Page 1

Page 2

INSTRUCTION BOOK

Part No. 501528

TRIUMPH

SPORTS CAR

TR3

SIXTH EDITION

Third Printing

Issued by

STANDARD-TRIUMPH SALES LIMITED

COVENTRY, ENGLAND

Page 3

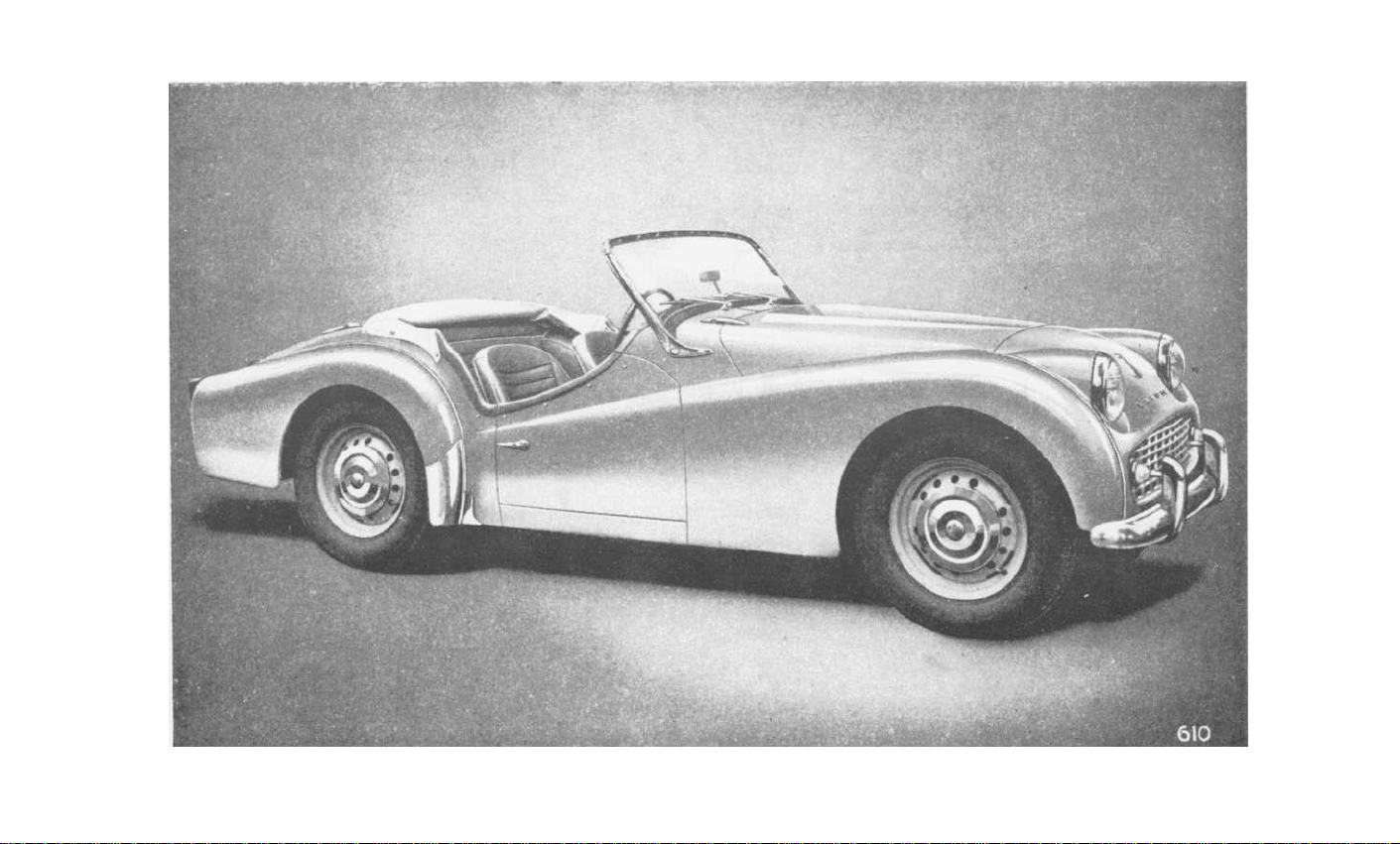

Fig.1.'THE TRIUMPH TR3 SPORTS CAR

Page 4

FOREWORD

Triumph vehicles are so designed that a minimum of attention is required

to keep them in satisfactory running order.

maintenance operations which must be undertaken regularly.

this instruction book is to assist the owner to understand the various operations

required, and so ensure that the vehicle receives regular and correct attention.

If in doubt about the vehicle's performance the owner should at once consult

a

Triumph dealer, preferably the one from whom the car was purchased.

Triumph dealers are very carefully selected and are suitably equipped to give

satisfactory and expert after-sales service

There is a Training organisation at the factory at which our dealers' representatives acquire a first hand knowledge of up-to-date service procedure. Valuable

information is given regarding special technique and equipment which ensures

that all maintenance operations are carried out economically.

.

There are, however, certain

The object of

THE STANDARD-TRIUMPH REVIEW

Standard-Triumph Review is

The

authentic information regarding the activities and products of The Standard

& Triumph Motor Co. Ltd. It is obtainable from most Triumph dealers.

Please write to the Publicity Department

The Company reserves the right, on the sale of any vehicle, to make before

delivery, without notice, alterations to or departures from the specification,

design or equipment, detailed, described or illustrated in this or other

Company publications.

a journal published monthly which gives

for a free specimen copy.

Page 5

all

IMPORTANT—In

quote the Commission Number (Chassis Number).

LOCATION OF COMMISSION AND UNIT NUMBERS

Commission

bonnet.)

Number—On Scuttle Panel. (May be seen by lifting the

communications

relating to Service or Spares please

Engine

Gearbox

Rear Axle

Number—On L.H. side of Cylinder Block.

Number—On L.H. side of housing.

Number—On upper face of Hypoid Housing Flange.

SPARE PARTS SERVICE

To ensure the best possible service on replacement parts it is important to

note the following points :

Spare parts are not supplied direct to the general public. All supplies

(a)

are directed through Distributors who, in turn, will supply their

Dealers.

may be obtained from the Service and Spares Directory included

with each motor vehicle.

(b)

It is recommended that only "

Triumph spare parts) are used, only these carry a guarantee.

Experience gained by the manufacturers ensures that only highest

quality

manufacture.

The name and address of the Distributors and Dealers

Stanparts " (

material is used and the strictest accuracy maintained in

i.e.,genuine Standard/

If in doubt about a particular part required, it is always advisable to

(c)

give the vehicle commission number and engine number, in addition

to the fullest description possible.

Owners of this model who wish to be kept informed of modifications and

competition tuning hints should register as a member of the Triumph Sports

Owners' Association ; details are given in the booklet enclosed with this

literature, or apply to the Publicity Dept., Standard-Triumph Sales Limited,

Coventry, England, for a copy of the book, together with enrolment form.

4

Page 6

LIST OF SECTIONS

Foreword

General Specification

Instruments, Switches and Controls

Driving the Car

Starting—Gear Changing—Desirable Speed Limits—New Engines

General Upkeep

Regular Inspection — Cooling System — Lubrication — Engine

—Gearbox—Rear Axle—Brake and Clutch Operation—Road

Wheel Hubs—Front Suspension and Steering—Rear Road Springs

—Hydraulic

Dampers—Propeller

Shaft—Hinges, Controls,

Door Locks, etc.—Tyres—Front Wheel Alignment—The Jack

—Wheel Attachment

Tools

Bodywork

Door Adjustment—Soft Top Maintenance—Removal and Stowage

of Soft Top

Running Adjustments

Engine—Twin S.U. Carburettors (Type H.6)—Fuel Pump—

Clutch—Brakes—Propeller

Shaft—Hydraulic

Dampers—Loose

Bolts and Nuts

3

6

8

11

13

26

27

31

Electrical System ...

Ignition—The Battery—The Generator—The Starter Motor—

Control

Direction Indicators—Windtone

Box — Fuses — Lamps — Wiring Diagram —

Horns—Electrical

Specification

Optional Extras

Lubrication Charts

Summary of Lubrication Points

5

42

Component

51

52

54

SPORTS CAR

Page 7

GENERAL SPECIFICATION

Engine

Number of cylinders

Bore of cylinders

(Special Order)

Stroke of crankshaft

Piston area

(Special Order)

Cubic capacity

(Special Order)

Compression ratio

Brake H.P. (gross) ...

(Special

Oil Capacity

Engine

Gearbox

Rear Axle

Water Capacity

Fuel Capacity

...

Order)

with overdrive—From dry ...

...

...

...

...

From Dry

(see page 14)

Drain and Refill ... ...

Drain and Refill ...

of cooling system

with heater fitted

... ...

...

3.386 in. (86 mm.)

3.268 in. (83 mm.)

3.622 in. (92 mm.)

36 sq. in. (232 sq. cm.)

33.5 sq. in. (216 sq. cm.)

130.5 cu. in.

121.5 cu. in.

105 at 4750 r.p.m.

100 at 5000 r.p.m.

I

mperial

Pints

...

...

11

10

1½

3½

2¾

1½

13

14

Gallons

12

U.S.

Pints

13.2

12

1.8

4.2

3.3

1.8

15.7

16.8

14.4

4

(2138 c.c.)

(1991 c.c.)

9 or 7

(6.25 litres)

(5.7 litres)

(0.8 litres)

(2.0 litres)

(1.6 litres)

(0.8 litres)

(7.4 litres)

(8.0 litres)

(54.5 litres)

Dimensions:

Wheelbase

Track—Front and Rear (Disc Wheels)

Front and Rear (Wire Wheels) ...

Ground clearance (under axle)

Turning circle (between kerbs)

Tyre size

Overall Dimensions:

Length

Width

...

Height (unladen)—Hood erect

Top of screen

Hood down and screen

removed

Weights

(excluding extra equipment)

Complete, tank full of petrol

Shipping weight

...

... ...

... ...

...

... ...

6

7'

4"

...

3'

9"

10"

3'

...

35'

6"

0'

(224 cm.)

(114 cm.)

(117 cm.)

(15.2 cm.)

(10.6 metres)

5.50"/5.90"—15

12'

7"

4'

7½"

4'

2"

...

3'

10"

3'

4'

(384 cm.)

(141 cm.)

(127 cm.)

(117 cm.)

(102 cm.)

19 cwts. 0 qrs. 7 lbs.

(2135 lb.) (970 kg.)

17 cwts. 3 qrs. 21 lbs.

(2009 lb.) (910 kg.)

Page 8

GENERAL SPECIFICATION

VALVE TIMING.

With valve-rocker clearance set at 0.0165" (0.42 mm.)].

[

Inlet and exhaust valves to be equally open at T.D.C. on the exhaust

stroke.

VALVE-ROCKER CLEARANCES

IGNITION TIMING

(see page 31).

(see page 31).

Set to fire at 4° before top dead centre (distributor contact points just

opening).

As the advance is fully automatic, the setting is at full retard.

Contact breaker gap should be set at 0.015" (0.4 mm.).

ROAD SPEED DATA

Engine Speeds (3.7 axle)

Using

Dunlop Textile

Tyres:

at 10 m.p.h.

at 10 km./hr.

Using Michelin X Tyres:

at 10 m.p.h.

at 10 km./hr.

Engine Speeds (4.1 axle)

Using

Dunlop Textile

Tyres:

at 10 m.p.h.

at 10 km./hr.

Using Michelin X Tyres:

at 10 m.p.h.

at 10 km /hr.

...

...

...

O.D.

Top Top

412

250

409

254

455 556

283

452

281 343 373

O.D.

3rd

545

501

310 340

498

541 660

309 336

604

345 375

552

601

O.D.

2nd 2nd

3rd

664 825 1007 1573 1615

410

510

820

1001 1563 1605

509 622 971

410

736

916

467

731

454

1170 1744 1790

579

910

1110

565 691

1st

620

970

694 1083

1733 1779

1077 1105

Rev.

1005

997

1112

Gearbox Ratios

3.7 : 1

Axle

Overall Ratios

4.1:1

Axle

Overall Ratios

...

...

...

GEAR RATIOS

O.D.

Top Top

0.82

3.034

3.36

3.7

4.17 4.46

O.D,

3rd 3rd

1

1.09 1.325 1.65 2.01

4.02

4.9

5.44

7

O.D.

2nd

2nd

6.1

7.44

6.76 8.24

1st

Rev.

3.139 3.223

11.61 11.93

12.87 13.21

SPORTS CAR

Page 9

INSTRUMENTS, SWITCHES AND CONTROLS

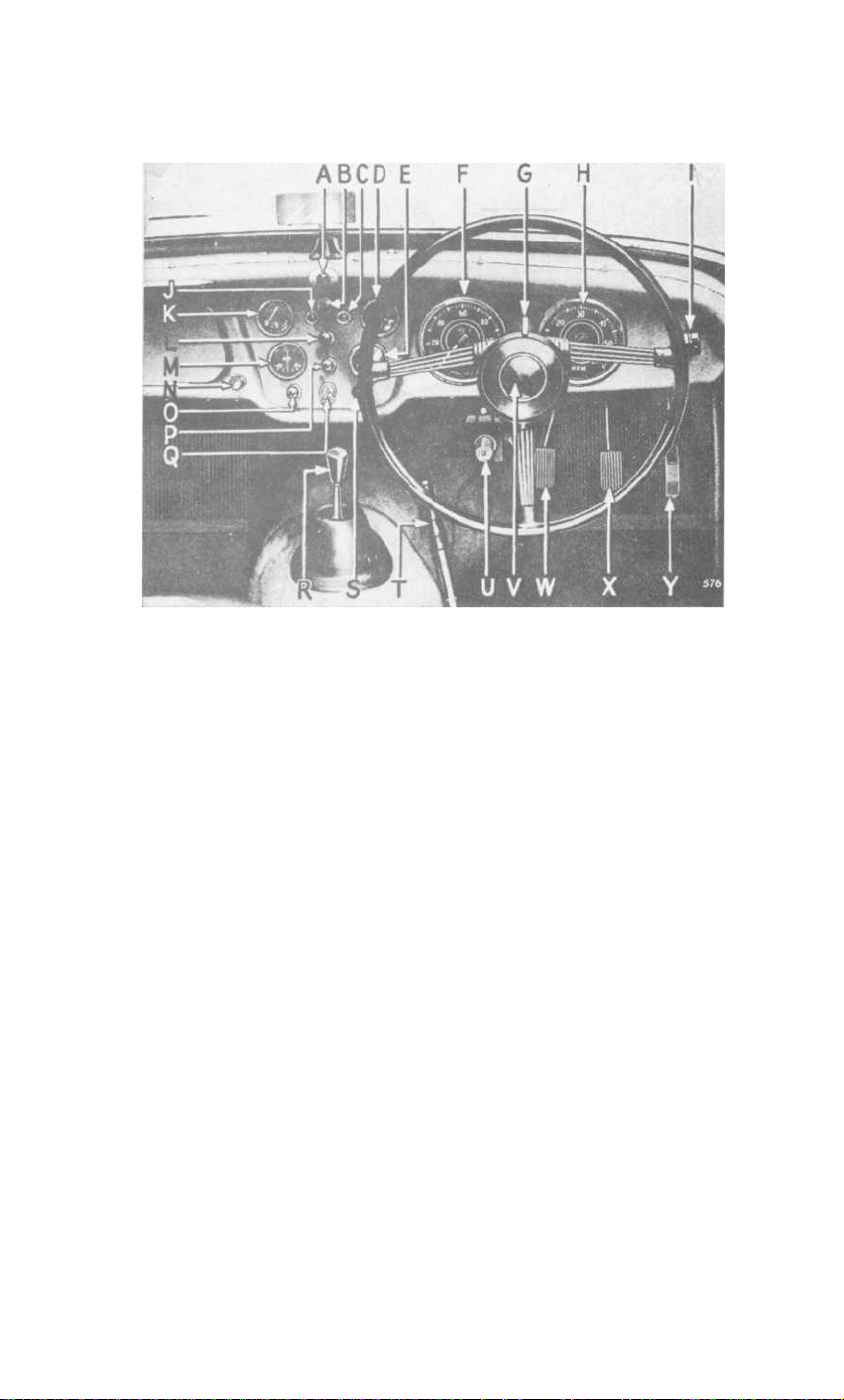

Fig. 2. Instruments, switches and controls.

NOTE :—In left-hand drive cars D changes with K, E with M, and F with H.

A

Scuttle Ventilator Control.

B

Windscreen Wiper Switch.

To open ventilator pull control knob.

Pull knob to operate ; they will only

function when the ignition is switched on. They will return automatically

to the parked position when switched off.

C

Direction Indicator Warning Light.

Will flash when the switch G

is operated and the ignition is switched on.

D

Oil Pressure Gauge.

Indicates pressure of oil at the bearings.

The gauge should read 70 lb./sq. in. minimum when the car is travelling

at normal speeds and the oil is hot.

Low pressure may be registered when the engine is idling or running at

low speeds ; this is quite normal.

E

Water Temperature Gauge.

the cooling water at the thermostat.

The gauge shows the temperature of

Under normal motoring conditions

the water temperature should not exceed 185°F.

F

Speedometer. Registers vehicle's speed and total distance covered,

and is fitted with a trip which is cancelled by pushing up the serrated

knob (situated under the instrument) and turning anti-clockwise.

G

Direction Indicator Switch.

These self-cancelling indicators will

only operate with the ignition switched on, and a warning light (C)

will flash on the dash panel when the switch is operated.

8

Page 10

INSTRUMENTS, SWITCHES AND CONTROLS

H

Tachometer.

Indicates the engine speed in revolutions per minute.

(See page 12).

I

Overdrive Control Switch.

J

Ignition Warning Light.

See page 51.

Glows red when the ignition is switched on

with the engine idling or stopped. It is an indication that current is

being drawn from the battery for the ignition circuit, or other purposes

that are controlled by the ignition switch.

K

Fuel Contents Gauge.

Registers the approximate amount of fuel in

the tank. It operates automatically when the ignition is switched on.

L

Instrument Panel Light Switch.

Turn knob clockwise to switch

on panel lights, further clockwise movement will progressively dim

the illumination.

These lights will only operate when the parking lights are switched on.

M

Ammeter. Indicates the flow of current into or out of the battery.

N

Screen Wash Control

(where fitted).

To operate push the control

knob.

O

Starter Switch.

Press to operate engine starter (see page 11 for full

instructions).

P

Head, Tail and Parking Lamp Switch.

parking lights.

head lights.

Turn slightly clockwise and pull again to switch on the

Press foot operated switch (U) to dip head lights, press

Pull knob to switch on

again for " full on " position, in which position a small red light

appears at the bottom of the speedometer dial.

Q

Ignition Switch.

Insert key and turn clockwise to switch on. Do not

leave the switch " on " when engine is stationary.

R

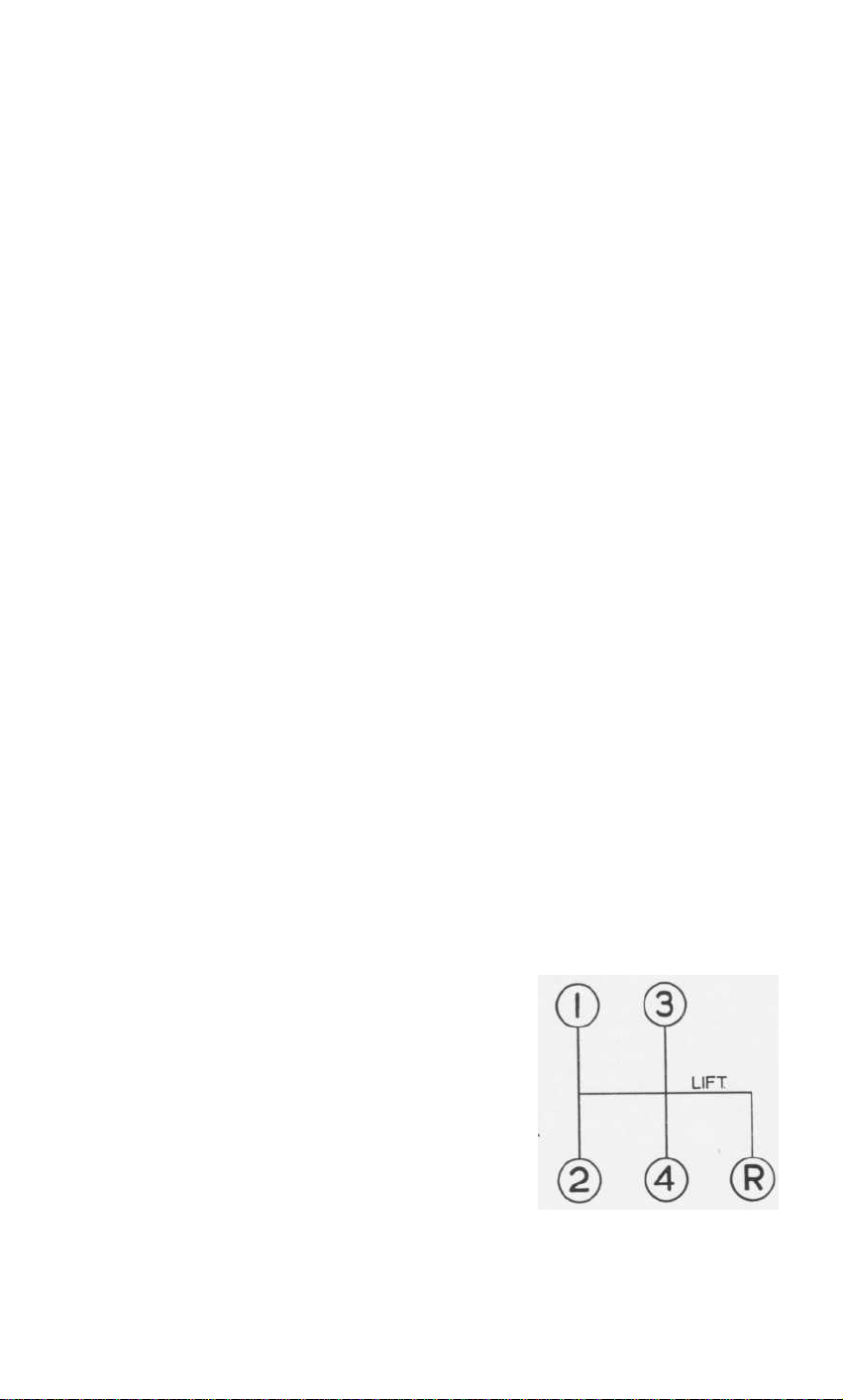

Gear Change Lever.

Choke Control. See page 11 for full instructions.

S

T

Handbrake.

Pull to operate rear wheel brakes, the handbrake lever can

See Fig. 3 for gear positions.

be retained in any position by pressing the button on the top of the lever.

To release the handbrake lever, first pull it, this will cause the pawl to

be automatically disengaged from the ratchet, the lever is then free to

move forwards and release the brakes.

Headlamp Dipper Switch.

U

Press foot

operated switch to dip headlamps; press again

for high beam position. A small red indicator

light in the speedometer glows when the

headlamps are operating in this position.

V

Horn Button.

Press button in centre of

steering wheel to operate horns.

Fig. 3.

9

Gear lever positions.

SPORTS CAR

Page 11

INSTRUMENTS, SWITCHES AND CONTROLS

W

Clutch Pedal.

Press pedal to disengage drive from engine to gearbox.

Do not rest your foot on the pedal when driving, or hold clutch out to

free wheel.

X

Brake Pedal.

Y

Accelerator Pedal.

Press to operate all wheel brakes hydraulically.

Press to accelerate the vehicle.

Radio Controls.

Seat Adjustment.

See page 51.

The seats are adjustable for " leg length " after operating

the lever which is situated at the side of the seat.

Heater Switch.

Bonnet Locks.

See page 51.

The fasteners at each side of the bonnet can be released by

turning them anti-clockwise with the special key provided. The safety catch is

situated under the front of the bonnet, in line with the " H " of TRIUMPH

and may be released with the fingers. (Fig. 4).

Fig. 4.

846

Releasing bonnet safety catch.

1

0

Page 12

DRIVING THE CAR

TO START THE ENGINE

IMPORTANT

If the engine does not start when the starter is first operated,

operate the starter again until both starter motor and engine have

come to rest.

Starting when Engine is Cold

Place the gear lever in the neutral position and apply the handbrake. Pull

the carburettor choke control out to its stop, switch on the ignition and

press the starter switch button.

the choke control and allow it to return to the

to lock in this position.

undue hesitation, push the control fully home. If the battery is low use

the starting handle.

the engine, do not keep the choke control out for too long or the sparking

plugs will become wet with petrol.

drying them.

in the carburettor float chambers may have evaporated.

circumstances, operate the hand primer on the fuel pump before the starter

is operated. (See page 37).

When operating the starter in very cold conditions, depress the clutch

pedal to relieve the motor of the considerable drag in the gearbox.

This will avoid damage to the starter pinion.

When the engine has warmed up, turn

half-out

position and turn

When the engine is sufficiently hot to run without

Should difficulty be experienced when starting

This will necessitate removing and

When the car has been left standing for some time, the fuel

do not

Under such

Starting with Engine Warm or Hot

When restarting a hot engine, depress the accelerator pedal to about onethird of its travel before pressing the starter button, the choke control

should not be used.

Warming up

In order to minimise cylinder wear when starting from cold in winter,

the engine should be warmed up quickly. Idle the engine until the oil

circulates and then speed it up. It should not be allowed to idle for long

periods and must not be raced up to high speeds when cold. An engine

speed of approximately 1,500 r.p.m. may be regarded as a desirable

warming up speed.

1

1

SPORTS CAR

Page 13

DRIVING THE CAR

DRIVING

Gear Changing

Use a slow and deliberate movement to change gear, and always move

the gear lever fully home.

of 15 m.p.h.

Reverse gear must not be engaged whilst the car is moving

Do not engage first gear at speeds in excess

forward.

Desirable Speed Limits (Particularly in gears lower than top)

Avoid over-revving, particularly in the lower gears.

not to drive the car continuously at engine speeds above

r.p.m. in any gear.

gears it is permissible to attain

However, whilst accelerating through the

5,000

The driver is advised

4,500

r.p.m. for short periods.

this speed being indicated by a red mark on the tachometer.

New Engines (see "Running Adjustments")

For at least the first 500 miles, the working surfaces of the engine will be

bedding down. The power and performance will improve only if the vehicle is

carefully driven at moderate speeds during the running-in period.

The engine should not be driven at speeds exceeding 3,500 r.p.m. during this

period, and the " running-in " should be progressive. The engine may " rev."

fairly fast so long as it is thoroughly warm and provided it is not

hard.

Do not let the engine pull hard at low speeds, always select a lower gear.

pulling

1

2

Page 14

GENERAL UPKEEP

REGULAR INSPECTION

Every 250 miles

necessary.

push fully home before withdrawing for reading. The lower mark on the dip-

stick indicates that 4 pints (Imperial) of oil will be required for topping up.

The regular addition of oil not only maintains the correct level, but also

to keep up the quality of the lubricant.

which must be lifted straight off.

Weekly,

Check :

clean rain water and keep the neck of the filler at least half full of water.

Re-check after the engine has been warmed. The use of hard water results

in a deposit on the inner side of the cooling surfaces, thus reducing efficiency.

Tyre pressures.

the spare tyre inflated to a slightly higher pressure than that recommended,

and reduce its pressure when the tyre is required for use.

Maintain the electrolyte level in the battery

separators.

subsequently attack the surrounding metal panels.

water when replenishing.

to prevent leakage.

electrolyte level.

check the oil level when the engine is cold, and top up if

Withdraw dipstick (F) (Fig. 5) and wipe clean, then insert and

Replenishment is via the cap (D)

The water level in the radiator and replenish if necessary.

The correct pressures are given on page 23.

level

with the top of the

Overfilling will cause electrolyte spillage which will

Use only distilled

Keep the filler plugs (A) (Fig. 5) screwed tight

Never use a naked light when checking the

tends

Use

Keep

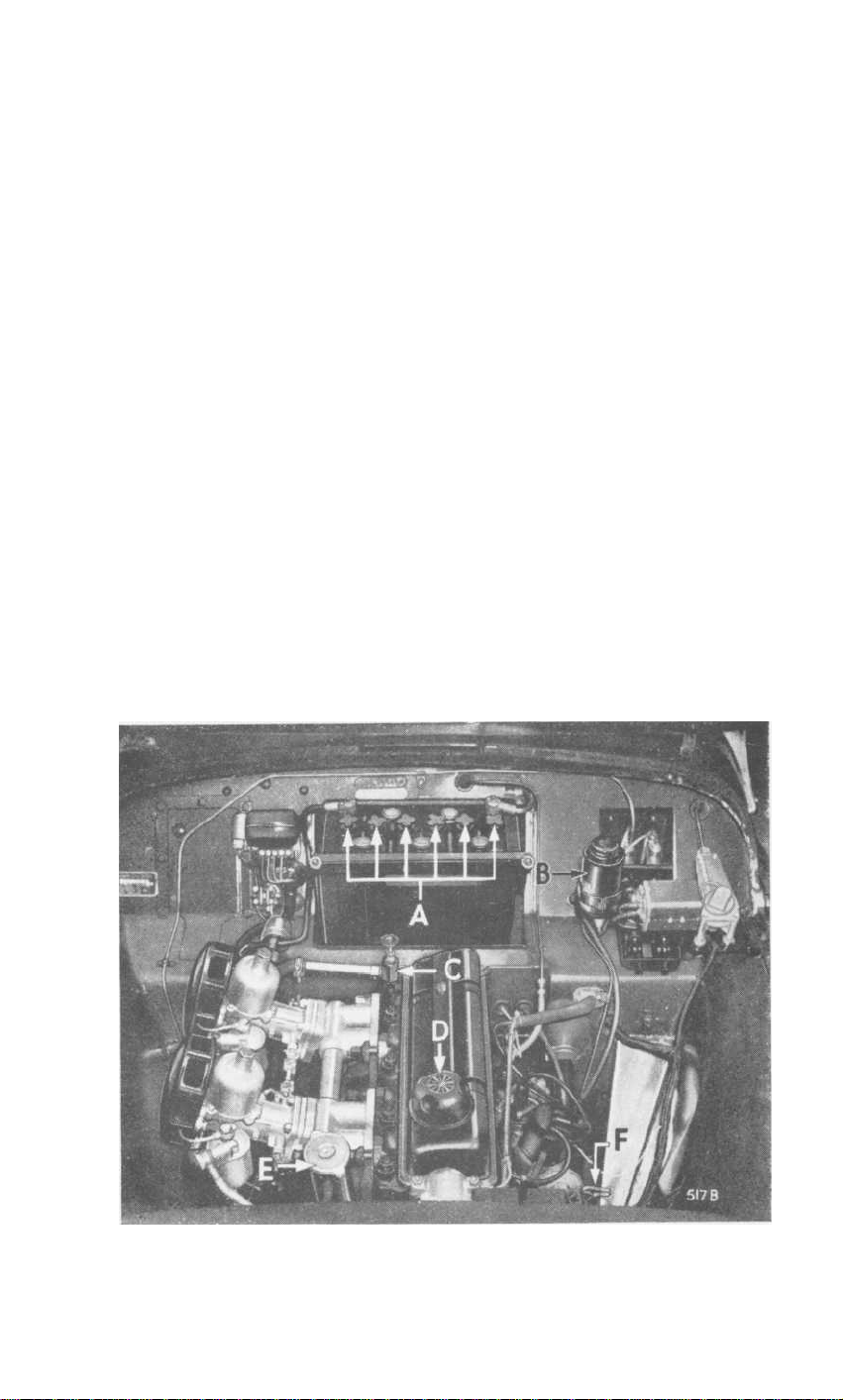

Fig.

5.

View under bonnet.

13

SPORTS CAR

Page 15

GENERAL UPKEEP

COOLING SYSTEM

Filling

(see page 13).

Draining

Taps are provided in the bottom tank of the radiator and at the rear of the

cylinder block on the right-hand side. As the cooling system is pressurised

it

will be necessary, when draining, to remove the radiator cap (E) (Fig. 5).

If a heater is fined, ensure that the tap (C) (Fig. 5) is open before draining.

Anti-Freeze Mixtures

Protect the cooling system during frosty weather and reduce corrosion to

a minimum, by use of an inhibited anti-freeze. The use of Smith's "Bluecol",

Duckham's

Anti-freeze,

Esso

Anti-freeze,

Castrol

Anti-freeze,

Shell

" Snowflake " or Mobil Permazone Anti-freeze (inhibited Glycol base

compound) is recommended. The cooling system is fitted with a thermostat

and there is a risk of the radiator block freezing while the engine is running

during the warming up period when the thermostat is shut, even though the

car has been left in a warm garage and water is not frozen at the start of the run.

Provide ample protection for the cooling system against a sudden fall in

temperature down to 0°F. (-18°C.) during frosty weather by using 3 pints

(Imperial) of anti-freeze.

In countries where sub-zero temperatures prevail, consult your Triumph

dealer regarding the quantity of anti-freeze required.

Do not use the same anti-freeze for more than one season since the

inhibitor becomes exhausted and the components in contact with the

cooling water may corrode.

LUBRICATION

This is one of the most important subjects in connection with the upkeep of a

car, and careful attention to the following instructions will be amply repaid by

the results obtained.

For the recommended periods of lubrication, see the lubrication

chart (page 54). The correct lubricants to be used are given on pages

52 and 53

.

1

4

Page 16

GENERAL UPKEEP

Draining

To drain the engine, gearbox and rear axle, remove the plug provided

beneath each unit.

This process is assisted by opening the filler to allow

ingress of air and by draining when the oil is hot, i.e., immediately after

a run.

ENGINE

Only first quality oils are recommended for use in the engine sump. These are

of correct viscosity and character to afford complete lubrication protection

for normal driving.

protection must

Additives which dilute the oil or otherwise impair this

not be used.

Engine Oil Drain Period

The frequency of the drain period should be related to the driving conditions

to which the vehicle is subjected. 3,000 mile intervals are recommended for

average driving conditions as defined below.

This should be reduced for

unfavourable conditions and may be extended for those more favourable.

Favourable

Long distance journeys, with little or no engine idling, on well surfaced

roads, reasonably free from dust.

Average

Medium length journeys on well surfaced roads with a small proportion of

stop/start operation.

Unfavourable

Any of the following:

(a)

Frequent stop/start driving.

Operation during cold weather, especially when appreciable

(b)

engine idling is involved.

(c)

Where much driving is done under dusty conditions.

An upper cylinder lubricant may be used to advantage, during the runningin period of a new engine. The lubricant should be mixed with the fuel in the

proportions given on the container.

Such lubricants

may be used with

advantage throughout the life of the vehicle, particularly during wintry

weather.

1

5

SPORTS CAR

Page 17

GENERAL UPKEEP

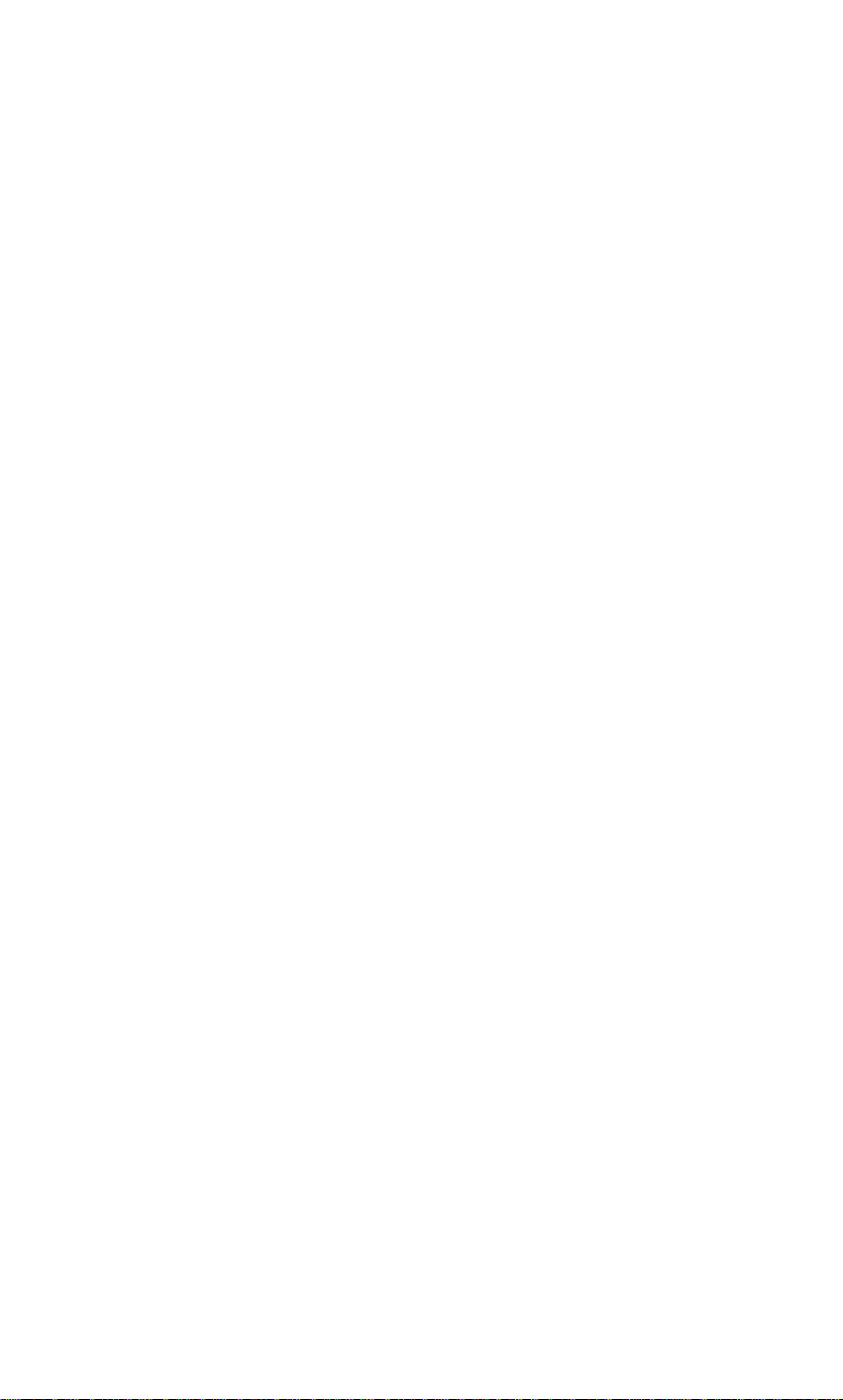

Fig.

6.

Replenishing dashpots.

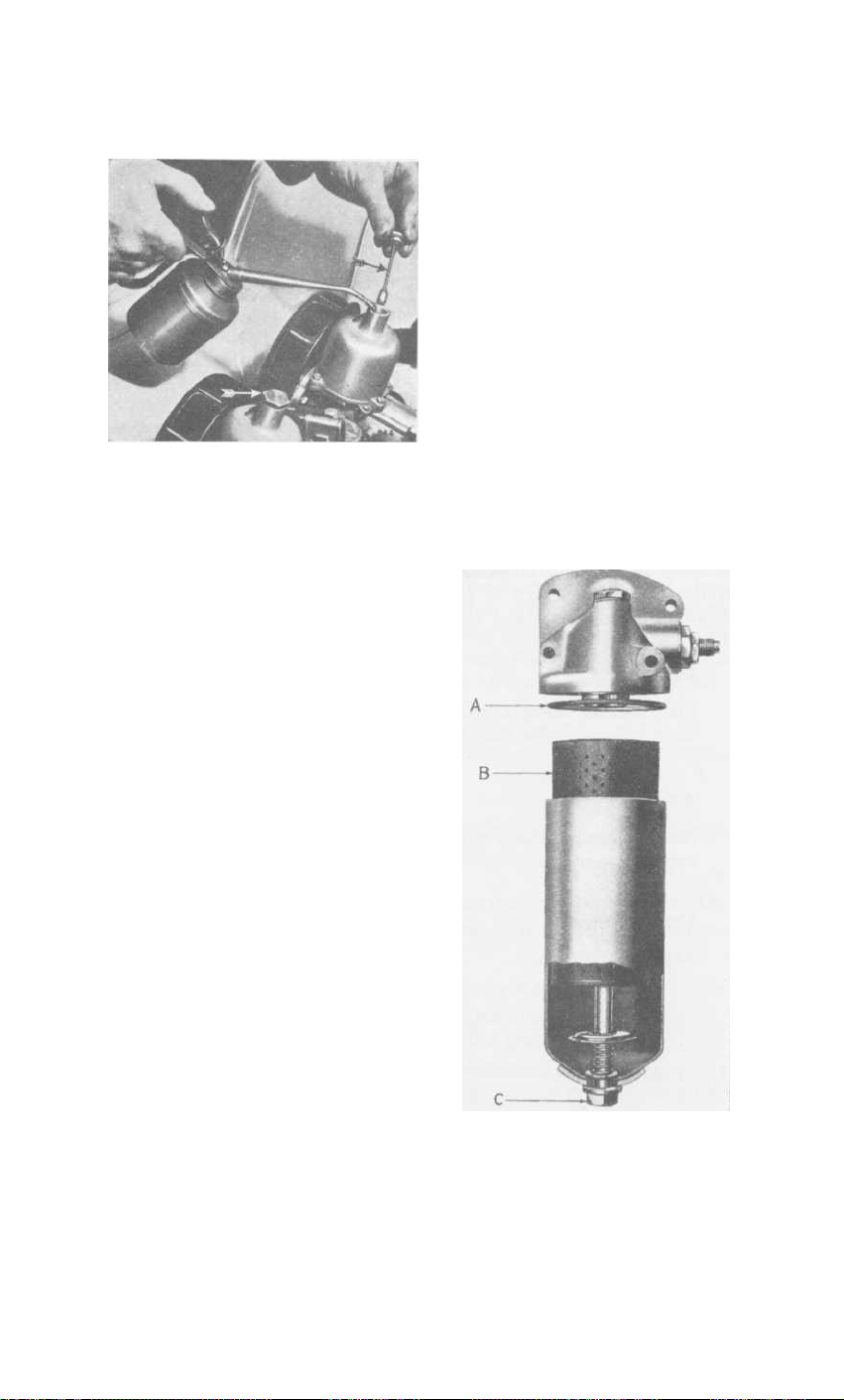

The Oil Filter

The oil filter is designed to filter the

oil to a very fine degree. It will continue to do this provided that the old

cartridge (B) is removed and a new

replacement cartridge is fitted at periods

not exceeding 6,000 miles. Should this

operation be neglected, the cartridge

will become choked and unfiltered oil

will then be passed to the engine via the

balance valve in the filter. To renew the

cartridge,

unscrew the securing bolt

(C), remove the container and withdraw

the cartridge.

Wash out the container to remove

foreign matter trapped by the filter, and

discard the old container washer (A),

replacing it with a new one each time

the cartridge is renewed.

When reassembling the container, ensure that

the washer is correctly positioned in the

groove in the filter body.

Do not

tighten the bolt (C) more than is necessary to obtain an oil-tight joint.

Drain

the engine oil and refill with fresh oil

before re-starting the engine.

Every

3,000

miles

remove the

dampers (indicated by arrows) and

replenish the dashpots with oil. The

oil level is correct when, utilizing

the damper as a dipstick its threaded

plug is approximately ¼"above the

dashpots,

when resistance is felt.

Apply oil to the throttle linkage but

do not oil the bearings of the transverse rod attached to the bulkhead

as this will seriously deteriorate the

sealing compound.

Fig.

7.

Oil

Filter " full-flow " type.

1

6

Page 18

GENERAL UPKEEP

Ignition Distributor

Every 6,000 miles smear the cam (B) with engine oil.

squeak occurs when the cam is dry.

(Fig. 8)

A pronounced

Withdraw the moulded rotor arm

from the top of the spindle and apply a few drops of thin machine oil

around the edge of the screw (A) to lubricate the cam bearings and

distributor spindle.

At the same time, place a single drop of clean engine

oil on the pivots (C) and (D).

Fig. 8.

Ignition distributor.

Water Pump

One nipple is provided (see arrow Fig. 9) to which the grease gun should

be applied every 6,000 miles.

Give five strokes only with the gun.

Fig. 9.

Water pump.

Grease nipple arrowed.

Generator

After completing 20,000—30,000 miles, remove the generator for cleaning,

adjustment and repacking the front bearing with grease.

This should

be done preferably by the nearest Triumph or Lucas Service Depot.

Every 6,000 miles pour a few drops of engine oil through the hole in the

centre of the rear end cap.

1

7

SPORTS CAR

Page 19

GENERAL UPKEEP

Air Cleaners

Every 6,000 miles, remove the air cleaners and wash them in petrol,

particularly the gauzes, which must then be soaked in oil and allowed

to drain before finally wiping them over and refitting. It is very important

when refitting the air cleaners that the holes immediately above the

setscrew holes in the carburettor are aligned with similarly positioned

holes in the cleaner.

Oil Filler Cap

Every 6,000 miles remove and rinse the cap in fuel, dry off and re-fit.

GEARBOX

Every 6,000 miles check, and if necessary, top up the oil level via the plug (1).

Every 12,000 miles drain the gearbox by removing the plugs (1) and (2).

Replace the plug (2), replenish via plug hole (1) and finally tighten both plugs.

If an overdrive is fitted, see page 51.

Fig. 10.Gearbox oil filler level plug (1)

and drain plug (2).

REAR AXLE

To ensure efficient operation and long life of the hypoid bevel gears, use only

those special lubricants recommended

pages 52 and 53. Drain the axle

on

and replenish with new " Hypoid " oil every 6,000 miles.

1

8

Page 20

GENERAL UPKEEP

Check the oil level during this period, especially after the first 1,000 miles,

and replenish if necessary to level with bottom of the threads in the filler

orifice.

Should a top-up be necessary, investigate the cause of oil loss.

filler plug fitted to the rear axle cover is accessible from underneath the car

(see arrow A, Fig. 11). Clean away mud before unscrewing the filler plug to

avoid grit falling into the axle.

BRAKE AND CLUTCH OPERATION

The hydraulic fluid for clutch and brake operation is contained in a single

reservoir

which has an inner and outer chamber.

The inner chamber is

connected to the clutch withdrawal mechanism and the outer chamber to the

brakes.

Check the fluid level every 1,000 miles.

with the top of the inner chamber.

use only the special fluid recommended.

The fluid must be maintained level

When filling or topping up the reservoir,

Any other fluid may be dangerous.

Clutch Shaft Bearings

Apply the grease gun to the clutch shaft bearing grease nipples (one at each

side of the clutch housing) every 6,000 miles.

One shot is sufficient.

nipples are accessible from underneath the car. (See arrow (3), Fig 32, page

38).

The

The

Clutch and Brake Pedal Bearings

Apply the oil can to the various pivots, etc., of the pedal linkages, both

under the bonnet and in the driving compartment.

Fig. II.Rear axle oil filler and handbrake compensator.

1

9

SPORTS CAR

Page 21

GENERAL UPKEEP

Handbrake Cable Conduit

Every 6,000 miles, apply the grease gun to a grease nipple fitted in the conduit,

as shown on the lubrication chart.

During the winter months it is important to keep the cable regularly lubricated.

This will prevent the entry of water and the possibility of freezing which would

lock the brake cable.

When lubricating the cable, pump the gun until grease exudes from the end of

the conduit.

Handbrake Compensator.

Lubricate the handbrake compensator via the two grease nipples (B) (Fig. 11)

every 6,000 miles.

ROAD WHEEL HUBS

Front

Every 12,000 miles (if the vehicle is used for competition work every 6,000

miles) repack the hubs with grease. This involves removing the hubs and

washing the bearings to remove all traces of the old grease before packing

the rollers and races with new grease.

Do not disturb the pipe unions but

unbolt and move the complete caliper to allow the hub and disc to be

removed.

Take care not to lose shims which may be fitted between the

caliper and the vertical

link.

When replacing, ensure

that the inner race is tight

against

its

shoulder.

Tighten the hub nut until

resistance is felt to hub

rotation, then slacken off

the nut by one half flat

and insert the split pin

through one of the two

holes provided.

Rear

Every 6,000 miles, give

five strokes of the grease

gun to a nipple (2) (Fig.

12), situated behind the

rear

backing plate and

facing downwards.

Fig. 12.Brake Backing plate Details.

20

Page 22

GENERAL UPKEEP

FRONT SUSPENSION AND STEERING

Nipples are provided for lubricating the steering swivels (A), outer tie rod,

ball joints, outer bushes of. the lower wish-bones (B) (Fig. 13), and the

steering slave drop arm pivot.

drop arms as they contain rubber.

Do not lubricate the joints attached to the

Lubricate the inner nylon wish-bone

bushes with oil occasionally. A pronounced squeak develops when these bushes

become dry.

When greasing the lower suspension swivels it is an advantage

to jack up under the road spring pan until the front wheel is free of the

ground.

This allows grease to cover the thrust faces.

Grease these points

every 1,000 miles.

After greasing the steering swivels, wipe away all surplus grease.

This will

prevent it from contaminating the disc brakes.

Fig. 13.

Front suspension lubrication.

2

1

SPORTS CAR

Page 23

GENERAL UPKEEP

Every 6,000

miles,

lubricate the steering

box after removing

the rubber plug

situated on the steer-

ing column and top

up with oil to the

level of the orifice.

Fig.

14.

Steering box filler/level plug (arrowed).

REAR ROAD SPRINGS

Paint over the spring blades with old rear axle or engine oil, particularly

around the blade tips and clips. Avoid lubricating the rubber bushes which

are fitted in all the rear spring eyes.

HYDRAULIC DAMPERS

The front telescopic dampers do not require " topping up."

Top-up the rear dampers with

to the level of the bottom of the plug hole (arrowed Fig. 35), every

son)

12,000 miles.

When topping up, it is essential that dirt is prevented from

Armstrong Shock Absorber Fluid (Crim-

finding its way into the interior. Faulty dampers can only be serviced by the

manufacturers.

PROPELLER SHAFT (Fig. 15)

Every 1,000 miles, lubricate the

needle roller bearings and splines.

Supply the nipple (B) at each end

of the shaft with oil for the bearings,

and the nipple (A) with grease for

Fig. 15

Propeller shaft lubrication points.

.

the splines.

HINGES, CONTROLS, DOOR LOCKS, ETC.

Give occasional attention with an oil can to the bonnet catches, hinges and

several small control joints.

Door locks should receive a drop of oil every

month to ensure easy operation and to prevent corrosion. Attention given to

the connections on the handbrake and ratchet mechanism, etc., will enable the

controls to work freely and prevent unnecessary wear.

2 2

Page 24

TYRE PRESSURES

OPERATING CONDITIONS

Normal motoring with sustained

speeds limited to 85 m.p.h.

Fast motoring on Motorways and

similar

speeds up to 100 m.p.h.

High speed tuning with speeds

regularly in excess of 100 m.p.h.

roads

with

sustained

Goodyear Allweather

Rib

and

Dunlop Gold Seal

5.50/5.90-15 5.50/5.90-15 5.50/5.90-15

Lbs. per sq. in. Lbs. per sq. in.

Front

...

...

20

26 30 20 24

Not

recommended

Rear

24

Goodyear Allweather

Rib Nylon

and

Dunlop Gold Seal

Nylon

Front

20

26

Rear

24

30

Goodyear Motorway

Special

and

Dunlop Road Speed

R.S.5

Lbs. per sq. in.

Front

20

20

20 24 24 32

Rear

24

24

Goodyear D.F.S.

(165—380)

Michelin

(165/15X)

(165/15X)

Lbs. per sq. in.

Front

24

24 32

and

Rear

32

Page 25

GENERAL UPKEEP

TYRES

The maintenance of correct tyre pressures is important to the life of the tyres

and behaviour of the steering and suspension.

Examine the tyres occasionally for flints or other road matter which may have

become embedded in the tread. By using fuel sparingly, clean off any oil which

may have got on the tyres. Driving into or over sharp edged kerbs is liable

to fracture the walls of the tyres and should be avoided where possible.

Changing Position of Tyres

Every 3,000 miles interchange the front tyres with rear tyres.

Diagonal

interchanging between left front and right rear and between right front and

left rear provides the most satisfactory first change. This reverses the direction

of rotation and keeps the wear of the tyres even and uniform.

FRONT WHEEL ALIGNMENT

Alignment of the front wheels is most important in its effect on tyre wear

and good steering. Excessive toe-in will lead to severe tyre wear, particularly

on the " kerb side " front tyre.

The front wheel alignment should be parallel to ⅛

"

toe-in when the following

tyres are fitted :

Dunlop Gold Seal, Dunlop Gold Seal Nylon, Dunlop Road Speed, Goodyear

Allweather Rib, Goodyear Allweather Nylon, Motorway Special.

When Goodyear D.F.S. and Michelin X tyres are fitted the front wheel align-

ment should be parallel to 1/16

" toe-in.

To Check and Adjust Wheel Alignment

If adjustment is found necessary it should be carried out equally on the

two outer tie-rods.

When adjustment is complete ensure that the ball

joints are in the centre of " swing " before securely tightening the tierod locking nuts.

THE JACK

A screw-jack is provided which is adapted to lift either side of the car as required.

Apply the handbrake, or chock the wheels which will remain on the ground,

before operating the jack.

To fit the jack in position (Fig. 16), turn up the

carpet and remove the rubber plug situated just in front of the seat. Engage

the lower lip of the jack boss with the bottom edge of the rectangular hole,

then swing the jack into a vertical position and lift, make sure that it is right

2 4

Page 26

GENERAL UPKEEP

home in its socket

before operating the

jack handle.

If a jack is used under

the rear axle case,

ensure that the jack

pad does not touch

the rear cover plate

when lifting, otherwise there is a risk

of damage and consequent oil leakage.

Fig.

16.

Jacking the car.

WHEEL ATTACHMENT

Before removing a road wheel ensure that the wheel is clear of the ground and

the vehicle is safely supported.

Pressed Steel Wheels

After removing the nave plate (Fig. 17), the wheel nuts (R.H. thread) can

be detached with the wheel brace (2) (Fig. 20).

Wire Wheels

A copper faced hammer is provided with cars fitted with wire (" knock on ")

wheels to facilitate hub cap removal. Turn the huh caps on the right-hand side

of the car clockwise and the hub caps on the left-hand side anti-clockwise to

remove.

Fig. 17.

Removing nave plate.

2 5

Fig. i8.

Removing L.H. front hub

SPORTS

cap.

CAR

Page 27

TOOLS

Fig.

19.

Tools stowed in spare wheel compartment.

The jack and wheel brace are situated in the spare wheel compartment

(Fig. 19).

luggage compartment. If the vehicle has wire wheels, then the wheel brace

(2), combination tool (5) (Fig 20), are omitted from the tool kit and a

screwdriver, tommy bar and copper-faced hammer are included.

The remaining tools are placed in the tool roll and stowed in the

1.

Jack handle.

2.

Wheel brace.

3.

Starting handle. (Special Order)

4.

Jack.

5.

Combination tool

(Screwdriver, tommy bar,

and nave plate remover).

6. Valve core remover/replacer.

7.

Pliers.

8.

Spanner.

9.

Spanner.

Fig.

20.

2 6

Tools.

Coach key.

10.

11.

Headlamp rim remover.

12.

Spanner. (⅝" x ¾" A.F.)

13.

Tool roll.

Adjustable spanner.

14.

15.

Box spanner.

16.

Box spanner.

17.

Grease gun.

18.

Feeler gauges.

19.

Screwdriver and feeler gauges

(distributor points).

Page 28

BODYWORK

Dust may be removed from the exterior by using a soft cloth only, but if it has

been wet at any time it is advisable to use a sponge and water. Always use

water when removing mud and when the car is clean finally wipe over with

an almost dry chamois leather.

of the paintwork over an indefinite period and it may become necessary to

use a cleaner to remove all grease and dirt. It is advisable to acquire the

cleaner from a reputable dealer who will be able to supply you with the best

cleaner to suit the particular paintwork of your car.

may be used to advantage.

Special cleaners are available for removing traffic film and tar.

plated parts need cleaning with soap and water, and wax polishing is beneficial.

due to neglect, the plate becomes spotted, it may be necessary to use a

If,

chromium plate cleaner.

Dust interior of the car occasionally and brush the carpet with a stiff brush.

The upholstery may be cleaned by the application of a little soap and damp

cloth, followed by a final wipe down with an almost dry sponge or chamois

leather.

Never use detergents as these may affect the surface of the material.

When a vacuum cleaner is available it can be used with advantage to help

clean the interior.

Washing alone will not keep up the brilliance

A non-abrasive polish

Chromium

DOOR ADJUSTMENT

The doors are provided with special locks which, when correctly adjusted,

prevent any movement of the closed door.

Only the striking plate requires

repositioning when adjustment becomes necessary.

This adjustment is best carried out by a coach fitter.

SOFT TOP MAINTENANCE

The top should be washed with the same regularity as the rest of the car.

With the exception of warm water and non-caustic soap, the use of all cleansing

agents, detergents and wax polishes must be avoided.

Never leave the top folded when it is wet or damp.

Occasionally oil the hinge points of the hood sticks (support frame) with

engine oil, work the moving parts, and wipe all surplus oil away.

Removal and Stowage of Side Screens

The key provided for opening the bonnet also releases the special catches

which secure the side screens to the door panel.

Release the fastener securing the short strap on the centre of the screen to the

door.

Turn the key in an anti-clockwise direction to release the catches and lift the

screen clear of the door.

The side screens may be completely removed from

the car or stowed away in the luggage locker.

2 7

SPORTS CAR

Page 29

BODYWORK

A.

Soft top rear attachment points.

B.

Hood support sticks raised.

C.

Soft top front attachment points.

Fig. 21.Soft top details.

D.

E.

F.

28

Hood support sticks lowered.

Hood support stick cover.

Utilizing key 10 (Fig. 20) to

detach side screens.

Page 30

BODYWORK

Fig.

22.

"

Tenax " soft top fasteners.

Removal and Stowage of Soft Top

Two types of fasteners are used.

They are " Lift the Dot " and " Tenax ".

When fitting either type it is only necessary to push fasteners over the securing

stud as shown in Fig. 22.

With the " Tenax " type (as illustrated) do not press

or pull the small knob before engagement as there will be risk of damage to the

inner prongs.

After fitting, the knob may be pressed to ensure correct engagement.

To

remove the fasteners, either pull the small knob, or in the case of the " Lift

the Dot ", do as its title suggests, lift the outer edge.

When removing the fasteners from the screen, relieve the tension on the

fasteners by applying a slight hand pressure, in the forward direction, to the

corner of the soft top where it passes over its supports.

Release the fasteners at the top of the windscreen, allow the material to hang

down on the seats and release the fasteners from rear waist moulding.

Fold the top material taking care not to crease the rear windows and stow

it away in the locker.

Press the hood sticks downwards into the back of the car. The lower hinge

must be pushed below centre and then forward to enable the sticks to fold

down into line with the rear of the body.

Fit and secure the hood stick cover utilising the pegs on the waist line and the

rear of the seats.

2 9

SPORTS CAR

Page 31

BODYWORK

Fig. 23.

A.

Hard top fitted.

B. Tonneau cover fitted.

Hard top and tonneau cover.

C.

Front hard top fixings (3 off)

D.

Rear hard top fixings (5 off)

30

Page 32

RUNNING ADJUSTMENTS

Various adjustments are necessary from time to time in order to maintain the

mechanism in good running order.

carrying out these adjustments since this is dependent upon the manner in

which the vehicle is used.

The most important adjustments and the re-

commended intervals between, are as follows.

Cylinder Head Nuts

After the first 1,000 miles check the cylinder head nuts for tightness

whilst the engine is hot, in the order shown on Fig. 24.

No definite period can be stated for

ENGINE

Fig.

24.

Order of tightening cylinder head nuts.

Valve-Rocker Clearances(measured cold)

Set the inlet and exhaust valve-rocker clearances at 0.010". These

settings are correct for both normal and high speed running.

Ignition Timing

4° before Top Dead Centre (crankshaft angle).

Use only Premium grade fuels of 95 octane or higher and so long as the

engine is free from carbon, it will not pink. A substantial carbon build-up

may cause " pinking ". This will necessitate retarding the ignition slightly

so that " pinking " is just audible when pulling hard when the engine

speed is in excess of 1,500 r.p.m.

To advance ignition, rotate the knurled screw on the distributor. Each

division on the distributor vernier scale represents 2° on the distributor,

i.e.,4° on the crankshaft.

The firing order is 1, 3, 4, 2.

3

1

SPORTS CAR

Page 33

RUNNING ADJUSTMENTS

Fig. 25.

Ignition leads.

To obtain TDC rotate the

crankshaft until the inlet

valve of No. 1 cylinder is

open then slowly turn the

crankshaft until the small

hole in the crankshaft belt

pulley

ti

aligns

with

ming cover pointer (Fig.

the

26).

Fig. 26.

TDCindication.

Sparking Plugs

It is important that the correct type of sparking plugs are fitted when making

replacements, and that the electrode gaps are set to 0.025" (0.65 mm.).

For normal road work use

For high-speed touring use

For competition work use

...

LODGE, CNY

...

LODGE, HN

...

LODGE, 2HN

In certain cases when a lower compression ratio is used due to the nonavailability of high octane fuel, it may be necessary to use softer plugs,

Lodge CN.

Incorrect gap settings may cause misfiring or erratic slow running.

Clean

and adjust the sparking plugs at 3,000 miles (5,000 km.). Renew all sparking

plugs at 12,000 miles (20,000 km.).

32

i.e.

,

Page 34

RUNNING ADJUSTMENTS

TWIN S.U. CARBURETTORS (Type H6)

Tuning

Multi-carburettor installations cannot be successfully tuned unless the

general engine conditions (such items as tappet clearance compressions) and the

ignition system are in a satisfactory state.

With regard to the carburettors

themselves the cleanliness of the suction piston units, the position of the

needles, the jet centring and oil level in dampers, etc., should be checked.

With the aforementioned in a satisfactory state, refer to Fig. 27 and proceed as

follows :-

Remove air cleaners from carburettors.

1.

Slacken clamping bolt on throttle connecting rod (4) so that throttles may

2.

be set independently.

Ensure that the throttle adjusting screws (3) are

holding the throttles open and that the jet adjusting nuts are not screwed

right up.

Ensure that the screw (2) is clear of its abutment and that the choke

3.

Disconnect the mixture control rod (5).

cable is not likely to hamper jet adjustment. If necessary, disconnect

choke cable.

With the engine at normal running temperature and the idling speed

4.

approximately 500 r.p.m., check the hiss of air at carburettor intakes

with a piece of tubing approx. ⅜" (9.5 mm.) bore.

Carburettors.

3.

4.

Mixture control rod.

Throttle adjusting screws.

Throttle connecting rod.

1.

Air cleaners.

2.

Choke control screw.

Fig. 27.

5.

3 3

SPORTS CAR

Page 35

RUNNING ADJUSTMENTS

5.

With a downwards pressure on the throttle adjusting screw (3), adjust

the appropriate screw until the level of hiss is similar at both carburettor

intakes and the idling speed approximately 500 r.p.m.

To reduce hiss at carburettor intake, UNSCREW the adjusting screw.

6.

When level of hiss is similar, stop engine and with a downward pressure

on the rear throttle arm, tighten the throttle spindle clamping bolt and

re-check hiss.

7.

Start the engine and allow it to idle at approximately 500 r.p.m.

Check mixture on each carburettor in turn by lifting the piston approxi-

8.

mately ⅛"(3 mm.) with a pen-knife blade or lifting pin (3) (Fig. 28).

9.

If when the piston is lifted the engine speed increases the mixture is too

rich and the nut (7) should be screwed up one flat. If the engine speed

decreases unscrew nut (7) one flat.

10.

Continue adjustment on

no increase, or a very slight increase followed by a fall in engine speed is

noticed.

regular and even.

11.

Attach choke cable (if previously disconnected).

control rod, ensuring that the jet levers are pressed forward and the

control rod is adjusted correctly for length.

12.

Replace air cleaners.

13.

Re-check idling speed and mixture.

The mixture is then satisfactory and the exhaust note should be

each carburettor until when the piston is lifted,

Reconnect the mixture

Jet Centralizing

When the suction piston is lifted by hand (engine not running), it should fall

freely and hit the jet bridge with a soft metallic click—that is, with the jet

adjusting nut (7) in its topmost position.

If this click is not audible, but is so when the test is repeated with the jet in

the fully lowered position, then the jet unit requires re-centralising on the

needle, as described below.

may be helpful to understand that the complete jet unit, clamped in

It

position by the gland nut (4), is held in a clearance bore that permits a limited

amount of radial float, prior to being locked.

slackened, the jet assembly can be moved until it is concentric with the needle,

thus enabling the piston to move freely to its lower position.

The procedure for re-centralising is as follows :

1. Remove air cleaners.

2.

Remove return spring (6), pivot pins (8), and swing linkage to one side

(disconnect the choke cable if necessary).

3.

Withdraw jet (9), unscrew adjusting nut (7) and remove spring (5).

4.

Remove damper assembly (2).

Replace adjusting nut (7), screwing it to its upper position.

5.

6.

Slacken gland nut (4) and insert jet (9).

(Fig. 28)

Therefore, if the gland nut is

3

4

Page 36

RUNNING ADJUSTMENTS

Air cleaners.

1.

2.

Dampers.

3.

Piston lifting pin.

4.

Gland nut.

5.

Jet spring.

Fig.

28.

Carburettors.

Mixture control rod.

11.

6.

Return spring.

7.

Jet adjusting nuts.

8.

Pivot pins.

9.

Jets.

10.

Choke cable.

Whilst holding the jet (9) in its upper position, move the jet assembly

7.

laterally

gland nut (4).

until the jet is concentric with the needle, then tighten

This condition has been achieved when the piston

assembly will fall freely and evenly, hitting the jet bridge with a soft

metallic click.

Withdraw the jet and re-check to see if there is any difference in the

sound of the impact, if there is and the second test produces a sharper

mpact sound, the centralising operation will have to be repeated until

i

successful.

In the occasional obstinate case the jet adjusting nut (7) as well as the

8.

spring (5) should be temporarily removed to enable the jet to reach a

higher position and make the centralising effect more positive. Replace

the spring (5), adjusting nut (7), jet (9), pivot pins (8) and

secure with new split pins after the successful conclusion of the operation.

Before replacing the air cleaners, replenish the dampers and tune the

carburettors, see pages 16 and 33.

35

SPORTS CAR

Page 37

RUNNING ADJUSTMENTS

Float Chamber Fuel Level

The level of the fuel in the float chamber is adjusted by setting the fork

lever in the float chamber lid. It is suggested that the following procedure for

its adjustment is adopted,

1.

Disconnect the fuel feed pipe from the float chamber lid, then remove the

lid securing nut, washers and overflow pipe.

2.

Lift the lid off the float chamber.

3.

The set of the forked lever is correct, when, with the lid of the float

chamber inverted and the shank of the forked lever resting on the needle

of the delivery valve, it is possible to pass a 7/16"(11

mm.) diameter rod,

see " A " Fig. 29, between the inside radius of the forked lever and the

flange of the lower face of the float chamber lid.

If the forked lever fails to conform within 1/32"(.8

mm.) of the check

figure, it must be carefully bent, at the start of the fork section, taking

care to keep both prongs of the fork level with each other.

must be emphasised that it is not advisable to alter the fuel level

It

unless there is trouble with flooding. Although too high a level can cause

slow flooding, particularly when a car is left ticking over on a steep drive,

it should be remembered that flooding can also be caused by grit in the

fuel jamming open the needle valve, undue friction in the float mechanism,

excessive engine vibration, or a porous float.

Re-assemble the carburettor and connect fuel pipe.

4.

Fig.

29.

Adjusting the fuel level.

Cleaning Suction Chamber and Piston

This should be done at approximate intervals of twelve months.

After

detaching the unit, clean the main inside bore of the suction chamber, and the

two outside diameters of the piston with a rag moistened in petrol and then

re-assemble in a dry and clean condition with a few spots of thin oil on the

piston rod only.

Do not forget to replenish the damper reservoir after this

operation.

3 6

Page 38

RUNNING ADJUSTMENTS

Needles

The correct needle for normal and competition work is S.M.

When the

carburettors are fitted with oil bath air cleaners use CIW needles.

The needle should be fitted with its shoulder flush with the under face of the

piston (Fig. 30). It is retained in position with a screw.

FUEL PUMP

The mechanically operated fuel pump, mounted on the left-hand side of

the crankcase, provides a constant pressure of fuel to the carburettors.

hand primer is fitted, which can be used to pump fuel to the carburettors

if the float chambers are not already full, under which condition a slight

pumping resistance is felt before the lever reaches its stop.

This resistance

ceases when the chambers are full.

A

Fig.

31.

3 7

Fuel pump.

SPORTS CAR

Page 39

RUNNING ADJUSTMENTS

The glass bowl acts as a sediment chamber for the petrol passing to the pump.

This foreign matter collects on the underside of the gauze and, being washed

off by petrol, sinks to the bottom of the bowl. To remove the sediment, detach

the bowl by unscrewing the nut (arrowed Fig. 31) at its base and wash out

the bowl with the fuel that will be in it.

the nut sufficiently to ensure a fuel-tight joint.

When refitting the bowl, tighten

Over-tightening

may result

in damage.

CLUTCH

The clutch reservoir is the same as that used for the brake system. (See (B)

Fig 5, page 13).

There is a partition in the container which separates the two systems and

ensures that any defect in one system does not affect the other.

Adjustment of the mechanism is checked at the connecting rod between the

operating cylinder and the shaft operating lever end (see Fig. 32). The correct

setting is when there is 0.1" end float of the rod between operating cylinder

and lever, in the " foot off " condition.

total

movement of the operating lever by hand and if different from the

To achieve this setting, measure the

specified amount release the locknut (2, Fig. 32) and adjust the length of the

connecting rod to the correct figure.

The adjustable connection between

pedal and master cylinder is set on initial assembly and MUST NOT be altered.

If a pipe has been disconnected, it will be necessary to bleed the system.

A bleeder nipple is shown by the arrow (1, Fig. 32). For instruction on bleeding

the system see page 40.

Fig.

32.

Clutch slave cylinder.

3

8

Page 40

RUNNING ADJUSTMENTS

BRAKES

The pedal operates the brakes on all four wheels hydraulically, whilst the

handbrake operates the brakes on the rear wheels by means of cables.

See page 19 for checking level of fluid in reservoir. If the level of fluid is

particularly low, this indicates that a leak has developed in the system.

This

must be traced and rectified without delay.

It

must be remembered that the presence of oil, grease or similar foreign

matter on a drum brake shoe will seriously affect retarding effect of that

particular brake, in spite of the fact that it is being applied with the same

force as the others. In such cases thoroughly clean the brake drum with

fuel and fit new replacement shoes. Cleaning the brake shoes is not satisfactory.

Do not re-line the shoes but fit genuine Girling replacement shoes. These have

the right type of lining machined to the correct radii.

Should the shoes be removed, exercise care when replacing them to ensure

that the pull-off springs are located behind the shoes and hooked through the

correct holes, as shown.

Fig. 33.

R.H. front disc brake

assembly.

Fig.

34.

R.H. rear brake assembly.

Front Brakes

The disc brakes, fitted to the front axles, are self-adjusting and should

only need replacing when the shoe pads are reduced to approximately

⅛"

thickness.

Rear Brakes

The rear brakes are provided with a small adjuster (3) Fig. 12 which is

positioned on the backing plate, above the axle case, and easily accessible

with the road wheel removed. To correctly adjust the shoes, turn the

adjuster clockwise until the shoes are hard against the drum, then

slacken off adjuster by one notch.

If the drum is then not free to

rotate slacken adjuster still further.

3

9

SPORTS CAR

Page 41

RUNNING ADJUSTMENTS

Handbrake Adjustment

Adjustment of the rear brake shoes as previously described automatically

readjusts the handbrake mechanism.

leaving the works, and only maladjustment will result from tampering with

the mechanism.

Bleeding the Brake and Clutch Hydraulic System

If a pipe joint is uncoupled, the wheel cylinder cups or clutch operating cylinder are inspected or replaced, the system must be bled in order to expel any

air which may have been admitted.

Air is compressible, and its presence in the system will affect the working

of the brakes and clutch.

Whilst the majority of owners will prefer to have these operations carried

out by a Triumph Agent, for the benefit of those desiring to carry out

their own running adjustments, the procedure is as follows :

Clean the bleeder nipple and fit a piece of rubber tube over it,

1.

allowing the tube to hang in a clean container partially filled with

fluid, so that the end of the pipe is below the level of the fluid.

The cables are correctly set before

2.

Unscrew the bleeder nipple one complete turn.

bleeder nipple to each wheel and one nipple on the clutch operating

cylinder.

3.

The fluid reservoir should be filled before commencing the bleeding

operation, and must be kept at least half-filled during the whole

operation, otherwise air will be drawn into the system via the

master cylinder.

system for maintaining the level.

filler cap before removing it.

Depress the pedal quickly and allow it to return without assistance.

4.

Repeat this pumping operation with a slight pause between each

depression of the pedal. Observe the flow of fluid being discharged

into the glass jar and when all air bubbles cease to appear, hold the

pedal firmly down and securely tighten the bleeder nipple.

NOTE.—Depending upon the position at which a pipe joint in the brake

system has been uncoupled, it will be necessary to bleed the system at

either both front or both rear wheels. If the pipe was uncoupled at the

master cylinder, then the system must be bled at all four wheels.

Do not use fluid that has been expelled from the

Always clean the area around the

4

0

There is only one

Page 42

RUNNING ADJUSTMENTS

PROPELLER SHAFT

If the propeller shaft has been taken apart it is essential to ensure that the arrows

on the universal joint and propeller shaft are aligned during re-assembly (see

Fig. 15, page 22).

HYDRAULIC DAMPERS

The front telescopic dampers cannot be adjusted or topped-up. If they

have been removed, hold them the right way up and pump the pistons to each

end of the stroke before refitting them.

Check the level of the fluid in the rear dampers and replenish if necessary,

then pump the pistons to each end of the stroke. This pumping action dispels

any air which may have entered the chambers. After this operation, keep the

dampers the right way up until they are fitted into place.

Fig. 35.

L.H. rear damper.

LOOSE BOLTS AND NUTS

All the vital nuts are locked in position by split pins, locking wire, or by an

additional locknut or lock washer.

It is, however, desirable that the car be

examined every 6,000 miles and a check made for nuts which may require

attention.

The wheel nuts can periodically be checked by the owner

himself and occasionally removed, oiled and refitted.

The general examination of the chassis is a mechanic's job.

4

1

SPORTS CAR

Page 43

ELECTRICAL SYSTEM

A 12 volt earth return lighting and starting set is fitted.

be disconnected from the battery terminal before removing any

electrical unit, otherwise there is risk of a serious " short ".

A list of the maker's numbers and descriptions of electrical equipment will

be found on page 50.

IGNITION

Failure of the red warning light will not affect the ignition system, but the

bulb should be replaced at the earliest opportunity.

should be examined occasionally and if they are perished or worn through,

replace with the correct ignition cable, which should be obtained only from

your dealer, and should be of the correct length.

The moulded distributor cover should be removed occasionally and wiped all

over with a soft cloth. See that the carbon brush on the inside of the moulding

works freely in its holder.

contact breaker points.

commended on page 7. The distributor has the radio suppressor built into

the distributor head.

the ignition and coil leads a suppressor will not be apparent.

placement or spare distributor head is required, take care to ensure

that it is of the correct type with the long carbon pick-up, which is,

in fact, the suppressor.

Clean away any trace of dirt or dust around the

The points should be adjusted to the setting re-

This, of course, means that on outward inspection of

One cable should

The high tension leads

If a re-

THE BATTERY

Keep the terminals clean and well covered with petroleum jelly. If they are

corroded, scrape them clean, assemble and cover with petroleum jelly.

away all dirt and moisture from the top of the battery, and make sure that

the connections are clean.

battery as this may result in the case becoming cracked.

The generator operates in conjunction with the regulator unit which is housed

alongside the cut-out in the control box.

the generator charges the battery at the rate best suited to its condition.

automatically provides a large charging current for a discharged battery

Do not over-tighten the nyloc nuts securing the

THE GENERATOR

The regulator unit ensures that

4

2

Wipe

It

Page 44

ELECTRICAL SYSTEM

and a low trickle charge for a battery in the fully charged state.

The cut-

out, operated by generator voltage, prevents discharge of the battery through

the generator when the generator is not charging, in which condition the

ignition warning light will be glowing.

Belt Tightness

It is important that the belt is sufficiently tight to drive the generator,

but not too tight as would put undue load on the generator and water pump

bearings.

The correct tension is achieved when the belt can be pressed

inwards ½"—¾" on the longest run, i.e., from the dynamo pulley to

the crankshaft pulley.

It is essential after adjustment has been made

to securely tighten the attachment nuts and bolts (2), (3), (4) and

Fig. 36.

(5),

Fig. 36.

Generator.

THE STARTER MOTOR

Cleaning and Lubrication

The starter brush gear and commutator will not normally require attention.

After

48,000

miles however, it is advisable to have the unit serviced at

a Triumph or Lucas Service Depot.

3

4

SPORTS CAR

Page 45

ELECTRICAL SYSTEM

Should the starter pinion become jammed in mesh with the flywheel, then

may be released by turning the crankshaft with the starting handle, or by

it

selecting top gear and rocking the car backwards and forwards, or by removing

the metal cap on the end of the starter motor and turning the end of the shaft

with a spanner, Fig. 37.

Fig. 37.

Releasing pinion from flywheel.

CONTROL BOX

The control box, mounted on the bulkhead, houses the voltage regulator and

cut-out.

These units are carefully and accurately set before leaving the works

and must not be tampered with.

FUSES

The fuse carrier is located forward of the control box and houses two operating

and two spare fuses. The L.H. fuse (35 amp.) protects the horn, while the other

fuse (35 amp.) protects those items which can only operate when the ignition

switched on, i.e., direction indicators, windscreen wipers, brake light,

is

petrol gauge and heater (if fitted). A 25 amp. line fuse housed in a container

is situated behind the centre instrument panel on U.S.A. vehicles. This fuse

protects the side, tail and panel lamps.

When replacing a fuse, it is im-

portant to use the correct replacement ; the fusing value is marked on a

coloured paper slip inside the tube.

A blown fuse will be indicated by the failure of all the units protected by it

and is confirmed by examination of the fuse. If it is not possible to locate the

cause of the trouble and the new fuse blows immediately, the equipment

should be examined by a Triumph or Lucas Agent or Service Depot.

4 4

Page 46

ELECTRICAL SYSTEM

LAMPS

Headlamps

The lamps have the reflector

and glass sealed as a unit.

The bulb has a " pre-focus "

cap

accurately located and

correctly positioned relative to

the reflector, thus no adjustment to focusing is required

when a replacement bulb is

fitted..

It is not possible with these

types of lamps to alter the

direction of dip entirely by

Fig. 38.

Headlamp unit with adaptor removed.

fitting bulbs of the opposite dipping characteristics, as some of the dip effect

is

produced by the shape of the glass in the lens.

Bulb Replacement

Remove the Snap-on rim by inserting the end of the special tool (provided

in the kit) behind the lower edge of the rim and levering sideways as shown

on Fig. 41. Press in the lamp unit against the tension of the three adjusting

screw springs and turn in an anti-clockwise direction until the key-slot holes

in the rim line up with the screw heads. The lamp unit can then be drawn off.

Do not rotate any of the screws, as this will affect the alignment of the

reflector when assembled.

Rotate the adaptor anti-clockwise and pull off, then the headlamp bulb can

be removed. (See Fig. 38). Care should be taken to see that the .bulb does not

drop out.

Lamp Alignment

The lamp must be set to ensure that the beam is not projected above the

horizontal, taking into account road inequalities and the normal loading

of the car.

45

Fig. 39. Sealed beam head-

lamp unit (special export)

1.

Vertical adjusting screw.

2.

Horizontal adjusting

screw.

3.

Unit retaining screws.

SPORTS CAR

Page 47

ELECTRICAL SYSTEM

To Check and Adjust Alignment

Park the car in front of a garage door or wall and square to it.

(A)

FRONT OF VEHICLE TO BE SQUARE WITH SCREEN

(B)

VEHICLE TO BE LOADED AND STANDING ON LEVEL GROUND

(C)

RECOMMENDED DISTANCE FOR SETTING IS AT LEAST 25FT.

(D)

FOR EASE OF SETTING ONE HEADLAMP SHOULD BE COVERED

Fig.

40.

Headlamps correctly aligned.

Fig. 41.

Removing the rim.

46

Page 48

ELECTRICAL SYSTEM

Switch on the headlamps and adjust the lamps, if necessary, until the

centre of each circle of light coincides with the centre of its respective cross.

If adjustment is necessary, proceed as follows :

Withdraw the front rim as shown on Fig. 41.

dust-excluding rubber.

This will reveal three screws (see Fig. 42),

which can be adjusted to align the reflector correctly.

Remove the

When the

correct alignment has been obtained, replace the rubber and rim.

It is advisable to start adjustment with each screw screwed out half-way ;

this will ensure correct fitting of the rim when assembled.

3.

1.

Vertical adjusting screw.

2.

Dust excluding rubber.

Fig.

42.

Adjusting headlamp alignment.

Front rim.

4.

Horizontal adjusting screws.

Parking Lamps (Front) and Direction Indicator Flashing Lamps

(front and rear)

To remove bulb, peel back the rubber ring and remove rim, then the bulb

can be withdrawn.

When replacing rim, first slip the edge over the two

small lugs, then peel back rubber as rim is fitted. Ensure that the rubber

is located correctly over the rim edge, otherwise vibration may cause the

rim to become detached.

Tail and Stop Lamps

To gain access to the bulb, remove the cover, which is secured by two

screws.

Number Plate Lamp

To gain access to the bulb, remove the securing screw and withdraw

the cover.

4 7

SPORTS CAR

Page 49

ELECTRICAL SYSTEM

Fig. 43.

Wiring Diagram.

4

8

Page 50

Fig. 44.

for

Wiring Diagram

Overdrive Unit.

ELECTRICAL SYSTEM

KEY TO COMPONENTS

I

STOP/TAIL LAMP

2

FLASHER LAMP

3

NO. PLATE LAMP

4

FLASHER LAMP

5

STOP/TAIL LAMP

SPEEDOMETER

6

7

REVOLUTION COUNTER

8

PANEL LAMPS

9

HIGH BEAM INDICATOR LAMP

IGNITION COIL

10

II

DISTRIBUTOR

PETROL TANK UNIT

12

13

FUSE UNIT

14

STOP LAMP SWITCH

15

SIDE (PARKING) AND FLASHER LAMP

16

HEADLAMP

17 HORNS

18

DIPPER SWITCH

19

HORN PUSH AND DIRECTION INDICATOR

20

HEADLAMP

SIDE (PARKING) AND FLASHER LAMP

21

22

FLASHER UNIT

23

CONTROL BOX

24

SOLENOID STARTER SWITCH

25

STARTER MOTOR

26 1

GENERATOR

27

28 IGNITION SWITCH

29 STARTER SWITCH

30

AMMETER

31

PANEL LAMP

32

TEMPERATURE GAUGE

WINDSCREEN WIPER MOTOR

33

SCREEN WIPER SWITCH

34

IGNITION WARNING LAMP

35

36

FLASHER WARNING LAMP

37

PANEL LIGHTING SWITCH

38

PANEL LAMP

39

LIGHTING SWITCH

40 FUEL GAUGE

41

FUSE (FITTED U.S.A. ONLY)

4 2

OIL PRESSURE GAUGE

STEERING COLUMN SWITCH

43

44

RELAY UNIT

TO A ON CONTROL BOX

45

GEARBOX SWITCH

46

47

OVERDRIVE SOLENOID

48

TO IGNITION VIA A3 ON FUSE UNIT

Fig. 43.

SWITCH

2V. BATTERY

OVERDRIVE ONLY :

Fig. 44.

4 9

Page 51

ELECTRICAL SYSTEM

Ignition Warning Light

Direction Indicator Warning Light

High Beam Warning Light

Instrument Panel Lights

Each bulb holder can easily be

withdrawn from the rear of the

panel for bulb renewal.

Replacing these bulbs is best left to the safe hands of a Service Station.

DIRECTION INDICATORS

These are of the flashing type operating in the dual filament bulbs in the

parking lamps at the front and the tail lights at the rear.

The flasher unit is

situated close to the control box underneath the bonnet.

WINDTONE HORNS

Each electric horn is accurately adjusted before being passed out of the

works and will give long periods of service without any attention.

No adjustment is provided for in service.

ELECTRICAL COMPONENT SPECIFICATION

SPECIFICATION OF EQUIPMENT

Model

Battery ...

Control Box

Coil

Generator

Distributor

Starter

Fuse Box

Flasher Unit

Horns

Windscreen

Wiper Motor

Petrol Gauge

Tank Unit ...

BT9A

RB106/2

...

HA12

...

C40/1

25D4

...

M418G

..

4FJ 033283

F.L.5

...

WT618LN

HN

DR 3A

Jaeger No.

Jaeger No.

4016417

2530120

FT3331 /

02/MM2/

12V.

BULBS

Service

No. No.

37283

22700

40795

25550

35020

69046E

69047E

Headlamps

Left-hand dip, both lamps

(home model)

Left-hand dip, both lamps

(export model)

Right-hand dip

" Vertical dip "

Front Parking Lamps

Number plate Illumina-

tion Lamps

Direction Indicator Lamps

(rear)

Tail/stop Lamps

Ignition and High Beam

Warning

Lights

Indicator Warning Lights

Fuses

Lights,

and

...

„

„

Panel

Direction

...

...

50

Lucas

404 12

354

301

370

380

222

382

380

987

35 amp.

Volt-

age

12

12

12

12

12

12

12

12

Watt.

60/36

42/36

36/36

45/40

6/21

21

6/21

2.2

Service No.

188218

4

Page 52

OPTIONAL EXTRAS

RADIO

For operating instructions, see the radio leaflet provided with the set.

set is protected against electrical damage by a 5 amp. fuse housed in the

main lead union.

set is not operating.

The heater is of the re-circulating type, with a combined rheostat and

ON/OFF switch on the dash panel to regulate the speed of the fan. At

the right-hand rear end of the cylinder head, under the bonnet, a screwed

cock can be turned to vary the amount of hot water which is supplied to the

heater unit. Shutters on the underside of the heater unit control the downward