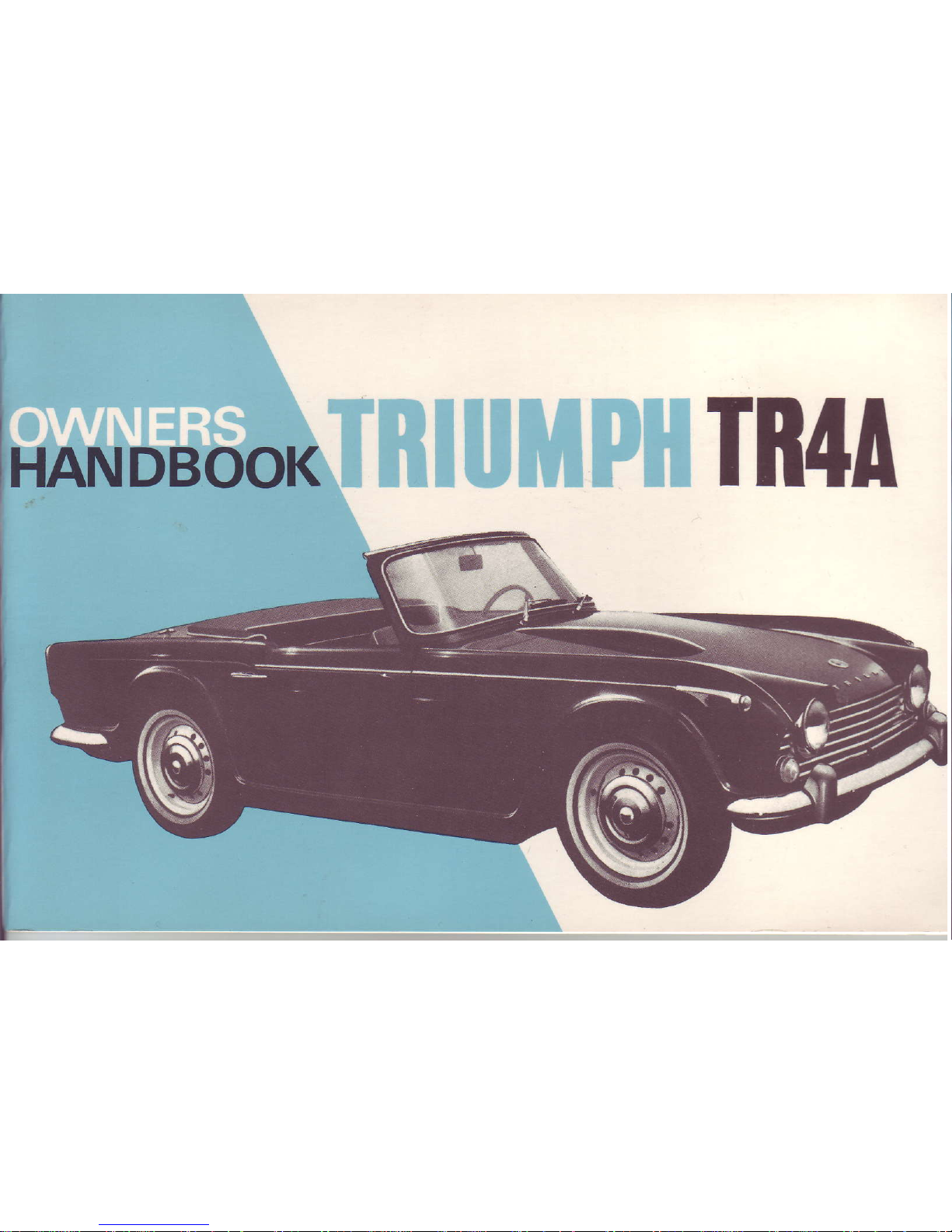

Triumph TR4A Owner's Handbook Manual

HANDBOOK

TR4A

IMPORTANT

IN THE

INTERESTS

OF

SAFETY,

THE

IMPOR.

TANCE

OF MAINTAINING

CORRECT

TYRE

PRESSURES

CANNOT BE

OVER

EMPHASTSED.

PRESSURES

SHOULD BE

CHECKED

AT LEAST

EVERY

TWO WEEKS

OR

1,000

MTLES

(1600

KMS.)

AND

MAINTAINED

IN

ACCORDANCE

WITH

RECOMMENDATIONS

GIVEN

ON

PAGE

58.

TRIUMPH

TR4A

OWNERS

HANDBOOK

Issued

b!

STAN D ARD.TRI U MPH SALES LTD,

COVENTRY,

ENGLAND

A member of

the Leylad Motors

Corporation

FOREWORD

Surress,

rlre osDirution

of all human

pursuits.

has. in the

worlil of motor

sport.

bccome synonymous

with

the

nane of Triuiph.

The-many

loureli

obtained

by T,R.'s in intprnational

and locol competitions

haD?

gained

them

ait enviabie rcputotion

i7 *hi"h

,urry ownir

is

justifably

ptouil.

The newest of the

Ttiumph

thotoughbreds,

the T.R.AA,

combines

na@ deuelopments

with

the well

prou.en rally

rcsred

featuris

ol its

predicessors.

-Wc

welcom"

owaers to

on eDpr b;ilening

circle of

enthusiasts

and uish them

many-pledsont'houri

of

motoring in

aililing na o honours

to a name

alreaily renowr.eil.

To

cnsure a continuance

of

thc superb

periormonce whieh

a

-T.R,4A.is

capable

ofgiuing. coupled

with reliability

anil economy,

regular

core onil dttention

ore

neccssary. Au

essennal inJormalton

ancl

thP pcrtods

allpr unr.n

attention

is" recokmended.,

are

cotutained,

in the

following

pages, Owners

ate aih;ised

to read

them carefully

and note

particularly the

ad'aice on

lubrication'

New.parts or

accessories,

when needed,,

arc obtainable

only

through authofiseil

Triumph

dealers,

u;ho in

ad,ilition

to being trained

n

girn expert adnice

and attentiin,

are

also equipped

to utuilertahe

repairs

and

ooerhauls which

are bevonil

the scope

of most owners,

STANPART

Spare

Parts Service

Rept@ment

pdrs

are

nol supplied from

ltre facrory.Iirect

ro the

gen€ral

public,

but are

diEted throush

Distributors who,

id turn, supplv

their

cenuire

spe

parls

are markered

under rhe uade

marl Sldpan

an<t caiiy rhe same

gu&mlee

as lhe

orieinal

parr.

The" same

high

qualirv

dalerial is: u$d dd rhe srricLed

aeuracy mainrsined

duritrg

muufacture,

you

are advi$d. (heeibre.

ro iosist on

the use ol

Lbese

pans

shouro

iliii!1.;,!i,ti.;;

ii-""1,"".v.^'i;];;-b.;;i.i;iii"t

d. noirc'arrv

rhe trade

nrk stanpa(

qil

invaridare rhe

eueant@

if nlted 10

vou.

vehicre.

The .lescriorions and iltu{rarions

aDDearins

in rhis boor

are nor bindine.

The MANUFACIURER,

therefore.

rcFru€s

$e rishl-$hilst

*li','iiii if,l

"r;liil-i."'ii'Li

,liiii'iriiiir":t'ii.i,'

desribed atrd

irrusrar;d - ro

make at atry ride.

ivithour Decas&lv

brinsitre.rhis

book

;;:6:a'"i.'5ffi;";ii;;;i

i;

;"f;;';G;ori!s

aeenea

oaveueot

ror imp.oveFeat

or fo' itrv meufactu'ing

or comerciar

r€ason'

CONTENTS

Pate

4

7

l0

ll

l3

l5

29

3l

33

Instruments and Indicatols

Switches

and Controls ..

Heating and

Ventilation

Locks and

Keys ..

Ddving

Reconmendations

Routine

SeNicing

Cooling

System .. ..

Road Wheels and Tyres ..

Running

Adjustments

..

Electrical System .. ,.

soft Top ..

Surrey Top

Care of Bodywork

Recommended

Lubricants

GeneralSpecification

..

Road Speed Data..

..

Tyre Pressures

Index

Pate

40

46

48

5l

52

54

5'l

58

63

IMPORTANT

In

all

communications relating to

Service or Spares

please quote

the

Commission

Numb€r

(Chassis

Number),

and Paint and Trim Numb€rs

I-OCATION OF CO]IIDtrSSION

AAID

LINIT

]\{IMBERS

Commission,

Paint and

Trim Numbers-On

Scuttle

Panel.

(May

be seen

by lifting the bonnet.)

Engine

Number-On L.H. side

of

Cylinder

Block.

Gearbox

Number-On L.H. side

of housing.

Rear

AxIe Number-On

face of HyPoid

Housing Flange.

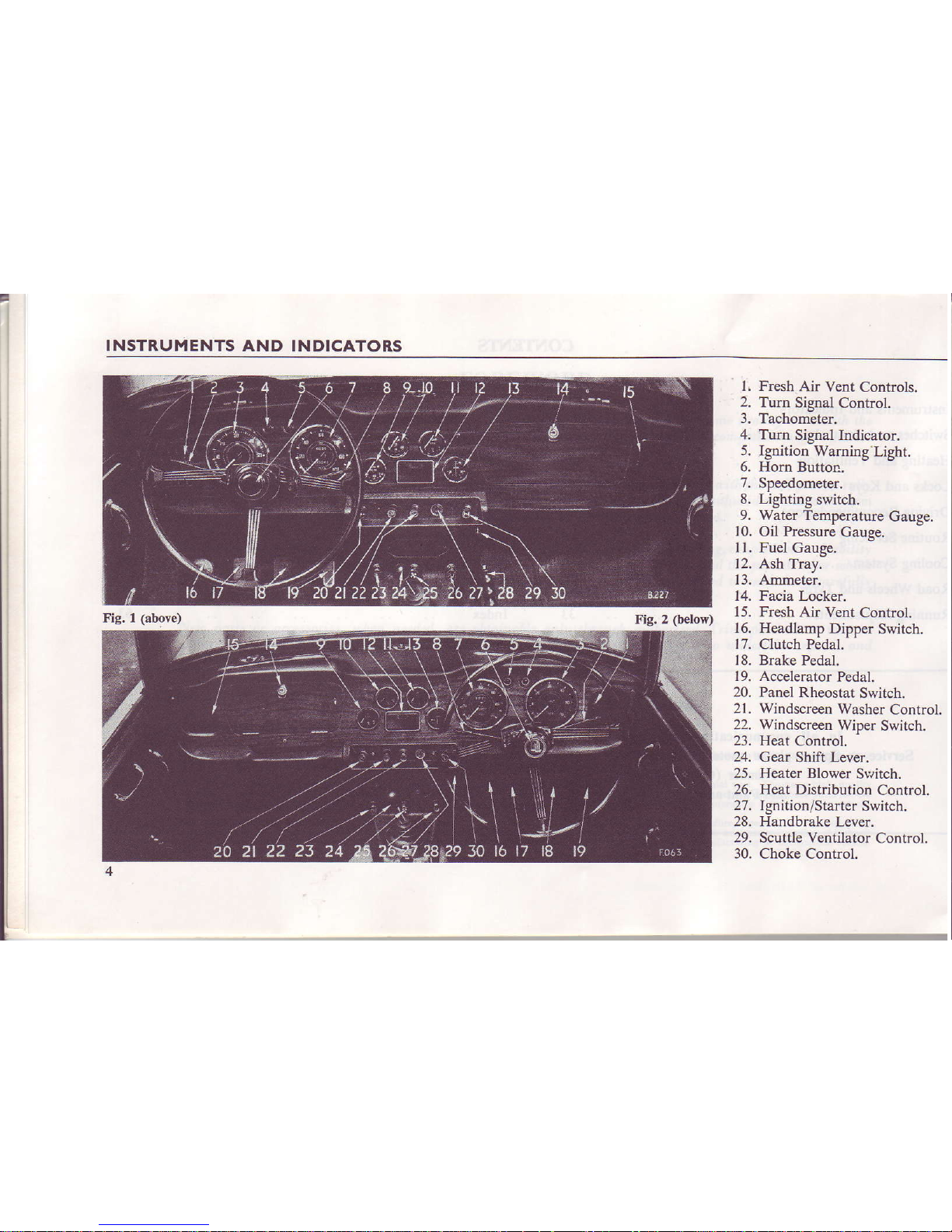

INSTRUMENTS AND INDICATORS

Fig. 1

(above)

Fig. 2

(below)

l, Fresh

Air Vcnt

Controls.

2.

Tum

Signal Control.

3.

Tachometer.

4. Turn

Signal

Indicator.

5. Ignition

Waming

Light.

6, Hon Button.

7.

Speedometer.

8. Lighting

switch.

9. Water Temperature

Gauge.

10.

Oil

Pressure

Gauge.

I l. Fuel

Gauge.

12. Ash Tray.

13, Arruneter.

14. Facia Locker.

15,

Fresh Air

Vent Control.

16.

Headlamp Dipper

Switch.

17. Clutch Pedal.

18. Brake Pedal.

19. Accelerator

Pedal.

20.

Panel Rheostat

Switch.

21, Windscreen Washer

Control.

22, Windscreen

Wiper

Switch.

23. Heat Control.

24.

Gear Shift Lever.

25. Heater

Blower

Slvitch.

26. Heat Dist

bution

Control.

27.

Ignition/Starter

Switch.

28. Handbrake

Lever.

29. Scuttle Ventilator

Control.

30. Choke Control.

INSTRUMENTS

AND

INDICATORS

INSTRUMENTS

AND I]\DICATORS

The instruments,

indicators

and controls shown on Figs.

I

and

2,

and

indicated in brackets within the text,

perform

the

following functions:-

Tachometer

(3)

The

tachometer, indicates the

engine

speed in revolutions

per minute and is calibrated in divisions of 100, extending

to

6,000. The speed

range

within the red segment

is subject to

special

precautions. These are giyen on page 14.

Turn Sienal Indicator

(4)

The green

flashing

indicator monitor light, glows intermit-

tently when the

direction

control is operated and

the ignition

is switched on. See

"T\rm

Signal Control" on page 9.

Flesh

Air

Vents

(1

and 15). Refer

to page

10.

Ignition Wamiry Light

(5)

The small

red warning

light glows when

the ignition

is

switched on and is extinguished when the engine

is

acc€lerated.

Should the indicator

continue to glow

when the engine is running

above idling speed

an electrical

fault is indicated li,hich should be

traced and

rectified

immediately.

Spe€dometer

(7)

The speedometer

indicates

the road speed of the vehicle

in

miles

per

hour and is calibrated

in divisions of

2, extending to I 20.

The fiqures within

the aperture above

the centre of the dial

may be fsed

to record individual

joumeys.

Provided

that the

figures

are re-set to

zero at the beginning.

This is achieved by

pushing

up and

turning clockwise

the knob

which

extends

downwards

from behind the

instrument.

The figures within

the aperture below

the c€ntre of the dial

show the total

mileage of the v€hicle

ard may be used as a

guide

for

periodic

lubdcation and

maintenanca.

The High Beam indicator

near the bottom

of the dial glows

only when the

headlamp main beams

are in use. When the

diPper

switch is operated

tbe indicator is extinguished.

INSTRUMENTS AND INDICATORS

Water Temperature

Gauge

(9)

Normal operating temperature

is reached when the needle

registers in the

central sector of the dial. Should the needle

reach the highest mark,

stop the engine immediately, allow it to

cool and check the level of the

coolant

in the radiator.

When the

ignition is

switched on

the

needle moves slowly across its scale,

taking up

to

one

minute

to reach a true rcading.

Oil Pressure Gauge

(10)

The oil pressure relief valve is set to

control the pressure at

65-75 lb. per sq. in. at 2,000 r.p.m. with normal

oil temperatures.

i.e.,

about ?O'C. During sustained high speed operation,

th

resulting increase in oil temperature may

cause

the

oil pressur

to drop. This will have no detdmental effects

providing it do(

not fall below 30 lb. per

sq.

in.

Severe operating conditions, such as competition work, ma

cause the oil pressure to fall below 30 p.s.i., indicating that the

o

temperature is excessive. Under these circumstances,

an o

cooler kit is recommended to ensure that a maximum

sump o

temperature of 125"C. is not

exceeded.

Fuel

Gauge

(ll)

The fuel

gauge indicates the approximate

contents

of tt

fuel

tank. When the ignition is switched on, the needle mov(

slowly across its

scale taking up

to

one

minute to reach a stead

reading which

it will maintain, regardless of vehicle movemen

unril the ignition is

switched

otr

Ammeter

(13)

The ammeter is calibrated in amperes and indicates the ra1

of battery charge and discharge. The charging rate is indicat€

when

the

pointer

moves to the left-hand side of

"zero",

an

discharge.

b) movement to the right.

SWITCHES

AND CONTROLS

Fig. 4

Panel R.heostat

Switch

(20)

Turn the knob clockwise to illuminate the

instruments.

Futher rotation

of the knob

diminishes

the light intensitv.

Operate

only when

the lighting

switch is

"on".

Lighting Switch

(8)

Move the column switch

lever

downwards to the fust Dosition

to illuminate

the side, rear, number plate and centre instrument

panel

lights. Move the lever down to the s€cond position to

illuminate the headlamps. See

"Dipper

Switch", page 8.

Witrdsq€en

Washer

Control

(21)

Use the

windscreen washer cootrol in coniunction with the

windscreen

wiper.

Operate by pushing the conirol to spray clean

fluid

on

to the screen as the wiper blades dispers€

the mud. If the

washer has remained unused for some

time, depress the control a

few times to charge

the

system.

Windsqeen Wiper Switch

(22)

Pull the switch knob to its first position

to operate the wipers

at fast speed and to

its

second

position to operate them at slow

speed.

Push the knob fully home to switch off, when

the wipers

will automatically return to the parked

position at the base of the

windscreen. The wipers can only be

operated when the ignition

switch is

turned to

the

"ignition"

or auxiliary positions,

Ignition/Starter Switcb (27)

Op€rated

by a separate key, the combined ignition and stalter

switch has

four positions. These are: l,

"Off",

in

which

SWITCHES

AND CONTROLS

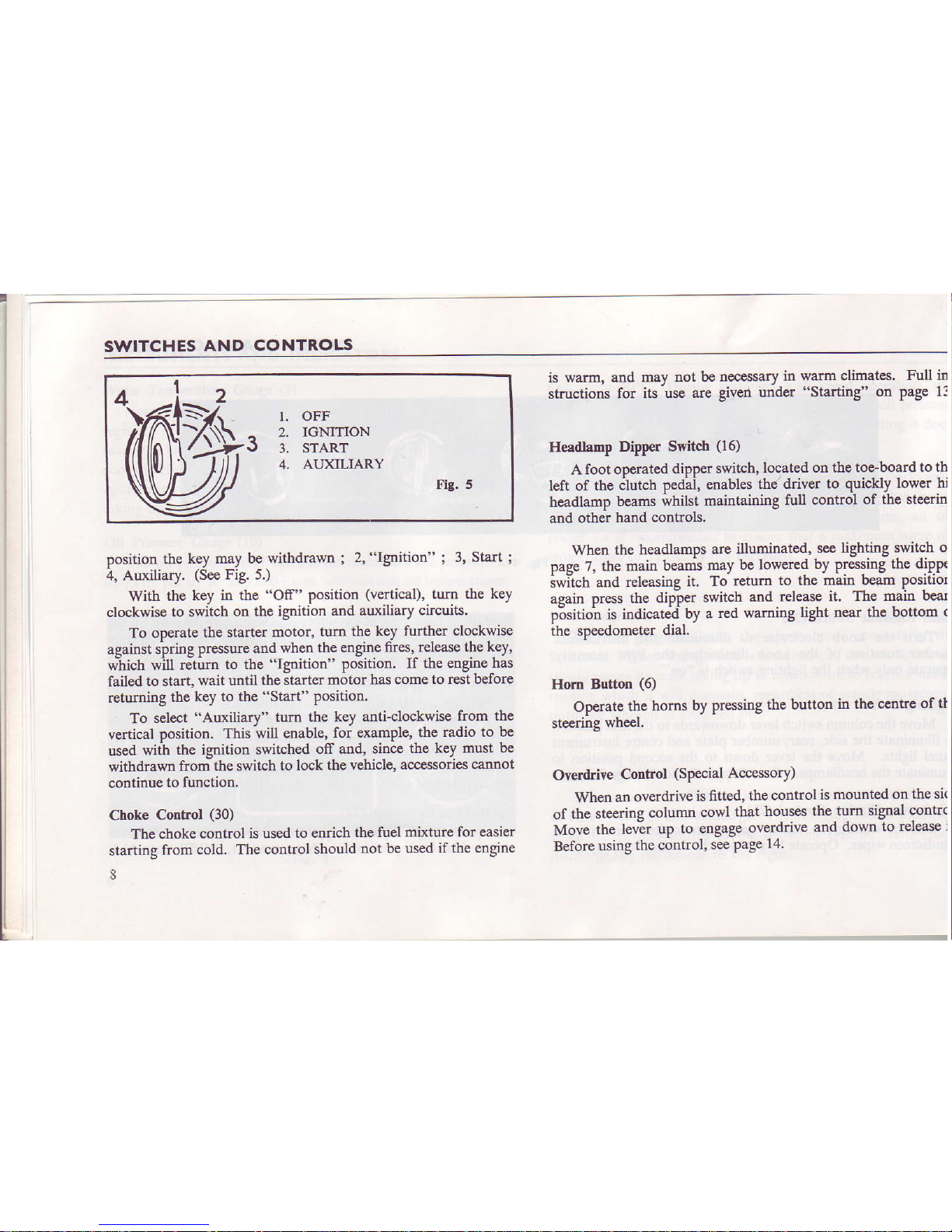

I. OFF

^

2. IGMTION

J

3. srART

4.

AIIXILIARY

Flg.5

position

t}Ie

key may be

withdrawn

;

2.

"Ignition"

;

3,

Start

;

4.

Auxiliary.

(See

Fig. 5.)

With

the

key in the

"Off"

position

(vertical),

turn the

key

clockwise

to

switch on the ignition

and

auxiliary circuits.

To operate

the starter

motor, turn

the key further

clockwise

against spring

pressure

and

when

rhe engine

fires. release the

key.

*hich

*il-t retum

to the

"lgnition"

Position.

It the enBineias

failed to start,

wait

until

the starter

motor has come

to rest befbre

retumiug

the

key to the

"Start"

Position.

To

select "Auxiliary"

turn

the key anti-clockwise

from the

vertical

position.

This

will enable,

for €xamPle, thc

radio to be

used

witj\

the ignitioo

switched

off and, since

the key must

be

withdrawn

fronithe

switch to

lock the

vehicle, accessodes

cannot

continue to

function.

Choke

Control

(30)

The choke

control is used

to enrich

the fuel

mixture for easier

startiog

from cold.

The control should

not be

used if the engine

3

is warm.

and mav

not be oe€gssary

in walm

climates. Full in

structions

for

its'use are given

urider "starting'

on

page 13

Headlamp

Dippr Switch

(16)

A

foot operated

dipper switch,

located on the toe-board

to th

left of the itutctr

peAai,

enables

the ddver

to

quickly

lower bi

headlamp beams

whilst

maintaining

full

conhol of th€ stocrin

and othar

hand

controls.

When

the headlamps

are

illuminated,

see lighting

switch o

page

7. the main

beams

may be lowered

by pressing

the dippe

iwi-tch

and

releasing

ir. To

retum lo the

main beam

Positior

apain

Dress

rhe dipier

switcb

and

release ir. The

main bear

p6sition

is indjcate'd'

by a

red

waming liSht near

the bottom

(

ahe speedometer

dial.

Hom Button

(6)

Operate

the

homs by

prcssing

the button

in the c€ntre

of tt

steering

wheel.

Overd

ve Control

(SPecial

Accessory)

When

an

overdrive

is fitted,

the control

is

mounted on

the si(

of the

steering

column

cowl

that

houses

the turn signal

contrc

Move

the lever

up

to engage

overdrive

and down

to release

i

Before

using

the control,

see

page

14

SWITCHES

AND CONTROLS

Turn

Signal

Control

(2)

The turn signal

lamps are controlled by a

lever

mounted on

the outboard side

of the steering column cowl.

Before making

a right-hand

turn, move the

lever

clockwise.

Move it anti-

cloc[wise

before

tuming left. When either left- or right-hand

turn signal

lamps are operating, a green indicator

light on the

facia,

flashes intermittently,

Clutch,

Brake and

Accelerator Pedals

(17,

18 and 19)

These are

conventional items which do

not

need

further

explanation.

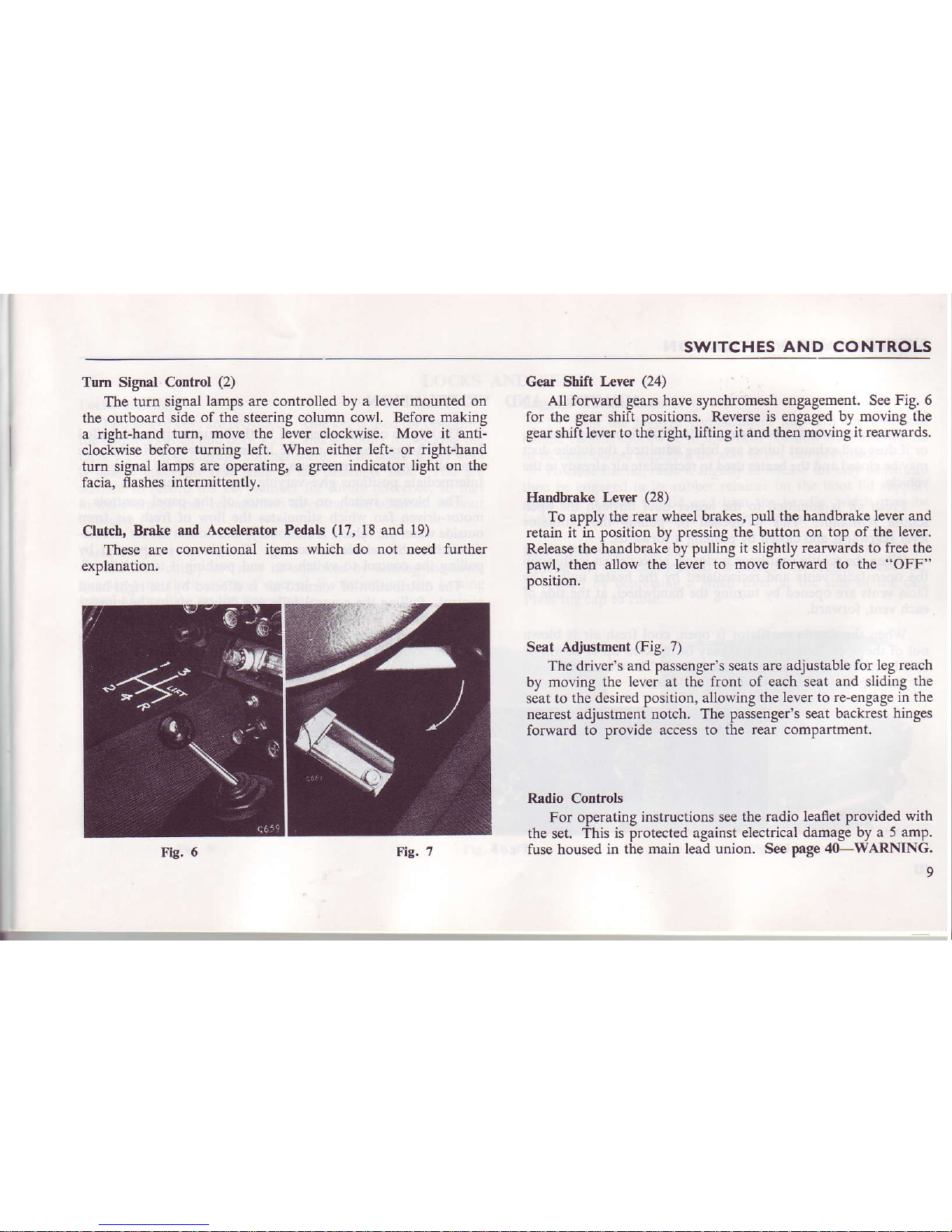

Gear Shift

Lever

(24)

AU forward geals have synchromesh engagement. See

Fig. 6

for the gear shift positions.

Reverse is engaged by moving the

gear shift

lever to the right, lifting it and ther

moving it rearwards.

Handbrake Lever

(28)

To apply the

rear

wheel brakes, pull

the handbruke lever and

retain it in

position

by pressing the button on

top of the lever.

Release the handbrake by pulling

it slightly rearwards to free the

pawl, then

allow the lever to move forward

to the

"OFF"

position.

Seat

Adiustment

(Fig.

7)

The driver's

and passenger's seats are adjustable

for leg reach

by moving

the lever

at

the front of each seat and sliding

the

seat to

the desired

position,

allowing the

lever to re-engage in the

nearest adjustment notch. The passenger's

seat backrest hinges

forward to provide

access to the rear compartment.

Radio

Controls

For operating

instructions see the rudio leaflet provided

with

the set.

This is protected against electrical

damage by a

5 amp.

fuse housed in

the main lead union. See page 40-WARNING.

HEATING

AND

VENTILATION

IIEATING

AND

The heater is designed to heat and distribute incoming fresh air,

or if dust and exhaust fumes are being admitted, thc intake

duct

may be closed and

the heater

used

to recirculate air aheady in the

vehicle.

Fresh air is admitted to the heater duct tirough the open

scuttle ventilator, This is opened by pulling

t}le ventilator

leyer rearwards and closed by

pushing

it forwards.

When the scuttle ventilato! is closed, air

is

drawn

in tbrough

the open facia vents and recirculated by the heater unit, The

facia vents are opened by turning the handwheel, at

the side of

each

vent, forward.

When

the

scuttle ventilator is open,

cool fresh air is blown

out of the open facia vents and may be directed up or down,

or

may be cut-off by adjusting

the

handwhe€l.

There is no provision

for heatine the air blown from the facia vents.

Vf,NTILATION

The degree of heat given out by the heater unit is controlle

by the left-hand control on the

heater conhol panel. Pull

th

control fully out for

maximum

heat, or push it fully in for colc

Intermediate positions give varying degees

of heat,

The blower switch on the ccntre of the panel controls

motor-driyen

fan which

stimulates

the flow of fresh air fror

outside when the vehicle is stationarv. and boosts the air cftculs

tioo

when the vehicle is moving. The blower is operated b

pulling the control to switch on, and pushing it to switch of

The distribution of warmed air

is

effected

by

the right-han

control.

Pulling the contuol fully out directs air to the

intedc

of the vehicle. With the control pushed to the half

way

positior

air is dire€ted to the screen for demisting or defrosting. Inter

mediate

positions

direct ak to the screen and interior in varyin

proportions. With the control pushed fully home the system

j

inoDerative.

Fig. E

10

LOCKS AND KEYS

LOCKS

Locks and Keys

Two sets of keys are provided. One

key is used for operating

the ignition switch and door locks, and the other for

locking the

facia locker and

luggage

compartment.

The

spare

set of keys

is housed

inside the rear lamp at

the passenger

side. You are

advised

to record the key number for future reference, so

that

in the event of

loss, replacement keys may be obtained without

diffculty.

Facia Locker

(Fig. 9)

The facia cubby box may be unlocked by turning the key a

quarter turn clockwise and opened by depressing the locking

barrel and pulling

on the lipped plate.

AND KEYS

Luggage Compartment

(Fig.

1l)

To open the luggage

compartment lid, turn

the unlocked

handle counter-clockwise

to a vertical position

and raise the lid

to its limit

before engaging the stay

in the slot

Provided.

To close the lid,

raise it slighdy to

release the

stay

which can

then be engaged

in its rubber retainer

on the boot lid suPPort

assembly,

Lower the

lid

and

turn the handle, which

may be

locked by turning

the key a half turn

counter-clockwise.

Fuel Filler Cap

(Fig.

10)

The fuet

fitler cap, located forward

of the luggage locker lid,

is opened

by depressing a small

lever at the side

of

the

cap.

Press the caD

to

close.

Fic.

ll

ll

LOCKS

AND KEYS

Door Ircks

Either door may be locked from inside or outsidc

irrespective

of

which

door

was last

used

as an exit, The mechanism auto-

matically prevents the inside handle being

set in the locked

position whilst the door

is

open.

This eliminates the possibility

of being locked out of the car in the event of the

key being

inadvertently left inside.

Interior

Locking

To lock the door it must be closed fust. Only then will the

mechanism pemit the inside handle to be moved forwards.

The

handle

will

automatically

retum to the normal

position

as soon

as it is released.

IMPORTANT. Do not attempt to force the

handle into the

locked

position

whilst the door is. open.

Exterior Locking

When leaving the car, move the door

handle forward and

leave the

vehicle by the other door, which may then be locked by

using the key as follows :-

Inse the key in the lock and turn it approximately a quarter

tum towards

the

shut-face.

The key will automatically retum

to rhe horizontal position from wheie it may be

wirhdriwn,

when the dools are locked, pressurg

on the outside push

buttons,

which may be fully depressed, cannot

force or damage

the lock,

l2

To UDlock

Re-enter from either

door by inserting

the key in the lo(

and tuming

it approximately a

quarter tum away

from

tl

shut-face. The

key will again automatically

return to the hor

zontal position

to enable it to

be removed.

Lubrication

It will be beneficial, particularly

during

freezing

weather,

l

fuifoduce a few droDs

of thin machine

oil into the latch slot ar

the lock

key

slots

ai intervats

of not more than once a mont

IMPORTANT. Urder no

circumstances should grease

I

applied

to the lock cylinders

or keys.

Bomet

Release

To open the bonnet pull

the contuol situated

below

the right-hand side

of tlle

facia. The bonnet will

rise

sufficiendy

to enable the

fingers to be

inseded under

the rear edge to raise it to a

near

vertical position,

where

it will be supported by a

stay. Disengage

the

stay

from its recess before clos-

ing the bonnet.

Fie. 12

DRIVING

RECOMMENDATIONS

DRIVING RECOMMENDATIONS

Running-in

The

importance of correct running-in cannot be too strongly

emphasized, for during the f,Ist 500 miles of motoring, the

work-

ing surfaces

of a new engine

are bedding

down.

Du

ng this

period

the valve

seats stabilise,

causing in

some

instances, slight distortion and preventing proper seating of a

valve.

Avoid

possible

damage resulting from

such a condition,

by

having the compression pressures checked early in the life

of the engine after

"running-in"

is completed.

If the

pressures

are unequal,

valve

grinding

is recommended.

Further attention to the valves should not then be required for

a considerable

mileage,

or

until the

pressures

have again become

unequal.

Whilst no specific speeds are recommended during the

running-in period,

avoid

placing

heavy loads upon the engine,

such as using full throttle at low speeds or when the engine is

cold. Running-in

should be

progressive and

no harm will result

from the engine being allowed to

"rev."

fairly fast provided that

it is thoroughly

warm

and

not

pulling hard.

Always

select a

lower gear

if necessary to relieve the engJne of load.

Full power should not be used until at least 500 miles have

been covered

and even then, it

should

be

used only

for

short

periods at a time. These periods can be extended as the engine

becomes

more responsive. After 1,000 miles running, the engine

can be considered as fully run-in.

Starting the

Engine

from Cold

Check,

and

if necessary top up, the

radiator water level and

the engine oil

level. If the car

has not been used for several days

and

fuel has evaporated

from the carburettors,

refill them by

operaling the

priming lever on the fuel pump.

The slight resistance

ciuses wEen the floaichambers

are fu .

Apply the

handbrake and ensure

that the gear lever is in

"Neutral".

Pull the choke

control out to

its

stop and

tum the

key to the

"ignition"

position.

The ignition

waming light should

then

glow

and

the fuel gauge

should register the contents of

the

fuel tank.

From the

"ignition"

position,

tum the key clockwise against

spring

pressure ro operate the slarter motor.

lmmediatel) lhe

eigini

hres. release the key.

which will rerurn to the

"igniiion'

position.

Should the

engine fail to start at

the first attempt, do

not re-operate

the starter switch until

the starter motor has

come

to

test.

As soon

as it starts, push

the choke to the

"half-in"

position

and warm the engine at a

fairly fast idling speed

of approximately

1,500 r.p.m.

This will cause the

ignition waming light to

be

extinguished, thus indicating

that the generator is

charging. The

oil gauge should

indicate the pressure

of oil circulating. lf the

gauge

remains at zero, stop

the engine immediately and

establish

the cause.

Failure to do so may

result in serious damage to the

eDgroe.

DRIVING RECOMMENDATIONS

Cylinder wear is minimized ifthe engine is warmed

up quickly

by driving away as soon as oil is circulating after

stading the

engine. Do not race the

engine to speed up the process but, if

possible, maintain a speed of approximately 25 m.p.h.

until the

choke can be

pushed

fully in.

In

warm

climates, use of the choke

may be unnecessary. Avoid the

use of full throttle during the

warmiog-up period. A themostat incorporated in

the cooling

system

enables the engine to

be

warmed

up quickly from cold.

Starting with the Engine Warm or Hot

When

re-starting

a hot engine, depress the accelerator

pedal

to about one-third ofits travel

before operating the starter switch.

The choke conrrol should not be used.

Recornmetrded Speed Limits

Avoid over-rewing,

particularly in the iower gears. The driver

is advised not to drive the

car continuously atengine speeds above

5,000 r.p.m.

in

any gear. However, whilst accelerating

through

the

gears

it is

permissible

to

attain 5,500 r.p.m. for short periods,

these speeds being indicated

by the beginning and the end of the

red segment on the tachometer.

When an overdrive

is fitted, do not change from overdrive

to normal 3rd or 2nd

gears

at

engine speed exce€ding 4,500 r.p.m.,

otherwise damage may result from

"over-rewing".

Overdrive Unit

(when

fitted)

Ao overdrive unit senes

as a convenient method ofproviding,

at wili, a numericalll lower

overall gear ratio ro redice enginl

speed and wear, and to efect fuel

economy,

t4

The Laycock de Normanville

overdrive unit incorporal

an

epicyclic gear train which is engaged,

to give overdri

condition,

by a cone clutch moving under the influence

of t

hydraulic

pressure genemted by a small piston pump. Wh

pressure is released, via a control valve, the

clutch is return

and held

in direct drive by compression

springs, A ur

directional roller

clutch enables the change into, or out

(

overdrive to be made when transmitting

full power, without lc

of road

speed.

The hydraulic

control valve is linked to an electro-magne

solenoid which is operated, via a relay,

by a two-position swit

mounted

on the stee ng column.

Greatest benefit

will

accrue from

judicious

use of the ov(

drive, the

governing

factor

being

that

the vehicle continues

run

easily without sign of engine labouring,

combined wj

the ninimum

amount of throttle opening necessary to mainte

this condition.

Suggested

minimum

engagement speeds are:-

Top gear 40 m.p.h.

Third gear

30 m.p.h.

Do not change from overdrive to normal drive

at engj

speeds in excess of 4,400 r.p.m.

The above disengagement

speed corresponds approximatl

to peak revs.

in

norrnal gears. Disengagement of the O/D

a speed higher than that

stated

may

cause damage fr(

"over-revving".

ROUTINE SERVICING

ROUTINE

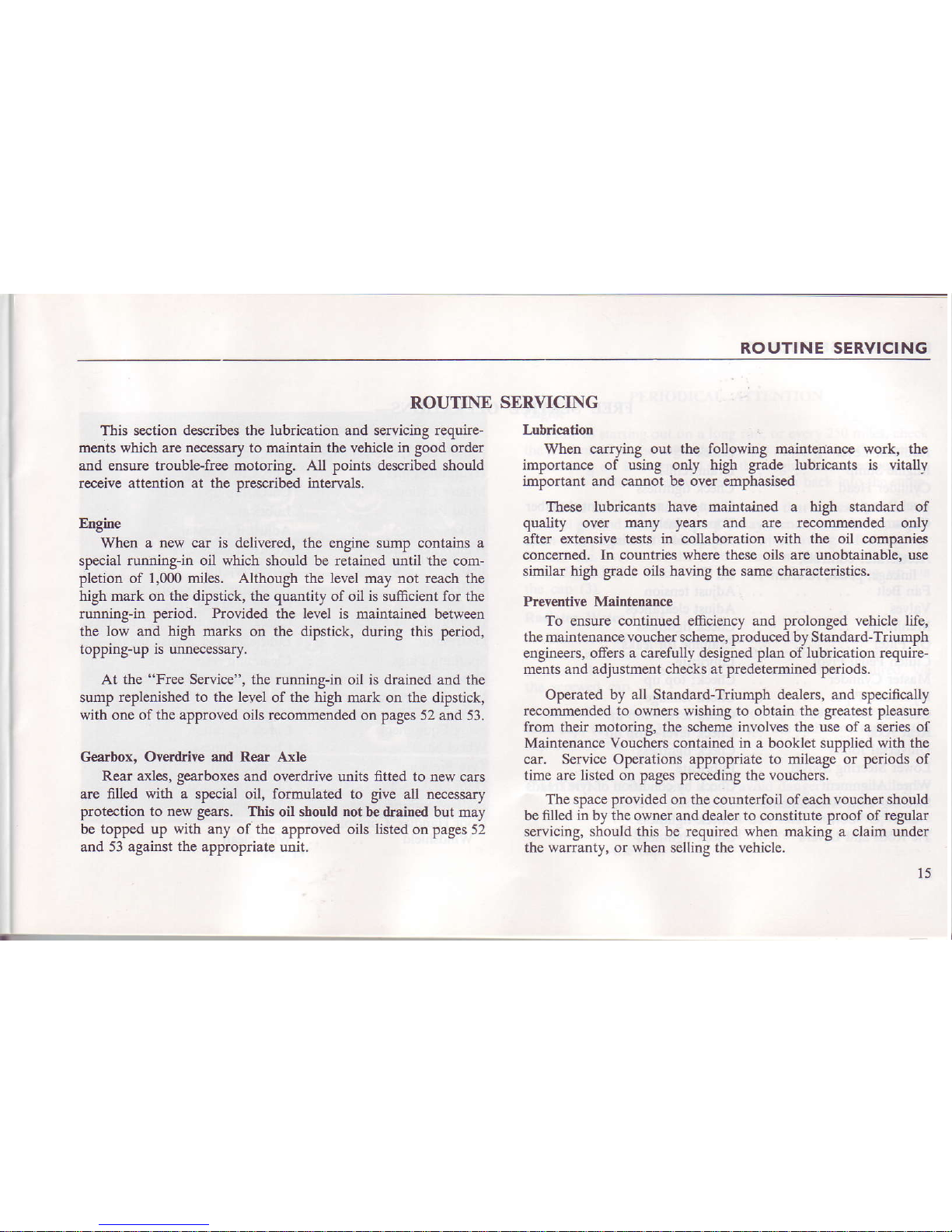

This section describes the lubrication and servicinq requirements which are neaessary to maintain tbe vehicle in g6od order

and ensure trouble-free motodng. All points desc

bed

should

receive attention at the prescdbed intervals,

Engrne

When a new car is delivered, the engine sump contains a

special

running-in oil

which should be retained until the completion of 1,000 miles. Although the level may not reach the

high mark on the dipstick, the

quantity of oil

is

sufficient

for

the

running-in pedod.

Provided

the level is maintained between

the low and high marks on the dipstick, during this

period,

topping-up

is unnecessary.

At the

"Free

Seryice",

the running-in oil is drained

and

the

sump

replenished to the leyel

of

the high

mark on the dipstick,

with one of

the

approved oils recommended on pages 52 and 53.

Gearbox.

OYerdriYe and Rear

Axle

Rear

axles, gearboxes and overdrive units fitted to new cars

are filled with a special oil, formulated to

give all necessary

protection

to new gears. This

oil should

not

be drained but may

be topped up with any

of

the

approved oils

listed

on pages 52

and 53

against the

appropriate uDit.

SERYICING

Lubrication

When carrying out the

following maintenaDce

work, the

importance of using only high

grade

lubdcants is

yitallv

important and canrot be over emphasised

These lubricants have mainta,ined a high standard of

quality over

many

years and are

recommended

only

after extensive tests in collaboration with the oil companies

concemed. In count es where these oils are unobtainable, use

similar

high

grade

oils having the same characteristics,

PreYentive Maintenance

To ensure continued emciency and prolonged vehicle life,

the maintenance

voucher

schem€, produced by Standard-Triumph

engineers, ofers a carefullv designed

plan

of lubrication require-

ments and adjustment checks at predetermined periods.

Operated by all Standard-Triumph dealerc, and specifically

recommended

to

owners wishing to obtain the greatest pleasure

from thei motoiing, the scheme involves the use of a sedes of

Maintenance

Vouchers

contained in a booklet suDDlied with the

car.

Service Operations appropriate ro mileage or

periods

of

time are listed on pages

preceding

the vouchers.

The space

provided on the counterfoil ofeach

voucher

should

be filled in by the owner and dealer to constitute proof of regular

seryicing,

should this

be

required when

making a claim under

the wananty, or when selling the vehicle.

IJ

ROUTINE

SERVICING

FREE

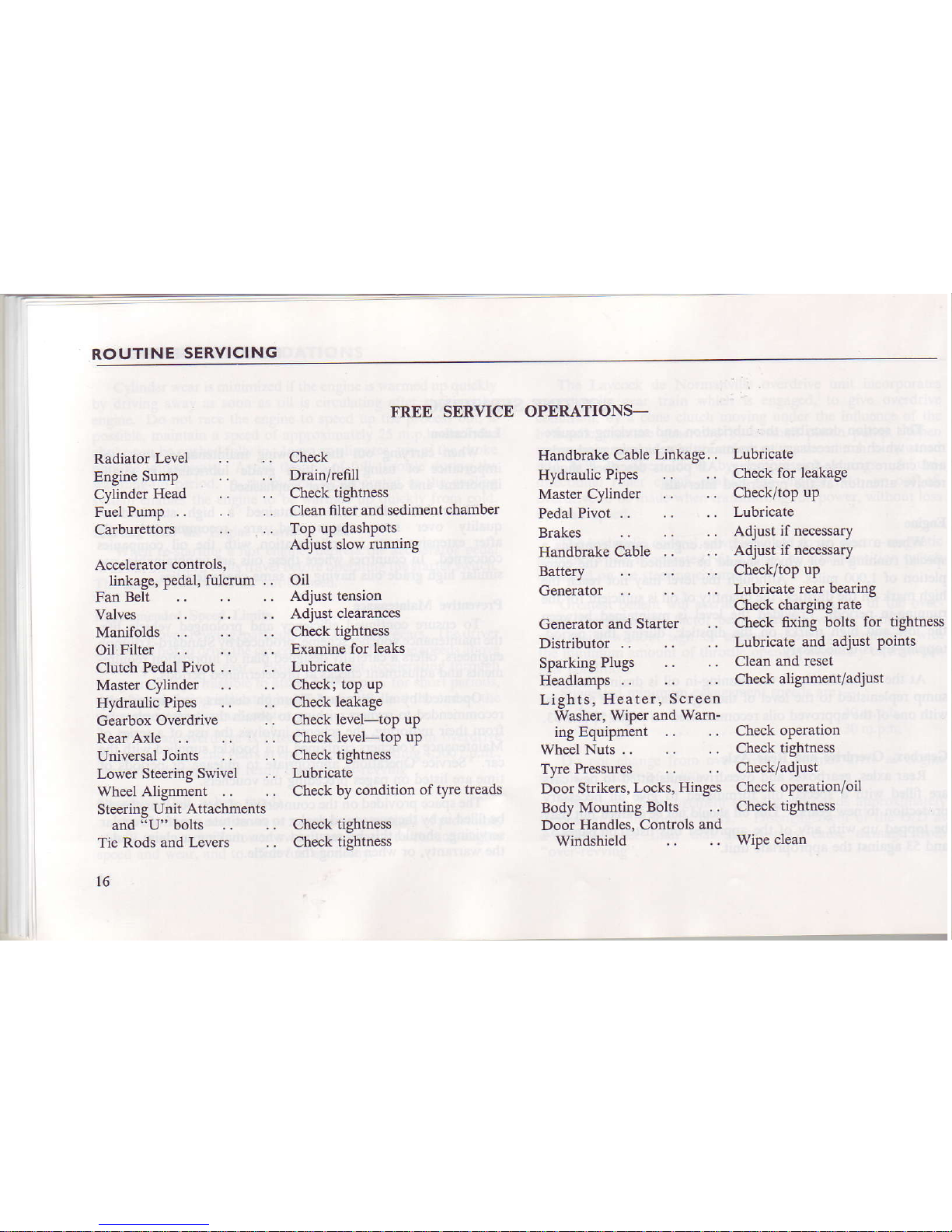

SERVICE OPERATIONS-

Radiator

Level

Engine

Sump

Cylinder

Head

Fuel Pump

.. ..

CarburettoIs

Accelerator

controls,

linkage,

pedal,

fulcrum ..

Fan

Belt

Valves

Manifolds

.. ..

Oil

Filter

Clutch

Pedal Pivot .. ..

Master Cylinder

Hydraulic

Pipes

Gearbox

Overdrive

Rear Axle

.. ..

Universal

Joints

Lower Steedng

Swivel .,

wheel Alignment ..

..

Steering

Unit Attachments

and

"U"

bolts .. ..

Tie Rods and

Levers

l6

Check

Drain/refill

Check

tightness

Clean filter

and sediment

chamber

Top up dashpots

Adjust slow

running

oil

Adjust tension

Adjust

clearanc€s

Check

tightness

Examine

for

leaks

Lubricate

Check;

top

up

Check

leakage

Check

level-top up

Check

level-top

up

Check

tightness

Lubdcate

Check by

condition

of tyre treads

Check

tightness

Check

tightness

Handbrake

Cable

Linkage..

Hydrautic

Pipes

Master Cylinder

Pedal

Pivot .. ..

Brakes

Handbrake Cable

..

..

Battery

Generato! ..

..

Generator

and

Starter

..

Distdbutor ..

..

Sparking

Ptugs

Headlamps

..

..

Lights,

He ater,

screen

washer, Wiper

and Warn-

ing Equipment

..

..

WheelNuts,.

..

Tyrc

Pressures

Door Strikers,

Locks,

Hinges

Body Mounting

Bolts

. .

Door Handles,

Controls

and

windshield

Lubricate

Check for

leakage

Check/top

up

Lubricate

Adjust

if nocessary

Adjust

if necessary

Check/top

up

Lubricate

reax

beaing

Check

charging

rate

Chack

fixing bolts

for tightncss

Lubdcate

and adjust

points

Clean

and reset

Check alignment/adjust

Check

operation

Check

tightness

Check/adjust

Check

operation/oil

Check

tightness

Wipe clean

ROUTINE

SERVICING

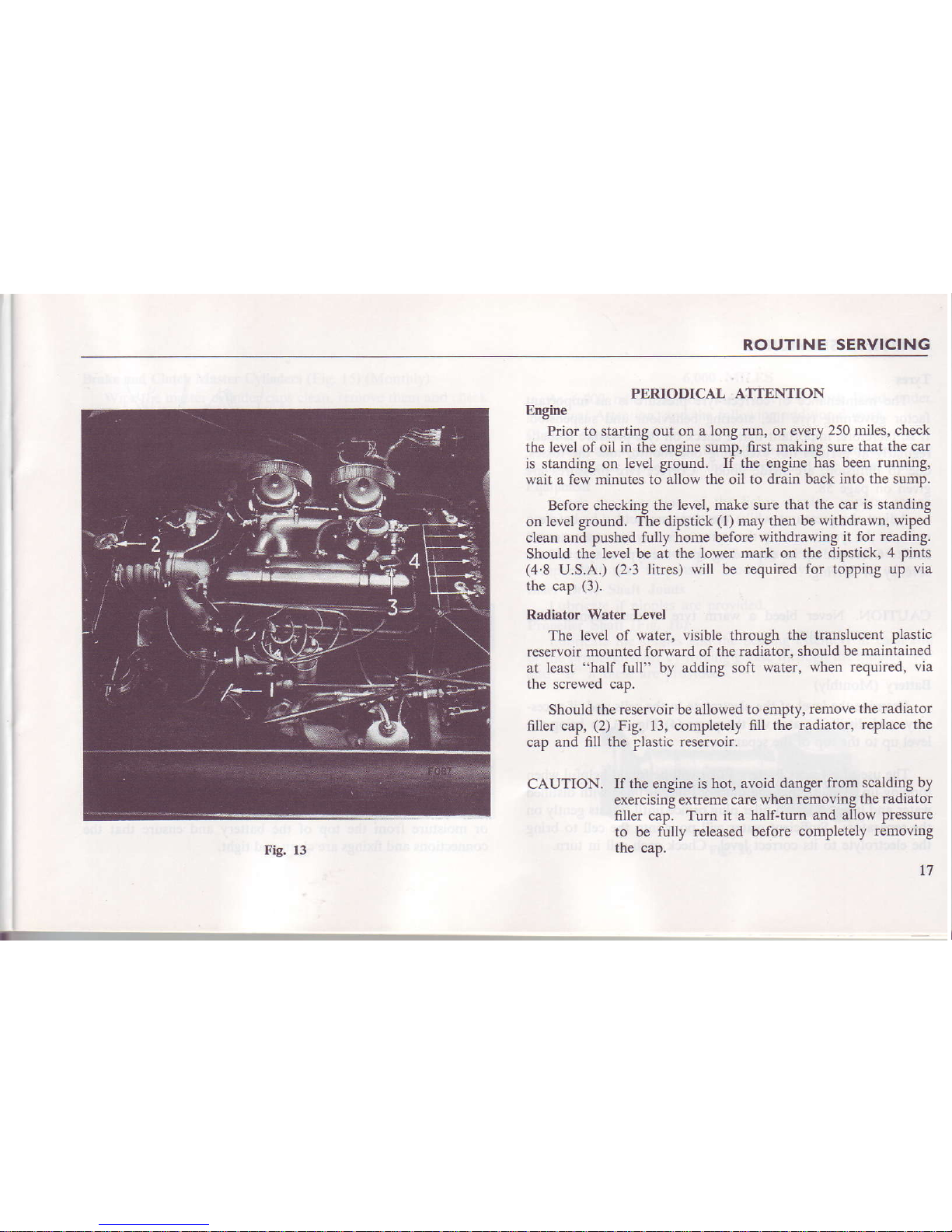

PERIODICAL

ATTENTION

Engrne

Prior

to starting

out on a long run, or every

250 miles, check

the level of oil in the engine sump,

fust making sure that the car

is standing on

level

ground.

If the engine has been

running,

wait a few minutes

to allow the oil to drain back

into the sumP.

Before checking the

level, make sure that

the car is standing

on

level

ground.

The dipstick

(l)

may then be withdrawn, wiped

clean and pushed fully home before

withdrawing

it for reading.

Should the

level be at the lower mark on

the dipstick, 4

Pints

(4

8

U.S.A.)

(2

3 litres) will be

required for topping up

via

the cap

(3).

Radiator

water l,€Y€l

The

level of water, visible through

the translucent plastic

reservoir mounted forward of the radiator,

should be maintained

at least

"half

full" by adding soft

water,

when required, via

the

screwed

cap.

Should the

reservoir be allowed to empty,

remove the radiator

filler cap,

(2)

Fig. 13, completely

fill the radiator,

rePlace the

cao and fill the rlastic reseryoir.

CAUTION. If the engine

is hot, avoid danger

from scalding

by

exercising extreme care when

removing

the radiator

filler cap. Tum

it a half-turn and

allow pressure

to be fully released before

comPletely

removing

me cap.

Fig. 13

ROUTINE

SERVICI NG

Tyres

The

maintenance of corect tyre

pressure

is

an

important

factor

governing tyre life,

steering behaviour aod suspension.

It is, therefore, important

that a check on tyre

prcssurc

is made

regularly at periods

not

exceeding one month,

and the losses,

due to diffusion, are n-ude

good. Correct tyre

pressures are

given on page 58.

Adjust the pressures whilst

the tyres are cold,

i.c., belore a

run. As the tyres warm

up their pressures

may increase as much

as 5 to 6 lbs. per sq. in. depending

upon the type of tyre and the

severity of driving.

CAUTION,

Never

bleed a warm

tyr€ to the recommended

pressure.

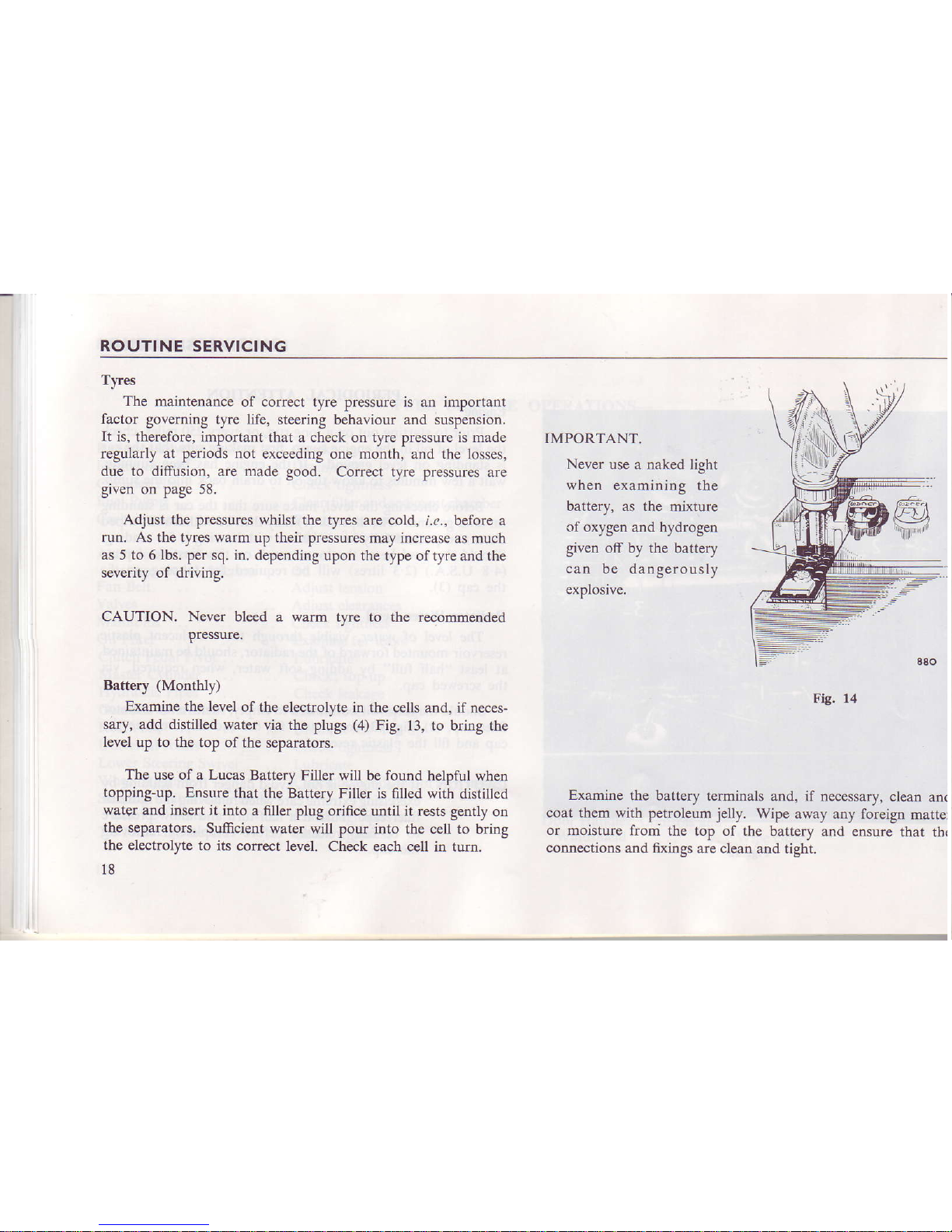

Battery

(Monthly)

Examine the level

of the electrolyte

in the cells and, if neces-

sary, add distilled water

via the plugs

(4)

Fig.

13, to bring the

Ievel up to the

top of the

sepamto$.

The use of a Lucas

Battery Filler will

be

found

helpful when

topping-up.

Ensure that

the Battery Filler is 6lled

with distilled

water

and

jnsert

it into

a filler

plug

orifice until it

rests gently on

the separaton.

Sufficient water

will pour into the cell to

bring

the electrolyte

to its corect

level. Check each cell

in turn.

l8

IMPORTANT.

Never

use a naked light

when examin

ing the

battery, as the

mixture

of oxygen and hydrogen

given off by the battery

can be

dangerously

explosive.

Fig.

14

Examine

the battery terminals

and, if necessary,

clean

anc

coat them with

petroleum

jelly.

Wipe away any

foreign matter

or

moisture froni the top

of the battery and

ensure that th(

connections

and nxings

are clean and tight.

ROUTINE

SERVICING

Brake and

Clutch

Master Cylinders

(Fig.

15)

(Monthly)

Wipe the master cylinder

caPS clean.

remove them and

check

the fluid level in

the clutch and brake

master cylinder

reservoirs.

Ifnecessary,

top up the

fluid until it is level

with the alrow on

the

side

of the reservoirs.

NOTE. As the

brake

pads

wear.

the leyel of fluid in the

master

cylinder

falls. ^ The

addition of fluid

to comPensate

for

oad wear

is unnecessarv. Should

the level have

fallen

ippreciably,

check

the tondition of

the

Pads.

If their

condition

is satisfactory establish

the cause of

loss and

reatify the defect

inlmediately. Refer

to Page 38,

"Ble€ding the Brake and Clutch

Hydraulic System".

6,000

MILES

At 6,000 mile

intervals, carry

out

the work

listed under

Periodical Attention,

and the

following

additional

work.

Chassis Attachments

Check

the tightness

of all bolts

and

nuts,

Particularly

the

front and rear suspension,

the steering

and the

wheel nuts.

Equipment

'Check

the operation

of

the lighls.

heater.

wiPers. screen

washer and

wamlng equlPmenr.

Wheel Aliqnment

Check

-the

front

wheel track

alignment

(front

and

rear,

independent rear

suspension

model)

if tyre

wear is uneven.

Inner

Drive Shaft Joints

Lubricate if

nipples are

Provided.

Propeller Shaft

(Fig.

I6)

iubricate the sp-line:

and

the bearing

assembly

at each

end

of

the propeller shaft

by

forcing grease

through

the nipPles

"A"

and

"B" if these are provided.

Fig. 15

Fig.

16

l9

Loading...

Loading...