0 TRtllcBILT' ----

Operator's Manual

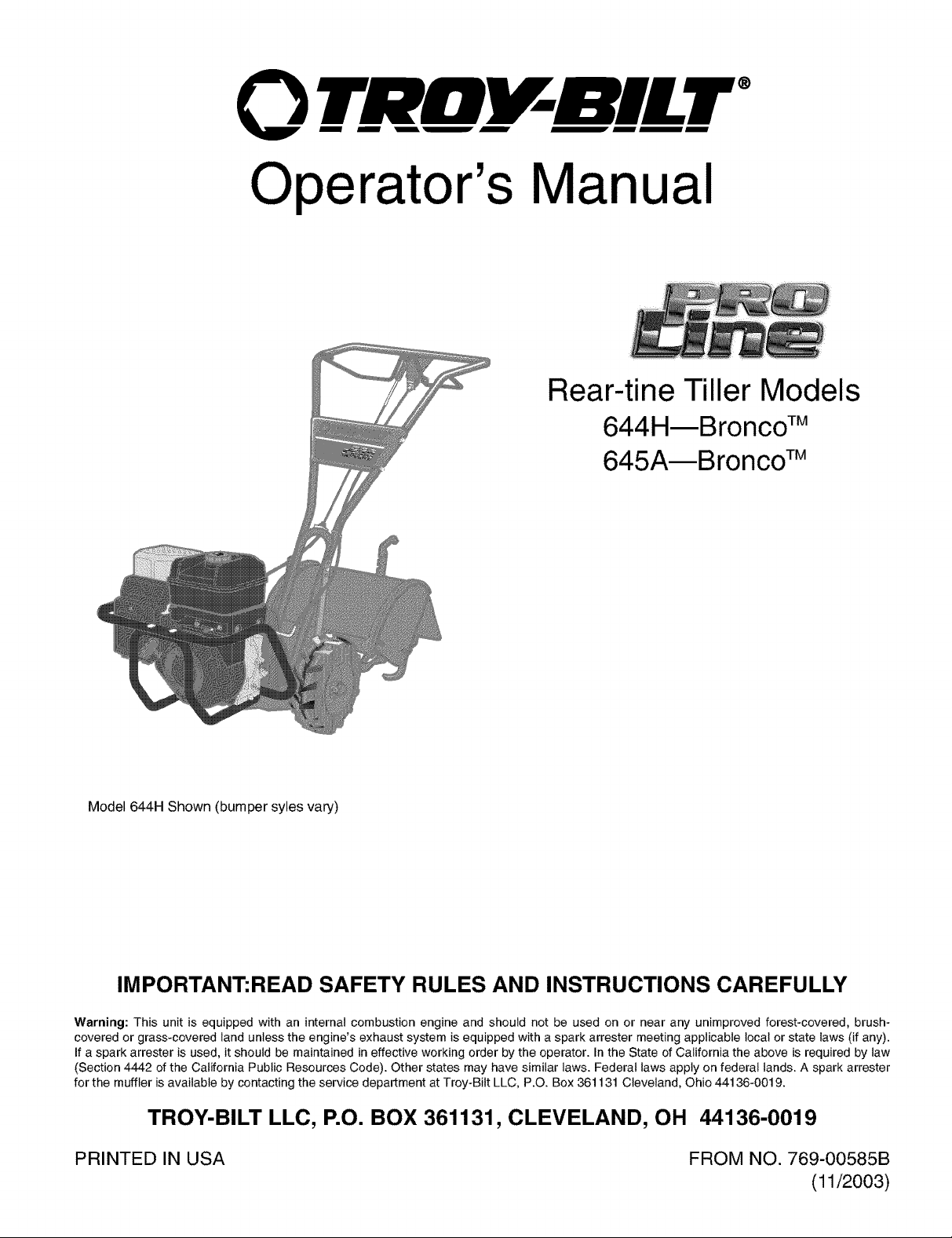

Rear-tine Tiller Models

644HmBronco TM

645AmBronco TM

Model 644H Shown (bumper syles vary)

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 769-00585B

(11/2003)

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 19

Safety 3 Off-season Storage 24

Assembly 6 Troubleshooting 25

Features and Controls 10

Operation 13 Warranty Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Copy the model number here:

Copy the serial number here:

www.troybilt:com CLEVELAND,01144136

330-558-7220

1-800-520"5520

CUSTOMERSUPPORT

PleasedoNOTreturntheunittotheretailerwithoutfirstcontactingCustomerSupport.

Ifyou have difficultyassembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

willget the four options reproduced here. Click on the appropriate buttonand help is

immediately available.

_S

The answer you are _ The answer you are

I lOOKingfor could be just ....,,_y.... _ ,,.........,_0._......... looking for could bejust

a mouse click away! a mouse click away!

I

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty to engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

and service. Please refer the

n

Safety

SPARKARRESTERWARNINGTO RESIDENTSOFCALIFORNIAANDSEVERALOTHERSTATES

UnderCalifornia law, and under the laws of several other states, you are not permitted to operatean

internalcombustion engine using hydrocarbon fuels on anyforest, brush, hay, grain, or grass

covered land; or land covered byanyflammable agricultural crop without an engine spark arrester in

continuous effectiveworking order.

The engineonthe unit is an internal combustion engine which burns gasoline,a hydrocarbon fuel, and must be equippedwith a

spark arrester muffler in continuous effectiveworking order. Thespark attester must beattachedto the engine exhaustsystem in

such a mannerthat flames or heatfrom the system will not igniteflammable material. Failureof the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may also beaviolation of otherstate

and/orfederal regulations, laws, ordinancesor codes. Contactyour localfire marshal or forest service for specific information

aboutwhich regulationsapply in your area.

Training

1. Carefully readthis

Owner's Manual,the

separateEngineOwner's

Manual,andany other literature you may

receive.Bethoroughly familiar with the

controls and the proper useof the tiller

and its engine. Know howto stop the unit

and disengagethe controls quickly.

2. Neverallow children to operate the

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe area of operationclear of all

persons, particularly children and pets.

4. Keepin mind that the operator or user

is responsiblefor accidents or hazards

occurring to other people,their property,

andthemselves.

Preparation

1. Thoroughly inspect thearea wherethe

tiller isto be usedand removeallforeign

objects.

2. Besure all tiller controls are released

and both wheelsare in the WheelDrive

position beforestarting the engine.

3. Do not operatethe tiller without

wearingadequateoutergarments. Avoid

loosegarments or jewelry that could get

caught in moving parts.

4. Do not operatethe tiller when barefoot

or wearing sandals,sneakers,or light

footwear. Wear protectivefootwear that

will improve footing on slippery surfaces.

5. Donot till near underground electric

cables,telephonelines, pipesor hoses. If

in doubt, contact your telephoneor utility

company.

6. Warning: Handlefuel with care; it is

highlyflammable and its vaporsare

explosive. Besureto takethe following

precautions:

a. Storefuel in containers specifically

designedfor this purpose.

b. Thegascap shall never be removed

or fuel addedwhile the engine is

running. Allow the engineto cool

for several minutes beforeadding

fuel.

c. Keepmatches,cigarettes, cigars,

pipes, openflames, and sparks

awayfrom the fueltank and fuel

container.

d. Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Useafunnel or spout to prevent

spillage.

e. Replaceall fuel tank and container

caps securely.

I. If fuel isspilled, do not attempt to

start the engine, but movethe

machineawayfrom the areaof

spillage and avoidcreatingany

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustments whenengine

is running (unless recommendedby

manufacturer).

Operation

1. Do not put hands or feet nearor under

rotating parts. Thetines begin to rotate

oncethe engine startsand the Forward

Clutch Bail (or ReverseClutch Control) is

engaged.

2. Exerciseextremecaution whenon or

crossing gravel drives,walks, or roads.

Stay alert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine,remove the wire from the spark

plug and prevent it from touching the

spark plug, thoroughly inspectthe

machinefor any damage,and repair the

damagebeforerestarting and operating

the machine.

4. Exercisecaution to avoidslipping or

falling.

5. If the unit should start to vibrate abnor-

mally, stop theengine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and check

immediately for thecause.Vibration is

generallya warning of trouble.

6. Stopthe engine,disconnectthe spark

plug wire and preventit from touching

the spark plug wheneveryou leavethe

operating position, beforeunclogging the

tines, or when making any repairs,adjust-

ments or inspections.

Section1: Safety

7. Takeall possible precautions when

leavingthe machineunattended. Stop the

engine. Disconnectspark plug wire and

move it awayfrom the spark plug. Be

sure both wheels are in the Wheel Drive

position.

8. Before cleaning, repairing, or inspect-

ing,stop the engineand makecertain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching the spark plugto prevent acci-

dentalstarting.

9. The flap on the tine hood must be

down when operatingthe tiller.

10. Never usethe tiller unless proper

guards, plates,or othersafety protective

devicesare in place.

11. Do not run engine in an enclosed

area.Engineexhaustcontains carbon

monoxide gas,a deadly poisonthat is

odorless, colorless, andtasteless.

12. Keepchildren and petsaway.

13. Never operatethetiller under

engine powerif the wheels are in the

Freewheelposition.Inthe Freewheel

position,the wheelswill notholdthe

tiller backand therevolvingtines could

propelthe tiller rapidly, possibly

causinglossof control.Always engage

the wheelswith the wheel drive pins in

the WheelDrive position before starting

the engine orengaging thetines/wheels

with the Forward Clutch Bailor the

ReverseClutchControl.

14. Beawarethat thetiller may unexpect-

edly bounceupward or jump backward

and bepropelled toward you if the tines

should strike extremely hard packedsoil,

frozen ground, or buried obstacleslike

largestones, roots, or stumps. If in doubt

about thetilling conditions, alwaysuse

thefollowing operating precautionsto

assist you in maintaining control of the

tiller:

a. Walk behindandto oneside ofthe

tiller, usingone handonthe han-

dlebars. Relaxyour arm, butusea

securehandgrip.

b. Use a deepdepthregulator

setting.

c. Useslowerenginespeeds.

d. Clear the tilling area of all large

stones,rootsandotherdebris.

e. Avoidusingdownwardpressure

on handlebars.If needbe, use

slightupwardpressureto keep the

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lilt handlebarsto raise

tines out ofthesoil.

g. In an emergency,stoptines and

wheels by releasingwhichever

clutchcontrolis engaged. Donot

attemptto restrainthe tiller.

15. Do not overloadthetiller's capacity

by attempting to till too deeplyattoo fast

a rate.

16. Neveroperatethetiller at high

transport speeds on slippery surfaces.

Look behind andusegreat care when

backing up.

17. Do not operatethe tiller on a slope

that istoo steepfor safety.When on

slopes,slow down and makesure you

havegood footing. Never permit the tiller

to freewheel down slopes.

18. Neverallow bystanders nearthe unit.

19. Only use attachments and acces-

sories that areapproved bythe manufac-

turer of the tiller.

20. Usetiller attachments and acces-

sories when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller ifyou are

tired, or underthe influenceof alcohol,

drugs or medication.

23. Operatorsshall not tamper with the

engine-governorsettings on the machine;

the governor controls the maximum safe

operatingspeedto protect the engineand

all moving partsfrom damage causedby

overspeed. Authorized serviceshall be

sought if a problem exists.

24. Do nottouch engine parts which may

be hot from operation. Let parts cool

down sufficiently.

25. Pleaseremember:You canalways

stop the tines and wheels by releasingthe

Forward Clutch control or the Reverse

Clutchcontrol (whichevercontrol you

haveengaged),or by moving thethrottle

control leveron the engineto "OFF"or

"STOP".

26. To load or unload thetiller, seethe

instructions in Section4 of this Manual.

27. Useextremecaution when reversing

or pulling the machinetowards you.

28. Startthe engine carefully according to

instructions andwith feet well awayfrom

the tines.

29. Neverpick up or carry a machine

while the engine is running.

Maintenance and Storage

1. Keepthe tiller, attachments and acces-

sories in safe working condition.

2. Checkall nuts, bolts, and screws at

frequent intervalsfor proper tightness to

besure the equipment is in safeworking

condition.

3. Neverstore thetiller with fuel in the

fuel tank insidea building where ignition

sources are presentsuch as hot water

and space heaters,furnaces, clothes

dryers,stoves, electric motors, etc.).

Allow engine to cool before storing in any

enclosure.

4. To reducethe chancesof afire hazard,

keepthe enginefree of grass, leaves,or

excessivegrease.

5. Storegasoline in a cool, well-ventilated

area,safelyaway from any spark- or

flame-producing equipment. Store

gasoline in anapprovedcontainer, safely

away from the reachof children.

6. Referto the Maintenancesections of

this Manualand theseparate Engine

Owner's Manualfor instructions if the

tiller isto be stored for an extended

period.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire

is connected,except when specifically

instructed to do so.

8. If the fuel tank hasto be drained,do

this outdoors.

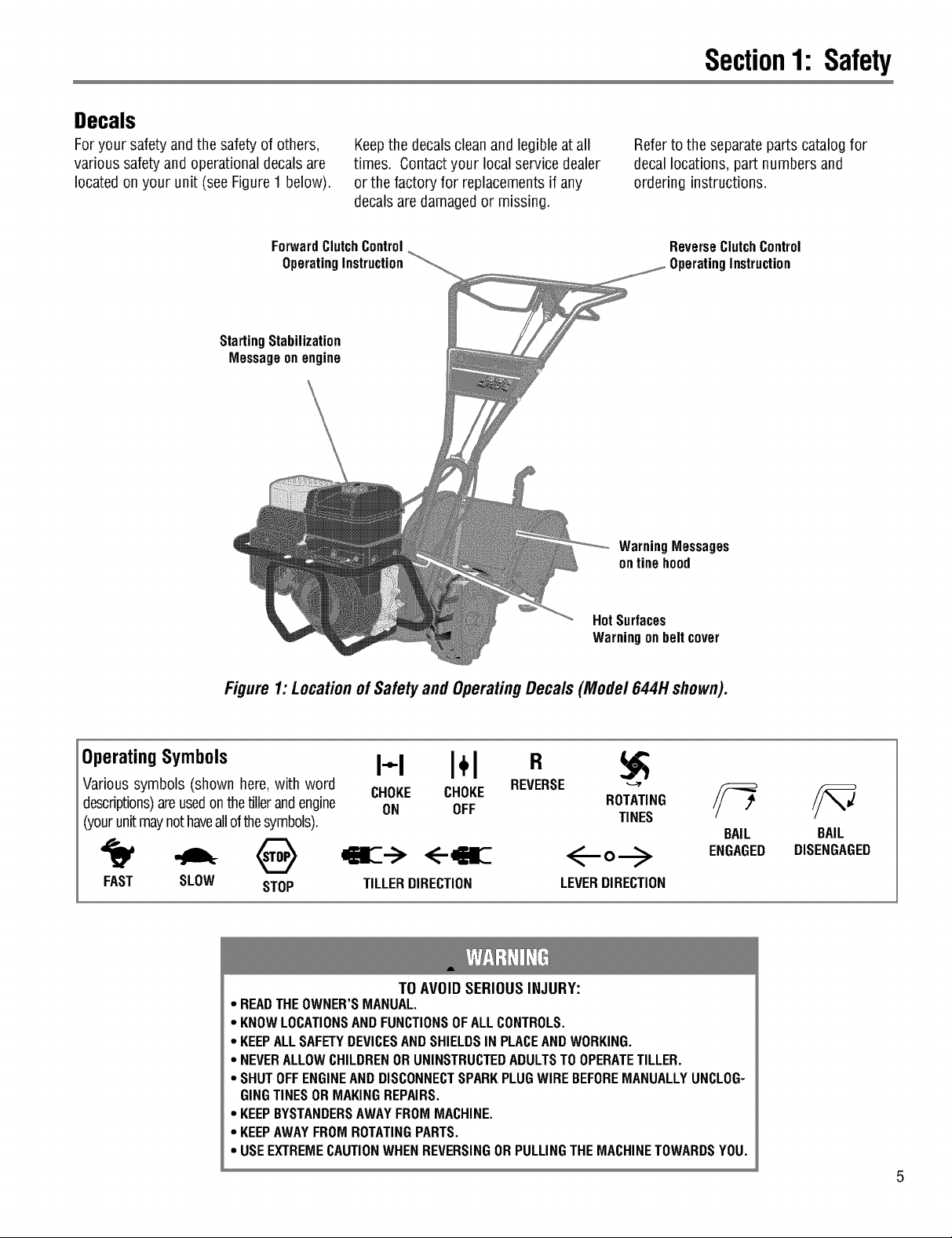

Decals

For your safety and the safety of others,

various safety and operational decals are

located on your unit (see Figure 1 below).

Keepthe decalsclean and legible atall

times. Contactyour local service dealer

or the factory for replacementsif any

decalsare damagedor missing.

Section1: Safety

Referto the separate parts catalogfor

decallocations, part numbers and

ordering instructions.

ForwardClutchControl

OperatingInstruction

StartingStabilization

Messageon engine

Warning Messages

ontine hood

HotSurfaces

Warningonbelt cover

ReverseClutchControl

OperatingInstruction

Figure 1: Location of Safety and Operating Decals (Model 644H shown).

Operating Symbols

Various symbols (shown here, with word

descriptions)are used on the tiller and engine

(your unit may not haveallof the symbols).

FAST SLOW STOP

• READTHEOWNER'S MANUAL.

• KNOWLOCATIONSANDFUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEAND DISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINESOR MAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHEMACHINETOWARDSYOU.

i÷i I÷1 R

CHOKE CHOKE REVERSE

ON OFF

€,E--> <--lZ,

TILLERDIRECTION

TO AVOID SERIOUS INJURY:

ROTATING

TINES

BAIL BAIL

_-_ 0 _ ENGAGED DISENGAGED

LEVERDIRECTION

n

Assembly

WARNING

To prevent personal injury or

property damage, do not start

the engine until all assembly

steps are complete and you

have read and understandthe

safety and operating instruc-

tions in this manual.

Introduction

Carefullyfollow these assembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in its entirety beforebeginning assembly.

NOTE: Enginesylesvary by model. The

engineon your tiller may appeardiffer-

ently than those shown in illustrations

and Figuresthroughout this manual.

Inspectunit

Inspectthe unit and cartonfor damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

aclaim. To protect your rights, put your

claim in writing and mail acopy to the

carrierwithin 15 days after the unit has

beendelivered.

STEP1: Unpacking Instructions

1. Removeanycardboard inserts and

packagingmaterial from the carton.

Removeany staples from the bottom of

the carton andthen lift the carton up and

off the unit.

2.Thetiller is heavyand you should not

attempt to remove itfrom the shipping

platform until the handlebarsare

installed. The procedurefor removing the

tiller isexplainedin Step3 ofthese

assemblysteps.

NOTE:Becareful not to severely bendany

of the control cables on the unit.

3. Removeall unassembledparts and

the separatehardware bagfrom the

carton. Checkthat you havethe items

listed below (contact your local dealeror

the factory if any items are missing or

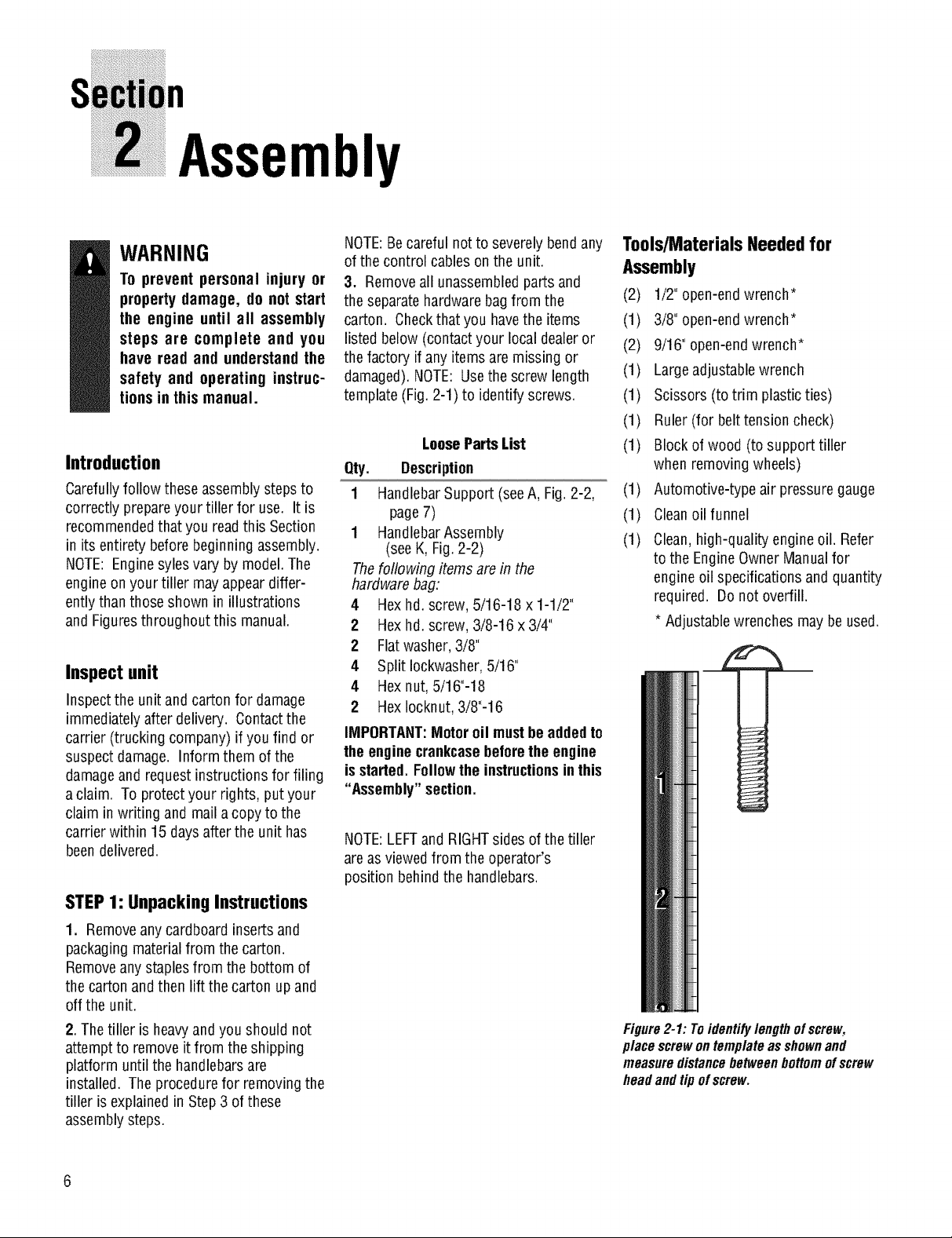

damaged). NOTE: Usethescrew length

template (Fig. 2-1)to identify screws.

LooseParts List

Qty. Description

1 HandlebarSupport (seeA, Fig.2-2,

page7)

1 HandlebarAssembly

(seeK, Fig.2-2)

Thefo//owing itemsare in the

hardwarebag:

4 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

4 Split Iockwasher,5/16"

4 Hexnut, 5/16"-18

2 HexIocknut, 3/8"-16

IMPORTANT:Motoroil mustbe addedto

the enginecrankcasebeforethe engine

isstarted. Followthe instructionsinthis

"Assembly" section.

NOTE:LEFTand RIGHTsides of the tiller

are as viewed from the operator's

position behindthe handlebars.

Tools/MaterialsNeededfor

Assembly

(2) 1/2" open-endwrench*

(1) 3/8" open-endwrench*

(2) 9/16" open-endwrench*

(1) Largeadjustable wrench

(1) Scissors (to trim plastic ties)

(1) Ruler (for belttension check)

(1) Block of wood (to support tiller

when removing wheels)

(1) Automotive-type air pressure gauge

(1) Cleanoil funnel

(1) Clean,high-quality engine oil. Refer

to the EngineOwnerManualfor

engine oil specifications and quantity

required. Do not overfill.

* Adjustable wrenchesmay be used.

Figure2-1: Toidentifylengthofscrew,

placescrewontemplateasshownand

measuredistancebetweenbottomofscrew

headandtipofscrew.

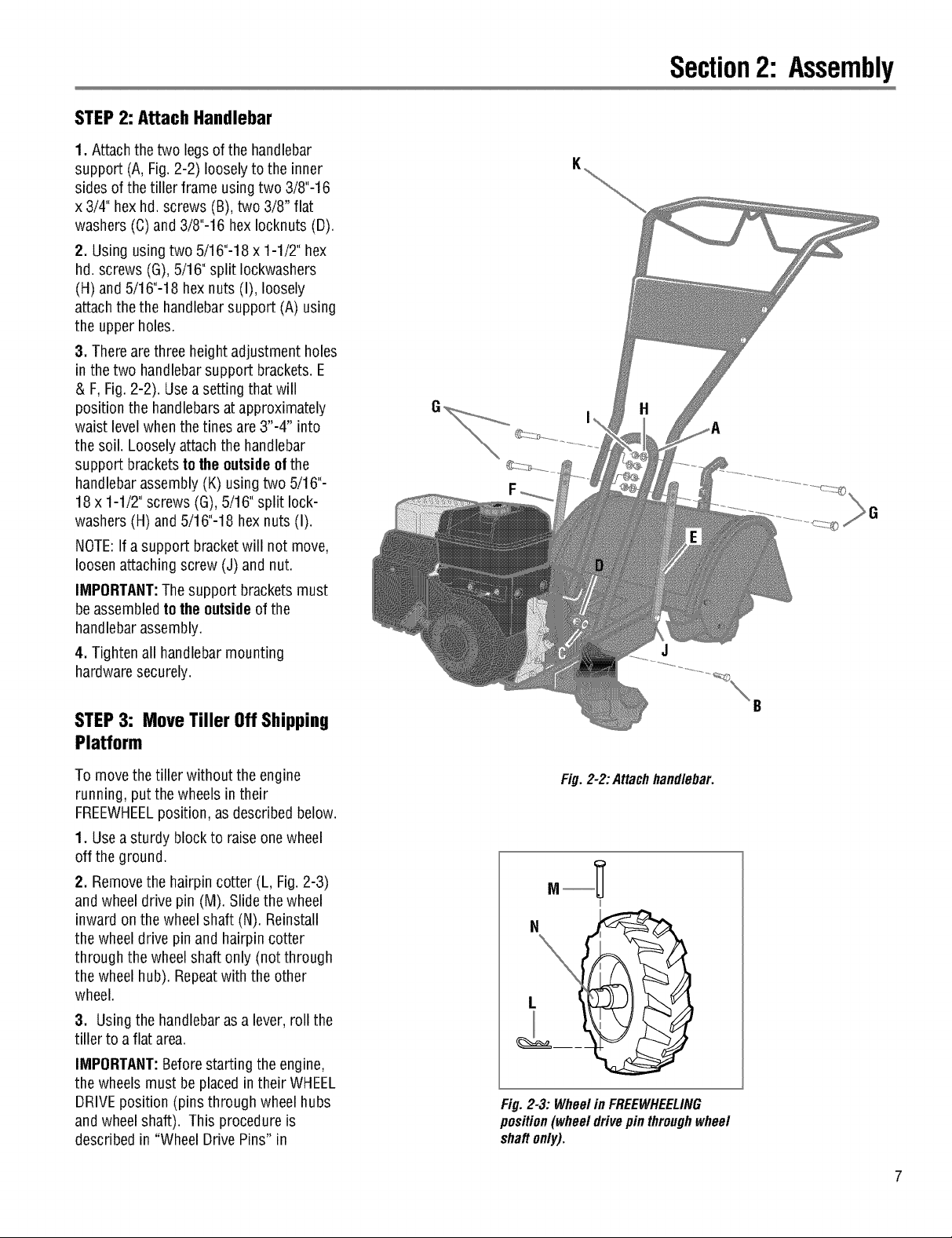

STEP2: Attach Handlebar

1. Attachthe two legsof the handlebar

support (A, Fig.2-2) loosely to the inner

sides of thetiller frame using two 3/8"-16

x3/4" hexhd. screws (B), two 3/8" flat

washers(C)and 3/8"-16 hexIocknuts (D).

2. Using using two 5/16"-18 x 1-1/2" hex

hd. screws (G), 5/16"split Iockwashers

(H) and 5/16"-18 hex nuts (I), loosely

attachthethe handlebarsupport (A) using

the upper holes.

3. Thereare three heightadjustment holes

in the two handlebarsupport brackets.E

& F, Fig.2-2). Usea setting that will

position the handlebarsat approximately

waist levelwhenthe tines are 3"-4" into

the soil. Looselyattachthe handlebar

support bracketstothe outsideofthe

handlebarassembly (K) usingtwo 5/16"-

18 x 1-1/2" screws (G),5/16" split lock-

washers(H) and 5/16"-18 hexnuts (I).

NOTE:If a support bracket will not move,

loosenattaching screw (J) and nut.

IMPORTANT:Thesupport brackets must

be assembledto the outsideof the

handlebarassembly.

4. Tighten all handlebar mounting

hardwaresecurely.

Section2: Assembly

STEP3: Move Tiller Off Shipping

Platform

To move the tiller without the engine

running, put the wheels in their

FREEWHEELposition, as described below.

1. Usea sturdy block to raise onewheel

off the ground.

2. Removethe hairpin cotter (L, Fig.2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheelshaft (N). Reinstall

the wheel drive pin and hairpin cotter

through the wheelshaft only (not through

the wheel hub). Repeatwith the other

wheel.

3. Using the handlebaras a lever, roll the

tiller to aflat area.

IMPORTANT:Beforestarting the engine,

the wheels must be placedin their WHEEL

DRIVEposition (pins through wheel hubs

and wheel shaft). This procedureis

described in "Wheel Drive Pins" in

Fig. 2-2: Attachhandlebar.

Fig. 2-3: Wheel in FREEWHEELING

position (wheel drivepin throughwheel

shaftonly).

Section2: Assembly

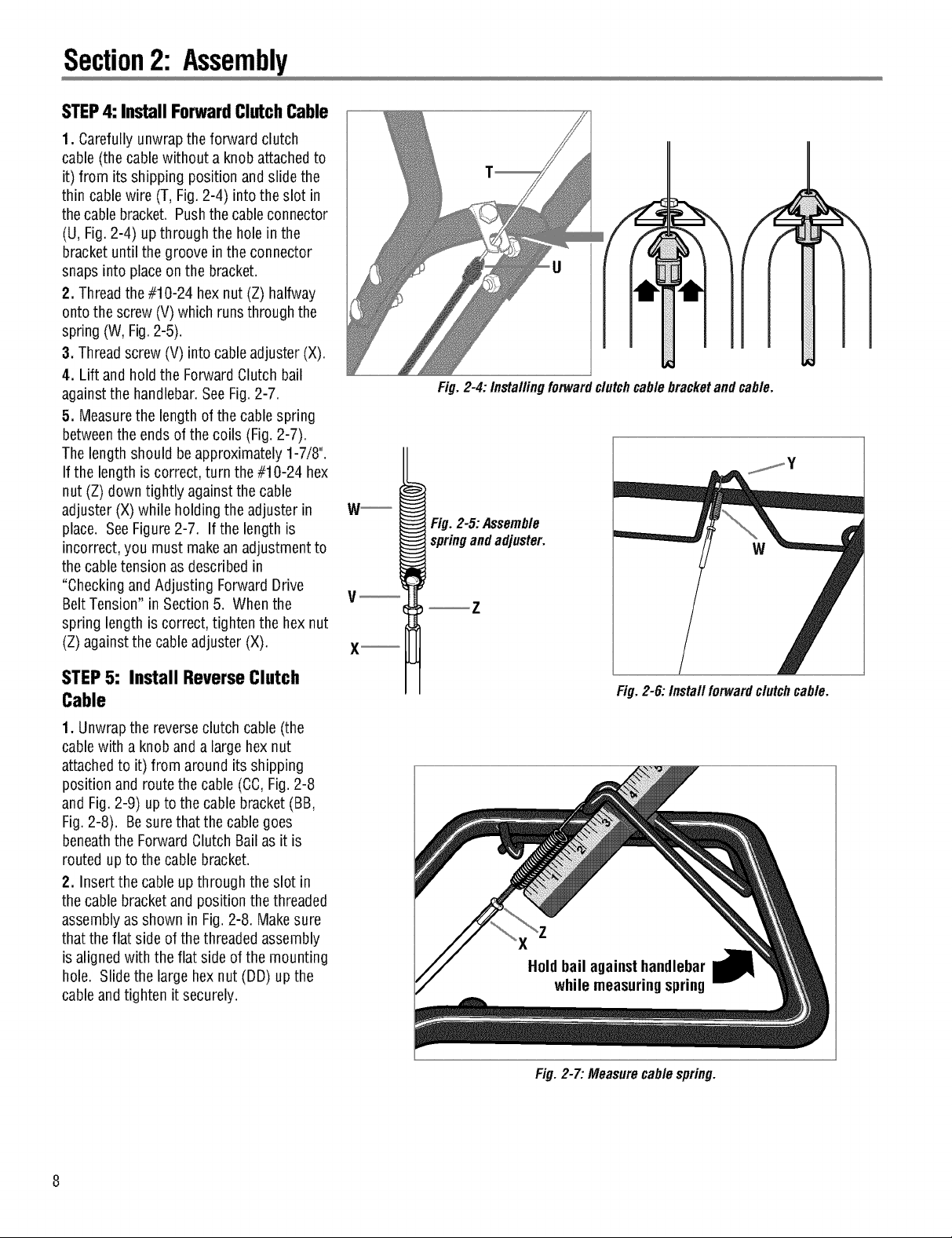

STEP4: Install ForwardClutch Cable

1. Carefully unwrap theforward clutch

cable (thecablewithout a knob attached to

it) from its shipping position and slidethe

thin cable wire (T, Fig.2-4) into the slot in

thecablebracket. Pushthe cableconnector

(U, Fig.2-4) up through the hole in the

bracketuntil the groove in the connector

snaps into placeon the bracket.

2. Threadthe #10-24 hexnut (Z) halfway

onto the screw(V) which runs through the

spring (W, Fig.2-5).

3. Threadscrew (V) into cable adjuster (X).

4. Lift and hold the ForwardClutch bail

against the handlebar.SeeFig.2-7.

5. Measurethe length of the cablespring

betweenthe ends ofthe coils (Fig.2-7).

Thelength should beapproximately 1-7/8".

If the length is correct, turn the #10-24 hex

nut (Z) down tightly againstthe cable

adjuster (X) while holding the adjuster in

place. SeeFigure2-7. If the length is

incorrect, you must makean adjustment to

the cabletension as described in

"Checking andAdjusting ForwardDrive

BeltTension" in Section 5. When the

spring length is correct, tighten the hex nut

(Z)against the cableadjuster (X).

Fig. 2-4: Installing forwardclutchcable bracket and cable.

Fig. 2-5: Assemble

springand adjuster.

STEP5: Install ReverseClutch

Cable

1. Unwrapthe reverseclutch cable (the

cablewith a knoband a large hex nut

attachedto it) from around its shipping

position and route the cable(CC,Fig.2-8

and Fig. 2-9) up to the cable bracket (BB,

Fig.2-8). Besure that the cablegoes

beneaththe ForwardClutch Bail asit is

routed upto the cablebracket.

2. Insertthe cableup through the slot in

the cablebracketand position the threaded

assembly as shown in Fig.2-8. Makesure

that the flat side of thethreaded assembly

isaligned with the flat sideof the mounting

hole. Slide the large hex nut (DD) up the

cableand tighten it securely.

Fig. 2-6: Install forwardclutch cable.

Fig. 2-7: Measure cable spring.

Section2: Assembly

3. Usea cable tie (EE,Fig.2-9) to fasten

the reverseclutch cableto the left side

handlebar.

4. Test the function of the reverseclutch

cable by pulling the knob out and

releasingit. The knob should return to its

neutralposition (resting against bracket)

when it is released. If it doesn't, contact

your local dealer or the factory for

technical assistance.

BB

DD

Flat Side

Fig. 2-8: Install reverse cablemounting

bracketand the reverse clutchcable.

STEP6: CheckLevelof

TransmissionGearOil

Thetransmission was filled with gear oil

at thefactory. However,you should check

the gear oil levelto makecertain it is

correct.

IMPORTANT:Do notoperatethe tiller if

the gear oil level is low. Doingso will

result insevere damageto the transmis-

sign components.

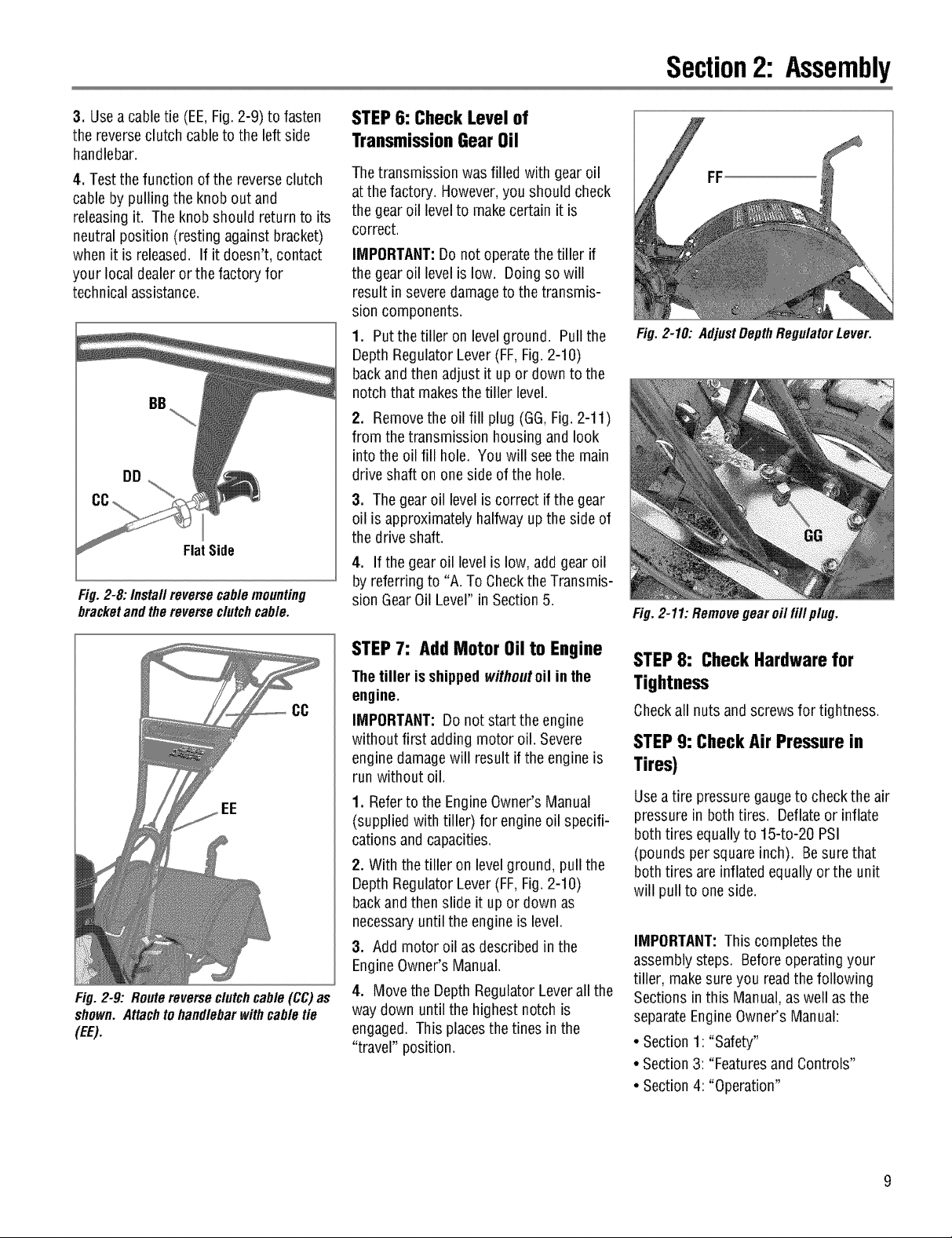

1. Putthe tiller on levelground. Pullthe

DepthRegulator Lever(FF,Fig.2-10)

backand then adjust it up or down to the

notch that makesthe tiller level.

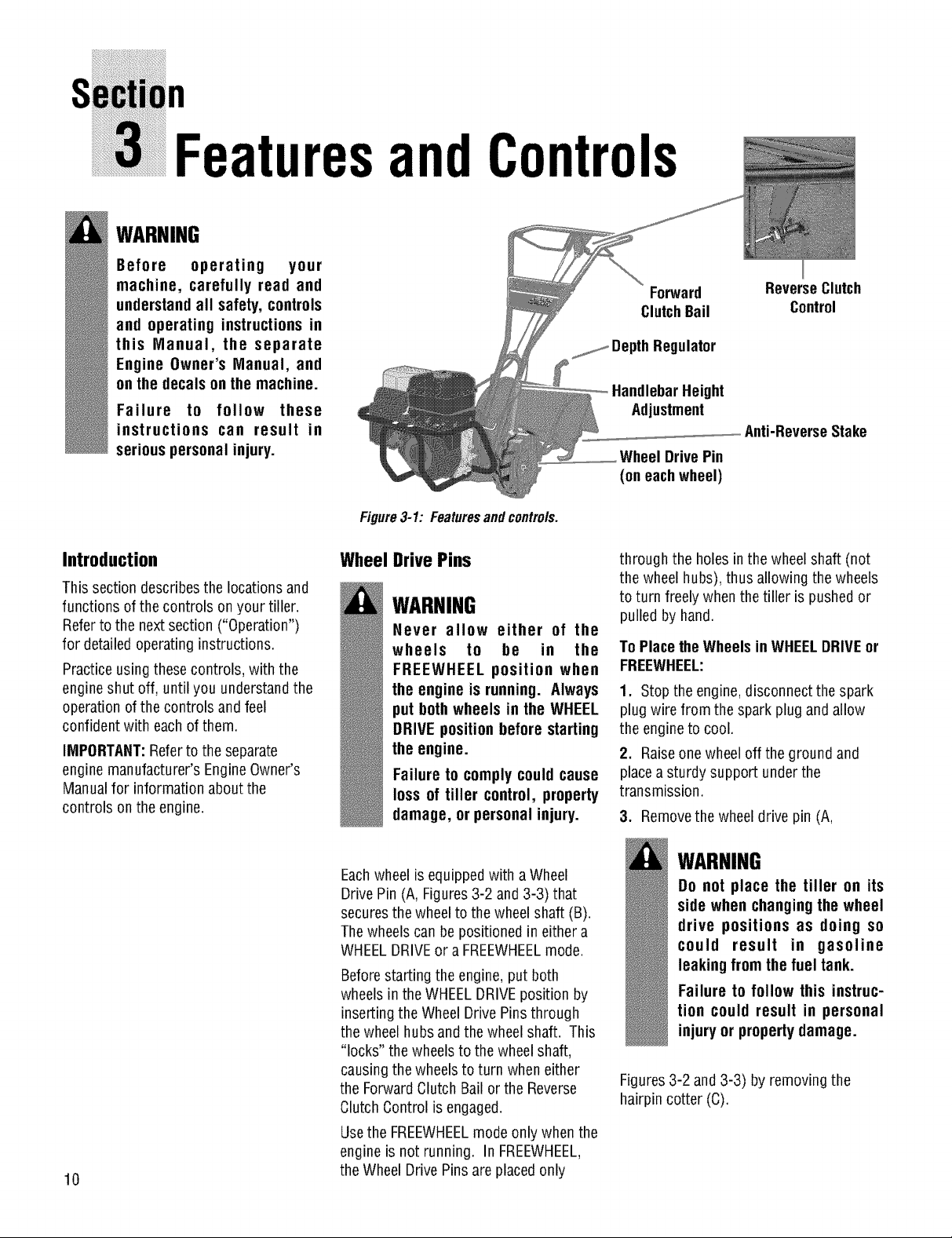

2. Removethe oil fill plug (GG,Fig. 2-11)

from the transmission housing and look

intothe oil fill hole. You will seethe main

drive shaft on oneside of the hole.

3. Thegear oil leveliscorrect if the gear

oil is approximately halfwayup the side of

the drive shaft.

4. If the gear oil level is low, add gear oil

byreferring to "A. To Checkthe Transmis-

sion GearOil Level" in Section 5.

Fig. 2-10: AdjustDepthRegulator Lever.

Fig. 2-11: Removegear oil fill plug.

CC

Fig. 2-9: Route reverse clutchcable (CC)as

shown. Attachtohandlebar withcable tie

(EE).

STEP7: Add Motor Oil to Engine

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not start the engine

without first adding motor oil. Severe

engine damagewill result ifthe engine is

run without oil.

1. Referto the EngineOwner's Manual

(suppliedwith tiller) for engine oil specifi-

cations and capacities.

2. With the tiller on levelground, pull the

DepthRegulator Lever(FF,Fig.2-10)

backand then slide it up or down as

necessaryuntil the engine is level.

3. Add motor oil asdescribed in the

EngineOwner's Manual.

4. Movethe Depth RegulatorLeverall the

way down until the highest notch is

engaged. This placesthe tines in the

"travel" position.

STEP 8: Check Hardware for

Tightness

Checkall nuts and screwsfor tightness.

STEP9: CheckAir Pressurein

Tires)

Usea tire pressuregaugeto checkthe air

pressure in both tires. Deflateor inflate

both tires equallyto 15-to-20 PSI

(pounds per square inch). Besure that

both tires are inflatedequallyor the unit

will pull to one side.

IMPORTANT:This completesthe

assembly steps. Beforeoperating your

tiller, make sureyou readthefollowing

Sections in this Manual, aswell as the

separateEngineOwner's Manual:

• Section 1: "Safety"

• Section3: "Featuresand Controls"

• Section 4: "Operation"

n

FeaturesandControls

WARNING

Before operating your

machine, carefully read and

understand all safety, controls

and operating instructions in

this Manual, the separate

Engine Owner's Manual, and

on the decals onthe machine.

Failure to follow these

instructions can result in

serious personal injury.

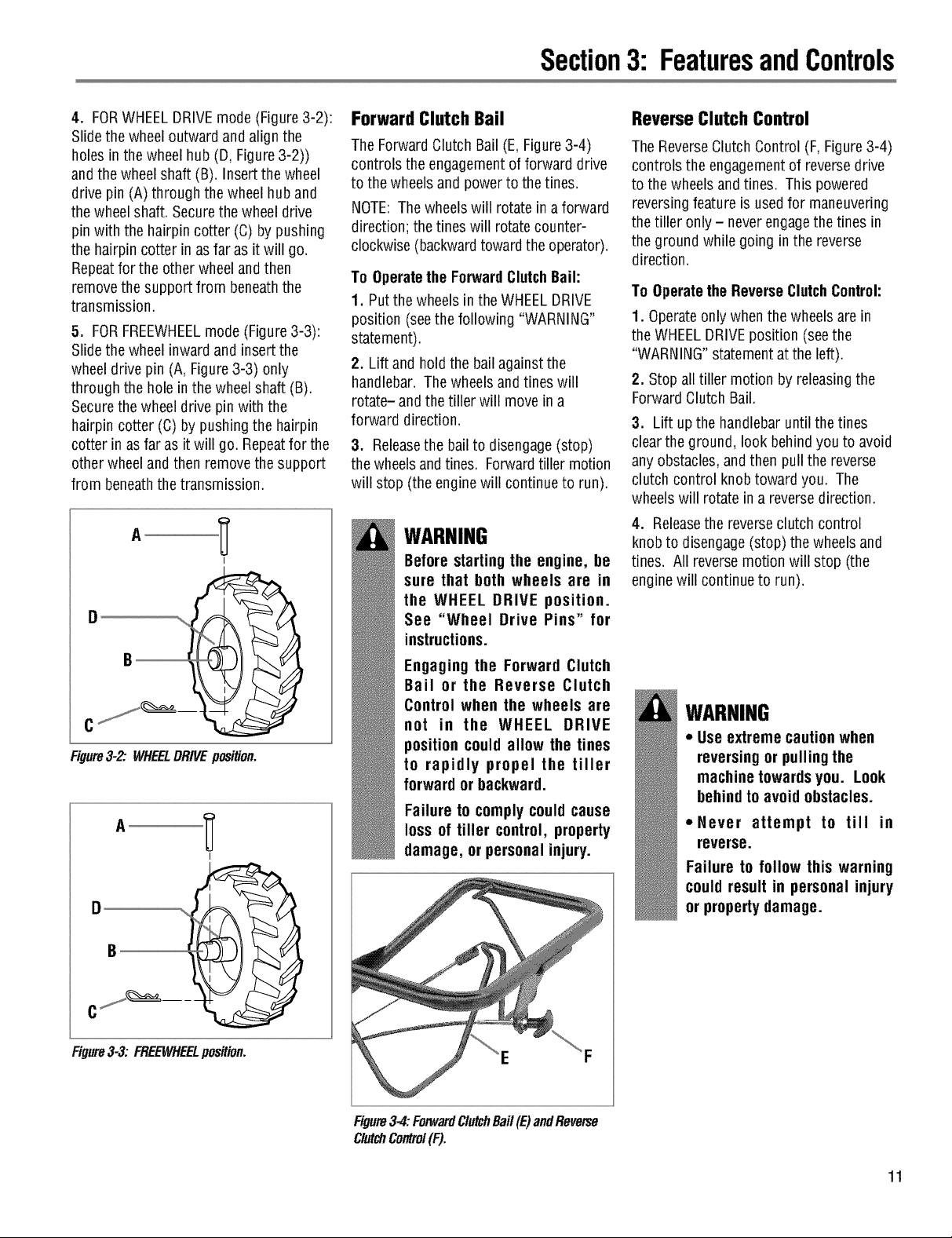

Forward ReverseClutch

ClutchBail Control

Regulator

HandlebarHeight

Adjustment

Anti-ReverseStake

DrivePin

(on eachwheel)

Figure3-1: Featuresand controls.

Introduction

This section describesthe locations and

functions of thecontrols on your tiller.

Referto the nextsection ("Operation")

for detailed operating instructions.

Practiceusingthese controls, with the

engine shut off, until you understandthe

operationof the controls and feel

confident with eachof them.

IMPORTANT:Referto the separate

engine manufacturer's EngineOwner's

Manualfor informationabout the

controls on the engine.

10

WheelDrivePins

WARNING

Never allow either of the

wheels to be in the

FREEWHEEL position when

the engine is running. Always

put bothwheels in the WHEEL

DRIVE position before starting

the engine.

Failure to comply could cause

loss of tiller control, property

damage, or personal injury.

Eachwheel is equippedwith a Wheel

Drive Pin (A, Figures3-2 and 3-3) that

securesthewheel to the wheel shaft (B).

Thewheels can be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

Beforestarting the engine, put both

wheels in the WHEELDRIVEposition by

inserting the WheelDrive Pinsthrough

the wheelhubs andthe wheel shaft. This

"locks" the wheels to the wheelshaft,

causing the wheels to turn when either

the ForwardClutch Bail or the Reverse

ClutchControl isengaged.

Usethe FREEWHEELmode only when the

engine is not running. In FREEWHEEL,

the WheelDrive Pinsare placedonly

through the holesin the wheel shaft (not

the wheelhubs), thus allowing the wheels

to turn freely when the tiller is pushedor

pulled by hand.

To Placethe Wheels in WHEELDRIVEor

FREEWHEEL:

1. Stop the engine,disconnect the spark

plug wire from the spark plug and allow

the engineto cool.

2. Raiseone wheel off the ground and

placea sturdy support underthe

transmission.

3. Removethe wheeldrive pin (A,

WARNING

Do not place the tiller on its

side when changing the wheel

drive positions as doing so

could result in gasoline

leaking from the fuel tank.

Failure to follow this instruc-

tion could result in personal

injury or propertydamage.

Figures3-2 and 3-3) by removingthe

hairpin cotter (C).

Section3: FeaturesandControls

4. FORWHEELDRIVEmode (Figure3-2):

Slide the wheeloutward and align the

holesin the wheel hub (D, Figure3-2))

and the wheelshaft (B). Insertthe wheel

drive pin (A) through the wheel hub and

the wheelshaft. Securethe wheel drive

pin with the hairpin cotter (C) by pushing

the hairpin cotter in asfar as it will go.

Repeatfor the other wheel and then

removethe support from beneaththe

transmission.

5. FORFREEWHEELmode(Figure 3-3):

Slide the wheel inwardand insert the

wheel drive pin (A,Figure 3-3) only

through the holein the wheelshaft (B).

Securethe wheeldrive pin with the

hairpin cotter (C)by pushing the hairpin

cotter in asfar as it will go. Repeatfor the

other wheeland then removethe support

from beneaththetransmission.

I

Forward Clutch Bail

The Forward ClutchBail (E, Figure3-4)

controls the engagementof forward drive

to the wheelsand powerto the tines.

NOTE:Thewheels will rotate in a forward

direction; the tines will rotatecounter-

clockwise(backwardtoward the operator).

To Operatethe Forward ClutchBail:

1. Put the wheels in the WHEELDRIVE

position (seethe following "WARNING"

statement).

2. Lift and hold the bail againstthe

handlebar. The wheels andtines will

rotate- and thetiller will move in a

forward direction.

3. Releasethe bail to disengage(stop)

the wheelsandtines. Forwardtiller motion

will stop (the engine will continueto run).

WARNING

Before starting the engine, be

sure that both wheels are in

the WHEEL DRIVE position.

See "Wheel Drive Pins" for

instructions.

ReverseClutchControl

The ReverseClutchControl (F, Figure3-4)

controls the engagementof reverse drive

to the wheels and tines. This powered

reversingfeature is used for maneuvering

the tiller only - neverengagethe tines in

the ground while going in the reverse

direction.

To Operatethe ReverseClutchControl:

1. Operateonlywhen the wheels are in

the WHEELDRIVEposition (seethe

"WARNING"statementat the left).

2. Stopall tiller motion by releasingthe

ForwardClutch Bail.

3. Lift upthe handlebaruntil the tines

clear theground, look behindyou to avoid

any obstacles,and then pull the reverse

clutch control knobtoward you. The

wheels will rotate in a reverse direction.

4. Releasethe reverseclutch control

knobto disengage (stop) the wheels and

tines. All reversemotion will stop (the

engine will continue to run).

Figure3-2: WHEELDRIVEposition.

I

D

B

Figure3-3: FREEWHEELposition.

Engaging the Forward Clutch

Bail or the Reverse Clutch

Control when the wheels are

not in the WHEEL DRIVE

position could allow the tines

to rapidly propel the tiller

forward or backward.

Failure to comply could cause

loss of tiller control, property

damage, or personal injury.

Figure34: FonvardClutchBail (E)andReverse

ClutchControl(F).

WARNING

• Use extreme cautionwhen

reversing or pulling the

machine towardsyou. Look

behindto avoid obstacles.

• Never attempt to till in

reverse.

Failure to follow this warning

could result in personal injury

or propertydamage.

11

Loading...

Loading...