Triumph TR6 1976 Handbook

RIU

TRIUMPH TR6

HANDBOOK

i

'

I

i

l

ROVER

ROVER TRIUMPH SERVICE

Coventry CV4 9DB

England

JAGUAR and ROVER TRIUMPH Parts and Accessories

P.O. Box 150, Coventry CV4 9DB

England

BRITISH LEYLAND MOTORS INC.

600 Willow Tree Road

Leo~ia, N.J. 07605

BRITISH LEYLAND MOTORS CANADA LTD.

P.O. Box 5033, 4445 Fairview Street

Burlington

Ontario L7R 4A3

Canada

TRIUMPH

SALES

or

Publication Part No. 545111176

TRIUMPH TR6

Introduction

Dmmm

your TR6 embodies inany new safety features, the very presence of which will

Read carefully the contents of tlk book ivl~ich gives, ill the simplest

possible terms, information vital

The TR6 complies

and State Regulations concerning Safety, Engine Crankcase Emission and

of

Because

these regulations, owners ure strongly urged to read the Emission

Control System, Maintenance and Wurlmlty i~lformation in this handbook.

AND

BUILT

to give long and co~lsistent trouble-jke service,

add to your conjidence.

!o the proper operation, care and regular

maintenance of the car.

with, and in many cases exceeds, all current Federal

Fuel Evaporative Control.

The operations carried out by your Dealer will be in accordance

with the current recommendations and may be subject to

r'ei'ision from time to time.

These publications should be passed to each subsequent owner of

the vehicle and the Servicing

vehicle is kept within the Federal limits in respect of the

Details completed to ensure that the

Clean Air Act.

LOCATION OF VEHICLE IDENTIFICATION (V.I.N.)

I

NUMBER

Note.

L.H.

and

R.H.

Important

In all communications relating

to Service or Parts please

quote the V.I.N. Number

Paint and Trim Numbers

The information contained herein applies to a range of vehicles and not to a specific vehicle. For the specification of a particular vehicle, an Owner

should consult his Dealer.

The manufacturers reserve the right to vary their specifications with or without notice, and at such times and in such manner as they think fit. Major

as wellas minor changes may be involved in accordance with the Manufacturer's policy of constant product improvement.

Whilst every efforl is oade to ensure the accuracy of the particulars contained

this handbook is supplied, shall in any circumstances be held ],able for any inaccuracy or the co&equences thereof.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted. in any form electronic mechanical

photocopying, recording or other means without prior written permission from the Service Division

(U.K.) Ltd Coventry, England.

Replacement parts are not supplied from the factory direct to the general ~ublic, but are directed through Distributors who, in turn, supply their

Dealers.

Genuinespare parts are marketed under the trade mark "Unipart" and carry the same guarantee period as the original part. The same high quality

material is used and the strictest accuracy maintained during manufacture. You are advised, therefore, to ins~st on the use of these parts should

replacements be necessary. Remember, parts which do not carry the trade mark "Unipart" will invalidate the guarantee if fitted to your vehicle.

The descriptions and illustrations appearing in this book are not binding.

retaining the basic features of the Models herein described and illustrated

up-to-date, any alteration to units. parts or accessories deemed convenient for improvement or for any manufacturing or commercial reason.

I

side of the vehicle viewed from the driving position.

V.I.N., Paint and Trim Numbers-On rear door pillar

(may be seen by opening driver's door). Also on

visible through the windscreen on the left hand windscreen

~illar.

Engine Number-On

Gearbox Number-On L.H. side of Housing

I

-

Rear Axle Number-On Hypoid Housing Flange

I

in

this Handbook neither the Manufacturer nor the Dealer, by whom

UNIPART

Parts Service

The MANUFACTURER therefore, reserves the right

-

to make at any time, hhout necessarily brin@ng this book

refer to Left-hand and Right-hand

L.H.

side of Cylinder Block

of

Rover Triumph 'Motors ~riish Leyland

-

a

whilst

tag

Page

List

Sect ions

Introduction

Location of unit numbers

Controls. Instruments and Indicators

Safety Harness

Seats

Locks and Keys

Soft Top

Hwd

Top .

Care of Bodywork

Wheel

Cooling System

Electrical System

Driving Recommendations

Routine Servicing

Emission and Control Evaporative System .

Periodic Checks

Regular Maintenance

Lubrication Specification . .

Windshield Wipers

General Specification

.

. . . . . . .

.

. .

.. . . . . .

. .

. . .

.

. . . . .

. . .

and Tires . .

. .

. .

.

. .

. .

.

.

.

.

. . .

.

.

.

. . .

. . .

. .

.

.

.

.

.

. .

. .

.

.

. . . .

. . .

.

. .

.

. .

. . .

.

.

.

.

.

.

. . .

. . . .

.

.

.

.

.

. . . . . . .

. . .

.

.

.

. .

..

.

. . .

.

.

.

.

.

.

.

. . . .

. . .

.

.

.

. .

.

. . . . . 28

.

.

. . .

.

. . .

.

. . .

.

.

.

. .

.

.

.

.

. .

.

. .

.

. . .

.

. . .

. .

. . .

..

..

.

.

.

. . 16

.

. 18

.

.

.

.

.

. . 25

.

.

.

.

.

.

. 66

. . . 67

.

.

.

.

.

.

3

4

6

14

15

20

21

22

37

39

40

49

51

68

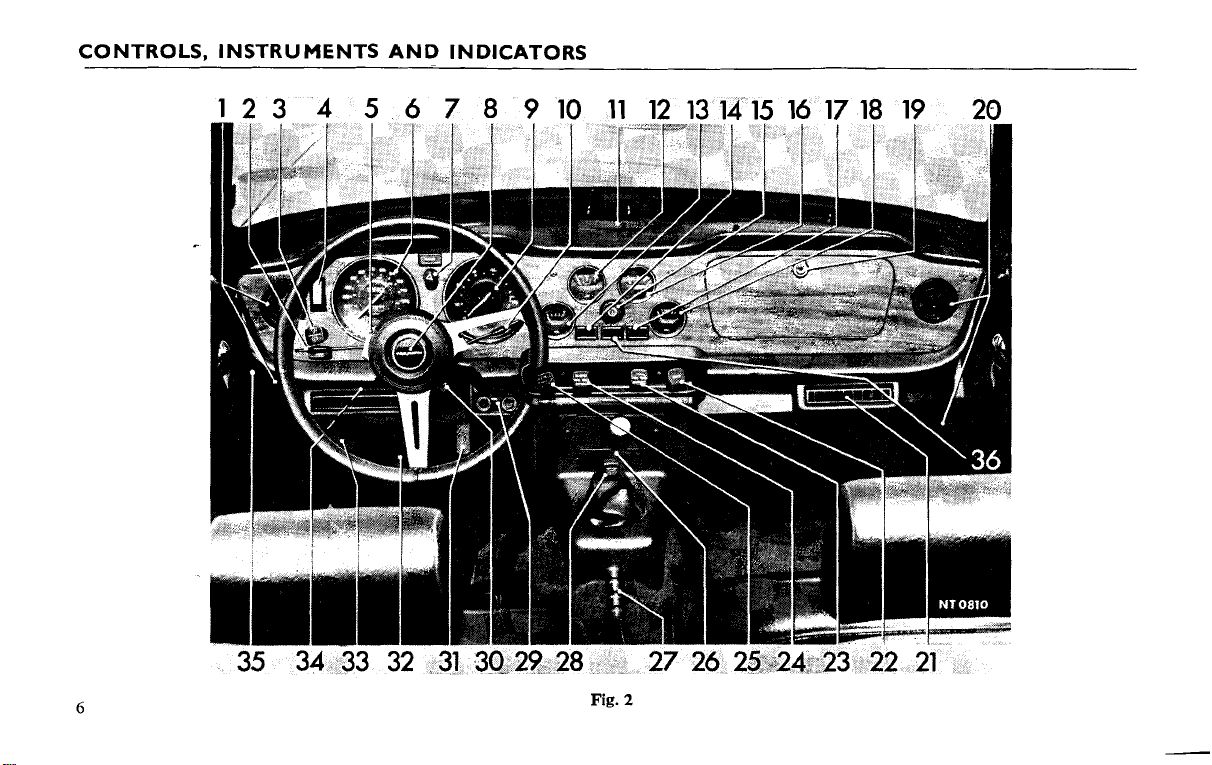

CONTROLS, INSTRUMENTS AND INDICATORS

3

32

Fig.

2

CONTROLS, INSTRUMENTS AND INDICATORS

KEY

Fresh-air vents

Turn-signal control

Windshield wiper washer switch 17. Seat belt warning indicator

Lighting switch

Overdrive switch (optional)

Speedometer

Hazard warning switch and indicator

Horn-push

Tachometer

Headlight dipper switch

Ashtray

Oil pressure gauge

Temperature gauge

Brake-line failure/handbrake warn-

ing indicator

15.

Instrument illumination rheostat

16.

Fuel gauge

Voltmeter

Glove-box lock

Fresh-air vents

Air conditioning (optional) outlets

Choke control

Heat control

Blower switch

Air distribution control

Gear shift lever

Hand-brake lever

Interior light switch

TO

FIG.

2

Air conditioning (optional) control

panel

Ignitionlsteering column lock

Throttle pedal

Brake pedal

Clutch pedal

Trip reset control

Hood release control

E.G.R. service indicator

High-beam indicator

Turn-signal indicator

Oil pressure warning light

Ignition warning light

Odometer

Trip odometer

to

Fig.

5

CONTROLS, INSTRUMENTS AND INDICATORS

CONTROLS, INSTRUMENTS AND INDICATORS

The controls, instruments and indicators shown on Figs. 2 and 6 and described in the following pages are positioned within easy

reach of the driver to afford maximum ease of operation and minimum distraction. The bracketed figures in the text cross-refer with

the key on page

7.

Fresh-Air Vents (1)

The swivelling vents can be adjusted to admit cold air only

in

any chosen direction within the limits of movement. Each vent

incorporates a valve, operated by a knob in the center of the

vent. To diminish or shut off the supply of air, turn the knob

clockwise. The air flow may be boosted by use of the blower

motor (See item 24).

Turn

Signal Control

Move the control lever upwards to operate the right-hand

turn-signal lights or downwards to operate the left-hand turnsignal lights.

Windshield Wiper/Washer Switch

Depress the switch to spray clean fluid onto the windshield and

release the switch when sufficient fluid has been dispensed.

Turn the switch clockwise to operate the wipers at slow speed

and turn the switch clockwise again to operate the wipers at high

speed. Turn the switch fully anticlockwise to switch the wipers

off, when they will automatically return to the parked position

at the base of the windshield.

See

(2)

(38)

Page 1

3.

The wipers and washer will only operate when the ignition

switch is turned 'ON'.

Lighting Switch (4)

Depress the lower portion of the switch to the first position

to illuminate the tail, license plate, parking lights and side

marker lights.

Depress the switch again to the second position to illuminate

the headlights. (See "Headlight Dipper", 10).

(5)

Overdrive Switch

When an overdrive unit is fitted to the vehicle the operating

switch is mounted on the left-hand side of the steering column.

Move the lever up to engage the overdrive and down to release

it. Before using the control, refer to page

Speedometer (6)

Additional to indicating the road speed of the vehicle in

miles

and kilometres per hour, the instrument also combines the

turn signal and high beam warning lights and the total and trip

odometers.

(Optional)

38.

CONTROLS, INSTRUMENTS AND INDICATORS

i

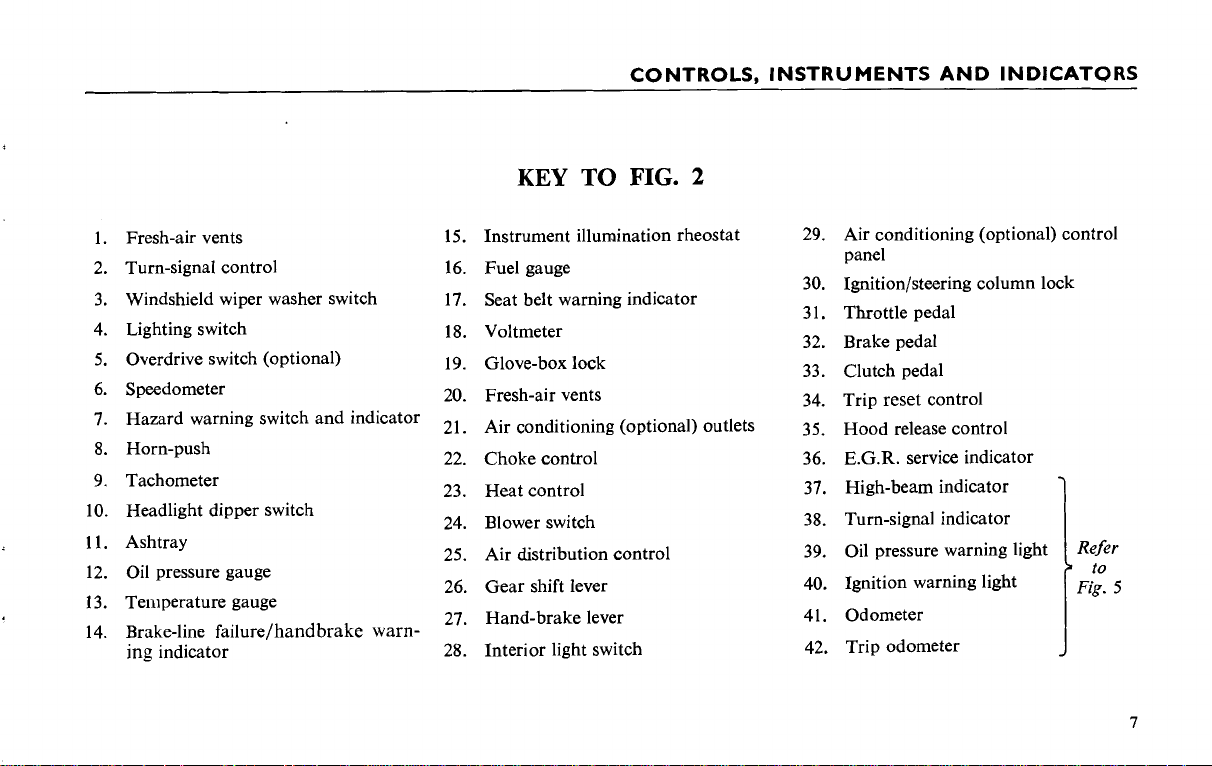

Hazard Warning Switch and Indicator (7)

If the vehicle is immobilised and constitutes a hazard to other

vehicles, warning may be given by using the "hazard warning

system". To operate, pull the switch (7) when all turn-signal

lights will flash intermittently.

When the hazard switch is operated, a bulb in the switch will

flash in unison with the exterior warning lamps.

Horn Push (8)

Press to operate the horns.

Oil Pressure Gauge (12)

Oil pressure at 2,000

tions, should

such

as

be

competition work, may cause the oil pressure to drop

45-65 Ibs./sq. in. Severe operating conditions,

r.p.m. under normal operating condi-

below 25 lb./sq. in., indicating that the oil temperature is

excessive. Under these circumstances fitment of an oil cooler may

be

necessary.

Temperature Gauge

(1

3)

When the ignition switch is turned 'ON' the pointer moves

slowly across the dial taking up to one minute to reach a true

Tachometer

The tachometer indicates the engine speed in revolutions per

minute and combines two warning indicators (39,40. See Fig. 5).

The speed range within the colored segments is subject to the

"Recommended Speed Limits" mentioned on page 38.

Headlight Dipper Switch (10)

When the headlights are illuminated (see 'Lighting Switch' on

page

To return to the high beam position, move the lever up.

The high beam position is indicated by a blue warning light

(37) near the bottom of the speedometer dial.

Lifting the lever towards the steering wheel flashes the headlight high beams.

(9)

S),

the high beams may be lowered by moving the lever down.

reading.

Normal operating temperature is reached when the pointer

registers in the central sector of the dial. Should the pointer reach

the highest mark, stop the engine immediately and check the

level of coolant

the radiator. Refer to page

49.

in

Brake-line Failure/Handbrake Warning Indicator (14)

When the ignition switch is turned on the "brake line failure"

and "low oil pressure" indicator lights glow faintly and are

extinguished when the engine is running. Should failure of the

front or rear brake lines occur, the indicator (14) will glow

brightly.

A

broken bulb filament is indicated by the warning light

failing to glow when the ignition is turned on, before starting the

engine.

(1

Ashtray

1)

An ashtray is provided

in

the center of the facia top. To

empty, lift the assembly from the surround.

The warning light will also glow brightly, as a reminder to

the driver, when the handbrake is applied, provided that the

ignition switch is "ON".

9

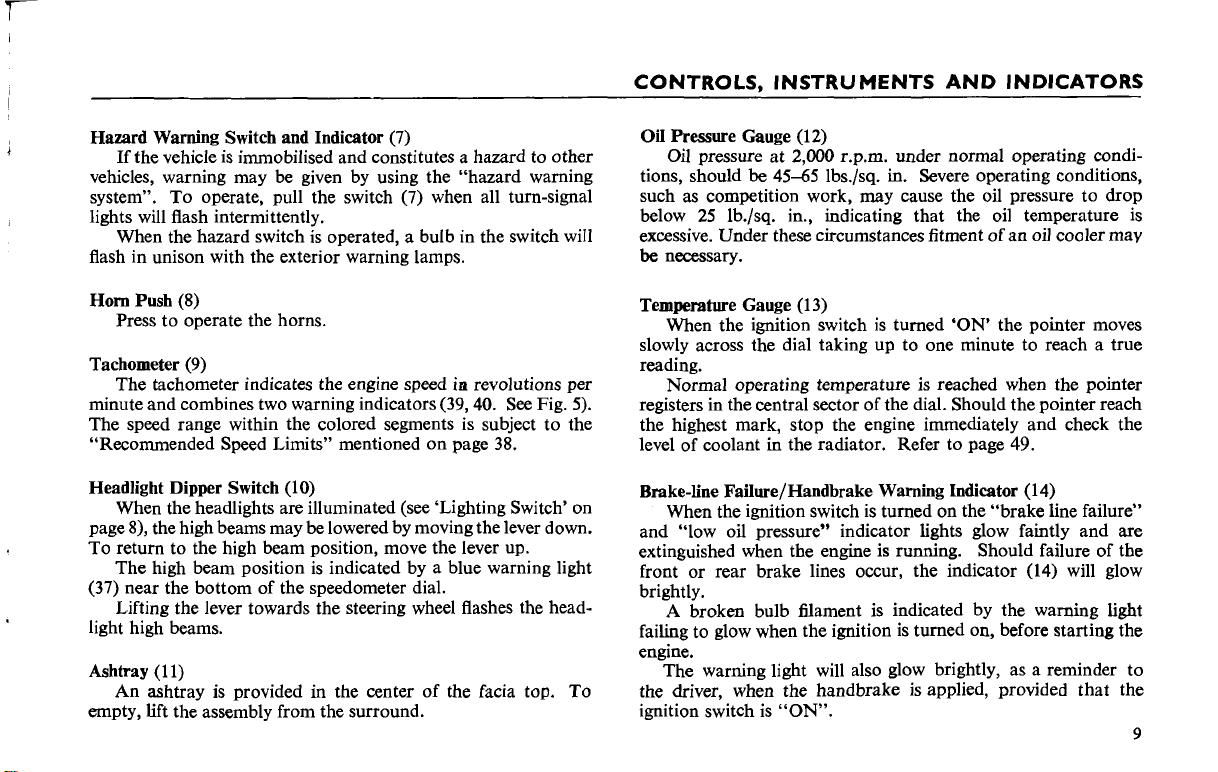

CONTROLS, INSTRUMENTS AND INDICATORS

Instrument Illumination Rheostat

Turn the knob clockwise to illuminate the instruments.

Further rotation of the knob diminishes the light intensityoperates only when the lighting switch is

Fuel Gauge

The fuel gauge indicates the approximate contents of the

fuel tdnk. When the ignition switch is turned

moves slowly across the dial taking up to one minute to reach a

steady reading which it will maintain regardless of vehicle movement, until the ignition is switched

(1

6)

Seat Belt Warning Indicator

A lamp and an audible warning system are actuated if an

attempt is made to start the car without the seat belts in use.

For full details of the system and correct starting sequence see

page 37-'Driving the Car'.

Voltmeter

battery's state of charge. With the engine running above idling

speed the indicator should register approximately 14 volts.

reading above 15 volts, which continues after

is too high and should be investigated. A reading of 13 to 13-5

volts is too low unless the headlamps and other electrical equipment are in use.

Glove Box Lock

turn clockwise and opened by depressing the locking barrel.

Fresh Air Vents

(1 8)

This gauge is a battery condition indicator and registers the

(1

The glove box may be unlocked by turning the key a quarter

See (1) page 8.

9)

(20)

(17)

(1 5)

'OFF'.

'ON'.

'ON'

10

minutes running,

the pointer

A

Air Conditioning Outlet

This is an optional item and reference should be made to

the manufacturer's literature when it is fitted.

(21)

Use of the Choke Control

Under cold ambient temperatures

Pull the choke control out fully tostart the engine. As soonas

the engine starts push the choke control in until the engine maintains an idling speed of approximately

control should

maintain normal running without its use.

Under warm ambient temperatures

Use full choke to fire engine, return to fast idle position when

engine fires, where definite notch will be felt on the cable pull.

After approximately one minute of engine running return the

control knob to the fully in position.

Heat Control

The heat control operates a water valve which regulates the

flow of water through the heater unit. The control may

any intermediate position as required. The water valve is closed

when the control is pushed in; maximum heat is available when

the control is pulled out.

Blower Switch

The blower motor boosts the flow of air through the heater

unit. Pull the switch to its first position to operate the blower

motor at slow speed or to its second position for high speed

operation. The blower will operate only when the ignition switch

is turned

(23)

'ON'.

be

pushed in fully as soon as the engine will

(24)

1100 r.p.m.

The choke

be

set at

CONTROLS, INSTRUMENTS AND INDICATORS

Air

Distribution

i

The air distribution control operates a 'flap' valve which

directs air from the heater unit to the windshield or to the

windshield and interior. The maximum volume of air is

directed to the windshield (for demisting and

when the control is pulled halfway out. When the control is

pulled fully out, air is distributed to the interior and to the windshield. The 'flap' valve is closed when the control is pushed fully in.

Gear

Shift

Moving the gear shift lever from neutral, the gear positions

are as follows

1st

2nd

3rd

4th (top)

Reverse

Always select neutral before starting the engine.

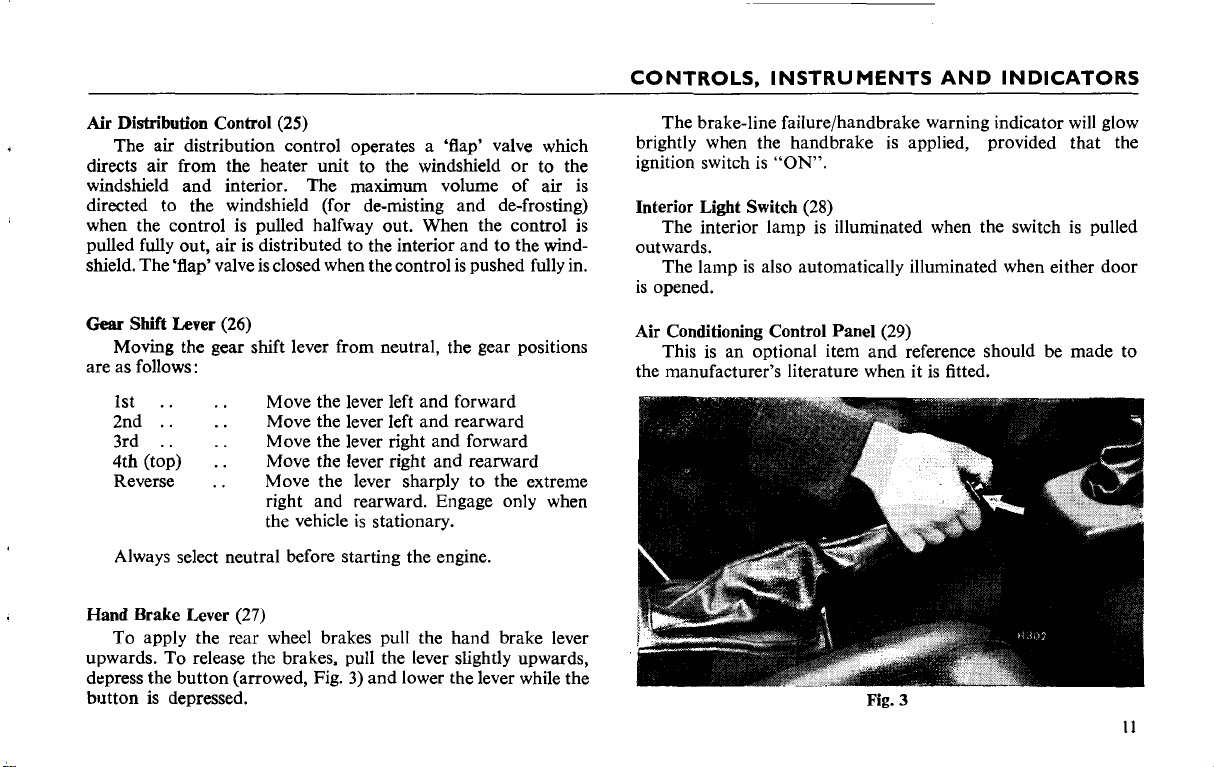

Hand Brake Lever

To apply the rear wheel brakes pull the hand brake lever

upwards. To release the brakes, pull the lever slightly upwards,

depress the button (arrowed, Fig. 3) and lower the lever while the

button is depressed.

Lever

.

. .

.

.

. .

Control (25)

(26)

:

.

.

.

. .

.

.

.

.

(27)

de-frosting)

Move the lever left and forward

Move the lever left and rearward

Move the lever right and forward

Move the lever right and rearward

Move the lever sharply to the extreme

right and rearward. Engage only when

the vehicle is stationary.

The brake-line failurelhandbrake warning indicator will glow

brightly when the handbrake is applied, provided that the

ignition switch is

Interior Light Switch (28)

The interior lamp is illuminated when the switch is pulled

outwards.

The lamp is also automatically illuminated when either door

is opened.

Air Conditioning Control Panel (29)

This is an optional item and reference should be made to

the manufacturer's literature when it is fitted.

"ON".

Fig.

3

11

CONTROLS, INSTRUMENTS AND INDICATORS

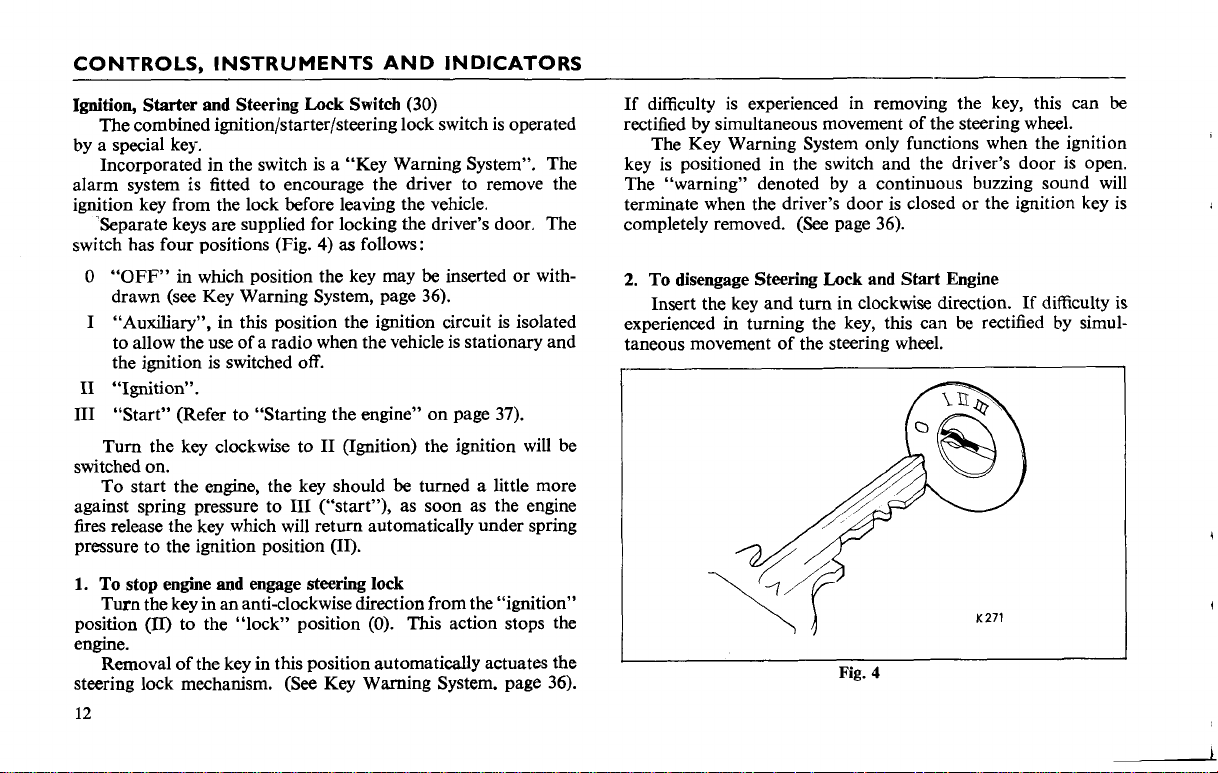

Ignition, Starter and Steering Lock Switch (30)

The combined

ignitionlstarterlsteering

lock switch is operated

by a special key.

Incorporated in the switch is a "Key Warning System". The

alarm system is fitted to encourage the driver to remove the

ignition key from the lock before leaving the vehicle.

-Separate keys are supplied for locking the driver's door. The

4)

as

switch has four positions (Fig.

0

"OFF"

in which position the key may be inserted or with-

follows:

drawn (see Key Warning System, page 36).

I "Auxiliary", in this position the ignition circuit is isolated

to allow the use of a radio when the vehicle is stationary and

the ignition is switched off.

I1

"Ignition".

I11 "Start" (Refer to "Starting the engine" on page 37).

Turn the key clockwise to

I1 (Ignition) the ignition will be

switched on.

To start the

engine,

against spring pressure to

the key should be turned a little more

I11

("start"), as soon as the engine

fires release the key which will return automatically under spring

pressure to the ignition position (II).

1.

To stop engine and engage steering lock

Turn the key in an anti-clockwise direction from the "ignition"

(II)

position

to the "lock" position (0). This action stops the

engine.

Removal of the key in this position automatically actuates the

steering lock mechanism. (See Key Warning System. page 36).

If difficulty is experienced in removing the key, this can

rectified by simultaneous movement of the steering wheel.

The Key Warning System only functions when the ignition

key is positioned in the switch and the driver's door is open.

The "warning" denoted by a continuous buzzing sound will

terminate when the driver's door is closed or the ignition key is

(See

completely removed.

2.

To disengage Steering Lock and Start Engine

page 36).

Insert the key and turn in clockwise direction. If difficulty

experienced in turning the key, this can be rectified by simultaneous movement of the steering wheel.

I

Fig.

4

be

is

I

CONTROLS, INSTRUMENTS AND INDICATORS

t

These are conventional items which should require no further

explanation.

Trip Reset Control

The trip odometer

'Ihroffle, Brake

(34)

knob

Hood Release Control

To open the hood, pull the control knob located below

the parcel shelf at the left hand side of the car. This disengages

the locking plate and allows the hood to rise sufficiently for

the safety catch to be released using the fingers.

and

Clutch Pedals

(34)

(42)

may

(31, 32

and

be

reset to zero by pushing the

upwards and turning anticlockwise.

(3 5)

33)

See page

17.

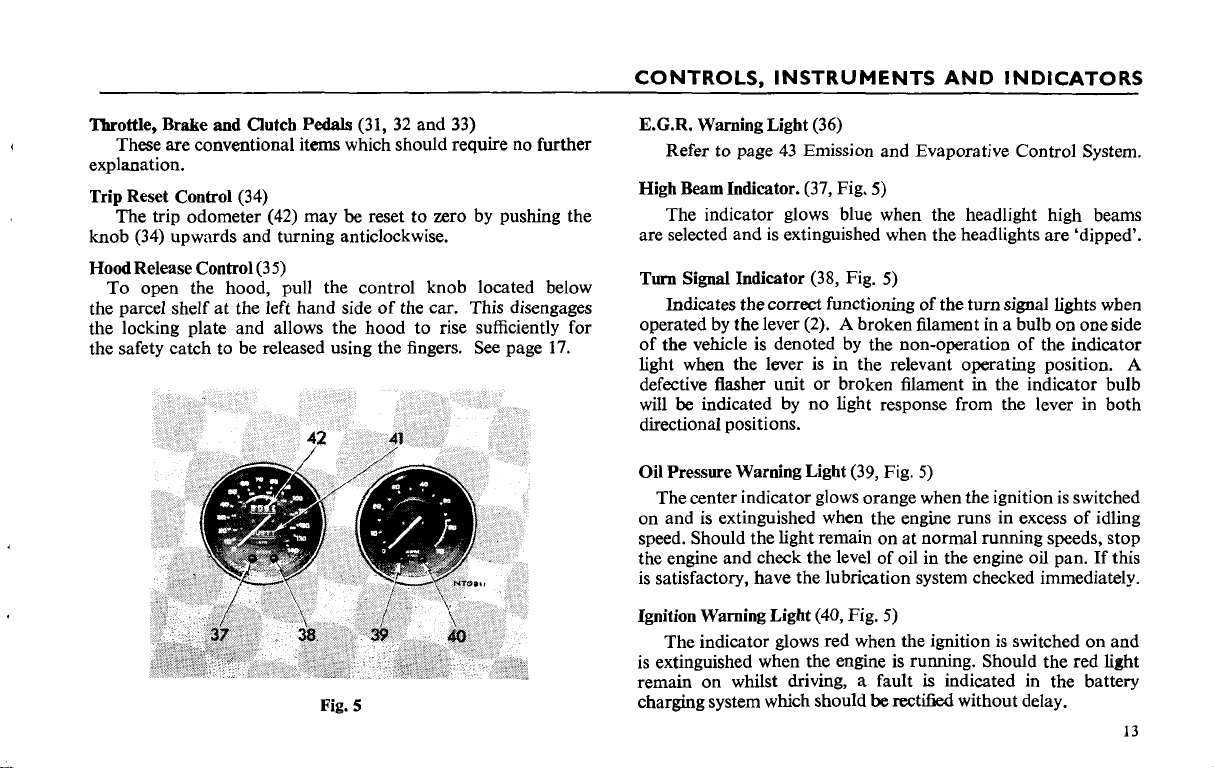

E.C.R. Warning Light

Refer to page

High Beam Indicator.

(36)

43

Emission and Evaporative Control System.

(37,

Fig,

5)

The indicator glows blue when the headlight high beams

are selected and is extinguished when the headlights are 'dipped'.

(38,

Fig.

Turn Signal Indicator

Indicates the

correct

operated by the lever

(2).

5)

functioning of the turn signal lights when

A

broken lilament in a bulb on one side

of the vehicle is denoted by the non-operation of the indicator

in

light when the lever is

the relevant operating position.

A

defective flasher unit or broken filament in the indicator bulb

will

be

indicated by no light response from the lever in both

directional positions.

Oil Pressure Warning Light

(39,

Fig.

5)

The center indicator glows orange when the ignition is switched

on and is extinguished when the engine runs in excess of idling

speed. Should the light remain on at normal running speeds, stop

the engine and check the level of oil in the engine oil pan. If this

is satisfactory, have the lubrication system checked immediately.

(40,

Fig.

Ignition Warning Light

5)

The indicator glows red when the ignition is switched on and

is extinguished when the engine is running. Should the red light

a

fault

is

indicated in the battery

rectified without delay.

Fig.

remain on whilst driving,

5

charging system which should

be

CONTROLS, INSTRUMENTS AND INDICATORS

Odometer (41, Fig.

The figures within the aperture below the center of the speedometer dial show the total mileage of the vehicle and may be

used as a guide for periodic lubrication and maintenance.

Trip Odometer (42, Fig.

The figures within the aperture above the center of the

speedometer dial may

journey, provided that the figures are initially set at zero. (See

'Trip Zero Control', 34.)

Radio Controls

The radio aeriel fitted to the left front wing is raised by pulling

the protruding tip upwards. The aeriel should always be lowered

before the car is put through an automatic car wash plant.

Two radio speakers are fitted in the facia

tion to an approved radio receiver. Refer to the radio leaflet

supplied with the set for operating instructions.

Sun Visors

Two adjustable sun visors, padded to reduce the risk of

impact injury, may be

and swung to eliminate side glare. The passenger's sun visor

incorporates a vanity mirror.

Rear View Mirror (See page 20)

Safety harness anchorage points are built into the vehicle and

automatic, reel type safety belts are fitted before the car is

delivered.

5)

5)

be

used to record the distance of each

consol for connec-

unclipped from the centre support brackets

SAFETY

HARNESS

Using the Harness

Ensure that the buckle unit is conveniently situated by the

side of the seat and pass the seat buckle over the shoulder nearest

to the car door. With the lap and body belts passing across the

body, plug the belt buckle into the nearest centre buckle unit.

This is denoted by a positive 'click'.

To release the harness depress the marked panel on the centre

buckle unit.

Seat Belt Warning System

The seat belt warning device will operate if an attempt is made

to start the car without the seat belts in use. For full details see

page 37 "Driving the Car".

Cleaning

Badly stained safety belts can be dry cleaned. The cleaner

should be advised of the nature of staining. Belts subjected to

normal soiling can be cleaned with soap, or detergents dissolved

in hot water.

Inertia Reel Mechanism Check

Every 10,000 km

check to ensure that the safety harness inertia reel mechanisms

for both driver and passenger continue to operate satisfactorily.

IMPORTANT. Road tests must only be carried out under

maximum safe road conditions, i.e. level, dry road with no

following or oncoming traffic of any kind.

(a) With the safety harness fitted to driver and passenger as

previously described, start the engine and accelerate the

vehicle to approximately 24

that it is safe to do so, brake sharply.

(6000 miles), carry out the following road

km/h (15 m.p.h.). Ensuring

Fig.

2

(lower)

S

EATS

(b) The safety harness should automatically lock, holding both

driver and passenger securely in position.

It is important when braking that the reaction of both driver

and passenger is normal, i.e. the body must not be thrown

forward in anticipation, thus causing a 'snatching' action

of the reel which will not operate the locking mechanism.

The harness is locked by retardation of the car, not by body

movement.

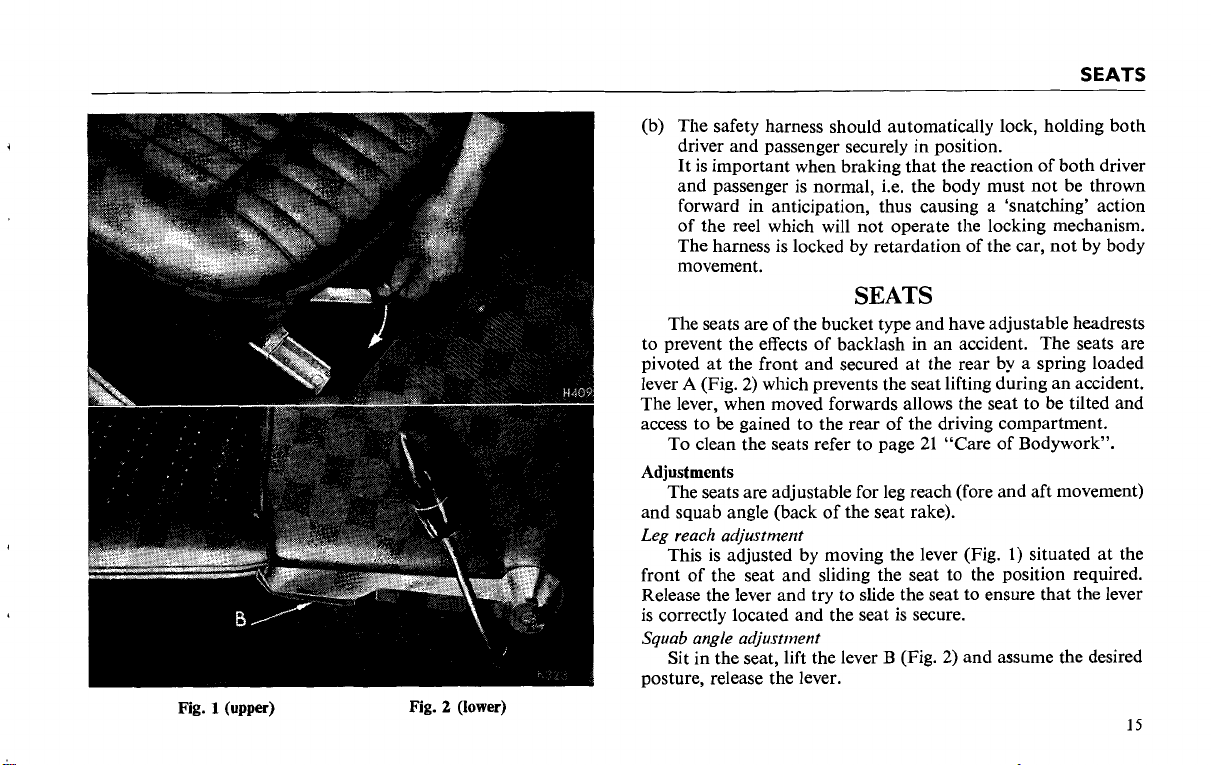

SEATS

The seats are of the bucket type and have adjustable headrests

to prevent the effects of backlash in an accident. The seats are

pivoted at the front and secured at the rear by a spring loaded

A

lever

The lever, when moved forwards allows the seat to be tilted and

access to

Adjustments

and squab angle (back of the seat rake).

Leg reach adjustmerzt

front of the seat and sliding the seat to the position required.

Release the lever and try to slide the seat to ensure that the lever

is correctly located and the seat is secure.

Squab angle adjustment

posture, release the lever.

(Fig. 2) which prevents the seat lifting during an accident.

be

To clean the seats refer to page 21 "Care of Bodywork".

The seats are adjustable for leg reach (fore and aft movement)

This is adjusted by moving the lever (Fig.

Sit in the seat, lift the lever B (Fig. 2) and assume the desired

gained to the rear of the driving compartment.

1)

situated at the

15

LOCKS

AND

KEYS

LOCKS

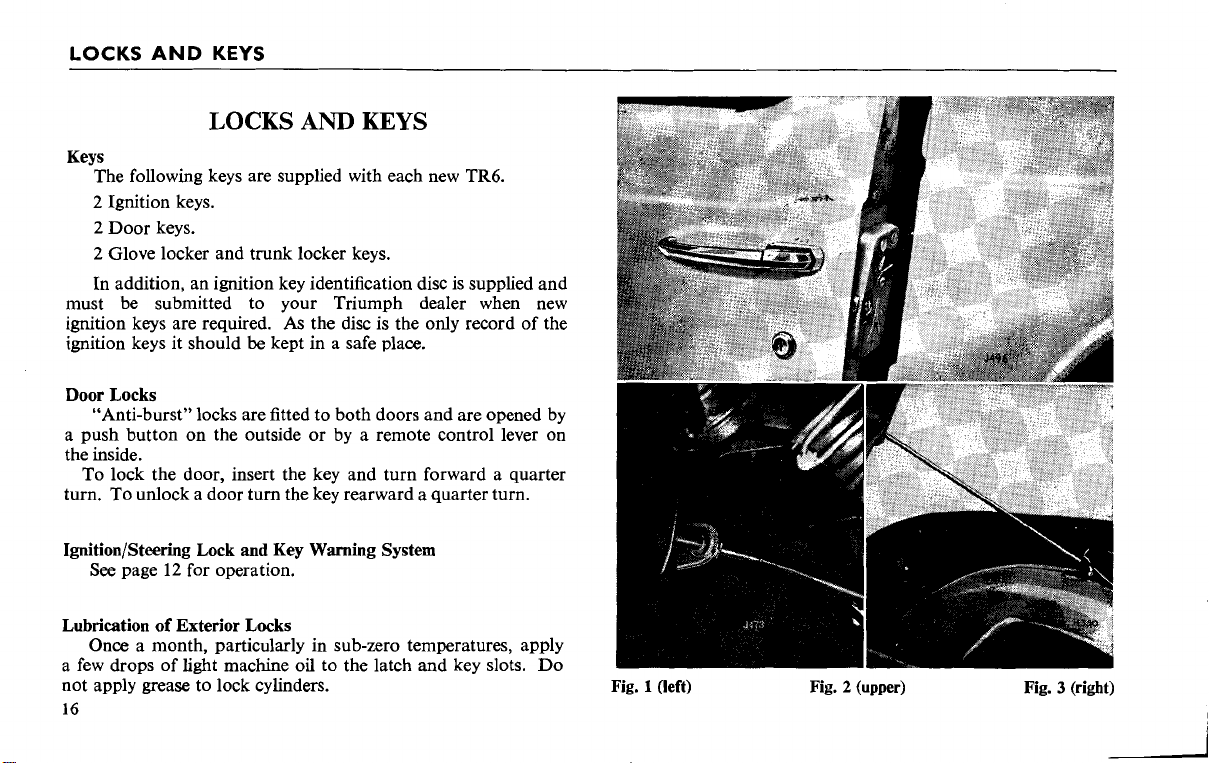

Keys

The following keys are supplied with each new TR6.

2

Ignition keys.

2

Door keys.

2

Glove locker and trunk locker keys.

In addition, an ignition key identification disc is supplied and

must be submitted to your Triumph dealer when new

ignition keys are required.

ignition keys it should

Door Locks

"Anti-burst" locks are fitted to both doors and are opened by

a push button on the outside or by a remote control lever on

the inside.

To lock the door, insert the key and turn forward a quarter

turn. To unlock a door turn the key rearward a quarter turn.

Ignition/Steering Lock

See

page

12

Lubrication of Exterior Locks

Once a month, particularly in sub-zero temperatures, apply

a few drops of light machine oil to the latch and key slots. Do

not apply grease to lock cylinders.

16

and

for operation.

AND

As

be

kept in a safe place.

Key Warning System

KEYS

the disc is the only record of the

Fig. 1

(left)

Fig. 2 (upper) Fig. 3 (right)

LOCKS

AND

KEYS

Fig. 4

(left)

Fig. 5 (upper) Fig. 6 (right)

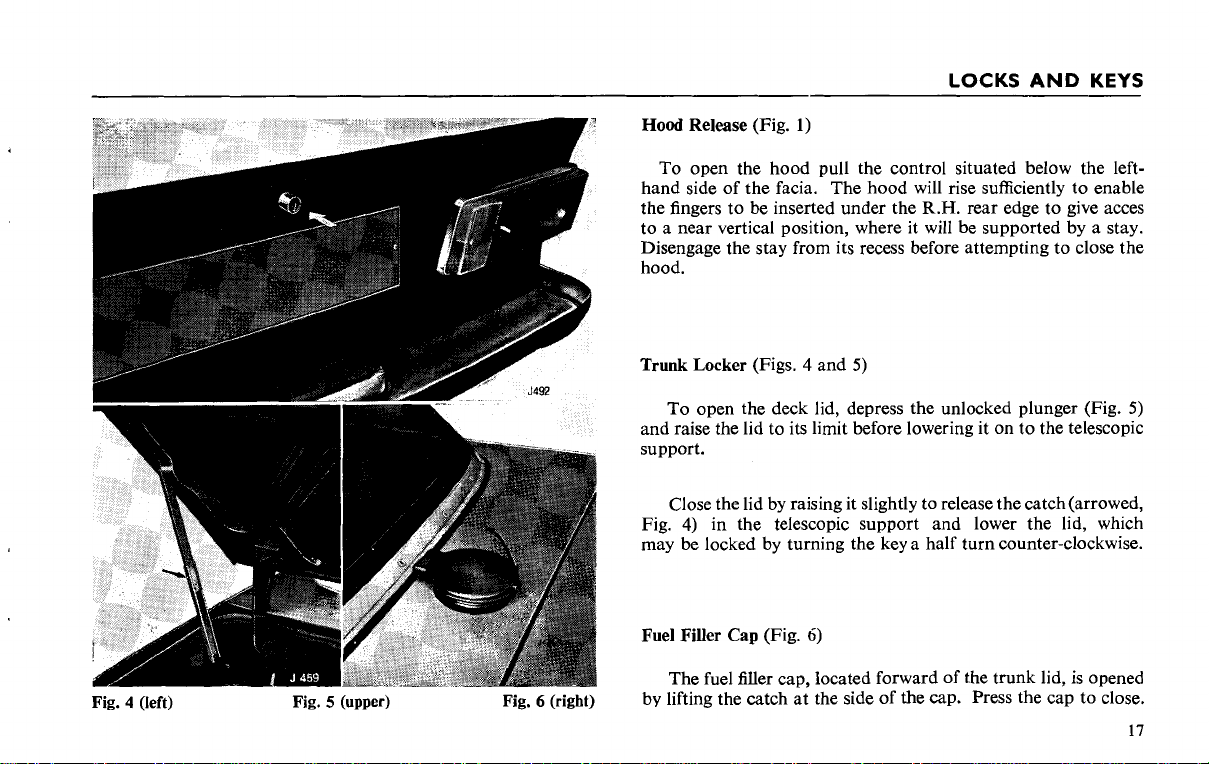

Hood Release (Fig.

To open the hood pull the control situated below the left-

hand side of the facia. The hood will rise sufficiently to enable

the fingers to be inserted under the

to a near vertical position, where it will be supported by a stay.

Disengage the stay from its recess before attempting to close the

hood.

Trunk Locker (Figs.

To open the deck lid, depress the unlocked plunger (Fig.

and raise the lid to its limit before lowering it on to the telescopic

support.

Close the lid by raising it slightly to release the

Fig.

4)

in the telescopic support and lower the lid, which

may be locked by turning the key a half turn counter-clockwise.

Fuel Filler

by lifting the catch at the side of

Cap

The fuel filler cap, Iocated forward of the trunk lid, is opened

(Fig.

1)

R.H.

rear edge to give acces

4

and

5)

5)

catch(arrowed,

6)

the

cap. Press the cap to close.

SOFT

TOP

TOP

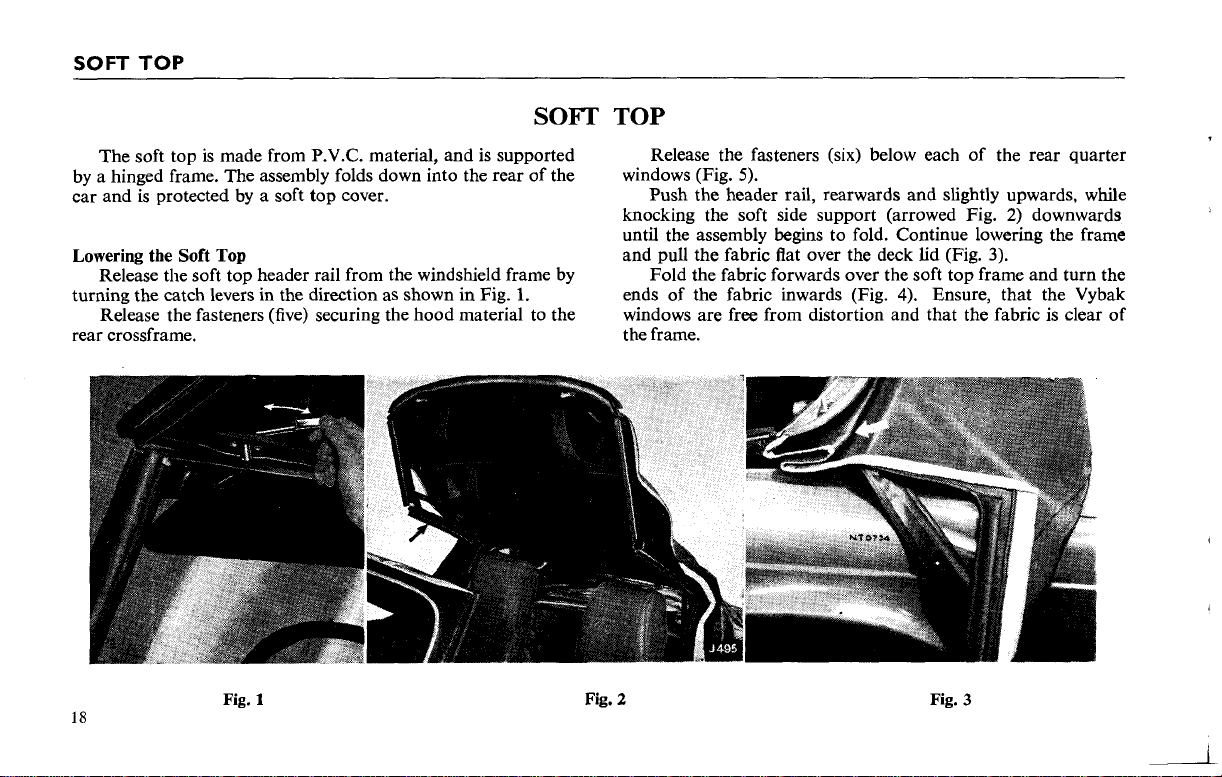

The soft top is made from P.V.C. material, and is supported

by a hinged frame. The assembly folds down into the rear of the

car and is protected by a soft top cover.

Lowering the Soft Top

Release the soft top header rail from the windshield frame by

turning the catch levers in the direction as shown in Fig.

1.

Release the fasteners (five) securing the hood material to the

rear crossframe.

18

Fig. 1

Release the fasteners (six) below each of the rear quarter

windows (Fig.

5).

Push the header rail, rearwards and slightly upwards, while

2)

knocking the soft side support (arrowed Fig.

downwards

until the assembly begins to fold. Continue lowering the frame

and pull the fabric flat over the deck lid (Fig.

3).

Fold the fabric forwards over the soft top frame and turn the

4).

ends of the fabric inwards (Fig.

Ensure, that the Vybak

windows are free from distortion and that the fabric is clear of

the frame.

Fig.

2

Fig.

3

SOFT

TOP

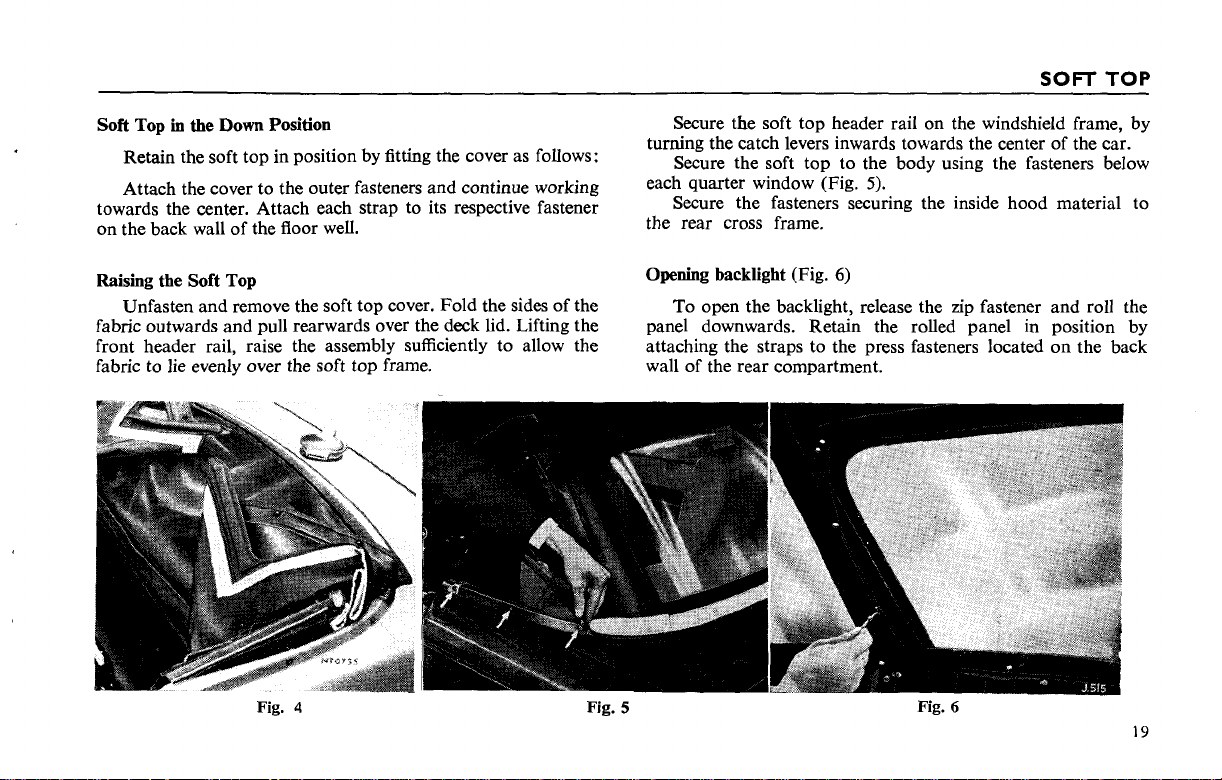

Soft Top

in

the

Down Position

Retain the soft top in position by fitting the cover as follows:

Attach the cover to the outer fasteners and continue working

towards the center. Attach each strap to its respective fastener

on the back wall of the floor well.

Raising the Soft Top

Unfasten and remove the soft top cover. Fold the sides of the

fabric outwards and pull rearwards over the deck lid. Lifting the

front header rail, raise the assembly sufficiently to allow the

fabric to lie evenly over the soft top frame.

Secure the soft top header rail on the windshield frame, by

turning the catch levers inwards towards the

center of the car.

Secure the soft top to the body using the fasteners below

each quarter window (Fig.

5).

Secure the fasteners securing the inside hood material to

the rear cross frame.

Opening backlight

(Fig.

6)

To open the backlight, release the zip fastener and roll the

panel downwards. Retain the rolled panel in position by

attaching the straps to the press fasteners located on the back

wall of the rear compartment.

Fig.

Fig.

4

Fig.

5

6

19

TONNEAU COVER-HARD

TOP

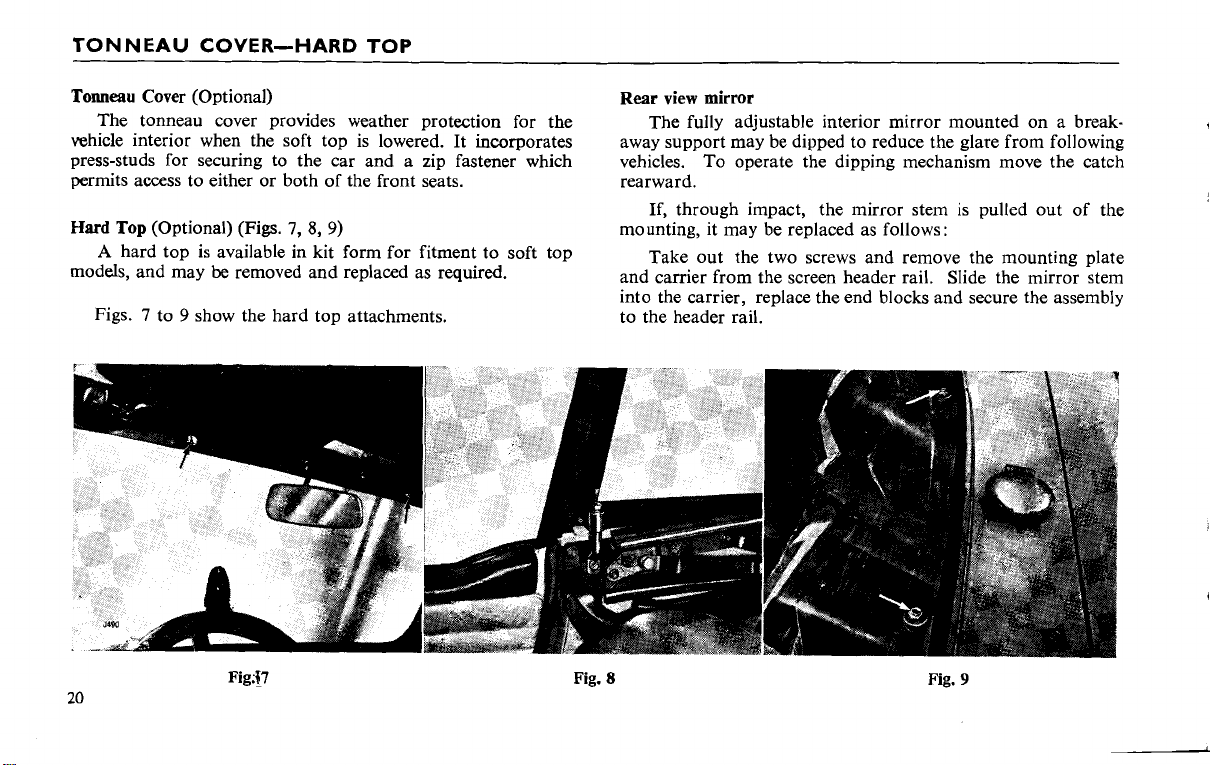

Tonneau Cover (Optional)

The tonneau cover provides weather protection for the

vehicle interior when the soft top is lowered. It incorporates

press-studs for securing to the car and a zip fastener which

permits access to either or both of the front seats.

Hard

Top (Optional) (Figs.

A

hard top is available in kit form for fitment to soft top

models, and may

be

7,

8,

9)

removed and replaced as required.

Figs. 7 to 9 show the hard top attachments.

Rear

view

mirror

The fully adjustable interior mirror mounted on a breakaway support may be dipped to reduce the glare from following

vehicles. To operate the dipping mechanism move the catch

rearward.

If, through impact, the mirror stem is pulled out of the

mounting, it may be replaced as follows:

Take out the two screws and remove the mounting plate

and carrier from the screen header rail. Slide the mirror stem

into the carrier, replace the end blocks and secure the assembly

to the header rail.

Fig.

8

Fig.

9

CARE OF BODYWORK

AND

UPHOLSTERY

CARE

Washing

Avoid using a dry cloth to wipe dust from the paintwork and

plated surfaces. Dust is an abrasive and if removed

will scratch the polished surfaces. Wash the vehicle frequently

with plenty of running water and a clean soft sponge. Soften and,

if possible, remove the mud with water before using the sponge.

When all dirt is removed, sponge off and dry with a clean damp

chamois leather. Never wash or polish the vehicle under a hot

sun.

When using an automatic car wash ensure that the radio aerial

is fully retracted.

Removing Grease and Tar

Remove grease or tar by sparing use of white spirit, but do

not apply this to rubber, particularly windshield wiper

Glass Surfaces

Glass is easily scratched. This can be avoided by always using

a damp chamois leather which is specially reserved for use on

glass only. If silicone polishes have been used on the body, take

care that the polish does not come in contact with the glass. It is

extremely difficult to remove and causes the windshield wipers to

smear.

Chromium Plating Inflammability

Frcquent washing and thorough drying is recommended,

especially during the winter months when there is likelihood of

corrosion through contamination with road salt. described above.

in

OF

this way it

bIades.

BODYWORK

Polishing

After a period of use, the formation of traffic film will cause

the paintwork to lose some of its lustre, even though the vehicle

has been carefully and

may be restored after washing by using a reputable non-abrasive

cleaner and polish.

Being the most durable, wax preparations are

where these are used regularly the old wax must first be removed

with a cleaner before further application of new wax. The frequency at which polishing is necessary will depend upon local

conditions of air pollution.

Care of Interior, Soft Top and

Brush and clean the inside of your

polish the outside of it. Use a vacuum cleaner where possible and

ensure complete removal of all dust from the interior and trim.

Wash the Upholstery (and exterior fabric) with luke-warm

non-caustic soapy water. Do not use detergents or household

cleaners

with a clean damp cloth and thoroughly dry the upholstery with

a dry duster or towel.

Wax or other polishes should not be used inside the car.

To preserve this condition do not clean interior other than as

as

these may cause damage. Remove all traces of suds

Wipe the facia and instrument panel with a damp cloth only.

The car conforms to State and Federal laws on flammability.

regularly washed. The original brilliance

preferablc, but

Tonneau Cover

car

each time you wash and

21

WHEELS

AND

TIRES

Tires

Wheels

and tires, of correct types and pressures, are an

integral part of a vehicle's design. Thus the regular maintenance

of the tires contributes not only to the safety but to the designed

functioning of the vehicle, as road holding steering and braking

are especially vulnerable to the use of incorrect

l

y pressurised,

badly fitted or worn tires.

Pressures

Adjust tire pressures in accordance with the recommendations

given below. These pressures are satisfactory for sustained

speeds up to 112 m.p.h. (180 km.h.).

Front Rear

185 SRI5 G800

185 SRI5

X

20

lblin.2 24 lbIin.2

(1.40 kg/cmz)

(1.68 kg/cmz)

NOTE: Should the vehicle be tuned to increase its maximum

be

speed, or

used for racing, consult the respective tire

company regarding the need for tires of full racing

construction.

Never bleed a warm tire but always adjust the pressure whilst

the tires are cold, i.e. before a run. As the tires

warm up their

pressures will increase.

To prolong tire life, avoid severe braking, sudden changes of

direction at speed, and driving over or against

as

this can result

in

severe damage to the tire walls. Examine the

high

kerbstones,

tires occasionally and remove flints or other road matter which

may have become embedded in the treads.

CIeoning

Wipe off any oil or grease which may

a cloth moistened in gasoline. The tires should then

be

on the tires by using

be

washed,

using only soap and water.

Tie

Wear

The characteristics of tires vary considerably and, therefore

when new tires are fitted, all four tires must be of the same type

and rating. (185-15 radial ply).

Occasionally remove flints and other road matter from the

treads and exanline the tires for sharp fins, flats and other

irregularities. An upstanding sharp fin on the edge of each

pattern rib is a sure sign of

Fins

on the inside of the pattern ribs indicate toe-in. Fins on

road,wheel misalignment (Fig. 1).

the outside edges indicate toe-out. Sharp pattern edges may also

be

caused by road camber, even when wheel alignment is correct.

In such cases, it is better to make sure by having the track

checked with an alignment gauge.

"Spotty" tread wear or flats. can result from grabbing brakes

or unbalanced wheel assemblies. Your Triumph Dealer

will check the action of the brakes and re-balance the tires if

required. The original degree of balance is not necessarily

maintained, and it may be affected by uneven tread wear, by

repairs, by tire removal and refitting, or by wheel damage and

eccentricities. The vehicle may also become more sensitive to

unbalance due to normal wear of moving parts.

1

WHEELS

AND

TIRES

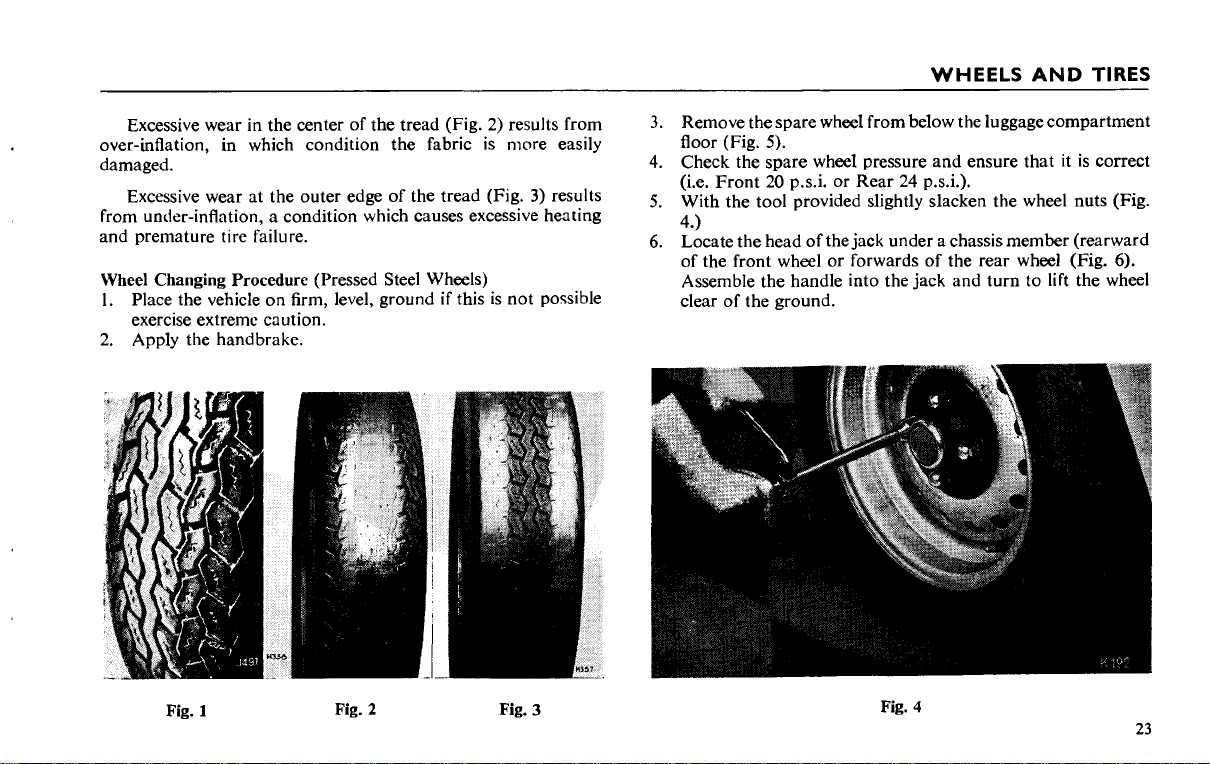

Excessive wear in the center of the tread (Fig. 2) results from

over-inflation, in which condition the fabric is more easily

damaged.

Excessive wear at the outer edge of the tread (Fig.

from under-inflation, a condition which causes excessive heating

and premature tire failure.

Wheel Changing Procedure

Place the vehicle on firm, level, ground if this is not possible

1.

exercise extreme caution.

2. Apply the handbrake.

(Pressed Steel Wheels)

3)

results

Remove the spare wheel from below the luggage compartment

floor (Fig.

Check the spare wheel pressure and ensure that it is correct

(i.e. Front 20 p.s.i. or Rear 24 p.s.i.).

With the tool provided slightly slacken the wheel nuts (Fig.

4.)

Locate the head of the jack under a chassis member (rearward

of the front wheel or forwards of the rear wheel (Fig.

Assemble the handle into the jack and turn to lift the wheel

clear of the ground.

5).

6).

Fig.

Fig.

1

Fig. 2 Fig.

3

4

23

Loading...

Loading...