Page 1

i.'V', jVv,'

OWNER/OPERATOR MANUA

:insfi)^iE3[№i'5 ,'

- -' ,-','•*/,f;*'.' _'!■ •' ;..■«■ /i“,- ''’^.%-V>r^--iii -'!i^.-‘-':«-."r'*.'v_-"j,:-' ■■*'

«m«p M ;■ ■ve^-'-f--;i^v---

uir::i-i ii7I-ie:i:i

Assembly, Safety, Operating and Maintenance Instructtons.

PLEASE READ CAREFULLY!

Page 2

TABLE OF CONTENTS

Page

INTRODUCTION 1

FOR SERVICE OR PARTS 1

MOWER IDENTIFICATION NUMBERS 1

SECTION 1: RULES FOR

SAFE OPERATION

Training................................................................................. 2

Preparation

Operation.............................................................................. 3

Maintenance and Storage

Safety Decals....................................................................... 4

SECTION 2: ASSEMBLY INSTRUCTIONS

Check For Shipping Damage

Toois Needed For Assembiy

Mower Assembly Steps .................................................... 5

Electric Start Assembly Steps

SECTION 3: MOWER AND

ENGINE CONTROLS

Blade Drive Controls......................................................... 15

Wheel Drive Controls

Handlebar Height Adjustment ........................................ 16

Height of Cut Adjustment................................................. 16

Engine Throttie Control

Fuel Shut-Off Valve............................................................ 17

Engine Recoii Starter

Key Switch Starter ............................................................ 17

SECTION 4: OPERATING INSTRUCTIONS

Preparation Before Starting............................................. 18

To Start the Engine............................................................ 19

To Engage the Blade

To Engage the Wheels

To Stop the Engine............................................................ 20

Operating the Mower......................................................... 20

..........................................................................

................................................

...........................................

............................................

.......................................

........................................................

...................................................

........................................................

........................................................

......................................................

2

4

5

5

10

16

16

17

19

20

SECTION 5: MAINTENANCE AND

ADJUSTMENTS

Maintenance Chart

Adjusting Wheei Drive Traction

Height of Cut Adjustment

Handlebar Height Adjustment ....................................

Sharpening or Repiacing the Mower Biade ..

Clean the Mower Housing and Discharge

Chute............................................................................

Check Tire Pressure......................................................

Check Bolts, Screws and Nuts....................................

Lubrication......................................................................

Wheel Drive Belt Tension.............................................

Repiacing the Wheel Drive Belt

Blade Drive Belt Tension

Replacing the Blade Drive Belt ..................................

Wheel Drive Chain Tension

Replacing the Blade Brake Band

Battery Care In Service ................................................

Battery Storage

Battery Removal and Replacement

Starting the Electric Start

Engine With the Recoil Starter

Engine Crankcase Oil

Engine Air Cleaner

Carburetor Adjustments...............................................

Air Cooling Service........................................................

Spark Plug.......................................................................

Throttle Cable Adjustments ........................................

Off-Season Storage

Engine Identification Numbers

Blade Brake Control Test Procedure

SECTION 6: TROUBLESHOOTING

Swivel Wheel Kit

........................................................

..................................

............................................

..................................

............................................

........................................

...............................

..............................................................

...........................

...............................

...................................................

........................................................

.......................................................

...................................

.......................

......................

............................................................

MAINTENANCE RECORD . Inside Back

Page

21

22

23

23

24

25

25

25

25

25

26

27

28

29

29

30

31

31

32

32

33

33

33

33

33

33

33

34

35

36

Cover

MODEL IDENTIFICATION

22" Push Model. 5HP

Recoil Start Engine.

NOTE: Optional swivel wheels are available for your TUFF-CUT® Mower. Please refer to Page 36 for additional details.

22"Self-Propelled Model.

5HP Recoil Start or

optional Electric Start Engine.

24" Self-Propelled Model.

8HP Recoil Start or

optional Electric Start Engine.

P

Page 3

INTRODUCTION

Dear Owner:

Vi/e at Garden Wa/ want to thank you for purchasing our TROY-BILT TUFF-CUT® High

Wheei Mower.

Your new mower is a professionai-quaiity, rugged machine that wiii handie most ter

rain and perform dependabiy for many iong hours of heavy use. The big rear wheeis

roii smoothly through tall grass, and over uneven ground and rough areas with ease. Its

perfect balance makes it much more responsive and maneuverable than conventional

mowers. And its wide mowing path, extra horsepower, and easy trimming abilities

mean you’ll get your mowing chores done in as little time as possible.

We have prepared this Manual to assist you in the safe operation and care of your

new TUFF-CUT High Wheel Mower. BEFORE YOU OPERATE THE MOWER PLEASE

READ THIS WHOLE MANUAL CAREFULLY! Most importantly, please follow all of the

safety instructions given in Section 1, “Rules for Safe Operation.’’ Failure to do so could

result in serious injury or damage to equipment or property.

It is our sincere hope that you enjoy using your mower. It is designed and con

structed to give you superior results and dependable service. Of course, if you have

any questions or problems in operating or servicing your mower, please remember that

we are here to serve you. We want to do everything we can to make sure that you are

completely satisfied 100 percent of the time.

Thank you.

Dean Leith, Jr.

Sales Manager

FOR SERVICE OR PARTS

For service or operating questions, or replacement

parts, you can either contact the factory or see your

local servicing dealer. Our addresses and telephone

numbers are listed below for your convenience.

Our telephone numbers are:

In the U.S.A.:

For Technical Service call Toll-Free: 1-800-833-6990

For Parts Service call Toll-Free: 1-800-648-6776

In Canada:

Call Toll-Free: 1-800-225-3585

Send correspondence to:

In the U.S.A.:

Troy-Bilt Mfg. Company

102nd St. & 9th Ave.,

Troy, New York 12180

In Canada:

Garden Way Canada, Inc.,

1515 Matheson Blvd., EUnitBII

Mississauga, Ontario L4W 2P5

For engine service, contact an Authorized Briggs &

Stratton Service Dealer. Look in the Yellow Pages of

your telephone directory, under "Engines-Gasoline."

Your Service Dealer can handle all parts, repairs, and

warranty service for problems concerning the engine

alone. For full details on the engine manufacturer's

limited warranty, please see the separate engine

owner's pamphlet that was included with this Manual.

(If you have any difficulty in locating an authorized

dealer or in obtaining warranty service, please contact

our Technical Service Department for assistance.)

RECORD YOUR MODEL

AND SERIAL NUMBERS

The arrow in the photo below shows the location of

the Model and Serial Number decal on your mower.

We will need these numbers if you call or write us for

parts or service assistance. For ready reference,

please record these numbers in the spaces provided

below.

MODEL NUMBER:.

SERIAL NUMBER:

DATE OF DELIVERY:

Page 4

SECTION 1

A Rules for Safe Operation

Safe Operation is So Important...

Read the following rules carefully, and pay particular

attention to safety instructions printed elsewhere in this

manual. Failure to comply with safety instructions could

endanger your personal safety and the equipment and

property of yourself and others.

SAFETY ALERT SYMBOL

This symbol is used to alert you to important safety

messages in this manuai. When you see this

A

symbol, carefully read the message that follows.

The TUFF-CUT® Mower conforms to the CPSC

(Consumer Product Safety Commission) safety

standard 16 CFR Part 1205 for walk-behind pow

er lawn mowers. The CPSC is an agency of the

Federal Government, established and empowered

by Congress in 1972, to make and enforce safety

standards for consumer products sold in the Unit

ed States. All rotary walk-behind power lawn mow

ers manufactured after June 30, 1982 are

required to meet CPSC federally-mandated stan

dards. Accordingly, the TUFF-CUT® Mower meets

the standards in effect at the time of manufacture.

The TUFF-CUT® Mower also meets voluntary

safety standard B-71.1-1986, which is sponsored

by the Outdoor Power Equipment Institute and is

published by the American National Standards

Institute.

TRAINING:

1. Read both this Owner/Operator Manuai and the sep

arate engine owner’s pamphlet completely before using

the mower. Be thoroughly familiar with the controls and

proper use of the mower. Know how to stop the mower

and disengage the controls quickly in an emergency.

2. Never allow children to operate the mower. Do not

allow adults to operate the mower without proper

instruction.

3. Keep the area of operation clear of all persons, par

ticularly small children, and pets.

4. Under California law, and under the laws of several

other states, you are not permitted to operate an inter

nal combustion engine using hydrocarbon fuels on any

forest-covered, brush-covered, or grass-covered land, or

on land covered with grain, hay, or other flammable

agricultural crop, without an engine spark arrester in

continuous effective working order.

The engine on your power equipment, like most out

door power equipment, is an internal combustion engine

that burns gasoline, a hydrocarbon fuel. Therefore, your

power equipment must be equipped with a spark arrester

muffler in continuous effective working order. The spark

arrester must be attached to the engine exhaust system

in such a manner that flames or heat from the system will

not ignite flammable material. Failure of the owner/operator of the equipment to comply with this regulation is a

misdemeanor under California law, and may also be a

violation of other state and/or federal regulations, laws,

ordinances, or codes. Contact your local fire marshall or

forest service for specific information about what regula

tions apply in your area.

PREPARATION:

1. Thoroughly inspect the area where the mower is

to be used and remove all stones, sticks, wires,

bones, nails and other foreign objects.

2. Do not operate the mower when barefoot or

wearing open sandals. Always wear substantial

footwear. The operation of any powered machine can

result in foreign objects being thrown by high speed

rotating parts. Always wear approved safety glasses

or other eye protection when using the mower.

3. Do not wear loose-fitting clothing that could get

caught in moving parts.

4. Mow only in daylight, or in good artificial light.

5. Disengage the blade drive mechanism, and the

self-propelled mechanism on units so equipped,

before starting the engine.

6. Never operate the mower in wet grass. Always be

sure of your footing; keep a firm hold on the

handlebar and walk; never run.

Disengage Blade

and Wheel Drive

Controls Before

Starting

Page 5

7. Never attempt to make a wheel height adjustment

while the engine is running.

8. Never operate the mower without the grass dis

charge deflector and all guards in place.

9. Never attempt to disconnect any safety devices or

to defeat the purpose of these safety devices.

10. Gasoline is highly flammable and its vapors are

explosive. Handle with extreme care. Use an approved

fuel container.

11. Check the fuel before starting the engine. Do not

fill the gasoline tank indoors, when the engine is run

ning or until the engine has been allowed to cool for

several minutes after running. Replace the fuel cap

securely and clean off any spilled gasoline before start

ing the engine.

12. Keep smoking materials, sparks and flame away

from the fuel tank or fuel container.

13. Move machine away from gasoline fumes before

starting engine.

14. Poison/Danger — Causes Severe Burns. The bat

tery on electric start models contains sulfuric acid. Avoid

contact with skin, eyes or clothing. Antidote: EXTER

NAL - Flush immediately with lots of water. INTERNAL

- Drink large quantities of water or milk. Follow with

milk of magnesia, beaten egg or vegetable oil. Call

physician immediately. Eyes - Flush with water for 15

minutes and get prompt medical attention. Keep out of

reach of children.

15. Batteries produce explosive gases. Keep sparks,

flame, or cigarettes away. Ventilate when charging or

using in an enclosed space. Always shield eyes when

working near batteries.

16. At the start of each season and every 10 operating

hours, perform the Blade Brake Control Test Procedure

described on Page 34.

OPERATION:

1. Do not put hands or feet near or under any rotating

parts. Keep clear of the mower blade and discharge

opening at all times.

2. Do not change the engine governor settings or over

speed the engine.

Stop The Blade

Before Crossing

Gravel Areas

5. Stop the engine, disconnect the spark plug wire,

and wait for all moving parts to stop before inspecting,

cleaning, adjusting or repairing the mower.

6. Never leave the mower unattended with the engine

running. Disconnect the spark plug wire and keep the

wire away from the spark plug to prevent accidental

starting. Remove the key on electric start models to

prevent unauthorized use.

7. Shut off the engine, disconnect the spark plug wire

and keep the wire away from the spark plug to prevent

accidental starting. Make sure that rotating parts have

completely stopped before cleaning out the discharge

opening.

Disconnect Spark Plug

Wire To Avoid

Accidental Starts

8. If the mower should start to vibrate abnormally, stop

the engine, disconnect the spark plug wire, and wait

for all moving parts to stop. Then, check immediately

for the cause. Vibration is generally a warning of

trouble.

9. After striking a foreign object, stop the engine and

disconnect the spark plug wire. Keep the spark plug

wire away from the plug to prevent accidental starting.

Wait for all moving parts to completely stop and then

inspect the mower for damage. Repair the damage

before restarting and operating the mower.

10. Do not run the engine indoors. Exhaust gases

contain carbon monoxide, a deadly gas that is odor

less and colorless. Always run the engine outdoors

and make sure there is adequate ventilation.

11. The Outdoor Power Equipment Institute recom

mends that you mow across the face of slopes; never

up and down. Exercise extreme caution when chang

ing direction on slopes. Do not mow excessively steep

slopes.

12. Do not touch engine parts which may be hot from

operation. Allow parts to cool before inspecting, clean

ing or repairing.

3. Stop the blade when crossing gravel drives, walks,

or roads where thrown objects would be a hazard.

4. Stop the blade when you are approached by any

child, pet, or inattentive person. (Curious toddlers can

too quickly endanger themselves.)

Page 6

MAINTENANCE AND

STORAGE:

1. Check the blade and the engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

3. Never store the mower with gasoline in the tank in

side a building where fumes may reach an open flame

or spark.

4. Allow the engine to cool before storing in any

enclosure.

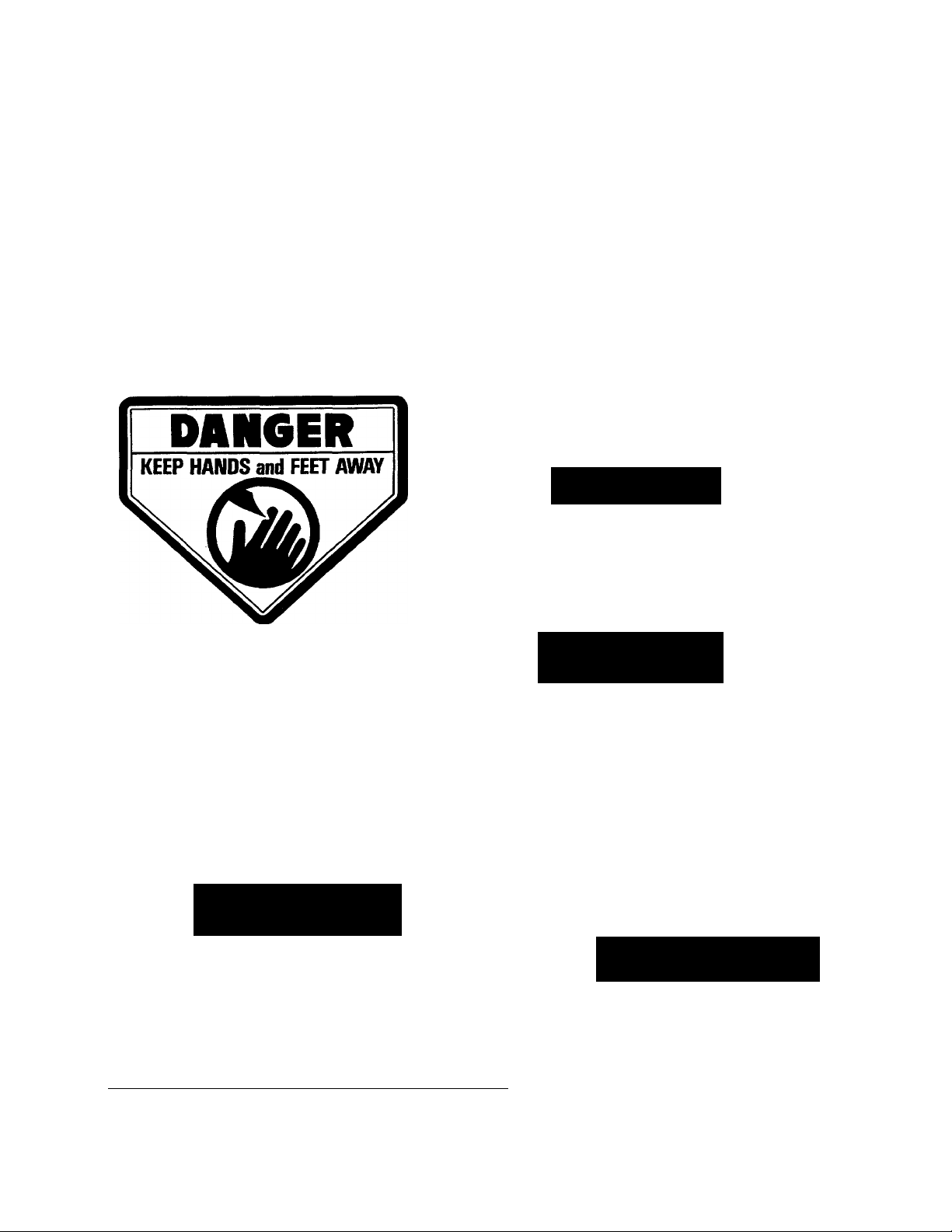

^SAFETY DECALS

Safety decals are located near any area of potential

danger. Please contact us for replacement decals if

5. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

6. Store gasoline in a cool, well-ventilated area, safely

away from any spark or flame-producing equipment.

Store in an approved container, safely out of the reach

of children.

7. Stop the engine, disconnect the spark plug wire,

and wait for ail moving parts to stop before inspecting,

cleaning, adjusting or repairing the mower. If the engine

has been running, allow the hot muffler to cool before

working near it.

they are missing, illegible, or damaged. See your Parts

Catalog for Part Number identification.

GRASP HANDLE GRIP WHEN

PULLING RECOIL STARTER.

1240263 (10/87)

ROTATING BLADE OR THROWN 0BJE(H^ CAN RESULT IN SERIOUS INJURY.

DO NOT OPERATE MOWER WITHOUT GRASS

DISCHARGE DEFLECTOR OR GUARD IN PLACE.

DO NOT PUT HANDS OR FEET NEAR OR UNDER

ROTATING PARTS. KEEP CLEAR OF THE DIS

CHARGE OPENING AT ALL TIMES.

Awarning

FAILURE TO FOLLOW SAFE OPERATING PROCEDURES MAY RESULT IN

INJURY. TO HELP REDUCE RISK:

1. READ OWNER/OPERATOR MANUAL.

2. KEEP ALL SAFETY GUARDS AND SHIELDS IN PLACE.

3. KEEP AREA OF OPERATION CLEAR OF ALL PERSONS AND PETS.

4. STOP ENGINE, DISCONNECT SPARK PLUG WIRE, AND WAIT FOR

ALL MOVEMENT TO STOP BEFORE CLEANING, INSPECTING OR

REPAIRING MACHINE.

For replacemenl Manual write lo: GARDEN WAY MFG. CO., TROY, N.Y. 1Z180 eooTBO/a?) J

ADANGER

80073 (9/87)

ACAUTION

DO NOT START ENGINE OR RUN MOWER UNLESS

BELT/PULLEY SAFETY COVER IS SECURELY FAS

TENED IN PLACE.

FAILURE TO INSTALL COVER CAN RESULT IN

INJURY FROM MOVING PARTS SUCH AS BELTS,

PULLEYS, CHAINS, ETC. T240226<9/87,

Page 7

SECTION 2

Assembly Instructions

Your TUFF-CUT® Mower is shipped partially unassembled for safe shipment to you. You’ll find all the

loose parts and necessary hardware packed inside the shipping carton. Please follow the simple steps in

this Section for quick, easy and complete mower and engine preparation. After your mower is assembled,

carefully read and follow all of the safety and operating instructions in this manual and in the separate

engine owner’s pamphlet.

IMPORTANT

The engine on your mower was shipped without oil in

the crankcase. See Step 6 for oil filling instructions.

CHECK FOR SHIPPING DAMAGE

If you notice any freight damage or missing parts

either at the time of delivery or later during assembly,

make sure that you put it in writing, within 15 days, that

you intend to file a claim. Tell the driver, or phone the

truck terminal, that you intend to file a written claim.

They will advise you on how to proceed. However, if you

have any problems with this procedure, please call us

so that we can help you to get satisfaction.

Also, be sure to notify us if you find any parts are miss

ing or damaged. We will arrange to replace damaged

or missing parts as quickly as possible.

TOOLS NEEDED FOR ASSEMBLY

All Models:

• Two each of 7/16", 9/16", or Adjustable-Style

Wrenches

• Small Adjustable Pliers

• Phillips Head Screwdriver

• Oil Funnel

• Tire Pressure Gauge (pocket-type)

Electric Start Models:

• 1/2" or Adjustable-Style Wrench

E. Remove any protective wrapping from the upper and

lower ends of the handlebars. Also, there may be a plas

tic protective cap on the outer ends of the two rear wheel

mounting studs. If so, remove and discard the caps.

F. For shipping purposes only, a cardboard sleeve was

placed underneath the mower deck. Using care to avoid

cutting yourself on the sharpened blade (wear thick

gloves for extra protection), raise the front of the mower

and remove the cardboard sleeve.

HARDWARE PACKAGE

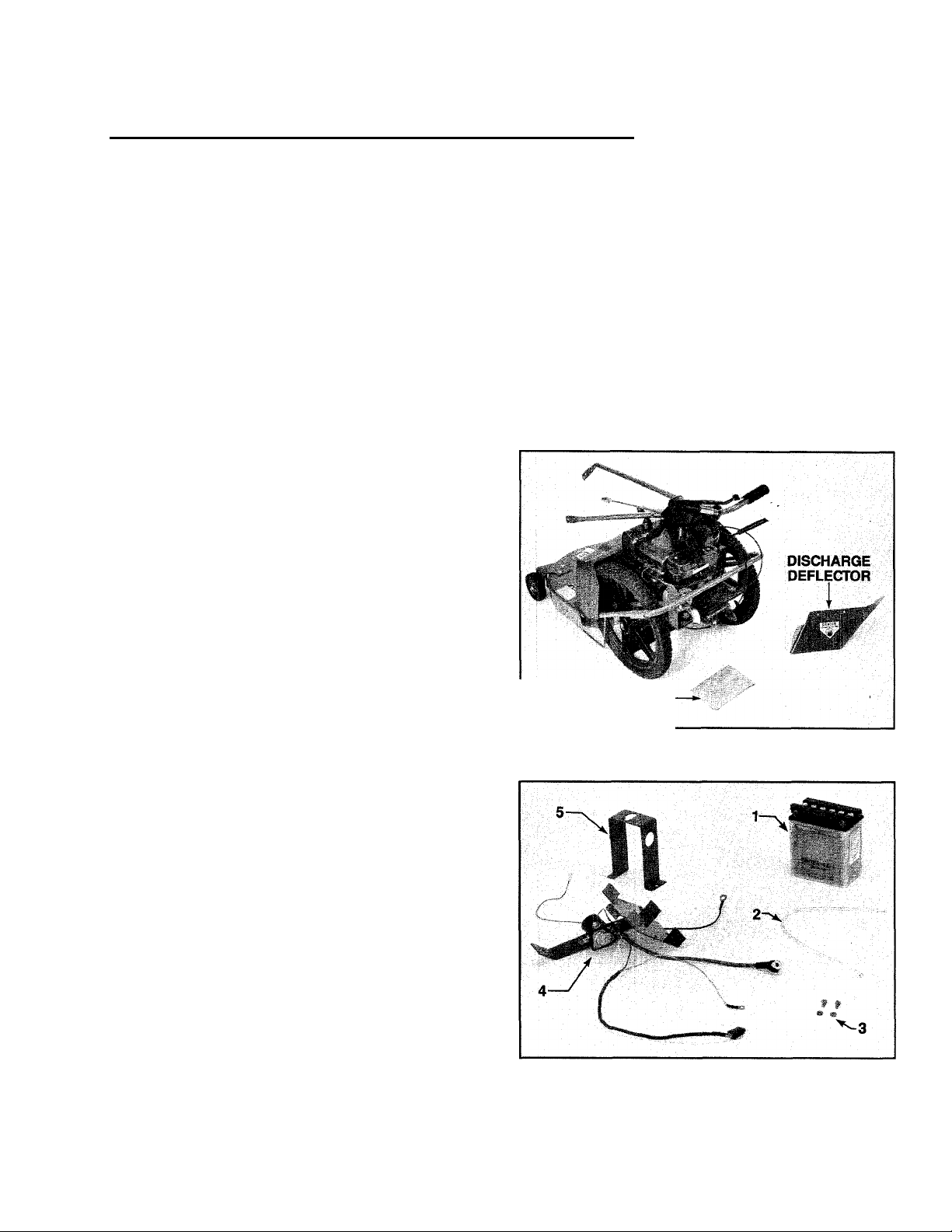

Photo 2-1: Remove mower, discharge deflector and

hardware package.

MOWER ASSEMBLY STEPS:

NOTE: All references to “Left” and “Right” are given

from the operator's position behind the handlebars.

STEP 1: Unpacking and Loose Parts

A. Remove the mower, discharge deflector, and hard

ware package from the shipping carton (lift carton off

base to remove mower). See Photo 2-1.

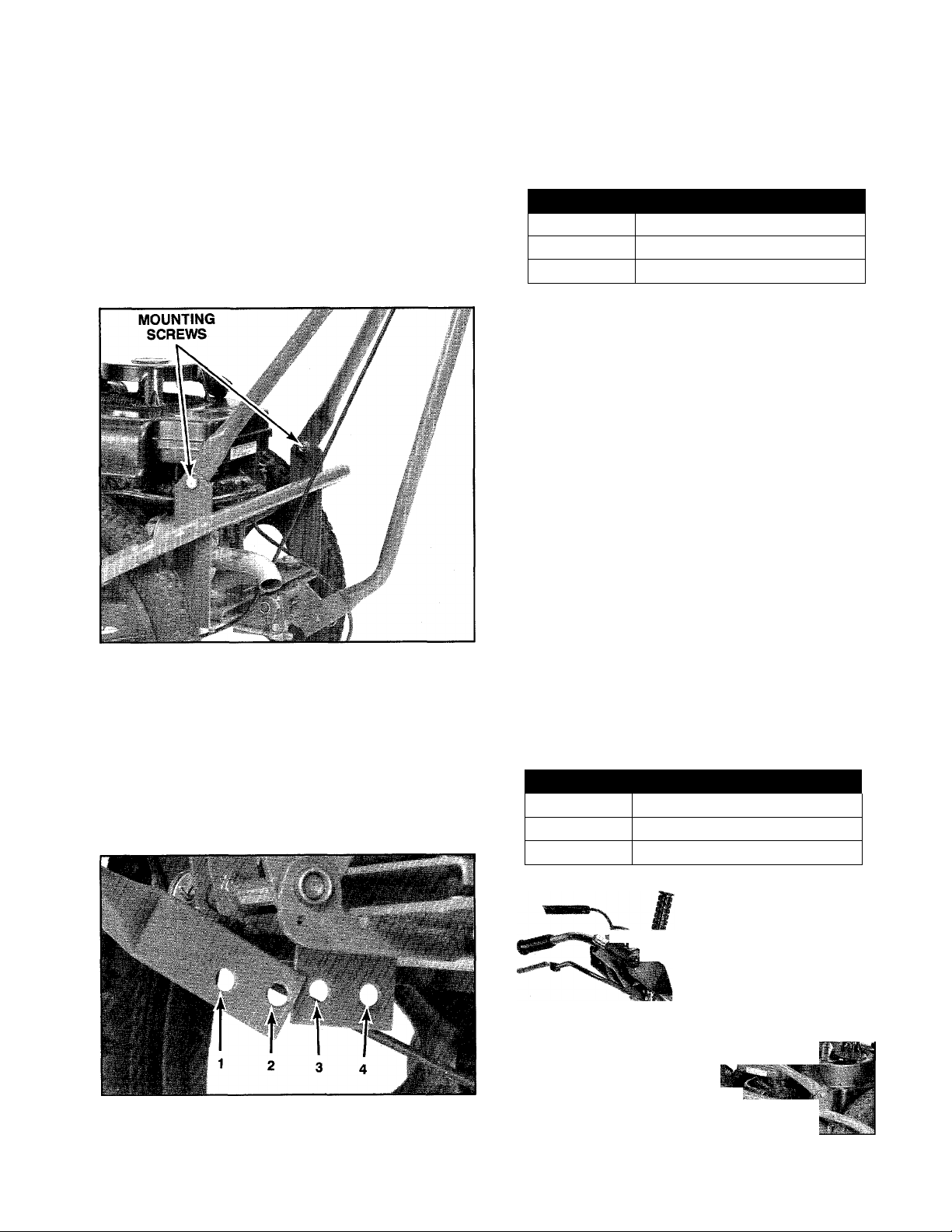

B. If you ordered an electric start model, also remove

the battery carton (containing battery, vent tube, and bat

tery bolts and nuts), the battery mounting bracket

assembly, and the battery hold-down clamp. See Photo

2-2.

C. The contents of the hardware bag can be identified

by referring to the separate “Hardware Bag Contents”

sheet that is included in your literature package.

D. Assembly should be done on a clean, level surface.

If you need to move the mower, be careful not to severely

bend or stretch any wires or cables.

Photo 2-2: Loose parts for electric start models include:

1. Battery

2. Vent Tube

3. Two Bolts and Nuts

4. Battery Mounting Bracket Assembly

5. Battery Hold-Down Clamp

Page 8

STEP 2: Attach Handlebars

A. Parts Needed: (3) 3/8"-16x3/4" long Hex Hd.

Screws, (3) 3/8" Lockwashers, (3) 3/8"-16 Hex Nuts,

(1) Plastic Tie (for 22" Mower Only).

B. Gently fold back the handlebars from their shipping

position atop the mower and align the holes in the

ends of the left and right handlebars with the holes in

the mower frame handlebar mounting brackets. See

Photo 2-3. Note that the ends of the handlebars can be

positioned to either the inside or the outside of the

mounting brackets (make certain that both ends are

positioned the same way: either both inside or both

outside).

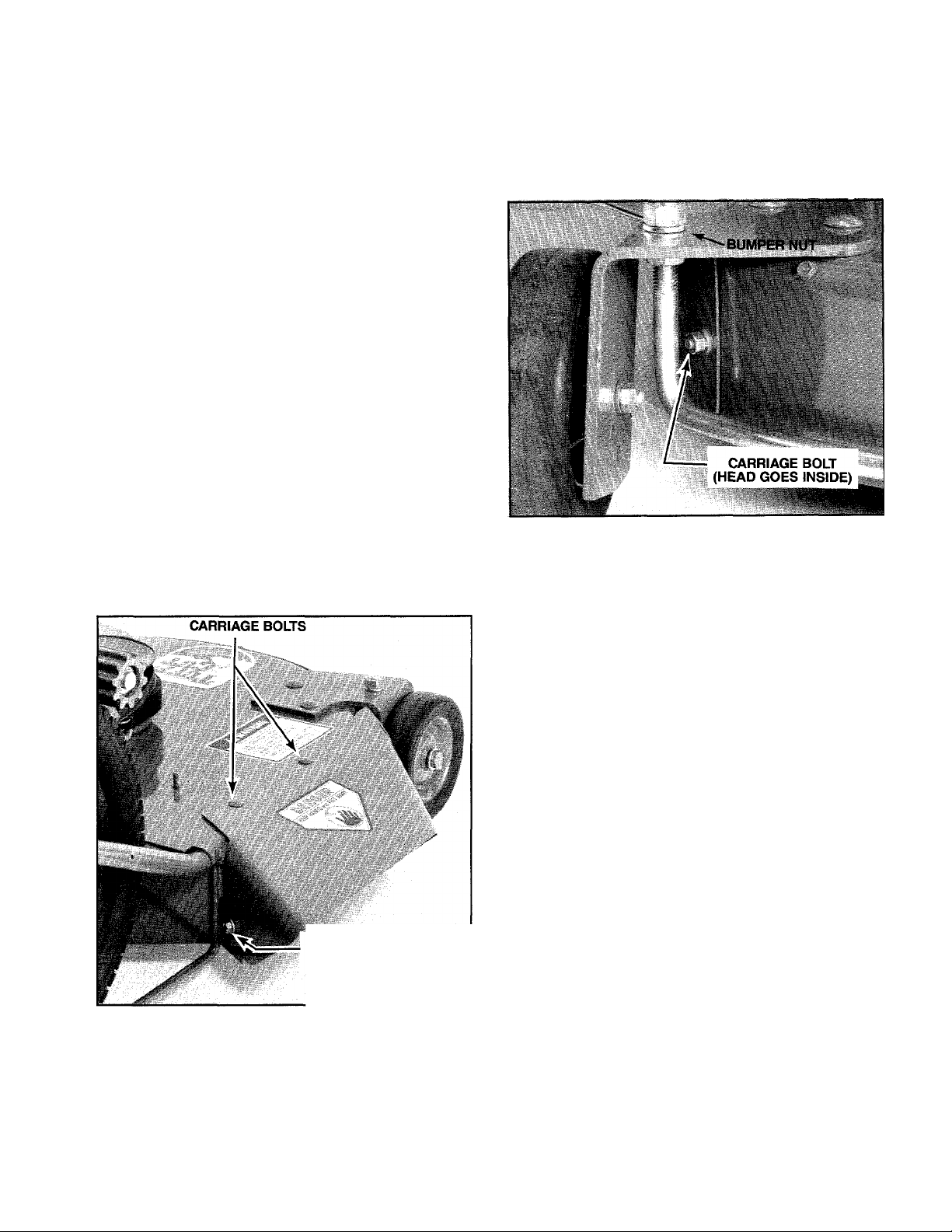

E. Select a hole combination according to the chart

below, then temporarily insert a 3/4" long screw through

the brace and bracket from right to left. Check that the

handlebars are set at a comfortable operating height

and readjust the setting if necessary. When you are

satisfied with the height setting, add a 3/8" lockwasher

and 3/8" hex nut and tighten securely using two 9/16"

wrenches.

USE HOLES

1-4

1-3 & 2-4

2-3

LOWEST HANDLEBAR HEIGHT

MEDIUM HANDLEBAR HEIGHT

HIGHEST HANDLEBAR HEIGHT

TO OBTAIN:

F. Securely tighten the two upper handlebar mounting

screws that you finger-tightened in Step C.

G. On the 22" mower (5HP engine) only, use a plastic

tie to secure the blade drive control cable (the thick

black cable attached to the blade drive control on the

left handlebar) to the center handlebar brace. Locate

the tie 3" to 4" above the bend at the lower end of the

center brace.

NOTE: For future handlebar height adjustments, refer

to the instructions found in Section 5.

Photo 2-3: Attach left and right handlebars.

C. Install two 3/4" long screws through the mounting

holes with the screw heads facing outside. Add 3/8"

lockwashers and hex nuts and tighten both screws

finger-tight.

D. There are two height adjustment holes at the bottom

of the center handlebar brace and two adjustment

holes in the height adjustment bracket which is welded

to the mower frame. See Photo 2-4. The four holes

allow you to choose three different handlebar height

positions: LOW, MEDIUM and HIGH.

STEP 3: Attach Wheel Drive Control Rod (Self-Propelled Models Only)

A. Parts Needed: (1) Clevis Pin, (1) Spring Clip.

B. One end of the upper wheel drive control rod is

already attached to the wheel drive lever located on

the right side of the handlebars. See Photo 2-5. The

clevis at the bottom of the control rod must be attached

to the bellcrank located at the rear of the mower. See

Photo 2-6.

C. There are three positioning holes in the bellcrank

that are identified in Photo 2-6 with the letters “H”, “M”

and “L”. As shown in the chart below, the clevis must

be installed in the correct bellcrank hole, relative to the

height setting of the handlebars.

USE HOLE

“H”

“M”

iilJl

IF HANDLEBARS ARE IN:

HIGHEST HEIGHT SETTING

MEDIUM HANDLEBAR SETTING

LOWEST HANDLEBAR SETTING

ff -«-WHEEL DRIVE LEVER

'i.'

Photo 2-4: Handlebar height adjustment holes. (Bell-

crank plate on self-propelled model has been rotated

upward for photo clarity.)

WHEEL DRIVE

CONTROL ROD

1

Photo 2-5: Wheel drive lever and upper control rod.

Page 9

Photo 2-6: Clevis attaches to bellcrank. Do not remove

alignment screw and nut during attachment steps.

IMPOFnANT

Whenever the handlebar height is changed, the posi

tion of the control rod clevis must be changed accord

ingly. Moving the handlebars changes the tension on the

upper control rod and this tension must be adjusted by

relocating the clevis in the appropriate bellcrank hole.

Refer to the “Handlebar Height Adjustment" instructions

in Section 5 for the correct procedure to follow.

D. Before the mower left the factory, the bellcrank was

rotated upward and secured in place with a #10-24 x

5/8" long Phillips head screw and #10 lockwasher/nut.

See Photo 2-6. This aligns the bellcrank. The bellcrank

must be aligned in this manner every time the control

rod clevis is relocated to a different bellcrank position

ing hole. Do not remove the screw and lockwasher/nut

at this time.

NOTE: If the screw and lockwasher/nut has been

removed, rotate the bellcrank upward and reinstall the

screw and lockwasher/nut.

E. Slide the arms of the clevis over the bellcrank, push

ing the clevis forward as far as it will go.

F. Pull the handle on the wheel drive lever all the way

back into its most reanward position and, while holding

the lever in this position, try to align the clevis hole with

the appropriate bellcrank hole. Do not let the wheel

drive lever move from its most rearward position while

you are moving the clevis.

G. If the holes line up, insert the clevis pin through the

right side of the clevis and secure it with the spring

clip. See Photo 2-7. If the holes do not line up, remove

the clevis from the bellcrank and adjust the clevis by

rotating it up or down the control rod.

H. Repeat Steps E, F and G until the holes are

aligned.

I. Remove the screw and lockwasher/nut (shown in

Photos 2-6 & 2-7) from the bellcrank alignment holes.

You may have to jiggle the bellcrank slightly to free

them. Be sure to save the screw and lockwasher/nut

for any future readjustments of the upper wheel drive

control rod.

J. At this time, check to see that the wheel drive rollers

are not touching the rear tires. See Photo 2-8. With the

wheel drive lever in the upward, NEUTRAL position,

there should be a minimum clearance of 1/16" be

tween the rollers and the tires. This clearance ensures

that the rollers will not drive the wheels when the wheel

drive lever is in NEUTRAL. If there is not at least 1 /16"

of clearance, an adjustment must be made before the

engine is started. Please refer to Section 5, “Adjusting

Wheel Drive Traction” for the necessary adjustment

procedure.

Photo 2-8: Check for minimum clearance of 1/16"

between rollers and tires. (Belt/pulley safety cover re

moved for photo clarity.)

STEP 4: Check Tire Pressure

A. Use a pocket-type tire pressure gage to check the

inflation pressures in the rear tires. See Photo 2-9. The

tires should be equally inflated to between 25-30 psi.

B. Incorrect or unequal air pressure can result in ab

normal tire wear and difficult steering. On self-propelled

models, it can result in poor traction between the wheel

drive rollers and the tires. For best results, check the

inflation pressures after every 10 hours of operation or

once a week, whichever occurs sooner.

Photo 2-7: Secure clevis with clevis pin and spring clip. Photo 2-9: Check tire pressures in rear tires.

Page 10

STEP 5: Attach Mower Discharge Deflector

CAUTION

• The discharge deflector must be installed before

operating the mower.

• Before installing the deflector, disconnect the

spark plug wire and keep the wire away from

the spark plug to prevent accidental starting.

• It will be necessary to reach below the blade

housing to install the discharge deflector.

Before doing so. put on heavy gloves to protect

your hands from the sharpened mower blade.

A. Parts Needed: (1) Discharge Deflector, (4) 1/4"-20

X 5/8" long Carriage Bolts, (4) 1/4" Lockwashers,

(4) 1 /4"-20 Hex Nuts.

B. It will be easier to install the deflector if you raise

the front of the mower a few inches off the ground and

then block the rear wheels.

C. Place the discharge deflector on the right side of

the mower deck so that the two square holes on the top

of the deflector are aligned with the square holes in the

top of the mower deck. Make sure that the right side of

the deflector overlaps the front wrap of the mower deck

and the left side of the deflector overlaps the rear mount

ing bracket. See Photo 2-10.

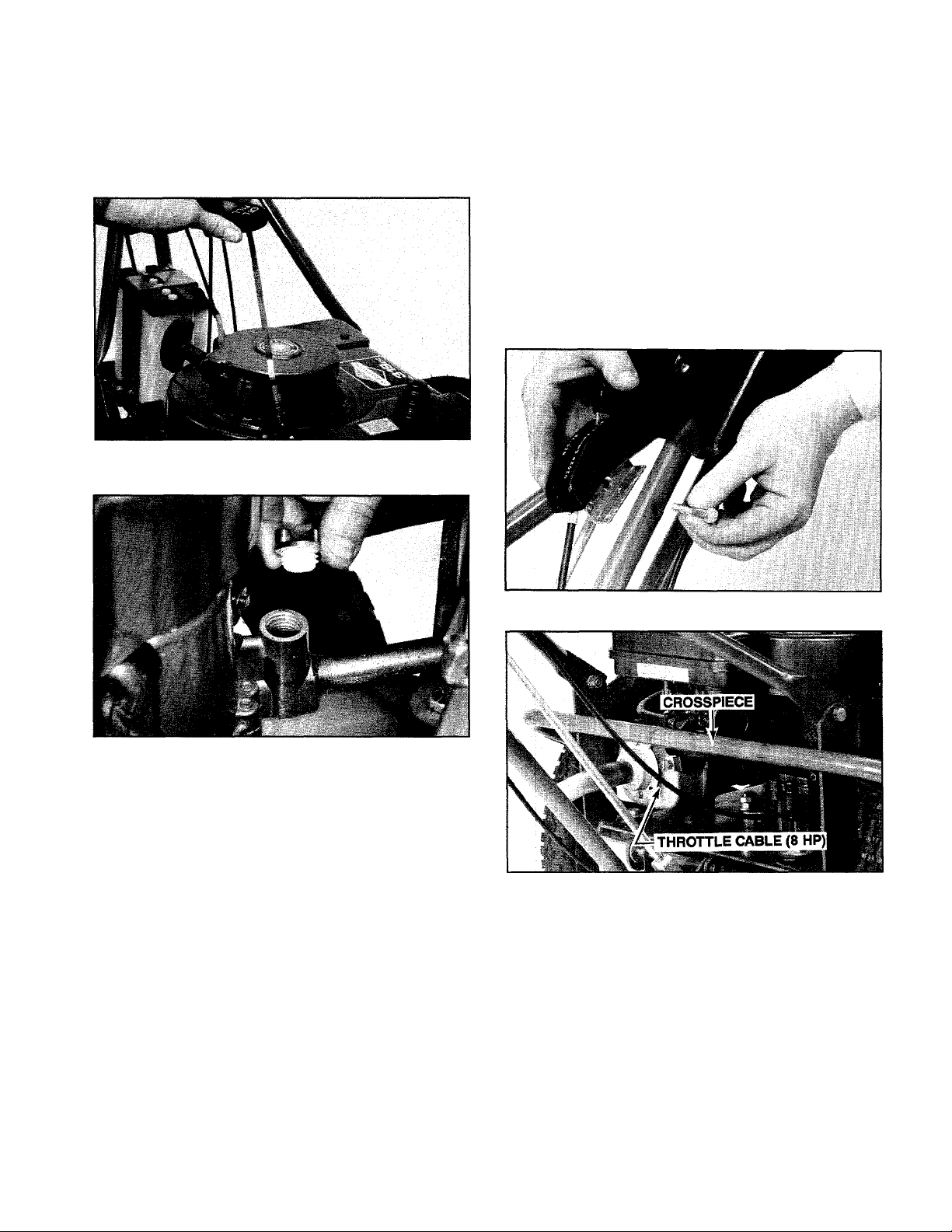

D. Insert two 5/8" carriage bolts down through the

holes in the top of the deflector and loosely attach 1 /4"

lockwashers and hex nuts. See Photo 2-10.

side of the mower deck out through the holes in the

front wrap and the deflector. Loosely attach a 114" lockwasher and hex nut. See Photo 2-11. If necessary, loosen

the bumper nut (shown in Photo 2-11) to gain clearance

for the carriage bolt and nut. After adding the bolt and

nut, securely tighten the bumper nut.

G. Using a 7/16" wrench, tighten all four carriage bolts

securely.

Photo 2-11: Location of fourth carriage bolt.

STEP 6: Add Oil to Engine Crankcase

CARRIAGE BOLT

(HEAD GOES INSIDE)

Photo 2-10: Location of three carriage bolts. (Belt/pulley

safety cover removed for photo clarity.)

E. Insert a 5/8" carriage bolt from the inside of the

mower deck out through the holes in the bottom, left

side of the mounting bracket and the deflector. Loosely

attach a 114" lockwasher and hex nut. See Photo 2-10.

F. On the bottom, right side of the deflector (behind

the front wheel), insert a 5/8" carriage bolt from the in

CAUTION: The engine was shipped to you

“dry", and oil must be added to the crank

O

case before the engine is started to avoid damag

ing the engine.

A. Make sure that the engine is level.

B. Use a high quality detergent oil classified "For

Service; SE, SF, or SG." Above 40°F, use SAE 30.

From 0° to 40°F, use 5W-30 or 10W-30. (See the

engine owner's pamphlet for synthetic oil

recommendations.) No special additives should be

added to the oil. DO NOT MIX OIL WITH

GASOLINE.

C. The 5HP engine (22" mower) requires

approximately 20 ounces; the 8HP engine (24"

mower) requires approximately 36 ounces.

D. Clean the area around the oil fill hole before

removing the oil fill plug or dipstick.

IMPORTANT: Always stop engine before adding oil.

E. 8 HP ENGINE: Remove the dipstick by rotating it

counterclockwise. See Photo 2-12. Using a clean funnel,

slowly pour oil into the filler neck. While adding oil, fre

quently check the level by replacing the dipstick and

rotating the cap until it is secure. Then remove the dip

stick and check the oil level by reading the dipstick

markings (wipe the dipstick with a clean rag each time

before replacing it). Stop adding oil when the level

reaches the FULL mark. Do not overfill. ALWAYS MAIN

TAIN THE OIL LEVEL AT THE FULL MARK ON THE

DIPSTICK.

8

Page 11

F. 5 HP ENGINE: Remove the oil fill cap by rotating it

counterclockwise. See Photo 2-13. Using a clean fun

nel, slowly add oil until it reaches the point of overflow

ing at the oil fill hole. ALWAYS MAINTAIN THE OIL

LEVEL AT THE POINT OF OVERFLOWING.

G. After adding oil, securely replace the oil fill cap or

the dipstick.

Photo 2-12: Oil fill hole on 8 HP engine.

NOTE: On the 22" mower (5 HP engine) the throttle

cable should be routed above the tubular frame cross

piece located behind the engine; on the 24" mower {8

HP engine) the cable should be below the crosspiece.

See Photo 2-15.

C. Insert a 1 1/2" long screw through the handlebar

and into the metal clamp that is attached to the throttle

control. Add a 1/4" lockwasher and hex nut and

tighten securely using two 7/16" wrenches.

D. On the 24" mower only, use a plastic tie to secure

the throttle control cable and the blade control cable

(the thick, black cable that is attached to the blade drive

control on the left handlebar) to the center handlebar

brace. Locate the tie approximately in the middle of the

center brace.

Photo 2-13: Oil fill hole on 5 HP engine.

IMPORTANT

Check the oil level each time before starting the

engine and after each 5 hours of continuous opera

tion.

Change the oil after the first 5 operating hours and

every 25 hours thereafter. Change the oil more fre

quently in extremely dusty or dirty conditions.

Clean the air cleaner after every 25 operating hours,

or sooner under extremely dusty or dirty operating

conditions.

STEP 7: Attach Engine Throttle Control

A. Parts Needed: (1) 1/4"-20 x 1 1/2" long Hex Hd.

Screw, (1) 1 /4" Lockwasher, (1) 1 /4"-20 Hex Nut, (1)

Plastic Tie (for 24" Mower Only).

B. Uncoil the throttle cable and position the throttle

control on the inside edge of the left handlebar as

shown in Photo 2-14.

Photo 2-14: Install engine throttle control.

Photo 2-15: Throttle cable goes below crosspiece on 8

HP engine (as shown above), and above crosspiece

on 5 HP engine.

IMPORTANT

This completes the mower assembly steps if you have a

recoil (rope pull) starting engine. If you have an electric

(key switch) starting engine, please continue with the

following electric start assembly steps.

CAUTION: To avoid personal injury, carefully

read and follow all of the Safety, Controls,

B

and Operating instructions in this manual and in

the separate engine owner's pamphlet before

attempting to start the engine or operate the mower.

Page 12

ELECTRIC START ASSEMBLY STEPS:

IMPORTANT

Your new battery must be activated with eiectroiyte and

fuiiy charged before placing it in service.

The optional electric start system includes a 12-volt

side-vented battery, a key switch ignition system, a

solenoid, a starter motor (attached to the engine), and

the cables and wires that connect the electrical

system. A built-in recharging circuit automatically

recharges the battery during mower operation.

The following steps explain how to activate and

charge the battery, and how to assemble the electric

start system. For your safety, please follow each step

carefully and observe all of the accompanying Safety

Warnings and Cautions.

DANGER — POISON -

A.

■ CAUSES SEVERE BURNS!

• Electrolyte is a sulfuric acid solution.

• Avoid contact with skin, eyes or clothing.

• To prevent accidents and avoid personal injury,

wear protective clothing, rubber gloves, and

shield eyes with safety goggles.

• Neutralize acid spills with baking soda and

water solution. Neutralize empty container with

baking soda and rinse with watei.

ANTIDOTE: External — Flush with water. Eyes

— Flush with water for 15 minutes ana get prompt

medical attention.

ANTIDOTE: Interna! — Drink large quantities of

water or milk. Follow with milk of magnesia, beat

en eggs, or vegetable oil. Call physician immedi-

KEEP OUT OF REACH OF CHILDREN.

DANGER — BATTERIES PRODUCE

B

• Keep sparks, fiame. cigarettes away.

• Ventilate area when charging or using battery

in enclosed space.

• Make sure venting path of battery is alv/ays

open once battery is filled with acid.

EXPLOSIVE GASES!

B. There may be a sealed plastic tube covering the

vent fitting on the positive (-i-) side of the battery. Be

sure to remove and discard this tube before activating

the battery. See Photo 2-16.

C. Piace battery on level surface and remove all filler

caps. Leave caps off during filling and charging

procedures.

POSITIVE

(+)POST

VENT.

Photo 2-16: Add electrolyte to UPPER LEVEL line.

NEGATIVE

(-)POST

UPPER

LEVEL

LINE

WARNING: Remove metal jev,ielry before

working near the battery or any pari of the

n

electrical system. Failure to do so can cause a

short circuit that could result in electrical burns,

an elect'ical shock, or an explosion of battery

D. Carefully fill the cells with battery grade electrolyte

(1.265 Specific Gravity sulfuric acid) until it reaches

the UPPER LEVEL LINE that is marked on the outside

of the battery case. See Photo 2-16. The temperature of

the battery and the electrolyte should be between 60°F

to 80°F for best results. No water or other liquid should

be added to the battery during this initial activation.

E. Allow the battery to stand for 30 minutes. Then

check each cell and, if necessary, add more electro

lyte until it reaches the UPPER LEVEL LINE. DO NOT

overfill with electrolyte as this may cause electrolyte to

flood over during battery charging.

STEP 1: Activate and Charge the Battery

A. The battery is shipped to you “dry”, and it cannot

be used until it has been activated with electrolyte (bat

tery grade sulfuric acid) and given a proper start-up

charge. Activating a battery with electrolyte is danger

ous work (the acid can eat through clothing and burn

skin) and we therefore strongly recommend that you

take the battery to a reliable service station, battery

store, or farm/outdoor power equipment center where

a trained battery technician can complete the job safe

ly. PLEASE DO NOT ATTEMPT TO ACTIVATE THE

BATTERY YOURSELF UNLESS YOU ARE FULLY EX

PERIENCED IN BATTERY SERVICE WORK!

10

DANGER

A

Batteries generate explosive gases Keep sparks

and flames away from battery at all times.

Ventilate area when charging or using battery

in enclosed space.

We recommend that the battery not be left on

charge while unattended (the charging time

need not be continuous).

Carefully follow charging instructions and

Safety Rules provided by the manufacturer of

the charging equipment being used.

Page 13

F. To obtain maximum starting capacity and longest

life, the battery must be fully charged at a rate of 1 to 2

amperes until all cells are gassing freely. (To determine

this, WEAR SAFETY GOGGLES and use a flashlight

to look down into each cell while the battery is being

charged. When gassing freely, the surface of the liquid

electrolyte should be covered with tiny bubbles). The

total charging time should not exceed 12 hours.

CAUTION: Do not charge the battery at a

rate higher than 1 to 2 amperes. Higher

®

amperages can generate excessive heat and gas

sing, permanently damaging the battery.

G. When the battery is fully charged, turn off the

charger and then disconnect the cables. Check the

electrolyte levels, and if necessary add distilled or

demineralized water until it just reaches the UPPER

LEVEL LINE.

H. Replace the filler caps and use a baking soda and

water solution to wash off any electrolyte which may

have spilled on the battery.

Photo 2-17: Install battery mounting bracket.

IMPORTANT

When the battery will not be used for extended periods

(such as during the winter months), the foiiowing

charging scheduie should be followed:

a. Charge the battery before prolonged storage.

b. Charge the battery after prolonged storage.

Please refer to Section 5 of this manual for battery

maintenance and recharging instrucdons.

STEP 2: Install Battery Mounting Bracket

A. Parts Needed: (2) 1 /4"-20 x 1 1 /4" long Hex Hd.

Screws, (2) 1/4"-20" Locknuts, (1) Battery Mounting

Bracket.

B. The battery mounting bracket must be attached to

the mower’s frame and engine mounting platform at

the three locations shown in Photo 2-17.

C. Using two 9/16" wrenches, remove the 1 7/8" long

hex hd. screw, 3/8" lockwasher, and 3/8" hex nut from

the right side of the engine mounting platform. See

Photo 2-17. Save this hardware.

D. Align the two holes in the top, front of the mounting

bracket with the two holes in the mower frame cross

piece. Insert the two 1 1 /4" long screws down through

the bracket and frame and loosely attach the two 1 /4"

locknuts.

E. Align the hole at the bottom of the battery bracket

support leg with the hole in the bottom of the engine

mounting platform (leg goes below platform). Replace

the 1 7/8" long screw, add the lockwasher and nut,

and tighten securely.

F. Now return to the two upper mounting screws and

tighten them securely using two 7/16" wrenches.

STEP 3: Connect Battery Recharging Line

A. Parts Needed: (1) Plastic tie.

B. The battery recharging line is a thin red wire, approx

imately 12" long. One end is already connected to the

upper stud on the solenoid (the solenoid is a black,

can-like device that is mounted on the battery bracket

support leg). On the unattached end of the line there is

a white plastic bayonet terminal.

C. Bring the recharging line over to the right side of

the engine and plug the white terminal into the red term

inal that is attached to the engine with black wires. Push

the terminals firmly together. See Photo 2-18 or 2-19.

Photo 2-18: Connect recharging line on 22" (5HP

engine) mower.

11

Page 14

Photo 2-19: Connect recharging line on 24" (8HP en

gine) mower. (Wheel removed for photo clarity).

D. Use a plastic tie to secure the recharging line to the

strut. See Photo 2-20.

Photo 2-21: Attach starter motor cable to lower stud oh

solenoid.

STEP 5: Attach Ignition Ground Wire

A. The ignition ground wire is a thin green wire that

leads from the key switch wiring harness (the wiring

harness also contains a red and a white wire).

B. At the rear of the engine, remove the nut from the

engine ground stud, attach the wire terminal, and re

place the nut securely. See Photo 2-22 or 2-23.

Photo 2-20: Add plastic tie to recharging line (wheel

removed for clarity).

STEP 4: Attach Starter Motor Cable

A. Parts Needed: (1) 5/16"-24 Hex Nut, (1) 5/16" Lock-

washer.

B. The starter motor cable is a thick red cable, approx

imately 20" long. One end is already attached to the

starter motor at the front, right side of the engine.

C. Bring the cable terminal over to the solenoid that is

mounted on the battery bracket support leg. As shown

in Photo 2-21, attach the cable terminal to the lower

stud on the solenoid and add the 5/16" lockwasher and

5/16" hex nut. Tighten the hex nut securely to ensure a

good electrical contact.

12

Photo 2-22: Attach ignition ground wire on 22" (5HP

engine) mower.

Photo 2-23: Attach ignition ground wire on 24" (8HP

engine) mower.

Page 15

STEP 6: Attach Vent Tube to Battery

A. Parts Needed; (1) Vent Tube (shipped in battery

carton).

B. Attach the long, clear plastic vent tube over the

vent fitting on the positive ( + ) side of the battery. See

Photo 2-24.

Photo 2-24: Attach vent tube to battery. Photo 2-25: Install battery and hold-down clamp.

STEP 7: Install Battery and Hold-Down Clamp

A. Parts Needed: (1) Hold-Down Clamp, (2) 1/4"-20 x 1"

long Hex Hd. Screws, (2) 1/4"-20 Locknuts.

B. Place the battery on the mounting bracket exactly

as shown in Photo 2-25. Make sure that the positive (-t-)

post on the battery is facing the engine.

C. Run the plastic vent tube straight down the side of

the battery so that the end is pointing toward the ground.

D. Position the hold-down clamp over the battery ex

actly as shown in Photo 2-25, making sure that the large

hole in one side of the clamp is on the left side of the

battery.

E. Fasten the two sides of the clamp to the bracket by

inserting the two 1" long screws up through the mount

ing holes. Add 1/4" locknuts and tighten securely using

two 7/16" wrenches. The clamp should be tight enough

to prevent the battery from moving, but do not overtigh

ten the screws, which would bend the tabs on the clamp.

WARNING

ik

• Do not touch the positive (+) battery post and

any other surrounding metal with tools, jewelry,

or other metal objects. Doing so can cause a

short circuit that could result in electrical burns,

an electrical shock, or an explosion of battery

STEP 8: Attach Positive (-f) Battery Cabie

A. Parts Needed: (1) 1/4"-20 x 1/2" long Battery Bolt,

(1) 1/4"-20 Hex Nut (shipped in battery carton). Note;

Battery bolts and nuts are metric sizes. The sizes given

above are in U.S. size equivalents.

B. The positive ( + ) battery cabie is a thick red cable,

approximately 14" long. One end is already attached

to the upper stud on the solenoid. There is a rubber in

sulating boot located on the cable.

C. Place the battery nut on the inside of the battery

positive (-i-) post and the cable terminal on the outside

of the post. Install the battery bolt securely using a Phil

lips head screwdriver. See Photo 2-26.

D. Slide the rubber boot over the battery post, making

sure that it covers the post completely. If necessary,

use a screwdriver with a wide, flat tip to help seat the

boot between the battery nut and the battery case.

• Install the battery exactly as shown in Photo

2-25. If the battery is installed in reverse, the

battery and other electrical system parts will

be damaged.

• Make certain that the vent tube is not crimped,

pinched, or folded anywhere along its length.

Improper venting could result in a battery ex

plosion.

Photo 2-26: Attach positive (-i-) battery cable.

13

Page 16

STEP 9: Attach Negative (-) Ground Wire and Negative (-) Battery Cabie

A. Parts Needed: (1) Va”-20 x Уг" long Battery Bolt, (1)

1/4 "-20 Hex Nut (shipped in battery carton).

B. The negative (-) ground wire is a thin black wire,

approximately 11" long. One end is already connected

to the upper bolt that secures the solenoid to the battery

bracket support leg.

C. The negative (-) battery cable is a thick black cable,

approximately 22" long. One end is already connected

to the engine mounting screw on the left side, rear of

the engine.

D. Place the battery nut on the inside of the battery

negative (-) post and position the wire and cable ter

minals on the outside of the post. Install the battery

bolt securely using a phillips head screwdriver. See

Photo 2-27.

Photo 2-28: Connect receptacle to key switch.

Photo 2-27: Attach negative (-) wire and cable.

STEP 10: Connect Wire Harness Receptacle

to Key Switch

CAUTION: Remove the ignition key from

the key switch before connecting the wire

B

harness receptacle to the switch.

A. Parts Needed: (1) Plastic Tie.

B. Connect the wire harness receptacle (which has

three wires leading out of it) to the bottom of the key

switch assembly. See Photo 2-28. Make certain that the

connection is good and tight.

C. Use a plastic tie to secure the wire harness to the

negative (-) ground wire and negative battery cable as

shown in Photo 2-29.

D. Do not replace the ignition key in the key switch until

you have read all of the Safety, Controls and Operating

instructions in this manual and in the separate engine

owner’s pamphlet.

Photo 2-29: Secure wire, cable and harness with tie.

WARNING

A

Never br.ng a gasoline can near the battery

posts. A short c.rcuit caused oy touching the

positive (■+ ) post and any meta'. could cause

an explosion of the gasoline or of battery gases.

Never attempt to “jump start" the battery with

an automobile battery or its charging system.

Doing so could result in serious personal injury

or property damage from such causes as a

battery explosion, or acid or electrical burns.

To avoid personal injury, always remove the key

from tne switch, disconnect the spark plug v,riro.

and keep the wire away from the spark plug

v;hen leaving the mower unattended or when

the mower is not in use.

To avoid personal injury when servicing the

mower or engine, alv^ays remove the spark plug

w.re from the spark plug and keep the wire away

from the plug. Then disconnect the negative

I -) cable from the battery post and bend it

safely aviay from the battery post.

14

Page 17

SECTION 3

Mower and Engine Controls

Before operating your mower, familiarize yourself with all mower and engine controls. Taking the time now

to understand fully the location, function, and operation of these controls will greatly increase your ability to

operate your mower efficiently and safely.

IMPORTANT

This mower is equipped with a blade brake which is

designed to stop the mower blade within three seconds

after release of the blade control handle. This feature is

required to meet the federally mandated safety stan

dards described in Section 1 of this Manual. Never

tamper with, or attempt to defeat the purpose of this

safety device. Doing so may result in personal injury

through contact with the rotating blade. Check that the

Blade Brake Control System is operating properly. See

the Blade Brake Control Test Procedure described on

Page 34.

MOWER CONTROLS

NOTE: Ail references to “Left” and “Right” are given

from the operator’s position behind the handlebars.

Because the blade brake system stops the blade but

not the engine, you can disengage the biade drive at

anytime without having to stop and then restart the

engine. This feature is particularly useful when you

need to cross gravel drives or rough terrain and you do

not want the rotating blade to throw stones or strike

hidden obstacies.

WHEEL DRIVE LEVER

(Self-Propelled Model)

Photo 3-1: Location of mower controls.

BLADE DRIVE CONTROLS

The blade control handle and blade control are

located on the left handlebar of your mower. See Photo

3-1. These controls are used to engage and disengage

the mower blade.

To engage the blade drive mechanism, first pull the

blade control handle down and hold it against the han

dlebar grip. Then, set the blade control by pushing the

control forward until a distinct “click” is heard. See

Photo 3-2. This action tightens the blade drive belt,

allowing the blade to begin rotating. It also resets a

friction brake mechanism located on the blade spindle

which will stop the blade within three seconds after

you release the biade control handle.

The blade control handle must be depressed against

the handlebar grip in order to keep the blade rotating.

Releasing the blade control handle will disengage the

blade control and stop the blade within the three se

cond safety limit.

BLADE CONTROL HANDLE

WHEEL DRIVE HANDLE

(Self-Propelled Model)

BLADE CONTROL

Photo 3-2: Operation of blade control handle and blade

control.

CAUTION: When starting the engine, the

blade control handle should be in the fully

released position. This position ensures that the

H

blade will not start rotating when the engine starts.

To avoid personal injury, do not engage the blade

drive controls until you are ready to begin mowing.

WARNING: If the blade brake system is dam

aged or maladjusted, the blade may continue

to rotate after you have released the blade control

H

handle. If the blade does not stop within 3 seconds

of release of the blade control handle, move the

engine throttle control to the STOP position.

Immediately refer to the Blade Brake Control

System Test Procedure on Page 34. To avoid per

sonal injury, do not operate the mower until the

Blade Brake Control System is operating properly.

15

Page 18

WHEEL DRIVE CONTROLS (Self-Propelled Models Only)

The wheel drive handle is located below the left side

handlebar grip and the wheel drive lever is located

toward the right side of the handlebars. See Photo 3-1.

These controls are used to engage and disengage

traction drive to the wheels on self-propelled models.

To engage the wheel drive mechanism, first pull the

wheel drive handle up and hold it against the

handlebar grip. Then, push the wheel drive lever all

the way forward until it latches in the fonward position.

See Photo 3-3. This action pulls back the lower wheel

drive control rod which is connected to the wheel fric

tion drive rollers. The rollers then push against the

wheels to propel the mower forward.

The wheel drive handle must be depressed against

the handlebar grip in order to keep the wheels turning.

Releasing the wheel drive handle will disengage the

wheel drive lever, which then disengages the rollers

from the wheels.

For trimming or maneuvering in tight places, you

can disengage the wheel drive (by releasing the wheel

drive handle), and then “creep” the mower forward by

gradually pushing the wheel drive lever forward until

the wheel friction drive rollers contact the wheels. To

stop the fonward motion, simply pull back on the wheel

drive lever.

HEIGHT OF CUT ADJUSTMENT

The cutting height can be adjusted to any of four dif

ferent settings: 1-5/8", 2-1/4", 2-7/8", and 3-1/2".

The cutting height has been set at the factory at the

2-7/8" setting. This cutting height is recommended for

initial mowing in rough terrain as it will minimize the

chances of the blade hitting rocks or other hidden

obstructions (see CAUTION statement below).

To change the cutting height to a higher or lower set

ting, refer to the “Height of Cut Adjustment” instruc

tions in Section 5.

CAUTION: Before mowing, thoroughly in

spect the area where the mower is to be used

B

and remove all stones, sticks, wires, bones, nails

and other foreign objects, to prevent personal in

jury caused by throv^n objects.

ENGINE CONTROLS

The following are descriptions of the controls of your

5 HP or 8 HP Briggs & Stratton Engine. Additional in

formation on the safe, efficient operation of your

engine is given in the engine owner’s pamphlet which

was included in your mower literature package. Please

read that pamphlet carefully.

Photo 3-3: Operation of wheel drive handle and wheel

drive lever.

CAUTION: When starting the engine, the

wheel drive lever should be in the upward.

H

NEUTRAL position. This postion ensures that

the wheels will not starl turning when the engine

starts. To avoid personal injury, do not engage the

wheel orive lever uniti you are reaoy to move the

CAUTION: To avoid personal injury, do not

attempt to start your engine at this time.

B

Complete starting instructions for your mowe' are

provided in Section 4. ■ 'Operating Instructions.”

ENGINE THROTTLE CONTROL

On all models, the engine throttle control is located

on the left handlebar. See Photo 3-4. This control

operates a full range of engine speeds. It also activates

the engine choke control when starting the engine,

and stops the engine by grounding out the ignition.

HANDLEBAR HEIGHT ADJUSTMENT

The handlebars can be adjusted to any of three dif

ferent height settings; LOW, MEDIUM and HIGH.

To change the handlebar height, refer to the “Han

dlebar Height Adjustment” instructions found in Sec

tion 5.

16

Photo 3-4: Engine throttle control settings.

Page 19

There are three operating positions identified on the

throttle control: CHOKE, F-S (Fast-Slow), and STOP.

The Fast and Slow settings are provided with detent

type stops that “catch” the lever when those settings

are engaged. To move the lever out of the detent stops,

push the lever a short distance to the right.

Before starting the engine, always make sure that

the blade drive and wheel drive controls are disengag

ed. Then, move the throttle lever all the way forward

(past the Fast detent stop) to the CHOKE position. As

soon as the engine starts, gradually pull the lever back

to the Slow detent stop. Do not leave the throttle in the

choke position. Doing so could harm your engine.

NOTE: A warm engine requires less choking than a

cold engine.

Once the engine is sufficiently warm, move the lever

to the desired engine speed for your particular mowing

task. The engine is designed to be operated at full

speed to give you the best cut and fastest traction drive

(on self-propelled models). However, if preferred,

slower speeds can be used.

To stop the engine, release the blade and wheel

drive control handles, put the engine throttle lever in

the Slow position, and then pull the throttle lever all the

way back to the STOP position.

FUEL SHUT-OFF VALVE

(8 HP Engine Only)

The 8 HP (24" mower) engine is equipped with a

fuel shut-off valve. The valve is located on the back of

the engine below the air cleaner assembly. See Photo

3-5.

To shut off the fuel flow to the carburetor, turn the

valve clockwise until it stops turning. To open, turn the

valve counterclockwise several turns. Always remember

to open the fuel valve before attempting to start the

engine.

NOTE: Close the fuel shut-off valve when the engine is

transported to prevent fuel leakage.

Photo 3-6: Engine recoil starter rope (5 HP engine

shown).

To start the engine, first place your left hand on the

right side handlebar grip to help stabilize the mower.

Then grasp the starter rope handle with your right

hand and pull the rope out slowly until it is harder to

pull because of engine compression. Next, pull the

rope with a rapid, continuous, full-arm stroke. Do not

let the starter rope snap back against the rope guide.

Let the rope rewind slowly.

KEY SWITCH STARTER (Electric Start Engine Only)

The key switch starter for electric start engines is

located on the right handlebar. See Photo 3-7. There

are three operating positions identified on the switch:

OFF, RUN, and START.

Photo 3-5: Fuel shut-off valve (8 HP engine).

ENGINE RECOIL STARTER

On all models, the recoil starter rope handle is

located on top of the engine, on the right side as view

ed from the operator’s position behind the handlebars.

See Photo 3-6.

Photo 3-7: Key switch starter

To start the engine, first insert the key firmly into the

slot. Then, turn the key to the START position. Do not

hold the key in the start position for longer than a few

seconds. Prolonged cranking can damage the starter

motor if cranked more than 15 seconds per minute.

When the engine starts, release the key and It will

automatically return to the RUN position.

There are two ways to stop the electric start engine:

1. Release the blade control and wheel drive handles,

put the engine throttle lever in the SLOW position, and

then pull the throttle lever all the way back to the STOP

position. Turn the key to the OFF position and remove

the key.

2. Release the blade control and wheel drive handles,

then put the engine throttle lever in the SLOW posi

tion. Turn the key to the OFF position and remove the

key.

17

Page 20

SECTION 4

Operating Instructions

Your TUFF-CUT Mower is very easy to operate and in this Section you wiii find not oniy detaiied operating

instructions, but aiso tips and suggestions to heip you get the greatest possible satisfaction from your mower.

Please read this Section thoroughly before you attempt to start the engine. Then, find a clear area where you

can safely learn to start, stop and maneuver your mower.

IMPORTANT

Before operating your mower, be sure that you have

carefully read and fully understand the “Rules for Safe

Operation” given in Section 1 of this manual, in addition

to those presented in this Section.

PREPARATION BEFORE

STARTING

A. CHECK ENGINE OIL LEVEL. Check the oil level in

the engine crankcase. Do not run the engine unless

the proper oil level is maintained. Refer to Section 2 for

instructions.

IMPORTANT

Check oil level before each use and after each five hours

of continuous operation. Change oil after first five oper

ating hours and every 25 operating hours thereafter.

B. FILL FUEL TANK

1. Remove fuel tank cap and check fuel level (see

Photo 4-1 or 4-2). Clean area around fuel cap before

removing to prevent the entrance of dust, dirt and mois

ture.

2. Use clean, fresh, lead-free, automotive gasoline.

Leaded gasoline may be used if lead-free is not avail

able. (The use of lead-free gasoline results in fewer

combustion deposits and longer valve life.) A minimum

of 77 octane is recommended. DO NOT MIX OIL WITH

GASOLINE.

Photo 4-1: Fuel tank on 5HP engine (22" mower).

Photo 4-2: Fuel tank on 8HP engine (24" mower).

3. Do not fill the fuel tank to the point of overflowing.

Fill to within V2" of top of fuel tank to prevent spills and

to allow for fuel expansion. The fuel tank capacity is 2

quarts on the 5HP engine and 3 quarts on the 8HP

engine.

4. Replace the fuel cap securely before starting the

engine.

DANGER: Gasoline is highly flammable and

its vapors are explosive. Handle with extreme

n

care. Never fill tank when engine is running or

still hot from operation. Do not allow open flame,

matches or smoking in area. Do not fill tank in

doors or in poorly ventilated area. Wipe any spills

and move mower away from gasoline fumes before

starting engine. Use an approved container.

C. CHECK AIR CLEANER. Check the cleanliness of

the oil foam air cleaner and service it if necessary. Refer

to the engine owner’s pamphlet for instructions.

D. CHECK NUTS AND BOLTS FOR TIGHTNESS.

Check all nuts and bolts for tightness and keep them

tightened securely at all times.

E. CHECK TIRE PRESSURE. Make sure that the rear

tires are inflated equally to between 25-30 psi.

F. CHECK CUTTING HEIGHT. Check that the wheels

are adjusted for the desired cutting height as described

in Section 5.

G. ATTACH SPARK PLUG. Be sure that the spark plug

wire is securely attached to the spark plug.

18

Page 21

H. CHECK BATTERY (Electric Start Models). Check

that the battery is properly filled and that all electrical

connections are clean and tight. Refer to Section 5 for

instructions.

IMPORTANT

At the start of each season and after every 10 operating

hours, perform the Blade Brake Control Test Procedure

described on Page 34.

TO START THE ENGINE

WARNING: Never run the engine in an en

closed or poorly ventilated area Engine ex

H

haust contains carbon monoxide, an odorless and

deadly gas.

A. Be certain that the blade control handle and the

wheel drive handle (on self-propelled models) are in the

disengaged (reieased) position. See Photo 4-3.

for longer than a few seconds. Prolonged cranking can

damage the starter motor if cranked more than 15

seconds per minute. Release the key when the engine

starts.

NOTE: If necessary, the electric start engine can be

started with the recoil starter rope. See Section 5 for

detailed instructions.

F. If your engine does not start in four or five tries, let

the engine set for 10 minutes and then repeat the start

ing procedure.

G. As soon as the engine starts, move the engine throt

tle lever gradually to the SLOW (S) setting and allow

the engine to warm up. Then, move the lever to the

desired speed for your mowing task.

IMPORTANT

Do not leave the throttle lever in the CHOKE position.

Doing so could harm your engine.

TO ENGAGE THE BLADE

A. When you are ready to begin mowing, first pull the

blade control handle down and hold it against the han

dlebar grip. Then push the blade control forward until a

distinct “click” is heard. See Photo 4-4.

Photo 4-3: Release blade control and wheel drive han

dles before starting engine.

B. On 8HP engines (24" mower), open the fuel shut

off valve.

C. Set the engine throttle lever at the CHOKE position.

NOTE: A warm engine requires less choking than a

coid engine.

D. For recoil start engines, place your left hand on the

right side handlebar grip to help stabilize the mower.

Then grasp the starter rope handle with your right hand

and pull the rope out slowly until it is harder to pull be

cause of engine compression. Next, pull the rope with

a rapid, continuous, fuil-arm stroke. Do not let the starter

rope snap back against the rope guide. Let the rope

rewind slowly.

CAUTION: To avoid personal injury, be sure

that there are no obstacles behind you when

O

you pull out the starter rope handle

E. For electric start engines, turn the key switch to the

START position. Do not hold the key in the start position

Photo 4-4: To engage the blade drive.

DANGER: To avoid personal injury from

rotating blade and thrown objects, keep

B

face, hands and feet clear of the mower blade

and discharge opening at all times.

B. Increase or decrease the engine speed to adjust

the blade speed. For best cutting results, the blade

should be operated with the engine at full or nearly full

throttle.

C. TO STOP THE BLADE, release the blade control

handle completely from its position against the handle

bar grip.

IMPORTANT

At the start of each season and after every 10 operating

hours, perform the Blade Brake Control Test Procedure

described on Page 34.

19

Page 22

CAUTION: To avoid personal injury, disen

gage the cutting blade before crossing gravel

B

drives, roads, or sidewalks to prevent the blade

from throwing stories or other hazardous objects.

TO ENGAGE THE WHEELS

(Self-Propelled Models Only)

A. Pull the wheel drive handle up and hold it against

the handlebar grip. Then push the wheel drive lever

forward until it latches in the forward position. See Photo

4-5.

Photo 4-5: To engage the wheel drive on self-propelled

models.

B. Increase or decrease the engine speed to adjust the

ground speed.

C. TO STOP THE WHEELS, release the wheel drive

handle from its position against the handlebar grip.

TO STOP THE ENGINE

A. Release the blade control handle and the wheel

drive handle (on self-propelled models).

B. Put the engine throttle lever in the Slow (S) posi

tion.

C. Pull the engine throttle lever all the way back to the

STOP position (and turn the key to OFF on electric start

models).

CAUTION: To prevent injury from accidental

or unauthorized starting, disconnect the

^

spark plug wire and move the wire away from tho

olug when leaving the mower unattended or Vi/hen

the mower is not in use. Always remove the key

from the switch on electric start models.

OPERATING THE MOWER

Use the following tips to help you in getting the best

possible use from your TUFF-CUT® Mower.

A. Although your TUFF-CUT® Mower is wider and

longer than ordinary mowers, its large rear wheels and

perfect balance make it surprisingly easy to maneuver.

Become familiar with your mower by first practicing

with it in a clear, level section of your property, with the

engine throttle control set at a slower engine speed

setting. Practice engaging and disengaging the con

trols until you are completely comfortable with their

ease and manner of operation. Remember, with the

self-propelled model, let the powered wheels do the

work while you simply guide the mower along.

B. Making turns is exceptionally easy because the

weight of the engine is centered over the rear wheels.

Thus, you need only apply light downward pressure on

the handlebars to tip up the front of the mower prior to

making a turn. On self-propelled models, it’s easier to

make a turn if you first disengage the powered wheels

by releasing the wheel drive handle. With the wheel

drive disengaged, the inside wheel will pivot in place

while the outside wheel rolls freely. After completing

your turn, simply reengage power to the wheels and

continue with your mowing.

WARNING*

TO HELP AVOID PERSONAL INJURY:

Exercise extreme caution when changing direc

tion on slopes to prevent loss of control, slip

ping or falling.

When mowing or turning on a slope with a self-

propelled mower, keep the wheel drive lever

ENGAGED until you aie sure that you have

complete control of the mower. Failure to do so

could result in loss of control of the mower.

Do not mow excessively steep slopes.

C. For precision trimming with the self-propelled mower,

simply disengage the powered wheels by releasing the

wheel drive handle. Then inch the mower forward by

gradually pushing the “feather-touch” wheel drive lever

forward until the drive cogs contact the wheels. To stop,

pull back on the wheel drive lever.

D. When cutting tall growth, or if you are on uneven

terrain, use the highest cut setting. Then gradually

reduce to the desired cutting height over the course of

2 or 3 mowings. Go easy in extra tough grass or weeds

as forcing the mower tends to make it slow down or stall.

E. Keep the blade sharp. A dull blade will tear, bruise

and split the ends of grass.

F. Vary your cutting pattern from week to week. This

helps to prevent matting and graining of the grass.

G. Always trim using the left side of the mower, as the

discharge deflector is on the right side of the machine.

Mow around obstacles in a counterclockwise direction

(viewed from the operator’s position). Also, mow with the

discharge deflector pointed away from the obstacles on

the first two passes. Then, reverse the direction. This

will reduce the chances of damage to property from

any thrown objects.

H. When mowing alongside a street or walk, mow with

the discharge deflector pointed onto your own property

(away from the street or walk). This will eliminate the

need to sweep clippings from the sidewalks, etc.

i. Mow ditches in the direction of the ditch. This will

result in debris and clippings being discharged into

the ditch. Mow both sides of the ditch first, and then

mow the bottom. When mowing ditches, watch out for

cans, bottles, or other debris which could become dan

gerous high-speed projectiles.

J. While mowing, never point the discharge deflector

at any person at any time.

20

Page 23

SECTION 5

Maintenance and AcMustments

CAUTION; To avoid personal injury stop

the engine, disconnect the spark plug wire,

S

keep the wire away from the soark plug, and let

tne engine ana muffler cool down before inspect

ing O’’ servicing the mower or engine.

RECOMMENDED MAINTENANCE INTERVALS

Every 10

Maintenance

Procedure:

Check blade for tightness

Inspect nuts & bolts for tightness

Inspect operator controls

Clean underside of mower and inside of

discharge chute

Inspect blade for sharpness

Inspect electric start wires and cables

Inspect electrolyte level in battery

Recharge battery

Lubricate traction drive chain, linkages,

pivot points, throttle control cable, and

wheel mounting bolts and studs

Check tension on wheel drive belt and

chain

Check tension on blade drive belt

Check tire pressure

Perform the Blade Brake Control

3-second Stop Test described on

Page 34

Sharpen or replace blade

ENGINE

Inspect engine crankcase oil level

Inspect throttle cable

Clean air filter

Change engine crankcase oil I

Adjust carburetor

Cooling system maintenance

Clean engine !

Clean and reset spark plug

Every

Use

•

•

•

•

•

•

•

•

Operating

Hours

•

•

•

•

•

•

As

Noted

Before and after prolonged storage

Or once a week, whichever is sooner.

At the start of each season and after

every 10 operating hours.

Whenever damaged, out of

balance, or dull

And after every 5 hours of continuous

operation

At least every 25 operating hours —

see engine owner’s pamphlet.

After 5 break-in operating hours

and every 25 hours thereafter

As required — see engine

owner’s pamphlet

See engine owner’s pamphlet

See engine owner’s pamphlet

See engine owner’s pamphlet

21

Page 24

MOWER MAINTENANCE