Page 1

Instruction Handbook

Advanced

CLP 4532

Colour Printer

Page 2

Page 3

Contents

1 Handling Paper ..............................................................................................1-1

General Guidelines ................................................................................................................. 1-2

Selecting the Right Paper ....................................................................................................... 1-4

Paper Type ............................................................................................................................ 1-10

2 Using the Operation Panel ...........................................................................2-1

General Information ................................................................................................................ 2-2

Understanding the Operation Panel ........................................................................................ 2-3

Canceling a Printing Job ......................................................................................................... 2-8

Using the Menu Selection System .......................................................................................... 2-9

Status Pages ......................................................................................................................... 2-12

e-MPS ................................................................................................................................... 2-15

Changing the Interface Parameters ...................................................................................... 2-24

Making Default Settings ........................................................................................................ 2-30

Pagination ............................................................................................................................. 2-38

Setting Print Quality ............................................... .................................. ..... ...... .................. 2-41

Operating the Storage Device ............................................................................................... 2-42

Paper Handling ..................................................................................................................... 2-50

Selecting Monochrome or Color Printing .............................................................................. 2-63

Reading Life Counters .......................................................................................................... 2-64

Other Modes ......................................................................................................................... 2-65

3 Options ..........................................................................................................3-1

General Information ................................................................................................................ 3-2

Expansion Memory Modules ................................................................................................... 3-5

Network Interface .................................................................................................................... 3-8

Hard Disk ................................................................................................................................ 3-9

CompactFlash (Memory) Card .............................................................................................. 3-10

4 Computer Interface ................................. .... ..................................................4-1

General Information ................................................................................................................ 4-2

Parallel Interface ..................................................................................................................... 4-3

USB Interface .......................................................................................................................... 4-5

Serial Interface (Option) .......................................................................................................... 4-6

RS-232C Protocol ................................................................................................................... 4-7

Glossary ....................................................................................................... Glossary-1

Index ................................................................................................................... Index-1

i

Page 4

ii

Page 5

Introduction

This guide has the following chapters:

1 Handling Paper

Explains how choose, handle and load paper.

2 Using the Operation Panel

Explains how to use the operation panel to configure the printer.

3 Options

Shows the available options.

4 Computer Interface

Describes the possible connections between the printer and your computer.

Glossary

A Glossary of terms used is provided here.

iii

Page 6

Conventions

This manual uses the following conventions:

Convention Description Example

Italic T ypeface Used to emphasize references

to additional information.

Courier T ypeface Used to denote messages or

names displayed on the

operation panel.

Bracket Bold T e xt

Typeface

Bold T ypeface Used to emphasize button or

Note Used to provide additional or

Used to denote operatio n panel

keys.

items to be selected in dialog

boxes, and titles displaying in

dialog boxes.

useful information about a

function or feature.

Refer to T oner Cont ainer Replacemen t on

page 3-3.

Replace the waste toner box when the

Check waste toner box message is

displayed.

Press [Menu].

Click Next.

NOTE: For information about storing the

pin, refer to step 10.

Important Use to provide important

information.

Caution Cautions are statements that

suggest mechanical damage

as a result of an action.

Warning Used to alert users to the

possibility of personal injury.

IMPORTANT: Ensure pa per is not folde d,

curled, or damaged.

CAUTION: Do not pull the cassette out

when holding the front of the machine.

WARNING: High voltage is present in

the charger section.

iv

Page 7

1 Handling Paper

This chapter contains ex planations on the following topics:

• General Guidelines...1-2

• Selecting the Right Paper...1-4

• Paper Type...1-10

1-1

Page 8

Handling Paper

General Guidelines

The machine is designed to print on standard copier paper (the type used in ordinary dry copier

machines), but it can also accept a variety of other types of paper within the limits specified below.

NOTE: The manufacturer assumes no liability for problems that occur when paper not satisfying

these requirements is used.

Selection of the right paper is important. Using the wrong paper can result in paper jams, curling,

poor print q ual ity, and paper waste, a nd in extreme cases can d am age the machine. The g ui del ines

given below will increase the productivity of your office by ensuring efficient, trouble-free printing

and reducing wear and tear on the machine.

Paper Availability

Most types of paper are compatible with a variety of machines. Paper intended for xerographic

copiers can also be used with the machine.

There are three general grades of paper: economy, standard, and premium. The most significant

difference between grades is the ease with which they pass through the machine. This is affected

by the smoothness, size, and mois ture co nten t of the paper, and the way in which the paper is cut.

The higher the grade of p aper you us e, the les s risk there w ill be of pa per jams and other pr oblems,

and the high er the level of quality your printed output will reflect.

Differences between paper from different suppliers can also affect the machine’s performance. A

high-quality printer cannot produce high-quality results when the wrong paper is used. Low-priced

paper is not economical in the long run if it causes printing problems.

Paper in each gra de is av ai lab le in a range of basis weights (defined la ter). The traditional standard

weights are 60 to 105 g/m² (16 to 28 lb/ream).

Paper Specifications

The following table summarizes the basic paper specifications. Details are given on the following

pages.

Item Specification

Weight Cassette: 60 to 105g/m² (16 to 28 lb/ream)

Thickness 0.086 to 0.110 mm (3.4 to 4.3 mils)

Dimensions Refer to Paper Sizes on page 1-4.

Dimensional accuracy ±0.7 mm

Squareness of corners 90° ±0.2°

Moisture content 4% to 6%

Direction of grain Long grain

Pulp content 80% or more

MP Tray: 60 to 220 g/m² (16 to 53 lb/ream)

1-2

Page 9

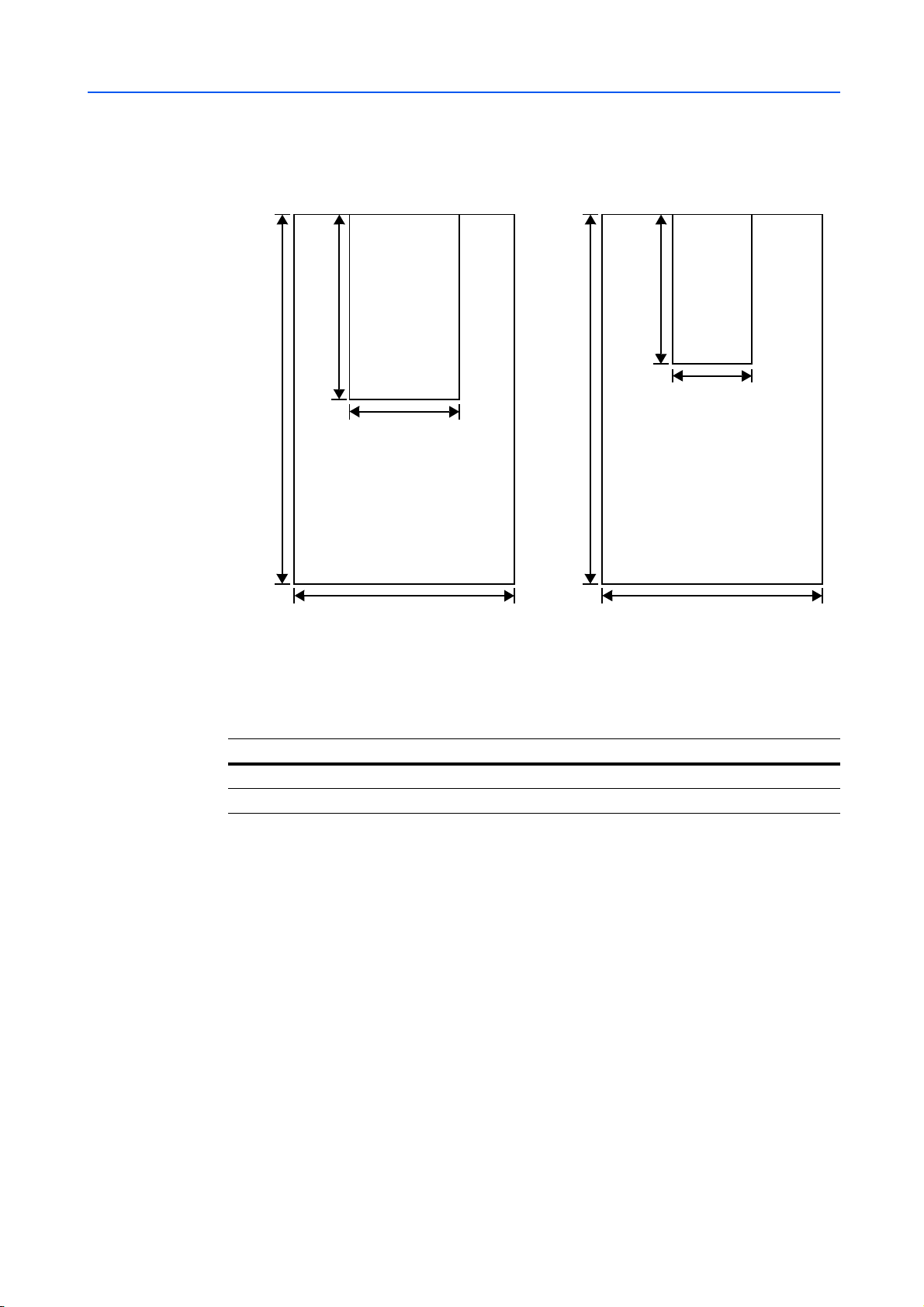

Minimum and Maximum Paper Sizes

The minimum and maximum paper sizes are as follows. For non standard paper, the MP tray must

be used.

Paper cassette

Handling Paper

MP tray

Recommended Paper

The following products are recommended for use with the printer for optimum performance

Minimum

Paper Size

210 mm

8-1/4 inches

432 mm

17 inches

140 mm

5-1/2 inches

Maximum

Paper Size

297 mm

11-11/16 inches

432 mm

17 inches

Minimum

Paper Size

148 mm

5-13/16 inches

98 mm

3-3/8 inches

Maximum

Paper Size

297 mm

11-11/16 inches

Size Product Weight

Letter, Legal Hammermill LASER PRINT 90 g/m² (24 lb)

A4 NEUSIEDLER COLOR COPY 90 g/m²

1-3

Page 10

Handling Paper

Selecting the Right Paper

This section describes the guidelines for selecting paper.

Condition

Avoid using paper that is bent at the edges, curled, dirty, torn, embossed, or contaminated with lint,

clay, or paper shreds.

Use of paper in these conditions can lead to illegible printing and paper jams, and can shorten the

life of the machin e. In p articular, avoid using paper with a s urface coati ng or othe r surface treatment.

Paper should have as smooth and even a surface as possible.

Composition

Do not use paper that has been coated or surface-treated and contains plastic or carbon. The heat

of fusing can cause such paper to give off harmful fumes.

Bond paper should contain at least 80% pulp. Not more than 20% of the total paper content should

consist of cotton or other fibers.

Paper Sizes

Cassettes and the MP tray are available for the paper sizes listed in the table below. The

dimensional tolerances are ±0.7mm for the length and width. The angle at the corners must be 90°

±0.2°.

MP tray Size Cassette or

MP tray

Envelope C4 229 × 324 mm Ledger 11 × 17 inches

Envelope C5 162 × 229 mm Legal 8-1/2 × 14 inches

Envelope Monarch 3-7/8 × 7-1/2 inches Letter 8-1/2 × 11 inches

Executive 7-1/4 × 10-1/2 inches ISO A3 297 × 420 mm

Envelope #10 4-1/8 × 9-1/2 inches ISO A4 210 × 297 m m

Envelope DL 110 × 220 mm ISO A5 148 × 210 mm

Envelope #9 3-7/8 × 8-7/8

Envelope #6 3-5/8 × 6-1/2 inches JIS B5 182 × 257 mm

ISO B5 176 × 250 mm Statement 5-1/2 × 8-1/2 inches

ISO A6 105 × 148 mm Oficio II 8-1/2 × 13 inches

JIS B6 128 × 182 mm Folio 210 × 330mm

Hagaki 100 × 148 mm 8 kai 273 × 394 mm

Ofuku-Hagaki 148 × 200 mm 16 kai 197 × 273 mm

Youkei 2 114 × 162 mm

Youkei 4 105 × 235 mm

Custom 98 × 148 to 297 × 4 32mm

(3-3/8 × 5-13/16 to

11-11/16 × 17 inches)

inches JIS B4 257 × 364 mm

Size

Smoothness

1-4

The paper should have a smooth, uncoated surface. Paper with a rough or sandy surface can

cause voids in the printed output. Paper that is too smooth can cause multiple feeding and fogging

problems. (Fogging is a gray background effect.)

Page 11

Basis Weight

Basis weight is the weight of paper expressed in grams per square meter (g/m²). Paper that is too

heavy or too light may cause feed errors or paper jams as well as premature wear of the product.

Uneven weight of pa per, namely uneven paper thickness may ca us e mu ltip le -sh eet feeding or print

quality problems such as blurring because of poor toner fusing.

The recommended basis weight is between 60 and 105 g/m² (16 and 28 lb/ream) for the cassette

and between 60 and 220 g/m² (16 to 53 lb/ream) for the MP tray.

Paper Weight Equivalence Table

The paper weight is listed in pounds (lb) and metric grams per square meter (g/m²). The shaded

part indicates the standard weight.

U. S. Bond Weight (lb) Europe Metric Weight (g/m²)

16 60

17 64

20 75

21

22 81

24 90

27

28 105

32 120

34 128

36 135

39 148

42 157

43 163

47 176

53 199

80

100

Handling Paper

Thickness

Moisture Content

The paper used with the machine should be neither extremely thick nor extremely thin. If you are

having problems with p a per jams , multip le feeds , and fain t print ing, the p a per you are using ma y be

too thin. If you are havi ng pro blems with paper jams and blurred printi ng the pa per ma y be too thick.

The correct thickness is 0.086 to 0.110 mm (3.4 to 4.3 mils).

Moisture content is defined as the percent ratio of moisture to the dry mass of the paper. Moisture

can affect the paper’s appearance, feed ability, curl, electrostatic properties, and toner fusing

characteristics.

The moisture content of the paper varies with the relative humidity in the room. When the relative

humidity is high and the paper absorbs moisture, the paper edges expand, becoming wavy in

appearance. When the relative humidity is low and the paper loses moisture, the edges shrink and

tighten, and print contrast may suffer.

Wavy or tight edges can cause jams and alignment anomalies. The moisture content of the paper

should be 4 to 6%.

1-5

Page 12

Handling Paper

To ensure correct moisture content, it is important to store the paper in a controlled environment.

Some tips on moisture control are:

• Store pap er in a cool, dry location.

• Keep the paper in its wrapping as long as possible. Re-wrap paper that is not in use.

• Store paper in its or iginal carton. Place a pall et etc. under the carton to separate it from the

floor.

• After removing paper from storage, let it stand in the same room as the machine for 48 hours

before use.

• Avoid leaving paper where it is exposed to heat, sunlight, or dampness.

Paper Grain

When paper is manufactured, it is cut into sheets with the grain running parallel to the length (long

grain) or parallel to the width (short grain). Short grain paper can cause feeding problems in the

machine. All paper used in the machine should be long grain.

Other Paper Properties

Porosity: Indicates the density of paper fiber.

Stiffness: Limp paper may buckle i n the machine, resulting in pap er jams.

Curl: Most paper naturally tends to curl one way if left unpacked. When paper passes through the

fixing unit, it curls upward a little. To produce flat printouts, load the paper so that the upward

pressure from the machine can correct their curling.

Electrostatic discharge: During the printing process the paper is electrostatically charged to

attract the toner. The paper must be able to release this charge so that printed sheets do not cling

together in the output tray.

Whiteness: The contrast of the printed page depends on the whiteness of the paper. Whiter paper

provides a sharper, brighter appearance.

Quality control: Uneven sheet size, corners that are not square, ragged edges, welded (uncut)

sheets, and crushed edges and corners can cause the machine to malfunction in various ways. A

quality paper supplier should take considerable care to ensure that these problems do not occur.

Packaging: Paper should be packed in a sturdy carton to protect it from damage during transport.

Quality paper obtained from a reputable supplier is usually correctly packaged.

Specially pro ces sed paper: Avoid us ing the types of specially process ed p aper listed below, even

if the paper meets the other basic specifications defined in this manual. Be sure to perform some

test prints before purchasing any type of paper in large quantities.

• Shiny paper

• Very thin paper

• Rough paper

• Perforated paper

1-6

Page 13

Special Paper

Handling Paper

The following types of special paper can be used:

Paper type to be used Paper type to be selected

Thin paper (60 to 64 g/m²) Vellum

Thick paper (90 to 220 g/m²) Thick

Colored paper Color

Recycled paper Recycled

Overhead projector transparencies Transparency

Postcards Cardstock

Envelopes Envelope

Label Labels

Preprinted paper Preprinted

Use paper that is sold specifically for use with copiers or printers (heat-fusing type). When using

transparencies, la bel s, thin pap er, envelopes, postcards, or thick pap er, feed the paper from the MP

Tray.

Since the composition and quality of special paper vary considerably, special paper is more likely

than white bond pape r to gi ve trouble during print ing . No li abi lity will be assumed if mo is ture and so

forth given off during printing on special paper causes harm to the machine or operator.

NOTE: Before purchasing any type of special paper, test a sample on the machine and check that

printing quality is satisfactory.

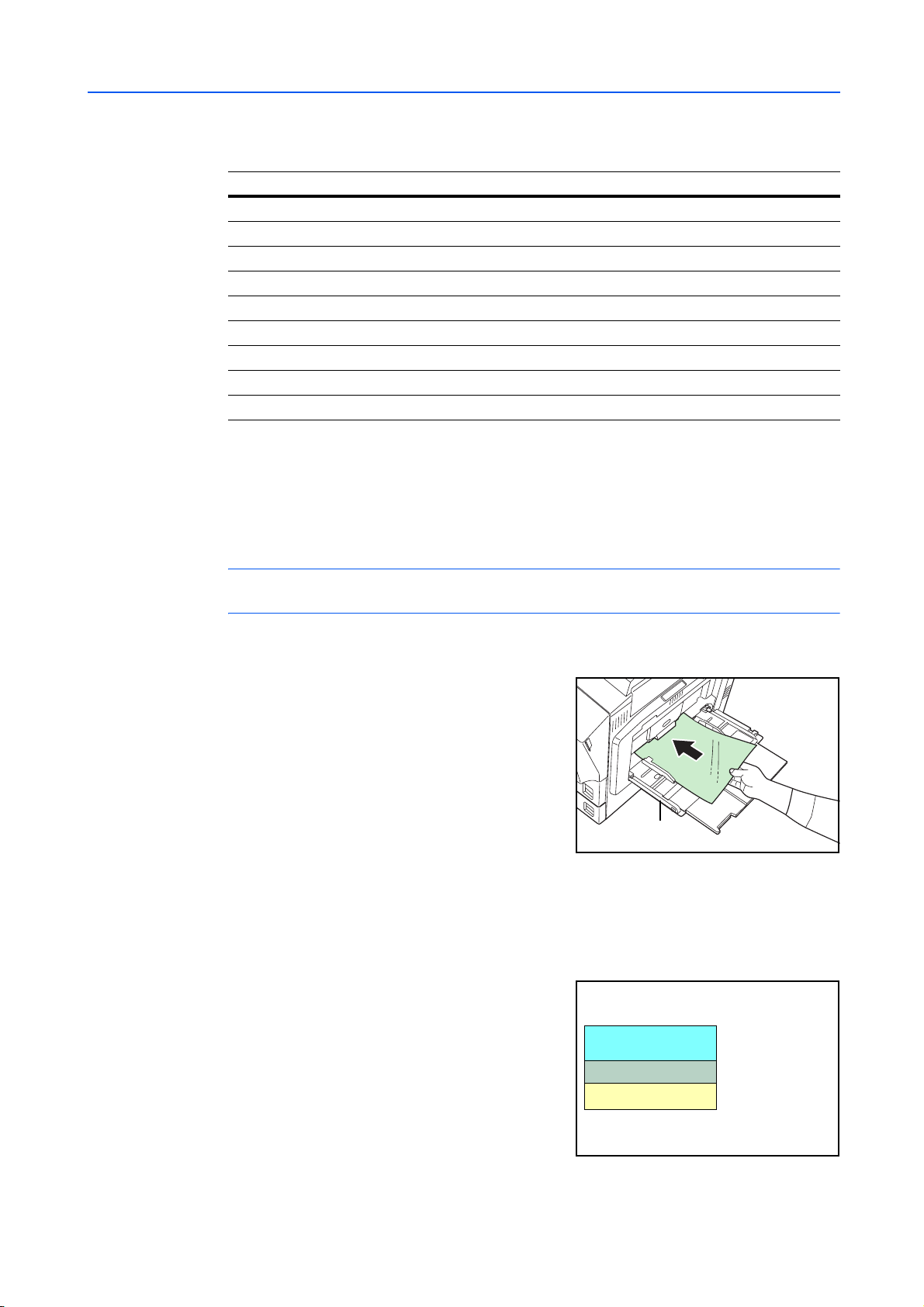

Transparency

Transparencies must be able to withstand the heat of

fusing during the printing process. The recommended

transparency product is 3M CG3700 (Letter, A4).

Transp arenci es must be plac ed on th e MP tray with t he

long edge towards the printer.

When unloading transparencies (e.g., for clearing

jams), hold them carefully by the edges to avoid

leaving fingerprints on them.

MP Tray

Labels

Labels must be fed from the MP Tray.

The basic rule for printing on adhes ive labels is that the adhes ive must never co me into cont act with

any part of the machine. Adhesive paper sticking to the drum or rollers will damage the machine.

Label paper has a struc ture com prisi ng of three layers,

as shown in the diagram. The top sheet is printed on.

The adhesive layer consists of pressure-sensitive

adhesives. The carrier sheet (also called the linear or

backing sheet) holds the labels until used. Due to the

complexity of its composition, adhesive-backed label

paper is particularly likely to give printing problems.

Adhesive label paper must be entirely covered by its

top sheet, with no spaces between the individual

labels. Labels with s paces in between a re liabl e to peel

off, causing serious paper jam problems.

Top sheet (white

bond paper)

Adhesive

Carrier sheet

1-7

Page 14

Handling Paper

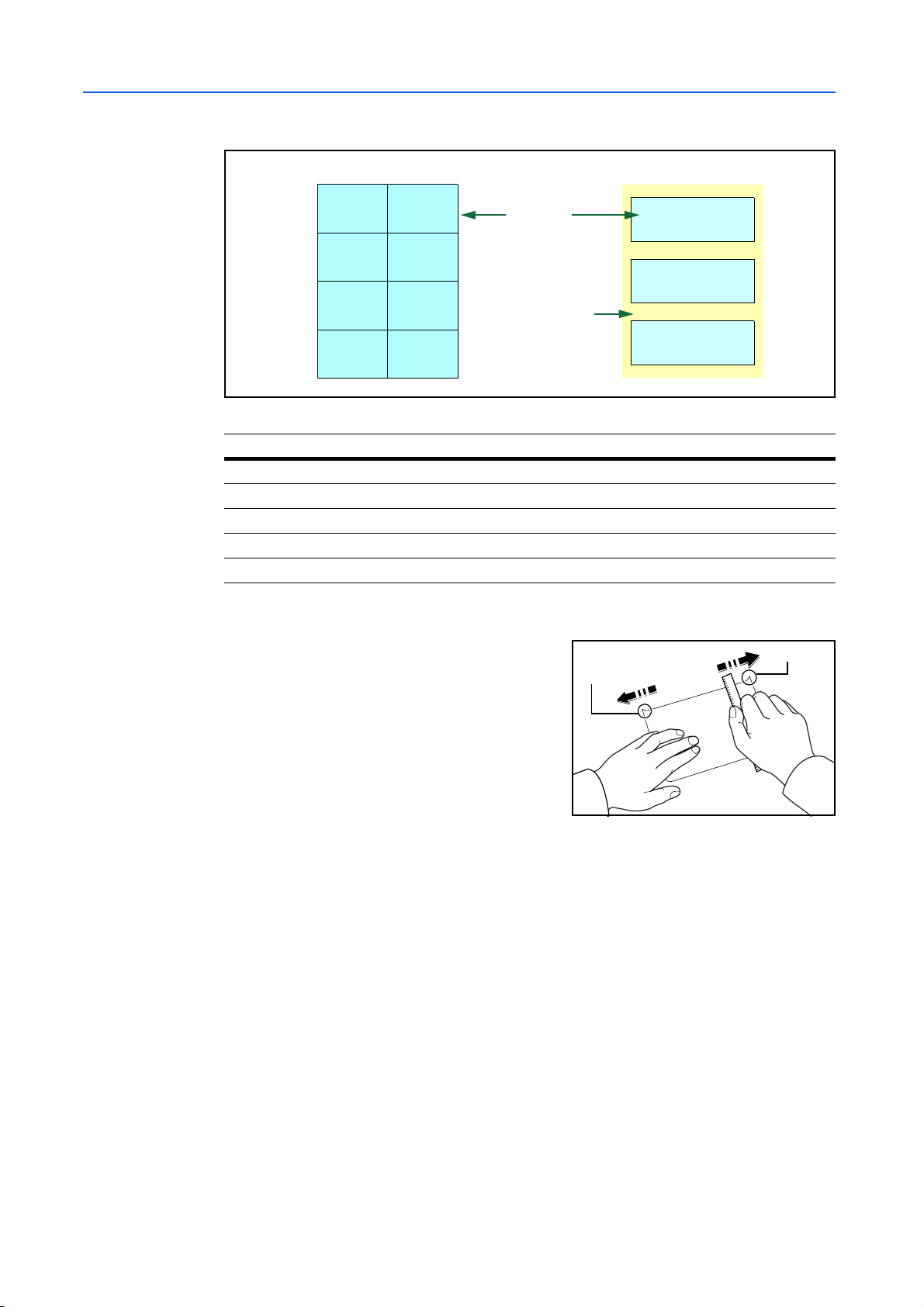

Some label paper is manufactured with an extra margin of top sheet around the edge. Do not

remove the extra top sheet from the carrier sheet until after printing is finished.

UnacceptableAcceptable

Top sheet

Carrier sheet

The table below lists the specifications for adhesive label paper.

Item Specification

Weight of top sheet 44 to 74 g/m² (12 to 20 lb/ream)

Composite weight 104 to 151 g/m² (28 to 40 lb/ream)

Thickness of top sheet 0.086 to 0.107 mm (3.9 to 4.2 mils)

Composite thickness 0.115 to 0.145 mm (4.5 to 5.7 mils)

Moisture content 4 to 6% (composite)

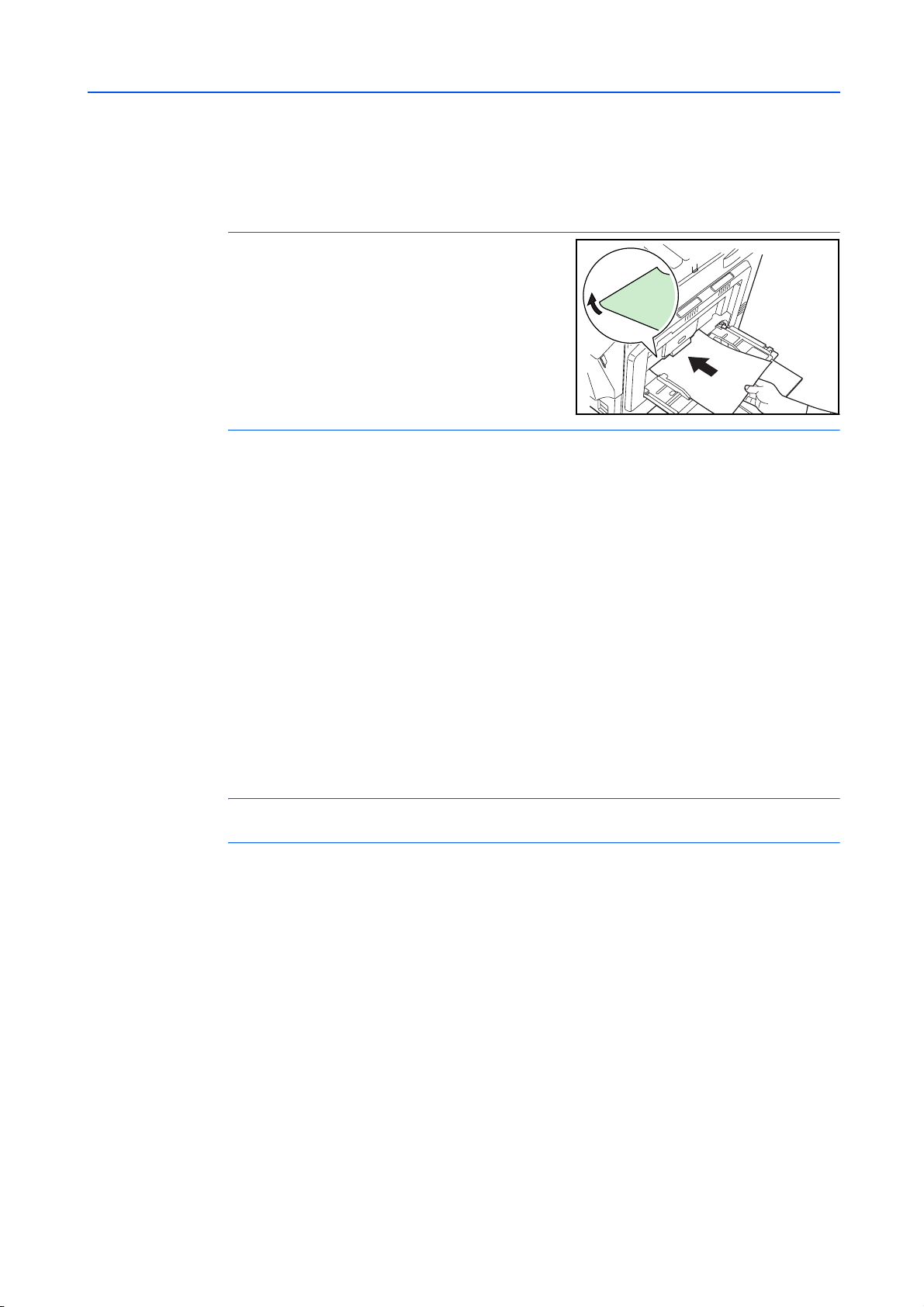

Postcards

Fan the stack of postcard s and ali gn the edg es before

loading them in the MP tray. Make sure the postcards

you are goin g to set are not curled. Feeding curled

postcards may cause paper jams.

Some postcards have rough edges on the back (those

are created when the p aper is cut). In thi s case, put the

postcards on a flat place and rub the edges with, for

example, a ruler to smooth them.

Rough Edge

Rough Edge

Envelopes

Envelopes should be fed in the face-up position, front or right edge first.

Since the composition of an envelope is more complex than that of ordinary paper, it is not always

possible to ensure consistent printing quality over the entire envelope surface.

Normally, envelopes have a diagonal grain direction. Refer to Paper Grain on page 1-6. This

direction can easily cause wrinkles and creases when envelopes pass through the printer. Before

purchasing envelopes, make a test print t o check whether the printer accepts the envel ope.

• Do not use envelopes that have an encapsulated liquid adhesive.

• Avoid a long printing session for envelopes only. Extended envelope printing can cause

premature printer wear.

• If jams occur, try setting a lesser number of envelopes on the MP tray.

1-8

• To avoid jams caused by curled envelopes, stack no more th an 10 printed envelopes on the

output tray.

Page 15

Handling Paper

Thick Paper

Fan the stack of pap er and align the ed ges before loa ding them in the MP tray. Some types of paper

have rough edges on the back (thos e are crea ted wh en the p aper i s cut). In this ca se, put th e pa per

on a flat place and rub the edges once or twice with, for example, a ruler to smooth them. Feeding

rough edged paper may cause paper jams.

NOTE: If the paper jams even after y ou smooth it out,

load the paper in the MP Tray with the leading edge

raised up a few millimeters as shown in the illustration.

Colored Paper

Colored paper should satisfy the same conditions as white bond paper, Paper Specifications on

page 1-2 In addition, the pigments used in the paper must be able to withstand the heat of fusing

during the printing process (up to 200°C or 392°F).

Preprinted Paper

Preprinted paper should satisfy the same conditions as white bond paper, refer to Paper

Specifications on page 1-2. The preprinted ink must be able to withstand the heat of fusing during

the printing process, and must not be affected by silicone oil.

Do not use paper with any kind of surface treatment, such as the type of paper commonly used for

calendars.

Recycled paper

Select recycled paper that meets the same specifications as the white bond paper except for

whiteness, refer to Paper Specifications on page 1-2.

NOTE: Before purchasing re cycl ed pa per, test a sample on the machine and check that the pr inting

quality is satisfactory.

1-9

Page 16

Handling Paper

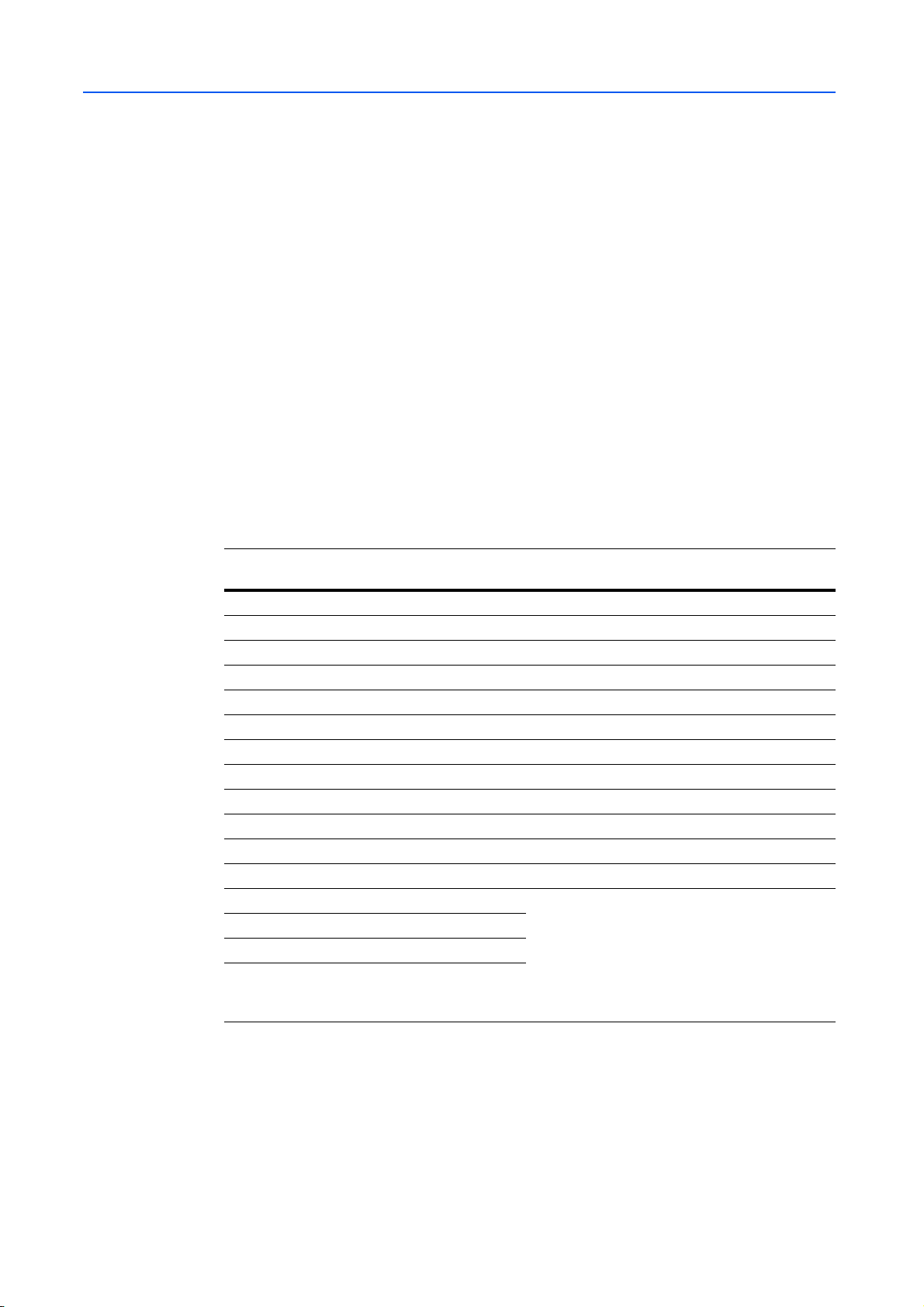

Paper Type

The printer is capable of print ing under the opti mu m se ttin g for the type of p ape r being used .

Setting the paper type for the paper source from the printer’s operation panel will cause the printer

to automatically select the paper source and print in the mode best suited to that type of paper.

A different paper type setting can be made for each paper source including the MP tray. Not only

can preset paper types be selected, but it is also possible for you to define and select customized

paper types. Refer to Creating Custom Paper Type on page 2-58. The following types of paper can

be used.

Paper T ype Paper source

MP tray Paper

Cassette

Plain Yes Yes Normal 2 Yes

Transparency Yes No Extra Heavy No

Preprinted Yes Yes Normal 2 Yes

Labels Yes No Heavy 1 No

Bond Yes Yes Normal 3 Yes

Recycled Yes Yes Normal 2 Yes

Vellum Yes Yes Light No

Rough Yes Yes Normal 3 Yes

Letterhead Yes Yes Normal 2 Yes

Color Yes Yes Normal 2 Yes

Prepunched Yes Yes Normal 2 Yes

Envelope Yes N o Heavy 2 No

Cardstock Yes No Heavy 2 No

Coated Yes No Normal 3 No

Thick Yes No Heavy 2 No

High quality Yes Yes Normal 2 Yes

Custom 1 (to 8) *

Yes: Can be stored No: Cannot be stored

Yes Yes Normal 2 Yes

Paper Weight Duplex path

(MP tray available only

in Cassette mode)

1-10

* This is a paper type defined and regi stered by the user. Up to eight types of user setting s m ay be

defined. For details, refer to Creating Custom Paper Type on page 2-58.

Page 17

2 Using the Op e ra ti o n Pan e l

This chapter contains ex planations on the following topics:

• General Information...2-2

• Understanding the Operation Panel...2-3

• Canceling a Printing Job...2-8

• Using the Menu Selection System...2-9

• Status Pages...2-12

• e-MPS...2-15

• Changing the Interface Parameters...2-24

• Making Default Settings...2-30

• Pagination...2-38

• Setting Print Quality...2-41

• Operating the Storage Device...2-42

• Paper Handling...2-50

• Reading Life Counters...2-64

• Other Modes...2-65

2-1

Page 18

Using the Operation Panel

General Information

This chapter provide s the i nforma tio n you n eed to con fig ure the Ec osys pri nter. In general you need

to use the operation p a nel only to make default settings. You can make most changes to the printer

settings using the printer driver through the application software.

NOTE: Changes to printer set tings made using a soft ware appl ication o verride ch anges m ade using

the operation panel.

Y o u can a lso rely on o ther printe r utili ties such as KM-NET for Clie nts if you need to ch ange set tings

that are not available on the printer driver. It will allow remote access to printer settings. Printer

utilities are supplied in the CD-ROM supplied with the printer.

The chapter describes the operation panel in detail, including its menus and the procedures for

changing various printer settings.

2-2

Page 19

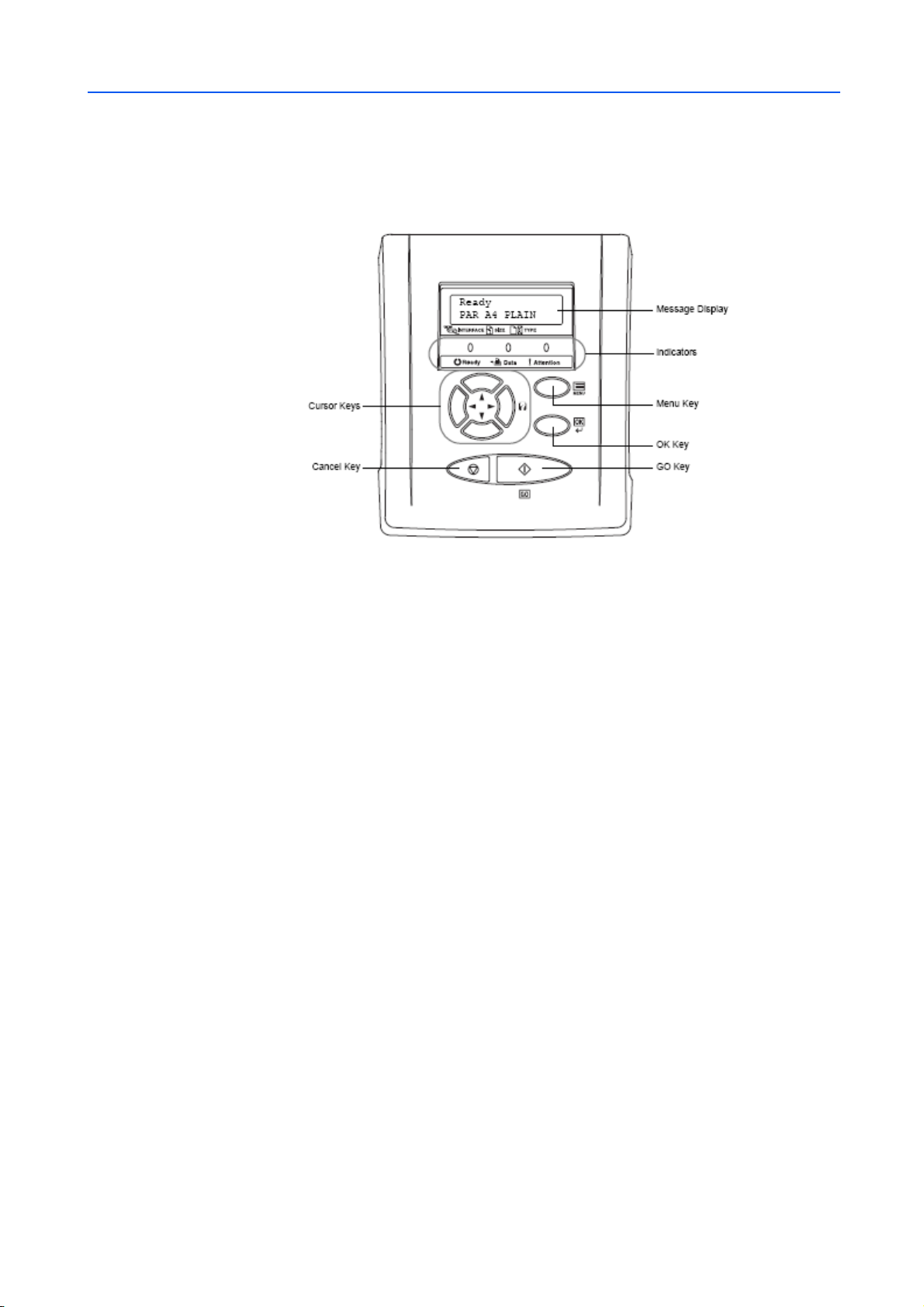

Understanding the Operation Panel

The operation panel on the top of the printer has a 2-line by 16-character liquid crystal display

(LCD), eight keys, and three indicators (LED).

Using the Operation Panel

Message Display

Messages that appear on the display and functions of indicators and keys are explained in this

chapter.

The message display on the operation panel shows:

• Status information, the messages listed below which are displayed during normal operation.

• Error codes, when the printer requires the operator’s attention; as explained in the Operation

Guide.

2-3

Page 20

Using the Operation Panel

Status Information

Message Meaning

Self test The printer is performing self-diagnostics after power-up.

Please wait The printer is warming up and is not ready. When the printer is switched

Please wait

(Adding toner)

Please wait

(Calibrating)

Ready The printer is ready to print.

Processing The printer is receiving data to print. Thi s is also sho wn when the p rinter is

Sleeping The printer is in Auto Sleep. The printer wake s fr om Auto Slee p whe never

Cancelling data The printer is cancelling the data.

Skipping data The printer is skipping the data.

Waiting The printer is waiting for the rest of print job before completing the last

FormFeed TimeOut The printer is printing the last page after a waiting period.

Paper Loading Paper in the paper cassette is being moved. This message may be

Overwriting HDD is being overwritten. Refer to Data Security Kit (D) Operation Guide.

on for the first time, this message will take several minutes.

Toner is currently being replenished. This message may be dis pla ye d

during continuous printing of a large volume of pages which require a

large amount of toner such as with photographs, etc.

The color calibration functi on is bei ng perfo rme d auto ma tic all y as you

powered on the printer.

You can also execute this function manually on the operation panel. For

details, refer to Color Calibration on page 2-79.

reading a memory card, hard disk or RAM disk.

a key on the operation panel and [GO] is pressed, the cover is opened or

closed, or a print job is received. The printer then warms up and goes

on-line. For details on Auto Sleep, refer to Sleep Timer Timeout Time on

page 2-67.

page. Pressing [GO] allows you to obtain t he last page im mediatel y. Refer

to below.

displayed if the paper cassette is inserted again after paper is loaded.

Error codes

Refer to the Troubleshooting section in the Operation Guide.

Indicators in Message Display

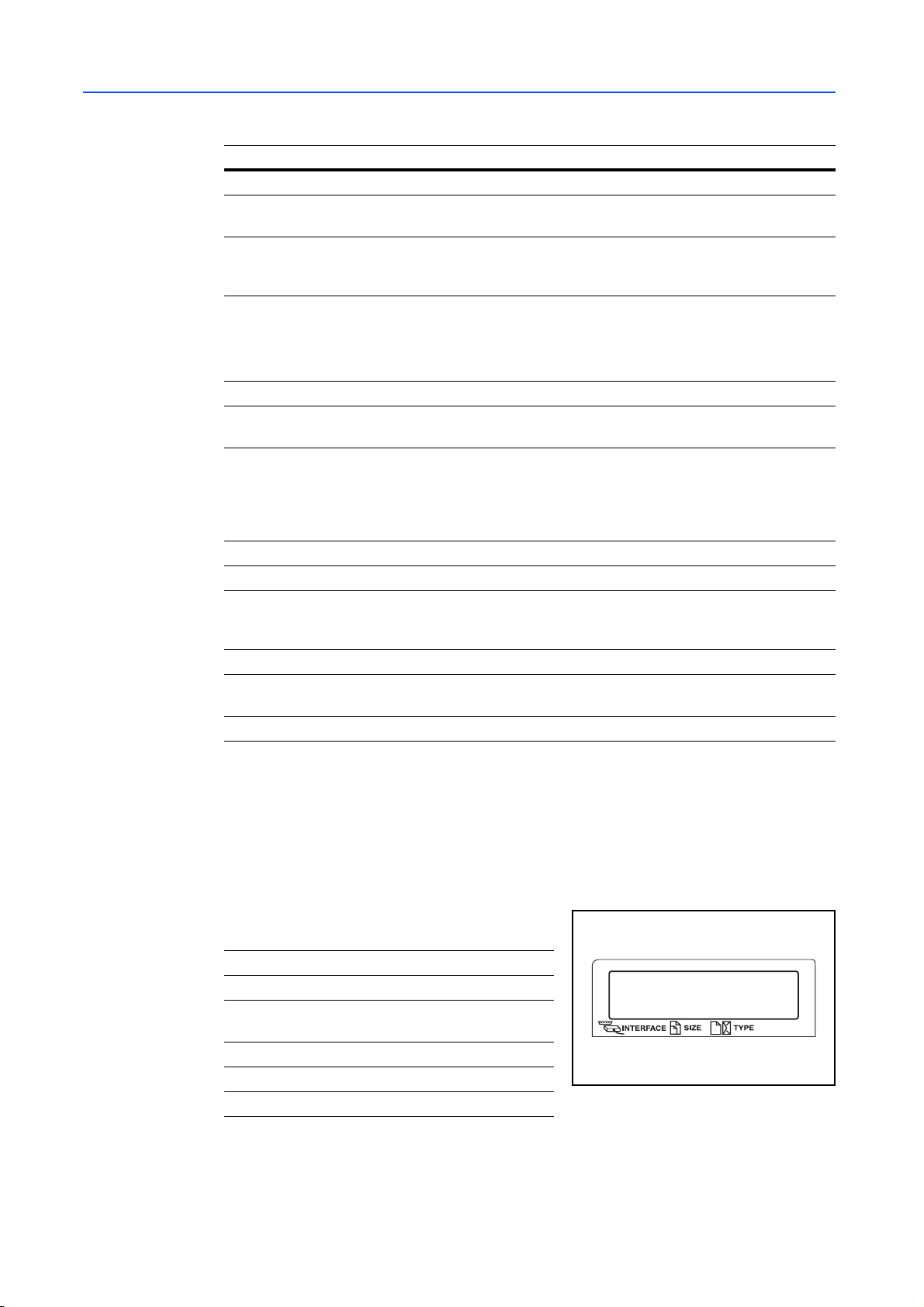

Interface Indicator (INTERFACE)

The interface indicator show s the int erfa ce tha t is

currently in use:

PAR Parallel interface is in use.

USB USB interface is in use.

SER Serial (RS-232C) interface is in use.

(option)

NET Network int erfa ce is in use.

OPT Network interface is in use. (option)

--- No interface is in use.

Each interface has a timeout time of 30 seconds (factory default) during which the other interface

should wait to receive a print job. Even after a print job has been completed on the interface, you

should wait for this period until the other interface begins printing the job.

Ready

PAR A4 PLAIN

2-4

Page 21

Using the Operation Panel

Paper Size Indicator (SIZE)

This indicator shows:

• While the printer is in standby, the paper size of the current cassette. The default paper

cassette is determined by the operation panel keys. For details, refer to Paper Handlin g on

page 2-50.

• While the printer is printing, the paper size used to format the document to print by the

application software.

The abbreviations used to indicate the paper sizes and their dimensions are as follows:

A3 ISO A3 (297 × 420 mm)

A4 ISO A4 (210 × 297 mm)

A5 ISO A5 (148 × 210 mm)

A6 ISO A6 (105 × 148 mm) *

B4 JIS B4 (257 × 364 mm)

B5 JIS B5 (182 × 257 mm)

B6 JIS B6 (128 × 182 mm) *

LD Ledger (11 × 17 inches)

LT Letter (8-1/2 × 11 inches)

LG Legal (8-1/2 × 14 inches)

MO Envelope Monarch (3-7/8 × 7-1/2 inches) *

DL Envelope DL (110 × 220 mm) *

C4 Envelope C4 (229 × 324mm) *

C5 Envelope C5 (162 × 229mm) *

b5 ISO B5 (176 × 250 mm) *

EX Executive (7-1/4 × 10-1/2 inches) *

#6 Envelope #6 (3-5/8 × 6-1/2 inches) *

#9 Envelope #9 (3-7/8 × 8-7/8 inches) *

10 Envelope #10 (4-1/8 × 9-1/2 inches) *

HA Hagaki (100 × 148mm) *

OH Oufuku Hagaki (148 × 200 mm) *

O2 Oficio II (8-1/2 × 13 inches)

8K 8 kai (273 × 394 mm) *

16K 16 kai (197 × 273 mm) *

ST Statement (5-1/2 × 8-1/2 inches)

FO Folio (210 × 330 mm)

Y2 Yokei 2 (114 × 162 mm) *

Y4 Yokei 4 (105 × 235 mm) *

CU Custom Size (98 × 148 t o 297 × 432mm, 3-3/8 × 5-13/16 to 11-11/16 ×

16-5/8 inches) *

* Only with MP tray feeding

2-5

Page 22

Using the Operation Panel

Paper Type Indicator (TYPE)

This indicator shows the paper type defined for the current paper casette. The paper type can be

manually defined using the operation panel. For more information, refer to Paper Handling on

page 2-50. The following abbreviations are used:

(none) Auto LETTERHD Letterhead

PLAIN Plain paper COLOR Colored paper

TRANSP. Transparency *

PREPRINT Preprinted paper ENVELOPE Envelope *

LABELS Labels * CARDSTOCK Card stock *

BOND Bond paper COATED Coated paper *

RECYCLED Recycled paper THICK Thick paper *

VELLUM Vellum HIGH QLT High-quality paper for color

ROUGH Rough paper CUSTOM 1 (to 8) Custom 1 (to 8)

* Only with MP tray feeding

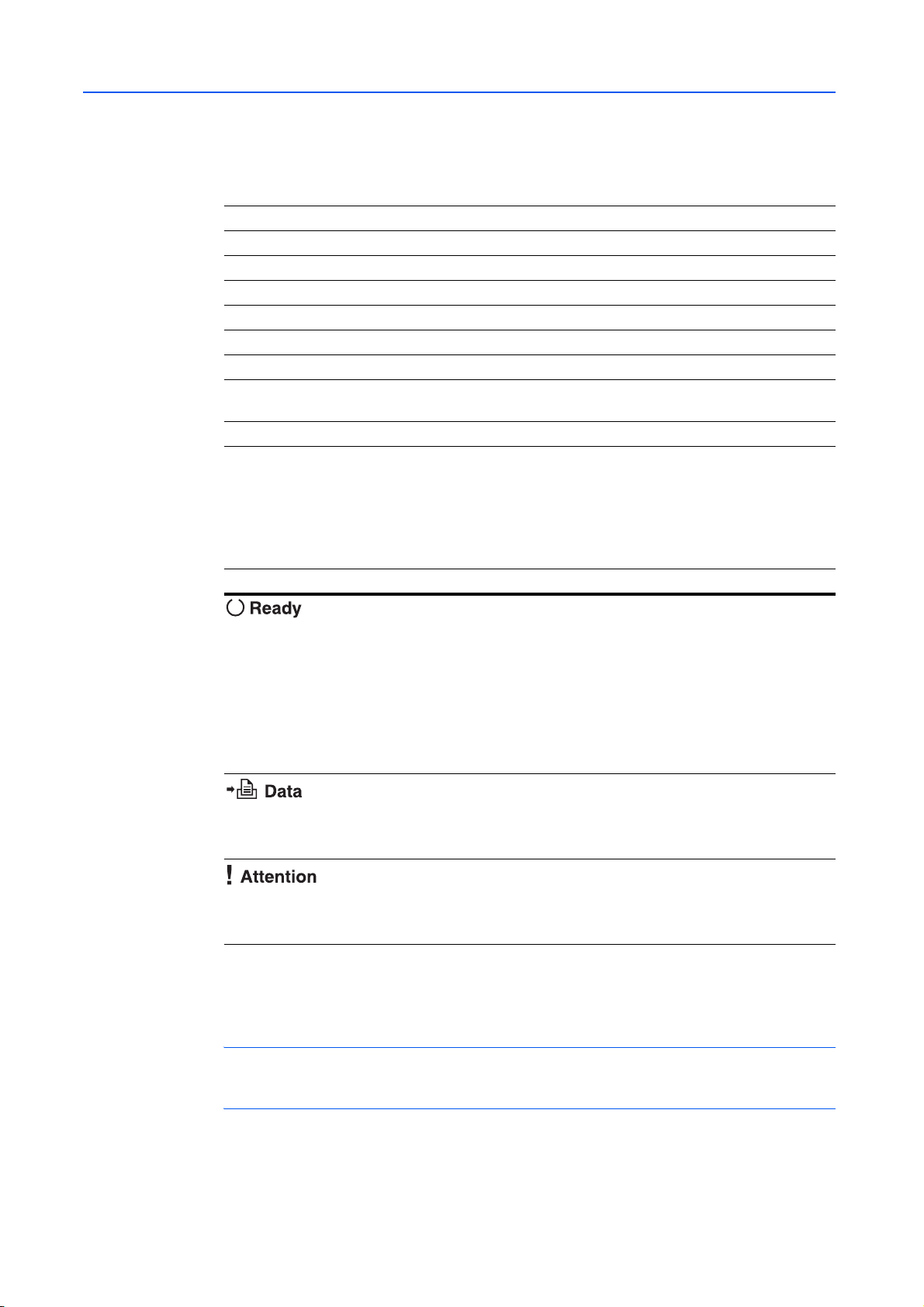

READY, DATA, and ATTENTION Indicators

PREPUNCH Prepunched paper

printing

Keys

The following indicators light during normal operation and whenever the printer needs attention.

Depending on the status of lighting, each indicator has the following meaning:

Indicator Description

Flashing. In dicates an error that you can resolve. For details, ref er to the

Troubleshooting section in the Operation Guide.

On. Indicates that the printer is ready and on-line. The printer prints the

data it receives.

Off. Indicates that th e printe r is of f-lin e. Dat a ca n be rece ived b ut will no t

be printed until the printer is switched on-line by pressing [GO]. Also,

indicates when printing is automatically stopped due to an error

condition. For details refer to the Troubleshooting section in the

Operation Guide.

Flashing. Indicates that data is being received.

On. Indicates either that dat a received is being proce ssed before p rinting

starts, or that data received is being written to a memory card, hard disk

or RAM disk.

Flashing. Indicates that the printer requires maintenance or is warming

up.

On. Indicates the occurrence of a problem or an error. For details, refer

to the Troubleshooting section in the Operation Guide.

2-6

The operation panel keys are us ed to con fig ure the printer operation. Note that cert a in ke ys have a

secondary function.

NOTE: The printer has a parallel, USB, network, and an optional interface. Configuration of the

printer settings affect only the interface that is currently active (shown by the INTERFACE indicator

on the message display). Refer to Interface Indicator (INTERFACE) on page 2-4.

Page 23

Using the Operation Panel

GO Key

GO switches the printer between on-line and off-line. Use this key to:

• Toggle the printer’s on-line and off-line states. You can temporarily stop the print job by

switching the printer off-line.

• Print and feed out one page when the printer displays Waiting.

• Recover from certain errors.

• Recover from Auto Sleep.

(Cancel) Key

This key is used to:

• Cancel a printing job. (Refer to Canceling a Printing Job on page 2-8.)

• Stop the alarm sound.

• Reset numeric values or cancel a setting procedure while using the menu system.

Menu Key

Menu lets you enter the menu system to change the setup and printing environment of the printer.

Pressing this key during a menu selection will terminate the selection and return the printer to the

normal operation.

Cursor Keys

The four cursor keys are used in the menu system to access an item or enter numeric values.

The arrow key with the question mark ( ) may be pressed when the paper jam message has

appeared on the message display. A help message will then appear to facilitate jam clearing in the

location.

OK Key

This key is used to:

• Finalize settings of numeric values and other selections.

• Set the paper source when Use alternative? is shown in the message display.

NOTE: If you hold down [OK] and press [Menu] when Ready is shown on this printer, the

AdministrationID menu wil l be displayed. This menu is the se tting menu for adm inistrati on under the

Account Management System and is normally not used. Press [Menu] to return to Ready.

2-7

Page 24

Using the Operation Panel

Canceling a Printing Job

While the printer displays Processing, press [Cancel].

1

Print Cancel? appears on the message disp lay foll owed by the interf ace in use. The interfac e is

indicated by one of the following messages:

Parallel

USB

Network

Serial (option serial interface)

Option (option network interface)

Press [OK]. Cancelling data appears on the message display and printing stops after the

2

current page is printed.

2-8

Page 25

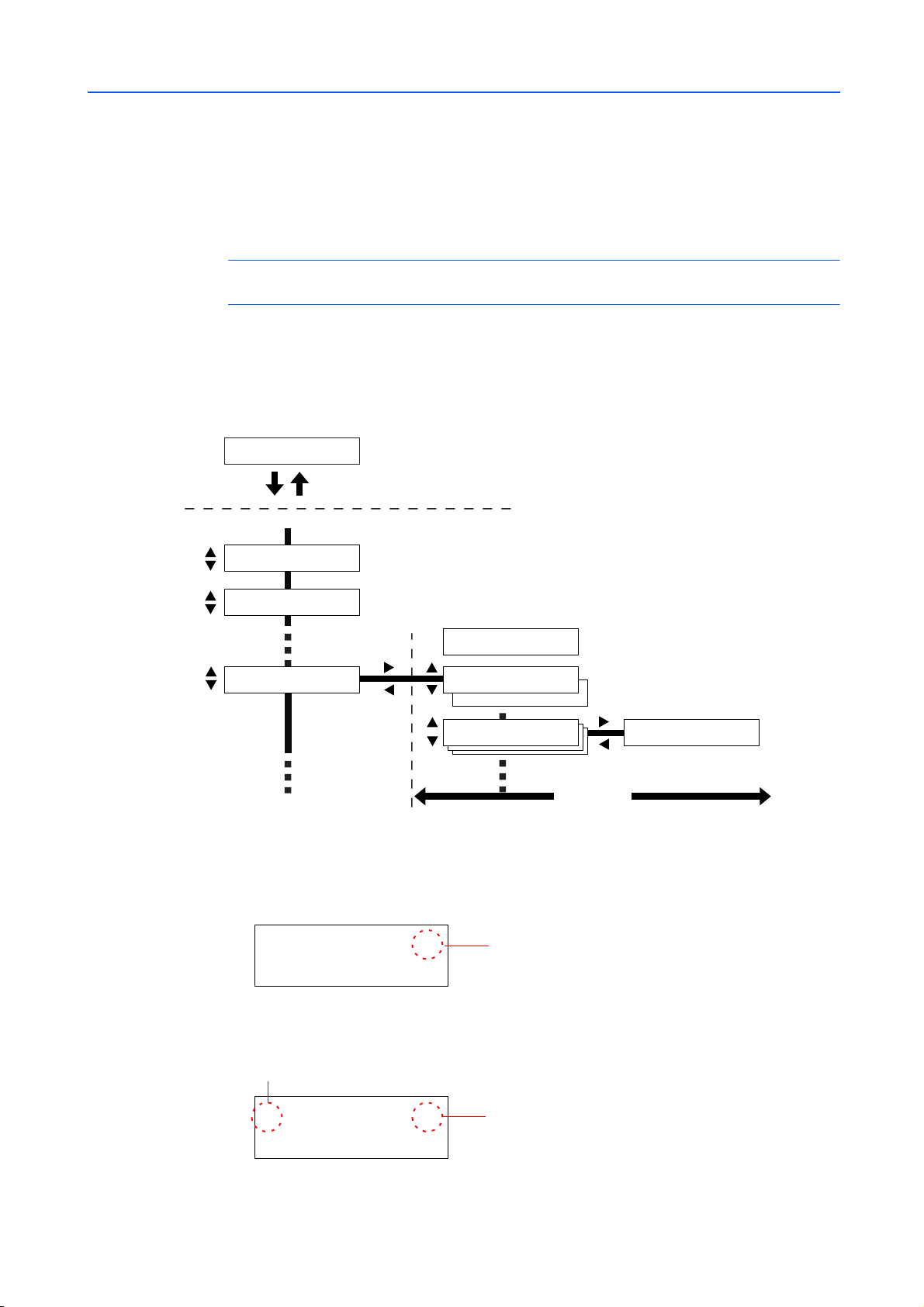

Using the Menu Selection System

Menu Selection System

This section explain s how to us e t he me nu se lec tion system. [Menu] on the operation panel allows

you to use the menu to configure the printer settings to your specific needs. Settings can be made

when Ready is indicated on the printer message display.

NOTE: Settings that are received from application software and the printer driver will take priority

over settings made in the operation panel.

Entering the Mode Selection Menu

Press [Menu] when Ready is indicated on the printer message display.

The mode selection menu is displayed.

Ready

PAR A4 PLAIN

Press [Menu].

Mode Selection Menu

Using the Operation Panel

Print

Menu Map

Print

Status Page

Paper Handling >

Press [OK].

Press [OK].

>Type Adjust >

>MP Tray Mode

Cassette

>MP Tray Mode

First

>Type Adjust > >>Paper Weight

Press [OK].

Normal 1

Sub-menu

Selecting a Menu

The mode selection menu is hierarchical. Press or to display the desired menu.

If the selected menu has a sub-menu, > is displayed after the menu.

Paper Handling >

Indicates that there is a sub-menu

Press [OK].

Press to move to the sub-menu or to go back.

> is displayed before the sub-menu.

Indicates that this is the sub-menu

>Type Adjust >

Indicates that there is another sub-menu

2-9

Page 26

Using the Operation Panel

Press to move to another sub-menu or to go back.

>> is displayed before the second sub-menu.

Indicates that this is the second sub-menu

>>Paper Weight

Normal 1

Setting a Menu

Select the desired menu and press [OK] to set or change the configuration.

Press or to display the desired item and [OK] to finalize the value or selections set.

Cancelling Menu Selection

If you press [Menu] when a menu is selected, the message display returns to Ready.

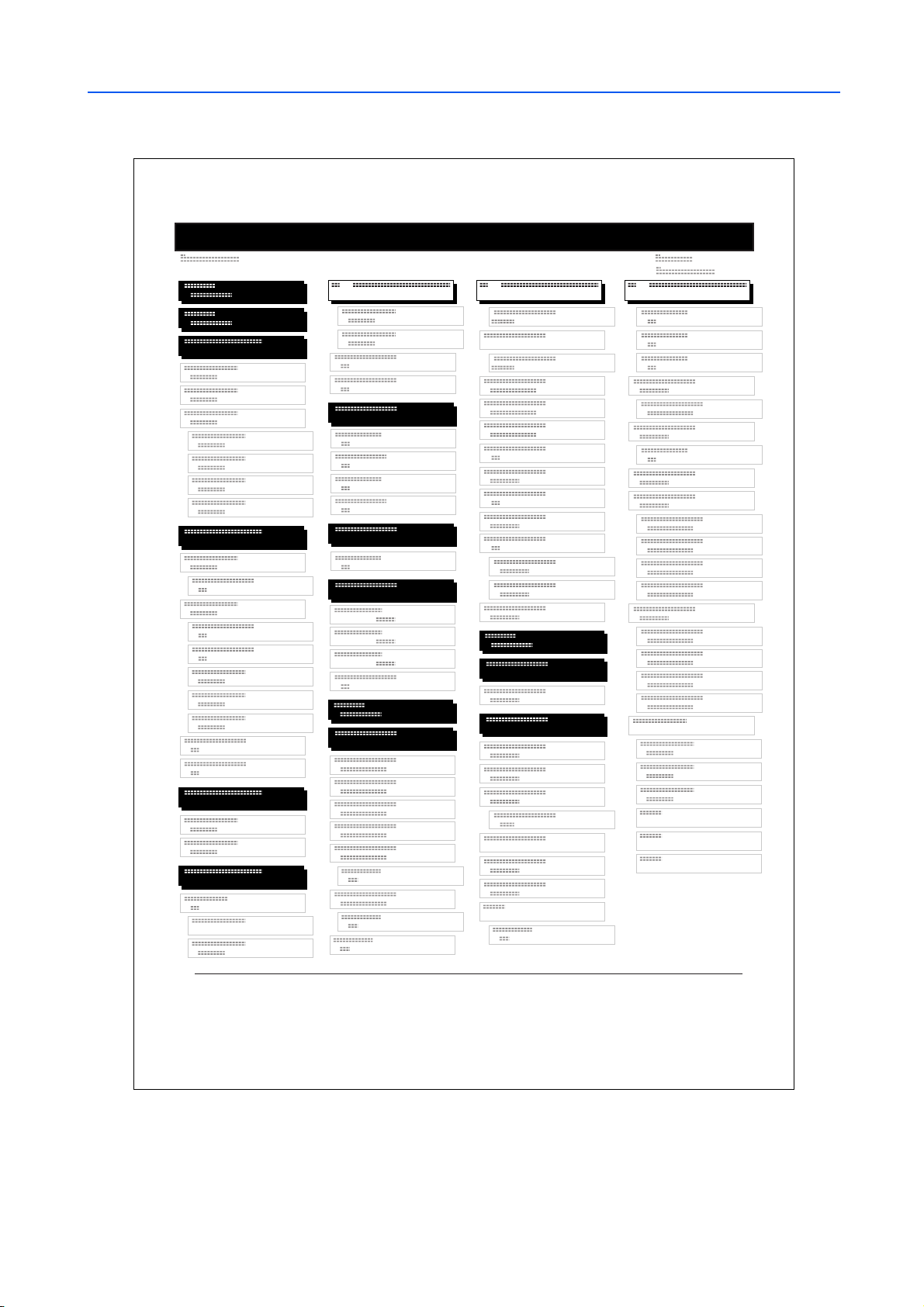

Menu System Road Map

The menu map is the hie rarchy diagra m o f the me nu se lectio n sys tem of the prin ter. The menu map

is useful as a reference to guide yourself through the menu selection system.

Printing a Menu Map

The printer prints a full list of the menu selection system — Menu Map. Note that menus shown in

the list may vary depending on which optional units are installed in the printer.

Press [Menu].

1

Press or repeatedly until Print Menu Map appears.

2

Press [OK]. A question mark (?) appears.

3

Press [OK]. The message Processing appears and the printer prints a Menu Map.

4

Print

Menu Map

Print

Menu Map ?

2-10

Page 27

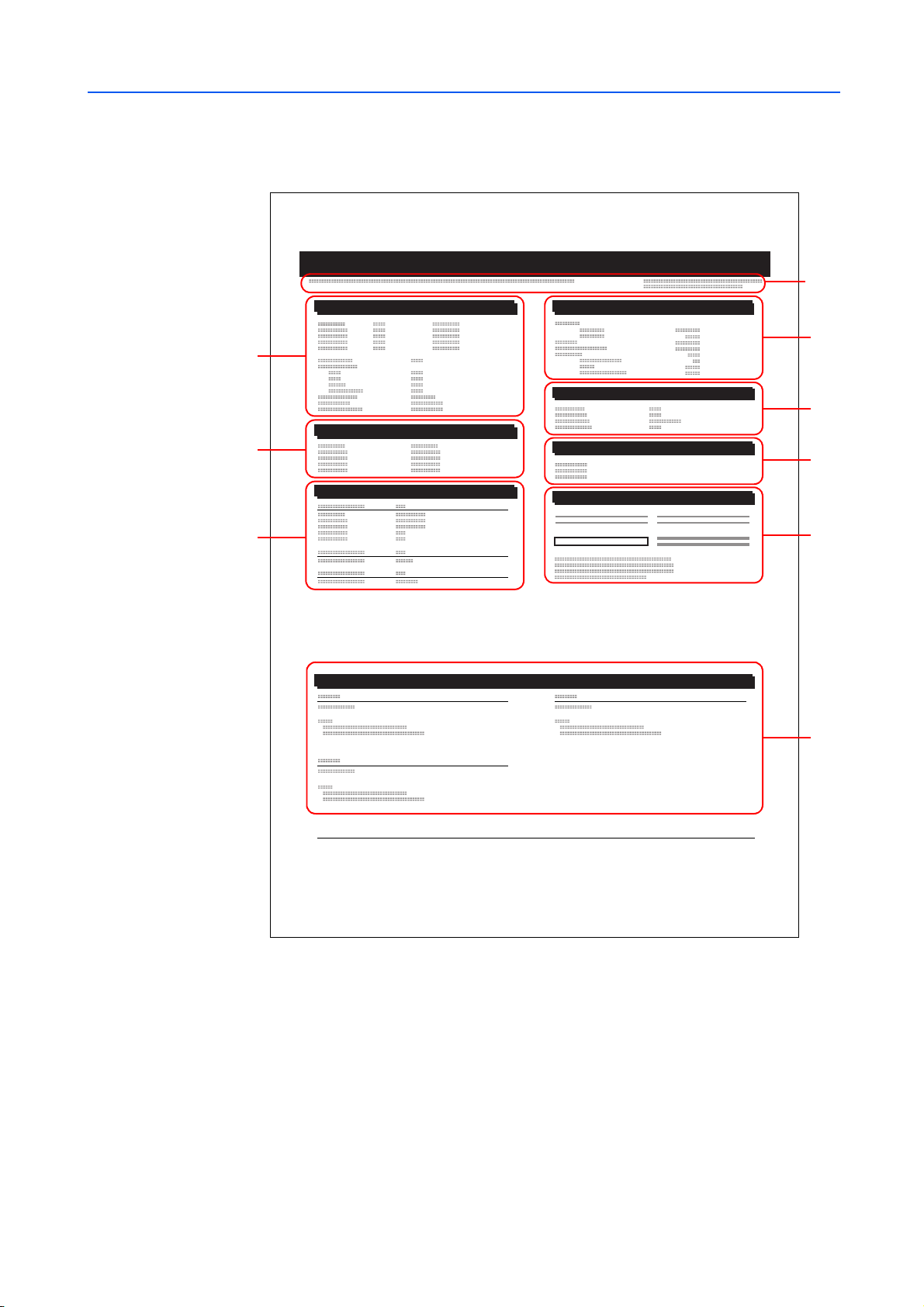

Menu Map Sample

Using the Operation Panel

MENU MAP

2-11

Page 28

Using the Operation Panel

Status Pages

This section explains the procedure for printing the status pages. The status page is a list of

parameters and settings for most basic printer configurations. You may be required to produce a

status page when requesting service to the printer.

Printing a Stat us Page

Y ou can check the printer’s current status, including available memory space and option settings by

printing a status page.

Press [Menu].

1

Press or repeatedly until Print Status Page appears.

2

Press [OK]. A question mark (?) appears.

3

Press [OK] again. The message Processing appears and the printer prints a status page.

4

For a sample status page and its full description, refer to Understanding the Status Page on

page 2-13.

Print

Status Page

Print

Status Page ?

2-12

Page 29

Using the Operation Panel

Understanding the Status Page

The numbers in the following diagram refer the items explained below the diagram. The items and

values on the status page may vary depending on the printer’s firmware version.

STATUS PAGE

Hardware Information

2

Memory

1

3

Installed Options

5

Page Information

4

Network Status

6

Interfaces

Emulation

Consumable Status

7

8

9

Firmware Version

1

This item shows the version and release date of the printer firmware.

2-13

Page 30

Using the Operation Panel

Hardware Information

2

This item shows various printer settings for hardware-related items:

Memory

3

This item shows:

Page Information

4

This item shows the page rel ated items:

• MP tray paper size and type

• Paper cassette size and type

•Duplex mode

• Buzzer cont rol

• Host buffer size

• Sleep time timeout time

• Formfeed timeout time

• Standard memory in the printer

• Option memory slot status in kilobytes

• Total memory in the printer

• Current status of the RAM disk

• Tone mode, Normal or Fine

• Number of copies, from 1 to 999

• Total page count

Installed Options

5

This item shows the options installed in the printer:

• Hard disk

•Option ROM

• Memory card

• HDD Security

Network Status

6

This item shows the IP addres s, subne t mask a ddress, and d efault gate way add ress for the ne twork

interface card in the printer.

Emulation

7

This item shows all available emulations of the printer. The PCL 6 emulation is set as default when

the printer is shipped from the factory. The emulations are:

•PCL 6

•KC-GL

• KPDL3

2-14

Consumable Status

8

This item shows the approximate level of remaining toner. When the value is 100, the toner

container is full. The closer to 0, the smaller the amount of remaining toner.

If you use non-original toner kit, the toner gauge measurement will not be indicated correctly.

Interface Information

9

This information shows the emulation and the default font for all interfaces installed in the printer.

Page 31

e-MPS

Using the Operation Panel

e-MPS is an abbreviation for enhanced-Multiple Printing System which implements the following

functions that are available from the printer driver:

• Job Retention

• Job Stor ag e

In either job mode, when print ing a document, the print dat a is trans ferre d from the c om pute r to the

printer then stored on the printer’s hard disk. Since copies of the document are printed using the

stored data, printing is performed faster with less computer spooling time and less network traffic.

NOTE: To use the e-MPS system, an optional hard disk must be installed in the printer. For details,

refer to Hard Disk on page 3-9.

The RAM disk may als o be use d in the Proof-and-Hold and Private Print modes. Refer to Using the

RAM Disk on page 2-48 for details on RAM disk setup.

Job Retention

Job Retention has four modes as summarized below. These modes are selected from the printer

driver through the application software:

Quick Copy Proof-and-Hold Private Print Stored Job

Primary function To later print additional

copies

Start storing by Printer driver Printer driver Printer driver Printer driver

On terminating print

setting from application

software

Retrieved by Operation panel Operation panel Operation panel Operation panel

Default number of

copies printed at

retrieval

Maximum number of

jobs stored*

PIN security No No Yes Yes (if necessary)

Data after printing Stored Stored Deleted Stored

Data at power off Deleted Deleted Deleted Stored

* Jobs in excess will cause the earlier ones to be delet ed.

Prints simultaneously Prints one copy

Same as storing

(can be changed)

32, expandable to 50 32, expandable to 50 Depends on the hard

To proof the first copy

before printing multiple

copies

simultaneously

One less

(can be changed)

T o hold the document in

printer to prevent

unauthorized access

Does not print Does not print

Same as storing

(can be changed)

disk capacity

To electronically store

documents such a s fax

cover pages

One

(can be changed)

Depends on the hard

disk capacity

Job Storage

Job storage stores print jobs either temporarily or permanently, or in virtual mailboxes, as you click

an appropriate radio button on the printer driver when printing from a computer.

Virtual Mailbox

Virtual mailbox is part of Job Storage, which stores print jobs on the hard disk without printing. It

enables you to retrieve jobs later from the operation panel.

Each mailbox may be used by an individual who desires to share the printer in this mode. By

default, each mailbox is numbered from ‘Tray 001,’ ‘Tray 002,’... etc. To ‘post’ a job in one of these

mailboxes, you assign a numbered or named mailbox on the printer driver when printing.

2-15

Page 32

Using the Operation Panel

To retrieve the stored job for printing, refer to Retrieving Jobs from Virtual Mailbox (VMB) on

page 2-19.

NOTE: The virtual mailbox can be used in PCL 6 emulation only.

Using Quick Copy

This mode enables you to prin t the requested number of copie s of a jo b, s imultaneously storing the

job on the hard disk. When additional copies are required, you can reprint the required number of

copies from the printer operation p an el.

The default number of print jobs that can be stored on the hard disk is 32. This value can be

increased to up to 50 from the e-MPS Configuration menu. For details, refer to Changing the

Maximum Number of Quick Copy/Proof-and-Hold Jobs on page 2-21. When the number of jobs

reaches the limi t, the ol dest job w ill b e over writte n by the new one . When th e printe r is turn ed of f , all

stored jobs will be deleted.

Printing Additional Copies using Quick Copy

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

e-MPS >

Press .

3

Press or repeatedly until >Quick Copy appears followed

4

by the user name (Harold, in this example). The user name is

assigned when printing using the printer driver.

Press [OK]. A blinking question m ark (?) appears before the user

5

name.

Press or to display the desired user name, Arlen, in this

6

example.

Press [OK]. The job name entered in the printer driver (Report,

7

in this example) appear with a blinking question mark (?) before

the letters.

Press or to scroll to the desired job title.

8

Press [OK]. The number of copies to be printed can be set. To

9

increase the copy count, press ; to decrease the copy count,

press .

>Quick Co py

Harold

>Quick Copy

?Harold

>Quick Copy

?Arlen

>Arlen

?Report

>Report

Copies 001

2-16

Press [OK] to finalize the copy count. The printer prints the specified number of copies for the job.

10

Page 33

Deleting a Quick Copy Job

Follow steps 1 through 8 in the above section to display the title of the job to be deleted.

1

When the title of the job to be deleted is displayed, e.g. Report,

2

press [OK]. The cursor below the copy count starts to blink.

Press repeatedly until Delete appears below the title.

3

Press [OK]. The stored quick copy job is deleted.

4

Using Proof-and-Hold

When you print multiple copies, this mode first prints one copy so that you can proof it before

continuing to print the remaining copies. Since you can proof the printouts before printing the

remaining copies, paper waste can be reduced.

The printer prints one copy and, at the same time, saves the print job on the hard disk/RAM disk.

You can also change the number of copies when resuming printing from the operation panel.

Using the Operation Panel

>Report

Copies 001

>Report

Delete

When the printer is turned off, all stored jobs will be deleted.

Printing Remaining Copies of a Proof and Hold Job

Printing a Proof-and-Hold job on the operation panel is similar to printing a quick copy job. Refer to

Printing Additional Copies using Quick Copy on page 2-16.

Printing a Private Print/Stored Job

In private printing, you can specify that a job is not printed until you release the job from the

operation panel. When sending the job from the application software, specify a 4-digit access code

in the printer driver. The job is released for printing by entering the access code on the operation

panel ensuring confidentiality of the print job.

In the stored job mode, access codes are not mandatory, but can be set on the printer driver if

printing with PIN security is requir ed. Then, the access code must be entered on the operat ion panel

to print a stored job. Print data will be stored in the hard disk/RAM disk after printing.

Releasing a Private/Stored Job

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

e-MPS >

Press .

3

Press or repeatedly until >Private/Stored appears. The

4

name entered in the printer driver (Harold, in this example) also

appears.

>Private/Stored

Harold

2-17

Page 34

Using the Operation Panel

Press [OK]. A blinking question m ark (?) appears before the user

5

name.

Press or to display the desired user name (Arlen, in this

6

example).

Press [OK]. The user name and the job name (Agenda, in this

7

example) entered in the printer driver appear with a blinking

question mark (?).

Press or to display the desired job tit le.

8

Press [OK]. The ID input line appears. Enter the four-digit acces s

9

code entered in the printer driver and press [OK].

To enter the ID, press or to move the cursor to the numbe r to

be changed and then enter the correct number by pressing or

.

>Private/Stored

?Harold

>Private/Stored

?Arlen

>Arlen

?Agenda

>Agenda

ID 0000

You can set the number of copies to be printed. To increase the

10

copy count, press ; to decrease the copy count, press .

>Agenda

Copies 001

Press [OK] to finalize the copy count. The printer prints the specified number of copies for the job.

11

Deleting a Private/Stored Job

You can individually delete stored jobs by performing the following procedure. Jobs saved using

Private Print will be automatically deleted if you turn the power off after printing, but jobs saved

using Stored Job will not be deleted automatically.

Follow steps 1 through 8 in the above section.

1

When the title of the job to be pri nted is dis played (Agenda, in this

2

example), press [OK]. Enter the four-digit access code entere d in

the printer driver and press [OK].

Press repeatedly until Delete appears for the number of

3

copies.

Press [OK]. The private job is deleted.

4

>Agenda

Copies 001

>Agenda

Delete

2-18

Printing a Code Job

To print a code job, ensure that the KM-NET for Clients is installed on the computer. The KM-NET

for Clients is provided on the Software Library CD-ROM.

For details, refer to the KM-NET for Clients Operation Guide.

Page 35

Using the Operation Panel

Printing a List of Code Jobs

If you select Permanent Job Storage on the printer driver, you can print a List of Code Jobs using

the operation panel.

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

Press .

3

Press or repeatedly until >Print Code Job List

4

appears.

Press [OK]. A question mark (?) appears.

5

e-MPS >

>Print

Code Job List

>Print

Code Job List?

Press [OK] again. The printer prints a Code Job list as shown below.

6

PERMANENT CODE JOB LIST

Retrieving Jobs from Virtual Mailbox (VMB)

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

e-MPS >

Press .

3

Press or repeatedl y until >Print VMB Data appears. The

4

virtual mailbox number will also appear.

>Print VM B Data

Tray001:

2-19

Page 36

Using the Operation Panel

If you have named the virtual mailbox with an alias, the alias

(Richard, in this example) will follow the number:

>Print VM B Data

Tray001:Richard

Press [OK]. A blinking question mark (?) appears.

5

>Print VM B Data

Tray001?Richard

Press [OK]. The document in the mailbox is printed and automatically deleted from the mailbox.

6

Printing a List of VMB

A Virtual Mailbox list includes the jobs currently stored in the mailboxes.

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

3

Press .

e-MPS >

Press or repeatedly until >List of VMB appears.

4

>Print

VMB List

Press [OK]. A question mark (?) appears.

5

>Print

VMB List ?

Press [OK] again. The printer pri nt s a lis t of jobs currently posted in th e vi rtua l m ail box es as show n

6

in the following illustration.

VIRTUAL MAIL BOX LIST

2-20

Page 37

Changing e-MPS Configuration

You can change the following parameters for e-MPS operation:

• Maximum number of Quick Copy/Proof-and-Hold jobs

• Maximum space assigned to temporary code jobs

• Maximum space assigned to permanent code jobs

• Maximum space assigned to virtual mailboxes

NOTE: The total amount of storage areas specified must not exceed the total size of the hard disk.

Changing the Maximum Number of Quick Copy/Proof-and-Hold Jobs

This changes the m axi mum number of Quic k Copy /Proof-and-Hold jobs f rom 0 t o 50. The default is

32.

Press [Menu].

1

Press or repeatedly until e-MPS > appears.

2

Using the Operation Panel

e-MPS >

Press .

3

Press or repeatedly until >e-MPS Configuration >

4

appears.

>e-MPS >

Configur ation

Press .

5

Press or repeatedly until >>Quick Copy appears.

6

>>Quick Cop y

32

Press [OK]. A blinking cursor (_) appears.

7

>>Quick Cop y

32

Press or to increase or decrease the value at the blinking cursor. The value can be set

8

between 0 and 50. Use and to move the cursor right and left.

When the desired maximum number of jobs is set, press [OK].

9

Press [Menu]. The display returns to Ready.

10

Maximum Space Assigned to Temporary Code Jobs

This changes the hard disk space that holds temporary code jobs. You can change the maximum

space from 0 to 999 9 (m egabytes). The actual m axim um s ize de pen ds on the size of free hard dis k

space. The default size is 1/6 of the total hard disk space, rounded off in units of 50 MB. For

example, if the total hard disk space is 10 GB, the default size is 1550MB.

Press [Menu].

1

2-21

Page 38

Using the Operation Panel

Press or repeatedly until e-MPS > appears.

2

Press .

3

Press or repeatedly until >e-MPS Configuration >

4

appears.

Press .

5

Press or repeatedly until >>Temp. Code JOB Size

6

appears.

To change the maximum disk space, press [OK]. A blinking

7

cursor (_) appears.

e-MPS >

>e-MPS >

Configur ation

>>Temp. Code JOB

Size 1550MB

>>Temp. Code JOB

Size 1550

MB

Press or to increase or decrease, respectively, the value at the blinking cursor. Use and

8

to move the cursor right and left.

When the desired size is displayed, press [OK].

9

Press [Menu]. The display returns to Ready.

10

Maximum Space Assigned to Permanent Code Jobs

This changes the hard disk space that holds permanent code jobs. You can change the maximum

space from 0 to 9 999 (megabytes). The actual maximum size dep ends on the size of free hard disk

space. The default size is 1/6 of the total hard disk spac e, rounded off in units of 50 MB. For

example, if the total hard disk space is 10 GB, the default size is 1550 MB.

Press [Menu].

1

Press or and select e-MPS >.

2

Press .

3

Press or and select >e-MPS Configuration >.

4

e-MPS >

>e-MPS >

Configur ation

2-22

Press .

5

Press or and select >>Perm. Code JOB Size.

6

>>Perm. Code JOB

Size 1550MB

Page 39

Using the Operation Panel

Press [OK], the message display shows a blinking cursor (_).

7

>>Perm. Code JOB

Size 1550

Press or to increase or decrease, respectively, the value at the blinking cursor. Use and

8

to move the cursor right and left.

When the desired size is displayed, press [OK].

9

Press [Menu] and the display returns to Ready.

10

Maximum Space Assigned to Vi rtual Mailboxes (VMB)

This changes the h ard disk s pac e for vi rtual mai lboxe s. You can change the maxim um sp a ce from 0

to 9999 (megabytes). The actual maximum size depends on the size of free hard disk space. The

default size is 1/6 of the tot al hard disk sp ace, roun ded off in un its of 50MB. For example, if the total

hard disk space is 10 GB, the default size is 1550 MB.

Press [Menu].

1

Press or and select e-MPS >.

2

e-MPS >

MB

Press .

3

Press or and select >e-MPS Configuration >.

4

>e-MPS >

Configur ation

Press .

5

Press or and select >>VMB Size.

6

>>VMB Size

1550MB

To change the maximum size, press [OK]. The message display

7

shows a blinking cursor (_).

>>VMB Size

1550

Press or to increase or decrease, respectively, the value at the blinking cursor. Use and

8

to move the cursor right and left.

When the desired size is displayed, press [OK].

9

Press [Menu] to exit the menu selection.

10

MB

2-23

Page 40

Using the Operation Panel

Changing the Interface Parameters

This printer is equipped with a parallel interface, a USB interface and a network interface. An

optional serial interface and a network interface can be installed. Various printing environment

parameters such as the default emulation can be changed independently on different interfaces by

using the printer’s menu selection system. Select the interface to apply the changes in the

procedure described below.

NOTE: This interface selection described below does not select the interface from which data will

be received. The printer automatically selects the interface.

Changing Parallel Interface Mode

The parallel interface supports a bi-directional/high-speed mode according to IEEE standards.

Normally, this interface is used under the default se ttin g Auto. For detai ls, refer to Pa rallel I nterfac e

on page 4-3. After setting the interface, be sure to reset the printer or turn the power off at least

once. The new setting will be enabled thereafter. You can select from the following:

• Auto (default)

•Normal

• High speed

• Nibble (high)

Press [Menu].

1

Press or repeatedly until Interface > appears.

2

If the interface is other than parallel, press [OK]. A blinking

3

question mark (?) appears.

Interface

? Serial

Press or repeatedly until Parallel appears.

4

Interface

? Parallel

Press [OK] again. The question mark disappears.

5

To change the parallel interf ace mode, press . The current communication mode appears.

6

To change the communication mode, press [OK]. A blinking

7

question mark (?) appears.

>Parallel I/F

? Nibble (high)

Press or to scroll through the following communication modes:

8

Auto

Normal

High speed

Nibble (high)

2-24

When the desired communication mode is displayed, press [OK].

9

Press [Menu] to exit the menu selection.

10

Page 41

Changing Serial Interface Parameters

NOTE: This section applies to the printer having the optional serial interface board kit (IB-11)

installed.

You can confirm or change the serial interface parameters including baud rate, data bits, stop bits,

parity, and protocol. These parameters must match those of the computer’s serial interface.

Press [Menu].

1

Press or repeatedly until Interface > appears.

2

If the interface is othe r than serial, press [OK]. A blinkin g question

3

mark (?) appears.

Press or repeatedly until Serial appears.

4

Using the Operation Panel

Interface

? Parallel

Interface

? Serial

Press [OK] again.

5

Press . One of the following serial parameters is indicated (Baud rate for example).

6

Pressing or toggles through the serial parameters as follows. To change the serial parameter,

press [OK]. Use or to change the value or selection.

Range

>Baud Rate

1200, 2400, 4800, 9600 (Default), 19200, 38400, 57600,

115200

9600

>Data Bits

7 or 8 (Default)

8

>Stop Bits

1 (Default) or 2

1

>Parity

None (Default), Odd, Even, or Ignore

None

>Protocol

DTR(pos.)&XON

DTR(pos.)& Xon (Default), DTR(positive),

DTR(negative), XON/XOFF, or ETX/ACK

2-25

Page 42

Using the Operation Panel

For example, to change baud rate from 9600 to 115200, display

the baud rate menu following the above procedure. When the

display shows baud rate, 9600 (bps), press [OK]. A blinking

question mark (?) appears.

Press or to scroll through values. When 115200 is displayed, press [OK]. Press [Menu] to

7

exit the menu selection.

NOTE: Some computers may not be able to handle a baud rate of 115200 bps. If you set the baud

rate to 115200 and encounter communication problems, select a lower baud rate.

Changing Network Interface Parameters

This printer supports TCP/IP, NetWare and AppleTalk protocols. In addition, you can install the

optional network interface card in the option interface slot.

Using the operation panel, you can:

• Activate or deactivate TCP/IP, NetWare, and AppleTalk

• Activate or deactivate DHCP

• Enter IP address, subnet mask address, and default gateway address

• Determine whether to print a network status page when the printer is turned on

>Baud Rate

? 9600

Press [Menu].

1

Press or repeatedly until Interface > appears.

2

If the current interface is other than Network, press [OK]. A

3

blinking question mark (?) appears.

If the optional network interface card is installed in the printer,

Option will be displayed. The setting procedure is basically the

same even in this case.

Press or repeatedly until Network appears.

4

Press [OK] again.

5

Interface >

? Parallel

Interface >

? Network

2-26

Page 43

Using the Operation Panel

Press . One of the follo wing men us is indi cated . To change settings for the item , press [OK]. Use

6

or to change the value or selection.

Set this item to On when you connect to a network using NetWare.

In submenu (>), frame mode can be selected from Auto, 802.3,

Ethernet II, SNAP, and 802.2.

>NetWare >

On

Set this item to On when you connect to a network using TCP/IP.

Submenu (>) has items incl udi ng DHCP, BOOTP, IP address,

subnet mask address, and gateway address. To resolve IP address

for the network card, refer to Resolving IP Address on page 2-27.

AppleTalk must be activated (On) for networking with Macintosh

computers.

When the item is set to On, the printer prints out a network status

page when it prints the printer status. refer to Printing a Network

Interface Status Page on page 2-28.

Activate the appropriat e prot oc ol th at is requ ired to connect the printer to the network . To activate a

7

protocol, display the protocol, press [OK], pres s or to ch ange from Off to On, and press [OK].

Press [Menu]. The di splay retu rns to Ready. You can print a network status page to confirm that the

8

IP address, subnet mask address, and the gateway address have been properly set. To print a

network status page, refer to Printing a Network Interface Status Page on page 2-28.

Resolving IP Address

To connect the printer to the network using TCP/IP protocol, you must set the IP address on the

printer. The IP address must be unique to the printer and should be obtained from your network

administrator.

>TCP/IP >

On

>AppleTalk

Off

>Network Status

Page Off

Activate TCP/IP protocol in the manner described above.

1

>TCP/IP >

On

2-27

Page 44

Using the Operation Panel

Enter the submenu by pressing . Each time you press or ,

2

the selection change s.

>>DHCP

On

>>BOOTP

On

>>IP Address

000.000.000.000

>>Subnet Ma sk

000.000.000.000

>>Gateway

000.000.000.000

When >>IP Address is di splay ed, pres s [OK]. A blink ing cu rsor

3

(_) appears at the last digit.

Press or to increase or decrease, respectively, the value at the blinking cursor. Use and

4

to move the cursor right and left.

When the IP address is entered, press [OK].

5

Press or to move to Subnet Mask. Perform the same procedure to complete entering the

6

subnet mask address.

Then, press or to move to Gateway. Perform the same procedure to complete entering the

7

gateway address.

Press [Menu]. The display returns to Ready. You can print a network status page to confirm tha t the

8

IP address, subnet mask address, and the gateway address have been properly set. To print a

network status page, refer to Printing a Network Interface Status Page on page 2-28.

Printing a Network Interface Status Page

You can have your printer print out a network status page when the printer prints the status page.

The network status page shows the network addresse s, and oth er inform at ion under various

network protocols about the netw o rk inte rfac e card . The defa ult se tting is Off (print disable).

>>IP Address

000.000.000.000

2-28

NOTE: Printing out a network interface status page may not be possible with the optional network

interface card. For details, refer to the manual for the network interface.

Press [Menu].

1

Press or repeatedly until Interface > appears.

2

Page 45

If the current interface is other than Network, press [OK]. A

3

blinking question mark (?) appears.

Press or repeatedly until Network appears. Press [OK].

4

Press and then press or repeatedly until the display

5

shows >Network Status Page.

Press [OK]. A blinking question mark (?) appears.

6

Press or to select On.

7

Using the Operation Panel

Interface

? Parallel

Interface

? Network

>Network St atus

Page O ff

>Network Status

Page ? Of f

>Network Status

Page ? On

Press [OK] again.

8

Press [Menu]. The display returns to Ready.

9

NETWORK STATUS PAGE

2-29

Page 46

Using the Operation Panel

Making Default Settings

Using the operation panel, you can set the default for the following items.

Default Emulation

You can change the emulation mode and character code set for the current interface.

The printer can autom atic al ly cha nge the e mu lati on mod e ac co rding to the print job that is recei ve d

from the computer. To do this, select KPDL (AUTO) in the following procedure.

Press [Menu].

1

Press or repeatedly until Emulation > appears on the message display. One of the

2

emulation modes appears, indicating the emulation currently in use.

PCL 6 (default)

KC-GL

KPDL

KPDL (AUTO)

To change the de fault emulation, press [OK]. A blinking question

mark (?) appears.

Emulation

?PCL 6

Press or repeatedly until the desired emulation mode is displayed.

3

Press [OK].

4

Press [Menu]. The display returns to Ready.

5

Alternative Emulation for KPDL Emulation

KPDL is Kyocera’s implementation of the PostScript language. The KPDL (AUTO) emulation

enables the printer to automatically change the emulation mode according to the data received

when printing.

In addition to KPDL (AUTO) emulation, you can use the operation panel to set another emulation

mode that is used very often. The default setting is PCL 6.

Press [Menu].

1

Press or repeatedly until Emulation > appears.

2

Press [OK]. A blinking question mark (?) appears.

3

Press or repeatedly until KPDL (AUTO) appears.

4

Emulation

?PCL 6

Emulation

?KPDL (AUTO)

2-30

Press [OK].

5

Press . When >Alt. Emulation is displayed, press or . The names of alternative

6

emulations appear — PCL 6 or KC-GL.

Page 47

Press [OK]. A blinking question mark (?) appears.

7

Press or repeatedly until the desired alternative emulation appears.

8

Press [OK].

9

Press [Menu]. The message display returns to Ready.

10

Printing KPDL Errors

The printer can print error descriptions when printing error occurs during KPDL emulation. The

default is Off — the printer does not print KPDL errors.

Press [Menu].

1

Press or repeatedly until Emulation > appears.

2

Press [OK]. A blinking question mark (?) appears.

3

Using the Operation Panel

>Alt. Emulation

? PCL 6

Emulation

?PCL 6

Select KPDL or KPDL (AUTO) using or .

4

Press [OK].

5

Press . Press or until >Print KPDL Errs (errors)

6

appears.

Press [OK]. A blinking question mark (?) appears.

7

Select On using or . Press [OK].

8

Press [Menu]. The display returns to Ready.

9

KC-GL Pen Width and Color

The KC-GL emulation mod e enables you to set the pe n w idths in dots, indi vidual pen colors for p en

numbers 1 to 8, and the KC-GL page size.

Emulation

?KPDL

>Print KP DL Errs

Off

>Print KP DL Errs

? Off

Press [Menu].

1

Press or repeatedly until Emulation > appears.

2

If the current emulation is other than KC-GL, press [OK]. A blinking question mark (?) appears.

3

2-31

Page 48

Using the Operation Panel

Select KC-GL using or .

4

Press [OK].

5

Press . To change th e pen wi dth and /or pen co lor , press [OK]. A

6

blinking question mark (?) appears.

Press or repeatedly until the desired pen number of 1 to 8 appears.

7

Press [OK].

8

To change the pe n width, press , then press [OK]. A blinking

9

cursor appears at the width value.

Press or repeatedly until the desired pen width in dots (00 to 99) appears.

10

Emulation

?KC-GL

>KC-GL Pen

Adjust ? Pen ( 1)

>>Pen(1) Wi dth

02

dot(s)

Press [OK].

11

To set the pen color, press or .

12

Press [OK]. A blinking question mark (?) appears.

13

>>Pen(1) Co lor

? Black

Press or repeatedly until the desired pen color (Black, Red, Green, Yellow, Blue,

14

Magenta, Cyan, White) appears.

Press [OK].

15

To set the KC-GL page size, press , then press or until >KC-GL Page set appears.

16

Press [OK]. A blinking question mark (?) appears.

17

>KC-GL Pa ge Set

? [A2]

Press or repeatedly until the desired page size (A2, A1, A0, B3, B2, B1, B0, and SPSZ)

18

appears. When selecting SPSZ, printing will be done with the paper size specified by the

PRESCRIBE SPSZ command.

Press [OK].

19

2-32

Press [Menu]. The display returns to Ready.

20

Page 49

Default Font

Using the Operation Panel

You can select the default font for the current interface. The default font can be one of the internal

fonts or a font that is downloaded to the printer memory or stored in a memory card, hard disk or

option ROM.

In this menu, you can also set the type and pitch for Courier and Letter Gothic; as well as to print a

font list.

Press [Menu].

1

Press or repeatedly until Font > appears.

2

Font >

Press . Press or until >Font Select > appears.

3

>Font Select >

Internal

To select an internal font, make sure that Internal is displayed

4

and press . The display chan ges. If Internal is not disp layed ,

press [OK], then press or until it appears.

>> I000

To select an optional font, press [OK] while >Font Select > is

displayed. Press or repeatedly until Option appears and

then press [OK]. Press next to display the font selection shown above. You can perform this

operation only when optional fonts are installed in the printer.

The letter before the number indicates the location of the font, as shown below:

I Internal font

S Soft (downloaded) font

M Fonts in optional memory card

H Fonts in RAM disk or optional hard disk

O Fonts in optional ROM (API)

Press [OK]. A blinking question mark (?) appears.

5

>>?I000

Press or repeatedly until the desired font number appears. For font numbers of the internal

6

fonts, refer to Printing Lists of Fonts on page 2-36.

When the desired font is displayed, press [OK].

7

Press [Menu]. The display returns to Ready.

8

Selecting Regular or Dark Courier/Letter Gothic

Courier or Letter Gothic font thickness can be selected as Regular or Dark. In the procedure

below, it is assumed that Courier is selected. The procedure is the same for Letter Gothic.

Press [Menu].

1

Press or repeatedly until Font > appears.

2

Font >

2-33

Page 50

Using the Operation Panel

Press . Press or until >Font Select > appears.

3

Make sure that Internal is displayed and press .

4

Press or repeatedly until >>Courier appears. If you are

5

selecting the thickness of the Letter Gothic font, choose >>

Letter Gothic here instead.

Press [OK]. A blinking question mark (?) appears.

6

Select Regular or Dark using or .

7

Press [OK].

8

Press [Menu]. The display returns to Ready.

9

>Font Select >

Internal

>>Courier

Regular

>>Courier

? Regular

Changing the Default Font Size

You can change the size of the default font. If you selected a proportional font, the character size

can also be changed.

Press [Menu].

1

Press or repeatedly until Font > appears.

2

Press . Press or until >Font Select > appears.

3

Make sure that Internal is displayed and press .

4

Press or repeatedly until >>Size appears.

5

Press [OK]. A blinking cursor (_) appears.

6

Font >

>Font Select >

Internal

>>Size

012.00 point(s)

>>Size

012.00

point(s)

2-34

Press or to increase or decrease the value at the blinking cursor. The font size can be set

7

between 4 and 999.75 points, in 0.25-point increments. Use or to move the cursor right and

left.

When the desired size is displayed, press [OK].

8

Press [Menu]. The display returns to Ready.

9

Page 51

Using the Operation Panel

Character Pitch for Courier/Letter Gothic