Trojan T2-C User Manual

T2-C User Guide

Trojan™ T2-C User Guide

Part Number 22834689-EN-E

Revision 1.0

2/2018

Trojanlabel, An AstroNova™ Company

Marielundvej 46A, 2.

2730 Herlev

Denmark

Phone +45 2964 0005

www.trojanlabel.com

© 2018 Trojanlabel

This document, attachments and information contained herein are the confidential and

proprietary property of Trojanlabel and their suppliers. As such, this document, attached files

and information contained herein are subject to all nondisclosure and proprietary information

agreements currently in effect with your organization. Copies of this document, any portion of

this document or attachments may not be transmitted or disclosed to any third party without the

prior written permission of Trojanlabel.

All content is the confidential property of, or licensed to, Trojanla bel ("Trojanlabel," "we," or "us")

and is protected under Danish and Foreign copyright, trademark and other intelle ctual property

laws.

Trademarks

Trojan™ is a trademark of AstroNova, Inc.

Microsoft® Windows® XP, Windows® Vista, Windows® 7, Windows® 8, and Windows® 10 are

registered trademarks of Microsoft Corporation.

Certificate of compliance and Safety information

T2-C User Guide 7

Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview and application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2: Setting up the T2-C press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Physical setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cabling (network and power supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3: Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Visible safety check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power on process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing ink tanks and the printhead . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the ink tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unpacking the printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 4: Loading the label material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Unwinder and rewinder roll direction . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rolling direction unwinder - Ink jet coating on the inside or outside . . . . . . 29

Rolling direction rewinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Threading the label material from scratch . . . . . . . . . . . . . . . . . . . . . . . . 31

Adjusting the label edge sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Calibrate tension for the label web . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Splicing and changing the label roll . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contents

Chapter 5: Select and queue print / start print job . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6: Pause, resume, or stop a print job . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 7: Moving the label web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 8: Printing modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Continuous printing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Die-cut printing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Calibrating the label gap sensor . . . . . . . . . . . . . . . . . . . . . . . . . 46

Blackmark printing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calibrating the label gap/blackmark sensor . . . . . . . . . . . . . . . . . . . 48

Gap size and speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 9: Shutting down the T2-C press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 10: Driver installation and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Driver installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Driver features and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

General driver settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Integrating additional color profiles . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 11: User Interface (UI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Right side status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

General settings (HOME tab) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Overview menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Settings menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Statistics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Exporting statistics data to a CSV file / viewing statistics from a

browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

T2-C press handling menus (TrojanTwo tab) . . . . . . . . . . . . . . . . . . . . . . 74

Overview menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Handling menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Job Library menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Print Queue menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Media Settings menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter 12: Updating software and firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Updating via the online updater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Updating via the offline updater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Chapter 13: Using the built in slitter for the T2-C press . . . . . . . . . . . . . . . . . . . . . . 93

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacing the slitter blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter 14: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Regular cleaning/checking tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8 T2-C User Guide

Contents

Cleaning the NIP roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Cleaning other rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Emptying the waste ink bottle . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Replacing the wiper roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Manual printhead wiping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Clean or replace aerosol filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 15: Preparing the T2-C press for transportation . . . . . . . . . . . . . . . . . . . . 109

Removing the printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Storing used or opened printheads . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Removing the ink from the reservoir ink tanks . . . . . . . . . . . . . . . . . . . . . 111

Removing the ink from the ink filters . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Empty and clean the waste ink bottle . . . . . . . . . . . . . . . . . . . . . . . . . 113

Removing the ink tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Chapter 16: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Error states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Error messages on screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Appendix A: Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Print engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Tubes, cables, and other parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

T2-C User Guide 9

Contents

10 T2-C User Guide

1

Introduction

Original instructions

These instructions are Trojanlabel's original instructions for the Trojanlabel press

(henceforth called the machine or TrojanTwo-Compact press or T2-C press).

Purpose

The purpose of these instructions is to ensure correct installation, use, handling and

maintenance of the machine.

Accessibility

The instructions are to be kept in a location known to the staff and must be easily accessible

for the operators and maintenance personnel.

Knowledge

It is the duty of the employer (the owner of the machine) to ensure that anyone who is to

operate, service, maintain, or repair the machine have read the instructions. As a minimum ,

they should have read the part(s) relevant for their work. In addition, anyone who is to

operate, service, maintain, or repair the machine is under obligation to look for in formation

in the instructions themselves.

General information

Manufacturer

The machine has been manufactured by:

Company name: Trojanlabel

Address: Marielundvej 46A 2 sal, 2730 Herlev, Denmark

The machine's designation

The machine's complete designation is Label Press type T2-C.

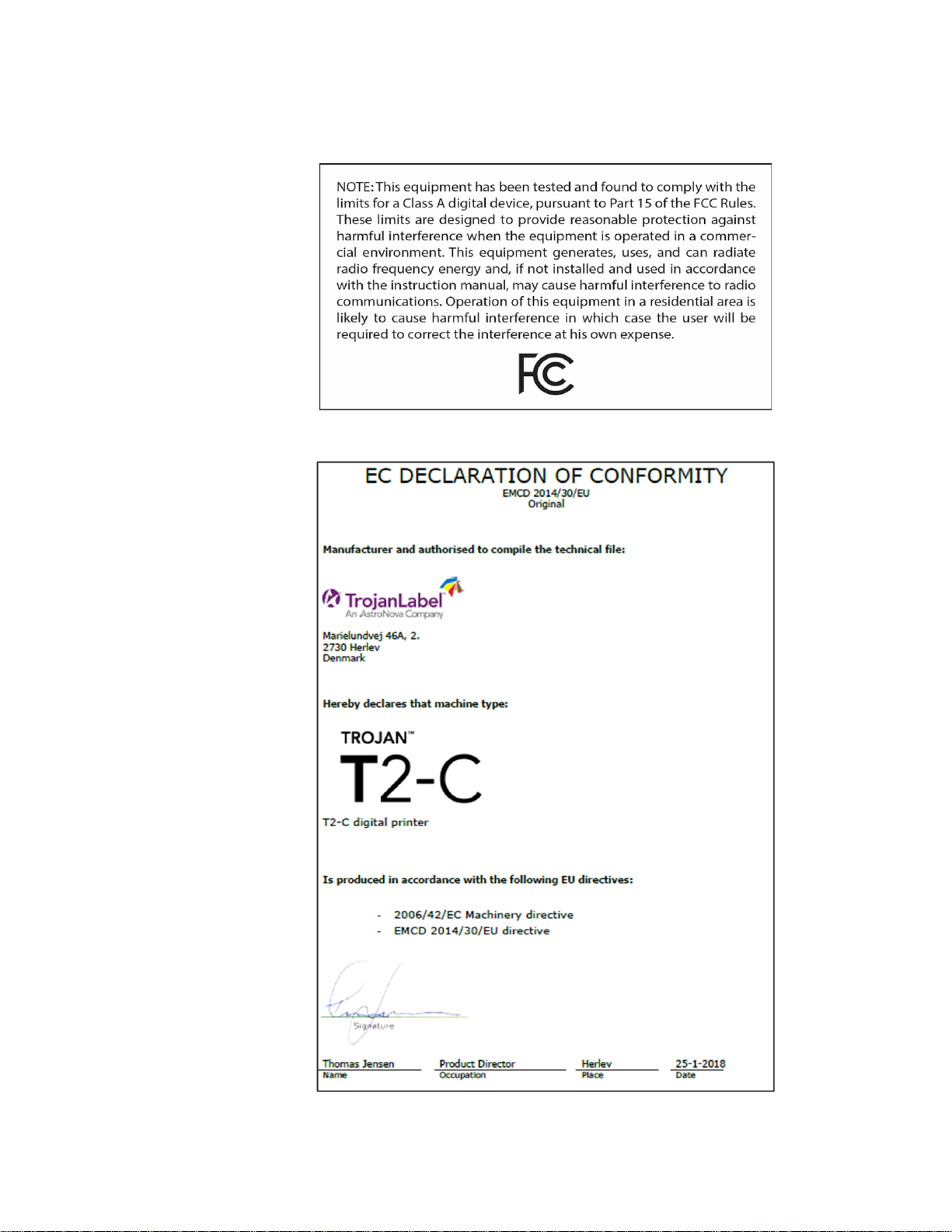

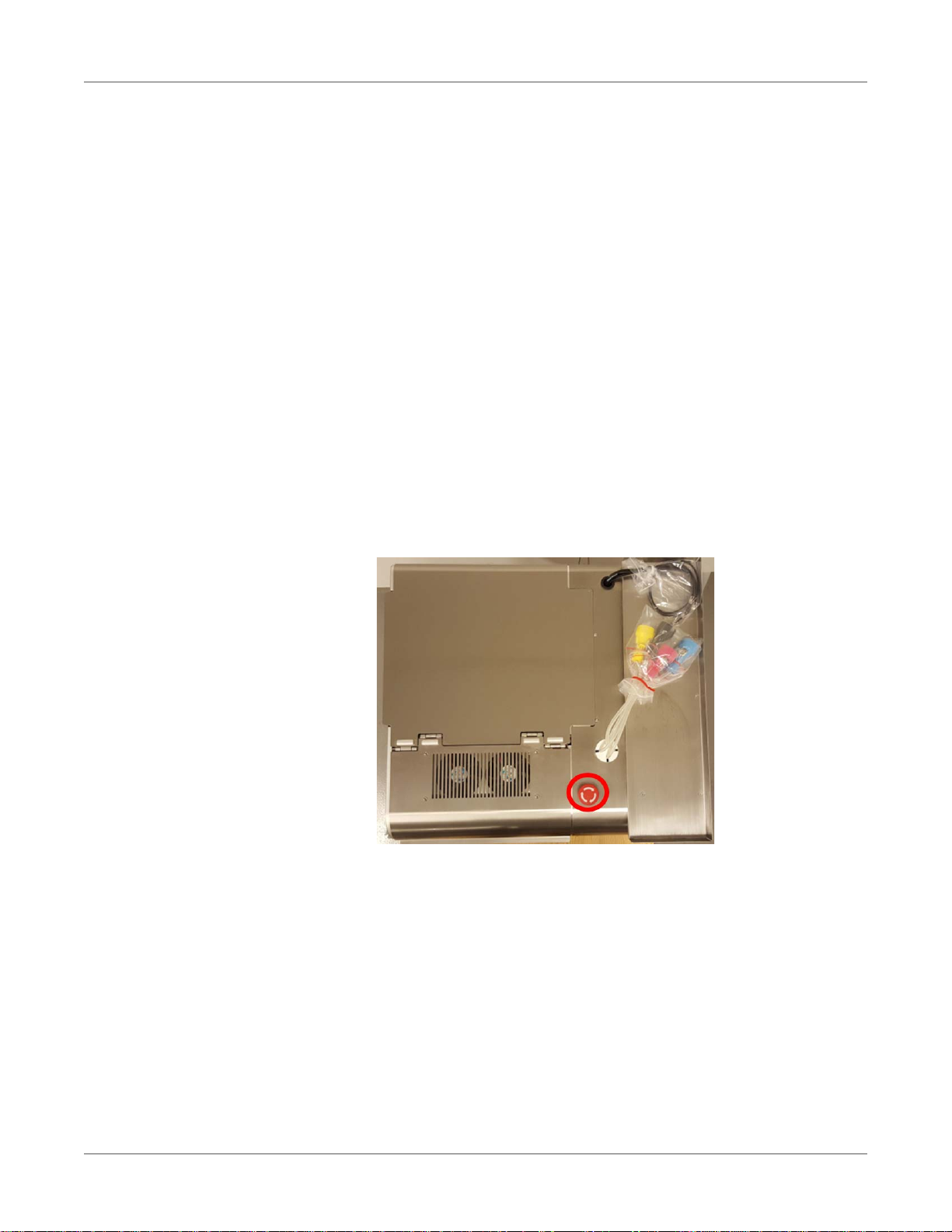

Machine plate

The machine plate (picture) is situated on the back side of the machine on the middle

bottom:

T2-C User Guide 11

Introduction

Overview and application

General description

The machine consists of an unwinder/rewinder, label edge sensor, label gap and

blackmark sensor, NIP roller, slitter and 4 ink tanks.

If any changes or alterations are made to the ma chine, the se chan ge s o r al te ratio ns must

be reflected in these instructions as necessary.

The machine's purpose and intended use

Application: The machine is only to be used to print labels.

The machine must not be used for any other purpose than the purpose mentioned above.

Warning about foreseeable misuse

The T2-C press may not be used with inks not endorsed by Trojanlab el. All inks purchased

from Trojanlabel or from official Trojanlabel distributors worldwide are endorsed by

Trojanlabel.

Technical specifications

Physical dimensions in inches and millimeters:

• Length 23.8" x Width 22.8" x Height 31.3"

• Length 606 mm x Width 580 mm x Height 795 mm

Weight:

• 132.3 lbs. (60 kg) without ink tanks and label roll

Electrical:

• Nominal supply voltage: 100-240V AC

• Nominal supply frequency: 50-60hz

• Estimated peak consumption: 240W

• Full-load current: 3.6 A

• Machine power supply:

240 W (48 VDC, 5 A), please see "T2-C_Meanwell_SP-240-SPEC.PDF" for details:

http://www.trojanextranet.com/media/59742/t2-c_meanwell_sp-240-spec.pdf

Operating positions, location, and arrangement

The machine is intended to be used in a light industrial/office environment. The operator

operates the machine in a standing or sitting position.

The machine should be placed on a properly leveled worktable or cabinet wh ich is able to

handle the T2-C press weight and size. Use spirit level to check leveling.

Note: Improper leveling of the machine might cause print quality issues and shorten the

printhead life.

12 T2-C User Guide

Introduction

Temperature

Recommend operational temperatures

• Operation: 20° to 30° Celsius at RH 22-80% (non-condensing)

• Storage: -5° to 50° Celsius at RH up to 85%, non-condensing at 65°

If transferring the machine from different temperatu re cond itions, ensur e that th e machine

has time to acclimatize.

Operating Environment

It is important that the machine is placed in a clean environ ment as possible, with sufficient

air conditioning/cleaning. Avoid placing it in an environment with dust and paper debr is, as

the printhead nozzles are sensitive to this.

Label Materials

The machine requires ink jet coated label materials for optimal print quality; some

non-coated materials will also work. Please contact Trojanlabel or your distributor for

recommendations of suited materials.

It is imperative to have a local source of material, to ensure a stable production.

Media specifications

• Roll Size: max. 12"(300 mm), inner core diameter 2.99" (76 mm)

• Media Types: Plain Paper, Gloss Paper, Matte Pape r an d Syn th et ic

pressure-sensitive; Ink jet treatment (coating) recommended.

• Media Thickness 4 pt. /mil to 12 pt. /mil (0.1-0.3 mm) - with default print height setting,

print height is adjustable for thicker media.

• Label Size/Print Area

Width 1.0" (25.4 mm) to 8.66" (220 mm)

Length 0.59" (15 mm) - 30.0" (762 mm) - 30.0" (762 mm) maximum length can be

extended with stitch function.

Print Speed and Resolution

• Printing Technology: Thermal Inkjet

• Resolution and Speed:

6 ips (9m/min.) at 1600 x 1600 dpi

12 ips (18m/min.) at 1600 x 800 dpi

T2-C User Guide 13

Introduction

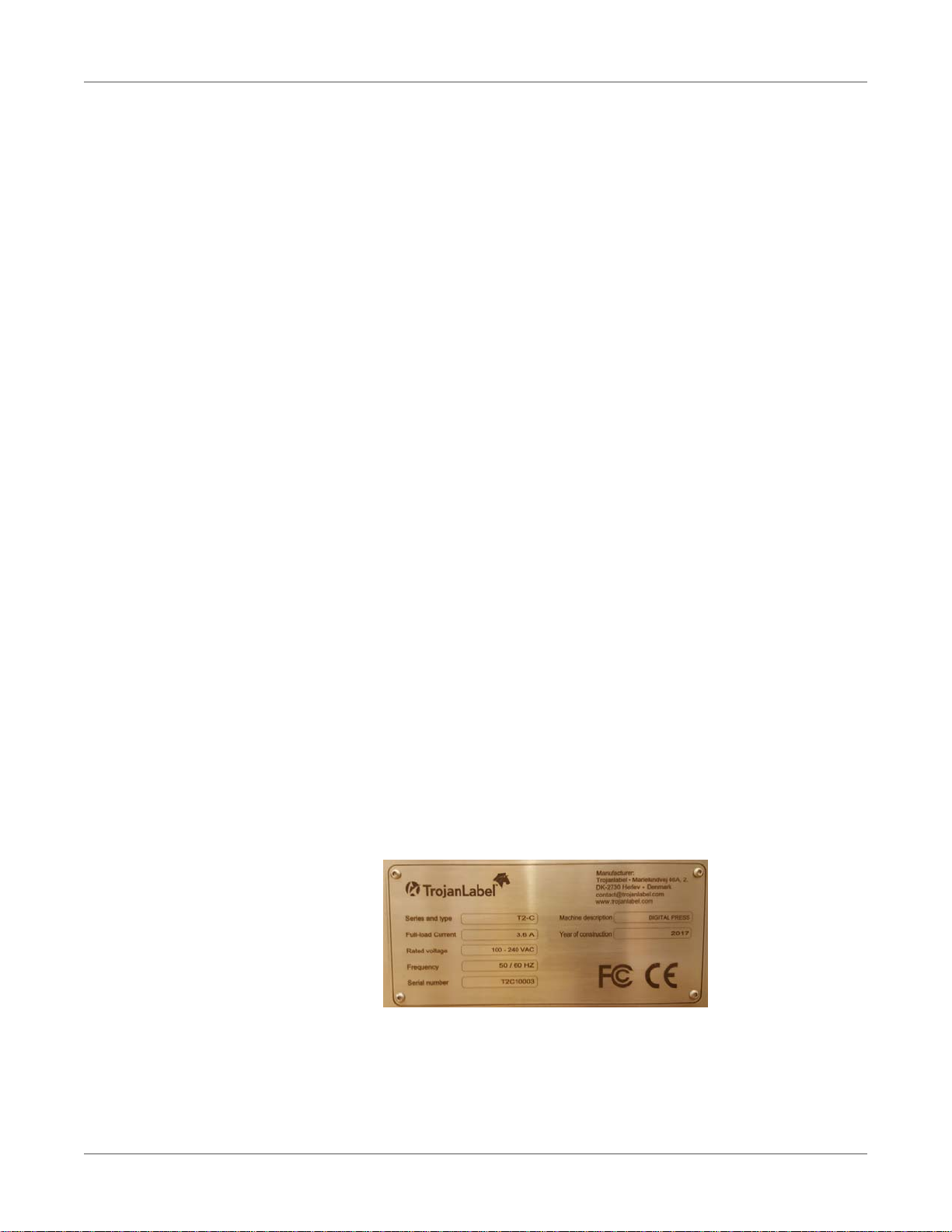

Overview

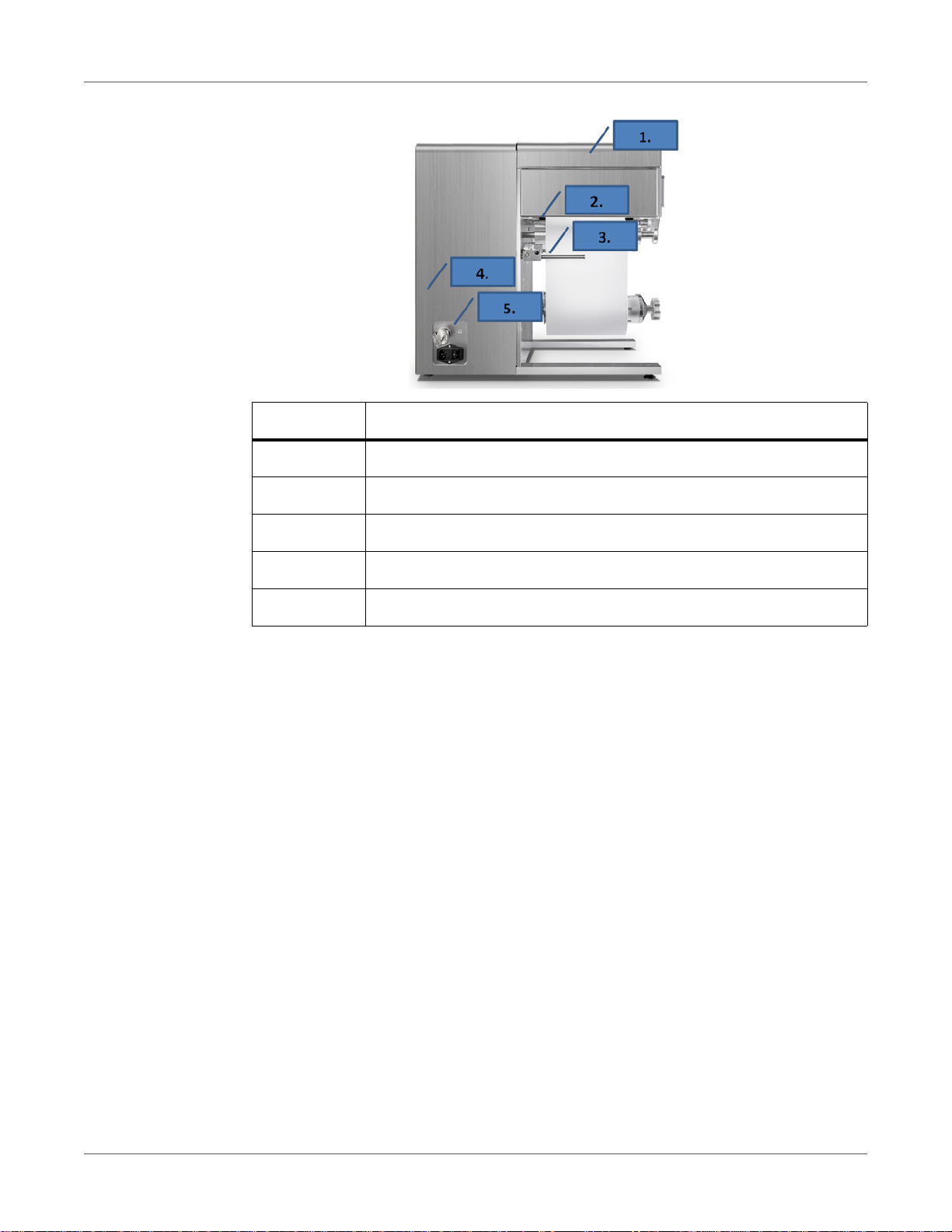

# Description

1 NIP clamp

2 7" Touch screen display

3 Lid to access aerosol filter and slitter knifes

4 Built-in slitter knifes

5 Unwinder

6 Rewinder

14 T2-C User Guide

Introduction

# Description

1 Lid for easy access to gap/blackmark sensor and maintenance

2 Sensor for gap/blackmark detection

3 Label edge sensor

4 Waste Ink bottle inside (can be accessed via drawer)

5 Easy installation (Ethernet and power outlet 100-240V AC - 50/60 Hz)

T2-C User Guide 15

Introduction

16 T2-C User Guide

2

Physical setup

The T2-C press is packed in a wooden crate and shipped strapped on top of a wooden pallet

(total weight of the package including the crate is around 80kg). After opening the wooden crate

the machine must be lifted out from the crate. The approximate weight of the machine is 132.3

lbs. (60 kg). Therefore it is advised to lift the machine out of the box with multiple perso ns to

avoid injury.

The machine should be placed on a properly leveled worktable or cabinet which is able to

handle the T2-C press' weight and size. Footprint: Length 23.8" (606mm) x Width 22.8"

(580mm) x Height 31.3" (795mm). The machine is standing on 4 height adjustable feet. In case

it is not possible to set the worktable to level, then each foot's height can be adjusted by tur ning

the foot clockwise (lifting the machine) or turning the foot counter-clockwise (lowering the

machine). Make sure the machine is standing stable and legs are adjusted so that the machine

is horizontally level. Check leveling using a spirit leveler.

Warning: Improper leveling of the machine might cause print quality issues and shorten the

printhead life.

Remove any zip ties and other remaining packaging materials, such as bags covering the ink

tank connectors. Open the lids and make sure that the luers for the ink tubes are tightened to

avoid ink leakage.

Setting up the T2-C press

T2-C User Guide 17

Setting up the T2-C press

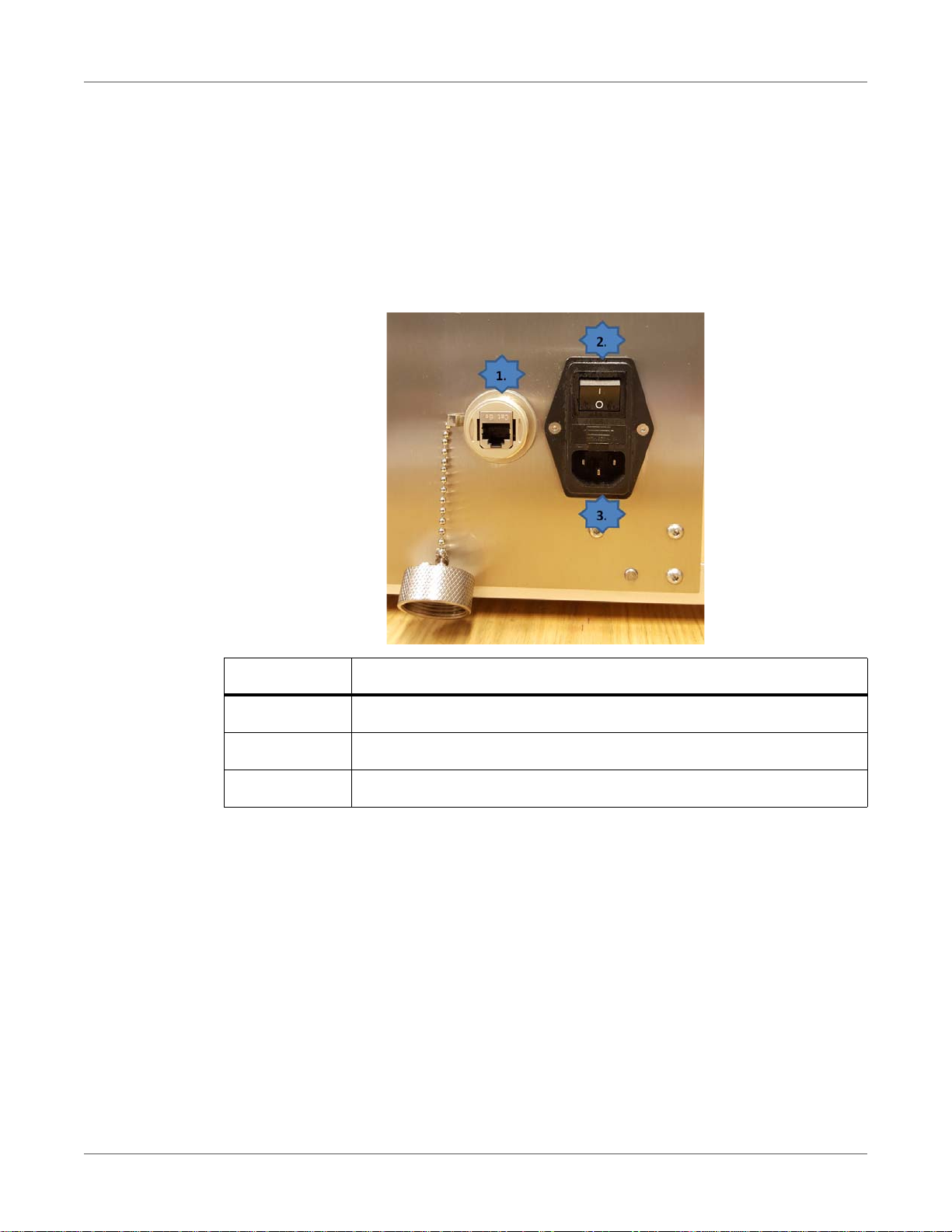

Cabling (network and power supply)

The machine has two cable inlets:

1) Power supply

2) Ethernet

Only the power supply cable is necessary for powering up the machine. The network cable is

necessary for sending new print jobs to the T2-C press and for remote support/software

updates.

# Description

1 Ethernet port

2 Power on/off switch

3 Power supply

Note: Ethernet cable is not included in the T2-C press package. It is recommended to use

Cat5, Cat5e or Cat6 Ethernet cable versions to connect the T2-C press to the local network

and/or to the Internet.

18 T2-C User Guide

3

Visible safety check

Before powering on the machine, visibly ensure that no foreign objects are interfering with the

print engine module and web-path.

Power on process

1 Press the physical power switch on the left side of the T2-C press, switching it fro m 0 to 1.

Turning the main power switch on starts the TrojanControl software on the touch screen

and also starts the print engine.

2 Release the Emergency Stop (ER) button in case it is pressed down. To release the ER

button, the button has to be twisted clockwise. As long as the ER button is pressed down,

the servo motors for the Unwinder, Rewinder, and NIP are powered off for safety reasons.

It is advised to press the ER button whenever the operator wants to perform any actions on

the web path system other than threading the label materi al or splicing and installing a new

label roll.

Power on

T2-C User Guide 19

Power on

3 The machine is fully functional when the TrojanTwo tab is visible in the TrojanControl

software. In the right side status bar the System State field is online, and Media Path State

is ready.

Note: System state can only be online if all ink tanks are installed and the printhead is also

installed and primed with ink. See “Installing ink tanks and the printhead” on page 20.

Note: Web state can only be ready if the label material is loaded in the unwinder and

rewinder and tension for the label web is calibrated. See “Loading the label material” on

page 29.

Installing ink tanks and the printhead

Installing the ink tanks

The T2-C press uses CMYK ink tanks. Each contains 2 liters of ink when opened. Every T2-C

ink tank is QA chip protected ensuring that only genu in e Tr oja n lab el ink tanks can be used.

The tray for the ink tanks is situated on top of the machine. The ink tanks are installed from left

to right in CMYK order.

20 T2-C User Guide

1 Connect the black QA chip reader cables.

Connect one QA chip reader cable to each ink tank. It do es not matter which QA chip reader

cable is connected to which ink tank. However, the length of these cables are made to best

fit to the closest ink tank.

2 Connect the matching ink tube connector to each ink tank. The particular ink tube

connector's color is matched to the corresponding ink tank. Once the connector is pushed

onto the matching slot on the ink tank, the connector clicks into the right position.

Power on

Warning: Do not mix up the colors! Each ink tube connector has to be connected to the

matching colored ink tank. Mixing up the ink tube connectors (if the yellow connector is

connected to the black ink tank, for example) will contaminate the inks in the system and

leads to significant financial damage because the contaminated ink is wasted.

T2-C User Guide 21

Power on

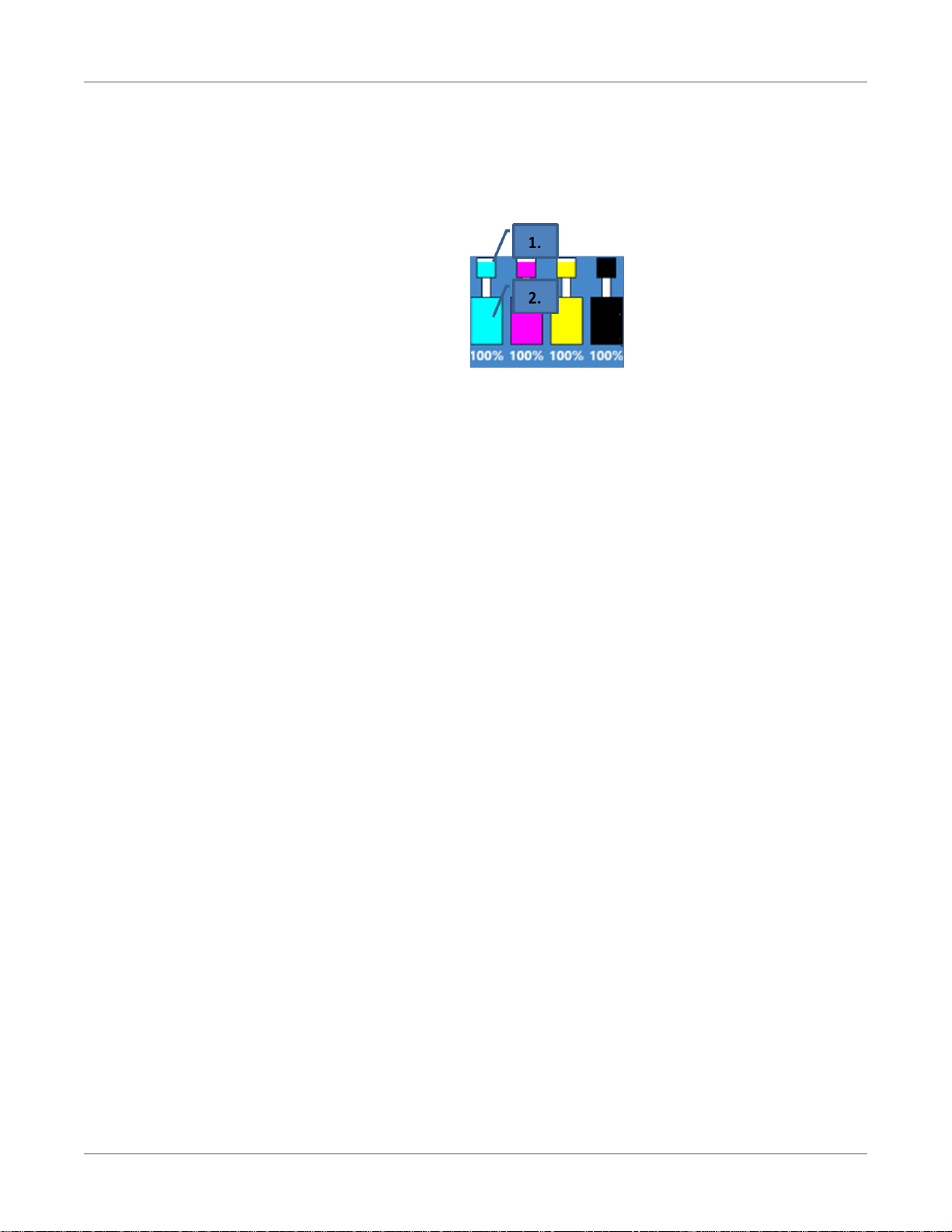

3 Put the white plastic protector cap on top of the ink tanks.

When a 2 liter ink tank is connected, the proper ink level is displayed in percentages in

status bar on the touch screen. Reservoir ink tank levels (1) and 2 liter ink tank levels (2)

are displayed.

During operation, the ink used for printing comes from the built in reservoir ink tanks. The

reservoir tanks have ink level sensors and refilling of these reservoir ink tanks is done from

the 2 liter ink tanks directly. This refilling process is performed automatically by the system

when ink level drops under a certain limit for the particular reservoir ink tank.

During the first time installation when the ink system is empty, after installing the 2L ink

tanks, the system automatically starts filling up the reservoir ink tanks (located inside the

machine) with ink. This is done one by one in CMYK order and the process is displayed o n

the screen where the movement of the ink is indicated between 2L ink tank and reservoir

ink tank.

The reservoir ink tanks have the capacity of 200ml and all 4 reservoir ink tanks ar e around

half full when the process is finished.

The amount of ink used to fill the reservoir ink tanks and tubes for the first time is not

registered back to the QA chip of the 2L ink tanks (ink consumption is measured based on

the ink going through the printhead nozzles), therefore for th e first set of ink it is likely that

the 2L ink tanks will run out of ink physically when still around 5% ink level is displayed on

the screen. This is normal and this around 5% ink is not wasted but used to fill the ink

system. From the second ink set, the ink level % calculation is normal and ink tanks run out

of ink according to the ink level % displayed on the screen.

Note: T2-C 2L ink tanks are not refillable and shall be treated as hazardous waste when

empty.

22 T2-C User Guide

Power on

Unpacking the printhead

Caution: DO NOT touch the printhead cartridge's ink couplings, nozzle surface or the

electrical contacts when installing the printhead cartridge. Hold the printhead cartridge ONLY

by the handles.

Caution: DO NOT unpack the printhead cartridge until the machine is ready for installation.

Once unwrapped, delay in installing the printhead can compromise print quality due to

dehydration.

Caution: DO NOT place an unwrapped printhead on any surface before installing. Protect the

printhead at all times from dust, fibers, dirt and ot he r co nt am in an ts.

Important: Do not throw away the printhead p ackaging. The white b ox has the serial number ,

part number and manufacturing date of the printhead. Also it is recommended to store

printheads which are currently not installed in the original packaging.

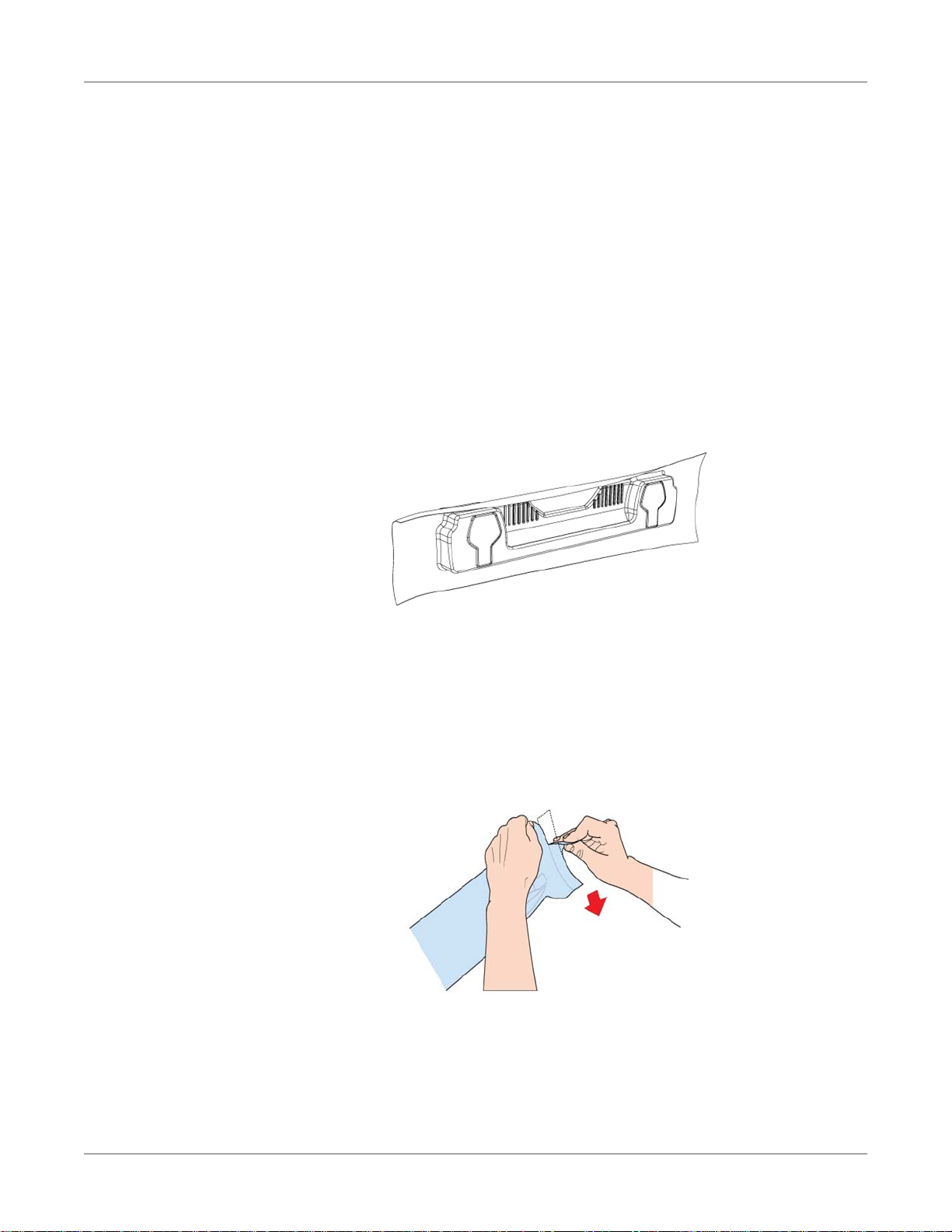

1 Open the end of the printhead package outer box and slide out the foil bag.

Inspect the integrity of the foil vacuum sealing. The foil bag should be forme d tightly to the

contours of the printhead cartridge as shown above. If the foil is loose to any degree then

the seal has been compromised.

Note: If a poor seal is suspected, DO NOT USE the printhead. Report the issue to your

supplier.

2 Carefully rip the foil packaging open at the notch. Use scissors if your foil bag d oes not have

a notch or you are finding it difficult to tear the bag.

3 Remove the printhead from the foil bag.

T2-C User Guide 23

Power on

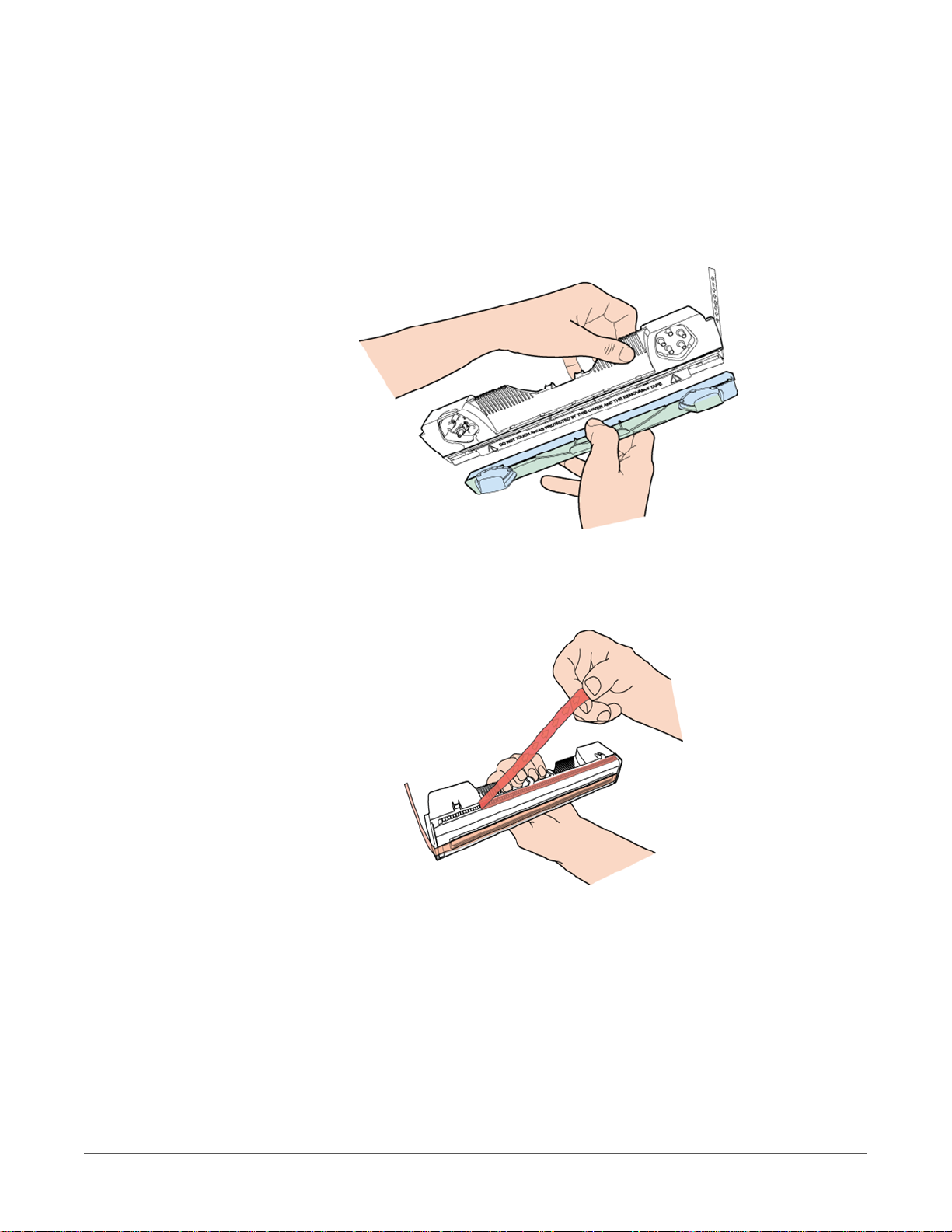

4 Remove the orange protective plastic cover from the printhead cartridge. Holding the

printhead cartridge by the handle:

a) Release the flaps covering the ink ports.

b) Release the clip retaining the cover near the center of the printhead cartridge.

c) Carefully remove the protective cover.

5 Remove the protective strip from the electrical contacts. While holding the printhead

cartridge by the handle with one hand, grasp the pull tab with the other hand and, slowly

and carefully, peel back the plastic strip covering the electrical contacts.

Note: Dispose of the removed strip immediately and do not allow the removed strip to

contact the electrical contacts.

24 T2-C User Guide

Power on

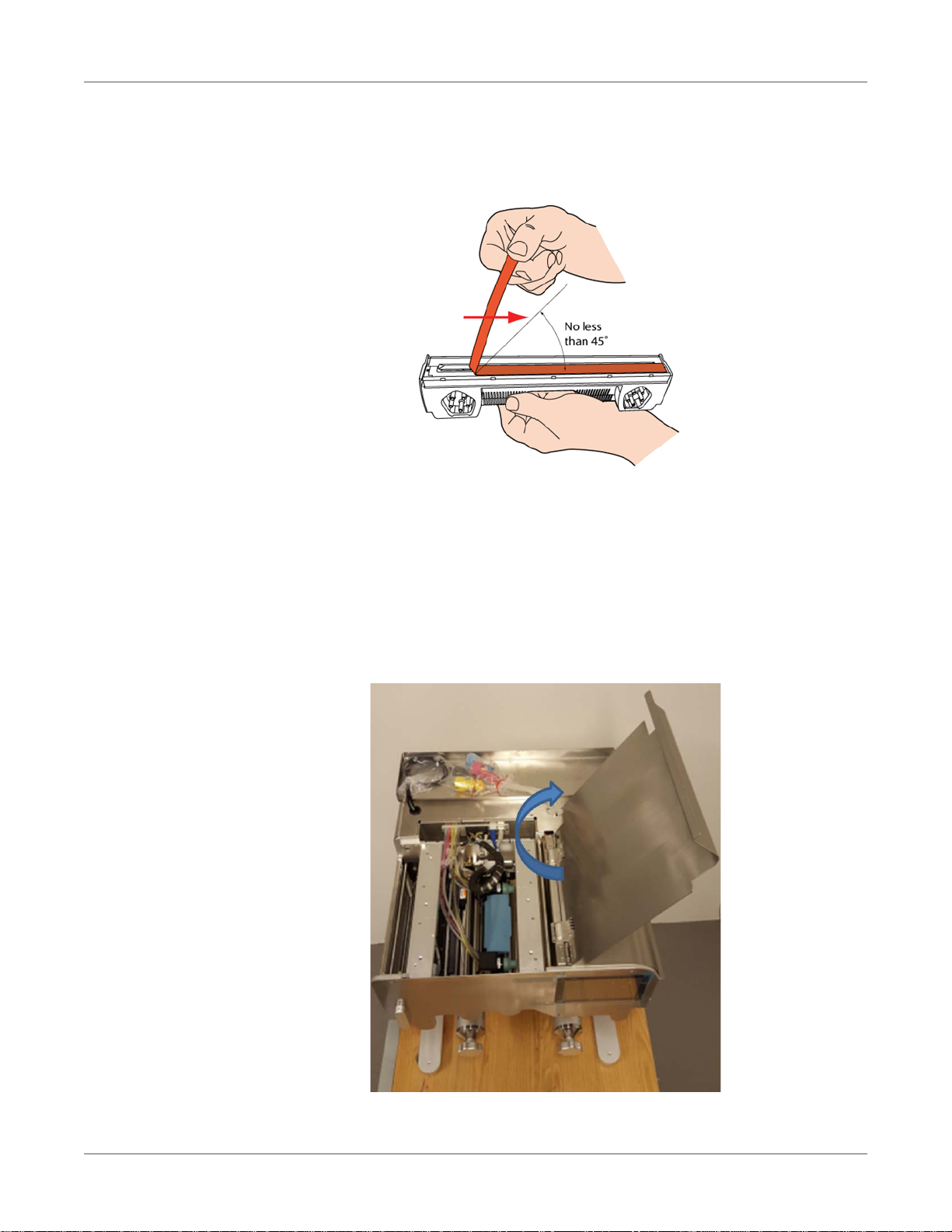

6 Remove the protective strip from the printhead nozzles. While holding the printhead

cartridge by the handle with one hand, grasp the pull tab with the other hand and slowly and

carefully peel back the plastic strip covering the printhea d nozzles. Maintain an angle of no

less than 45° with the printhead surface when pulling on the strip.

Note: Dispose of the removed strip immediately and do not allow the removed strip to

contact the electrical contacts or the printhead nozzles.

Installing the printhead

Important: The printhead can only be filled with ink when the reservoir ink tanks are filled. For

the first time installation, the printhead can only be primed when filling the reservoir tanks

procedure is completed.

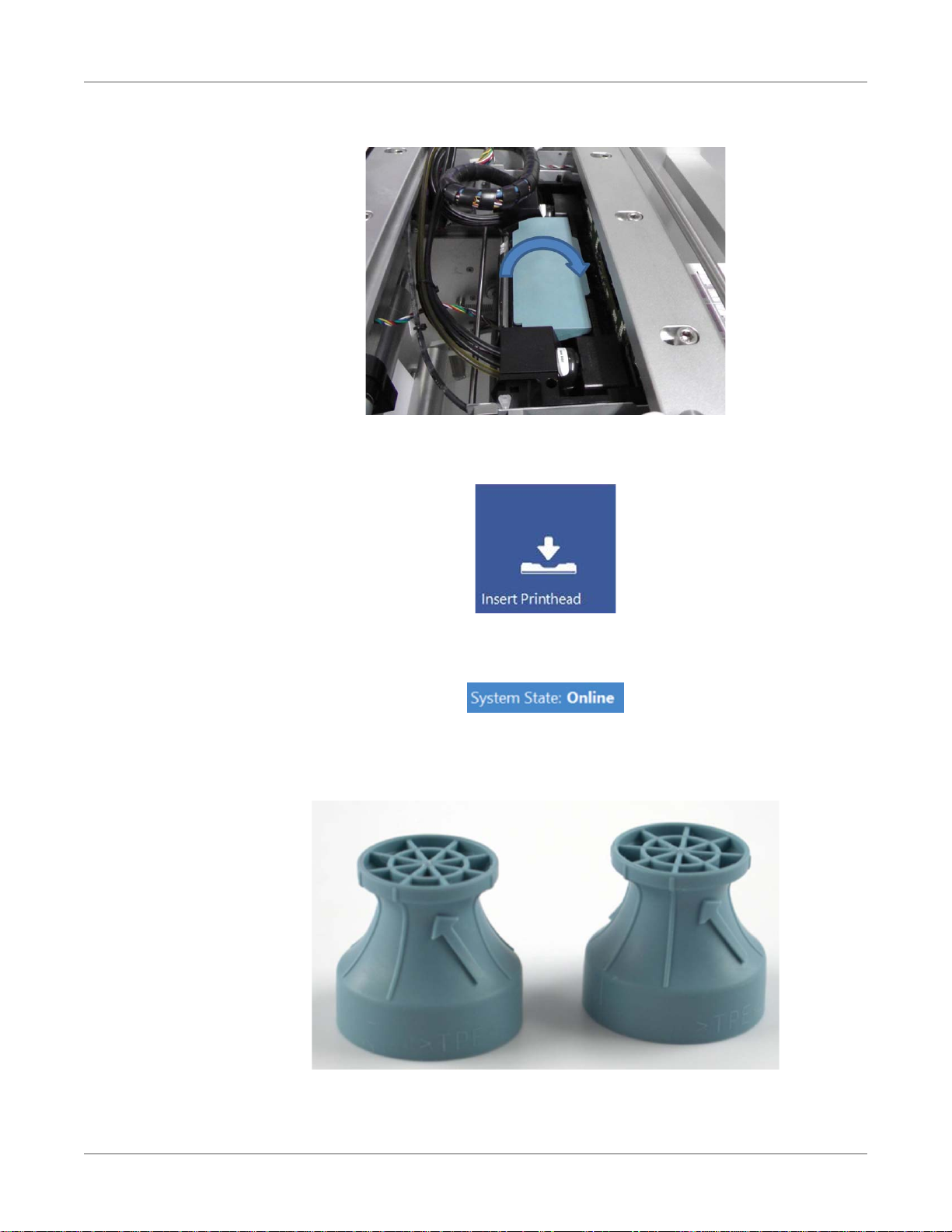

1 Open the top lid on the T2-C press to gain access to the print engine.

T2-C User Guide 25

Power on

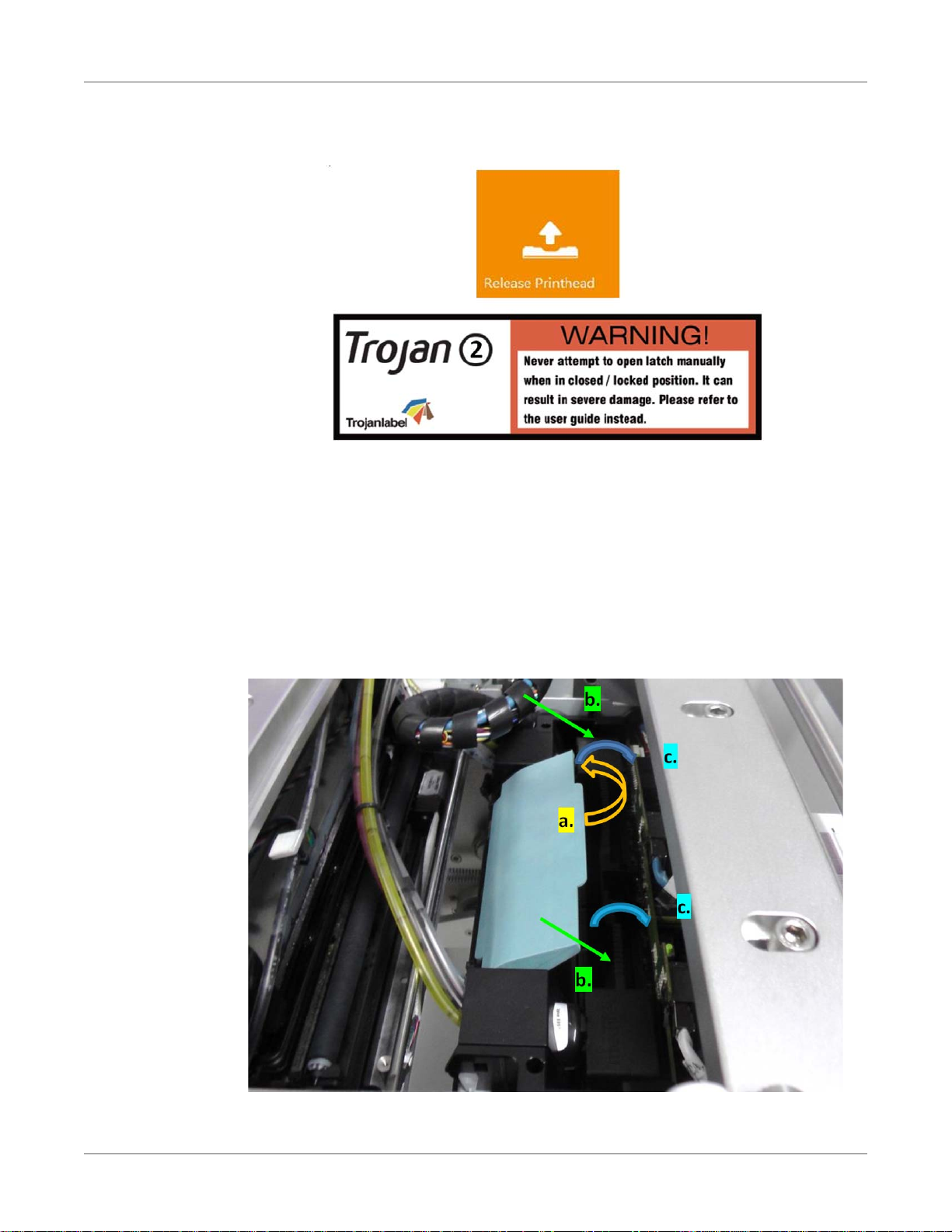

2 Press the Release Printhead button in the TrojanTwo ta b > Maintenance menu to open

the printhead latch.

Note: The above warning label can be found on the printhead latch. Trying to open the

blue plastic latch manually by the handle will most likely break the latch. Breaking the latch

is considered as improper usage and therefore replacement is out of warranty. Breaking

the latch also causes the machine to be non-op er at ion a l until the br oken part is replaced.

3 Insert the printhead by the handle into the crad le.

a) Open the printhead latch all the way up.

b) Insert the printhead into the cradle by the handles.

c) Pull the printhead backwards until it snaps into the proper place standing upright.

26 T2-C User Guide

Power on

4 Close the printhead latch.

5 Press the Install Printhead button in the TrojanTwo tab > Maintenance menu to start

priming the printhead with ink.

Printhead priming takes about 3-5 minutes and the system state become s online when the

process is finished and the machine is ready for printing.

Note: Do not throw away the blue rubber dock protector caps (included with the T2-C

press). These prevent ink leaking from the revolvers during transportation or when there is

no printhead installed.

T2-C User Guide 27

Power on

28 T2-C User Guide

Loading the label material

4

There are two common methods of threading the machine: threa ding from scratch, i.e. there is

no material present in the machine, or using the currently installed material to thread the

machine.

Unwinder and rewinder roll direction

Rolling direction unwinder - Ink jet coating on the inside or outside

Regardless of the threading procedure, you mus t inse rt th e lab el roll on th e un win de r co re

according to the ink jet coated side (coated side must be up for printing).

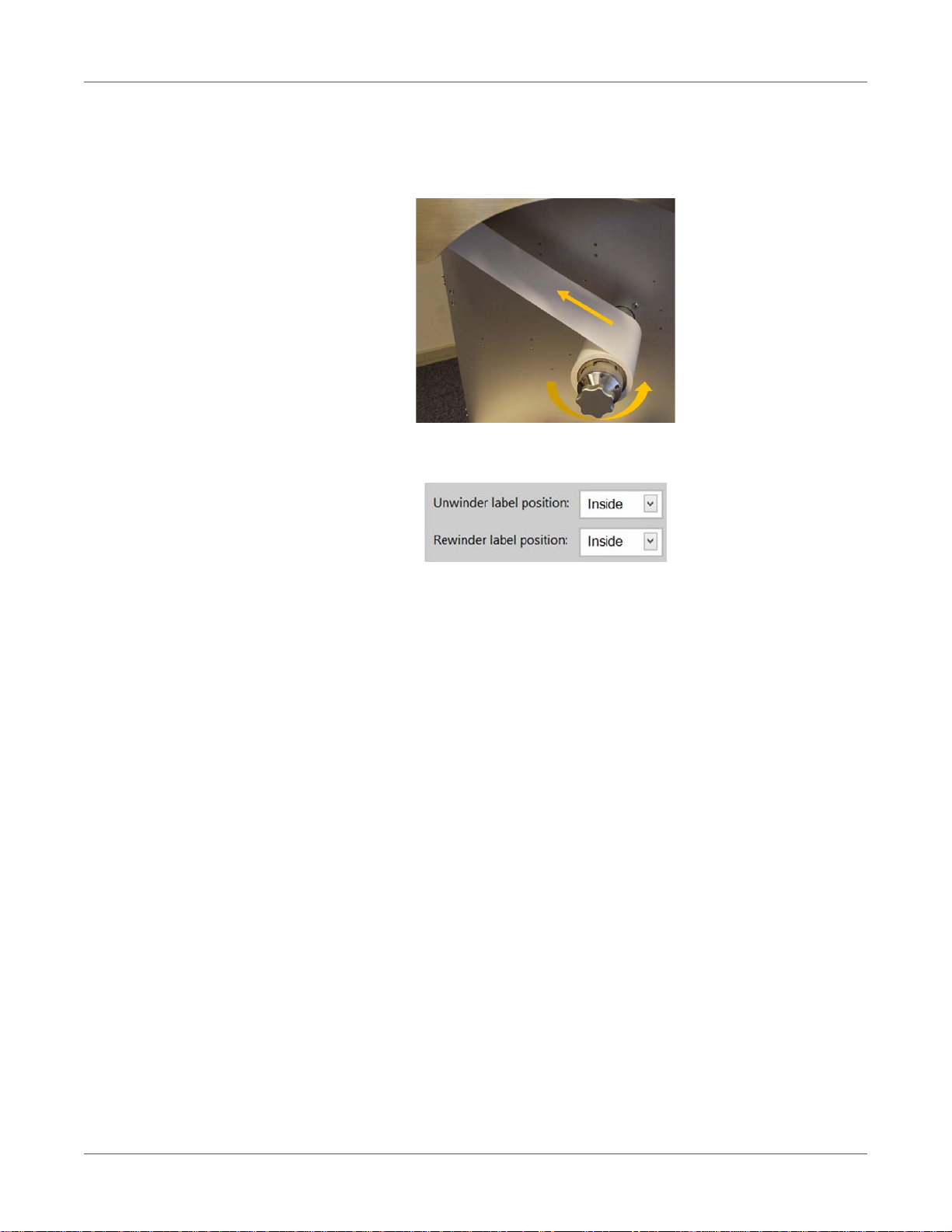

1 Outside - Printing on the outside of the label roll

If the ink jet coating is on the outside of the material, which is the most common, place the

roll so the end of the material is facing clockwise.

Important: Ensure Media Settings > Unwinder or Rewinder label position states:

Outside

T2-C User Guide 29

Loading the label material

2 Inside - Printing on the inside of the label roll

If the ink jet coating is on the inside of the material, then place the roll so the end of the

material is facing counter-clockwise.

Important: Ensure Media Settings > Unwinder or Rewinder label position states:

Inside

Rolling direction rewinder

The rewinder can place the label material on the outside or inside of the roll. The criteria are the

same as for the unwinder, please refer to the above for placement and direction and update the

Media settings to reflect this.

30 T2-C User Guide

Loading...

Loading...