Triumph Tigress 1964 Instruction Manual

SCOOTER

(COIL

IGNITIO

MODELS

T

www.triumphtigress.com

Part

0 e

COl4

C 'P'

hf

Triumph

in

~in

Co.

Lrd.

1J.s.A..

Pr

'It,-

1964..

www.triumphtigress.com

HORN

BUTTON

Fig.

I.

COI\'TROLS

ON

THE

RIGHT

HANDLEBAR

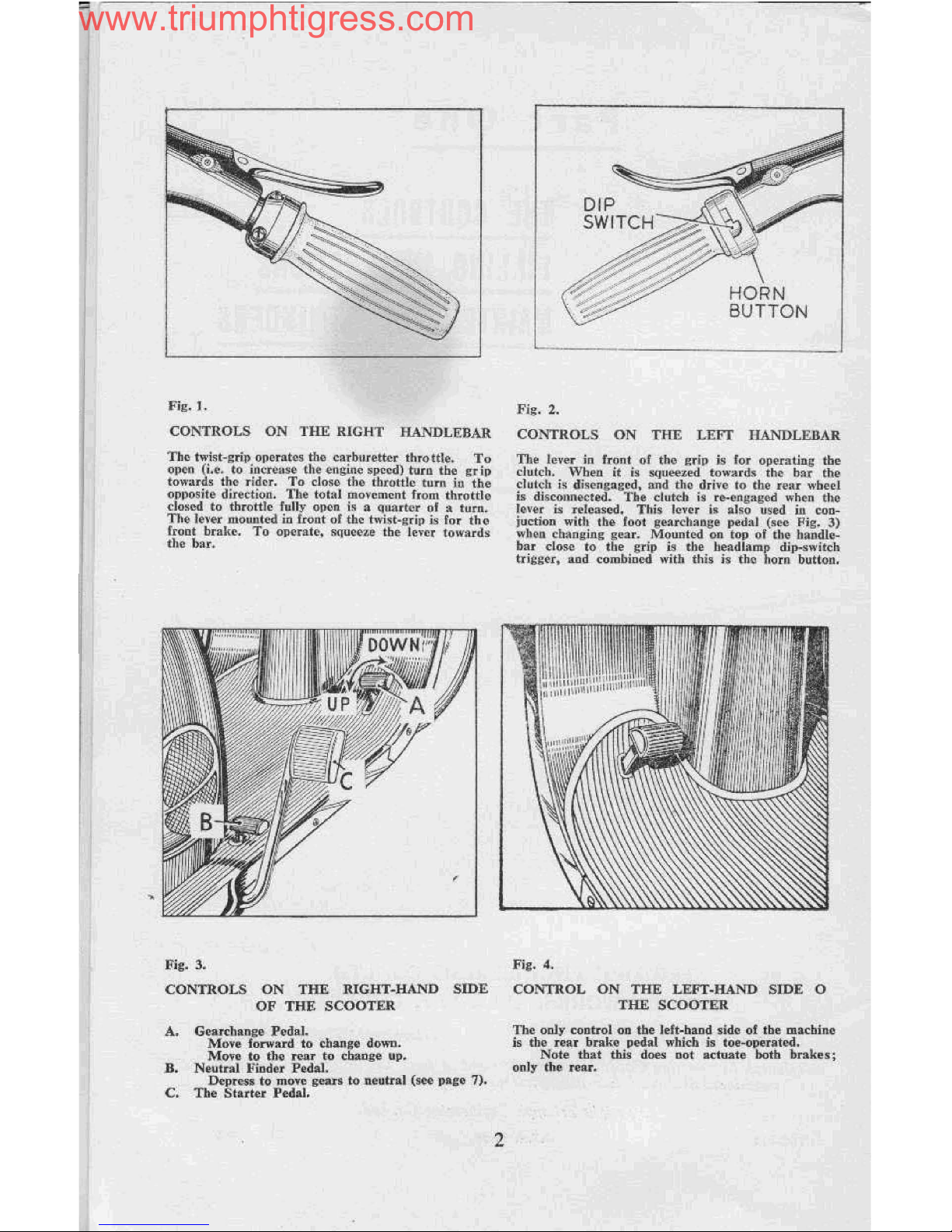

Tha

twist-grip operote. the carbmetter throttle.

To

open (i.e. to

incr<\aSe

tbe engine speed) rutn tbe !:T

ip

towards tho

ridu.

To

close

toe throttle turn ill t.he

opposite direction. The total movement

(rolll

throttle

dosed

to throttle fuRy open is a

qlL."lrterofa turn.

The. lever mOlmted io front or the

twi

t-I{rip

is

fol'

tho

(roDt brake.

To

operate,

5(1Ueeze.

tbe·

h~"'cr

tow~rds;

the bar.

Fig.

2.

CONTROLS

ON

urn

LEFT

HANDLEJIAR

The

lever in front01tbe grip is for operating tbe

clutch. Wben iti9squeelied towards the bar the

clutch is

disengaged.

nnd

tho

drj,.·etoth,e

rear wbeel

is discounected. The clute"

is!

re-engaged

when

the

lever is released. This lever

ilil;

also used

in.

cora-

juctioo witb tbe foot geareb.age pedal (see Fig.

3)

when ebanging gear. Mounted on top of the bandlebar

dose

to tbe grip is tbe beadlamp dJp-switcb

trigger, and

combined

with

this is tho horn button.

Fig.

3.

CONTROLS

ON

THE

RlGHT-HAND

SIDE

OF

THE

SCOOTER

A.

Gea,.hange

Pcdlll.

Move

lorward to

.h""ge

down.

Mo••10

the

rear

to cbaOlle

up.

B. Neut...>!

Fioder Pedlll.

Dep"",.

to move gears toneotral (see pago 7).

C.

The

Starle< Pedal.

2

Fig. 4.

COlll"TROL

ON

THE

LEFT-HAND

SIDE

0

THE

SCOOTER

Tbe

ouly cootrol on

tbe

lelt-baod side01tbe macbine

i.

the

rear

brake pedlll wbichi.loe-operated.

Note

tbat this does

Dot

actuate botb

brakes;

only

lb.

rear.

www.triumphtigress.com

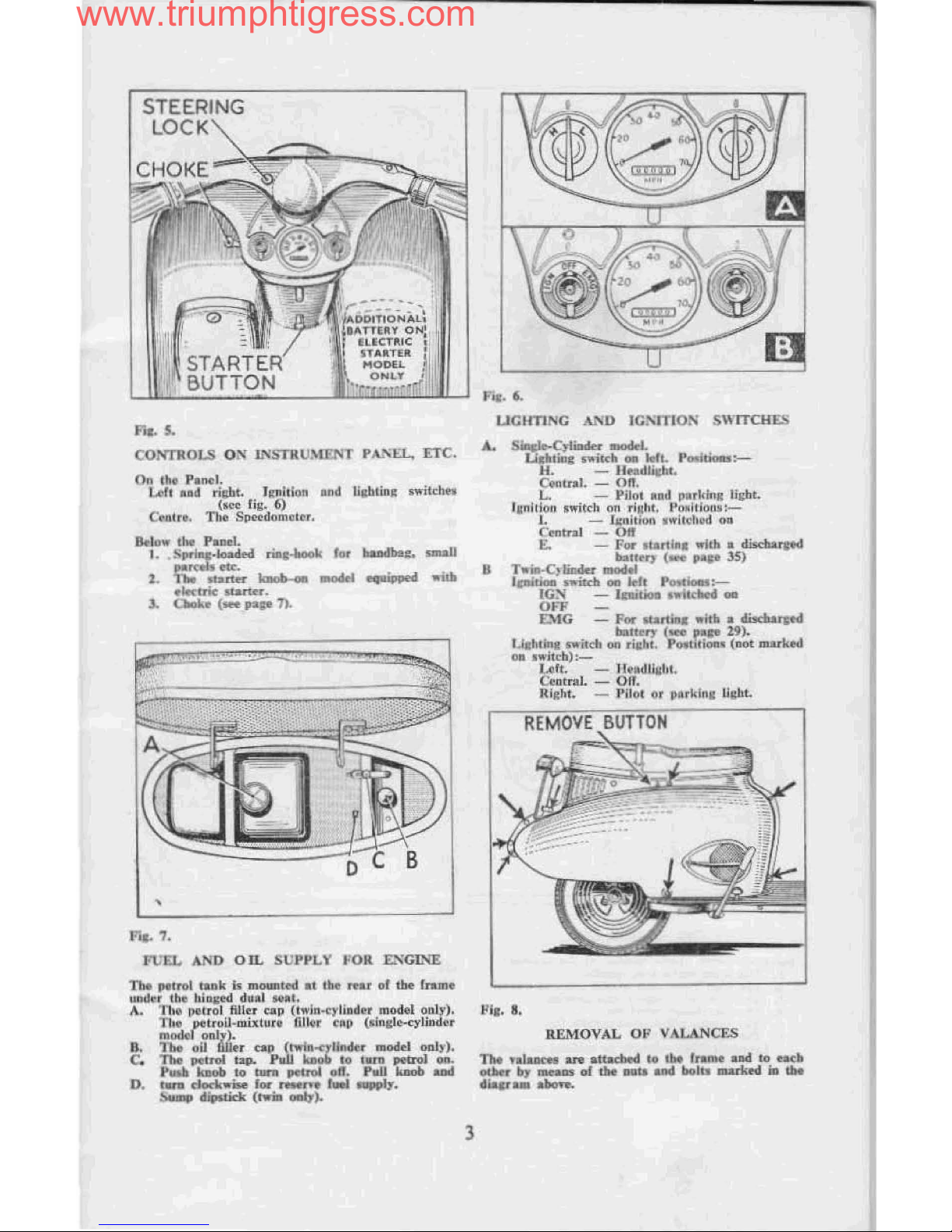

G

REMOVAL

01'

LAN

REMOVE

BUTTON

~I

•

u

o

III .

8.

STH

o

ifRO

.

~.

n

lh

Pan

I.

f!

Ilod

rig!>

11(11111

n and

II

lInll

""ikh

(00

..

flg. 6)

ntr.. Tb

p""don\ol~.

STEERI G

LOCK

www.triumphtigress.com

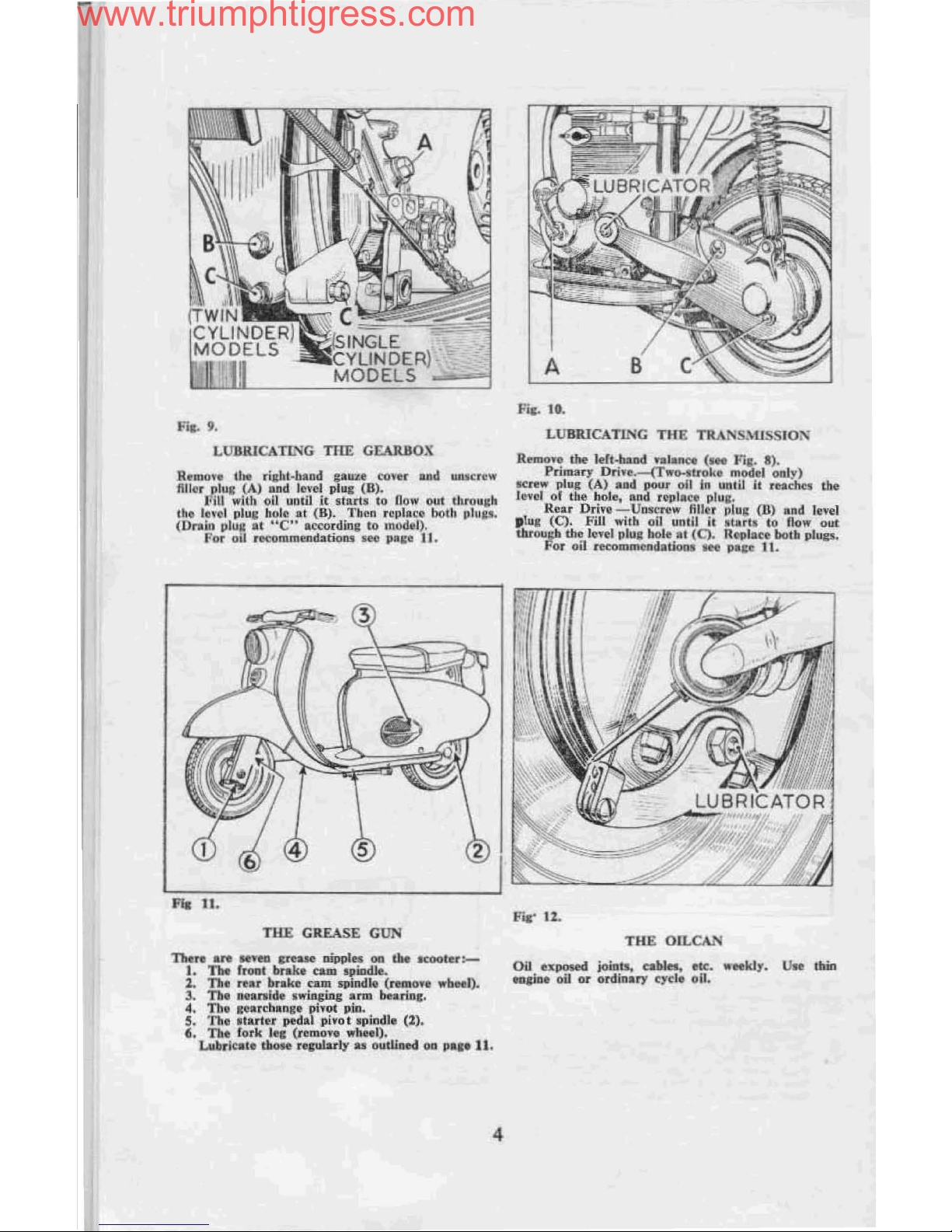

Fla. 9.

LUBlU

TING

TIlE

G£ARB

~'

Bemove

Ih

rigl\t-hand galU co.

rand

UJUcr

..

lillor

ptu

(A)

DUd

level plug (B).

Nil

willioUuDtil

it

olart

10

no. out tbeouuh

II,

I." I plu

hoi

at

(D). Then replaco

bOlb

"llIe••

(Drain

plu~

at

"C"

accordiDg

10Indel).

'or

oil

r~mmmd.atioml.s

pRI: 11.

F

...

10.

LUBlU

TlNG

T T

.\US

10.-

Rmo..~the left-band~I.nc:e

(

Fl.

8).

Prunary

Drivo.-(

troke

m I only)

scrVIplug (Al

and

pour

onInualUilreach the

Ic

..er01

the hole. and

,epl

e plu •

Re....

Drive-

osc",..flU

r

plu~

(D) nod level

pll1Jl

(C).

Fill

wllh all unlll

ic

la,

10

flow

out

throut;b

th~

Ie cl plug boleat( R

plac.

both plugs.

For oil reeommfllldlllion

p.

11.

nm

CREASE

G

Th

Te

are ..... &I'

,...,

trippl

00

the

ICOOI

,0-

J. The frool

brake

cam

Opiodle.

1.

Th

r r

brake

CIlIIl

sPindle (rema. "boel).

3.

The

"ellft

de

swinging

arm

bevinc.

4.

Tbe

loorabaagepival pin.

S.

Th

Ilarter

pedal pivol splodle (2).

45.

TI, lork lec (ramov.

"heel).

Lubricale

thOOf!

'1ll:u11lr1y

as

outUaed

On pal'

11.

4

1'H£

OCL

OU

exposed

jaia

cabl

Ie.

Kid)'.

gloe oilorordioary cycle

011.

www.triumphtigress.com

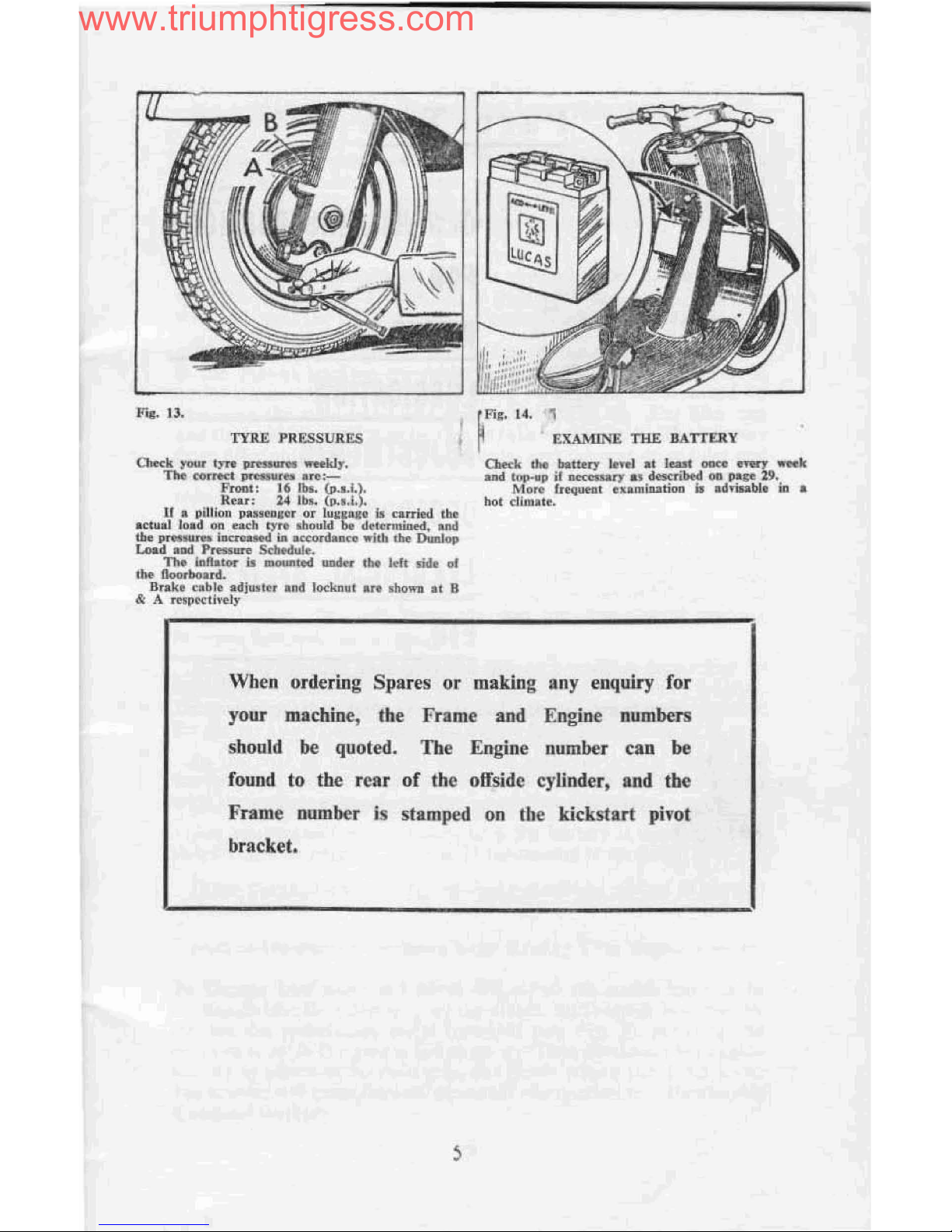

Illg.

13.

TIRE

PRESS R

klT.

ue:-

16

Ibo.

(p

••

.l.).

Rcar:

14lb••

(p

•••I.).

[[ a

pUlion

pao,,,,,uo.

or

IugBRgIcarried

til

actu

....

load on eacb

tyr

bould be dClomn.ioed. and

the p

in<:nllUl!d

lA

aceord

dl

Ib lbe

DunI!

P

LHd

nd

Press.....

OOule.

Th

nllator.il

IIIDUIlled

lIIIlk>r til I

fl'

of

the

Ooorboa.rd.

Brake

cnble

adjUllICl'

Dnd

locknut

Ire

hoWIIIt8

& A

re!p~ll.ely

EXAMINE

TB£

JlATT

Qed<

th

bat1e:Q'

I

.cl

at

1eas.1

oocc

n1!rY

IlDd

loP'Up il

neccaal')'

.,

described..Pig«

29.

Mo.

IrequODt xaminlltioolJlId"abl.

n a

bot

clilDale.

When ordering pares

or

making any enquiry for

your m

chine,

the

Fr

me

and ngine numbe

should be quoted. Tb Engine number

can be

found to the r

8r

of

th

offside cylinder

nd

the

ram

number tamp d on tb kickst

rt

pivot

bracket.

www.triumphtigress.com

Part

Two

GENERAl

INSTRUCTlolIS

FOR

RIDING

LUBRICATION

AoJUSTMEIITS

oECARBoNISATloN

ElECTRICAl

SYSTEM

ETC.

,

www.triumphtigress.com

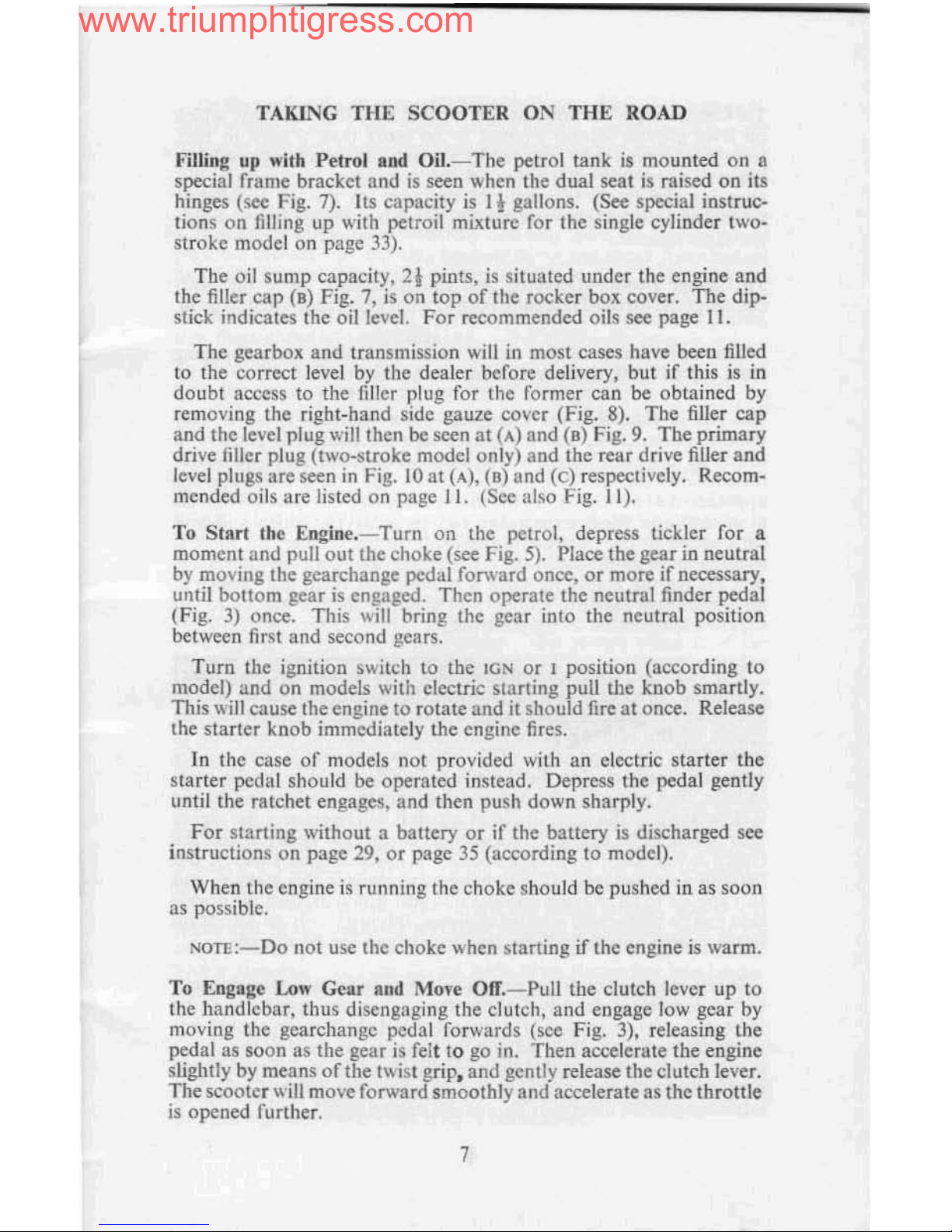

TAKING

THE

SCOOTER

ON

THE

ROAD

Filling

up

with Petrol and

Oil.-

The pelto[ tank

is

mounted

all

a

special frame brackct andisseen when the dual seatisraised on its

hinges

(see Fig.

7).

Its capacity

is

I!

gallons. (See special instruc-

tions on filling up

Wilh

pelroil mixture for the single cylinder two·

stroke model on page

33).

The oil sump capacity,

2,

pints,issituated under the engine and

the filler

cap

(8)

Fig. 7,ison topofthe rocker box cover. The dip-

stick indicates lhe oil level.

For

recommended oils see page

II.

The gearbox and transmission

will

in

most cases have been filled

to the

correct

level

by the dealer before delivery, but

if

this

is

in

doubt access to the liller plug for the former can

be

obtained by

removing the right-hand side gauze cover (Fig. 8). The filler cap

and the level plug willihen

be seen

at

(A)

nnd (8) Fig.9.The primary

drive filler plug (two-stroke model only) aod the rear drive

flUer

and

level

plugs areseeninFig.10at

(A), (0) lind (e) respectively. Recom-

mended oils

:.Ire

listed on page JI.(See also Fig.

II).

To Slarl the

Engioe.-

Turn on the petrol, depress tickler for a

moment and pull out the choke

(see Fig.

5).

Place tbe gearinoeutral

by

moving lhe gearchaoge

P'o:dal

forward once,

or

more if necessary,

until bottom

gearisengaged. Then operate the neutral finder pedal

(Fig.

3)

once. This

will

bring the gear iota the neutral position

between

first

and second genrs.

Turn the ignition switch to the

lGN

or I position (according to

model) and on models with electric starting pull the knob smartly.

This

"ill

cause the engine to rOlate and it should

fireatonce. Release

the slarter knob immediately the engine

fires.

In

the case

of

models not provided with an electric starter the

Slarter pedal should

be operated instead. Depress the pedal gently

until lhe

ratchet engages, and then push down sharply.

For

starting without a battery

or

if the batteryisdischarged see

instructions on

page 29, or page

35

(according to model).

When the engine

is

running Ihe choke should be pushedinas soon

as possible.

Norn:-Do

not use the choke when startingifthe engineiswarm.

To

Engage

Low

Gear and Move

Ofr.-Pull

the clutch lever

up

to

the handlebar, thus disengaging the clutch, and engage low gear by

moving the gearchangc pedal forwards (see Fig.

3),

releasing the

pedal

as soon as the gearisfelt to go in. Then accelerate the engine

slightly by means

of

the twist griP. and gently release the clutch lever.

The scooter

will

move forward smoothly and accelerate as the throttle

is

opened further.

7

www.triumphtigress.com

To Change

Up.-As

soon as the scooter is well under way,

whkh

on

level ground should amount to no more than a yard

or

two,

second

gear should be engaged by moving the gearchange pedal

to

the rear and releasing it again,

at

the same time momentarily dis-

engaging the clutch

by

meum

of

the lever on the left handlebar.

Changing

to

third gear and finally to top are elTected in precisely

the same manner.

To Change

Down.-Declutch

and simultaneously move the gear·

change pedal forward releasing both as soon

as

the gearisfelttogo in.

This operation

is

carried out

in

the same manner when changing

from top to third, third

to

second,

Rnd

second

lO

first.

The

Art

of

Smooth Gear

Cbanging.-

The

gearbox is

of

a very

robust construction. and the gearchange mechanism is positive in

action

so

Ihat gearchanges will

be

made wilhout fail even by a novice

if

he follows the inSlructions given above. but wilh practice and the

application

of

a littleskill

to the manipulationofthe variouscontrols

a smooth and silent gcarehangc can

be

achieved, which will give

satisfaction

10

the

rider and bring credit to the scooter, for there

is

nothing more gratifyingtothe experienced rider than the knowledge

that he has the ability to make a smooth

and

silent gearchange

at

aU

times, and that his scooter will respond in this matter

to

his

expert manipulation

of

the controls.

For

example, when changing up the rider should not only select

a suitable speed

al

which to perform the operation, but he should

also time his gearchanges in such a way

that

engine speeds and the

speeds

of

the moving parts in the gearbox should be allowed to

coincide as far as possible. This laHer requirement

is

mel usually

by momentarily closing the throtlle before

dcclutching for

the

gear-

cbange. thus removing the

power drive from the gearbox and lening

it slow doy,,"

to

the lower speedatwhicbitwill operate in the higher

gear about

to

be engaged. As soon as the gearisengaged and the

clutch

is

released the throttle should

be

opened again smartly. but

without a sudden jerk.

If

gcarchanges are made in this manner. and

mis applies

to

all changes up from low gear upwards. then the opera·

tion can be performed silenlly and smoothly with only an alteration

in

me

engine note to indicate that the change has been made.

When changing to a low gear

it

will be seen from a consideration

of

the conditions described above that the engine speed has to be

increased relative to that

of

the scooter and the throllle should not

therefore

be

closed while making the change. As soon as the clutch

is

released the engine

will

automatically speed

up

and if the change

is

made smarlly and confidently, the lower gear selected

",':ill

slide

into engagement qujetly at the correct engine

speed.

8

www.triumphtigress.com

To

the novice the above instructions may sound somewhat compli-

catedalthough they are in faet

ex-trem

ly simple,

and

ridersofaverage

potential skill and ability rapidly acquire the correct knack

in

a very

short mileage after first acquaintance with the scooter, so

that

neat

and

precise gearchanging quickly becomes second nature.

Itisemphasized

that

it i de irable to acquire the ability to operate

a gearchange mechanism smoothly

not

only from the view-point

of

personal satisfaction,

but

also because silent and shock free changes

naturally impose less strain on the rapidly moving parts, with the

result that wear and

tear

are reduced to the absolute minimum, and

the scooter

will continue to operate in a .tateofmechanical perfec-

tion throughout its

useFul

life.

To Stop the

Engine.-Select

neutral gear close the tbrottJe, and

turn the ignition switch to the

"OFF"

position.

LUBRICATION

SYSTEM

(Twin-Cylinder model)

The

Engine.-The

engine is lubricated

by

a circulating system in

which

oil

is

drawn from a

rc

crvoir upplied under pressure to

various working

part

of

Lhe

engine, and here·after returned to

the

reservoir for Te-circulation.

The

system operates

in

the following

manner:-

The reservoir take

the

fonn

of

a ump bolted to the underside

of

the crankcac,and

a supply pipc draws

oil

from this sump through

a filter and carries it to the oil pump.

This pump, whichisof

the

plunger type

is

driven

by

a connecting rod

by

an eccentric on the

camshaft,

and

draws the oil through the supply pipe referred to

above, and delivers

it

under pressure through drilled passages, first

to the offside crankshaft bearing

and

then through oil-ways drilled

in the crankshaftitselfto the connecting rod big-cnd bearings. After

Lubricating the e bearings, the oil emerges into the crankcase

in a

finely divided condition whichischurned

up

into mist by the rapidly

rotating parts and spreads over the entire internal structure

of

the

engine, thus providing lubrication for the connecting

rod

small-ends,

the pistons, the cylinder bores, the nearside crankshaft bearing,

which

is

a ballrace,

and

the timing gear.

The

oil then condenses

into liquid form, and returns by gravity through a filter tray to the

sump. A by-pas i

al

0 taken from the

pump

supply, and this is

taken first to the camshaft and then through a metering hole in the

ofIside bearing to an external pipe which feeds it to the overhead

rocker spindles.

It

then drains back from the rocker box lubric-

ating both primary drive and timing gears before returning

to

the

sump.

The

Iubrication system

is

thus self-contained and

[ully

automatic

in

action.

It

is

quite foolproofand calls for no attention on the

part

of

the rider

apart

from the obvious precaution

of

checking the oil

in

the

sump

at

regular intervals by inspecting the dipstick (Fig. 7)

to ascertain

that

the correct level is maintained.

9

www.triumphtigress.com

As

seen

in

the maintenance instructions it

is

recommended that

the sump should be drained and refilled with fresh

oil

cvery 2,000

miles. The sump should be removed for cleaning every

6,()(X)

miles

and this involves raising the scooter on a trestle or a couple

of

suit-

able boxes so that the twelve scrcws by means

of

which itisbolted

to the crankcase may

be

taken out. When thisisdone the filter tray

and also the supply filter should

be

removed and thoroughly cleaned

by

rinsinginparaffin.

Primary

Drjvc.-This

consists

ora

clutch on the engine shaft coupled

to tbe engine shaft pinion which drives a larger pinion on the gearbox mainshaft, thus giving the primary reduction.

The case forms part

of

the engine lubrication system on the lwin-

cylinder models and after the initial filling there

will

be no need for

furtber attention.

With the single-cylinder model the primary drive

oil

level should

be checked periodically (sec page 4, Fig.

10).

Gearbox.-

The gearbox has an entirely independent

oil

system which

is

supplied through a filling orifice on

top

or

the box (see Fig. 9).

There

is

also a plug which determines the correct level.

It

is

so

arranged that tbe larger

of

mainshaft gears dip into it and piek up

sufficient

oil

to churn it into mist for distribution throughout the

entire box, including the gearchange mechanism. The only

main·

tenance necessaryisto check the

levelatintervalsasdescribed under

"Routine

Maintenance", and to drain and refill after prolonged

mileages

by

which time the lubricating qualities

of

the

oil

may have

become somewhat impaired.

Rear

Drh·e.-The

rear drive, which

is

by chain, operates in a cast

aluminium oilbath chaincase, and it

is

provided with an independent

oil supply which is controlled

at

the correct

level

by the filler plug

seen

in

Fig.

10.

The

level

plug is

so

positioned that it ensures the

correct quantity

of

oil being poured in.

The rear drive lubrication system requires no attention beyond a

periodical check

of

the

oj]

level, together with draining and re-filling

when necessary as described under "Routine Maintenance".

Other

Parts.-Grease

gun lubrication is provided for the brake cam

spindles, the front fork, the nearside rear suspension swinging arm,

and the foot gearchange pivot as outlined on page

11.

Other working parts which require lubrication arc packed with

grease during assembly and this should suffice until such time that

a major overhaul becomes necessary.

10

www.triumphtigress.com

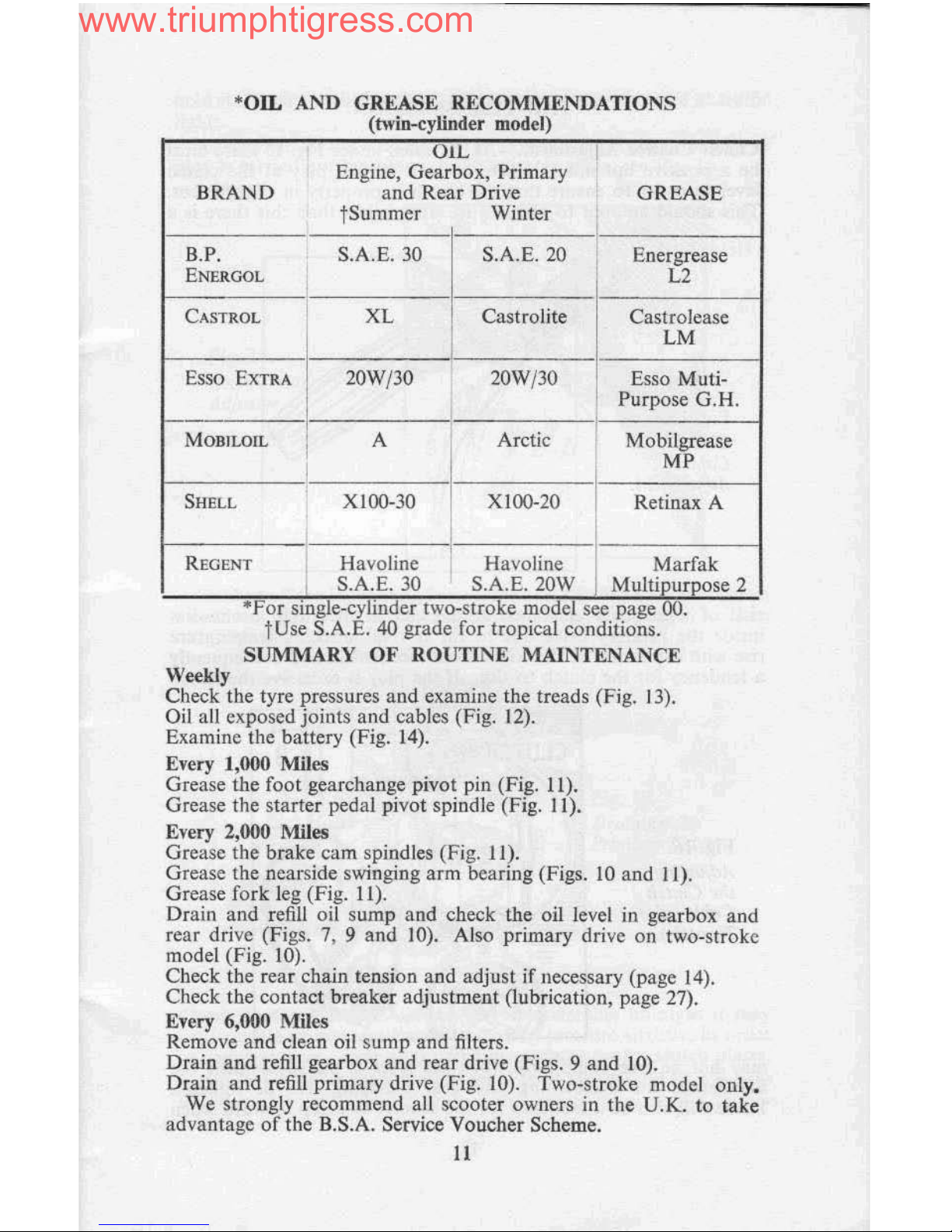

·OIL

AND GREASE

RECOMMENDATIONS

(twin-cytinder model)

g y

oe

pg

tUse

S.A.E. 40

grade

for tropical conditions.

SUMMARY

OF

ROUTINE

MAINTENANCE

Weekly

Check

the

tyre pressures

aud

examine

the

treads (Fig. 13).

Oil atl exposed

joints

and

cables (Fig. 12).

Examine

the

battery

(Fig. 14).

Every J,ooO

Miles

Grease

the

foot

gearchange pivot pin (Fig. 11).

Grease

the

starter

pedal pivot spindle (Fig.

II).

Every 2,000

Miles

Grease

the

brake

cam spindles (Fig.

II).

Grease

the nearside swinging

arm

bearing

(Figs.

10

and

11).

Grease

fork

leg (Fig. 11).

Drain

and

refill oil

sump

and

check

the

oil level in

gearbox

and

rear drive (Figs.

7,

9

and

10). Also

primary

drive

on

two-stroke

model (Fig.

10).

Check

the

rear

chain tension

and

adjust if

necessary (page 14).

Check

the

contact

breaker

adjustment

(lubrication, page 27).

Every 6,000 Miles

Remove

and

clean oil

sump

and

filters.

Drain

and

refill

gearbox

and

rear

drive (Figs. 9

and

10).

Drain

and

refill

primary

drive (Fig. 10).

Two-stroke

model

only.

We

strongly

recommend atl

scooter

owners in

the

U.K. to

take

advantageofthe

B.S.A. Service

Voucher

Scheme.

II

OIL

I

Engine,

Gearbox,

Primary

BRAND

and

Rear

Drive

GREASE

tSummer

Winter

I

,

B.P.

S.A.E.30

S.A.E.20

Energrease

ENERGOL

L2

CASTROL

XL

CastroJite Castrolease

LM

Esso

EXTRA

20W/30 20W/30 Esso Muti-

Purpose

G.H.

MOBILOIL

A Arctic

MobiJgrease

I

MP

SHELL

XIOQ-30

Xl00-20

Retinax A

,

REGENT

Havoline HavoJine

Marfak

I

S.A.E. 30

S.A.E.20W

MultiourDOse 2

·For

sin

le-c

hnder

two-stroke

m d 1see

a e 00.

www.triumphtigress.com

Loading...

Loading...