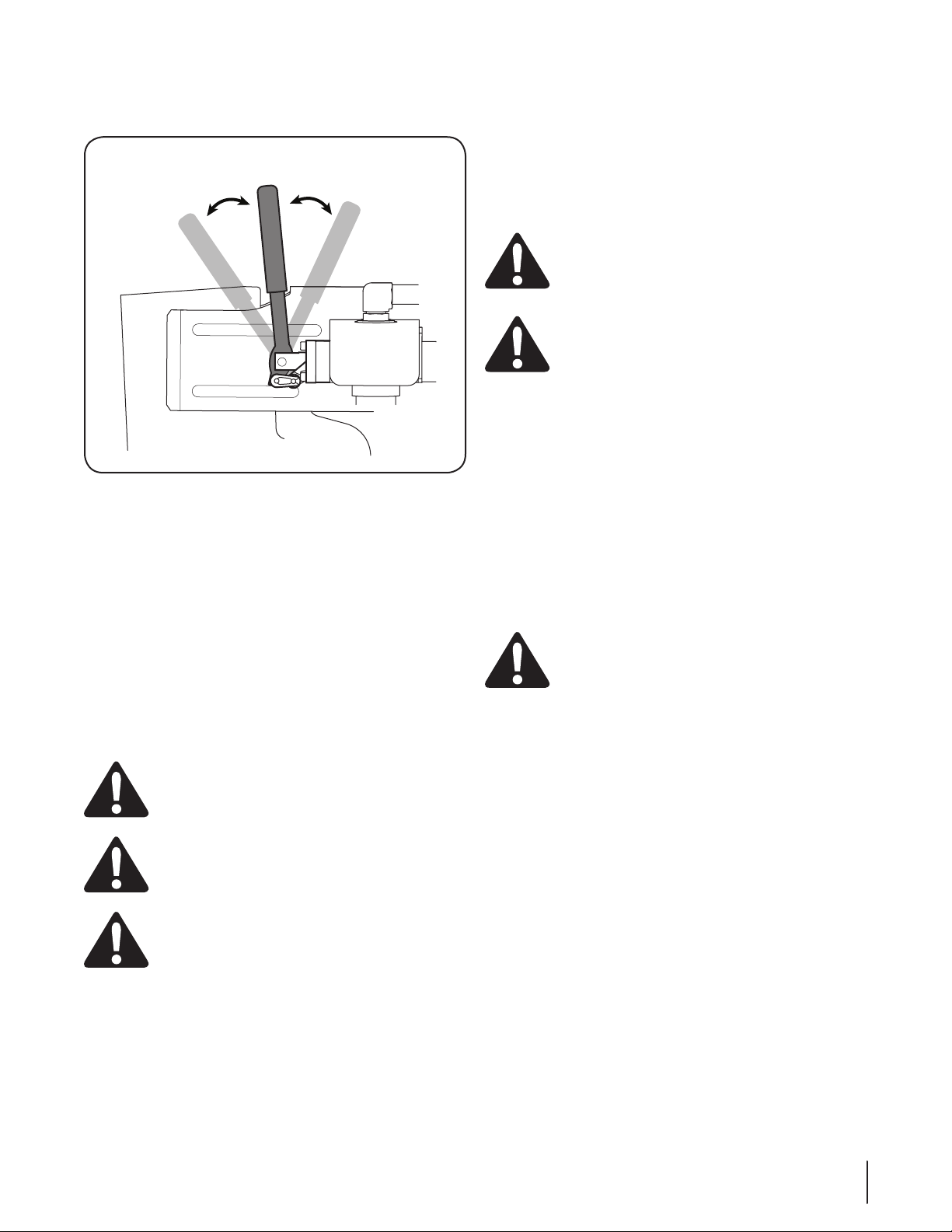

Using the Control Handle

Neutral

(To stop wedge)

Forward

(To split wood)

Reverse

(To return wedge)

The control handle has three positions. See Figure 5-4.

Figure 5-4

• FORWARD — Move the control handle to the FORWARD

position to move wedge toward the log to split.

NOTE: The control handle will return to the NEUTRAL position

as soon as the handle is released (FORWARD position only).

• NEUTRAL — Release the control handle or move the lever

to the NEUTRAL position to stop the wedge movement.

• REVERSE — Move the control handle to the REVERSE position

to return the wedge toward the cylinder. The control handle

stays in the REVERSE position and returns to the NEUTRAL

position automatically when fully retracted. Do not hold the

handle in the REVERSE position when fully retracted.

NOTE: The REVERSE position may also be moved back to

the NEUTRAL position manually, if necessary.

WARNING! If the control handle on your log splitter

is not functioning properly, STOP USE IMMEDIATELY

and contact an authorized service dealer.

Splitting the Wood

1. Start the engine as instructed in the Engine Operator’s

manual included with the log splitter.

2. Place the log against the end plate and only split the wood

in the direction of the grain.

3. To stabilize the log, place your left hand on the side of the

log opposite the beam as shown in Figure 5-1.

WARNING! Never place a hand on the ends of the

log, between the log and the end plate or the log

and the splitting wedge.

WARNING! Only one operator permitted. The

adult who loads and stabilizes the log, must be the

person who operates the control handle.

4. Move the control handle to the forward position to split the

wood.

5. Remove left hand from the side of the log once wedge just

contacts the log. Continue moving control handle forward

to split the log.

6. Release the control handle to stop the wedge movement.

7. Move the control handle to the reverse position to return

the wedge.

8. To remove partially split wood from wedge, move the

control handle to the REVERSE position until the wedge is

fully retracted to allow split wood portion to contact the

log dislodger.

WARNING! Never remove partially split wood from

the wedge with your hands. Fingers may become

trapped between the split wood.

9. Once removed from the wedge with the log dislodger, split

the wood from the opposite end or in another location.

WARNING! Do not attempt to service, repair or

replace control valve. Contact an authorized service

dealer.

WARNING! Do not attempt to adjust or modify the

control valve or the hydraulic system from its

original settings or manufacture in any way.

13Section 5 — oper ation

Page 14

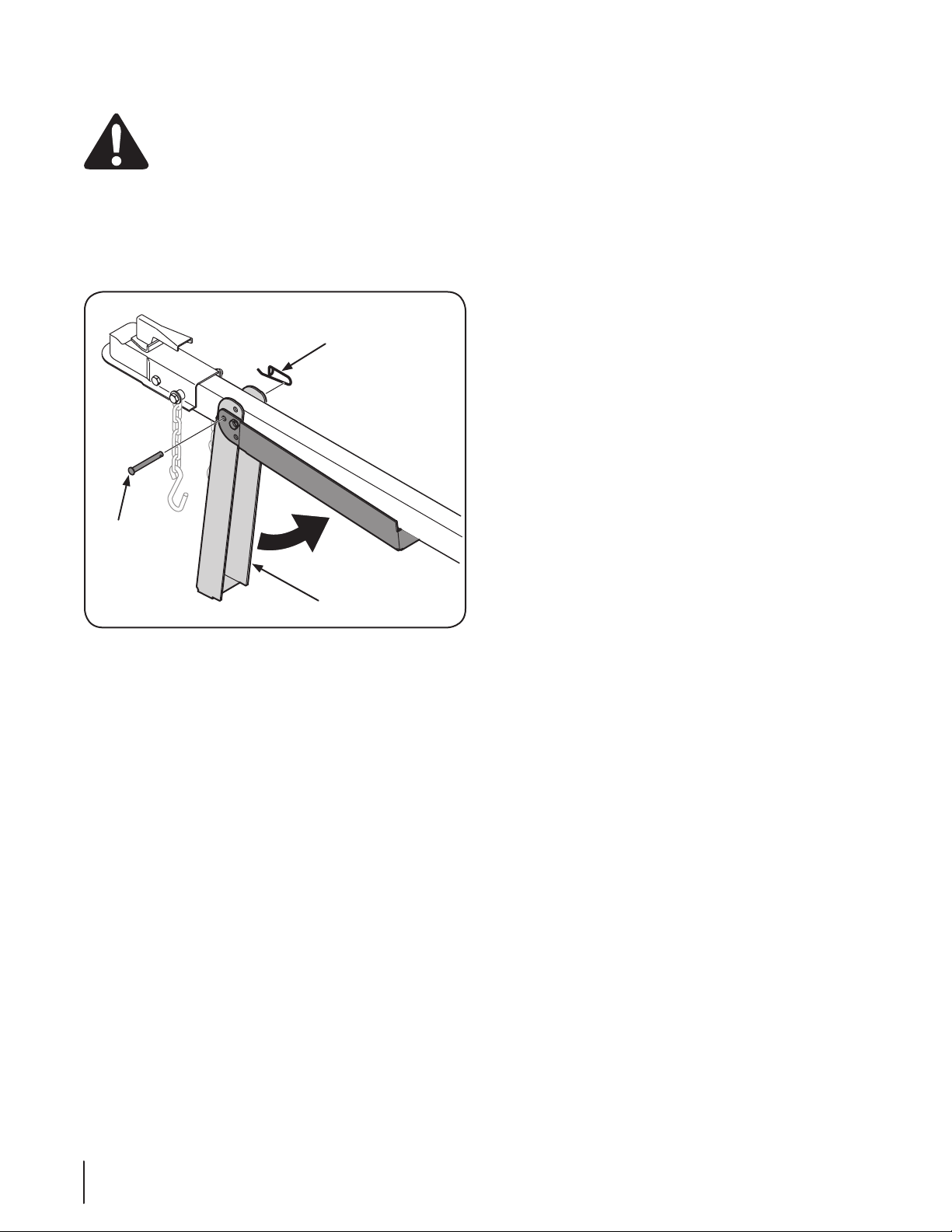

Transporting the Log Splitter

Spring Clip

Clevis Pin

Jack Stand

WARNING! Do not tow faster than 45mph and

check the local, state and federal requirements

before towing on any public road.

1. Lower the beam to its horizontal position. Make certain the

beam is locked securely with the horizontal beam lock.

2. Remove the spring clip and clevis pin from the jack stand.

3. Support the tongue and pivot the jack stand up against the

tongue. See Figure 5-5.

Operating Tips

Always:

1. Use clean fluid and check the fluid level regularly.

2. Use an approved hydraulic fluid. Approved fluids include

Shell Tellus® S2 M 32 Hydraulic Fluid, Dexron® III/Mercon®

automatic transmission fluid, Pro-Select™ AW-32 Hydraulic

Oil or 10WAW-ISO viscosity grade 32 hydraulic oil.

NOTE: It is recommended that fluids not be mixed.

3. Use a filter (clean or replace regularly).

4. Use a breather cap on fluid reservoir.

5. Make sure the pump is mounted and aligned properly.

6. Use a flexible “spider” type coupling between the engine

and pump drive shafts.

7. Keep the hoses clear and unblocked.

8. Bleed the air out of the hoses before operating.

9. Flush and clean the hydraulic system before restarting after

servicing.

10. Use “pipe dope” on all hydraulic fittings.

11. Allow time for the engine to warm up before splitting wood.

12. Prime the pump before the initial start-up by turning over

the engine with the spark plug disconnected (if not already

done at factory).

13. Split wood along the grain (lengthwise) only.

Figure 5-5

4. Secure with the spring clip and clevis pin previously

removed. See Figure 5-5.

5. Attach the coupler hitch to a class I or higher 2” ball on the

towing vehicle; latch securely.

a. If the coupler hitch does not fit on the ball, turn the

adjustment nut one turn counter-clockwise.

b. If the coupler hitch is too loose on the ball, turn the

adjustment nut one turn clockwise. Then recheck

and adjust accordingly.

6. Connect the safety chains to the towing vehicle.

NOTE: Use caution when backing up, a spotter outside the vehicle

is recommended.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Use a solid engine/pump coupling.

3. Operate through relief valve for more than 5 seconds.

4. Attempt to adjust the unloading or relief valve settings.

5. Operate with air in hydraulic system.

6. Use teflon tape on hydraulic fittings.

7. Attempt to cut wood across the grain.

8. Attempt to remove partially split wood from the wedge

with your hands. Fully retract the wedge to dislodge wood

with log dislodger.

14 Section 5— operation

Page 15

Maintenance & Adjustments

Suction

Hose

Inlet

Filter

Suction

Hose

Inlet

Filter

Inlet Filter

6

WARNING! Do not make any adjustments without

stopping the engine, disconnecting the spark plug

wire, grounding it against the engine and relieving

the hydro system pressure. Always wear safety

glasses during operation or while performing any

adjustments or repairs.

Engine

Refer to the Engine Operator’s Manual packed with your log

splitter for all engine maintenance.

Tire Pressure

The max recommended operating pressure is 30 psi. Do

not, under any circumstances, exceed the manufacturer’s

recommended psi. Maintain equal pressure on all tires.

WARNING! Excessive pressure when seating beads

may cause the tire/rim assembly to burst with force

sufficient to cause serious injury. Refer to the

sidewall of the tire for recommended pressure.

Hydraulic Fluid

Check the hydraulic fluid level in the log splitter reservoir tank

before each use. Maintain the fluid level within the range specified

on the dipstick at all times.

Change the hydraulic fluid in the reservoir every 100 hours of

operation. The filter should also be changed with each hydraulic

fluid change. Follow the steps below:

1. Place a suitable oil collection container under the tank.

2. If your engine has a horizontal engine set-up shown in Figure

6-1, refer to Figure 6-1 for changing the hydraulic fluid.

3. If your engine has a vertical set-up shown in Figure 6-2,

refer to Figure 6-2 for changing the hydraulic fluid.

Figure 6-2

4. Disconnect the suction hose from the bottom of the

reservoir tank. See Figure 6-1 for horizontal engines or

Figure 6-2 for vertical engines.

5. Carefully unthread the inlet filter and clean it with

penetrating oil. See Figure 6-3.

Figure 6-1

Figure 6-3

6. Allow the fluid to drain into a suitable container.

NOTE: The reservoir tank has a capacity of 3 gallons and

the entire hydraulic system has a capacity of approximately

4.7 gallons.

15

Page 16

7. Reinstall the cylinder, hoses, pumps, filter and suction hose.

Dipstick

MAX

MIN

Hydraulic Fluid

Only

Tighten the hose clamps to 50-60 in-lbs.

8. Check the fluid level using the dipstick. Do not overfill.

NOTE: Approved fluids include Shell Tellus® S2 M 32 Hydraulic

Fluid, Dexron® III / Mercon® automatic transmission fluid, Pro-

Select™ AW-32 Hydraulic Oil or 10WAW-ISO viscosity grade 32

hydraulic oil. It is recommended that fluids not be mixed.

9. Replace the vented dipstick securely, tightening it until the

top of the threads are flush with top of the pipe.

10. Disconnect the spark plug and prime the pump by pulling the

recoil starter as far as it will go. Repeat approximately 10 times.

11. Reconnect the spark plug wire and start the engine

following the instructions in the Engine Operator’s manual.

12. Use the control handle to engage the wedge to the farthest

extended position. Then retract the wedge.

13. If necessary Refill the reservoir within range marked on the

dipstick. See Figure 6-4.

Figure 6-4

14. Extend and retract the wedge 12 complete cycles to remove

trapped air in the system (the system is “self-bleeding”).

WARNING! Much of the original fluid has been drawn

into the cylinder and hoses. Make certain to ref ill the

reservoir to prevent damage to the hydraulic pump.

Failure to refill the tank will void the log splitter’s warranty.

16 Section 6— Maintenance & adjuStMentS

NOTE: Some fluid may overflow from the vent plug as

the system builds heat and the fluid expands and seeks a

balanced level. Do not operate the log splitter without the

proper amount of fluid in the reservoir tank.

15. Maintain the fluid level within the range specified on the

dipstick at all times. When checking the fluid, always make

sure to tighten the dipstick until the top of the threads are

flush with the top of the pipe.

NOTE: Always dispose of any used hydraulic fluid and

engine oil at approved recycling centers only.

16. Contaminants in the fluid may damage the hydraulic

components. Flushing the reservoir tank and hoses with

kerosene whenever service is performed on the tank,

hydraulic pump or valve is recommended. Contact an

authorized service dealer.

Hose Clamps

Check the clamps on the return hose before each use and check

the clamps on the suction hose once a season.

Hydraulic Filter

Change the hydraulic filter every 50 hours of operation. Use only

a 10 micron hydraulic filter. Order part number 723-0405.

Beam

Lubricate both sides of the beam (where it comes into contact with

the splitting wedge), before each use, with engine oil.

Off-Season Storage

If the log splitter will not be used for more than 30 days, prepare

it for storage as follows:

WARNING! Never store the machine with fuel in

the fuel tank inside of building where fumes may

reach an open flame or spark, or where ignition

sources are present such as hot water and space

heaters, furnaces, clothes dryers, stoves, electric

motors, etc.

1. Refer to the Engine Operator’s manual packed with your

log splitter for information on the off-season storage of the

engine.

2. Clean the log splitter thoroughly.

NOTE: Using a pressure washer or garden house to clean

the log splitter is not recommended. They may cause

damage to the bearings or the engine. The use of water will

result in a shortened life and reduce serviceability.

3. Wipe the machine with an oiled rag to prevent rust,

especially on the wedge and the beam.

4. Store the log splitter in a clean, dry area. Do not store it

next to corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage shed,

be certain to rustproof the equipment by coating it with a

light oil or silicone.

Page 17

Service

.090

.020

Flange Lock Nuts

Hex Screw

Set Screw

7

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert, located

between the pump and the engine shaft. Over time, the coupler will

harden and deteriorate. Replace the coupler if you detect vibration

or noise coming from the area between the engine and the pump. If

the coupler fails completely, you will experience a loss of power.

NOTE: On vertical shaft engines, it will be neccessary to remove

the engine to access the hex screws securing the pump to the

engine shaft. Taking the log splitter to an authorized service

dealer is recommended.

NOTE: Never hit the engine shaft in any manner, as a blow will

cause permanent damage to the engine.

1. Disconnect the spark plug wire and ground it against the

engine.

2. Remove the three flange lock nuts and hex screws that

secure the pump to the coupling shield. Two flange lock

nuts and hex screws are at the bottom corners and one is in

the top center. See Figure 7-1

7. Install the nylon “spider” onto the engine coupling half.

8. Install the pump coupling half and key on the pump shaft.

Rotate the coupling half until the set screw faces down. Do

not tighten set screw.

9. Align the pump coupling half with the nylon “spider” by

rotating the engine using the starter handle. Slide the

coupling half into place while guiding the three mounting

bolts through the holes in the pump support bracket.

10. Secure with the nuts removed earlier.

11. Set .020” to .090” of a clearance/gap between the nylon

“spider” and the engine coupling half by sliding a feeler

gauge between the nylon “spider” and the engine coupling

half and moving the pump coupling half as needed. Install

the set screw and torque to 78 in-lbs to secure the pump

coupling half. See Figure 7-1.

NOTE: Make certain the proper clearance/gap is obtained

before tightening the set screw.

12. Reconnect the spark plug.

Figure 7-1

3. Remove the pump.

4. Loosen the set screw on the pump coupling half and remove

the coupling half.

5. Rotate the engine by slowly pulling the starter handle until

the engine coupling half set screw is at the bottom. Loosen

the set screw using an allen wrench and slide the coupling

half off the engine shaft.

6. Slide the new engine coupling half onto the engine shaft

until the end of the shaft is flush with the inner portion of

the coupling half. (There must be space between the end of

the engine support bracket and the coupling half ). Tighten

the set screw.

17

Page 18

Troubleshooting

Problem Cause Remedy

8

Cylinder rod will not move 1. Broken drive shaft.

2. Shipping plugs left in hydraulic hoses.

3. Set screws in coupling not adjusted properly.

4. Loose shaft coupling.

5. Gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil level.

9. Damaged control valve.

10. Blocked control valve.

Slow cylinder shaft speed

while extending and

retracting

Leaking Cylinder 1. Worn seals.

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil level.

6. Contaminated oil.

7. Control valve leaking internally.

8. Internally damaged cylinder.

2. Scored cylinder.

1. See authorized service dealer.

2. Disconnect hydraulic hoses, remove shipping

plugs, reconnect hoses.

3. See authorized service dealer.

4. Correct engine/pump alignment as necessary.

5. See authorized service dealer.

6. See authorized service dealer.

7. Flush and clean hydraulic system.

8. Check oil level.

9. See authorized service dealer.

10. Flush and clean hydraulic system

1. See authorized service dealer.

2. Make certain the pump inlet hoses are clear

and unblocked. Use short, large diameter

inlet hoses.

3. See authorized service dealer.

4. See authorized service dealer.

5. Check oil level.

6. Drain oil, clean reservoir and refill.

7. See authorized service dealer.

8. See authorized service dealer

1. See authorized service dealer.

2. See authorized service dealer.

18

Page 19

Problem Cause Remedy

Wood will not split or wood

splits too slowly

Leaking pump shaft seal 1. Broken drive shaft.

Wedge continues to move

forward when control

handle is released

Control handle does not

return to neutral when

released from forward

position

1. Small gear section damaged.

2. Pump check valve leaking.

3. Excessive pump inlet vacuum.

4. Incorrect oil level.

5. Contaminated oil.

6. Control valve leaking internally.

7. Overloaded cylinder.

8. Internally damaged cylinder.

2. Engine/pump misalignment.

3. Gear sections damaged.

4. Damaged shaft seal.

5. Plugged oil breather.

1. Damaged control valve 1. See authorized service dealer.

1. Hydraulic fluid too cold.

2. Hydraulic fluid too thick.

3. Hydraulic fluid contaminated.

4. Damaged control valve.

1. See authorized service dealer.

2. See authorized service dealer.

3. Make certain pump inlet hoses are clear and

unblocked.

4. Check oil level.

5. Drain oil, clean reservoir and refill.

6. See authorized service dealer.

7. Do not attempt to split wood against the grain.

8. See authorized service dealer.

1. See authorized service dealer.

2. Correct alignment as necessary.

3. See authorized service dealer.

4. See authorized service dealer.

5. Make certain reservoir is properly vented.

1. Warm up engine.

2. Replace hydraulic fluid.

3. Replace hydraulic fluid.

4. See authorized service dealer.

19Section 8 — troubleShooting

Page 20

Replacement Parts

Component Part Number and Description

9

737-0348A Vented Dipstick

735-04103 Spider Bushing

718-04395 Coupling, .875

718-04392 Coupling, .500

710-1842A Set Screw

723-0405 Hydraulic Oil Filter

737-04308 Inlet Filter

727-04290 Inlet Hose

727-04288 Hydro Hose

727-0443 Return Hose

727-04362 Hydro Hose

726-0132 Hose Clamp

634-0186 Complete Wheel, 16.0 x 4.8 x 8.0

98079-56846 Spark Plug (572 Models)

951-10292 Spark Plug (57M Models))

16952-ZA8-800 Fuel Filter (572 Models)

N/A Fuel Filter (57M Models)

17211-ZL8-023 Air Cleaner (572 Models)

951-10794 Air Cleaner (57M Models)

Phone (800) 828-5500 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready).

Parts Manual downloads are also available free of charge at www.troybilt.com.

20

Page 21

Notes

10

21

Page 22

22 Section 10— noteS

Page 23

23Section 10 — noteS

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR

The limited warranty set forth below is given by Troy-Bilt LLC with

respect to new merchandise purchased and used in the United States

and/or its territories and possessions, and by MTD Products Limited

with respect to new merchandise purchased and used in Canada and/

or its territories and possessions (either entity respectively, “Troy-Bilt”).

This warranty is in addition to any applicable emissions warranty

provided with your product.

“Troy-Bilt” warrants this product (excluding its Normal Wear Parts

and Attachments as described below) against defects in material and

workmanship for a period of two (2) years commencing on the date of

original purchase and will, at its option, repair or replace, free of charge,

any part found to be defective in materials or workmanship. This

limited warranty shall only apply if this product has been operated and

maintained in accordance with the Operator’s Manual furnished with

the product, and has not been subject to misuse, abuse, commercial

use, neglect, accident, improper maintenance, alteration, vandalism,

theft, fire, water, or damage because of other peril or natural disaster.

Damage resulting from the installation or use of any part, accessory

or attachment not approved by Troy-Bilt for use with the product(s)

covered by this manual will void your warranty as to any resulting

damage.

Normal Wear Parts are warranted to be free from defects in material

and workmanship for a period of thirty (30) days from the date of

purchase. Normal wear parts include, but are not limited to items such

as: batteries, belts, blades, blade adapters, tines, grass bags, wheels,

rider deck wheels, seats, snow thrower skid shoes, friction wheels,

shave plates, auger spiral rubber and tires.

Attachments — Troy-Bilt warrants attachments for this product against

defects in material and workmanship for a period of one (1) year,

commencing on the date of the attachment’s original purchase or

lease. Attachments include, but are not limited to items such as: grass

collectors and mulch kits.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE, through your local authorized service dealer. To

locate the dealer in your area:

In the U.S.A.

Check your Yellow Pages, or contact Troy-Bilt LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-866-840-6483,

1-330-558-7220 or log on to our Web site at www.troybilt.com.

In Canada

Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800668-1238 or log on to our Web site at www.mtdcanada.com.

This limited warranty does not provide coverage in the following cases:

a. The engine or component parts thereof. These items may

carry a separate manufacturer’s warranty. Refer to applicable

manufacturer’s warranty for terms and conditions.

b. Log splitter pumps, valves, and cylinders have a separate one-

year warranty.

c. Routine maintenance items such as lubricants, filters, blade

sharpening, tune-ups, brake adjustments, clutch adjustments,

deck adjustments, and normal deterioration of the exterior finish

due to use or exposure.

d. Service completed by someone other than an authorized service

dealer.

e. Troy-Bilt does not extend any warranty for products sold or

exported outside of the United States and/or Canada, and their

respective possessions and territories, except those sold through

Troy-Bilt’s authorized channels of export distribution.

f. Replacement parts that are not genuine Troy-Bilt parts.

g. Transportation charges and service calls.

h. Troy-Bilt does not warrant this product for commercial use.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose, applies

after the applicable period of express written warranty above

as to the parts as identified. No other express warranty,

whether written or oral, except as mentioned above, given

by any person or entity, including a dealer or retailer, with

respect to any product, shall bind Troy-Bilt. During the period

of the warranty, the exclusive remedy is repair or replacement

of the product as set forth above.

The provisions as set forth in this warranty provide the sole

and exclusive remedy arising from the sale. Troy-Bilt shall

not be liable for incidental or consequential loss or damage

including, without limitation, expenses incurred for substitute

or replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions or limitations may not apply to

you.

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of safety features

of the product shall void this warranty. You assume the risk and

liability for loss, damage, or injury to you and your property and/or to

others and their property arising out of the misuse or inability to use

the product.

This limited warranty shall not extend to anyone other than the original

purchaser or to the person for whom it was purchased as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This limited

warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

IMPORTANT: Owner must present Original Proof of Purchase to

obtain warranty coverage.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-866-840-6483, 1-330-558-7220

GDOC-100020 REV. A

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

Page 25

Medidas importantes de seguridad • Conguración • Funcionamiento • Mantenimiento • Servicio • Solución de problemas • Garantía

Manual del OperadOr

LS 27 TB — Máquina rompe troncos

ADVERTENCIA

LEA Y RESPETE TODAS LAS NORMAS DE SEGURIDAD E INSTRUCCIONES INCLUIDAS EN ESTE

MANUAL ANTES DE PONER EN FUNCIONAMIENTO ESTA MÁQUINA.

SI NO RESPETA ESTAS INSTRUCCIONES PUEDE PROVOCAR LESIONES PERSONALES.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Impreso en Estados Unidos de América

Formulario No. 769-09000

(Mayo 20, 2013)

Page 26

Al propietario

Gracias

Gracias por comprar una MTD máquina rompe troncos. La

misma ha sido diseñada cuidadosamente para brindar excelente

rendimiento si se la opera y mantiene correctamente.

Por favor lea todo este manual antes de operar el equipo.

Le indica cómo configurar, operar y mantener la máquina

con seguridad y fácilmente. Por favor asegúrese de seguir

cuidadosamente y en todo momento las prácticas de seguridad

recomendadas, y hacérselas seguir a cualquier otra persona que

opere la máquina. En caso de no hacerlo podrían producirse

lesiones personales o daños materiales.

Toda la información contenida en este manual hace referencia

a la más reciente información de producto disponible en el

momento de la impresión. Revise el manual frecuentemente

para familiarizarse con la unidad, sus características y

funcionamiento. Por favor tenga en cuenta que este Manual

del Operador puede cubrir una gama de especificaciones de

productos de diferentes modelos. Las características y funciones

incluidas y/o ilustradas en este manual pueden no ser aplicables

a todos los modelos. MTD se reserva el derecho de modificar

las especificaciones de los productos, los diseños y el equipo

1

estándar sin previo aviso y sin generar responsabilidad por

obligaciones de ningún tipo.

En su caso, los datos de prueba de potencia utilizados para

establecer la máxima potencia equipado en esta máquina se

pueden encontrar en www.opei.org o sitio web del fabricante

del motor. Si tiene algún problema o duda respecto a la unidad,

llame a un distribuidor de servicio MTD autorizado o póngase en

contacto directamente con nosotros. Los números de teléfono,

dirección del sitio web y dirección postal de la Asistencia al

Cliente de MTD se encuentran en esta página. Queremos

garantizar su entera satisfacción en todo momento.

En este manual, las referencias al lado derecho o izquierdo de la

máquina se observan desde la posición del operador.

El fabricante del motor es el responsable de todas las

cuestiones relacionadas con el rendimiento, potencia de salida,

especificaciones, garantía y mantenimiento del motor. Para

obtener mayor información consulte el Manual del Propietario /

Operador entregado por el fabricante del motor, que se envía, en

un paquete por separado, junto con su unidad.

Índice

Medidas importantes de seguridad ...................... 3

Montaje y Conguración ........................................ 7

Controles y Características ....................................11

Funcionamiento .....................................................12

Registro de información de producto

Antes de configurar y operar su equipo nuevo, por favor localice

la placa de modelo en el equipo y registre la información en el

área situada a la derecha. Puede encontrar la placa del modelo

en la brida del motor de lado la placa de montaje. Si tiene

que solicitar soporte técnico a través de nuestro sitio web, el

Departamento de Asistencia al Cliente, o de un distribuidor de

servicio autorizado local, necesitará esta información.

Mantenimiento y Ajustes .......................................15

Servicio ....................................................................18

Solución de problemas ..........................................19

Garantía ................................................................. 24

NúMero de Modelo

NúMero de Serie

Asistencia al Cliente

Por favor, NO devuelva la unidad al minorista o distribuidor sin ponerse en contacto primero con el Departamento de

Asistencia al Cliente.

En caso de tener problemas para montar este producto o de tener dudas con respecto a los controles, funcionamiento o

mantenimiento del mismo, puede solicitar la ayuda de expertos. Elija entre las opciones que se presentan a continuación:

◊ Visite nuestro sitio web en www.mtdproducts.com

Ver Vídeos demostrativos de instalación de mantenimiento y piezas en www.mtdparts.com/KnowledgeCenter

◊ Llame a un representante de Asistencia al Cliente al (800) 800-7310 ó (330) 220-4683

◊ Escríbanos a MTD LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

2

Page 27

Medidas importantes de seguridad

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones de

seguridad importantes que se deben respetar para evitar poner en peligro su seguridad

personal y/o material y la de otras personas. Lea y cumpla todas las instrucciones de este

manual antes de intentar operar esta máquina. Si no respeta estas instrucciones puede

provocar lesiones personales.

Cuando vea este símbolo. ¡TENGA EN CUENTA LAS ADVERTENCIAS!

PROPOSICIÓN 65 DE CALIFORNIA

ADVERTENCIA: El escape del motor de este producto, algunos de sus componentes

y algunos componentes del vehículo contienen o liberan sustancias químicas que el

estado de California considera que pueden producir cáncer, defectos de nacimiento

u otros problemas reproductivos.

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las normas

de seguridad contenidas en este manual. Al igual que con cualquier tipo de equipo

motorizado, un descuido o error por parte del operador puede producir lesiones graves.

Esta máquina es capaz de amputar manos y pies y de arrojar objetos con gran fuerza.

De no respetar las instrucciones de seguridad siguientes se pueden producir lesiones

graves o la muerte.

2

Capacitación

1. Lea, entienda y cumpla todas las instrucciones incluidas en

la máquina y en el(los) manual(es) antes de intentar realizar

el montaje de la unidad y utilizarla. Guarde este manual

en un lugar seguro para consultas futuras y periódicas, así

como para solicitar repuestos.

2. Familiarícese con todos los controles y con el uso adecuado

de los mismos. Sepa cómo detener la máquina y desenganchar los controles rápidamente.

3. No permita nunca que los niños menores de 16 años utilicen

esta máquina. Los niños de 16 años en adelante deben

leer y entender las instrucciones de operación y normas

de seguridad contenidas en este manual y en la máquina y

deben ser entrenados y supervisados por un adulto.

4. Nunca permita que los adultos operen esta máquina sin

recibir antes la instrucción apropiada.

5. Muchos accidentes ocurren cuando más de una persona

hace funcionar la máquina. Si un peón lo está ayudando

a cargar los troncos, nunca active el control hasta que el

peón se encuentre por lo menos a 10 pies de distancia de

la máquina.

6. Mantenga a los observadores, mascotas y niños por lo menos

a 10 pies de la máquina siempre que esté funcionando.

7. Nunca permita que ninguna persona se desplace en

la máquina.

8. Nunca traslade cargas en esta máquina.

9. Las máquinas rompetroncos hidráulicas desarrollan altas

presiones de fluido durante el funcionamiento. Si sale fluido

a través de la abertura de un orificio de pasador puede

penetrar en la piel y causarle envenenamiento de la sangre,

gangrena o la muerte. Preste atención a las siguientes

instrucciones en todo momento:

a. No controle las fugas con la mano.

b. No opere la máquina si las mangueras, los accesorios

o los tubos están deshilachados, enroscados,

agrietados o dañados.

c. Detenga el motor y libere la presión del sistema

hidráulico haciendo pasar la palanca de control de

la válvula de la posición de avance a la de retroceso

varias veces mientras el motor no está en marcha;

regresando a la posición neutral antes de realizar la

reparación o el ajuste de los accesorios, las mangueras, los tubos u otros componentes del sistema.

d. No ajuste los valores de presión de la bomba o válvula.

10. Las fugas se pueden detectar pasando un cartón o madera

sobre el área sospechosa, usando guantes de protección

y anteojos de seguridad. Fíjese si el cartón o la madera

pierden color.

11. Si es lastimado por un escape de fluido, consulte a un mé-

dico de inmediato. Si no se administra tratamiento médico

adecuado inmediatamente se puede producir una infección

o reacción grave.

12. Mantenga la zona del operador y el área adyacente despe-

jadas, para poder estar parado con firmeza y seguridad.

3

Page 28

Horizontal

Vertical

13. Si la máquina está equipada con un motor de combustión

interna y existe la intención de usarla cerca de un terreno

agreste cubierto de bosque, arbustos o pasto, el escape del

motor debe estar provisto de un amortiguador de chispas.

Asegúrese de respetar todos los códigos locales, estatales y

federales aplicables. Lleve el equipamiento adecuado para

combatir incendios.

14. Esta máquina se debe utilizar únicamente para cortar

madera, no la use con ningún otro propósito.

15. Siga las instrucciones del(de los) manual(es) entregado(s)

con cualquier accesorio de esta máquina.

Preparativos

1. Siempre use zapatos de seguridad o botas reforzadas.

2. Siempre use anteojos o antiparras de seguridad cuando

hace funcionar esta máquina.

3. No use nunca joyas ni vestimenta floja que pudieran quedar

atrapadas en las partes móviles o giratorias de la máquina.

4. Compruebe que la máquina esté sobre suelo nivelado, seco

y resistente antes de su operación.

5. Siempre bloquee las ruedas para evitar que se mueva accidentalmente y trabe la vigueta ya sea en posición horizontal

o vertical.

6. Siempre opere la máquina desde la(s) zona(s) del operador

que se especifican en el manual. Vea la Fig. 2-1.

Figura 2-1

7. Antes de cortar los troncos con esta máquina se les deben

cortar los extremos en escuadra.

8. Use la máquina rompetroncos a la luz del día o con buena

luz artificial.

Manejo seguro de la gasolina

Para evitar lesiones personales o daños materiales sea sumamente

cuidadoso al manipular la gasolina. La gasolina es sumamente

inflamable y sus vapores pueden causar explosiones. Si se derrama

gasolina encima o sobre la ropa se puede lesionar gravemente

ya que se puede encender. Lávese la piel y cámbiese de ropa de

inmediato.

a. Utilice sólo los recipientes para gasolina autorizados.

b. Apague todos los cigarrillos, cigarros, pipas y otras

fuentes de ignición.

c. Nunca cargue combustible en la máquina en un

espacio cerrado.

d. Nunca saque la tapa del combustible ni agregue com-

bustible mientras el motor está caliente o en marcha.

e. Deje que el motor se enfríe por lo menos dos

minutos antes de volver a cargar combustible.

f. Nunca llene en exceso el tanque de combustible.

Llene el tanque no más de 1/2 pulgada por debajo

de la base del cuello del filtro para dejar espacio para

la expansión del combustible.

g. Vuelva a colocar la tapa del combustible y ajústela bien.

h. Limpie el combustible que se haya derramado sobre

el motor y el equipo y mueva la máquina a otra área.

Espere cinco minutos antes de encender el motor.

i. Nunca guarde la máquina o el recipiente de

combustible en un espacio cerrado donde haya

fuego, chispas o luz piloto, como por ejemplo de

calentadores de agua, calefactores de ambientes,

hornos, secadores de ropa u otros aparatos a gas.

j. Deje que la máquina se enfríe por lo menos

5 minutos antes de guardarla.

Funcionamiento

1. Antes de poner en marcha esta máquina, repase las “Medidas

de seguridad”. Si no se respetan estas normas se pueden

producir lesiones graves tanto al operador como a los

observadores.

2. Nunca deje la máquina en funcionamiento sin vigilancia.

3. No utilice la máquina bajo la influencia de alcohol, drogas

o medicamentos.

4. Nunca permita a nadie operar esta máquina sin recibir

antes la instrucción apropiada.

5. Siempre opere la máquina con todo el equipamiento de

seguridad en su lugar y en condiciones. Asegúrese de que

todos los controles funcionen adecuadamente para una

operación segura.

6. Zona del operador

a. Posición horizontal de funcionamiento: Párese del

lado de la palanca de control de la máquina rompetroncos y estabilice el tronco como se indica, si es

necesario. Vea la Fig. 2-1.

b. Posición vertical de funcionamiento: Párese delante

de la máquina rompetroncos y estabilice el tronco

como se indica, si es necesario. Vea la Fig. 2-1.

7. Cuando cargue un tronco, siempre coloque las manos a los

lados del mismo, no en los extremos, y no use nunca el pie

para estabilizar un tronco. Si no respeta estas instrucciones,

se puede producir el aplastamiento o la amputación de

dedos, dedos de los pies, manos o pies.

ADVERTENCIA! Cuando estabiliza el tronco

¡

con la mano izquierda, quite la mano después de

que la cuña esté justo en contacto con el tronco o

puede lesionarse gravemente.

4 Sección 2 — MedidaS iMportanteS de Seguridad

Page 29

8. Use únicamente la mano derecha para operar los controles.

9. Nunca intente cortar más de un tronco a la vez.

10. Para los registros que no están cortados en ángulo recto, el

extremo menos cuadrado de la sesión se debe colocar hacia

el rayo y la cuña, y el extremo cuadrado colocado hacia la

placa terminal.

11. Cuando corte en posición vertical, estabilice el tronco antes

de mover la manija de control. Corte según se indica a

continuación:

a. Coloque el tronco en la placa del extremo y gírelo

hasta que se incline contra la vigueta y quede estable.

b. Al dividir extra grande o desigual registros, el registro

debe ser estabilizado con cuñas de madera o de

madera dividida coloca entre el registro y la placa

terminal o tierra.

12. Siempre mantenga los dedos alejados de cualquier hendi-

dura que se abra en el tronco mientras realiza el cortado.

Estas separaciones se pueden cerrar con rapidez y atrapar

o amputar dedos.

13. Mantenga limpia el área de trabajo. Retire inmediatamente

la madera cortada que quede alrededor de la máquina para

no tropezarse con la misma.

14. No cambie la configuración del regulador del motor ni

acelere demasiado el motor. El regulador del motor controla

la velocidad máxima de funcionamiento seguro del motor.

15. Nunca mueva la máquina mientras el motor está en

funcionamiento.

16. Esta máquina no se debe remolcar en ninguna calle, ruta o

camino público sin verificar los requisitos aplicables a los

vehículos según las reglamentaciones federales, estatales

o locales que se encuentren en vigencia. Cualquier autorización o modificación que se deba realizar, por ejemplo, en

relación con luces traseras, etc., es responsabilidad exclusiva

del comprador. Si en su estado se exige una “Declaración

de Origen”, consulte con su distribuidor local.

17. No remolque la máquina por encima de las 45 mph.

18. Vea la sección 'Transporte de la máquina rompetroncos'

de este manual para consultar las instrucciones de

remolque adecuadas después de haber cumplimentado

todos los requisitos federales, locales o estatales.

Mantenimiento y almacenamiento

1. Detenga el motor, desconecte la bujía y haga masa contra

el motor antes de limpiar o inspeccionar la máquina.

2. Detenga el motor y libere la presión del sistema hidráulico

haciendo pasar la palanca de control de la válvula de la

posición de avance a la de retroceso varias veces mientras

el motor no está en marcha; regresando a la posición

neutral antes de realizar la reparación o el ajuste de los

accesorios, las mangueras, los tubos u otros componentes

del sistema.

3. Para evitar incendios, limpie la suciedad y grasa de las áreas

del motor y del silenciador. Si el motor está equipado con

un silenciador con amortiguador de chispas, límpielo e

inspecciónelo regularmente según las instrucciones de los

fabricantes. Reemplácelo si está dañado.

4. Periódicamente controle que todas las tuercas y pernos,

abrazaderas de mangueras y accesorios hidráulicos estén

ajustados, para verificar que el equipo se encuentra en

condiciones de trabajo seguras.

5. Controle todos los protectores y escudos de seguridad

para verificar que se encuentren en posición adecuada.

Nunca opere la máquina si se han retirado los protectores o

escudos de seguridad u otros dispositivos de protección.

6. La válvula de descarga de presión viene preconfigurada

de fábrica. No la ajuste.

7. No intente nunca mover la máquina en terreno en

pendiente o desparejo sin un vehículo de remolque o sin

ayuda adecuada.

8. Por su seguridad, cambie todas las piezas dañadas o

desgastadas inmediatamente utilizando únicamente

equipo del fabricante original ('OEM'). El uso de piezas que

no cumplen con las especificaciones del equipo original

puede resultar en rendimiento inadecuado y puede poner

en peligro la seguridad.

9. No modifique esta máquina de ningún modo; si se realizan

modificaciones tales como agregado de una cuerda o alargador a la manija de control, o el aumento del ancho o la altura

de la cuña, se pueden producir lesiones personales graves.

10. Según la Comisión de Seguridad de Productos para el

Consumidor de los Estados Unidos (CPSC) y la Agencia

de Protección Ambiental de los Estados Unidos (EPA),

este producto tiene una vida útil media de siete (7) años

o 130 horas de funcionamiento. Al finalizar la vida útil

media haga inspeccionar anualmente esta unidad por un

distribuidor de servicio autorizado para cerciorarse de que

todos los sistemas mecánicos y de seguridad funcionan

correctamente y no tienen excesivo desgaste. Si no lo hace,

pueden producirse accidentes, lesiones o la muerte.

Amortiguador de chispas

ADVERTENCIA: Esta máquina está equipada

con un motor de combustión interno y no debe

ser utilizada en o cerca de un terreno agreste

cubierto por bosque, malezas o hierba excepto

que el sistema de escape del motor esté equipado

con un amortiguador de chispas que cumpla con

las leyes locales o estatales correspondientes (en

caso de existir).

Si se utiliza un amortiguador de chispas el operador lo debe

mantener en condiciones de uso adecuadas. En el Estado de

California las medidas anteriormente mencionadas son exigidas

por ley (Artículo 4442 del Código de Recursos Públicos de

California). Es posible que existan leyes similares en otros estados.

Las leyes federales se aplican en territorios federales.

Puede conseguir el amortiguador de chispas para el silenciador a

través de su distribuidor de mantenimiento de motores autorizado

más cercano o poniéndose en contacto con el departamento de

servicios, P.O. Box 361131 Cleveland, Ohio 44136-0019.

5Sección 2 — MedidaS iMportanteS de Seguridad

Page 30

Símbolos de seguridad

En esta página se presentan y describen los símbolos de seguridad que pueden aparecer en este producto. Lea, entienda y cumpla

todas las instrucciones incluidas en la máquina antes de intentar realizar el montaje de la unidad y utilizarla.

Símbolo Descripción

LEA LOS MANUALES DEL OPERADOR

Lea, entienda y cumpla todas las instrucciones incluidas en los manuales antes de realizar

el montaje de la unidad y utilizarla.

ADVERTENCIA— RIESGO DE APLASTAMIENTO

Mantenga las manos alejadas de la cuña, la placa del extremo, la madera que esté

parcialmente cortada y las piezas móviles.

OBSERVADORES

Mantenga a los observadores, ayudantes y niños por lo menos a 10 pies de distancia.

OPERADOR ÚNICO

Sólo debe operar la máquina una persona a la vez. El adulto que carga y estabiliza el tronco

debe ser la persona que opere la manija de control.

ADVERTENCIA— FLUIDO PRESURIZADO